Abstract

Abstract

The prevalent manual destalking of dried red chillies is a labour-intensive, tedious, and unhealthy practice that can cause severe health ailments to the labourers. This study focuses on the design and fabrication of a mechanized system for removing stalks from dried chillies to reduce the drudgery involved in manual operation. The machine’s primary components including hopper, rotating cylinder, triangular bridges, cutting blades, destalked chilli outlet, and stalk outlet were fabricated based on the design considerations and ease of operation. The machine was evaluated considering the independent parameters viz. feed rate, cylinder speed, and cylinder inclination for optimization of its performance using one-factor-at-a-time statistical design. Physical properties of chillies, destalking efficiency of the machine, and the effect of destalking on powder characteristics were determined. Optimal performance of the machine was achieved with the chillies having 8–10% (moisture), 6.5 kg/h (feed rate), 20 rpm (cylinder’s speed), and 3° (cylinder’s inclination) with destalking efficiency of 85–87%. The evaluation of powder characteristics also revealed the prominence of destalking with enhanced colour attributes. The developed machine is compact, efficient, economical, requires less labour and thereby it may encourage its adoption at the farmer’s level and strengthening of the value chain of dried chillies.

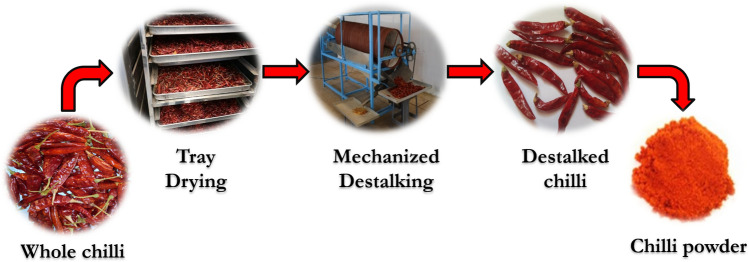

Graphical abstract

Keywords: Destalking, Cylinder inclination, Cylinder speed, Feed rate, Colour

Introduction

Chilli is a significant spice crop all over the world. It is the dried ripe fruit of the genus ‘Capsicum’ called red pepper and constitutes an important commercial crop used as a condiment, culinary supplement, or fresh vegetable. Although chilli is cultivated throughout the world, bulk production is concentrated in Asian countries. The major chilli growing countries are India, Myanmar, Bangladesh, Pakistan, Thailand, Vietnam, Romania, China, Nigeria, and Mexico. India is the world leader in chilli production, having a 50–60% share in global production. In India, chillies are grown on about 7.32 lakh hectare area with the production of 19.88 lakh tonnes during 2020–2021.

Owing to the unique pungent characteristic of Indian chillies, their demand is continuously increasing from the countries like China, Mexico, Thailand, Malaysia, Sri Lanka, Indonesia, USA, UK, Singapore, Nepal, Germany and Sweden. Chilli is the largest exported single spice from India and accounts for 38% of the volume and 31% of all exported spices (Anonymous 2021). India exported about 6.01 lakh tonnes of red chillies worth about 1144.43 million USD (₹ 8430 crores) in 2020–2021. Chillies are exported as whole, stem/stalk-less, powder, dried, pickled, and oleoresins.

Chillies generally contain about 53% pericarp, 7% stalk and calyx, and 40% seeds, with modest variation among the cultivars. The maximum tolerance limit for pods with stalk shall be 3% by count and pods with calyx 7% by count applicable for all the grades and varieties (Satyanarayana and Sukumaran 2002). Stem and calyx are considered as foreign matter and will either reduce the value of processed chilli or render it unmarketable. The stem is one of the significant contaminants during value addition as it might add fungi, mites, and fibre materials to the processed products, and hence, destalking is considered of paramount importance. Destalking is referred to as the process of removal of stem and calyx from fresh/dried chilli pods (Herbon et al. 2010). The removal of the stalk is considered mandatory by the buyers for the industries where chillies are preferred for export purposes (Satyanarayana and Sukumaran 2002). In some instances, for powder making, the malpractice of not removing the stalks has been followed at the commercial scale, which increases the powder yield (≤ 25%) and simultaneously diminishes the colour attributes (Bosland and Votava 2000).

Chile peppers are extensively cultivated in the State of New Mexico, and it is reported that manual destalking is prevalent for primarily removing stem and calyx from the fresh peppers. This manual destalking needs to be overcome as the adoption of improved destalking equipment is considered helpful for the mechanical harvesting of peppers (Wall et al. 2003). Therefore, researchers have developed a series of mechanical destalkers with variable working mechanisms (mechanical/electromechanical) for destalking of green peppers. Such mechanical destemmers have the potential to be adopted by industries (Herbon et al. 2009, 2010; Walker and Funk 2014). It is important to note here that many such machines are suitable only for the destalking of fresh or green chillies.

However, in India, predominantly, the destalking of dried red chillies is prevailing rather than fresh green chillies. This destalking is being performed at the trader’s level wherein women workers are engaged who can manually destalk 12–15 kg dried chillies/day with the labour charge of 0.20–0.27 USD/kg (Balakrishnan et al. 2013). Approximately 10.6 million labour days are required to handle the country’s total chilli production, and about 4.34 million USD expenditure is incurred annually for this purpose (Satish Kumar 2016). This manual process is unhygienic, drudgery, time-consuming, cumbersome, and causes serious health hazards to the engaged workers.

Prabhavathi et al. (2021) conducted a survey to identify the health prospective of women labourers engaged in manual destalking and reported that the majority of the women can remove stalks from ≥ 6 pods simultaneously and can destalk ≥ 6 kg/day of dried chillies. The destalking causes injuries like scars and itchiness in fingers, pain in hands, with discomfort in carrying daily household responsibilities. This substantiates the emerging need for mechanized destalking and the development of protective, comfortable, and low-cost hand gadgets.

In recent years, intending to mechanize the destalking of fresh/dried chilli, researchers have reported the development and performance evaluation of such machines. Literature confirmed that there had been various techniques/machines developed where the principles of mechanical cutting, machine vision, and laser sensors are employed to mechanize the destalking process. Mangraj et al. (2001) developed a manually operated batch type (0.25 kg/h) fresh red chilli destalking machine integrated with a punching system in which stalks were separated upon application of pressure. Knorr and Victor (2008) have developed chilli destalker using laser sensors and machine vision algorithms where for recognition of chilli, shoulder and stem are made to generate a controlled signal and initiate destalking. Herbon et al. (2010) have reported chilli destalking machines based on different mechanisms such as puller de-stemmer (62% efficiency), angled belt de-stemmer (35% efficiency), mechanical positioning de-stemmer (54% efficiency), and cup de-stemmer (73% efficiency). Gunes and Badem (2016) demonstrated software algorithms for aligning and destalking red pepper. Phong et al. (2017) developed a semi-automatic destalking machine and reported the destalking rate (88.37%), damaging rate (6.34%), specific power consumption (20.14 Wh/kg), and capacity (13.89 kg/h) at belt conveyor velocity (0.13–0.18 m/s).

