Abstract

Xanthones are significant bioactive compounds and secondary metabolites in mangosteen pericarps. A xanthone is a phenolic compound and versatile scaffold that consists of a tricyclic xanthene-9-one structure. A xanthone may exist in glycosides, aglycones, monomers or polymers. It is well known that xanthones possess a multitude of beneficial properties, including antioxidant activity, anti-inflammatory activity, and antimicrobial properties. Additionally, xanthones can be used as raw material and/or an ingredient in many food, pharmaceutical, and cosmetic applications. Although xanthones can be used in various therapeutic and functional applications, their properties and stability are determined by their extraction procedures. Extracting high-quality xanthones from mangosteen with effective therapeutic effects could be challenging if the extraction method is insufficient. Although several extraction processes are in use today, their efficiency has not yet been rigorously evaluated. Therefore, selecting an appropriate extraction procedure is imperative to recover substantial yields of xanthones with enhanced functionality from mangosteens. Hence, the present review will assist in establishing a precise scenario for finding the most appropriate extraction method for xanthones from mangosteen pericarp by critically analyzing various conventional and unconventional extraction methods and their ability to preserve the stability and biological effects of xanthones.

Keywords: extraction, process, mangosteen, xanthones, pericarps, by-products

1. Introduction

Mangosteen (Garcinia mangostana L.) is one of the essential commercial fruits of Thailand and also in many countries in Southeast Asia and is generally recognized as the queen of fruit as its appearance has petals on the head that resembles a queen’s crown. It is a round fruit that is green when unripe and turns dark purple upon fully ripe. The fruit contains several petals of white, consumable flesh, which has a sweet taste, and the number of petals can be easily known by the calyxes present beneath the fruits. Thailand is the second largest producer after Indonesia in Southeast Asia, whereas India is the largest producer in the world. From Thailand, the export of mangosteen in 2020 was 292,147 t accounting for 409,466 USD. The export was divided into two main categories, including fresh mangosteen (291,951 t) and frozen mangosteen (196 t) [1]. The demand for mangosteen in the world market will likely increase and expand continuously if the product has been certified with good agricultural practice standards. The main markets for fresh mangosteen from Thailand are China, Vietnam, and Hong Kong, while frozen mangosteen is exported to South Korea, Taiwan, and the United States [2]. Transporting fresh mangosteen is highly problematic due to the transportation delay and cost; compared with the costlier air transport, ocean transport is inexpensive, and, due to time consumption, the fruits get spoiled before they reach their destination, which restricts the expansion of the distribution chain of fresh mangosteen fruits. Therefore, the transportation of fresh mangosteen is a significant problem for exporters. Exporting processed mangosteen products is a promising means to resolve the transportation problem of fresh mangosteen and increase the product’s shelf life. There are several types of processed products of mangosteen, such as frozen mangosteen, mangosteen juice, mangosteen jam, stirred mangosteen, mangosteen cider, and mangosteen vinegar [3].

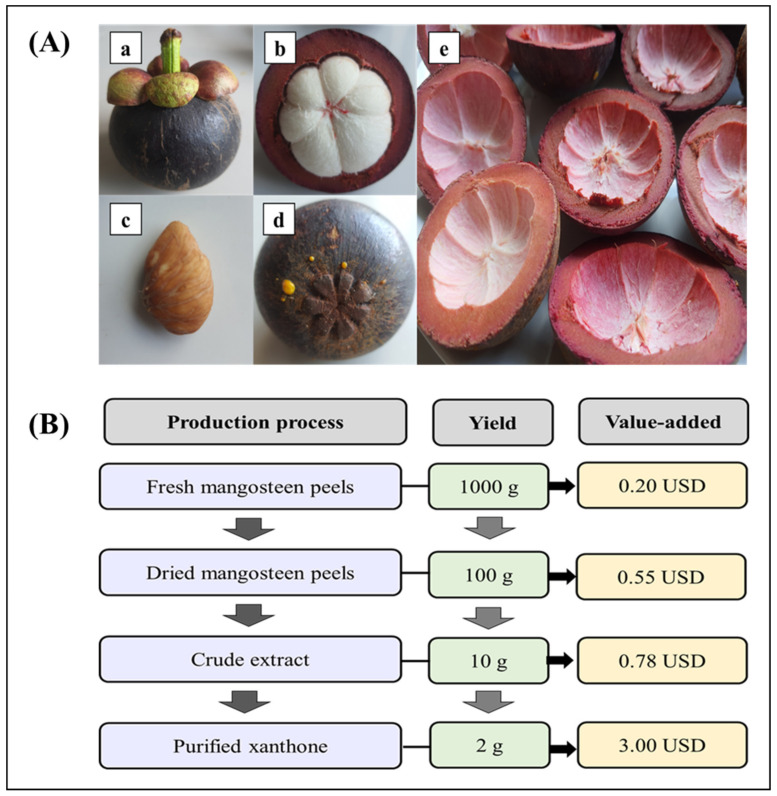

A mangosteen contains 83% pericarps, 15% pulp, and 2% seeds by weight [4]. Mangosteen pericarps are a by-product of mangosteen processing (Figure 1A). Mangosteen pericarps are a nutrient-rich by-product which contains 82.50% carbohydrate, 6.45% fat, 3.02% protein, 2.17% ash, and 2.17% free sugars [5]. Mangosteen pericarps contain several health-beneficial and functional phenolic compounds, including xanthones, benzophenones, tannins, flavonoids, and anthocyanins [6]. Mainly, xanthones are abundantly found in the mangosteen pericarp compared to the other phenolics. It is estimated that there are 200 different types of xanthones are present in nature, with the majority belonging to the families of Bonnetiaceae, Clusiaceae, and Podostemaceae. There are more than 40 xanthones in Mesua thwaitesii, especially mangosteen [7]. The xanthone compound is a powerful bioactive compound that exhibits excellent health benefits. It acts as an antioxidant, antimicrobial, anti-cancer and anti-tumor molecule and has high resistance against the virus [8]. Typically, the fresh mangosteen pericarp has a low economic value (0.2 USD per 1 kg). However, it contains many beneficial properties and can be converted to a valued added product when the functional chemicals, particularly xanthones from the pericarp, are extracted. Studies have proven that 1 kg of fresh mangosteen could provide 2 g of pure xanthones, which is 15 times higher than the cost of fresh pericarp alone [9] (Figure 1B). Therefore, the extraction process of pure xanthones plays a significant function in many industries. There are several methods of extraction and purification of xanthones from mangosteen pericarps, and the extracts obtained can be commercialized. Therefore, the collection of knowledge about the extraction techniques and various biological effects of xanthones from mangosteen pericarp are extensively discussed in this review.

Figure 1.

Mangosteen fruit and its parts ((a) fruit, (b) pulp, (c) seed, (d) sepals under the mangosteen, and (e) peel) (A), and the value added from mangosteen pericarps to xanthones extract (B).

2. Characteristics of Mangosteen

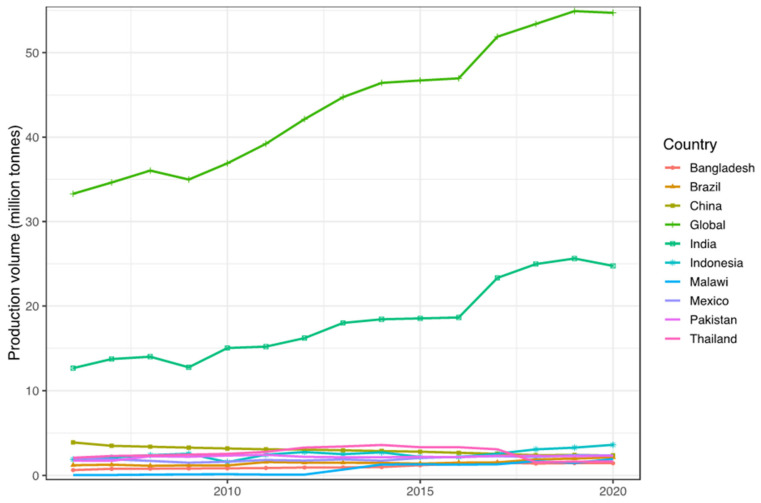

The mangosteen plant is native to Indonesia and Malaysia. The most cultivated mangosteen is G. mangostana var. mangostana and another two varieties of mangosteen are wild species, G. mangostana var. malaccensis and G. mangostana var. borneensis [10]. It is cultivated on a large scale in countries such as Bangladesh, Brazil, China, India, Indonesia, Malaysia, Malawi, Mexico, Pakistan, and Thailand (Figure 2), and for small-scale production in other countries, including Australia (Southern Queensland, New South Wales), Cambodia, Cuba, Dominica, Ecuador, Guatemala, Honduras, Jamaica, Laos PDR, Madagascar, Myanmar, Panama, Puerto Rico, Singapore, Sri Lanka, Trinidad, Tobago, USA (Florida, Hawaii), and Vietnam. Mangosteen is a tropical evergreen tree categorized as slow-growing, erect with a pyramidal crown, and normally the plant height ranges between 6 and 25 m.

Figure 2.

The top 10 producers of fresh mangosteen in the world. Data [11].

