Abstract

Bread staling and microbial growth is a complex physiochemical change that occurs during bread storage mainly reducing the quality and consumer acceptance. It is significant to understand the causes of physical, chemical, and microbial spoilage of bakery products in the food industry, to prevent quality decay and economic loss for manufacturers and consumers. Traditional packaging has limitations in protecting and preserving the final products’ safety, hygiene, and quality. Effective novel strategies must be included in food packaging, especially to minimize the organoleptic losses of baked foods during their shelf life. Furthermore, owing to the spread of foodborne diseases, which directly affect the safety of the products, customer demand is increasing significantly to reduce the use of synthetic preservatives instead of natural ones. Innovative packaging is altering the way food items are packed in several ways to extend and monitor product shelf life. Traditional packaging includes packaging food in synthetic polymer film; however, modern technology allows them to interact with active/functional substances. This paper discusses innovative bread packaging strategies such as modified atmosphere packaging (MAP), active packaging (AP), intelligent packaging (IP), biosensor, and nano packaging. Furthermore, MAP and AP have received greater attention in this study due to their considerable effect in prolonging the shelf life of bread and naturally preventing fungal activity, and have gained a lot of interest among producers and consumers in recent years.

Key words: Active packaging, Food safety, Modified atmosphere packaging, Shelf-life extension

Introduction

Bread is still regarded as one of the best breakfast options worldwide, and people prefer different kinds of bread, like wheat bread with high fiber content because of its health benefits. People consume bread every day, however it only has a short shelf life due to various contaminating factors, including physical, chemical, and microbial spoilage (Salgado et al., 2021; Pateras, 1998). Additionally, the product’s shelf life is influenced by several extrinsic and intrinsic factors, including temperature, rainfall, humidity, and light. Intrinsic factors include oxygen availability, preservatives, environmental behavior of the pathogen in the food matrix, and water activity (Aider, 2010; Pal et al., 2019). Mold formation in bakery products is a significant factor that affects shelf life since it mostly depends on environmental factors that are favorable to pathogens, mainly Aspergillus spp., Penicillium spp., and Eurotium spp. are the three most prevalent fungi that cause bread products to deteriorate (Legan, 1993). Packaging is a technical process that is used to enclose and protect finished food products to keep them fresh and safe to transport. The major goal of packaging is to safeguard food integrity and preserve sensory characteristics from microbial deterioration and staling. During the cooling process, starch crystallizes and aggregates causing, staleness in bread which is a significant source of economic loss (Fadda, Sanguinetti, Del Caro, Collar, & Piga, 2014). The other vital reasons for the decline in shelf-life are high water activity and post-baking issues resulting in the development of mold growth, which leads to mycotoxin production (Marques et al., 2012). The atmospheric air is recognized as one of the primary sources of contamination in bread products, specifically after baking, due to the presence of the fungal spore in the slicing and packaging stages, resulting in high chances of contamination. Since microbial decomposition is a key concern that affects the shelf life of bread and other bakery goods, it is critical to limit its proliferation. Various measures and strategies such as good manufacturing and hygiene practices are followed, ensuring proper process control parameters, including packaging and post-storage procedures, to overcome the safety issues and critical demand of global consumption (Smith et al., 2004). The food revolutionary in packaging aids in novel packaging techniques development such as active packaging (AP), and intelligent packaging (IP). It involves effective interaction between the packaging material and the antimicrobial components forming a protection layer around the food material and its surroundings, which increases the shelf-life, decreases sensory losses, and enhances the hygiene, safety, and security of the food product (Abdullahi., 2018).

Modified atmospheric packaging (MAP), on the other hand, works on replacing the air with a mixture of carbon dioxide (CO2), nitrogen, and inert gas in packaging, mainly decreasing the oxygen (O2) content to less than 1% of the surface of the packed food, commonly known as headspace. The fungistatic properties of CO2 also inhibit the growth of mold by changing the metabolic activity of the cell membrane, resulting in a detrimental effect on growth (Pasqualone, 2019). Alternatively, another research, stated high concentration of CO2 increases the acidity of bakery food, affecting the taste and other sensory characteristics thereof varying conflicts of using MAP techniques many researchers conclude that MAP in bread packaging, only delays mold growth but could not prevent growth. Due to these reasons, the European Food Safety Authority (EFSA) developed new and innovative concepts for packing foods such as AP, and IP which permits intentional interaction between food and packing material by carrying the functional material and deliberately interact with the food substances and protect the food from external contamination such as light, oxygen, pathogens, chemical pollutants, and pests, resulting in enhancing food safety and quality, and extension of shelf-life of final products (Pasqualone, 2019). Table 1 lists the functional and technical understanding of active and intelligent packaging (Malhotra et al., 2015; Biji et al., 2015; Melini and Melini, 2018). Utilizing triple-layered highbarrier oxygen packaging with a low initial oxygen level, the bakery sector has demonstrated tremendous potential for increasing the shelf-life of white bread by up to 7 days through the implementation of the MAP and AP processes (Upasen et al., 2018). Figure 1 explains the roles, functions, and advantages of packaging. In addition, a study reported that active packaging increased the shelf-life while preserving the sensory characteristics of gluten-free bread (Melini and Melini, 2018). Preserving food from internal and external contamination is the principal purpose of food packaging, however, interactions between food and packaging material can also jeopardize food quality, safety, and the integrity of food packaging (Alamri et al., 2021).

