Abstract

The aim of this study is to highlight the key elements for optimizing printed circuit board (PCB) fabrication productivity through improving manufacturing process efficiency. Failure mode and effect analysis (FMEA) is a technique used to reduce the percentage of finished goods that are found to be defective during the manufacturing process and final inspection, resulting in low rejection ratios and optimized PCB design. This paper presents all the quality steps to achieve high efficiency in PCB design. The study is done in electronics manufacturing industry in which its production begins from receiving PCBs, raw material then bringing them into punching and assembly processes through surface mount machines (SMT). To find defective items and lower the possibility of defective final products, or IPQC (in-process quality control), is used. The average of customer manufacturers lot reject rate (%LRR of CMs) has been improved by using improved quality control. For assessing the risk connected to probable issues discovered during a failure mode and effects analysis, the risk priority number (RPN) methodology technique is applied. The FMEA RPN assists the responsible team or individual in prioritizing risks and choosing the appropriate remedial measures. Lot reject rate (LRR) improved by FMEA is from 5500 parts per million (PPM) to 900 parts per million (PPM), and faults have decreased by 0.76% as a result of improved quality control.

Keywords: Failure mode and effect analysis (FMEA), PCB, Risk priority number

Introduction

The globalization of markets and industrial production processes was significantly impacted by Covid-19. Lean manufacturing strategies are being used by more firms in an effort to pursue the elimination of waste/defects through continuous improvement, enhance product quality, and boost supply chain competitiveness. This trend is driven by rising consumer demands for product quality, affordability, and flexibility. The paper discusses the quality control in electronics manufacturing industry in which its production begins from receiving PCBs and then bringing them into punching and assembly processes through surface mount machines (SMT). Surface mount machines are also called pick-and-place machines or smt component placement systems. In practical circuit applications, a printed circuit board (PCB) is a crucial component, and its failure can lead to large financial losses as well as safety issues.

Failure mode and effects analysis (FMEA) is an organized method for identifying potential flaws in a product or process design. A possible process failure modes are its methods. Effects are the ways in which these mistakes can cause waste, flaws, or negative results for the client. To identify, prioritize, and restrict certain failure modes, failure mode and effects analysis is used. FMEA improves the quality control process of flexible printed circuit boards. A root cause analysis is necessary to prevent the failures from reoccurring. The terms "failure modes," "failure mechanisms," and "root causes" are all used interchangeably. An open circuit (failure mode) due to conductor corrosion (failure mechanism) produced by an inadequate protective coating is an example (root cause). While identifying failure modes is simple since they can be seen or measured, identifying failure mechanisms and core causes is more difficult [1]. The FMEA RPN (risk priority number) measures the risk priority level of a failure mode in an FMEA analysis numerically. The FMEA RPN assists the responsible team or individual in prioritizing risks and choosing the appropriate remedial measures. Severity (Sev.), occurrence (Occ.), and detection (Det.) are the indexes, and RPN is calculated as:

Severity, occurrence, and detection indexes are derived from the FMEA. Severity measures the failure's prospective effects in terms of their seriousness. Occurrence evaluates how likely it is that the failure will take place and detection and assesses the possibility that the issue will be found and fixed before it affects the end user or client. A high severity ranking indicates severe risk. Table 1 presents the effect analysis of severity on the basis of severity score. Score analysis of occurrence criteria is presented in Table 2. The criteria in Tables 1, 2, and 3 have been prepared from the Failure Mode and Effects Analysis Reference Manual by the Automotive Industry Action Group (AIAG) [1].

Table 1.

Severity criteria

| Severity criteria | ||

|---|---|---|

| Score | Rank | Comments |

| 1 | None | No effect |

| 2 | Very minor | Defect noticed by discriminating customer. Performance nominal |

| 3 | Minor | Defect noticed by average customer. Performance nominal |

| 4 | Very low | Defect noticed by most customer. Performance nominal |

| 5 | Low | Device operable, but convenience options operate at reduced performance level. Customer experiences some dissatisfaction |

| 6 | Moderate | Device operable, but convenience options inoperable. Customer experiences some dissatisfaction |

| 7 | High | Device operable, but at reduced performance levels. Customer dissatisfied |

| 8 | Very high | Device inoperable with loss of primary functions |

| 9 | Hazardous (with warning) | A potential failure mode makes operations unsafe to operator and/or involves non-compliance with government regulations with warning |

| 10 | Hazardous (without warning) | A potential failure mode makes operations unsafe to operator |

Table 2.