The mangosteen tree has dark brown or nearly black flaking bark, and the tree’s inner bark contains yellow, gummy, and bitter latex [12]. At the same time, the leaves are short-stalked, ovate-oblong, or elliptic, leathery, thick, dark green, slightly glossy above, yellowish-green, and dull beneath. The leaf size is around 9 to 25 cm long and 4.5 to 10 cm wide, with a conspicuous, pale midrib [13]. Flowers are 4–5 cm wide, fleshy, male, or hermaphrodite on the same tree, with four sepals and four ovate. The fruit is rounded, dark purple to red–purple, and smooth externally, 3.4–7.5 cm in diameter and weighs 70–150 g; the rind is 6–10 mm thick, with four to eight triangular segments of snow-white, juicy, soft flesh [14]. Mangosteen trees require an average annual rainfall of around 1270 mm, the ideal temperature for mangosteen growth is between 25 and 35 °C, with more than 80% relative humidity, and this tree can grow well in coarse soils, slit and is able to be well-drained. Mangosteen can be cultivated in a wide range of altitudes, between 76 and 500 m above sea level [15].

3. Xanthones in the Mangosteen Pericarp Uses

3.1. Xanthones in the Mangosteen Pericarp

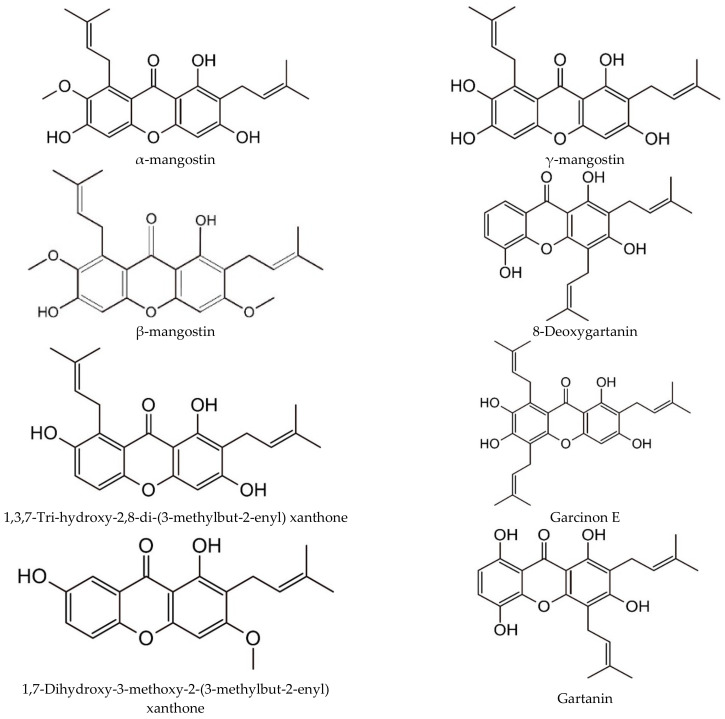

Xanthones (CH3H8O2) are found in various parts of mangosteen, such as heartwood, bark, yellow gum (or yellow latex), leaves and pericarp (Figure 3). Studies have found that the concentrations of α-mangostin and γ-mangostin in the yellow gum collected from the outside of mangosteen pericarp were 382.2 and 144.9 mg/g wet basis, respectively [11]. The concentrations of α-mangostin and γ-mangostin in yellow gum were approximately six times and seven times higher than those in the mangosteen pericarp. The yellow gum is a rich source of xanthones in mangosteen fruit, followed by the pericarp and pulp [11]. The main components in the yellow gum of mangosteen are triterpenoids, flavonoids, and tannins, while mangosteen pericarps contain lignin, phenolic, benzophenones and xanthones and these compounds exhibit a strong pharmacological effect [16]. α-mangostin is the most important xanthone found at 69.02% in the mangosteen pericarp, followed by γ-mangostin, which is around 17.86%. Additionally, the minor compounds (13.13%), including gartanin, 8-deoxygartanin, garcinon E, 1,7-dihydroxy-3-methoxy-2-(3-methylbut-2-enyl) xanthone, and 1,3,7-tri-hydroxy-2,8-di (3-methylbut-2-enyl) xanthone, are also found in the pericarps. Furthermore, anthocyanin pigments (31.29%) and tannin (7.14%) are also found in the mangosteen pericarp [7]. The pericarp of mangosteen contains ten times higher levels of phenolics than the pulp; furthermore, pericarp antioxidant activity is twenty times higher than in the pulp. The extraction of mangosteen pericarp by organic solvents leads to the separation of polar and non-polar compounds. Non-polar components include xanthones and their prenylated benzophenone, and polar compounds consist of catechins, procyanidins, and anthocyanidins. Ethanol has been used to extract xanthones from mangosteen pericarp.

Figure 3.

Chemical structure of major and minor xanthone compounds.

According to Rizaldy et al. [17], 14 types of xanthone derivatives were found in mangosteen pericarp, which include 7-odemethylmangostanin, mangostanin, 8-deoxygartanin, gartanin, garcinone E, trapezifolixanthone, padiaxanthone, tovophyllin A, 1,5,8-trihydroxy-3-methoxy-2 [3-methyl-2-butenyl] xanthone, garcinone B, 1,3,7-trihydroxy-2,8-di-(3-methylbut-2-enyl) xanthone, mangostenone D, mangostinone, and 1,7-dihydroxy-2-(3-methylbut-2-enyl)-3-methoxyxanthone.

3.2. Bioactivity of Xanthones

3.2.1. Experimental Studies

The α-mangostin from mangosteen pericarp is the major component of xanthones. Many biological activities and pharmacological properties are associated with it, including antioxidant activity, antimicrobial properties, anti-obesity properties, anti-inflammatory properties, anti-hyperglycemia properties, anti-diabetic properties, anti-neoplastic properties, anti-proliferative properties, apoptosis-inducing properties and anti-tumor properties. The γ -mangostin is the second most common compound in mangosteen pericarps. It inhibits the digestion of carbohydrates with the action of the α-glucosidase enzyme. It is in the small intestinal wall and used to digest the starch and carbohydrates into single sugar molecules through enzymatic hydrolysis. It impairs glucose absorption into the bloodstream and helps reduce sugar levels in the blood. In addition, γ-mangostin has also exhibited antioxidant activity, anti-inflammatory, anti-cancer, and neuroprotective effects. β-mangostin can hinder the increase of glioma cells, the most public and assertive virulent nervous system tumor. Two other bioactive xanthones that appear in mangosteen pericarps are garcinone E and gartinin. The garcinone E inhibits ovarian cancer cells and has an anti-proliferative effect on cancer cells including cervical, liver, stomach, breast, and large intestinal cancers. Gartinin has a preventive effect on cervical cancer cells and lymphoma [18]. The important health properties of pure xanthones extracted from mangosteen pericarp include anti-acne [19], anti-inflammatory, anti-irritating, antibacterial, and anti-blackmark effects [20], protection against free radicals [21], and skin whitening [22]. Currently, mangosteen pericarp extract and mangosteen xanthones are widely used in the medical, food supplement, oral care, and cosmetic industries. In the medical industry, pericarp extract from mangosteen is used as a raw material to produce various oral-based health products, including topical anti-inflammatories to reduce itching caused by fungi and medicinal mixtures to treat various ulcers. In the supplementary food industry, mangosteen pericarps are used to develop various dietary supplements, such as antioxidant and anti-ageing supplements, to enhance immunity. In the oral care industry, the extract from mangosteen pericarp is developed into various oral-based hygienic products such as mouthwash, toothpaste, a mixture of dental floss, and spray to remove bad breath. In the food industry, mangosteen pericarp extract is used to develop into products for consumer consumption, such as antioxidant snack-based foods, foods to increase energy, snack bars, rice powder, and healthy drinks [23]. In the cosmetic industry, pure xanthones from mangosteen pericarp are used to develop various skin care products designed to control acne and ageing, and some xanthones products promote good skin health and increase skin brightness [24].

A study from Narasimhan et al. [25] found that xanthones extracted from mangosteens inhibit the tyrosinase activities in the skin and, consequently, control the production and accumulation of melanin. γ-mangostin exhibited an anti-hyaluronidase activity and protected the skin from hyperpigmentation [21]. Janardhanan et al. [24] found that the pericarp extract of mangosteen inhibited several cariogenic bacteria, such as Streptococcus mutants, S. sanguis, S. salivarius, S. oralis and Lactobacillus acidophilus [24]. An α-mangostin is the main component from the pericarp extract that demonstrated antimicrobial activities, mainly antibacterial, against Escherichia coli, Staphylococcus aureus, Bacillus subtilis, and Pseudomonas aeruginosa, as well as anti-fungal effects against Aspergillus niger and Candida albicans [25,26]. Furthermore, Leelapornpisid [26] found that the pericarp extract from the mangosteen exhibited anti-plaque properties and controlled severe dental cavities. The in vitro study from Koh et al. [27] found that the application of xanthones from mangosteen pericarp exhibited significant inhibitory activity against the Mycobacterium tuberculosis, which was done by disrupting the inner membrane and led to ATP depletion with no cross-resistance with the current anti-TB drugs.

3.2.2. Molecular Docking Studies

Using the molecular docking technique to model the interaction between a small molecule and a protein at the atomic level [28], we can define the behavior of small molecules at the binding sites of target proteins and understand basic biochemical processes. Many molecular docking studies define the biological activities of xanthones inappropriately [20,29,30,31,32]. Mangostins and garcinones from mangosteen pericarps were found to have anti-ageing properties against enzymes such as matrix metalloproteinase 1 (MMP1), nuclear export protein (NEP), and prophenoloxidase (PPO3) [20]. Furthermore, the MMPs also damage the blood–brain barrier, consequently inducing hemorrhage, neuronal inflammation, and neuronal cell death [29]. A study from Siahaan et al. indicated that mangosteen extract is a potential drug for treating traumatic brain injury (TBI) by inhibiting the expression of MMP-2 and MMP-9 in the animal model [30].

