Abstract

Two experiments were conducted to evaluate the effect of different corn milling methods for high-moisture and dry corn on finishing cattle performance, carcass traits, and nutrient digestion. In experiment 1, steers (N = 600 [60 pens]; initial body weight [BW] = 402 ± 17 kg) were fed for 134 d to evaluate the effect of milling method and corn type on performance and carcass characteristics. Treatments were evaluated as a 2 × 3 factorial design with factors being milling method (Automatic Ag roller mill [ROLL] or hammer mill [HAMMER]) and corn type (high-moisture [HMC], dry [DC], or 50:50 blend of HMC and DC [BLEND]). There were no milling method × corn type interactions for final BW, gain (ADG), or dry matter intake (DMI; P ≥ 0.32), but there tended to be an interaction for G:F (P = 0.09). Cattle fed ROLL HMC had 4.7% greater gain:feed (G:F; P ≤ 0.01) with 55% lower fecal starch (P < 0.01) compared to HAMMER HMC, whereas processing did not impact (P = 0.74) G:F in DC diets. There were no further effects (P ≥ 0.14) on performance or carcass traits regardless of milling method or corn type. In experiment 2, seven ruminally fistulated steers were utilized in a 4 × 7 incomplete Latin rectangle to evaluate the effects of DC or HMC processed with either ROLL or HAMMER (2 × 2 factorial treatment design) on nutrient digestion. Feeding HMC decreased the amount of excreted dry matter (DM) and organic matter (OM; P ≤ 0.01) regardless of mill type, but there was a tendency (P ≤ 0.13) for an interaction between corn type and mill type for DM and OM digestibility. There was no difference between milling treatments fed as HMC (P ≥ 0.69), but the HAMMER DC diet was more digestible than the ROLL DC (P = 0.05). As expected, HMC-based diets had greater (P < 0.01) starch digestibility compared to DC, but milling method had no impact on starch digestibility (P = 0.56). There were no differences (P = 0.56) in average ruminal pH, but HMC diets had greater variance (P = 0.04) and greater area less than pH 5.6 (P = 0.05) compared to DC based diets while milling method did not impact either (P > 0.33). Processing HMC with a roller mill improved G:F compared to processing with a hammer mill, but had little effect when corn was fed as dry corn or HMC:DC blend. Furthermore, feeding cattle HMC compared to DC increases nutrient digestibility, but milling method had little impact.

Keywords: corn processing, feedlot cattle, hammer mill, high-moisture corn, roller mill, starch

Using a roller mill improved feed efficiency of feedlot cattle when using high-moisture corn compared to a hammer mill, but milling type did not impact performance when processing dry corn. Digestion was improved for high-moisture compared to dry corn, but also increased risk of ruminal acidosis.

Introduction

Historically, the first corn sheller and hammer mill were invented in the 1840s, although commercial cattle feeding did not emerge until the 1940s (Matsushima, 2006). Processing grains is utilized to improve animal efficiency by altering the physical composition of the grains (Matsushima, 2006). Mechanical processing of grains is achieved by damaging the kernel and reducing particle size for more efficient microbial digestion in the rumen (Owens and Sonderlund, 2006). For dry and high-moisture corn fed to cattle, a hammer mill or roller mill are the most common methods for processing.

Although both hammer mills and roller mills are effective at processing grains, they each have unique advantages and disadvantages. Hammer mills reduce particle size by impacting a slow-moving objects, like cereal grains, with a fast-moving hammer. This collision reduces particle size (Koch, 2002). Screens may be used to help dictate maximize size, but the distribution of particle sizes will vary widely around the geometric mean diameter (Koch, 2002). Hammer mills generally require less expense for maintenance but they are less energy efficient than a roller mill and often results in more variable particle size (Koch, 2002). Roller mills decrease particle size through shearing or compression depending on machine-specific design (Koch, 2002). Roller mills are more energy efficient and produce a more uniform particle size compared to hammer mills, but tend to have a higher initial investment with more expensive maintenance (Koch, 2002).

While numerous studies have focused on processing method for grain including reviews (Owens et al., 1997; Rowe et al., 1999; Owens and Zinn, 2005), much of the research was done prior to the widespread use of distillers’ grains in finishing diets. Therefore, the objectives of these studies were to evaluate the effect of feeding dry, high-moisture, or a blend of high-moisture and dry corn processed with a hammer mill or roller mill in diets containing 20% modified distillers’ grains plus solubles on steer performance, carcass characteristics, and nutrient digestion.

Materials and Methods

All procedures used in these experiments were reviewed and approved by the University of Nebraska-Lincoln Institutional Animal Care and Use Committee (IACUC #1785).

Experimental design and procedures: experiment 1—cattle finishing experiment

Crossbred steers (N = 600; initial BW = 402 kg; SD = 17 kg) were utilized in a 134-d finishing trial with a 2 × 3 factorial treatment design. Factors consisted of two milling methods (roller mill [ROLL; Automatic Ag, Pender, NE] or hammer mill [HAMMER; Haybuster, Jamestown, ND for high-moisture corn or Might Giant Tub Grinder, Jones Manufacturing, Beemer, NE for dry corn]) and corn fed one of three ways (100% dry corn [DC], 100% high-moisture corn [HMC], or a 50:50 blend [BLEND]). Steers were assigned randomly to pen (N = 60; 10 steers per pen) and pen was assigned randomly to treatments, with 10 replications per treatment. Two start blocks were utilized, started 1 wk apart, with 2 body weight (BW) blocks in the first start block (four replications in the light block and one replication heavy block) and one BW block in the second start block with five replications. Data were analyzed with three blocks to account for weight and week started as a randomized block design. Cattle were started at two separate times due to size of the experiment with 60 total pens, and 600 steers.

Steers were sourced from auction markets and transported to the University of Nebraska Eastern Nebraska Research Extension and Education Center (ENREEC) located near Mead, NE. At the time of arrival, all steers were individually identified (panel tag, electronic button, and metal clip). All steers received an infectious bovine rhinotracheitis virus, parainfluenza-3 virus, bovine viral diarrhea virus (types I and II), bovine respiratory syncytial virus, Manheimia haemolytica and Pasteurella multocida combination vaccine (Vista Once, Merck Animal Health, DeSoto, KS), a Clostridium chauvoei, specticum, novyi, sordellii, perfringens Types B, C, and D bacterin-toxoid (Vison 7, Merck Animal Health), a 10% fenbendazole oral suspension for the control of lung worms, stomach worms, and intestinal worms (Safe-Guard Dewormer, Merck Animal Health), and 1% doramectin injectable for treatment and prevention of gastrointestinal and external parasite control (Dectomax, Zoetis Inc., Florham Park, NJ).

Before trial initiation, steers were limit fed at 2% of BW for 5 d a diet consisting of 50% Sweet Bran (Cargill Corn Milling, Blair, NE) and 50% alfalfa hay (DM basis) to minimize variation in gastrointestinal fill (Watson et al., 2013). Steers were weighed 2 consecutive days (days 0 and 1) and averaged to establish initial BW. Steers were blocked by day 0 BW (light or heavy), stratified by BW within blocks and assigned randomly to pen within block. Trial initiation date was also used as a block, with two starting dates 1 wk apart and 30 pens starting each week. Pens were assigned randomly to 1 of 6 treatments with 10 pens per treatment.

HMC was harvested at ENREEC in September 2018, processed respective of treatment, and ensiled in plastic-covered bunkers until trial initiation in July 2019. DC was processed on site as needed for both milling methods throughout the trial. Both HMC and DC were processed using a 15.88-mm screen in the hammer mill, and the roller mill was adjusted as needed to ensure all kernels were broken. Corn samples were collected at reimplant date (day 50) for all corns and processing methods for particle size analysis. Cattle were implanted on day 1 with 80 mg trenbolone acetate (TBA) and 16 mg estradiol (E2; Revalor-IS, Merck Animal Health). Steers were weighed and reimplanted with 200 mg TBA + 20 mg E2 (Revalor-200; Merck Animal Health) on day 50 (84 d on terminal implant). Fecal samples were collected from 2 steers per pen at reimplant (day 50) and composited wet on an equal volume basis and pen floor fecal samples (N = 2) were collected on approximately day 100 for fecal starch analysis.