The food revolutionary in packaging aids in novel packaging techniques development such as AP and IP. It involves effective interaction between the packaging material and the antimicrobial components forming a protection layer around the food material and its surroundings, which increases the shelf-life, decreases sensory losses, and enhances the hygiene, safety, and security of the food. This review’s objective is to evaluate the importance of bread packaging innovations, like modified atmospheric packaging, active packaging, intelligent packaging, and nano packaging, and their applications in increasing bread’s shelf-life and enhancing sensory qualities using a combination of packaging techniques focusing on the addition of natural preservatives.

Conventional bread packaging methods and their limitations

The most common packing material used in the pre-modern era was parchment paper with paraffin wax and wax paper. In many parts of the world, wooden boxes, cane baskets, China pots, and metal cans are still used for packing bread. Today, the food industry uses low-density polyethylene and polypropylene bags for bread packaging. The primary function of packaging is to protect food from contaminants (Pal et al., 2019). The usage of multilayered packing films shows a highly effective barrier against intrinsic and extrinsic contamination factors. Traditional techniques including MAP, irradiation, aseptic packing, artificial preservatives, and organic acids like propionic acids protect baked products from microbial infection. The most common packaging material used in MAP techniques to pack bread is polyamide, Polypropylene (PP), Ethylene vinyl alcohol (EVOH), Polyvinylidene chloride (PVDC), Lowdensity polyethylene (LDPE), and High-density polyethylene (HDPE). Different polymer matrices such as LDPE/nylon, PVDC-coated PP, and Polyethylene (PE) are combined to produce medium and high gas barrier films, and sometimes ionomer is replaced with PE (Smith et al., 2004; Jideani and Vogt, 2016). In the UK, a combination of oriented polypropylene films with the acrylic coating is used instead of LDPE films coated with aluminum for higher oxygen and water vapor barrier (Smith et al., 2004). A study discussed the migration of chemicals from packing materials made from Perfluorooctanoic acid (PFOA), Hexafluoropropylene oxide dimer acid (PFOS), Perfluoro octane sulfonic acid (HFPO-DA), and per- and Polyfluoroalkyl substances (PFASs) to foods. These materials are primarily used in the baking industry due to their oil-repelling properties as food contact materials (FCMs) like silicon trays, paper, and boards. The research is still unclear regarding PFAS and their potential precursor’s risk assessment on their exposure and quantification of the impurities which might migrate from FCM into food products, but it is clear that these chemicals are used in bread packaging material having a strongly fluorinated carbon chain, might cause a health risk and several illnesses to humans. The use of PFAS in FCMs necessitates extensive investigation, including a toxicity study to determine the danger to human health (Bokkers et al., 2019).

Figure 1.

Role, functions and advantages of packaging.

Table 1.

Main functions of Active and Intelligent packaging.

| Components of Active packaging | Components of Intelligent/Smart packaging |

|---|---|

| - Consists of various chemical components that have huge anti-fungal/microbial properties, incorporated in the form of sachets/films. | - Packaging material capable of indicating time temperature for identifying contamination |

| - Incorporating ethylene scavengers/ethanol emitters/oxygen absorbers in packaging sachets/films | - Food products with sensors/indicators in controlling the micro spoilage. |

| - Packing contains inbuilt heating or cooling mechanism according to the functions and requirements. | - Shock indicators for identifying physical damage to food products |

| - Moisture absorbing /carbon dioxide emitters in the form of pads and sheets in food products | - Food packaging sensor that distinguishes between allergen and non-allergen |

| - Sachets /films made to remove/absorb odor and flavor | - Leakage indicators with microbial growth sensors. |

| - Contaminants causing food spoilage organisms are controlled in the form of sachets, films, and coating. | - Identification of indicators /sensors for contaminants. |

Current trends in bread packaging

Modified atmospheric packaging

Primary gases involved in MAP are CO2, and nitrogen, which may be utilized separately or combined in food packaging. MAP works generally by displacing air with a gas combination composed of 60% CO2 and 40% nitrogen. CO2 used at high levels aids in removing oxygen from the headspace and lowers the oxygen concentration in the headspace of packages to less than 1% (Smith et al., 2004; Alhendi and Choudhary., 2013). CO2 dissolved in water forms carbonic acid, which lowers the pH of food products and functions as an antimicrobial agent. It eliminates mold and yeast growth by using the combination of gases at different concertation. Nitrogen is an inert gas with no antibacterial properties; rather, it is used to avoid food package collapse and oxidative rancidity. MAP is better at retarding yeast and mold growth than bacteria. MAP can delay mold growth and extend shelf-life but cannot indefinitely prevent contamination (Upasen et al., 2018). The combination of the MAP technique with mixing O2 absorbers and mustard oil vapors inhibited the toxic organisms in wheat and rye bread by extending the shelf life to 30 days with possible implications for bread quality improvement (Suhr and Nielsen, 2005). The use of MAP in conjunction with active and intelligent packaging improves the shelf-life, nutritional characteristics, and safety of food products (Abdullahi, 2018). Alternative to MAP, Wheat dough with calcium propionate increased the shelf-life of bread to 26 days at 22 – 25 °C; storing at low temperatures such as 15 – 20 °C increased the shelf life to 52 days; soy bread’s shelf life was increased by at least four days (200%). In addition, adding 0.1% potassium sorbate produced mold-free bread, and the shelf life extended up to 21 days (Alhendi and Choudhary, 2013; Jideani and Vogt, 2016; Soltani Firouz et al., 2021). Consumers are most concerned about the addition of preservatives to foods or the treatment of foods with radiation to increase their shelf life (Alhendi and Choudhary, 2013). The US Food and Drug Administration states that the gases used in MAP are thought to be natural and aren’t always need to be disclosed on food product labels. However, there are several limitations in using chemical preservatives due to their health hazards in humans. In contradiction, an anaerobic neurotoxin pathogen, such as Clostridium botulinum, a gram-positive bacterium, poses a food safety risk to most of the bakery items and causes illness to humans when packed using MAP. Similarly increased CO2 levels in the packaging environment had little effect on lactic acid bacteria or other anaerobic microbes. When compared to gram-positive bacteria, gramnegative bacteria have been shown to suppress bacteria at a higher degree (Alhendi and Choudhary, 2013).