In addition to the attempts executed for destalking, few authors have also worked on the extraction of seeds from chillies. Balakrishnan et al. (2006) have developed a continuous type chilli seed extractor machine (400 kg/day) and reported seed extraction efficiency (94%) and seed germination (92%). Borkar et al. (2015) have developed an integrated chilli seed extractor-seed grader (100–125 kg/h) and recorded extraction-grading time (55 min/100 kg), seed extractability (98.71%), and grading efficiency (86.20%). Another chilli seed extractor machine was developed at Anand agricultural university, (Gujarat, India) having capacity of 60–70 kg/h, and seed recovery of 98% (Anonymous 2019).

It is evident from the literature that the above-described machines were specifically designed for the destalking of fresh chillies. Due to the inherent variation in cultivars, moisture content, and morphological characteristics, the developed mechanisms are not suitable for destalking of dried chillies. The literature also corroborates a paucity of scientific documentation related to mechanized destalking. Therefore, keeping in view the above facts and foreseeing the requirement of a continuous and low-cost destalking machine, the present investigation was taken up to develop a mechanized system for stalk removal of dried chillies. In addition, the authors have performed a comparative analysis of powder quality characteristics from whole and destalked dried chillies.

Materials and methods

Dried red chillies (cv. Guntur) were procured from the local market of Abohar (Punjab), India. Cleaned chillies were dried in a single layer using the cabinet dryer (M/s Macro Scientific, 40–50 kg capacity) at 50 ± 5 °C (Doymaz and Pala 2002) to bring the moisture content from 12–14% to 8–10% before feeding into the machine. Chillies were dried using the cabinet dryer to 7, 9, and 11% moisture content to identify the appropriate moisture range for effective destalking. The reagents viz. acetone, petroleum ether, sodium sulphate, etc. used for the biochemical analysis were of analytical grade.

Physical characteristics

Moisture content was determined by keeping the samples in a hot air oven (M/s Perfit, max. temperature 250 °C) at 60 ± 2 °C for 24 h (AOAC, 1990). The spatial dimensions specified as length (L), width (W), and thickness (T) of whole chilli and its corresponding fractions were measured using digital vernier calipers (M/s Mitutoyo, Japan, ± 0.01 mm) of randomly selected 50 chilli pods (Mahawar et al. 2019, 2020; Bibwe et al. 2022; Altuntas and Mahawar 2022). The weight of the chillies and their fractions (stalk, calyx, seeds) was determined using a digital balance (M/s Goldtech, India, ± 0.001 g).

Stalk cutting force

The dried chillies of 7, 9, and 11% moisture content were subjected to the measurement of the force required for cutting the stalk and the corresponding deformation using a texture analyzer (M/s Stable Micro Systems, UK). The blade set probe equipped with a double bevel blade was used with the calibration settings of test speed (1 mm/s), pre-test speed (1 mm/s), post-test speed (10 mm/s), probe height prior to the test (10 mm) in compression mode, time (1 s) and data acquisition rate (200 pps). The test was conducted by placing chilli on the bottom plate so that the blade would cut the stalk in almost two halves. The test was conducted with pre-set conditions to record the cutting force. A total of 10 samples were used for each moisture content and the average value was reported.

Description of chilli destalking machine

The destalking machine was designed to cut the stalks without damaging the calyx. In the preliminary trials, it was observed that pulling of the stalks was not effective because breakage took place. On the contrary, the cutting phenomenon while holding the chilli resulted in effective destalking. Thus, it was essential to orient the chillies so that a knife may come in contact with the stalk near the calyx. Therefore, it was kept in mind that a complete stalk may pass through a plate having a slot (> 4 mm width), whereas the calyx portion may remain on the other side, and thus, a knife may cut the stalk without damaging the calyx. Further, based on the stalk length, it was decided to have a slot length of around 50 mm to facilitate the stalk protrusion through the slot once it comes in contact with the slot.

It was essential to orient the chilli so that the stalk should come in contact with the slots while flowing in bulk. The movement or rotation of the chillies in a horizontal plane with any kind of agitation may not work because it always remains in the rest position, and hence the stalk would not come in contact with slots. Therefore, the rotation of chilli in the vertical plane with a cylinder with slots was considered. The chilli will remain stationary and in contact with the rotating surface during upward motion into the vertical plane due to the centrifugal force. The following conditions expressed in Eq. 1 and 2 may prevail when the chilli rotates in a vertical plane:

- Chilli will rotate with cylinder when

1 - Chilli will leave the cylinder surface before contact point rotates π radian in vertical plane when

where ω is rotation speed of the cylinder (rad/s); g is the acceleration due to gravity (m/s2), and R is the radius of the cylinder (m).2

In case (a), the chilli will contact the cylinder surface and rotate at the speed of the cylinder moving in the vertical plane without falling. In case (b), the chilli may fall due to gravity when ɷ is sufficient to rotate the chilli in contact with the cylinder surface between π/2 and π radian rotation in the vertical plane. In this case, the stalk may not come in contact with the slots. When ‘ω’ is sufficient to keep the chilli in contact with the cylinder surface up to π/2 rad rotation in the vertical plane, the chilli will slide along the cylinder periphery and the possibility of contact between slots and stalks may be increased. Thus, the stalk may move out of the slot, and the cutting force may be applied.

The chilli will be in a rest position and may orient in any direction while moving in the vertical plane. Therefore, a provision of triangular projections between the slots may orient the chilli in the direction of motion, and chances of contact between stalks and slot may increase. The projections may also provide the necessary friction to keep chilli in contact with the cylinder surface. While sliding down along the periphery, the stalk will slide out of the slot and calyx remain inside the cylinder due to its larger diameter. The rectangular slots from which the stalk protrusion occurs facilitate stalk cutting by exposure towards a series of equidistant cutting blades placed at the outer periphery. Keeping the above theories and mechanisms in view, the destalking machine was envisaged as a slotted cylinder rotating in a vertical plane keeping triangular bridges between the slots. Cutting blades were mounted outside the periphery at π/2 rad height in the vertical plane.

The properties viz. moisture content of chilli and stalk, length and width of chilli, length and thickness of stalk, stalk cutting force were considered while designing the machine components. The fabrication materials were selected based on the function of the component, availability, and ease of fabrication. Further, the machine was designed to have sufficient strength, sturdiness, and stability while also considering cost-effectiveness. The overall machine dimensions were decided to facilitate easy workability, and the components were fabricated for easy replacement, repair, and maintenance.

Machine description and specifications

The principal components of the machine were feed hopper, vibrator, cylinder, triangular projections, stalk outlet, destalked chillies outlet, pulleys, rectangular slots, central shaft, motor, cutting blades, and stalk collection chute.

