Abstract

The impact of dry‐ageing of beef and wet‐ageing of beef, pork and lamb on microbiological hazards and spoilage bacteria was examined and current practices are described. As ‘standard fresh’ and wet‐aged meat use similar processes these were differentiated based on duration. In addition to a description of the different stages, data were collated on key parameters (time, temperature, pH and aw) using a literature survey and questionnaires. The microbiological hazards that may be present in all aged meats included Shiga toxin‐producing Escherichia coli (STEC), Salmonella spp., Staphylococcus aureus, Listeria monocytogenes, enterotoxigenic Yersinia spp., Campylobacter spp. and Clostridium spp. Moulds, such as Aspergillus spp. and Penicillium spp., may produce mycotoxins when conditions are favourable but may be prevented by ensuring a meat surface temperature of −0.5 to 3.0°C, with a relative humidity (RH) of 75–85% and an airflow of 0.2–0.5 m/s for up to 35 days. The main meat spoilage bacteria include Pseudomonas spp., Lactobacillus spp. Enterococcus spp., Weissella spp., Brochothrix spp., Leuconostoc spp., Lactobacillus spp., Shewanella spp. and Clostridium spp. Under current practices, the ageing of meat may have an impact on the load of microbiological hazards and spoilage bacteria as compared to standard fresh meat preparation. Ageing under defined and controlled conditions can achieve the same or lower loads of microbiological hazards and spoilage bacteria than the variable log10 increases predicted during standard fresh meat preparation. An approach was used to establish the conditions of time and temperature that would achieve similar or lower levels of L. monocytogenes and Yersinia enterocolitica (pork only) and lactic acid bacteria (representing spoilage bacteria) as compared to standard fresh meat. Finally, additional control activities were identified that would further assure the microbial safety of dry‐aged beef, based on recommended best practice and the outputs of the equivalence assessment.

Keywords: Meat, wet‐ageing, dry‐ageing, maturation, safety, bacterial growth

Summary

Following a request from the European Commission, the Scientific Panel on Biological Hazards (BIOHAZ) was asked to provide a scientific opinion on the impact of prolonged ageing of meat using the dry‐ageing process for beef and the wet‐ageing process for ungulates on the load of microbiological hazards and spoilage bacteria in comparison with standard fresh meat.

In Term of Reference 1 (ToR1), the European Food Safety Authority (EFSA) was asked to provide an overview of the current practices used by food business operators (FBOs) for dry‐ageing and wet‐ageing of meat (e.g. time, temperature, relative humidity, air flow, type of packaging, etc.).

Historically beef was preserved by removing water in a dry‐ageing process that resulted in tenderisation and enhanced flavour. However, in the 1960s, vacuum packaging was developed and since then most meats, including beef, pork and lamb, are wet‐aged in vacuum packs because it requires less time, incurs less weight loss, has lower investment costs and the resultant product requires less trimming.

There are different combinations of temperature, relative humidity (RH), airflow and time used in academic studies on the dry‐ageing of beef but most used 0–4°C, a RH of 70–80% and an airflow of 0.5–2.5 m/s for 14–35 days. Under these conditions, the surface pH of the beef was usually 5.5–6.0 and the aw 0.95–0.99. Studies on the wet‐ageing of beef, pork and lamb typically used temperatures of −0.6 to 4°C, a RH of 75–85% and an air flow of 0.2–7.0 m/s for 21–35 days (in vacuum packs) resulting in surface pH values of 5.1–6.0, 5.4–6.3 and 5.5–5.9 for beef, pork and lamb, respectively. The aw values for beef were 0.97–0.99 but similar data were not available for pork or lamb.

Information on current commercial practices was obtained using a questionnaire targeting relevant FBOs and their professional associations. Under commercial conditions beef is usually dry‐aged at 1–4°C and a RH of 75–85% for 21–35 days (no data available for air flow). Wet‐ageing of beef is undertaken at 0–4°C for 14–49 days with a resultant surface pH of 5.4–5.8. Wet‐ageing of pork is undertaken at a similar temperature for 2–6 days and the range of pH values is the same as for beef. In contrast, lamb is wet‐aged at −1 to 5°C in a process that requires 7–77 days (pH data not available).

In ToR2, EFSA was requested to identify public health‐relevant microbiological hazards and spoilage bacteria occurring during the dry‐ageing and wet‐ageing of meat, also considering their possible use for the production of minced meat and mechanically separated meat (MSM). The microbiological hazards that may be present in all aged meats included Shiga toxin‐producing Escherichia coli (STEC) (more common in beef), Salmonella spp., Staphylococcus aureus, Listeria monocytogenes, enterotoxigenic Yersinia spp. (usually pork), Campylobacter spp. and Clostridium spp. Moulds such as Aspergillus spp. and Penicillium spp., may produce mycotoxins when conditions are favourable. However, as there is limited information available and that which is available is primarily focused on plant‐based foods, it was unclear as to exactly what temperature conditions prevent mycotoxin production during dry‐ageing of beef. Four studies published in the 1970s report that mycotoxins can be produced at very low concentrations all‐be‐it very slowly by Penicillium spp. at temperatures as low as, for example 0–1°C on fruits, corn and other crops but these do not provide data for meat. Meat and Livestock Australia (MLA) in their 2019 review concluded that Penicillium spp. and Aspergillus spp. are not capable of producing mycotoxins on dry‐aged meat at temperatures between −0.5 and 3°C, a RH of 75–85% and an airflow of 0.2–0.5 m/s.

The main meat spoilage bacteria include Pseudomonas spp., Lactobacillus spp. Enterococcus spp., Weissella spp. and Brochothrix spp., which produce slime on meat, Weissella spp., Leuconostoc spp., Enterococcus spp. and the former Lactobacillus spp., associated with hydrogen peroxide greening, and Shewanella spp. and Clostridium spp., responsible for hydrogen sulfide greening. Meat spoilage is also characterised by off‐odours such as sulfide odour (Clostridium spp. and Hafnia spp.) and cabbage odour (Providencia spp.) and souring caused by lactic acid bacteria (LAB), Enterococcus spp., Micrococcus spp., Bacillus spp. and Clostridium spp. It is generally accepted that Pseudomonas spp. are the main spoilage bacteria under the aerobic conditions encountered during dry‐ageing while facultative anaerobic bacteria such as LAB and strict anaerobes such as Clostridium spp. are the main spoilage bacteria of wet‐aged meat which is vacuum packaged and therefore under anaerobic conditions.

In ToR3, EFSA was requested to assess the impact that dry‐ageing and wet‐ageing of meat, produced according to selected current practices, could have on the load of public health‐relevant microbiological hazards and spoilage bacteria, when compared to standard fresh meat. In ToR4, EFSA was requested to provide those conditions during the production of dry‐aged beef and wet‐aged beef, pork and lamb and possible further storage that would result in a similar or lower load of the relevant microbiological hazards and spoilage bacteria as compared to those obtained during standard fresh meat preparation.

Fresh meat is meat that has not undergone any preserving process other than chilling, freezing or quick‐freezing and the majority of fresh beef, pork and lamb is matured/stored in vacuum packaging under chilled conditions. Wet‐aged meat is meat that has been vacuum packaged and stored under chilled conditions. There is currently no scientific, commercial or legislative basis for differentiating between ‘standard fresh meat’ and ‘wet‐aged meat’. For the purposes of this Opinion, differentiation, as agreed with the European Commission, was based solely on the time in chilled storage. ‘Standard fresh beef’ was considered to be matured in vacuum packs for up to and including 14 days, while for pork and lamb it was typically matured for up to and including 4 days.

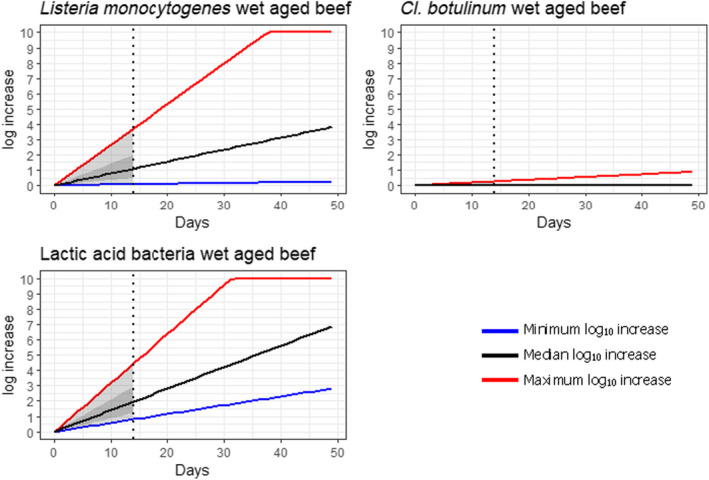

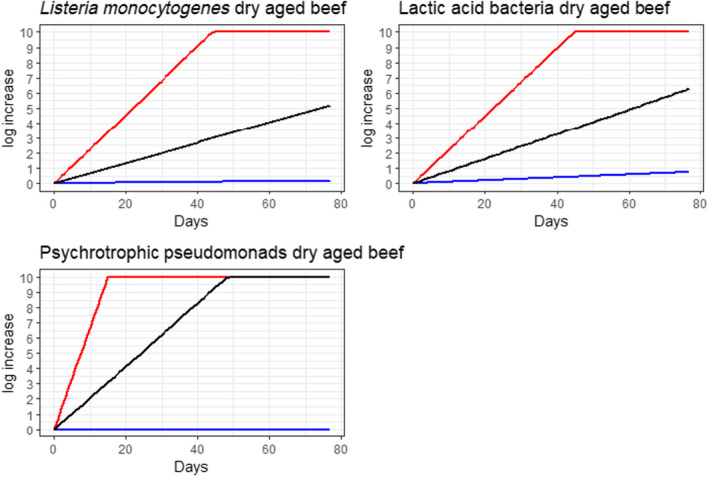

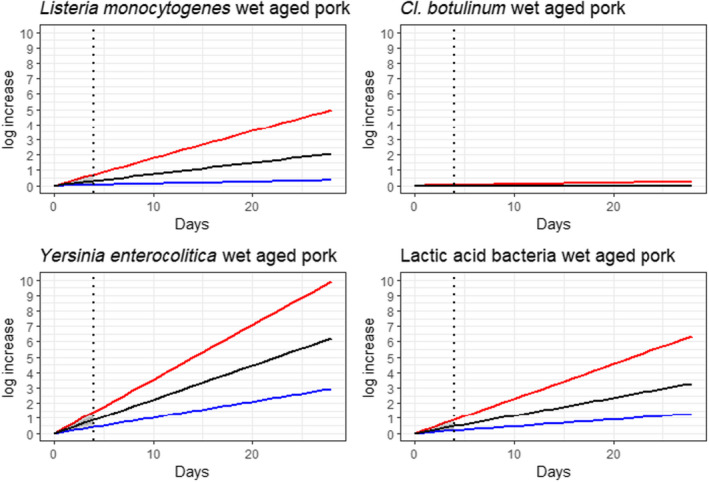

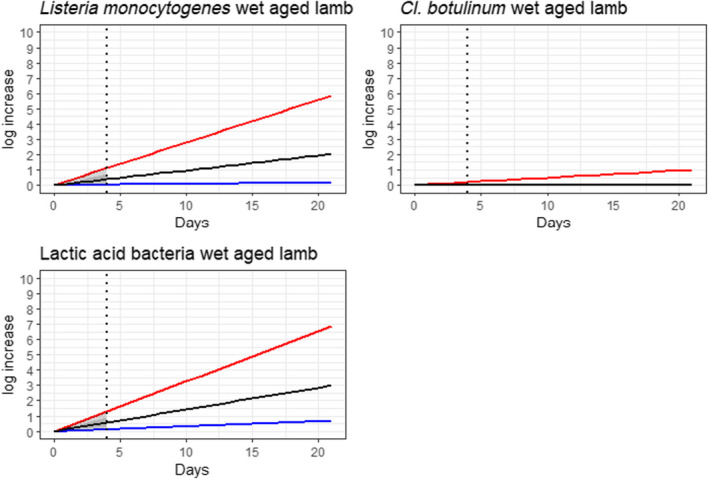

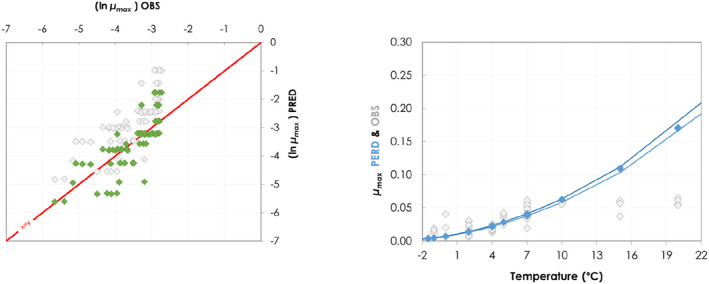

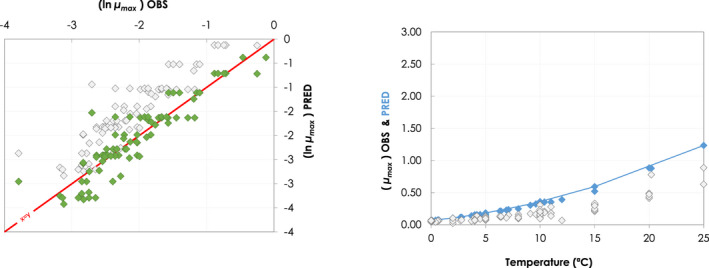

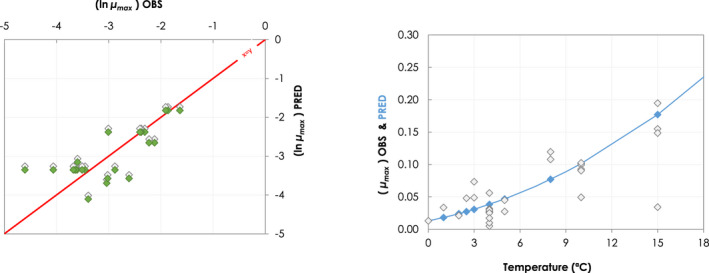

Due to the lack of sufficient data on the growth or inactivation of potentially relevant microorganisms during different ageing practices or processes a simulation approach was adopted for ToR3 and ToR4 and compared with the available data. The growth (expressed as log10 increase) of relevant microorganisms during different ageing scenarios was simulated using predictive microbiology models. The relevant bacteria to evaluate were selected from the pathogenic and spoilage bacteria present on the different types of meat, based on their potential for growth and the availability of suitable models. By comparison with experimental data in ComBase and the scientific literature, growth rate predictions of the models were calibrated using bias factors to correct for systematic over‐ or underestimations. To cover differences in practices during standard fresh meat preparation, dry‐ageing of beef and wet‐ageing of beef, pork and lamb in Europe, scenarios of ageing temperature, pH and aw were defined based on the outputs of ToR1.

