Abstract

Background

Agricultural handle equipment is present on all production areas' farms. They are handy and portable; however, excessive use can lead to acute traumas or accidental injuries. Repetitive movements, awkward postures, and hand-arm vibrations predispose them to pain and work-related musculoskeletal disorders. The purpose of this study was to observe the interaction of handle equipment in terms of electromyographic activity and analyze the postural work-related alterations.

Materials and methods

Twenty male agricultural operators, mean age 24 ± 1.54 years, underwent the electromyographic analysis testing their muscular activities with a brushcutter, electric saw, and hedge trimmer in four different test conditions.

Results

The brushcutter proved to be the agricultural handle equipment with the higher mean frequency (3.37 ± 0.38 Hz) and root mean square (5.25 ± 1.24 ms−2). Furthermore, the digital postural analysis showed a general asymmetry of the main arm and the respective side of the trunk. The head resulted right inclined in the anterior frontal plane by 5.7° ± 1.2°; the right scapula lower than the left in the posterior frontal plane (8.5° ± 1.8°), and a working trunk inclination of 34.15° ± 5.7°.

Conclusions

Vibrations of handle equipment and awkward working postures represent a risk for agricultural operators. Preventive measures are required to avoid young operators from experiencing musculoskeletal disorders all lifelong.

Keywords: agricultural workers, musculoskeletal disorders, occupational injuries, posture, prevention

1. Introduction

Agricultural employment comprises a large portion of the world's workforce, estimating 1.3 billion people involved in this field. However, this job has been recognized as one of the most harmful industries [1]. Agricultural handle equipment (AHE) is present on all production areas' farms. Brushcutters are necessary to control weeds; electric saws and hedge trimmers to redefine the shape of trees, bushes, and hedges. Numerous studies observed the effects of mechanical and physical–chemical methods used for this practice [[2], [3], [4]] to quantify the various risks to which operators are often exposed, such as whole-body vibrations (WBV), hand-arm vibrations (HAV), noise, physical fatigue, improper postures, and exposure to chemicals [5,6]. AHE is easily maneuverable and transportable; however, it can often cause acute traumas such as accidental injuries to the feet or hands, and chronic injuries resulting in weakening the hand nerves or low back pain [[7], [8], [9], [10]]. Hand-arm vibration syndrome (HAVS) is a condition that occurs due to consistent use of vibrating equipment (e.g., brushcutter or electric saw) affecting operators that are continuously exposed to HAV. The distal part of the body, i.e., fingers and hand, absorb the vibrations, causing HAVS's vascular and sensorineural symptoms [11]. The vibrations reach then the arm and the shoulder, affecting the sensorineural component leading to pain and partial hand loss of functions [11].

Work-related musculoskeletal disorders are the most disabling condition among agricultural operators [12], whereas repetitive movements, long hours of activities, awkward working posture, or WBV lead to chronic pain. Over time repeated use of portable equipment can predispose operators to pain in wrists, hands, shoulder, and neck, as found in 92% of a population of Spanish agricultural workers [13]. The usual working posture places a significant physical demand on the body, especially the back, doubling the risk of lower back pain than the general working population [14]. Several studies analyzed the use of professional brushcutters, highlighting the increased risk of developing HAVS, including circulatory, sensory, and manual disorders [[15], [16], [17], [18]].

The surface electromyography (sEMG) and the digital postural analysis can measure the adverse effects of the AHE vibrations on the body and the posture alterations arising from its incorrect use during the daily working time. This study aimed to observe the response capacity of sEMG deriving from three different agricultural portable equipment in different static and dynamic conditions. Furthermore, we analyzed the altered postures and the trunk stress to understand any complementarity between the prolonged use of these tools and the musculoskeletal pain onset.

2. Materials and methods

Twenty male young agricultural operators were recruited at the Occupational Medicine Clinics, University of Catania. The mean age of our sample was 24 ± 1.54 years, mean weight 75 ± 2.76 kg, mean height 176.13 ± 6.01 cm, with an experience of 4.3 ± 1.49 years in the field of agriculture, all right-side dominant. The exclusion criteria were recent traumas to the upper limbs, neurodegenerative or musculoskeletal diseases, and heart diseases. Portable sEMG evaluated the muscles' activity while holding AHE. The data collection was approved by the Research Center in Motor Activities (CRAM), University of Catania (protocol n.: CRAM-016-2020, 16/03/2020), in accordance with the Declaration of Helsinki. Prior to testing, all participants provided written informed consent. The participants were instructed to perform four different measurements while holding an AHE: static with the engine off; static at minimum engine speed; static at maximum engine speed; dynamic with repeated gestures in a vertical and horizontal direction (simulating the cutting gesture).

