Abstract

Chronic wounds have become one of the most important issues for healthcare systems and are a leading cause of death worldwide. Wound dressings are necessary to facilitate wound treatment. Engineering wound dressings may substantially reduce healing time, reduce the risk of recurrent infections, and reduce the disability and costs associated. In the path of engineering of an ideal wound dressing, hydrogels have played a leading role. Hydrogels are 3D hydrophilic polymeric structures that can provide a protective barrier, mimic the native extracellular matrix (ECM), and provide a humid environment. Due to their advantages, hydrogels (with different architectural, physical, mechanical, and biological properties) have been extensively explored as wound dressing platforms. Here we describe recent studies on hydrogels for wound healing applications with a strong focus on the interplay between the fabrication method used and the architectural, mechanical, and biological performance achieved. Moreover, we review different categories of additives which can enhance wound regeneration using 3D hydrogel dressings. Hydrogel engineering for wound healing applications promises the generation of smart solutions to solve this pressing problem, enabling key functionalities such as bacterial growth inhibition, enhanced re-epithelialization, vascularization, improved recovery of the tissue functionality, and overall, accelerated and effective wound healing.

Keywords: Wound healing, Wound dressing, Hydrogel, Tissue engineering, 3D culture

Graphical abstract

Highlights

-

•

Wound care technologies have evolved over the last few decades to offer holistic solutions to this major health problem.

-

•

Hydrogels have been widely used for wound regeneration due to their similarities to the extracellular matrix.

-

•

Bioactive agents, such as nanoparticles, cells, and molecules, enhance hydrogel performance in wound-healing applications.

-

•

Biofabrication technologies have significantly expanded the toolbox for designing functional would dressings.

1. Introduction

The skin is the biggest organ in the body, and its major role is to protect the body from external elements. A wound is known as an injury or disintegration of skin tissue, which could happen due to different causes, including thermal injury, trauma, and chronic ulcerations derived from diabetes mellitus, pressure, and venous stasis [1]. Chronic wounds are becoming increasingly common. Venous ulcers, whether active or healed, affect 1% of the population in the United States [2]. Pressure ulcers will affect 0.75% of the population. Every year, one million of the 30 million + diabetic individuals in the United States will develop a foot ulcer, and another 6 to 7 million will develop ulcers over their lifetimes [2], many requiring amputations. Another 3 million people in the United States suffer from pressure and leg ulcers, including venous ulcers, with yearly treatment expenditures of up to $8 billion [1]. Although recent therapeutic interventions, including skin substitutes, have improved skin healing in the clinic, they are still very perfectible and have not fully shown the ability to effectively restore normal skin structure and function. Despite the advances in wound healing, the ultimate purpose would be to engineer tissues that could provide appropriate biological and structural features to effectively regenerate the wounded area [1,3]. In this regard, it is critical to investigate the nature of wound healing and its underlying mechanisms in order to follow and mimic them as closely as possible.

Inflammation, proliferation, and remodeling are three major phases of wound healing that overlap significantly. Clot development is the initial tissue response to a wound to prevent bleeding. At the same time, inflammatory cytokines that control blood flow to the wound bed are released, and lymphocytes and macrophages are recruited to fight infection. Subsequent to the primary inflammatory response, the proliferation phase takes place with angiogenesis, fibroblast proliferation, and collagen deposition [4]. Later, granulation tissue, a tissue with a high content of cells and blood capillaries, is formed. Ultimately, during remodeling, the proliferation and migration of keratinocytes are induced by myofibroblasts and factors such as TGF-β, to replace granulation tissue with scar tissue and to reconstruct the epidermal structure. A chronic wound can occur if any of these healing processes is continued for an extended period.

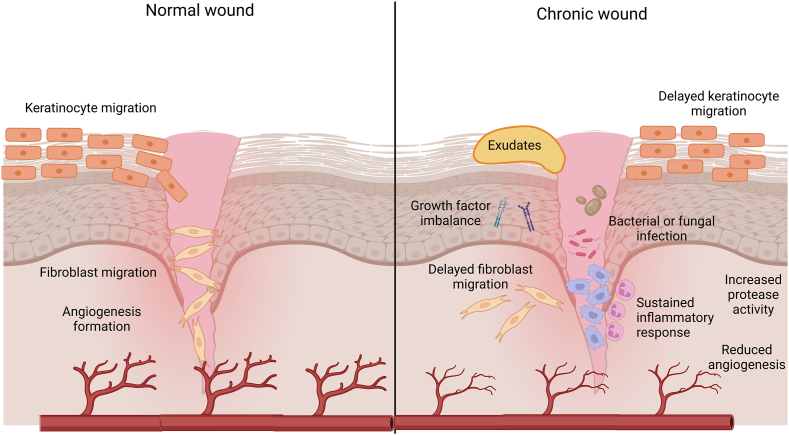

Chronic wounds are frequently linked to basic medical disorders that impede wound healing (Fig. 1). Subsequently, these abnormalities may be associated with a loss of tissue viability, suboptimal local tissue permeability, and an elevated and sustained inflammatory response [4]. One of the key differences between acute and chronic wounds is that the ordered phases associated with acute wound healing are not identical to the asynchrony of the healing process occurring in chronic human wounds [5]. Within the chronic wound, several phases of the wound repair process may be occurring simultaneously or out of sequence [5]. Nonhealing wounds are plagued by bacterial and, in rare circumstances, fungal colonization or infection [5]. These features include a lack of epithelium and its barrier capabilities, continuous wound exudation caused by bacterial products and inflammation, inadequate blood flow, and hypoxia [6]. Growth factor imbalances have been linked to the inadequate healing response seen in chronic wounds [7]. Another problem is that all chronic wounds have reduced angiogenesis, which exacerbates the tissue damage already caused by persistent hypoxia and poor nutrient supply [6]. For instance, impaired angiogenesis in diabetics leads to inadequate blood vessel creation and a reduced entry of inflammatory cells and their growth factors [8]. Experimental diabetic wound models have shown lower levels of growth factors, such FGF-2 and PDGF, which are crucial for wound healing [[9], [10], [11]]. Topical injection of high concentrations of glucose into wounds in rat models was demonstrated to impede the normal angiogenic process, demonstrating that high glucose levels had a direct and negative impact on angiogenesis [12]. In addition, increased protease activity has the potential to damage granulation tissue and degrade growth factors.

Fig. 1.

Differences between normal and chronic wounds. Created with BioRender.com

An imperative requirement for a wound dressing is protecting the wound bed while also stimulating skin regeneration to speed up wound healing. Many issues must be considered when selecting a wound dressing product for a wounded individual, including the condition of the existing wound, the frequency of dressing replacement, the expense of treatment, and the need for other supplies (such as antibiotics and sedatives) [13]. An ideal construct for wound healing applications must be biocompatible, non-sensitizing, and display suitable physiochemical properties (i.e., appropriate viscosity and/or mechanical properties). An ideal wound dressing should be able to absorb the tissue fluid that has been secreted (exuded) and exchange gases in a timely manner. It must also protect the wound from bacterial infection and preserve a humid environment in interaction with the wound bed to allow the cells to adhere and proliferate appropriately, aiding wound healing. The rate and extent of biodegradation is another issue that should be considered in fabricating wound dressings. Ideally, the wound dressing should progressively free up space for newly formed ECM and proliferated cells. In a parallel fashion, the degradation products must be metabolically eliminated from the body to prevent inflammation [14]. An additional consideration for wound dressings should be the minimization of discomfort upon removal [15,16]. For example, conventional wound dressings, such as gauze, may solidify into a clot-gauze composite that sticks to the wound bed, causing further pain and bleeding [15,17,18]. An ideal wound dressing should not cause secondary damage during its removal [15,16].

Hydrogels have shown great promise in various applications in the fields of tissue engineering and wound dressings [19]. Hydrogels are hydrophilic three-dimensional polymeric network structures that can hold a considerable amount of water in their networks while maintaining their structure. Hydrogels can be biocompatible and undergo biodegradation, while also exhibiting desirable properties, such as similar elasticity to native tissue, providing a humid environment, the ability to absorb wound exudates, presenting a porous structure suitable for gas exchange, playing a key role as a barrier to bacterial infections, and providing a suitable environment for improving cellular functions, such as migration and proliferation [20]. Further, hydrogels should hydrate wounds to provide a moist environment and facilitate wound scab removal via autolysis [16]. Due to the weak adhesion of hydrogels, they do not attach to the wound bed and can be removed without pain or without damaging the newly formed tissue [16,18].

Moreover, hydrogels could be incorporated with different additives to tailor their structural and biological properties. Several bioactive components, such as anti-biotics and anti-inflammatory molecules, and living cells, could be easily encapsulated into hydrogels to promote wound healing. Hydrogels can also be injected into the defect site, which can be helpful to fill wounds with irregular geometry and provide adhesiveness to the wound bed [21]. All these features make hydrogels a great platform for wound healing and skin regeneration. However, several issues related to their structure, mechanical stability, and biological characteristics limits hydrogels to be a standard wound treatment in the clinic. In the last decade, many researchers have shown the great wound healing and skin regeneration potential of 3D hydrogel constructs with different polymer precursors, crosslinkers, biomolecules, nanoparticles, and living cells [[22], [23], [24]].

In this review, we will highlight a selection of recently published papers that illustrate the design, characterization, and evaluation of hydrogels for wound-healing applications. Excellent reviews have been written on this topic [13,18,20,25]. Our aim was to provide a fresh and relevant perspective; therefore, the focus of our discussion is on the engineering of hydrogel constructs that, through the fabrication process and the incorporation of additives, provide enhanced functionalities for wound-healing applications. Arguably, the fabrication process is not the major determinant of the hydrogel structure. However, we firmly believe that the fabrication method, as well as the set of additives used during fabrication to impart or enhance particular properties of a wound dressing, are fundamental to the design/customization of ideal mechanical and biological performance of wound dressings.

Firstly, we will discuss the desired structural characteristics of 3D hydrogel wound dressing and the results of the corresponding papers based on the method of fabrication. Later, we will comprehensively review the biological engineering of 3D hydrogels via bioactive components that have been used efficiently to promote wound healing.

