Abstract

3D bioprinting or additive manufacturing is an emerging innovative technology revolutionizing the field of biomedical applications by combining engineering, manufacturing, art, education, and medicine. This process involved incorporating the cells with biocompatible materials to design the required tissue or organ model in situ for various in vivo applications. Conventional 3D printing is involved in constructing the model without incorporating any living components, thereby limiting its use in several recent biological applications. However, this uses additional biological complexities, including material choice, cell types, and their growth and differentiation factors. This state‐of‐the‐art technology consciously summarizes different methods used in bioprinting and their importance and setbacks. It also elaborates on the concept of bioinks and their utility. Biomedical applications such as cancer therapy, tissue engineering, bone regeneration, and wound healing involving 3D printing have gained much attention in recent years. This article aims to provide a comprehensive review of all the aspects associated with 3D bioprinting, from material selection, technology, and fabrication to applications in the biomedical fields. Attempts have been made to highlight each element in detail, along with the associated available reports from recent literature. This review focuses on providing a single platform for cancer and tissue engineering applications associated with 3D bioprinting in the biomedical field.

Keywords: 3D bioprinting, bioprinting technology, cancer therapy, fabrication strategy, tissue engineering

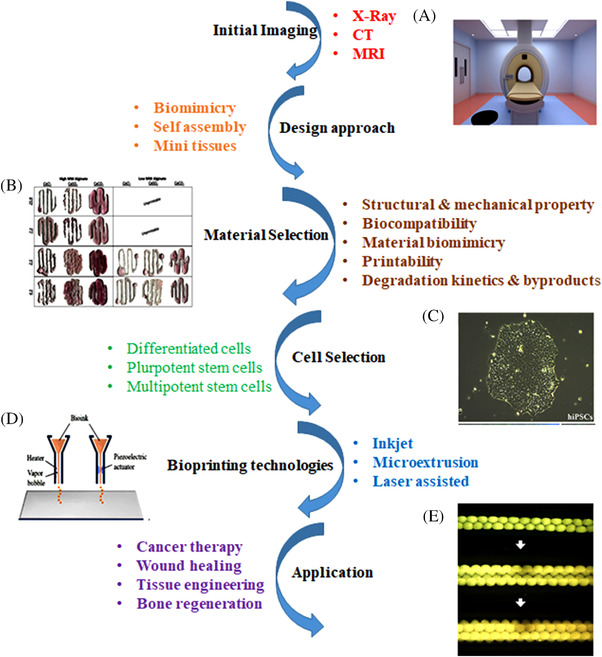

Design and discovery pipeline of 3D bioprinting technology for biomedical applications.

1. INTRODUCTION

Since the 15th century, printing has been known as one of the most vital processes of producing texts or images for quicker and broader information dissemination. It is also known as a novel and creative way to transfer information. It has also marked an impact on society by affecting the nation's education, politics, religion, and language. 1 Since 2D printing is a high‐cost technology, increasing the time and reducing the scalability of developing a particular product is the need of the hour. These limitations are overcome by these 3D printing technologies as they helped overcome various manufacturing challenges globally. 2 , 3 In 1983, Chuck Hull invented stereo lithography (SL), also called 3D printing, thereby he is popularly gaining as the father of 3D printing. 4 This novel approach globally transformed printing technology to a new level. It also proved to be a new door for the industries, manufacturing and medical technologies in making technological advancements by overcoming specific challenges. This invention modified the earlier 2D printing technologies and helped to advance from 2D to 3D components by using different additives that create a successive multilayer to form the desired 3D shapes.

3D printing defines the layer‐by‐layer deposition of bioinks (tissue spheroids, microcarriers, cell pellets, etc.) in an exceptionally designed fashion as prescribed by a software‐supported system to create the desired 3D structure. 2 Earlier, this technique was used only from the mold to develop the desired 3D structures from the biological materials. However, the designs became more complex upon developing the technology from resin‐based to solvent‐free aqueous system. The introduction of direct printing of biomaterials with or without the incorporation of live cells could further be used for transplantation. With rapid technological advancement in cell biology and material science, 3D bioprinting was better modernized, and tissues were incorporated into the complex models making the researcher close to eradicating the problem. These tissue engineering models have been used to create medical devices in prosthodontics. 1 Although bioprinting is increasing, it has faced several problems in every aspect, from materials to incorporating live cells into the fabricated system. Biomaterial selection is one of the significant steps in fabricating the structure. The pure synthesized materials are functionalized and incorporated with many functionalities and associated groups, which increase the biocompatibility of materials as compared with pure materials. Several factors guide this transition. These factors include proper control over the mechanical properties (macro and microscale), achieving tissue designs with physiological heterogeneity, developing methods to extract and expand functional cells from stem cells, and interfacing the bioprinted tissues with a specific physiological vasculature network. Many models at the early stages lack essential elements like vasculature, lymphatics, and several practical and supportive cell types necessary for the normal functioning of large and complex tissues/organs. Due to these challenges, earlier models included the superficial cells and tissues, but later models had an advanced version with clinically relevant complex geometries. 5 Mainly, 3D bioprinting comprises three main components: biomaterials, cells, and growth factors. The live cells are incorporated with the biomaterials and printed into a desired complex form with the help of various types of printers. These growth factors can also be functionalized to enhance biological and cellular activity making the system closer to the real human body models for several biomedical applications. Initial imaging needs to be done to construct a designated 3D bioprinted structure. Various diagnostic tools like MRI, CT, and X‐ray are popularly used these days for imaging. 6 The diagnostic is followed by deciding the design, material, and cell selection, as shown in (Figure 1). 7 , 8 , 9 , 10 Upon careful selection of bioink, bioprinting technology plays a significant role in forming the complex construct to use in various applications. Conventional approaches involved thoroughly optimizing various parameters for batch manufacturing. In 3D printing, any prior formula or ingredient optimization is not affected. It deals with the incorporation of different sophisticated software that smoothens the processing and helps give the predictability of the desired result beforehand. It does not require prior optimization of the quality and quantity of desired biomaterials. Earlier development of these complex models involved high cost, time, effort, and resources with reasonably low chances of success on the first attempt. 3D printing provides a highly efficient, resourceful, and cost‐effective personalized approach through its highly advanced imaging and additive manufacturing techniques. These techniques allow fast design and development of specific complex models suitable for the desired disease, application or location instead of a population‐centric approach. 4 The processes involved, materials used, and possible applications for 3D bioprinting are schematically shown in (Figure 1).

FIGURE 1.

Step‐by‐step schematic processes involved in 3D bioprinting. (A) Magnetic resonance imaging (MRI) reproduced with permission from Ref. 6, copyright 2018 MDPI. (B) Printability of alginate for 3D printing of tissues reproduced with permission from Ref. 9, copyright 2017‐The Author(s). (C) Pluripotent cell reproduced with permission from Ref. 7, copyright 2021 The Author(s). (D) Inkjet Printing reproduced with permission from Ref. 10, copyright 2019 The Author(s). (E) Pattern of multicellular spheroids assembled into tubular form reproduced with permission from Ref. 8, copyright 2009 ‐Elsevier.

With increasing advancement, the market size of 3D bioprinting is valued at 1.7 billion USD alone in 2021 and is expected to reach 1.94 billion by 2025. This value is increasing and is expected to reach the compound annual growth rate (CAGR) of 15.8% from 2022 to 2030. 5 Several reasons for this high growth include limited organ donors, rising R&D investment, technological advancement, and other private funding sources. Financial and technical assistance is provided across different development phases of the printing techniques. Switzerland‐based bioprinting company from the European Union in May 2021 has developed a miniature model of the pancreas using their Tomolite 3D bioprinting technique. The Curtin University was also supported by their Australian counterpart to develop and optimize the 3D technology for bioprinting skin tissue directly onto model wounds as a prologue to human skin restoration. Another Canadian‐based industry, Aspect Biosystems, also worked in this field to enhance its technology for the 3D printing of human tissues. 11

The global pandemic has left several types of chronic respiratory diseases, which has helped in the sudden growth of the market size of 3D bioprinting. With every new COVID‐19 wave, new hurdles are faced by healthcare professionals, the community, and also the government as to how to reduce its effect and aftermath. The last few waves faced the lack of availability of test kits for COVID‐19. Several 3D bioprinting companies handled this major problem, and test kits were manufactured on a large scale. One of the U.S.‐based companies, Formlabs, reportedly manufactured 100,000 nasal swabs for COVID‐19 testing each day. 12 Recently, many pharmaceutical companies, R&Ds, and healthcare workers are rallying to fight this deadly global pandemic in every possible way. Stratasys is one of the leading manufacturers of 3D printing in America and has manufactured face shields with the help of a 3D printer. Around 100,000 face shields were shipped in the US until March 2020.

