Abstract

Envisage a world where discarded electrical/electronic devices and single-use consumables can dematerialize and lapse into the environment after the end-of-useful life without constituting health and environmental burdens. As available resources are consumed and human activities build up wastes, there is an urgency for the consolidation of efforts and strategies in meeting current materials needs while assuaging the concomitant negative impacts of conventional materials exploration, usage, and disposal. Hence, the emerging field of transient technology (Green Technology), rooted in eco-design and closing the material loop toward a friendlier and sustainable materials system, holds enormous possibilities for assuaging current challenges in materials usage and disposability. The core requirements for transient materials are anchored on meeting multicomponent functionality, low-cost production, simplicity in disposability, flexibility in materials fabrication and design, biodegradability, biocompatibility, and environmental benignity. In this regard, biorenewables such as cellulose-based materials have demonstrated capacity as promising platforms to fabricate scalable, renewable, greener, and efficient materials and devices such as membranes, sensors, display units (for example, OLEDs), and so on. This work critically reviews the recent progress of nanocellulosic materials in transient technologies toward mitigating current environmental challenges resulting from traditional material exploration, usage, and disposal. While spotlighting important fundamental properties and functions in the material selection toward practicability and identifying current difficulties, we propose crucial research directions in advancing transient technology and cellulose-based materials in closing the loop for conventional materials and sustainability.

1. Introduction

With more than 20% of global deaths, rising loss in ocean output, impairment of habitats and biodiversity, detrimental climate changes, devastating global warming, increasing food insecurity, and more, all attributable to pollution-related challenges;1−6 the international community, in pursuit of assuaging these perilous concerns have, through initiatives such as the sustainable development goals (SDGs),7 prioritized efforts toward making the earth a safer and better place for all (including the living and nonliving components). Because materials science and engineering are the cornerstones in determining the advancements and sustainability of any civilization;8,9 therefore, mitigating and lessening the associated environmental challenges in their extraction, derivation, production processes, usage, and disposal, which are well-known significant contributors to environmental degradation and pollution, remain indispensable for achieving environmental wholesomeness and sustainability. Pollution contributes to the changing dynamics of natural environments and the state of matter, resulting in the compromise, modification, or alteration of fundamental features, conditions, and functions, with potentially negative impacts.3,10−19

Electrical/electronic wastes (E-waste) and fossil-based plastics (hereafter referred to as plastics) are significant contributors to global environmental burdens and health challenges. For example, plastic pollution and climate change are fundamentally connected, with plastics contributing to greenhouse gases (GHGs) throughout the product life cycle.12,20 In addition to the associated health challenges such as respiratory disorders, negative impact on animal behaviors, and the carcinogenesis of living cells, plastic pollution contributes to the mutation of environments and the destruction of ecosystems.12,19,21,22 And with plastic production exceeding 7.9 billion metric tons between 1950 and 2015,12 it is undeniable that humanity has an environmental crisis that cannot be overemphasized. Equally, e-wastes contribute significantly to ecological burdens.23,24 Projected to exceed 70 million metric tons by 2030,23,25 e-wastes rank among the most complex stream of wastes generated by humankind and are associated with various adverse health and environmental challenges such as gastroduodenal ulcers, leukemia, and degradation of soil structures, among others.24,26,27 Because plastics are essential components found in e-waste streams either as encasements, insulating elements or functional materials; hence, e-wastes and plastic pollution are mutually inclusive events;26,28 therefore synergistically, they contribute to climate change (with negative impacts on the ecosystems), exacerbate water crisis (pollution plays a significant role in the loss of global freshwater quality), global warming (which is detrimental to biodiversity), thereby threatening humanity and the natural environment as represented in Figure 1.29−31 Advances in technology have seen unprecedented growth in human development. For example, a couple of years ago, devices such as personal computers, mobile devices, and related technologies were out of the reach of many; however, today, human civilization as we know it will fall apart without them. In addition, if the advancement of electrical and electronic technologies continues (that is, consistency of Moore’s law),32−34 without the urgent consideration of the environment, coupled with the issue of plastic pollution, it is near impossible to determine the long-term impacts of these burdens on biodiversity (critical for environmental balance and smooth functioning), soil and water productivity, and, by extension, survival of the human race. Any substance or energy becomes toxic and environmentally disruptive at sufficient concentrations; therefore, the threat that e-waste and plastic pollution present to the quality of human life and the other components of the environment are issues intimately bound to the advancement of human civilization and the consistent demand humanity is making on the planet’s resources.12,35

Figure 1.

Selected impacts of E-waste and Plastic Pollution on the living and nonliving components of the environment. Original figure drawn based on information available in refs (12,19,20,24,25,36−38).

As shown in Figure 2, key trends such as economic growth, increasing automation of industrial production and manufacturing processes, mobility (for example, automobiles), consumables (for example, packaging and encapsulation materials), water and food security, health (for example, artificial limbs and devices for monitoring of body vitals), artificial intelligence (that is, the merging of biological and machine intelligence), defense and security (for example, advanced electronic warfare systems such as drones), and others, driving the technological advancements of the human race; it is unarguable that materials consumption will continue to be on the increase.39,40 Humanity currently generates over 100 billion metric tons of materials each year, more than the combined weight of 13 million African elephants (although there are currently less than 500 000 wild elephant populations); however, less than 9% of this figure is cycled back into the global economy, thus leaving more than 90% uncaptured and unaccounted for,39−41 thereby demonstrating the enormous material and environmental crisis facing humanity. As a matter of urgency, stakeholders (for example, the scientific community) must accept that we are all complicit in our environmental misfortunes and the consequent fallouts. Hence, taking full ownership of these problems behooves humankind to forge a consolidated front in embracing holistic solutions. Therefore, the earnestness for innovative strategies and a fundamentally new class of materials (for example, microplastic–free polymers) capable of meeting our material needs while alleviating several of the current environmental challenges is of high priority.

Figure 2.

Trends that will continue to influence human technological advancements.

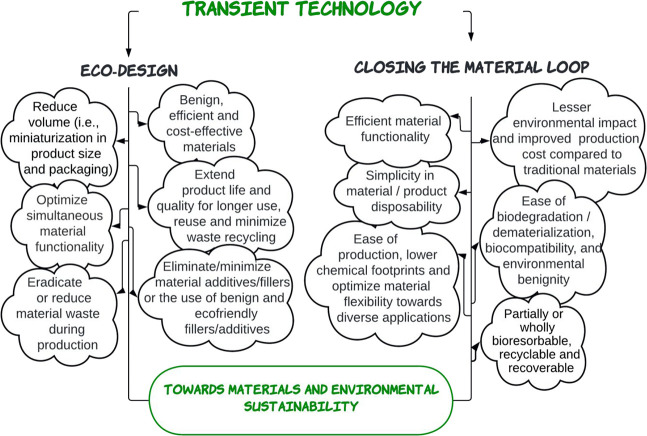

Consequently, the emerging concept of transient technology (that is, green technology) is gaining momentum in the scientific community and stakeholders along the materials value chain toward achieving the mandate of the SDGs.7,26 Taking responsibility as stewards of our planet, as conceptually represented in Figure 3, transient technology offers humanity the benefits of eco-design and the possibility of closing the material loop.26 Where eco-design encompasses removing environmentally associated challenges (wherever and whenever possible) from a product’s development life cycle, without sacrificing quality, efficiency, durability, and affordability.26 Furthermore, the idea of closing the material loop necessitates the purposeful fabrication or manufacturing of a product or constituent components from bioresorbable materials that are benign to the environment, and will subsequently dematerialize on exposure to particular stimuli (for example, light, heat, biofluid, and so forth) with minimal or nontraceable remnants, with negligible or net-zero impact or providing positive ecological effect on the environment.26,42 Ideally, among the benefits of transient technology are that in the case where wastes (for example, e-wastes and plastics) escape the waste-capturing and recycling processes, they will constitute less environmental burdens.

Figure 3.

Basically, the idea of transient technology is broadly conceptualized on eco-design and closing the material loop, where possible. Original diagram drawn based on information available in refs (19,26,42).