2. Engineering the architecture and structure through fabrication

The structure and architecture of the hydrogel constructs for wound healing applications should favor the creation of an environment that fosters proper regeneration (Fig. 2A). A 3D structure seems to be very beneficial, acting as a framework for regeneration and healing processes. Mechanical strength should match the native tissue to provide a bio-mimicked environment for cell attachment, spreading, and proliferation [26]. For cell function, morphological characteristics and porosity are also essential to be helpful not only to mimic the morphology of ECM compounds but also to have suitable porosities and pore sizes for cell infiltration and enhanced nutrient transport. Degradability is also an important principle for any tissue engineering application, permitting native tissue to be generated as the scaffold degrades. Water retention capability is another factor which is crucial specifically for wound dressings. Cells need a humid environment to display their normal behavior, such as attachment and proliferation, to restore the damaged area. Despite their water-retaining properties, wound dressings should absorb excessive wound exudates that could otherwise provide an environment for microorganisms, such as bacteria, to thrive [27].

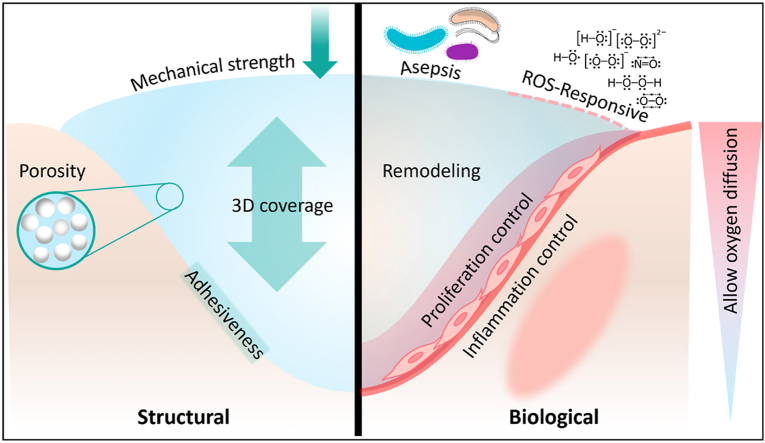

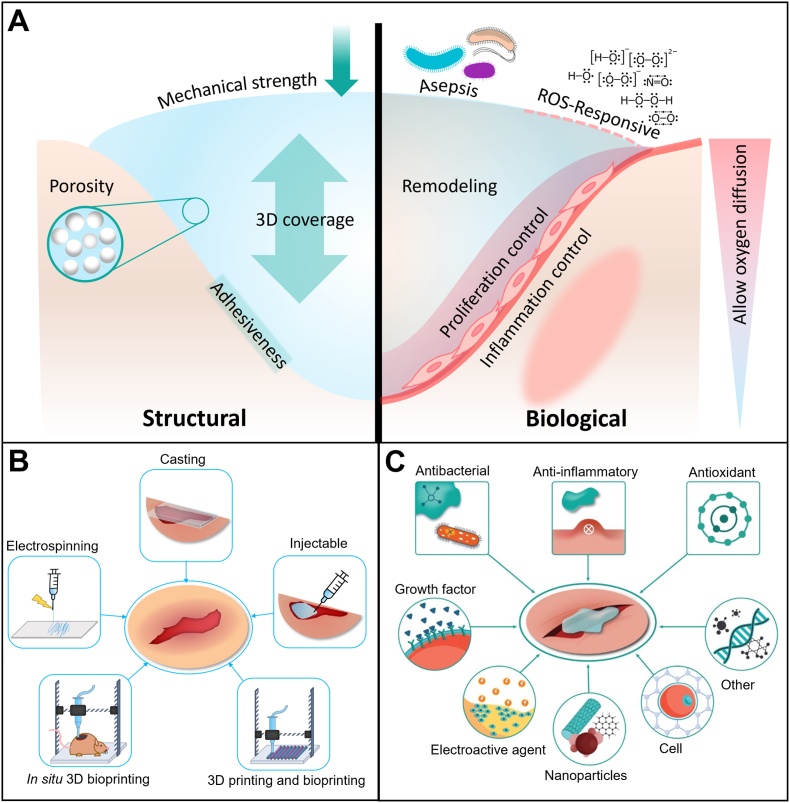

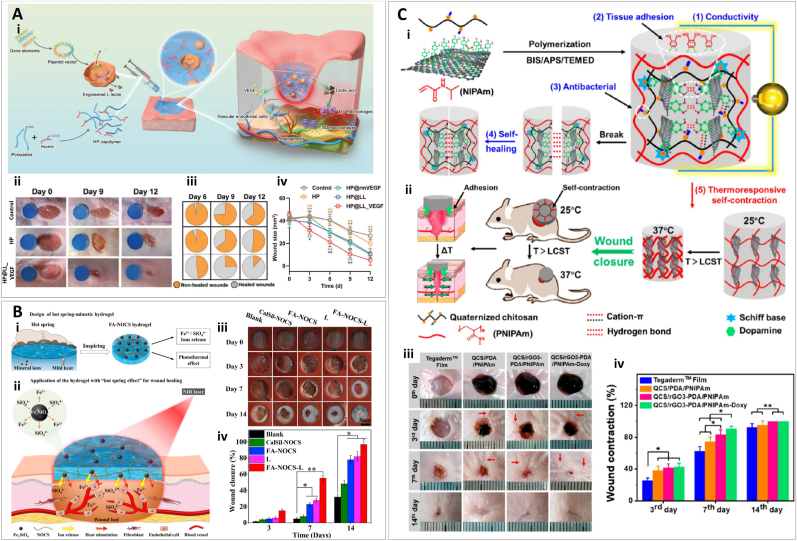

Fig. 2.

Structural and biological engineering of 3D hydrogels for wound healing applications. (A) Structural and biological features of hydrogels, necessary for wound healing improvement. (B) Different fabrication methods which are reported for wound healing applications. (C) Different bioactive agents that could be loaded within hydrogels to promote wound healing.

A wide range of hydrogels have been investigated for wound healing applications, exhibiting different ranges of mechanical properties. Hydrogels could be categorized into three classes: natural, synthetic, and semi-synthetic polymers. Aside from the chemical nature of each polymer and its concentration, the fabrication method and crosslinking method may also influence structural properties. Thus, hydrogels could exhibit a wide spectrum of properties, including various morphological, mechanical, rheological, degradation, and water retention features. Furthermore, according to the application, different additives can be incorporated into hydrogel 3D structures, which can alter and adjust the structural characteristics of the 3D hydrogels.

A deep wound is a highly complex and dynamic environment in which many stimuli occur sequentially or simultaneously, both from the host cells (e.g., inflammatory or healing responses) and the environment (e.g., infection, dehydration). Therefore, stimuli-responsive hydrogels have a wide spectrum of applications and advantages in wound healing.

In this section, we will review representative studies in which hydrogels have been structurally engineered for wound healing applications. We have categorized studies based on the method of fabrication (Fig. 2B) and elaborated on their structural characteristics.

2.1. Casting/molding

The simplest and cheapest method to fabricate a hydrogel for wound dressing application is casting. This method is based on molding the polymeric solution and inducing the solidification by different possible mechanisms. This gelation could take place through different crosslinking routes, including chemical or physical. The wound bed itself can be considered as the mold for injectable hydrogels capable of being crosslinked in situ. Thus, in the following discussion, we subdivide the molding of hydrogels used for wound healing into two categories. First, we describe applications in which the wound healing construct is fabricated and then applied to the wound site (i.e., casting outside the wound). Then, we discuss reports in which the wound dressing hydrogels are directly cast into the wound site (i.e., in situ molding).

2.1.1. Casting outside the wound

The most obvious advantage of casting is its ease of use in creating structures that will later be applied to deep wounds. The process of fabrication can be entirely and carefully controlled in the lab or manufacturing facility. This can lead to the integrated use of sophisticated resources to tune the performance of the hydrogel construct. In this category of wound dressings, hydrogel precursor solutions, either cell-laden or not, will be placed in the molds and then solidified by a specific crosslinking mechanism. In particular, photo-crosslinkable hydrogels, hydrogels that can be crosslinked by light stimulus (e.g., ultraviolet [UV] light or visible light), are extensively used in wound healing due to their numerous advantages. Additional crosslinking mechanisms of hydrogels for wound healing and different tissue engineering applications have been discussed in several review papers [13,20,28,29].

Among photo-crosslinkable hydrogels, gelatin methacryloyl (GelMA) is the most extensively used. GelMA [30] is a gelatin derivative, very attractive to researchers due to its high affinity for native mammalian ECM and ease of crosslinking. GelMA contains a high amount of methacrylamide groups and a minority of methacrylate groups which could be crosslinked through radical polymerization, in the presence of photo-initiator upon UV exposure [30]. Based on its wavelength and exposure time, UV light could be hazardous for living cells and the skin. Despite the investigations which have shown the safety of UV lights with particular wave length and specifications [31], the long-term clinical side effects are still not evident. Moreover, patients might not tend to expose UV to their skin. Thus, molding hydrogels could be an ideal choice to manipulate characteristics of photo-crosslinkable hydrogel wound dressings, without direct exposure of risky irradiations to living tissue. Many examples of use of photo-crosslinked hydrogels used for casting wound healing dressings can be found in recent literature. We have chosen only a few of them to illustrate some representative characteristics of the casting of photo-sensitive hydrogels for wound healing.

