Abstract

Children with a variety of diagnoses have impairments that limit their arm function. Despite the fact that arm function is important for early learning and activities of daily living, there are few tools to assist movement for these children, and existing devices have challenges related to cost, accessibility, comfort, and aesthetics. In this article, we describe the design process and development of the first garment-based exoskeleton to assist arm movement in young children with movement impairments: the Playskin Lift™. We outline our design process, which contrasts with the traditional medical model in that it is interdisciplinary, user-centered, and addresses the broad needs of users, rather than device function alone. Then we report the results of field-testing with the initial prototype with respect to our design metrics on a toddler with significant bilateral arm movement impairments. Finally, we summarize our ongoing development aimed at increasing comfort, aesthetics, and accessibility of the garment. The interdisciplinary, user-centered approach to assistive technology design presented here can result in innovative and impactful design solutions that translate to the real world.

Keywords: assistive technology, design for disability, functional design, open source design, user-centered, wearable technology

Introduction

Mobility and exploration are important components for typical physiological and cognitive development in children (Gibson, 1995; Thelen, 2000). Early active mobility and exploration impacts the progression of cognitive, language, and social skills (Lobo & Galloway, 2008; Needham, 2000). For children with limited early mobility and exploration, such as related to the diagnoses of arthrogryposis multiplex congenita (arthrogryposis), brachial plexus palsy, or brain injury, movement amount and quality is often impaired, and there is increased risk for future developmental delays (Lobo, Harbourne, Dusing, & McCoy, 2013; Lobo, Kokkoni, Cunha, & Galloway, 2015; Rink, 2011). Studies indicate children with physical disabilities who use assistive devices to improve their mobility improved environmental participation, independent activity, and self-concept (Cowan & Khan, 2005; Henderson, Skelton, & Rosenbaum, 2008; Moir, 2010; Ostensjø, Carlberg, & Vøllestad, 2005; Ryan et al., 2009).

Although a variety of devices exist, such as scooters, crutches, and wheelchairs, to assist mobility for children with leg movement impairments, there are few commercially available devices to assist mobility for children with arm movement impairments. One system, the Universal Exercise Unit (Therasuit, LLC, Largo, FL, USA), involves attaching elastic cords between the child and a large, stationary structure external to the child to provide assistance to lift the arms (Bailes et al., 2011). Key limitations to this type of solution are that it is expensive, bulky, stationary, and is not feasible for use in the natural environments children typically experience. Another example of an existing solution is the Wilmington Robotic Exoskeleton (WREX). This is the only commercially available exoskeleton children can wear to assist arm movement (Haumont et al., 2011). The WREX consists of either steel or three-dimensional (3D)-printed exoskeletal links that extend alongside the upper arm and forearm with elastic bands that stretch across the shoulder and elbow joints to produce torque and elevate the child’s arms against gravity. Key limitations to this solution are that it is expensive, bulky, difficult to obtain, unattractive, and it must attach to a chair or plastic trunk brace. While the WREX has been shown to improve function for children with a variety of diagnoses, it is clear there are key needs of users the device does not meet (Babik et al., 2016; Haumont et al., 2011). The result is that many families who acquire the device choose to discontinue using it. This was the scenario for the participant involved in this study.

The purpose of this article is to describe the interdisciplinary, user-centered design process used to develop the first exoskeletal garment for rehabilitation: the Playskin Lift™. The Playskin Lift™ was developed to address the need for a rehabilitative device to assist mobility for children with arm movement impairments. The goal was to create a device that could provide immediate assistance to help children lift their arm(s) against gravity. Our team has shown that providing this anti-gravity movement assistance can improve reaching and playing—two key behaviors that facilitate early learning, independence, and participation—for a toddler with bilateral arm movement impairments (Babik et al., 2016; Lobo et al., 2015). We have also shown devices that provide this type of movement assistance can potentially serve as rehabilitative tools to improve strength and independent function over time (Babik et al., 2016).

Below, we discuss the development of the Playskin Lift™ passive exoskeletal garment. We outline the specific design methodology for our process (Methods) and the design outcome (Results). The project was led by a pediatric physical therapist, with team members from the mechanical engineering and apparel design disciplines. The design approach utilized contrasts with the traditional model for assistive technology by applying an interdisciplinary, user-centered process that addresses not only the user’s functional needs for physical assistance, but also other key user needs. The traditional medical model tends to involve engineers working in an environment isolated from end users, and designing assistive and rehabilitative devices focused on improving bodily function, while inadequately addressing other needs of users, such as accessibility, cost, and appearance (de Ana, Umstead, Phillips, & Conner, 2013; DeMarco, 2011). For example, available devices may function to assist with movement, but they are typically expensive and have limited availability (Yan, Cempini, Oddo, & Vitiello, 2015). Moreover, these devices can be physically uncomfortable as well as potentially stigmatizing for users and their families by drawing unwanted attention to users’ impairments (Parette & Scherer, 2004). This can be seen in traditional power wheelchairs and exoskeleton or robotic devices, for instance. By combining design processes from apparel studies and engineering, and applying them to the domain of health science, we present an integrated approach to rehabilitative device design that can serve as a model for developing innovative and impactful devices that translate out of labs and clinics and into the real world of users.