The most common tools used in gardening, i.e., monobloc brushcutter, electric saw, and electric hedge trimmer were used as AHE to test their vibrations over the upper arms. The monobloc brushcutter (Fig. 1A) had a nominal power of 0.8 kW and a weight of 5.6 kg, consisting of the motor, a tubular metal rod within which the transmission shaft rotates, and the rotating tool. The electric saw (Fig. 1B) had a cutting bar length of 40 cm, a rated power of 1.6 kW, and a weight of 3.9 kg. The electric hedge trimmer (Fig. 1C) was equipped with a double-action blade 50 cm long, with a distance between the teeth of 16 mm, had a nominal power of 0.58 kW, and a weight of 4.1 kg.

Fig. 1.

Agricultural handle equipment. (A) brushcutter, (B) electric saw, and (C) hedge trimmer.

Four portable and lightweight sEMG data loggers with an internal lithium-ion battery (OT Bioelectronics, Italy) were placed on the forearms and shoulders. All sEMG signals were sampled at a frequency of 800 Hz; then amplified and filtered. Two pairs of adhesive circular surface electrodes were applied with a diameter of 24 mm and a 15 cm cable together with the reference electrode as indicated by the manufacturer [19]. The electrodes were positioned over the neck area, i.e., transverse fibers of trapezius, rhomboids major and minor, levator scapulae, and in the inner part of the forearm, i.e., flexor digitorum superficialis, flexor pollicis longus (Fig. 2), according to occupational medicine guidelines [20]. The data collected were processed to extract the mean frequency (MNF), a fatigue index based on observing the frequency of the surface electromyographic signal [[21], [22], [23]], i.e., myoelectric signal and conduction velocity alterations of the examined muscles during the dynamic exercise proposed in the experiment [24].

Fig. 2.

sEMG application over the neck and shoulders (A), and the forearm (B).

The AHE's vibrations flowing through the handle were collected with a triaxial accelerometer hand/arm (10mV/G) weighing 4 grams, according to the indication of UNI EN ISO 5349-1, placed on a unique handle (Fig. 3) between two fingers, as suggested by Peterson et al. [25]. Only the vibrations of the holding hand were collected for the experiment. The collection frequency was 24.5 Hz, as proposed by Seman et al. [26]. The elaboration process consisted of extracting the central area of the acquisition and calculating the root mean square value (RMS) of the frequency weighted acceleration, expressed in ms−2.

Fig. 3.

The analyzer used to collect the vibrations (A) made of an accelerometer (B) and an handle equipment (C) to hold the accelerometer.

The postural assessment has been carried out through a digital tablet application, APECS mobile app (New Body Technology SAS, Grenoble, France), able to reconstruct the posture from photography [27]. We placed adhesive markers over the anatomical landmarks, and then, after the photography, we conducted the digital marker placement to analyze the whole body posture as reported in Fig. 4. Furthermore, we analyzed the working posture, i.e., trunk inclination (TI), leg – hip – shoulder complex (LHS), Fig. 5. We analyzed the TI by measuring the angle between a line passing through the C7 process and the posterior superior iliac spine and a straight line passing through the same points. For the analysis of LSH complex, we placed the markers at the lateral malleolus, greater trochanter, and humeral greater tuberosity.

Fig. 4.

Digital postural analysis in frontal (A), posterior (B), and sagittal (C) planes. The white points indicate the anatomical landmarks examined for the postural assessment. The yellow lines indicate the symmetry evaluation between the two sides of the same anatomical landmark. The green line indicates the perpendicular of the body. In figure (A), the red line indicates the lateral shift of the body. In figure (C), the fuchsia zones indicate the angular variation to the axis.

Fig. 5.

Explanatory image of the postural analysis of the working posture in the upright position (A), slightly forward inclined (B), and excessive forward inclination (C).