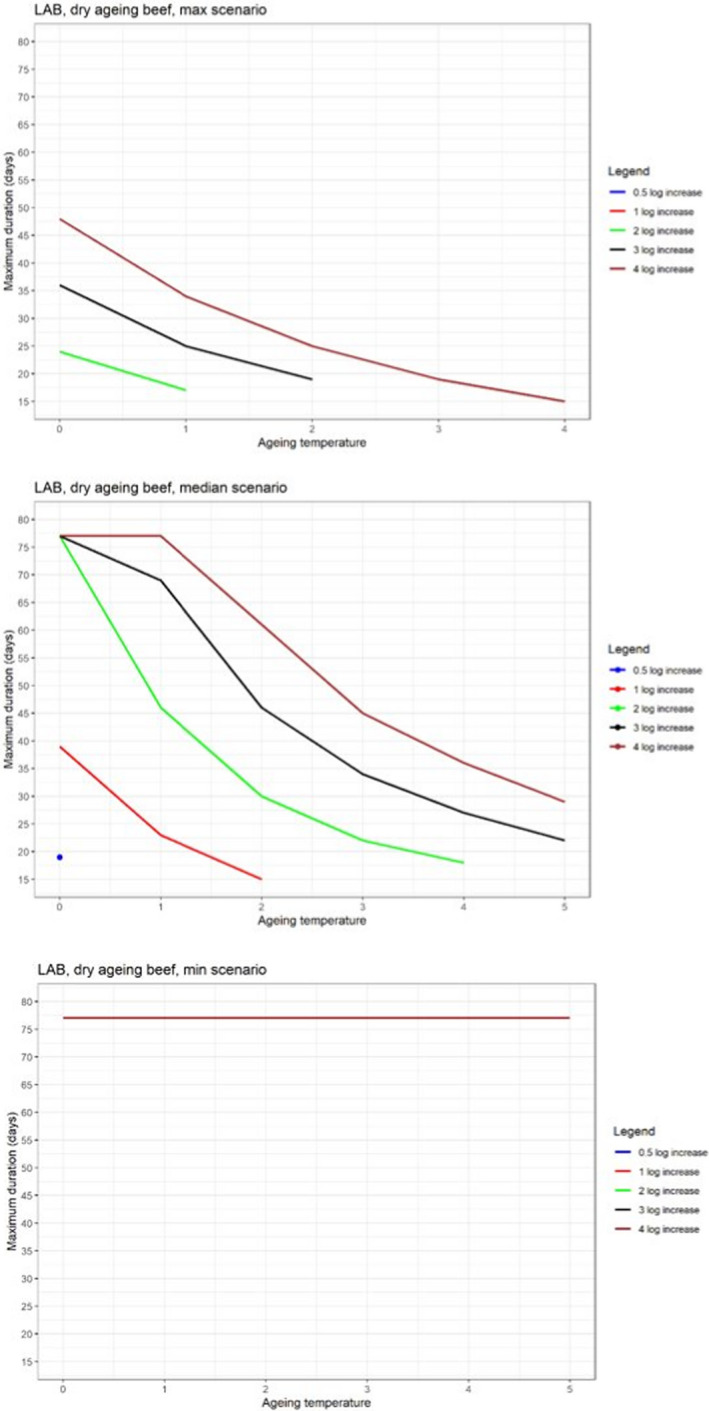

Under current practices, the ageing of meat may have an impact on the load of microbiological hazards and spoilage bacteria as compared to fresh meat preparation. Based on the ability to grow in the conditions encountered during meat ageing, the most relevant pathogenic bacteria for inclusion in the assessment were L. monocytogenes, and Y. enterocolitica (pork only) and the most relevant spoilage bacteria were LAB and pseudomonads (dry‐aged beef only).

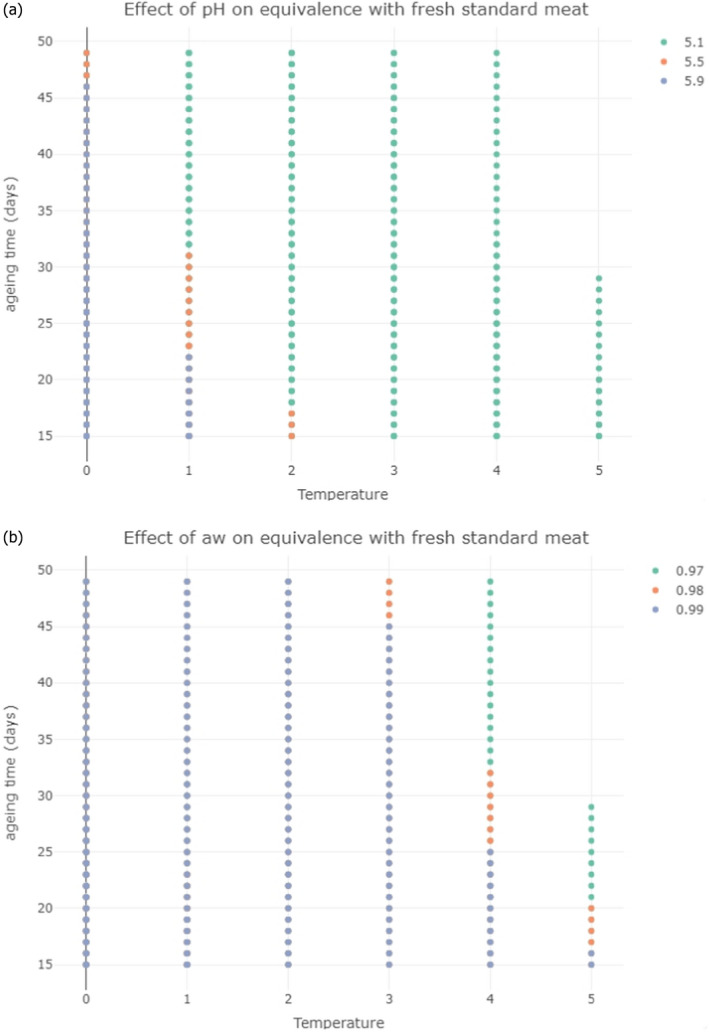

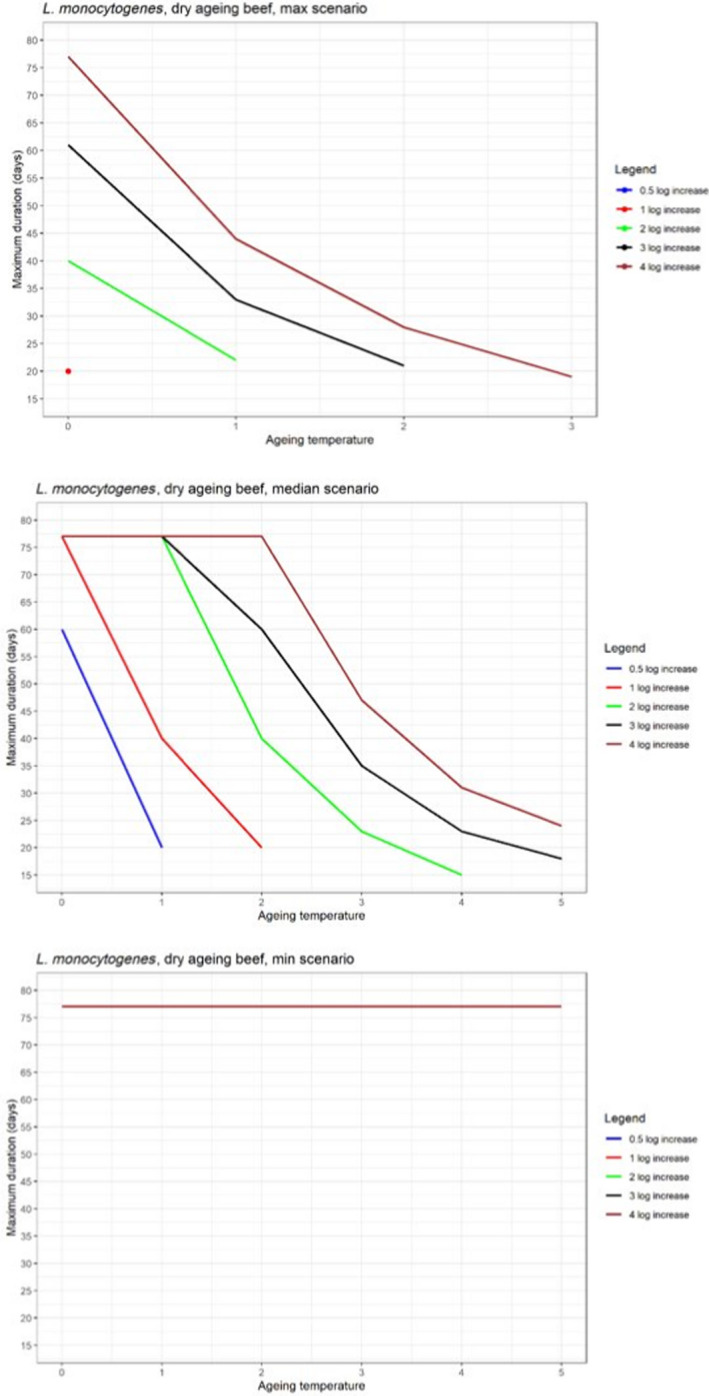

Ageing under defined and controlled conditions can achieve the same or lower loads of microbiological hazards and spoilage bacteria than the variable log10 increases predicted during standard fresh meat preparation. The determination of the actual conditions to achieve equivalence depends on the extent of the variable log10 increase considered typical for that achieved during standard fresh meat preparation, and on the interpretation of the direction and magnitude of the uncertainties of the predictions.

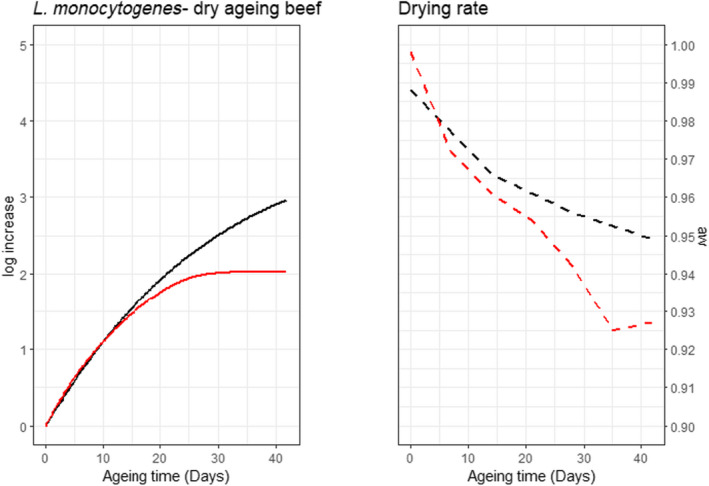

Ageing of meat is a complex process that depends on a multitude of parameters many of which change with time (particularly aw in dry‐ageing), resulting in different bacterial behaviour. This is reflected in a wide range of predicted log10 increases when the minimum and maximum scenarios are considered. For instance, the range of predicted log10 increases of L. monocytogenes after 77 days of dry‐ageing ranged from 0.1 to over 10, and log10 increases of 0.2 to over 10 after 49 days of wet‐ageing. The complexity is also reflected in the occurrence of conflicting studies in some cases reporting growth (log10 increase), survival (no relevant change) or inactivation (log10 decrease), both for wet‐ageing and dry‐ageing. The predictive modelling approach only captured the effects of parameters included in the models and the factors considered in the developed scenarios and uncertainty analysis.