Moreover, transient technology will minimize the environmental and cost implications of waste handling, recycling, and disposability; and consequently advance the technology of self-destructive products and devices toward the security and protection of sensitive information and technologies, lessen the environmental burdens of short-term use electronics (for example, disposable diagnostic devices), advance biofriendly implantable devices and scaffolds, assuage the impacts of single-use plastics and consumables such as latex gloves and condoms, sanitary pads and diapers, bank cards, facemasks, and so forth, through the purposeful fabrication of these products partially or wholly from materials that can environmentally dematerialize and subsequently resorbed by nature, within a short time frame (for example, few days after discarding), with no detrimental impact or superficially upcycled into high-value products with negligible chemical footprints in the environment.26,43

Among the prerequisites for materials selection in transient technology is practicability in application (for example, efficient alternatives to conventional materials), suitability for large scale production, low-cost sourcing (for example, ease of supply and replenishment of in-use stock), sustainability, operational efficiency, biodegradability, biocompatibility, environmentally benignity, ease of formability, and flexibility in product development.26,44 Therefore, we believe that, where possible, products and materials used on a large-scale (that is, high demand or usage), such as shopping bags, facemasks, diapers, and so forth, should be constructed from materials that meet these requirements.

Natural occurring polymeric systems (for example, cellulose) represent a growing area of interest in polymer materials science and engineering; hence, by suitable physicochemical modifications of these biomaterials, the use of oligomers or monomeric polymerizations, the development of innovative materials with impressive properties are possible.45−48 Hence, nanoscale cellulose materials (that is, nanocellulosics or nanocelluloses), which can exist as cellulosic nanocrystals and nanowhiskers, have gained considerable research interests in industry and academia as materials of choice for engineering and fabrication of high-performance devices, structural templates, and single-use consumables;49−51 thereby, demonstrating that biorenewable resources hold great promise in the materials value chain with the capacity to replace various conventional materials (for example, plastics) in a wide range of application portfolios, while mitigating many of the current environmental challenges for sustainable development.44,46,52 It is no secret that in addition to the enormous availability (more than 1 trillion metric tons of native cellulose are synthesized annually by plant biomass alone), nontoxicity, biodegradability, and biocompatibility; cellulose-based materials as polysaccharidal resources are environmentally benign, sustainable and renewable (for example, nature synthesizes, and humans harvest), possess the ease of processability, and can be modified for enhanced properties (for example, mechanical, electrical, optical, and barrier properties), with high formability and flexibility in structural components and product development.45,46,52,53

Distinct from existing reviews,26,54−57 this report critically examines and summarizes recent progress of nanocellulosics in transient technology toward mitigating of current environmental challenges resulting from traditional material exploration, usage and disposability. While spotlighting important fundamental properties and functions in the material selection toward practicability; we identify current challenges and propose important research directions for advancing the concept of transient technology and cellulose-based materials in closing the material loop; with outlooks aimed at viable solutions for effectual, multifunctional, and benign materials toward sustainability.

2. Summary of Properties and Fundamentals in Materials Selection

Hydrocarbon materials such as cellulose-based materials have recently gained prominence as versatile and capable materials of choice in an assortment of application portfolios in many old and new areas of interests such as cellulose-based flexible organic light-emitting diodes (OLEDs),58,59 super strong, and lightweight materials for military and automotive applications, and so forth.46,60 Cellulose materials are currently derived or prepared from biological systems through two main approaches namely, the top-down approach (for example, deconstruction and extraction) such as employing vegetable biomass; and the bottom-up approach (for example, biosynthesis construction or production) such as using bacteria (for example, Komagataeibacter species), algae (for example, Ptilota species) and animals (for example, Tunicates).61−63 Dubbed the material of yesterday, today, and tomorrow;45 this carbohydrate heterochain polymer has demonstrated capacity as a model, efficient, and functional alternative to mineral and fossil-based materials.44,46 Cellulose is a loadbearing material that exists in nature in four different polymorphs, that is, celluloses I, II, III, IV;64 and as shown in Figure 4, it is composed of linear structural discrete glucose molecules interlinked by way of acetal bridges between the C1 and C4 carbon atoms within the glucopyranose ring (that is, β-d-glucose monomers linked together through β-(1,4) glycoside linkage), which is the configuration with the lowest energy conformation and most dominant polymorph of native cellulose in higher plant biomass.65 The cellobiose is the repeating unit of cellulose and regularly alternates at 180° along the polymer chain (that is, stereochemical arrangements) with different degrees of polymerization (DP).66 The inherent crystalline and mesostructural arrangements in nanocellulosic materials influence the interactions with other materials and ultimately the bulk properties,64 thereby making nanoscale cellulosics ideal candidates for the fabrication of hierarchical structured mesoporous materials with versatile functionalities.67−69

Figure 4.

(a) Structural arrangement of cellulose fibers described from the macroscale to the nanoscale. The enhanced structural representation of cellulose with the reducing and nonreducing ends [SEM image insert]. (b) Selective reaction of cellulose with a strong acid toward extraction of nanocellulosics, while showing the amorphous and crystalline regions [TEM image insert]. Reproduced with permission from ref (70). This is an open-access article and it was published under a Creative Commons Attribution 3.0 International License. Photograph courtesy of M. Kaushik, M. This is an open-access article and it was published under a Creative Commons Attribution 3.0 International License.

Cellulose is ubiquitous with almost endless supply in nature (that is, sustainable), and naturally consists of complex and insoluble substructural fibrous systems.70 The molecular surface of cellulose is loaded with reactive hydroxyl groups (−OH); at the nanoscale, the reactivities are more pronounced due to enhanced specific surface area and atomic exposures, conferring on nanocellulose high hydrophilicity (good wettability), enhanced functionalization, with notable redox centers (for conduction and the hoping of electrons), while enhancing chain aggregation and possibly cross-linking through intra- and inter-molecular hydrogen bonds which influences densification, chain packing, and barrier properties.53,71 In addition, the pore configuration, an essential feature of the fibril morphology of nanocellulosics, contributes to the chemical reactivity and enzymatic degradation efficacy; hence, the capacity to efficiently manipulate pore structures in cellulosic materials affords the possibilities for expansive product development that meet various specifications and application needs.72 In the structural configuration of cellulose, the hydroxyl group at the 2-position is more reactive than that at the 3-position. The chemistry of the hydroxyl group at the 6-position is more of a primary alcohol. At the same time, those at the 2- and 3- positions behave as secondary alcohols, which play significant roles in the chemistry and reactions of cellulose.52,73 It is noteworthy that hydrogen bonding is only one of the several molecular-level interactions to explain the complex structure–property chemistries of cellulose and cellulose-based materials, which are sometimes exaggerated and ultimately incorrect for explaining some exceptional phenomena observed in cellulosic chemistry.74 For example, the high axial modulus and fiber strengths of cellulose are usually attributed to hydrogen bonding, while neglecting the concept of molecular dynamics.74,75 Another example is the argument on the physical dynamics of cellulose dissolution mechanisms and the insolubility in water, which are widely accepted that hydrogen bonds play a significant role in these; however, this is unlikely as the contribution of hydrogen bonds to cellulose insolubility, for example, is negligible and lesser than the hydrophobic solvation energy (ΔGvdw).74,76 Because factors such as molecular geometry, multibody interactions of neighboring atoms, the shape of molecular interfaces, and slight changes in water density surrounding a cellulose molecule all contribute to the chemistry of hydrophobic solvation.77 Hence, there is a knowledge gap in understanding the fundamental forces at play in cellulose chemistry, whether at the molecular, intermolecular, fibril interactions, and subsequent arrangements in crystals, layer-to-layer interactions of the cellulose fibril arrangements with other fibrils, and so on.74 Moreover, the complex superstructure of nanoscale cellulose and the inherent chirality and chiral inversions over different atomic length scales makes it impossible to limit the capabilities of cellulosic materials; therefore, a better understanding is of utmost importance to assist in the engineering of tailored materials with unique and peculiar mechanical and optical properties such as chiral nematic liquid crystals and photonic and super strong aerogel materials.78 There is a need for broader research advancements toward bridging the knowledge gap between the theoretical and experimental observations on the chirality behavior and the substructural manipulation and arrangement of nanocellulosic fibrils under various processing conditions, which holds abundant possibilities in the advancement of a bottom-up approach (that is, construction and reconstruction) toward new technologies and fabrication of groundbreaking innovative metamaterials from cellulose. Moreover, observed twisting of all forms of bundled and single nanocellulosic fibers are intrinsically oriented toward the right side in the crystalline regions of cellulose;78 hence, the research question is, what kind of structural material could be constructed from left-handed chiral nanocellulosics employing substructural construction using a bottom-up layer-by-layer approach? What physicochemical properties could this structure exhibit? Conley et al.79 agrees this is possible. Moreover, studies on the selectivity of molecules to preferentially bond to the right-handed twists of the cellulose molecule is still at the infant stages.80