2.1. Data analysis

Statistical analysis was performed using R Project for Statistical Computing (Vienna, Austria). The data have been processed through descriptive and inferential analysis. The Shapiro–Wilk test verified the normality distribution; the Breusch–Pagan test verified the homogeneity of the variance. The analysis of variance (ANOVA) was applied to test the differences among the different agricultural equipment in static or dynamic conditions. A post hoc test and the Duncan test measured specific differences between pairs of means (p-value <0.01). The dependent variables were the MNF representing electromyography and the RMS for vibrations. The independent variables were the different AHE used, the test conditions (static or dynamic), the direction of the movements (vertical or horizontal), and the body segments. Mean and SD were used to analyze the data of the digital postural analysis.

3. Results

The highest MNF and RMS values were observed under the dynamic conditions of all three AHE involved in the study. The brushcutter's electromyography showed high values even in the static condition with the engine at maximum speed. Meanwhile, the RMS values of the static conditions of the saw and hedge trimmer showed values close to those obtained under dynamic conditions. Table 1 reports the maximum values recorded, mean value, and standard deviation.

Table 1.

Results of electromyographic and vibrational tests in different conditions referred to the shoulder holding the AHE

| AHE | Test condition | MNF (Hz) |

RMS (ms−2) |

||||

|---|---|---|---|---|---|---|---|

| Max | Mean (SD) | Max | Mean (SD) | ||||

| Brushcutter | Static engine off | 8,75 | 2,07 | (0,42) | |||

| Static min engine speed | 9,52 | 2,30 | (0,37) | 5,91 | 5,61 | (0,18) | |

| Static max engine speed | 14,99 | 4,04 | (0,72) | 6,38 | 6,25 | (0,12) | |

| Dynamic horizontal | 15,50 | 5,54 | (0,95) | 9,26 | 9,13 | (0,11) | |

| Electric saw | Static engine off | 8,47 | 2,20 | (0,44) | |||

| Static min engine speed | 9,55 | 2,45 | (0,50) | 2,79 | 2,60 | (0,20) | |

| Dynamic vertical | 12,54 | 3,41 | (0,60) | 3,09 | 2,92 | (0,12) | |

| Hedge trimmer | Static engine off | 6,94 | 1,88 | (0,33) | |||

| Static min engine speed | 9,40 | 2,40 | (0,49) | 5,04 | 4,88 | (0,11) | |

| Dynamic vertical | 20,22 | 4,64 | (0,99) | 5,16 | 4,99 | (0,08) | |

| Dynamic horizontal | 16,64 | 3,80 | (0,82) | 5,25 | 5,08 | (0,11) | |

MNF: mean frequency; RMS: root mean square; AHE: portable agricultural equipment.

The ANOVA showed that the values of MNF for electromyography of the right shoulder and RMS for vibrations had a normal distribution with homogeneity between the variances. The ANOVA on the MNF values revealed a no variability between operators (p-value> 0.05). On the contrary, a statistical difference (p-value < 0.01) of the MNF was found between the brushcutter, electric saw, and hedge trimmer; between the four different test conditions (static, dynamic, engine on, and off); and between the right and left side of the body. The ANOVA conducted on RMS values revealed a significant influence between the static or dynamic conditions (p-value <0.01).

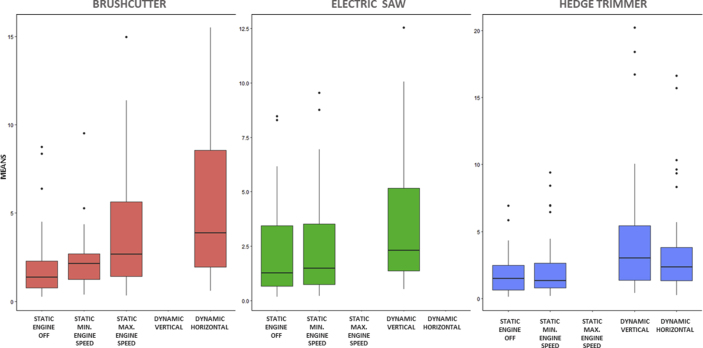

The Duncan test (Fig. 6) showed a statistical difference between the different test conditions (static with engine off, static at min engine speed, static at max engine speed, dynamic in vertical and horizontal movements), with mean MNF values of approximately double at maximum engine rpm. Among the AHE of the study (Fig. 7), the brushcutter showed the highest mean MNF value (3.37 ± 0.38 Hz), the hedge trimmer (3.18 ± 0.42 Hz), and the saw (2.68 ± 0.51 Hz).