Hopper’s description and its design

An open hopper was designed in a trapezoidal shape having dimensions (460 × 540 × 180 mm) using a stainless steel sheet (20 gauge) attached with a vibrator (1320 rpm, 80 W) and flexible springs (04 No.s) for continuous feeding. Chillies were fed constantly as per the desired feed rate using a tray, and the curved bottom assisted in the uniform and smooth flow into the cylinder. The angle of inclination was considered important for uniform feeding of chillies and the angle was calculated using Eq. 3:

| 3 |

where θ is Angle of inclination; µ is Coefficient of static friction between chilli and steel = 0.5018 (Jalgaonkar et al. 2017).

Thus, .

Rotating cylinder's description and its design

It was a specialized designed rotary structure having slots (4 mm wide) throughout its circumference. The cylinder was supported on a central shaft (30 mm diameter and 2060 mm length) rotating clockwise to ensure adequate strength and stiffness while power transmission under various operating circumstances. The cylinder was inclined towards the outlet to attain smooth movement while also maintaining the optimum retention time of chillies for destalking. The cylinder was fitted with multiple triangular bridges (46 No.s, 300 mm length) made of polyurethane foam fitted hemi-spherically over the inner surface throughout the length with a uniform spacing of 30 mm between the two bridges. Based on the envisaged capacity, the length of the cylinder was taken as 1870 mm for cutting and ensuring a single-layer flow of chilli. The volume and diameter of the rotating cylinder were calculated using Eqs. 4 and 5:

Volume

| 4 |

where V is cylinder's volume, m3; M is mass of chilli processed per day, kg (Assumed as 45 kg capacity); ρ is bulk density of chilli, kg/m3, (ρ for cv. Guntur is 130 kg/m3 (Jalgaonkar et al. 2017)).

Thus, .

Diameter

The following equation was used to calculate the diameter of the rotating cylinder:

| 5 |

where D is cylinder's diameter, m; V is cylinder's volume, m3; L1 is cylinder's length, m.

Therefore,

Outlets description

There were two individual outlets for the collection of destalked chillies and stalk with seeds. A collection chute was fitted below the cylinder at 20° from the horizontal to facilitate the collection of stalks and seeds. Further, a screen was fixed at the outlet such that the stalk collected as overflow and seeds were collected as underflow. The destalked chillies were carried forward and collected in a separate outlet. Feeding of chillies and the removal of destalked chillies, stalks and seeds were done in a continuous mode.

Power transmission mechanism

The machine was powered by a motor (M/s Crompton Greaves, India, 750 W), and the required rotation speed was achieved with a suitable combination of V-belts and pulleys having variable diameters. The driven pulley diameter (D2) was calculated from the following Eq. 6:

| 6 |

where D1 and N1 are the diameter and speed (rpm) of the driving pulley, D2 and N2 are the diameter and speed (rpm) of the driven pulley.

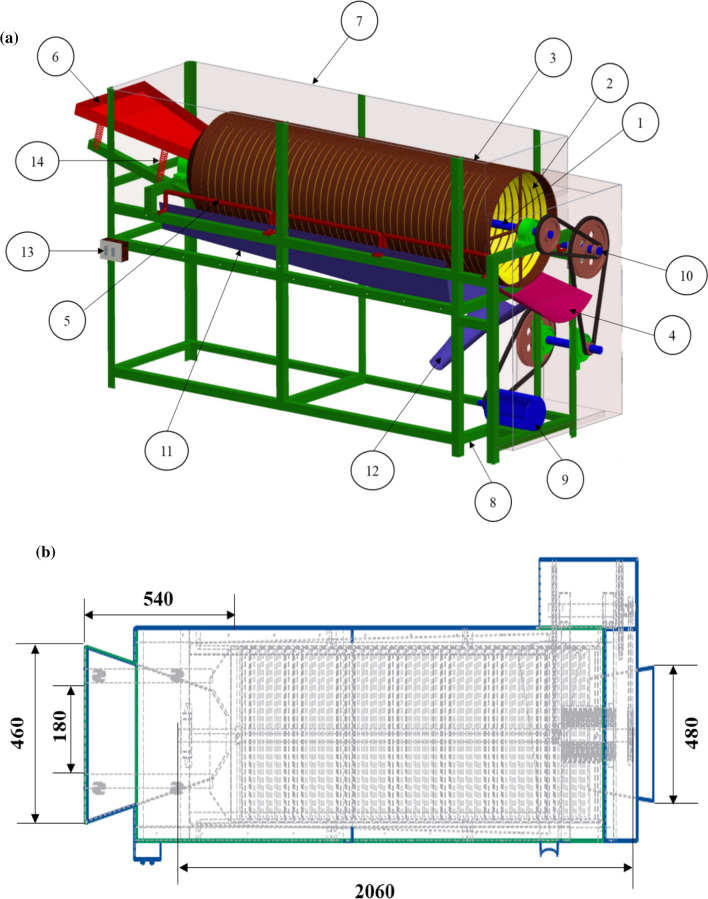

The components and detailed specifications of the developed machine are listed in Table 1. The projection views showing different machine components with dimensions are presented as Fig. 1a (isometric view), 1b (top view), 1c (side view), and 1d (front view), respectively.

Table 1.

Components and specifications of the chilli destalking machine

| Component | Material | Specifications |

|---|---|---|

| Feed hopper | Stainless steel (304) | Trapezoidal in shape with curved bottom with dimensions (460 × 540 × 180 mm), fitted on a vibrator (220 V, 50 Hz, 80 W, 1320 rpm) for uniform flow |

| Rotating cylinder | Mild steel sheet | Core part of the machine with diameter (480 mm) and length (1870 mm) |

| Central shaft | Mild steel rod | Cylinder was embedded on a central shaft (30 mm diameter, 2060 mm length) supported on bearings (P 206) |

| Cutting blades | Mild steel hexa blades | 4 No. s fitted on a sturdy assembly along the cylinder circumference |

| Triangular bridges | Polyurethane foam (PUF) | (46 No., length 300 mm), fitted hemi-spherically over the cylinder surface throughout the length with a uniform spacing of 30 mm between the two bridges. Forming a triangle with an angle of 60° from the base |

| Rectangular slots | - | 3–4 mm width from which stalk protrusion takes place |

| Pulleys | Standard | Pulleys of 305 mm, 254 mm, 204 mm, 76 mm, 51 mm were used to achieve desired rotation speed |

| Stalk collector | Galvanized iron | Fitted below the cylinder at 20° from the horizontal |

| Destalked chilli outlet | Stainless steel (304) | Inclined for easy flow of chillies |

| Motor | Standard | 1 HP motor (1440 rpm) |

| Bearings | Standard | Pillow block ball bearings with bore 30 mm (P 206) |

Fig. 1.