Methods

Participants

The participants in this project were a 23-month-old with impaired bilateral arm function due to a diagnosis of arthrogryposis and his parents. This child had a history of muscle fibrosis, decreased muscle mass, and symmetrical contractures in his shoulders, elbows, hips, knees, and ankles. As a result, even after stretching restored functional passive range of motion in his arms, he could not fully lift his arms (shoulder flexion) or bend his elbows (elbow flexion) against gravity. The child was able to sit, transition from sitting to lying down, and roll on the floor independently. The child exhibited many typical cognitive abilities for his age, such as recognizing and seeking out his family, requesting desired toys, and cause–effect learning. Without assistance, the child could reach for and contact objects at his hip level, but could not actively move either arm against gravity into more than 15 degrees of shoulder flexion, and thus could not contact objects at chest or eye level. This article focuses on design process and device outcome, while impact of the Playskin Lift™ on function for this participant is more thoroughly detailed in Lobo and colleagues (2016).

Design and prototypingset headings in sentence caps

The design process for this project used an interdisciplinary approach and kept engagement with the users central throughout. The project team was led by a pediatric physical therapist and consisted of an apparel design expert, a mechanical engineering professor, five undergraduate engineering students, and two professional mechanical engineers. Team members worked together with the family on all stages of the design process from concept development through final testing. The engineering members led bench testing efforts; the apparel expert led efforts to design the garment, select textiles, and integrate mechanical components within the garment; and the team leader led the overall design process and data collection.

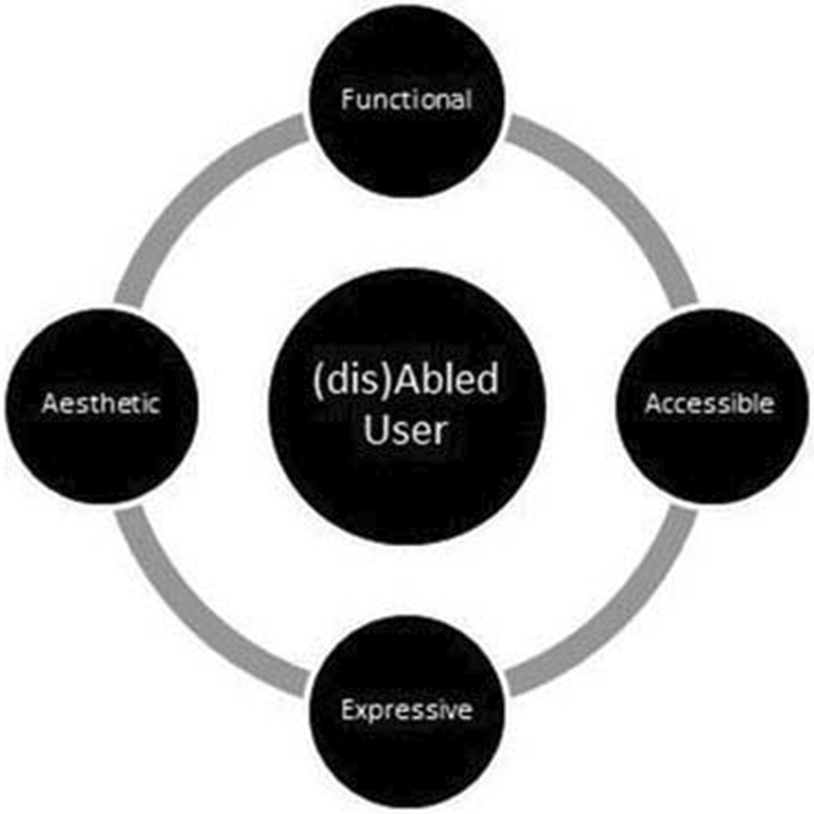

In order to holistically address the participants’ needs related to function, expressiveness, aesthetics, and accessibility, design approaches from engineering and apparel design were combined (Figure 1; Lamb & Kallal, 1992). The apparel design process focused on three stages: (1) Problem definition: the team defines the problem according to the client, then researches existing solutions and safety standards, and redefines the problem; (2) Creative exploration: the team ideates initial design solutions, creates prototypes, and evaluates them; and (3) Implementation: the team refines the prototypes in order to produce a design solution for comprehensive evaluation (LaBat & Sokolowski, 1999). In conjunction, we incorporated a typical engineering approach by reviewing safety standards and inter-viewing the participants to clearly identify relevant measurable metrics for the design problem, noting the limitations and constraints for the final design (Watkins, 1988). Table 1 lists each of the metrics by the corresponding category of user needs (functional, expressive, aesthetic, or accessibility). Metrics were identified via informal, conversational interviews with participants, reviews of safety standards, and domain-specific expertise of the team members. The participants previously discontinued using the WREX, so they had clear ideas of what they would and would not like from an upper extremity exoskeleton.

Figure 1.

User-centered conceptual model for designing assistive/rehabilitative wearable technology, expanded from the consumer needs model of Lamb and Kallal (1992).

Table 1.

Metrics, desired target outcomes, and method of assessment during field-testing for each metric relating to the functional, expressive, aesthetic, and accessibility needs identified via informal, conversational interviews with the participants, reviews of safety standards, and domain-specific expertise of the team members.

| Metric | User needs | Targeted outcome | Assessment method |

|---|---|---|---|

| Amount of arm lift against gravity | Functional | 85 ± 5 degrees of shoulder flexion | Observation and goniometric measurement of the arm at rest with the garment. |

| Weight of prototype | Functional | <230 g | Weight of prototype on balance. |

| Lack of restriction of movement in other directions at the shoulder | Functional | Functional range of motion for shoulder abduction/adduction (0°–130°) and flexion/extension (0°–130°) | Experimenter passively moved the child’s arms through the range of motion as the garment permitted. |

| Safety | Functional | Comply with childrenswear safety standards: no small parts, drawstrings, or hazardous materials | Visual inspection of the final prototype and research on safety of all materials used. |

| Comfort | Functional | User able to wear the garment without expressing emotional signs of discomfort or showing physical signs of skin irritation | Emotional affect of the child was assessed throughout the testing based on facial expression and vocalizations. Skin irritation was assessed by visual inspection of the skin after a 1-hour period of wear. |