Steers were adapted to finishing rations over 23 d with corn replacing alfalfa hay in the step-up diets. All finishing diets included (DM basis; Table 1): 70% corn (DC, BLEND, or HMC), 20% modified distillers grains plus solubles (MDGS), 5% corn stalks, and 5% supplement. The supplement was formulated for 9.7 mg/kg tylosin (DM-basis; Tylan; Elanco Animal Health, Greenfield, IN), and 33 mg/kg monensin (DM-basis; Rumensin; Elanco Animal Health), 0.5% urea (DM-basis), as well as calcium, salt, trace minerals, and vitamins to meet or exceed requirements (NASEM, 2016). Ractopamine hydrochloride (Optaflexx, Elanco Animal Health) was fed for the last 28 d prior to harvest targeting 300 mg per steer. Dietary net energy and metabolizable energy were calculated from animal intake, gain, and BW using equations adapted from the NRC (1996).

Table 1.

Composition (DM basis) and chemical analysis of diet fed to finishing steers (experiments 1 and 2)

| ROLL | HAMMER | |||||

|---|---|---|---|---|---|---|

| Item | DC | BLEND | HMC | DC | BLEND | HMC |

| Dry corn | 70 | 35 | — | 70 | 35 | — |

| High-moisture corn | — | 35 | 70 | — | 35 | 70 |

| Modified distillers + solubles | 20 | 20 | 20 | 20 | 20 | 20 |

| Corn stalks, ground | 5 | 5 | 5 | 5 | 5 | 5 |

| Supplement1 | ||||||

| Fine ground corn | 2.29 | 2.29 | 2.29 | 2.29 | 2.29 | 2.29 |

| Limestone | 1.69 | 1.69 | 1.69 | 1.69 | 1.69 | 1.69 |

| Tallow | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 |

| Urea | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Salt | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Trace mineral | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Vitamin A-D-E | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| Rumensin-90 | 0.017 | 0.017 | 0.017 | 0.017 | 0.017 | 0.017 |

| Tylan-40 | 0.011 | 0.011 | 0.011 | 0.011 | 0.011 | 0.011 |

| Chemical composition | ||||||

| CP, % | 14.55 | 14.62 | 14.69 | 14.63 | 14.62 | 14.62 |

| Ca, % | 0.65 | 0.65 | 0.65 | 0.65 | 0.66 | 0.66 |

| P, % | 0.41 | 0.40 | 0.39 | 0.41 | 0.39 | 0.37 |

| NDF, % | 17.08 | 16.72 | 16.37 | 17.96 | 17.28 | 16.60 |

| ADF, % | 7.40 | 7.56 | 7.72 | 7.28 | 7.44 | 7.61 |

| Starch, % | 52.96 | 52.50 | 52.04 | 52.33 | 52.14 | 51.95 |

1Supplement formulated to provide 33 mg/kg monensin (Rumensin, Elanco Animal Health) diet DM, 90 mg/steer daily of tylosin (Tylan, Elanco Animal Health), and trace mineral package that meet or exceed animal requirements (NASEM, 2016).

Cattle were housed in open feedlot pens with approximately 91 cm of linear bunk space and 56 m2 of pen space per steer. Feed bunks were assessed once daily at approximately 0600 hours for the presence of feed, and feed amounts were adjusted to maintain ad libitum intake. Cattle were fed once daily between 0700 and 0900 hours and had ad libitum access to feed and water for the duration of the trial. Weekly samples of feed ingredients were collected by university personnel, composited by month, and sent to a commercial laboratory (Ward Laboratories Inc., Kearney, NE) for chemical analysis. When refusals were present, orts were weighed, sampled, and frozen for later analysis of DM. Steers were visually evaluated daily, and if a steer was determined to be sick or injured based on visual appraisal as lethargic or abnormal, it was removed from the pen and taken to the processing facility for diagnosis and appropriate treatment based on body temperature or lameness symptoms prior to being returned to their original pen.

Carcass data

Cattle were transported to a commercial abattoir on two separate days, 1 wk apart, based on start block. All steers were fed for 134 d. On the day of shipping, steers were offered 50% of the previous day’s called feed. Steers were weighed on a pen scale in the afternoon prior to shipping and loaded in the evening. All steers were harvested at a commercial abattoir (Greater Omaha Packing, Omaha, NE) the following morning. Hot carcass weights and liver scores were recorded on each harvest date and longissimus muscle area, USDA marbling score, and 12th rib fat thickness were collected following a 48-h chill using camera data. The scoring system used was as follows: 0, no liver abscesses; A-, one or very few small abscesses; A, 1 large abscess or a few small abscesses; A+, many large abscesses (Brink et al. 1990). Yield grade (USDA, 2016) was calculated from the following formula: 2.50 + (0.98425 × 12th rib fat, cm) + (0.2 × 2.5 KPH, %) + 0.00837 × HCW, kg) − (0.0496 × LM area, cm2). Final live BW and dressing percentage were calculated using the pen average final live BW pencil shrunk 4% to adjust for gut fill. Carcass-adjusted performance was calculated by dividing hot carcass weight by a common dressing percentage of 63%.

Particle size analysis

Samples of corn grain from each processing method were taken at time of trial initiation and reimplant. Samples were analyzed as-is for particle size (ASAE, 2008) to prevent damage to the kernels, then dried to determine particle size distribution. Samples were measured in duplicate to determine distribution, geometric mean diameter, and geometric standard deviation for each treatment corn.

Fecal starch analysis

Animal and pen fecal samples were composited wet on a pen basis and dried using a forced air oven at 60 °C for 48 h (AOAC, 1999; method 4.1.03). Dry samples were ground through a 1-mm screen for analysis. Ground fecal samples were then analyzed for presence of starch through the hydrolysis of starch granules into D-glucose with α-amylase and amyloglucosidase (Megazyme International Total Starch Assay Kit, AOAC International, 2000; Method 996.11).

Statistical analysis: experiment 1

Animal performance, carcass characteristics, and fecal starch were analyzed as a 2 × 3 factorial arrangement of treatments using the MIXED procedure of SAS (SAS Institute, Inc., Cary, NC). The model consisted of the fixed effects of block (three blocks), corn type, milling method, and their interaction. Pen was considered the experimental unit and block was analyzed as a fixed effect. Interactions between corn type and milling method were tested and if not significant (P > 0.10), were removed from the model. Interaction of time of fecal sample was also included in the model for fecal starch analysis and removed if not significant (P > 0.10). Liver abscess data were analyzed using GLIMMIX as a binomial distribution. Significance was considered at α ≤ 0.05 and a tendency was considered at 0.05 < α ≤ 0.10.

Experimental design and procedures: experiment 2—cattle metabolism experiment

Seven ruminally fistulated steers were used in a 4 × 7 Latin rectangle, with each steer assigned randomly to each dietary treatment once for four consecutive, 21-d periods. Periods allowed for 14 d adaptation (5 d of blend from previous period’s diet and 9 d of new diet), followed by 7 d of collections. Treatment arrangement was a 2 × 2 factorial design, with DC or HMC processed with a roller mill or hammer mill. Steers were fistulated approximately 9 mo. prior to trial initiation. High-moisture and DCs were the same as utilized in experiment 1. Diets were mixed twice weekly and stored in a cooler (4 °C) to ensure freshness. Experimental diets included (DM basis; Table 1): 70% corn, 20% MDGS, 5% corn stalks, and 5% supplement. Supplement was formulated to provide 33 mg/kg monensin (Rumensin; Elanco Animal Health), 90 mg per steer daily of tylosin (Tylan; Elanco Animal Health), 0.5% diet DM urea, calcium, salt, trace mineral, and vitamins to meet or exceed requirements (NASEM, 2016). Ingredients were sampled twice during each 21-d period and analyzed for DM using a 60 °C forced air oven to ensure proper formulation of treatment diets. Feed refusals were collected from days 16 to 21 and subsampled, DM determined, and DMI calculated.