Native cellulose consists of various degrees of alternating regions of crystalline and amorphous domains, which influence the structural integrity and mechanical properties of the bulk material.81 The terminal groups of each cellulosic chain impart directional asymmetry. Moreover, the reducing and nonreducing ends of the cellulose chain contain hemiacetal and hydroxyl groups, respectively;82 which allows coupling the chain ends with other compatible materials. Nanoscale cellulose is usually grouped into three types according to morphology: (i) cellulose nanocrystals (CNCs), (ii) cellulose nanofibrils (CNFs), and (iii) bacterial cellulose (BNCs).81 CNFs and BNCs are more nanofibrils with well-defined crystalline and amorphous regions; in contrast, CNCs are elongated monocrystals that occur in rod-like forms with higher rigidity, possessing remarkable elastic modulus (around 143 GPa at 1.62 g cm–3), and exhibit excellent self-assembly behaviors (that is, Bouligand architectures).59,81 CNCs can form cholesteric liquid crystal phases in aqueous media or suspensions, making them promising platforms in developing sustainable optical materials with tunable properties to replace inorganic and fossil-based polymers.81 For example, as demonstrated in Figure 5, using a pilot roll-to-roll (R2R) approach, Droguet et al.83 successfully demonstrated the possibilities of commercial scale fabrication of structurally colored CNC films and effective photonic pigments/glitters that are ecological, for a wide range of applications. This revolutionary procedure offers the possibilities for large scale coating and casting methodologies in employing sustainable and functional materials from bioresources.83

Figure 5.

Schematic representations of the R2R processing of CNCs into large-scale photonic films and pigments. (a) Description of the key steps in the preparation of the photonic CNCs. (b) Corona etching process follows immediately after unwinding the web. (c) Snapshot of the slot-die depositing the CNC suspension on the central region of the PET web. (d) Statically drying of the CNC suspension at ambient temperature. (e) Almost-dried CNC film after going through an in-line hot air dryer, with a stepwise continuous movement of the web. (f) CNC film peeled-off the PET web roller. (g) Tailored color variations from R2R-cast CNC films on a black PET web. (h) Standalone R2R-cast CNC films. (i) On the left is the pristine and on the right is the heat-treated photonic CNC particles, submerged in transparent varnish before size sorting, respectively. (j) After size-sorting and immersion in 50% aqueous ethanol and water, the heat-treated photonic CNC particles are ready for use as pigments. (k.) Outline of the R2R trajectory, depicting the position of the hot air in relation to the slot-die and optimal length for static drying (lR2R = 3.2 m). Note: width of the web is 14 cm, for reference. Reproduced with permission from ref (83). Copyright 2022, Springer Nature. Photograph courtesy of B. E. Droguet. Copyright 2022, Springer Nature.

CNCs are the crystalline portion of cellulose, with degree of crystallinity ranging between 54–88%, which is largely dependent on the material source and extraction process; and they possess good shear-thinning characteristics which makes them ideal for developing advanced hydrogels and injectable materials.84−86 On the contrary, CNFs possess significant amorphous domains with varying macromolecular chain widths and pore sizes ranging from a few to several tens of nanometers, and similar to CNCs, the fundamental characteristics of CNFs such as morphology, degree of fibrillation, fiber pore size, and mechanical properties are influenced by material source and extraction procedures.46,52,81 Moreover, a common isolation of CNFs from hardwood pulp is achieved by using (2,2,6,6-tetramethylpiperidine-1-yl) oxidanyl (TEMPO)-oxidation.81,87 Desmaisons et al.88 have proposed a multicriteria method for obtaining the quality index of CNFs and benchmarking toward the applicability in commercial products. CNFs possess low coefficient of thermal expansivity and anisotropic properties with high water dispersibility, thus, making them suitable for forming suspensions and spinnability. The reported longitudinal elastic modulus of the highly crystalline CNFs ranged around 150 GPa and around 18–50 GPa in the transversal orientation. However, by mechanical stretching to orientate the fiber directions, enhanced mechanical properties can be achieved.62,89 Despite possessing interesting mechanical properties, the typical width length of the fibers (5–20 nm) and a length of a few micrometers makes them too short for the production of ecofriendly composites with commensurate strength.89,90 Besides, until recently, it was evidenced that “dry” CNFs possess high electrical energy storage capacity (that is, 221 mJm–2, 13.1 Wkg–1); thereby affording the possibility for the fabrication of high-performance, flexible, greener and sustainable paper-based rechargeable batteries (that is, supercapacitors).91

For BNCs, in addition to Komagataeibacter species (generally found on rotten fruits), several other bacterial species such as Rhizobium, Sarcina, Pseudomonas and so forth, have been employed in the bioproduction of BNCs. The configuration and properties of BNCs can be adjusted through variation of the cultivation parameters (for example, incubation time, nutrient type and source, type of bacteria strain, oxygen ratio, and so forth),72,81 and even by merely shaking the culture media, this can result in structural variation of the produced material.92 BNCs possess significant structural constituents and characteristics to that of plant derived cellulose (that is, composed of discrete glucose molecules interconnected by acetal bridges between the C1 and C4 carbon atoms within the glucopyranose ring).93 However, because BNCs are biosynthesized by well-defined biochemical steps and subsequent self-assembling of secreted cellulose fibrils in the culture medium, they possess a major advantage over plant-derived cellulosics as they are largely dominated by nanoscale cellulose fibers, that is, characteristic absence of lignin, hemicellulose and pectin that are inherent in plant-based cellulosics (for example, wood biomass); thus, BNCs does not require the process of deconstruction, delignification, and purification associated with the extraction of plant-based cellulosics, which makes them the purer and more greener form of cellulosics; however, they are currently more expensive to produce on a significant scale compared to plant-based cellulosics. Therefore, research and development for a low-cost, simple, and environmentally friendly process for the commercial production of BNCs is desirable. In addition, BNCs are free of secondary functional groups such as carbonyls and carboxyl that are usually introduced into plant cellulosics during the extraction and purification procedures.92,93 With a complex 3D-architecture of nanoscale cellulosic fiber network and fibril diameters ranging around 30 nm (shown in Figure 6), BNCs fibers are finer than most plant derived nanocellulosics, and possess high chain-to-chain packing which enhances the barrier properties.92 Hence, due to the nanoeffect resulting from such increased surface area, BNCs possess higher surface reactivity and have the capacity to bind to large amount of water (99%) during the cultivation in aqueous media.92 Moreover, due to the strong surface reactivity of BNCs, interactions between other polymeric systems including extracellular matrices with BNCs hydrogels make it possible for fabricating multifunctional composite materials and the ease of nanoparticle fixation that are well anchored and unmovable in the matrix;93 which is advantageous, especially in wound dressing applications where bioactive materials embedded in the BNCs are needed to remain immovable and in regular contact with the injured area for accelerated healing. Moreover, BNCs are characterized by long polymeric chains (that is, ∼3000–9000 repeating units) with unique crystallinity between 80–90% and impressive mechanical properties, for example, tensile strength comparable to that of steel and Kevlar; thus making them promising platforms for manufacturing acoustic products such as high fidelity loudspeakers and headphones.94 In contrast to plant-derived cellulosics, the characteristics of BNCs are not compromised during the purification process.93

Figure 6.

Typical BNCs 3D-fiber networks produced by random motion of bacteria as viewed under an electron micrograph, magnification ×1000. Reproduced with permission from ref (93). Copyright 2010, Springer Nature.

Shown in Figure 7 are usual chemical and surface modifications employed to overcome some of the basic limitations of nanocellulosics such as hydrophilicity or to improve on the properties such as good dispersibility in matrices or substrates. These techniques range from polymerization (for example, coupling and grafting), phosphorylation, etherification, sulfonation, and so on. Moreover, depending on the type and source of cellulosic materials the extraction and processing methods are application specific; hence, various preparation and extraction methods have been discussed extensively in cited references.62,81,84,95−98 Other name variations used in text for nanoscale cellulose include nanocrystalline cellulose, cellulose nanowhiskers, cellulose nanofibrils, fibrillated nanocellulose, and so forth, although there are no unanimous fixed terminologies. Notwithstanding, fibril or fibrillated nanoscale cellulosics generally reflects a higher aspect ratio compared to whiskers or crystals, although this is not a rule cast in stone.