The anti-diabetic drugs α-mangostin and γ-mangostin have been shown to control PPAR- γ receptors, the diphenyl peptidase-4 (DPP-4) enzyme, and aldose reductase [31]. The binding affinity showed more negative or almost similar affinity binding values than the several ligand-based drugs on the market. It also demonstrated several models of protein-bound bonds, including hydrogen bonding, allowing these compounds to be predicted in anti-diabetes drugs such as thiazolinediones (TZDs), which target PPAR- receptors [31]. In the study of 272 xanthones against seven fungal and two viral enzymes, they were reported as possible antimicrobial and antiviral agents. [32]. Miladiyah et al. demonstrated that xanthone derivatives could be effective as potential COX-2 inhibitors, which indicated the possibility of anti-inflammation activity [33].

3.3. Uses of Xanthones

Currently, the crude and pure xanthone extract from the pericarp of mangosteen is used widely in several industries, including medical, food supplement, oral care, food, and cosmetic industries [23]. Xanthones can be used as an oral product in the medical industry to cure ulcers and as a topical ailment to control itching and any inflammatory problems [23]. Mangosteen pericarp extract has been used to develop various dietary supplements in the food industry, enhancing immunity and antioxidant activities and aiding early ageing problems [23]. Extracts from mangosteen pericarp are used to produce mouthwash, toothpaste, dental floss, and mouth spray are a few significant products that are widely developed in the oral care industries [23]. Several products can be developed with mangosteen pericarp extracts in the food industry, such as antioxidant snack products, snack bars, and healthy beverages [23]. In addition, pure xanthone extracts from mangosteen pericarps can also be used to produce various supplementary and pharmaceutical-based products. Mangosteen pericarp extracted using ethyl acetate exhibits an inhibitory effect against the tyrosinase enzyme, which play a major role in melanin synthesis [34]. Although the pericarp extract from mangosteen showed potent antioxidant, anti-collagenase and anti-elastase activities, while γ-mangostin showed potent anti-hyaluronidase [20], the crude extract of mangosteen is a dark brown to black color, and when using this extract as an ingredient in high-value cosmetic product formulations (facial care products), it will cause the products to have an appearance that is not friendly to consumers and will make the products look inferior. Furthermore, the crude extract also retains a very small amount of xanthones [23]. Therefore, the extraction process of pure xanthones plays an important role in many industries producing value-added products from mangosteen. The bioactivities of xanthones and common uses of mangosteen pericarps extract are summarized in Table 1.

Table 1.

The bioactivities of xanthones and common uses of mangosteen pericarps extract.

| Bioactivity/Use | Component | References | |

|---|---|---|---|

| Bioactivities | antioxidant | α-mangostin | [18,19,20,21] |

| γ-mangostin | [20] | ||

| crude | [19,20,22,35] | ||

| anti-obesity/ anti-amylase/anti-glucosidase/anti-lipase | α-mangostin | [36] | |

| anti-inflammatory | α-mangostin | [37,38] | |

| γ-mangostin | [38] | ||

| anti-hyperglycemias, anti-diabetic | α-mangostin | [39] | |

| γ-mangostin | [40] | ||

| anti-neoplastic, anti-proliferative, anti-cancer | α-mangostin | [41] | |

| γ-mangostin | [42] | ||

| β-mangostin | [43] | ||

| crude | [44] | ||

| anti-apoptosis | α-mangostin | [35] | |

| neuroprotective effects/ brain protective effect | α -mangostin | [45] | |

| crude | [30] | ||

| anti-tyrosinase/ anti-collagenase/anti-elastase/ anti-hyaluronidase | α-mangostin | [20,35] | |

| anti-bacteria | α-mangostin | [19,20,21,25,26] | |

| crude | [13,19,24] | ||

| anti-TB | xanthone derivatives | [27] | |

| anti-fungi and yeast | α-mangostin | [13,25,26] | |

| Uses | cosmetic/ anti-acne | crude | [13] |

| food industry/ food supplement | crude | [46] | |

| oral care | crude | [47] | |

| deodorant | crude | [21] |

4. Extraction of Xanthones from Mangosteen Pericarps

4.1. Mangosteen Pericarp Preparation

Generally, the mangosteen fruit pericarp for xanthone extractions is selected based on the fruit maturity and ripening conditions. Studies have reported that the mangosteen fruit’s maturation period is between 1 to 4 months after flowering; however, the phytochemical contents in the fruit’s pericarp vary significantly between stages of maturation [48]. Within the maturation period, the fruit will have six stages of ripening and color, and the level of sap on the pericarp acts as a key maturity index (Table 2). However, the selection of fruit pericarp can be made from an unripe greenish yellow to fully ripe purple-black color, and fruits’ pericarps, when fully grown, despite the color of the pericarp, normally have the richest level of xanthones [49]. The extraction of xanthones from mangosteen pericarp is highly possible in fresh and/or dried forms. However, fresh mangosteen pericarps have a high moisture content, which may interfere with some solvents in the extraction [50]. Furthermore, fresh fruits have a high possibility of microbial contamination, which causes the extract to spoil easily.

Table 2.

The mangosteen ripening in all six levels.

| Level | Apparent |

|---|---|

|

5–50 % pink dots on a greenish-yellow background. The fruit is unripe and has a lot of gum. It’s difficult to separate the mangosteen pulp from the pericarps. |

|

Dots spread 51–100 %, yellow-green with pink. The fruit is practically ripe, and the gum level is less than 1. It’s difficult to separate the pulp from the pericarps of mangosteen fruit. |

|

Although the spots are not as apparent as at level 2, the mangosteen pulp can be separated from the pericarps. |

|

Mangosteen pulp can be removed from the pericarps and eaten, ranging in color from red to purple red. |

|

Mangosteen pulp is readily extracted from the pericarps and has a dark purple color. It is ready to eat and has no gum. |

|

The purple and black color pericarp represent the perfectly ripe fruit, ready to eat. |

Therefore, several studies used dried mangosteen pericarps as a suitable raw material for xanthones extraction and are more popular than fresh mangosteen pericarps [50]. The process for the preparation of dried mangosteen pericarps powder has several steps, including grading, washing, baking, or drying, grinding into powder, packing, and storing [51]. Normally, the pericarp of mangosteen is cut into small pieces and dried by either sun-drying or oven-drying between 60 to 90 °C; the pericarps are dried to obtain 14 % moisture, which is suitable for xanthone extractions [52]. The dried pericarps are ground into powder by either stone mortars or grinders to reduce the particle size and increase the contact surface area between the raw material and the solvent. After the grinding process, the ground pericarps are passed through a sieve to make the uniformly fine powder. The powder is then packed in airtight containers and stored in dry and cool conditions to prevent pest and microbial infestations. Suvarnakuta et al. [52] found that mangosteen pericarps extracted using low-pressure superheated steam drying at 75 °C retained more xanthones in the mangosteen pericarp as compared with traditional methods. In another study, Sotong and Ruaypom [53] used a fluidized bed technique with a recirculation air temperature of around 60–80 °C to dry the mangosteen’s pericarp of mangosteen. Their study found that an increased temperature to 80 °C rapidly decreased the pericarp moisture to 13.58% without severely affecting the xanthones.

4.2. Extraction

Solvent extraction is a common procedure used to separate desired components from raw materials without dissolving other components in the extraction. Generally, there are two major types of extraction categories: (1) liquid–liquid extraction is used to extract a liquid from a liquid and (2) solid–liquid extraction, or leaching, is used to dissolve the desired substance out of a solid mixture [54]. Important factors affecting solid–liquid extraction are solvent properties and solid preparation properties, such as the size, surface area, encapsulation (cell wall), time, and extraction temperature [54]. The increasing solubility and diffusion rate can vary with the influence of temperature, but the decreasing viscosity of the liquid is not affected by the temperatures. However, the high temperature will cause the impurity to dissolve and may cause the desired biological substance to be damaged. The extraction of active substances in mangosteen pericarp mostly uses solid–liquid extraction [54]. The mechanism that occurs during the extraction of xanthones from solid mangosteen pericarp powder with liquid solvent can be described as follows: (a) mass transfer of solvent to the surface of mangosteen pericarp powder, (b) the surface of the raw material is coated with a solvent, (c) extraction solvent is diffused from the surface to the porosity of the raw material, (d) solute in the raw material is dissolved in the solvent and (e) the desired solute is dispersed onto the surface of the raw material [54]. A study by Kusmayadi et al. [55] found that xanthones in mangosteen pericarp were extracted with seven different major organic solvents, including ethanol, acetone, ethyl acetate, methanol, hexane, acetic acid, and water, and their study showed that all solvents had significantly differed among each other with the extracted xanthones. Among the solvents, ethanol performed best in extracting xanthones and antioxidants. In addition, their study also found that extraction time plays a key role in retaining xanthones, and when xanthones were extracted for 48 h, they were extracted at a high level using acetone, and in short-range (24 h) extraction durations, ethanol performed well in extracting xanthones. Generally, the extraction methods of xanthones can be divided into two major types, which are (1) traditional extractions and (2) modern extractions.

