Abstract

Since the isolation of graphene in 2004, two-dimensional (2D) materials research has rapidly evolved into an entire subdiscipline in the physical sciences with a wide range of emergent applications. The unique 2D structure offers an open canvas to tailor and functionalize 2D materials through layer number, defects, morphology, moiré pattern, strain, and other control knobs. Through this review, we aim to highlight the most recent discoveries in the following topics: theory-guided synthesis for enhanced control of 2D morphologies, quality, yield, as well as insights toward novel 2D materials; defect engineering to control and understand the role of various defects, including in situ and ex situ methods; and properties and applications that are related to moiré engineering, strain engineering, and artificial intelligence. Finally, we also provide our perspective on the challenges and opportunities in this fascinating field.

Keywords: 2D Materials, Defect Engineering, Theory-Guided Synthesis, Moiré Engineering, Strain Engineering, Artificial Intelligence, Magnetic and Topological Properties, Excitonic Properties

Introduction

The past decade has catalyzed the interest of the scientific community to study atomically thin materials (also known as two-dimensional (2D) materials). According to the Web of Science, the number of publications related to 2D materials have increased from ∼1900 in 2004, when graphene was first isolated experimentally,1 to ∼49100 in 2021.2 In that time, interest has expanded far beyond graphene. Other 2D materials, such as transition metal dichalcogenides (TMDs: WS2, MoS2, etc.), topological insulators (TIs: MnBi2Te4), and recently discovered 2D non-noble metals (2D Ga, 2D In, etc.), have gained substantial interest due to their tunable bandgap, surface and edge reactivity, unique electronic and optoelectronic properties, and the realization of multilayer architectures incorporating atomically abrupt interfaces.3−7 Their unique 2D structure offers an open canvas to tailor 2D materials through knobs such as layer number, emerging synthesis approaches, defect engineering, morphology control, moiré engineering, and strain engineering.8,9 As 2D systems become increasingly complicated by controlling these knobs, it is vital to converge interdisciplinary efforts in this field and to enhance interactions of theory and experiment.

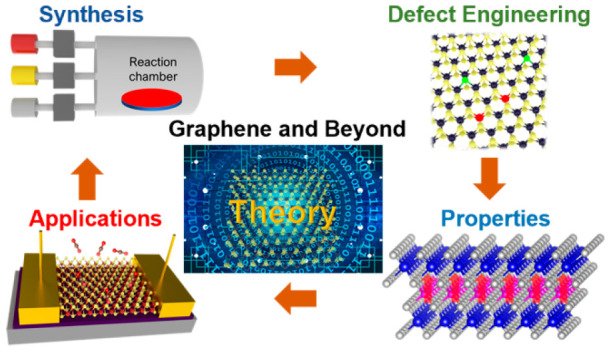

This review reflects the content of the 2021 Graphene and Beyond workshop hosted at the Pennsylvania State University, in which a diverse group of experts discussed recent advances in the field of 2D materials from both theoretical and experimental perspectives. As summarized in Figure 1, we first highlight recent progress in theory-guided synthesis including substrate-directed growth, liquid exfoliation, metal–organic chemical vapor deposition (MOCVD), and confinement heteroepitaxy (CHet) of 2D materials. Subsequently, we review methods for engineering atomic defects in these materials including in situ and ex situ methods. Next, the review focuses on properties including magnetism, topological properties, photonics, and moiré engineering of 2D materials. Finally, we discuss emergent applications discussed during the conference including 2D electronics, sensors, strain engineering, and 2D artificial intelligence (AI).

Figure 1.

Overview of the scope of this paper. Focusing on the recent advancements in the field of 2D materials, we discuss theory guided synthesis via different approaches, engineering of atomic defects, study of emergent properties, and the development of devices for functional applications. Adapted with permission from ref (4). Copyright 2020 Springer Nature.

1. Theory Guided Synthesis

As the field advances, one must consider large-scale synthesis of 2D materials that possess desired properties, with improved control over their morphology, degree of crystallinity, and layer numbers via bottom-up or top-down approaches. In this case, it is prudent to explore theoretical and experimental endeavors to achieve this goal. On one hand, calculations and theory predictions are performed to provide guidelines for developing novel 2D materials with potentially high mobility and to evaluate 2D material integration with complementary metal oxide semiconductor (CMOS) processes. On the other hand, experimental studies are carried out to investigate epitaxial growth for large-area, single-crystalline films, morphological control, and methods to develop novel 2D materials unattainable by standard material synthesis. In this section, we review some of these recent advances in the synthesis of 2D materials.

1.1. Theory Guidelines for Predicting/Screening High-Mobility 2D Materials

Carrier mobility characterizes the average velocity of carriers (electrons/holes) moving through a material in the presence of an electric field. In this case, a high carrier mobility is desired for most electronic and optoelectronic applications. The room-temperature mobility of current 2D monolayer semiconductors is on the order of ∼10–1–102 cm2 V–1 s–1,10,11 whereas the electron mobilities of bulk Si, Ge, and InAs are ∼1400, 3900, and 33000 cm2 V–1 s–1,12,13 respectively. As a result, it is crucial to understand what limits the carrier mobility in 2D semiconductors and develop guidelines in the search for novel high-mobility 2D materials.

In a recent work, Liu et al. demonstrate that this limitation is largely due to effects resulting from the dimensionality.14 Using first-principles calculations to study the intrinsic mobility of various monolayer 2D semiconductors, and reformulating the transport equations to isolate and quantify contributions of different mobility-determining factors, it is found that the low electron mobility originates from a high density of electron–phonon interactions (scatterings) that naturally occur even in perfect 2D semiconductors. Adopting a “density of scatterings” concept leads to simple guidelines in the search for high-mobility 2D semiconductors: one should look for a single, deep, and sharp valley in electronic structure,14 a high phonon frequency, and/or a high sound velocity.15 These properties can help reduce the density of scatterings. Moreover, for some polar 2D semiconductors such as HfS2, in addition to the density of scatterings, another factor that limits the mobility is the strong interaction between carriers and longitudinal optical (LO) phonons, as a result of large Born effective charge and poor screening.16 Thus, one should also avoid strongly polar materials in the search for a high-mobility 2D semiconductor.

1.2. Theory-Guided Understanding of TMD Reactivity

The semiconducting properties of TMDs enable the scaling of CMOS to dimensions which would not be attainable with silicon technology. However, several roadblocks exist that prevent these materials from reaching their full potential including: difficulties in maintaining their high mobility (see previous section);17 the occurrence of intrinsic defects; adhesion issues; and their sensitivity to the different integration steps, such as integrating with metals to form ohmic contacts,8,18 the building blocks of a transistor. Therefore, gaining an understanding of the chemical reactivity of TMDs is key to their engineering.

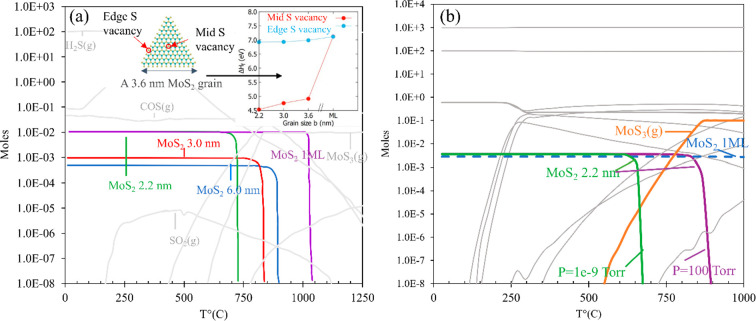

The evaluation of the thermodynamic driving forces of chemical reactions using first-principles simulations is a convenient approach that allows linking the material evolution occurring through the growth, the deposition of a dielectric, their doping, etc., while accounting for the role of grains, defects, impurities, and device processing conditions. In this context, a thermodynamic database was computed, including more than 250 W and Mo volatile and solid sulfides related derivatives, including molecules, cluster prototypes, flakes (with lateral dimensions up to 6 nm), multiple sources of interstitial impurities (C, N, O, etc.), and a broad range of thermal and pressure conditions, going from 10–9 to 100 Torr, to account for different possible processing conditions. MOCVD is a highly scalable process used for the growth of TMDs on a variety of substrates.19 This deposition method is a high-pressure (1–700 Torr) synthesis process, and in many cases, it relies on the reaction between, for example, M(CO)6 (M = W, Mo) and H2S, in a thermal window that spans from 400 to 1000 °C. Since carrier gases such as H2, N2, and Ar are typically used,20,21 the total pressure present within the reactor does not necessarily reflect the partial pressure of the reactants which, in some instances, can be extremely low (e.g., 10–9 Torr). As an attempt to capture the impact of a distribution of grain dimensions22 on their stability during the growth, the evolution of the equilibrium composition during the growth of three equilateral triangular-shaped grains with dimensions spanning from 2.2 to 6.0 nm (Figure 2a) was simulated. It was observed that, depending on their size, the MoS2 grains tend to undergo a self-etching process that releases gaseous MoS3 with a critical temperature that increases with their size, going from 700 °C (2.2 nm) to 1000 °C (for large systems). The growth process is modulated with the reactor pressure as illustrated by the ∼250 °C variation obtained when going from 10–9 to 100 Torr (Figure 2b). This effect is attributed to the difference in the formation energies of S vacancies (ΔHf) that vary from the middle to the edge of the grains as a function of the base size (Figure 2a inset). While ΔHf of the “middle grain” S vacancies shows a minimal dependency on the grain size, the one computed at the edge of the grain is significantly lowered and increases gradually with the size of the grain due to the difference in atomic coordination. S vacancies, being more prominent on the edges, act as etching/reactive centers for the flakes as observed in ref (23). In a MOCVD process, the reactor pressure and the nature of the carrier gas used drives the size of the grains due to the modulation of the sublimation/etching temperature.