a Isometric view of the chilli destalking machine showing different components i.e. 1. Central shaft 2. Triangular projections 3. Cylinder having rectangular slots 4. Destalked chillies outlet 5. Cutting blades 6. Feed hopper 7. Machine cover 8. Machine frame 9. Motor 10. Power transmission system 11. Stalk collection chute 12. Stalk outlet 13. Starter 14. Vibrator. b Top (Plan) view of the chilli destalking machine (All dimensions are in mm). c Side view of the chilli destalking machine (All dimensions are in mm). d Front view of the chilli destalking machine (All dimensions are in mm)

Performance evaluation

It was noteworthy to observe that the higher moisture content of chillies (> 12%) makes the stalk soft and flexible, and therefore cutting off the stem does not take place properly. On the contrary, chillies with moisture content (< 8%) are brittle, resulting in higher breakage during destalking. The developed machine was evaluated with three independent parameters i.e. feed rate (FR) (4.5, 5.5, 6.5, 7.5 and 8.5 kg/h), cylinder’s speed (CS) (10, 15, 20, 25 and 30 rpm) and cylinder’s inclination (CI) (2°, 3°, 4°, 5° and 6°). The range of variables was decided on the basis of preliminary experimental trials. The performance was determined in terms of destalked chilli (DSC), unstalked chilli (US), partially stalked chilli (PSC), and machine efficiency (ME) using the Eqs. 7, 8, and 9, respectively:

| 7 |

| 8 |

| 9 |

Optimization of machine parameters

Preliminary experiments corroborated that FR was the significant process affecting parameter than CS and CI. Therefore, initially, the experiments were conducted for optimizing the FR, and based on the observations, 6.5 kg/h was selected for further investigations. A total 25 number of experiments were conducted at varied CS and CI for their corresponding optimization and based upon the results, the best working range of the operational variables were observed. The optimization goal was to maximize destalking efficiency and achieve minimum unstalked/partially stalked chillies. Validation experiments further substantiated the optimized machine parameters.

The fabrication cost of the developed machine was calculated by considering the quantum of material utilized. Cost of the materials like mild steel, stainless steel, galvanized iron, belt, pulleys, bearings, and motor, etc., including labour cost, were considered.

Effect of destalking on quality characteristics

After optimizing machine parameters, destalked chillies were pulverized into powder using a mixer grinder (M/s Philips, 750 W). The powder characteristics were compared with whole chillies powder in terms of a* value, total extractable colour (TEC), and total carotenoid content. The pulverized powder of both samples was passed through 500 µm sieve (IS 2322:2010) and packed in zip-lip low-density polyethylene pouches until further analysis.

Colour parameters were measured using a Hunter colourimeter D25 optical sensor (M/s Hunter Associates Laboratory, USA), in which a* value represents the greenness/redness. TEC was measured as per the American Spice Trade Association units (ASTA) analytical methods (Chetti et al. 2014). The absorbance of the sample was recorded at 460 nm in UV–VIS dual beam spectrophotometer (M/s Labomed, Inc., USA). TEC was computed using the following Eq. 10:

| 10 |

Total carotenoids content was determined by the method described by Ranganna (1986) using the following Eq. 11:

| 11 |

Statistical analysis

One-factor-at-A-time design was adopted for conducting the experiments. FR was the most critical factor in determining the length of the cylinder, and therefore it was optimized initially, followed by the optimization of CS and CI. The data obtained from performance evaluation and other quality parameters were subjected to univariate analysis in a general linear model for analysis of variance (ANOVA) at 5% level of significance. Duncan's Multiple Range Test determined significant differences among the means at the 95% confidence level using SPSS 16.0 software. The destalking parameters viz. DSC, US, PSC, and ME were presented as mean ± standard deviation of three replications. Similarly, the average values of three observations of powder characteristics (a* value, TEC, and total carotenoids content) were presented.

Results and discussions

Physical properties

The moisture content of chilli was 9 ± 0.50 (% w.b.), and the weight of whole chilli, chilli with calyx was 1.04 ± 0.27 g and 1.01 ± 0.27 g, respectively. Separation of the whole chilli into pericarp, seed, calyx and stalk showed that pericarp constituted (46%), seed (44%), calyx, and stalk collectively (8–10%). The length of chilli with and without stalk was 113.48 ± 9.53 mm, and 86.20 ± 8.80 mm, respectively, whereas the width of chilli was 13.52 ± 2.68 mm. The length and thickness of the stalk were 27.28 ± 3.93 mm and 2.64 ± 1.17 mm, respectively. The force required to cut the stalk at 9% (w.b.) was observed to be 24.24 ± 1.86 N.

The findings were in the range of reported values in the literature for other chilli varieties where, Satishkumar and Basamma (2015) reported 100.3 mm (size), 22.87 (L*), 10.89 (a*) and 10.14 (b*) of dried chilli (cv. Byadgi). Jalgaonkar and Mahawar (2017) reported the corresponding single chilli weight and length of Byadgi, Guntur, and Guntur Brown were 1.35 g, 0.85 g, 1.37 g, and 95.91 mm, 113.06 mm, 113.21 mm, respectively. The stalk and seed content was highest in Byadgi (10.97% and 51.51%) followed by Guntur Brown (6.98% and 30.81%) and Guntur (7.08% and 13.96%).