Occurrence criteria

| Occurrence criteria | |||

|---|---|---|---|

| Score | Rank | Comments | Failure rate |

| 1 | Remote | Failure is unlikely | < 1 in 1,000,000 |

| 2 | Very low | Relatively few failures | 1 in 150,000 |

| 3 | Low | Not uncommon | 1 in 15,000 |

| 4 | Moderate | Occasional failures | 1 in 2000 |

| 5 | Likely | Frequent failures | 1 in 100 |

| 6 | High | Failure is typical | 1 in 25 |

| 7 | Very high | Repeated failures | 1 in 10 |

| 8 | Severe | Failure is almost inevitable | 1 in 5 |

| 9 | Extreme | Failure is normal | > 1 in 2 |

Table 3.

RPN range

| RPN level | Range |

|---|---|

| None | 0 |

| Low | 8–40 |

| Medium | 80–240 |

| High | 320–1000 |

RPN range is described in Table 3. Typically, the higher RPN values for the identified failure mode will be given priority for additional corrective actions [2, 3].

The paper is organized as follows; Sect. 2 discusses relevant literature of FMEA. In Sect. 3 the entire process of PCB design and fabrication is discussed. Section 4 discusses risk assessment methodology. The entire case study of electronics company using the FMEA method is presented in section Sect. 5. Improved quality control process is discussed in Sect. 6.

Literature Survey

FMEA is a methodical procedure for detecting every potential flaw in a design, a production or assembly process, a product, or service. It investigates how failures could happen [4]. The technique can be used to highlight issues with an ongoing procedure or potential dangers in a product design that is still being developed. The technique has some flaws and is based on a military procedure of the US Department of Defense [5]. It has been heavily utilized by numerous National Aeronautics and Space Administration (NASA) space programs [6]. FMEA is now widely used in manufacturing-related businesses. It is one of the most effective methods for identifying the absence of a design or manufacturing process for a product. FMEA is now widely used in manufacturing-related businesses. It is one of the most effective strategies for identifying a product design or production process that does not exist. The article in [7] discusses the DFMEA during the development of automotive CMOS image sensors' feasibility phase. The stock production process is assessed using a comprehensive PFMEA [8]. There are several studies; hence, there are numerous literature review papers in the literature. A wide range of research was used to review FMEA procedures [9]. An analysis of the state of the art based on 220 articles and 100 patent information is summarized in [10]. An insights into the future of FMEA are represented with a rigorous research study in [11]. The effective integration of other approaches, such as the problem-solving methodology, quality function deployment, and root cause analysis, is covered in [12]. The risk priority number (RPN), which is the product of the severity, probability, and detectability values for each risk, should then be computed [13]. The two fundamental ideas of uncertainty in risk analysis—objective and subjective—are described in [14]. Subjectivity and objectivity are founded on differences in the physical world and, respectively, ignorance. Some characteristics, including safety functions, variable qualities, and experimental data, can have objective uncertainty when risk factors are observed and documented across samples [15]. In addition, subjectivity uncertainty relates to ambiguities, vagueness, or imprecision regarding the quality of FMEA. This is particularly true in accident-related situations where subjectivity manifests itself in the identification of FMs and the estimation of risk factors during the FMEA procedure. Here, we have considered both subjective causes like receipt, inspection, and issuance of raw materials and objective factors like placement of components, automation process, PCB cleaning, etc. All these factors contribute to RPN calculation with high accuracy and low uncertainty.