4.2.1. Traditional Extraction

Traditional extraction is the easiest because it uses conventional solvents and heaters. This is still limited in many aspects; particularly, a large amount of solvent is required and takes a long time to extract while the productivity is low. The most used method is maceration. A study from Pojanaukij and Kajorncheappunngam [56] examined the capacity of the maceration method on xanthone extraction from mangosteen pericarp, and their study found that when extracting 1 kg of mangosteen pericarp that was macerated with 4 L of 95% ethanol for seven days, it was possible to obtain 1.19 mg/g of xanthones from the mangosteen pericarp. Additionally, dried mangosteen powder was also recommended for maceration extraction. A study from Yoswathana et al. [57] found that 5 g of dried mangosteen pericarp powder was extracted using 100 mL of 95% ethanol solvent without a shaker generating a yield of 31.55 mg/g of xanthone. Solvent extraction of mangosteen pericarp for the isolation of α-mangostin is performed directly or indirectly using solvent partitioning. The former approach involves direct contact of the plant material in a single solvent, e.g., chloroform [58] or methanol [59] or sequentially in multiple solvents [60], whereas the latter typically involves indirect extraction via successive solvent partitioning. A comparison of three different extraction methods using methanol and ethyl acetate as solvents was conducted to compare the yield of α-mangostine. This involved direct extraction with methanol and ethyl acetate and indirect extraction using solvent partitioning with an initial methanol extract. The results showed that direct extraction yields higher α-mangostine than indirect extraction (direct methanol extraction: 318 mg; ethyl acetate direct extraction: 305 mg; ethyl acetate indirect extraction: 209 mg per 5 g total dried pericarp) [61]. In another study, Kusmayadi et al. [55] studied the effects of different solvents (ethanol, acetone, ethyl acetate, methanol, hexane, acetic acid, and aquadest) and extraction times (24, 36, and 48 h) on total xanthone and antioxidant yield of mangosteen peel extract. Their result reported that the solvents and extraction time significantly affected total xanthone and antioxidant yield. Mangosteen peel extracted by acetone shows the best results on total xanthone at 48 h. Meanwhile, mangosteen peel extracted by ethanol for 24 h was the best result on antioxidant yield.

In addition, percolation is a continuous extraction method that uses an instrument called a percolator for the xanthone extractions. A total of 10 g of powdered dried mangosteen fruit rind was combined with 10 mL of 95% ethanol, and the combination was let to stand for 1 h. A percolator was used to add 95% ethanol to the mixture once it had been moved there (3.6L). Once the percolate was gone, the extraction was carried out at room temperature with a flow rate of 3 mL/min (20h). The α-mangostin content in the extract by percolation was 12.71 % w/w [19]. Soxhlet extraction is another traditional method for determining lipid content in food samples or essential oil content in raw materials by continuous extraction using a low-boiling solvent. Soxhlet extraction was employed to extract xanthones from dried mangosteen pericarp. The results presented that the xanthones extracted by Soxhlet were 31.26 mg/g of dried mangosteen pericarp [57]. Mangosteen pericarp was dried at a temperature of 65 °C to 15% moisture content (dry basis) and then extraction with ethanol by Soxhlet extraction obtained α-mangostin content at a level of 34.82 ± 0.17 w/w from the crude extract. The main disadvantage of the Soxhlet extraction method is that it requires large solvent volumes and takes a long extraction time at high temperature that causes the degradation of heat-sensitive compounds [62]. Ethanol extracts important substances from dried mangosteen fruit pericarps with different methods, namely maceration, percolation, Soxhlet extraction, ultrasonic extraction, and extraction using a magnetic stirrer; these substances had an anti-acne effect. With Soxhlet, crude extract (26.60% dry weight), α-mangostin (13.51%, w/w of crude extract) and anti-acne activity were obtained at a concentration of 50% ethanol, an optimal amount for extraction by Soxhlet [19].

Infusion is an extraction over a short period using hot or cold water. A ripe mangosteen with a blackish-purple tint was used. The mangosteen pericarps were shelled and briefly wetted to preserve the secondary metabolites. Then, 1000 mL of drinking water and 330 g of pericarps were combined, and the mixture was submerged for 12 h until the water turned dark red and smelled fresh. The stock solution, which contained 1.87% of the flavonoid in the mangosteen pericarps infusion, was then obtained. Furthermore, concentrations of 0.25, 0.5, 1 and 2% were used to create the working solution. The infusion of mangosteen pericarps was prepared once every two weeks, kept in bottles covered in aluminum foil to block off light, and kept at 4 °C. Additionally, a 2% concentration of mangosteen pericarps infusion was made up [63]. The conventional methods, such as maceration, Soxhlet extraction and heat reflux, are time-consuming, high in operating costs and low in product recovery [64]. A comparison of xanthones and α-mangostin content from the mangosteen pericarp extract using traditional extraction methods is shown in Table 3.

Table 3.

A comparison of xanthones, α-mangostin content from the mangosteen pericarp extract by traditional extraction.

| Extraction Method | Conditions | Xanthone Compounds | Reference |

|---|---|---|---|

| Maceration | 1 kg of mangosteen pericarp that macerated with 4 L of 95 % ethanol for 7 days, and was able to obtain 1.19 mg/g of xanthones from the mangosteen pericarp | Xanthones | [56] |

| Maceration | The optimum conditions for extracting xanthones from mangosteen pericarp were at 33 °C, amplitude was set to 75, and 80% ethanol by the maceration at 2 h could be able to extract xanthones at a concentration of 0.0565 mg/g of dry mangosteen. | Xanthones | [65] |

| Percolation | 10 g of powdered dried mangosteen fruit rind was combined with 10 mL of 95 % ethanol, and the combination was let to stand for 1 h. A percolator was used to add 95% ethanol to the mixture once it had been moved there (3.6 L). Once the percolate was gone, the extraction was carried out at room temperature with a flow rate of 3 mL/min (20 h). The α-mangostin content in extract by percolation was 12.71 % w/w | α-mangostin | [19] |

| Soxhlet | Soxhlet extraction was employed to extract xanthones from dried mangosteen pericarp. The results presented that the xanthones extracted by Soxhlet, 31.26 mg/g of dried mangosteen pericarp | Xanthones | [57] |

| Soxhlet | crude extract (26.60 % dry weight), α-mangostin (13.51%, w/w of crude extract) and anti-acne activity, were obtained at a concentration of 50 % ethanol, an optimal amount for extraction by Soxhlet | α-mangostin | [19] |

| Soxhlet | The optimum conditions for extracting xanthones from mangosteen pericarp were 33 °C, amplitude was set to 75, and 80% ethanol by Soxhlet extraction at 2 h, which was able to extract xanthones at a concentration of 0.1221 mg/g of dry mangosteen. | Xanthones | [65] |

| Infusion | 1000 mL of drinking water and 330 g of pericarps were combined, and the mixture was submerged for 12 h until the water turned dark red and smelled fresh. The stock solution, which contained 1.87 % of the flavonoid in the mangosteen pericarps infusion, was then obtained. | Flavonoid content such as xanthones, tannins, and catechins. | [64] |

4.2.2. Modern Extraction Techniques

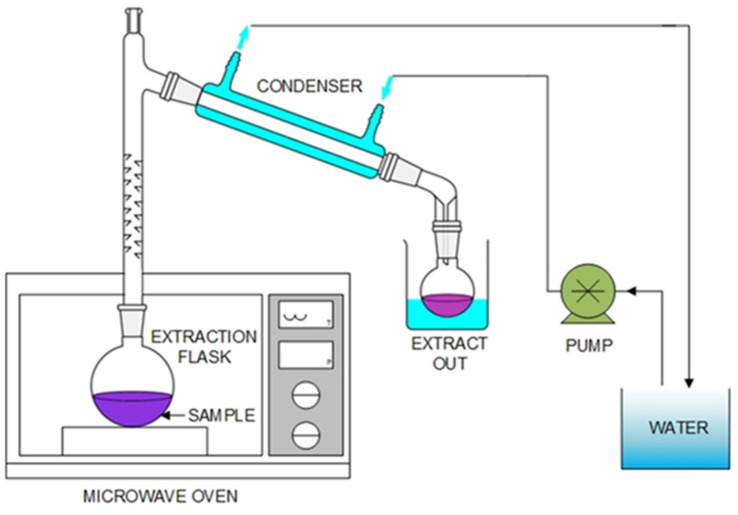

Higher yields, faster extraction times, and lower solvent contents characterize modern extraction techniques. Modern methods are implemented on an industrial scale; microwave extraction is an extraction method using microwaves, which are electromagnetic waves [66,67]. This wave is converted to heat by causing polarized particles or molecules to friction and heated up. In other words, this happens when the extracted substance is placed in an electromagnetic field. The polarity of molecules within the substance to be extracted causes resistance to movement or friction with each other, causing heat that affects plant cells and results in the extraction of active substances [68]. The principle of extraction by using microwaves is that it uses frequencies in the range of 3 × 102 to 3 × 105 MHz and wavelengths in the range of 0.01 to 1 m together with organic solvents to extract important substances [69]. When the extracted substance is placed in an electromagnetic field, with the polarity properties of the molecules within the extracted substance, there will be resistance to motion, causing heat, which affects the cell tissue of the extract and influences the solubility of the desired active substance. Electricity or microwave heating is caused by energy transfer from two mechanisms, dipole rotation and ionic conduction through dipole changes. This replaces charged ions in a substance and a solvent where both processes occur simultaneously. Ion transport induced by changing electric fields is called ionic conduction. If a solvent resists the movement of the ions, it results in friction and heat [70]. Modifying the dipole of a molecule in conjunction with a change in the electric field is called a dipole rotation, where the frequency of 2450 MHz causes microwaves to change the electric component at a speed of 4.9 × 104 times per second, thus generating frictional heat [71]. Energy transfer is a key feature of microwave heating; 2450 MHz is the most popular frequency, with a power range of 600–700 watts [72]. Usually, the heat transfer of traditional extraction processes is the energy transferred to the raw material to be extracted by convection, conducting, and radiation. In the case of microwave extraction, the microwaves are converted to heat by causing polarized particles or molecules to cause friction and generate heat. In microwave extraction, the effectiveness of the extraction depends on the use of suitable conditions (Figure 4).

