Abstract

Face masks have been an effective and indispensable personal protective measure against particulate matter pollutants and respiratory diseases, especially the novel Coronavirus disease recently. However, disposable surgical face masks suffer from low filtration efficiency for particles ranging from nano- to micro-size, and the limited service life of ~ 4 h. Here, a nano/micro fibrous hybrid air filter mask composing of electrospun nanofibrous network and poly(3,4-ethylenedioxythiophene:poly(styrenesulfonate) coated polypropylene (PP) is proposed. Furthermore, the resultant filter is supplied with tribo-charges by a freestanding sliding triboelectric nanogenerator. Through the enhanced synergistic effect of mechanical interception and electrostatic forces, the hybrid air filter demonstrates high filtration efficiency for particle size of 11.5 nm to 2.5 µm, with a 9.3–34.68% enhancement for particles of 0.3–2.5 µm compared to pristine PP, and 48-h stable filtration efficiency of 94% (0.3–0.4 µm) and 99% (1–2.5 µm) with a low pressure drop of ~110 Pa. In addition, sterilization ability of the tribo-charge enhanced air filter is demonstrated. This work provides a facile and cost-effective approach for state-of-the-art face masks toward high filtration performance of nano- to micro- particles with greatly extended service life.

Keywords: Nano/micro fibrous hybrid air filter, Particulate matter, Face masks, Triboelectric nanogenerator, PEDOT:PSS

Graphical Abstract

A tribo-charge enhanced hybrid air filter mask is developed for efficient nano- to micro- sized particulate matter capture, with a 9.3–34.68% filtration enhancement for particles of 0.3–2.5 µm compared to state-of-the-art air filter used in disposable mask. A greatly extended service life to 48 h of stable filtration efficiency of 94% for 0.3–0.4 µm and 99% for 1–2.5 µm at a low pressure drop of ~110 Pa is demonstrated.

1. Introduction

Airborne particulate matter (PM) has become one of the most hazardous air pollutants that severely affect the air quality, public health, and the ecosystems [1], [2]. PM is typically categorized as PM1, PM2.5, and PM10, referring to particle sizes below 1, 2.5, and 10 µm, respectively. PM2.5, capable of penetrating the respiration system and blood vessels, can cause severe health problems, such as lung cancer, asthma, and heat disease [1], [2], [3]. According to the Global Burden of Disease Study, 4.2 million premature deaths were associated with the exposure of outdoor PM2.5 in 2015, which has become the fifth leading risk factor for death [4]. Especially, aerodynamic particles with size of 1.0 µm and 0.3 µm, and ultrafine particulates (UFPs) with particle size diameter under 0.1 µm are regarded the most dangerous because submicron particles can travel farther in the air. The high surface area enables these particles to carry a vast number of pathogens and penetrate deeply into the lung tissue and blood-circulation system, causing various respiratory and cardiovascular diseases [5], [6].

In addition, the outbreak and global spread of novel Coronavirus (COVID-19) disease, which is caused by the severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), has infected 40 million people and caused over 1 million deaths (by the time of writing) all over the world. Face masks are recommended by the World Health Organization (WHO) to reduce the spread of SARS-CoV-2 through respiratory droplets from coughs and sneezes [7], [8], [9]. As reported in two hospitals in Wuhan, China, the aerosols containing SARS-CoV-2 were mainly found in the size range of 0.25–1 µm, with peak concentration in 0.25–0.5 µm [10]. Thus, to break the transmission pathway, face masks with high filtration efficiency for airborne particles at nano- to micro-sized region is highly demanded, where disposable surgical masks suffer from low filtration efficiency as well as limited service life of ~4 h.

Recently, to face the challenges imposed by the spread of SARS-CoV-2, scientists are devoted to exploring new design of face masks or improving the current prototypes to enhance the capture efficiency. It is reported that high filtration efficiency can be reached by multiple layers of fabrics which is associated with high pressure drop [11]. Compared to porous membrane filters, nanofibrous network filters have higher porosity and lower pressure drop [12]. Electrospinning is one of the facile and scalable techniques to fabricate polymer nanofibers. The in-situ high-voltage poling during the electrospinning process endows the nanofiber filters with enhanced electrostatic effect, resulting in high capturing efficiency for airborne particles. As such, nanofibrous polyvinylpyrrolidone (PVP), polyvinyl alcohol (PVA), polystyrene (PS), polyacrylonitrile (PAN), and polybenzimidazole have been explored for high-efficient PM2.5 removal [13], [14], [15], [16].

On the other hand, triboelectric nanogenerator (TENG), as an emerging technology invented in 2012 [17], is capable of converting various kinds of mechanical energy into electricity [18], [19], [20], [21], [22], based on triboelectrification and electrostatic induction[23], [24]. The high open-circuit voltage of the TENG enables it as an effective technique for air quality control and the development of self-powered healthcare products [25], [26], [27]. For example, a 207.8% enhanced filtration efficiency was reached by a rotating TENG assisted polyimide nanofiber filter for the particle size of ~80 nm [28]. A self-powered face mask composed of a respiration-driven TENG and poly(vinylidene fluoride) nanofiber film demonstrated removal efficiency of 99.2% for coarse and fine particles [29]. Additionally, poly[(vinylidenefluoride-co-trifluoroethylene) (PVDF-TrFE) nanofibrous air filter showed a high PM1.0 filtration efficiency of ~88% after dipole polarization and further enhanced to ~94% after triboelectrification [30]. Thus, inspired by the previous research work [28], [31], [32], taking advantages of nanofibrous network and tribo-charges to develop face masks with high filtration efficiency specially at submicron size region to fight against COVID-19, low pressure drop, easy incorporation with current manufacturing process, and long service time is highly desirable and essential at present.

Herein, we developed a tribo-charge enhanced hybrid nano/micro fibrous air filter for face masks by improving the current design of a surgical mask. A freestanding-triboelectric layer sliding TENG (FS-TENG) was introduced to supply tribo-charges for the hybrid air filter. To improve the wear comfort, different from previous studies that utilize metal mesh electrode (such as Cu, stainless steel) [28], [33], poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) was employed as the charge collector, owing to its high conductivity, biocompatibility, and high stability [34], [35], [36]. As a consequence, the synergistic effect of enhanced mechanical interception (via hybrid nano/micro fibrous structure) and electrostatic forces (via tribo-charges) enabled the hybrid air filter has high filtration efficiency at 11.5 nm to 2.5 µm. In addition, its stable and greatly extended service life has been demonstrated by the capture efficiency as high as 94% (0.3–0.4 µm) and 99% (1–2.5 µm) with no degradation after 48 h.

