Abstract

Anatomical complications of the craniofacial regions often present considerable challenges to the surgical repair or replacement of the damaged tissues. Surgical repair has its own set of limitations, including scarcity of the donor tissues, immune rejection, use of immune suppressors followed by the surgery, and restriction in restoring the natural aesthetic appeal. Rapid advancement in the field of biomaterials, cell biology, and engineering has helped scientists to create cellularized skeletal muscle‐like structures. However, the existing method still has limitations in building large, highly vascular tissue with clinical application. With the advance in the three‐dimensional (3D) bioprinting technique, scientists and clinicians now can produce the functional implants of skeletal muscles and bones that are more patient‐specific with the perfect match to the architecture of their craniofacial defects. Craniofacial tissue regeneration using 3D bioprinting can manage and eliminate the restrictions of the surgical transplant from the donor site. The concept of creating the new functional tissue, exactly mimicking the anatomical and physiological function of the damaged tissue, looks highly attractive. This is crucial to reduce the donor site morbidity and retain the esthetics. 3D bioprinting can integrate all three essential components of tissue engineering, that is, rehabilitation, reconstruction, and regeneration of the lost craniofacial tissues. Such integration essentially helps to develop the patient‐specific treatment plans and damage site‐driven creation of the functional implants for the craniofacial defects. This article is the bird's eye view on the latest development and application of 3D bioprinting in the regeneration of the skeletal muscle tissues and their application in restoring the functional abilities of the damaged craniofacial tissue. We also discussed current challenges in craniofacial bone vascularization and gave our view on the future direction, including establishing the interactions between tissue‐engineered skeletal muscle and the peripheral nervous system.

Keywords: 3D bioprinting, bioengineering, biomaterials, craniofacial tissue complex, soft tissues

1. INTRODUCTION

The terms regenerative medicine and tissue engineering are often used interchangeably in medicine. However, regenerative medicine is a general term that incorporates tissue engineering and, at the same time, is concerned about the research in self‐healing. During self‐healing, the body uses its cellular mechanisms and foreign materials to recreate the cell and its functions and reorganize them in tissues and organs. 1 Tissue engineering, on the other hand, has grown independently from the field of biomaterials. It combines the extracellular matrix (ECM) scaffolds, cells, and physiologically active compounds into functional tissue capable of improving or replacing the damaged one. FDA has already approved the engineered skin and cartilage in clinical use for limited indications. The field of tissue engineering is evolving rapidly, and its application is extended from the replacement of damaged tissues to the research tools to study the pharmacological activity, pharmacokinetics, educational models, etc. 2 , 3

Before the tissue regeneration and engineering concept, clinical options available to tackle the issue of tissue degeneration or loss of it were limited to organ transplantation, use of prostheses and implants, and transplantation of autologous tissue. Scarcity of organ donors, biocompatibility, and limited supply of autologous tissues (if tissue loss is more, e.g., skin burn) are some of the significant limitations of these approaches. Surgical reconstructions using autologous tissue along with the implants and prostate still have a widespread application when it comes to replacing volume or structural deficits. 4 Complete replacement of the metabolic deficiencies using the surgical reconstructions approach is still an unmet challenge. Autologous tissue transfers have the additional problem of the other surgical site, with the risk of complications and donor site morbidity.

To some extent, organ transplantation has overcome some of the issues of autologous transplant. Organ transplantation can successfully replace the lost or damaged tissue and restore its physiological and metabolic functions. Whole organ transplants like liver and kidney have saved the life of several critically ill patients by restoring their vital functions. 5 However, this approach has inherent limitations, including organ rejection and immunogenic risk, limited availability of donors, and regulatory approvals. Lastly, in the last few decades, prosthetics and implants have become highly advanced and sophisticated but are still limited in their use in replenishing the lost tissue volume or metabolic functions. Immune activation and distortion are still significant challenges that need to be overcome to optimize prosthetics and implants. 6

At the organizational level, the tissue is placed between the cellular and organ level. A group of cells produces the necessary biochemical components and maintains physiological functionality. A particular group of cells also secrete the ECM/scaffold, which supports the structure and cellular growth and helps to transmit the signaling biomolecules essential for the organ's physiological function. In general, the local environment influences the role of individual cells. A group of cells can start the chain of actions via primary and secondary cellular signaling that determines the response of the same group of cells and surrounding cells. By understanding the primary and secondary cellular signaling processes and their effect on the individual and group of cells, the scientist is now equipped with sufficient advanced tools to manage and fix the damaged tissues or create new ones. The development of the new tissue or organs begins with the construction of the scaffold made up of biocompatible materials. 3 Scaffolds were then seeded with the different types of cells supplemented with the growth factors. Tissue starts developing if the growth factors, cells, and scaffold are sufficient to provide the right environment. Alternatively, scaffold material, cells, and growth factors could be mixed, letting the tissue assemble and grow independently. One recent advancement in tissue engineering is decellularized donated organs and populating the remaining collagen scaffold with the cells to build new tissue. Ott et al. decellularized rat heart to get the myocardial scaffold, which was later repopulated with the myocardial and endothelial cells to revitalize the heart functions. 7 These findings were extrapolated to the pig heart, confirming the scalability to the bigger organs. 8 Wang et al., on the other hand, focused their attention on making the cardiac patch from the decellularized porcine heart. 9 Studies are now emerged reporting acellular human myocardial scaffolds. 10 Wang et al. also developed a robust protocol to decellularized the porcine heart to obtain the three‐dimensional (3D) acellular scaffold with very well preserved cellular gaps and ECM. 9

Several studies confirmed the effectiveness of embryonic stem cells and adult mesenchymal stem cells (bone marrow or cord‐derived) in regenerating various tissues and organs; however, the long‐term viability of such reconstructs is limited due to the limited ability of cell division. 11 To overcome the hurdle of limited cell division capability, the concept of multipotent progenitors derived from embryonic stem cells (ESC) is getting more popular because of their multipotent nature and proliferativeness, which enables them to recellularized the complex scaffolds. 12 In the recent time, cells like pluripotent human embryonic stem cells (hESCs) have appeared as an attractive candidate stem cell source for obtaining complex tissues (e.g., cardiac cells) because of their remarkable capability for expansion and undisputed potential to differentiate into smooth muscle and endothelial cells including terminally differentiated cardiomyocytes. 13 Identification of the multipotent stem cells, including the induced pluripotent stem cells, has raised new hope in the tissue engineering of complex tissue. However, the issues like nutrient and oxygen transport in thicker tissues, cell penetration, and toxicity of the degraded products of the scaffold are the major hurdles in its successful clinical application. 14

Although remarkable development has been made in this field, engineered and regenerated tissue has some challenges that must be overcome before their clinical applications, including selecting appropriate cells, biocompatible scaffold, growth factors, low engraftment rate, and durability. To overcome the significant issues, alternative approaches for tissue engineering have emerged during the last decade. 3D bioprinting, which was initially developed for industrial purposes, is the latest approach adapted for tissue engineering, in which cells of interest in bioinks patterned in the desired shapes. The overall bioprinting process is controlled by the programs monitored by the computing systems.

The most critical factor in tissue engineering is the 3D scaffold, which provides a suitable microenvironment for cell proliferation and metabolic functions. A biocompatible material, stem cells, growth factors, and various imaging techniques have significantly supported the advancement in the field. Interdisciplinary research efforts from several areas have contributed immensely to developing the two‐dimensional (2D) flat, non‐vascular, and tubular organs that are being tested in the preclinical stage, and few are commercially available. On the other hand, solid, more complex tissues, including thick tissues, heart, kidney, and lungs, require innervation and vasculature to support oxygen and nutrient transport. This makes solid‐organ engineering much more complicated than flat 2D tissues. Solid 3D organs required more than one cell type with a 3D porous scaffold to support cell division and provide mechanical strength—this requires radial technical advancement to support the vessel growth within the 3D construct. One of the significant challenges in mimicking the natural tissues and organs is accommodating the multiple cell types and their spatial arrangement in 3D‐oriented ECM. Overall, the scaffold must be porous, biocompatible, biodegradable, or bioabsorbable for optimum growth and must provide mechanical support to the organ.