Figure 4.

Schematic diagram of microwave-assisted extraction apparatus.

The factors affecting microwave extraction include the solvent system and solvent-to-powder ratio (solvent nature and solvent feed ratio; S/F ratio), microwave power, extraction temperature, extraction time and cycle, plant matrix characteristics, and the effect of stirring [66]. For example, the microwave-assisted extraction (MAE) of xanthones from mangosteen pericarps showed that the optimum conditions for the extraction of antioxidant-rich xanthones are the 2.24 min irradiation time, the solvent ratio of mangosteen pericarps powder of 25 mL/g and a 71% ethanol concentration [22]. A study from Ghasemzadeh et al. [73] found that mangosteen pericarp was extracted using 72.40 % (v/v) ethyl acetate with microwave extraction, and the conditions were set to 189.20 W output power and 3.16 min irradiation time, which was able to extract xanthones, particularly α-mangostin, at about 120.68 mg/g of mangosteen pericarp (dry matter). Microwave-assisted extraction has been successfully applied to extract bioactive compounds from plant matrices, which needed hours to complete with conventional methods. There are many advantages of MAE, including reduced extraction time, reduced solvent usage, improved extraction yield and environmental friendliness [64].

In ultrasonic extraction, the resulting supersonic energy has chemical, biological, and physical effects through a phenomenon known as cavitation, which is a phenomenon that occurs when many small bubbles exist in the liquid body, the surface of the solid, or the surface of the container containing the liquid where compression and amplification due to the pressure of supersonic waves occur. This causes the bubbles to grow and shrink as the gas inside the liquid diffuses in and out of the bubbles alternately, causing a strong stirring effect. This can increase the efficiency of solid–liquid extraction (Figure 5).

Figure 5.

Schematic diagram of ultrasonic-assisted extraction apparatus.

Gases and solid particles in the extraction medium are the major factors influencing cavitation. In addition, the pressure inside the liquid, the viscosity of the liquid, the frequency of sound waves, the temperature, and the intensity of the supersonic waves could also affect the cavitation. For example, a comparative study from Yoswathana [65] using three different extraction methods (ultrasonic-assisted extraction, Soxhlet extraction, and maceration) to extract xanthones from mangosteen pericarp found that the optimum conditions for extracting xanthones from mangosteen pericarp were a temperature of 33 °C, an amplitude of 75, and 80% ethanol; the ultrasonic-assisted extraction method for 0.5 h, Soxhlet extraction at 2 h, and maceration at 2 h could able to extract xanthones at a concentration of 0.1760, 0.1221, and 0.0565 mg/g of dry mangosteen, respectively. Ultrasonic extraction is proven to be an economical and effective method. It is an alternative technique at the laboratory or industry scale due to shorter extraction time and higher extraction yield [74]. Ultrasonics can penetrate the cellular wall, reduce the particle size, and increase the mass transfer between the cell walls and the outside because of the cavitation effect [75]. Fresh mangosteen rind was mixed with 95% (v/v) ethanol and extracted in an ultrasonic bath, which generated the frequency of 30 kHz, for 10 min at room temperature, which was able to yield the α-mangostin and 8-desoxygartanin contents at a level of 47.82 ± 3.76 mg/g and 1.43 ± 0.30 mg/g (d.b.), respectively [52].

Pressurized liquid extraction (PLE) is a technique that involves extraction using liquid solvents at elevated temperature and pressure, which enhances the extraction performance as compared to those techniques carried out at near room temperature and atmospheric pressure [76,77]. The enhanced solubility and mass transfer properties are the merits of enabling the use of solvents at temperatures above their atmospheric boiling point. This technique is also known as accelerated solvent extraction, pressurized liquid extraction, and enhanced solvent extraction. In the case when water is used as the extraction solvent, the technique is referred to as pressurized hot water extraction, sub-critical water extraction or superheated water extraction. Subcritical water extraction of phenolic compounds from mangosteen pericarps was examined at temperatures of 120–180 °C and pressures of 1–5 MPa. In a batch system, the maximum yield of xanthone was 34 mg/g sample at 180 °C and 3 MPa with 150 min reaction time [78]. The development of a subcritical water extraction method using deionized water, which contains a deep eutectic solvent at 10–30% volume, was used as an extraction medium instead of water. The xanthone and phenolic compounds extracted in 10% deep eutectic solvents at 160 °C, and 5 MPa for 180 min in the semi-batch system were yielded at a level of 27.15 mg/g dried sample and 372.69 mg of GAE/g dried sample, respectively. Adding deep eutectic solvent in the subcritical water extraction process could accelerate the hydrolysis reaction to extract the plant biomass components matrix [79]. In addition, the use of natural deep eutectic solvents (NADES) as a green solvent for the extraction of α-mangostin from the pericarp of mangosteen was studied [80]. The NADES consisted of choline chloride, a quaternary ammonium salt, and four hydrogen bond donors: 1,2-propanediol, citric acid, glycerol, and glucose. The highest α-mangostin extraction yield of 2.6 % (w/w) was garnered from dried pericarp using a mixture of choline chloride and 1,2-propanediol in a 1:3 mole ratio. The results conclude that NADES made of choline chloride and diol-based hydrogen bond donors are adequate for extracting bioactive compounds from the mangosteen pericarp. This method is widely used because of its good extraction efficiency compared to other methods and as a clean technology because it does not use organic solvents. This new method uses a liquid solvent under pressure (Figure 6).

Figure 6.

Schematic diagram of pressurized liquid extraction apparatus.

Carbon dioxide is determined to be in the superfluid or supercritical SC-CO2 (Tc = 31.2 °C and Pc = 7.28 MPa) with the properties of CO2 compressed to a water-like liquid and being flow-like (Figure 7) [81]. Supercritical fluid extraction has received much attention, especially in the food and pharmaceuticals industry, because it presents an environmentally responsible and efficient extraction technique for solid materials that were introduced and extensively studied for the separation of active compounds from herbs and other plants [82]. Normally, the air is allowed penetrate the material to be extracted. This method is generally used to extract low-polarity substances. However, it has now been applied to allow the extraction of more polar substances by adding a more polarized organic solvent to the extraction, known as a co-solvent [83]. Extraction of α-mangostin from mangosteen pericarps by supercritical fluid extraction (SFE) techniques using CO2 as a solvent under optimal operating conditions at a temperature of 40 °C and a pressure of 10 MPa, the mole fraction of extracted α-mangostin reached 4.5 × 10−7 [84]. Furthermore, the improved supercritical fluid extraction by ethanol-modified SC-CO2 (SC-CO2 + 4% ethanol) extraction performed at 20 MPa and 40 °C provides good antioxidant activity and is a suitable technique for the concentration of bioactive compounds from mangosteen [85].

Figure 7.

Schematic diagram of supercritical fluid extraction apparatus.

Compared with the PLE technique, the SFE technique can extract exceptionally high levels of xanthones with good purity. A comparison of xanthones and α-mangostin content from the mangosteen pericarp extract using modern extraction methods is shown in Table 4.

Table 4.

A comparison of xanthones and α-mangostin content from the mangosteen pericarp extract by modern extraction techniques.

| Extraction Method | Conditions | Xanthone Compounds | Reference |

|---|---|---|---|

| Microwave | The optimum conditions for the extraction of antioxidant-rich xanthones are the 2.24 min irradiation time, the solvent ratio of mangosteen pericarps powder of 25 mL/g and a 71% ethanol concentration. | Xanthones | [22] |

| Microwave | The mangosteen pericarp was extracted using 72.40 % (v/v) ethyl acetate with microwave extraction, with 189.20 W output power and irradiation time was set to 3.16 min, which was able to extract xanthones, particularly α-mangostin, at about 120.68 mg /g of mangosteen pericarp (dry matter). | α-mangostin | [73] |

| Ultrasonic | The optimum conditions for extracting xanthones from mangosteen pericarp were 33 °C, an amplitude of 75, and 80% ethanol by the ultrasonic-assisted extraction method for 0.5 h, which could extract xanthones at a concentration of 0.1760 mg/g of dry mangosteen. | Xanthones | [65] |

| Subcritical Water Extraction | Extraction of xanthone compounds from mangosteen pericarps was examined at temperatures of 120–180 °C and pressures of 1–5 Mpa using a batch extractor. The maximum yield of xanthone was 34 mg/g sample at 180 °C and 3 Mpa with 150 min reaction time. | Xanthones | [78] |

| The supercritical fluid extraction technique | Extraction of α-mangostin from mangosteen pericarps by supercritical fluid extraction technique using CO2 as a solvent under 35, 40 and 50 °C, pressure 10 to 20 Mpa could extract α-mangostin up to 4.5 × 10−7. | α-mangostin | [84] |

A review of modern extraction techniques reveals that the microwave-assisted extraction method has many advantages, such as low solvent consumption, less time consumption, and fast energy transfer through the irradiation that permits the good diffusion of solvent within the extraction medium, especially for the preparation of antioxidant-rich plant extracts. M’hiri et al. [86] have evaluated that microwave-assisted and ultrasound-assisted extraction could extract the highest value of total phenolic content and antioxidant activity of the plant. In addition, microwave-assisted extraction methods have been studied for scaling up to an industrial scale [87]. Thus, has MAE led to the most prevailing extraction techniques compared to other methods: conventional solvent extraction, ultrasonic-assisted extraction, high-pressure extraction, and supercritical fluid extraction. In terms of stability, mangosteen pericarp extract has been developed into a throat spray, and research has been conducted on the stability of the extract by using the mangosteen pericarps throat spray, which contains 1% of the crude mangosteen extract, by checking its stability at 4 °C, 30 °C, 40 °C and room temperature for 180 days. The throat spray samples were found to be quite stable for up to 180 days at all tested conditions [88].