| Ease of donning/doffing | Functional | <5 minutes | The parent was timed donning and doffing the garment for the first time without any instruction. |

| Scalability | Functional | Design that allows for the provision of different levels of support to variably assist different users that contrast in size and ability, and to variably assist the same user as the user’s abilities change across time | Provision of variable levels of support and goniometric measurement of corresponding arm lift angles during testing. |

| Product appeal | Aesthetic | User/family satisfaction with design; positive or neutral ratings for aesthetics | User rating of aesthetic appeal on a scale from 1 (low)–5 (high). |

| Sleekness | Aesthetic | Maximum protrusion of the components of the garment no more than 1 cm from the child’s body | Identify the location with the highest level of component protrusion of the garment and measure the perpendicular distance to the child’s body using a tape measure. |

| Quality construction | Aesthetic | Typical wear and care should cause no damage or distortion | Visual inspection of the garment after 1 hour of wear and after washing. |

| Social psychological comfort | Expressive | Matches users’ needs for discretion or attention based on users’ early input on design preferences | User-written feedback on perception survey. |

| Cost | Accessibility | <$100.00 in material costs per unit | Sum of final material costs. |

| Availability | Accessibility | Solution that lends itself to the creation of an open-access DIY material list and fabrication guide | Compilation of a complete material list and step-by-step illustrated DIY fabrication manual. |

For this study, the design problem was defined by the team as the need for a device that would help the user lift his arms, while also being discreet, comfortable, safe, aesthetically appealing, and affordable.

Research on existing devices (described in the introduction) and design processes specifically for users with disabilities suggested that in order to design products users would choose to wear, designers need to address the spectrum of wearable technology needs for the user: not only needs related to improving mobility and function, but also needs that impact product acceptance (Wilkinson & De Angeli, 2014). In this case, our final product needed to provide physical support, without stigmatizing the user by negative social psychological and cultural associations with disability (Freeman, Kaiser, & Wingate, 1985; Lamb, 2001; Shields, 2009; Wilkinson & De Angeli, 2014; Wingate, Kaiser, & Freeman, 1986). Appearance management in the form of dress may be used to positively present the individual with disabilities by concealing the source of the disability and allowing the individual to present other, arguably more positive, perceiver variables (Freeman et al., 1985; Wingate, Kaiser, & Freeman, 1986). However, individuals with disabilities may alternatively choose not to use dress to conceal embodied differences, but rather to express other more salient identity characteristics, including aesthetic and expressive dress preferences. For this study, the participants reported a desire for discretion during informal, conversational interviews. They wanted a device that could be concealed beneath the child’s typical clothing.

Since the final device design would be a child’s wearable, the project team also researched federal regulations for textile and apparel product safety for children’s wear (Consumer Product Safety Improvement Act, 2008). The Consumer Product Safety Commission provides guidelines for selecting non-flammable and non-toxic textile materials, as well as identifying potential choking hazards. The final device design would need to comply with these guidelines.

Based on client interviews and our review of existing solutions, safety standards, and design processes, the team identified key outcome metrics (Table 1) and redefined the problem according to these metrics. We learned that the participants needed a wearable device that would provide immediate physical assistance for the child, be comfortable and safe, and look discreet according to the participants. The design goal was to design and fabricate an exoskeletal garment that would lift the child’s arms against gravity, while being comfortable and non-stigmatizing for the participants. A key focus was to make the design outcome accessible to other families by keeping the garment affordable and the design simple enough that an open access do-it-yourself (DIY) manual could be created for use across communities.

Prototype testing

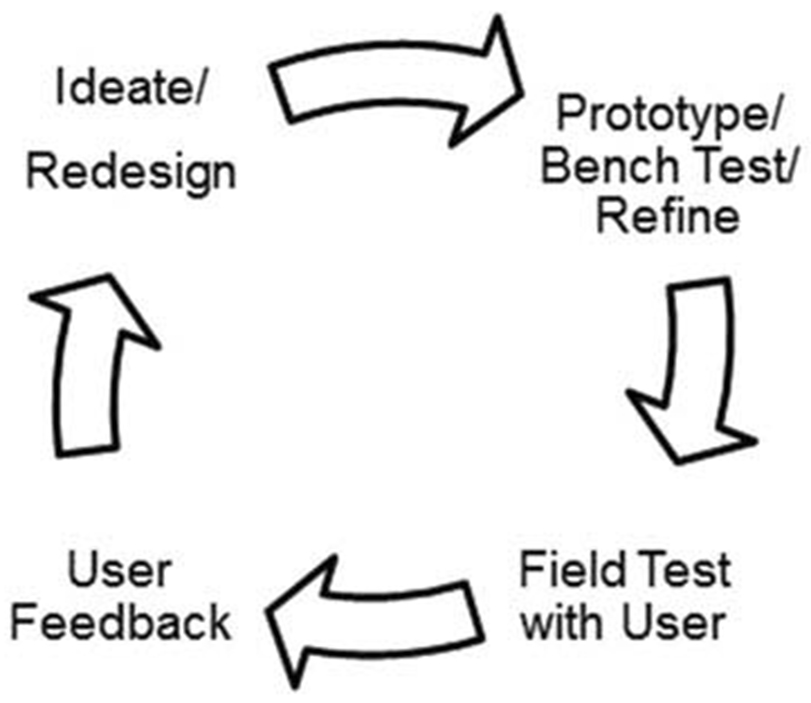

Once the design problem and metrics were defined, the next phase in the design process was to ideate initial design solutions, create first prototypes, and evaluate their effectiveness. This was a cyclical, iterative process with user testing and feedback essential to project success (Figure 2).