Figure 7.

Common modification methods employed in overcoming the limitations of nanocellulosics in sundry applications. Reproduced with permission from ref (84). Copyright 2018, American Chemical Society.

3. Applications

The necessity for innovative strategies such as transient technology, toward mitigating many of the current environmental challenges has led to a growing interest in finding green(er) alternatives (for example, microplastic-free polymers) to conventional materials with commensurate or exceeding properties, capable of meeting our materials needs in various old and new areas applications. Nanoscale cellulosic materials are not only plastic-free polymers but have demonstrated capacity as efficient and sustainable alternatives to mineral and fossil-based materials that are not ecofriendly. In addition, they have found increasing applications either as standalone or combined with other materials in various applications ranging from membrane technology, biomedicals, smart agriculture and so forth. This section will discuss important developmental strides of nanocellulosic materials toward sustainability.

3.1. Sensory and OLED Devices

With increasing demand for high-tech gadgets and electronic devices, there would be a corresponding growth in e-waste generated. Moreover, the limited recycling rates for generated e-wastes remain a worldwide challenge.26 One of the underlying concepts of transient technology with regards to electronic devices is not only to develop recyclable electronics or to recapture liquid-metal traces but the possibility of all components or a substantial amount of the device is fabricated entirely from ecofriendly materials that are bioresorbable or entirely recyclable and recoverable. Therefore, to lessen the challenges of e-wastes and plastic pollution, cellulose based-substrates are gaining increasing research innovation in ecofriendly and flexible electronics.99 For example, utilizing paper as substrate and crystalline nanocellulosic (CNC) dielectric ink (at room temperature), compatible with carbon nanotube (CNT) and graphene inks, thin-film transistors (TFTs) that are all-carbon based and fully recyclable have been manufactured.100 Adding about 0.15 mM (mM) of sodium chloride (NaCl) to the aqueous CNC ink appreciably improved the dielectric characteristics, thereby, enhancing the sweep rates of the devices (∼600 m V s–1), lowered subthreshold swing (SS, 132 m V dec–1), ON/OFF current ratios of 104, and elevated on-current (87 μA mm–1). The TFTs were used to create fully printed, paper-based biological sensors capable of lactate sensing at a concentration sensitivity range less than 2 mM (the required range for diagnosis of septic shock), with an operational stability exceeding 6 months. Thereby demonstrating the possibilities of ecofriendly techniques for printing of tailored transient electronic devices.100 Elsewhere, by combining wood derived lignin (Lignin sulfonate, LS) and nanoscale cellulose (cellulose nanofiber, CNFs), a high-performance and low-cost composite substrate with an elastic modulus of 16.16 GPa, an ultimate tensile strength of 146 MPa, the reduced surface roughness of 4.68 nm, good transmittance of 59.57% @ 750 nm, and outstanding thermal, electrical stability and impressive flame retardancy, was produced.101 As demonstrated in Scheme 1, using TEMPO-oxidation and mechanical homogenization on cellulose pulp fibers, the CNFs were isolated, while the lignin is a byproduct of the pulping process. By way of dialysis fractionation and subsequent epoxidation reactions; a fractionated and epoxidized lignin sulfonate (FE-LS) with superior molecular weight and consistency, impressive surface activity, and high compatibility with the CNFs resulted.101 It was demonstrated that the FE-LS and CNF formed a uniform mixture even at a 50% FE-LS loading (FE-LS/CNF). The low-cost lignin-nanocellulose composite was characterized by exceptional robustness, impressive surface smoothness (comparable to the high-cost transparent nanopaper, ∼5 nm), transparency, and degradability. The substrate was used in the construction of RFID (radio frequency identification) antennas using standard magnesium (Mg) coil.101 The application possibilities of such fabricated substrates could be extended for memory devices, sensors, flexible solar cells, display units, and so forth.101

Scheme 1. Outlining the Preparatation and Application of the Adapted FE-LS/CNF Nanocomposite Material as Substrate for Organic Electronic Device.

(a) Wood as a resource for the materials. (b) Cut-out wood bulk. (c) Normal cellulose derived fibers. (d) Derived nanocellulose fibers. (e) Lignin powder of lignin sulfonate (LS). (f) Lignin sulfonate powder. (g) Fractionated and epoxidized lignin (FE-LS). (h) FE-LS/CNF blend (50 wt % each). (i) Obtained substrates for electoni application. (j) Ecofreindly RFID antenna fabricated with Mg coil. (k) Demonstrating the device degradability in water. Reproduced with permission from reference.101 Copyright 2022, Elsevier Science Ltd. Photograph courtesy of D. Jia. Copyright 2022, Elsevier Science Ltd.

Nanocellulosics are efficient alternatives to plastic substrates in electronic sensors, capable of delivering billions of sensing elements and coordination in addition to minimal environmental and economy costs.102 Therefore, there is a rising interest in developing sensors and sensory systems employing nanocellulosic materials. For example, a nanocellulose improved organo-hydrogel with exceptional strength, impressive conductivity, good transparency, and antifreezing properties for wearable strain sensors is reported.103 This was achieved using the radical polymerization of polyacrylamide (PAM)/sodium alginate (SA)/TEMPO-oxidized cellulose nanofibrils (TOCNs) in a mixture of dimethyl sulfoxide (DMSO)/Water solution, and subsequently followed by immersion in calcium chloride (CaCl2) solution. The reported tensile strength, stretchability, transparency, and ionic conductivity of the fabricated organo-hydrogels are 1.04 MPa, 681%, >84% transmittance, and 1.25 S m–1, respectively. The gauge factor (GF) was determined at 2.1, an impressive strain sensitivity with a toughness of about 3.74 MJ m–3; which makes this organo-hydrogel an ideal candidate for manufacturing multifunctional sensors for human health monitoring, and electronic skin.103 The organo-hydrogel could bend up to 180° and retained conductivity (1.01 S m–1) at minus 20 °C. In this work, biobased nanocellulosic replaces the commonly employed fossil-based conductive polymers such as polyaniline (PANI) and polypyrrole (PPy).103 In addition, the cellulosic material demonstrated a double effect by reinforcing the mechanical properties and ionic-conductivity of the fabricated hydrogels, thereby, mitigating the trade-off between improving the mechanical properties and conductivity characteristics for ion-conductive antifreezing hydrogels with good sensitivity to tensile deformation.103 In another report, to achieve the possibility of fabricating transient conductive hydrogels as multifunctional sensors and signal transmitters, while tackling the well-known challenge of interfacial incompatibility existing between solid state conductive fillers and soft polymeric systems, TEMPO-oxidized nanofibrillated cellulose (CNFs) was employed as an interfacial stabilizer and for the encapsulation of liquid metal nanoparticles (LMNPs).104 Acrylic acid was added into CNF-LMNPs suspension mixture, which was then homogenized and allowed to gel at room temperature for about 10 min. It was then cured in an oven at 40 °C for about 3 h to allow for complete polymerization. Employing this strategy comes with associated advantages, (i) free radicals generated during the ultrasonication of the liquid metals were available to initiate the polymerization of the system.104 (ii) the CNFs absorbed on the surface of the LMNPs improved the interfacial interactions between the poly(acrylic acid) (PAA) matrix and the LMNPs, which enhanced both the resultant mechanical properties and expandability, (iii) because the hydrogen network is formed entirely from the chemistry of the ionic interaction and hydrogen bonding with no chemical cross-linking agent, it imparted self-healing capability, self-recovery, crack-insensitivity, and ease of dematerialization (that is, transiency).104 In addition, compared to fossil-based materials employed as interfacial compatibilizers, CNFs enhanced the electrical properties of the hydrogel, imparted solvent-independence (that is, a lower chemical footprint which is part of the eco-design strategy), improved the strain sensing sensitivity (optimal gauge factor, GF = 12.5 @ strain range of 1500% to 2000%). Therefore, with these benefits the fabricated PAA-CNF-LMNPS transient conductive hydrogels exemplify a sustainable, greener, durable, and transient material that simultaneously embodies mechanical resilience, environmental constancy, and material recoverability after the end of useful life.104