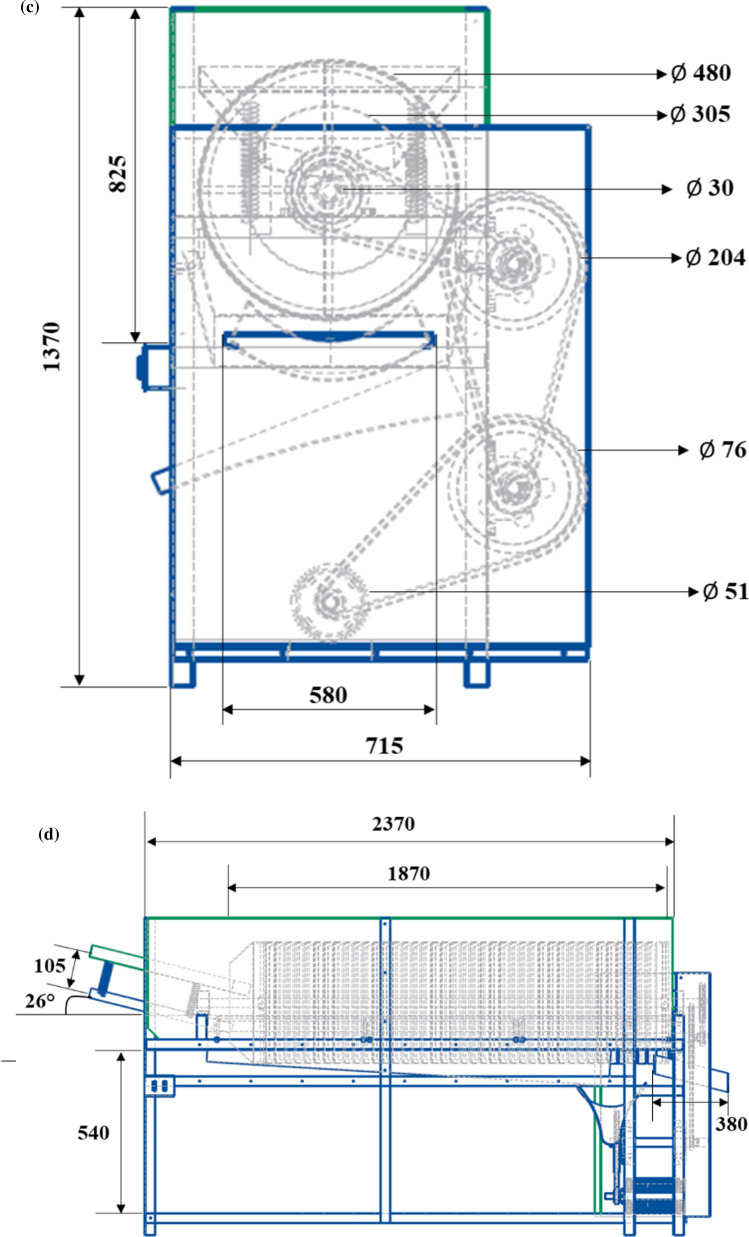

Cutting force

Typical cutting force–deformation behaviour of chilli stalks at different moisture contents is shown in Fig. 2a. The cutting force at the bio-yield point of the stalks having 7, 9 and 11% moisture contents was 17.44 ± 2.13 N, 25.49 ± 2.77 N, and 16.68 ± 2.37 N, respectively and the corresponding deformation at the bio-yield point was 0.96 ± 0.16 mm, 1.74 ± 0.18 mm, and 4.15 ± 0.38 mm, respectively. The cutting force of the stalks at 7% and 11% moisture contents did not differ significantly (p ≥ 0.05), whereas the cutting force at 9% moisture was significantly (p < 0.05) higher. The deformation at the bio-yield point of stalks increased significantly (p < 0.05) with increasing moisture content. At lower moisture content (7%), cutting of the stalks took place at minimal deformation of stalks (< 1 mm deformation), whereas, at higher moisture (11%), stalk cutting was observed after large deformation of the stalks (> 3.5 mm).

Fig. 2.

a Force deformation behavior of chilli stalks at different moisture content. b Representation of chillies and powder with differential stalk percentage

The work of shear (area under the curve) for cutting of the stalks at 7, 9, and 11% moisture contents were 7.77 ± 1.11 N.mm, 18.97 ± 1.28 N.mm, and 28.02 ± 2.09 N.mm, respectively. The variations of force and work of shear with moisture content may be expressed by the following relationships mentioned as Eqs. 12 and 13, respectively:

| 12 |

| 13 |

where Fc is force to cut the stalks (N); MC is moisture content of stalks (%, wet basis); and Wc is work of shear (N-mm).

The cutting force increased with moisture and then decreased, whereas the work of shear increased linearly with the increase in moisture content. Thus, at lower moisture values, the cutting blade might cut the stalk protrusion immediately at the point of contact. At higher moisture levels, the cutting might not occur because the stalk protrusion would pass the cutting blade after deformation as the chilli would move upward with the cylinder surface. Therefore, the moisture content of about 9% was considered suitable for efficient destalking of chillies.

Performance evaluation and optimization of the process parameters

The performance of the machine significantly depends on the FR, CS, and CI and their corresponding optimization was performed sequentially to minimize the number of experiments.

Feed rate

Initially, it was imperative to optimize the feed rate, and thus, experiments were conducted at different FR (4.5–8.5 kg/h) by operating the machine at 20 rpm (CS) and 3° (CI). The results (Table 2) showed that maximum destalked chilli percentage (84.63%) with minimum percentage of unstalked chillies (4.15%) and partially stalked chillies (5.28%) were observed at 6.5 kg/h. In addition, the highest machine efficiency (90.57%) was achieved, which substantiated the selection of 6.5 kg/h for advanced trials. It was also observed that feeding chillies at 6.5 kg/h provided sufficient time for stalk protrusion, and consequently stalk cutting as well as machine efficiency was amplified. The comparative results along with statistical significance are reported in Table 2.

Table 2.

Effect of feed rate on destalking parameters of dried chillies

| FR (kg/h) | 4.5 | 5.5 | 6.5 | 7.5 | 8.5 | F value | P value | CV |

|---|---|---|---|---|---|---|---|---|

| DSC (%) | 75.75 ± 0.60b | 73.74 ± 0.95c | 84.63 ± 0.82a | 69.26 ± 0.72d | 64.31 ± 0.72e | 334.99 | 0.000S | 0.98 |

| US (%) | 12.78 ± 1.11a | 12.01 ± 0.92ab | 4.15 ± 0.40d | 8.76 ± 0.32c | 10.70 ± 0.95b | 44.27 | 0.000S | 9.26 |

| PSC (%) | 5.51 ± 0.64c | 7.56 ± 0.79b | 5.28 ± 0.38c | 16.97 ± 1.01a | 18.30 ± 0.95a | 191.40 | 0.000S | 7.46 |

| ME (%) | 81.72 ± 1.06b | 80.43 ± 0.86b | 90.57 ± 0.93a | 74.27 ± 0.77c | 71.00 ± 1.04d | 156.71 | 0.000S | 1.31 |

Values are mean ± standard deviation of three replications; mean in the same row followed by same superscript letter are not differed significantly at P ≤ 0.05; SSignificant; FR feed rate, DSC destalked chilli, US unstalked chilli, PSC partially stalked chilli, ME machine efficiency, CV coefficient of variation

Cylinder inclination and cylinder speed

The next set of experiments was executed to optimize the cylinder inclination as well as cylinder speed. Therefore, extensive experiments were conducted at 6.5 kg/h FR and at different combinations of CS (10–30 rpm) and CI (2°–6°). The results (Table 3) corroborated that 20 rpm (CS) and 3° (CI) resulted in maximum destalked and minimum unstalked/partially destalked chilli. It may be attributed to the reason that upon consequent feeding at higher CS (> 20 rpm) and higher CI (> 3°), the chillies slide down rapidly through the rotating cylinder. This resulted in less retention time for the stalk protrusion from the slot, yielding a higher quantum of unstalked chillies at the outlet. On the contrary, subjecting the chillies to lower CS (< 20 rpm) and lower CI (< 3°), the required onward movement of chillies in the cylinder was not attained, and accordingly, the retention time inside the cylinder also increased, leading to diminished destalking efficiency.

Table 3.