The present review highlights the important parameters from developing several bioinks to the fabrication of the 3D printed constructs along with the ongoing and completed clinical trials. This review also focusses on the criteria for selecting biomaterial for the crosslinking strategy and its application in biomedical arena. It has been elaborated on the biomedical application by discussing its use in cancer models and tissue engineering. Further, this review also covers the perspective introduction of machine learning (ML) and 4D printing.

2. MAJOR APPROACHES FOR 3D BIOPRINTING

3D printing is one of the viable and most efficient approaches to the problems faced by 2D printing structures. Flexible design, rapid prototyping, print‐on‐demand, and strong and lightweight parts are the benefits of 3D printing over 2D printing. To print a complex structure, one needs a proper way or approach to overcome the specific issues and design the system accordingly. 3D bioprinting has been used to construct 2D tissues for solid organs. Skin, hollow tubes (blood vessels), hollow nontubular organs (bladder), and other solid organs such as kidneys can be constructed using 3D bioprinting. Hollow organs are more complex to construct as compared with solid ones. Thus, they take an unusually long time to develop. 1 , 3 Scientists have developed different methods to produce living components, structures, and organs with similar biological and mechanical properties. Here, three main central approaches are described, for example, biomimicry, autonomous self‐assembly and mini tissue building block. 1

2.1. Biomimicry

Millions of years of evolution have molded the world around us and have led to the creation of vast amounts of incredible and magnificent things. Per the definition, biomimicry makes technological and industrial designs by copying natural processes/objects. The main idea behind biomimicry is to observe nature, learn the process, and try to solve the challenges already available in nature. 11 It helps to create, fabricate, synthesize, or engineer structures identical or similar to the natural structures as observed. In biological structure, intracellular and extracellular components and the environment of tissues and organs in the human body are the essential factors while the synthesis and functioning of any 3D constructs. It needs to duplicate the shape, framework, and micro and macroenvironment of the organs and tissue of any human body. The 3D printing platforms enable the multimaterial printing of complex 3D constructs consisting of living cells and a vivid variety of biomaterials and growth factors. To construct these complex structures, one must have thorough knowledge and understanding of the microenvironment, structural arrangement, biological factors, and composition. Structural arrangement includes the organization of functional and supporting cell types. Growth factors include the gradient of soluble and insoluble factors. The constituent of the different cellular environments and the nature of the biological forces present in the microenvironment are essential for accurate design. 1 , 5 , 12

Replicating biological tissues on the microscale level is an essential step for these complex structures. Gecko lizards are known for their sticky pads as they can walk up the smooth surface like stone walls and glass. The special microscopic hairs help present on their pads help them stick to walls vertically. Scientists have used this property to develop adhesives to create wounds without stitches. 13 Tissue‐tissue and organ‐organ interfaces were created using organomimetic microdevices. A liver chip was formed using hepatocytes cells and flow chambers detached by a microfabricated baffle as a barrier. The barrier separated the cultured hepatocytes from the fluid flow to mimic the endothelial–hepatocyte interface of the liver sinusoid. The structure's geometry plays a significant role in separating the cell chamber, promoting the linear arrangement of hepatocytes in two lines, thereby facilitating the production of functional bile canaliculi along the hepatic‐cord‐like structures. 14

In vitro model of tumor–stromal interactions was engineered in a microfluidic device. The device consists of two poly (dimethylsiloxane) (PDMS) microchannels separated by a semipermeable membrane. Cancer cells were deposited in a pattern in the top channel at a spatially defined position relative to the source and sink cells. This particular pattern was used to create physiological chemotactic gradients that helped the migration of the cancer cells. The alveolar–capillary interface was recreated in the breathing lunch‐on‐a‐chip system. The 3D architecture of the angiogenesis model was created using a microfluidic model. In this model of the human umbilical vein, endothelial cells were cultured in two parallel microchannels, separated by a 3D collagen gel. The sprouting in the endothelial system was optically monitored while applying fluid shear stress. It was also induced by interstitial flow through the 3D collagen gel (100 mm, bar). 14 Researchers have taken inspiration from normal grass as they are super lightweight, but at the same time, they are very robust. The grass can bend when we step on it, but it returns to its natural shape due to its microstructure. Porous, cellular microstructure and its hollow microstructure are the main reasons for the attractive property of grass. Scientists used both these fascinating properties and came up with the idea of ceramic ink. They have helped to produce tissue scaffolds, thermal insulators, and lightweight structural materials. The ceramic foam developed by the scientist is made out of natural materials such as water, air, and alumina particles. 15 The development of vast knowledge and research from engineering, imaging, biomaterials, cell biology, biophysics, and medicine is required for successfully creating these complex similar artificial models mimicking natural structures and functions.

The layer‐by‐layer fabrication requires high precision and repeatability as it is essential for completing the goal of imitating the tissue and cell‐specific composition of extra and intracellular components. Sometimes, the development of a more advanced bioprinting system acts as a catalyst in achieving the proposed biomimicry using various types of bioink in a single approach. 16 Wanjun Liu and his research group used the extrusion‐based bioprinting technique to command the dispensing pattern through a single nozzle by utilizing up to seven controllable valves in a rapid and continuous fashion. 17 This strategy increased specificity and functionality in the fabricated ECM components at a predefined spatial position. Bioink plays an important role in the fidelity and cell viability of the printed complex constructs. Several bioprinting strategies have been enhanced and implemented to manipulate the microenvironment needed for printing the 3D design. This manipulation can be achieved by controlling the reversible crosslinking mechanisms of composite polymer bioinks and by hybrid bioprinting of both cell‐laden hydrogels with synthetic biodegradable polymers of different volumes. Nanostructuring, macromolecular crowding, and reinforcing thermoplastic polymer can be used vividly to transform the microenvironment of the printed complex. 18 , 19 , 20 , 21 The composite hydrogel facilitated good printability for achieving good structural integrity. Muller and his research group used composite hydrogel by mixing acrylate with the unmodified Pluronic F127; it displayed an excellent printing property of pluronic and stable gel created using UV crosslinking. The system increased the cell viability from 62 to 86% on days 14. 18 Pluronic F127 has also enhanced the efficiency of the crosslinked PEG‐fibrinogen conjugates in other studies. 19 , 22 Natural polymers like gelatin and alginate have also been incorporated into the hydrogel to form the composite, enhancing the printability and cellular viability of the printed constructs. 23 , 24 , 25 Chitosan is also used for 3D printing technology because of its biocompatible, biodegradable and antimicrobial properties. However, when used alone, it has slow gelation and low mechanical properties. Gelatin is used to make hydrogel composite, thus, leading to better osteogenic cell proliferation and differentiation. Hence, good printability at room temperature, high 3D constructs shape fidelity, and good biocompatibility can be achieved. 26 , 27 , 28 Macromolecular crowding has been used to describe intra and inter‐cell biochemistry. Collagen is used within most native tissues to form highly complex hierarchical structures within the native tissues. 29 , 30 , 31 PCL is used as a reinforcing polymer due to its good biocompatibility, comparatively long degradation time, and low melting temperature. The rapid cooling property also avoids the damage caused to the cells due to the high temperature processing while constructing the 3D printing design. 32 The graphene/PCL composites were used for neural tissue regeneration and promoted chondrogenic differentiation of MSCs in the scaffold fabricated using the SL‐based printing techniques. 33