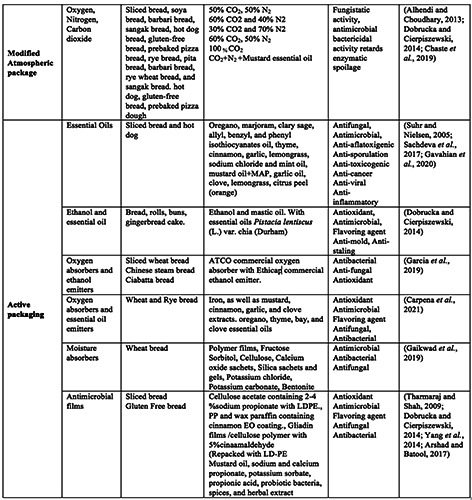

Active packaging in bread

Active packaging is defined as a deliberate incorporation of unique components such as oxygen scavengers, moisture absorbers, antimicrobial agents, essential oils, sachets/films, containing spices and herbs, freshness enhancers, ethanol emitters, antioxidants etc., to a packaging material or in the package’s headspace to improve the package system’s quality and enhance the shelf life (Ahmed et al., 2017). Active packaging preserves the food from extrinsic factors such as heat, UV rays, oxygen, water vapor, and pressure by effective packing techniques. Therefore, there should be continuous interaction between the active package material and food to control the microbial spoilage leading to increased shelf-life of bread and assured safety of the packed bread (Sharma et al., 2021). Active packaging, comparing to MAP is effective in preserving flavor and sponginess while eliminating hardness and crumbliness (Gutiérrez et al., 2011). It also improves the preservation process and lowers packaging costs when compared to traditional polymer packaging (Majid et al., 2018). Table 2 illustrates the most common components used in MAP and active packaging techniques for extending the shelf-life of bread.

Antimicrobial packaging

Antimicrobial packaging, a type of active packaging, incorporates antimicrobial agents into packed foods to improve food quality and safety during storage and transit (Qian et al., 2021). This packaging assists in the reduction or prevention of microbial development in bread by combining antimicrobial additives into packaging materials to extend shelf-life (Jideani and Vogt, 2016). Essential oils and biodegradable films enhanced with cinnamon and clove oils are often used as antimicrobial agents, providing antifungal activity against Penicillium spp. and Aspergillus niger (Sachdeva et al., 2017). The traditional method of preventing bacterial development in bread is followed by adding synthetic preservatives such as calcium propionate and propionic acid to bread products according to food regulations (Lewis, 2015). However, postbaking processing steps are a source of microbial contamination in bread. Also, customer demand for natural preservatives rather than synthetic preservatives is rising mainly due to their immense range of characteristics such as antifungal, antiviral, antioxidant, and effectiveness against pathogenic organisms. Antibacterial compounds from plants and probiotic organisms are a natural source of antimicrobial agents. Many studies have revealed that infusing natural products into active packaging decreased microbial contamination. Hence, essential oils derived from clove, cinnamon, eugenol, mustard, lemon grass, oregano, thyme, garlic essential oils, grape seed extract, spices, metabolites from probiotic bacteria, and naturally occurred organic acids are used in the active packaging of food products as they show antibacterial, antifungal, antioxidant and anticarcinogenic effects (Tharmaraj and Shah, 2009; Mahmud and Khan, 2018). Similarly, probiotic bacteria, spices, and herbal extracts also have numerous health benefits (Yang et al., 2014).

The increased addition of antimicrobial agents to the polymer matrix is of great concern, since it alters the attributes of packaging materials such as tensile strength, tearing strength, stiffness, and oxygen and gas permeability, which in turn affects the processing, physical, chemical, and optical properties of polymers (Jideani and Vogt, 2016). Antimicrobial and antioxidantenhanced films and coatings on food surfaces plays a vital role in retarding fungal growth and slowing the oxidation rate. It results in preventing rancidity, increasing shelf life, enhancing the mechanical strength of the packaging and maintaining the sensory attributes of the packaged food (Abdullahi, 2018). For instance, when used as an antimicrobial agent in rye bread, Allyl isothiocyanate inhibited the growth of Aspergillus and Penicillium spp was primarily effective against gram-negative bacteria. Active packaging containing antimicrobial-agent delivering to packed foods has the potential to significantly contribute to satisfy the demand of current needs (Rasooli, 2007).

Ethanol emitters

Ethanol emitters are effective in slowing down mold growth in baked goods such as rye bread as the sachets obtained from them have antifungal, antioxidant, and antimicrobial (Upasen et al., 2018). Combining the impact of an ethanol emitter with oxygen an absorber is a replacement for chemical preservatives, has shown to prolong the shelf life of sliced bread (Latou et al., 2010). Ethanol plasticizes the protein network of breadcrumbs, especially in combination with essential oils to prevent staling (Melini and Melini, 2018). Oxygen absorbers with ethanol vapor has an effective anti-staling and antimicrobial property by denaturing the yeast and mold’s protein network in Chinese steam bread even treated at low concentrations (1% v/v) (Sheng et al., 2015).

Table 2.

Most commonly used MAP and active packaging techniques for shelf-life extension in different kinds of bread products.

