Abstract

Purpose:

To comparatively assess the color stability of indirect composite block, nanohybrid, and microhybrid resin composites after immersion in red wine and repolishing.

Materials and methods:

Specimens (2x7x12 mm) were prepared using an indirect composite block (Cerasmart), a nanohybrid (Ceram X), and a microhybrid (Charisma Smart) resin composite. The specimens’ color was recorded based on the CIE L*a*b* system in a spectrophotometer (Spectroshade). After recording the initial color, the specimens were immersed in red wine for 3 hours per day for 15 days. The color measurement was done again. The specimens were repolished with a multistep polishing system (SuperSnap). The color was measured for the third time. The color change values (ΔE) were calculated with the L*, a*, and b* coordinates obtained at baseline, after the immersion procedure, and after repolishing. Statistical analyses were performed with one-way ANOVA, Tukey’s post hoc, and paired t-tests (p=0.05).

Results:

The composite block presented the lowest ΔE value (p <0.05). No statistically significant difference was found between the ΔE values of the nanohybrid and microhybrid resin composites. The repolishing promoted a decrease in the color change of all three materials (p<0.05). The ΔE value of the composite block was clinically acceptable after repolishing.

Conclusion:

The composite block showed higher color stability. The staining resistance of the nanohybrid and microhybrid resin composites was not different. The repolishing decreased the discoloration of all three materials.

Keywords: CAD/CAM, color, composite dental resin, polishing, staining

Introduction

The resin composites are restorative materials with increasing indications due to their tooth-like aesthetic appearance and improved mechanical properties (1). A variety of resin composite materials that differ from each other according to the resin matrix composition, number of filler particles, and filler particle size have been developed for restoration procedures (2). These characteristics of the resin composites influence the esthetic and physical properties of the materials (1, 2). Although direct composite restorations are a widespread treatment choice for posterior teeth, the incomplete polymerization of the resin composites, resulting in a low degree of conversion, may cause a reduction in the mechanical properties and staining resistance (3, 4). The discoloration resistance of the materials is as important as the mechanical properties of the material (3, 4, 5).

The conversion degree of materials has improved with the prefabricated resin-based blocks for computer-aided design and computer-aided manufacturing technology (CAD/CAM) (6). The resin-based blocks have optimal physical and mechanical properties because they are polymerized under high temperatures and high pressure (7). The use of CAD/CAM has rapidly increased in recent years due to its facilitation of indirect restorations (6). New CAD/CAM materials have been introduced specifically for esthetic restorations to overcome the disadvantages associated with the use of direct resin composites (8). The ceramic and resin-based composite blocks are used with CAD/CAM technology (6,7). The mechanical and optical properties of the ceramic are superior to those of composites (9). However, the composite blocks do not require firing as ceramic materials in the finishing and polishing procedures (7,10). Thus, the restorations are completed after clinically manual polishing in a single visit (7). Besides, they have ease of manufacturing and repairability properties (10). Unfortunately, the indirect composite blocks may be sensitive to discoloration when exposed to different conditions (11, 12).

Color stability of the restorations is a factor that affects the esthetic success (13, 14). Color stability is the ability to resist color changes of material over time (14). It is affected by the environment, material composition, and technique procedures (15). Discoloration of the materials may form in the oral environment due to extrinsic and intrinsic factors (16). The properties of resin-based materials influence the intrinsic staining, including the resin matrix composition, the amount of filler particles, the size of filler particles, and the degree of polymerization (4, 5,13,17). Extrinsic staining is caused by the adsorption and absorption of colorants in exogenous sources, such as food and beverages (15).

The discoloration is a prominent issue. The loss of the esthetic properties and inappropriate color match of restoration may be a reason for replacing the restoration (4, 5). The superficial staining on the restorations may be removed by a repolishing procedure hence improving the longevity of restorations (5,9,18). Repolishing is a favorable and conservative treatment option to improve the esthetics of non-severely discolored composite restorations by removing the stains on the surface (5,9,16).