2.2. Autonomous self‐assembly

Self‐assembly is a process where atoms, molecules or nanoscale building elements spontaneously organize themselves into ordered structures or patterns with nanometer features without human intervention. It is one of the most promising practical, low‐cost, and high throughput approach for nanofabrication. 34 This approach helps to replicate the tissues of interest using embryonic organ development models. 12 Tissue structures present at earlier stages have different structural and biological components compared with the later stages. In the early development stage, the cells create their extracellular matrix (ECM) components, specific cell signaling, autonomous organization, and patterning. These properties help them to give specific biological functions and microarchitecture. 35 , 36 This approach needs information about the embryo's developmental techniques, including its tissues, organs, and functioning. The field of developmental biology has one of the best possible examples of tissue self‐organization and self‐assembly. One of the examples uses a “scaffold‐free” version of this approach. This version uses self‐assembling cellular spheroids with the property to undergo fusion and cellular organization to reconstruct the evolving tissues with the same structure and function. Researchers rely on the cells as the fundamental carrier of histogenesis, leading the tissues’ composition, localization, and functional and structural properties. 3 , 37 Autonomous self‐assembly is a complex phenomenon requiring information of the development phenomenon of embryonic tissue genesis and organogenesis. It also needs the ability to control the environment to initiate embryonic mechanisms in 3D bioprinted tissues. Okano et al. 38 have developed sheet based approach for cardiac tissue engineering using a self‐assembly approach. Quick electrical coupling between the layered cardiomyocyte sheets was seen through functional gap junction formation after the harvest. Further, after the implantation in the subcutaneous position, pulsatile, layered cardiomyocyte sheets survived. The sheets developed for an extended period. The self‐assembly approach has been used for various cells, including the epidermal keratinocytes, kidney epithelial cells, and periodontal ligaments. 39 , 40 , 41

2.3. Mini tissues

This approach is mainly the combination of both mimicry and self‐assembly approaches. It is relevant in both the strategies mentioned earlier. 42 As the name says, mini tissues comprise smaller, functional building blocks of organs and tissues. For example, the nephron is the mini tissue for constructing kidney tissues. Two major strategies can be seen in this approach. First self‐assembling cell spheres are gathered into a macrotissue through biologically inspired design and organization. 42 , 43 In the second strategy, accurate high‐resolution reproductions of tissue units are designed, followed by their self‐assembling into a functional macrotissue. The emerging mini tissue‐based approach in tissue engineering has made a wide variety of improvements in the 3D printing of complex structures. This approach is generally based on the developmental biology‐inspired assumption that 3D materials of specific required material and composition could be fabricated without solid porous biodegradable synthetic or natural scaffolds. It also demands the synthesis of more sophisticated soft natural biomaterials and ECMs such as hydrogels. 44 Mini tissues approach was used for the Self‐assembly of vascular building blocks to make a branched vascular network. 45 , 46 “Organ‐on‐a‐chip” is constructed using functional tissue units and sustained and associated by a microfluidic network. It is used in in vitro models of disease for the screening of drugs and vaccines. 47 , 48 Gu et al. 49 created neural tissues by printing human neural stem cells, differentiating in situ into functional neurons and supporting neuroglia. Polysaccharide‐based bioink using alginate, carboxymethyl‐chitosan, and agarose were used as a biomaterial for encapsulating the stem cells for in situ expansion and differentiation. The differentiated neurons formed synaptic contacts and established networks. Spontaneous activities were seen in the neurons, and as a result, calcium response increased, and gamma‐aminobutyric acid expression was predominant. Axel Gunther and coworkers used a microfluidic device to fabricate a resistance artery structure and function under physiological conditions under 37°C and 45 mm Hg transmural pressure. This device allowed on‐chip fixation long‐term culture and fully automated acquisition of up to ten dose–response sequences of complete mouse mesenteric artery segments in a definite environment having 250 μm diameter and 1.5 mm length. The phenylephrine or acetylcholine application caused dose–response relationships, which were virtually similar to the conventional myography. 50

The above strategies have been used in several bioprinting approaches for creating a 3D printed construct for the desired functional, mechanical, or structural property. These strategies can produce a construct that can produce multiple components and properties simultaneously. Material selection is one of the crucial steps in fabricating the 3D printed system. These systems are used for in vitro analyses after successful and desired in vivo fabrication.

3. MATERIALS SELECTION CRITERIA

Printing technology was mainly related to nonbiological applications like firearms, military, and certain manufacturing products. These applications mainly deal with organic solvents, high temperatures, and other crosslinking agents, which help deposit metal, ceramics, and thermoplastic polymers. These processing conditions are not suitable for biological materials and live cells. Material selection is essential for printing desired complex biological models with specific mechanical and physical properties to fulfil the desired applications. As mentioned earlier, materials used for the 3D printing techniques have been denoted with a particular name of bioinks. This printing method manufactures a wide range of complex structures using ceramics, metals, and polymers and their combinations in various hybrids to form composites. Materials used for biomedical applications are mainly natural or synthetic polymers. Natural polymers are primarily similar to the human ECM and have natural bioactivity, making the models closer to the original shape. Naturally found polymers include alginate, gelatin, collagen, chitosan, silk, HA, fibrinogen, agar, and other biocompatible polymers used alone or incorporated with other polymers to form a suitable matrix. 51 These polymers include the main component of bioinks. At the same time, synthetic polymers like acrylonitrile butadiene styrene (ABS), poly(lactic acid) (PLA), poly(glycolic acid) (PGA), poly(lactide‐co‐glycolic acid) (PLGA), polyurethane (PU), polyamides, and several other polymeric hydrogels can be functionalized and molded with specific properties to match specifically designed applications. 52 , 53 , 54 Although poor biocompatibility, toxic degradation products, and loss of mechanical properties during degradation are some disadvantages of synthetic polymers, they are still one of the primary materials used for synthesis.

Materials used for this application should have long‐term and short‐term stability as they are desired to be incorporated with the cells. Long‐term stability mainly includes biocompatibility as it is a long process. The desired bioink needs to remain biocompatible at every fabricated stage until the desired stage has been achieved. Short‐term stability is necessary to maintain the integrity of the material at the initial stage by ensuring correct tissue structures such as pores, channels and networks and by keeping that they do not fail until printing has been done. Bioinks should have different structural and printing properties to be considered an ideal material for fabricating complex 3D structures using 3D Bioprinting. An ideal bioink should have the desired physiochemical properties like mechanical, biological, rheological and chemical characteristics. These properties lead to (a) fabrication of tissue constructs with desired mechanical stability and robustness along with retention in the tissue matching mechanics, mainly in a tunable matter, (b) gelation and stabilization should be adjustable to help the bioprinting of structures with high shape reliability, (c) biocompatibility and biomimicry of the natural microenvironment of the tissue, (d) suitable for chemical modifications to get desired tissue environment, (e) potential to have large scale production with minimum batch‐to‐batch variations. 55 , 56 , 57 The material's printability, biocompatibility, degradation kinetics, byproducts, structural, mechanical property, and material biomimicry are vital requirements for 3D bioprinting.

3.1. Printability

As the name suggests, it includes the property of the material that makes it easy and most suitable to print to form the desired shape. It is essential as it allows the material to be deposited precisely while maintaining the 3D control. The printing capability of a material is one of the limiting factors present in different types of printers for printing complex 3D constructs. Inkjet‐type printers have limitations on the viscosity of materials, but in microextrusion, materials require specific crosslinking mechanisms or shear thinning properties. Parameters like time and nozzle gauge also affect the printing process, and in turn, it affects the quality of printed 3D material. 58 The nozzles and/or energy used to ejaculate the bioink is generally limited by the factor of viscosity of liquid and surface tension. 59 Crosslinking of polymers is also a vital phenomenon for printing 3D constructs. Specific crosslinkers are required for inkjet printing as they help in layer‐by‐layer formation for 3D structures. However, in the case of microextrusion, final crosslinking is done after fabrication to incorporate the deposited highly viscous material. 2 Cell viability defines the number of healthy cells present in a sample. It is an essential indicator of the proliferation of cells for understanding the mechanism in action of specific bioactive components like genes, proteins and other biomaterials.