Effect of various cylinder speeds at constant feed rate (6.5 kg/h) on destalking parameters

| CS (rpm) | CI (°) | DSC (%) | US (%) | PSC (%) | ME (%) |

|---|---|---|---|---|---|

| 10 | 2° | 68.53 ± 1.24bc | 3.64 ± 0.07c | 16.57 ± 0.33c | 79.79 ± 2.52b |

| 3° | 75.55 ± 1.55a | 2.86 ± 0.06e | 9.32 ± 0.19e | 87.82 ± 1.60a | |

| 4° | 68.08 ± 1.45bc | 3.26 ± 0.05d | 18.07 ± 0.25b | 78.68 ± 0.17bc | |

| 5° | 66.51 ± 0.55c | 5.14 ± 0.15b | 19.13 ± 0.59a | 75.73 ± 2.12c | |

| 6° | 68.61 ± 0.23b | 6.80 ± 0.70a | 15.19 ± 0.28d | 78.01 ± 1.02bc | |

| F value | 28.97 | 1058.90 | 352.55 | 21.984 | |

| P value | 0.000S | 0.000S | 0.000S | 0.000S | |

| CV | 1.63 | 1.99 | 2.27 | 2.13 | |

| 15 | 2° | 74.75 ± 1.42b | 7.00 ± 0.08d | 7.00 ± 0.04c | 86.00 ± 2.79ab |

| 3° | 79.27 ± 1.57a | 3.71 ± 0.08e | 6.87 ± 0.10c | 89.43 ± 1.15a | |

| 4° | 79.14 ± 0.35a | 9.45 ± 0.13b | 5.84 ± 0.24d | 84.71 ± 2.49b | |

| 5° | 69.88 ± 1.01c | 11.47 ± 0.22a | 11.11 ± 0.30b | 77.42 ± 1.98c | |

| 6° | 59.63 ± 2.24d | 8.55 ± 0.19c | 16.500.45a | 74.95 ± 1.65c | |

| F value | 94.24 | 1099.22 | 814.6 | 25.22 | |

| P value | 0.000S | 0.000S | 0.000S | 0.000S | |

| CV | 2.01 | 1.89 | 2.84 | 2.54 | |

| 20 | 2° | 76.36 ± 1.06c | 5.35 ± 0.22d | 10.10 ± 0.11a | 84.55 ± 1.84b |

| 3° | 84.95 ± 1.56a | 4.15 ± 0.09e | 5.28 ± 0.06d | 90.57 ± 2.54a | |

| 4° | 79.39 ± 0.79b | 6.91 ± 0.15c | 6.93 ± 0.14c | 86.16 ± 1.81b | |

| 5° | 65.10 ± 1.59e | 13.12 ± 0.29b | 9.51 ± 0.20b | 77.37 ± 1.49c | |

| 6° | 69.98 ± 1.51d | 13.80 ± 0.29a | 9.66 ± 0.07b | 76.54 ± 0.67c | |

| F value | 101.83 | 1227.87 | 811.51 | 34.11 | |

| P value | 0.000S | 0.000S | 0.000S | 0.000S | |

| CV | 1.78 | 2.56 | 1.54 | 2.14 | |

| 25 | 2° | 72.95 ± 2.14b | 7.36 ± 0.09d | 10.63 ± 0.25c | 82.01 ± 1.50b |

| 3° | 77.07 ± 0.36a | 5.51 ± 0.10e | 8.64 ± 0.12d | 85.85 ± 2.05a | |

| 4° | 75.96 ± 0.78a | 10.10 ± 0.22c | 6.92 ± 0.20e | 82.98 ± 1.46b | |

| 5° | 62.13 ± 1.49c | 14.12 ± 0.32a | 16.03 ± 0.32b | 69.85 ± 0.94c | |

| 6° | 56.32 ± 1.14d | 11.74 ± 0.09b | 25.97 ± 0.19a | 62.29 ± 1.54d | |

| F value | 143.49 | 981.58 | 3480.22 | 128.67 | |

| P value | 0.000S | 0.000S | 0.000S | 0.000S | |

| CV | 1.93 | 1.94 | 1.66 | 2.01 | |

| 30 | 2° | 63.10 ± 0.43c | 4.34 ± 0.07d | 19.98 ± 0.87c | 75.68 ± 0.95b |

| 3° | 72.63 ± 0.26a | 2.93 ± 0.05e | 12.49 ± 0.11d | 84.58 ± 0.06a | |

| 4° | 69.74 ± 0.78b | 13.85 ± 0.95a | 10.60 ± 0.07e | 75.55 ± 1.02b | |

| 5° | 58.82 ± 0.16d | 8.23 ± 0.10c | 25.55 ± 0.08b | 66.22 ± 0.18c | |

| 6° | 54.35 ± 0.37e | 9.30 ± 0.01b | 29.55 ± 0.21a | 61.16 ± 0.20d | |

| F value | 829.40 | 301.04 | 1194.50 | 618.07 | |

| P value | 0.000S | 0.000S | 0.000S | 0.000S | |

| CV | 0.71 | 5.58 | 2.08 | 0.88 |

Values are mean ± Standard deviation of three replications; mean in the same row followed by same superscript letter are not differed significantly at P ≤ 0.05; SSignificant; CS cylinder speed, CI cylinder inclination, DSC destalked chilli; US unstalked chilli, PSC partially stalked chilli, ME machine efficiency, CV coefficient of variation

The quantum of destalked chillies obtained at different CS were 75.55% (10 rpm), 79.27% (15 rpm), 84.95% (20 rpm), 77.07% (25 rpm), and 72.63% (30 rpm), respectively. Similarly, the observed values of machine efficiency were varied in the range of 87.82% (10 rpm), 89.43% (15 rpm), 90.57% (20 rpm), 85.85% (25 rpm) and 84.58% (30 rpm), respectively (Table 3).

The selection of CS was executed based on the destalking parameters as reported in Table 4. The statistical significance showed that 20 rpm was the optimal speed for destalking. Overall results of performance evaluation suggested the optimized operating conditions for achieving maximal performance were FR (6.5 kg/h), CS (20 rpm), and CI (3°) while keeping the moisture content (8–10%). The destalking efficiency of various developed prototypes predominantly relies on their respective working mechanisms, type of chillies (fresh/dried), and cultivar. Moreover, the reported findings on the destalking of dried red chillies are limited, and therefore the published results of the destalking of fresh chillies are only discussed.

Table 4.