5. Conclusions

Mangosteen pericarp is a potential source of natural xanthones and can be used as raw materials for xanthone compound extraction to apply in the healthcare industry. The information from this preliminary gathering may benefit those interested in the benefits of mangosteen pericarp and xanthones extraction methods. Data from various extraction methods show that modern extraction methods provide higher quantitative and temporal efficiency than traditional extraction methods. In the future, extraction methods may combine several methods or develop new techniques for better efficiency. This also includes the creation of guidelines for their further use in other industries. Building knowledge on developing suitable machinery and technology for industrial xanthone extraction processes may support xanthone extraction’s quantity and quality. Methods for extracting xanthones from mangosteen pericarps must be developed in quantity and quality, including scaling up to industrial production. The extraction method must be environmentally friendly for sustainability. Moreover, there must be research on developing foods, cosmetics, and medical products. Future studies and developments on how to use xanthones in various aspects are recommended to expand the utilization of industrial by-products or local fruit wastes in accordance with the Bio-Circular-Green Economy approach (BCG). This refers to the cost-effective use of biological resources while maintaining environmental balance.

Author Contributions

Conceptualization, V.Y.; writing-original draft preparation, V.Y. and N.C.; writing review and editing, K.V., W.K.K., P.S. and J.W.; visualization, K.V., P.S. and T.P.; validation, N.C. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Funding Statement

This research received no external funding.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Pittayapruek P., Meephansan J., Prapapan O., Komine M., Ohtsuki M. Role of matrix metalloproteinases in photoaging and photocarcinogenesis. Int. J. Mol. Sci. 2016;17:868. doi: 10.3390/ijms17060868. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Centre for Agricultural Information Mangosteen. [(accessed on 30 August 2022)]; Available online: https://www.oae.go.th/assets/portals/1/files/jounal/2564/commodity2563.pdf.

- 3.Trade Policy and Strategy Office Potential and Future of Mangosteen, Queen of Thai Fruits. [(accessed on 30 August 2022)]; Available online: http://www.tpso.moc.go.th.

- 4.Charoenphun N., Setarnawat S., Sai-Ut S. Chemical composition and trends in utilization of by-products and wastes from 4 types of tropical fruit processing. TJST. 2020;28:113–128. [Google Scholar]

- 5.Adriani L., Widjastuti T., Nurdianti R.R., Wiradimadja R. Effects of mangosteen peel extract (Garcinia mangostana L.) on blood lipid of ntiox chicken growth phase; Proceedings of the 3rd International Conference of Integrated Intellectual Community (ICONIC); Hannover, Germany. 27–29 April 2018; pp. 1–5. [Google Scholar]

- 6.Kumar D., Sekar S. Analysis of physio-chemical properties of mangosteen rind extract from industrial waste. IJTSRD. 2018;2:1522–1526. [Google Scholar]

- 7.Chudhangkura A. Xanthones in mangosteen. Food. 2015;45:37–40. [Google Scholar]

- 8.Wittenauer J., Falk S., Schweiggert-Weisz U., Carle R. Characterisation and quantification of xanthones from the aril and pericarp of mangosteens (Garcinia mangostana L.) and a mangosteen containing functional beverage by HPLC–DAD–MSn. Food Chem. 2012;134:445–452. doi: 10.1016/j.foodchem.2012.02.094. [DOI] [Google Scholar]

- 9.Sukatta U. Xanthones from Mangosteen Peels in the Cosmetic Industry. [(accessed on 30 August 2022)]. Available online: https://www3.rdi.ku.ac.th/?p=62656.

- 10.Krishnamurthi S., Rao N.V.M. Mangosteen deserves wider attention. Indian Hort. 1962;7:3–8. [Google Scholar]

- 11.Nazre M., Newman M.F., Pennington R.T., Middleton D.J. Taxonomic revision of Garcinia section Garcinia (Clusiaceae) Phytotaxa. 2018;373:1–52. doi: 10.11646/phytotaxa.373.1.1. [DOI] [Google Scholar]

- 12.Bin Osman M., Milan A.R. Mangosteen—Garcinia mangostana. Southampton Centre for Underutilized Crops, University of Southampton; Southampton, UK: 2006. [Google Scholar]

- 13.SCUS . Field Manual for Extension Workers and Farmers. ICUC; Southamton, UK: 2006. Mangosteen, Garcinia mangostana. [Google Scholar]

- 14.Orwa C., Mutua A., Kindt R., Jamnadass R., Simons A. Agroforestree Database: A Tree Reference and Selection Guide Version 4.0. World Agroforestry Centre; Nairobi, Kenya: [(accessed on 30 August 2022)]. Available online: http://apps.worldagroforestry.org/treedb2. [Google Scholar]

- 15.Sukatta U., Takenaka M., Ono H., Okadome H., Sotome I., Nanayama K., Thanapase W., Isobe S. Distribution of major xanthones in the pericarp, aril, and yellow gum of mangosteen (Garcinia mangostana Linn.) fruit and their contribution to antioxidative activity. Biosci. Biotechnol. Biochem. 2013;77:984–987. doi: 10.1271/bbb.120931. [DOI] [PubMed] [Google Scholar]

- 16.Dorly, Tjitrosemito S., Poerwanto R., Juliarni Secretory duct structure and phytochemistry compounds of yellow latex in mangosteen fruit. HAYATI J. Biosci. 2008;15:99–104. doi: 10.4308/hjb.15.3.99. [DOI] [Google Scholar]

- 17.Rizaldy D., Hartati R., Nadhifa T., Fidrianny I. Chemical compounds and pharmacological activities of mangosteen (Garcinia mangostana L.)—Updated review. Biointerface Res. Appl. Chem. 2022;12:2503–2516. [Google Scholar]

- 18.Mello R.F.A., Pinheiro W.B.S., Benjamim J.K.F., Siqueira F.C., Chiste R.C., Santos A.S. A fast and efficient preparative method for separation and purification of main bioactive xanthones from the waste of Garcinia mangostana L. by high-speed countercurrent chromatography. Arab. J. Chem. 2021;14:103252. doi: 10.1016/j.arabjc.2021.103252. [DOI] [Google Scholar]

- 19.Pothitirat W., Chomnawang M.T., Supabphol R., Gritsanapan W. Free radical scavenging and anti-acne activities of mangosteen fruit rind extracts prepared by different extraction methods. Pharm. Biol. 2010;48:182–186. doi: 10.3109/13880200903062671. [DOI] [PubMed] [Google Scholar]

- 20.Widowati W., Ginting C.N., Lister N.E., Gisang E., Amalia A., Wibowo S.H.B., Kusuma H.S.W., Rizal Anti-aging effects of mangosteen peel extract and its phytochemical compounds: Antioxidant activity, enzyme inhibition and molecular docking simulation. Trop. Life Sci. Res. 2020;31:127–144. doi: 10.21315/tlsr2020.31.3.9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Chaiwong N., Phimolsiripol Y., Leelapornpisid P., Ruksiriwanich W., Jantanasakulwong K., Rachtanapun P., Seesuriyachan P., Leksawasdi N., Simirgiotis M.J., Barba F.J., et al. Synergistics of carboxymethyl chitosan and mangosteen extract as enhancing moisturizing, antioxidant, antibacterial, and deodorizing properties in emulsion cream. Polymers. 2022;14:178. doi: 10.3390/polym14010178. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Mohammad N.A., Zaidel D.N.A., Muhamad I.I., Hamid M.A., Yaakob H., Jusoh Y.M.M. Optimization of the antioxidant-rich xanthone extract from mangosteen (Garcinia mangostana L.) pericarp via microwave-assisted extraction. Heliyon. 2019;5:e02571. doi: 10.1016/j.heliyon.2019.e02571. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Quality Plus Aesthetic International Co., Ltd. Purified Xanthoneextract from Mangosteen Peel. [(accessed on 30 August 2022)]. Available online: https://www.qualityplus.co.th/quality-plus-deep-technology/deep-biotechnology/purify-xanthone/

- 24.Janardhanan S., Mahendra J., Girija A.S., Mahendra L., Priyadharsini V. Antimicrobial effects of Garcinia mangostana on cariogenic microorganisms. J. Clin. Diagn. Res. 2017;11:ZC19–ZC22. doi: 10.7860/JCDR/2017/22143.9160. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Narasimhan S., Maheshwaran S., Abu-Yousef I.A., Majdalawieh A.F., Rethavathi J., Das P.E., Poltronieri P. Anti-bacterial and anti-fungal activity of Xanthones obtained via semi-synthetic modification of α-Mangostin from Garcinia mangostana. Molecules. 2017;22:275. doi: 10.3390/molecules22020275. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Leelapornpisid W. Efficacy of alpha-mangostin for antimicrobial activity against endodontopathogenic microorganisms in a multi-species bacterial-fungal biofilm model. Arch. Oral Biol. 2022;133:105304. doi: 10.1016/j.archoralbio.2021.105304. [DOI] [PubMed] [Google Scholar]