Titanium dioxide was ruminally dosed at a rate of 5.0 g per steer twice daily at 0700 and 1700 hours for 7 d prior to and for the duration of the collection period. Fecal grab samples (approximately 300 g) were collected on days 17 through 21, three times daily at 0700, 1300, and 1900 hours. Fecal samples were composited within day on a wet basis and freeze-dried (Virtis Feeezemobile 25ES, SP Industries, Warminster, PA). Daily composites were ground to 1-mm and composited by steer within period (equal dry weight by day) to create a period composite sample. Freeze-dried fecal samples were subsequently analyzed for neutral detergent fiber (NDF) using α-amylase and sodium sulfite (Van Soest et al., 1991), acid detergent fiber (ADF; Van Soest et al., 1991), starch (Megazyme International, AOAC International, 2000; Method 996.11; AOAC Method 76.13), and titanium concentration (Spectra MAX 250, Molecular Devices, LLC, Sunnyvale, CA; Meyers et al., 2004). Ingredient and fecal samples were analyzed for gross energy using a bomb calorimeter (Parr Instrument Company). Digestible energy (DE) was calculated as intake energy minus fecal energy. Ruminal pH was measured with submersible wireless pH probes (Dascor, Inc., Escondido, CA). Ruminal pH probes were inserted in the rumen on day 14 and recorded pH data every minute until removal on day 21. Rumen pH data were analyzed from days 16 to 20 to capture collection week and five full days of rumen pH measurements. Cylindrical weights were attached to the probes to ensure placement in the ventral sac of the rumen. All pH probes were calibrated prior to rumen insertion and after removal by submersing them in pH 7 and 4 standard solutions. Ruminal pH measurements were adjusted by assuming a linear drift from pH (with average drift between pH of 4 or 7 used) across the time period. These adjustments were small (less than 0.1 pH units) over the 7 d. Ruminal pH measurements were recorded every minute (1,440 measurements per d) and downloaded on day 21 of each collection period. Measurements for pH include average ruminal pH, minimum and maximum pH, and magnitude of change. Ruminal pH variance and time and area below 5.6 were calculated as described by Cooper et al. (2002). Diet ingredients were also composited into period samples and analyzed for DM, OM, NDF, ADF and starch using the same procedures previously described.

Statistical analysis: experiment 2

Total tract nutrient intake and digestion data were analyzed using the MIXED procedure of SAS (SAS Institute, Inc., Cary, NC) with treatment considered a fixed effect and period treated as a random effect. The interaction between corn type and milling method was included in the model and removed if not significant. Ruminal pH data were analyzed using the MIXED procedure of SAS. Day was included as a repeated measure, treatment included as fixed effects, and period included as a random variable. One steer had reduced intake during period 3 on the HAMMER HMC but he was switched to his treatment for period 4 (HAMMER DC) and intake was restored and not different during that period. Treatment differences were considered significant when α ≤ 0.05 and a tendency was considered when 0.05 < α ≤ 0.15.

Results and Discussion

Geometric mean diameter (GMD), geometric standard deviation (GSD), and particle size distribution for corns used in experiments 1 and 2 are presented in Table 2. The GMD for corns processed with ROLL were 3,514 and 2,867 µm for DC and HMC, respectively. The GMD for corns processed with HAMMER were 2,248 and 1,808 µm for DC and HMC. For both DC and HMC, corns processed with HAMMER had more variable distribution across screens from 600 to 6,300 µm compared to ROLL, which were more closely distributed between 1,700 and 4,750 µm. The samples with the greatest proportion of large particles (> 6,300 µm) were HMC processed with HAMMER, but statistical comparisons are not possible in evaluation of particle size differences. The average weekly DM percentage across all weeks of the feeding period for ROLL HMC and ROLL DC were 68.2% and 90.0%, respectively, and the average weekly DM of the HAMMER HMC and DC were 65.4% and 89.6%, respectively, for the duration of the feeding periods for both experiments 1 and 2.

Table 2.

Particle size distribution by percent retained on screen, geometric mean diameter (GMD) and geometric standard deviation (GSD) for corns fed in experiments 1 and 2

| Item | ROLL1 | HAMMER | ||||||

|---|---|---|---|---|---|---|---|---|

| Screen size, µm | DC | CV2 | HMC | CV | DC | CV | HMC | CV |

| 6,300 | 1.7 | 43.8 | 9.7 | 30.0 | 10.9 | 16.9 | 30.1 | 13.1 |

| 4,750 | 29.5 | 17.5 | 34.5 | 9.0 | 8.3 | 6.9 | 18.7 | 14.8 |

| 3,350 | 39.8 | 18.7 | 26.1 | 6.4 | 15.8 | 16.9 | 22.2 | 5.32 |

| 1,700 | 23.8 | 21.6 | 17.3 | 10.9 | 29.0 | 8.2 | 20.9 | 8.9 |

| 1,410 | 1.3 | 77.9 | 2.1 | 28.2 | 11.6 | 5.3 | 2.1 | 44.7 |

| 850 | 1.7 | 93.8 | 3.8 | 27.0 | 8.5 | 7.6 | 2.9 | 57.6 |

| 600 | 0.5 | 117.6 | 2.0 | 42.5 | 5.3 | 21.6 | 1.1 | 89.1 |

| <600 | 1.7 | 117.4 | 4.5 | 32.6 | 10.7 | 25.2 | 1.7 | 78.9 |

| GMD, µm | 3,514 | — | 2,867 | — | 1,808 | — | 2,248 | — |

| GSD, µm | 1,160 | — | 1,335 | — | 924 | — | 501 | — |

1Treatments were corn processed with a roller mill (ROLL) or hammer mill (HAMMER) and fed as dry corn (DC), 50:50 blend of DC and high-moisture corn (BLEND) or high-moisture corn (HMC).

2Coefficient of variance for each screen size within corn type.

Experiment 1—cattle finishing experiment

There were no interactions between corn type × milling method (Table 3) for carcass-adjusted final BW, DMI, or ADG (P ≥ 0.32), but there was a tendency for an interaction between corn type and milling method for G:F (P = 0.09). Steers fed the ROLL HMC diet had an improvement in G:F of 5.0% (P ≤ 0.01) compared to HAMMER HMC. Within corns processed with ROLL, G:F was improved when fed as HMC (P < 0.01) compared to BLEND which was not different from DC (P = 0.35), suggesting a negative associative effect. Feed efficiency improved (P = 0.04) when HMC was fed compared to DC when milled as HAMMER, with BLEND being intermediate and not different from either DC or HMC (P > 0.20). We conclude the reason for the observed interaction and difference between milling methods was due to the greater magnitude of response of feeding HMC relative to that of DC. Feeding ROLL HMC improved G:F (P < 0.01) by 8.5% for those diets compared to ROLL DC. Feeding HAMMER HMC improved G:F (P = 0.04) by 3.9% compared to HAMMER DC. These data suggest that if planning to use HMC, then rolling will improve G:F (P < 0.01) compared to hammer milling, which may be related to the particle size (large particles > 6,300 µm) or more variable distribution of particles. Within DC, processing with HAMMER compared to ROLL increased large and small particles (thus more variation) and decreased mean particle size, which normally decreases fecal starch (Schwandt et al., 2016) and presumably increases starch digestion in the rumen. But, an improvement in digestion does not always result in improvements in growth performance (Galyean et al., 1981; Schwandt et al., 2016). These results are also similar to Mader et al. (1991) who observed that steers fed rolled HMC (3,965 µm), gained similar to cattle fed whole HMC, but consumed less, leading to an improvement in feed efficiency. In their study, ground HMC (3,303 µm) was thought to be the most digestible but resulted in the poorest growth performance, suggesting that acidosis may be a concern when grains are processed resulting in a small, fine particle size.