Destalking parameters of various cylinder speeds at cylinder inclination (3°) and feed rate (6.5 kg/h)

| CS (rpm) | 10 | 15 | 20 | 25 | 30 | F value | P value | CV |

|---|---|---|---|---|---|---|---|---|

| DSC (%) | 75.55 ± 1.55c | 79.27 ± 1.57b | 84.95 ± 1.56a | 77.07 ± 0.36bc | 72.63 ± 0.26d | 43.01 | 0.000S | 1.60 |

| US (%) | 2.86 ± 0.06d | 3.71 ± 0.08c | 4.15 ± 0.09ba | 5.51 ± 0.10 | 2.93 ± 0.05d | 640.18 | 0.000S | 1.93 |

| PSC (%) | 9.32 ± 0.19b | 6.87 ± 0.10d | 5.28 ± 0.06e | 8.64 ± 0.1c | 12.49 ± 0.11a | 1431.29 | 0.000S | 1.46 |

| ME (%) | 87.82 ± 1.60ab | 89.43 ± 1.15a | 90.57 ± 2.54a | 85.85 ± 2.05bc | 84.58 ± 0.06c | 6.30 | 0.008S | 1.95 |

Values are mean ± Standard deviation of three replications; mean in the same row followed by same superscript letter are not differed significantly at P ≤ 0.05; SSignificant; CS cylinder speed, DSC destalked chilli, US unstalked chilli, PSC partially stalked chilli, ME Machine efficiency, CV coefficient of variation

Herbon et al. (2009) reported the development of three destalking machines, i.e. mechanical puller, water knife, and compression machine for ‘New Mexico’ green chile and fresh red ‘Cayenne’ peppers. The authors have reported that the water knife mechanism had highest destalking for green chile (90%) and Cayenne peppers (90%). The compression type mechanism also showed promising results, however, it was adjudged suitable only for Cayenne peppers.

Sawantranon and Chansuwan (2019) developed a continuous chilli pepper destalking mechanism which was evaluated at a processing speed of 1–5 pepper/s. It was found that the machine efficiency was reduced drastically from 94 to 30% with increased processing speed. Another study conducted by Huynh et al. (2021) has reported a specific method to identify and classify cracked chillies caused by destalking using the application of a convolution neural network model in integration with image processing, tensor flow data structure, and the Keras programming interface. The corresponding identification rate achieved was 97% (static) and 95.3% (working) conditions.

In the present study, an important key observation was that the spatial dimensions of chillies didn’t affect the destalking efficiency. However, the presence of chillies having curved stalks which sometimes did not pass through the slot resulted in reduced destalking efficiency. The total fabrication cost of the machine was estimated to be about 960 USD. The energy requirement for destalking of 1 kg dried chillies was observed to be 0.1 kWh.

Effect of destalking on quality of dried chillies

Colour is one of the prominent and desired quality attributes of chillies and is an indicator of the market value of chilli powder. It was observed that destalking has significantly affected the a* value of chilli powder as the highest increase (4.33%) was observed in the destalked powder (85.33 ± 4.69) as compared to powder prepared using whole chilli (81.79 ± 4.16). This substantiated that grinding of chilli with stalk has deteriorated its colour value. The pictorial representation of chillies with differential stalk percentage and powder is shown in Fig. 2b.

Extractable colour measures total pigment content and are useful when the powder is added as an ingredient in oil-based foods. TEC was found to be highest in destalked chilli powder (1066.30 ± 0.18 ASTA units) than in whole chilli powder (905.15 ± 0.12 ASTA units). About a 12.29% increase in TEC was observed due to destalking. As the main colouring compounds were concentrated in the pericarp, grinding of the whole chilli deteriorated the TEC owing to the presence of stalk.

Red colour of chillies signifies the availability of the carotenoid pigments. The total carotenoid content (mg/100 g) was on the higher side (5.73%) for destalked powder (90.90 ± 1.45) than whole chilli powder (85.91 ± 0.35) for all the samples. As stalk does not contain carotenoid pigments and hence its removal has improved the carotenoid content. The colour analysis indicated that destalked chilli contains higher chemical composition, which emphasized the need for the destalking before pounding.

Conclusion

The present investigation has reported the design and development of a mechanized, cost-effective, efficient, easily operated, and durable chilli destalking machine. The developed machine has shown promising results with operating conditions of feed rate (6.5 kg/h), cylinder speed (20 rpm), cylinder inclination (3°), and chilli moisture content (8–10%) that has yielded in highest destalking efficiency (85–87%) with minimum unstalked chilli (5–10%). The fabrication cost for a single unit was estimated as 960 USD. The powder quality analysis substantiated that destalking has a profound effect on the powder characteristics. The corresponding values of destalked chilli powder obtained were, a* value (85.33 ± 4.69), total extractable colour (1066.30 ± 0.18 ASTA units), and total carotenoids (90.90 ± 1.45 mg/100 g) substantiated the need for stalk removal prior to processing. Destalked chillies and seeds can be utilized for making processed products and the separated stalks can be used for composting. The simple, compact, and continuous nature of the designed system further strengthened its adoption potential at the farmer’s level. Future research may be oriented to improve the structural design of the machine, particularly making the rotating cylinder detachable and enhancing the adaptability of the machine to handle different chilli cultivars with higher capacity.

Acknowledgements

The authors wish to thank Dr. P.C. Sharma for his motivation and guidance while formulating the hypothesis of the work. The authors also wish to acknowledge Dr. Prerna Nath for carrying out packaging studies of dried chillies with the first author. The suggestions given by Dr. Bhushan Bibwe and Dr. Srinivas Girjal during the performance evaluation of the machine were also acknowledged. The authors sincerely acknowledge the technical support provided by Mr. Dalu Ram, Mr. Chiman Lal, Mr. Brijmohan, and Mr. Satpal, who has dedicatedly helped in the fabrication of the machine. Financial support given by ICAR-CIPHET Ludhiana to conduct this study is also duly acknowledged.

List of symbols

- L

Length of chilli

- W

Width of chilli

- T

Thickness of chilli

- ω

Rotation speed of the cylinder

- g

Acceleration due to gravity

- R

Radius of the cylinder

- rpm

Revolutions per minute

- W

Watts

- θ

Angle of inclination

- µ

Coefficient of static friction

- V

Cylinder's volume

- M

Mass of chilli processed per day

- ρ

Bulk density of chilli

- D

Cylinder's diameter

- L1

Cylinder's length

- FR

Feed rate

- CS

Cylinder’s speed

- CI

Cylinder’s inclination

- DSC

Destalked chilli

- US

Unstalked chilli

- PSC

Partially stalked chilli

- ME

Machine efficiency

- TEC

Total extractable colour

- IS

Indian standard

- ASTA

American Spice Trade Association units

- N

Newton

- Fc

Force to cut the stalks

- MC

Moisture content of stalks

- Wc

Work of shear

- kWh

Kilowatt hour

- ANOVA

Analysis of variance

- L*, a* b*

Lightness value, redness value and yellowness value

Author contributions

KJ: Conceptualization, Resources, Software, Writing-original draft, Writing-review & editing; MKM: Conceptualization, Methodology, Resources, Supervision, Writing-review & editing; RKV: Conceptualization, Validation, Writing-original draft, Writing-review & editing, Supervision.

Funding

Indian Council of Agricultural Research, New Delhi.

Data availability

All data generated or analysed during this study are included in this published article.

Declarations

Conflict of interest

The authors declare that they don’t have any conflict of interest.

Consent to participate

The authors declare their consent to participate in reviewing the manuscripts from JFST.

Consent for publication

The authors declare for the consent for publication.