Essential oil emitters

Essential oils are food preservatives with a wide range of antimicrobial activity due to their presence of active and natural constituents such as terpenes, terpenoids, carotenoids, coumarins, and natural curcumins. Their progress in food application is fast and enormous since it holds GRAS (Generally recognized as safe) status by regulatory bodies, which means the food additives with this status are fit for human consumption or their intended use. In addition, they are a better replacement for conventional synthetic preservatives (Pandey et al., 2017). A study observed that Cinnamon-infused active packaging was a good and effective solution for preserving the sensory and micro properties of glutenfree loaves (Jideani and Vogt, 2016). Oregano essential oil inhibits yeast and mold growth in sliced bread. Essential oil from marjoram and clary sage is also effective, but due to their strong odor, it was not wellaccepted (Passarinho et al., 2014).

Essential oils are effective antimicrobial agents against bacteria, including Staphylococcus aureus, Pseudomonas aeruginosa, Listeria monocytogenes, and Salmonella enterica, especially when combined with factors like low water activity, low pH, chelators, mild heat, and food additives like sodium chloride, sodium nitrite, or nisin. clove, fennel, cypress, lavender, thyme, pine, and rosemary are some of the most commonly utilized essential oils (Gómez-Estaca et al., 2010). A study showed that essential oils such as thyme, clove, oregano, cinnamon, and lemongrass in the vapor phase were highly efficient against Aspergillus niger and a safe and suitable alternative to chemical preservatives in the treatment of bread without affecting the sensory characteristics (Císarová et al., 2020).

When tested with different packaging materials to preserve the white bread invitro, incorporation of poly (3-hydroxybutyrate-co-4-hydroxybutyrates) films in thyme oil 30% w/v microencapsulated eugenol, and citral antifungal essential oil sachets showed maximum inhibition against yeast and mold. It also enhanced inhibition of the mold growth to prolong the life of bakery products considerably when compared to control (Ju et al., 2020). While Essential oils have a variety of beneficial qualities, including antibacterial and antioxidant capabilities, further research is needed to determine their safety (Haro-González et al., 2021). Regulations on essential oils include evaluations of their uses in flavorings, cosmetics, and animal nutritional additives (Barbieri and Borsotto, 2018).

Food producers have faced substantial challenges in producing safer foods with longer shelf life while sustaining nutritional benefits along with sensory attributes. Preserving the functional qualities of essential oils as food preservatives without affecting the taste of food or growing consumer demand remains a challenge for many food manufacturers. A bakery industry must maintain the baked goods with high safety and secured products for its consumers without compromising sensory parameters such as taste, color, flavor, texture, and overall acceptability. The addition of essential oil as a preservative over the organic acid such as sorbic and propionic acids has gained interest among consumers worldwide due to the antibacterial efficacy of essential oil against foodborne pathogens such as Penicillium spp., Aspergillus spp., Escherichia coli., and Staphylococcus aureus, and extending the shelf life of the baked products (Tzortzakis, 2009; Haro-González et al., 2021).

Oxygen absorbers with ethanol and essential oil emitters

Oxygen absorbers, ethanol emitters, ethylene absorbers, and preservative releasers retard microbial growth during storage. Ethanol emitters and oxygen absorbers could replace chemical preservatives. The O2 absorbers extend the shelf life of white bread packed in a polypropylene bag from 5 to 45 days (Smith et al., 2004). Concept of integrating active packaging with a superior packaging material with effective barrier such as polyethylene terephthalate-silver oxide/ Low-density polyethylene (PET-SiOx/ LDPE) has extended the shelf-life of sliced bread (Harrop, 2012). Antimicrobial properties of spice-based essential oils such as mustard oil, oregano, basil, clove, carvacrol, thymol, and cinnamon are also studied. Oregano essential oil is a moderate preservative that utilizes an O2 absorber in conjunction with an ethanol emitter has substantially extended wheat bread’s shelf life to 30 days as per sensory and microbiological data (Suhr and Nielsen, 2005).

Moisture absorbers

The accumulation of moisture inside bread can lead to bacteria and mold growth decreasing food quality and making it inedible. Therefore, moisture absorbers are used to regulate the water content and function of bread products as preservatives. These absorbers are hygroscopic, absorbing and retaining water from their external surroundings. Moisture absorbers are two types, relative humidity absorbers that absorb water in the headspace of packaging (desiccants) and absorbers that suck the water directly from the food that is often in the shape of pads and sheets placed beneath the food products. Commercially, moisture absorbers are made using polymeric films; fructose, cellulose, sorbitol are used in organic absorbers, whereas calcium oxide sachets, silica gels and sachets, potassium chloride, potassium carbonate, and bentonite in inorganic absorbers (Gaikwad et al., 2019).

Carbon dioxide emitters

High CO2 levels in bread products (10 – 80%) can effectively arrest microbial growth to act as a food preservative. When CO2 is flushed into a packaging system in the form of active/intelligent packaging, it creates a partial vacuum in the process of soluble gas stabilization (SGS) (Vilela et al., 2018).

Future perspective of bread packing

Intelligent packaging

Intelligent packaging is a revolutionary and innovative technology that monitors changes in both the interior and exterior surroundings and transmits the status of the packed food items about the interaction of the packaging system to support decisionmaking. The process involved in intelligent packaging is the system that continuously monitors the integrity and effectiveness of active packaging (Ghaani et al., 2016). It includes biosensors, temperature regulators, ripeness monitors, time-temperature indicators, and radio frequency tag monitors, which facilitate deciding on increasing the shelf-life and monitoring the quality and safety of the product. Intelligent packaging is so-called because it can connect with humans and warn about packaging flaws. Radio frequency identification tags are particularly promising since they employ radio waves to track food products and convey product information to consumers (Pramatari et al., 2010).