Table 3.

Simple effect means of corn type and milling method on finishing cattle performance, energy content of diets, fecal starch, and carcass characteristics (experiment 1)

| ROLL1 | HAMMER | SEM | Corn type | Mill type | Corn × Mill | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Item | DC | BLEND | HMC | DC | BLEND | HMC | ||||

| Initial BW, kg | 412 | 413 | 413 | 414 | 413 | 414 | 0.4 | 0.39 | 0.02 | 0.22 |

| Live performance | ||||||||||

| Final BW, kg | 698 | 690 | 691 | 696 | 691 | 688 | 3.4 | 0.06 | 0.66 | 0.82 |

| Dress, % | 61.9 | 62.4 | 62.5 | 62.2 | 62.3 | 61.9 | 2.37 | 0.35 | 0.54 | 0.13 |

| Carcass-adj. performance2 | ||||||||||

| Final BW, kg | 685 | 683 | 685 | 686 | 683 | 676 | 4.1 | 0.45 | 0.44 | 0.32 |

| DMI, kg/d | 13.1 | 12.8 | 12.1 | 13.2 | 12.8 | 12.3 | 0.13 | <0.01 | 0.40 | 0.88 |

| ADG, kg | 2.04 | 2.03 | 2.04 | 2.04 | 2.03 | 1.96 | 0.032 | 0.42 | 0.32 | 0.32 |

| G:F | 0.156b,c | 0.158b,c | 0.169a | 0.155c | 0.158b,c | 0.161b | 0.0021 | <0.01 | 0.07 | 0.09 |

| NEm, Mcal/kg3 | 1.86c | 1.89b,c | 1.99a | 1.85c | 1.89b,c | 1.92b | 0.019 | <0.01 | 0.07 | 0.10 |

| NEg, Mcal/kg | 1.22c | 1.26b,c | 1.34a | 1.22c | 1.25b,c | 1.28b | 0.016 | <0.01 | 0.04 | 0.16 |

| ME, Mcal/kg | 2.80c | 2.83bc | 2.96a | 2.79c | 2.83b,c | 2.87b | 0.021 | <0.01 | 0.06 | 0.10 |

| Fecal Starch, % | 15.9b,c | 13.0b | 7.4a | 17.4c | 16.7b,c | 16.6b,c | 1.40 | <0.01 | <0.01 | 0.02 |

| Carcass characteristics | ||||||||||

| HCW, kg | 432 | 430 | 432 | 432 | 430 | 426 | 2.6 | 0.42 | 0.41 | 0.34 |

| LM area, cm2 | 92.3 | 94.2 | 94.8 | 94.2 | 94.8 | 94.2 | 1.10 | 0.29 | 0.46 | 0.31 |

| Marbling score 4 | 484b | 515a | 475b | 488b | 477b | 474b | 10.7 | 0.12 | 0.18 | 0.09 |

| 12th rib fat, cm. | 1.35 | 1.32 | 1.30 | 1.27 | 1.30 | 1.27 | 0.051 | 0.93 | 0.14 | 0.66 |

| Calculated YG 5 | 3.29 | 3.10 | 3.09 | 3.20 | 3.15 | 3.10 | 0.06 | 0.05 | 0.85 | 0.52 |

| Liver Abscess, % | 28.0 | 27.0 | 38.8 | 24.2 | 29.0 | 28.4 | 5.8 | 0.19 | 0.43 | 0.37 |

1Treatments were corn processed with a roller mill (ROLL) or hammer mill (HAMMER) and fed as dry corn (DC), 50:50 blend of DC and high-moisture corn (BLEND) or high-moisture corn (HMC).

2Calculated from final BW adjusted to a common dressing percent of 63%.

3Calculated using ADG, DMI, and final BW using equations adapted from NRC, 1996.

4400 = small, 500 = modest, 600 = moderate.

5Yield grade = 2.50 + (0.98425 × 12th rib fat, cm) + (0.2 × 2.5 KPH, %) + 0.00837 × HCW, kg) − (0.0496 × LM area, cm2), where KPH is assumed to be 2.5%.

a,b,c Means without common superscripts differ (P ≤ 0.05).

There was a tendency for an interaction between corn type and milling method for net energy for maintenance (NEm) and metabolizable energy (P = 0.10; Table 3). Diets processed with the roller mill had greater NEg (P = 0.04), and there was a tendency for the roller mill diets to have greater NEm and ME (P ≤ 0.07) compared to processing with the hammer mill (Table 3). The response to rolling was mostly due to improvements with ROLLER HMC compared to HAMMER HMC and calculated energy contents were very similar in magnitude for BLEND and for DC milling methods. The increase in energy from processing grains ultimately improves feed efficiency (Peters, 2006). Like the current study, Macken et al. (2006) observed a 10% increase in net energy for gain (NEg) of corn when fed as rolled HMC compared to dry-rolled corn; however, the authors reported only a 5% increase in NEg was observed for corn when fed as ground HMC compared to fine ground corn, suggesting something other than digestibility or energy density (possibly increased incidence of acidosis) was influencing performance. Unsurprisingly, the increase in NEg of the corn corresponded with improved G:F.

There was an interaction (P = 0.02; Table 3) between milling method and corn type for fecal starch percent. There was little difference in fecal starch percent when corn was fed as DC or BLEND and processed with ROLL or HAMMER. However, fecal starch was reduced by 55% (P ≤ 0.01) when HMC was processed with ROLL compared to HAMMER HMC resulting in an interaction for fecal starch. There is a close relationship between fecal starch and total tract digestibility in diets that are similar in DM digestibility. Zinn et al. (2002) reported that fecal starch can explain 91% of the variability in starch digestion. Corona et al. (2005) evaluated the relationship between fecal starch and total tract digestibility in finishing steers and showed the inverse relationship to explain 97% of variability in starch digestion. Vander Pol et al. (2008) concluded that G:F and fecal starch are inversely correlated, and as G:F is decreased, fecal starch is increased. Although the relationship is strong, dietary components, cattle background and genetics, and DMI may all greatly influence nutrient digestibility (Schwandt et al., 2015).

There were no interactions between corn type × milling method for hot carcass weight (HCW), dressing percent, longissimus muscle (LM) area, 12th-rib fat thickness, calculated yield grade or liver abscess percent (P ≥ 0.25; Table 3), but there was a tendency for an interaction between corn type and milling method for USDA marbling score (P = 0.09) with ROLL BLEND having the greatest USDA marbling score, although the biological reason is unclear. It is important to note that there was a high incidence of liver abscesses in this trial suggesting that cattle experienced episodes of acidosis as anticipated with a high-concentrate, low-roughage diet. Lack of treatment differences between milling method or corn type suggest acidosis was not influencing treatment outcomes which contradicts particle size influence.