Figure 2.

Thermodynamic computation for MoS2 synthesis at various temperatures. (a) Comparison of the equilibrium composition of different grain size models for MoS2 at 1 × 10–9 Torr. An initial molar ratio of 100:1 is used for H2S and Mo(CO)6. The ordinate corresponds to the number of moles of different reactants and products present in the reaction chamber. The different MoS2 grain sizes are shown in color with their corresponding base lengths in nm, and byproducts are colored in gray; inset, evolution of the S vacancy formation energies (ΔHf) for different MoS2 grain sizes going from 2.2 nm to an ideal monolayer (1 ML). The blue circles depict the formation energies corresponding to the edge S vacancy, and the red circles represent the formation energies of the middle S vacancies. (b) Evolution of the equilibrium composition of different grain size models.

1.3. Large Area Growth by MOCVD: The Case of WS2

MOCVD is a standard semiconductor synthesis process and also a promising technique for scalable synthesis of TMD monolayer films on wafers.19,24,25 It also provides the flexibility to control the source partial pressure independently during growth. Compared to solid source or powder-based CVD (ssCVD or P-CVD) widely used for the synthesis of TMD monolayer domains, MOCVD can operate at temperatures lower than ssCVD and still deliver appreciable metal source flux. Figure 3a provides an illustration of a MOCVD system in a cold-wall reactor geometry for TMD synthesis.26 The substrates for film deposition are placed on the graphite susceptor, which is heated to high temperature by the radiofrequency (RF) induction coil. The substrate is constantly spinning at a constant rate during deposition to achieve good film uniformity over the inch-size area. The MOCVD system utilizes volatile precursors and gaseous molecules to deposit WS2, MoS2, and other TMD films.27 W(CO)6 stored in a bubbler is delivered into the reactor by regulating the carrier gas flow and bubbler pressure with the mass flow and pressure controller. H2S gas is also used to supply sulfur. C-Plane sapphire ((0001) α-Al2O3) not only has good thermal and chemical stability but also exhibits crystallographic compatibility with TMDs. The lattice mismatch between WS2 and sapphire (30%) can be reduced significantly by the formation of domain epitaxy (i.e., 3 unit-cells of WS2 match with 2 unit-cells of α-Al2O3). Therefore, it is a promising substrate for the epitaxial growth of WS2 at high temperatures.

Figure 3.

Wafer scale synthesis of epitaxial 2D WS2 by MOCVD. (a) Illustration of a MOCVD system (left) and close view of reactor (right) used for the growth of WS2 monolayer films. (b) Illustration of precursor and carrier gas flow rates and substrate temperatures during the multistep process at variable temperature. (c) AFM image of WS2 monolayer grown at 1000 °C for 10 min when nucleation and ripening were carried out at 850 °C. (d) Schematic shows that well-aligned domains oriented by the substrate step edges are observed when the surface step structure is modified less by performing the nucleating and ripening stages at 850 °C. (e) Isolated WS2 domains obtained at a constant-temperature process at 1000 °C. (f) High-temperature exposure starting at the beginning of the process distorts the surface step structure, resulting in WS2 domains nucleating in various orientations. (g) Photograph of a WS2 monolayer film grown on a 2 in. sapphire using the multistep process described in (b). (h) AFM image of films deposited at a growth rate of 3 monolayer/min shows a continuous monolayer (1L) with a small amount of bilayer domains. (i) In-plane XRD φ-scans of the (1010) and (3030) planes of WS2 and sapphire, respectively, show the coincidence of their peak positions, indicating that the film/substrate relationship is epitaxial. (j) High-resolution Z-contrast STEM image shows that two domains with the same orientation are separated by a line defect caused by the translational offset between the two domains. Their same orientation is highlighted by the WS2 models superimposed on the image. Adapted from ref (26). Copyright 2021 American Chemical Society.

In order to reduce high-angle grain boundaries caused by misoriented WS2 domains and the inversion domain boundaries (IDB) that form between coalesced 0° and 60° domains, Choudhury et al. reported a multistep MOCVD process for WS2 that etches and modifies sapphire steps to orient all WS2 nuclei at the same direction (Figure 3b).26 In this process, the nucleation step of WS2 with a high W(CO)6 flow is carried out at a lower temperature of 850 °C. After the nucleation step, the deposited nuclei on sapphire are heated to 1000 °C at the ripening step without a W(CO)6 flow to minimize H2-induced sapphire surface roughening. After these early steps, a smaller flow of W(CO)6 is reintroduced to grow WS2 nuclei into larger domains and ultimately to form a continuous monolayer film. The multistep WS2 synthesis recipe can regulate domain orientation such that the zigzag edge of each domain is parallel to the straight sapphire step edge (Figure 3c,d).26 A high density of epitaxial WS2 domains from this process that orient at the same direction is also observed in the AFM image, which can help reduce the density of IDB in a continuous WS2 film. On the other hand, if the early stages for both WS2 nucleation and ripening are conducted at 1000 °C, the etching of sapphire steps can proceed at a faster rate than nuclei formation and growth, leading to misoriented WS2 domains along curved sapphire steps (Figure 3e,f).26 By following this recipe, a 2 in., fully coalesced, WS2 monolayer film (Figure 3g) with an atomically flat surface (Figure 3h) can be achieved. Additionally, the growth rate is controlled at 3 layers/hour to minimize bilayer coverage. In-plane X-ray diffraction (XRD) Phi scans of (1010) and (3030) planes of WS2 and sapphire, respectively, reveal the coincidence of the WS2 peak positions with sapphire peak positions, indicating that (1010) WS2 is parallel to (100) sapphire (Figure 3i).26 A dark-field STEM image shows that two WS2 domains are unidirectional but separated by a line defect due to translational offset between the two domains (Figure 3j). Therefore, to push film quality to electronic grade, each domain needs to grow larger to minimize the density of such line defects in continuous films induced by the translational offset.

1.4. Patterned Growth/Substrate Mediated Growth

The morphology and dimensionality of 2D crystals determine many of their key physical properties.28 Recent work on the synthesis of graphene and TMD nanoribbons29−34 has been motivated by an interest in constraining the dimensionality of 2D crystals toward the 1D limit to realize a tunable bandgap,35,36 enhanced thermoelectric performance,37 ferromagnetism,38 width-dependent phase stability,39 and spatially heterogeneous electronic properties.30 However, while many intriguing material properties are dictated by crystal morphology and dimensionality, synthetic control of a 2D crystal’s size, shape, phase, and layer number is still a major hurdle. Typically, bulk and 2D TMDs are prepared by CVD during which TMD precursors undergo surface adsorption, surface diffusion, and bond formation/rearrangement to yield a planar 2D crystal lattice.40−45 Top-down fabrication methods are frequently used to pattern raw crystals, but these methods involve lithography and etching processes that present some challenges, namely, intrinsic resolution limits which complicate efforts to tune materials to atom-levels of precision, and etch processes which can damage 2D crystals. A number of approaches to prepare dimensionally restricted forms of graphene and 2D TMDs include molecular beam epitaxy,30 ledge-directed epitaxy,32 CVD growth through vapor–liquid–solid processes,31,33 and highly anisotropic growth by CVD on Ge(001) substrates.34,46

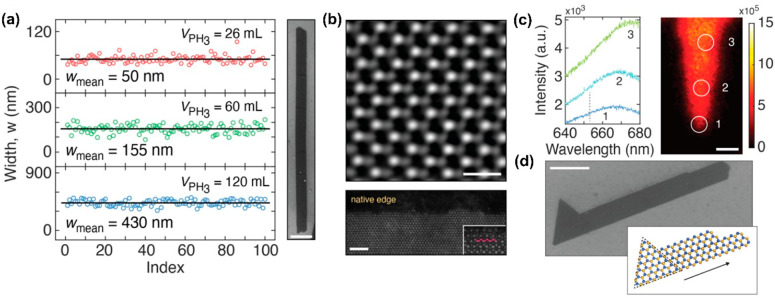

Recently, rational strategies have been demonstrated for controlling the dimensionality of 2D TMD crystals. It was shown that synthetic surfaces, in this case Si substrates pretreated with phosphine (PH3), can precisely control the lateral growth of TMD crystals. ssCVD synthesis of MoS2 on Si(001) surfaces functionalized with phosphine yields high aspect ratio and straight nanoribbons which have uniform widths.29 Notably, the width of these nanoribbons is systematically controllable between 50 and 500 nm through adjustment of the phosphine partial pressure during the Si surface treatment process (Figure 4a). It is also notable that this gas-phase method can significantly transform the dimensionality (i.e., from 2D to nominally 1D) of TMD crystals without the use of pattern and etch processes, which as discussed above have their attendant limitations. Aberration-corrected scanning transmission electron microscopy (STEM) reveals that the nanoribbons are crystalline (predominantly of the 2H phase) and exhibit an excellent edge sharpness and uniformity that rivals that found in most graphene and TMD nanoribbons prepared through conventional fabrication routes (Figure 4b). Because of their restricted dimensionality, the MoS2 nanoribbons exhibit photoluminescence which is 50 meV higher in energy than that emitted from 2D MoS2 crystals. This emission is dependent on the crystal width, which is synthetically tunable (Figure 4c). Cluster expansion and density functional theory (DFT) calculations suggest that the nanoribbons preferentially nucleate within regions of the substrate coated with Si–P surface dimers. Meanwhile, inhibition of lateral growth in the direction of the regions coated with P–P surface dimers manifests as heterogeneous nucleation of the MoS2 nanoribbon nuclei to yield crystal growth which is laterally restricted in one direction (Figure 4d).

Figure 4.