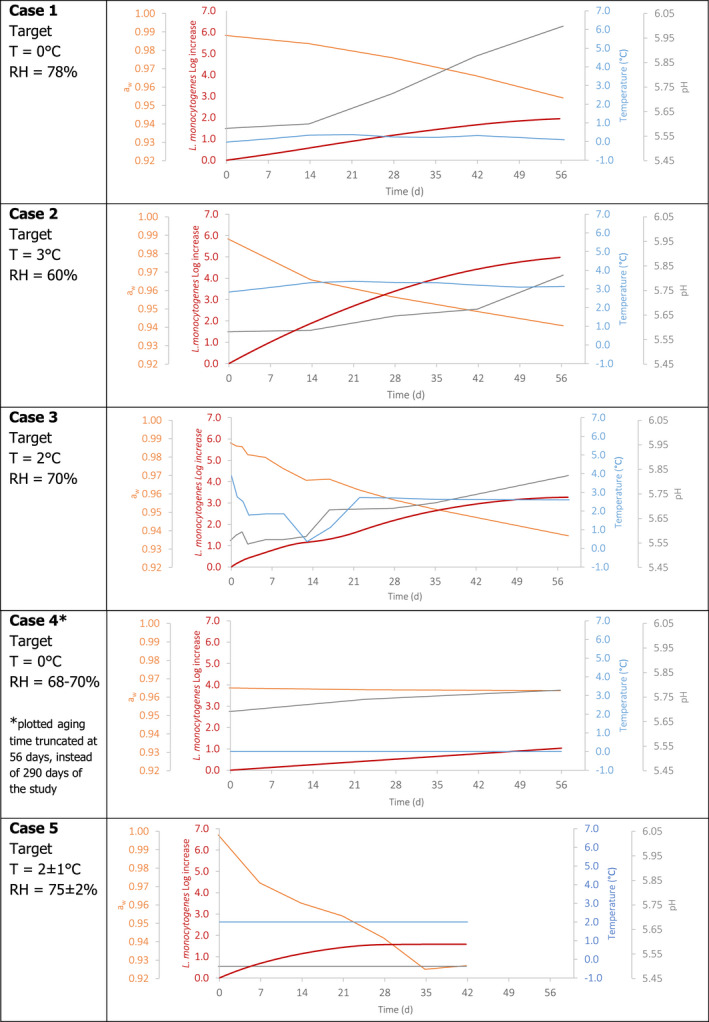

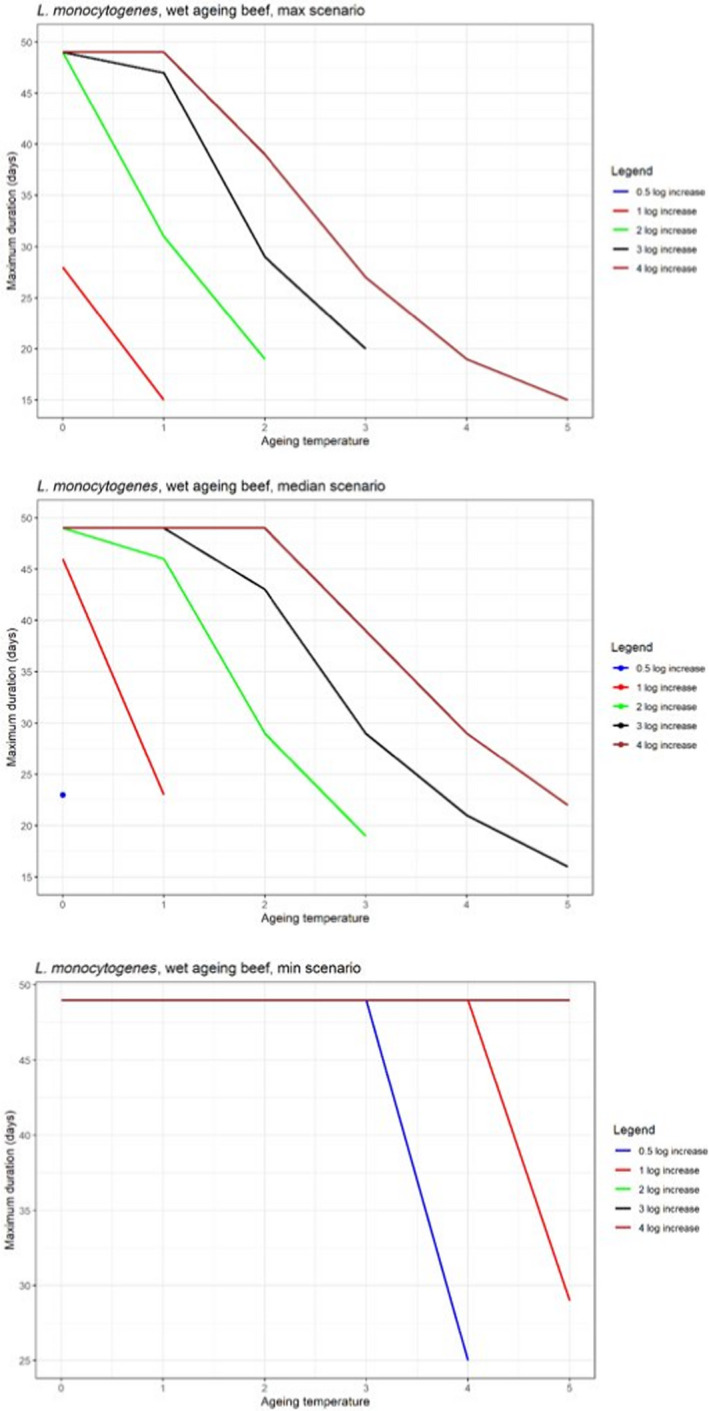

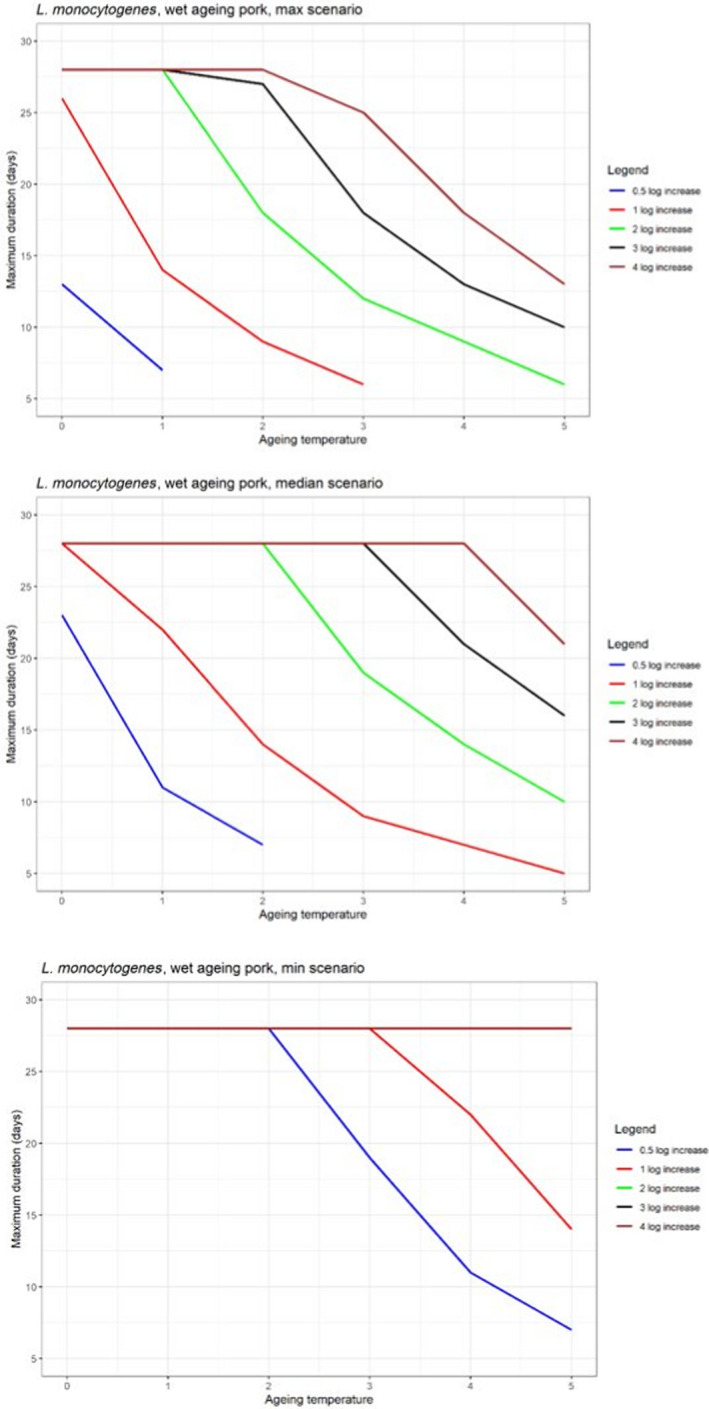

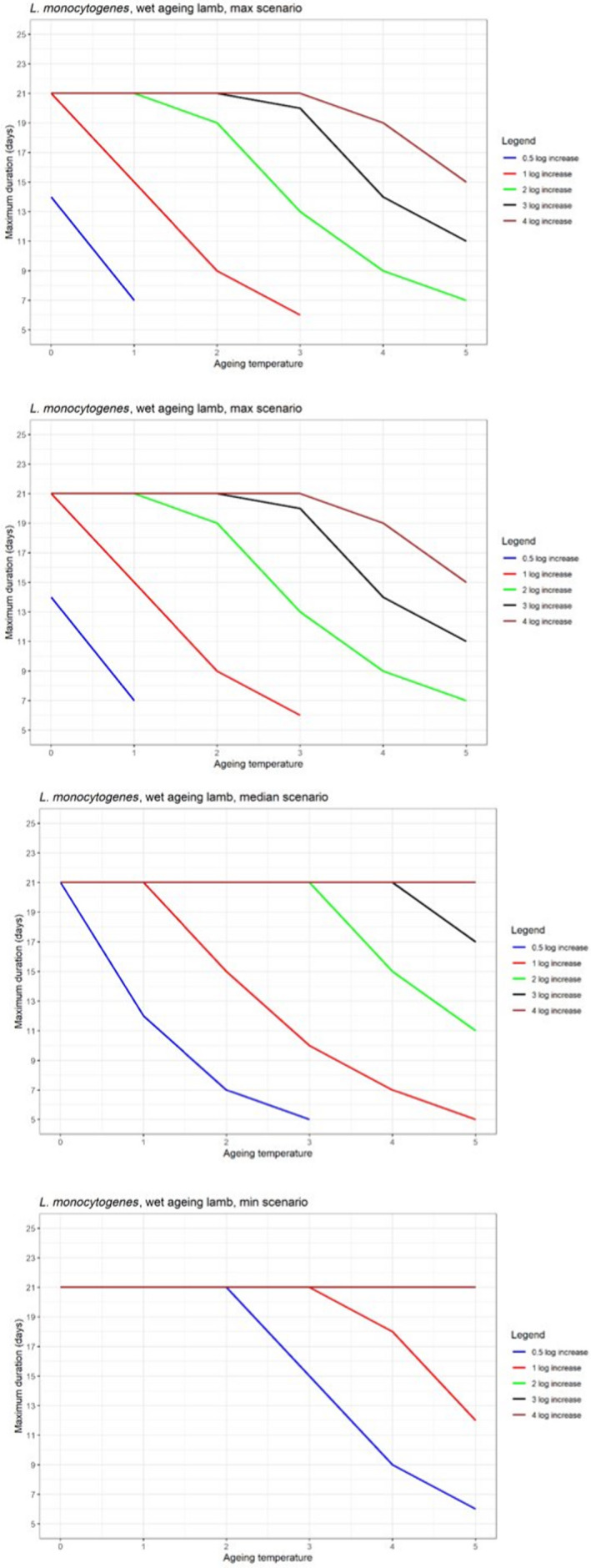

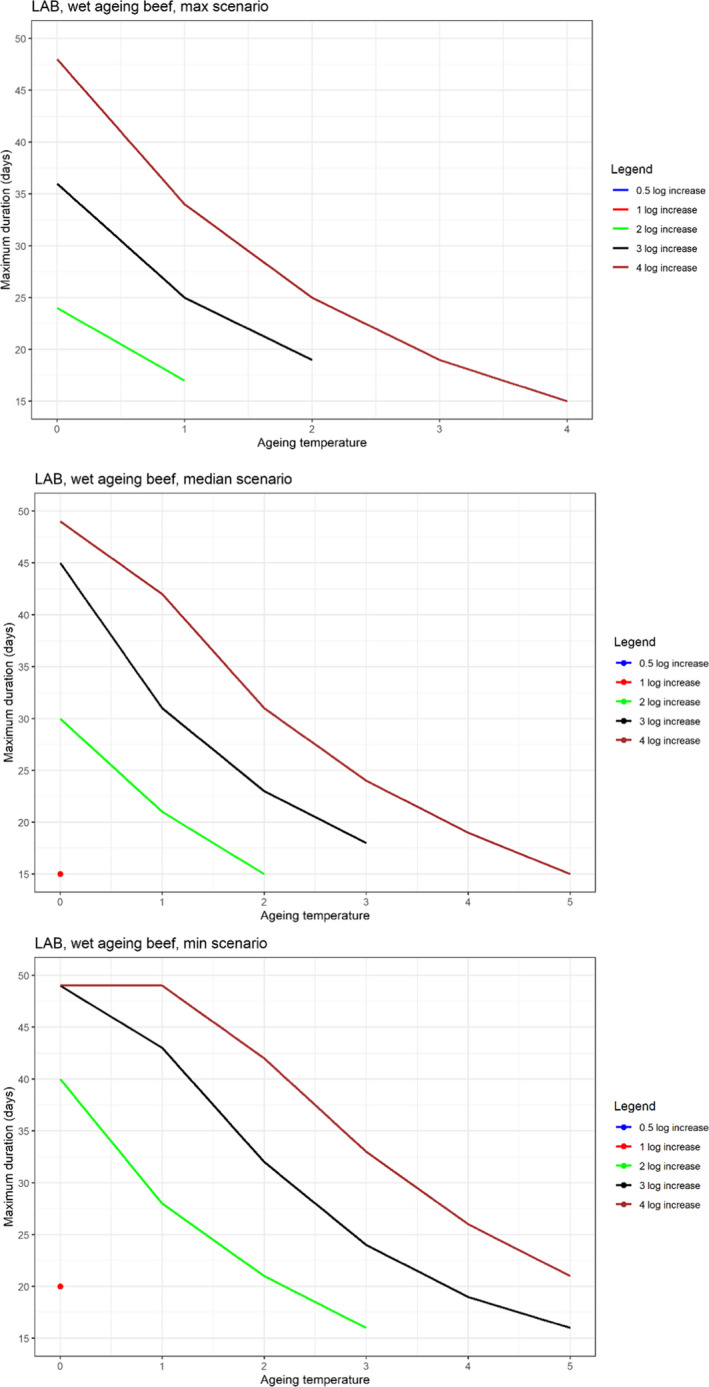

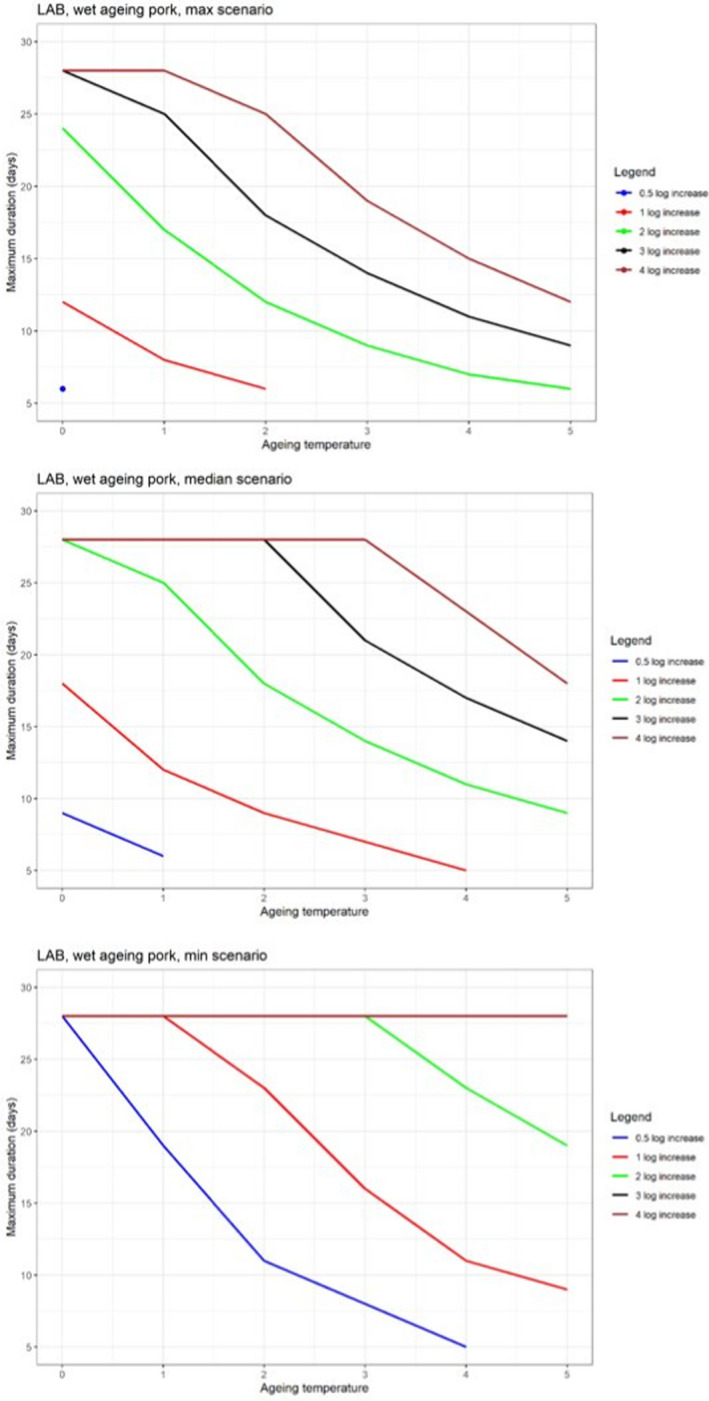

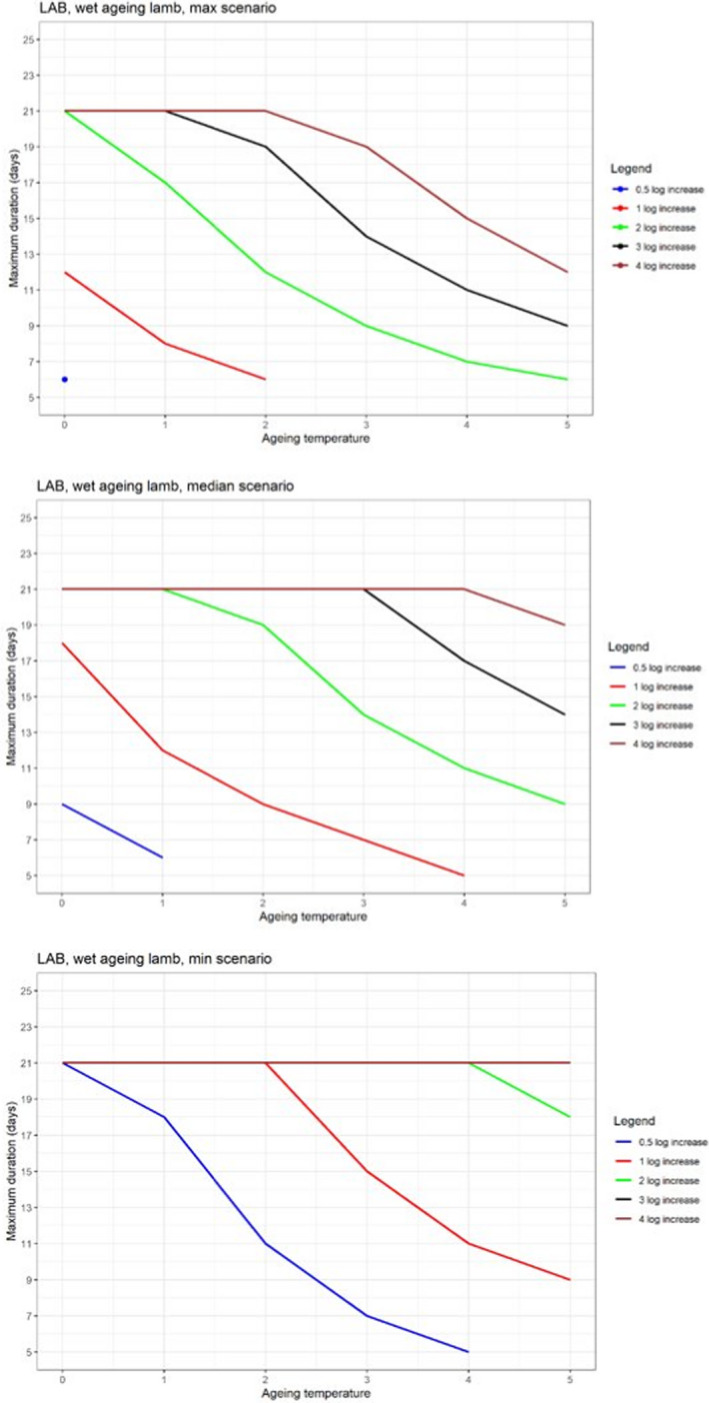

In ToR4, based on the predicted log10 increases during standard fresh meat preparation, it was decided to evaluate conditions of time and temperature during ageing that results in an increase of up to 0.5, 1, 2, 3 or 4 log10 of pathogenic or spoilage bacteria using developed combinations between predicted time and temperature under different scenarios of pH and aw. Different scenarios for aw and pH were analysed since these parameters have an impact on predicted log10 increases, are not easily controlled nor monitored, and vary dynamically during the standard fresh meat preparation and ageing processes. The impact of sources of uncertainty due to, for example the effects of microbial competition between spoilage and pathogenic bacteria (wet and dry‐ageing), inactivation (dry‐ageing), trimming (mainly dry‐aged beef) and storage, and the variable and dynamic (over time) pH and aw were considered and assessed through an expert knowledge elicitation (EKE). Conditions ensuring an equivalent log10 increase of L. monocytogenes as the most relevant pathogen under the scenario of medium pH and aw in the meat were assessed. The outputs included, for example dry‐ageing of beef for 35 days at a temperature of 3°C will not result in a higher log10 increase in the concentration of L. monocytogenes than an assumed 2 log10 increase on standard fresh beef with 80–95% certainty.

In ToR5, EFSA was requested to recommend additional good hygiene practices (GHPs) specific to the production and storage of dry‐aged and wet‐aged meat, as compared to those relevant for the production and storage of standard fresh meat.

The food safety of meat is assured through the development and implementation of hazard analysis and critical control point (HACCP) and prerequisite programme (PRP) activities, including GHPs and good manufacturing practices (GMPs). As standard fresh meat preparation and wet‐aged meat differ only in the time applied, the control activities for these processes are similar. The GHP identified from the scientific and grey literature that contribute to the hygienic production of dry‐aged beef included using good quality beef in a dedicated purpose‐built room or chamber; not loading the beef into the chamber until the required temperature and RH have been achieved; hanging from the bone to prevent internal contamination or if using a shelf, ensuring sufficient perforation to facilitate air flow with regular turning using hygienic methods; applying the highest airflow at the start of the ageing process to facilitate early crust development and reduce the surface aw, thereby restricting bacterial growth; regular cleaning and disinfection of the chamber; using air conditioning refrigeration system components that can be effectively cleaned and disinfected; using calibrated thermometers, RH probes and other equipment to accurately monitor and facilitate control of chamber conditions; filtering or UV treating the air in contact with the beef; trimming the crust in a hygienic manner in a dedicated air controlled environment and applying treatments such as heat or high pressure to trimmings to eliminate any pathogens present.

Specific interventions addressed in experimental studies, such as treating the dry‐aged beef trimmings using high pressure processing or washing with hot acidic solutions have been shown to decrease bacterial counts but these may not be suitable for application if, for example the organoleptic characteristics of the product are adversely affected. The outputs of ToR4 may be used to establish time–temperature critical limits for the dry‐ageing of beef and the wet‐ageing of beef, pork and lamb (see Section 4 ‘Conclusions’, ToR4 for examples).

Minced meat must be prepared either within no more than 6 days after the slaughter of the ungulates, or within 15 days in the case of boned, vacuum‐packed beef and veal (Point 2(b) of Chapter III to Section V of Annex III to Regulation (EC) No 853/2004). Before the production of MSM, the maximum storage period of the (chilled) raw material can be no more than 7 days when derived from the on‐site slaughterhouse and 5 days in other cases (Points 3(a) and 4(a)of Chapter III to Section V of Annex III to Regulation (EC) No 853/2004). Thus, meat that is aged for 14 days or more is not currently allowed to be used for minced meat or MSM.

Although it might be expected that longer meat ageing times would facilitate higher bacterial counts, the scientific data to support this is limited and contradictory. Thus, it is currently not possible to conclude on the relative food safety of minced meat and MSM prepared from dry or wet‐aged meat, as compared to standard fresh meat due to the lack of information on the impact of the time between slaughter, chilled storage and minced meat or MSM preparation on bacterial growth and the limited microbiological data on bacterial counts in minced meat and MSM prepared from prolonged (more than 14 days) aged meat. However, if the minced meat (including trimmings from dry‐aged beef) or MSM are thoroughly cooked any vegetative bacterial pathogens such as STEC, Salmonella or L. monocytogenes will be eliminated.

In addition to providing answers to the ToRs, several recommendations are made including research to establish the exact conditions of dry‐ageing of beef in which moulds produce mycotoxins and on the effect of the time between slaughter and minced meat or MSM preparation on the bacterial (pathogenic and spoilage) counts. Finally, research (challenge tests) is also recommended to assess the growth of pathogens such as L. monocytogenes during different conditions of dry‐ageing of beef and wet‐ageing of beef, pork and lamb and during subsequent storage.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