There is no universal material in restorative dentistry. The indirect restorations might currently be preferred for appropriate indications since they have higher mechanical properties and discoloration resistance than direct composite restorations (4). However, there are a limited number of studies that have comparatively evaluated the color stability of indirect composite blocks and direct resin composites and the influence of repolishing on the color change (3,19). Therefore, the aim of the current study was to comparatively assess the color stability of composite block, nanohybrid, and microhybrid resin composites after immersion in red wine and repolishing. The first null hypothesis tested was that the color stability of composite block, nanohybrid, and microhybrid resin composites would not be different. The second null hypothesis tested was that the repolishing would not affect the discoloration of the composite block, nanohybrid, and microhybrid resin composites.

Materials and methods

Study materials

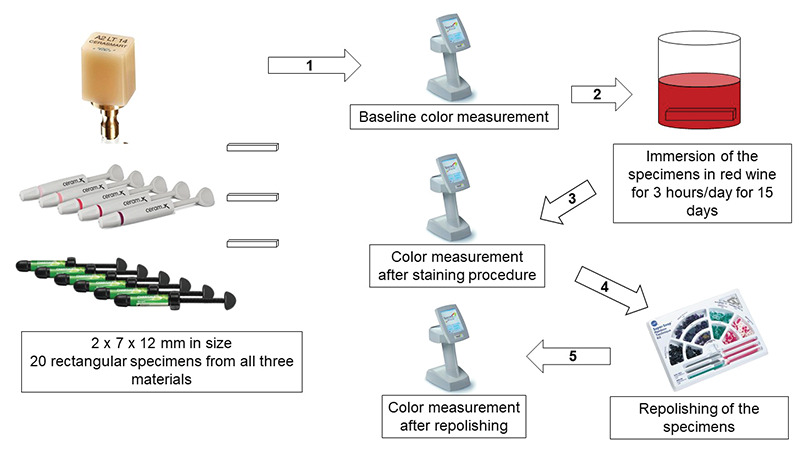

In this in vitro study, an indirect composite block (Cerasmart; GC, Tokyo, Japan, LT, A2), a nanohybrid (Ceram X;Dentsply Sirona, Konstanz, Germany, A2), and a microhybrid (Charisma Smart; Heraeus Kulzer, Hanau, Germany, A2) resin composite was used. The characteristics of the materials are described in Table 1. The schematic representation of the study methodology is displayed in Figure 1.

Table 1.

The materials, chemical composition and application procedure. Composition as provided by the manufacturers: BisMEPP, 2,2-bis(4-methacryloxypolyethoxyphenyl) propane; DMA, dimethacrylate; Bis-GMA, bisphenol-glycidyl methacrylate; UDMA, urethane dimethacrylate; TEGDMA, triethylene glycol dimethacrylate.

| Material | Composition | Application procedure |

|---|---|---|

| Cerasmart Lot no: 1909277 (GC, Leuven, Belgium) | Bis-MEPP, UDMA, DMA, silica and barium glass nanoparticle (20 nm) (71% wt) | CAD/CAM material |

| Ceram X Lot no: 0823 (Dentsply Sirona, Konstanz, Germany) | Bis-GMA, UDMA, TEGDMA, Barium-aluminum-borosilicate glass (1.1-1.5 µm), methacrylate functionalized silicone dioxide nano filler (10 nm) (76% wt) | 1. Apply in 2 mm layers |

| 2. Light-cure for 20 s | ||

| Charisma Smart Lot no: K010516 (Heraeus Kulzer, Hanau, Germany) | Bis-GMA, UDMA, TEGDMA Barium aluminum fluoride glass filler (0.02-2 μm), 5 vol% pyrogenic silicon dioxide filler (0.02-0.07 μm) (78% wt) | 1. Apply in 2 mm layers |

| 2. Light-cure for 20 s |

Figure 1.

Schematic illustration of the experimental design.