Substrate-mediated control of TMD nanocrystal growth. (a) Average widths (wmean) for randomly sampled MoS2 nanoribbons grown on surfaces treated with the indicated PH3 dosages (VPH3). SEM of a single nanoribbon. Scale bar: 500 nm. (b) HAADF-STEM images of the interior and edge of a MoS2 nanoribbon. Scale bars: 5 Å (top), 2 nm (bottom). (c) PL spectra (left) from the indicated regions of a MoS2 nanoribbon with tapered width. Scale bar: 1 μm. (d) SEM image of the early stage of MoS2 nanoribbon growth and corresponding schematic. Scale bar: 500 nm. Adapted from ref (29). Copyright 2020 Springer Nature.

1.5. Confinement Heteroepitaxy

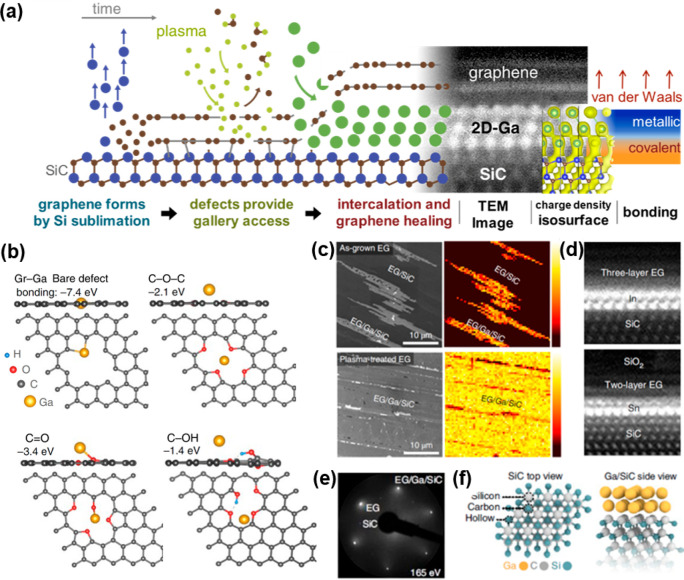

Confinement is also advantageous for developing novel low-dimensional materials. Reducing the material dimensions from 3D to 2D can lead to band structure renormalization and novel material properties because of quantum confinement.47−49 While hexagonal boron nitride (hBN), graphene, and TMD monolayers are excellent examples of insulating, semimetallic, and semiconducting layered materials in the 2D limit, the synthesis and properties of 2D metals remain nebulous. Metals rarely exist in layer form, and most of their surfaces rapidly oxidize in ambient conditions.50,51 This means that making ultrathin metals without structural and chemical degradation is difficult outside of an inert environment. Intercalation enables the decoupling of surface layers from the rest of bulk body or substrates and serves to stabilize atomic species that are sensitive in ambient conditions. Both epitaxial graphene (EG) and carbon buffer layer grown on SiC can be physically and electronically decoupled from the SiC by intercalating atomic species, such as F, O, H, Ge, and Li, to their interface.52,53 The intercalation with metal had not been explored extensively except for a few demonstrations with transition metals such as Pd, Au, and Cu.52 Recently, 2D forms of Ga, In, Sn, Cu, Bi, Pb, and Ag confined between EG and SiC were made possible by CHet.4,54Figure 5a illustrates the CHet method for 2D metal synthesis at the EG/SiC interface. First, SiC (0001) is annealed at high temperature to sublime Si atoms and leave C atoms on the surface to recrystallize into a carbon-rich layer (the buffer layer) partially bound to SiC. Further annealing leads to continued Si-sublimation, and this first layer fully detaches from the SiC, while a second layer, underneath the first, forms the next buffer layer (Figure 5a). Second, EG/SiC is treated with an O2/He plasma to generate vacancies that serve as the entry for intercalated elements. Finally, metal precursor atoms placed in a crucible beneath the plasma-treated EG are annealed with the EG/SiC at 700–1000 °C at 300–700 Torr to vaporize the metal onto the graphene surface, which subsequently diffuse through the EG defects to reach the EG/SiC interface. After intercalation, Z-contrast STEM reveals that 2D metals (e.g., Ga) release the buffer layer and exhibit an asymmetric bonding environment at the interface. They are covalently bonded to SiC at the bottom, whereas their top surface adjacent to the released buffer layer only has van der Waals (vdW) bonds.

Figure 5.

CHet with defect-engineered epitaxial graphene/SiC. (a) Schematic representation of CHet and the resulting atomic structure of the 2D metals (using Ga as the prototypical example) formed via CHet. (b) DFT study of interactions between a Ga atom and unpassivated and passivated defects of graphene suggests that graphene defects passivated with oxygen termination facilitate metal diffusion through the graphene sheet. The binding energy of a Ga atom to each defect is shown in each model. (c) SEM images and corresponding Ga AES maps of as-grown EG with intercalated Ga (top row) and O2/He plasma-treated EG with intercalated Ga (bottom row). Defects formed on EG due to O2/He plasma treatment can improve intercalation uniformity significantly. The AES color scales show low (dark) to high (light) Ga signal across the map. (d) Atomic structure of CHet-grown 2D In and Sn metals with two and one atomic layer, respectively. LEED pattern for EG/Ga/SiC indicating the presence of EG and SiC with no additional spots, implying the Ga is lattice matched to top EG or bottom SiC. (f) (Left) DFT-generated, top-down schematic of hexagonal SiC with silicon, carbon, and hollow sites labeled. (Right) Side view of DFT-predicted model shows intercalated Ga layers exhibit an ABC stacking over the SiC substrate. Adapted with permission from ref (4). Copyright 2020 Springer Nature.

The C–O bonding previously detected by X-ray photoemission spectroscopy (XPS) and the defect-induced Raman characteristic peak of graphene (D peak) in O2 plasma-treated EG disappear after intercalation, indicating the EG heals at elevated temperature in the presence of the metal intercalant and becomes an oxidation barrier that improves the sample air stability. These O-related functional groups are not trivial but play an important role. The energetics based on first-principles calculations suggest that termination of graphene vacancy with O atoms and OH groups can facilitate metal adhesion and transport to the EG/SiC interface prior to EG healing. Otherwise, the metals could have passivated these graphene vacancies and blocked the intercalating channels because C–Ga binding energy appears to be several eV higher than those between Ga and a few C–O terminations (Figure 5b).4 Auger electron spectroscopy results of EG/Ga samples on pristine vs plasma-treated EG reveal that the plasma treatment is the key to achieve a high lateral surface coverage of intercalated Ga (Figure 5c).4 The 2D metals are found to generally be 1–3 atomic layers thick (Figure 5d) based on equilibrium phase stabilities relative to their own bulk 3D form. The successful intercalation of most elements suggests that they react with graphene defects created at the early stage of CHet in a similar way and follow similar transport kinetics during the intercalation, due to similar elemental properties. Low-energy electron diffraction of EG/SiC patterns does not include any distinct spots that belong to inserted 2D metal layers. Since the Ga lateral spacing observed by STEM closely matches the spacing of SiC, it was determined that SiC and Ga share the same diffraction pattern in LEED, thereby having an epitaxial relationship (Figure 5e).4 The structural optimization based on first-principle calculations provides the top and side views of epitaxial Ga/SiC (001) (Figure 5f).4

1.6. Liquid Exfoliation

Other than the bottom-up approaches mentioned above, the liquid phase exfoliation (LPE) of layered crystals such as graphite and TMDs is a scalable top-down method to produce novel 2D nanosheet based inks such as graphene and ultrathin 2D TMDs.55 The layered crystal starting materials are stacked by vdW forces; hence, it is necessary to peel them apart without introducing significant structural defects on the lattice of the 2D nanosheet. Mechanical exfoliation using the Scotch-tape method yields the highest-quality monolayered 2D samples, which are ideal for demonstration of high-performance devices and condensed-matter phenomena.56 On the other hand, the liquid-phase exfoliation has the advantages of producing 2D materials in bulk quantities, with fairly good crystalline quality that suits most applications at an affordable price to industry.1 The manipulation of 2D materials in the liquid phase enables their chemical functionalization which can improve their functionality.57 These 2D nanosheet based inks can be easily processed and can be adapted for many thin film membranes and device fabrication techniques.6,58 However, the 2D nanosheets produced using the LPE still face some significant disadvantages.

First, the use of ultrasonication and high shear mixing in the LPE often introduces structural defects in the lattice of the 2D nanosheets.59 Defect healing by chemical functionalization in LPE processed 2D nanosheets could be a viable strategy for producing high performing 2D nanosheets in thin film devices. For example, recent studies have shown that sulfur vacancy defects in TMD nanosheets of the form MS2 could be healed by reacting the TMD inks with 1,4-benzenedithiol.60 The opposite ends of the 1,4-benzenedithiol react with different MS2 flakes and, as a result, act as a covalent bridge between adjacent flakes. This approach can be applied to thin films by exposing them to such molecular linkers as indicated in the scheme in Figure 6a, resulting in the formation of long-range pathways in 2D nanosheet films that exhibit superior charge-transport characteristics. Second, the use of ultrasonication and high shear mixing in the LPE of bulk layered crystals produces 2D nanosheets with a broad thickness distribution, which makes it hard to assess exfoliation quality and limits the suitability of the 2D nanosheets for applications. The chemical intercalation followed by dispersion of layered crystals is an effective method of preparing additive-free, ultrathin, and uniform dispersions of 2D nanosheets, in low-boiling-point solvents.61−63 High quality thin film-based devices can be fabricated from the deposition of 2D nanosheet based inks prepared using the redox driven intercalation and dispersion of layered materials.6 Third, the use of stabilizing agents and high-boiling-point solvents to assist in the LPE usually results in the trapping of these substances between the 2D nanosheets, thus inhibiting strong interlayer coupling in thin films.6 To achieve compact stacking postdeposition, ultrathin, uniform, and additive-free 2D nanosheet dispersions in low-boiling-point solvents are required. The chemical intercalation followed by dispersion of layered crystals is an effective method of preparing additive-free, ultrathin, and uniform dispersions of 2D nanosheets, in low-boiling-point solvents.61−63

Figure 6.