2. Results and discussion

2.1. Design of hybrid nano/micro fibrous air filter

Fig. 1a shows the fabrication process of the hybrid nano/micro fibrous air filter, which mainly involves three steps. First, nanofibrous polyacrylonitrile (PAN) films with various thicknesses were fabricated by electrospinning technique [37], [38] through adjusting the electrospinning time (Details in Experimental Section). Second, PEDOT:PSS doped with 5% of DMSO was spray-coated on one side of the polypropylene (PP) to make it conductive. A narrow Cu tape was adhered at the four edges of the coated PP, leaving one end to connect with TENG. Finally, the PAN film was stacked with the PP layer with the conductive side facing outside, to fabricate the hybrid PP/PAN air filter. Digital photos of the pristine PP and coated PP together with their corresponding surface morphologies of the single fiber observed by field emission scanning electron microscopy (FESEM) are shown in Fig. 1b (I-IV). The dark blue color and coarse morphology of the coated fiber (Fig. 1b-III and IV) compared to pristine fiber (Fig. 1b-I and II) are associated with the PEDOT:PSS coating on PP fibers. The variation of fiber thickness between Fig. 1b-II and Fig. 1b-IV was due to the uneven diameter of pristine PP fibers. In addition, the spray coating of PEDOT:PSS on the fibers causes certain unevenness. The XRD spectra of PP with and without coating is shown in Fig. S1. Similar characteristic diffraction peaks of PP were observed on these two samples. No obvious peaks of PEDOT:PSS were observed on the coated sample, which is mainly ascribed to the low spraying amount that is beyond the measurement limit. An optical image of electrospun PAN is shown in Fig. 1b-V. Fig. 1c shows the morphologies of PP and PAN associated with their corresponding diameter distributions (insets). As seen, PP has an average diameter of 2.3 ± 1.0 µm, while the average diameter of PAN is 187 ± 31 nm. The hybrid air filter face mask composed of four layers, namely outer layer, PAN/nonwoven layer, PEDOT:PSS coated PP, and inner layer, and its digital photos as well as the cross-sectional SEM image are shown in Fig. S2.

Fig. 1.

Fabrication process and characterization of the hybrid air filter. (a) Schematic illustration of the fabrication process. (b) Digital photos of PP before and after PEDOT:PSS coating and the corresponding single fiber FESEM images, and a digital photo of PAN film. (c) FESEM images of PP and PAN with the insets showing their fiber diameter distributions.

2.2. Architecture design and filtration mechanism

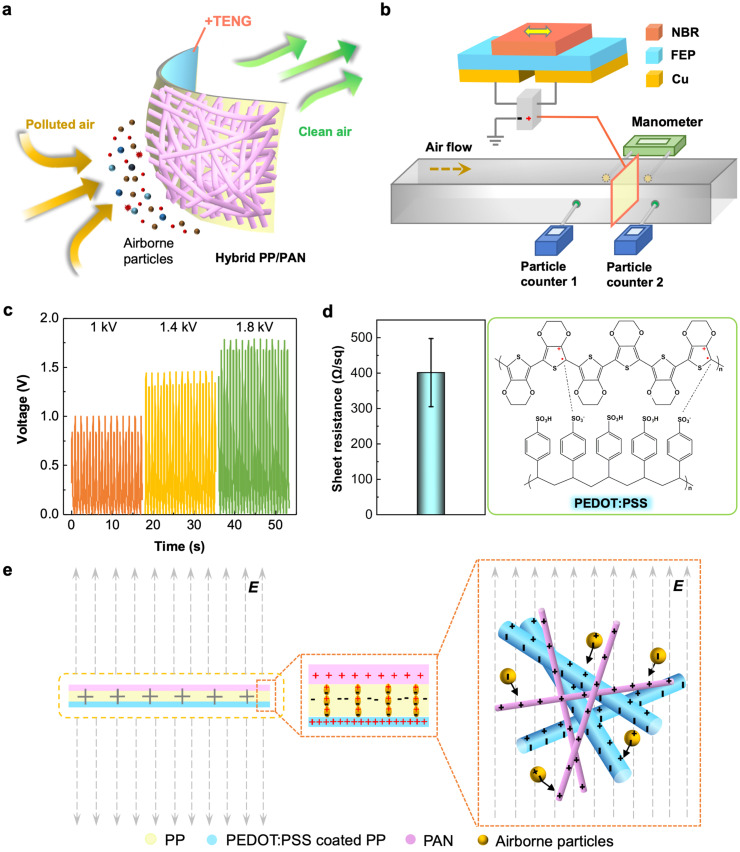

The filtration concept of the tribo-charge enhanced hybrid PP/PAN face mask is schematically illustrated in Fig. 2a. The conductive side of the mask is connected to a TENG, and the air containing airborne particles are synergistically removed by the enhanced mechanical interception (via hybrid nano/micro fibrous structure) and electrostatic forces (via tribo-charges), resulting in clean air after the filtration. To evaluate the filtration performance, a measurement setup [39] (photo shown in Fig. S3) along with an FS-TENG was designed with an effective cross-sectional area of the hybrid PP/PAN of 6 cm × 6 cm, as shown in Fig. 2b. Steady air flow was provided by a draught fan equipped at one end of the acrylic testbed with two particle counters (1&2) placed on both sides of air filter to monitor the particle concentration in the air. Fig. S4 shows the average size distribution of PM in the environment (25 °C, relative humidity of ~60%), where the particle number found in the air was as high as 105 cm–3 for the size range of 0.3–2.5 µm (Fig. S4a) and 2500 cm–3 for the size range of 11.5–205.4 nm (Fig. S4b). Especially, the highest PM concentration comes from 0.3 to 0.4 µm, which is also the most challenging filtration diameter for regular face masks. The pressure drop of the hybrid filter was recorded at the two sides of the filter by a manometer. Further, tribo-charges were supplied by the FS-TENG (Fig. S5), which composed of a nitrile rubber (NBR) as the tribo-positive material, a fluorinated ethylene propylene (FEP) film (thickness of 50 µm, 200 mm × 150 mm) as the counterpart, and two Cu films (95 mm × 150 mm) as the electrodes. The working principle of FS-TENG is based on the coupling of triboelectrification and electrostatic induction [40], [41], [42], as shown in Fig. S6. The relative sliding movement between NBR and FEP results in positive charges on NBR and negative charges on FEP. Due to the electrostatic induction, tribo-charges will be induced on the metal electrodes underneath FEP. Consequently, the unbalanced charges on the two electrodes drive electrons to flow through the external loads upon NBR sliding forward and backward. As such, periodical alternating electrical signals are generated. Through a full-bridge rectifier, the output electrical signals were rectified and connected with the conductive side of the air filter. The sliding motion was driven by a linear motor (frequency of ~0.7 Hz) and different output voltage (1, 1.4, and 1.8 kV) of the FS-TENG was registered, as shown in Fig. 2c. In a real application scenario, the tribo-charges are produced by a wearable FS-TENG that has the capability of harvesting mechanical energy from the human motion [40], [43], [44], [45] or wind/air flow [46].