There were no significant differences in carcass-adjusted final BW or ADG (P ≥ 0.42) based on corn type (Table 4). Cattle fed DC had the greatest DMI (P < 0.01), BLEND was intermediate and HMC cattle had the lowest DMI. The differences in DMI could be because of increased NE concentration of HMC than DC and greater acidosis potential of the HMC. This is consistent with an extensive review from Owens et al. (1997), who reported that more extensive processing of grains decreased DMI and slightly decreased ADG due to increased volatile fatty acid production in the rumen and subclinical acidosis. However, like the present study, Owens et al. (1997) also reported an improvement in feed efficiency with more extensive processing. Vander Pol et al. (2008) also observed a 5.1% and 7.9% decrease in DMI compared to DRC based diets when cattle were fed a 1:1 blend of DRC:HMC or HMC with 30% WDGS. Furthermore, Vander Pol et al. (2008) observed no differences in ADG based on corn processing, thus leading to a 1.6% and 3.2% increase in feed efficiency for cattle fed DRC:HMC or HMC, respectively, compared to DRC alone. Conversely, a combination of rapidly fermenting grain and a slower fermenting grain (i.e., DC and HMC) has previously been shown to increase gain and feed conversion compared to feeding DC or HMC alone (Stock and Erickson, 2006). In this study, BLEND did not improve feed efficiency compared to DC and HMC, suggesting there was not a positive associative effect. The lack of associative effect is consistent with the work previously discussed by Vander Pol et al. (2008), who observed no associative effect when a 1:1 blend of DRC:HMC was fed compared to DRC or HMC alone. Gut fill may have resulted in a tendency (P = 0.07) for increased final live BW for cattle fed DC. There were no differences due to corn type for HCW, dressing percent, LM area, USDA marbling score, 12th rib fat thickness, or liver abscess percent (P ≥ 0.12); however, steers fed HMC diets had a lower (P = 0.05) calculated YG compared to DC, but these treatments did not differ from BLEND. The lack of differences in HCW is somewhat surprising as an increase in carcass-adjusted final BW, and therefore, HCW, has been consistently reported for DC compared to HMC-based diets (Scott et al., 2003; Vander Pol et al., 2008; Corrigan et al., 2009).

Table 4.

Effect of milling method and corn type on total tract digestibility of nutrients in diets containing MDGS (experiment 2)

| Treatment1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| ROLL | HAMMER | P-Value2 | ||||||

| Item | DC | HMC | DC | HMC | SEM | Grain | Mill | Corn x Mill |

| Dry matter | ||||||||

| Intake, kg/d | 8.87 | 7.86 | 8.77 | 8.18 | 0.646 | 0.20 | 0.85 | 0.74 |

| Excreted, kg/d | 2.13 | 1.29 | 1.77 | 1.36 | 0.232 | <0.01 | 0.47 | 0.31 |

| Digestibility, % | 76.4b | 83.3a | 80.0a | 82.9a | 2.54 | <0.01 | 0.22 | 0.13 |

| Organic matter | ||||||||

| Intake, kg/d | 8.54 | 7.59 | 8.48 | 7.87 | 0.623 | 0.20 | 0.85 | 0.77 |

| Excreted, kg/d | 1.94 | 1.11 | 1.57 | 1.17 | 0.218 | <0.01 | 0.45 | 0.28 |

| Digestibility, % | 77.7c | 85.3a | 81.5b | 84.5ab | 2.39 | <0.01 | 0.26 | 0.10 |

| NDF | ||||||||

| Intake, kg/d | 1.71 | 1.27 | 1.65 | 1.52 | 0.115 | 0.02 | 0.42 | 0.18 |

| Excreted, kg/d | 0.81 | 0.54 | 0.68 | 0.54 | 0.092 | 0.04 | 0.45 | 0.51 |

| Digestibility, % | 53.1 | 57.3 | 58.6 | 64.4 | 5.39 | 0.30 | 0.18 | 0.95 |

| ADF | ||||||||

| Intake, kg/d | 0.74 | 0.71 | 0.74 | 0.64 | 0.056 | 0.20 | 0.53 | 0.48 |

| Excreted, kg/d | 0.32 | 0.22 | 0.26 | 0.24 | 0.034 | 0.05 | 0.52 | 0.18 |

| Digestibility, % | 56.0b | 69.7a | 63.9ab | 61.6ab | 5.25 | 0.16 | 0.98 | 0.05 |

| Starch | ||||||||

| Intake, kg/d | 4.70 | 4.09 | 4.59 | 4.25 | 0.319 | 0.43 | 0.81 | 0.30 |

| Excreted, kg/d | 0.40 | 0.04 | 0.29 | 0.07 | 0.062 | <0.01 | 0.51 | 0.27 |

| Digestibility, % | 91.5 | 99.0 | 93.7 | 98.4 | 1.21 | <0.01 | 0.56 | 0.29 |

| Energy | ||||||||

| GE Intake, Mcal/d | 38.15 | 34.70 | 37.73 | 35.94 | 2.817 | 0.34 | 0.88 | 0.76 |

| DE Intake, Mcal/d | 28.70 | 29.25 | 30.41 | 30.25 | 2.687 | 0.92 | 0.50 | 0.86 |

| DE, Mcal/kg | 3.28 | 3.71 | 3.44 | 3.68 | 0.107 | <0.01 | 0.29 | 0.13 |

| DE, % of GE | 76.3 | 83.9 | 80.0 | 83.6 | 2.53 | <0.01 | 0.22 | 0.15 |

1Treatments were corn processed with a roller mill (ROLL) or hammer mill (HAMMER) and fed as dry corn (DC) or high-moisture corn (HMC).

2Grain = P-value associated with the main effect of grain type, Mill = P-value associated with main effect of milling method, Int = P-value associated with grain × mill.

a,b,c Values without common superscripts differ (P ≤ 0.10).

There was no effect on carcass-adjusted final BW, ADG, or DMI based on mill type (P ≥ 0.15; Table 3). In the current study, the average particle size for ROLL was 3,191 µm compared to 2,028 µm for HAMMER. Research has consistently shown that decreasing particle size regardless of grain type will increase ruminal starch digestion (Galyean et al., 1981; Schwandt et al., 2016), but not always translate into improved feed efficiency (Mader et al., 1991; Schwandt et al., 2016). Processing with a roller mill generally produces particles that are more uniform in size compared to the hammer mill, which, in combination with MDGS, may improve the consistency of the diet and mitigate the risk of subacute acidosis (Koch, 2002; Lundy et al., 2015; Schwandt et al., 2015). Schwandt et al. (2016) also observed no differences in feedlot performance as DC particle size was reduced, although in situ digestibility was seemingly increased with finer particle size, which could be due to washout from bags. There was no effect of milling method on carcass characteristics (P ≥ 0.14). The lack of differences from milling method are consistent with Schwandt et al. (2016) who observed no differences for any carcass traits measured based on processing method when wet distillers grains plus solubles (WDGS) was included at 20% of the diet. Furthermore, Swanson et al. (2014) observed no differences in HCW, 12th-rib fat, or LM area when corn was rolled as coarse or fine and dry distillers grains plus solubles (DDGS) was included at 20% or 40% of the diet.