Fig. 6.

Duncan test to compare means of the different test conditions.

Fig. 7.

Boxplot to compare means of each AHE in the different test conditions.

The mean RMS values were statistically different (p-value <0.01) with higher values for the brushcutter (5.25 ± 1.24 ms−2), then the hedge trimmer (3.74 ± 0.65 ms−2), and the saw (1.84 ± 0.12 ms−2). The test conditions were also statistically different from each other (p-value> 0.01). Horizontal movements had the highest mean value (7.10 ± 1.75 ms−2), then the static test with the engine at the maximum rpm (6.24 ± 1.08 ms−2), the static test at minimum rpm (4.37 ± 1.02 ms−2), and finally the vertical movements showed the lower mean value (3.95 ± 0.48 ms−2). Mean MNF differences were significant between the right (1.99 ± 0.04 Hz) and left (4.00 ± 0.12 Hz) part of the body, between both forearms (4.72 ± 1.09 Hz) and both shoulders (1.8 ± 0.37 Hz). The correlation between electromyography and vibrations (Fig. 8) was significant for more than 60%. The tests showed higher MNF values corresponding to higher AHE accelerations (Fig. 9).

Fig. 8.

Average MNF in the two observed body regions (forearms and shoulders) distinguished between right and left.

Fig. 9.

A line plot to compare MEAN with RMS (A) the gray area indicates the confidence interval based on the SD. RMS boxplot of the different AHE (B).

The digital postural assessment showed an asymmetry of the main arm involving the respective side of the trunk. As reported in Table 2, there is a general asymmetry of the main anatomical landmarks presenting a constant misalignment bending on the right side. The frontal and back sides data indicate a general lean toward the right side; the data of the sagittal plane indicate a forward lean. The segments reporting a relevant difference are head right inclined in the anterior frontal plane (5.7° ± 1.2°); the right scapula lower than the right in the posterior frontal plane (8.5° ± 1.8°); the head forward-shifted in the sagittal plane (37.6° ± 10.9°). Furthermore, the trunk inclination and the leg-hip-shoulder angle of the working posture indicate a TI = 34.15° ± 5.7° and LHS = 136.8° ± 6.9°.

Table 2.

Results of digital postural analysis

| Body plane | Body segment | Mean | SD |

|---|---|---|---|

| Anterior frontal | Body alignment | 1.4° R | 0.46 |

| Head | 5.7° R | 1.23 | |

| Acromion | 3.3° R | 1.03 | |

| ASIS | 1.8° R | 0.70 | |

| Posterior frontal | Shoulders | 3.2° R | 0.90 |

| Scapulae | 8.5° R | 1.80 | |

| PSIS | 8.1° R | 1.67 | |

| Sagittal | Body alignment | 4.4° F | 1.27 |

| Head | 37.6° F | 10.9 | |

| Acromion | 7.1° F | 3.10 | |

| Pelvis | 11.5° F | 4.80 | |

| Femoris | 8.1° F | 2.60 | |

| Fibula | 8.5° F | 2.49 |

ASIS: anterior superior iliac spine; PSIS: posterior superior iliac spine; R = right-shifted; F: forward-shifted.