Specimen preparation

The composite block was cut into sizes of 2x7x12 mm using a diamond saw mounted on a cutting machine under water cooling (Minitom, Struers, Denmark). Twenty test specimens were acquired from the block (n=20). The specimens were sequentially polished with #180, 320, 400, and 600 silicon carbide papers under a semi-automatic grinding and polishing device (Tegramin 25, Struers, Denmark) to achieve a standardized smooth surface. Then, the specimens were polished with aluminum oxide discs of a multistep polishing system (SuperSnap; Shofu, Kyoto, Japan). The thickness of 2±0.05mm of the prepared specimens was confirmed by a digital micrometer (Digimatic Micrometer; Mitutoyo, Tokyo, Japan). The specimens were cleaned in an ultrasonic bath with distilled water.

Twenty rectangular specimens, 2x7x12 mm in size, were prepared using a Teflon mold from each resin composite (n=20). The resin composites were encased into the Teflon mold. A mylar strip (SS White Co., Philadelphia, PA, USA) was suppressed onto the mold surface and sandwiched between the two glass slides on both sides to promote smoothness and extrude the resin composite excess. The resin composites were polymerized on both sides for 20 seconds using a LED light-curing unit (Smartlite Focus, Dentsply, Milford, DE, USA) at 1000 mW/cm2. After the polymerization process, the specimens were replaced from the mold and stored in distilled water at 37°C for 24 hours. Each surface of the specimens was polished with the multistep polishing system (SuperSnap) by thoroughly rinsing with water and air-drying to remove debris after each polishing step.

Baseline color assessment

Before the staining procedure, the baseline color values of all specimens were recorded under standardized ambient conditions according to the Commission Internationale de l’Eclairege L*a*b* (CIELAB) color space system using a spectrophotometer (Spectroshade; MHT Optic Research AG, Niederhasli, Switzerland). The spectrophotometer was calibrated on a white calibration tile before measurements. All color measurements were performed over a white background. The color of each specimen was measured three times in the center of the specimens and averaged (L0, a0, b0). The color measurements were assessed regarding three coordinate values based on the CIE L*a*b* color space system.

The axis L* refers to the lightness coordinate, and its value ranges from zero (black) to 100 (white). The a* value represents redness (positive a*) or greenness (negative a*). The b* value represents yellowness (positive b*) or blueness (negative b*) (5).

Specimen staining

All the specimens were immersed in red wine for 3 hours a day for a total of 15 days. The specimens were stored in distilled water at 37°C until the following day’s immersion. The specimens were dried and cleaned with blotting paper during transfers from red wine to distilled water. The red wine was refreshed every day. As previously described, the color of the specimens was measured with the spectrophotometer after the staining period (L1, a1, b2).

After this measurement, the stained surfaces of specimens were repolished using the multistep polishing system (SuperSnap) as in specimen preparation, simulating the clinical repolishing procedure. Then, the color measurement of the specimens was performed again for the third time with the same method (L2, a2, b2).

Assessment of color change

The values of the changes of L* (ΔL), a* (Δa), and b* (Δb) were calculated from the color measurements at different times. The color difference (ΔE) was calculated from the mean ΔL, Δa, and Δb values for each specimen using the following formula: ΔE = [(ΔL)2+ (Δa)2+ (Δb)2]1/2. The color difference after staining to baseline was calculated as ΔE1. The color change after repolishing to baseline was calculated as ΔE2. In the present study, the perceptibility threshold of 1.2 and the acceptability threshold of 2.7 were accepted or color differences based on previous studies (18,20).

Statistical analysis

The SPSS program (Statistical Package for the Social Sciences version 20.0; SPSS, Chicago, IL, USA) was used to analyze the data. The normality of the data distribution was evaluated by the Kolmogorov–Smirnov test. Levene’s test was used to check for homoscedasticity. The data were analyzed with a one-way analysis of variance test (ANOVA). Multiple comparisons were performed with Tukey’s post hoc test. A paired t-test was conducted to compare ΔE values calculated after staining and repolishing. The statistical significance level was set at 0.05 for all analyses.