Flexible displays and optoelectronics such as hand-held foldable devices (for example, mobile phones) have gained considerable research and application possibilities in recent years due to their capacity for excellent deformation, flexibility in operational conditions, emission of self-illumination, high contrast ratio, lightweight, and considerable viewing angles, among others.59,105,106 In this regard, organic light emitting diodes (OLEDs) are fabricated from greener materials such as cellulosics instead of conventional plastics (for example, polycarbonates), and ultrathin glasses have become the growing trends toward sustainable development among other benefits.59,105,106 For example, a highly transparent and multifunctional membrane (referred to as HTBC), shown in Figure 8, was fabricated from bacterial cellulose incorporated with organic–inorganic sol composed of boehmite (Boe) nanoparticles and epoxy modified siloxane (GTPS), and subsequently coated with silicone oxide (SiO2) and indium tin oxide (ITO) (HTBC/SiO2/ITO) and employed in the fabrication of biocompatible OLEDs.107 It was shown that more than 80% visible light transmission was achieved with a resistivity of 2.7 × 10–4 Ω cm, a carrier concentration of −1.48 × 1021 cm–3, and mobility of 15.2 cm2 V–1 s–1; these values compare to those obtained from conventional glass-based substrates doped with ITO.107 Furthermore, optimal efficiencies of 1.95 cd/A and 1.68 cd/A were obtained for the reference OLED and the HTBC OLED, respectively. The HTBC OLED efficiency exceeded 85% of the standard ITO-based OLED, a remarkable improvement to previously reported bacterial cellulose standard OLED.107

Figure 8.

Inserted photos demonstrating the optical transparency of the fabricated HTBC material (the picture on the left) compared to the native bacterial cellulose (the picture on the right). The green lines on the optical transmission spectra are for the HTBC material and the gray/black line for the native bacteria cellulose. Reproduced with permission from ref (107). Copyright 2019, Springer Nature. Photograph courtesy of C. Legnani. Copyright 2019, Springer Nature.

Elsewhere, challenges such as the wrinkling of conventional polymer cover windows used in foldable OLED displays, which is attributable to the weak folding resistance of these materials during operational uses, are well-known.106,108 Although increasing the thickness of the used material (for example, colorless polyimide, CPI) for OLED polymer cover windows can improve the resistance to wrinkling that would trade-off the touch sensitivity of the OLED touchscreen panels.106 Hence, to overcome this challenge, inspiration is taken from the theory of elasticity, making it possible to manufacture nanocellulose/ceramic/polymer cover windows with high bendability, exceptional sensitivity, and impressive transparency for OLED screens.106 The contributory properties of CNCs (such as good mechanical strength and transparency) and that of zirconia (ZrO2), such as excellent chemical and thermal constancy, biocompatibility, optical, and electrical sensitivity, were momentous. Thus, rigid CNCs and ZrO2 were incorporated into the colorless polyimide (CPI) to manufacture a CNC/ZrO2/CPI hybrid cover window. Through hydrolysis of the oxalic acid and subsequent mechanical treatment the CNC suspension were obtained, while the homogeneous ZrO2 particles were synthesized via alkali hydrolysis and hydrothermal treatments, respectively. However, the polycondensation of 2,2′-bis (trifluoromethyl)-4,4′-diaminophenyl ether (6FODA) and 4,4′-(hexafluoroisopropene) diphthalic anhydride (6FDA) at low temperature resulted in the poly(amic acid, PAA).106 The ZrO2 particles remarkably enhanced the touch sensitivity of the display, and the incorporation of the nanoparticles (CNCs and ZrO2) appreciated the elastic modulus of the composite from 1432 to 2221 MPa, more than a 30% improvement. The dielectric constant of the nanocomposite appreciated to 3.36 from 2.95 (@ 1 × 106 Hz), more than 10% improvement; thereby, demonstrating a significant enhancement in the material foldability and sensitivity.106 Another work has exemplified the benefits of nanocellulosic materials over plastics in OLEDs; although plastics can be used for fabricating OLEDs with good flexibility and transparency, and are suitable for the roll-to-roll (RTR) industrial process, they, however, demonstrate dimensional distortions during the high-temperature manufacturing process as a result of their high coefficient of thermal expansion (CTE); thereby, resulting in the difficulty in the laying down and precise alignment of the OLED functional materials, which subsequently affects the product output and optimization.105 The greenness of cellulose nanofibrils (CNFs) makes them excellent materials and compatible fillers to improving the functionality and efficiency of OLED systems. By incorporating CNF into polyarylate (PAR) and subsequently doping with indium tin oxide (ITO), a novel ITO@CNF/PAR hybrid material with impressive transparency with improved mechanical, thermal and dimensional stability, with no apparent loss in the material transparency (whatsoever) during and after the manufacturing processes was obtained. The glass transition temperature (Tg) of the resulting composite was 192 °C, with a maximum service temperature (Tm) of 501 °C. The optical transmittance ranged over 85% with a low haze of about 1.75% @ 600 nm. In addition, OLED devices fabricated on the ITO@CNF/PAR hybrid substrates exhibited better optoelectrical performance than that fabricated from conventional plastics such as poly(ethylene terephthalate, PET) substrates.105

3.2. Energy Conversion and Storage Systems

Energy is the bedrock of any civilization and energy security is a global challenge. Moreover, energy security plays a critical role in maintaining the territorial sovereignty and integrity of any nation.44,52 With the emerging agreement to phase out fossil-based energy sources such as coal; and coupled with the fact that renewable energy sources such as sunlight (solar) are intermittent and irregular in supply, this becomes a challenge.44,52 As a result, there is the urgent and growing need for high-efficient batteries, supercapacitors and solar cells for the efficient capturing, conversion and storage of energy for subsequent use as electricity.109 However, the emerging agreement toward pursuing dependable energy conversion and storage systems with the high power density and cycle life that employ green(er) processes and materials in the product life cycle development is a welcome development toward the sustainability mandate.52,109 Organic polymers such as cellulosic materials have been shown to be efficient and promising choices for the fabrication of green(er), sustainable, scalable, and versatile dielectric and energy storage devices.44,52,109 Recent years have seen intensified efforts in this area of interests and considerable progress have been recorded. In addition to the growth of computational technologies, strategies involving the collaboration of biological and machine intelligence have contributed to the advancement of this field.44,52,109 Various energy conversion and storage systems exist today, such as superconducting magnetic energy storage (SMES) systems, supercapacitors or electrochemical capacitors (ECs), dielectric capacitors (that is, electrostatic capacitors), batteries (that is, chemical energy storage systems), solid oxide fuel cells (SOFCs), and flywheels.110 And as evidenced in the Ragone plot shown in Figure 9(a), there is a trade-off between the energy and power densities of energy storage devices (ESDs); that is, no single ESD exhibits the desirable characteristics of high energy density and high power density simultaneously.110 It is also clear, from the graph, that batteries are characterized by high energy density, nevertheless they possess low power density.110 On the other hand, capacitors exhibit higher charge/discharge rates (that is, higher power density) compared to batteries because they store energy through the displacement of bound charged elements while batteries employ chemical reactions. Therefore, capacitors have found increasing applications in a wide range of areas, as shown in Figure 9(b).110

Figure 9.

(a) Ragone plot for a variety of ESDs. The dash lines running across the graph and times (s and h) relate to the characteristic times of each ESDs. (b) Application ranges of capacitors. Reproduced with permission from ref (110). Copyright 2019, Elsevier Science Ltd. Photograph courtesy of L. Yang. Copyright 2019, Elsevier Science Ltd.

