Abstract

The increasing need for joint replacement surgeries, musculoskeletal repairs, and orthodontics worldwide prompts emerging technologies to evolve with healthcare’s changing landscape. Metallic orthopaedic materials have a shared application history with the aerospace industry, making them only partly efficient in the biomedical domain. However, suitability of metallic materials in bone tissue replacements and regenerative therapies remains unchallenged due to their superior mechanical properties, eventhough they are not perfectly biocompatible. Therefore, exploring ways to improve biocompatibility is the most critical step toward designing the next generation of metallic biomaterials. This review discusses methods of improving biocompatibility of metals used in biomedical devices using surface modification, bulk modification, and incorporation of biologics. Our investigation spans multiple length scales, from bulk metals to the effect of microporosities, surface nanoarchitecture, and biomolecules such as DNA incorporation for enhanced biological response in metallic materials. We examine recent technologies such as 3D printing in alloy design and storing surface charge on nanoarchitecture surfaces, metal-on-metal, and ceramic-on-metal coatings to present a coherent and comprehensive understanding of the subject. Finally, we consider the advantages and challenges of metallic biomaterials and identify future directions.

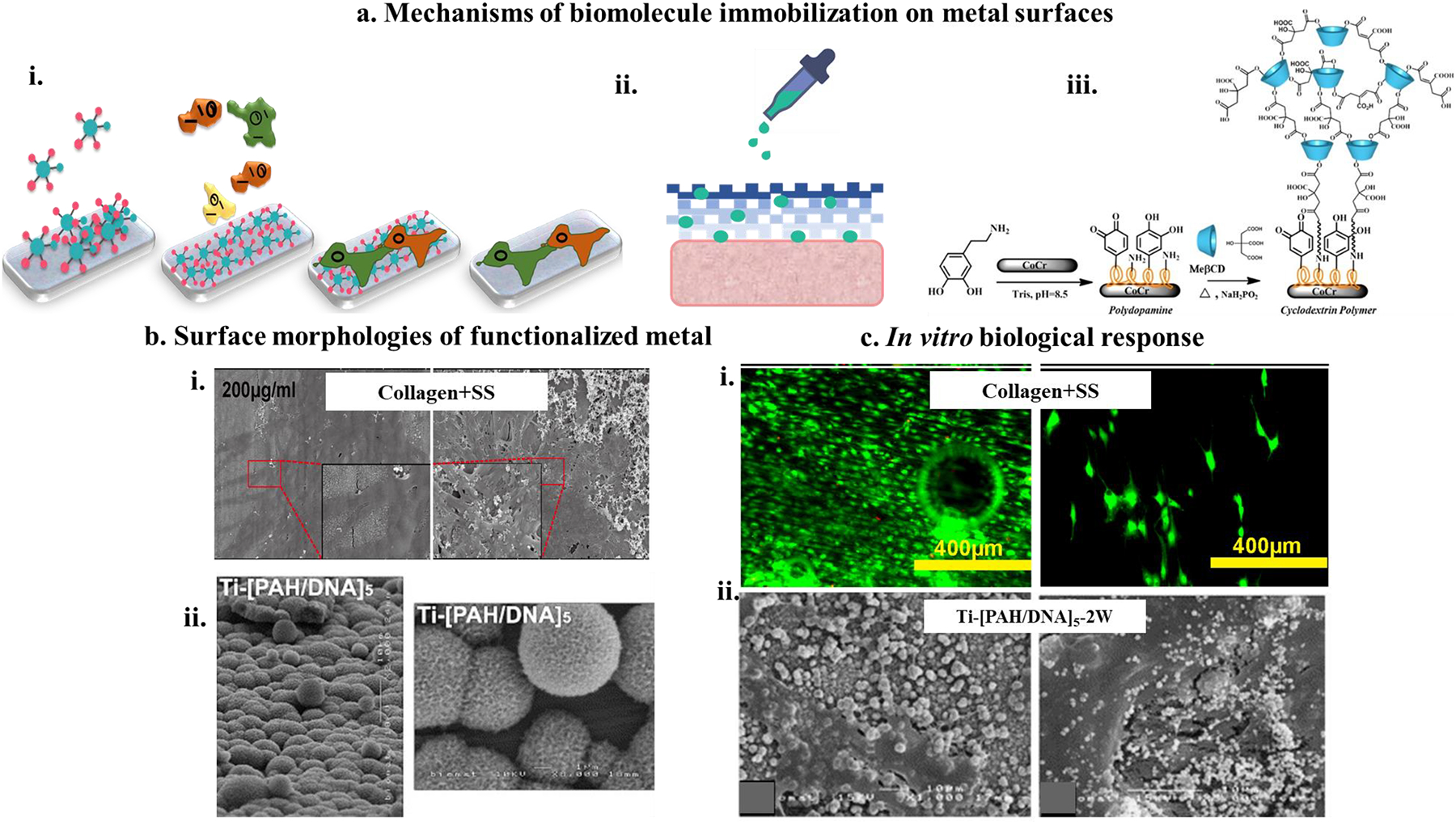

Keywords: Implants, Metals, Alloys, Biocompatibility, 3D Printing, additive manufacturing