Results

The values of L*, a*, and b* coordinates at baseline and ΔL, Δa, and Δb values at the experimental conditions are presented in Table 2. The mean and standard deviations of overall color change after staining and after repolishing are shown in Table 3. The statistical analysis results of ΔE values are also displayed in Table 3.

Table 2.

Mean and standard deviation of L, a, b values at baseline, and ΔL, Δa, Δb values at measurement intervals. Same small superscript letter indicates no statistical difference in the column p†: The significance level of ΔE values between groups p‡: The significance level between ΔE1 and ΔE2 values

| Materials | Baseline | After staining | After repolishing | |||

|---|---|---|---|---|---|---|

| Cerasmart | L* | 76.38±2.03 | ΔL1 | -1.08±2.54 | ΔL2 | 0.54±1.92 |

| a* | 0.76±0.67 | Δa1 | 2.90±1.14 | Δa2 | -0.70±1.14 | |

| b* | 14.30±1.95 | Δb1 | 2.41±1.14 | Δb2 | 1.09±1.08 | |

| Ceram X | L* | 78.26±0.45 | ΔL1 | -4.52±1.96 | ΔL2 | -1.34±1.63 |

| a* | 1.07±0.37 | Δa1 | 3.27±2.21 | Δa2 | -1.01±1.52 | |

| b* | 17.05±2.02 | Δb1 | 3.15±2.24 | Δb2 | -1.66±1.82 | |

| Charisma Smart | L* | 75.23±1.70 | ΔL1 | -1.23±2.29 | ΔL2 | 1.69±2.09 |

| a* | 0.45±0.88 | Δa1 | 2.80±1.50 | Δa2 | -0.39±1.57 | |

| b* | 13.57±1.79 | Δb1 | 5.85±2.28 | Δb2 | 1.82±2.12 |

Table 3.

Means and standard deviations of color changes (ΔE values) after the staining and repolishing procedures. Same small superscript letter indicates no statistical difference in the column. p†: The significance level of ΔE values between groups, p‡: The significance level between ΔE1 and ΔE2 values.

| Materials | After staining/ ΔE1 | After repolishing/ ΔE2 | p‡ |

|---|---|---|---|

| Cerasmart | 4.82±0.88a | 2.62±1.00a | 0.000 |

| Ceram X | 7.04±2.17b | 3.45±1.27ab | 0.000 |

| Charisma Smart | 7.23±1.87b | 3.94±1.28b | 0.000 |

| p† | 0.000 | 0.004 |

After the staining procedure, all the materials presented color change. The ΔE values were above the acceptability threshold. The composite block showed the lowest ΔE value (p <0.05). The ΔE values of the nanohybrid and microhybrid resin composites were statistically similar. The repolishing procedure caused a decrease in the color change of all three materials (p <0.05). After repolishing, the ΔE values of the composite block and the nanohybrid resin composite were not statistically different, but there was a significant difference between the ΔE values of the composite block and the microhybrid resin composite (p <0.05).

The ΔE value of the composite block was clinically acceptable after repolishing. However, the ΔE values of the two resin composites were above the acceptability threshold.

Discussion

Color match is a factor that affects the longevity of resin- based composite restorations (5). The complex oral environment may lead to a change in the color of materials (10). The restorative materials must show resistance to discoloration over the years (4,14). The color stability of materials may be objectively measured by instrumental methods like a spectrophotometer (21). The CIE L*a*b* coordinate system is used to evaluate the color change (22). Because this system has advantages such as accuracy, repeatability, sensitivity, and objectivity (3,5). In this study, a spectrophotometer and CIE L*a*b* coordinate system were used to determine the color alterations. CIEDE 2000 is another color difference evaluation system. However, it has been reported that the CIELab and CIEDE 2000 systems are highly correlated (12).