- 27.Koh J.-J., Zou H., Mukherjee D., Lin S., Lim F., Tan J.K., Tan D.Z., Stocker B.L., Timmer M.S.M., Corkran H.M., et al. Amphiphilic xanthones as a potent chemical entity of anti-mycobacterial agents with membrane-targeting properties. Eur. J. Med. Chem. 2016;123:684–703. doi: 10.1016/j.ejmech.2016.07.068. [DOI] [PubMed] [Google Scholar]

- 28.Meng X.Y., Zhang H.X., Mezei M., Cui M. Molecular docking: A powerful approach for structure-based drug discovery. Curr. Comput.-Aided Drug Des. 2011;7:146–157. doi: 10.2174/157340911795677602. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Yong V. Metalloproteinases: Mediators of pathology and regeneration in the CNS. Nat. Rev. Neurosci. 2005;6:931–944. doi: 10.1038/nrn1807. [DOI] [PubMed] [Google Scholar]

- 30.Siahaan A., Loe M.L., Dalimunthe N. Mangosteen extract reduces the expression of matrix metalloproteinase -2 and -9 in traumatic brain injury. Int. J. PharmTech Res. 2017;10:1–8. doi: 10.20902/IJPTR.2017.1011. [DOI] [Google Scholar]

- 31.Mahmudah R., Adnyana I.K., Sukandar E.Y. Molecular docking studies of α-mangostin, γ-mangostin, and xanthone on peroxisome proliferator-activated receptor gamma diphenyl peptidase-4 enzyme, and aldose reductase enzyme as an anti-diabetic drug candidate. J. Adv. Pharm. Technol. Res. 2021;12:196–208. doi: 10.4103/japtr.JAPTR_255_20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Bernal F.A., Coy-Barrera E. Molecular docking and multivariate analysis of xanthones as antimicrobial and antiviral agents. Molecules. 2015;20:13165–13204. doi: 10.3390/molecules200713165. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Miladiyah I., Jumina J., Haryana S.M., Mustofa M. In silico molecular docking of xanthone derivatives as cyclooxygenase-2 inhibitor agents. Int. J. Pharm. Pharm. Sci. 2017;9:98–104. doi: 10.22159/ijpps.2017v9i3.15382. [DOI] [Google Scholar]

- 34.Chang T.S. An updated review of tyrosinase inhibitors. Int. J. Mol. Sci. 2009;10:2440–2475. doi: 10.3390/ijms10062440. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Abate M., Pagano C., Masullo M., Citro M., Pisanti S., Piacente S., Bifulco M. Mangostanin, a xanthone derived from Garcinia mangostana fruit, exerts protective and reparative effects on oxidative damage in human keratinocytes. Pharmaceuticals. 2022;15:84. doi: 10.3390/ph15010084. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Liu Q.Y., Wang Y.T., Lin L.G. New insights into the anti-obesity activity of xanthones from Garcinia mangostana. Food Funct. 2015;6:383–393. doi: 10.1039/C4FO00758A. [DOI] [PubMed] [Google Scholar]

- 37.Mohan S., Syam S., Abdelwahab S.I., Thangavel N. An anti-inflammatory molecular mechanism of action of α-mangostin, the major xanthone from the pericarp of Garcinia mangostana: An in silico, in vitro and in vivo approach. Food Function. 2018;9:3860–3871. doi: 10.1039/C8FO00439K. [DOI] [PubMed] [Google Scholar]

- 38.Chen L.G., Yang L.L., Wang C.C. Anti-inflammatory activity of mangostins from Garcinia mangostana. Food Chem. Toxicol. 2008;46:688–693. doi: 10.1016/j.fct.2007.09.096. [DOI] [PubMed] [Google Scholar]

- 39.Mekseepralard C., Areebambud C., Suksamrarn S., Jariyapongskul A. Effects of long-term alpha-mangostin supplementation on hyperglycemia and insulin resistance in type 2 diabetic rats induced by high fat diet and low dose streptozotocin. J. Med. Assoc. Thail. 2015;98:S23–S30. [PubMed] [Google Scholar]

- 40.Chen S.P., Lin S.R., Chen T.H., Ng H.S., Yim H.S., Leong M.K., Weng C.F. Mangosteen xanthone γ-mangostin exerts lowering blood glucose effect with potentiating insulin sensitivity through the mediation of AMPK/PPARγ. Biomed. Pharmacother. 2021;144:112333. doi: 10.1016/j.biopha.2021.112333. [DOI] [PubMed] [Google Scholar]

- 41.Herdiana Y., Wathoni N., Shamsuddin S., Muchtaridi M. α-Mangostin nanoparticles cytotoxicity and cell death modalities in breast cancer cell lines. Molecules. 2021;26:5119. doi: 10.3390/molecules26175119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Chang H.F., Yang L.L. Gamma-mangostin, a micronutrient of mangosteen fruit, induces apoptosis in human colon cancer cells. Molecules. 2012;17:8010–8021. doi: 10.3390/molecules17078010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Li K., Wu L., Chen Y., Li Y., Wang Q., Li M., Hao K., Zhang W., Jiang S., Wang Z. Cytotoxic and anti-proliferative effects of β-mangostin on rat C6 glioma cells depend on oxidative stress induction via PI3K/AKT/mTOR pathway inhibition. Drug Des. Devel. Ther. 2020;14:5315–5324. doi: 10.2147/DDDT.S278414. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Mohamed G.A., Al-Abd A.M., El-halawany A.M., Abdallah H.M., Ibrahim S.R.M. New xanthones and cytotoxic constituents from Garcinia mangostana fruit hulls against human hepatocellular, breast, and colorectal cancer cell lines. J. Ethnopharmacol. 2017;198:302–312. doi: 10.1016/j.jep.2017.01.030. [DOI] [PubMed] [Google Scholar]

- 45.Reyes-Fermin L.M., Gonzalez-Reyes S., Tarco-Alvarez N.G., Hernandez-Nava M., Orozco-Ibarra M., Pedraza-Chaverri J. Neuroprotective effect of α-mangostin and curcumin against iodoacetate-induced cell death. Nutr. Neurosci. 2012;15:34–41. doi: 10.1179/1476830512Y.0000000011. [DOI] [PubMed] [Google Scholar]

- 46.Foiklang S., Wanapat M., Norrapoke T. Effect of grape pomace powder, mangosteen peel powder and monensin on nutrient digestibility, rumen fermentation, nitrogen balance and microbial protein synthesis in dairy steers. Asian-Australas J. Anim. Sci. 2016;29:1416–1423. doi: 10.5713/ajas.15.0689. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Park J.Y., Ko K.A., Lee J.Y., Oh J.W., Lim H.C., Lee D.W., Choi S.H., Cha J.K. Clinical and immunological efficacy of mangosteen and propolis extracted complex in patients with gingivitis: A multi-centered randomized controlled clinical trial. Nutrients. 2021;13:2604. doi: 10.3390/nu13082604. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Kurniawati A., Poerwanto R., Sobir, Efendi D., Cahyana H. Character, xanthone content and antioxidant properties of mangosteen fruit’s hull (Garcinia mangostana L.) at several fruit growth stadia. J. Agron. Indones. 2011;39:188–192. [Google Scholar]

- 49.Gondokesumo M.E., Pardjianto B., Sumitro S.B., Widowati W., Handono K. Xanthones analysis and antioxidant activity analysis (applying ESR) of six different maturity levels of mangosteen rind extract (Garcinia mangostana Linn.) Pharmacogn. J. 2019;11:369–373. doi: 10.5530/pj.2019.11.56. [DOI] [Google Scholar]

- 50.Neelapong W., Phonyotin B., Sittikijyothin W. Extraction of active compounds from Thai herbs: Powder and extract. KMUTNB. 2019;29:157–166. [Google Scholar]

- 51.Boonrat C., Indranupakorn R. Influence of extraction techniques and solvents on α-mangostin amounts from mangosteen (Garcinia mangostana L.) pericarp. Thai Bull. Pharm. Sci. 2015;10:1–11. [Google Scholar]

- 52.Suvarnakuta P., Chaweerungrat C., Devahastin S. Effects of drying methods on assay and antioxidant activity of xanthones in mangosteen rind. Food Chem. 2011;125:240–247. doi: 10.1016/j.foodchem.2010.09.015. [DOI] [Google Scholar]

- 53.Sotong S., Ruaypom K. Research on mangosteen pericarp drying using by hot air recycle. J. Ind. Tech. UBRU. 2016;6:197–213. [Google Scholar]

- 54.Megawati, Ginting R.R., Kusumaningtyas R.D., Sediawan W.B. Mangosteen Peel Antioxidant Extraction and Its Use to Improve the Stability of Biodiesel B20 Oxidation. [(accessed on 30 August 2022)]. Available online: http://lib.unnes.ac.id.