By taking advantage of the ultrahigh specific surface areas (SSA, around 2630 m2 g–1) of graphene nanosheets and their excellent electrical conductivity, a hybrid composite aerogel consisting of low-cost biomass activated carbon (Bio-AC)/reduced graphene oxide (rGO)/cellulose nanofibers (CNFs) (Bio-AC/rGO/CNF aerogel) for potential large-energy storage application has been reported.111 From the environmental and economic perspectives, the biomass-derived activated carbon (Bio-AC) offers the advantage of sustainability and a cheap alternative to the traditionally employed functional materials such as nanotubes, metal wires, and metal oxides, to mention a few. In addition, the pore size and the specific surface area of the Bio-AC can be manipulated to optimize the characteristics; moreover, activated carbon is a well-known electrode material.111 Employing a one-step self-assembly process, Bio-AC were distributed effectively into the rGO framework preventing agglomeration of the rGO nanosheet, thereby resulting in impressive conductivity characteristics and SSA. The negatively charged CNFs were used as green matrix binders to enhance the mechanical integrity of the rGO nanosheets and Bio-AC particles. Moreover, the CNF allowed for effective interactions between the Bio-AC and rGO sheets. At 76% Bio-AC loading (mass ratio), the hybrid aerogel exhibited an excellent mechanical strength of around 240 kPa with an SSA of 1007.9 m2 g–1, achieving an efficient manganese oxide (MnO2) deposition of 33.9 mg cm–2, and an impressive pseudocapacitive performance of 4.8 F cm–2 as a self-supporting supercapacitor.111

Selecting the right material for implantable energy devices possessing high storage capacity as well as excellent biodegradation, biocompatibility, and biological benignity before and after dematerialization, is a challenge, because conventional energy systems contain heavy metals, plastics, and so forth.112 Hence, to overcome these challenges, Zhou et al.112 fabricated a promising implantable energy device with solid state zinc ion batteries (ZIBs) encapsulated in superassembled hierarchical cellulose aerogel-gelatin (CAG) that is entirely biodegradable in 30 days in buffered proteinase K solution, as demonstrated in Figure 10. By employing ZIBs as the electrolyte, the safety challenge of employing traditional lithium batteries is overcome. In addition, this device demonstrated high-level electrochemical performance and meets the requirement for controlled degradation toward materials transiency. The device demonstrated a specific capacity of 211.5 mAh g–1 at a current of 61.6 mA.g–1 with a voltage range of 0.85–1.9 V, and whether bent or folded, there was no significant depreciation functional efficiency.112

Figure 10.

In vivo studies of the degradation and bioresorbing of the thin-film zinc battery. (a) Photograph of the battery before surgical insertion. (b–f) In vivo asssesment of the degradation of the thin film-battery after subcutaneous surgical insertion in rats. Reproduced with permission from ref (112). Copyright 2022, John Wiley & Sons. Photograph courtesy of J. Zhou. Copyright 2022, John Wiley & Sons.

Elemental sodium (Na) represents one of the most abundant and ubiquitous elements on earth and holds promise toward the fabrication of rechargeable sodium-ion batteries (NIBs), as a viable alternative to nonsustainable lithium-ion batteries (LIBs).113,114 In addition, NIBs offers reliability, low-cost, safety, room temperature operability, and environmental friendliness compared to LIBs; moreover, the construction, structure and charge storage process for LIBs and NIBs are similar.113,114 Notwithstanding, NIBs are encumbered with challenges that hampers the wider application and acceptability. For example, sodium cations are comparably bulkier (23.00 u vs 6.94 u) and larger (1.02 Å vs 0.76 Å) than the lithium cation; hence, the diffusion rates for sodium in conventional intercalation materials are much slower.114 Moreover, the large size of the sodium cation is attributable to more than 15% reduction in the total binding energies for sodium cations as a result of weaker solvation shells and a decreased charge-to-radius ratio.114 Recently, attempts to construct alternatives to conventional materials for NIBs have intensified. For example, biodegradable cellulose-based nanomaterials were used to construct a hierarchical polymer gel electrolytes for stable sodium electrodeposition in NIBs.115 The constructed system delivered a constant Na plating/stripping that outperformed NIBs containing fossil-based separator–liquid electrolytes, and yielded optimal current densities up to ±500 μA cm–2.115 When paired with Na2Fe2(SO4)3 cathode, the fabricated battery attained an energy density of 240 Wh kg–1, and delivered up to 69.7 mAh g–1 after 50 cycles @ rate of 1 C. Thus, opening the opportunity for ecofriendly and economically sustainable rechargeable batteries from sodium.115 In a related report, it has been established that a relationship exist between microstructural characteristics of materials and the electrochemical performance in batteries.116 Native cellulose treated with sulfuric acid was converted into chiral nematic nanocrystalline cellulose (NCC); subsequently, by employing a combination of acid hydrolysis, hydrothermal carbonization, and high temperature pyrolysis, tailored carbon microstructures for efficient NIB electrodes were successfully fabricated.116 The obtained carbon exhibited an exceptional initial Coulombic efficiency (ICE) of 90.4% with an outstanding reversible capacity of 314 mAh g–1 @ 0.1 C; thereby demonstrating the potential and performance possibilities of NIBs.116 However, it was noted that further research is needed toward the quantification of the specific relationship between parameters (for example, pore/heteroatoms/defects and electrochemical performance), with relation to ICE of the carbon anodes toward optimizing the anodic output for higher efficiencies.116

In another development, to boost the storage energy densities and to mitigate the challenge of low specific capacities of existing commercial anodic materials (for example, graphitic and titanate) employed in LIBs toward next-generation rechargeable energy systems, a vacuum-assisted filtration technique was used to fabricate free-standing, flexible anode composed of black phosphorus (BP) nanosheets and nanocellulose (NC) nanowires (BP@NC), as demonstrated in Figure 11.117 BP is gaining interests as promising anodic material for constructing flexible high-energy-density LIBs. The constructed BP@NC offers a combination of 3-D conductivity for the Li+/e– transports for high-quality reaction kinetics.117 Remarkably, the added NC enhanced the flexibility characteristics of the anode by more than 10%, thereby improving the volume expansion of the BP@NC electrode, in addition to the notably enhanced interboundary diffusion of the Li+ and reduction of potential repulsive forces.117 Electrochemical analysis concluded that the BP@NC electrode possesses a high capacity into sufficient cycling stability and rate performance. The highest capacity of 1020.1 mAh g–1 at a current density of 0.1 A g–1 after 230 cycles was recorded. Interestingly, at higher current density of 0.2 A g–1, the capacity peaked at 994.4 mAh g–1 and remained consistent after 400 cycles.117 Furthermore, the NC improved the mechanical integrity of the BP@NC and impacted positively on the specific capacities of the electrode with good retention capacity at moderate current densities; hence, the NC acted as a multifunctional component.117 Nanocellulose-based gel polymer electrolytes for LIBs have become recent object of research interests, due to the associated benefits of mitigating the impact of fossil-based commercial separators such as polyolefin materials, improving the structural, mechanical, and thermal stability of electrolytes and assuaging the challenges of leakage arising from liquid electrolytes, among others.118,119 Hence, acetylated cellulose nanofibrils (CNFs) were solvent cast and subsequently employed in a gel polymer electrolyte which improved the electrolyte absorption and the cycling durability of the LIB.118 The acetylation of the CNFs provided active reactive sites introduced through the highly lyophilic ester groups and markedly reduced side reactions. The electrolyte uptake exceeded 300% with ionic conductivity reaching 2.73 × 10–3 S cm–1.118 The study demonstrated that the lithium-ion transfer number ranged at 0.65, and as a result of the enhanced mechanical characteristics, the material flexibility was impressive, with good transportation properties.118 The electrolyte/electrode resistance was shown to be around 152 Ω and remained so for about 18 days. When fully assembled into a battery storage system the capacity retention exceeded 88% after 100 cycles @ 0.2C.118 This demonstrates how simple techniques can be used to fabricate efficient and sustainable storage systems employing nanocellulose.118

Figure 11.

Illustrating the fabrication procedure for the free-standing electrode BP@NC. It can be seen that the composite exhibited high capacities ranging at 1020.1 mAh g–1 at 0.1 A g–1 after 230 cycles and 994.4 mAh g–1 at 0.2 A g–1 after 400 cycles, agreeing with excellent retention capacities of 87.7% and 84.9% respectively. Reproduced with permission from ref (117). Copyright 2020, American Chemical Society. Photograph courtesy of R. Wang. Copyright 2020, American Chemical Society.