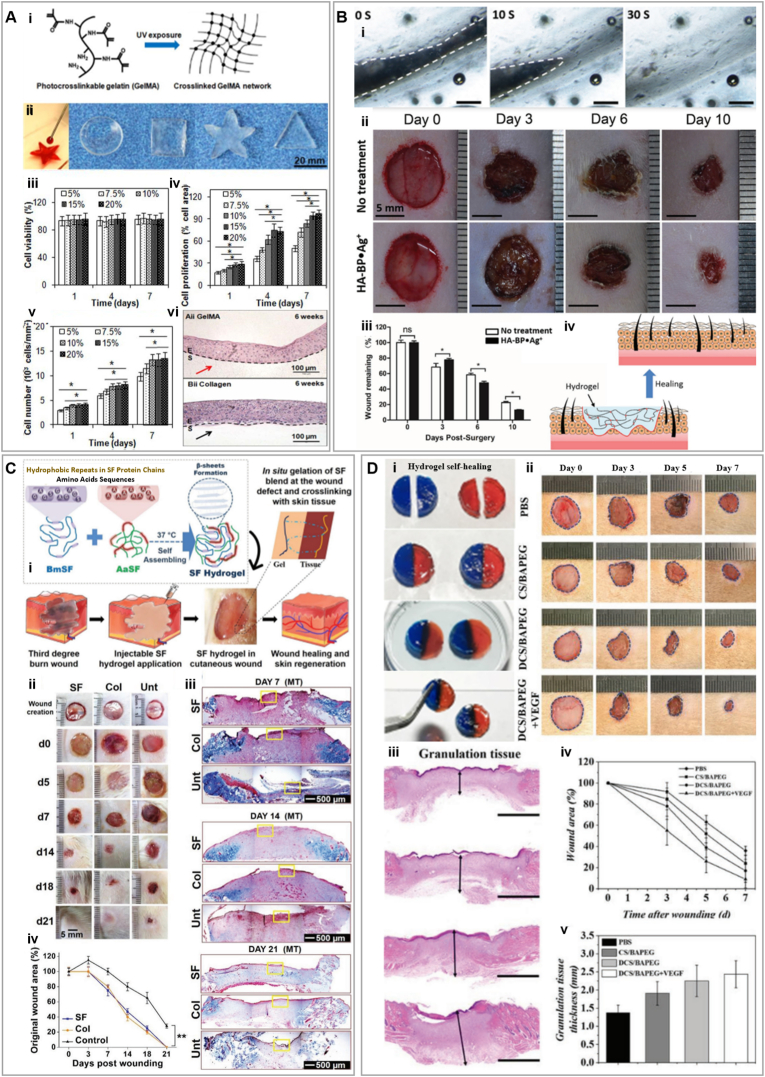

Zhao et al., investigated a GelMA hydrogel (75% of methacrylation) with adjustable mechanical and degradation features based on different concentrations (5%–20%), for wound healing (Fig. 3A). Mechanical analyses were performed after injecting the polymer in a PDMS mold and UV crosslinking. The compressive and elastic moduli were 3 kPa and 5 kPa, respectively, for 5% GelMA. The compressive and elastic moduli were significantly enhanced by increasing the concentration of GelMA to 20%, and reached ≈110 kPa and ≈200 kPa, respectively. This observation was expected due to a higher degree of crosslinking by increasing the concentration of GelMA. Reaching these high values of moduli is relevant in the context of wound healing applications; compressive moduli in the range of 100 kPa are advantageous for keratinocyte growth [32]. The high elastic moduli and tensile strength of 20% GelMA hydrogels are also sufficient to withstand stretching and bending forces applied throughout wound healing [33]. The authors also observed that cell adhesion and proliferation were significantly higher in 20% GelMA hydrogels than in softer GelMA hydrogels. Furthermore, immortalized human keratinocytes grown on 20% GelMA were able to differentiate and stratify after being lifted to the air-liquid interface [34]. Skin tissue is the exterior layer of the body that is exposed to a vast range of mechanical stresses, including compression, tension, shear, torsion, and bending. Different studies with different testing methods have reported a wide range of elastic moduli for human skin, ranging from 0.001 to 57 MPa [35]. Mimicking this range of values is ideal for wound dressings not only to induce appropriate skin cell behavior but also to tolerate the external stresses. An increase in GelMA concentration (and therefore crosslinking densities), also decreased degradability. Degradation tests using collagenase showed complete degradation of 5% GelMA in less than 72 h. However, this degradation happened for 20% GelMA after 8 weeks, which is desirable for long-term wound healing and prevention of secondary bacterial infection [34].

Fig. 3.

Casted hydrogels for wound healing applications (A) Casted gelatin methacryloyl (GelMA) (i) Schematic formation of GelMA hydrogel network. (ii) Injection of 20% GelMA solution into the molds with different shapes to form hydrogels upon UV exposure. Cell viability (ii), proliferation (iii), and number of cells cultured on surfaces with different GelMA concentrations. (v) Hematoxylin and eosin (H&E) stained sections of reconstructed epidermis on GelMA (top) and control collagen (bottom) scaffolds after 6 weeks of culture at air-liquid interface (ALI). Reprinted and adapted with permission from Zhao et al., 2015 [34]. (B) Self-healing hydrogel (i) Micrographs of hydrogel self-healing at 0, 10, and 30 s after the hydrogel cut. (ii) Images of wounds treated with hyaluronic acid (HA) chains were modified with pendant bisphosphonate (BP) ligand, incorporated with silver (Ag+) ions (HA-Bp Ag+) or untreated at different time points. (iii) Percentage of remaining wound size relative to day 0, asterisks show statistical differences between treatment and control. (iv) Schematics of HA-Bp Ag + hydrogel filling the wound without the need for premolding. Reprinted and adapted with permission from Shi et al., 2018 [50]. (C) Silk fibroin (SF) and collagen hydrogels (i) Schematic of in situ formation of SF blend hydrogel at 37 °C in wound bed. (ii) Images of wounds implanted with SF, collagen (Col) or left untreated (Unt) on excised third-degree burn wounds showing the healing process through time. (iii) Masson's trichrome (MT) staining of full wound biopsy sections at 4x magnification. (iv) Percentage of original wound area calculated at different time points using ImageJ. Reprinted and adapted with permission from Chouhan et al., 2018 [51]. (D) Benzaldehyde-terminated polyethylene glycol (BAPEG) and dodecyl-modified chitosan (DCS) hydrogels. (i) BAPEG/DCS hybrid hydrogels in blue and red, were cut into two parts, one piece of each was coupled together and they were kept in integral blended disks for 20 min, and the integrated healed hydrogel disks were maintained for 2 h in PBS. (ii) Images of skin wounds treated with PBS, CS/BAPEG, DCS/BAPEG, and vascular endothelial growth factor (VEGF)-loaded DCS/BAPEG. (iii) H&E staining of the wounds at day 7 post-injury. Mean wound area (iv) and quantification of granulation tissue thickness (v). Reprinted and adapted with permission from Chen et al., 2018 [56].

Arguably, due to the simplicity of the casting method, the researchers can focus on other aspects of the engineering, such as designing more sophisticated chemistry. Methods such as 3D printing and in situ application of polymeric solutions restrict scientists to using a limited number of components which exhibit desired characteristics compatible with these methods (such as being shear thinning and having good fidelity after injection and printing). Therefore, using a wider range of materials and reagents is one of the main advantages of preparing hydrogels by casting. Illustratively, heparin, as a natural highly sulfated glycosaminoglycan which is capable of binding to growth factors, has been used as a photo-crosslinkable wound dressing hydrogel [36]. One study reported the use of a thiol-ene reaction to connect thiolated heparin (Hep-SH) to polyethylene glycol diacrylate (PEG-DA) to create a heparin-based hydrogel sheet using UV irradiation [36]. Heparin-based and pristine PEG hydrogel sheets were characterized after lyophilization and rehydration in phosphate-buffered saline (PBS) [36]. The swelling capacities of both hydrogels were similar, suggesting equal degrees of chemical crosslinking. However, when compared to heparin gel sheets, it took longer for PEG gel sheets to equilibrate. This result suggests that heparin-based hydrogel is capable of quicker absorption of exudate from the wound bed and is appropriate for use as a wound dressing. The storage modulus (G′) of both samples was in the same range before swelling (i.e., nearly 14 kPa), comparable to that of human skin, demonstrating a desirable mechanical property as a wound dressing [37,38]. The water vapor transmission rate (WVTR) of the heparin-based hydrogel and the PEG hydrogel, were 1010 ± 100 and 1080 ± 50 g/m2/day, respectively. These values are in the appropriate range to absorb enough extrude and prevent wound dehydration (2000–2500 g/m2/day) [39]. Interestingly, while both hydrogels exhibited a similar swelling ratio, they greatly differed in their capacity to release proteins. Human epidermal growth factor (hEGF) embedded in hydrogels showed a gradual release over 21 days for heparin-based hydrogels, while a complete release in 5 days was observed for PEG hydrogels. This result was attributed to the interaction of a heparin-based hydrogel sheets with hEGF, which finally improved wound healing in vivo as compared to the PEG hydrogel [36]. Goh et al. also performed in vivo wound healing experiments in mice, and the results showed that hEGF loaded heparin-based hydrogel sheets improved wound closure as compared to PEG-based hydrogel sheets, which was evident from day 7 after injury. Such wounds achieved up to 90% closure in two weeks, whereas other treatments only achieved 50%–60%. These results were attributed to the slower hEGF release from the heparin hydrogel, which protects it from proteases and allows continuous stimulation for the proliferation and differentiation of keratinocytes and other cells [36].

Engineers can easily combine hydrogels with solid materials like mats and gauze by casting them together. This enables the fabrication of hybrid structures that can be used for various purposes, such as reinforcing the wound dressing, improving functionality, etc. In a study by Anjum et al., a wound dressing was fabricated by coating a cotton fabric with a blend of chitosan (CS), PEG, and polyvinyl pyrrolidone (PVP) [40] and freeze drying. The authors observed that the pores of the CS/PEG/PVP-coated cotton fabric (CPPC) were more spherical than the elongated porous structures in the samples without PVP. This observation could be related to the phase separation that limited interaction between chitosan and PEG, which could be changed upon the addition of PVP that may have enabled a stronger hydrogen bonding with chitosan [41]. In addition, adding PVP (50%) decreased porosity (from 68% to 58%) and increased water absorption as the swelling rate improved from ⁓400%–1210%. The WVTR of cotton fibers coated with CS, CS/PEG, and CS/PEG/PVP blends was measured ≈2600, ≈3380, and ≈2230 g/m2/day, respectively. Moreover, the air permeability of the samples was also altered by adding PVP, from ≈8.65 cc/cm2/sec for the CS/PEG coating to 5 cc/cm2/sec for 50% PVP. These experiments also showed that PVP could significantly increase the tensile strength of the composite. The tensile strength of CS/PEG/PVP blends (i.e., 16 MPa) was an order of magnitude higher than the tensile strength of CS/PEG-coated cotton fabric (i.e., 1.6 MPa). The CPPC composite showed an initial burst release over 8 h and then a more gradual release of 60%–78% of Tetracycline (TC) by 48 h. These results suggest the potential of this fabrication strategy for the early-stage antibacterial treatment of wounds. In vivo wound healing studies carried out in Wistar rats demonstrated that CPPC-TC-based wound dressings promoted faster and better wound healing (with 76% and 98% wound contraction by days 4 and 12, respectively) than the control (which only achieved 20% and 66% wound contraction on the same days). In addition, the amount of scar tissue was lower with CPPC-TC wound dressings (only 0.33%) than in the control group (10.67%) [40].