Time temperature indicators

These indicators are intelligent/smart packaging that enhances the food quality and safety. They are a simple device that provides information about the timetemperature change of food products. When food packaging is tampered with or contaminated, it undergoes an irreversible physical, chemical, or biological change that manifests as physical deformation (Kuswandi and Jumina, 2020; Young et al., 2020).

Radio frequency identification tags

Radio frequency identification tags incorporate tags or transponders (information carriers), readers (receivers), and computer systems (software, hardware, networking, and database) to reduce and minimize food waste, empty shelves, theft, fraud, and recalls of spoiled or harmful items in the food supply chain (Harrop, 2012), radio frequency identification (RFID) tracks goods wirelessly and provides the product information about the food quality (Pramatari et al., 2010). These devices can be easily mounted on any packing commodity such as cartons, boxes, pallets, or containers and can be easily traced and readily detected. These tags are visible even from a distance of several meters. RFID tags with pH, oxygen, temperature, humidity, and gas sensors, among other sensors, are being employed in MAP and other novel packaging techniques to detect the freshness and volatile components of diverse food products (Fuertes et al., 2016).

Oxygen and carbon dioxide indicators

The food, flushed with gas like carbon dioxide or nitrogen, is often applied in MAP packaging. These indicators are based on luminescence, calorimetric redox dye, and oxygen binding complexes generate a color change in contaminated food resulting in an enzymatic or chemical reaction (Chaste et al., 2019; Garcia et al., 2019). According to a research, the interior of ciabatta bread packets included an oxygen sensor linked with ethanol-emitting sachets before gas cleansing and sealing, monitored oxygen continuously without any disruption for a longer time (Hempel et al., 2013).

Freshener indicators

Freshener indicators tracks and assess the freshness of packaged foods. If there is an undesirable change to the food’s freshness, the indicators activate the following changes:

Color changes due to changes in titratable acidity, microbiological changes, such as the formation of toxic compounds, unpleasant odor, and pH changes.

Lipid and pigments oxidation produce flavors/odors, discoloration, and other adverse chemicals/biological reactions (Mills, 2005).

Biosensors

Biosensors are small devices that detect, record and transmit changes in food products via biochemical reactions. They are constructed using a two-part system: a biological recognition component (such as enzymes, nucleic acids, or other ligands) that aids in the high specificity binding of the target analyte, and a unit for signal conversion (transducer such as calorimetric, optical, or electrochemical). Currently, existing biosensors are mostly based on the detection of pathogens and toxins, as well as contaminants (Park et al., 2015).

Limitations of traditional methods are due to the expensive costs, tedious sampling procedures, long wait times, and the need for highly skilled and competent personnel. Studies have shown that biosensors were the most efficient option for accurately identifying contaminants such as toxins and pesticides with high specificity, especially when dealing with complex food matrices, at a cheap cost, and in an appropriately reliable manner (Fuertes et al., 2016; Bunney et al., 2017). Biosensors are most commonly used to assure product quality and safety of a food product, to detect physical, chemical, biological, and surface contamination in products and production lines, and to eliminate cross contaminationrelated issues. These tools may be used to separate high-quality products from lowquality ones on or at the manufacturing line, reducing the amount of time and money spent on production (Tetyana et al., 2021).

Colorimetric biosensors are used mainly to detect the presence of pathogens in food products through the action of N-[(2- tetradecanamide)-ethyl]-ribonamide (TDER), microelectromechanical systems, heterobifunctional crosslinkers, and immobilized antibodies (Radke et al., 2004; Kim et al., 2015). While bacterial contamination is detected via biosensors, removal of contaminated products may require the development of a separate mechanism.

Nano packaging

Nanomaterials are effective as packaging materials due to their large surface area, they can increase barrier properties against gas permeation, ultraviolet permeation, moisture, and volatile compounds. They are used in intelligent and active packaging because of their antimicrobial activity. Challenges include removing nanoparticles from packaging materials, which might cause environmental harm, and oxidative stress in people as a result of nano components migrating from the packaging material into the food (Sokovicx́ et al., 2010).

Clove bud and oregano essential oil combined with methylcellulose generated a nano-emulsified edible film that lowered yeast and mold levels by a substantial amount in sliced bread (preserved for 15 days). Droplet size reduction even showed a pronounced effect in increasing the antimicrobial properties (Schifferstein et al., 2021). However, a few critical attributes should be verified and validated before using nano packing techniques in foods, such as quality and safety concerns of the food, costeffectiveness, simplicity and ease of use, reproducibility across a wide range of operations, environmentally safety, easy disposal, and packaging by meeting the regulatory standards (Otoni et al., 2014).

The freshness of the food is detected using a Nano sensor that is highly sensitive to gases, such as an electronic tongue attached to the food packing material. A few Nano sensors incorporated in packaging has various applications such as of pathogens and toxins detection, consumer likes and dislikes, temperature and moisture variation (Fuertes et al., 2016). However, these nanoparticles, on the other hand, are dangerous and harmful to humans and the environment because of their smaller size, which allows them to infiltrate human cells and target the immune system. The smaller the particle, the faster it absorbs and distributes in the metabolic system. Several standard regulations allow the use of nano packaging techniques for food to decrease the risk of harm to consumers and the biological system. These regulations should be followed and maintained properly (Pradhan et al., 2015).