Fig. 2.

(a) Schematic illustration of the filtration concept of the tribo-charge enhanced hybrid air filter face masks. (b) Schematic diagram of the setup of PM filtration efficiency measurement. (c) Output voltage of FS-TENG. (d) Sheet resistance of PEDOT:PSS-coated PP and the molecular structure of PEDOT:PSS. (e) Filtration mechanism of the nano/micro fibrous air filter under electrostatic field.

To realize a good charging performance, the conductivity of the layer connected with TENG needs to be ensured. PEDOT:PSS was doped with DMSO to improve the conductivity, which was spray-coated on one side of PP. The surface sheet resistance is around 400 Ω/sq (Fig. 2d). PEDOT:PSS is a bio-compatible, highly conductive polymer, which can replace the metal electrode, with the advantages of no add-on weight as well as comfort for face mask application. Due to the electret melt-blown technique, PP fibers have strong electrostatic interaction with the charged PEDOT:PSS (Fig. 2d), which enables a stable coating on the PP fibers.

The filtration mechanism of the hybrid nano/micro fibrous air filter under electric field is illustrated in Fig. 2e. Generally, in the absence of electric field, the dominant filtration mechanisms of fibrous air filters for PM capture are inertial impaction, mechanical interception, and Brownian diffusion [47], [48]. Firstly, the hybrid architecture (PP/PAN) strengthened the mechanical filtration mechanisms. Secondly, the presence of electrostatic force associated with the external electric field (induced by FS-TENG), acting as a long-range force [49], can significantly enhance the filtration efficiency except for the above-mentioned mechanisms. In this study, hybrid PP/PAN was positively charged by FS-TENG. The resulting potential difference between PAN and PEDOT:PSS coated PP side increased while being charged at a higher voltage (Fig. S7). As such, the electric field across the hybrid PP/PAN was in opposite direction with the airflow (Fig. 2e). Accordingly, when this pulsed electric field was on, PMs passing through the PP/PAN underwent different electrostatic forces, namely Coulombic and polarization. The Coulombic force is due to the charged airborne particles within the electric field, while the polarization force stems from the charged PP/PAN fibers [50], [51]. Given that the carrying charge of PMs depends on the environmental circumstances, which means PMs have the possibility of carrying positive, negative, or neutral charges. Thus, the PMs were not singly pre-charged during our experiment. As a consequence, owing to the Coulombic force, PMs with negative charges are prone to be attracted by the positive electrostatic charges generated on the surface of PAN. Meanwhile, the polarized electret PP fibers as well as PAN fibers have strong tendencies to capture the polarized PMs that are originally neutral [52]. The positively charged airborne particles will be mainly captured by the mechanical interception of the PAN nanofibers.

2.3. Filtration performance of particulate matter

To demonstrate the advantage of the hierarchical structure and the impact of the tribo-charges on the filtration efficiency of the hybrid air filter, the thickness of PAN nanofibers and the magnitude of the electric fields were investigated. Fig. 3a shows a comparison of the filtration performance of single-layer PP (pristine PP and coated PP) and the hybrid PP/PAN with different PAN thicknesses. The filtration efficiency was calculated based on Eq. (1):

| (1) |

where C 0 and C 1 are the particle number concentrations in the upstream and downstream directions of the air filters, respectively. Coated PP showed similar filtration efficiency with pristine PP, which means that PEDOT:PSS coating on the PP surface had negligible influence on the filtration behavior of PP. However, too higher loading of PEDOT:PSS may affect the mechanical property of the PP. Furthermore, regulating the electrospinning time of PAN (2, 4, and 5 h), hybrid PP/PAN with different thicknesses are denoted as PP/PAN-2h, PP/PAN-4h, and PP/PAN-5h, respectively. It is noted that compared to single-layer PP, hybrid PP/PAN enhanced filtration efficiency in the particle size of 0.3–2.5 µm - more significantly for particle size below 0.5 µm at airflow velocity of 0.15 m/s. The filtration efficiency of particle size of 0.3–0.4 µm reached 74.98%, 85.54%, and 96.48% for PP/PAN-2h, PP/PAN-4h, and PP/PAN-5h, respectively, compared to 54% for single PP. While for 1–2.5 µm, the filtration efficiency achieved 90.45% (PP/PAN-2h), 96.05% (PP/PAN-4h), and 99.95% (PP/PAN-5h), compared to 89.72% for PP. This is mainly ascribed to the hierarchical pore structures [53] of PP/PAN. In addition, the higher dipole moment of PAN facilitates a better filtration performance of PM particles [13]. The further enhanced filtration efficiency of PP/PAN with increasing PAN thickness was due to the higher mechanical interception.

Fig. 3.

Filtration efficiency for particle size of 0.3–2.5 µm (T = 25 oC, RH=61–65%). (a) Comparison of single-layer PP and hybrid PP/PAN with different thicknesses in the absence of electric field. Filtration performance of (b) PP/PAN-2h, (c) PP/PAN-4h, and (d) PP/PAN-5h at various charging voltages (0, 1, 1.4, and 1.8 kV).

With the aid of FS-TENG, the filtration efficiency of PP/PAN under various charging voltages (0, 1, 1.4, and 1.8 kV) (T = 25 oC, RH=61–65%) is shown in Fig. 3b–d. With electric field, PP/PAN-2h exhibited a considerable improvement of filtration efficiency for particle size of 0.3–2.5 µm as compared to that without electric field. At higher charging voltage, more airborne particles can be removed (Fig. 3b). The PP/PAN-4h filter also followed the same trend, with an increasing filtration efficiency with increasing voltage (Fig. 3c). However, the enhancement was relatively smaller compared to PP/PAN-2h. In addition, as shown in Fig. 3d, the applied voltage on PP/PAN-5h filter had no significant impact on the filtration efficiency even at 1.8 kV.

To further elucidate the above observation, we measured the surface potential of the PAN side and PEDOT:PSS coated side under various charging voltages (Fig. S7). For a certain hybrid air filter, increasing the charging voltage increased the surface potential difference across the air filter. Thus, higher charging voltage (electric field) contributed to higher electrostatic forces, resulting in higher filtration efficiency, which agrees with the results obtained for PP/PAN-2h and PP/PAN-4h (Fig. 3). Additionally, the potential difference across the air filter also increased with increasing PAN thickness, due to the higher charge holding capacity of thicker layers under continuous charging by FS-TENG. However, the reason why the filtration efficiency of PP/PAN-5h did not increase much with applied voltage, is the decreased electric field strength at higher thickness. Thus, mechanical interception was the dominant filtration mechanism for PP/PAN-5h. As for the thinner PAN, in addition to the mechanical interception, the electric field strength across the filter was higher, resulting in higher electrostatic forces facilitating the enhancement of filtration efficiency.