Experiment 2—nutrient digestion experiment

There were no interactions (P ≥ 0.18; Table 4) between corn type and milling method for DM intake, DM excreted, OM intake, OM excreted, NDF digestibility, ADF intake, or ADF excretion. There tended to be an interaction (P = 0.13) between corn type and milling method for total tract DM digestibility, resulting from a larger improvement in DM digestion for HMC compared to DC processed as ROLL (6.9% units) compared to the increase observed from HMC and DC processed as HAMMER. Organic matter digestibility followed the same trend, with the interaction (P = 0.10) occurring because of a greater increase in OM digestion for ROLL HMC than ROLL DC (85.3% and 77.7% for ROLL HMC and ROLL DC, respectively) compared to corns processed with HAMMER (84.5% and 81.5% for HAMMER HMC and DC, respectively). The moisture content of grain and the particle size of processed grains largely dictate degree of digestibility, particularly in the rumen (Owens and Sonderlund, 2006). The larger particle size of ROLL DC compared to HAMMER DC (Table 2) likely hindered total tract digestion. The lack of differences between HMC regardless of processing types is not surprising because of the high digestibility of HMC regardless of processing type. The diet containing ROLL HMC had the greatest ADF digestibility but was not different from HAMMER HMC or HAMMER DC, and ROLL DC had the lowest ADF digestibility; however, it is unclear what caused the differences in ADF digestibility. There were no interactions (P ≥ 0.27) for starch intake, excretion, or digestibility among all treatments. Total gross energy intake (Mcal/d) and total digestible energy (DE) intake was not different (P ≥ 0.34) among treatments. There was a weak tendency (P = 0.13) for an interaction between corn type × milling method for DE intake per kilogram of DM intake. The HMC diets regardless of processing method had the greatest DE intake (Mcal/kg DM), HAMMER DC was intermediate, and ROLL DC had the lowest DE intake (Mcal/kg DM). As corn is more extensively processed, through both fermentation and mechanical processing, energy availability is increased (Peters, 2006). Additionally, as the moisture content of grains increase, such as from DC to HMC, metabolizable energy content also increases (Owens et al., 1997). In the current study, the change in DE from DC to HMC was observed; however, HAMMER HMC had a slightly lower DM than ROLL HMC (65.4% and 68.2%, respectively). Although metabolizable energy was not measured, the differences in DM of HMC processed as HAMMER or ROLL likely did not result in an increase in DE as reported by Owens et al., 1997. Across the spectrum of 60% to 80% DM, a linear increase is observed in 7-h in vitro digestibility as DM content of HMC decreases (Ferraretto et al., 2014). The relatively small difference in DM coupled with that fact that the HMC in this study was relatively low in DM content for both milling methods, a difference in G:F, digestibility, or DE content between milling methods due to DM content of HMC is unlikely.

Effect of corn type on nutrient digestion

There was no effect (P = 0.20; Table 4) of corn type on DM orOM intake of cattle; however, feeding HMC decreased (P < 0.01) DM and OM excretion, which resulted in increased (P < 0.01) DM and OM digestion compared to DC. Increased ruminal and total tract digestibility is common with fermented feeds, especially in high-concentrate diets (Owens and Sonderlund, 2006). Although the current study only evaluated total tract digestion, previous research suggests that reduced particle size and fermented feeds had the greatest influence on ruminal digestibility through improved rumen fermentation (Hale, 1973; Owens and Sonderlund, 2006). Similarly, cattle consuming HMC based diets had reduced NDF intakes (P = 0.02) and excretion (P = 0.04) and had no effect on NDF digestibility (P = 0.30). These results agree with the observations of Corrigan et al. (2009), who reported that cattle fed HMC-based diets consumed less NDF than that of dry-rolled corn-based diets, with no effect on NDF digestibility. There was no difference (P = 0.20) between DC and HMC for ADF intake, but ADF excretion decreased slightly (P = 0.05) for HMC compared to DC. Digestibility of ADF was not influenced (P = 0.16) by processing method. Corn type did not influence (P = 0.43) starch intake, but as expected, HMC decreased starch excretion (P < 0.01) and improved starch digestion (P < 0.01) compared to DC. As previously discussed, it has been well-documented that HMC increases total tract starch digestion. HMC has greater ruminal starch digestibility compared to DC, which means that more starch from DC enters the small intestine (Owens and Zinn, 2005; Owens and Sonderlund, 2006). Although a greater amount of starch is digested in the small intestine as a percent of total starch intake in DC-based diets, the starch in HMC is more digestible in the small intestine compared to DC, improving total tract digestibility of starch (Owens and Zinn, 2005). In a review by Huntington (1997), total tract starch digestion was increased from 92.2% when cattle were fed DC to 95.3% when HMC was fed. Cooper et al. (2002) observed an increase in total tract starch digestion when HMC was fed compared to DC (98.7% and 96.1%, respectively), which agrees with results reported by Galyean et al. (1976) where total tract starch digestibility was 96.3% for DC and 99.1% for ground HMC. These results agree with the total tract starch digestibility in the current study, where digestibility was increased from 92.5% for DC to 98.6% for HMC. Interestingly, in the feedlot performance study, HAMMER DC had the greatest fecal starch concentration, which may indicate reduced total tract digestibility, contradicting these nutrient digestion results and from what would be expected with reduced particle size of the HAMMER DC compared to ROLL DC. The inconsistency between fecal starch percent from the pen study and starch digestion values from the current study may indicate that change in DMI or passage rate may play a role in total tract digestibility in combination with factors previously discussed (Rowe et al., 1999). Total energy intake (Mcal/d), expressed as GE or DE, was unaffected by corn type, but cattle consuming HMC consumed more (P < 0.01) energy per kilogram of DM.

Effect of mill type on nutrient digestion

Overall, there were no differences (P ≥ 0.18; Table 4) in nutrient digestion between corns processed with ROLL or HAMMER. Data regarding the effect of processing corn with a roller mill or hammer mill are lacking in the literature; however, the primary differences in the end product between the milling methods is particle size and variation across screen sizes. In this trial, reduction in particle size with the hammer mill, regardless of corn type, was not enough to influence nutrient digestibility. Furthermore, the literature related to the effect of altering corn particle size in diets containing distiller’s grains is limited. Some evidence suggests that addition of WDGS in diets containing highly-processed corn, resulting in smaller particle size, is sufficient to improve homogeneity of the diet, bind fines, and possibly dilute readily ruminally-available starch to reduce the incidence of acidosis (Schwandt et al., 2016). Conversely, Corrigan et al (2009) and Luebbe et al. (2012) showed no effect on ruminal pH parameters compared to a negative control when WDGS displaced rapidly fermentable starch (DRC, HMC, or steam-flaked corn), suggesting no influence on ruminal acidosis when WDGS displaced starch.

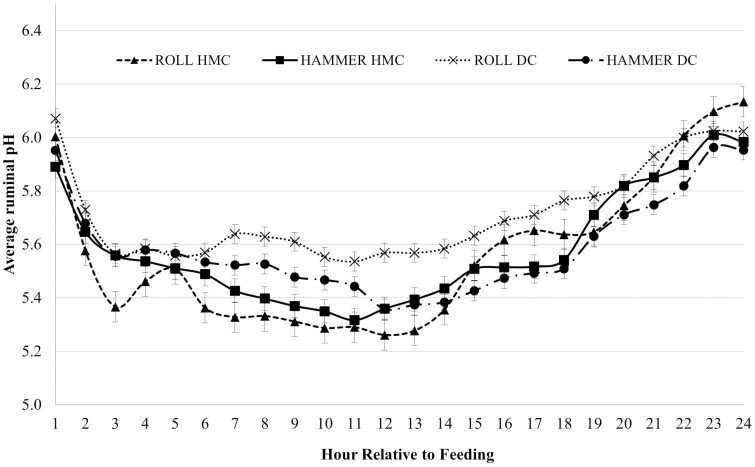

Effect of corn type and milling method on ruminal pH

There were no interactions (P ≥ 0.18; Table 5) between corn type × milling method for any pH parameters, with the exception for a tendency (P = 0.07) for an interaction of minimum pH. Minimum ruminal pH was the least for ROLL HMC but was not different from HAMMER DC and HAMMER HMC. Neither HAMMER treatment did not differ from ROLL DC (P > 0.10), which had the greatest minimum pH. There was no effect (P ≥ 0.20) of milling method on any of the ruminal pH parameters. Mean, minimum, or maximum pH were not influenced (P ≥ 0.34) by corn type; however, HMC had greater (P = 0.04) pH variance compared to DC. With greater variance in ruminal pH, it is not surprising that HMC increased the (P = 0.05) time (min/d) less than pH 5.6 and tended (P ≤ 0.10) to increase time and area (min/d) less than pH 5.3. Observed changes in pH between DC and HMC are similar to results reported by Corrigan et al. (2009), who observed an increase in pH variance and increased time with pH < 5.0 in steers that were fed HMC compared to DC. Moreover, Cooper et al. (2002) observed a decrease in ruminal pH in cattle fed HMC compared to DC and remained lower than DC for up to 15 h post feeding, which differs from the results of the current study (Figure 1).

Table 5.