4. Discussion

Agricultural operators are often subjected to harmful conditions that expose the body to discomfort and awkward postures. The vibrations deriving from prolonged use of AHE can predispose the upper arms to joint inflammation. Additionally, assuming the wrong posture repeated over time overburdens the trunk, causing low back pain or disc degeneration. Based on these conditions, we investigated the interaction between the AHE's vibrations and working postures on agricultural operators. Prolonged and excessive WBV or HAV are associated with various occupational health disorders, mainly concerning hands, arms, and spine [28,29]. Our results showed that the brushcutter is the AHE that induces higher stress in sEMG activity and vibration stress. It presents the higher sEMG value during the horizontal movements, probably because it requires a greater muscle force to move it due to its length. Furthermore, it produces the higher vibrations stress value during these conditions. Then follows the hedge trimmer, with the higher sEMG activity during the vertical movements, presenting the higher vibrations during the horizontal movements. Finally, the electric saw is the AHE inducing less sEMG activity and vibration stress attesting to its higher values only during the horizontal movements. All the AHE considered produce higher values during the movements, which is the most alarming condition since agricultural operators actively use these tools. WBV can cause muscle inflammation and microtrauma of the spine, conditioning the biodynamic response to vibrations. Tian et al. [30] analyzed the prevalence of degenerative lumbar osteoarthritis in 3859 Chinese adults; they reported that WBV is a predominant risk factor in developing spine osteoarthritis (OR 2.21, 95% CI 1.51–3.23). The increased risk of developing low back pain due to WBV has also been investigated among farmers, assessing an OR of 2.44 (95% CI 0.95–6.43) [31]. Vihlborg et al. [32] observed that exposure to HAV increases the risk of carpal tunnel syndrome with an OR of 1.61 (95% CI 1.46–1.77), and this risk increases for every mean year exposure of 2.5 ms−2 with an OR of 1.84 (95% CI 1.38–2.46). They conducted these analyses in men <30 years of age, as we did. It corroborates our idea that the HAVS occurs when operators are young, but they cannot feel the harmful effect of vibration because the body hides them. This mechanism predisposes young operators to encounter chronic pathologies in old age [[33], [34], [35]]. An antivibration handle could be used to mitigate the adverse effects of WBV or HAV. They can reduce vibrations by about 60%, keeping the vibrations within the exposure limit values defined by the European Union [36]. Another method could be using vibration-reducing gloves which substantially reduce the vibrations transmitted to the palm, hand dorsum, and wrist [37].

We detected several differences between the right and left arm, observing a general lower sEMG activity for the right arm. The sample was all right-side dominant, which explains this side's reduced sEMG activity. However, this condition can alter the balance of the body. The digital posture analysis highlighted an altered posture due to awkward working positions. All participants had the right side lower than the left, specifically the shoulder, scapula, and elbow; furthermore, the head was right tilted. The right anatomical landmarks lowered may be a work-induced side effect; however, the effects of weight-bearing asymmetry may lead to postural instability and increase the contralateral's compensatory activity [38]. The operators constantly keep an awkward posture, whereas the left side is kept higher to compensate for the overburden of the right side. Repeated over time, it establishes a definitive paramorphism that leads early to sporadic pains, lately to musculoskeletal disorders, i.e., low back pain or disc herniation. The sagittal trunk inclination of 34.15° ± 5.7° highlights a risky condition. Different authors analyzed the association between trunk inclination and LBP, assessing the risk of developing it when working with a trunk flexion greater than 60°. Punnett et al. [39] classified the trunk inclination into three categories: “normal” equal to 20°, “mild” from 20° to 41°, and “severe” when exceeding 45°. The risk to develop LBP is four times higher (OR 4.2, p-value = 0.014) for those working at least 10% of the working time (8 hours) in mild trunk flexion, and six times higher for those working more than the 10% of the working time in mild trunk flexion (OR 6.1, p-value = 0.014). Hoogendoorn et al. [40] found that exceeding 10% of the working time with the trunk flexed more than 30° can increase the risk of developing LBP (RR 1.19, 95% CI 0.86–1.65). Meanwhile, Coenen et al. [41] observed that exceeding 5% of the working time with the trunk flexed more than 60° has a higher risk of developing LBP (OR 2.35, 95% CI 1.46–3.79).

The predisposition to musculoskeletal disorders due to work-related conditions is a red flag that the Ministry of Labour has to consider. Industrial policies and rural development strategies should offer innovative solutions since operators are unaware of the potential risks of their job. For instance, in Italy, the incidence of injuries in the agricultural sector is significant—targeted interventions should be addressed and implemented [42]. Educational and training models could support the operators, such as: specialized courses, learning of risk analysis and accident prevention, increase in workplace safety checks, financial support in the purchase of more advanced products, or dissemination of the communications promoting awareness to job accidents.