Crosslinking is an essential part of the formation of complex 3D constructs. It allows the formation of the bonds between the materials and thus acts like a substrate for cell incorporation. It also helps to provide a structural framework for the printed system. Various crosslinking methods are used for 3D printing, for example, polymer crosslinking, photo crosslinking, and thermal crosslinking, and so on. 43 , 60 The viscosity and flow rate of the materials also affect the printing and cellular study phenomenon. Biological materials with either low thermal conductivity or the capacity to cushion cells during delivery may enhance cell viability and function in the case of thermal inkjet printing and laser‐assisted printing (LAB). 61 , 62 However, printing the cell viability may depend on the printer specifications, material properties, resolution, and the cell types used to print with the material. Out of inkjet, microextrusion and LAB, only LAB and inkjet printing have viability greater than 85%, whereas microextrusion printing gives cell viability between 40 and 80%. 63 , 64 , 65

3.2. Biocompatibility

It is one of the most common terminological requirements in biomedical applications. It is considered one of the primary and the most vital features of a material to be suitable enough to be used for a biological or biomedical application. Biocompatibility can be defined in many ways, but all the definitions reach one robust understanding: the material should be compatible with the living cells, tissues or organs so that it can be incorporated together, printed and ultimately form a complex 3D model. The material should cohabit with the host's internal tissues without causing any unwanted local or global effect. Several factors can be considered for biocompatibility. The material should not cause any inflammatory or immune response, should be biodegradable and has similar function and behavior in situ and ex situ. The material should be versatile enough to be functionalized so that it can be used to enhance the efficiency of any desired application. The byproducts formed upon fabrication or disintegration should not be less or no harmful to the host. The materials should also facilitate proper cellular, mechanical and molecular signaling systems for the host's essential functioning, especially in organ transplantation. 1 , 64 Many natural and synthetic materials are used for 3D printing for biomedical applications. PLA is extensively used for biomedical applications such as breast reconstruction surgery. 66

3.3. Degradation kinetics and byproducts

One of the key mottos of 3D printing is the reconstruction of the desired organs or tissues. It also helps to print or design scaffolds, which can be used to deliver biological components like drugs, DNAs, and proteins in a controlled manner. Upon delivery, these scaffolds must be degraded to cause the least or no harm to the host. When the scaffolds devalue, the incorporated cells secrete proteases and produce ECM proteins that outline the new tissues. 67 Many factors are considered during the kinetics of degradation. Different enzymes can degrade each polymer in different reaction environments (Table 1). The degradation rates should match the cell replacement ability of materials with their own ECM proteins. The degradation by products should be nontoxic, readily metabolized, and instantaneously excreted from the body of the host. Upon degradation of any polymer, it clears to small molecular weight polymers that can be recognized by other cells. It may cause inflammation and other deteriorating effects on the host. Sometimes few polymers swell and contract to cause inhibition in the proper functioning of cells with the materials. The extra fluids in the surroundings are sometimes absorbed by the polymers causing them to swell. In other cases, the contraction of the polymer causes variation in the size and weight, sometimes closing pores or vessels and impacting the migration and cell delivery process. Degradation products are sometimes used to define any polymer's biocompatibility at its preliminary stage.

TABLE 1.

Various bioink polymers used in 3D bioprinting

| Bioink polymers | Cell viability | Gelation method | Mechanical property | Degradation property | References |

|---|---|---|---|---|---|

| Agarose and its blends | >70% | Thermal/ionic | Better mechanical strength | Protease XIV enzyme caused a 45% reduction in mass after 28 days. | 68 , 69 , 70 |

| Alginate | 90.8% | Ionic crosslinking | Pure alginate has low mechanical stability | Good degradability | 71 , 72 , 73 |

| Gelatin | 91% | Thermal | Mechanical strength increases with crosslinking | More than 90% degraded after 35 days in the presence of l‐lysine diisocyanate ethyl ester | 74 , 75 , 76 |

| Hyaluronic acid with gelatin | >95% | Photoinitiated gelation | – | Enzymatic degradation at 37°C, controllable degradation | 77 , 64 , 78 , 79 |

| Fibrin | 74.27% | Fibrinogen‐thrombin | Unique viscoelastic properties among polymers | Controlled and adjustable biodegradation | 80 |

| Pluronic F127 | 91.3% | Photo‐polymerization | High elongation at break | More than 85% degradation in PBS after 1 week | 81 |

| Pluronic F127/alginate | 85% | Ionic | Low mechanical property | – | 72 , 79 |

| Gelatin methacrylate | 75–90% | Photo‐polymerization | Mechanically strong | No significant degradation over the 2 months assay | 82 |

3.4. Structural and mechanical properties

Maintaining the structural and mechanical integrity of the printed model is one of the crucial parameters for material selection. The materials should have similar mechanical properties like elasticity and strength to the native biological cellular and tissue components. These properties make the materials better fit than the replica of the original tissues. Mechanical properties vary depending on the different structural requirements from the outer skin to the innermost bone. Nowadays, sacrificial materials are used, which provide required structural and mechanical properties only for a certain period. These materials sacrifice themselves after the task has been over. They are either used at the time of printing for sufficient crosslinking for the complex model or incorporated into the model so that they can function efficiently until the assigned material can efficiently carry out the same function. 43 , 60 , 61 Carbohydrate glass/elastomer was used as a sacrificial material for the 3D printing the soft elastomer. 83 These sacrificial materials also affect the biocompatibility and degradation rate of the bioinks and can affect the host. Mechanical properties like tensile strength and stiffness also play a vital role in reconstructing and 3D printing bones. 84

3.5. Material biomimicry

As described earlier, bio stands for biomimicry's life or natural components, and mimesis means imitation or resemblance. It explains the resemblance of the printed 3D constructs, which resemble biological components present in nature in an analogous or homologous way. It helps us observe and learn from nature to incorporate its patterns to find a solution for our designs. Biomimicry is one of the essential properties of 3D bioprinting. It helps to study the constructed complex natural systems inside and outside our biological system. It helps to fabricate identical cellular and an extracellular component of a tissue or organ. 61 For fabricating a branching pattern of nerve cells, one needs to mimic the branching patterns of the vascular tree with physiologically correct biomaterial types and gradients. 3 A thorough understanding of the micro and macroenvironment and proper composition of the specific material suited for that cause is required to understand the arrangement and position accurately.

The precise anatomical and architectural information helps to fabricate a precise 3D printed model. Various bioprinting techniques have been designed and improved for 3D construction. Different bioprinting techniques also affect the tissue and organ design of the construct. Some techniques form continuous structures, whereas discrete structures can be formed in some cases. The design and capabilities of the printed construct are very much influenced by the types and properties of the bioprinting systems and will be discussed in the next section.

4. BIOPRINTING TECHNIQUES FOR 3D PRINTING

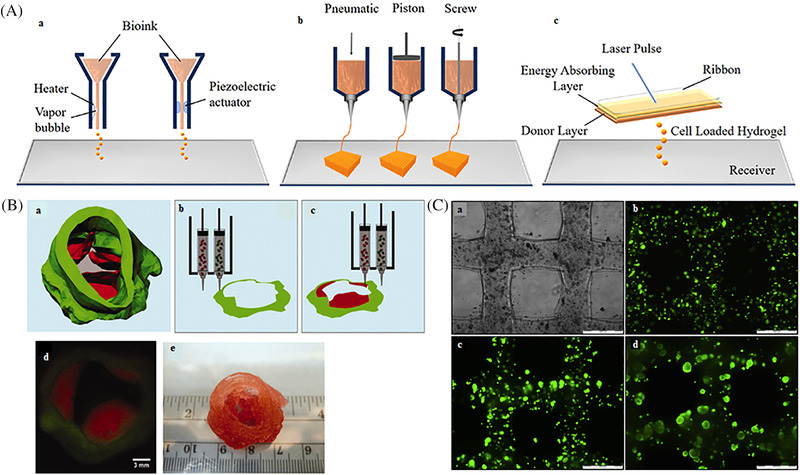

Technology is the term used to create systems or setups for any applications. It enables to use the scientific knowledge for any practical purpose. Bioprinting technologies enable printing by accurately depositing cells in the biomaterial in a specific orientation to form a complex structure using a computer‐aided printer. Factors like surface resolution, cell viability and the nature of biomaterials affect the type of technology used for 3D bioprinting. This process requires a medium to be suitable enough for the cells to acclimatize and survive to the printing system and biomaterials associated with it. Three major 3D printing technologies are used for various applications; Inkjet, laser‐assisted and microextrusion (Figure 2A). 1 , 10

FIGURE 2.

Various bioprinting technologies and printability. (A) Schematic presentation of (a) inkjet printing, (b) extrusion printing, and (c) laser‐assisted reproduced with permission from Ref. 10, copyright 2019 The Author(s). (B) (a) Aortic valve model reconstructed from micro‐CT images, (b) and (c) schematic illustration of the bioprinting process with dual cell types and dual syringes, (d) fluorescent image of first printed two layers of aortic valve conduct SMC for valve root were labeled by cell tracker green and VIC for valve leaflet was labeled by cell tracker red, (e) as‐printed aortic valve conduit reproduced with permission from Ref. 76, copyright 2013 ‐John Wiley & Sons, Inc.. (C) High viability cell‐laden gelatin scaffolds, (a) bright‐field images, cell viability within scaffolds in (b) Day 1, (c) Day 7, (d) Day 14 (scale bar‐500 μm) reproduced with permission from Ref. 181, copyright 2014 ‐Elsevier.