LPE of vdW and non-vdW materials. (a) Schematic of S-vacancy healing mechanism in MoS2 films by means of dithiolated molecules and related interflake networking. Adapted with permission from ref (60). Copyright 2021 Springer Nature. (b) Pyrite exfoliation process, showing photographs of pyrite mineral, crushed mineral before and after cleaning treatment, and exfoliated pyrite dispersion obtained after liquid-phase exfoliation process. Adapted with pemission from ref (65). Copyright 2021 American Chemical Society. (c) Top left: bright-field TEM image of a single sheet. Scale bar, 0.5 μm. Top right: high-magnification bright-field TEM image of a monolayer and bilayer hematene. Scale bar, 50 nm. Bottom: HRSTEM image of hematene in the (001) orientation with its Fourier transform in the inset and position of atoms shown by red (O) and yellow (Fe) spheres. (d) Planar and cross-sectional simulated view of the hematene (001)-oriented plane.64 Adapted with permission from ref (64). Copyright 2018 Springer Nature.

More recently, the LPE technique has been utilized to produce new and exotic non-vdW 2D nanosheet based inks by exfoliating nonlayered materials such as earth abundant chemical compounds composed of iron and sulfur or oxygen (Figure 6b).65 For example, the sonication-aided LPE of the abundantly occurring minerals, hematite (α-Fe2O3)64 and pyrite (FeS2),65 yielded new 2D materials, ultrathin hematite (hematene) and ultrathin FeS2 inks, respectively (Figure 6b). The exfoliation and formation of mono- and bilayer hematene structures were confirmed by HRTEM (Figure 6c,d). The exfoliated 2D α-Fe2O3 materials exhibit ferromagnetic order, as opposed to the bulk form which exhibits antiferromagnetic order. The exfoliated 2D Fe2S flakes exhibit anomalous ferromagnetic-like behavior different from their diamagnetic bulk counterparts. The 2D Fe2S platelets were also used to produce Li-ion battery anodes with excellent capacities approaching 1000 mAh/g.66,67

2. Defect Engineering

The manipulation of defects in 2D material presents important opportunities for fine levels of material property control. 2D materials can possess a variety of structural defects with dimensions ranging from 0D (e.g., vacancy, adatom, and dopant) to 2D (e.g., layer stacking faults), which significantly influence their physicochemical properties.8 As a result, if the density and specificity of these defects can be controlled and the properties of certain defects understood, defect engineering can be realized for tuning properties and/or inducing new functionalities into 2D materials. With 0D point defects taken as an example, routes for engineering them in 2D materials can be classified into two categories: (1) in situ approaches which directly introduce or minimize defects during the growth process; and (2) ex situ approaches which are based on post-synthesis treatments that create or heal point defects. Because of the great significance of developing robust techniques for engineering defects in 2D materials, many efforts have been made along this direction in recent years. In this section, we will highlight recent advancements regarding approaches for in situ and ex situ defect engineering of 2D materials.

2.1. In Situ Substitutional Doping/Alloying of 2D Materials

Early work on in situ substitutional doping of TMD monolayers utilized a two-step approach, in which chemical vapor transport (CVT) was first used to synthesize doped TMD single crystals, and monolayers were then isolated from these single crystals by mechanical exfoliation. This method has been reported to yield TMDs doped with Nb, Re, Au, etc.68,69 To improve the yield and simplify the preparation of monolayers, CVD using mixed metal precursor powders was then developed to synthesize doped TMDs in a single step.70,71 Recently, an alternative in situ doping approach has been devised, which relies on the chalcogenization of mixed liquid-phase metal precursors coated on the growth substrate (i.e., liquid-phase precursor-assisted approach). Since metal precursors are uniformly mixed at the atomic level in the liquid phase and spin-coated onto the growth substrate prior to the chalcogenization process, this method circumvents the difficulty of controlling vapor pressures of both host and dopant precursors to enable effective doping. As a result, by using a liquid-phase precursor-assisted doping approach, it is likely that the spatial variation of precursor supply can be reduced, leading to improved spatial homogeneity of dopant distribution when compared to the conventional CVD using powdered metal precursors.72,73

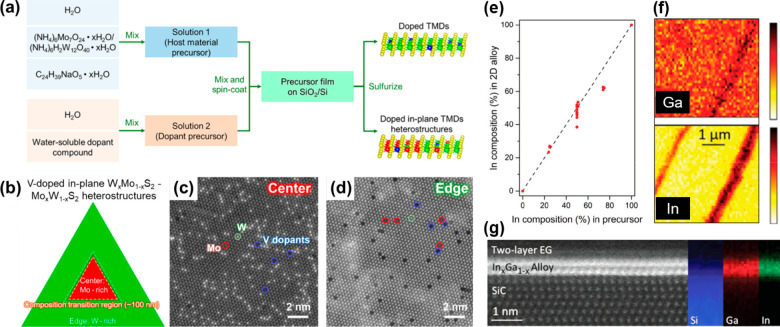

In a recent work by Zhang et al., liquid-phase precursor-assisted in situ substitutional doping of Fe, Re, and V into monolayer WS2, MoS2, and WxMo1–xS2 – MoxW1–xS2 in-plane heterostructures, respectively, was achieved. The flow diagram describing the substitutional doping process is shown in Figure 7a. First, water-soluble ammonium heptamolybdate ((NH4)6Mo7O24) and ammonium metatungstate ((NH4)6H2W12O40) were used as Mo and W precursors, which were mixed in the aqueous solution with sodium cholate (C24H39NaO5·xH2O, serving as a growth promoter) and the water-soluble compound containing the desired dopant element. Subsequently, the mixed solution was spin-coated onto a clean SiO2/Si wafer, followed by a sulfurization process carried out at 800 °C inside a tube furnace. To verify the incorporation of Fe, Re, and V dopants, the synthesized doped monolayers were characterized using atomic-resolution STEM. As an example, the schematic of V-doped WxMo1–xS2 – MoxW1–xS2 in-plane heterostructures and corresponding high-angle annular dark field (HAADF)-STEM images from center (Mo-rich) and edge (W-rich) regions are demonstrated in Figure 7b–d. Based on the atomic Z-number differences, V dopants, Mo, and W are unambiguously identified in both images (Figure 7c,d) according to their increasingly brighter contrasts, indicating the successful incorporation of V dopants into the host lattice.72 Similar liquid-phase precursor-assisted methods have also been developed to obtain different types of doped TMD monolayers. For example, Nb-doped WS2 was synthesized and characterized, demonstrating tunable optical properties and p-type transport characteristics as a function of doping level.73 V-doped MoS2, WS2, and WSe2 synthesized via similar methods were also reported by a number of separate studies. Intriguingly, apart from V dopants-induced modification of optical and electronic properties, room-temperature ferromagnetic ordering was also observed in these systems.74−77 These recent studies indicate that this doping approach is efficient, reliable, and highly likely to be generalized for the incorporation of other metal dopants that are not yet explored.

Figure 7.

In situ substitutional doping and alloying of 2D materials and heterostructures. (a) Flow diagram of the liquid-phase precursor-assisted substitutional doping approach. (b) Schematic illustration of V-doped in-plane WxMo1–xS2 – MoxW1–xS2 heterostructures. (c,d) Atomic-resolution HAADF-STEM images from center and edge regions of the V-doped WxMo1–xS2 – MoxW1–xS2 heterostructures. Examples of Mo, W, and V atoms are marked with red, green, and blue circles, respectively. Adapted from ref (72). Copyright 2020 American Chemical Society. (e) The composition of the 2D-InxGa1–x alloys can be tuned by adjusting the precursor composition, with a near linear relationship between alloy and precursor compositions. (f) Ga and In AES maps of the 2D-In 0.5Ga0.5 alloy shows uniform distribution of Ga and In across the map. (g) Atomic structure of the 2D-InxGa1–x alloys and accompanying EELS mapping show a uniform 2D-In0.5Ga0.5 alloy bilayer confined between EG and SiC. Adapted with permission from ref (82). Copyright 2020 John Wiley & Sons, Inc.

Doping TMD atomic layers by MOCVD has also advanced significantly and can control the doping range at the parts per million (ppm) level inside a grown 2D crystal.78,79 Kozhakhmetov et al. demonstrates controllable doping of V and Re originally from (C5H5)2V and Re2(CO)10, respectively, into WSe2 monolayers during MOCVD.78,79 Re2(CO)10 which provides Re is delivered into the MOCVD chamber through the bubbler manifolds by H2 carrier gas flow rate. By reducing the flow rate through the bubbler manifold for Re2(CO)10, 0.07% Re in WSe2 monolayer can be achieved. It is essential to control the doping concentration on the ppm level for bilayer, trilayer, or thicker TMD crystals, since their electronic properties are more sensitive to the density of dopants because the quantum confinement effect becomes less significant on thicker TMD.80,81 Excessive dopants can degrade the electronic transport of a few-layer TMD device in comparison with the field-effect transistor (FET) made of 1L TMDs.80