Ethical approval

The authors approve the ethics for submission.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Kirti Jalgaonkar and Manoj Kumar Mahawar have equally contributed to this work.

References

- Altuntas E, Mahawar MK. Mass modeling of potato cultivars with different shape index by physical characteristics. J Food Process Eng. 2022 doi: 10.1111/jfpe.14126. [DOI] [Google Scholar]

- Anonymous (2019) An overview of machines developed. Published by College of Food Processing Technology and Bio-Energy, Anand Agricultural University, (Gujarat), India Publication Series No. EDU-6:6:2016:500. http://www.aau.in/sites/default/files/Booklet_2_2019.pdf Accessed 21 July 2022

- Anonymous (2021) https://www.moneycontrol.com/news/business/commodities/chinese-love-for-indian-red-chilli-hoists-exports-of-the-spice-to-a-record-7183011.html. Accessed 17 Sept 2021

- AOAC (1990) Official method of analysis of the association of official analytical chemists, 15th edn, Washington, DC

- Balakrishnan M, Thirupathi V, Sree Narayanan VV. Development and testing of a chilli seed extractor. Agric Mech Asia Afr Latin Am. 2006;37(4):95. [Google Scholar]

- Balakrishnan M, Jayashree E, Thirupathi V, Visvanathan R (2013) Spices and condiments. In: Hand book of agricultural engineering. Indian Council of Agricultural Research, New Delhi, pp 559–581

- Bibwe B, Mahawar MK, Jalgaonkar K, Meena VS, Kadam DM. Mass modeling of guava (cv. Allahabad safeda) fruit with selected dimensional attributes: regression analysis approach. J Food Process Eng. 2022 doi: 10.1111/jfpe.13978. [DOI] [Google Scholar]

- Borkar PA, Umbarkar SP, Murumkar RP, Rajput MR. Testing of chilli seed extractor coupled with chilli seed grader. Int J Innov Sci Eng Technol. 2015;2(6):200–205. [Google Scholar]

- Bosland PW, Votava EJ (2000) Peppers: vegetable and spice capsicums. Crop Production Science in Horticulture Series No. 12. CABI Publishing, United Kingdom. ISBN: 9781845938253. 10.1079/9781845938253.0000

- Chetti MB, Deepa GT, Antony RT, Khetagoudar MC, Uppar DS, Navalgatti CM. Influence of vacuum packaging and long term storage on quality of whole chilli (Capsicum annuum L.) J Food Sci Technol. 2014;51(10):2827–32. doi: 10.1007/s13197-012-0763-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Doymaz I, Pala M. Hot-air drying characteristics of red pepper. J Food Eng. 2002;55(4):331–335. doi: 10.1016/S0260-8774(02)00110-3. [DOI] [Google Scholar]

- Gunes M, Badem H. Detecting direction of pepper stem by using cuda-based accelerated hybrid intuitionistic fuzzy edge detection and ANN. J Sens. 2016 doi: 10.1155/2016/4052101. [DOI] [Google Scholar]

- Herbon R, Cillessen D, Gamillo E, Hyde A (2009) Engineering a machine to remove stems from chile peppers—a critical need for the New Mexico chile industry. In: Proceedings American Society Agril Biol Eng Paper No. 095710. 10.13031/2013.26942

- Herbon R, Cillessen D, Gamillo E, Hyde A (2010) Designing a high volume Chile de-stemming machine. ASABE annual international meeting 1–10. 10.13031/2013.30000

- Huynh QK, Nguyen CN, Vo-Nguyen HP, Tran-Nguyen PL, Le PH, Le DKL, Nguyen VC. Crack identification on the fresh chilli (Capsicum) fruit destemmed system. J Sens. 2021 doi: 10.1155/2021/8838247. [DOI] [Google Scholar]

- IS 2322:2010 (2010) Indian Standard Spices and Condiments-Chillies, Whole and Ground (Powdered)-Specification (Third Revision), p 4

- Jalgaonkar K, Mahawar MK. Evaluation of physico-chemical properties of selected chilli cultivars. Int J Chem Stud. 2017;5(6):2076–2079. [Google Scholar]

- Knorr JR, Victor J (2008) Pepper de-stemming, Patent no. US 2008/0289515 A1

- Mahawar MK, Bibwe B, Jalgaonkar K, Ghodki BM. Mass modeling of kinnow mandarin based on some physical attributes. J Food Process Eng. 2019;42(5):e13079. doi: 10.1111/jfpe.13079. [DOI] [Google Scholar]

- Mahawar MK, Jalgaonkar K, Bibwe B. Development of composite mechanical peeler cum juice extractor for kinnow and sweet orange. J Food Sci Technol. 2020;57(12):4355–4363. doi: 10.1007/s13197-020-04472-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mangraj S, Singh A, Samuel DVK, Singhal OP. Comparative performance evaluation of different drying methods for chillis. J Food Sci Technol. 2001;38(3):296–299. [Google Scholar]

- Phong NT, Duc LA, Hung BN. Study on designing, manufacturing and testing a chilli de-stemming semi-automatic machine. J Technol Educ Sci. 2017;45:34–42. [Google Scholar]

- Prabhavathi R, Anitha D, Vastrad J, Neeraja T, Kiran Prakash K (2021) De-stalking and its impact on health of women de-stalkers of dry chilli pods in Guntur district. Pharma Innov J 10(4):1169–1173. 10.22271/tpi.2021.v10.i4q.6172

- Ranganna S. Handbook of analysis of fruit and vegetable products. 2. Tata McGraw Hill: New Delhi; 1986. [Google Scholar]

- Satish Kumar BS (2016) A new chilli variety that saves labour cost. The Hindu published on 28th January 2016

- Satishkumar KSK, Basamma KA. Study of different physico-chemical properties of Byadagi chilli powder. Int J Trop Agric. 2015;33(2):559–564. [Google Scholar]

- Satyanarayana CHVV, Sukumaran CR (2002) Post-Harvest profile of chillies. AICRP Post Harvest Technology (ICAR), Post-Harvest Technology Centre Archarya N.G. Ranga Agricultural University Agricultural College Campus, Bapatla, Andhra Pradesh, India, pp 1–39

- Sawantranon P, Chansuwan C. The development of a continuous chili pepper destemming mechanism. Kasetsart Eng J. 2019;32(108):33–44. [Google Scholar]

- Walker SJ, Funk PA. Mechanizing chile peppers: challenges and advances in transitioning harvest of New Mexico’s signature crop. HortTechnology. 2014;24(3):281–284. doi: 10.21273/HORTTECH.24.3.281. [DOI] [Google Scholar]

- Wall MM, Walker S, Wall AD, Hughs E, Phillips R. Yield and quality of machine harvested red chile peppers. HortTechnology. 2003;13(2):296–302. doi: 10.21273/HORTTECH.13.2.0296. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

All data generated or analysed during this study are included in this published article.