Pressure drop, being an important factor to evaluate the performance of air filters, was recorded by a manometer [54]. As shown in Fig. 4a, compared to pristine PP (74 Pa), the pressure drop of the hybrid air filters slightly increased to 87, 107, and 133 Pa for PP/PAN-2h, PP/PAN-4h, and PP/PAN-5h, respectively, at an airflow velocity of 0.15 m/s. In addition, the overall filtration performance of the hybrid PP/PAN in comparison with the pristine PP was quantified using the quality factor, as calculated by Eq. (2) [37]:

| (2) |

where η is the filtration efficiency of air filters for particle size of 0.3–0.4 & 1–2.5 µm with and without FS-TENG, and ΔP (Pa) is the pressure drop. Fig. 4b shows that without FS-TENG, the quality factor of PP/PAN increased with increasing thickness as compared to pristine PP, with further increase when FS-TENG was connected. Especially, (1.1–1.4)-fold enhancement of the quality factor when charging at 1.8 kV was achieved by PP/PAN-2h and PP/PAN-4h. The filtration efficiency of PP/PAN-2h and PP/PAN-4h for particle size of 0.3–0.4 & 1–2.5 µm with and without FS-TENG is provided for comparison in Fig. 4c. With FS-TENG, the overall filtration efficiency of PP/PAN-2h increased from 74.98% to 81.81% for 0.3–0.4 µm and from 90.45% to 97.47% for 1–2.5 µm. Likewise, PP/PAN-4h reached an enhancement of around 3%, from 85.54% to 88.68% for 0.3–0.4 µm and from 96.05% to 99.02% for 1–2.5 µm. Furthermore, the impact of airflow velocity on the filtration efficiency of PP/PAN-4h was investigated, as shown in Fig. 4d. The filtration efficiency of 0.3–0.4 & 1–2.5 µm particles gradually decreased with increasing airflow velocity from 0.1 to 0.2 m/s with and without FS-TENG charging, which agrees well with previous research [55]. Meanwhile, the pressure drop of the hybrid air filters linearly increased with the increased speed of airflow (Fig. 4e).

Fig. 4.

Filtration performance with/without FS-TENG (charging at 1.8 kV). (a) Pressure drop. (b) Quality factor. (c) Filtration efficiency of PP/PAN-2h and PP/PAN-4h for particle size of 0.3–0.4 and 1–2.5 µm with/without charging by FS-TENG (T = 25 oC, RH=61–65%). (d) Filtration efficiency for particle size of 0.3–0.4 and 1–2.5 µm under various airflow velocity with/without FS-TENG. (e) Pressure drop of hybrid air filter as the function of various airflow rates. (f) 48-h filtration stability of PP/PAN-4h for 0.3–0.4 µm and 1–2.5 µm particles together with pressure drop (T = 23 °C, RH=50%). (g) Photos and SEM images of PP/PAN-4h before and after the 48-h long-term stability test.

In addition, to ensure a long service life of the hybrid face mask, the stability of the PP/PAN-4h with FS-TENG charging was studied under a continuous airflow velocity of 0.15 m/s for 48 h (T = 23 °C, RH=50%). As observed in Fig. 4f, the filtration efficiency of PP/PAN-4h was stable during 48 h, with over 94% and 99% capture efficiency for 0.3–0.4 and 1–2.5 µm particles, respectively, which demonstrates effective long-term stability of the hybrid air filter for face mask development. Meanwhile, the pressure drop only showed a slight increase from 107 Pa to 115 Pa after 48-h continuous filtration. The filtration performance of the hybrid air filter as compared to the previously reported air filter with the aid of triboelectric effect was summarized in Table S1. Fig. 4g shows the digital photos along with the surface morphologies of PP/PAN-4h before and after 48-h test. Agglomerated particles can be clearly found on the surface of the filter, which demonstrates the high effectiveness of the hybrid air filter for capturing environmental airborne particles. In addition, environmental RH, as verified by the previous research [25], [29], has a big impact on the tribo-charges of TENG as well as filtration efficiency of the filters, especially for particles with size smaller than 1 µm. Thus, we conducted the humidity experiment in the range of 55–90% by adjusting the environmental RH through humidifier and dehumidifier (Fig. S8, detailed experiment process and discussion shown in Supporting Information). It is observed that the environmental moisture shows no significant impact on the filtration performance of our hybrid air filter.

2.4. Filtration performance for particle size of 11.5–205.4 nm and sterilization effect

In addition to the filtration performance of particle size of 0.3–2.5 µm, the removal efficiency of particle sizes in the range of 11.5–205.4 nm was also conducted at different thicknesses of the hybrid air filters, and charging voltages with and without FS-TENG, as shown in Figs. 5a and S9. It is noticed that the filtration efficiency of pristine PP and coated PP was quite low, with only 50% for particle size of 100 nm. However, the efficiency significantly increased when hybrid air filter was employed, and further increased with increasing PAN thickness, exhibiting similar capture behavior of the hybrid air filter for 0.3–2.5 µm. Nevertheless, the enhancement of filtration efficiency for UFPs was not that significant when external voltage was applied. This is because Brownian diffusion is mainly responsible for the filtration of UFPs [56]. A comparison of filtration performance for particle size of 115.5–154 nm and 154–205.4 nm by the hybrid air filters with and without FS-TENG at 1.8 kV is plotted in Fig. 5b, where enhancement of 1.6–3% and 3.4–6.8% for 115.5–154 nm and 154–205.4 nm, respectively, was achieved.

Fig. 5.

Filtration efficiency for particle size of 11.5–205.4 nm. (a) Comparison of single-layer PP and hybrid PP/PAN with different thicknesses in the absence of electric field. (b) Filtration efficiency of particle sizes at 115.5–154 nm and 154–205.4 nm by PP/PAN with/without FS-TENG. (c) Photographs of agar plate representing the sterilization effect of hybrid air filter. Control: AgNW-coated PP/PAN with E. coli suspensions without charging. With TENG: AgNW-coated PP/PAN with E. coli suspensions charged by FS-TENG at 1.8 kV for 2.5 h.