Figure 2.

Our cyclical design process for this project.

Prototype testing began with bench testing using a model to assess functionality of lifting mechanisms. The model was a quasi-static model that replicated the user’s arm, simulating the general size, weight, and arm moment. Three lifting mechanisms were bench tested to determine feasibility for use in the exoskeletal garment. These included (1) using a magnet array embedded in the sleeves and body of the garment, (2) a system of embedded pulleys and elastic cables to provide lift, and (3) steel springs encased in the sleeves that would support the weight of the arm.

Six field testing sessions were then performed where mechanisms deemed functional in bench testing were incorporated into garments and multiple prototypes were tested briefly within sessions with participants to assess performance and fit of the garments and to gain feedback about which prototypes participants preferred the team to pursue. The final prototype emerged from this process and detailed measurements for all project metrics were taken at the final 2-hour home field-testing session. Table 1 lists the desired target outcome and a description of the planned assessment methods to be used during field-testing for each metric. Complete metric data on unsuccessful prototypes were not collected.

Results

Prototype testing

The magnet array did not provide enough lift for the static model arm. The pulley and cable system lifted the model arm during bench testing, but performed poorly when integrated into garments and field-tested with the participants—primarily due to issues related to comfort and function.

Steel spring supports proved to be a viable option. The springs were strong enough to support the weight of the model arm and could potentially be made comfortable and discrete via soft encasement within a child’s shirt. Although the springs provided support, they did limit range of motion of the model. The steel springs tested were feeler gauges (long, narrow, and flat metal bands), which provided sufficient arm lift (flexion), but limited shoulder movement in other planes (adduction/abduction, rotation). For this reason, other steel spring shapes were tested. Cylindrical bundles of steel wire were found to provide sufficient shoulder flexion support without limiting shoulder movement in other planes. The wires could be bundled together, sealed with heat shrink tubing, and capped with athletic tape to create insert units.

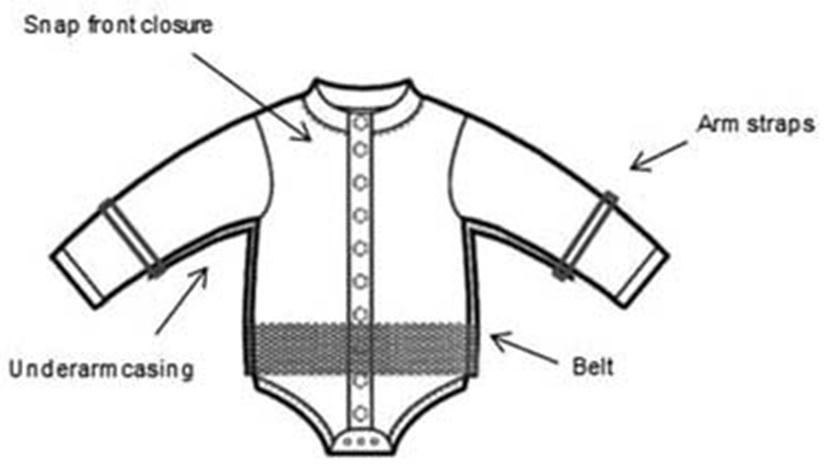

After determining the optimal mechanism for providing lift, the team needed to design a solution to integrate the wire bundles within a child’s garment that was both comfortable and discreet. In order for the wire inserts to function properly for arm support, they needed to maintain proper alignment with the body while the user moved and played. Therefore, the garment needed to have a custom, compressive fit, yet still be comfortable. The team created a prototype based on an infant “onesie” garment: a crewneck longsleeve shirt with a snap front closure and crotch strap. To achieve a close fit, a knit fabrication was needed to maximize user comfort while minimizing garment ease. A polyester blend four-way stretch performance fabric was used for the garment construction. This fabric was chosen because it (1) featured both mechanical and fiber stretch to allow for close and comfortable fit, (2) had a fiber content blend that would keep the user cool and free of moisture, (3) complied with federal safety regulations, and (4) was low cost and easy to clean. Casings were stitched along the garment sideseams from waist level along the sleeve inseam, ending midforearm to encase the wire inserts. A composite material with a polyvinyl chloride (PVC) face and a knit polyester backing was selected because it was strong enough to house the bundles and thick enough to provide padding between the bundles and the child’s body. The vinyl casings also enhanced the overall garment aesthetic by concealing the wire bundles. To prevent potential rotation of the inserts during user testing, a belt and narrow arm bands, each made with polyester webbing and adjustable hook and loop closures, were stitched to the garment (Figure 3).

Figure 3.

Computer-aided drawing of the initial selected solution. The prototype was a onesie-style garment featuring a snap front closure with crotch strap, underarm casings made of composite material to house the wire bundles, and attached nylon webbing belt and wrist straps to stabilize the supports.

The vinyl casings were designed to allow user access to the wire inserts. The bundles could be easily inserted and removed from the garment. This design feature is deliberate so that the garment not only provides assistance, but also can used as a rehabilitative device. By allowing easy access to the wire inserts, users can change the level of support provided, based on the number and diameter of wires inside the selected bundle. The prototype can provide progressively less support, with the goal of increasing the user’s upper limb function over time. This makes the device customizable and potentially rehabilitative for users.