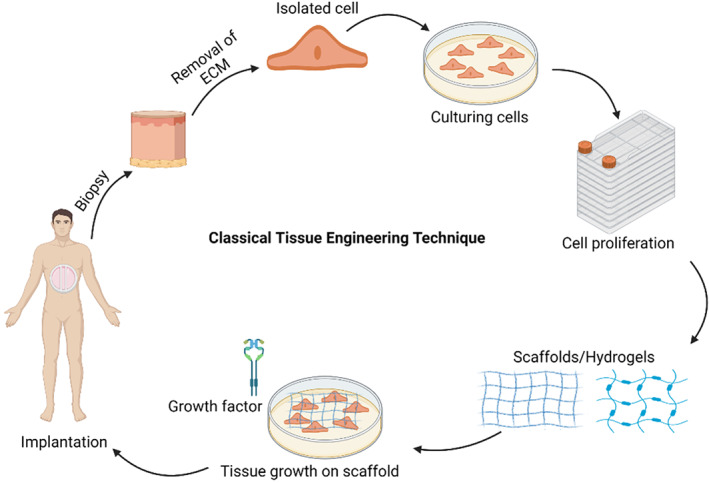

3D bioprinting offers precise control over the placement and layering of the cells within the scaffold. Compared to the traditional bioengineering method (Figure 1), 3D bioprinting allows higher precision in the space orientation relationship between the constituent elements of the tissue. In the near future, 3D bioprinting has the potential to overcome all the major issues of traditional tissue engineering. This review is the birds‐eye view on the advances made in 3D printing and its application in tissue engineering of bones and skeletal muscles. We also propose challenges and future viewpoints in implementing the principles of 3D printing and general tissue engineering to the craniofacial bones and skeletal muscles.

FIGURE 1.

The classical tissue engineering approach

2. SOFT FACIAL TISSUES

In anatomy, at the organizational level, tissues are the structure between cells and the complete organ. A functional tissue is a complex of similar cells and ECM secreted by the participating cells. Tissues combine together to form the physiologically active organ—different tissues combine to serve a common function of the organs. In Vertebrate, tissues are grouped into connective, muscle, nervous, and epithelial tissues. 15 The appearance of all the tissues varies depending on the type of the organism, organs, and precursor cells. For example, during embryonic development, endoderm and ectoderm give rise to the epithelium layers. A minor contribution from the mesoderm gives rise to the specialized epithelium that creates the vasculature. 16 A typical epithelial tissue is covered by a single layer of cells with tight junctions having selective permeability. 17 Epithelial tissues cover all the tissue surfaces that come in direct contact with the external environment, such as the digestive system, oral cavity, breathing tracks, and skin. Its location explains its functions of selective absorption, secretion, protection, and separation from the adjoining organs. 17 Similarly, neural ectoderm gives rise to neural tissues like the brain, motor nerves, retina, etc., and non‐neural ectoderm gives rise to epidermal tissues like nails, hair, feathers, breaks. On the other hand, mesoderm gives rise to skeletal tissues (e.g., bone and cartilage of skull), connective tissue (e.g., dermis, fat), muscular tissues (e.g., voluntary muscles), and vascular and hemato tissues (e.g., vessels, osteoclasts). 18 Whereas endoderm developed to form pharyngeal tissue (e.g., Auditory tube) and glandular tissues like thyroid, thymus, parathyroids. During embryonic development, the neural crest also gives rise to skeletal tissues (bone and cartilage, dentin), neural tissues (Neurons, sensory ganglia, glia), connective tissues (dermis, fat), and vascular tissues (pericytes, smooth muscles). 17

The skeletal muscles of the head are known as craniofacial muscles. 19 Superficial epidermis and dermis layers are innervated with nerves by the peripheral nervous system. A little deeper, the muscles that control the expression (smile, wink, superficial muscles of expression) are placed. Deeper, craniofacial complex has the muscle of chewing (pterygoid, temporalis, masseter, digastric, mylohyoid, etc.), which helps close or open the jaws. The craniofacial complex also has the eyes' muscles that move them in orbit, for example, extrinsic ocular muscles. 19 Blood vessels that bring oxygenated blood and remove deoxygenated blood (part of the circulatory system) are the crucial component of the complex. Different tissues like skeletal, vascular, muscular, nervous, and connective tissue contribute to the head complex. 20 During embryonic development, the neural crest gives rise to skeletal tissues (bone and cartilage, dentin), neural tissues (Neurons, sensory ganglia, glia), connective tissues (dermis, fat), and vascular tissues (pericytes, smooth muscles). All these tissues do not form in isolation but rather interact with each other to form so that each cell knows where to connect to blood vessels and bones. 20

In parallel to tissue engineering, the present research is also focused on how all these muscles come together and form a complex system. The current research focuses on identifying the molecular and cellular mechanisms and processes that control head and craniofacial muscle development and the structural integration of all these parts to form the complex. 21 How this muscle knows where to attach to bones and move in relation to other structure and how the blood vessels and connective tissues come together with hard and soft tissues to build craniofacial complex is also the unresolved mystery. For craniofacial tissue engineering, it is crucial to know how the precursor cells learn where and when to differentiate into appropriately patterned head components.

The craniofacial system is the most affected system in terms of congenital disabilities, somewhere around 1 out of 300–500 live birth. 22 Study of the origin of this tissue, differentiation, and integration could be useful to regenerate these tissues in disease, congenital disabilities, or in cases of trauma.

3. LIMITATIONS OF CURRENT SURGICAL OPTIONS

One of the most devastating, frequent, and expensive problems in healthcare is the partial or complete functional loss of tissue or organs. The most widely used treatment option is surgical repair, mechanical devices, or tissue transplantation from a different site or the matching donor. Unlike modern tissue engineering techniques, which are still in their initial development phase, the classical surgical option is still preferred. Modern tissue engineering aims to replace the damaged tissues with implants or constructs that could maintain and restore the natural function of the damaged tissues or organs. Although artificial skin and cartilage are some of the engineered tissue that has been approved by the FDA, they still have limited application. Although surgeries are still one of the most widely used options to restore the function of the damaged tissues, they still have their inherent problems. On the other hand, tissue engineering is based on the principles of engineering, molecular biology, and material science to develop functional substitutes to replace, restore, and improve the lost functions of tissues and organs.

Surgical approaches evolved over time, including replacing the damaged tissue with the tissue of the unaffected site in the same individual and organ transplantation from the donor individual. Surgical strategies like replacing damaged tissues and organs with artificial devices such as joints, heart valves, and bones have evolved over time. Surgical procedures often are not enough to recapture the original physiological functions of the tissues and hence require supplements to support the lost metabolic function. This often required the use of growth hormones, calcium, proteins, etc. Surgeries are benefited by the significant advances in the field of medicines, but they have several limitations of their own, which includes (1) hormonal supplements are most widely used in case of the loss or damage of the endocrine glands, for example, insulin is chronically given to lose of pancreatic gland. Such hormonal replacement therapy to normalized the metabolic functions often leads to hormonal imbalance, for example, insulin imbalance could lead to the hypo glycemic or hyperglycemic situation and several other physiological complications. (2) Implants often require repeated surgeries; this is crucial in pediatric patients because, in such patients, they are required to replace because of the growth and anatomical changes. (3) The major issue is the lack of biocompatibility and immune rejection in the case of the implants made up of nonbiological materials like keen joints, mechanical valves for the heart, stents, prostheses, etc. (4) Implants made up of nonbiological materials sometimes lead to the complications like thrombosis, carcinogenicity, bacterial infections, and toxicity due to the degraded products. (5) Surgical replacement of the damaged organ or tissue with the different tissue type often lacks the ability to mimic the original function in a new environment. The donor site also suffers major damage in such procedures. Furthermore, increasingly donor scarcity also limits the surgical options. Another major limitation is the high cost and serious side effects of the immunosuppressant drugs, which are required for a long time. On the other hand, tissue engineering provides a novel solution to the replacement of damaged or lost tissues. The tissue engineering principles are based on replacing the lost function with the constructs or implants developed from the host's own cells or from the donor's cells. With the advancement in cell engineering and biomaterials, the day is not far when the living tissue developed and constructed in the lab will replace lost tissue and organ functions, eliminating donors' needs. In the modern tissue engineering approach, a healthy site of the patients could use to donate the cells, which can then expand in the lab, essentially eliminating the risk of immune rejection. Moreover, during in vitro development, if required, cells could be genetically modified to repair the genetic fault before implanting the developed genetically modified tissue on the required site. This approach not only eliminates the need for donors and the long waiting list for the patients, but surgeons can adapt with the advances in tissue engineering to carry out minimally invasive surgery. Tissue engineering is now an established technique, and promising results are coming worldwide. Hopes are very high; the need is massive, and potential benefits are endless. However, much work still needs to be done, and many questions remain unanswered. One of the most fundamental questions is the expansion of the target cells and the generation of the growth signals, which could direct the cells to form functional 3D organs with proper vasculature for oxygen and nutrient supply. Knowledge of the basic physiology of the tissue and individual cells is complimenting the growth of tissue engineering. However, signaling to govern the tissue growth and cell migration in culture and in vivo needs better understanding. For example, understanding why skeletal muscle satellite cells multiply rapidly while cardiac myocytes do not divide at all in culture is essential. Cardiomayocytes are terminally differentiated and cannot replace the damaged site due to the infraction. Understanding the signaling that governs the rapid division of the skeletal muscle satellite cells could be useful to modify cardiomyocytes to replace the infracted site genetically. Similarly, liver cells rapidly regenerate in vivo however grow poorly in culture. Remarkable progress has been made in identifying the organ‐specific stem cells and their ability to differentiate into required cells types. Stem cells hold the ability to provide a limitless supply of cells. However, it is necessary first to identify the protocol and standardize it to isolate the stem cells and confirm their ability to differentiate into required cell types. At the same time, a detailed investigation of the signaling and growth factors is required, which leads to differentiation. One major task is identifying and isolating the subpopulation and investigating their characteristic features that contribute to their division and chemotactic migration to form the specific organ. To overcome the challenges of tissue engineering, close collaboration between clinicians, biologist, chemist, material scientists, engineers are required. In addition, the adaption of 3D bioprinting, which has the highest feasibility toward the synthesis of living tissues, is essential to meet the inherent challenges of tissue engineering.