Self-healing hydrogels have been an interesting class of materials for biomedical applications. These hydrogels have the ability to repair their repeated structural defects and restore their original function through reversible interactions, such as hydrogen bonds, charge interactions, host−guest interactions, and coordination bonds [42]. For example, Tian et al. developed a self-healing hydrogel made of hyaluronic acid (HA) and capable of an on-demand release of antibacterial agents. HA is a non-sulfated glycosaminoglycan (GAG) and the main component of skin ECM. The hydrogel was fabricated via reversible supramolecular interactions, providing self-healing ability using a dynamic coordinate bond between the ethylene-diamine-tetra-acetic acid (EDTA)−Fe3+ complex and HA. In the presence of bacterial infection, the hyaluronidase (HAase) secreted by the microorganisms degrades HA, leading to the local release of Fe3+ which consequently kills bacteria (via reduction to Fe+2 and reaction with H2O2 to form a hydroxyl radical). The authors conducted an extensive characterization of this active system. Rheological analysis showed higher storage modulus (G′) than loss modulus (G″) for different ratios of Fe3+−EDTA complexes (4:1, 5:1, and 6:1), indicating self-standing hydrogel formation [42]. At day 7, mass spectrometry (MS) spectra revealed degradation of the hydrogels by the bacteria secreted HAase, which is required to release Fe3+. Atomic absorption spectroscopy showed that Fe3+ in the HA-Fe-EDTA hydrogel gradually lowers with increasing treatment time in vivo, indicating the efficient release of Fe3+ from the hydrogel to the infection environment, which is consistent with MS data. Continuously produced Fe3+ can kill bacteria, inhibiting infection and reducing infection-related microbial/skin metabolites. Complete wound closure was achieved in a 10 day period whilst also avoiding infection by Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus) [42].

Adding nanoparticles is one of the most common strategies not only to improve structural properties but also to enhance the bioactivity of hydrogels in tissue engineering. Casting as a simple method of fabrication enables researchers to easily fabricate hydrogel composites containing micro/nano particles. Producing homogenous suspensions of nanoparticles for casting may post a challenge. However, including particles in pregel solutions for in situ injection and 3D printing methods may be even more challenging. Nanoparticles may disturb the rheology of the suspension and make them more difficult to design/implement in in situ injection applications. For instance, not all the combinations of micro/nano particles with polymeric solutions are injectable and printable. Moreover, including additives might impede the crosslinking mechanism, which needs to take place instantly after injection or printing. An illustrative example of the fabrication of nano-particulated hydrogels for wound healing and fabricated by casting methods follows. Gan et al. fabricated a plant derived hydrogel consisting of lignin-coated Ag nanoparticles (NPs), and an interpenetrating network of pectin into the poly-acrylic acid (PAA) [43]. The NPs-P-PAA hydrogel exhibited resilience and stretchability up to 26 times its preliminary length, demonstrated by load–unload tensile stress–strain curves. Compression analysis also indicated complete deformation and complete recovery after 2 min. Typical tensile stress–strain curves showed maximum tensile strain of 2660% for the highest mass of NPs (0.03 gr), compared to 860% and 380% for P-PAA and PAA, respectively. The 0.03 NPs-P-PAA hydrogel also showed the highest strength and ductility (300 MPa%). Moreover, the fracture energy of 0.03NPs sample was measured at 5500 Jm−2 which is much higher compared to the amount for human skin, which is ≈ 2000 Jm−2. These results are associated with the interpenetrated network and reinforcing the hydrogels by Ag-Lignin NPs, which through noncovalent interactions with polymers can dissipate energy, leading to an improved mechanical property. The adhesiveness of the hydrogel was quantified using tensile adhesion test. Adhesion strengths to porcine skin was measured for NPs-P-(poly acrylamide) PAM, NPs-P-P poly (acrylic acid-co acrylamide) (AA-co-AM) and NPs-P-PAA hydrogels 12 kPa, 15 kPa, and 25 kPa, respectively. These findings indicated that carboxyl groups of PAA and catechol groups of Ag-Lignin NPs could enhance the adhesiveness of the hydrogel. In vivo performance was better for the NPs-P-PAA hydrogel as compared to the control and the P-PAA hydrogel in a wound healing assay. The NPs-P-PAA hydrogel treated wounds reached a healing ratio of 90%, whereas the control group and the P-PAA hydrogel only reached 59% and 78%, respectively. The authors also evaluated the quality of the regenerated tissue by hematoxylin and eosin (H&E) staining, which showed collagen fibers in the NPs-P-PAA hydrogel-treated sample, whereas there were still many granulation tissues in the controls [43].

Casting is the easiest and simplest way to fabricate wound dressing hydrogels; however, it normally produces an isotropic, monolithic hydrogel construct. With this method, the structural properties, such as pore size and mechanical properties, are usually determined by the type and concentration of polymer, the choice of crosslinkers, the type of additives, etc. In addition, a relatively wide variety of polymers, components, and additives could be used in casting methods without concerns such as altering the rheology and fidelity of the pregel solution/suspension. Furthermore, during the molding process, it will be possible to add solid compartments such as 2D sheets to make a hybrid wound dressing. Besides, molding hydrogels before applying them to the skin tissue prevents exposing the skin of patients to UV light and enables scientists to even consider crosslinking mechanisms that might release toxic byproducts. On the other hand, the main disadvantages of prefabricating hydrogels by casting could be the limited geometrical complexity that the method provides which translates in difficulties in adapting to irregular wound beds, difficulty of handling, and poor engraftment with the wounded area.

2.1.2. In situ molding

Compared to traditional hydrogel casting, the in situ application of hydrogels has the important advantage of completely filling the wound bed in three dimensions. The fluidity of injectable hydrogels allows them to fill deep wound cavities with irregular dimensions, which cannot be done by prefabricated hydrogels. Furthermore, when compared to prefabricated hydrogels, in situ crosslinking can result in a more appropriate integration and attachment of the wound dressing to the wound site. However, the other side of the coin is that not all types of hydrogels are injectable. This limits the in situ application of the hydrogels in tissue engineering. Injectable hydrogel solutions have to exhibit non-Newtonian characteristics of shear-thinning fluids, leading to a decreased viscosity when exposed to shear strain [44]. This will ensure cell survival throughout syringe-needle flow [45]. Another aspect to consider is the gelation time of the injectable solutions. If gelation happens very slowly, there may be significant solution and cell loss from the injected site [44]. Thus, the application of micro/nano additives that may impede shear-thinning properties and/or rapid sol–gel transition is also limited in injectable systems. The crosslinking mechanism is another important consideration. Although chemically-crosslinked hydrogels are rather strong and stable in terms of mechanical properties, physical crosslinking is more appropriate for in situ application of hydrogels due to safety considerations [46].

Many examples of the in situ application of hydrogel-based wound dressings can be found in recent literature. Here we discuss some illustrative reports. Lazurko et al. designed a thermosensitive hydrogel suitable for wound healing, made of different compositions of collagen type I, poly-d-Lysine (PDL), and chondroitin sulfate [47]. Gelation time was reported to be less than 5 min for the samples containing no chondroitin sulfate, whereas including this polymer in the matrix extended the gelation time up to 1 h. This result was possibly related to alterations in the conformation of the collagen which impaired inter-chain crosslinking. All the hydrogels (Collagen type I, Collagen/PDL, Collagen/chondroitin sulfate, and Chondroitin sulfate/PDL) denaturate at an average temperature of 50 °C, which is far from 41 °C, the highest possible fever temperature [48]. All samples showed a water content in the 94%–96% range, and CRYO-scanning electron microscope (SEM) images of PDL-containing ones exhibited fibrous architecture, indicating that the collagen and the poly-peptide formedan interpenetrated-network-like-structure [49]. Additionally, the pore size of collagen and collagen/PDL hydrogels was reported to be 16 μm and 10 μm, respectively. However, when air microbubbles were added to the matrix during its preparation, the pore size increased in both samples and reached up to ≈30 μm–40 μm. Having this range of pore size, collagen hydrogel could support migration of cells from mouse microscopic skin tissue column (MSTC) up to 21 days, suggesting the regenerative potential of this collagen-based hydrogel as a wound healing platform. Wounds in diabetic mice closed two times faster after treatment with the MSTC/collagen matrix than those treated with collagen matrix alone. Meanwhile, untreated diabetic mice showed impaired wound healing [47].

A moldable self-healing HA supramolecular hydrogel was fabricated by dynamic metal–ligand coordination bonds (Fig. 3B) [50]. HA chains were modified with pendant bisphosphonate (BP) ligands via carbo-di-imide coupling and “click” reactions. Upon silver (Ag+) addition to the solution, the reversible crosslinking occurred. The precursor concentrations used in the hydrogel were 3% (w/v) and 15 × 10−3 M for HA-BP and Ag+, respectively. Rheology analysis showed G′ of ≈400 Pa and G″ of ≈100 Pa confirming the hydrogel formation. Morphology of the hydrogels after freeze drying was assessed by SEM. No fibrous architecture was observed for these hydrogels, which could be associated with Ag+ ion crosslinkers with low-molecular weight, which usually cannot form fibrils with polymeric macromolecules. The HA-BP Ag+ hydrogels were tested in a rat full-thickness wound model to determine the remaining wound rates. The remaining wound rates for treated samples with HA-BP Ag+ hydrogels were 13%, while the controls exhibited remaining rates of 22.6%, ten days post-injury. Wounds treated with HA-BP Ag+ hydrogels also developed a thicker and more complete epithelium (144 μm) than the control wounds (63 μm) as observed by H&E staining on day 10 [50].