4.1. Inkjet bioprinting

The inkjet printer was primarily invented by Ichiro Endo in Japan during the 1970s. 85 Unlike dot matrix printers, it involved using many tiny dots of ink so small that naked eyes could not see them. In 1988, Klebe described the method of cytoscribing. 86 This involves the cell being deposited over a substrate using cell adhesion proteins using a computer. It enables the establishment of precise spatial interrelationships between cells. It was deposited either by an inkjet printer or a graphics plotter. This method helped create a 2D patterned tissue onto a flexible substrate. 87 After this approach, the inkjet printers were modified, and elevating the platform was introduced to provide a vertical movement. The inks were replaced by biological components, for example, cells, ECM components, and several other biological materials, leading to the use of inkjet printers for 3D bioprinting. 1 , 43 , 88 , 89 It is the second most common technology and is involved in most extrusion‐based bioprinters for commercial manufacturing. The recent trend shows a significant rise in the number of published papers per year from 2000 to 2020. 3 These printers have 17% of their share compared with all other bioprinting techniques used in the market. 3 Bioinks like alginate, PEG, fibrinogen/fibrin, hydroxyapatite, growth‐based bioink, PCL, PVP, and commercial bioink like Derma‐matrix are few of the materials used for the inkjet bioprinting technique. 57 Inkjet printing is a noncontact printing technique that delivers a controlled amount of liquid solution to the specified location. Thermal or sound was used as a driving force for the ejection of the droplets onto the substrate. 63 , 90 , 91 , 92 It consists of thermal, piezoelectric, and electrostatic inkjet nozzles for printing cells and tissue scaffolds. Few modifications depend on the materials for deposition and the size of the complex model to be printed. 93

4.1.1. Thermal inkjet printers

As the name suggests, the electrical component is used to heat the solution and deposit it on the substrate. It is used to release an air bubble to break liquid into droplets. 89 Thermal inkjet printers function by electrically heating the print head to produce pulses of pressure that force the droplets from the nozzle. 94 The thermal element can heat up to 300°C. The high temperature is usually for the short term, causing the overall rise of 4–10°C; therefore, the biological components are unaffected by such a range of temperatures. 50 , 96 , 97 , 98 , 99 The wide availability, low cost, and high print speed are the most importance advantages of this type of printing. However, the exposure to thermal conditions, mechanical stress, low droplet directionality, nonuniform droplet size, and frequent nozzle clogging tend to be disadvantageous here and reduce the efficiency of the printer (Table 2). 1 , 3 , 43 The thermal inkjet printer was used to print hamster ovary cells and rat primary embryonic motor neurons. 34 , 96 , 100 The fibroblast growth factor‐2 (FGF), ciliary neurotrophic factor (CNTF), and fetal bovine serum (FBS) was printed using a modified thermal inkjet printer (Canon BJC‐2100) on a polyacrylamide‐based hydrogel. 63 , 101 Thermal inkjet bioprinting was also used to fabricate neuroglia‐FGF‐2, CNTF, and FBS in a polyacrylamide‐based hydrogel. The printed substrate was further printed, and NSCs 38 cells were seeded on them. This printing was also used to print rat embryonic motor neurons and primary rat embryonic hippocampal and cortical neurons. These printed systems displayed greater viability. 63 , 64 , 89

TABLE 2.

| Bioprinting techniques | Main components | Droplet speed | Viscosities | Resolution | Preparation time | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| Inkjet based |

|

Size: 1–300 pl Speed: 1–10,000 droplets per second |

3.5–12 mPa/s | <5–50 μm | Less |

|

|

| Laser‐assisted |

|

Speed: 200–1600 mm/s | 1–300 mPa/s | >50 micron | Medium to high |

|

|

| Extrusion |

|

Speed: 10–50 μm/s |

30 mPa/s–>6 × 107 mPa/s | >5 micron | Low to medium |

|

|

Inkjet printer uses piezoelectric or electrical components for the source, whereas laser beam and heat are used as a source for laser and microextrusion printing, respectively.

4.1.2. Acoustic inkjet

These printers use piezoelectric crystals to form the droplet at regular intervals and further deposit on onto the substrate. 1 These crystals generate an acoustic wave inside the head of the printer. Piezoelectric crystals contain piezoelectric materials that undergo deformation when an external voltage is applied to system. 3 These acoustic waves generated in the head of the system cause the liquid to break into droplets, which causes the easy ejection of the liquid from the nozzles. These waves can be adjusted to control the size of droplets as well as the ejection rates. These printers can generate and control uniform droplet sizes. Directionality is maintained in the ejection of the liquid and avoids the exposure of heat and pressure to cells, unlike thermal inkjet bioprinters. 87 , 88 Earlier single nozzles were used to eject and deposit a single type of material on the substrate and form 3D bioprinted models. As technology advances, multiple acoustic ejectors can be used simultaneously in an adjustable array format. These multiarray systems enable simultaneous printing of more than one kind of cells and materials on a similar substrate, thus, reducing the processing time. 89 The piezoelectric materials require an external pressure or stimulus to produce the desired electric effect. These printers generally use 15–25 kHz frequencies to form the droplet, which can induce damage to the cell membrane and cause lysis of cells to be printed. 98 The printer uses different types of materials; thus, viscosity of the systems varies in each case. However, the viscosity of the liquid affects the ejection of the liquid. Therefore, this mechanism limits the use of highly concentrated and viscous bioinks as their viscosity might dampen the applied acoustic waves and thus, they can obstruct the ejection of droplets. Generally, the viscosity of the material is kept below 10 centipoises as excessive force is required for high viscous material to eject droplets on to the substrate. 102 Low viscosity solutions can avoid this, but it becomes inconvenient for printing 3D structures. 103 A piezoelectric printing system was used to print bone morphogenic protein‐2 onto fibrin‐coated glass slides. This area was further used to culture the muscle‐derived stem cells isolated from adult mice. 89 , 101 Piezoelectric‐based systems were also used to print heparin‐binding epidermal growth factor (EGF) like macromolecules. The proliferation and migration of the external growth factor gradients were used for the in vitro study of mesenchymal cells. 104 , 105 Inkjet printing was used to fabricate full‐thickness skin models with pigmentation. 106 After 1 day of culturing in the fibroblast medium, keratinocytes were printed on top of the dermal model and again placed in the culture medium for another day. This skin construct had individual and distinguishable epidermal and dermal skin layers. Freckle‐like pigmentation was seen on the skin construct upon maturation. 106 The wound healing capacity of the 3D bioprinted skin grafts from inkjet printing has been studied. 107 It has also been used to construct layered cartilage constructs in vitro through electrospinning (ES). 108 Ease of modification, low cost, simple operation, fast color printing speed, and compatibility with many biological materials are the advantages associated with this type of printing. It exhibits a high resolution of 5–50 μm and high cell viability. 3 This process provides the accurate position of droplet deposition on the substrate as well as simultaneous deposition of multiple cell types, as mentioned previously. 108 , 109 This printer allows electronic control over the droplet size and deposition rate and can vary from 1 to 300 μl volume with the rate of 1–10,000 droplets per second (Table 2). 46 , 89 , 95 Drop sizes have been altered in various patterns by introducing concentration gradient of cells, materials or growth factors. 98 , 99 Even a single drop can be deposited having only one or two cells in line with ∼50 μm width. 109 However, this process has certain limitations that restrict its use for fabricating all types of 3D bioprinted constructs. The low polymer viscosity, bulky size, low cell density (less than 10 million cells/ml) and low structural heights are the few limitations of this type of printing. 98 Higher viscous materials cause clogging in the nozzles and reduce shear stress. In the case of low viscosities, crosslinking agents are often used, but sometimes they cause reduced printing processes and change the chemical and structural properties of materials. 5 , 101 , 110 Further, some crosslinking agents require specific products or conditions toxic to cells causing reduced cell viability and functionality of the printed constructs. 111