4. 3D PRINTING: THE CURRENT STATE OF THE ART

3D printing, an additive manufacturing technique, is widely used for the precise fabrication of tissues. One essential requirement for the bioprinting of tissues and bones is the materials compatibility for the bioprinting process. 23 3D fabrication using printers requires printable biomaterials compatible with the live cells. Other crucial factors are non‐toxicity, crosslinking ability, biocompatibility, sufficient load‐bearing ability, shear‐thinning properties, and support for cell proliferation and adhesion with adequate plasticity.

Like noncraniofacial bones and tissues, the craniofacial complex is composed of nerves, blood vessels, bones, cartilages, muscles, and ligaments. Together, these complex components perform several face functions like speech, smile, mastication, and esthetics. Irreparable damage to the craniofacial complex could have a long‐term psychosocial impact highlighting the requirement of precise restructuring of the damaged part. 24 For restructuring, if a transplant is required, the autologous source is considered a gold standard. However, in the case of significant damage, the autologous source could not be sufficient to fulfill the volume. This makes tissue engineering a potential source of bones and tissues for transplantation. As esthetics are an important feature, precession in craniofacial tissue engineering is crucial. In general, the craniofacial complex has several similarities with the other organs and tissues. Hence, the concepts of surgeries, therapies, tissue culture, transplantation, and 3D bioprinting are also applicable to the craniofacial complex. However, due to the complex geometry, craniofacial bones and tissues engineering face unique hurdles.

3D bioprinting involved fabricating the structure similar to the one that needs replacement by depositing biomaterials loaded with the cells (bioinks) or without cells (mostly for scaffold) at the micrometer scale. 3D printing takes place with the help of an extruder move along three axes oriented in space. 25 The movement of the extruder along all the axes is controlled by design developed using an image program and shaved in file format (e.g., g.code) that is followed by the printer. Due to the potential of 3D printers in tissue engineering, their application has increased over the last few years, and various printable bioinks with printing properties like printability, flexibility, and printing fidelity have been developed.

In order to create a bioprinter that is capable of producing complex artificial tissues several innovations in extrusion, stereolithography, Inkjet and laser printing, is taking place. One of the most sought after latest advancement is the two photon polymerization based 3D bioprinting.

Two‐photon polymerization, which was first demonstrated by the Göppert‐Mayerin 1931, allows the fabrication of the 3D complex structures and critical dimensions of the order of 100 nm. 26 Since then, it has found applications in microrobotics, 27 biosensing, 28 biomedical research, 29 etc. The key functional elements of the two‐photon polymerization techniques are the lasers, which are able to provide the pulse of the femtoseconds, photosensitive material, stage and the program, and the computer to monitor the process of polymerization. It offers the huge 3D designing freedom by precise direct laser point polymerization. These traits are highly crucial for the 3D printing of tissues and bones.

Among the other 3D printing principles, two‐photon polymerization‐based 3D printing offers the best spatial resolution because of its nonlinear light‐induced effects in the photosensitive material. During the process of two‐photon polymerization, the oxygen present in the surrounding quenches the radicals up to some extent. This ultimately helps the process to take size down to around 100 nm. Another distinct advantage of this process is that many polymers have almost nonlinear absorption in the near infra‐red region of the spectrum, which help the laser to penetrate deep inside the material. This feature helps creating nano structures that are otherwise difficult to build.

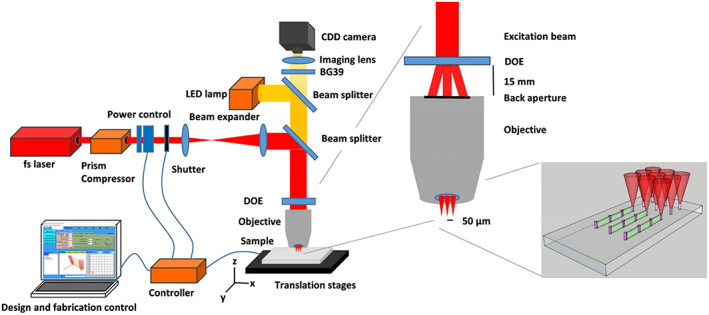

The first commercial two‐photon polymerization‐based 3D printer was made available by Nanoscribe in 2007. Other major commercial payers are Microlight3D, Multiphoton Optics, UpNano, and Femtika. 3D printing by two‐photon polymerization is a direct laser writing technique in which the solid structure is written into a liquid resin voxel‐by‐voxel, by scanning a femtosecond‐pulsed tightly focused laser beam (Figure 2). The commercial system typically uses the pulsed laser with a pulse repetition of the order of tens of MHz and the light in the range of color green and near infrared or the combination of both. 31 The most common resin used with system is acrylate or epoxy derivatives. In the recent times as the application of the two‐photon polymerization‐based 3D printing expanded to the several field including the biomedical research, the development of the in‐house and more versatile material is dominating the field of material research.

FIGURE 2.

Schematic representation of the TPP experimental setup 30

As two‐photon polymerization application in biomedical research increased, research on the effect of the geometric topographies in the differentiation of the iPSC imitated by Aliasgar et al. The group printed the topological patterns of different spatial size and arrangement and studied their effect on the cellular differentiation. The group found out that when iPSC attached to such patterns for a week, the cells started expressing several genetic markers, which are the hallmark of differentiation of the stem cells toward the heterogeneous population of multipotent progenitors from all three germ layers. 32 Similarly, Nieder et al. demonstrated that cell proliferation increases in the presence of the 3D microstructures compared to the planer surfaces. 30 The group also confirmed that the cell adopted the elongated morphology when cell are attached to the 3D microstructure surface. Both observations indicate that the 3D microstructures fabricate using two‐photon polymerization could be the tool to study cellular interaction, cell signaling, migration, cancer metastasis, and tissue engineering. 30

Overall, two‐photon polymerization‐based 3D bioprinting is an excellent approach for the development of the nanoscale structures. Its application in the biomedical and tissue engineering is not only limited to the fabrication of the 3D bioprinted tissues and drug delivery vehicles but now extended to the test the effects of the geometric topographies on the stem cell differentiation. In future, two‐photon polymerization could be the catalyst for the development of the self‐healing and self‐regenerating 3D tissues where stem cells could be patterned in the two photon polymerized nanoscale scaffold, which then depending on the spatial arrangement, and clues will differentiate into the required cell type. 32

5. BIOINKS FOR 3D BIOPRINTING OF SOFT SKELETAL TISSUES AND BONES

Bioprinting is an excellent opportunity to engineer 3D tissues and organs that match and mimic anatomical and physiological functions. ECM, which governs many physiological functions of the cells apart from giving the structural features, is difficult to replicate artificially because of its complexity. The success of bioprinting depends on the survival and proliferation of cells in the constructs. In recent times to enhance cellular viability, several innovations have taken place in design and materials development (e,g biopolymer, hydrogels,). The formulation of live cells in biomaterial, which facilitates the task of bioprinting, is called bioink. They must meet certain characteristics like biocompatibility, physio‐chemical, and rheological properties to be effective. Bioink is considered the most advanced innovation in bioengineering as it provides higher reproducibility with accurate control over the anatomical features. At the same time, it offers flexibility and can be extruded out as filaments or droplets from the nozzles. Irrespective of the various advantages, its overall adaptability depends on how sensitive the biomaterials is to the bioprinting process. 33

Fundamentally, bioinks must copy the functions of cell support, proliferation, differentiation, and cell‐ adhesion from ECM of the target tissue. Further, to be printable, bioinks should have the optimum rheological properties. Bioinks with think vicious constancy are mostly suitable for extrusion‐based bioprinting, whereas less viscous bioinks are suitable for inkjet bioprinting. The gelling time along with the viscosity of the bioinks determines the resolution of the fabricated construct. 34 As high polymer in the bioink is not suitable for cell migration and proliferation, a recent trend is toward using less polymers in bioinks to support better cell growth. 35 The development of suitable bioink is a dynamic area of research, especially for soft skeletal tissue engineering.