Post‐mortem ageing (or ripening or conditioning) is a natural process when meat is subjected to controlled refrigerated storage conditions. It implies cold storage of fresh muscle far beyond the onset of rigor mortis and the enzymatic and physico‐chemical modifications that confers the typical meat characteristics (in particular tenderness and flavour) to the skeletal muscles as in the case of the conventional maturation of carcasses. While meat from any species could be aged, post‐mortem ageing is generally limited to beef, due to the relative youth of pork, lamb, and veal at the time of slaughter. The length of the process is variable, but routinely 14 days are considered the minimum period to obtain the typical characteristics of the aged meat. The aim of meat ageing is to allow and enhance the palatability of meat according to consumers' expectations in terms of meat characteristics (i.e., improving the tenderness, juiciness and flavour).

There are two types of ageing techniques: dry‐ageing and wet‐ageing (Dashdorj et al., 2016; Kim et al., 2018).

Dry‐ageing is the process carried out in aerobic conditions of hanging beef carcasses or sub‐primal or placing primal cuts either unpacked or packed in bags permeable to water vapour in a refrigerated room and left to age for several weeks or even months at controlled environmental conditions of temperature, relative humidity and air flow;

Wet‐ageing is the process carried out in anaerobic conditions of placing the vacuum packaged meat of beef or different ungulates at controlled temperature conditions.

Following post‐mortem inspection, meat of ungulates (other than offal) must be immediately chilled to not more than 7°C throughout the meat (Point 1(a) of Chapter VII to Section I of Annex III to Regulation (EC) No 853/20041). EU requirements do not impose the maximum durability of such meat (left to the food business operator). When chilled (not frozen) meat is used for mincing, the minced meat must be prepared either within no more of six days after the slaughter of the ungulates, or within 15 days in case of boned, vacuum‐packed beef and veal (Point 2(b) of Chapter III to Section V of Annex III to Regulation (EC) No 853/2004). Before the production of mechanically separated meat, the maximum storage period of the (chilled) raw material can be no more than 7 days when derived from the on‐site slaughterhouse and 5 days in other cases (Point 3(a) and 4(a) of Chapter III to Section V of Annex III to Regulation (EC) No 853/2004).

Regulation (EC) No 2073/2005 lays down a number of microbiological criteria that must be applied in any case:

A food safety criterion being no detection of Salmonella in 25 g of minced meat and mechanically separated meat derived from dry‐aged or wet‐aged meat;

Process hygiene criteria on Salmonella, Enterobacteriaceae and aerobic colony counts on carcasses of domestic ungulates;

Process hygiene criteria on E. coli and aerobic colony counts on minced meat and mechanically separated meat.

Meat for ageing must be derived from carcasses that are considered fit for human consumption after the ante‐mortem and post‐mortem inspections. However, such inspection does not routinely detect most public health microbiological hazards. Therefore, microbiological hazards might derive from:

microorganisms already present in the meat but not evidenced by meat inspection,

external contamination during the ageing process, including from e.g., mechanical tenderisation procedures.

Several physical parameters during the dry‐ageing of meat might have an influence on the survival and growth of microorganisms, hence on the safety of aged meat for human consumption.

Additional concerns have been expressed on the safety of such meat since ageing is not only carried out by professional food businesses, but new trends in meat consumption show also the interest of the consumers of meat, with ‘dry‐ageing at home’ advertisement and the publication of videos/tutorials and guidelines (i.e., UmaiDry, BarbecueBible, how to dry‐age steak at home). Furthermore, specific dry‐ager refrigerators are available for domestic and commercial use.

This raises additional concerns about the possible risks related to such processes without professional equipment, to the correct handling/trimming of the meat and to the shelf life of this type of meat. Possible risks that might not be appropriately perceived from consumers.

There is also a demand from certain Member States to allow the use of dry and wet‐aged meat for the production of minced meat and possibly mechanically separated meat. Before considering such authorisation (i.e., the review of the limits for storage period of raw materials for such products), the safety of such an approach should be assessed.

In addition, the European Commission considers that scientific advice is needed as regards the growth of spoilage bacteria during the ageing process. The purpose of this request is to ensure compliance with Article 14(5) of Regulation (EC) No 178/2002 laying down that, ‘in determining whether any food is unfit for human consumption, regard shall be had to whether the food is unacceptable for human consumption according to its intended use, for reasons of contamination, whether by extraneous matter or otherwise, or through putrefaction, deterioration or decay’.

In accordance with Art. 29 of Regulation (EC) No 178/2002 the Commission asks EFSA to deliver a scientific opinion on the impact of prolonged ageing of meat using the dry‐ageing process for beef and the wet‐ageing process for ungulates on the load of microbiological hazards and spoilage bacteria in comparison with standard fresh meat.