4.2. Extrusion bioprinting

Extrusion is a technique where the molten polymer is forced through a die to produce components of fixed cross‐sectional areas to produce rods, sheets, pipes, films, wire insulation coating, and so on. The material is conveyed forward by a feeding screw and is forced through a die, thus forming into a continuous polymer product. 112 , 113 These are the most common and inexpensive nonbiological 3D printers. It is a widespread bioprinter due to its low cost and ease of use. 1 This type of printing was first introduced in 2001, but it expanded primarily after 2015 upon expanding commercial bioprinters in the market. 34 , 93 It consists of 39% of the total shares owned by bioprinters in the international market. 3 The low‐cost technology allows extrusion‐based bioprinters to be the most studied printers in the literature and allows printing a wide range of materials. 114 The high demand for extrusion‐based printers has allowed a significant increase in papers from 2000 to 2020. 3 Roughly 30,000 printers are sold worldwide every year, and among them, academic institutions have mostly preferred microextrusion technology for research in tissue and organ engineering. 1 Microextrusion printers are used primarily for industrial purposes. They tend to be more expensive due to advanced features like better resolution, spatial control, speed, and versatility in the material to be printed. 1 , 102 , 103 , 104

Extrusion‐based bioprinting is a pressure‐driven approach in which bioink (polymer solutions with or without cells, growth factors and other bioactive components) is extruded through a nozzle. The ejection or extrusion is pneumatic or mechanically assisted, and the droplets are deposited on the substrate in a predesigned manner. 3 , 103 This type of printer consists of several components. A temperature‐controlled material handling and dispensing system and a stage are present, with one or both capable of moving along the x, y, and z axes. It contains a fiber optic light source, which illuminates the deposition area and can act as a photo initiator. The printer is in control through CAD‐CAM software, and the images are recorded using a video camera capable of having movement in all three directions. Few systems consist of multiple print heads that enable the serial dispensing of various materials simultaneously. 37 , 103 The polymeric solutions are solidified using chemical and physical processes, including sol–gel transformation, polymerization, crosslinking, and various enzymatic degradations. 115 , 116 Materials whose viscosity lie in the range from 30 to 6 × 107 mPa/s and are more compatible with these types of the printer as higher viscosity materials provide structural support for the printed model, and lower viscous material may provide a suitable environment to maintain cell viability and other functions. 117 These printers include pneumatic or mechanical dispensing systems for the ejection of liquid. Mechanical dispensing systems deliver more direct control over the flow of material as delay of compressed gas volume is seen in these systems. Mechanical systems have smaller and more complex components, but pneumatic printers have simpler drive‐mechanism components. 113 Screw‐based systems are more beneficial for distributing hydrogels with higher viscosities as they give more spatial control. Sometimes pneumatic systems are suited for distributing high viscosity materials. 65 , 118 , 119 , 120 , 121 Microextrusion printing technology uses a wide selection of materials and porous constructs as it can deposit dense cells very highly. It helps to control ejection speed, multimaterial printing, and high resolution and is convenient to fabricate large organs compared with other printing technologies. 1 Multicellular cell spheroids were deposited and allowed to self‐assemble into the desired 3D construct. These spheroids act as a homologous and anatomical system to the ECM tissue. 8 , 43 , 44 These self‐assembly structures can possibly accelerate and direct the formation of complex structures. The mechanical microextrusion printing approach was used to fabricate scaffold‐less tissue spheroid. This printing method has several advantages, but they are not so efficient in constructing complex 3D structures. Cell viability is one of the most important parameters in biomedical applications. Microextrusion printing has lower cell viability as compared with inkjet printing. The cell survival rate of 40–86% decreases with increasing extrusion pressure and nozzle gauge (Table 2). 65 , 122 Factors like temperature and nozzle size can affect the cell viability of the printed system. These parameters are important for the researchers to present essential functions of printed 3D tissue constructs. Cell viability can be retained using low‐pressure conditions, and nozzle size can be increased in some cases, but these changes may cause major loss in the resolution and print speed. 58 Limited material selection is another problem faced by this type of printer. The use of improved biocompatible materials might help to maintain cell viability and function after printing. Crosslinked hydrogels are mechanically strong, and sometimes they develop secondary mechanical properties that help increase cell viability and cause sturdiness in printed 3D constructs. 110 , 123

Moreover, improvements in the nozzle, syringe, and motor control systems reduce print times and allow the simultaneous deposition of multiple types of materials. 124 , 125 The extrusion technique requires materials with high water content and the ability to suspend cells; hydrogels are primarily used for the technique. Natural materials like gelatin, alginate, agarose, chitosan, dextran, fibrinogen, gellan gums, HA, and so on are used. Poly(ethylene glycol)s (PEG), pluronics, polyacrylamide, and poly(2‐hydroxyethyl methacrylate) are the synthetic polymers used for this technique. 126 , 127 , 128

This technique was used to regenerate an ear formed of auricular cartilage and fat tissues. The hydrogel of PCL and PEG was used along with the chondrocytes and adipose‐derived stromal cells to fabricate an ear‐shaped scaffold. The system's viability was found to be more than 95%. 129 In another system, similar materials were used to fabricate cartilage scaffolds by extruding alginate hydrogel onto PCL. The chondrocyte printed scaffold system has 85% viability toward the cells. Both with and without turbinate‐tissue‐derived mesenchymal cells scaffold were printed within the alginate bioink. The cellular printed system caused an increase in ECM production without any severe effect upon implantation into the dorsal subcutaneous spaces of mice. 130 A hierarchical cell‐laden structure was fabricated to mimic multicellular tissues. In vitro studies were performed using PEG diacrylate and methacrylate gelatin (GelMA) hydrogel. The hydrogel was incorporated with NIH/3T3 fibroblasts and C2C12 skeletal muscle cells to print structures, which mimic the musculoskeletal junctions, muscle strips and tumor angiogenesis. Proper proliferation rate and interfaces were seen in the system after 3, 5, and 7 days of cell culture. 131 Biodegradable conductive polymers like tetraaniline‐b‐polycaprolactone‐b‐tetraaniline were synthesized, and 3D printed using the extrusion technique to construct a porous scaffold for tissue regeneration. 132 Pati et al. 32 fabricated a hybrid scaffold combining PCL and decellularized ECM. The bioink was mixed with stem cells derived from adipose, cartilage, and heart tissues and deposited onto the PCL framework. The cell viability of the system was found to be 90% on day 7, and intracellular interconnectivity was observed within 24 h. 32 Stimuli‐responsive conductive nanocomposite hydrogel was prepared using the extrusion technique. The hydrogel displayed good electrical conductivity, rapid self‐healing and adhesive properties, flexible and stretchable mechanical properties, as it is highly sensitive to near‐infrared light and temperature. 133

4.3. Laser‐assisted bioprinting

LASER is an acronym for light amplification by stimulated emission of radiation. It is a device that monochromatic light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. 134 The laser was first built by Theodore H Maiman at Hughes research laboratories in 1960 by Charles Hard Townes and Arthur Leonard Schawlow. 135 Laser‐based bioprinting uses laser‐induced forward transfer phenomenon to deposit a very small amount of bioink in liquid or solid phase. 87 , 136 It was initially developed to deposit metals onto receiver sheets, but it has been successfully applied in biological applications as well. DNA, cells, tissue, and organ printing are the typical applications where laser‐assisted printing is used. 96 Odde and Renn developed this technique to print viable embryonic chick spinal cord cells. 137 It has three parts donor side or ribbon, a laser pulse and a receiver side. The ribbon consists of a layer of transparent glass, a thin layer of metal and a layer of bioink. The transport ribbon acts as a support for the energy‐absorbing layer. The bioink is in liquid/gel condition and is transported from the donor side onto the receiver slide when the metal layer under the hydrogel is vaporized by a laser pulse. 138 , 139 All the components of this technique (laser energy, laser frequency, and biomaterial viscosity) have the potential to impact the resolution of printed complex structures. 140 Surface tension, wettability of the substrate, the air gap between the ribbon and the substrate, thickness and viscosity of the biological layers affect the resolution of the printed construct. 138 This technique is nozzle free, making it an excellent approach for depositing cells or materials, which cause clogging at nozzles. It can deposit cells at a density of up to 108 cells/ml with a microscale resolution of a single cell per drop while using a laser pulse rate of 5 kHz with the speed of 1600 mm/s.59 It can print up to bioinks having viscosity up to 300 mPa/s.141 High energy laser pulse has a minimal effect on the cell's viability, structure, and function. It can cause selective writing of multiple cell types, but UV light may affect the cells. 142 Laser‐assisted bioprinting has a comparatively low overall flow rate due to the rapid gelation kinetic required for high shape reliability. 143