3.3. Biomedical and Tissue Engineering

To mitigate the challenges of plastics such as polypropylene (PP) commonly used in medical implants to support, lift, or hold in position debilitated tissues,120 research are gearing toward benign, ecofriendly, and biocompatible materials.121 For example, bacterial nanocellulose (BNC) is well-known as a comparable template to extracellular matrix, and characterized by good wettability, suturing suitability, and sterilization capability; while maintaining capability for structural transformations under load (a critical feature needed for bioengineering) was used to produce auxetic structures for biomedical application. Using a combination of additive manufacturing and mold templating methodologies the auxetic BNC constructions exhibited controlled structural configurations, defined apertures, and high mechanical enhancement and robustness (for example, 48–456 MPa tensile strength and more than 87% structural integrity after 100 burst loading/unloading circles). With an excellent porosity (within the mesoporous to microporous ranges), and is a promising candidate for replacing PP meshes in supportive biological implants.121 In a related development, to eliminate the associated negative effect of synthetic plastic meshes employed in surgical implants (for example, internal soreness, adverse pains, postsurgical infections, and implant chemical migration), an innovative biocompatible nanocellulose and chitosan hydrogel, for implant mesh matrices are reported.122 Relying on the electrostatic interactions arising from the layer-by-layer assemblage of anionic TEMPO-oxidized fibrillated nanocellulose (TOCNF) and that of positively charged chitosan (without the need for cross-linking agents, that is, reducing chemical footprint) direct ink writing (DIW) employing single and multihead extrusion is used to fabricate cross-linked nanocellulose and chitosan hydrogels for implant mesh matrices.122 The DIW procedure is a demonstrable vehicle for regulating or fine-tuning geometrical details from shapes to dimensions, infill density and opening size. Dissolution of chitosan in moderated acetic acid activated the inherent amino groups into their corresponding ammonium cations.122 After which equal amounts of the chitosan and TOCNF are thoroughly mixed in equal mass ratios toward 3D printing. The optimal modulus for the chitosan-sorbed nanocellulose ranged at 683 ± 63 MPa and with tensile strength of 2.46 ± 0.44 MPa, respectively. The biological studies showed negligible cytotoxicity in biological systems, with good biocompatibility.122 Thereby demonstrating the capacity of nanocellulosics as a candidate for green(er) and ecofriendly implantable mesh.

Meanwhile, because removing sutures from deep tissue or difficult to access anatomical areas is a clinical challenge; therefore, employing materials that possess optimal biodegradability, and biocompatibility while possessing the required mechanical property for medical suturing is desirable; hence, in another report, resorbable surgical sutures for post medical operations, based on TEMPO-mediated oxidation regenerated cellulose (TORC) is described.123 The braided TORC suturing material demonstrated better biological tolerance and activity (for example, nonallergenicity, hemostatic, and wide-range of antibacterial properties), lower-cost implication, biodegradability, biocompatibility, good mechanical strength, and sustainability compared to other suturing materials such as catgut, collagen, poly(lactic-co-glycolic acid, PGLA), and so forth.123 Zhao et al.124 have reported a strategy involving the chemical assemblage of nanocellulose and biosynthetic protein for the production of high-performance protein-nanocellulose composite fibers with excellent biocompatibility as potential materials for surgical suturing. With notable mechanical strength (551.2 MPa), toughness (40.6 MJ m–3), and capacity to withstand a gravity potential in the range of 0.020 J, this material exhibited more than 10% multidirectional extensibility, with potential for use as green fiber in high-tech applications.124

Recent years have seen advancements in nerve tissue engineering, and various methods are emerging such as nerve guide conduit (NGC), which mitigates the incursion of scar tissue, and offers an alternative to autologous transplants.125 Materials employed in NGCs are required to meet basic safety regulations and demonstrate efficiency. Moreover, requirements such as biocompatibility, biodegradability, mechanical robustness, and so on, are critical for repairing peripheral nerve injury (PNI).125 Nanocellulosics such as BNCs have demonstrated capacity as green(er) scaffolding materials of choice that meets the requirements for fabricating NGCs, compatible with living cells with no hematological and histological toxicity on living tissues.125 By integrating chitosan nanoparticles (CSNPs) into a BNC matrix using an ionic gelation technique and with no cross-linking agents or dispersants (that is, eco-design), a composite CSNPs-BNC with impressive antibacterial activity capable of promoting the adhesion and proliferation of Schwann cells, with high biocompatibility and impressive in vitro and in vivo conclusions toward a sustainable NGC conduit is reported.126 An emerging possibility for BNCs to be used as candidates for blood vessel replacement is reported.127 The possibility of using the mercerization process on tubular BNCs to effectively control their properties and enhance performance in small-caliber vascular grafts is a testament to the possibilities green(er) material technology presents to humanity.127 Cardiovascular diseases (CVDs) rank top among the major contributors to global mortality and disability.128 Therefore, surgical processes such as coronary bypass employing autologous blood vessels (that is, vascular systems) are among the most common clinical treatment techniques. Materials such as polyethylene terephthalate (PET) and expanded polytetrafluoroethylene (ePTFE) are generally used to fabricate large caliber (>6 mm diameter) vascular graft replacements; however, there are scanty commercial successes in the production of smaller (<6 mm diameter) vascular systems that meet clinical requirements.128 Hence, Bao et al.128 to assuage the challenge of plastic pollution and pursue green technology, have shown in a comparative study that air-dried bacterial nanocellulose (BNC-Dry) can be employed for small-caliber artificial blood vessels (ϕ 3 mm), and they possess better mechanical properties, hemocompatibility, and cytocompatibility compared to BNC-hydrogel conduits.128 In addition, the animal trial to replace carotid artery, the implanted BNC-Dry showed retained efficiency for more than 40 days, while allowing for autologous tissue growth on the outer wall of the material; which indicates a favorable application in small diameter prothesis vessels.128 A double-modified bacterial cellulose/soybean protein isolate (DMBC/SPI), was used to create a new type of urethral tissue scaffold that possesses optimal biocompatibility, biodegradability (with notable degradation rate), ease of suturing, and cell-oriented growth, to mitigate the problems (for example, stenosis recurrence, fistula formation, and foreign body reactions) associated with currently employed acellular matrix and degradable polymers (for example, polycaprolactone and polylactic acid) in urethral tissue engineering.129 Animal test studies showed that the DMBC/SPI promoted the healing of the damaged urethra with no inflammatory reactions; moreover, the repaired urethra was smooth and continuous.129

In another vein, a cheap fabrication technique using all-biobased materials such as nanohydroxyapatite (n-HAP), oxidized bacterial cellulose (OBC), and chitosan for bone repair, is reported.130 The n-HAP was prepared employing in situ crystallization of Ca2+/PO42– solution and subsequently distributed evenly into the OBC and CS mixture, poured into a mold for freeze-drying, after which CS/OBC/n-HAP scaffolds were constructed.130 Analytical studies using CS/n-HAP as a control to the CS/OBC/n-HAP scaffold demonstrated that the latter exhibited notable improvement in mechanical properties, enhanced water retention characteristics, and improved stability toward degradation. Cell studies affirmed that the CS/OBC/n-HAP scaffolds possessed remarkable biocompatibility, significantly promoted the proliferation of MC3T3-E1 cells, and induced the regeneration of bone tissues with notable in vivo stability.130 A naturally occurring biodegradable polymer industrially known as β-G (β-Glucan), widely employed in a range of pharmaceutical and medical applications, was employed for the fabrication of 3-D biocomposite scaffold for bone engineering. Using the free radical polymerization and the freeze-drying process the bacterial cellulose (BC) and β-G via mixture was prepared as green substrates. Hydroxyapatite nanoparticles (n-HAP) and graphene oxide (GO) were subsequently added as reinforcing materials at various ratios, as shown in Table 1, for the construction of the GO/n-HAP/BC/ β-G biocomposite scaffold.131 Antibacterial studies against gram – ve and + ve strains showed that BgC-1.4 exhibited the highest antibacterial activities. Further cell culture and cytotoxicity investigations were evaluated using the MC3T3-E1 cell culture, and it was observed that cell growth for BgC-1.4 was more pronounced which is attributable to the even pore distribution and interconnectivity.131 Moreover, the BgC-1.4 sample demonstrated good surface roughness, notable biochemical attraction for cell adhesion, and proliferation in addition to excellent biocompatibility. Which demonstrates the potential for effectual bone repair and regeneration.131

Table 1. Constitution of the Biocomposite Scaffoldsa.

| scaffold sample | β-G (g) | BC (g) | n-HAP (g) | GO (mg) | pore size (μm) | porosity (%) |

|---|---|---|---|---|---|---|

| BgC-1.1 | 1 | 1 | 2.5 | 0.1 | 357 ± 6.34 | 73 ± 2.23 |

| BgC-1.2 | 1 | 1 | 2.5 | 0.2 | 293 ± 2.92 | 61 ± 5.67 |

| BgC-1.3 | 1 | 1 | 2.5 | 0.3 | 185 ± 2.81 | 53 ± 2.91 |

| BgC-1.4 | 1 | 1 | 2.5 | 0.4 | 127 ± 3.42 | 47 ± 1.26 |

Reproduced with permission from reference.131 This is an open-access article and it was published under a Creative Commons Attribution 3.0 International License.