Beyond TMDs, in situ alloying is also possible in 2D metals. By alloying the composition of 2D metals, the interband contributions to dielectric properties, Fermi surface geometry dependent on alloy composition, and both optical and electrical response could be possibly tuned. Rajabpour et al. reported the synthesis and characterization of 2D-InxGa1–x via CHet discussed in Section 1.5, and achieved near-complete solid solubility without evidence of phase segregation.82 XPS measurement performed on 2D-InxGa1–x with varying composition reveals a nearly linear correlation between the composition of the InxGa1–x precursors and the resulting stoichiometry of the 2D metal alloys, indicating the full range of x between 0 and 1 can be achieved by tuning the precursor compositions (Figure 7e). Additionally, Auger electron spectroscopy (AES) mapping reveals that intercalated 2D alloys are uniformly distributed without evident in-plane segregation, as evidenced by the uniform spectral intensity of Ga and In across the mapped area (Figure 7f).82 This unform dispersion of Ga and In inside the 2D alloy was also confirmed by Z-contrast STEM image of a 2D In0.5Ga0.5 bilayer film at the EG/SiC. Electron energy-loss spectroscopy (EELS) mapping indicates a unform distribution of Ga-L2,3 and In-M4,5 EELS signals within the bilayer without oxygen, and the ratio of Ga/In close to 1 (Figure 7g).82

2.2. Plasma-Assisted Carbon–Hydrogen (CH) Doping of Monolayer TMDs

Atomic dopants can also be substitutionally incorporated into 2D TMDs via post-synthetic treatments. In a recent work, a plasma-assisted approach was applied to achieve C doping in monolayer WS2. During the doping process, an inductively coupled plasma was used to decompose methane (CH4), the gaseous dopant precursor, into reactive radicals (possibly carbon and hydrocarbons), which were likely to be incorporated into the lattice of as-grown WS2 through sulfur vacancies. Through aberration corrected high-resolution STEM (AC-HRSTEM) in combination with DFT calculations, it was identified that carbon–hydrogen units at sulfur sites (CHS) are the most stable dopant structure within WS2. Interestingly, electronic transport measurements of CH-doped monolayer WS2 reveal the emergence of p-branch that is tunable by varying CH doping concentrations, demonstrating that CH units can effectively modulate electronic properties of 2D TMDs.83 Plasma-assisted CH doping was further performed on WS2 grown on EG/SiC substrate, and scanning tunneling microscopy and spectroscopy (STM/S) were employed to further characterize CHS defect properties. The CHS defect is negatively charged detected by a significant upward band bending in the unoccupied states (positive sample bias) and the presence of hydrogenic bound states in the occupied spectrum (at negative bias).84,85 Notably, such negatively charged defects were also observed by STM/S in as-grown pristine WS2 and WSe2 samples, which unambiguously indicates that CH units at chalcogen sites are a common type of charged impurity in nominally undoped CVD-grown TMDs. This work not only corroborated the previous finding that CH4 plasma-assisted approach could selectively introduce CH units into TMDs, but also demonstrated STM/S as a powerful tool to characterize atomic defects in 2D materials.85

2.3. STM Tip-Induced Creation of Carbon Radical Ion (CRI) in Monolayer WS2 and Its Vibronic Properties

Atomic manipulation using the STM tip is a novel route to defect engineering of 2D materials. This technique has previously been used to create complex patterns on surfaces using adatoms.86 Lateral manipulation relies on weak forces between the tip and sample to pull or push atoms around. In covalently bonded materials, this is extremely difficult to realize, given their significantly higher bond strengths. Alternatively, voltage pulses from the STM tip can be used to break weak bonds. Thereby electrons are injected at a comparably high energy of usually a few eV, which can transiently populate antibonding orbitals and excite lattice vibrations that lead to bond cleavage.87 Typical examples of tip-induced bond dissociation include hydrogen–carbon and halogen–carbon bonds in organic molecules.20−22 In solid-state systems, voltage pulses can desorb individual hydrogen atoms from a hydrogen-terminated silicon surface.87−89 This so-called hydrogen resist lithography can be used, for instance, to build single-atom transistors.90

By a chemical methane plasma treatment of the TMD surface described in the preceding section, it is possible to introduce CHS defects in the TMD lattice. Using a scanning probe tip, one can apply a local voltage pulse to desorb hydrogen from an individual CH-dopant in monolayer WS2. This process exposes the dangling bond of the carbon atom remaining at the sulfur site.91 Thereby, the STM contrast at positive bias changes from a circular dark depression to a bright threefold symmetric protrusion superimposed on the dark depression (see Figure 8a). The hydrogen depassivation process is highly selective and can be targeted at a single defect.91 After hydrogen depassivation, the defect exhibits two in-gap resonances in scanning tunneling spectroscopy (STS), one at positive and one negative bias (see Figure 8b). These defect resonances correspond to the electron attachment/detachment from a singly occupied orbital. Because it is singly occupied and the defect still carries a negative net charge, this defect can be denoted as a carbon radical ion (CRI) or CS•–. DFT calculations show that the CRI has a spin-polarized ground state (see Figure 8c) with a magnetic moment of 1 μB.91 Despite the rather directional bonding, the magneto crystalline anisotropy energy is only 0.3 meV with an easy-axis perpendicular to the WS2 plane.

Figure 8.

Creating the CRI in WS2 by tip-induced hydrogen-depassivation from CHS. (a) STM images (V = 1.1 V, I = 100 pA) after sequential H desorption using 2.5 V and 15 nA. (b) Constant height dI/dV measurement across CHS in monolayer WS2 before (left) and after (right) H dissociation. Both CHS and CS are negatively charged. The half-occupied dangling bond state of the CRI appears as two resonances in the band gap at positive and negative bias in (left). (c) Calculated band structure of the negatively charged CHS and CS, respectively. (d) Vibronic excitations associated with charge state transitions of CRI. Electron/hole attachment to the unoccupied/occupied defect state in monolayer (1 ML) and bilayer (2 ML) WS2, respectively. Adapted with permission under a Creative Commons CC-BY License from ref (91). Copyright 2021 Springer Nature.

The defect resonances exhibit a striking oscillatory fine-structure with equidistant peaks, as seen in Figure 8d. One can assign these peaks to inelastic excitations of local lattice vibrations in response to the transient electron/hole attachment process. The vibronic satellite peaks can be modeled by considering the electron–phonon coupling between the electronic defect state and a small number of local vibrational modes. Using density functional perturbation theory, three contributing modes are identified at ℏω = 75 meV, ℏω = 22 meV, and ℏω = 5 meV, corresponding to a local out-of-plane C vibration, an out-of-phase breathing motion involving the C–S bond and the neighboring three W atoms, and a low-frequency resonant flexural mode.7 The difference in coupling strengths to these modes is what ultimately gives rise to the very different sideband structure shown in Figure 8d.

Interestingly, the electron–phonon coupling strengths described by the Huang–Rhys factors Sω critically depend on the spin state (cf. left column vs. right column in Figure 8d). The considerable spin–phonon coupling originates not only from differences in the exchange-correlation potential that depends explicitly on spin density but also from small differences in the charge density distributions.91 The coupling to a certain vibrational mode is in general stronger if the wave function of the defect state is more localized at the lattice sites where the vibration occurs. Moreover, it is observed that the vibronic coupling is in general stronger for monolayer WS2 as compared to bilayer WS2 (cf. top row vs. bottom row in Figure 8d), because the defect wave function in the bilayer spreads across both layers, reducing the degree of localization. This first demonstration of atomic editing of the TMD surface via STM-induced hydrogen depassivation opens new avenues for defect engineering of 2D semiconductors.

2.4. Defect Control by MOCVD

As stated above, MOCVD utilizes chemical compounds with low to moderate vapor pressure and gases as precursors for large-scale TMD synthesis.45 It provides a wide window of growth pressures and growth temperatures and can be conducted in an intermediate growth regime that off-limits to other thin film methods (Figure 9a).92 For example, in the low-temperature regime below 600 °C (Figure 9b), TMD domains and defect density synthesized by MOCVD are more tunable than those from atomic layer deposition (ALD) and molecular beam epitaxy (MBE).92 The precursor ratios between chalcogen and transition metals are controllable during MOCVD and can be tuned to provide a chalcogen-rich or -poor environment to form or suppress the point defects in the resulting TMD films.19,24,93

Figure 9.

In situ defect control for 2D TMD during MOCVD. (a,b) Operation windows of common scalable synthesis methods including P-CVD, MOCVD, MBE, ALD, and solution-based synthesis: (a) synthesis conditions as a function of growth temperature and pressure, and (b) map of domain size vs. growth temperature for similar deposition methods. Data points with S, Se, and Te are marked with triangle, square, and diamond, respectively. (c) Atomic structure of the domain boundary (DB) in WSe2 films grown at 650 °C, 700 °C, and 770 °C. Large vacancies and high-angle DB depend on the growth temperature. Above 700 °C the epitaxial relationship of WSe2 and sapphire was improved, confirmed by the electron diffraction patterns of the WSe2 films grown at 700 and 770 °C. (d) Atomic structure of a WSe2 domain grown at 500 °C has various point defects dominated by Se vacancies. (e) Atomic structure of a WSe2 domain grown at 800 °C has a better quality. The defect density can be reduced from >1014 cm–2 at 500 °C to 1012 cm–2 at 800 °C. (f) STM image of 1L WSe2 grown on epitaxial graphene without a post-growth anneal with H2Se. (g) Defect density and nanoscale clusters on the surface of WSe2 was reduced after a post-growth anneal with H2Se (10 min) was included. Adapted from ref (24). Copyright 2018 American Chemical Society.

The growth temperature can serve as a tuning knob for defect engineering in vapor phase synthesis. At low growth temperatures, reactant surface adsorption is high, and lateral growth rate is low. This kinetically controlled process that occurs at low growth temperatures typically produces small domain size and numerous domain boundaries in TMD films. On the other hand, at higher growth temperatures, reactant surface adsorption/desorption rates become similar, which reduces nucleation density and increases adatom surface mobility. In addition, higher growth temperatures also lead to larger domains due to higher lateral growth rates and also better film/substrate epitaxial relationship. Figure 9c shows dark-field STEM images of WSe2 films grown in increased growth temperatures and the corresponding results.24 At 650 °C, WSe2 domains are randomly oriented on sapphire, resulting in high-angle domain boundaries that host numerous large-size vacancies. Once the growth temperature increases to 700 °C and above, however, WSe2 film crystallinity and domain boundaries are improved.