The formation of a ribbon is one of the crucial phenomena in printing complex structures. The preparation of individual ribbons is time consuming and causes difficulty during the codeposition of multiple biomaterials and cells. This simultaneous deposition can be time consuming since it is difficult to accurately target cells and materials to their desired location on the printing substrate. To overcome this difficulty “aim and shoot” procedure is developed. This cell‐recognition scanning technology is used, which enables the laser beam to select a single cell per pulse specifically, and it ensures that each printed droplet contains a predefined number of cells. 2 Metallic residues are present in the final printed constructs due to the vaporization of the metallic layer from laser radiation. To avoid this phenomenon, a nonmetallic absorbing layer is used nowadays, and the printing process is modified such that it does not need an absorbable layer. 144 , 145 This system's cost is higher than other printing technologies due to monochromatic high‐energy laser beams. Owing to such disadvantages, laser‐assisted techniques for the printing of 3D complexes are less than 4% share of the total bioprinter available in the market. 114 Bioinks like alginate, collagen, fibrin/fibrinogen, hydroxyapatite, matrigel and blood plasma are the few materials used for laser‐assisted bioprinting. 57 This technique was used to fabricate a 3D printed skin model with specific cell densities in a layered tissue construct. 146 Gruene et al. used laser‐assisted technology to print the biomaterial incorporated with the mesenchymal stem cells (MSCs). The study showed no effect of the laser pulse on the cells as no change in the gene expression occurred due to heat shock produced by the laser pulse. The system had an enhanced proliferation rate and was similar to the control of the nonprinted cells even after 5 days of cell culture. 147 In another study, laser‐assisted technique was used for sprinting in situ MSCs onto collagen/hydroxyapatite (nHA) disks to favor bone regeneration in a calvaria defect model in mice. The printed disc demonstrated a larger bone volume after 2 months compared with a cellular collagen/nHA disc. 148 Keratinocytes were printed on top of 20 layers of fibroblast placed on the top of a matrix Matriderm. Layers of keratinocytes were printed on the matrix, which provided mechanical stability to the overall printed construct. After the complete development of keratinocytes cells, the in vivo study was conducted for 11 days leading to the conversion of cells into a stratified dense tissue when implanted subcutaneously in mice. 146 The study also demonstrated filling of a 3 mm diameter, 600 μm deep calvarial hole using the composite polymeric biomaterial. Similar polymeric devices is used to fabricate medical components such as a customized, noncellular, bioresorbable tracheal splint, which was used for the patient with localized tracheobronchomalacia. 149

4.4. Other technical approaches

4.4.1. Microvascular printing technique

This technique has attracted a lot of attention for its several applications in drug screening for toxicology studies, fundamental cell biology research, tissue models, and wound generation applications. It consists of a 3‐axis movable robotic platform and an array of multiple electromechanical microvalve print‐heads. Individual gas connection is provided along with the gas regulator to each microvalve print head. It provides a positive pneumatic pressure along with a 0.1 ms valve opening time, which is controlled by the movement of the plunger and the solenoid coil. The magnetic field is induced by the applied voltage, which opens the nozzle by ascending motion of the plunger. The bioink is deposited when the pneumatic pressure overcomes the fluid viscosity and surface tension at the opened orifice. Nozzle diameter, viscosity, and surface tension of the bioink, pneumatic pressure, and valve opening time are vital parameters on which the microvascular process depends 150 ,. 151 The microvascular technique offers several advantages to the printing process, including the synchronized ejection of biomaterial and cells from various print heads and thin material deposition of about 1–2 μm thickness. Precise cellular positioning is also possible, along with higher viability and high throughput printing of about 1000 droplets per second. 150 However, the process is disadvantageous during hydrogel printing within a limited range of viscosities. The cell concentration of up to 106 cells per ml is allowed to print as a small nozzle orifice (100–250 μm) can cause clogging during the printing and disrupt the process. The cells do not always disperse and settle over time, which hampers the overall homogeneity of the cells within the bioinks. 151 , 152 Homogeneous patterning of cells was facilitated on the thin layers of bioprinted ECM in a controlled area. The 3D printed cell displayed more homogeneous cellular layers with ECM 1–2 μm thickness, whereas the manual seeding cells were of 20–30 μm ECM thickness of discrete multilayered cellular clusters. The 3D printed cells induced higher structural and functional resemblance to the native barrier. 153 The microvalve technique was used to print organs with improved mimetic nature to the original organs. In one study, this technique was used to print a construct of (6 × 6 × 1.2 mm3) by repeated deposition of the collagen precursor. The printed structure was mechanically stable to retain its shape and dimensions compared with the manually seeded complexes, where profound changes in shapes and dimensions were observed during the culture. 152

4.4.2. Vat polymerization

It is a 3D printing method that involves photopolymerization to cure the liquid ink placed in a vat into a layered volumetric construct. The technique has been commercially available for more than 30 years, used mainly for the fabrication of tissue scaffolds along with the conventional cell‐seeding approach. Stereolithography (SLA) is the primary technique of vat polymerization. It leads to the fast production of volumetric structures with precise internal and external structures in several biomedical applications. This method utilizes a laser beam that helps to sweep around polymerizing single lines of ink in a faster scan mode until each layer has been completed. The SLA system uses a photocurable bioresin to print the construct using top‐down and bottom‐up printing approaches 154 ,. 155 Another method is used in the Vat polymerization technique, known as digital light‐processing (DLP), which has emerged as an improved method in VP printing. It uses a digital micromirror device (DMD) in DLP, which causes immediate crosslinking of a layer of photocurable resin instead of printing at the single dot in SLA. The DMDs provide the rotation to be in either an ON or OFF position, which helps the photocrosslinking of a bioresin layer. The rotation reduces the build time as the process only depends on the thickness of the layer and the necessary time of exposure. 156 , 157 Two‐photon polymerization (2PP) is another technique used in vat polymerization to print the material. The process uses a near‐infrared femtosecond laser (∼740 nm from titanium: sapphire femtosecond laser) to fabricate precise 3D structures with high resolution on the nanoscale. This polymerization process starts with the 3‐order nonlinear absorption within the focal region. The laser beam is tightly focused on the photoresist on a glass coverslip with an oil‐immersion objective lens. Further, it causes fabrication of high‐resolution 3D structures beyond the optical diffraction limit by adjusting the beam within the photoresist. 158 , 159 Bioinks like PEG, PCL, PEG‐co‐PDP, PEGDA, PCL/HA, HA/PEEK, and titanium are some of the materials used for the vat polymerization for printing a 3D construct.

The nature of the 3D construct printed is affected by the fabrication strategy of the different bioprinting techniques. The crosslinking process and the crosslinking agents mainly dominate the fabrication of the 3D constructs. Some hydrogels require support while processing, whereas some are mechanically stable to withstand and to complete the process. These fabricating strategies will be discussed in the next section.

5. BIOPRINTING FABRICATION STRATEGIES

3D bioprinting is a complex process starting with the material selection and ending with the fabrication of a similar biomimetic structure as proposed. Fabrication deals with the crosslinking strategies used for different bioprinting techniques, as discussed earlier. These fabrication techniques are used to accomplish print reliability and resolution. The rheological property of biomaterial plays an important role in preserving the structural integrity of the printed 3D constructs for cell deposition.