Most of the bioink characters match with the hydrogel. However, hydrogels intrinsically do not have the printable filament formation property. Hydrogels are often developed into pippeitable and filament‐forming forms, which could be cast into the molds. Transformation of the hydrogels into printable filament formation form is often done before printing or sometime after the deposition. Classically, bioprinting involves the continuous deposition of cell‐laden biomaterials onto the support. As higher shear stress could damage the cell and affect its viability, reducing it nozzle diameter and pressure need to be taken into account while printing. Overall the parameters that influence the printing process include (1) viscosity of the bioink, (2) temperature at the nozzle (to reduce the cell damage), (3) feasible crosslinking process, (4) uniformity in filament formation, (5) optimum pressure (to reduce the cell damage), and (6) gellation. 33

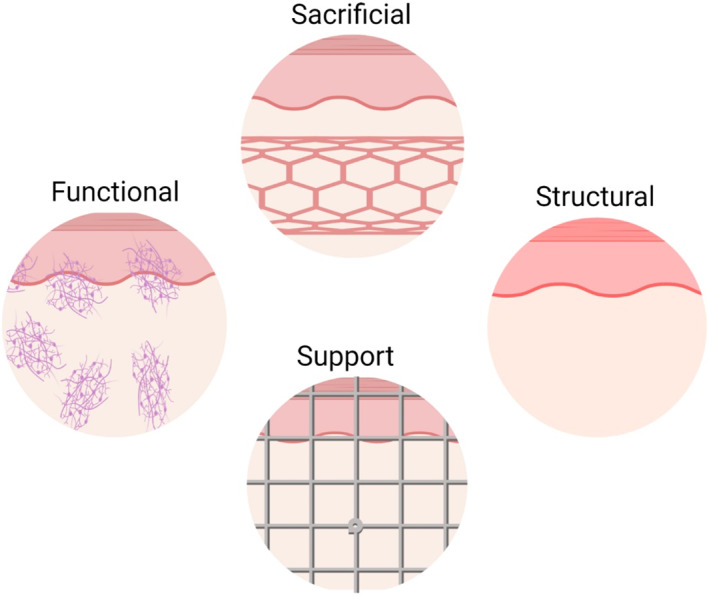

Based on the functions, bioinks are classified into: Structural bioink: These bioinks are mainly used to create the frame of the structure. The most commonly used polymer/biomaterials to make this bioink included gelatins, alginate, cellulose, decellularized, and demineralized ECM, etc. The selection of materials for bioinks depends upon required properties, including cell viability, shape, and size. 36 Sacrificial bioink: As the name indicates, these bioinks are generally removed from the fabricated structure to give rise to the desired geometry within the structure. Most widely, such bioinks are used to make channels to mimic the natural vasculature. To conveniently remove from the structure, the properties of such bioink need to be different from the surrounding material. These bioinks are crucial to make the thick, functional tissues and organs with proper arrangement for the transport of oxygen and nutrients. Carbohydrates, sugars, pluronic, and uncrossed gelatins are the most commonly used sacrificial materials. 37 Functional bioink: These bioinks are very crucial for the success of the final constructs. They are not only associated with the structural integrity and functions of the constructs, but primarily it is associated with the differentiation of the cell. Other than the biomaterials like polymers, these inks often contain the growth factors to stimulate stem cell differentiation. 38 Support bioink: as the name indicates, these bioinks are widely used to offer support to the final construct. These bioinks are meant to grow the construct up to the desired points, after which the construct supports themselves. These bioinks could also be removed from the fabricated structure once they start to support themselves (Figure 3). 39

FIGURE 3.

Different types of bioinks

Synthetic and natural polymers are widely explored for their utility in the bioprinting of skeletal muscles. Natural polymers like fibrin, alginate, collagen, and gelatin calcium alginate have been used widely for skeletal muscle fabrication for better crosslinking and cell‐supportive properties. 40 Among them, alginate is the most popular natural polymer used in modern 3D bioprinting because of its fast and reversible ionic gelation (in the presence of CaCl2). Tamayol et al. recently used alginate as a sacrificial bioinks to entrap and polymerized different polymers like gelatin, agarose, gelatin methacryloyl, polyethylene glycol diacrylate (PEGDA), and polyvinyl alcohol. The process involves two steps; in the first step, alginate is used to entrap various pre‐polymer solutions physically; in the second step, pre‐polymeric solution entrapped inside the alginate network is crosslinked to form an independent polymeric network. 41 For personalized patient care, Negar Faramarzi et al. prepared the alginate‐based bioink using patients' own platelet‐rich plasma. Platelet‐rich plasma is believed to contain growth factors to induce angiogenesis, stem cell recruitment, and tissue regeneration. 42

To enhance the strength of the structure, a group like methacryloyl was added to make various derivatives of synthetic and natural polymers. Methacryloyl derivatives of the polymers have better‐crosslinking characters. Few methacryloyl derivatives with the crosslinking character better than their natural counterparts are gelatin methacryloyl (GeMA), hyaluronic acid methacrylate (HAMA), carboxymethyl cellulose methacrylate (CMCMA), glycidyl methacrylate (GMHA), oxidized methacrylate alginate (OMA), and methacrylate alginate (MA). 43 Photocorsslink is one of the most widely used crosslinked methods employed to crosslink these derivatives. UV spectrum of radiation is the most widely used source and its intensity and time of exposure determine the extent of crosslinking, cell viability, and mechanical strength. Due to the cancerous nature of the UV light, although less instance, the visible light source also offers the alternate approach to the UV light. Luiz E Bertassoni et al. developed a photolabile HEPG2 cell‐laden bioprinting method for bioink made up of methacrylate gelatin hydrogels. 44 Cells like MCF‐7, NIH 3T3, and HUVECs were found to survive and perform well when presented in a bioink composed of 1.5%–2% gelatin methacryloyl hydrogels then 1% GelMA. 45 Jia et al. to prepare vasculature smooth muscle used bioink composed of gelatin methacryloyl, sodium alginate, and 4‐arm poly(ethylene glycol)‐tetra‐acrylate bioprinted with two‐layered coaxial extrusion 3D bioprinting system. 46 Endothelial cells and mesenchymal stem cells, which were present in the bioink, differentiated into the smooth muscle cells in the presence of TGF‐β1. 46

Decellularized ECM (DeECM), which could be obtained by discarding the native cell to leave behind the ECM scaffold, is also explored as an option for bioink. As such materials are obtained from the tissue itself, it has the advantage of being close to the natural tissue and hence is considered as the best choice for tissue and organ regenerations. DeECM is also found to contain the cytokines, various proteins, and proteoglycans that could assist the stem cell in differentiation, proliferation, and adhesion. 47 To date, various tissues are regenerated using the DeECM based bioinks; the most prominent among them are bone, spinal cord, brain tissue, vasculature, adipose tissue, heart, liver, kidney, and skeletal muscles. 48 As DeECM‐based bioinks are weak with low‐stress bearing capacity, it requires a stiffening agent to carry out the crosslinking. To overcome this issue, DeECM‐based bioinks are prepared by mixing components like gelatin and PEG derivatives to enhance mechanical properties and viscosity. 49

Synthetic polymers like PLGA, PCL, PVA, and PEG are also used widely for bioinks. Among them, PEG‐based hydrogels are used most popular. 50 Further, to make them photocrosslinkable various methacrylate and acrylate derivatives of such polymers are prepared. Some of the examples of such derivatives are polyethylene glycol diacrylate, poly(ethylene glycol) dimethacrylate, poly(ethylene glycol‐co‐lactide) acrylate, and poly(ethylene oxide) dimethacrylate. 51 Polyurethane, which is a synthetic derivative, is widely accepted for medical and tissue engineering purpose because of high stress‐bearing capacity, flexibility, and biocompatibility. Toxicity is one of the major concerns of synthetic polymers and their derivatives. To overcome this challenge, research is now focused on developing the less toxic variants of such polymers by using green chemistry and removing toxic ingredients from synthesis process.