In addition to temperature dependent reduction and healing of domain boundaries, a high density of point defects dominated by chalcogen vacancies such as single- and double-Se vacancies in WSe2 films grown at 500 °C were reduced by two orders after the temperature was increased to 800 °C due to increased Se adatom mobility (Figure 9d,e).24 Finally, post-growth annealing with a chalcogen gas flow can be utilized to control the defect density and impurity density in as-grown films. It was found that without in situ post-growth annealing with H2Se, Se vacancies and O substitutional dopants at the anion sites are ten times more than the sample with the post-growth annealing (Figure 9f,g).24,94 Based on these examples, the utilization of the intrinsic parameters of MOCVD can be a means to in situ engineer defect density and type in 2D TMDs.

3. Emerging Physics in 2D Materials

The controllable synthesis of novel 2D materials with engineered morphology and defects are key facets for the 2D community. A fundamental understanding of the structure–property relationships of 2D materials themselves are also of paramount importance. This section highlights work related to emergent properties in 2D materials and their interfaces. In particular, we review recent works in intrinsic magnetic TIs, single photon emission (SPE), excitons in heterostructures, and twist angle dependent moiré heterostructures.

3.1. Intrinsic Magnetic TI (MnBi2Te4): From Bulk to 2D

VdW solids have widely varied electronic properties including TI behavior (Bi2Se3/Bi2Te3) and ferromagnetism in 2D (CrI3). However, these materials are distinct (i.e., they possess topological or magnetic properties but not both). The intrinsic magnetic TI MnBi2Te4 (MBT) was recently proposed3,95 and experimentally verified as a bulk antiferromagnetic TI that hosts both intrinsic magnetism and topological protection.96 As the first intrinsically magnetic TI, MBT offers new possibilities to realize exotic quantum states;97 as a vdW compound, MBT also constitutes a model system to study layer dependent phase transitions.95 Notably, a series of ternary chalcogenides can be derived from MBT (e.g., MnBi4Te7,98−100 MnBi2-xSbxTe4101,102), greatly expanding the materials space to explore the interplay between magnetism with topology. In this section, we will start discussing the magnetic properties of bulk MBT, followed by highlighting recent advances in studying the correlated magnetism and topological properties of ultrathin MBT with a few septuple layers (SL).

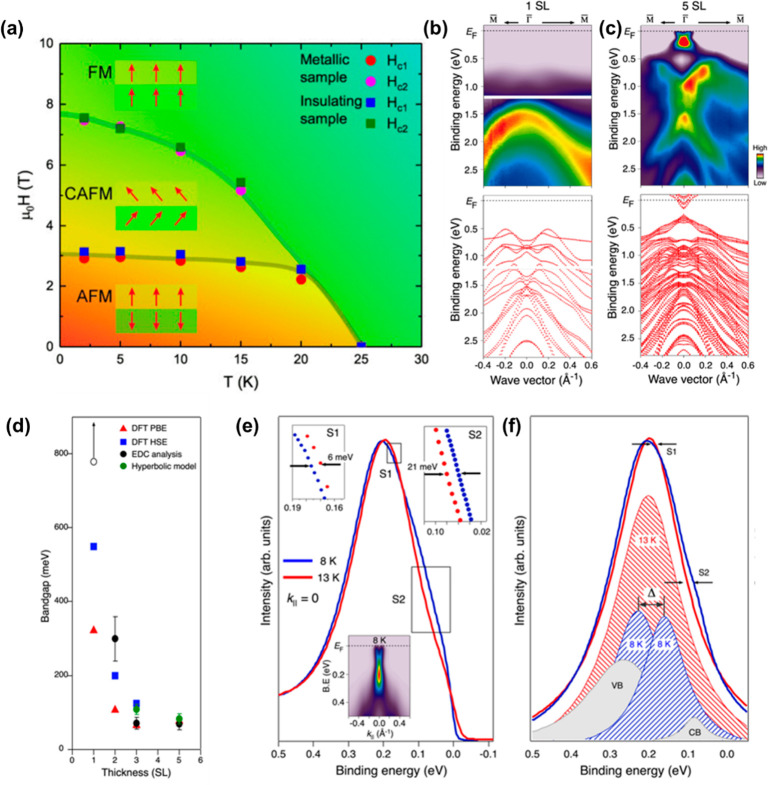

Magnetization and transport measurements performed on bulk MBT by different groups largely agree.103−108 A phase diagram has been compiled from these field- and temperature-dependent measurements (Figure 10a103). The magnetic ground state of bulk MBT is A-type antiferromagnetic (AFM): intralayer coupling is ferromagnetic (FM) along the out-of-plane direction, while interlayer coupling is AFM. At base temperature, applying a perpendicular magnetic field above 3.5 T induces a spin-flop transition. Upon this metamagnetic transition, the system enters a canted AFM state. Further, increasing the field to 7.7 T aligns all the spins and eventually turns the system into a FM state. The Neel temperature (TN = 24–25 K) is consistent among reports and has almost no dependence on sample details (such as carrier density or mobility).

Figure 10.

Intrinsic magnetic TI-MnBi2Te4. (a) Phase diagram of magnetic states in bulk MnBi2Te4. Adapted with permission from ref (103). Copyright 2019 American Physical Society. ARPES intensity (top) and DFT calculation (bottom) of (b), 1 SL; (c), 5 SL along Γ̅M̅. (d) Bandgap as a function of thickness including data from energy distribution curve (EDC) analysis (black), massive Dirac model (green), DFT calculation (blue), and data from ref (95) (red). Open circle for 1 SL reflects EF–EVBM. (e) EDCs taken at k∥ = 0 at 8 and 13 K for 5 SL MnBi2Te4. The regions S1 and S2 indicate a clear broadening and pronounced shoulder at 8 K. The inset in (e) shows the ARPES map taken at 8 K. (f) Simulated peak fitting results from the spectra in (e) correspond to a magnetic gap of 70 ± 15 meV at 8 K and 15 ± 15 meV at 13 K. Adapted from ref (126). Copyright 2021 American Chemical Society.

Neutron diffraction has been performed to investigate the magnetic structure of bulk MBT.108−111 Neutron diffraction data confirms the overall A-type AFM order with a TN = 24 K, in accordance with bulk magneto-transport and magnetization data. The magnetic space group is assigned as Pc3̅c1 in a powder diffraction study108 and assigned as RI3̅c in another crystal diffraction study.110 Independent works have found that the magnetic moments of Mn2+ ions are lower than the expected value (5 μB/Mn2+) by about 20%.108,110 Comparing diffraction data with a Heisenberg model allows quantitative estimation of the exchange parameters: within a Mn triangular layer, the next-nearest-neighbor AFM interactions are not negligible and are competing with the nearest-neighbor FM interactions. The competition introduces frustration to the exchange interactions and renders the magnetic order potentially tunable by external perturbations.111

For a TI with A-type AFM order, the massless Dirac cone is expected to open a finite gap below the Neel temperature. To probe the correlation between magnetism and band topology in bulk MBT, angle-resolved photoelectron spectroscopy (ARPES) experiments have been performed by several groups to measure the gap size.104,105,112−117 The results fall into two classes. In some cases, a finite gap is observed below TN, but this gap does not close above TN.104,105,116,117 The exact size of the gap varies among reports, ranging from tens to hundreds of meV, depending on experimental conditions (sample, temperature, wavelength, etc.). In other cases, clear gap opening is not observed either below or above TN.112−115 In all cases, the observations differ from theoretical expectations. Multiple mechanisms have been proposed, such as local magnetic moments in the paramagnetic states, instantaneous spin polarization, or reconstructed surface magnetism.107,118,119 More work may be needed to fully address the discrepancy.

MBT samples of a few septuple layers (SL), mechanically exfoliated from bulk crystals grown via a flux method,108 offer a platform to explore exotic topological states by controlling layer number, magnetic states, and Fermi level. Quantum transport performed in atomically thin devices revealed an intricate interplay between magnetism and topology. Zero-field quantum anomalous hall effect (QAHE) has been observed in a 5SL device.120 In this system, Anderson localization is proposed to play a key role.121 In 6SL devices, applying magnetic field can drive a quantum phase transition from an axion insulator phase to a Chern insulator phase.122,123 Under high magnetic field, 7SL devices can enter a helical Chern insulator phase with a pair of counterpropagating chiral edge states.124 High Chern number quantum hall effect without Landau levels have also been seen in 9SL devices.125

A material with out-of-plane magnetization may exhibit magnetic circular dichroism (MCD). Thus, MCD has been used to probe the surface magnetism of thin MBT flakes of varying thickness exfoliated on gold substrates.127 It is found that the critical field of spin–flop transitions differs significantly in even and odd SLs. This even–odd effect can be understood using an AFM linear-chain model and serves as an alternative guide to identify layer numbers. MCD measurements provide information on layer number and magnetic states—both are essential to interpret transport measurements. A recent work combines electrical with magneto-optical measurements in fabricated transport devices.128 The even–odd effect of the spin-field transition field is confirmed in transport devices by MCD. Magneto-transport measurements show that both odd (5SL) and even (6SL) layer devices behave as a Chern insulator in the FM state, while the odd layer (5SL) device is likely a trivial magnetic insulator in the AFM state.