Discussion and Conclusions

Improved packaging techniques have evolved significantly, providing new possibilities in the food industry’s development. The area of active and intelligent packaging materials is making significant progress, and it should be developed in tandem with the search for environmentally beneficial products. To improve product safety and extend the shelflife of bakery items, the HACCP (Hazard analysis and critical control point ) system should be used in the food industry to assure food safety (Marques et al., 2012). Changes in consumer preferences are increasing, particularly in using natural preservatives, which have led to new packaging innovations, developments in new technologies, and reducing bread wastage. In addition, novel packaging techniques play a vital role in the food safety management system by reducing food-borne illnesses and recalls. MAP and active packaging have long-term benefits in delaying the fungal contamination. However, the individual constituents in the essential oils are insufficient to prevent all kinds of physical, chemical, and micro contamination in the food. It is the fundamental hurdle of employing them as an alternative to the synthetic preservative in the foods as the antimicrobial activity eliminates the fungal activity depending on the food matrix and technology employed.

Additional study is needed to assess, evaluate and analyze the synergistic and antagonistic effects of essential oils and food components in all food matrixes to assess the antimicrobial impact and, if necessary, lower the dosage of EO to achieve the desired effect when commercially administered. Currently, global food packaging standards are not defined. With considerable differences in the specifics, future food safety and security rely on integrating diverse technical advancements of novel food packaging techniques, involving a complete analysis of food-package interactions based on legislative concerns, making it critical to assess and quantify a risk-based study of various innovative food packaging strategies used across the food chain to ensure the quality and safety of food products. To achieve clean label and green technology in the future, the possible usage of MAP, active and intelligent packaging components, as well as their safety tests with diverse food matrices, must be investigated. Future considerations must include performing food safety risk assessments of all innovative packaging techniques to satisfy legal, regulatory, and statutory requirements.

Acknowledgments

The authors express thanks to the SRM Institute of Science and Technology (SRMIST) for providing the M. Tech (Research) Scholarship.

Funding Statement

Funding: None.

References

- Abdullahi N, 2018. Advances in food packaging technology-A review. J Postharvest Technol 6:55-64. [Google Scholar]

- Ahmed I, Lin H, Zou L, Brody AL, Li Z, Qazi I M, Lv L, 2017. A comprehensive review on the application of active packaging technologies to muscle foods. Food Control 82: 163-78. [Google Scholar]

- Aider M, 2010. Chitosan application for active bio-based film production and potential in the food industry-Review. LWT - Food Sci Technol 6:837-42. [Google Scholar]

- Alamri MS, Qasem AAA, Mohamed AA, Hussain S, Ibraheem MA, Shamlan G, Alqah HA, Qasha AS, 2021. Food packaging’s materials: a food safety perspective. Saudi J Biol Sci 28:4490-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alhendi A, Choudhary R, 2013. Current practices in bread packaging and possibility of improving bread shelf life by nanotechnology. Int J Food Sci Nutr Eng 3:55-60. [Google Scholar]

- Arshad MS, Batool SA, 2017. Natural antimicrobials, their sources and food safety. In: Karunaratne DN, Pamunuwa G, eds. Food additives. InTech, London, pp 169-176. [Google Scholar]

- Barbieri C, Borsotto P, 2018. Essential oils: market and legislation. In: Cinzia B, Patrizia B, eds. Potential of essential oils. InTech, London, pp 179-186. [Google Scholar]

- Biji KB, Ravishankar CN, Mohan CO, Srinivasa Gopal TK, 2015. Smart packaging systems for food applications: a review. J Food Sci Technol. 52:6125-35. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bokkers B, van de Ven B, Janssen P, Bil W, Broekhuizen F, Zeilmaker M, Oomen A, 2019. Per-and polyfluoroalkyl substances (PFASs) in food contact materials. RIVM 3: 533-543. [Google Scholar]

- Bunney J, Williamson S, Atkin D, Jeanneret M, Cozzolino D, Chapman J, Power A, Chandra S, 2017. The use of electrochemical biosensors in food analysis. Curr Res Nutr Food Sci J 5:183-95. [Google Scholar]

- Carpena M, Nunez-Estevez B, Soria-Lopez A, Garcia-Oliveira P, Prieto MA, 2021. Essential oils and their application on active packaging systems: A review. Resources 10:7-16. [Google Scholar]

- Chaste MI, Chidozie K, Kingsley K, Udochukwu U, Nnenne O, 2019. Bread fungi: phytochemical constituents and antimicrobial activity of isolates. J Appl Environ Microbiol 7:20-4. [Google Scholar]

- Císarová M, Hleba L, Medo J, Tančinová D, Mašková Z, Čuboň J, Kováčik A, Foltinová D, Božik M, Klouček P, 2020. The in vitro and in situ effect of selected essential oils in vapour phase against bread spoilage toxicogenic Aspergilli. Food Control 110:107007. [Google Scholar]

- Dobrucka R, Cierpiszewski R, 2014. Active and intelligent packaging food - research and development -a review. Polish J Food Nutr Sci 64:7-15. [Google Scholar]

- Fadda C, Sanguinetti AM, Del Caro A, Collar C, Piga A, 2014. Bread staling: updating the view. CRFSFS 13: 473-492. [DOI] [PubMed] [Google Scholar]

- Fuertes G, Soto I, Carrasco R, Vargas M, Sabattin J, Lagos C, 2016. Intelligent packaging systems: sensors and nanosensors to monitor food quality and safety. J Sensors 2016:1-8. [Google Scholar]

- Gaikwad KK, Singh S, Ajji A, 2019. Moisture absorbers for food packaging applications. Environ Chem Lett 17:609-28. [Google Scholar]