The perceptible color difference to the human eyes and the acceptable color change are crucial in the assessment discoloration degree (3,5). There is no consensus about the perceptibility and acceptability threshold. Increased esthetic demands of patients have led to a decrease in the acceptability threshold over the years (18). In the current study, the perceptibility threshold of 1.2 and the acceptability threshold of 2.7 were chosen, as reported in a prospective multicenter study (20).

In the present study, the color stability of composite block, nanohybrid, and microhybrid resin composites was evaluated. After the staining procedure, all three materials showed unacceptable color changes. However, the color change value of the composite block was lower than that of nanohybrid and microhybrid resin composites. Therefore, the first null hypothesis that the color stability of composite block, nanohybrid, and microhybrid resin composites would not be different was rejected. The result is in agreement with previous studies, which have concluded that the indirect composite blocks had lower color change values than direct resin composites (3,19).

The CAD/CAM blocks show better resistance to discoloration than direct resin composites, even with similar compositions (3). The polymerization techniques used in the production procedure of CAD/CAM blocks promote their discoloration resistance (23). The resin-based materials that are used with CAD/CAM systems are polymerized industrially at high temperatures and pressures (6, 7). The materials have a high conversion degree, so the number of unreacted monomers is lower than direct resin composites (6). The low number of unreacted monomers provides superior physical properties, less water absorption, and better color stability to these materials (6,12).

The staining susceptibility of resin-based materials is associated with their hydrophilicity of the resin matrix and the amount of water sorption (17). The materials may absorb other fluids with colorant pigments besides water, which results in discoloration (24). Water sorption mainly occurs in the resin matrix of the materials. Therefore, the organic matrix content of the material may be more effective in discoloration potential than filler particles (5). The materials containing a hydrophilic resin matrix have a higher degree of water sorption and a higher potential for discoloration (3,5,8,17,18). It has been concluded that, under similar curing conditions, TEGDMA and Bis-GMA showed higher water sorption than UDMA (25).

The conversion degree of the resin matrix influences the water sorption of materials (17,25). The degree of conversion is directly related to the amount of unreacted monomer (17). The low monomer conversion causes the formation of a high number of unreacted monomers, leading to higher water sorption and discoloration (5,25). The conversion degree of resin-based materials under identical curing conditions is different according to their monomer content because some monomers have a lower degree of conversion (17,25). It has been reported that Bis GMA showed a lower conversion degree than UDMA and TEGDMA (25). Higher inorganic filler content might also cause lower water sorption, thus providing better staining resistance (18,26).

The treatment of silane on the filler particles of the resin-based materials is another factor that that affects the color stability of materials over time (27). A weak silanization results in insufficient filler-resin matrix binding, which induces large amounts of water sorption and thus less staining resistance(4,8). The effective silanization process in CAD/CAM materials might positively influence water sorption and color stability (8).

In this study, the composite block showed better color stability than the direct resin composites. The result might be attributed to the better silanization and the lower water sorption that result from the high conversion degree. Furthermore, the composite block Cerasmart does not contain a hydrophilic Bis-GMA monomer. It has a Bis-MPEPP monomer. Bis-MPEPP causes lower discoloration because it is a more hydrophobic monomer compared to Bis-GMA (4). The color stability of the nanohybrid and microhybrid resin composites was not different, as concluded in a previous study (28). It might be due to the similar resin matrix composition and inorganic filler ratio of these resin composites.

The discoloration of restorations could be removed by repolishing, depending on the material and the severity of staining (9,16). Repolishing is a minimally invasive operative procedure, which may remove the extrinsic discoloration on the restoration’s surfaces (5,18). Moreover, the surfaces become more resistant to discoloration again since they are smoother after repolishing (5,29). Thus, the repolishing may even prevent the replacement of the restorations (18,29). Repolishing might be more effective in direct resin composites because they are more susceptible to wear (5).