More specifically, EFSA is asked:

to provide an overview of the current practices used by food business operators for dry‐ageing and wet‐ageing of meat (e.g., time, temperature, relative humidity, air flow, type of packaging);

to identify public health‐relevant microbiological hazards and spoilage bacteria occurring in the process of prolonged dry‐ageing and wet‐ageing of meat, also considering its possible use for the production of minced meat and mechanically separated meat;

to assess the impact that dry‐ageing and wet‐ageing of meat, produced according to selected current practices, could have on the load of public health‐relevant microbiological hazards and spoilage bacteria, when compared to standard fresh meat;

to provide those conditions during the production of dry‐aged and wet‐aged meat and possible further storage that would result in a similar or lower load of the relevant microbiological hazards and spoilage bacteria as compared to standard fresh meat before consumption (i.e., at the end of the shelf‐life);

to recommend additional good hygiene practices specific to the production and storage of dry‐aged and wet‐aged meat, as compared to those relevant for the production and storage of standard fresh meat.

1.2. Interpretation of the Terms of Reference

When cattle, pigs and sheep are slaughtered, the carcasses are dressed and immediately chilled. This usually occurs at 0–2°C, although the temperature is carefully controlled, especially for beef, to ensure the carcass temperature does not decrease too quickly causing cold shortening and toughening of the meat. Although carcass chilling methods may vary, this process usually requires up to 24 h for pigs and sheep and 24–48 h for beef carcasses (Devine and Dikeman, 2014). Thereafter, the carcasses are either stored chilled for a period of time or are sent to the boning hall and cut into primal and sub‐primal cuts.

Data on the parameters of the meat before ageing is lacking, although the pH is usually 5.5–5.8 for beef (Ahnstrom et al., 2006; Li et al., 2013; Owczarek‐Fendor et al., 2014; Stenstrom et al., 2014; Gudjonsdottir et al., 2015; Hulankova et al., 2018a) and pork (Holmer et al., 2009) while Constantino et al. (2012) reported a pH of 5.6 for lamb. The rate and extent of post‐mortem tenderisation of beef depend on muscle type and processing conditions and there is no standard ageing time (Gagaoua et al., 2021). Moreover, there are no universally agreed ageing times for specific muscles (Stuby‐Souva, 1994; Benech et al., 2021).

Storing meat under chilled conditions for a period of time facilitates tenderisation (Lonergan et al., 2010; Benech et al., 2021). This process is referred to as ageing or maturation. The airflow and RH in the chill room or cabinet are also controlled and the meat may be stored aerobically or anaerobically (in vacuum packs). In Regulation (EC) No 853/2004, ‘fresh meat’ is defined ‘as meat that has not undergone any preserving process other than chilling, freezing or quick‐freezing, including meat that is vacuum packaged or packaged in a controlled atmosphere’. In everyday usage, the term ‘fresh’ is usually associated with food that has been recently harvested and not tinned, frozen or otherwise preserved. Thus, the different meaning of the term ‘fresh’ when applied to meat as compared to other food commodities may lead to confusion. There is no EU definition of ‘standard fresh meat’; nor are there any scientific, commercial or legislative basis for differentiating between ‘standard fresh meat’ and ‘wet‐aged meat’. Therefore, for the purposes of this Opinion, the following applies:

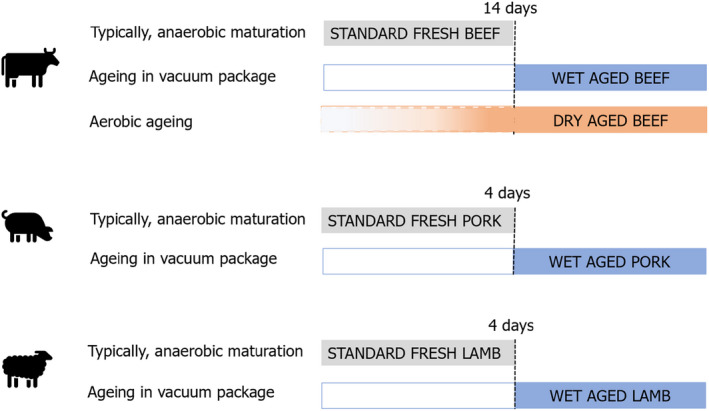

‘Standard fresh beef’ is beef that has been typically matured (usually in vacuum packs) for 14 days or less;

‘Wet‐aged beef’ is beef that has been vacuum packaged and aged for more than 14 days;

‘Dry‐aged beef’ is beef that has been aged aerobically in a dedicated chamber under specific conditions of temperature, RH and airflow for a specific period of time, usually at 1–4°C and a RH of 75–85% for 21–35 days;

‘Standard fresh pork’ is pork that has been matured for 4 days or less;

‘Wet‐aged pork’ is pork that has been vacuum packaged and aged for more than 4 days;

‘Standard fresh lamb’ is lamb that has been matured for 4 days or less; and

‘Wet‐aged lamb’ is lamb that has been vacuum packaged and aged for more than 4 days.

These are referred to as ‘the seven processes’ later in the text and are illustrated in Figure 1.

Figure 1.

Schematic overview of the processes (conditions/types of meat) considered in this opinion

This Scientific Opinion will initially describe the current practices in the dry‐ageing of beef and the wet‐ageing of beef, pork and lamb as required by ToR1. In addition to a description of the different stages and processes used, data on the key parameters such as the surface pH, aw and temperature of the meat, that could influence the survival or growth of pathogenic bacteria and spoilage bacteria as well as moulds and mycotoxin production will be provided. It was agreed with the European Commission that only meat ageing in commercial settings such as meat plants, butcher shops and restaurants was covered while meat ageing performed at home in domestic settings was excluded, and non‐commercial practices such as dry‐ageing in a bag, which has been the subject of academic studies, were also outside of the scope of this mandate.

The microbiological hazards and spoilage bacteria that may be present and grow on the meat during the different ageing processes will be identified as required in ToR2. For dry‐aged beef, mycotoxin production by moulds will also be investigated but other toxic secondary metabolites will be excluded. Furthermore, the European Commission was interested in the behaviour of these bacteria and mycotoxin producing moulds further along the meat chain up to the end of the shelf‐life of minced meat or mechanically separated meat (MSM). This was also clarified with the Commission as Regulation (EC) No 853/2004 requires that minced meat must be prepared within no more than 6 days of slaughter or within no more than 15 days from the slaughter of the animals in the case of boned, vacuum‐packed beef and veal. The same legislation specifies that for the preparation of MSM, the raw material for deboning from an on‐site slaughterhouse must be no more than 7 days old, otherwise raw material for deboning must be no more than 5 days old. Thus, meat that is aged for more than 15 days is not currently allowed to be used for the production of minced meat or MSM. Regardless, for the purposes of this Opinion, specifically to determine if minced meat or MSM from meat that is aged for longer than 15 days has higher bacterial counts and therefore represents a higher risk to consumers, minced meat and MSM were considered to be a part of the meat chain.

ToR3 requires an assessment of the impact that dry‐ageing and wet‐ageing of meat, produced as per the current practices identified in ToR1, have on the load of public health‐relevant microbiological hazards and spoilage bacteria, when compared to standard fresh meat. Since the objective of this ToR was to establish if there was increased growth under the conditions used in dry‐ageing and wet‐ageing of beef as compared to standard fresh beef, only microorganisms capable of growth are considered. Thus, parasites and viruses were excluded and only bacteria and/or mycotoxin‐producing moulds capable of growth under the conditions of pH, aw and temperature on the surface of the meat were relevant for this assessment. The same principle applies to wet‐aged pork vs standard fresh pork and wet‐aged lamb vs standard fresh lamb. Moreover, the European Commission agreed that any differences in the increase of the relevant hazards on the meat surface as a result of the different ageing processes would be expressed in relative terms (e.g. as log10 increase in case of bacterial growth or relative mycotoxin accumulation) rather than a prediction in absolute terms (e.g. bacterial concentration or mycotoxin concentrations) on each type of meat (dry and wet‐aged vs standard fresh). While the growth of bacteria was quantitively assessed through the application of predictive models, the mould growth and mycotoxin production were assessed qualitatively from the evidence reported in the scientific literature.

There is also the possibility that dry or wet‐ageing would reduce bacterial numbers or prevent growth. However, this was not considered in the main assessment thus ensuring the modelling reflects a worst‐case scenario. The impact of this assumption was evaluated in the uncertainty assessment. The European Commission also agreed that the assessment in ToR3 covers the meat ageing stage only and thus started with the carcass, primal or sub‐primal entering the dry‐ageing chamber or, in the case of wet‐aged and standard fresh meat, immediately before vacuum packaging and ended when these ageing processes were completed.

ToR4 will investigate (using the predictive modelling approach developed for ToR3) if changing the conditions (time and temperature) used for dry‐aged and wet‐aged meat could achieve a similar or lower levels of microbial hazards and spoilage bacteria as compared to standard fresh meat. The endpoint for the assessment is the end of ageing. Storage post ageing was not considered due to the lack of information on the impact of trimming and the absence of reliable data on catering/consumer practices and on the surface temperature of the meat during chilled storage in restaurants and domestic refrigeration systems.

Having identified the process parameters that would minimise microbial growth on dry and wet‐aged meat, ToR5 will complement these by identifying control practices during the production and storage of these products, to further assure their microbial safety and quality. This ToR was interpreted to include prerequisite programme (PRP) activities and critical control points (CCPs) that may be part of the hazard analysis and critical control point (HACCP) plan.

The ToRs have been translated into assessment questions (AQs) as follows:

ToR1: AQ1: What are the practices and processes used by meat FBOs and restaurants in the EU for the dry‐ageing of beef and the wet‐ageing of beef, pork and lamb? Specifically, what are the processing conditions (e.g. time, temperature and RH) and the associated intrinsic factors (e.g. pH and aw) of meat surface for each of these processes?

ToR2: AQ2: What are the relevant microbiological hazards and spoilage bacteria that occur and which of these can grow and/or produce toxins during the dry‐ageing of beef and the wet‐ageing of beef, pork and lamb and on the subsequently stored product, including in minced meat or MSM prepared from the aged meat?

ToR3: AQ3: What is the increase in the relevant microorganisms (from AQ2) during the dry‐ageing of beef and the wet‐ageing of beef, pork and lamb (from AQ1) and during subsequent storage, as compared to ‘standard fresh meat’?

ToR4: AQ4: What are the conditions for producing dry‐aged beef and wet‐aged beef, pork and lamb to ensure similar or lower counts/load/concentrations of pathogenic microorganisms, spoilage bacteria and, if relevant, mycotoxins at the end of shelf‐life as compared to standard fresh meat?

ToR5: AQ5: What additional control actions including prerequisite programme (GHP and GMP) and CCPs could be employed to minimise the prevalence and/or concentration of pathogenic and spoilage bacteria and mycotoxin formation (if relevant) on dry and wet‐aged meat?

1.3. Additional information

1.3.1. Approach to answer the ToRs

The approach to answer the ToRs was defined in advance and is described in the protocol (Annex A, available under the Supporting Information section on the online version of the scientific output). This covers both the problem formulation (i.e. what the assessment will address) and the methods that will be used. The problem formulation (‘what’) includes the clarification of the mandate (see further refined in Section 1.2) and consists of the following steps: (1) translation of the mandate into scientifically answerable AQs, (2) definition of the sub‐questions (SQs) for each AQ, and (3) the approach for undertaking the assessment. The planning of the methods for conducting the assessment (‘how’) consisted of: (1) specifying the evidence needs and the methods for answering each SQ, including uncertainty analysis and (2) the methods for integrating evidence across SQs and addressing of the remaining and overall uncertainty. The protocol development followed the draft framework for protocol development for EFSA's scientific assessments (EFSA, 2020).

The SQs related to each AQ are as follows:

SQ1 (for AQ1): What practices and processes are used by meat FBOs and restaurants in the EU to dry‐age beef?

SQ2 (for AQ1): What practices and processes are used by meat FBOs and restaurants in the EU to wet‐age beef, pork and lamb?

SQ3 (for AQ1): What is the shelf‐life of dry‐aged beef and wet‐aged beef, pork and lamb given by FBOs?

SQ4 (for AQ1): What are the resultant characteristics of the meat (surface temperature, pH, aw and concentrations of antimicrobials such as lactic acid)?

SQ4 (for AQ2): What pathogenic and spoilage bacteria occur and which of these can grow on dry‐aged beef and wet‐aged beef, pork and lamb?

SQ5 (for AQ2): Which moulds grow on dry‐aged beef and do these represent a hazard for human health (i.e. do they produce mycotoxins under the conditions used)?

SQ6 (for AQ2): What pathogenic and spoilage bacteria are relevant considering the potential use of dry‐aged beef and wet‐aged beef, pork and lamb for the production of minced meat and mechanically separated meat?

SQ7 (for AQ3): Which are the scenarios that represent current practices of dry‐ageing of beef, wet‐ageing of beef, pork and lamb and standard fresh meat preparation (time/temperature, pH, aw/relative humidity, with/out competition, etc.) including minced meat and MSM preparation from the aged meat?

SQ8 (for AQ3): Which are the relevant pathogenic bacteria, spoilage bacteria and/or mycotoxigenic moulds to evaluate (able to grow and/or produce toxin), relevant for meat type and type of ageing, worst case, available models and data?

SQ9 (for AQ3): What is the log10 change for each scenario and each microorganism and is there toxin produced by moulds?

SQ10 (for AQ4): What are the conditions for producing, handling (including trimming, cutting and packaging) and storing dry‐aged beef to ensure similar or lower counts/load/concentrations of pathogenic microorganisms, spoilage bacteria and, if relevant, mycotoxins at the end of shelf‐life as compared to standard fresh meat?

SQ11 (for AQ4): What are the conditions for producing, handling (including trimming, cutting, packaging) and storing wet‐aged beef, pork and lamb to ensure similar or lower counts/load/concentrations of pathogenic microorganisms, spoilage bacteria and, if relevant, mycotoxins at the end of shelf‐life as compared to standard fresh meat?

SQ12 (for AQ5): What control actions including GHPs and CCPs are currently used in meat plants and restaurants that produce dry‐aged beef and wet‐aged beef, pork and lamb and for the production and storage of ‘standard fresh meat’?

SQ13 (for AQ5): Based on the outcomes from ToR3, are additional control actions including specific GHP required for dry and wet‐aged meat to assure its food safety?

SQ14 (for AQ5): Based on the outcomes from ToR4 and a literature review what changes in current control practices formulated as GHP(s) and/or CCPs could be developed to achieve a similar or lower load of relevant microbiological hazards and spoilage bacteria on dry and wet‐aged meat as compared to standard fresh meat?