To demonstrate the sterilization effect of the hybrid air filter under electric field supplied by FS-TENG, gram-negative bacterium Escherichia coli was selected. Two hybrid air filters (PP/PAN-4h) were sprayed coated with a layer of Ag nanowires (NWs, 0.5 mg/mL) on the surface of PAN, followed by transferring 100 µL of E. coli suspension on the surface of the coated filters (details see Experimental Section). Accordingly, one sample was connected with FS-TENG and charged at 1.8 kV for 2.5 h while the other was left without charging (control). A colony-forming unit (CFU) method was applied to enumerate the number of E. coli colonies. As shown in Fig. 5c, the sample with TENG charging demonstrated 100% sterilization capability in comparison with the control sample. The main mechanism of sterilization effect is due to the synergistic effect of AgNWs as well as electric field. It is reported that AgNWs require a relatively long period of 30 h to produce sterilization effect [33], due to the slow oxidization process to release Ag+ ions [57]. On the other hand, the presence of FS-TENG (1.8 kV, 30 min) merely produced 35% of sterilization effect (not shown here), which is due to the insufficient electric field (< 105 V/cm) to break down the cell membrane [57]. While the conjunction of AgNWs and electric field facilitates the generation of Ag+ ions as well as an enhanced electric field along AgNWs edges, as a consequence, significant sterilization effect can be realized in a short time with the aid of tribo-charges. In addition, the loading of AgNWs on the hybrid air filter surface had almost no impact on the filtration performance (Fig. S10).

3. Conclusions

In summary, a hybrid air filter consisting of electrospun nanofibrous PAN and melt-blown PP was developed. Compared to single PP, the hierarchical structure of PP/PAN largely enhanced the filtration efficiency in the particle size range of 11.5 nm to 2.5 µm. Especially, higher filtration efficiency can be achieved with thicker PAN. Furthermore, with the aid of tribo-charges supplied by FS-TENG through PEDOT:PSS coated PP, the capture efficiency further increased by 3–7%. This improved design took the synergistic effect of enhanced mechanical interception (via hybrid nano/micro fibrous structure) and electrostatic forces (via tribo-charges), which enabled the filtration efficiency of particle size of 0.3–0.4 and 1–2.5 µm (PP/PAN-4h) to increase from 54% to 85.54%, and 89.72–96.05%, respectively, compared to the current conventional air filter used in surgical masks. The filtration efficiency was further promoted to 88.68% (0.3–0.4 µm) and 99.02% (1–2.5 µm) through charging by FS-TENG at 1.8 kV, resulting in a 9.3–34.68% efficiency enhancement for particles of 0.3–2.5 µm compared to the state-of-the-art air filters. In addition, PP/PAN-4 h shows 48-h long-term stability with high capture efficiency of 94% for 0.3–0.4 µm and 99% for 1–2.5 µm at an airflow rate of 0.15 m/s (T = 23 °C, RH=50%), demonstrating stable effective service life. Besides, the low price of the tribo-charge enhanced hybrid air filter mask was estimated in comparison with N95 mask as listed in Table S2. Furthermore, a 100% surface sterilization effect of the air filter can be realized by tribo-charges in conjunction with AgNW-coating. This study provides a promising approach for the redesign of current air filter used in surgical masks using a facile cost-effective process, with low pressure drop, high removal efficiency, and greatly extended service life. Further study will be devoted to the realization of lightweight and wearable FS-TENG face mask that is capable of scavenging daily human motions for tribo-charges supply.

4. Experimental Section

4.1. Materials

Polyacrylonitrile (PAN, Mw = 150,000), poly(3,4-ethylenedioxythiophene)- poly(styrenesulfonate) (PEDOT:PSS, 1.1% in H2O, surfactant-free), and dimethyl sulfoxide (DMSO, Mw = 78.13, ≥ 99.9%) were purchased from Sigma-Aldrich. N, N-dimethylformamide (DMF) was purchased from RCI Labscan Limited. Commercial polypropylene (PP, 26.4 ± 1.5 g/m2) derived from the medical face mask was purchased from Taobao, China.

4.2. Preparation of hybrid nano/micro fibrous air filter (PP/PAN)

Firstly, PAN was dissolved in DMF solvent to form a solution with a concentration of 6 wt%. Then, PAN nanofibrous films with various thicknesses were fabricated via an electrospinning machine by adjusting the electrospinning time from 2 to 5 h. PAN solutions were pumped out by a syringe pump and a Cu mesh was used to collect the electrospun PAN. A high voltage of 10 kV was applied between the micro-needle and the Cu mesh. Accordingly, PEDOT:PSS was mixed with 5 wt% of DMSO and stirred for 3 h at room temperature to improve the conductivity of the PEDOST:PSS. Then, one side of PP was spray coated PEDOT:PSS by a pneumatic airbrush (0.5 mm of nozzle) and dried. Finally, narrow Cu tape was adhered at the four edges of the coated PP side, leaving one end for the connection of FS-TENG. Consequently, the hybrid air filter was fabricated by stacking a PAN layer on the top of the uncoated side of PP. The resultant hybrid air filters were denoted as PP/PAN-2 h, PP/PAN-4h, and PP/PAN-5h with the thickness of 107.4 ± 8.4 µm, 140.2 ± 12.8 µm, and 154 ± 8.2 µm, respectively, as compared to PP of 95 ± 8.2 µm. Besides, the mechanical properties of the hybrid air filter (PP/PAN-4h) in comparison with the pristine PP and coated PP were examined (Table S3 and Fig. S9) to ensure a wearable potential of the hybrid air filter for face mask.

4.3. Fabrication of FS-TENG

A FS-TENG was fabricated composing of FEP (200 mm × 150 mm, thickness of 50 µm) as negative triboelectric material, NBR (95 mm × 146 mm) as positive counterpart (slider), and two copper film electrodes (95 mm × 150 mm) with a gap distance of 10 mm.

4.4. Filtration performance measurement

Fig. 2b exhibited the particle filtration process for the developed hybrid air filter. A draught fan provided a steady face velocity of 0.15 m/s and drove particles in the air towards the filter. Two particle counters (Model 9306, TSI) were employed to measure the particle number concentration before and after filtration. The particle sizes were divided into five bins: 0.3–0.4, 0.4–0.5, 0.5–0.7, 0.7–1, and 1–2.5 µm. For particle size of 11.5–205.4 nm, a scanning mobility particle sizer (Nanoscan 3910, TSI) was used to monitor the particle number concentration on both sides of the test filter. The particle sizes were divided into ten bins: 11.5–15.4, 15.4–20.5, 20.5–27.4, 27.4–36.5, 36.5–48.7, 48.7–64.9, 64.9–86.6, 86.6–115.5, and 115.5–205.4 nm. PM filtration efficiency was calculated by comparing the particle number concentration before and after filtration. PM particles in the environment were took into account in this study to simulate a real application scenario. The airborne particles mainly stemmed from two categories, namely natural particles (such as soil debris, sea salt, and dust) and anthropogenic particles (such as direct emissions, sulfates, organics, and black carbon). At least three specimens and three measurements for each specimen were carried out to minimize the impact of fluctuations of PM concentration in the environment. The PM particles in the ambient environment had a wide size distribution (Fig. S3).