3.4. Single-Use Consumables and Diagnostics

Microplastic free, fully recyclable or bioresorbable single-use disposables and consumables produced from eco-friendly materials have become necessary in light of environmental and material sustainability.12,26 It has been shown that ecofriendly facemasks based on nanocellulosics that meet and even exceed regulatory and safety standards are possible.132 Hossain et al.133 have demonstrated the possibilities of fabricating, from nanocellulose, cheap, and effective viral protective gowns, for COVID-19, in addition to mitigating the challenge of plastic pollution arising from the use of plastic-based personal protective equipment (PPE).133 Although poly(lactic acid) (PLA) has been considered as a promising replacement for plastics in sundry applications such as single use drinking straws due to the characteristic biodegradability of PLA; however, challenges such as poor thermal processing characteristics, mechanical brittleness, high cost of production and the needed conditions for selective microorganisms to achieve biodegradation on a realistic real-time scale, limits the potentials of this polymer.134,135 Plastics will continue to play significant roles in human advancements ranging from the Internet-of-Things (IoTs) to artificial organs to insulation materials to smart devices, to mention a few.12 Hence, the possibility of a world without plastics remains doubtful because we live in a polymer world.12 Moreover, the scientific community as stakeholders in the materials value-chain, are complicit in these environmental challenges and cannot avoid taking responsibility in urgently finding holistic approaches to the plastic challenge.12,19,46 Recent years have seen concerted efforts toward tackling the menace of plastics employed in packaging and single-use disposables and consumables.12,19 A major function of a packaging material is to provide protection, in addition to improving the shelf life of the food during storage, as well as wholesomeness and safety without any detrimental interference from the packaging material or constituent chemicals migrating into the food.12 It is known that plastics have the capacity to compromise food safety and detrimentally interfere with the integrity of packaged food with serious health consequences.12,19 Hence, various green(er), biocompatible, biodegradable, and benign materials from biobased materials such as nanocellulosics have found increasing research and applications potentials in packaging materials. For example, active pads for meat packaging incorporating the synergized properties of chitosan (CS) and cellulose nanocrystals (CNCs) using solvent casting is reported.136 By varying the concentrations of CNCs in the composite system (5, 10, 25, ad 50 wt %) the materials demonstrated good thermal stability, enhanced oxygen barrier characteristics, good water permeability, bacterial and fungicidal properties, reduction in total volatile basic nitrogen (TVB-N), and good mechanical properties (for example, tensile strength ranged from 8.93, 13.0, and 25.3 MPa, according to CNC concentration).136 However, with 10 and 25 wt % of the CNC, antimicrobial activities were absolute, as it was shown that bacterial and fungicidal activities were nonexistent. In conclusion, the efficiency of the composite packaging to retard meat’s spoilage under refrigerated conditions in real-life demonstrations, offers an overall ecological impact.136 Elsewhere, based on the circular-economy pursuit, using isolated sunflower proteins and bacterial nanocellulose (BNC), biodegradable packaging films for fresh fruit preservation were produced.137 The BNC as a reinforcing filler improved the mechanical characteristics (for example, 131.5% higher elongation at break, more than 75% increase in Young’s Modulus and over 60% improvement in tensile strength), in addition to good water retention and creating an atmosphere unsuitable for bacterial activity when used to package fresh strawberries, the fruits retained their initial freshness and vibrancy after long-term storage.137

A portable, cheap, efficient, easily disposable, and environmentally benign device employing nanocellulosic material (cellulose nanofibrils, CNFs) for the point-of-care device has been reported.138 This paper-based microfluidic biosensor is derived from the principle whereby selected areas of paper are imparted with hydrophobic characteristics and leaving the other areas as hydrophilic channels for the transfer of fluids.138 The excellent specific area of nanocellulosics, good pore size and structure, and mechanical resilience make them excellent support for enzymatic anchoring such as microbial glucose oxidase enzymes, as biosensors for monitoring and sensing of blood sugar concentration and management of diabetes.138 The fabricated microfluidic sensor showed a detection limit range of 0.1 × 10–3 M, with indicative color changes that are observable with the naked eye.138 However, there is still room for improving this versatile biosensing technique for multicomponent detection by incorporating various enzymatic systems for specific sensing applications.138 Another work has demonstrated an ecofriendly and easily recyclable silver nanoparticle (AgNP) and bacterial nanocellulose (BNC) composite, as an alternative to plastic substrates, for paste-and-read surface-enhanced Raman scatterings (SERS) system for the sensing of pesticides on fruit surfaces.139 The fabricated nanocomposite (AgNP-BNC) exhibited impressive SERS activity with good reproducibility and mechanical stability.139 With excellent anchoring of the AgNPs in the 3-D BNC network, giving rise to SERS hot spotting in the range of a few-micron depth on the substrate and was capable of detecting traces of 4-aminothiophenol and methomyl carbamate pesticide residues. In addition, the optical transparency of the substrate material, made it possible for the precise and instant sensing of methomyl on fruit peels.139 The versatility of this technique makes it possible for adaptation in other applications, thereby reinforcing the fact that biorenewable resources such as nanocellulosics offer humanity enormous possibilities in transient or green material technology toward sustainability.

4. Concluding Remarks and Outlook

The pursuit for environmental and materials sustainability, mitigation of microplastic polymers, assuaging the detrimental impacts of e-wastes has contributed to the emerging concept of transient or green technology. Fundamentally, a new class of materials capable of meeting our material needs while alleviating or not contributing to the current environmental challenges is the way to go. Transient technology holds enormous possibilities for alleviating the detrimental effects of materials exploration and disposal. The load-bearing capacity of our environment is finite, and it is our believe that if nature is given the chance, it can bounce back and reverse most of the current environmental issues facing humanity. It is evident without any deep analysis that that recapturing of used materials is not enough therefore employing materials that have the capacity to dissipate in the environment with minimal human intervention is a welcomed development. Humanity needs the environment and must strike a balance to ensure environmental exploitation is counterbalanced with commensurate remedial actions. With regards to the atom-economy (that is, construction instead of deconstruction), the biosynthesis and crystalline arrangements of native cellulose are not well understood coupled with the complex molecular features which currently make the synthetic modeling and production of cellulose from carbon dioxide, water, and sunlight a difficult challenge. Hence research needs to be intensified in this area. Moreover, an innovative class of materials can become possible through the concerted efforts of the scientific community. For example, short-life electronics such as ATM cards can possess a programmed lifespan (for example, 5 years), after which they are no longer functional and are returned to the issuing authority and subsequently biodegraded to recover the reusable electronic components, while the substrate material is recaptured for reuse for the production of another card. The possibility of dissolution of old and outdated mobile phones, laptop computers, and televisions can become possible, with components such as encasements manufactured from biodegradable and resorbable materials for full materials (that is, substrates, encasements, component electronic chips, and circuits) recovery.

With the advancement of computational chemistry and artificial intelligence (AI), transient technology can be applied to develop solvents capable of dematerializing or deconstructing previously nonbiodegradable materials into high value byproducts or reusable elementary constituents or into simple molecules that are resorbable by the environment. For example, model solvents can be simulated employing AI and computational chemistry to deconstruct conventional polyurethane foams into carboxylic acids, nitrogen, hydrogen, and benzoic acids that can be reused. Moreover, machine learning and quantum computing can contribute to these simulations by using complex solubility parameters for modeling and predicting simple and effectual solubilization of nonsoluble materials to aid the depolymerization and dematerialization into simpler and eco-friendly molecules, saving humanity years of laboratory trials and errors. Hence, the need to develop a global database accessible to the scientific community regarding degradation behavior simulated under real environmental conditions cannot be overemphasized.