2. Data and methodologies

2.1. Data

Information, specifically temperature, RH, airflow and time, was collected about the processes and practices used by meat plants to: (1) dry‐aged beef, (2) wet‐aged beef; (3) wet‐aged pork, and (4) wet‐aged lamb. The same information was collected for dry‐ageing beef in butcher shops and restaurants. This was used to answer ToR1. Information was also collected about the pathogenic and spoilage bacteria that may contaminate dry‐aged beef and wet‐aged beef, pork and lamb. The potential production of mycotoxins by moulds growing on beef during dry‐ageing was also investigated. This information was used to answer ToR2 and to identify the target organisms for the modelling tasks to answer ToR3. Information was also obtained on the current control and hygiene practices to identify additional control actions and GHPs that would minimise the incidence of pathogenic and spoilage bacteria on both dry and wet‐aged meat, as required to answer ToR5.

Data were collected related to the meat surface, specifically pH, aw and temperature of beef at the start, during and at the end of the dry‐ageing process and the pH, aw and temperature of beef, pork and lamb at the start, during and at the end of the wet‐ageing process. The same data were collected for standard fresh meat for beef, pork and lamb. Data were also collected on the duration of each process. All this was used to define the scenarios to be modelled in ToR3 and ToR4.

2.2. Methodologies

2.2.1. ToRs 1 and 2

Information and data, as described in Section 2.1, were obtained by undertaking a comprehensive review of the scientific and grey literature. The search strings used to search the published literature for information and data to answer ToR1 and ToR2 are provided in Annex A (Protocol). This search was limited to scientific papers, book chapters, reviews and reports written in English and published between the years 2000 and 2021. Studies undertaken in laboratory, pilot and industry setting were included from both within and without the EU. Each publication was screened by title, abstract and then full text with publications either included or excluded based on the relevance of the information and data provided. The information gathered was initially assessed by the reviewer extracting the data and later by the members of the WG. As with all scientific studies there were multiple sources of uncertainty as different publications reported different practices and parameters for each of the ageing processes. The sources of uncertainty were identified, listed in Table B.1 (Appendix B) and analysed for their impact on the outcomes using a qualitative approach.

Table B.1.

Qualitative assessment included the ‘sources or location of the uncertainty’, a description of the ‘nature or cause of the uncertainty’ associated with that source and a description of the Impact of the uncertainty on the conclusions

| Source or location of the uncertainty | Nature or cause of the uncertainty | Impact of the uncertainty on the conclusions (e.g. over/underestimation) |

|---|---|---|

| Defining ‘standard fresh meat’ versus ‘dry‐aged meat’ and ‘wet‐aged meat’ |

By definition, fresh meat is meat that has not undergone any preserving process other than chilling, freezing or quick‐freezing. The majority of fresh beef, pork and lamb is matured in vacuum packaging under chilled conditions. Wet‐aged meat is meat that has been vacuum packaged and stored under chilled conditions. There is no scientific, commercial or legislative basis for differentiating between the ‘standard fresh meat’ and ‘wet‐aged meat’. Thus for the purposes of this Opinion differentiation is based solely on the time in chilled storage. |

A misinterpretation or misunderstanding of what constitutes, ‘standard fresh meat’ versus ‘wet‐aged meat’ could result in an over or underestimation of the predicted growth of pathogenic and/or spoilage bacteria in ToR3, negate the ‘equivalence calculations’ in ToR4 and render any additional GHPs or CCPs in ToR5 redundant. |

|

Inaccurate, incorrect or incomplete information about current practices used by FBOs for dry‐ageing and wet‐ageing beef, pork and/or lamb in the scientific and grey literature. Information for wet‐aged pork and lamb was especially lacking and limited to 3 studies, none of which reported aw values. As none of these were observational studies, the reported values may not be representative. |

The scientific literature reports the time, temperature, RH and/or air flow used in experiments and these are selected based on the objective(s) of that study. Thus, these conditions may or may not reflect those used in commercial operations. Moreover, many of the scientific and technical reports are from countries outside of the EU and the conditions used may not be representative to practices within the EU. |

This lack of information on commercial practices reduces the certainty that the methods and conditions described in the response to ToR1 are an accurate description of current commercial practices in the EU. If parameters such as surface temperature, pH and aw are incorrect there is uncertainty about the outcomes of the predictive modelling in ToRs 3 and 4. |

|

The limited information about current practices provided by commercial FBOs involved in dry‐ageing beef or wet‐ageing beef, pork or lamb in response to the questionnaire. |

As this information was only provided by 8 FBOs and 2 FBO associations data were limited (for example, they do not routinely monitor and record surface temperature, pH and aw) and from a limited number of countries it may not be accurate or a reasonable representative of the entirety of European or regional practices. Moreover, for the dry‐ageing of beef, tradition and personal preference for specific organoleptic qualities in the final product are more important than strictly following a pre‐defined process. Thus, there may be differences in the processes used for different batches. |

An underestimation of the temperatures used for modelling could, for example, result in an underestimation of the growth rate of pathogens/spoilage bacteria. However this has been mitigated to some extent by using a range of temperatures. |

| Information on pathogenic and spoilage bacteria that may be on dry‐aged and wet‐aged meat and how these bacteria will behave in minced meat or MSM prepared the aged meat. | Although several studies have reported and reviewed the prevalence of pathogenic and spoilage bacteria in beef, pork and lamb relatively few have specifically studied dry or wet‐aged meat. | Specific pathogenic or spoilage bacteria may have been erroneously excluded from the answer to ToR2. However, this would have a minimal impact on the conclusions as the range of bacteria including those capable of growth under the conditions encountered were considered. |

| Information on the hygiene status of the carcass and the time between the end of carcass chilling and the preparation of meat cuts for dry and wet‐ageing. |

Few, if any, studies provide this information. Based on the available data, the pre‐ageing time (between slaughter and ageing) may vary considerably and counts at the start of ageing may be highly variable. |

The initial microbial counts at the commencement of dry or wet‐ageing may be higher or lower than reported in the few available studies cited in answering ToR2. However, as the assessment deals with log changes this will not impact on the outputs of the simulations using predictive models in ToRs 3 and 4. |

| The impact of competing microbiota on the predicted growth of L. monocytogenes, Y. enterocolitica and non‐proteolytic Clostridium spp. |

The effect of competing microorganisms was not included in the predictive models used for the main assessment, though the impact has been assessed in the framework of the effect of factors on the predictions focusing on the interaction between LAB and L. monocytogenes |

This uncertainty has been quantified in the uncertainty analysis and in general results in an overestimation (competing microbiota contributes to inhibit and/or stop pathogen growth). A possible exception is Pseudomonas spp. as some articles report the enhancement of L. monocytogenes growth in presence of pseudomonades. However, others have reported a suppression of L. monocytogenes maximum population density by Pseudomonas at low temperature (4°C, Buchanan and Bagi, 1999). |

| Determining if mycotoxins are produced by moulds during the dry‐ageing of beef | The specific conditions under which moulds, specifically Penicillium and Aspergillus spp. will not produce these toxins are based on a limited number (4) of studies, 3 of which focused on plant based foods. These conditions are not defined for meat and/or no specific studies have been undertaken during the dry‐ageing of beef. | It is not possible to definitively state whether or not mycotoxins are produced during the dry‐ageing of beef, even when this process is well described, although our current knowledge would suggest mycotoxin production is inhibited at temperatures below 3°C and at the aw values encountered. |

| Simulation of microbial growth ‐ lag phase | No lag phase was considered for any relevant microorganism assessed for the main assessment. | An overestimation of the potential growth can occur when no lag phase is included (conservative approach). However, if contamination is already present at slaughter, microorganisms can adapt to the environmental conditions during the pre‐ageing time. In this case, the impact of this uncertainty in ToR3 and ToR4 is considered to be limited/low. |

|

Simulation of microbial growth ‐ inactivation |

Only growth rate models were used in the assessment. No inactivation was considered for any relevant microorganism assessed for the main assessment, though the impact of this factor has been assessed in the framework of uncertainty analysis (Section 3.4.4.1). |

An overestimation of the growth can occur when no inactivation is included (conservative approach). This is especially relevant during dry‐ageing and the impact was evaluated and considered in the response to ToR4. |

| Simulation of microbial growth ‐ calibration factors for predictive models |

Observed growth rates from the collected experiments were estimated by fitting the primary growth model to data from challenge test (pathogens) or naturally contaminated means (spoilage). Depending on the design of the experiment and the available data the model fitting will be more or less robust. Predicted growth rates had to be obtained by assuming the input value for aw and for endogenous lactic acid concentration (if considered). For vacuum‐packaged meat, several scientific articles report no growth at all of L. monocytogenes. The growth model will represent the worst‐case scenario For dry‐ageing, the calibration factors have been obtained comparing growth data at high aw. The same behaviour was assumed for the entire range of aw occurring during dry‐ageing. |

Over‐ or underestimation of the Bf can over‐ or underestimate growth predictions in ToR3 and ToR4. |

| The additional actions required in the PRP and HACCP programmes to assure the food safety of dry‐aged beef. | There is a lack of information on the specific GHPs currently used in the meat ageing processes as these are rarely studied and seldom reported. | There may be additional GHPs or CCPs used in FBOs that are not reported and therefore unknown outside of those specific food businesses. Thus the response to ToR5 may be inadequate. |

Data were also sought from relevant stakeholders using questionnaires that were sent to six European associations in the field of meat processing and restaurant establishments for distribution to their members (The Liaison Centre for the Meat Processing Industry in the European Union (CLITRAVI), EuroCommerce Retail &Wholesale, Food Drink Europe, HOTREC Hospitality Europe, International Butchers Confederation (IBC), European Livestock and Meat Trades Union (UECBV)). Replies were received from two associations and eight FBOs. Data were also extracted from a previous Belgian survey (OPTIDRYBEEF) 1 and added to that collated by the WG.

An extended and a shorter version of the questionnaire distributed via different channels (EU survey platform and e‐mail) were used to increase the response rate (see version 1 in Appendix A.1 and version 2 in Appendix A.2). The data sought included data on the meat surface parameters (pH, aw and temperature) as well as bacterial counts including total viable count (TVC), total Enterobacteriaceae count (TEC), Salmonella, Shiga toxin‐producing Escherichia coli (STEC), Listeria monocytogenes, Staphylococcus aureus, Yersinia enterocolitica, and non‐proteolytic Clostridium spp. before, during and after ageing. Participants were asked about testing for mycotoxins in dry‐aged beef, good hygiene practices (GHP) used and storage conditions for each type of aged meat. Questions were also included to gather information about the preparation of minced meat and MSM from the different aged meats.

2.2.2. ToRs 3 and 4

Due to the lack of sufficient data on the growth or inactivation of potentially relevant microorganisms during different ageing practices or processes and the lack of a ‘standardised process’ for dry or wet‐ageing, a simulation approach was adopted for ToR3 and ToR4, and compared with the available data. The predicted growth (expressed as log10 increase) of relevant microorganisms were simulated by applying predictive microbiology models, using different ageing scenarios covering the main factors associated with the meat ageing processes.

Relevant scenarios to evaluate for the seven processes (i.e. standard fresh meat preparation for beef, pork and lamb, dry‐ageing of beef and wet‐ageing of beef, pork and lamb) were developed based on the responses to the questionnaire and literature data, and during discussions with the WG members. In the simulations, the scenarios were defined by the key intrinsic and extrinsic parameters varying over time for each of the processes.

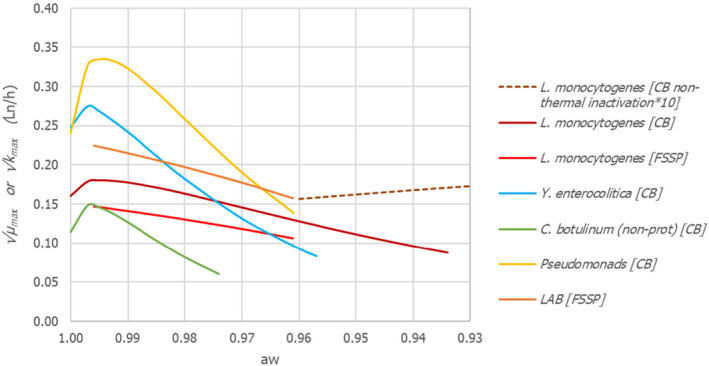

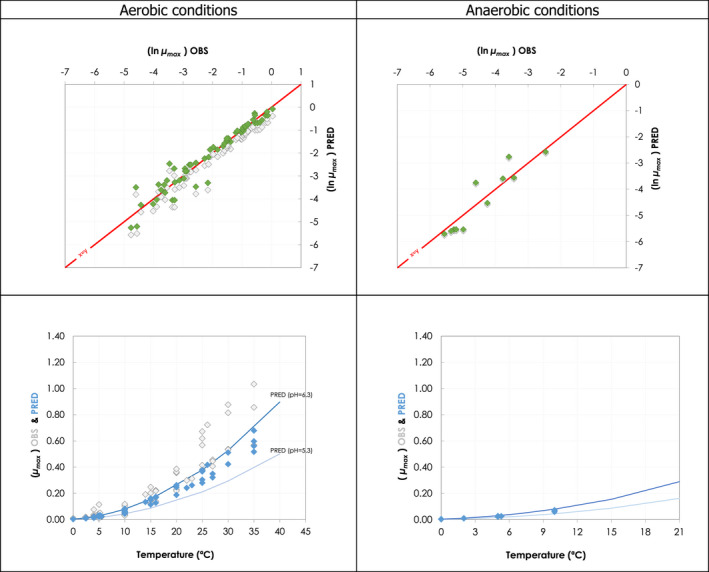

The selection of relevant microorganisms for the different scenarios was based on the magnitude of their growth rate at different values of the main factors associated with meat ageing, i.e. temperature (both for dry and wet‐ageing) and aw (for dry‐ageing).

The predictive models for each relevant microorganism used for evaluating the ageing processes in ToRs 3 and 4 are shown in Table 1. The predictive growth models do not distinguish between microbial growth on different meat types but do take into account the different intrinsic or extrinsic factors characteristic of the meat types. In general, the predictive models were developed using data from experiments made using laboratory media and/or the validation of the predictive performance did not specifically include fresh meat. Furthermore, except for non‐proteolytic C. botulinum (for which anaerobic conditions are assumed), the predictive models do not consider the impact of vacuum‐packaging (wet‐ageing) as compared with aerobic conditions (dry‐ageing). Therefore, growth rate data available in ComBase Browser 2 and the scientific literature dealing with the growth rate of the relevant microorganisms on fresh meat stored under anaerobic (vacuum packaged) and under aerobic conditions were compared with the predictions provided by the models as summarised in Appendix C. The comparison enabled the calculation of the calibration factors that allowed for a correction of the predictions provided by the mathematical models used in the simulations for ToR3 and ToR4 as detailed in Table 1.