In a study by Chouhan et al., a thermosensitive silk fibroin (SF) hydrogel capable of self-assembly was developed using a mixture of two types of SF extracted from silkworms of Bombyx mori (BmSF) and Antheraea assama (AaSF) (Fig. 3C) [51]. SEM micrographs of lyophilized SF blend hydrogels showed a porous structure with an average pore size of ≈155 which is appropriate for cell penetration, vasculature formation, and wound healing application [52,53]. Water retention of the SF blend after 12 h was measured at 75% as compared to 20% for control collagen (Col) hydrogels. This could be attributed to the long stability of the hydrogel due to the combined effect of hydrogen bonding and hydrophobic interactions connecting AaSF and BmSF proteins. Temperature-dependent inter- and intramolecular interactions, which caused the gelation of the SF blend, could be due to the presence of both hydrophilic and hydrophobic sites between BmSF and AaSF. It is known that hydrophobic β-sheet structures can be form due to the presence of (GAGAGS) protein sequence in BmSF, upon exposure to physical forces such as vortexing and sonication [51,54]. A rheological analysis demonstrated a temperature/concentration-dependent gelation trend for hydrogels as the SF blend gelled in 20 and 45 min at 37 °C and 20 °C, respectively. Furthermore, a significant difference was observed after gelation between G′ (336.42 Pa) and G″ (11.269 Pa) of the SF blend hydrogel (3% w/v). Viscoelastic behavior, which can lead to withstanding shear strain, was also demonstrated for SF gels as the value of the modulus was constant at a frequency range of 0.1–10 rad s−1 in the region of 0%–10% shear strain. Compression tests of SF hydrogels (3% w/v) revealed a compressive strength of ≈3 kPa and a compressive modulus of ≈7.4 kPa, suggesting mechanical properties of soft hydrogels. In the compression test, the SF blend reached 20% strain to break down and in the cyclic compression of 10% exhibited recovery up to 15 loading and unloading with reversible deformation. This indicated adequate stability for handling with minimal breakage for wound healing. Moreover, in vitro biodegradation analysis showed a significantly higher mass left for SF blend compared to Col gels. After 7 days, 97% and after 14 days, 85% of the initial weight was preserved for SF gel, in comparison with 75% and 65% for Col, respectively. Stable β-sheet networks in addition to the higher molecular weight of SF protein could be responsible for this higher stability [55]. This stability was also confirmed in vivo as SF hydrogel degraded after 4 weeks upon subcutaneous implantation in mice. In a third-degree burn wound model, SF hydrogel showed similar wound healing behavior compared to Col hydrogel. SF was able to firmly attach to ECM, showing comparable wound closure to collagen on day seven, and detaching itself to reveal the underneath native tissue by day 14. At this time point, only 40% of the SF-treated wounds were still open as compared to 80% in the control group. Furthermore, small blood vessels were visible on both SF and Col treated wounds by immunofluorescent staining on day 7. Even when Col hydrogel showed a higher angiogenic potential than SF hydrogels, SF blends still showed a 10-fold increment in vessel density compared to the control group. SF hydrogel also caused a milder immune response as observed by an earlier expression of CD163 (M2 macrophage marker) and a faster decrease in the expression of CD68 (inflammation marker) and TNF-α, compared to Col hydrogel and the control group [51].

The recovery properties of self-healing hydrogels, gel-to-sol, and then sol-to-gel transition make them very attractive for in situ application. An injectable self-healing hydrogel composed of benzaldehyde-terminated polyethylene glycol (BAPEG) and dodecyl-modified chitosan (DCS) was fabricated by Chen et al. for wound healing [56]. The hybrid hydrogels exhibited reversible self-healing enabled by a Schiff's base reaction between the benzaldehyde and amino groups in the polymer composite (Fig. 3D) [56]. The rheology analysis showed that DCS/BAPEG with 1/2 M ratios of -CHO and -NH2 and solid content of 9% exhibited the highest G′ (≈600 Pa) compared to samples with 1/1 and 1/4 M ratios and 13% and 5% solid content. Moreover, the gelation kinetics of the hydrogel showed a consistent G′ until around 100% strain and then collapsed to higher strains for G′, lower than G′′, indicating solid to fluid transition of the hydrogel. In addition, the viscosity of the hydrogel decreased when being injected through a syringe, and then recovered its gel state outside the syringe. Furthermore, oscillatory strain (1% and 300%, 10 Hz frequency) applied to the hydrogel showed that the high strain could cause the gel-to-sol transition by breaking the hydrogel network. Thereafter, when the strain is reduced to low values, the hydrogel can regain its normal initial shape, exhibiting the initial G′ value. This behavior can be attributed to the self-healing capability of the hydrogel due to dynamic equilibrium between the Schiff's base and the amine and the aldehyde reactants, which leads to dynamic uncoupling and recoupling of the bonds within the hydrogel networks. The BAPEG/DCS hybrid hydrogels were able to reach a value of 160 mmHg in a bursting pressure test, suggesting their potential application in vessel bleeding repair. These hydrogels also demonstrated their hemostatic capacity in acute wounds in a severe trauma model in mice. Finally, the BAPEG/DCS hybrid hydrogels with encapsulated vascular endothelial growth factor (VEGF) showed better wound healing in a S. aureus infected full-thickness skin defect than the hybrid hydrogels without VEGF as assessed by wound area, granulation tissue thickness, and the expression of TNF-α and IL-6 [56].

Besides extrudability and ease of in situ gelation, self-healing hydrogels can deliver desired molecules upon injection to the wound site. Another injectable self-healing hydrogel based on a Schiff's base reaction was developed by Wang et al. for wound healing application [57]. In this study, the multifunctional polypeptide-based hydrogel (named as FHE hydrogel) was formed through a reversible Schiff's base reaction between oxidative hyaluronic acid (OHA) and Poly-ε-l-lysine (EPL). FHE hydrogel was capable of releasing loaded bioactive exosomes (for antibacterial purposes) which were loaded through electrostatic bonds with EPL. This pH-dependent release would occur because of the interruption of the Schiff's base bond upon exposure to a weak acidic environment. A full-thickness diabetic wound model was used to assess the healing efficiency of FHE hydrogels. The exosome-loaded FHE hydrogels exhibited complete wound healing by day 21, whilst exosomes, pristine FHE hydrogels, and control groups achieved 76.3%, 64.3%, and 36.3%, respectively. Furthermore, compared to the rest of the treatments, exosome-loaded FHE promoted higher type I and III collagen deposition, cytokeratin and alpha-smooth muscle actin expression, and blood vessel formation [57].

Gao et al. designed an injectable hydrogel, responsive to near-infrared (NIR) light and thermosensitive for drug release into the wound bed [58]. In this study, polydopamine PDA NPs (which could generate local hyperthermia upon exposure to NIR) were loaded with ciprofloxacin (Cip), an antibiotic. Subsequently, the PDA NPs were crosslinked via Schiff's base reaction and/or Michael addition with amine-rich glycol chitosan (GC) to form a NP-Cip/GC injectable hydrogel (Gel-Cip). The shear thinning behavior of the hydrogels, a relevant characteristic for in situ application, was demonstrated when, by an increase in shear rate, the viscosity was reduced (from the range of 103 to several Pa) for both samples. Photo-thermal behavior of samples exposed to different NIR power densities revealed an increasing trend in accordance with laser power density. Upon NIR light irradiation using laser densities of 1.6, 1.0, and 0.5 W/cm2, the resulting temperatures of Gel-Cip were 78.1, 59.7, and 46.8 °C, respectively. NIR light irradiation of 0.5 W/cm2 was further analyzed and showed a remarkable release of Cip compared to Gel-Cip without irradiation. With 3-fold NIR light irradiation during 120 min, ⁓1.4 μg of Cip were released. In contrast, only ⁓0.4 μg of Cip were released from Gel-Cip hydrogels without irradiation. Gel-Cip + NIR exhibited 98.9% bactericidal efficacy in S. aureus-infected mice, where wounds almost disappeared by day 4 (with only 6.4% of surface area unhealed). Gel-Cip + NIR treated wounds also exhibited higher fibroblast proliferation, thicker epidermis, and more blood vessel and hair follicle formation than the rest of the treatments [58].

Injectable hydrogel solutions can also be used to make microgels. Microgels or hydrogel microspheres are widely used in tissue engineering for different purposes, such as encapsulating different functional components (i.e., cells, growth factors, particles, etc.). Microgels provide a micro-domain with a high surface area-to-volume ratio, which enables a more efficient interaction of the hydrogel with the environment [59]. Microfluidic strategies are the most widely used methods for producing microgels due to their ease of use, high output, and ability to carefully control monodispersity and dimension [60]. The majority of aqueous monodisperse droplets are generated by techniques such as T-junctions, flow focusing, and coaxial capillaries, which recruit constant pressure to produce monodisperse droplets in aqueous solutions. Droplet creation occurs as a result of the interaction between the dispersed phase and the continuous phase in these techniques, and pressure sources are positioned at a distance from the droplet-generating mechanism. Active methods, on the other hand, require an external power supply and may use piezoelectric actuators or electric field techniques to create droplets on demand [59]. Microgels have been used for wound-healing applications because of their specific advantages. Chen et al. used a microfluidic electrospray approach to prepare alginate microgels containing encapsulated copper-/zinc-niacin framework cores for wound healing [60]. The bacterial-responsive degradability of the alginate shells endowed the microcapsules with smart, selective, and programmable release of calcium, copper, and zinc ions in response to different levels of infection. The released ions could kill microorganisms, stimulate the release of nutrients, and activate copper/zinc superoxide dismutase (Cu/ZnSOD) to neutralize oxygen free radicals and protect cells from damage caused by oxidative stress. An in vivo study of an infected full-thickness skin defect model showed that microcapsules decrease inflammation and improve angiogenesis, collagen deposition, and phenotypic differentiation of fibroblasts [60]. Cui et al. developed micro-gel ensembles using two different polymers and a Y-channel microfluidic technique [61]. The micro-gel ensembles were composed of a poly(hydroxypropyl acrylate-co-acrylic acid)-magnesium ion (poly-(HPA-co-AA)-Mg2+) gel and a carboxymethyl chitosan (CMCS) gel, both of which can release and absorb hydrogen ions (H+) independently at various stages of wound healing in response to changes in the wound microenvironment. In vitro and in vivo analyses indicated that the micro-gel ensembles allow for persistent wound pH modulation throughout the four wound-healing stages. The micro-gel ensembles keep the wound milieu at a low pH during the hemostasis and inflammatory stages, thereby inhibiting bacterial development. The acidic environment also stimulates Mg2+, which causes adipocytes to proliferate and migrate, building a wall to shield the wound. The micro-gel ensembles then regulate an ideal alkaline environment for hyperplasia and remodeling, allowing fibroblast proliferation and migration to speed skin healing. Collagen deposition, macrophage polarization, and blood vessel development have also been aided by micro-gel ensembles [61].

Compared to preformed hydrogels, injectable hydrogels are easier to handle and minimally invasive to the adjacent tissues. Their fluid nature allows them to fill irregular and deep cavities in the wounds without wrinkling. They can also deliver drugs and cells in a concentrated manner to the wound bed. Moreover, by crosslinking to the tissue interface during their in situ formation, the hydrogels can exhibit appropriate adhesion and engraftment with the host tissue. However, some challenges remain, particularly limitations in cell-friendly extrudability, post-injection fidelity, quick gelation, and safe crosslinking mechanisms that must be overcome to expand and intensify the application of polymers and different bio-additives for in situ forming wound dressings.