In this study, repolishing reduced the discoloration degree of all materials. Therefore, the second null hypothesis that the repolishing would not affect the discoloration of the resin-based block, nanohybrid, and microhybrid resin composites was rejected. This result is in agreement with previous studies in which the repolishing provided a significant improvement in the discoloration of resin composites (5,16,18), ceramics, and resin-based composite blocks (9). In a previous study, repolishing did not affect the color change of the composite block Cerasmart, and this was attributed to a low discoloration degree (19). Nonetheless, internal discolorations may not be completely removed by repolishing (9,30). In the current study, the ΔE value of the microhybrid resin composites was higher than the resin-based block after the repolishing procedure. It might result from more internal discoloration in this resin composite.

In the present study, the color measurement was performed on a white background. The white background can simulate better the light reflectance in restorations surrounded by tooth walls (8,27). The color differences in these restorations are more evident (27). In the present study, red wine was chosen as a staining solution. It has been reported that red wine was a more effective coloring agent, although different staining solutions were available (3,8, 9, 10). The specimens were immersed in red wine daily and continuously for a specified time. It has been stated that this method might be assumed equal to a long duration of exposure to stains in clinical conditions (31).

The present study has some limitations. Different in vitro conditions may be effective on the color stability of the materials. The laboratory setting does not fully simulate intraoral conditions. In the clinical environment, the discoloration potential of restorative materials might be influenced by different factors, including saliva, oral temperature, tooth brushing, toothpaste, and diet content (9). Moreover, the geometrical shape of the specimens is not similar to typical dental restorations (19). Thus, more in vitro and clinical studies must be conducted to assess the color stability of the materials.

Conclusion

The composite block was more resistant to discoloration than the nanohybrid and microhybrid resin composites. There was no significant difference in discoloration between the nanohybrid and microhybrid resin composites. The repolishing procedure reduced the color alteration of the materials. After repolishing, the ΔE value of the composite block was clinically acceptable, but not that of the nanohybrid and microhybrid resin composites.

Footnotes

Ethics committee approval:Not required.

Informed consent:Not required.

Peer review: Externally peer-reviewed.

Author contributions: MU participated in designing the study. MU participated in generating the data for the study. MU participated in gathering the data for the study. MU participated in the analysis of the data. MU wrote the majority of the original draft of the paper. MU participated in writing the paper. MU has had access to all of the raw data of the study. MU has reviewed the pertinent raw data on which the results and conclusions of this study are based. MU has approved the final version of this paper. MU guarantees that all individuals who meet the Journal’s authorship criteria are included as authors of this paper.

Conflict of interest:The authors declared that they have no conflict of interest.

Financial disclosure: The authors declared that this study received no financial support.

References

- 1.Ilie N, Hickel R. Resin composite restorative materials. Aust Dent J. 2011. Jun;56 Suppl 1:59–66. 10.1111/j.1834-7819.2010.01296.x [DOI] [PubMed] [Google Scholar]

- 2.Ferracane JL. Resin composite—state of the art. Dent Mater. 2011. Jan;27(1):29–38. 10.1016/j.dental.2010.10.020 [DOI] [PubMed] [Google Scholar]

- 3.Alharbi A, Ardu S, Bortolotto T, Krejci I. Stain susceptibility of composite and ceramic CAD/CAM blocks versus direct resin composites with different resinous matrices. Odontology. 2017. Apr;105(2):162–9. 10.1007/s10266-016-0258-1 [DOI] [PubMed] [Google Scholar]

- 4.Ardu S, Duc O, Di Bella E, Krejci I, Daher R. Color stability of different composite resins after polishing. Odontology. 2018. Jul;106(3):328–33. 10.1007/s10266-017-0337-y [DOI] [PubMed] [Google Scholar]

- 5.Mundim FM, Garcia LF, Pires-de-Souza FC. Effect of staining solutions and repolishing on color stability of direct composites. J Appl Oral Sci. 2010;18(3):249–54. 10.1590/S1678-77572010000300009 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Mainjot AK, Dupont NM, Oudkerk JC, Dewael TY, Sadoun MJ. From Artisanal to CAD-CAM Blocks: State of the Art of Indirect Composites. J Dent Res. 2016. May;95(5):487–95. 10.1177/0022034516634286 [DOI] [PubMed] [Google Scholar]