Field testing the first prototype

The prototype was evaluated relative to the desired outcomes in the child’s home (Table 2). The device was determined to be functional: it lifted the arm against gravity to 90 degrees of shoulder flexion and did not restrict other shoulder movements. With the garment on, experimenters were still able to move the child’s arms through the full functional range of motion. The device was safe and comfortable. The arm straps caused temporary skin irritation, but the redness dissipated within 20 minutes. The device was easy for the parent to put on and take off of the user—similar to a typical onesie for children. The device was reported by the parents to be somewhat attractive. The device did not fully meet the users’ needs with regard to expressiveness: Parents reported they would like the design and materials to be more discreet. The black fabric, belt, and straps were lower profile than the child’s current 3D-printed exoskeleton, but reportedly looked too distinctively different from typical children’s clothing. The device was determined to be somewhat accessible: It was inexpensive, at about $30.00 for materials. However, the design required custom fit and skilled labor to construct.

Table 2.

Outcomes from field-testing of the prototype using steel wire bundles as springs inserted in vinyl tunnels in the garment to lift the arms.

| Metric | Outcome |

|---|---|

| Amount of arm lift against gravity | 90 degrees of shoulder flexion at rest with the garment |

| Weight of prototype | <140 g |

| Lack of movement restriction in other directions at the shoulder | Full functional range of motion permitted at the shoulder |

| Safety | No small parts, drawstrings, or hazardous materials were utilized. |

| Comfort | The child showed positive affect throughout testing and did not show any signs of skin irritation (areas of redness) that lasted for more than 20 minutes. |

| Ease of donning/doffing | Donning time: 65 s Doffing time: 30 s |

| Scalability | Three separate wire bundles supported the arms at about 30°, 60°, or 90° of shoulder flexion. Wire number, diameter, and length could be changed in insert bundles to vary levels of support for users of different sizes and abilities. |

| Product appeal | User rated the aesthetic appeal somewhat attractive (4/5). |

| Sleekness | Maximum protrusion of 2 cm in the axilla |

| Quality construction | No noticeable change after testing; long-term durability to be determined. |

| Social psychological comfort | User reported desire for a more discreet product. |

| Cost | Final material costs: $29.54 |

| Availability | A complete material list and step-by-step illustrated DIY fabrication manual detailing how to fabricate the garment and spring inserts was completed and posted online. |

In addition to making the garment appear more like typical children’s clothing, the family identified some other needs for improvement. First, the family suggested the garment could be made easier to don. The prototype had a snap closure front and crotch. According to the family, the snaps made the garment easy to doff, but difficult to don. Second, there was concern from the family that the selected fabric might be too hot for the child in the summer and may require special laundry care. Lastly, the family requested improvement of the aesthetics and expressiveness of the overall design. The family did not prefer the black color. They also suggested streamlining the design so that it was more discreet (such as by eliminating the stabilizing belt and straps), or using more child-friendly materials and design details to reflect the user’s typical clothing style.

Implementation

The final phase of the design process involved refining the prototype and re-evaluation with the user in order to produce a design solution. After analyzing test results and user feedback, the team created a refined prototype retaining design features that met or exceeded project metrics and incorporated improvements suggested by the participants. These improvements included changes to the garment fabrication and design.

To make the garment more aesthetically pleasing, more expressive, and easier to clean, a new knit fabric was selected. Since the device required a close fit in order to function properly, the new fabric needed to retain inherent stretch properties. A nylon spandex powernet fabric provided sufficient stretch with improved breathability compared to the black polyester blend. The powernet is machine washable, and the mesh structure of the fabric allowed for quick air drying, resulting in improved product care and maintenance. Powernet is available in several flesh tone and fashion colors, thus improving device expressiveness by being customizable for each user’s style preferences. The composite material used for the casings is also offered in an extensive color range from which users can select.

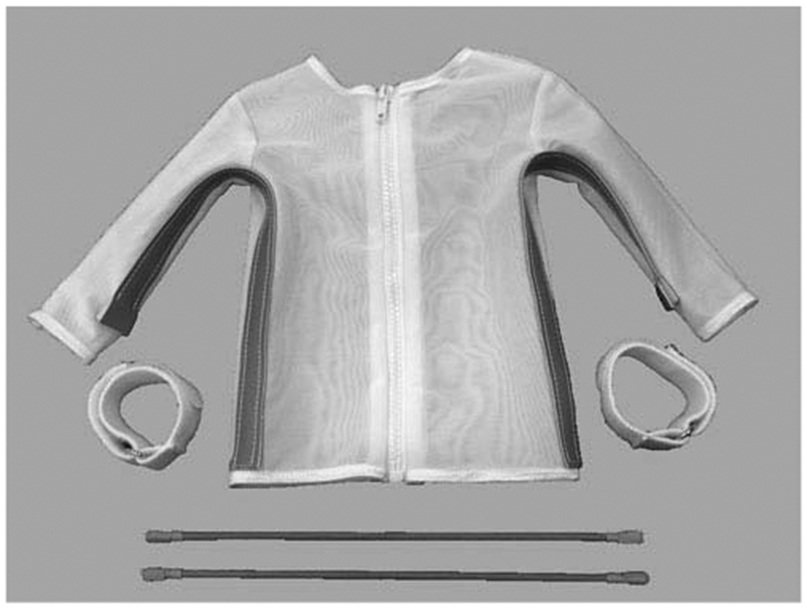

The design of the device was changed as well to improve ease of use for the parents and overall aesthetic. The garment closure was changed to make the device easier to don and doff. The snap closure was replaced with a sport zipper backed with a self-fabric placket. The zipper was quicker and easier to use and the placket protected users’ skin from zipper teeth. The design was streamlined to further improve aesthetic and expressive properties. The crotch strap was removed for children after infancy, and the improved stretch and strength characteristics of the powernet eliminated the need for the belt strap. Arm straps were detached, so they could be used only if needed in order to prevent the inserts from shifting (Figure 4).

Figure 4.