2.2. 3D printing

In tissue engineering, 3D printing has evolved to precisely fabricate complex geometries with desired porosities and morphologies with computer-aided design (CAD). Using CAD, it will be possible to create structures that fully match the geometry of any type of wound. Three 3D printing technologies have been mainly used for fabricating 3D structures for biomedical applications, including inkjet-based, extrusion-based, and light-based printing [62]. In the inkjet-based technique, via piezoelectric or thermal actuation, droplets of biomaterials are deposited on a platform in a layer-by-layer manner to form the required structure. Inkjet 3D printers have several advantages, such as a wide biomaterial availability, high speed, and accuracy [63]. In extrusion-based 3D printing, mechanical or pneumatic force is applied to extrude biomaterials through the print-head(s). The absence of heat during the process and a broad range of available biomaterials are the main advantages of extrusive bioprinting [63]. In the light-based techniques, by projecting a desired geometric pattern into a bed of hydrogel precursor using light (UV, laser or visible light), 3D hydrogels can be formed [62,64]. In tissue engineering and regenerative medicine, when 3D printing is implemented via cell-laden materials (bioinks), the technique is called bioprinting. Besides the desired geometry and morphology, bioprinted structures could contain co-culture of multiple cells and growth factors based on the target tissue [65]. Extrusion-based and ink jet-based techniques have been far more common for bioprinting [63]. 3D printed or bioprinted hydrogels have been applied in wound dressing application following two general types of fabrication strategies, prefabrication or in situ formation.

2.2.1. Prefabricated scaffolds

3D printing enables researchers to combine geometrical precision with different strategies to improve structural properties. This can lead the hydrogel to be beneficial in different structural aspects for proper wound healing and skin regeneration. In a study by Xu et al., a 3D printed (via extrusion-based 3D printing) cellulose nanofibril (CNF) hydrogel was fabricated. Two steps of crosslinking were implemented, using Ca2+ solution and chemical crosslinking with 1,4-butanediol di-glycidyl ether (BDDE) [66]. Compressive tests showed an increase in the Young's modulus from 3.45 kPa to 7.44 kPa for CNF 1.0 wt% hydrogels before and after secondary crosslinking. The authors observed that NIH-3T3 fibroblast cells could spread in a 3 kPa environment; cell spreading could be further enhanced on 10 kPa substrates [67]. The stress–strain curve showed excellent elasticity, which could be attributed to the Ca2+/carboxylate crosslinking combined with hydrogen bonding [66]. The microporosity of the hydrogels was enhanced after chemical crosslinking by 1,4-butanediol diglycidyl ether (BDDE), which agrees with the higher rigidity of the hydrogel. Human dermal fibroblasts were seeded in these CNF scaffolds. Results showed good cell survival, adhesion, and even higher proliferation in CNF scaffolds than in 2D cell cultures [66]. Using an extrusion-based low temperature 3D printing, Intini et al., developed a hydrogel scaffolds composed of chitosan, which could support 3D skin cell colonization [68]. The thickness of the scaffold was 2.1 mm and the distance between filaments of a grid-shaped hydrogel scaffold was 200 μm with a precise geometry and homogeneity of pore size (Feret diameter of ≈3.5 μm and ≈5 μm for the surface and within the scaffold, respectively) [51]. Keratinocytes and fibroblasts could properly grow within the scaffolds, filling the holes from bottom to top to colonize all the 3D construct. Additionally, by placing a chitosan film at the base of the 3D scaffold, the retention of the cells inside the hydrogel was significantly increased. Tensile testing revealed Young's modulus (YM) of the samples ≈105 kPa which is similar to the elastic modulus of skin tissue specifically in the volar forearm region [69]. The authors assessed the performance of CNF scafolds in vivo using an impaired wound healing model in streptozotocin-treated rats. Wounds treated with chitosan scaffolds exhibited a reduction of 50% of total wound area after seven days, and epidermis formation as opposed to the control group. Furthermore, 14 days after the initial injury, the group treated with chitosan showed the presence of hair follicles, blood vessels, sebaceous glands, and arrector pili muscles [68].

Hydrogels must be printable to form the desired complex geometries via 3D printing. After being extruded from the nozzle, hydrogel filaments must maintain their shape. If the filaments collapse after printing, the whole structure will be altered and may not fulfill the expected regenerative functions of the designer [70]. For example, poor shape fidelity may derive on the incomplete filling of the wound area. Moreover, in the case of bioinks, hydrogel solutions should provide performance characteristics that could enable high cell survival (post-printing viability) and normal functionality [71]. The rheological characteristics of a hydrogel play the main role in the printability of hydrogels. However, hydrogel printability and fidelity are related to many additional parameters such as innate features of monomer(s), their concentration and molecular weight, the effect of additives, and the degree of gelation. In a study by Pereira et al., a bioink was made of pectin methacrylate (PECMA) with adjustable mechanical and rheological behavior for skin regeneration [72]. This hydrogel bioink, which was designed for extrusion-based bioprinting, could be crosslinked by a two-step strategy including an ionic mechanism using CaCl2 and UV exposure. The printability of the bioink, PECMA 1.5 wt% supplemented with 0, 1, 3, 5, and 7 mM of CaCl2, were assessed. Only solutions with 5 and 7 mM of CaCl2 were able to form stable, neat filaments extruded from the nozzle. Moreover, the printed constructs did not collapse and showed sufficient integrity to sustain subsequent layers. The 5 mM CaCl2-containing solution was selected as the optimal for further analysis due to the lower yield stress needed to induce flow. Ma et al. designed photo-thermal printable hydrogels composed of calcium silicate (Calsil) nanowires, sodium alginate (SA), Pluronic F127, and l(+)-Glutamic acid (Calsil + SA hydrogels) [73]. Additionally, oligomeric proantho-cyanidin (OPC) was used as the crosslinking and photo-thermal agent, which made the rheological and mechanical properties of the hydrogels tailorable by NIR laser irradiation. Moreover, the temperature of the Calsil + SA + OPC hydrogels could be controlled by altering the NIR laser power density and the concentration of OPC. Rheological assessment showed an increased storage moduli G′, (in the range of 102 for Calsil + SA+6%OPC) after 30 min of NIR laser exposure, indicating an increase in hydrogel stiffness. Besides, upon NIR illumination, mechanical spectra of the samples exhibited a ‘strong gel’ character as demonstrated by parallel G′ and G″ curves, in a frequency independent manner [74]. It was also shown by amplitude sweeps on different OPC- containing hydrogels that G′ and G″ improved as a function of OPC concentration and/or the NIR exposure time. The compressive mechanical strength was also affected by the concentration of OPC and/or the exposure to NIR. The mechanical strengths of Calsil + SA, Calsil + SA+4%OPC and Calsil + SA+4%OPC after 30 min of NIR exposure were reported ≈2.5 kPa, 4 kPa and 8 kPa, respectively [73]. The in vivo performance of these hydrogels was assayed in 10 mm skin wounds inflicted on diabetic C57BL/6 mice. The Calsil + SA + OPC group exhibited a higher wound healing rate (with a relative wound area of 0.2% on day 16), than the Calsil + SA (relative wound area of 0.9%) and the blank group (relative wound area of 5.3%). The Calsil + SA + OPC group also developed more vascular networks than controls and a normal collagen arrangement with no signs of inflammation. These results were attributed to the capability of OPC to promote cell proliferation and angiogenesis, as well as the synergistic effect of Si ions in promoting collagen deposition and re-epithelialization. Mixing different types of polymers can adjust rheological behavior, leading to improved printability and fidelity. For example, it is known that the extracellular matrix (ECM) plays a crucial role as mechanical support and as a promoter of cell attachment and cell-cell interactions [75]. Besides, just like in situ injection, extrusion-based bioprinting requires hydrogels with shear thinning properties to flow through the nozzle without compromising cellular viability. In a study by Jorgensen et al., a cell-laden hydrogel construct of cells supplemented with fibrinogen and decellularized human skin-derived extracellular matrix (dsECM) was fabricated via extrusion-based bioprinting [76]. Printability tests revealed that fibrinogen + dsECM materials were suitable for printing applications. Shape fidelity and filament strength were observed to be higher in fibrinogen + dsECM than in controls [76]. The addition of dsECM to the fibrinogen matrix increased the structural stability of the construct after 15 days in culture. Also, a longer structural stability was observed in cell-containing hydrogels than in cell-free ones (≈400 kPa vs 200 kPa). The shear thinning properties of fibrinogen + dsECM were also demonstrated; viscosities of ≈100 Pa s and 0.1 Pa s were determined at low and high shear rates, respectively.