Natural polymers can adhere better with cells as compared to synthetic polymers, whereas synthetic polymers offer unique strength and tuneability when compared with natural polymers. To get the best from both classes, composite material bioinks made of synthetic‐natural, natural‐natural, and synthetic‐synthetic polymers were made to get the ink with good cell adhesion and supportive cell properties. Such composite bioinks are close to the ideal parameters of the bioinks. Oju Jeon et al., in their recent work, used oxidized methacrylated alginate/8‐arm poly(ethylene glycol) amine to prepare cell‐laden bioink of human bone marrow‐derived mesenchymal stem cells. The group demonstrated that this composite bioink is tunable by varying the degree of alginate oxidation and shown a biocompatible character. 52 Similarly, Luo et al. developed a 3D printed highly porous scaffold using a composite of highly concentrated alginate and polyvinyl alcohol. 53

It is challenging to prepare a single biomaterial that could be used to make bioinks for different cells and purposes and satisfy all the requirements of tissue engineering and regeneration. To overcome the issue, García‐Lizarribar et al. developed the library of different composites to be suitable for different tissue engineering needs. Natural polymers like cellulose and alginate were derivatized using methacrylic anhydride, and synthetic polymers poly(ethylene glycol) diacrylate were mixed with gelatin methacryloyl to obtain photopolymerizable hydrogel composites. 54

To form multiple microfilaments fibers or droplets, microfluidic heads were developed. The microfluidic head technique allows a fast switch between different bioinks to form the fibers of different bioinks. 35 Costantini et al. developed a new 3D bioprinting method to construct artificial skeletal muscle tissues. The group combined two different cell‐laden (C2C12 and BALB/3T3 fibroblasts) bioinks made up of PEG‐fibrinogen/alginate using the microfluidic head. Myotube formation was noted on the side seeded with C2C12 cell‐laden bioink. 55 Cameron J. Ferris et al. developed the specialized bioinks suitable for the drop‐on‐demand type of printing. To prepare the bioink Dubelcco's Modified Eagles Medium mixed with Poloxamer 188 was used to hydrate the gellan gum. The ink was found to be suitable for a drop of demand printing, with reproducibility and without cell precipitation. 56

Stimulus responsive character was exploited for the development of the smart bioink. Polymer like poly(N‐isopropylacrylamide) has a low critical solution temperature of 32°C and allows the phase transition at 32°C from liquid to gel phase (above 32°C). 57 This property enables the bioink to be in the liquid phase during the printing process. It turns to gel when it comes to the surface, having a temperature more than the critical solution temperature. This quick conversion from liquid to gel allows cell‐laden bioinks to maintain the shape of the bioprinted structure. Shear stress was also used to prepare the stimuli‐responsive smart bioink. Bioinks prepared from such materials loosed their viscosity under a high shear rate, allowing better printing under high pressure. 58

Kim et al. too fabricated the human skeletal muscle prepared the cell‐laden functional and sacrificial bioink. Functional human primary muscle progenitor cells‐laden bioink was prepared using fibrinogen, gelatin, hyaluronic acid, glycerol. The sacrificial bioink to generate the vasculature for the muscle was prepared using gelatin, HA, and glycerol. The bioprinted skeletal muscle preparation using these bioinks has shown that the bundle of muscle was composed of a tightly packed myofiber‐like structure. 59 Seyedmahmoud et al. prepared the hierarchical skeletal muscle to match the function of native tissues. They used C2C12 myoblasts cell‐laden gelatin methacryloyl (GelMA)‐alginate bioinks. The observations confirmed that the 10% (w/v) GelMA‐8% (w/v) alginate crosslinked using UV light and 0.1 M CaCl2 delivered the optimum condition to stimulate muscle tissue formation compared to other hydrogel compositions. Moreover, the improved metabolic function was seen with the addition of oxygen‐generating particles to the bioinks. 60

5.1. Cell‐laden bioinks for craniofacial tissue regeneration

For craniofacial tissue engineering, no specializes bioink is reported in the literature; however, considering the similarity of craniofacial skeletal tissues with non‐craniofacial skeletal tissues, cell‐laden bioinks developed for the skeletal muscle are applicable for craniofacial tissue regeneration. Skeletal limb and trunk muscles, during embryogenesis, are originate from paraxialmesoderm known as somites. Craniofacial muscles, which control facial expression, vision, mastication, and esthetics, arise from cranial paraxial mesoderm of pharyngeal arches. The difference in the origin of the two is also complemented by the different control over the gene expression controlling their development. Somite‐derived myogenesis is controlled by transcription factors PAX3 and PAX7, whereas craniofacial myogenesis is regulated by the transcription factors PITX2, TCF21, and HC2. Myosin heavy chain (MyHC) part of the myosin is responsible for the contraction of the muscle by acting on the actin fiber. 61 Craniofacial muscle expresses Myh3, Myh8, Myh6, Myh13, and Myh14 isoform of MyHC in addition to the common isoforms like Myh7, Myh2, Myh4, and Myh1. The common isoforms of MyHC are usually found in the noncraniofacial muscle‐like limbs. Additionally, different isoforms of MyHC are expressed in a single muscle, for example, extraocular muscle expresses multiple MyHC isoforms. 62 Another unique feature of the craniofacial skeletal muscle is related to the function of the satellite cells, adult muscle stem cells that are present under the muscle fiber lamina. Satellite cells are responsible for muscle tissue regeneration in case of trauma. 63 , 64 Craniofacial muscle cells and noncraniofacial muscle cells both contain the stem cells, but the noncraniofacial satellite muscle plays cells crucial role in the myogenic lineage differentiation by expressing a transcription factor called Pax7, where this transcription factor is not involved In the embryonic development of craniofacial muscle. 65

Additionally, less PAX7 is expressed by the satellite cells of craniofacial muscles, but they still express a crucial transcription factor called Pitx2, which is essential for embryonic development. 66 For example, the regenerative capacity of extraocular muscle is maintained irrespective of age and disease. 67 Since satellite cells of craniofacial muscle are implicated in the regeneration of crucial facial muscles, they have the potential to become the vital target for craniofacial tissue regeneration.

In addition to this, recently, Michael R. Hicks confirmed that Human pluripotent stem cells could be induced to differentiate into skeletal muscle progenitor cells. 68 Kim et al. successfully generated craniofacial myogenic progenitor cells from human induced pluripotent stem cells. 69 The application of human pluripotent stem cells to create progenitor cells for skeletal tissue regeneration is valuable information to future research about its use in whole cranial tissue regeneration. Induce pluripotent stem cells derived craniofacial muscles could be used as an autologous source for craniofacial tissue engineering or reconstruction surgery. 70 Further research is required to formulate induce pluripotent stem cell‐laden bioinks along with the factor that could induce the differentiation of the iPSC to skeletal muscle progenitor cells. At present, no standardize protocol is available for generating craniofacial myogenic precursor cells from human iPSCs. The immediate requirement is the standardization of such protocol by analyzing the crucial signaling pathways mechanisms during craniofacial embryonic myogenesis. 69

6. CRANIOFACIAL TISSUE ENGINEERING

Although the ex vivo skeletal muscle tissue culture was developed around a century ago, the reconstruction of tissues from progenitors began in the early 60s of the last century when cross‐striated muscle cells were developed in the petri dish from chick embryonic muscle cells. 71 The importance of extracellular materials for cell survival and proliferation was also pointed out by Konigsberg, which led to its widespread use in modern tissue engineering. 72 Several materials of natural and synthetic origin (polycaprolactone‐based polymers, fiber, alginate) were identified and developed to fabricate the skeletal muscle tissues in the lab.

Further, to enhance the differentiation to the skeletal muscle, skeleton/scaffold of specific functionalities like support to the cell growth, mechanical strength, chemical, and electrical conductivity, soluble growth factors were developed. For more complex tissue engineering, which required more than one type of cell (e.g., tissues with the vasculature) co‐culture technique was developed, for example, skeletal muscle cells with fibroblasts to engineer the myotendinous junction or endothelial cells to vascularize muscle or with neural cells to obtain neuromuscular junctions. 73 Despite the advance in skeletal muscle tissue engineering, the fabrication of fully functional skeletal muscle tissue is a distinct task. Specifically, the engineered skeletal muscle tissues are lacking in strength when matched with their natural equivalent. 74 As identified by Konigsberg et al., researchers are now focusing on matching the ECM to mimic the microenvironment of the skeletal muscles. All the classical methods were limited to the 2D culture or co‐culturing; however, research has confirmed the role of the 3D framework composed of ECM and growth factors to facilitate tissue restructuring and engineering. The bioinks that facilitate the complex tissues' fabrication can be remolded to be useful for craniofacial tissue engineering. For this purpose, natural, synthetic polymers, decellularized ECM, or the composites of natural‐synthetic‐decullarized ECM can be used to prepare the iPSC or adult muscle cell progenitor laden bioinks.