Effect of milling method and corn type on ruminal pH (experiment 2)

| Treatment1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| ROLL | HAMMER | P-value2 | ||||||

| Item | DC | HMC | DC | HMC | SEM | Grain | Mill | Int. |

| DMI, kg/d | 8.87 | 7.86 | 8.77 | 8.18 | 0.646 | 0.20 | 0.85 | 0.74 |

| Ruminal pH | ||||||||

| Minimum pH | 5.27a | 5.03b | 5.08ab | 5.15ab | 0.106 | 0.34 | 0.39 | 0.07 |

| Maximum pH | 6.46 | 6.55 | 6.39 | 6.45 | 0.159 | 0.58 | 0.51 | 0.93 |

| Mean pH | 5.73 | 5.54 | 5.54 | 5.60 | 0.149 | 0.56 | 0.61 | 0.27 |

| pH Variance | 0.082 | 0.141 | 0.096 | 0.110 | 0.0205 | 0.04 | 0.61 | 0.18 |

| Time < 5.6, min/d | 747 | 900 | 853 | 972 | 145.2 | 0.27 | 0.47 | 0.89 |

| Area < 5.63 | 156 | 324 | 245 | 390 | 79.6 | 0.05 | 0.33 | 0.88 |

| Time < 5.3, min/d | 231 | 489 | 442 | 629 | 133.5 | 0.10 | 0.20 | 0.79 |

| Area < 5.33 | 17 | 110 | 61 | 139 | 47.3 | 0.08 | 0.44 | 0.88 |

1Treatments were corn processed with a roller mill (ROLL) or hammer mill (HAMMER) and fed as dry corn (DC) or high-moisture corn (HMC).

2Grain = P-value associated with the main effect of grain type, Mill = P-value associated with main effect of milling method, Int = P-value associated with grain × mill.

3Area < 5.6 and < 5.3 = ruminal pH units below 5.6 and 5.3..

a,b,cValues without common superscripts differ (P ≤ 0.10).

Figure 1.

Average hourly ruminal pH on days 15 through 19 in experiment 2. Treatments were corn processed with a roller mill (ROLL) or hammer mill (HAMMER) and fed as dry corn (DC) or high-moisture corn (HMC).

Feeding cattle HMC processed with a roller mill increased feed efficiency by nearly 5% in the feedlot compared to cattle fed HMC processed with the hammer mill; however, processing method did not influence feedlot performance in DC or diets fed as a combination of dry and HMC. There were no interactions between corn type and milling method for intake, gain, or carcass traits. Feeding cattle HMC improved gain regardless of milling method compared to cattle fed BLEND or DC. Milling method alone had little effect on steer performance or carcass characteristics. Furthermore, the interaction for G:F between corn type and milling method may be explained by the observed interaction in OM digestion. As expected, corn type had the greatest influence on nutrient digestibility, with HMC increasing DM, OM, and starch digestibility compared to DC. Feeding HMC had the greatest effect on pH, resulting in greater pH variance, area < 5.6, and time and area < 5.3 compared to DC. There was no influence of milling method alone on nutrient digestion. Overall, processing HMC with a roller mill improves feed efficiency in finishing diets containing MDGS by 4.7%; however, there is little difference in nutrient digestion between HMC processed with ROLL or HAMMER.

Acknowledgments

A contribution of the University of Nebraska Agriculture Research Division, supported in part by funds provided through the Hatch Act. Funding provided by Automatic Ag (Pender, NE).

Glossary

Abbreviations

- ADF

acid detergent fiber

- ADG

average daily gain

- BW

body weight

- DC

dry corn

- DDGS

dry distillers grains plus solubles

- DE

digestible energy

- DM

dry matter

- DMI

dry matter intake

- DRC

dry-rolled corn

- E2

estradiol

- ENREEC

Eastern Nebraska Research Extension and Education Center

- G:F

gain to feed or feed efficiency

- GE

gross energy

- GMD

geometric mean diameter

- GSD

geometric standard deviation

- HCW

hot carcass weight

- HMC

high-moisture corn

- LM

longissimus muscle

- MDGS

modified distillers grains plus solubles

- ME

metabolizable energy

- NDF

neutral detergent fiber

- NEg

net energy for gain

- NEm

net energy for maintenance

- OM

organic matter

- TBA

trenbolone acetate

- WDGS

wet distillers grains plus solubles

Contributor Information

Caitlin A Coulson, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Bradley M Boyd, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Braden C Troyer, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Levi J McPhillips, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Mitch M Norman, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Nicole M Woita, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Hannah C Wilson, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Kylie M Butterfield, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Tyler J Spore, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Galen E Erickson, Department of Animal Science, University of Nebraska-Lincoln, Lincoln, NE 68583, USA.

Conflict of Interest Statement

The authors declare no real or perceived conflicts of interest.

Literature Cited

- AOAC. 1999. Official methods of analysis. 16th ed. Arlington (VA): Association of Official Analytical Chemists. [Google Scholar]

- AOAC INTERNATIONAL. 2000. AOAC Official Method 996.11. Gaithersburg, MD, Method 996.11. Total Starch Assay Procedure. Amylogucosidase/α-amylase method. Official methods of Analysis AOAC International, 17th ed. Horwitz William, ed. AOAC Int., Gaithersburg (MD). [Google Scholar]

- ASAE. 2008. Method of determining and expressing fineness of feed materials by sieving. ASAE Standard S319.2. St. Joseph (MI): American Society of Agricultural and Biological Engineers. [Google Scholar]

- Brink, D. R., Lowry S. R., Stock R. A., and Parrott J. C... 1990. Severity of liver abscesses and efficiency of feed utilization of feedlot cattle. J. Anim. Sci. 68:1201–1207. doi: 10.2527/1990.6851201x [DOI] [PubMed] [Google Scholar]

- Cooper, R. J., Milton C. T., Klopfenstein T. J., Scott T. L., Wilson C. B., and Mass R. A... 2002. Effect of corn processing on starch digestion and bacterial crude protein flow in finishing cattle. J. Anim. Sci. 80:797–804. doi: 10.2527/2002.803797x [DOI] [PubMed] [Google Scholar]

- Corona, L., Rodriguez S., Ware R. A., and Zinn R. A... 2005. Comparative effects of whole, ground, dry-rolled, and steam-flaked corn on digestion and growth performance in feedlot cattle. Prof. Anim. Scient. 21:200–206. doi: 10.15232/S1080-7446(15)31203-1. [DOI] [Google Scholar]

- Corrigan, M. E., Erickson G. E., Klopfenstein T. J., Luebbe M. K., Vander Pol K. J., Meyer N. F., Buckner C. D., Vanness S. J., and Hanford K. J... 2009. Effect of corn processing method and corn wet distillers grains plus solubles inclusion level in finishing steers. J. Anim. Sci. 87:3351–3362. doi: 10.2527/jas.2009-1836 [DOI] [PubMed] [Google Scholar]

- Ferraretto, L. F., Taysom K., Taysom D. M., Shaver R. D., and Hoffman P. C... 2014. Relationships between dry matter content, ensiling, ammonia-nitrogen, and ruminal in vitro starch digestibility in high-moisture corn samples. J. Dairy Sci. 97:3221–3227. doi: 10.3168/jds.2013-7680 [DOI] [PubMed] [Google Scholar]

- Galyean, M. L., Wagner D. G., and Johnson R. R... 1976. Site and extent of starch digestion in steers fed processed corn rations. J. Anim. Sci. 43:1088–1094. doi: 10.2527/jas1976.4351088x [DOI] [PubMed] [Google Scholar]

- Galyean, M. L., Wagner D. G., and Owens F. N... 1981. Dry matter and starch disappearance of corn and sorghum as influenced by particle size and processing. J. Dairy Sci. 64:1804–1812. doi: 10.3168/jds.S0022-0302(81)82769-5 [DOI] [Google Scholar]