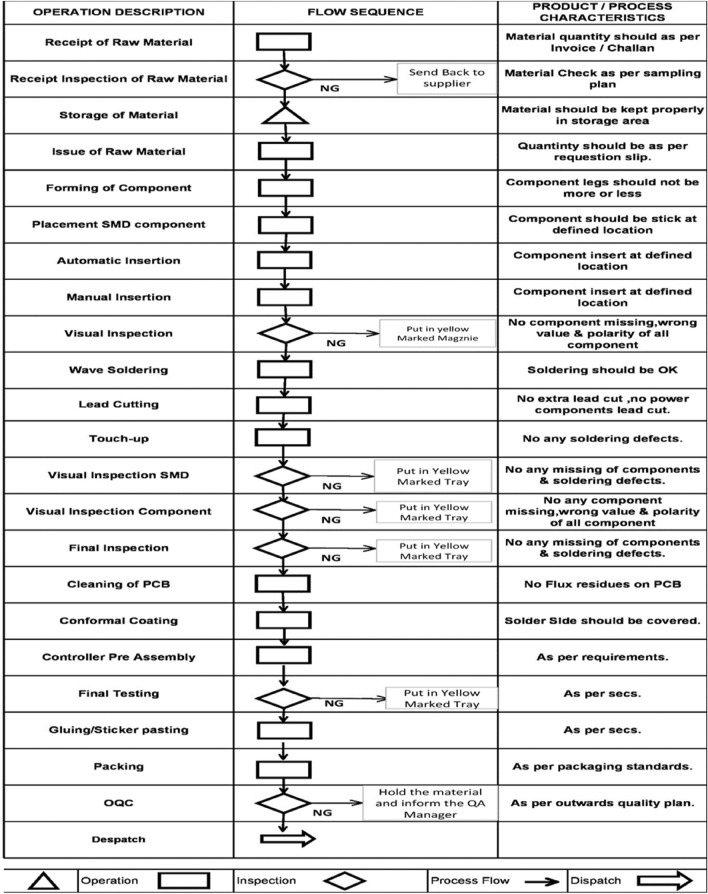

Process Flow

The entire process of PCB fabrication is represented in the form of flow diagram in Fig. 1. The FMEA analysis is done as per considering all steps taken to manufacture the PCB.

Fig. 1.

FMEA process PCB assembly

Risk Assessment Methodology

Risk assessment entails assessing risks while taking into account known vulnerabilities to a variety of potential threats or hazards, general or specific threat/hazard information, and the potential direct and indirect repercussions of an incident. A risk assessment matrix is presented in Table 4. In Table 5 the potential severity of each threat along with its impact/consequence analysis is discussed. Risk score analysis is done in Table 6. Risk identification, its impact, its likelihood of occurrence along with its consequence and risk category are discussed in Table 7.

Table 4.

Risk assessment matrix

| Likelihood | Impact/consequence | ||

|---|---|---|---|

| Low (1) | Medium (2) | High (4) | |

| Unlikely (1) | 1 Low | 2 Low | 4 Medium |

| Possible (2) | 2 Low | 4 Medium | 8 High |

| Likely (3) | 3 Low | 6 Medium | 12 Extremely high |

| Certain (5) | 5 Medium | 10 High | 20 Extremely high |

Table 5.

Risk analysis and its impact

| Likelihood | |

|---|---|

| Unlikely (1) | Very unlikely to occur—< 5% chance of occurrence in any one year |

| Possible (2) | Likely to occur in the medium term—10–25% chance of occurrence in any one year |

| Likely (3) | Likely to occur in the shorter term—25–50% chance of occurrence in any one year |

| Certain (5) | Almost certain to occur, could happen now—50–100% chance of occurrence in any one year |

| Impact/consequence | |

| Low (1) | Minor delay, inconvenience or impact. Very short-term effect. Little damage to business, insignificant financial cost or reputational damage |

| Medium (2) | Significant impact on customer service, operational function or finance. Medium-term effect with possible reputational damage |

| High (3) | Major impact on customer service, operational function or regulatory compliance. Reputational damage, mid- to long-term effect |

Table 6.

Risk score analysis

| Risk score | Action to be taken |

|---|---|

| 1–2-3 | Note and monitor risk. Management action possibly not required |

| 4–5-6 | Management action required. Monitor risk |

| 8–10 | Significant and urgent management action required and regular reporting |

| 12–20 | Extensive and ongoing management action and reporting required |

Table 7.

Risk and hazard identification

| S. no | Operation process | Risk description | Impact of risk | Likelihood (occurrence) | Consequence (severity) | Risk category |

|---|---|---|---|---|---|---|

| In which process it can occur | (certain/likely/possible/unlikely) | (low/medium/high) | (low/medium/high/extremely high) | |||

| 1 | Production planning & execution | Wrong loading plan | Not able to achieve production targets/delivery commitments made to customers, customer dis- satisfaction, loss of new orders | 1 | 4 | 4 |

| Equipment B/D | 1 | 2 | 2 | |||

| Material shortage | 1 | 2 | 2 | |||

| Untrained operator | 2 | 4 | 8 | |||

| Manpower shortage | 2 | 4 | 8 | |||

| Inventory build-up | 1 | 2 | 2 | |||

| Instrument/gauges are not available as per requirement | 1 | 4 | 4 | |||

| Use of PPE | Likelihood of injury to an employee | 2 | 2 | 4 | ||

| 2 | Process rejection, rework & scrap control | In-house rejection more than target | Not able to achieve production targets/delivery commitments made to customers, loss of profit | 2 | 4 | 8 |

| In-house re- work more than target | 2 | 4 | 8 | |||

| Failure in checking & verifying scrap for the daily manufacturing process | 2 | 2 | 4 |