5.1. Direct bioprinting

As the name suggests, this fabricating technique prints the desired complex biomimetic structures. The biomaterials are required to have desired rheological and mechanical properties throughout the printing process to attain a similar mechanical and structural complexity. Viscosity, yield stress, and mechanical reliability are a few necessary factors that need to be controlled during and after printing. 128 , 160 , 161 The viscosity of the biomaterial can be enhanced by pre‐exposure of photopolymer to UV light, adjusting temperature and adding enzymes crosslinker. 162 , 163 In a few cases, a thickening semi‐crosslinked mixture was used along with the thickening agent to directly print the 3D construct. 164 , 165 , 166 A similar study was performed by synthesizing photocrosslinkable hyaluronan‐gelatin hydrogels for printing a complex feasible tubular construct. The synthesized bioink displayed biocompatibility, supporting cell attachment and proliferation of HepG2 C3A, Int‐407, and NIH 3T3 cells in vitro. These photopolymers when exposed to UV light displayed improvement in the viscoelastic property and thereby similar values of storage modulus (G′) and loss modulus (G″) of the hydrogel. 163 Zhang et al. directly bioprinted vessels like tubular microfluidic channels. Chitosan and alginate hydrogels were used along with the cartilage progenitor cells and displayed average cell viability of 63% after 12 h of media perfusion postprinting of the complex. The viscosity of the structure was affected by the amount of chitosan used. 167 Only ∼3% chitosan was feasible to print microfluidic channels with required fabrication parameters as 2% lacked mechanical integrity, whereas 4% was so viscous that it was not coming out properly from the nozzle. The viscosity of the bioink can be altered using thickening agents like hydroxyapatite, nanocellulose, xanthum, and gum, thereby increasing the printability to form a complex 3D structure. 88 , 164 , 166 , 168 Wouter et al. used gelatin methyacrylamide hydrogels to print tissue‐engineered cartilage constructs. The printed hydrogel was tested with chondrocyte cells; efficient viability and differentiation were seen in cells, and enhancement in mechanical properties was also seen in the hydrogel. Gelatin methacrylate solution has low viscosity at normal body temperature, making it incompatible with biofabrication processes. However, the addition of HA or codeposition with thermoplastic enhanced the viscosity and, thus, favored as a compatible bioink material. 169 During the fabrication process, the biological hydrogels, composed of polysaccharides and proteins, are difficult to print as the in situ gelation is a critical stage as they need to be provided with support so that they do not collapse or deform under their own weight. 170 The support bath is used widely to fabricate complex hydrogel‐based overhanging structures. The support bath materials should have a rigid matrix, which yields by a passing nozzle and rapidly recovers itself after the motion of the nozzle. The support bath provides the necessary gelation to the hydrogel before integrating the subsequent layers without clogging the nozzle. Several materials have been used for providing support in the form of a support bath. Pluronic is one of the biocompatible materials playing the dual role as fugitive bioink and support bath due to its thermoreversible sol–gel phase transition property. The mechanical weakness and rapid dissolution are the main concerns with this material as they limit the duration up to which the hydrogel can be supported by the PF baths. 170 , 171 , 172 Wu and his research group modified PF with triblock copolymer to increase its efficiency as a support bath. They synthesized a fluorescent dyed fugitive ink, which comprises an aqueous solution of pluronic F127, a triblock copolymer with a hydrophobic poly(propylene oxide) (PPO) segment and two hydrophilic poly(ethylene oxide) (PEO) segments in a PEO–PPO–PEO fashion was used as a fluid filler. The diacrylate functionalized pluronic F127 solution was used as a physical gel reservoir. The 3D biomimetic microvascular networks with a 3‐generation hierarchical branching topology of 200–600 μm microchannel diameter were constructed using this system. Fumed silica nanoparticles‐based suspension was used as a hydrophobic support bath for the 3D extrusion printing. Hydrophobic silica‐mineral oil suspension was used to deposit hydrophobic inks like PDMS, SU‐8 resin, and epoxy‐based conductive ink. The structural integrity was maintained during printing as well as curing was done up to 90°C. The bath was further able to provide feasibility, versatility, and a much better resolution such as 30 micron for PDMS filaments. 173 , 174 , 175

5.2. In‐process crosslinking

Crosslinking is a vital step in 3D bioprinting that influences the printed construct's mechanical, physiochemical, and cellular properties. 88 Hydrogels with a rapid gelation mechanism are primarily used through the in‐process crosslinking method. This crosslinking is accomplished either by changing the extrusion head for coaxial extrusion of the precursor and crosslinker. This can be obtained by depositing precursor into a crosslinker bath. 176 , 177 The crosslinking can be modified by changing the material or by varying the printer's tool path design. 178 , 179 Recently, extrusion bioprinters are customized for specific applications, including core‐shell printing, combined extrusion and ES, and UV curing during and postprinting. 113 Photoinitiators are the critical components of photocurable polymerization systems. Various UV –light photoinitiators are utilized for photocrosslinking. Several limitations like low water solubility, inhibition with oxygen, high‐energy UV light exposure requirement and cell damages have also been reported in this crosslinking process. 180 Layer‐by‐layer UV curing of bioprinted photocurable GelMA‐based hydrogels was prepared using a rapid extrusion‐based bioprinting technique with an in‐built ultraviolet (UV) curing system. The GelMA improved the bioink printability and shaped fidelity before crosslinking and led to the fabrication of soft tissue constructs with a high aspect ratio (length to diameter) of ≥5. The cell viability of the printed layers was above 80% in all cases. 125 In another study, water‐soluble photoinitiator lithium phenyl‐2,4,6‐trimethyl‐benzoyl phosphinate (LAP) was emulsified in pentaerythritol triacrylate monomers. Extrusion‐based printing technique was used to print the 3D construct at the optimum concentration of 10 mM and 1.62 M for LAP and triethanolamine, respectively. 180 Billiet and his coworkers used and optimized VA‐086 as a photoinitiator to fabricate highly viable 3D printed macroporous gelatin methacrylamide constructs. 181 Alginate and fibrin are among the most common used materials for this type of printing due to their capacity to sustain structural stability and are versatile to be incorporated with any cellular component. 182 Nishiyama constructed the gel structure using state‐of‐the‐art inkjet technology. Sodium alginate solution was ejected from the inkjet nozzle and mixed with calcium chloride. The nozzle could move in three directions, thereby leading to a new fabrication method for the detailed fixation of 3D gel structures using living biological components. 176

5.3. Postprocess crosslinking

Crosslinking is essential to improve the biomechanical features of the polymers through network bonding. It establishes a connection between two functional groups of a polymer chain through covalent or noncovalent bonding. 183 However, in a few cases, extrusion technology was used for crosslinking. Still, it cannot be completed before and during the printing as the bioinks may consist of different types of polymer with different crosslinking patterns and mechanisms. In such cases, the printed construct is exposed to crosslinkers after printing. This bioink mixture used in this process is made of two types of materials: primary and secondary. Primary material forms the basic framework and helps to enhance printability and shape accuracy during the complete printing process. At the same time, secondary material undergoes crosslinking after printing to provide structural accuracy. 88 Seung et al. fabricated alginate scaffolds in a two‐step process; a modified dispensing process and an aerosol spraying method using calcium chloride as a crosslinking agent. A 3D pore‐structured, cell encapsulated alginate scaffold of 20 × 20 × 46 mm3 was constructed with varying crosslinker concentrations of the aerosol and dispensing process. The printed construct displayed 84% cell viability to prepsteoblast (MC3T3‐E1) cells. 184 In another gelatin‐methacrylamide (GelMA)/hyaluronic acid (HA) polymeric system, GelMA alone could not provide the desired structural property and integrity as well as printability. The acid improved the viscosity and therefore enhanced the printed structural 3D construct. The HA also improved the cell viability to 82% compared with the pristine GelMA system toward chondrocyte cells. 169 Postprocess crosslinking was used to construct heterogeneous aortic valve conduits using alginate/gelatin polymeric mixtures. The constructed aortic valve had viability over 80% for aortic root sinus smooth muscle cells (SMC) and aortic valve leaflet interstitial cells (VIC) (Figure 2B). 76

5.4. Indirect printing

This process involves using a sacrificial agent followed by inducing a crosslinking agent, which gets removed upon final printing of the desired 3D construct. This type of printing commonly uses build/support configuration for printing constructs or models with high structural reliability. Build materials are generally engineered tissue components (cells and/or hydrogels), which support or help base materials to provide mechanical strength to hold the structure with a strong grip 84 tightly. In most cases, the support material may be deposited with the build material but is removed through postprocessing procedures. This process has allowed the use of particular material, which was not favorable earlier due to its characteristics and can be used in indirect printing. 185 The 3D filament networks printed using carbohydrate glass displayed a rigid behavior. The printed networks were used for the biocompatible sacrificial template in several engineered tissues. These templates were further used to create cylindrical networks. The cylindrical networks were lined with endothelial cells also permeated with blood under pulsatile flow of high pressure. This approach allowed independent control of endothelialization, network geometry, and extravascular tissue. 161 Alginate and gelatin precursors are mixed with different concentrations of hydroxyapatite to print a 3D complex. It is a two‐step mechanism that combines gelatin's thermosensitive and alginate's chemical crosslinking properties to form the structure. 186 Materials like gelatin, pluronic F127, and agarose show reversible crosslinking mechanisms, making them suitable for support material. 88 Alginate was used to construct a scaffold for nerve tissue applications through indirect printing. It involved printing a sacrificial framework from gelatin, impregnating the framework with a low concentration of alginate, and finally, the gelatin framework was removed using an incubation process. The printed lower alginate scaffold has better cell viability and functionality as compared with the higher alginate scaffold. 187

5.5. Hybrid printing