- Hale, W. H. 1973. Influence of processing on the utilization of grains (starch) by ruminants. J. Anim. Sci. 37:1075–1080. doi: 10.2527/jas1973.3741075x [DOI] [Google Scholar]

- Huntington, G. B. 1997. Starch utilization by ruminants: from basics to the bunk. J. Anim. Sci. 75:852–867. doi: 10.2527/1997.753852x [DOI] [PubMed] [Google Scholar]

- Koch, K. 2002. MF-2048: Hammermills and Roller Mills. Kansas: Kansas St. University. [Google Scholar]

- Luebbe, M. K., Patterson J. M., Jenkins K. H., Buttrey E. K., Davis T. C., Clark B. E., McCollum F. T. III, Cole N. A., and MacDonald J. C... 2012. Wet distillers grains plus solubles concentration in steam-flaked-corn-based diets: Effects on feedlot cattle performance, carcass characteristics, nutrient digestibility, and ruminal fermentation characteristics. J. Anim. Sci. 90:1589–1602. doi: 10.2527/jas.2011-4567 [DOI] [PubMed] [Google Scholar]

- Lundy, E. L., Doran B. E., Vermeer E. E., Loy D. D., and Hansen S. L... 2015. Effect of corn particle size with moderate amounts of wet distillers grains in finishing diets on starch digestibility and steer performance. Prof. Anim. Scient. 31:535–542. doi: 10.15232/pas.2015-01387 [DOI] [Google Scholar]

- Macken, C. N., Erickson G. E., Klopfenstein T. J., and Stock R. A... 2006. Effects of corn processing method and protein concentration in finishing diets containing wet corn gluten feed on cattle performance. Prof. Anim. Scient. 22:14–22. doi: 10.15232/S1080-7446(15)31056-1 [DOI] [Google Scholar]

- Mader, T. L., Dahlquist J. M., Britton R. A., Krause V. E... 1991. Type and mixtures of high-moisture corn in beef cattle finishing diets. J. Anim. Sci. 69:3480–3486. doi: 10.2527/1991.6993480x [DOI] [PubMed] [Google Scholar]

- Matsushima, J. K. 2006. History of feed processing. Proc. Cattle Grain Processing Sym, pp. 1–16. Oklahoma State University, Stillwater OK. https://extension.okstate.edu/programs/beef-extension/symposiums/site-files/documents/cattle-grain-processing-symposium/osu-cattle-grain-processing-proceedings.pdf. [Google Scholar]

- Myers, W. D., Ludden P. A., Nayigihugu V., and Hess B. W... 2004. Technical Note: A procedure for the preparation and quantitative analysis of samples for titanium dioxide. J. Anim. Sci. 82:179–183. doi: 10.2527/2004.821179x [DOI] [PubMed] [Google Scholar]

- National Research Council. 1996. Nutrient requirements of beef cattle. 7th ed. Washington (DC):Natl. Acad. Press. [Google Scholar]

- NASEM. 2016. Nutrient Requirements of Beef Cattle: Eighth Revised Edition. 2016. National Academies of Sciences, Engineering, and Medicine. Washington (DC): Natl. Acad. Press. [Google Scholar]

- Owens, F. N., Secrist D. S., Hill W. J., and Gill D. R... 1997. The effect of grain source and grain processing on performance of feedlot cattle: A review. J. Anim. Sci. 75:868–879. doi: 10.2527/1997.753868x [DOI] [PubMed] [Google Scholar]

- Owens, F. and Soderlund S... 2006. Ruminal and postruminal starch digestion in cattle. Proc. Cattle Grain Processing Symp. pp. 116–128. Oklahoma State University, Stillwater, OK: https://extension.okstate.edu/programs/beef-extension/symposiums/site-files/documents/cattle-grain-processing-symposium/osu-cattle-grain-processing-proceedings.pdf. [Google Scholar]

- Owens, F. N. and Zinn R. A... 2005. Corn grain for cattle: Influence of processing on site and extent of digestion. Proc. Southwest Nutr. Conf. pp. 86–112. University of Arizona, Tucson. [Google Scholar]

- Peters, T. M. 2006. Comparing cost versus benefits of corn processing for feedlot cattle. Proc. Cattle Grain Processing Symp. pp. 137–144. Oklahoma State University, Stillwater, OK: https://extension.okstate.edu/programs/beef-extension/symposiums/site-files/documents/cattle-grain-processing-symposium/osu-cattle-grain-processing-proceedings.pdf. [Google Scholar]

- Rowe, J. B., Choct M., and Pethick D. W... 1999. Processing cereal grains for animal feeding. Aust. J. Agric. Res. 50:721–736. doi: 10.1071/AR98163 [DOI] [Google Scholar]

- Schwandt, E. F., Thomson D. U., Bartle S. J., and Reinhardt C. D... 2015. A survey of dry-processed-corn particle size and fecal starch in midwestern United States feedlots. Prof. Anim. Sci. 31:467–472. doi: 10.15232/pas.2015-01392 [DOI] [Google Scholar]

- Schwandt, E. F., Wagner J. J., Engle T. E., Bartle S. J., Thomson D. U., and Reinhardt C. D... 2016. The effects of dry-rolled corn particle size on performance, carcass traits, and starch digestibility in feedlot finishing diets containing wet distillers’ grains. J. Anim. Sci. 94:1194–1202. doi: 10.2527/jas.2015-9408 [DOI] [PubMed] [Google Scholar]

- Scott, T. L., Milton C. T., Erickson G. E., Klopfenstein T. J., and Stock R. A... 2003. Corn processing method in finishing diets containing wet corn gluten feed. J. Anim. Sci. 81:3182–3190. doi: 10.2527/2003.81123182x [DOI] [PubMed] [Google Scholar]

- Stock, R. A. and Erickson G. E... 2006. Associate effects and management – combinations of processed grains. Proc. Cattle Grain Processing Symp. pp. 166–172. Oklahoma State University, Stillwater, OK: https://extension.okstate.edu/programs/beef-extension/symposiums/site-files/documents/cattle-grain-processing-symposium/osu-cattle-grain-processing-proceedings.pdf. [Google Scholar]

- Swanson, K. C., Islas A., Carlson Z. E., Goulart R. S., Gilbery T. C., and Bauer M. L... 2014. Influence of dry-rolled corn processing and increasing dried corn distillers plus solubles inclusion for finishing cattle on growth performance and feeding behavior. J. Anim. Sci. 92:2531–2537. doi: 10.2527/jas.2013-7547 [DOI] [PubMed] [Google Scholar]

- USDA. 2016. Official United States Standards for Grades of Carcass Beef. Washington (DC):USDA Agriculture Marketing Service. [Google Scholar]

- Van Soest, P. J., Robertson J. B., and Lewis B. A... 1991. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74:3583–3597. doi: 10.3168/jds.S0022-0302(91)78551-2 [DOI] [PubMed] [Google Scholar]

- Vander Pol, K. J., Greenquist M. A., Erickson G. E., Klopfenstein T. J., and Robb T... 2008. Effect of corn processing in finishing diets containing wet distillers grains on feedlot performance and carcass characteristics of finishing steers. Prof. Anim. Scient. 24:439–444. doi: 10.15232/S1080-7446(15)30886-X [DOI] [Google Scholar]

- Watson, A. K., Klopfenstein T. J., Lomas L. W., Erickson G. E., and Nuttleman B. L... 2013. Limit feeding to decrease variation and increase accuracy of cattle weight. J. Anim. Sci. 91:5507–5517. doi: 10.2527/jas.2013-6349 [DOI] [PubMed] [Google Scholar]

- Zinn, R. A., Owens F. N., and Ware R. A... 2002. Flaking corn: processing mechanics, quality standards, and impacts on energy availability and performance of feedlot cattle. J. Anim. Sci. 80:1145–1156. doi: 10.2527/2002.8051145x [DOI] [PubMed] [Google Scholar]