Case Study

For problem analysis it is required to observe the entire process of PCB fabrication. The study was done in MS ELECTROVISION PVT LTD Electronic Design & Manufacturing Services company providing a packaged solution for Electronic Design Services, PCB Assemblies & Box Build Products for its valuable customers at IMT Manesar, Haryana. Using the FMEA method, the production crew and the researcher jointly assessed the risks of each process' failure modes. The various modes of operation associated in PCB manufacturing are Receipt Inspection of Raw Material, Storage of Material, Issue of Raw Material, Forming of Component, Placement SMD component, Automatic Insertion, Manual Insertion, Visual Inspection, Wave Soldering, Lead Cutting, Touch-up, Visual Inspection SMD, Visual Inspection Component, Final Inspection, Cleaning of PCB, Conformal Coating, Controller Pre-Assembly, Final Testing, Gluing/Sticker pasting, Packing, OQC, and Dispatch. Figure 2a shows how raw material is stored room. In SMT machine, automatic component insertion using PCB programming software is done as demonstrated in Fig. 2c.

Fig. 2.

a Store room for raw material, b SMT machine, c automatic component insertion using SMT machine, d PCB touch-up and visual inspection

PCB touch-up and visual inspection is done manually as shown in Fig. 2d.

Table 7 lists all the design processes for PCB fabrication that have been identified and evaluated for FMEA. Each process receives an RPN to carry out quality improvement measures. Table 8 provides scores for the severity, occurrence, and detection of failure modes for the procurement, storage of raw materials, and entire process required for PCB design. The value of Severity to any process is assigned based on the severity of the process on a scale of 1 to 10, after considering the possible impact of the failure and criticality of the risk identified in the process. Customer discontent due to performance degradation is represented by a severity rating of 4 to 6, whereas a severity rating of 9 or 10 indicates that the process is so unstable that accidents may occur, endangering the safety of personnel. The FMEA is created by those involved in the process; they are fully aware of the type of problem that is most likely to appear there. The production data are used to calculate the value of Occurrence and Detection. Tables 1, 2, and 3 are referred for the same. Tables 9 and 10 detail the full procedure for producing surface-mounted (SMD) components in an SMT machine using RPN analysis.

Table 8.

FMEA for PCB Fabrication

| Process step | Required function | Potential failure mode | Sev | Occ | Det | RPN | Consequences of each potential fault |

|---|---|---|---|---|---|---|---|

| Receipt of raw material | Component should be in standard packaging | Loose parts, not in standard packaging | 2 | 2 | 4 | 16 | Customer effect: nil |

| Mfr/assly effect: more/less qty can be recd | |||||||

| No physical damage of boxes | Open boxes, damaged boxes during transportation | 2 | 2 | 4 | 16 | Customer effect: nil | |

| Mfr/assly effect: parts can damage | |||||||

| Proper unloading of parts | Boxes fall down during unloading | 2 | 2 | 5 | 20 | Customer effect: nil | |

| Mfr/assly effect: parts can damage | |||||||

| Receipt inspection of raw material | Received quantity as per invoice | Less/more quantity received | 3 | 2 | 5 | 30 | Customer effect: nil |

| Mfr/assly effect: loss to company | |||||||

| Quality of parts as per acceptance criteria | NG parts recd | 4 | 2 | 5 | 40 | Customer Effect: Nil | |

| Mfr/Assly Effect: Line can stop due to shortage of parts | |||||||

| Material should not be expiry, with in shelf life | NG parts recd | 4 | 3 | 5 | 60 | Customer effect: nil | |

| Mfr/assly effect: line can stop due to shortage of parts | |||||||

| Storage of incoming material | Components at designated place | Mixing of components | 2 | 2 | 4 | 16 | Customer Effect: Nil |