- 7.Ruse ND, Sadoun MJ. Resin-composite blocks for dental CAD/CAM applications. J Dent Res. 2014. Dec;93(12):1232–4. 10.1177/0022034514553976 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Kang YA, Lee HA, Chang J, Moon W, Chung SH, Lim BS. Color stability of dental reinforced CAD/CAM hybrid composite blocks compared to regular blocks [CrossRef]. Materials (Basel). 2020. Oct;13(21):1–17. 10.3390/ma13214722 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Seyidaliyeva A, Rues S, Evagorou Z, Hassel AJ, Rammelsberg P, Zenthöfer A. Color stability of polymer-infiltrated-ceramics compared with lithium disilicate ceramics and composite. J Esthet Restor Dent. 2020. Jan;32(1):43–50. 10.1111/jerd.12525 [DOI] [PubMed] [Google Scholar]

- 10.Aydın N, Karaoğlanoğlu S, Oktay EA, Kılıçarslan MA. Investigating the color changes on resin-based CAD/CAM Blocks. J Esthet Restor Dent. 2020. Mar;32(2):251–6. 10.1111/jerd.12561 [DOI] [PubMed] [Google Scholar]

- 11.Choi YS, Kang KH, Att W. Evaluation of the response of esthetic restorative materials to ultraviolet aging. J Prosthet Dent. 2021. Nov;126(5):679–85. 10.1016/j.prosdent.2020.09.007 [DOI] [PubMed] [Google Scholar]

- 12.Stamenković DD, Tango RN, Todorović A, Karasan D, Sailer I, Paravina RD. Staining and aging-dependent changes in color of CAD-CAM materials. J Prosthet Dent. 2021. Nov;126(5):672–8. 10.1016/j.prosdent.2020.09.005 [DOI] [PubMed] [Google Scholar]

- 13.Sulaiman TA, Rodgers B, Suliman AA, Johnston WM. Color and translucency stability of contemporary resin-based restorative materials [CrossRef]. J Esthet Restor Dent. 2021. Sep;33(6):899–905. 10.1111/jerd.12640 [DOI] [PubMed] [Google Scholar]

- 14.Muhittin U, Burak TU, Kam HO. Color stability of microhybrid and nanofilled composite resins: effect of surface sealant agents containing different filler content. J Contemp Dent Pract. 2019. Sep;20(9):1045–50. 10.5005/jp-journals-10024-2636 [DOI] [PubMed] [Google Scholar]

- 15.Ren YF, Feng L, Serban D, Malmstrom HS. Effects of common beverage colorants on color stability of dental composite resins: the utility of a thermocycling stain challenge model in vitro. J Dent 2012;40 Suppl 1. [DOI] [PubMed]

- 16.Leite ML, Silva FD, Meireles SS, Duarte RM, Andrade AK. The effect of drinks on color stability and surface roughness of nanocomposites. Eur J Dent. 2014. Jul;8(3):330–6. 10.4103/1305-7456.137640 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Fonseca AS, Labruna Moreira AD, de Albuquerque PP, de Menezes LR, Pfeifer CS, Schneider LF. Effect of monomer type on the CC degree of conversion, water sorption and solubility, and color stability of model dental composites. Dent Mater. 2017. Apr;33(4):394–401. 10.1016/j.dental.2017.01.010 [DOI] [PubMed] [Google Scholar]

- 18.Mailart MC, Rocha RS, Contreras SC, Torres CR, Borges AB, Caneppele TM. Effects of artificial staining on bulk-filled resin composites. Am J Dent. 2018. Jun;31(3):144–8. [PubMed] [Google Scholar]

- 19.Ersöz B, Karaoğlanoğlu S, Oktay EA, Aydın N. Color stability and surface roughness of resin based direct and indirect restorative materials. Eur Ann Dent Sci. 2021;48:1–6. 10.52037/eads.2021.0004 [DOI] [Google Scholar]