The refined prototype (Playskin Lift™), shown with the removable wire bundles (bottom). The device is made with white nylon spandex powernet fabric with a zipper closure. The crotch strap and belt have been removed. The white soft Velstretch™ wrist straps are detached for use if needed. The casings under each arm are made with PVC composite fabric.

Following completion of improvements, the device was re-evaluated with the participants. The device retained its functionality, and the family was pleased with the stylistic and material changes. The design solution for this project was an exoskeletal garment, the Playskin Lift™, that (1) assists users in lifting their arms against gravity to facilitate play; (2) is comfortable, low-profile, aesthetically pleasing, and allows for stylistic expression; and (3) is inexpensive and easy to maintain. The cost of materials for the refined prototype was further reduced from about $30.00 to $10.00. Simplification of the product design and ease of sewing with the new fabric meant further reduction in cost for potential manufacturing. Cost and ease of manufacture are important factors when discussing garments for young children because they typically outgrow their clothing every few months.

Discussion

Summary of the project

This manuscript describes the interdisciplinary, user-centered design process used to create the Playskin Lift™ exoskeletal garment to assist arm mobility for a 23-month-old child with bilateral arm movement impairments. The team wanted to meet participants’ needs by creating a device that would both assist the child, while also potentially serving as a rehabilitative tool by providing variable levels of arm support over time. This can be achieved by varying the number and diameter of the wires incorporated in the support bundles. In addition, the device needed to look appealing and feel both physically and socially comfortable to the participants. According to testing and participant feedback, the design solution, the Playskin Lift™, met a broad range of design metrics. It (1) lifted and supported the user’s arm to 90 degrees of shoulder flexion without limiting other movements; (2) was comfortable and safe; (3) was easy to don, doff, and maintain; (4) was aesthetically pleasing; (5) was expressive, in that it was low-profile and discrete; and (6) was accessible via an online DIY guide (see Figure 5). The exoskeletal garment, when worn, also effectively improved the participant’s ability to reach for and contact objects across a larger reaching space to look at objects while contacting them, and to engage in more complex interactions with toys during play activities (details in Lobo et al., 2015). The child could reach for objects more often at hip, chest, and eye level, had improved visual motor coordination, and showed improved ability to manipulate objects when wearing the garment.

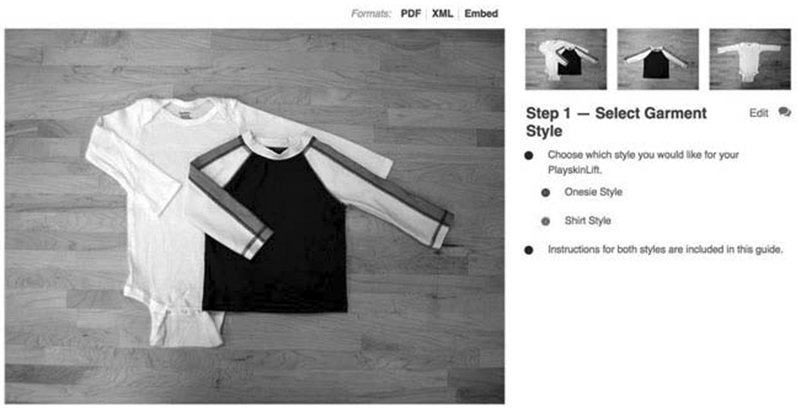

Figure 5.

Screenshot of one step from the open-source DIY fabrication manual. This manual is a step-by-step guide for making a version of the Playskin Lift™ using a commercial onesie or shirt-style child’s garment (available for download at the following link: http://sites.udel.edu/pt/michele-lobo/).

Accessibility

Because the number of children with arm movement impairments is too large for any one team to support, our team aimed to increase accessibility of the device by creating a detailed material list and step-by-step illustrated DIY fabrication manual (Figure 5). This manual is openly accessible for download via the corresponding author’s faculty web page (http://sites.udel.edu/pt/michele-lobo/).

The open access manual allows us: (1) to effectively disseminate instructions to the community and (2) to create a culture of co-creation. Disseminating information through a communication tool readily accessible by the public expedites widespread availability. In addition to providing the community with design solutions, the open source platform creates an environment focused on end users and collaboration. It allows us to explain the skills and illustrate the steps necessary to create our design solution, rather than simply providing the solution as a commercial product. In this way, individuals are equipped to innovate and contribute to the evolution of new solutions for a much wider variety of challenges.

Significance of this project

This study is significant in that it describes the design process behind the first soft exoskeletal garment for rehabilitation. Exoskeletal technology is fairly recent and these devices are typically made from bulky, heavy metallic or plastic materials that do not interface well with users (Haumont et al., 2011). Attachment, comfort, cost, and appearance of these devices remain key challenges (Babaiasl et al., 2015; “Device offers giant step forward,” 2015; Lajeunesse, Vincent, Routhier, Careau, & Michaud, 2015). This study provides an important first step in rethinking exoskeletal design, moving toward softer materials, improved user interface, comfort, and appearance, and lower cost, by embedding exoskeletons within typical clothing. Ongoing advancements in textile science (De Rossi & Veltink, 2010) and soft robotics (Kim, Laschi, & Trimmer, 2013) bring the promise of further innovations in this new area of soft exoskeletons.

This study is also significant in that it provides a new interdisciplinary framework and model for assistive and rehabilitative device design. User-centered design is not a new methodology, but it remains relatively novel for the design of medical equipment (Ma, Wu, & Chang, 2007). By keeping users’ broad needs and their feedback central throughout the design process, more desirable medical devices people will choose to use can be designed. Moreover, this design model engages users and communities in designing and even fabricating their own devices, empowering them to maximize their physical, psychological, and social comfort. Viewed through this lens, user-centered rehabilitative and assistive devices have the potential to garner higher levels of device acceptance, leading to increased patient compliance and higher dosage of wear.