| Mfr/Assly Effect: Line stoppage due to wrong issue of material | |||||||

| Components should be OK as per physical appearance | Damaged during storage | 2 | 2 | 6 | 24 | Customer effect: nil | |

| Mfr/assly effect: slight inconvenience to process, operation or operator | |||||||

| Stored beyond shelf life | 2 | 2 | 4 | 16 | Customer Effect: Nil | ||

| Mfr/Assly Effect: slight inconvenience to process, operation or operator | |||||||

|

Temp: 28°–38°C RH: 30–60% |

Storage temperature & RH not within specified limits | 5 | 2 | 5 | 50 | Customer effect: nil | |

| Mfr/assly effect: a portion of production run may have to rework | |||||||

| Issue of raw material | material issue as per BOM (bill of material) | Material issued not correct | 5 | 2 | 4 | 40 | Customer effect: nil |

| Mfr/assly effect: delay in production/wrong production | |||||||

| Quantity of material as required | Shortage of material | 2 | 2 | 4 | 16 | Customer effect: nil | |

| Mfr/assly effect: line stoppage |

Table 9.

FMEA for SMD components

| Process step | Potential Failure Mode | Sev | Occ | Det | RPN | Consequences of each potential fault | |

|---|---|---|---|---|---|---|---|

| Placement of SMD components | Solder paste mixing | Solder paste not homogeneous sly mixed | 5 | 2 | 5 | 50 | Customer effect: nil |

| Mfr/assly effect: less solder on pad requiring partial rework | |||||||

| PCB baking | Copper oxidation/rus ting. Carbon on pad | 5 | 3 | 5 | 75 | Customer effect: nil | |

| Mfr/assly effect: parts have to scrap | |||||||

| Loading of PCB | PCB loaded in upside down or wrong direction | 2 | 2 | 4 | 16 | Customer effect: nil | |

| Mfr/assly effect: slight inconvenience to process, operation or operator | |||||||

| Placement of SMD components | Solder paste printing | Insufficient solder, bridging, excess solder, missing, uneven print | 6 | 2 | 5 | 60 | Customer effect: function failure |

| Mfr/assly: partial rework | |||||||

| Components mounting | Extra Component | 6 | 2 | 4 | 48 | Customer effect: functional failure | |

| Missing component | 3 | 72 | Mfr/assly effect: a portion of production run may have to rework offline | ||||

| Wrong value component | 2 | 48 | |||||

| Reflow solderin g | Less solder, excess solder, tombstoning on wetting, miss aligned, bill board, solder ball | 6 | 3 | 4 | 72 | Customer effect: functional failure | |

| Mfr/assly: partial rework | |||||||

| Automat ic optical inspecti on | Defect passed on to next stage | 6 | 2 | 5 | 60 | Customer effect: functional failures | |

| 2 | 5 | 60 | Mfg/assy: partial rework off line | ||||

Table 10.

FMEA for SMD components

| Process step | Potential Failure Mode | Sev | Occ | Det | RPN | Potential effect of failure |

|---|---|---|---|---|---|---|

| Automatic insertion | Extra component | 5 | 2 | 4 | 40 | Customer effect: functional failure |

| Missing component | 3 | 60 | Mfr/assly effect: a portion of production run may have to rework offline | |||

| Wrong value component | 2 | 40 | ||||

| Manual insertion | Extra component | 5 | 2 | 4 | 40 | Customer effect: functional failure |

| Missing component | 3 | 60 | Mfr/assly effect: a portion of production run may have to rework offline | |||

| Visual inspection | Defect passed on to next stage | 6 | 2 | 5 | 60 | Customer effect: functional failures |

| Mfg/assy: partial rework off line | ||||||

| Wave soldering | Less solder, Excess solder, tombstoning, dry soldering, miss aligned,, solder ball | 6 | 3 | 4 | 72 | Customer effect: functional failure |

| Mfr/assly: partial rework | ||||||

| Touch—UP | Pad damage | 3 | 2 | 3 | 18 | Customer effect: functional failure |

| Mfr/assly: partial rework, circuit fail | ||||||

| Visual inspection (SMD) | Defect passed on to next stage | 6 | 3 | 4 | 72 | Customer Effect: Functional failures |

| Mfg/assy: partial rework off line | ||||||

| Visual inspection (component) | Defect passed on to next stage | 6 | 3 | 4 | 72 | Customer effect: functional failures |