- 55.Kusmayadi A., Adriani L., Abun A., Muchtaridi M., Tanuwiria U.H. The effect of solvents and extraction time on total xanthone and antioxidant yields of mangosteen peel (Garcinia mangostana L.) extract. Drug Invent. Today. 2018;10:2572–2576. [Google Scholar]

- 56.Pojanaukij N., Kajorncheappunngam S. Comparison of antimicrobial activity of mangosteen crude, turmeric and Gotu Kola extract. NUJST. 2010;18:1–9. [Google Scholar]

- 57.Yoswathana N., Eshtiaghi M.N. Optimization of subcritical ethanol extraction for xanthone from mangosteen pericarp. Int. J. Chem. Eng. Appl. 2015;6:115–119. doi: 10.7763/IJCEA.2015.V6.463. [DOI] [Google Scholar]

- 58.Ryu H.W., Cho J.K., Curtis-Long M.J., Yuk H.J., Kim Y.S., Jung S. α-Glucosidase inhibition and antihy-perglycemic activity of prenylated xanthones from Garcinia mangostana. Phytochem. 2011;72:2148–2154. doi: 10.1016/j.phytochem.2011.08.007. [DOI] [PubMed] [Google Scholar]

- 59.Mohamed G.A., Ibrahim S.R., Shaaban M.I., Ross S.A. Mangostanaxanthones I and II, new xanthones from the pericarp of Garcinia mangostana. Fitoterapia. 2014;98:215–221. doi: 10.1016/j.fitote.2014.08.014. [DOI] [PubMed] [Google Scholar]

- 60.Ee G., Daud S., Taufiq-Yap Y., Ismail N., Rahmani M. Xanthones from Garcinia mangostana (Guttiferae) Nat. Prod. Res. 2006;20:1067–1073. doi: 10.1080/14786410500463114. [DOI] [PubMed] [Google Scholar]

- 61.Eukun Sage E., Jailani N., Md Taib A.Z., Mohd Noor N., Mohd Said M.I., Abu Bakar M., Mackeen M.M. From the Front or Back Door? Quantitative analysis of direct and indirect extractions of α-mangostin from mangosteen (Garcinia mangostana) PLoS ONE. 2018;13:e0205753. doi: 10.1371/journal.pone.0205753. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Satong-aun W., Assawarachan R., Noomhorm A., Pathumthani K.L. The Influence of Drying Temperature and Extraction Methods on a-Mangostin in Mangosteen Pericarp. J. Food Sci. Eng. 2011;1:85–92. [Google Scholar]

- 63.Rusman J.R.A., Sundar S.A., Nuriliani A., Saragih H.T. Ameliorative effect of mangosteen (Garcinia mangostana L.) peel infusion on the histopathological structures of the liver and kidney of rats (Rattus norvegicus Berkenhout, 1769) after H2O2 induction. Vet. World. 2021;14:1579–1587. doi: 10.14202/vetworld.2021.1579-1587. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 64.Fang L., Liu Y., Zhuang H., Liu W., Wang X., Huang L. Combined microwave-assisted extraction and high-speed counter-current chromatography for separation and purification of xanthones from Garcinia mangostana. J. Chromatogr. B. 2011;879:3023–3027. doi: 10.1016/j.jchromb.2011.08.040. [DOI] [PubMed] [Google Scholar]

- 65.Yoswathana N. Accelerated extraction of xanthone from mangosteen pericarp using ultrasonic technique. Afr. J. Pharm. Pharmacol. 2013;7:302–309. doi: 10.5897/AJPP12.1135. [DOI] [Google Scholar]

- 66.Radoiu M., Kaur H., Bakowska-Barczak A., Splinter S. Microwave-assisted industrial scale cannabis extraction. Technologies. 2020;8:45. doi: 10.3390/technologies8030045. [DOI] [Google Scholar]

- 67.Radoiu M., Splinter S., Popek T. Continuous industrial-scale microwave-assisted extraction of high-value ingredients from natural biomass; Proceedings of the 53rd IMPI’s Microwave Power Symposium; Las Vegas, NV, USA. 18–20 June 2019. [Google Scholar]

- 68.Veggi P.C., Martinez J., Angela M., Meireles A. Fundamentals of microwave extraction. In: Chemat F., Cravotto G., editors. Microwave Assisted Extraction for Bioactive Compounds: Theory and Practice. Springer; New York, NY, USA: Heidelberg, Germany: Dordrech, The Netherlands: London, UK: 2013. [Google Scholar]

- 69.Moret S., Conchione C., Srbinovska A., Lucci P. Microwave-based technique for fast and reliable extraction of organic contaminants from food, with a special focus on hydrocarbon contaminants. Foods. 2019;8:503. doi: 10.3390/foods8100503. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 70.Sun J., Wang W., Yue Q. Review on microwave-matter interaction fundamentals and efficient microwave-associated heating strategies. Materials. 2016;25:231. doi: 10.3390/ma9040231. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 71.Eskilsson C.S., Björklund E. Analytical-scale microwave-assisted extraction. J. Chromatogr. A. 2000;902:227–250. doi: 10.1016/S0021-9673(00)00921-3. [DOI] [PubMed] [Google Scholar]

- 72.Muley P.D., Wang Y., Hu J., Shekhawat D. Catalysis. Volume 33. Royal Society of Chemistry; Washington, DC, USA: 2021. Microwave-assisted heterogeneous catalysis; pp. 1–37. [Google Scholar]

- 73.Ghasemzadeh A., Jaafar H.Z.E., Baghdadi A., Tayebi-meigooni A. Alpha-mangostin-rich extracts from mangosteen pericarp: Optimization of green extraction protocol and evaluation of biological activity. Molecules. 2018;23:1852. doi: 10.3390/molecules23081852. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 74.Toma M., Vinatoru M., Paniwnyk L., Mason T.J. Investigation of the effects of ultrasound on vegetal tissues during solvent extraction. Ultrason. Sonochem. 2001;8:137–142. doi: 10.1016/S1350-4177(00)00033-X. [DOI] [PubMed] [Google Scholar]

- 75.Entezari M.H., Hagh Nazary S., Haddad Khodaparast M.H. The direct effect of ultrasound on the extraction of date syrup and its microorganisms. Ultrason. Sonochem. 2004;11:379–384. doi: 10.1016/j.ultsonch.2003.10.005. [DOI] [PubMed] [Google Scholar]

- 76.Bruce E.R., Brian A.J., John L.E., Nathan L.P., Nebojsa A., Chris P. Accelerated solvent extraction: A technique for sample preparation. Anal. Chem. 1996;68:1033–1039. [Google Scholar]

- 77.Camel V. Recent extraction techniques for solid matrices-supercritical fluid extraction, pressurized fluid extraction and microwave-assisted extraction: Their potential and pitfalls. Analyst. 2001;126:1182–1193. doi: 10.1039/b008243k. [DOI] [PubMed] [Google Scholar]

- 78.Machmudah S., Shiddiqi Q.Y.A., Kharisma A.D., Widiyastuti, Wahyudiono, Kanda H., Winardi S., Goto M. Subcritical water extraction of xanthone from mangosteen (Garcinia mangostana Linn) pericarp. J. Adv. Chem. Eng. 2015;5:117. doi: 10.4172/2090-4568.1000117. [DOI] [Google Scholar]

- 79.Machmudah S., Lestari S.D., Kanda H., Winardi S., Goto M. Subcritical water extraction enhancement by adding deep eutectic solvent for extracting xanthone from mangosteen pericarps. J. Supercrit. Fluids. 2018;133:615–624. doi: 10.1016/j.supflu.2017.06.012. [DOI] [Google Scholar]

- 80.Mulia K., Krisanti E., Terahadi F., Putri S. Selected natural deep eutectic solvents for the extraction of α-mangostin from mangosteen (Garcinia mangostana L.) pericarp. Int. J. Technol. 2015;6:1211–1220. doi: 10.14716/ijtech.v6i7.1984. [DOI] [Google Scholar]

- 81.Pasquali I., Bettini R., Giordano F. Solid-state chemistry and particle engineering with supercritical fluids in pharmaceutics. Eur. J. Pharm. Sci. 2006;27:299–310. doi: 10.1016/j.ejps.2005.11.007. [DOI] [PubMed] [Google Scholar]

- 82.Lang Q., Wai C.M. Supercritical fluid extraction in herbal and natural product studies—A practical review. Talanta. 2001;53:771–782. doi: 10.1016/S0039-9140(00)00557-9. [DOI] [PubMed] [Google Scholar]

- 83.Ruen-ngam D. Extraction of antioxidants. J. Sci. Ladkrabang. 2014;23:120–139. [Google Scholar]

- 84.Mishima K., Kawakami R., Yokota H., Harada T., Kato T., Irie K., Mishima K., Fujiwara M., Matsuyama K., Mustofa S., et al. Extraction of xanthones from the pericarps of Garcinia mangostana Linn. With supercritical carbon dioxide and ethanol. Solvent Extr. Res. Dev. 2013;20:79–89. doi: 10.15261/serdj.20.79. [DOI] [Google Scholar]

- 85.Zarena A.S., Udaya Sankar K. Supercritical carbon dioxide extraction of xanthones with antioxidant activity from Garcinia mangostana: Characterization by HPLC/LC–ESI-MS. J. Supercrit. Fluids. 2009;49:330–337. doi: 10.1016/j.supflu.2009.03.004. [DOI] [Google Scholar]

- 86.M’hiri N., Ioannou I., Boudhrioua N.M., Ghoul M. Effect of different operating conditions on the extraction of phenolic compounds in orange peel. Food Bioprod. Process. 2015;96:161–170. doi: 10.1016/j.fbp.2015.07.010. [DOI] [Google Scholar]

- 87.Li Y., Radoiu M., Fabiano-Tixier A.S., Chemat F. From Laboratory to Industry: Scale-Up, Quality, and Safety Consideration for Microwave-Assisted Extraction. In: Chemat F., Cravotto G., editors. Microwave-Assisted Extraction for Bioactive Compounds. Springer; Boston, MA, USA: 2012. (Food Engineering Series). [Google Scholar]

- 88.Jujun P., Pootakham K., Pongpaibul Y., Tharavichitkul P., Ampasavate C. HPLC determination of mangostin and its application to storage stability study. CMU J. Nat. Sci. 2009;8:43–53. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.