- 20.Paravina RD, Ghinea R, Herrera LJ, Bona AD, Igiel C, Linninger M, et al. Color difference thresholds in dentistry. J Esthet Restor Dent. 2015;27 Suppl 1:S1–9. 10.1111/jerd.12149 [DOI] [PubMed] [Google Scholar]

- 21.Liberato WF, Barreto IC, Costa PP, de Almeida CC, Pimentel W, Tiossi R. A comparison between visual, intraoral scanner, and spectrophotometer shade matching: A clinical study. J Prosthet Dent. 2019. Feb;121(2):271–5. 10.1016/j.prosdent.2018.05.004 [DOI] [PubMed] [Google Scholar]

- 22.Saegusa M, Kurokawa H, Takahashi N, Takamizawa T, Ishii R, Shiratsuchi K, et al. Evaluation of Color-matching Ability of a Structural Colored Resin Composite. Oper Dent. 2021. May;46(3):306–15. 10.2341/20-002-L [DOI] [PubMed] [Google Scholar]

- 23.Stawarczyk B, Sener B, Trottmann A, Roos M, Özcan M, Hämmerle CH. Discoloration of manually fabricated resins and industrially fabricated CAD/CAM blocks versus glass-ceramic: effect of storage media, duration, and subsequent polishing. Dent Mater J. 2012;31(3):377–83. 10.4012/dmj.2011-238 [DOI] [PubMed] [Google Scholar]

- 24.Bagheri R, Burrow MF, Tyas M. Influence of food-simulating solutions and surface finish on susceptibility to staining of aesthetic restorative materials. J Dent. 2005. May;33(5):389–98. 10.1016/j.jdent.2004.10.018 [DOI] [PubMed] [Google Scholar]

- 25.Gajewski VE, Pfeifer CS, Fróes-Salgado NR, Boaro LC, Braga RR. Monomers used in resin composites: degree of conversion, mechanical properties and water sorption/solubility. Braz Dent J. 2012;23(5):508–14. 10.1590/S0103-64402012000500007 [DOI] [PubMed] [Google Scholar]

- 26.Randolph LD, Palin WM, Leloup G, Leprince JG. Filler characteristics of modern dental resin composites and their influence on physico-mechanical properties. Dent Mater. 2016. Dec;32(12):1586–99. 10.1016/j.dental.2016.09.034 [DOI] [PubMed] [Google Scholar]

- 27.Ardu S, Braut V, Gutemberg D, Krejci I, Dietschi D, Feilzer AJ. A long-term laboratory test on staining susceptibility of esthetic composite resin materials. Quintessence Int. 2010. Sep;41(8):695–702. [PubMed] [Google Scholar]

- 28.Poggio C, Beltrami R, Scribante A, Colombo M, Chiesa M. Surface discoloration of composite resins: effects of staining and bleaching. Dent Res J (Isfahan). 2012. Sep;9(5):567–73. 10.4103/1735-3327.104875 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Anfe TE, Agra CM, Vieira GF. Evaluation of the possibility of removing staining by repolishing composite resins submitted to artificial aging. J Esthet Restor Dent. 2011. Aug;23(4):260–7. 10.1111/j.1708-8240.2011.00435.x [DOI] [PubMed] [Google Scholar]

- 30.Fontes ST, Fernández MR, de Moura CM, Meireles SS. Color stability of a nanofill composite: effect of different immersion media. J Appl Oral Sci. 2009;17(5):388–91. 10.1590/S1678-77572009000500007 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Malhotra N, Shenoy RP, Acharya S, Shenoy R, Mayya S. Effect of three indigenous food stains on resin-based, microhybrid-, and nanocomposites. J Esthet Restor Dent. 2011. Aug;23(4):250–7. 10.1111/j.1708-8240.2011.00431.x [DOI] [PubMed] [Google Scholar]