4.5. Sterilization test

An E. coli TOP10 strain, a gram-negative bacterium, was grown in 5 mL of nutrient broth (NB) medium in a shaking incubator for overnight at 37 °C and 200 rpm. After that, 50 µL of the grown culture was added into 5 mL of sterile 0.85% sodium chloride solution and from this solution, 100 µL was transferred onto the surface of Ag NW-coated PAN which was then connected with FS-TENG for charging 2.5 h at 1.8 kV. Another Ag NW-coated PAN with the same inoculated bacteria without charging was used as the control. Subsequently, test samples inoculated with bacteria were transferred into sterile 50 mL conical centrifuge tubes containing 25 mL of 0.85% sodium chloride solution and were incubated for 2 h at 37 °C and 200 rpm. Finally, colony-forming unit (CFU) test on NB agar plate was carried out after serial dilution of the cultures.

4.6. Characterization

X-ray diffraction patterns of PP and PEDOT:PSS coated PP were collected on an X-ray diffractometer (XRD, SmartLab, Rigaku, Japan). The sheet resistance of the coated PP was measured by a four-point probe resistivity meter (Loresta-AX, MCP-T370, Japan). The surface morphologies of PP and PAN were observed by a field emission scanning electron microscopy (FESEM, JSM-7800F, Japan) at 5 kV. The surface morphologies of PP/PAN-4h before and after long-term stability test were observed by a scanning electron microscopy (SEM, Carl Zeiss EVO 10, Germany) at 15 kV. The surface potential of the PP with and without TENG charging was recorded on a grounded Surface DC Voltmeter (Model:SVM2, AlphaLab, USA). The output voltage of the FS-TENG was measured by an electrometer (Keithley 6514) at current channel in connection with a resistance of 1 GΩ.

CRediT authorship contribution statement

Lingyun Wang: fabricated the FS-TENG and the conductive air filter layer, conducted the air filtration experiments, did the sterilization experiment, and wrote the manuscript. Ye Bian: prepared PAN fibers, conducted the air filtration experiments, and revised the manuscript. Chee Kent Lim: did the sterilization experiment and revised the manuscript. Zhuolun Niu: helped the PAN preparation. Patrick K.H. Lee: reviewed and revised the manuscript. Chun Chen: supervised the air filtration experiments, reviewed, and commented on the manuscript. Li Zhang: reviewed and commented on the manuscript. Walid A. Daoud: supervised, reviewed, and revised the manuscript. Yunlong Zi: conceived the project, supervised, reviewed, and revised the manuscript, and provided funding acquisition.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was funded by Research Grants Council Early Career Scheme, HKSAR, China (Grant no. 24206919), Innovation and Technology Support Programme Tier 3, HKSAR, China (Grant no. ITS/085/18).

Footnotes

Supplementary data associated with this article can be found in the online version at doi:10.1016/j.nanoen.2021.106015.

Appendix A. Supplementary material

Supplementary material

.

References

- 1.Lelieveld J., Evans J.S., Fnais M., Giannadaki D., Pozzer A. The contribution of outdoor air pollution sources to premature mortality on a global scale. Nature. 2015;525:367–371. doi: 10.1038/nature15371. [DOI] [PubMed] [Google Scholar]

- 2.Nel A. Air pollution-related illness: effects of particles. Science. 2005;308:804–806. doi: 10.1126/science.1108752. [DOI] [PubMed] [Google Scholar]

- 3.Zhang Q., Jiang X.J., Tong D., Davis S.J., Zhao H.Y., Geng G.N., Feng T., Zheng B., Lu Z.F., Streets D.G., Ni R.J., Brauer M., van Donkelaar A., Martin R.V., Huo H., Liu Z., Pan D., Kan H.D., Yan Y.Y., Lin J.T., He K.B., Guan D.B. Transboundary health impacts of transported global air pollution and international trade. Nature. 2017;543:705–709. doi: 10.1038/nature21712. [DOI] [PubMed] [Google Scholar]

- 4.Cohen A.J., Brauer M., Burnett R., Anderson H.R., Frostad J., Estep K., Balakrishnan K., Brunekreef B., Dandona L., Dandona R., Feigin V., Freedman G., Hubbell B., Jobling A., Kan H., Knibbs L., Liu Y., Martin R., Morawska L., Pope C.A., Shin H., Straif K., Shaddick G., Thomas M., van Dingenen R., van Donkelaar A., Vos T., Murray C.J.L., Forouzanfar M.H. Estimates and 25-year trends of the global burden of disease attributable to ambient air pollution: an analysis of data from the global burden of diseases study 2015. Lancet. 2017;389:1907–1918. doi: 10.1016/S0140-6736(17)30505-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Liu H., Cao C.Y., Huang J.Y., Chen Z., Chen G.Q., Lai Y.K. Progress on particulate matter filtration technology: basic concepts, advanced materials, and performances. Nanoscale. 2020;12:437–453. doi: 10.1039/c9nr08851b. [DOI] [PubMed] [Google Scholar]

- 6.Schraufnagel D.E. The health effects of ultrafine particles. Exp. Mol. Med. 2020;52:311–317. doi: 10.1038/s12276-020-0403-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Sohrabi C., Alsafi Z., O’Neill N., Khan M., Kerwan A., Al-Jabir A., Iosifidis C., Agha R. World Health Organization declares global emergency: a review of the 2019 novel coronavirus (COVID-19) Int. J. Surg. 2020;76:71–76. doi: 10.1016/j.ijsu.2020.02.034. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Leung N.H.L., Chu D.K.W., Shiu E.Y.C., Chan K.H., McDevitt J.J., Hau B.J.P., Yen H.L., Li Y.G., Ip D.K.M., Peiris J.S.M., Seto W.H., Leung G.M., Milton D.K., Cowling B.J. Respiratory virus shedding in exhaled breath and efficacy of face masks. Nat. Med. 2020;26:676–680. doi: 10.1038/s41591-020-0843-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Feng S., Shen C., Xia N., Song W., Fan M.Z., Cowling B.J. Rational use of face masks in the COVID-19 pandemic. Lancet Respir. Med. 2020;8:434–436. doi: 10.1016/S2213-2600(20)30134-X. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Liu Y., Ning Z., Chen Y., Guo M., Liu Y.L., Gali N.K., Sun L., Duan Y.S., Cai J., Westerdahl D., Liu X.J., Xu K., Ho K.F., Kan H.D., Fu Q.Y., Lan K. Aerodynamic analysis of SARS-CoV-2 in two Wuhan hospitals. Nature. 2020;582:557–560. doi: 10.1038/s41586-020-2271-3. [DOI] [PubMed] [Google Scholar]