5. Conclusions

Vibrations of AHE and awkward working postures represent a risk that increases occupational illness, injuries, and chronic diseases among agricultural operators. We investigated these interactions by analyzing the sEMG activity of arm and trunk muscles using three AHE, i.e., monobloc brushcutter, an electric saw, and electric hedge trimmer, and the postural alterations present among a young group of agricultural operators. The results highlight that the prolonged vibration exposure and constantly awkward posture can predispose the operators to suffer from HAVS and neck and low back pain. The brushcutter is the handle equipment determining the higher muscle activity and vibration from the hands to the spine. Furthermore, the more evident postural alterations are: head right inclined and forward shifted asymmetry of the scapulae and an increased trunk inclination during the working posture. Young operators exposed to these risks mean adults with undeniable musculoskeletal pathologies. Preventive measures are required, i.e., antivibration handle to mitigate the adverse effects of vibrations, educational, and training models to prevent incorrect postures while working.

Funding

This work was supported by the University Research Project Grant (PIACERI Found-NATURE-OA, 2020-2022), Department of Biomedical and Biotechnological Sciences (BIOMETEC), University of Catania, Italy.

Conflicts of interest

All authors (Federico Roggio, Ermanno Vitale, Veronica Filetti, Venerando Rapisarda, Giuseppe Musumeci, and Elio Romano) declare no conflict of interest for the article titled: Ergonomic evaluation of young agricultural operators using handle equipment through electromyography and vibrations analysis between the fingers, submitted to Safety and Health at Work.

References

- 1.Momeni Z., Choobineh A., Razeghi M., Ghaem H., Azadian F., Daneshmandi H. Work-related musculoskeletal symptoms among agricultural workers: a cross-sectional study in Iran. J Agromedicine. 2020;25(3):339–348. doi: 10.1080/1059924X.2020.1713273. [DOI] [PubMed] [Google Scholar]

- 2.Ahmad M.T., Tang L., Steward B.L. In: Automation: The future of weed control in cropping systems. Young S.L., Pierce F.J., editors. Springer Netherlands; Dordrecht: 2014. Automated mechanical weeding; pp. 125–137. [Google Scholar]

- 3.Pannacci E., Tei F. Effects of mechanical and chemical methods on weed control, weed seed rain and crop yield in maize, sunflower and soyabean. Crop Prot. 2014;64:51–59. [Google Scholar]

- 4.Peruzzi A., Ginanni M., Fontanelli M., Raffaelli M., Bàrberi P. Innovative strategies for on-farm weed management in organic carrot. Renewable Agric Food Syst. 2007;22(4):246–259. [Google Scholar]

- 5.Colantoni A., Sirio C., Vello M., Dell'Antonia D., Malev O., Gubiani R. Risk analysis of agricultural, forestry and green maintenance working sites. Contemp Eng Sci. 2015;8:1257–1266. [Google Scholar]

- 6.Monarca D., Cecchini M., Guerrieri M., Santi M., Bedini R., Colantoni A. Safety and health of workers: exposure to dust, noise and vibrations. Acta Horticulturae. 2009;845:437–442. [Google Scholar]

- 7.Okubo N., Nakagawa H., Furuya K., Toi T. Springer; 2014. Vibration reduction of brush cutter. Proceedings of the 31st IMAC, A conference on structural dynamics; pp. 225–233. [Google Scholar]

- 8.Mohan D., Patel R. Design of safer agricultural equipment: Application of ergonomics and epidemiology. Int J Ind Ergon. 1992;10(4):301–309. [Google Scholar]

- 9.Lings S., Leboeuf-Yde C. Whole-body vibration and low back pain: a systematic, critical review of the epidemiological literature 1992–1999. Int Arch Occup Environ Health. 2000;73(5):290–297. doi: 10.1007/s004200000118. [DOI] [PubMed] [Google Scholar]

- 10.Rosecrance J., Rodgers G., Merlino L. Low back pain and musculoskeletal symptoms among Kansas farmers. Am J Ind Med. 2006;49(7):547–556. doi: 10.1002/ajim.20324. [DOI] [PubMed] [Google Scholar]

- 11.Shen S.C., House R.A. Hand-arm vibration syndrome: What family physicians should know. Can Fam Physician. 2017;63(3):206–210. [PMC free article] [PubMed] [Google Scholar]

- 12.McCurdy S.A., Samuels S.J., Carroll D.J., Beaumont J.J., Morrin L.A. Agricultural injury in California migrant Hispanic farm workers. Am J Ind Med. 2003;44(3):225–235. doi: 10.1002/ajim.10272. [DOI] [PubMed] [Google Scholar]