Table 1.

Overview of microorganisms and predictive models used to evaluate the log increase of pathogens and spoilage bacteria during different meat ageing processes in ToR3 and ToR4

| Group species | Meat ageing processes | Name | Description secondary model | Source | Calibration factor (b) |

|---|---|---|---|---|---|

| Pathogens | |||||

| Listeria monocytogenes | Wet‐ageing (beef, pork, lamb) | LM | CPM/Gamma (a) | (Mejlholm et al., 2010) | 1 |

| Dry‐ageing (beef) | 0.76 (0.74–0.78) | ||||

| Non‐proteolytic Clostridium botulinum | Wet‐ageing (beef, pork, lamb) | CB | CPM/Gamma (a) | (Koukou et al., 2021) | 1 |

| Yersinia enterocolitica | Wet‐ageing (pork) | YE | Square root model | based on data from (Gill and Reichel, 1989) | 1.10 |

| Non‐pathogens/spoilage bacteria | |||||

| Psychrotolerant LAB |

Wet‐ageing (beef, pork, lamb) Dry‐ageing (beef) |

LAB | CPM/Gamma (a) | (Mejlholm and Dalgaard, 2007) (JFP) or (Mejlholm and Dalgaard, 2013) | 1.89 (2.17–1.30) (c) |

| Pseudomonads | Dry‐ageing (beef) | PS | Square root model (equation for sub‐optimal temperature range) | (Neumeyer et al., 1997) | 1.80 |

LAB: lactic acid bacteria.

Cardinal Parameter Model employing the gamma concept.

Calibration factor equal to 1 means that the original model without correction was implemented. In parentheses the range of calibration factor values considered in the uncertainty analysis.

The same factor applies for aerobic conditions (i.e. when the model is used to simulate microbial interaction between LAB and L. monocytogenes during dry‐ageing). The few data available about LAB growth kinetics on meat under aerobic conditions indicates that the bias factor is within the same order of magnitude as for anaerobic (vacuum packaged) growth.

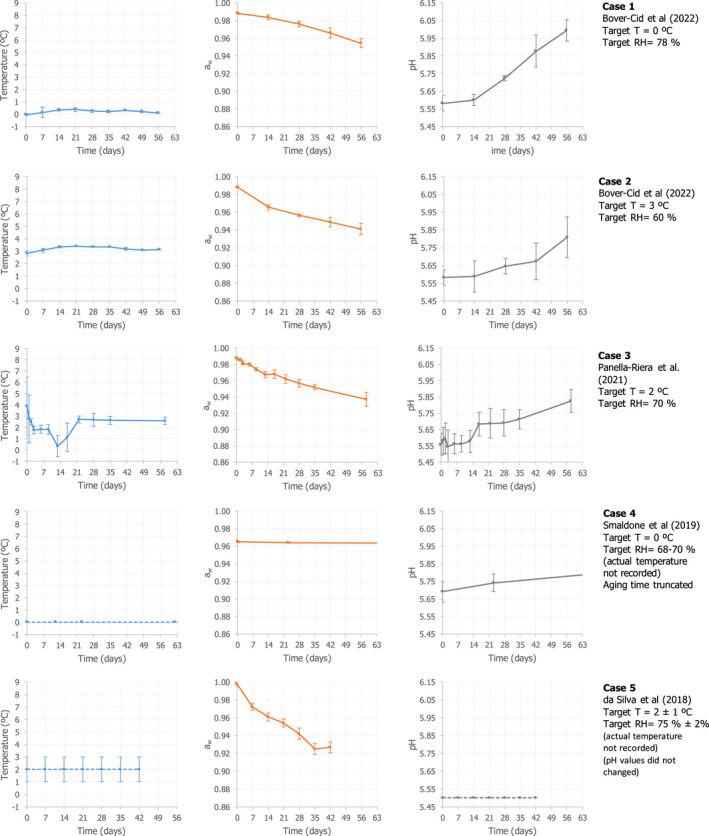

In ToR3, scenarios were developed and described using distributions for the key intrinsic and extrinsic parameters, i.e. temperature, pH, and aw, to capture the range of variation for each process. Modified Pert distributions were used to describe the parameters and were assumed to reflect variable average conditions in the EU (see Appendix D). To capture the variation of the mean values over time, scenarios were separated into a number of stages, each defined by the intrinsic and extrinsic factors at specified time points during ageing. After having defined and agreed a standard fresh meat preparation time for the different fresh meat species the minimum, maximum, median, 5th and 95th percentiles of the mean growth rates during the standard fresh meat preparation (as sampled at 0 and 14 or 4 days, respectively), were estimated. Between 0 and 14 days (or 4 days), a gradual (linear) change was implemented. To estimate the growth during meat ageing of the most relevant pathogens and spoilage bacteria, the estimated minimum, median, and maximum of the mean growth rates during the standard fresh meat preparation times were then used to predict and illustrate the log increase for different ageing times. Growth models were implemented in the statistical software R, version 4.1.1 (R Core Team, 2021), and in simulations the variable outcomes were estimated by calculating the variable growth rates and log increases over the ageing time by sampling the input temperature, pH and aw distributions at 0 and 14 days in 20,000 iterations.

Besides the overall scenarios covering the entire range of reasonably foreseeable conditions, specific realistic examples were developed for the dry‐ageing of beef. The change in the aw and pH of the meat surface and the temperature (recorded with dataloggers), during the ageing process of beef at different target temperature and RH conditions were collected from the scientific literature. Data were obtained from the authors or extracted from the figures with the WebPlotDigitizer tool (Rohatgi, 2021). The growth model for L. monocytogenes (Table 1) implemented in R was used to simulate growth (as log increase) under dynamic conditions of temperature, pH and aw.

In ToR4, the question of environmental parameters for meat ageing resulting in a similar log increase as compared to standard fresh meat preparation, was evaluated using data reflecting a wider range of conditions than in the scenarios in ToR3, to generate data appropriate for such a scenario analysis. The model was implemented in R. Parameters were kept constant during the standard fresh meat preparation or the meat ageing processes included in the quantitative evaluation. In contrast to ToR3, the duration of the ageing processes was described as variable to allow this factor to be evaluated. The parameters time and temperature were generated by taking a sequence of values between a minimum and maximum value in defined steps, and aw and pH were evaluated in three scenarios using the minimum, median and maximum parameter values (Table 2). This was undertaken to generate defined parameters values rather than evaluating a continuum. The scenario analyses were carried out for L. monocytogenes and LAB in wet‐aged beef, pork and lamb, as well as in dry‐aged beef. This was partly based on the outcome of ToR3 but also for simplicity, LAB were used in dry‐aged beef instead of Pseudomonas thus facilitating a comparison with standard fresh meat preparation, which is considered to be wet‐ageing for up to and including 14 days. Pseudomonas is not expected to grow well if at all, under the anaerobic conditions in vacuum packs during wet‐ageing.

Table 2.

The input parameter values for temperature (T) and duration, and the pH and aw values of the three scenarios for which predictions were generated to address ToR4. The predictions were used for scenario analysis to identify conditions resulting in assumed equivalent log10 increases of relevant pathogens and spoilage bacteria when simulating growth during wet and dry‐ageing of beef, and wet‐agieng of beef, pork and lamb

| Ageing | Stage | Duration (days) (a) | T (b) | Scenarios | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | Median | Maximum | |||||||||

| Type | Min | Max | Min | Max | pH | aw | pH | aw | pH | aw | |

| Wet beef | Standard | 14 | 14 | 0 | 5.0 | 5.1 | 0.97 | 5.5 | 0.98 | 5.9 | 0.99 |

| Ageing | 15 | 49 | 0 | 5.0 | 5.1 | 0.97 | 5.5 | 0.98 | 5.9 | 0.99 | |

| Dry beef | Standard | 14 | 14 | 0 | 5.0 | 5.5 | 0.92 | 5.85 | 0.955 | 6.2 | 0.99 |

| Ageing | 15 | 77 | 0 | 5.0 | 5.5 | 0.92 | 5.85 | 0.955 | 6.2 | 0.99 | |

| Wet pork | Standard | 4 | 4 | 0 | 5.0 | 5.4 | 0.95 | 5.85 | 0.97 | 6.3 | 0.99 |

| Ageing | 5 | 28 | 0 | 5.0 | 5.4 | 0.95 | 5.85 | 0.97 | 6.3 | 0.99 | |

| Wet lamb | Standard | 4 | 4 | 0 | 5.0 | 5.5 | 0.95 | 5.7 | 0.97 | 5.9 | 0.99 |

| Ageing | 5 | 21 | 0 | 5.0 | 5.5 | 0.95 | 5.7 | 0.97 | 5.9 | 0.99 | |

In steps of 1 day.

In steps of 1°C.

The parameters, models and scenarios used to answer ToR4 have associated uncertainties. Based on the outcome of the simulations in ToR3, the potential impact of important factors on the predictions, such as not including microbial competition and microbial inactivation, were quantified by estimating their effects on the overall log10 change. In this approach, the ageing processes were divided into two stages, the standard fresh meat preparation stage (up to 14 days) and the ageing stage. The input data, parameters and formulas used in the predictive models were implemented in R (mc2d package, 10,000 iterations) and the conditions of growth, competition and inactivation evaluated are shown in Table 3. The potential impact of competition was quantified using a Jameson effect approach (Jameson, 1962; Giménez and Dalgaard, 2004; Cornu et al., 2011; Leroi et al., 2015; Dalgaard and Mejlholm, 2019), by varying the initial concentrations of L. monocytogenes and LAB, and the maximum total population size (Nmax). The impact of potential inactivation of L. monocytogenes during conditions of ageing of beef that do not support growth was quantified using a Weibull primary model combined with a secondary lambda model (Coroller et al., 2012) or a model developed in this opinion based on decimal reduction times (D values) during dry‐ageing of beef reported by Van Damme et al. (2022). The predicted outcomes were compared with reported inactivation (Van Damme et al., 2022). The impact of drying rate was estimated deterministically, i.e. no iterations, using the data from the case studies (Section 3.6.4.3). The impact of trimming on the concentrations of bacteria was evaluated by using the available data in the scientific literature, although this was limited. The potential impact of neglecting lag phases was not quantified but was evaluated qualitatively together with other factors that could impact on the comparison between standard and ageing processes, based on the literature data.

Table 3.

A summary of input data used in the model for evaluating the effect of inactivation (dry‐aged beef) and competition (wet‐aged beef)

| Process | Parameter | Symbol (a) | Formula | Comment |

|---|---|---|---|---|

| Dry‐ageing | Temperature (°C) |

T1V T2V |

rpert, min = −0.6, mode = 2.0, max = 5.1, shape = 4 | |

| pH |

pH1V pH2V |

rpert, min = 5.5, mode = 5.7, max = 6.2, shape = 4 | ||

| aw | aw1V, aw2V | rpert, min = 0.88, mode = 0.96, max = 0.99, shape = 4 | ||

| Duration (days) |

d1V d2V |

14 rpert, min = 1, mode = 14, max = 42, shape = 4 |

||

| Inactivation rate (1/h) | log_red | (time/delta)p | Parameters depend on T, pH, aw (Coroller et al., 2012) | |

| Inactivation rate (1/h) | log_red_vd | rpert, min = 0.02/24, mode = 0.04/24, max = 0.07/24, shape = 4 | Parameters based on D‐values reported in Van Damme et al. (2022) | |

| Max log increase (log units) | Nmax | rpert, min = 7, mode = 9, max = 11, shape = 4 | ||

| Wet‐ageing | Temperature (°C) |

T1V T2V |

rpert, min = −0.6, mode = 2.0, max = 5.1, shape = 4 | |

| pH |

pH1V pH2V |

rpert, min = 5.1, mode = 5.5, max = 5.9, shape = 4 | ||

| aw | aw1V, aw2V | rpert, min = 0.97, mode = 0.98, max = 0.99, shape = 4 | ||

| Duration (days) |

d1V d2V |

14 rpert, min = 1, mode = 14, max = 35, shape = 4 |

||

|

Max log increase (log units) Max population density (log cfu/g) for competition |

Nmax | rpert, min = 4.0, mode = 7.23, max = 9.2, shape = 4 | ||

| Initial L. monocytogenes concentration (log10 CFU/g) for competition | LM0V | rnorm, mean = −1.40, sd = 0.55, rtrunc = TRUE, linf = −2, lsup = 1 | ||

| Initial concentration (log10 CFU/g) for competition | FF0V | 1, 2, 3 or 4 |

LAB: lactic acid bacteria.

Digit in symbol represents stage 1 is the first 14 days corresponding to standard fresh meat preparation, 2 is the additional ageing time.

2.2.3. ToR5

The control actions (GHPs and CCPs) currently used by FBOs that produce dry‐aged beef and wet‐aged beef, pork and lamb were described based on the information available in the scientific and grey literature. The search strings used to search the published literature (scientific papers, book chapters, reviews and reports written in English and published between the years 2000 and 2021) for information to answer ToR5 are provided in Annex A (Protocol). Each publication was screened as described for ToRs 1 and 2. Additional control activities, that achieve similar or lower bacterial counts for dry‐aged beef and wet‐aged beef, pork and lamb (as compared the standard fresh meat equivalent) were established based on the equivalence assessment in ToR4.

2.2.4. Uncertainty analysis

The uncertainty associated with the outcomes for all of the ToRs were assessed, including the identification and listing of ‘sources or location of the uncertainty’, a description of the ‘nature or cause of the uncertainty’ associated with that source and finally a description of the ‘impact of the uncertainty on the conclusions (e.g. over/underestimation)’. The results of this assessment are provided in Table B.1 in Appendix B.

An informal expert knowledge elicitation (EKE) was also undertaken, with the five members of the Aged Meat WG serving as the experts. To prepare for this EKE, individual judgements were elicited for the correctness of five statements, which were considered sufficient to illustrate the conclusions of the Opinion, one related to ToR2 (mycotoxins) and four related to the outcomes of the modelling undertaken in ToR4. Informed by the evidence collected in the draft opinion, including the uncertainty mentioned above (Table B.1), individual experts were asked to indicate how certain they were that the statements were correct. For expression of the uncertainty, they could use the standard ranges indicated in EFSA's approximate probability scale or any other probability range. Consensus was achieved during discussion in the WG meeting. The outcomes of this exercise are described in Appendix B.