| Mfg/assy: partial rework off line | ||||||

| Final inspection | Defect passed on to next stage | 6 | 3 | 4 | 72 | Customer effect: functional failures |

| Mfg/assy: partial rework off line | ||||||

| ICT testing | Defect passed on to next stage | 6 | 2 | 5 | 60 | Customer effect: functional failures |

| 2 | 5 | 60 | Mfg/assy: partial rework off line | |||

| Final testing | High/Low Current | 6 | 2 | 6 | 72 | 1. Functional failures |

| Misbehaving of peripherals | 2 | 7 | 84 | 2. A portion of production run have to be scrapped | ||

| Visual inspection/aesthetic checking | Defect passed on Customer, Customer Dissatisfaction | 6 | 2 | 5 | 60 | Customer effect: functional failures |

| OQC | Coating issue, Sticker issue, packaging issue, aesthetics | 6 | 2 | 5 | 60 | 1. End user: customer dissatisfaction |

| 2. Mfr/assly: totally rework | ||||||

| Dispatch | Delivery not as per schedule | 4 | 2 | 8 | 64 | 1. End User: customer line stop |

| 4 | 1 | 10 | 40 | 2. Mfr/assly: no effect |

Many processes are taken to create a PCB throughout the PCB assembly process of a window air conditioner, and a final visual inspection is carried out to cross-check all of the steps. Because of an operator error, this manual operation results in a shorting between TQFP pins that is passed during final testing, increasing the rejection ratio. A major incident happened that had an influence on output, reduced quality goals, and raised RPN. A joint inspection conducted by the company resulted in cutting and pin shorting caused by solder balls being caught in IC pins. A number of initiatives have been done, including the implementation of zoom machine for testing as shown in Figs. 3 and 4, respectively, during the visual inspection stage. A sensible decision like this leads to increased productivity and less RPN.

Fig. 3.

a Visual inspection done normal magnifier lens, b zoom machine

Fig. 4.

a Manual testing jig, b FCT jig—software controlled for decision making

Results and Discussion

Following improvements to the quality control approach for PCB design, Table 11 shows manufacturing data and testing defect of display PCB from November 2021 to September 2022. Studying the different types of flaws, their causes, and ways to prevent them are all things that FMEA aids in. The conformal coating and pre-testing process now has fewer flaws. Both pre-testing and coating were done incorrectly by the operator. After a quality improvement method, such as the zoom machine for testing and the FCT jig—software controlled for decision making, the number of defects tends to go down.

Table 11.

Testing defect—display PCB

| Month | Total production | Defect | % Defect |

|---|---|---|---|

| Nov–21 | 7512 | 72 | 0.96 |

| Dec–21 | 10,486 | 88 | 0.84 |

| Jan–22 | 9282 | 82 | 0.88 |

| Feb–22 | 9674 | 94 | 0.97 |

| Mar–22 | 3444 | 30 | 0.87 |

| Apr–22 | 17,284 | 22 | 0.13 |

| May–22 | 17,284 | 22 | 0.13 |

| Jun–22 | 3612 | 7 | 0.19 |

| Jul–22 | 10,072 | 18 | 0.18 |

| Aug–22 | 3696 | 6 | 0.16 |

| Sep-22 | 6156 | 5 | 0.08 |

Trends of the data of the inspection process are shown in Fig. 5a, b. The percentage difference in defects seen after taking action is 0.76% as demonstrated in Table 12. FMEA method is used for analyzing processes to estimate their failure modes’ risk. The average customer manufacturers lot reject rate has dropped from 5500 to 900 PPM, and faults have decreased by 0.76% as a result of improved quality control.

Fig. 5.

a Trends of the data of the inspection process. b Trends of the defects of the inspection process

Table 12.

Defect analysis

| Total PCB produced before action | 40,398 | Total PCB produced after action | 40,820 |

| Defects observed | 366 | Defects observed | 58 |

| % of rejection | 0.90599 | % of rejection | 0.14209 |

| % Difference in defects observed after taking action | 0.7639 | ||

Conclusion

In this paper, it has been demonstrated how the improvement in quality of PCB fabrication can be done by applying FMEA. The various FMEA techniques are implemented on manufacturing PCB to reduce defective products in a lot of finished PCB products during the manufacturing process and final inspection. The study was conducted in the electronics manufacturing sector. Improved quality control has resulted in a lower average customer manufacturer lot rejection rate (%LRR of CMs). The risk priority number (RPN) methodology technique is used to evaluate the risk related to potential issues identified during a failure mode and effects analysis. The FMEA RPN assists in ranking risks and choosing the most effective corrective measures. FMEA reduced the lot reject rate (LRR) from 5500 parts per million (PPM) to 900 PPM, and as a result of better quality control, the number of defected PCBs decreased by 0.76%.