- 13.López-Aragón L., López-Liria R., Callejón-Ferre Á.-J., Pérez-Alonso J. Musculoskeletal disorders of agricultural workers in the greenhouses of Almería (Southeast Spain) Saf Sci. 2018;109:219–235. [Google Scholar]

- 14.Holmberg S., Stiernström E.L., Thelin A., Svärdsudd K. Musculoskeletal symptoms among farmers and non-farmers: a population-based study. Int J Occup Environ Health. 2002;8(4):339–345. doi: 10.1179/107735202800338623. [DOI] [PubMed] [Google Scholar]

- 15.Cerruto E., Manetto G., Schillaci G. Vibration produced by hand-held olive electrical harvesters. J Agric Eng. 2012;43(2):e12. [Google Scholar]

- 16.Deboli R., Calvo A., Preti C., Inserillo M. Design and test of a device for acceleration reproducibility of hand held olive harvesters. Int J Ind Ergon. 2014;44:581–589. [Google Scholar]

- 17.Calvo A., Romano E., Preti C., Schillaci G., Deboli R. Upper limb disorders and hand-arm vibration risks with hand-held olive beaters. Int J Ind Ergon. 2018;65:36–45. [Google Scholar]

- 18.Bernardi B., Quendler E., Benalia S., Mantella A., Zimbalatti G. Occupational risks related to vibrations using a brush cutter for green area management. Ann Agric Environ Med. 2018;25(2):255–258. doi: 10.26444/aaem/75684. [DOI] [PubMed] [Google Scholar]

- 19.Bioelettronica O. User manual v 1.42 EMG-USB 2013 [Available from: https://www.otbioelettronica.it/index.php?preview=1&option=com_dropfiles&format=&task=frontfile.download&catid=53&id=33&Itemid=1000000000000.

- 20.Gazzoni M., Afsharipour B., Merletti R. Surface EMG in ergonomics and occupational medicine. Surf Electromyogr : Physiol Eng Appl. 2016:361–391. [Google Scholar]

- 21.Bonato P., Gagliati G., Knaflitz M. Analysis of myoelectric signals recorded during dynamic contractions. IEEE Eng Med Biol Mag. 1996;15(6):102–111. [Google Scholar]

- 22.Molinari F., Knaflitz M., Bonato P., Actis M.V. Electrical manifestations of muscle fatigue during concentric and eccentric isokinetic knee flexion-extension movements. IEEE Trans Biomed Eng. 2006;53(7):1309–1316. doi: 10.1109/TBME.2006.873680. [DOI] [PubMed] [Google Scholar]

- 23.González-Izal M., Malanda A., Navarro-Amézqueta I., Gorostiaga E.M., Mallor F., Ibañez J., Izquierdo M. EMG spectral indices and muscle power fatigue during dynamic contractions. J Electromyogr Kinesiol. 2010;20(2):233–240. doi: 10.1016/j.jelekin.2009.03.011. [DOI] [PubMed] [Google Scholar]

- 24.Cifrek M., Medved V., Tonković S., Ostojić S. Surface EMG based muscle fatigue evaluation in biomechanics. Clin Biomech. 2009;24(4):327–340. doi: 10.1016/j.clinbiomech.2009.01.010. [DOI] [PubMed] [Google Scholar]

- 25.Peterson D., Asaki T., Kudernatsch S., Brammer A., Cherniack M., editors. Incorporating a finger adapter into iso 10819 assessments to measure the vibration transmissibility of gloves at the fingers. Proceedings of the 4th American Conference on Human Vibration ACHV; 2014. [Google Scholar]

- 26.Seman M.T., Hamid M.N.A., Noor N.M.N. Hand arm vibration of coconut grater machine. Int J Innovative Technol Exploring Eng. 2019 [Google Scholar]

- 27.Roggio F., Ravalli S., Maugeri G., Bianco A., Palma A., Di Rosa M., Musumeci G. Technological advancements in the analysis of human motion and posture management through digital devices. World J Orthop. 2021;12(7):467–484. doi: 10.5312/wjo.v12.i7.467. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Hermanns I., Raffler N., Ellegast R., Fischer S., Göres B. Simultaneous field measuring method of vibration and body posture for assessment of seated occupational driving tasks. Int J Ind Ergon. 2008;38:255–263. [Google Scholar]