3. Assessment

3.1. ToR1: current dry‐ageing and wet‐ageing practices

3.1.1. Dry‐ageing of beef

3.1.1.1. Introduction

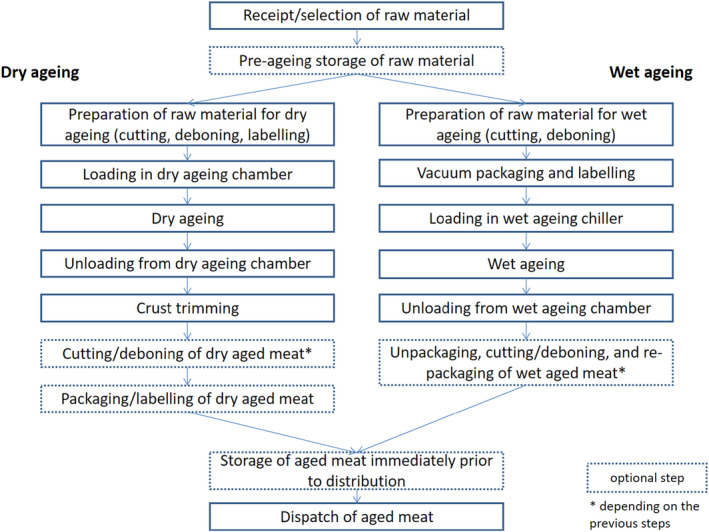

Drying is the process of removing water by evaporation and, before the development of vacuum packaging in the 1960s, was the only method available to age beef (Savell, 2008). Although other meat species may also be dry‐aged, dry‐ageing is almost exclusively used for beef. In the past the whole beef carcasses were dry‐aged but in recent years sub‐primal cuts are more often used (Kim et al., 2018). Dry‐ageing is performed under continuously controlled conditions of temperature, RH and airflow that usually takes several weeks. During this process (shown in Figure 2), water moves to the surface of the carcass or primal and evaporates. This drying process along with enzymatic reactions in the meat results in enhanced flavour and the creation of new flavour compounds (Savell and Gehring, 2018). The increase in the savoury or beefy flavour during ageing is due to the release of compounds such as nucleotides, Maillard reaction‐related sugar fragments (e.g. glucose), lipid oxidation related products as well as volatile compounds such as n‐aldehydes (e.g. hexanal and pentanal) and ketones (Martins et al., 2000; Yaylayan et al., 2000). The complex interaction between sulfur‐containing amino acids, aspartic acid and glutamic acid, nucleotide compounds, and β‐histidyl dipeptides also contribute to the beefy flavour (Dashdorj et al., 2015). Degradation of glycogen releases the substrates responsible for the Maillard reaction while prolonged ageing (over 28 days) increases the volatile compounds responsible for the aroma and enhanced flavour (Martins et al., 2000; Yaylayan et al., 2000; Watanabe et al., 2015).

Figure 2.

Generic process flow of dry and wet beef ageing

Dry‐aged beef is also more tender (Savell and Gehring, 2018). The tenderisation process occurs due to the post‐rigor degradation of cytoskeletal proteins, myofibrils, muscle fibers and connective tissue (Kristensen and Purslow, 2001; Koohmaraie and Geesink, 2006) by the calpain protease system (Hopkins and Thompson, 2002). The extent of tenderisation depends on the dry‐ageing conditions and the muscle characteristics including the bundle type, size/diameter, composition and extensibility of fibers, the rate of glycolysis and sarcomere length (Ertbjerg and Puolanne, 2017).

Post‐mortem proteolysis is influenced by the pH of the meat. Thus, the initial pH of the meat cuts affects tenderness and flavour formation. During the dry‐ageing process, the pH usually increases although a subsequent decrease has also been reported (Lautenschlaeger, 2012; Stenstrom et al., 2014). Several studies have reported that the final pH of dry‐aged meat is usually slightly higher than that of wet‐aged meat (Dikeman et al., 2013; Li et al., 2014) possibly due to the formation of nitrogenous compounds during the former (Obuz et al., 2014) and the slight acidification due to lactic acid growth under vacuum packaging in the later. However, other studies have reported similar pH values for standard fresh, dry and wet‐aged beef (Ahnstrom et al., 2006, DeGeer et al., 2009; Li et al., 2014; Dashdorj et al., 2016; Dashdorj et al., 2016), while Gudjonsdottir et al. (2015) found there was a correlation between the pH and growth of lactic acid bacteria, regardless of ageing process.

Dry‐ageing of beef (Figures 2 and 3) is considered to be superior, in terms of tenderness and flavour, to other ageing processes although the processes used are not standardised and often achieve inconsistent results (King et al., 1995; Sitz et al., 2006; Laster et al., 2008; Smith et al., 2008). Indeed, dry‐ageing beef is considered to be as much an art as a science‐based activity (Dashdorj et al., 2016).

Figure 3.

Dry‐ageing of beef. © Ana Allende

Conditions such as temperature, RH and airflow determine the characteristics of the final product (Terjung et al., 2021). Sensory trials reported by Kim et al. (Kim et al., 2016) found that dry‐ageing of beef at 3°C, 49% RH and an air flow of 0.2 m/s for 21 days was optimal for organoleptical quality. The same study reported that shear force (a measure of tenderness) is affected by storage temperature and meat dry‐aged at 3°C was more tender than at 1°C. Other authors agree that an RH below 85% achieves a better consumer evaluation (Kang et al., 2017). Lower air velocity may also result in a more tender dry‐aged beef product. Lee et al. (Lee et al., 2019) reported that dry‐ageing for 28 days at air velocities of 2.5 or 5 m/s reduced the shear force by 30 N (N) but at 0 m/s the shear force was reduced by 40 N. At least 2 studies have reported that using the same parameters for dry and wet‐ageing achieves beef products of equal tenderness (Oh et al., 2018; Kim et al., 2020), although it could be argued that the conditions used (85% RH and an airflow of 2–7 m/s) were not suitable for dry‐ageing. Dry‐aged beef has a beefy, buttery, nutty, and sweet flavour and may also have a pleasant savoury (umami) taste due to the high concentrations of glutamate. The dry‐ageing process is comparably costly as it is used on high‐quality cuts, incurs weight losses of 6–15% and trim losses of 3–4%. Moreover, as the beef is not usually packaged, there is a higher risk of open‐air contamination of the meat. This can be reduced by packaging the meat in moisture permeable bags which were first used approximately 15 years ago. Although beef dry‐aged in a bag is reported to have the same flavour as beef aged using unpackaged dry‐ageing this process is not used commercially (Ahnstrom et al., 2006). The different combinations of temperature, RH, airflow and duration used for dry‐ageing of beef in laboratory and/or pilot plant settings are provided in Table E.1 (Appendix E).

Table E.1.

The conditions and corresponding meat parameters reported for dry‐ageing beef in the scientific literature

| Conventionally dry‐aged beef | ||||||||

|---|---|---|---|---|---|---|---|---|

| Conditions | Surface parameters | |||||||

| T (°C)* | RH (%) | Airflow (m/s) | Pre‐ageing time (days) | Ageing time (days) | pH | aw | Surface T (°C) | References |

| 0 | 68–70 | Forced ventilation cell | 5 | 13, 36, 110, 170 and 290 | 5.69–6.00 | 0.965–0.953 | – | Smaldone et al. (2019) |

| −0.6 ± 1.8 | 78 ± 9.3 | – | 9 | 14, 21, 28 and 35 | – | – | – | Laster et al. (2008) |

| 0.5 ± 0.5 | 85 | 0.2–0.5 | 1 | 0, 7, 14, 21 and 28 | 5.6–5.8 | – | – | Kahraman and Gurbuz (2019) |

| 2 ± 1 | 75 ± 10 | 2.5 | – | 0, 7, 14, 21, 28, 35 | 5.7–5.9 | – | – | Oh et al. (2019b) |

| 1 | 85 | 0.5 | 5 | 30 | – | – | – | Kim et al. (2020) |

| 1 | 85 | 2–7 | – | 28 | – | – | – | Kim et al. (2019b) |

| 1 | 80–85 | 0.2–0.3 | 5 | 40 | – | – | – | Kim et al. (2019a) |

| 1 ± 1 | 85 ± 10 | 2–7 | 28 | – | – | – | Oh et al. (2018) | |

| 1 ± 0.5 | 80–85 | 0.5–1.5 | 12 | 20 and 40 | – | – | – | Kim et al. (2017a) |

| 1 | 78 | 1.5 | – | 17 | – | – | – | Kim et al. (2017b) |

| 1 | 75–85 | 5 ± 3 | – | 28 | – | – | – | Lee et al. (2017) |

| 1 | 73–76 | 0.2–0.5 | – | 21 | – | – | – | Kim et al. (2017a,b) |

| 1 | 70 | – | – | 14, 21, 28, 35, 42, and 49 | – | – | – | Lepper‐Blilie et al. (2016) |

| 1 ± 2 | 70–100 | – | – | 14 | – | – | – | Knudsen et al. (2011) |

| 1.6 | – | – | 2 | 13 | 5.6 | – | – | Stenstrom et al. (2014) |

| 1 ± 1 | 85 ± 2 | 0.5 ± 0.2 | – | 12 to 36 | 5.6–5.7 | – | – | Hulankova et al. (2018b) |

| 1 ± 2 | 83 ± 11 | – | 2 | 14, 21, 28 and 35 | – | – | – | Smith et al. (2008) |

| 2 ± 1 | 85 | 2 | – | 0, 20, 24, 40, and 50 | – | – | – | Utama et al. (2020) |

| 0–4 | 75 | 0 | – | 0, 14, 21, 28 | – | – | – | Oh et al. (2019a) |

| 1–3 | 75 | 2.5 | – | 0, 14, 21, 28 | – | – | – | Oh et al. (2019a) |

| 1–3 | 75 | 5 | – | 0, 14, 21, 28 | – | – | – | Oh et al. (2019a) |

| 1–4 | 80–90 | – | – | 3, 25, 40, 50 and 60 | – | – | – | Ryu et al. (2018) |

| 1–4 | 80–90 | – | – | 4, 11, 20, 30, 40, 50 and 60 | – | – | – | Iida et al. (2016) |

| 2 | 50 | 0.8 | – | 42 | 5.5 | 0.99 | – | Ribeiro et al. (2021a) |

| 2 | 85 | 1.5 | 2 | 0, 7 and 14 | 5.5–5.6 | – | – | Shi et al. (2020) |

| 2 ± 1 | 75 ± 2 | 2 ± 0.5 | 3 | 0, 7, 14, 21, 28, 35, or 42 | 5.5 |

0.99 (day 0) 0.97 (day 7) 0.93 (day 42) |

– | da Silva et al. (2019) |

| 2 | 65/75 | 2.5 | – | 20–60 | – | – | – | Ha et al. (2019) |

| 2 ± 1 | 75 ± 10 | 2.5 | – | 0, 7, 14, 21, 28 and − 35 | – | – | – | Oh et al. (2019b) |

| 2 | 78 | ˂ 0.2 | 7 | 28 | – | – | – | Berger et al. (2018) |

| 2 | – | – | 2 | 14 | – | – | – | Jiang et al. (2010) |

| 2.2 | 50 | – | – | 21 and 28 | 5.5 | – | – | DeGeer et al. (2009) |

| 2.5 ± 0.3 | 87 ± 2.6 | “Normal cooler conditions” | 11 | 21 | 5.7 | – | – | Ahnstrom et al. (2006) |

| 2.6 ± 0.4 | – | “Normal cooler conditions” | 11 | 14 | 5.5 | – | – | Ahnstrom et al. (2006) |

| 2.9 | 90 | 1.8–2.5 | – | 35 | 5.6 | – | – | Mikami et al. (2021) |

| 2.9 | 91 | – | 6 | 14 | 5.6 | – | – | Li et al. (2013) |

| 2.9 | – | – | 2 | 8 and 19 |

5.58–5.63 |

– | – | Li et al. (2014) |

| 3 | 49–55 | 0.2–0.5 | – | 21 | – | – | – | Kim et al. (2017a,b) |

| 3 | 80 | 0.25 | – | 28 | – | – | Tittor et al. (2011) | |

| 3.5 ± 1.5 | 75–100 | 0–0.6 | – | 14 | – | – | Knudsen et al. (2011) | |

| 4 | 75 | 2.5 | – | 28 | – | – | – | Kim et al. (2019b, 2020) |

| 4 ± 2 | – | – | – | 0, 7, 14, 21, 28, 42 and 63 | 5.5–6.8 | – | – | Lee et al. (2019) |

| 4 | 75 | 0, 2.5 and 5 | – | 14 and 28 | 5.6–6.0 | – | – | Lee et al. (2019) |

| 4 | 75 | 2.5 | – | 28 | 5.75 | – | – | Lee H.J. et al. (2018) |

| 4 | – | – | – | 7, 14, and 21 | 5.6–5.7 | – | – | Gudjonsdottir et al. (2015) |

| 4.0 ± 1.1 | 98.1 | 2 | 35 | – | – | Smith et al. (2014) | ||

| 8 ± 1 | 75 ± 2 | 2 ± 0.5 | – | 0, 7, 14, 21, 28, 35, and 42 | 5.5 | 0.95–0.88 | – | da Silva et al. (2019) |

The measured surface temperature when provided or when not provided the temperature setting in the chill room/chamber.

3.1.1.2. Temperature

Dry‐ageing must be performed at temperatures high enough to allow the enzymatic processes that are required to achieve tenderisation and flavour development but sufficiently low to inhibit the growth of pathogenic and spoilage bacteria and the development of off‐odours and off‐flavours. Dry‐ageing is therefore usually undertaken at 0–4°C, the same storage temperatures used for other meat products where controlling microbial growth is required. The reported studies have used a range of temperatures, between −0.6°C and 8°C (Table E.1). However, the higher temperatures (> 4°C) are only of academic interest and do not reflect the conditions used in commercial ageing practices. Specific studies of commercial processes are limited in the published literature. Gowda et al. (Gowda et al., 2022) conducted a cross‐sectional study in 15 Belgian companies producing dry‐aged beef and observed that the temperatures of the dry‐ageing chambers were set between –1°C and 3°C, whereas the actual recorded temperatures were as low as 0.0°C and on occasion reached as high as 5.9°C. In Brazil, many dry‐aged beef producers (18/37, 49%) reported using temperature settings during dry‐ageing of between 2 and 4°C (Rezende‐de‐Souza et al., 2021).

3.1.1.3. Relative humidity