Craniofacial tissue complex is involved in many critical functions, including mastication, speech, smile, and has high aesthetic importance. 75 Craniofacial bones, skeletal muscles, ligaments, blood vessels, nerves complex, and teeth are the critical component of the craniofacial complex. Damage to the craniofacial complex could not only severely affect the overall functions of the face, but because of the aesthetic appeal, it could take a toll on psychosocial behavior. In a broad sense, damage to the craniofacial tissues has a physical and social impact, and hence accurate reconstruction to restore the functional and aesthetic appeal is urgently required.

During embryonic development, mesenchymal cells (MSc) originate from the neural crest, which then subsequently differentiate into almost all the craniofacial tissues, including bone, ligaments, tendons, cartilages, teeth, etc. 76 The neural crest is the intermediate group of cells native to the vertebrates, originates from the ectoderm germ layer which later differentiates into smooth muscle, neurons, glia, melanocytes, and craniofacial bones and cartilages. For the formation of the craniofacial structure, MCs work with mesodermal cells. 77 During the development of craniofacial tissues, MC bifurcates into two lineages, one into the terminally differentiate stage and the other linage give rise to the off‐spring mesenchymal cells. 78 After complete morphological development of the craniofacial tissues, off‐spring MC continues to reside inside in all the cranial tissues as stem cells, which letter called as MC stem cells. In adults, MS stem cells help to maintain a constant turnover of the cells to keep the physiological function intact during injury; MC stem cells differentiate to regenerate the tissues of the craniofacial complex. 79 Irrespective of the very high potential, the inherent natural ability of MC stem cells to differentiate or regenerate into craniofacial tissues is not yet studied. Hence, there is substantial scope to its utility in craniofacial tissue regeneration.

Despite the several advantages of the MS stem cells, craniofacial tissue generation turns out to be a difficult task because of the complexity of the craniofacial complex. It requires the combined effort of remotely similar disciplines like robotics, polymer chemistry, mechanical engineering, cell biology, genetics, and material science. In the engineered tissue, cells must know their place with respect to the other cells, must participate in the coordinated cell signaling pathways, and must differentiate and synthesize ECM. In this respect, craniofacial structures are very complex and offer several hurdles in their artificial tissue engineering. Initially, craniofacial tissue engineering was based on the principles of classical methods. The focus was on the isolation of the stem cells and using them for tissue engineering. Several human‐shaped craniofacial tissues, including bones and cartilages prototypes, were prepared using the MC stem cells. Adipose tissue was also fabricated from the MC stem cells to be used in facial tissue restructuring. 79

Craniofacial muscles share several similar issues with noncraniofacial tissue engineering. This leads to use many of the tissue engineering concepts from noncraniofacial tissue engineering. But there are still enough differences that present unique hurdles, most of which are concerned with 3D orientation, complexity, and vascularization.

Apart from the congenital disabilities, the most common causes of craniofacial abnormality and damages are surgeries, trauma, cancers, sports injuries, etc. 80 Out of these, craniomaxillofacial injuries contribute to major deformities, and congenital disabilities are the primary cause of concerns among the infants. 81 In craniofacial muscle reconstruction, craniofacial bone plays a crucial role because they provide the anchoring platform for soft tissues and teeth. As craniofacial bones are the platform for the soft tissues of the craniofacial complex, accurate craniofacial bone reconstruction is essential to reinstate the regular functions of the complex. 82 For example, Gaihre et al. 83 addressed the defects of craniomaxillofacial bone by restoring it using biocompatible polymers like chitosan, alginate, cellulose, collagen, fibrin, and silk. The synthetic polymers used for scaffold preparation were poly (l‐lactic acid), poly(lactic‐co‐glycolic acid), polycaprolactone, and poly(propylene fumarate). 83 Tu et al. managed to resolve the craniomaxillofacial bone defects by employing prosthesis composed of the hand‐made customized prosthesis of hydroxyapatite /epoxide acrylate maleic. After implantation, none of the patient has shown any complications. 84 In a separate study conducted by Nunes et al. on nine patients with hydroxyapatite implants, bone ingrowth was observed with no indication of inflammatory reactions in the surrounding tissues. 85 Goetz et al. used 3D printed scaffold made up of tricalcium phosphate to repair the defects of craniofacial bone. 86 Rotaru et al. rehabilitate the craniofacial bone defects using customized 3D implants made up of autologous or alloplastic materials. In one radically revolutionary example, full‐face transplantation was done from a cadaver in 2005 in Italy. 87 The full face transplant is reserved for the situation where the person has unrecoverable injuries to the face. 87 In recent times, another important example of craniofacial restructuring using a complete full face transplant was conducted by a team of Spanish doctors. 88 Furthermore, modern techniques like 3D printing, CT, and CAD/CAM have offered the possibility of the customized craniofacial implants made up of biocompatible material. The option of the customized implants has opened up a new arena in the field of craniofacial tissue engineering with personalized patient care. After 2005, countries like Spain, Italy, China, and the United States have effectively implemented the facial transplantation for the indications like traumatic injury, neurofibromatosis, and disfigurement. 89 , 90 , 91 , 92 Progress made in the craniofacial bone transplant and reconstruction is fundamental for the effective regeneration of facial soft tissues.

An alternative approach to rehabilitate craniofacial tissue damage is the use of prostheses. Conventionally prostheses used face several challenges; the most critical one is matching the prostheses appearance with the patients in terms of color, stiffness, size, and shape. Such matching is a tedious and time‐consuming process. 3D printing could help match the shape and size of the prostheses as per the patient's requirement, and the overall process is not labor‐intensive. Rehabilitation using prostates is commissioned only when surgical restructuring is not possible. A few of the major advantages of prosthetic rehabilitation is lower costs with shorter treatment time than surgical reconstruction. 93 In craniofacial restructuring, typically, the prostheses are required to reconstruct the dental, oral, orbital, and nasal regions, and polysimethylsiloxane is the most widely used material for the fabrication. 94 With the advance in 3D imaging and 3D printing techniques, the fabrication of such prostheses has changed considerably in terms of shape and time. At present, very limited prostheses fabricated using 3D printing technology used in clinical settings are available. However, the availability of advanced additive technology can be used in complex craniofacial engineering to enhance the quality and outcomes of prosthetic restoration. In the future, PDMS prosthetics printed directly using advance 3D printers could considerably improve the quality at a lower cost for the craniofacial application.

6.1. Craniofacial bone regeneration

Autogenous bone grafts, especially from the iliac crest and rib bones, are considered as the most trusted source for craniofacial bone regeneration. 95 However, the origin of craniofacial and other long bone is from the different germ layers, which need to be considered for grafting. Another primary concern is similar to all the bone grafts, for example, inadequate supply and donor site morbidity. One critical post graft concern is the limited vascularization, which could lead to graft resorption and loss of structural features. Conservation of the periosteum layer and environment at the site of implantation was found to stimulate the revascularization process on the grafted bone. 96 One major issue with the craniofacial bones is their complex 3D structure compared to the long bones, which make bones like iliac, fibula, or ribs difficult to restructure to fit into craniofacial bones morphology. To overcome the challenge of limited availability and complex 3D structure, tissue and bone engineering has promised the concrete approach to treat the defect of craniofacial bone defects by synchronizing active constituents, cells, and growth inducers. 97 Craniomaxillofacial defects were successfully resolved in a clinical trial by using a stem cell‐mediated bone repair method. A similar approach was used to slow down the degeneration of bones in osteonecrosis of the femoral head and for prophylactic management of distal tibial fractures. 80 The use of the stem cells for bone engineering is based on the original work carried out by Friedenstein et al., who reported the osteogenic differentiation from multipotent‐stromal‐cell and mesenchymal‐stem‐cell. 98 Friedenstein was the first who reported that the bone marrow contains the specialized cells known as melanocytes, which are not only essential for the osteogenesis but also essential for the development of the native microenvironment. 98 Due to their favorable osteogenic potential, MSC is considered an important cell source for facial bone tissue engineering. 99 Adult bone marrow stem cells were the first to use for craniofacial bone regeneration among stem cells. Bone repair cells produced ex vivo also represent a class of stem cells potentially useful for stimulating osteogenic cell proliferation for bone regeneration. 100 Ksigler et al. used bone repair cells successfully produced from the bone marrow cells to regenerate craniofacial bones. 101 The experimental results confirmed the multilineage and clinical application of bone repair cells for craniofacial bone engineering. 100