- Garcia MV, Bernardi AO, Copetti MV, 2019. The fungal problem in bread production: insights of causes, consequences, and control methods. Curr Opin Food Sci 29:1-6. [Google Scholar]

- Gavahian M, Chu YH, Lorenzo JM, Mousavi Khaneghah A, Barba FJ, 2020. Essential oils as natural preservatives for bakery products: understanding the mechanisms of action, recent findings, and applications. Crit Rev Food Sci Nutr 60:310-21. [DOI] [PubMed] [Google Scholar]

- Ghaani M, Cozzolino CA, Castelli G, Farris S, 2016. An overview of the intelligent packaging technologies in the food sector. Trends Food Sci Technol 51:1-11. [Google Scholar]

- Gómez-Estaca J, López de Lacey A, López-Caballero ME, Gómez-Guillén MC, Montero P, 2010. Biodegradable gelatinchitosan films incorporated with essential oils as antimicrobial agents for fish preservation. Food Microbiol 27:889-96. [DOI] [PubMed] [Google Scholar]

- Gutiérrez L, Batlle R, Andújar S, Sánchez C, Nerín C, 2011. Evaluation of antimicrobial active packaging to increase shelf life of gluten-free sliced bread. I Packag Technol Sci 24:485-94. [Google Scholar]

- Haro-González JN, Castillo-Herrera GA, Martínez-Velázquez M, Espinosa-Andrews H, 2021. Clove essential oil (Syzygium aromaticum l. myrtaceae): extraction, chemical composition, food applications, and essential bioactivity for human health. Molecules 26:6387. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Harrop P, 2012. Radio-frequency identifiction (RFID) for food and beverage packaging applications. In: Yam KL, Lee DS, eds. Emerging food packaging technologies. Woodhead publishing, Cambridge, England, pp 153-74. [Google Scholar]

- Hempel A, Papkovsky D, Kerry J, 2013. Use of optical oxygen sensors in nondestructively determining the levels of oxygen present in combined vacuum and modified atmosphere packaged precooked convenience-style foods and the use of ethanol emitters to extend product shelf-life. Foods 2:507-20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jideani VA, Vogt K, 2016. Antimicrobial packaging for extending the shelf life of bread-A review. Crit Rev Food Sci Nutr 56:13-24. [DOI] [PubMed] [Google Scholar]

- Ju J, Xie Y, Yu H, Guo Y, Cheng Y, Qian H, Yao W, 2020. A novel method to prolong bread shelf life: sachets containing essential oils components. LWT 131:109744. [Google Scholar]

- Kim G, Moon J-H, Moh C-Y, Lim J, 2015. A microfluidic nano-biosensor for the detection of pathogenic Salmonella. Biosens Bioelectron 67:243-7. [DOI] [PubMed] [Google Scholar]

- Kuswandi B, Jumina, 2020. Active and intelligent packaging, safety, and quality controls. In: Mohammed WS, eds. Fresh-cut fruits and vegetables. Academic Press, Cambridge, pp 243-94. [Google Scholar]

- Latou E, Mexis SF, Badeka AV, Kontominas MG, 2010. Shelf life extension of sliced wheat bread using either an ethanol emitter or an ethanol emitter combined with an oxygen absorber as alternatives to chemical preservatives. J Cereal Sci 52:457-65. [Google Scholar]

- Legan JD, 1993. Mould spoilage of bread: the problem and some solutions. Int Biodeterior Biodegradation. 32:33-53. [Google Scholar]

- Lewis J, 2015. Calcium propionate - the bread preservative-gathering of minds. https://www.ourgom.com/calciumpropionate-the-bread-preservative/ Accessed February 21, 2022. [Google Scholar]

- Mahmud J, Khan RA, 2018. Characterization of natural antimicrobials in food system. Adv Microbiol 08:894-916. [Google Scholar]

- Majid I, Ahmad Nayik G, Mohammad Dar S, Nanda V, 2018. Novel food packaging technologies: Innovations and future prospective. J Saudi Soc Agric Sci 17:454-62. [Google Scholar]

- Malhotra B, Keshwani A, Kharkwal H, 2015. Antimicrobial food packaging: potential and pitfalls. Front Microbiol 6:611. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Marques N, Matias J, Teixeira R, Brojo F, 2012. Implementation of hazard analysis critical control points (HACCP) in a SME : case study of a bakery. Polish J Food Nutr Sci 62:215-27. [Google Scholar]

- Melini V, Melini F, 2018. Strategies to extend bread and GF bread shelf-life: from sourdough to antimicrobial active packaging and nanotechnology. Fermentation 4:9. [Google Scholar]

- Mills A, 2005. Oxygen indicators and intelligent inks for packaging food. Chem Soc Rev 34:1003. [DOI] [PubMed] [Google Scholar]

- Otoni CG, Pontes SFO, Medeiros EAA, Soares N de FF, 2014. Edible films from methylcellulose and nanoemulsions of clove bud (Syzygium aromaticum ) and oregano (Origanum vulgare) essential oils as shelf life extenders for sliced bread. J Agric Food Chem 62:5214-9. [DOI] [PubMed] [Google Scholar]

- Saranraj P, Geetha M, 2012. Microbial spoilage of bakery products and its control by preservatives. Int J Pharm Biol Arch 3:204-14. [Google Scholar]

- Pal M, Devrani M, Hadush A, 2019. Recent developments in food packaging technologies. 48:21-5. [Google Scholar]

- Pandey AK, Kumar P, Singh P, Tripathi NN, Bajpai VK, 2017. Essential oils: sources of antimicrobials and food preservatives. Front Microbiol 7:2161. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Park YW, Kim SM, Lee JY, Jang W, 2015. Application of biosensors in smart packaging. Mol Cell. Toxicol 11:277-85. [Google Scholar]