Acknowledgements

This study was done in MS ELECTROVISION PVT LTD, Electronic Design & Manufacturing Services company, providing a packaged solution for Electronic Design Services, PCB Assemblies & Box Build Products for its valuable customers at IMT Manesar, Haryana.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- [1].AIAG-VDA FMEA Handbook, 4th ed, (2019).

- [2].Cher-Ming Tan, Hsiao-Hi Chen, Jing-Ping Wu, Vivek Sangwan, Kun-Yen Tsai, and Wen- Chun Huang, Root cause analysis of a printed circuit board (PCB) failure in a public transport communication system, Applied Sciences, 12(2) (2022) 640.

- [3].Liu H-C, Liu L, Liu N. Risk evaluation approaches in failure mode and effects analysis: a literature review. Expert Syst. Appl. 2013;40:828–838. doi: 10.1016/j.eswa.2012.08.010. [DOI] [Google Scholar]

- [4].D.H. Stamatis, Failure Mode and Effect Analysis: FMEA from Theory to Execution; Quality Press, (2003)

- [5].A.S. Agarwala, Shortcomings in mil-std-1629A guidelines for criticality analysis. In: Annual Proceedings on Reliability and Maintainability Symposium; IEEE, (1990) pp. 494–496.

- [6].Office of Manned Space Flight, Apollo program, Apollo Reliability and Quality Assurance Office. (1966). Procedure for Failure Mode, Effects and Criticality Analysis (FMECA).

- [7].S. Maddalena, A. Darmon and R. Diels, Automotive CMOS image sensors. In Advanced Microsystems for Automotive Applications; Springer, Berlin, Heidelberg, (2005) pp. 401–412.

- [8].Y. Klochkov, A. Its and I. Vasilieva, Development of FMEA method with the purpose of quality assessment of can stock production. In Key Engineering Materials; Trans Tech Publications Ltd, (2016) vol. 684, pp. 473–476.

- [9].Sharma KD, Srivastava S. Failure mode and effect analysis (FMEA) implementation: a literature review. J. Adv. Res. Aeronaut. Space Sci. 2018;5:1–17. [Google Scholar]

- [10].Spreafico C, Russo D, Rizzi C. A state-of-the-art review of FMEA/FMECA including patents. Computer Science Review. 2017;25:19–28. doi: 10.1016/j.cosrev.2017.05.002. [DOI] [Google Scholar]

- [11].J. Huang, J.X. You, H.C. Liu and M.S. Song, Failure mode and effect analysis improvement: A systematic literature review and future research agenda, Reliability Engineering & System Safety, 106885 (2020).

- [12].W.C. Ng, S.Y. Teh, H.C. Low, and P.C. Teoh, The integration of FMEA with other problem solving tools: A review of enhancement opportunities. In J Phys Conf Ser; (2017) vol. 890, p. 012139.

- [13].Puvanasvaran AP, Jamibollah N, Norazlin N, Adibah R. Poka-Yoke Integration into process FMEA. Australian Journal of Basic and Applied Sciences. 2014;8(7):66–73. [Google Scholar]

- [14].Song W, Ming X, Wu Z, Zhu B. A rough TOPSIS approach for failure mode and effects analysis in uncertain environments. Quality and Reliability Engineering International. 2014;30(4):473–486. doi: 10.1002/qre.1500. [DOI] [Google Scholar]

- [15].Yazdi M. Hybrid probabilistic risk assessment using fuzzy FTA and fuzzy AHP in a process industry. J. Fail. Anal. Prev. 2017;17:756–764. doi: 10.1007/s11668-017-0305-4. [DOI] [Google Scholar]

- [16].Markowski AS, Mannan MS, Bigoszewska A. Fuzzy logic for process safety analysis. J. Loss Prev. Process Ind. 2009;22:695–702. doi: 10.1016/j.jlp.2008.11.011. [DOI] [Google Scholar]