- 29.Truta A., Cristea F., Arghir M. The influence of brush cutters vibrations on human body. Adv Eng Forum. 2013;8–9:445–452. [Google Scholar]

- 30.Tian W., Lv Y., Liu Y., Xiao B., Han X. The high prevalence of symptomatic degenerative lumbar osteoarthritis in Chinese adults: a population-based study. Spine (Phila Pa 1976) 2014;39(16):1301–1310. doi: 10.1097/BRS.0000000000000396. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Hartman E., Oude Vrielink H.H.E., Huirne R.B.M., Metz J.H.M. Risk factors for sick leave due to musculoskeletal disorders among self-employed Dutch farmers: a case-control study. Am J Ind Med. 2006;49(3):204–214. doi: 10.1002/ajim.20276. [DOI] [PubMed] [Google Scholar]

- 32.Vihlborg P., Pettersson H., Makdoumi K., Wikström S., Bryngelsson I.L., Selander J., Graff P. Carpal tunnel syndrome and hand-arm vibration: a Swedish national registry case-control study. J Occup Environ Med. 2022 doi: 10.1097/JOM.0000000000002451. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Nieradko-Iwanicka B. Hand-arm vibration syndrome. Reumatologia. 2019;57(6):347–349. doi: 10.5114/reum.2019.90364. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Aarhus L., Veiersted K.B., Nordby K.C., Bast-Pettersen R. Neurosensory component of hand-arm vibration syndrome: a 22-year follow-up study. Occup Med (Lond) 2019;69(3):215–218. doi: 10.1093/occmed/kqz029. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Guglielmino C., Musumeci G. Early elbow osteoarthritis in competitive enduro motorcyclist. Scand J Med Sci Sports. 2020;30(7):1287–1290. doi: 10.1111/sms.13664. [DOI] [PubMed] [Google Scholar]

- 36.Thota J., Kim E., Freivalds A., Kim K. Development and evaluation of attachable anti-vibration handle. Appl Ergon. 2022;98 doi: 10.1016/j.apergo.2021.103571. [DOI] [PubMed] [Google Scholar]

- 37.Xu X.S., Welcome D.E., McDowell T.W., Warren C., Service S., Lin H., Chen Q., Dong R.G. An investigation of the effectiveness of vibration-reducing gloves for controlling vibration exposures during grinding handheld workpieces. Appl Ergon. 2021;95 doi: 10.1016/j.apergo.2021.103454. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Anker L.C., Weerdesteyn V., van Nes I.J.W., Nienhuis B., Straatman H., Geurts A.C.H. The relation between postural stability and weight distribution in healthy subjects. Gait Posture. 2008;27(3):471–477. doi: 10.1016/j.gaitpost.2007.06.002. [DOI] [PubMed] [Google Scholar]

- 39.Punnett L., Fine L.J., Keyserling W.M., Herrin G.D., Chaffin D.B. Back disorders and nonneutral trunk postures of automobile assembly workers. Scand J Work Environ Health. 1991;17(5):337–346. doi: 10.5271/sjweh.1700. [DOI] [PubMed] [Google Scholar]

- 40.Hoogendoorn W.E., Bongers P.M., de Vet H.C., Douwes M., Koes B.W., Miedema M.C., Ariëns G.A., Bouter L.M. Flexion and rotation of the trunk and lifting at work are risk factors for low back pain: results of a prospective cohort study. Spine (Phila Pa 1976) 2000;25(23):3087–3092. doi: 10.1097/00007632-200012010-00018. [DOI] [PubMed] [Google Scholar]

- 41.Coenen P., Kingma I., Boot C.R., Twisk J.W., Bongers P.M., van Dieën J.H. Cumulative low back load at work as a risk factor of low back pain: a prospective cohort study. J Occup Rehabil. 2013;23(1):11–18. doi: 10.1007/s10926-012-9375-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Zambon I., Piergentili A., Salvati L., Monarca D., Matyjas-Łysakowska P., Colantoni A. Applied Research for a safer future: exploring recent job accidents in agriculture, Italy (2012–2017) Processes. 2018;6(7) [Google Scholar]