- Pasqualone A, 2019. Bread Packaging: Features and Functions. In: Preedy VR, Watson RR, eds. Flour and bread and their fortification in health and disease prevention. Academic Press, Cambridge, pp 211-22. [Google Scholar]

- Passarinho ATP, Dias NF, Camilloto GP, Cruz RS, Otoni CG, Moraes ARF, Soares NDFF, 2014. sliced bread preservation through oregano essential oil-containing sachet. J Food Process Eng 37:53-62. [Google Scholar]

- Pateras IMC, 1998. Bread spoilage and staling. In: Cauvain SP, Young LS, eds. Technology of Breadmaking. Springer, Boston, MA, pp 189. [Google Scholar]

- Perumal AB, Sellamuthu PS, Nambiar RB, Sadiku ER, 2016. Antifungal activity of five different essential oils in vapour phase for the control of Colletotrichum gloeosporioides and Lasiodiplodia theobromae in vitro and on mango. Int J Food Sci Technol 51:411-8. [Google Scholar]

- Pradhan N, Singh S, Ojha N, Shrivastava A, Barla A, Rai V, Bose S, 2015. Facets of nanotechnology as seen in food processing, packaging, and preservation industry. Biomed Res Int 2015:1-17. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pramatari K, Karagiannaki A, Bardaki C, 2010. Radio frequency identification (RFID) as a catalyst for improvements in food supply chain operations. In: Mena C, Stevens G, eds. Delivering performance in food Supply Chains. Wood head publishing, Cambridge, pp 432-55. [Google Scholar]

- Qian M, Liu D, Zhang X, Yin Z, Ismail BB, Ye X, Guo M, 2021. A review of active packaging in bakery products: Applications and future trends. Trends Food Sci Technol 114:459-71. [Google Scholar]

- Radke SM, Alocilja EC, Radke SM, Alocilja EC, 2004. Design and fabrication of a microimpedance biosensor for bacterial detection. IEEE Sens J 4:434-40. [Google Scholar]

- Rasooli I, 2007. Food preservation-A biopreservative approach. Foods 1:111-36. [Google Scholar]

- Sachdeva A, Vashist S, Chopra R, Puri D, 2017. Antimicrobial activity of active packaging film to prevent bread spoilage 2:2455-4898. [Google Scholar]

- Salgado PR, Di Giorgio L, Musso YS, Mauri AN, 2021. Recent developments in smart food packaging focused on biobased and biodegradable polymers. Front Sustain Food Syst 5: 630393. [Google Scholar]

- Schifferstein HNJ, de Boer A, Lemke M, 2021. Conveying information through food packaging: A literature review comparing legislation with consumer perception. J Funct Foods 86:104734. [Google Scholar]

- Sharma S, Barkauskaite S, Jaiswal AK, Jaiswal S, 2021. Essential oils as additives in active food packaging. Food Chem 343:128403. [DOI] [PubMed] [Google Scholar]

- Sheng Q, Guo X-N, Zhu K-X, 2015. The effect of active packaging on microbial stability and quality of chinese steamed bread. Packag Technol Sci 28:775-87. [Google Scholar]

- Smith JP, Daifas DP, El-Khoury W, Koukoutsis J, El-Khoury A, 2004. Shelf life and safety concerns of bakery products-A review. Crit Rev Food Sci Nutr 44:19-55. [DOI] [PubMed] [Google Scholar]

- Sokovicx́ M, Glamočlija J, Marin PD, Brkić D, Van Griensven LJLD, 2010. Antibacterial effects of the essential oils of commonly consumed medicinal herbs using an in vitro model. Molecules 15:7532-46. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Soltani Firouz M, Mohi-Alden K, Omid M, 2021. A critical review on intelligent and active packaging in the food industry: research and development. Food Res Int 141:110113. [DOI] [PubMed] [Google Scholar]

- Suhr KI, Nielsen PV., 2005. Inhibition of fungal growth on wheat and rye bread by modified atmosphere packaging and active packaging using volatile mustard essential oil. J Food Sci 70:37–44. [Google Scholar]

- Tetyana P, Morgan Shumbula P, Njengele- Tetyana Z, 2021. Biosensors: design, development and applications. In: Ameen S, Shaheer Akhtar M, eds. Nanopores. IntechOpen, London, pp 172-179. [Google Scholar]

- Tharmaraj N, Shah NP, 2009. Antimicrobial effects of probiotic bacteria against selected species of yeasts and moulds in cheese-based dips. Int J Food Sci Technol 44:1916-26. [Google Scholar]

- Tzortzakis NG, 2009. Essential oil: innovative tool to improve the preservation of fresh produce-A review. Fresh Prod 3:87-97. [Google Scholar]

- Upasen S, Wattanachai P, Wattanachai P, 2018. Packaging to prolong shelf life of preservative-free white bread. Heliyon 4:e00802. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vilela C, Kurek M, Hayouka Z, Röcker B, Yildirim S, Antunes MDC, Nilsen- Nygaard J, Pettersen MK, Freire CSR, 2018. A concise guide to active agents for active food packaging. Trends Food Sci Technol 80:212-22. [Google Scholar]

- Yang S-C, Lin C-H, Sung CT, Fang J-Y, 2014. Antibacterial activities of bacteriocins: application in foods and pharmaceuticals. Front Microbiol 5:241-252. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Young E, Mirosa M, Bremer P, 2020. A systematic review of consumer perceptions of smart packaging technologies for food. Front Sustain Food Syst 4:63. [Google Scholar]