Now we discuss thin layers of MBT grown via molecular beam epitaxy (MBE). Regarding the electronic band structure of MBT thin layers, to date, it has only been examined above the Néel temperature where it appears gapless. Hence, there has been no direct observation of the size or magnetic nature of the energy gap that would correspond to a temperature dependent topological phase transition from QAH insulator to paramagnetic gapless TI. Moreover, there has been no direct confirmation of the crossover from ferromagnetic (FM) insulator to QAH insulator with increasing layer thickness. In a recent report, 1–5 SL MBT were grown by MBE, and temperature-dependent ARPES above and below the Néel temperature was performed to understand the thickness-dependent gap size and magnetic nature of the gap.126 In Figure 10b, the ARPES spectrum of 1 SL MBT shows only a broad M-shaped valence band, with the valence band maximum ≈780 meV below the Fermi level, with no signature of the conduction band and a strong intensity bulk Si (111) band observed below 1.1 eV. The overall band shape confirms an indirect bandgap ferromagnetic insulator in excellent agreement with DFT results shown in the lower panel of Figure 10b. The gap size is comparable to other 2D ferromagnets, such as monolayer CrI3. Moving to 5 SL in Figure 10c, there is a clear thickness-dependent transition from 2D ferromagnetic insulator (DGAP > 780 meV) in 1 SL to an evolution to nearly Dirac-like dispersion in 5 SL, evidence of evolution toward nontrivial topological features. An EDC peak fitting analysis and a massive Dirac model were employed to analyze the ARPES spectra and determined the gap in 5 SL to be 70 ± 15 meV at 8 K. The evolution of the bandgap with thickness is plotted in Figure 10d.

To confirm that the gap in 5 SL MnBi2Te4 is magnetic in origin, additional temperature dependent ARPES measurements were conducted.126Figure 10e shows the energy distribution curves at k|| = 0 measured at temperature T = 8 and 13 K for 5 SL MBT (measurements were performed up to 33 K). A clear broadening upon cooling from 13 to 8 K is observed, and the right flank of the peak develops a clear shoulder. EDC peak fitting analysis (shown in Figure 10f) reveals a marked transition between 8 K that possesses a gap of 70 ± 15 meV to the 13 K data where the bandgap is significantly diminished and D < 15 meV. This reflects at 13 K a nearly gapless TI system that is now paramagnetic. This clear emergence of a magnetization induced gap with decreasing temperature provides a definitive signature for a temperature-dependent topological phase transition from large bandgap QAH insulator to a near gapless TI paramagnetic phase.

Yet, there is still further work needed to understand why given the reported large bandgap (>70 meV)126 that the QAH effect observed in MBT is limited to 6.5 K.129 Clearly, improvements in sample crystalline quality are needed and the role of magnetic disorder better understood. In particular, an understanding of whether there are spatial variations in the bandgap due to magnetic disorder, which has been previously observed in dilute magnetically doped TI’s,130 is required.

3.2. Single Photon Emission in 2D Crystals

Recently, SPEs have been observed and investigated in atomically thin 2D materials, such as hBN and TMDs.131,132 Tran et al. first reported SPEs at 2.1 eV in hBN,133 which gave rise to substantial interest in characterizing and controlling SPEs in 2D hBN.134,135 SPEs in hBN are particularly advantageous due to their high brightness, room temperature operation, high stability, and tunability.134 However, the large number of SPEs with varied spectral energies and photophysical properties has made it challenging to establish a clear understanding of the nature of these SPEs.134 A very promising development in the field of hBN-SPEs is the ability to optically initialize and control the spin state of SPEs in hBN, as demonstrated by recent optically detected magnetic resonance (ODMR) signals.136,137 Together with first-principles calculations, the ODMR signals can also be used to help identify individual defect centers,136 which is critical to advancing our understanding of how to control and manipulate defects. A recent theoretical work has elucidated the magneto-resonance parameters and optical absorption spectra for a number of boron vacancy derived defects in hBN,138 and comparison has been made to ODMR and photoluminescence excitation spectra in experiments.

SPEs in 2D TMDs were first experimentally observed in monolayer WSe2 in 2015.139−143 Subsequently, SPEs were also detected in WS2 and MoSe2,144,145 and recently in MoS2.146−148 It is generally accepted that SPEs in these TMDs arise from a strain-induced funneling of excitons to point defects.149,150 Employing semiconducting TMDs as host materials for solid state SPEs offers several advantages compared to diamond NV centers151 or SPEs in hBN.134 SPEs in semiconducting TMDs can be more easily controlled with a gate voltage and also may display novel spin–valley coupling characteristics. However, SPEs in TMDs are less stable and are generally detected at low energies.152 Optically addressable spin-polarized defects in TMDs have also not been reported so far.149,150

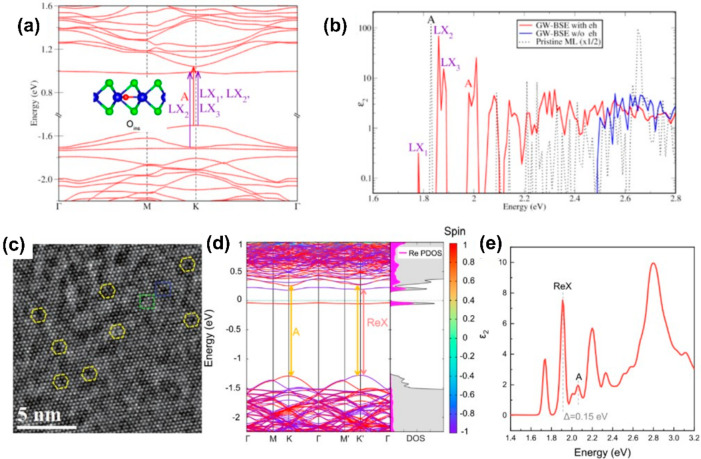

Combined experimental and theoretical characterizations have identified the most prevalent point defects in CVD-grown monolayer WSe2 as O/Se substitution OSe, O adatom Oad, and O interstitial Oins, due to incorporation of O atoms during the synthesis or processing steps.153 Another work has also identified substitutional O as the most common point defect in MoSe2 and WS2.154 State-of-the-art first-principles GW-BSE (Bethe–Salpeter equation) calculations show that, among the most plausible point defects responsible for SPEs in WSe2, Oins presents a defect band very close to the conduction band edge, and the resulting defect band-valence band maximum optical transitions exhibit spectral features very close to those of experimentally observed SPE sources (Figure 11a,b).153

Figure 11.

SPE in defect induced TMDs. (a) GW band structure and (b) BSE optical spectrum of point defect Oins in WSe2. Adapted from ref (153). Copyright 2019 American Chemical Society. (c) HRTEM image of redoped WSe2, with yellow hexagons highlighting ReW substitutional sites. Adapted with permission from ref (78). Copyright 2020 John Wiley & Sons, Inc. (d) DFT-SOC band structure and (e) BSE optical spectrum of ReW dopant in WS2. Adapted from ref (155). Copyright 2021 American Chemical Society.

There has also been recent experimental progress in the intentional incorporation of defect atoms within the TMD lattice.73,75,78,155 Re dopant induced optical emission is observed there with spectral energy ∼150 meV below the free exciton energy.155 From GW-BSE calculations, this localized emission is attributed to a transition from a re-induced defect band to the valence band maximum in one spin channel (Figure 11c-e).155 Although single photons were not detected due to the high density of defects, the emission was present at room temperatures, and controlling the defect density is critical for intentionally creating stable SPEs in TMDs.

3.3. Exciton in 2D Heterostructures

Excitons in TMDs present unique opportunities for applications in optoelectronics. Semiconducting TMDs are vdW materials that are highly air stable even in the monolayer limit.156 The strong exciton dominated light matter interaction, tunable valley physics in mono- and heterobilayers, as well as defect engineering makes them promising candidates for applications in the areas of optoelectronics, photovoltaics, photocatalysis, and quantum technologies.157−159 2D-based vdW materials can be combined in an arbitrary fashion into homo- or heterobi- and multilayers. An additional and highly relevant degree of freedom is the rotational alignment resulting in twist angle dependent and valley selective hybridization effects160−162 as well as moiré superlattice structures.163

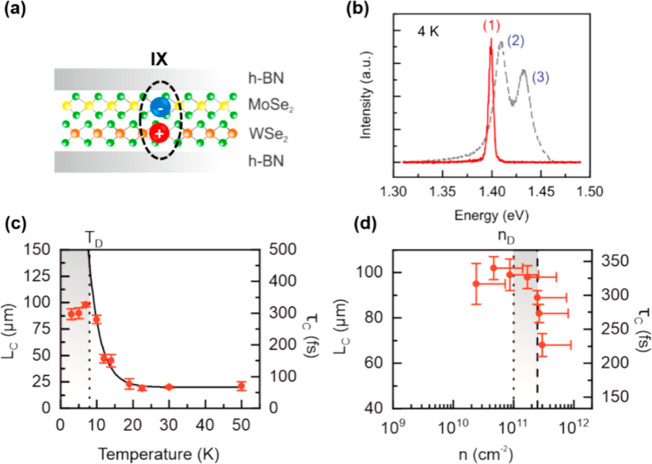

VdW heterobilayers are not only interesting to study moiré flat-band induced strongly correlated electron phases, which we will discuss in Section 3.4, but also offer access to study correlation phenomena in dense exciton ensembles. Excitons are electron–hole pairs coupled by strong Coulomb interaction. These two-body complexes are bosonic quasiparticles and are therefore able to form degenerate exciton fluids and to condense to a macroscopic ground state—a Bose–Einstein condensate.164 Increasing the interaction strength between quasiparticles can cause strong correlations, collective phenomena, and transition to emergent quantum phases. Atomistic vdW heterostacks are ideal systems for high-temperature exciton condensation because of large exciton binding energies, an interfacial dipole moment, and long lifetimes of the interlayer (IX) excitons also known as charge transfer excitons.162,165,166 Light emission and electron energy-loss spectroscopy showed first evidence of excitonic many-body states in such 2D materials.167,168 Pure optical studies also enable exploration of the phase diagram of photogenerated excitons. For the study of correlation phenomena of exciton ensembles in TMD heterobilayers, the absence of disturbing, superimposed moiré effects, in particular of moiré trapped exciton is desired. Atomic reconstruction allows the formation of commensurate R-type or H-type stacking orders in closely AA- or AB-stacked heterobilayers (0° or 60° twist angle) with a deviation in the twist angle of less than ±3°.169 Moreover, the combination of the TMD monolayers forming a heterobilayer needs to be carefully selected to ensure exciton ensembles formed by just one kind of interlayer excitons that is robust under external stimuli such as moderate changes in the exciting photon flux or static electric fields. For this reason, MoS2 /WS2 heterobilayers embedded in field effect structures are less capable for correlation studies of IX ensembles but nevertheless highly intriguing structures, since layer index, orbital character, lifetime, and emission energy of indirect excitons can be controlled by the electric field due to valley selective hybridization and multivalley physics.162 This kind of heterostructure might be suitable for the realization of a new type of charge qubits.170