Although the association of fat cells with bone formation is an intense field of research, various studies indicate the counter relationship between the differentiation of bone marrow‐derived mesenchymal stem cells or stromal cells to the adipocyte and osteoblast lineage pathways. 102 During the last decade, adipose‐derived mesenchymal cells appeared as a reliable source of cells for craniofacial bone tissue regeneration. 103 One advantage of the adipose‐derived mesenchymal cells over the bone marrow cells is their scalability and easy access. Cowan et al. were the first who studied adipose‐derived mesenchymal cells for their osteogenic ability to manage the critical‐size mouse calvarial defects successfully. 104 Very recently, in 2012, Gomes et al. treated the critical‐size calvarial defects with white adipose tissue. The recovery was confirmed with the expression of protein bone morphogenetic protein (BMP)‐2, which is essential for bone repair mechanism and homeostasis. 105 Similarly, Azevedo‐Neto et al. transplanted subcutaneous adipose tissue to repair the craniofacial damage. Adipose tissue was found to stimulate craniofacial bone damage and confirmed by the expression of adipolactin (expression specific to adipose tissue). 106 Craniofacial bone regeneration capacity of cells like amniotic epithelial cells, umbilical cord‐derived mesenchymal stem cells, and amniotic fluid mesenchymal cells was also evaluated. One major advantage of such cells is their ability to assist blood capillaries formation during bone healing. 107

Craniofacial bone marrow cells were also studied for their bone regeneration capacity. In a recent rat study, mandible‐derived BMSCs showed higher bone mineralization as compared to the BMSCs. BMSCs from the marrow of mandibular or maxillary bones have shown better osteogenesis and stimulated higher expression of osteoblastic markers than the bone marrow extracted from the long bones of the same patients. 108 On a similar line of research, BMSC obtained from the calvarial bones was found to stimulate bone regeneration. 109 Despite the positive results obtained from the craniofacial bone marrow cells, limited availability is the major hurdle in its widespread application. In several studies, growth stimulators have been found to play a crucial role in stimulating the progenitor cells to osteogenesis. In recent times, the use of growth factors has received wider acceptance. One of the most commonly used growth stimulators used for craniofacial bone tissue engineering is the bone morphogenic protein. 110

Despite the in vitro and ex‐in vivo success of craniofacial bone tissue engineering, its clinical application has several hurdles to overcome. This includes a limited supply of the autogenous progenitor cells, long‐term viability of the transplants, isolation, selection, storage of the stem cells, lack of proper 3D microenvironment for differentiation, and loss of multipotentiality character after six or seven cell cycles in vitro cell culture. 111 One of the most potent remedies to such issues is the use of a 3D scaffold of ECM and seeding them with the progenitor cells or creating the 3D cell culture to match with the natural microenvironment. Table 1 summarized a few of the crucial applications of stem cells for craniofacial bone regeneration.

TABLE 1.

Crucial applications of stem cells for craniofacial bone regeneration

| S. no | Cells | Bone engineered | Remark | Objective | Reference |

|---|---|---|---|---|---|

| 1 | Bone marrow stromal cells (MSCs) | Cranial defects | Three‐dimensional computerized tomography (CT) scan revealed an almost complete repair of the defect of the experimental group at 18 weeks. This study may provide insight for the future clinical repair of cranial defect | The objective of this study was to investigate the potential of using autologous MSCs to repair cranial bone defects by a tissue‐engineering approach | 112 |

| 2 | Dental mesenchymal cell | Mandibular defects | This pilot study supports the feasibility of tissue‐engineering approaches for coordinated autologous tooth and mandible reconstruction, and provides a basis for future improvement of this technique for eventual clinical use in humans | Investigated simultaneous mandibular and tooth reconstruction using a Yucatan minipig model | 113 |

| 3 | Genetically engineered bone marrow‐derived mesenchymal stem cells overexpressing hypoxia‐inducible factor‐1α | Calvarial defects in rats | HIF‐1α‐overexpressing BMSCs dramatically improved the repair of critical‐sized calvarial defects, including increased bone volume, bone mineral density, blood vessel number, and blood vessel area in vivo | The hypothesis that HIF‐1α gene therapy could be used to promote the repair of critical‐sized bone defects | 114 |

| 4 | Bone marrow‐derived mesenchymal stem cells (BMSCs) genetically engineered transient expression of osteogenic/angiogenic factors and growth factor expression | Calvarial bone healing | BMSCs accelerated the bone remodeling and regenerated the bone through the natural intramembranous pathway | Augmented healing of critical‐size calvarial defects by baculovirus‐engineered MSCs that persistently express growth factors | 115 |

| 5 | Amniotic epithelial cells | Maxillary sinus | The obtained data suggest that scaffold integration and bone deposition are positively influenced by allotransplantated oAEC | The bone regenerative property of an emerging source of progenitor cells, the amniotic epithelial cells (AEC), loaded on a calcium‐phosphate synthetic bone substitute, made by direct rapid prototyping (rPT) technique, was evaluated in an animal study | 107 |

| 6 | Human umbilical cord mesenchymal stem cells | Rat cranial defects | hUCMSC and hBMSC groups generally had statistically similar bone mineral density, new bone amount and vessel density | hUCMSC and hBMSC seeding on macroporous calcium phosphate cement (CPC), and to compare their bone regeneration in critical‐sized cranial defects in rats | 116 |

| 7 | Amniotic fluid mesenchymal cells engineered on MgHA/collagen‐based scaffold | Sinus augmentation | The osteoinductive effect of a biomimetic commercial scaffold may be significantly improved by the presence of ovine AFMC | To evaluate whether commercial magnesium‐enriched hydroxyapatite (MgHA)/collagen‐based scaffold engineered with ovine amniotic fluid mesenchymal cells (oAFMC) could improve the bone regeneration process in vivo | 117 |

6.2. 3D printed craniofacial bones

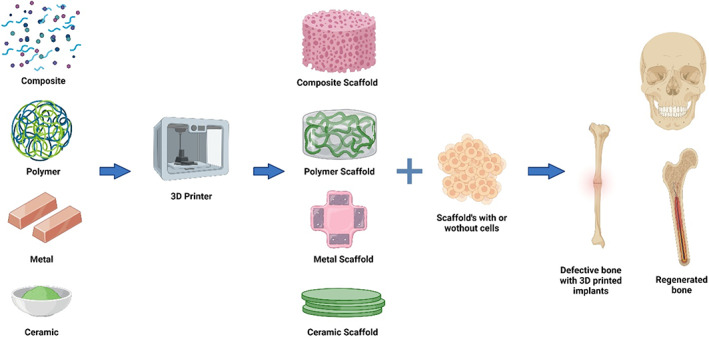

Due to the various limitation of craniofacial bone tissue engineering, interest in 3D bioprinted craniofacial bone implants has grown considerably. 3D bioprinting is a relatively new field of research that involves the considerate use of scaffold materials, growth factors, and stem cells. The terms 3D printing and 3D bioprinting are often used interchangeably. Live cell printing often involves the use of inert scaffold or dense cell printing without scaffold. Several reports confirm that the 3D bioprinting can revolutionize the field of craniofacial bone tissue engineering. 3D bioprinted craniofacial bones offer several benefits to patients who require augmentation because of trauma or congenital flaws. CAD could help print the implants that match with the patient's anatomy, confirming excellent implant and bone contact. 118 Bioprinting is still in the initial phase of development. One of the significant challenges in 3D bioprinting of craniofacial bone tissue engineering is developing and identifying suitable biocompatible materials that could support the function and growth of craniofacial tissues. Moreover, the materials must have proper crosslinking patterns to permit accurate deposition and bioactivity with sufficient strength over a long period of time. 34

Embryonic cells create craniofacial and noncraniofacial bones. Somites lead the path to the axial skeleton, mesoderm from the limb bones, whereas the neural crest gives rise to the craniofacial bones and cartilages. 119 Bone formation is the conversion of mesenchymal tissue to calcified bone, which is the target process needed to be translated in 3D bioprinting. The scaffold role is crucial in successful bone formation; hence, efforts are focused on developing feasible methods of fabrication. Traditional methods of bone tissue engineering like leaching, foaming, or frees drying lack the precision required to produce the accurate bone shape and size so that they could fit well in the puzzle of the craniofacial complex. On the other hand, in additive manufacturing controlled by a computer, the software program offers precise control over the topology and interconnectivity of the pores, which is crucial in the 3D bioprinting of craniofacial bones.