Important future directions for this project include the need to evaluate the assistive and rehabilitative effectiveness of the garment with larger, more diverse samples of users to improve the function of the device beyond the shoulder, incorporate active control mechanisms, and improve the expressiveness of the garment beyond discretion, so users can highlight personal style, or other desired identity traits (Hall & Orzada, 2013). It is also important to determine whether families can feasibly use this device for daily assistance, whether children can tolerate wearing the device for longer periods and more frequent usage, and whether daily intervention with the device has any lasting impact on assisted function (with the device) or independent function (without the device) across time.

Conclusion

Rehabilitation devices tend to be narrowly defined in scope, with focus remaining solely on improving physical function. Often, these devices are inaccessible to users due to prohibitive cost and limited or restricted availability. This project exemplifies the importance and impact of an interdisciplinary, user-centered approach to medical device design. The design process incorporated the identification and measurement of defined metrics and the development and testing of prototypes aimed at meeting these metrics (engineering design model) using a cyclical, user-centered design process (apparel design model). The solution was a novel and innovative device: the Playskin Lift™, the first soft exoskeletal rehabilitation garment that addresses a broad range of functional, aesthetic, expressive, and accessibility needs of children and their parents. The device is accessible to families via an online DIY material list and manual, increasing the likelihood that families with children with movement impairments can obtain the device. This design process can serve as a model for those interested in developing novel medical devices that truly meet the needs of users, increasing the likelihood the devices will actually be used to improve health and well-being.

Acknowledgements

We would like to acknowledge the efforts of the participants, undergraduate senior design team, and research assistants in supporting this work.

Funding

This research was supported in part by the Eunice Kennedy Shriver National Institute of Child Health and Human Development (1R21HD076092-01A1, Lobo PI).

References

- Babaiasl M, Mahdioun SH, Jaryani P, & Yazdani M (2015). A review of technological and clinical aspects of robot-aided rehabilitation of upper-extremity after stroke. Disability and Rehabilitation: Assistive Technology, 11(1), 263–280. doi: 10.3109/17483107.2014.1002539 [DOI] [PubMed] [Google Scholar]

- Babik I, Kokkoni E, Cunha AB, Galloway JC, Rahman T, & Lobo MA (2016). Feasibility and effectiveness of a novel exoskeleton for an infant with arm movement impairments. Pediatric Physical Therapy, 28, 338–346. doi: 10.1097/PEP.0000000000000271 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bailes AF, Greve K, Burch CK, Reder R, Lin L, & Huth MM (2011). The effect of suit wear during an intensive therapy program in children with cerebral palsy. Pediatric Physical Therapy: The Official Publication of the Section on Pediatrics of the American Physical Therapy Association, 23(2), 136–142. doi: 10.1097/PEP.0b013e318218ef58 [DOI] [PubMed] [Google Scholar]

- Consumer Product Safety Improvement. (2008). Act, 1 U.S.C. § § 101–104. [Google Scholar]

- Cowan DM, & Khan Y (2005). Assistive technology for children with complex disabilities. Current Paediatrics, 15(3), 207–212. doi: 10.1016/j.cupe.2005.02.003 [DOI] [Google Scholar]

- De Ana FJ, Umstead KA, Phillips GJ, & Conner CP (2013). Value driven innovation in medical device design: A process for balancing stakeholder voices. Annals of Biomedical Engineering, 41 (9), 1811–1821. doi: 10.1007/s10439-013-0779-5 [DOI] [PubMed] [Google Scholar]

- DeMarco CT (2011). Medical device design and regulation. Retrieved from http://app.knovel.com/hotlink/toc/id:kpMDDR0001/medical-device-design/medical-device-design [Google Scholar]

- De Rossi D, & Veltink P (2010). Wearable technology for biomechanics: E-textile or micromechanical sensors? IEEE Engineering in Medicine and Biology Magazine: The Quarterly Magazine of the Engineering in Medicine & Biology Society, 29, 3. [DOI] [PubMed] [Google Scholar]

- Device offers giant step forward, but at high cost; $77,000 exoskeleton helps paralyzed patients walk. (NEWS). (2015). Star Tribune (Minneapolis, MN), 1A. [Google Scholar]

- Freeman CM, Kaiser SB, & Wingate SB (1985). Perceptions of functional clothing by persons with physical disabilities: A social-cognitive framework. Clothing and Textiles Research Journal, 4(1), 46–52. doi: 10.1177/0887302X8500400107 [DOI] [Google Scholar]

- Gibson EJ (1995). Exploratory behavior in the development of perceiving, acting, and the acquiring of knowledge. Advances in Infancy Research, 9, xxi. [Google Scholar]

- Hall ML, & Orzada BT (2013). Expressive prostheses: Meaning and significance. Fashion Practice, 5(1), 9–32. [Google Scholar]

- Haumont T, Rahman T, Sample W, King M, Church C, Henley J, & Jayakumar S (2011). Wilmington robotic exoskeleton: A novel device to maintain arm improvement in muscular disease. Journal of Pediatric Orthopedics, 31(5), e44–e49. doi: 10.1097/BPO.0b013e31821f50b5 [DOI] [PubMed] [Google Scholar]

- Henderson S, Skelton H, & Rosenbaum P (2008). Assistive devices for children with functional impairments: Impact on child and caregiver function. Developmental Medicine and Child Neurology, 50(2), 89–98. doi: 10.1111/j.1469-8749.2007.02021.x [DOI] [PubMed] [Google Scholar]