Several criticalities with respect to photoluminescence intensity, line width, and temporal coherence are reported for photogenerated exciton ensembles in MoSe2/WSe2 heterobilayers.171 These phenomena are found for exciton ensembles hosted in nearly commensurate H- and R-type stacked MoSe2/WSe2 and hBN encapsulated structures. No signatures of moiré excitons in the emission spectra even for lowest excitation powers have been found indicating commensurate stacking. The described criticalities are found for a narrow emission line appearing for low to intermediate excitation densities and are interpreted as pointing toward the transition to a coherent many-body quantum state, consistent with the predicted critical degeneracy temperature on the order of a few-tens-of-Kelvin (see Figure 12). For this state, the estimated occupation is approximately 100% and the phenomena survive above 10 K. For larger excitation intensities with incoming photons and for higher temperature, the IX emission spectrum is dominated by a doublet emission peak that are blueshifted with respect to the degenerated emission line and that is fully consistent with multivalley emission as previously reported.166,172

Figure 12.

Signatures of a degenerate interlayer exciton ensemble in MoSe2/WSe2. (a) Scheme of a MoSe2/WSe2 heterobilayer encapsulated in hBN with the Coulomb-bound electron localized in MoSe2 and the hole localized in WSe2. (b) Photoluminescence spectra taken at an excitation power of 200 nW displays only peak (1) and for 420 μW two redshift peaks (2) and (3). Peak (1) is interpreted as a many-body-state emission peak. Excitation energy is Ephoton = 1.946 eV and bath temperature T = 4 K. (c,d) Critical behavior of the temporal coherence length lc and corresponding coherence time τc in the many-body state (1) indicating a critical temperature of around 10 K (c) and a critical exciton density of 2 × 1011 cm–2 at T = 7 K. Adapted with permission under a Creative Commons CC-BY License from ref (171). Copyright 2020 American Physical Society.

3.4. Moiré Effects in 2D Bilayers

As mentioned above, layers of 2D materials can be selectively stacked together, and new artificial vdW solids with novel emergent properties that were not present in the original host materials could be designed and fabricated. Moiré superlattices are generated when two stacked monolayers with different lattice constants or the same lattice constant but with a twisted angle are stacked together. The induced moiré potential results on one hand in deep periodically arranged potential traps for moiré excitons173 that might be interesting for the generation of arrays of quantum light sources. On the other hand, moiré superlattices can induce flat electronic bands (mini-band structures) that result in twist angle and filling dependent correlated electronic phases as shown initially for magic-angle graphene bilayers.174 As demonstrated by Tang et al.,175,176 twisted TMD heterobilayers are suitable as simulators for the Hubbard model, a theoretical model of interacting quantum particles in a lattice. The model is used to theoretically describe the essential physics of strongly interacting electrons, where strong correlations results in quantum phase transitions to many-body ground states such as high-temperature superconductors or magnetic insulators and other complex quantum many-body ground states.175

Magic-angle twisted bilayer graphene has emerged as a versatile experimental platform that combines metallic, superconducting, magnetic, and insulating phases in a single crystal.177−179 In particular, the ability to tune the superconducting/insulating state with gate voltage opens pathways to novel device functionality. Recently, a nanodevice based on the interplay between two distinct phases in adjustable regions of a single magic-angle twisted bilayer graphene crystal has been built.180 The superconducting and insulating regions of a Josephson junction are electrostatically defined and tunable DC and AC Josephson effects are observed. This work is an initial step toward devices where separate gate-defined correlated states are connected in single-crystal nanostructures.

Enhanced Coulomb interactions and flat bands in TMD moiré heterostructures, such as MoSe2/WSe2, provide another rich platform to explore correlated quantum phases of matter. Unlike their monolayer counterparts, excitons in heterobilayers feature an electric dipole which can be used to tune their emission energy electrically. For example, dipole–dipole interactions between electric field-tunable, localized interlayer excitons in MoSe2/WSe2 has recently been studied,181 the result of which can be exploited for quantum nonlinearity. Moreover, it has been recently reported that many-body interactions among interlayer excitons in WSe2/MoSe2 heterobilayers can result in a steady-state valley Zeeman splitting that corresponds to an exchange field with the strength of ∼6 T.182

And with all the exciting reports of magic-angle twisted bilayer graphene and twisted TMD bilayers, there are always more tuning knobs to play with, such as different layer numbers of materials (twisted trilayer graphene183 and twisted double bilayer graphene184), and the strength of interlayer coupling (which could be modified by inserting an atomically thin hBN layer between the two flakes) or the twisted material (for example, twisted hexagonal boron nitride185,186). In addition, there has not been much study on the twisted doped-TMD heterostructures. It is intriguing to synthesize high-quality doped TMD materials by CVD/CVT and then build homo/heterostructures with different twist angles, which can potentially build a solid ground for further band engineering and artificial excitonic crystal engineering.

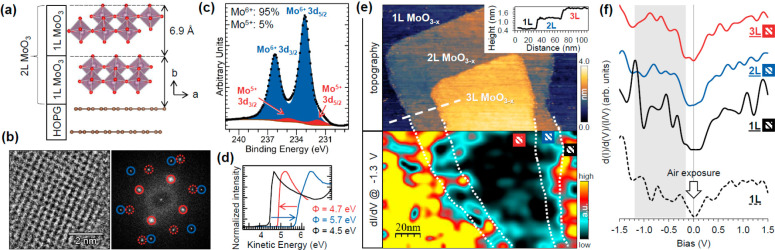

3.5. Emerging Properties of 2D Metals

Air-stable 2D metals exhibit distinctive properties from their 3D counterpart. The overlying graphene layers serve as a seal to prevent the oxidation of ultrathin non-noble metals and enable extensive ex situ characterization of these materials. Their novel properties include some of the highest nonlinear susceptibility values recorded for a single material (Figure 13a), high second harmonic generation intensity due to extreme bonding asymmetry (Figure 13b and inset), and superconductivity in 2D-Ga with a transition temperature (Tc) 4× higher than bulk Ga (Figure 13c).4 The band structure and properties of 2D InxGa1–x, such as complex dielectric function and Tc, can be tuned as a function of composition.82Figure 13d–f provides the results of ARPES performed on 2D InxGa1–x alloys (x = 0, 0.5, and 1). Figure 13d shows the ARPES-measured band dispersion (Left) and Fermi surface (Top right) along with the DFT-calculated Fermi surface for 2D Ga (Bottom right). The experimental Fermi surface indicates that the graphene Brillouin zone is 30° twisted from the underlying Ga/SiC Brillouin zone. With increasing In concentration in InxGa1–x alloys (Figure 13e,f for x = 0.5 and 1, respectively), both ARPES and DFT calculations show the Fermi level shifts downward and the pocket of states located around the K point also shrinks. Additionally, the corresponding interband transition energies along the K–M high-symmetry path, which are marked with black arrows in the band structures, decreases as the In concentration increases.

Figure 13.

Properties and band structures of 2D GaxIn1–x alloys. (a–c) The extreme asymmetry in the bonding yields the highest (a) nonlinear susceptibility and (b) second harmonic generation reported for a single material. The unique bonding of 2D-Ga also leads to (c) a 4× increase in the superconducting temperature compared to bulk Ga. (d–f) Calculated band structures and ARPES measured band structures (purple maps) of 2L InxGa1–x/SiC, ARPES-measured Fermi surface where kx and ky are the electron crystal momenta in the in-plane directions and DFT-calculated Fermi surface for 2L InxGa1–x/SiC (purple line) for the Fermi level deduced from experiment for 2D metals of (d) Ga, (e) Ga0.5In0.5, and (f) In. The dashed purple line in each band structure is the experimental Fermi level. Black arrows mark the interband transitions along the K–M path. In DFT-calculated Fermi surfaces, the BZ is plotted in gray, and Ef is the calculated Fermi level. Adapted with permission from ref (82). Copyright 2020 John Wiley & Sons, Inc.

4. Applications

One of the ultimate goals of 2D materials research is to realize their practical applications, such as electrocatalysis,159 sensing,187−192 and photodetection.193−195 All 2D materials inherently have large surface area to volume ratios granting them relatively high sensitivity to adsorbed molecules. This makes them good candidates for sensing devices as well as electrocatalysis.159 In addition, 2D materials are generally flexible, and several interesting properties can be observed when these systems are put under strain. The ultimate thinness, dangling bond free surfaces, and unique electronic and optoelectronic properties of 2D materials offer an excellent platform for ultrasmall and energy-efficient devices. This opens the door to interesting applications in neuromorphic computing and information security. Thus, in this section we review recent advancements in straintronics, 2D transition metal oxide (TMO), and its role for devices, sensing, and artificial intelligence related applications.

4.1. Straintronics Based on 2D Materials