6.2.1. Ceramics in 3D bioprinting of craniofacial bones

The present method available for handling craniofacial defects and damages is not reproducible and robust. It depends on the surgeon's skill and the natural response of the patient for the regeneration of the lost and damaged tissue. The 3D scaffold supports the growth of seeded cells at its offers the natural microenvironment. A technique like 3D bioprinting, which could design and construct the complex porous structure of scaffold, could revolutionize the field of craniofacial bone and tissue engineering. Components like plastics (synthetics and natural), ceramics, polymers, cells, and growth factors can be simultaneously used in the 3D printing of complex scaffolds for craniofacial bones. Such 3D printed scaffold with interconnected pores offers the advantage of fabricating patient‐specific implants, supporting cell growth and better vasculature formation. 120

Ceramics are one of the most widely used materials for bio‐implants. Ceramics mainly used for its biological role in the human body are known as bioceramics. Bioceramics has several applications, including treatment, diagnosis and reinstall, and support of the bone function by creating its replica. They are basically of two types: (1) bioinert and (2) bioactive. Bioactive ceramics are biodegradable and promote the formation of new bone, whereas bioinert ceramics are implanted to interact actively with tissues through bonding. Bioinnert ceramic scaffold is mostly composed of alumina, alumina/borosilicate glass, alumina/SiC, etc., and Zirconia; on the other hand, bioactive scaffolds are mainly made up of mesoporous bioactive glasses13‐93, bioactive glass, 6P53Bglass, alkali‐free bioactive glass, hydroxyapatite, tricalcium phosphate, and calcium silicate. 121

Bioinert ceramics are popular for implants because of their biocompatibility, corrosion resistance, and physiological stability. Alumina (Al2O3) and zirconia are the most widely used bioinert ceramics. 122 Al2O3 was used first and is still popular because of its non‐toxic nature, durability over a long period, biocompatibility, and inertness toward the tissues. 123 Zirconia is equally popular as Al2O3 because of its toughness among the available oxide ceramics. 124 Other novel bioinert ceramics, which are gaining importance, include titanium dioxide (TiO2), silicon carbide (SiC), and carbon materials. 125 For better mechanical strength, the incorporation of other material into Al2O3 or composites of hydroxyapatite was also proposed. 126 For example, Glass/Alumina composite was used to make the complex structure using 3D printing technology. 126 The CT scans and CAD created the prototypes of the complex structure, which is essential to disclose the minute details of the complicated craniofacial complex. 126 To bring the unique properties of different material together, Gonçalves et al. combined hydroxyapatite, carbon nanotubes, and polycaprolactone to fabricate the 3D printed scaffold having interconnected pores for cell adhesion and growth. 127

Hydroxyapatite and tricalcium phosphate are similar to natural bone and are considered attractive materials for bone tissue engineering. However, low mechanical barring strength and brittle nature limit the use of these materials in real clinical settings. Low strength is attributed to the calcium phosphate phases to which the HA decomposes. To enhance its mechanical strength, similar to alumina, HA is also combined with materials like zirconia, titania, calcium silicate, and alumina. 128 HA forms a strong bond with bones, and alumina is stable biomaterial material but cannot interact with bones. Hence attempts were made to combine alumina and HA to form the bioinert but at the same time, bone and tissue interacting composite. In one of the approaches, AYDIN et al. fabricated the porous a‐TCP‐CeO2‐Al2O3 composite via using bovine bone‐derived HA and alumina ceramics. 129 Several other reports also confirmed the role of calcium phosphate in bone reconstruction. The use of nanomaterials also offers an excellent method for bone tissue scaffold generation. Majid Rezaei et al. assessed the effect of nanoionization on biphasic calcium phosphate in the healing of canine mandible cavities. 130

6.2.2. Polymers and ceramic composites

Bioceramics have the excellent property of bioinnertness; however, the fragile nature of ceramics and the low mechanical strength of bioactive ceramics have restricted their clinical application. This makes it inevitable to pursue more research to be carried out to produce new materials or improve the properties of existing materials. Synthetic polymers have long been used for medical applications, including drug delivery and bone replacement. 131 For example, poly(methyl methacrylate) (PMMA) and ultra‐high molecular weight polyethylene (UHMWPE) are widely used for hip replacement. Based on the experience and several studies, the polymers like polyethylene (PE), polypropylene (PP), polyurethane (PU), polytetrafluoroethylene (PTFE), poly(vinyl chloride) (PVC), polyamides(PA), PMMA, polyacetal, polycarbonate (PC), poly(−ethylene terephthalate) (PET), polyetheretherketone(PEEK), and polysulfone (PSU) are considered as the biocompatible polymers. 132 , 133 The latest interest in tissue engineering has renewed the research interest in biopolymers like poly(lactic acid) (PLA), poly(glycolic acid) (PGA), poly(ε‐caprolactone) (PCL), polyhydroxybutyrate. 134 These polymers, either alone or combined with ceramics, could be used to fabricate the scaffold, seeded with different types of cells and growth factors. When combined with other materials, they are known as composites, and unlike the first‐generation classical materials, the composites are made for bio‐medical application, and hence they are termed as designer biomaterials or smart biomaterials.

Polymer‐like polylactic acid, which is linear aliphatic polyester, is also widely used for bone tissue engineering. 135 Other than preserving its mechanical strength in physiological conditions, it is less viscous, biocompatible and its degradation products are non‐toxic. Vazquez‐Vazquez et al. used the air‐jet spinning technique to form a submicron coat of PLA over the 3D printed scaffold to analyze the cell (human fetal osteoblast cells) adhesion, cell‐material interaction, and proliferation. 136 Polymers, like polycaprolactone and poly(lactic‐co‐glycolic acid) (PLGA), are widely popular in 3D bioprinting of bone tissue regeneration. 137 These polymers are useful for their mechanical load‐bearing strength, but they do not support the bone growth of their own. This drawback can be potentially overcome by making the composite with calcium‐based ceramics (HA, calcium phosphate, tricalcium phosphate) and hydroxyapatite crystals. The addition of HA or tricalcium phosphate was found to enhance the mechanical strength of the polymers. 138 Calcium phosphate and polymer‐like PLGA were found to stimulate osteoinductivity, an essential phenomenon to boost the osteogenesis process. 139 While polymer–calcium ceramics composites have positively promoted bone regeneration in various animal models, the complete healing of the damage and defects is not reported. This prompted the research toward refining the design and materials for clinically viable implants. One such advancement in the design is the use of a bone ECM to support the scaffold bioactivity. Bone ECM could be decellularized or demineralized. 140 For example, Bio Oss, developed by the Geistlich Biomaterials, is the natural substitute for bone and teeth implants. It is made up of the bovine trabecular bone from which most of the organic components are removed without changing the natural microstructure of the bone. A blend of decellularized bone matrix and polycaprolactone was compared with the Bio‐Oss, and no major difference in the differentiation of adipose‐derived mesenchymal stem cells into bone tissue was observed when cultured in hydrogels. 141 Hung et al. in 2016 has confirmed that the decellularized bone matrix blend successfully healed the cranial defect in a mouse model. 142 DMB, on the other hand, is the allogenic bone graft regularly used for filling the gaps and healing the defects. They are usually prepared by first removing the sift tissue, fats and blood followed by the acid‐based deminerilization and freez drying. 143 The final product usually contains the collagen and BMPs and transforming growth factor‐beta 1, 2, and 3 granting it the osteogenesis properties. 143 One limitation of demeralinized bone is its poor mechanical load‐bearing capacity, which has hampered its clinical development. One other challenge of such material is the limitation of processing it into a 3D porous scaffold to support the new vasculature formation and osteogenesis. This shortcoming was overcome by Freeman et al., who fabricated 3D bioprinted scaffold using composite PCL and decullarized bone filaments. The scaffold was also found to support angiogenesis and at the same time deliver the skeletal stem cells with growth factors to differentiate into osteoblasts. 144

At the damaged bone site, osteoblasts, osteoclasts, and progenitor cells undergo order of sequence to restore the damaged part. This intrinsic ability of bone regeneration was coupled with the bone grafts for faster recovery. However, this classical method has several disadvantages, as discussed above (site morbidity, infection, immune activation in case of Xeno or allograft, limited supply in case of autografts, etc.). A few major requirements of the bone grafts are interconnected pores for oxygen and nutrient supply, attachment site for cell, support for proliferation and differentiation and tissue growth factors, high load‐bearing capacity. 3D bioprinting, along with the high precision over the structure, also overcomes the shortcomings of the classical methods of bone fabrications. Moncal et al. took over these issues and 3D bioprinted a bone tissue composed of poly(e‐caprolactone)/poly(d,l‐lactide‐co glycolide)/hydroxyapatite composite with interconnects micropores and high mechanical strength. The fabricated structure because the presence of mineralized bone tissue was found to support the bone regeneration via support to the angiogenesis process. 145 Shah et al., in 2016, commercialized a new biomaterial compatible with 3d bioprinting used to fabricate hyperelastic bone. Hyperelastic bone consists of biodegradable 10% polymers used to link 90% of calcium phosphate ceramic. The hyperelastic bone has the ideal properties of bones like high porosity to support the bone growth, nutrient transport, and high mechanical strength. 146