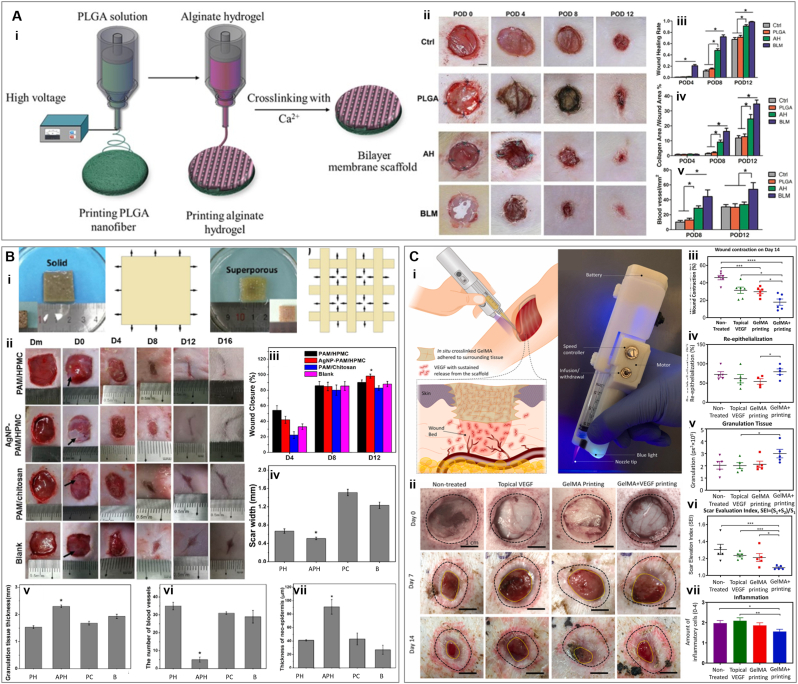

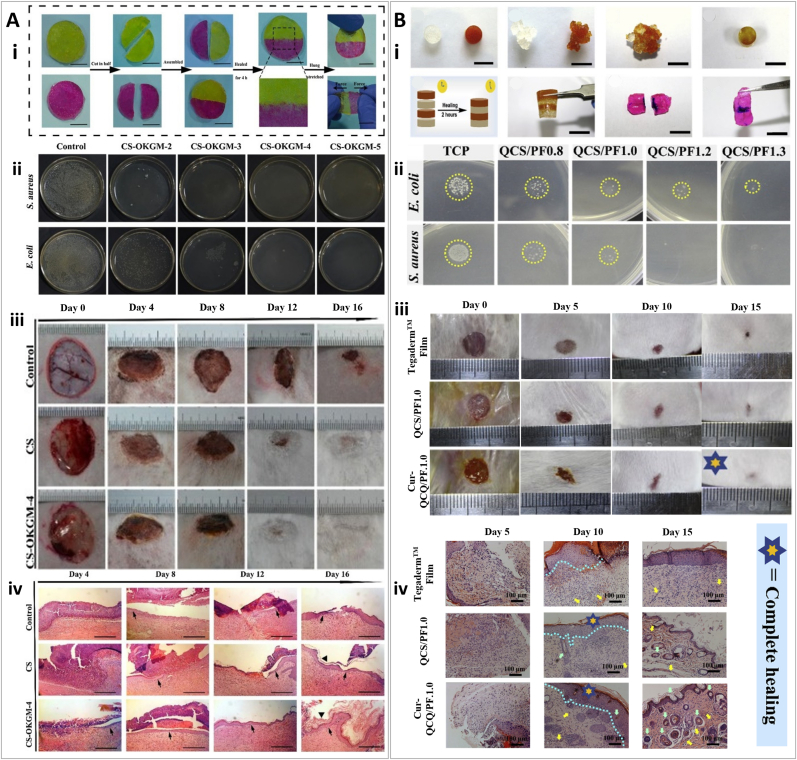

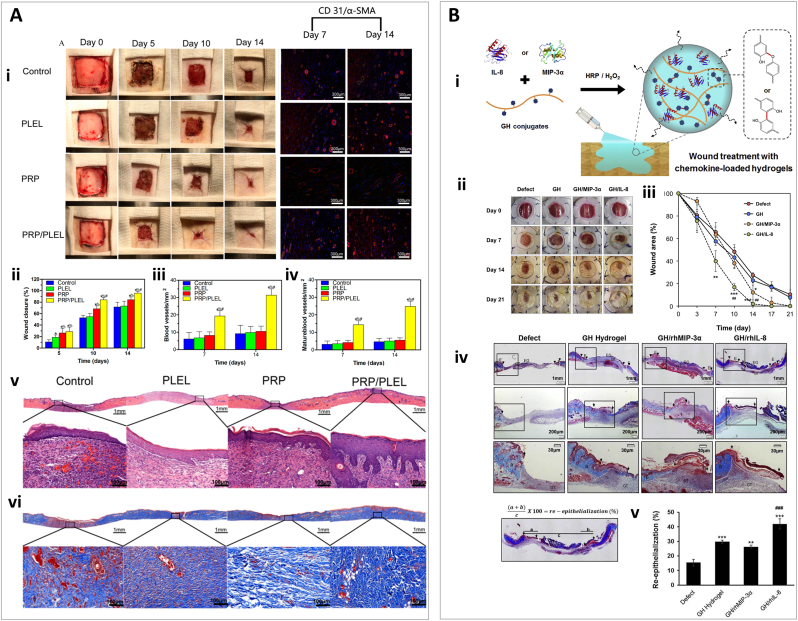

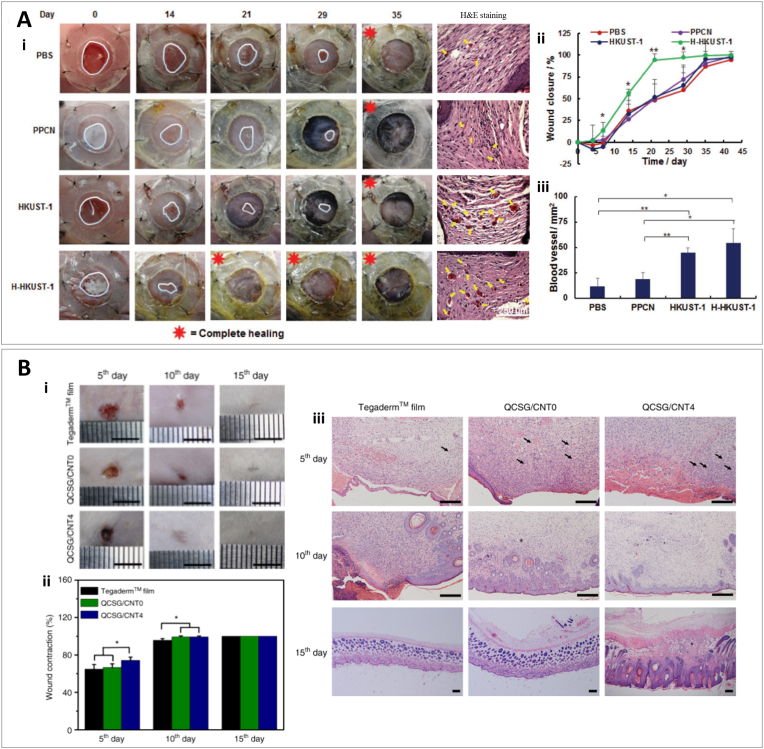

Among different types of 3D printing, digital light processing (DLP) has recently shown great promise in fabricating complex structures with advantages such as fast printing speed and high resolution for biomedical applications. DLP-based 3D printing is based on the movement of the platform containing polymer, being cured by light in a layer-by-layer manner. Zhou et al., developed a 3D printed double-layered skin structure using a biomimetic bioink composed of GelMA, N-(2-aminoethyl)-4-(4-(hydroxymethyl)-2-methoxy-5 nitrosophenoxy) butanamide (NB) linked hyaluronic acid (HA-NB), and lithium phenyl-2,4,6- trimethylbenzoylphosphinate (LAP) as photo-initiator [77]. The authors reported that the mechanical properties of the construct could be adjusted by the presence of HA-NB and by the extent of the reaction between the aldehyde groups and the amine groups of the GelMA chain induced by UV light. Dynamic time-sweep rheology showed very similar gelation points of ≈1.384 s and 1.385 s for GelMA/HA-NB/LAP and GelMA/LAP hydrogels, respectively, upon UV irradiation. In contrast, gelation happened to GelMA/HA-NB without lap after ≈33 s upon UV exposure. The hydrogel was printed in two layers to mimic the epidermal layer (as the dense upper layer) and the corium layer of natural skin (as a porous lower layer containing micro-channels). The aim of the dense upper layer with a thickness of 500 μm has been protection and sustainability against external mechanical stress. On the other hand, the 1.5 mm lower part provided microchannels for proper nutrient transfer, cell migration, and vascularization to facilitate wound healing and skin regeneration. It was seen that increasing the diameter of microchannels has a negative effect on compressive strength. Hydrogels with 200 μm channels showed strength of ≈35 kPa, while samples with 300 μm and 400 μm channels exhibited 30 kPa and 20 kPa, respectively. Moreover, 300 μm and 400 μm channels supported less cell adhesion than samples with 200 μm channels due to a higher surface-volume ration in the later. Therefore, samples with 200 μm microchannels were selected for further experimentation in vivo. For in vivo evaluation, Sprague-Dawley rats with full-thickness wounds were used. The functional living skin (FLS) was implanted into the wounds and a GelMA/HA-NB/LAP pregel was injected and crosslinked to fill any remaining gaps. FLS-treated wounds exhibited faster healing and advanced skin regeneration than controls, showing follicles and sebaceous glands, as well as the lowest inflammatory response [77]. In another study, Yang et al. developed a bilayer membrane scaffold (BLM) by printing poly (lactic-co-glycolic acid) (PLGA) as the outer layer, and alginate as the lower layer for wound healing application (Fig. 4A) [78]. Mimicking skin's dermis and epidermis, alginate and PLGA layers are intended to promote cell function and conserve moisture, respectively. SEM micrographs showed PLGA nanofibers with an average diameter of 857 nm and a microporous alginate layer. The thickness of the layers was also calculated to be nearly 20 μm for PLGA and 100 μm for the alginate hydrogel. In terms of moisture retention, it was shown that alginate hydrogel lost more than 90% of the water in 24 h, while the BLM scaffold maintained its wetness for 72 h. Consistently, the vapor transmission rate was observed to be much lower for PLGA nanofibers than BLM scaffolds. This lower evaporation rate, which can preserve adequate moisture, is advantageous for the wound bed as it can enhance the viability of epithelial cells and promote migration and proliferation. The experiments also revealed that by adding PLGA to the alginate hydrogel, the mechanical properties of the constructs were enhanced (the tensile stress of ≈231 kPa for alginate hydrogels reached≈ 2753 kPa; the elongation at break increased from ≈139 kPa to ≈304 kPa, and the YM was ≈24 kPa and 531 kPa for alginate hydrogel and BLM scaffold, respectively) [78]. Upon comparing the performance between BLM, PLGA, alginate and untreated wounds in Sprague-Dawley rats, the authors observed that BLM treated wounds healed completely by day 12. However, PLGA, alginate, and untreated wounds only achieved 71.5%, 91.2%, and 66.3% wound closure, respectively. Also on the 12th day, BLM treated wounds showed the highest blood vessel density and collagen deposition.

Fig. 4.

3D printing for wound healing application. (A) Poly (lactic-co-glycolic acid) (PLGA)/Alginate hydrogels (i) Schematic process of bilayer PLGA/Alginate membrane scaffold. (ii) In vivo wound healing of blank control, PLGA, alginate hydrogel (AH), and bilayer membrane scaffold (BLM) scaffold on days 0, 4, 8, and 12. (iii) Analysis of wound healing rates for different treatments. (iv) Quantification of collagen with trichrome blue staining. (v) Quantification of blood vessel area by analyzing the CD31-positive area. Reprinted and adapted with permission from Yang et al., 2019 [78]. (B). Polyacrylamide (PAM) based hydrogels (i) Swollen state of solid and 3D printed super porous polyacrylamide PAM/hydroxypropyl methylcellulose (HPMC) hydrogels and their schematic representation. (ii) Healing process of wounds treated by PAM/chitosan, (silver nanoparticle) AgNP-PAM/HPMC, or PAM/HPMC over time. (iii) Closure degree of wounds over time. Quantification of scar width (iv) and newborn granulation tissue (v) by H&E staining, and quantification of blood vessels (vi) and thickness of neo-epidermis (vii) by Mason's trichrome staining. Reprinted and adapted with permission from Wu et al., 2019 [79]. (C) Gelatin methacryloyl (GelMA)-vascular endothelial growth factor (VEGF) printing (i) Schematic illustration of in vivo printing of GelMA-VEGF hydrogel by a handheld bioprinter. The in situ crosslinking process promotes the proper adhesion of the hydrogel to the wound surface. (ii) Representative pictures of the wounds administrated with VEGF, GelMA or GelMA + VEGF on day 7 and day 14 post surgery. (iii) Wound contraction relative to the original wound size. (iv) wound re-epithelialization, calculated based on the area of new epithelium over the total wound area. (v) Amount of granulation tissue. (vi) scar elevation index (SEI) is calculated based on the total area of the healed skin over the area of normal skin below the buildup of hypertrophic scarring. (vii) The degree of inflammation was analyzed by the hematoxylin and eosin (H&E) staining of wound sections to observe the infiltration of inflammatory cells. Reprinted and adapted with permission from Nuutila et al., 2022 [81].