- Kim S, Laschi C, & Trimmer B (2013). Soft robotics: A bioinspired evolution in robotics. Trends in Biotechnology, 31(5), 287–294. doi: 10.1016/j.tibtech.2013.03.002 [DOI] [PubMed] [Google Scholar]

- LaBat K, & Sokolowski S (1999). A three-stage design process applied to an industry-university textile product design project. Clothing and Textiles Research Journal, 17(1), 11–20. doi: 10.1177/0887302X9901700102 [DOI] [Google Scholar]

- Lajeunesse V, Vincent C, Routhier F, Careau E, & Michaud F (2015). Exoskeletons’ design and usefulness evidence according to a systematic review of lower limb exoskeletons used for functional mobility by people with spinal cord injury. Disability and Rehabilitation: Assistive Technology, 11(7), 535–547. [DOI] [PubMed] [Google Scholar]

- Lamb JM (2001). Disability and the social importance of appearance. Clothing and Textiles Research Journal, 19(3), 134–143. doi: 10.1177/0887302X0101900304 [DOI] [Google Scholar]

- Lamb JM, & Kallal MJ (1992). A conceptual framework for apparel design. Clothing and Textiles Research Journal, 10(2), 42–47. doi: 10.1177/0887302X9201000207 [DOI] [Google Scholar]

- Lobo MA, & Galloway JC (2008). Postural and object-oriented experiences advance early reaching, object exploration, and means-end behavior. Child Development, 79, 6. [DOI] [PubMed] [Google Scholar]

- Lobo MA, Harbourne RT, Dusing SC, & McCoy SW (2013). Grounding early intervention: Physical therapy cannot just be about motor skills anymore. Physical Therapy, 93(1), 94–103. doi: 10.2522/ptj.20120158 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lobo MA, Kokkoni E, Cunha AB, & Galloway JC (2015). Infants born preterm demonstrate impaired object exploration behaviors throughout infancy and toddlerhood. Physical Therapy, 95(1), 51–64. doi: 10.2522/ptj.20130584 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lobo MA, Koshy J, Hall ML, Erol O, Cao HT, Buckley JM, … Higginson J (2016). Playskin Lift™: Development and initial testing of an exoskeletal garment to assist upper extremity mobility and function. Physical Therapy, 96(3), 390–399. doi: 10.2522/ptj.20140540 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ma M-Y, Wu F-G, & Chang R-H (2007). A new design approach of user-centered design on a personal assistive bathing device for hemiplegia. Disability and Rehabilitation, 29(14), 1077–1089. doi: 10.1080/09638280600949712 [DOI] [PubMed] [Google Scholar]

- Moir L (2010). Evaluating the effectiveness of different environments on the learning of switching skills in children with severe and profound multiple disabilities. British Journal of Occupational Therapy, 73(10), 446–456. doi: 10.4276/030802210X12865330218186 [DOI] [Google Scholar]

- Needham A (2000). Improvements in object exploration skills may facilitate the development of object segregation in early infancy. Journal of Cognition and Development, 1(2), 131–156. doi: 10.1207/S15327647JCD010201 [DOI] [Google Scholar]

- Ostensjø S, Carlberg EB, & Vøllestad NK (2005). The use and impact of assistive devices and other environmental modifications on everyday activities and care in young children with cerebral palsy. Disability & Rehabilitation, 27(14), 849–861. doi: 10.1080/09638280400018619 [DOI] [PubMed] [Google Scholar]

- Parette P, & Scherer M (2004). Assistive technology use and stigma. Education and Training in Mental Retardation and Developmental Disabilities., 39(3), 217. [Google Scholar]

- Rink BD (2011). Arthrogryposis: A review and approach to prenatal diagnosis. Obstetrical & Gynecological Survey, 66(6), 369–377. doi: 10.1097/OGX.0b013e31822bf5bb [DOI] [PubMed] [Google Scholar]

- Ryan SE, Campbell KA, Rigby PJ, Fishbein-Germon B, Hubley D, & Chan B (2009). The impact of adaptive seating devices on the lives of young children with cerebral palsy and their families. YAPMR Archives of Physical Medicine and Rehabilitation, 90(1), 27–33. doi: 10.1016/j.apmr.2008.07.011 [DOI] [PubMed] [Google Scholar]

- Shields N (2009). Self-concept is a concept worth considering. Physical and Occupational Therapy in Pediatrics, 29(1), 23–26. doi: 10.1080/01942630802574817 [DOI] [PubMed] [Google Scholar]

- Thelen E (2000). Grounded in the world: Developmental origins of the embodied mind. INFA Infancy, 1(1), 3–28. doi: 10.1207/S15327078IN0101_02 [DOI] [PubMed] [Google Scholar]

- Watkins S (1988). Using the design process to teach functional apparel design. Clothing and Textiles Research Journal, 7(1), 10–14. doi: 10.1177/0887302X8800700103 [DOI] [Google Scholar]

- Wilkinson CR, & De Angeli A (2014). Applying user centred and participatory design approaches to commercial product development. Design Studies, 35(6), 614–631. doi: 10.1016/j.destud.2014.06.001 [DOI] [Google Scholar]

- Wingate SB, Kaiser SB, & Freeman CM (1986). Salience of disability cues in functional clothing: A multidimensional approach. Clothing and Textiles Research Journal, 4(2), 37–47. doi: 10.1177/0887302X8600400206 [DOI] [Google Scholar]

- Yan T, Cempini M, Oddo MC, & Vitiello N (2015). Review of assistive strategies in power lower-limb orthoses and exoskeletons. Robotics and Autonomous Systems, 64, 120–136. doi: 10.1016/j.robot.2014.09.032 [DOI] [Google Scholar]