- 11.Zangmeister C.D., Radney J.G., Vicenzi E.P., Weaver J.L. Filtration efficiencies of nanoscale aerosol by cloth mask materials used to slow the spread of SARS-CoV-2. ACS Nano. 2020;14:9188–9200. doi: 10.1021/acsnano.0c05025. [DOI] [PubMed] [Google Scholar]

- 12.Wang H.L., Lin S., Yang S., Yang X.D., Song J.N., Wang D., Wang H.Y., Liu Z.L., Li B., Fang M.H., Wang N., Wu H. High-temperature particulate matter filtration with resilient yttria-stabilized ZrO2 nanofiber sponge. Small. 2018;14 doi: 10.1002/smll.201800258. [DOI] [PubMed] [Google Scholar]

- 13.Liu C., Hsu P.C., Lee H.W., Ye M., Zheng G.Y., Liu N.A., Li W.Y., Cui Y. Transparent air filter for high-efficiency PM2.5 capture. Nat. Commun. 2015;6:6205. doi: 10.1038/ncomms7205. [DOI] [PubMed] [Google Scholar]

- 14.Lee S., Cho A.R., Park D., Kim J.K., Han K.S., Yoon I.J., Lee M.H., Nah J. Reusable polybenzimidazole nanofiber membrane filter for highly breathable PM2.5 dust proof mask. ACS Appl. Mater. Interfaces. 2019;11:2750–2757. doi: 10.1021/acsami.8b19741. [DOI] [PubMed] [Google Scholar]

- 15.Li C.X., Kuang S.Y., Chen Y.H., Wang Z.L., Li C.J., Zhu G. In Situ Active Poling of Nanofiber Networks for Gigantically Enhanced Particulate Filtration. ACS Appl. Mater. Interfaces. 2018;10:24332–24338. doi: 10.1021/acsami.8b07203. [DOI] [PubMed] [Google Scholar]

- 16.Zhang Y.Y., Yuan S., Feng X., Li H.W., Zhou J.W., Wang B. Preparation of nanofibrous metal-organic framework filters for efficient air pollution control. J. Am. Chem. Soc. 2016;138:5785–5788. doi: 10.1021/jacs.6b02553. [DOI] [PubMed] [Google Scholar]

- 17.Fan F.R., Tian Z.Q., Wang Z.L. Flexible triboelectric generator! Nano Energy. 2012;1:328–334. [Google Scholar]

- 18.Wang Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors - Principles, problems and perspectives. Faraday Discuss. 2014;176:447–458. doi: 10.1039/c4fd00159a. [DOI] [PubMed] [Google Scholar]

- 19.Wang L.Y., Daoud W.A. Highly flexible and transparent polyionic-skin triboelectric nanogenerator for biomechanical motion harvesting. Adv. Energy Mater. 2019;9 [Google Scholar]

- 20.Xia X., Fu J., Zi Y. A universal standardized method for output capability assessment of nanogenerators. Nat. Commun. 2019;10:4428. doi: 10.1038/s41467-019-12465-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Wang L.Y., Liu Y.M., Liu Q., Zhu Y.Y., Wang H.Y., Xie Z.Q., Yu X.G., Zi Y.L. A metal-electrode-free, fully integrated, soft triboelectric sensor array for self-powered tactile sensing. Microsyst. Nanoeng. 2020;6:59. doi: 10.1038/s41378-020-0154-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Wang L.Y., Wang Y., Wang H., Xu G.Q., Doring A., Daoud W.A., Xu J.B., Rogach A.L., Xi Y., Zi Y.L. Carbon dot-based composite films for simultaneously harvesting raindrop energy and boosting solar energy conversion efficiency in hybrid cells. ACS Nano. 2020;14:10359–10369. doi: 10.1021/acsnano.0c03986. [DOI] [PubMed] [Google Scholar]

- 23.Liu Y., Mo J., Fu Q., Lu Y., Zhang N., Wang S., Nie S. Enhancement of triboelectric charge density by chemical functionalization. Adv. Funct. Mater. 2020;30 [Google Scholar]

- 24.Nie S., Guo H., Lu Y., Zhuo J., Mo J., Wang Z.L. Superhydrophobic cellulose paper-based triboelectric nanogenerator for water drop energy harvesting. Adv. Mater. Technol. 2020;5 [Google Scholar]

- 25.Bai Y., Han C.B., He C., Gu G.Q., Nie J.H., Shao J.J., Xiao T.X., Deng C.R., Wang Z.L. Washable multilayer triboelectric air filter for efficient particulate matter PM2.5 removal. Adv. Funct. Mater. 2018;28 [Google Scholar]

- 26.Han C.B., Jiang T., Zhang C., Li X.H., Zhang C.Y., Cao X., Wang Z.L. Removal of particulate matter emissions from a vehicle using a self-powered triboelectric filter. ACS Nano. 2015;9:12552–12561. doi: 10.1021/acsnano.5b06327. [DOI] [PubMed] [Google Scholar]

- 27.Zhang C., Lin X., Zhang N., Lu Y., Wu Z., Liu G., Nie S. Chemically functionalized cellulose nanofibrils-based gear-like triboelectric nanogenerator for energy harvesting and sensing. Nano Energy. 2019;66 [Google Scholar]

- 28.Gu G.Q., Han C.B., Lu C.X., He C., Jiang T., Gao Z.L., Li C.J., Wang Z.L. Triboelectric nanogenerator enhanced nanofiber air filters for efficient particulate matter removal. ACS Nano. 2017;11:6211–6217. doi: 10.1021/acsnano.7b02321. [DOI] [PubMed] [Google Scholar]

- 29.Liu G.X., Nie J.H., Han C.B., Jiang T., Yang Z.W., Pang Y.K., Xu L., Guo T., Bu T.Z., Zhang C., Wang Z.L. Self-powered electrostatic adsorption face mask based on a triboelectric nanogenerator. ACS Appl. Mater. Interfaces. 2018;10:7126–7133. doi: 10.1021/acsami.7b18732. [DOI] [PubMed] [Google Scholar]

- 30.Han K.S., Lee S., Kim M., Park P., Lee M.H., Nah J. Electrically activated ultrathin PVDF-TrFE air filter for high-efficiency PM1.0 filtration. Adv. Funct. Mater. 2019;29 [Google Scholar]

- 31.He X., Zou H.Y., Geng Z.S., Wang X.F., Ding W.B., Hu F., Zi Y.L., Xu C., Zhang S.L., Yu H., Xu M.Y., Zhang W., Lu C.H., Wang Z.L. A hierarchically nanostructured cellulose fiber-based triboelectric nanogenerator for self-powered healthcare products. Adv. Funct. Mater. 2018;28 [Google Scholar]