3D printing is not necessarily used to produce a final functional construct for tissue engineering and wound healing purposes. Using 3D printing, sacrificial structures can be made to act as molds to create hydrogels with desired geometrical features. In a study by Wu et al., a 3D-printed silver nanoparticle (AgNP)-containing polyacrylamide (PAM)/hydroxypropyl methylcellulose (HPMC) hydrogel was fabricated via silver−ethylene interaction [79]. To design this superporous antibacterial hydrogel, first a poly (lactic acid) (PLA) template was 3D printed using fused deposition modeling (FDM), and then the hydrogel precursor was cast into the template (Fig. 4B). N, N′-methylenebisacrylamide (MBAM) monomers was used as the main component of the precursors which can interact with Ag ions through the silver−ethylene interaction, leading to polymerization and forming AgNP-loaded nanocomposite hydrogels. Characterization of lyophilized hydrogels without casting in the 3D printed template showed an average pore diameter of 100 μm for PAM, PAM/HPMC, and AgNP-PAM/HPMC hydrogels. However, the PAM/HPMC and AgNP-PAM/HPMC hydrogels exhibited interconnected and open pores compared to the closed pores of the PAM hydrogel, which indicated the importance of incorporating HPMC into PAM to achieve open pores. SEM micrographs of 3D printed superporous hydrogel also showed an average of 100 μm pore size. However, the porosity of these hydrogels is enhanced by ≈ 37% compared to solid hydrogels, reaching around 91%. In addition, the mechanical strength of the 3D-printed hydrogels remarkably decreased (Young's modulus of less than 0.4 MPa) compared to the control solid hydrogels. This mechanical collapse could be related to the large pores of the 3D printed construct, but still in the suitable range for soft tissue engineering and wound healing application [79]. The wound healing ability of the superporous AgNP-PAM/HPMC hydrogels was assessed in a S. aureus infected full-thickness wound model in Sprague Dawley rats. Results demonstrated that even when all groups' wounds were completely closed by day 14, the closure rate was faster with AgNP-PAM/HPMC hydrogels, with a smoother surface and less scarring. It was also observed that this treatment formed the thickest granulation tissue with the smallest scar, as well as the thickest neo-dermis and collagen deposition.

3D printing has brought precision to the architectural design of regenerative constructs or wound dressings. Using this method, it is feasible to make multilayer structures with complex geometry mimicking skin to help wound healing and skin regeneration. However, from the fabrication point of view, there are limitations which should be considered. Printability is the main issue that narrows the range of biomaterials that can be used for 3D printing applications in biomedicine. The challenge is that not only the biomaterial itself, but also the bioactive additives, which are added to the system with the aim of tissue regeneration and wound healing, should not hinder the printability and fidelity properties of the biomaterial. Besides, biomaterials and composites should be shear thinning and have a compatible crosslinking mechanism with 3D printing. Moreover, talking about bioprinting, in which the living cells undergo a printing process, makes these issues even more complicated. Thus, the state of the art in 3D printed wound dressing is to adjust the functional biomaterials beneficial for wound healing (with or without cells), to be a good fit for the printing procedure.

2.2.2. In situ bioprinting

The direct printing of bioinks into the living tissues with the aim of repairing and/or regenerating is called in situ bioprinting (also known as “in vivo” bioprinting) [80]. The use of this strategy for wound healing minimizes the scaffold preparation time. In addition, more complicated geometries can be fabricated according to the curvature and depth of the wound [80,81]. Two main types of in situ bioprinting can be distinguished, robotic [75] and handheld in situ printing [82]. Robotic in situ bioprinting is highly precise and reliable, but needs complex and expensive instruments not yet widely available. Handheld bioprinters have recently shown great promise in dealing with irregular shapes and curvatures commonly found in real tissues, with the least complexity and being user friendly [81].

One of the major challenges of in situ 3D printing is fast delivery and deposition, especially when the intention is delivering cells to the defect site. Commonly, photo-crosslinkable hydrogels are used in in situ (bio)printing. Near instantaneous photo-polymerization could occur upon UV exposure of solutions containing thiolated HA, thiolated gelatin, and poly (ethylene glycol) di-acrylate (PEGDA) [83]. GelMA is also a frequently used material for in situ bioprinting [84,85]. Next, we describe recent examples. In a study by Skardal et al., a UV cross-linkable heparin-conjugated hyaluronic acid (HA-HP) hydrogel was designed. The authors used a homemade bioprinter, equipped with pressure-driven nozzles, to deliver cells and growth factors for wound healing [86]. The photo-polymerization induced crosslink within a few seconds, ensuring efficient encapsulation of cells for proper in situ delivery. Three types of cross-linkers were used in this study in order to modulate structural properties and release kinetics, including linear, four-arm, and eight-arm PEGDA cross-linkers. Results showed a more rapid and cumulatively higher release of bovine serum albumin (BSA) in linear cross-linker HA hydrogels, than that in hydrogels crosslinked with four-arm and eight-arm PEGDA. The microscopic architecture of the hydrogels was also assessed by SEM, indicating an average pore size of ≈100, 50, and 25 μm for linear, 4-armed, and 8-armed PEGDA, respectively. Rheological analysis also exhibited extremely higher G′ for hydrogels crosslinked with 8-armed crosslinker (≈5700 Pa) compared to 4-armed (≈2000 Pa) and linear group (≈200 Pa). Linear crosslinker was selected as the optimal one to have less crosslinking density for more proper delivery of the agents and also an appropriate pore size [86]. The HA-HP hydrogel was used to deliver amniotic fluid-derived stem (AFS) cells to a full-thickness skin wound in a murine model. Many AFS cells appeared in samples taken on day 1, but the amount decreased to 50% on day 7, and by day 14 there were no AFS cells in the harvested tissues. Despite this, HA-HP treated wounds achieved 99.8% closure, whereas HA-treated and control wounds achieved 98.9% and 97.6%, respectively. No significant difference was observed in re-epithelialization, and wound contraction, but the wound aspect ratio was 1.6 and 1.2 for HA-HP and HA treated wounds, respectively, while the control group obtained 2.1. HA-HP + AFS cell treatment also improved vascularization and ECM production and composition.

Besides the fidelity and mechanical stability of 3D printed hydrogels, another obstacle for their application as wound healing constructs is their lack of integration with the defect site. Although in situ printing can help to fill irregular cavities, the adhesive interaction of hydrogel with the wound bed is also vital for the proper engraftment and regeneration of tissue. Recently, Nuutila et al. bioprinted in situ a GelMA hydrogel containing VEGF using a handheld printer (Fig. 4C) [81]. By adjusting the speed range, the deposition rate of the bioprinter was controllable between 4 and 18 μL/s which is a suitable range to cover either small or large wounds. Moreover, the resolution was tunable by changing the printing speed (hand movement) to achieve fiber diameters ranging from 500 μm to 2500 μm (reduction in diameter by increasing the printing speed). The mechanical analysis of the hydrogels showed that the compressive modulus increased by an increase in the concentration of GelMA; the compressive modulus was determined to be ≈ 1.2, 4.1, and 10.6 kPa, for 6%, 9%, and 12% GelMA, respectively. Furthermore, the adhesion strength of the printed samples to porcine skin was ≈3.7, 6.3, and 10.3 kPa for 6, 9, and 12% GelMA, respectively. The robust GelMA-tissue adhesion observed after in situ crosslinking, could be attributed to merely physical interactions (i.e., hydrogen bonding) or even the creation of covalent bonds between the hydrogel and the tissue enabled by the production of free radicals induced by UV in situ exposure [87,88]. Both 9% and 12% GelMA printings showed proper shape fidelity. However, the 9% GelMA formulation exhibited lower stiffness, believed to be appropriate for spreading and infiltration of cells [89], with an average pore size of 9.57 μm as determined using SEM. In addition, this porous structure could provide a gradual long-term release of loaded VEGF from the hydrogel (60% in 350 h). For in vivo assessment, circular dorsal wounds in a porcine full-thickness wound model were treated with topical VEGF, pristine GelMA, GelMA + VEGF or left untreated. GelMA + VEGF displayed the largest contraction (18% contraction), as compared to 30% in pristine GelMA, 31% in topical VEGF, and 46% in untreated wounds. Microscopic evaluation revealed a higher level of wound re-epithelialization and granulation tissue in GelMA + VEGF treated wounds, as well as a significantly lower scar elevation index. The neoepidermis thickness for GelMA + VEGF treated wounds reached 165 ± 28 μm while the second-best treatment reached 130 ± 14 μm with blank GelMA. The GelMA + VEGF treated wounds also contained the fewest number of inflammatory cells as observed by H&E staining. These results support the use of in situ printed GelMA with sustained release of VEGF as an effective treatment for wound healing [81].

The composition of inks could be manipulated for different beneficial purposes besides printability, fidelity, mechanical stability, and integration. Engineering compositions can lead to advantageous properties in terms of wound healing and skin regeneration. For example, formulating a bioink containing interconnected pores up to hundreds of micrometers may enhance cell migration and nutrient transfer in the wound bed. In a study, an emulsion bioink composed of GelMA and polyethylene oxide (PEO) solutions was in situ printed by a handheld bioprinter [85]. These two biocompatible aqueous solutions are immiscible, leading to a bioprinted foam with a controllable pore size ranging between 20 μm and about 100 μm. In this emulsion, after forming the hydrogel matrix upon crosslinking of GelMA, PEO droplets leave the system by immersion of the construct in saline or cell culture medium. Not only could the concentration and ratio of the polymers affect the pore size, but also the mixing time was an influential variable. In a constant concentration of 10 wt% for GelMA and 1.6 wt% for PEO, the pore sizes of ≈105, 63, and 32 μm were achieved for the foams produced using mixing times of 5, 10, and 15 s, respectively. As the mixing time increased, the uniformity of the pores was also enhanced. These porous materials induced higher fibroblast proliferation and spreading than standard GelMA hydrogel [85].

Microfluidic techniques can control single or multiple fluids in microscale channels ranging from tens to hundreds of microns [90]. The combination of microfluidic technologies and traditional 3D printing platforms allows for fine control of the compositional and structural features of tissue engineering scaffolds throughout the printing process [90].