- 32.Ghatak B., Banerjee S., Ali S.B., Bandyopadhyay R., Das N., Mandal D., Tudu B. Design of a self-powered triboelectric face mask. Nano Energy. 2021;79 doi: 10.1016/j.nanoen.2020.105387. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Gu G.Q., Han C.B., Tian J.J., Jiang T., He C., Lu C.X., Bai Y., Nie J.H., Li Z., Wang Z.L. Triboelectric nanogenerator enhanced multilayered antibacterial nanofiber air filters for efficient removal of ultrafine particulate matter. Nano Res. 2018;11:4090–4101. [Google Scholar]

- 34.Rivnay J., Inal S., Collins B.A., Sessolo M., Stavrinidou E., Strakosas X., Tassone C., Delongchamp D.M., Malliaras G.G. Structural control of mixed ionic and electronic transport in conducting polymers. Nat. Commun. 2016;7:11287. doi: 10.1038/ncomms11287. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Manjakkal L., Pullanchiyodan A., Yogeswaran N., Hosseini E.S., Dahiya R. A wearable supercapacitor based on conductive PEDOT:PSS-coated cloth and a sweat electrolyte. Adv. Mater. 2020;32 doi: 10.1002/adma.201907254. [DOI] [PubMed] [Google Scholar]

- 36.Inoue A., Yuk H., Lu B.Y., Zhao X.H. Strong adhesion of wet conducting polymers on diverse substrates. Sci. Adv. 2020;6 doi: 10.1126/sciadv.aay5394. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Bian Y., Wang R., Wang S., Yao C., Ren W., Chen C., Zhang L. Metal–organic framework-based nanofiber filters for effective indoor air quality control. J. Mater. Chem. A. 2018;6:15807–15814. [Google Scholar]

- 38.Zhang S.C., Liu H., Tang N., Zhou S., Yu J.Y., Ding B. Spider-web-inspired PM0.3 filters based on self-sustained electrostatic nanostructured networks. Adv. Mater. 2020;32 doi: 10.1002/adma.202006930. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Bian Y., Chen C., Wang R., Wang S., Pan Y., Zhao B., Chen C., Zhang L. Effective removal of particles down to 15 nm using scalable metal-organic framework-based nanofiber filters. Appl. Mater. Today. 2020;20 [Google Scholar]

- 40.Wang S.H., Xie Y.N., Niu S.M., Lin L., Wang Z.L. Freestanding triboelectric-layer-based nanogenerators for harvesting energy from a moving object or human motion in contact and non-contact modes. Adv. Mater. 2014;26:2818–2824. doi: 10.1002/adma.201305303. [DOI] [PubMed] [Google Scholar]

- 41.Fu J., Xia X., Xu G., Li X., Zi Y. On the maximal output energy density of nanogenerators. ACS Nano. 2019;13:13257–13263. doi: 10.1021/acsnano.9b06272. [DOI] [PubMed] [Google Scholar]

- 42.Wang S., Lin L., Xie Y., Jing Q., Niu S., Wang Z.L. Sliding-triboelectric nanogenerators based on in-plane charge-separation mechanism. Nano Lett. 2013;13:2226–2233. doi: 10.1021/nl400738p. [DOI] [PubMed] [Google Scholar]

- 43.Yang W.Q., Chen J., Zhu G., Yang J., Bai P., Su Y.J., Jing Q.S., Cao X., Wang Z.L. Harvesting energy from the natural vibration of human walking. ACS Nano. 2013;7:11317–11324. doi: 10.1021/nn405175z. [DOI] [PubMed] [Google Scholar]

- 44.Xie Y.N., Wang S.H., Niu S.M., Lin L., Jing Q.S., Yang J., Wu Z.Y., Wang Z.L. Grating-structured freestanding triboelectric-layer nanogenerator for harvesting mechanical energy at 85% total conversion efficiency. Adv. Mater. 2014;26:6599–6607. doi: 10.1002/adma.201402428. [DOI] [PubMed] [Google Scholar]

- 45.Wang L.Y., Daoud W.A. Hybrid conductive hydrogels for washable human motion energy harvester and self-powered temperature-stress dual sensor. Nano Energy. 2019;66 [Google Scholar]

- 46.Lin H., He M., Jing Q., Yang W., Wang S., Liu Y., Zhang Y., Li J., Li N., Ma Y., Wang L., Xie Y. Angle-shaped triboelectric nanogenerator for harvesting environmental wind energy. Nano Energy. 2019;56:269–276. [Google Scholar]

- 47.Hinds W.C. John Wiley & Sons; 2012. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles. [Google Scholar]

- 48.Bian Y., Wang S.J., Zhang L., Chen C. Influence of fiber diameter, filter thickness, and packing density on PM2.5 removal efficiency of electrospun nanofiber air filters for indoor applications. Build. Environ. 2020;170 [Google Scholar]

- 49.He C., Wang Z.L. Triboelectric nanogenerator as a new technology for effective PM2.5 removing with zero ozone emission. Prog. Natl. Sci. Mater. Int. 2018;28:99–112. [Google Scholar]

- 50.Park H.S., Park Y.O. Simulation of particle deposition on filter fiber in an external electric field. Korean J. Chem. Eng. 2005;22:303–314. [Google Scholar]

- 51.Joe Y.H., Shim J., Shin W.G., Park H.S. Effects of an external electric field on the collection efficiency of air filters: Filtration mechanisms with an external e-field. Aerosol Sci. Technol. 2017;51:1409–1418. [Google Scholar]

- 52.Wang C.S. Electrostatic forces in fibrous filters - a review. Powder Technol. 2001;118:166–170. [Google Scholar]

- 53.Cai R.R., Li S.Z., Zhang L.Z., Lei Y. Fabrication and performance of a stable micro/nano composite electret filter for effective PM2.5 capture. Sci. The Total Environ. 2020;725 doi: 10.1016/j.scitotenv.2020.138297. [DOI] [PubMed] [Google Scholar]

- 54.Bian Y., Zhang L., Chen C. Experimental and modeling study of pressure drop across electrospun nanofiber air filters. Build. Environ. 2018;142:244–251. [Google Scholar]

- 55.Liu H., Zhang S.C., Liu L.F., Yu J.Y., Ding B. A fluffy dual-network structured nanofiber/net filter enables high-efficiency air filtration. Adv. Funct. Mater. 2019;29 [Google Scholar]

- 56.Liu J.Q., Jiang T., Li X.H., Wang Z.L. Triboelectric filtering for air purification. Nanotechnology. 2019;30 doi: 10.1088/1361-6528/ab0e34. [DOI] [PubMed] [Google Scholar]

- 57.Schoen D.T., Schoen A.P., Hu L.B., Kim H.S., Heilshorn S.C., Cui Y. High speed water sterilization using one-dimensional nanostructures. Nano Lett. 2010;10:3628–3632. doi: 10.1021/nl101944e. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material