1.0. Introduction

Orthopaedic disorders affect millions worldwide due to traumatic injuries, advanced age, developmental and degenerative diseases, and other causes1. The primary treatment for these conditions often requires invasive surgical interventions involving metallic implants to substitute for or supplement the affected bone. Historically, when considering fracture fixation, these surgeries have often been a two-step surgical process; the first is to place the implant for fixation, and the second is to remove the device post-healing to allow more normal bone remodeling and implant complications. To reduce such secondary surgeries, innovation in metallic devices has spearheaded the field of dental and orthopaedic load-bearing implantation for the past several decades. Recently, advanced materials research in implantable metallic devices for bone disorders has significantly influenced human life quality, especially with the population’s median age increasing. Improved metals and metal alloys have consistently been used in biomedical applications due to their exceptional corrosion and fatigue resistance, high strength-to-weight ratio, longevity, and general reliability. However, these devices’ practical usage still has several challenges concerning acquiring and retaining permanent biological fixation at the implant site to avoid revision surgeries. Current biomaterials research aims to induce and accelerate early-stage bone tissue ingrowth around the implants. In addition to wound healing properties, these implants must have adequate biomechanical characteristics and biocompatibility to be considered permanent fixation devices. The definition of biocompatibility, although controversial, suggests the successful interaction of living biological tissue in apposition with nonliving materials. Recently, there have been significant changes in the perspective of biocompatibility, not only for passive implant materials but also for active tissue-engineering materials. The two majorly accepted principles of biocompatibility are biosafety and bio-functionality (or promotion of body function). Biocompatibility of an orthopaedic implant can be further sub-classified into 1) mechanical biocompatibility in terms of proper placement and stability of the implant at the surgery site, 2) biological compatibility in terms of tissue-material interaction, 3) histocompatibility in terms of adverse inflammatory and immune response, and blood compatibility. This is defined as the implant material’s ability to bond with the host tissue and promote an affected region’s healing. However, most metals and alloys currently employed in medical devices were initially developed by the aerospace industry for their mechanical properties and not biological compatibility. Therefore, metallic implants are inert in a physiological environment, which induces biocompatible behavior, an essential factor in determining the efficient application of such implants.

The importance of biocompatibility lies in minimizing the inherent limitations of metallic implants. Most importantly, these include ensuring that the body does not experience an adverse effect due to the implant (e.g., stress shielding) or antagonistic tissue-material interaction leading to fibrous tissue formation, eventually disrupting implant stability. This would guarantee that the device is implanted at the surgery site long enough to initiate a favorable biological response from the host. For implantable and fracture fixation devices, the material’s surface is the first and foremost factor that guides a device’s efficiency. This is important because the surface comes in direct contact with the host’s physiological surroundings; therefore, a device’s surface should be appropriately constructed and efficacious. Another essential factor is mechano-transduction, which relates to the device’s bulk properties, but this becomes a guiding force in the later part of implantation and usually follows surface interaction.

A significant proportion of implant usage is driven by elderly patients with other conditions, such as obesity and stress, and lifestyle changes and product innovation cases. Indeed, multiple clinical confirmations today exemplify the safety and efficacy of metallic implants for bone disorders. According to the Centers for Disease Control and Prevention (CDC), in 2010, over 40 million people in the United States were aged 65 and above, constituting 13% of the total population. The aged population in 2030 is expected to be twice as large, increasing to ~72 million and making up nearly 20% of the total U.S. population. The growing older population is expected to drive the dental, reconstructive arthroplasty, and craniomaxillofacial implant markets.2. The worldwide biomedical implant market is segmented by orthopaedic implants, cardiovascular stents, dental prosthesis, ophthalmic devices, neurostimulation grafts/, and others, and by origins such as allograft, autograft, xenograft, and synthetic graft. This review article focuses on classifying metallic implants by material types and how the materials science aspects of bulk and surface of metallic biomaterials are modified to enhance biocompatibility, i.e., biological responses such as early-stage osseointegration as well as new bone formation.

2.0. Metallic biomaterials and their applications in orthopedics and dentistry

A global surge in road accidents leading to trauma cases and continuously increasing demand for minimally invasive surgeries are favorably driving the need for the next generation of metallic biomaterials. Based on the market segmentation, titanium is expected to hold the largest market share due to its optimal biocompatibility, high strength-to-weight ratio, excellent fatigue, and corrosion resistance compared to other metals, stainless steel, and cobalt-chromium alloys. The orthopaedic biomaterials segment is expected to register a comparatively higher compound annual growth rate (CAGR) up to 2025 due to the growing elderly population and the rising prevalence of chronic diseases, including osteoarthritis and osteoporosis. Asia-Pacific is the most significant contributor to this growing market due to its large patient population, rising trauma cases, developing healthcare awareness, and improving infrastructure. The current generation of metallic implants available in the market is fabricated and modified based on their niche applications shown in Figure 1. A comprehensive representation of bulk and surface modifications is necessary for improving biocompatibility.

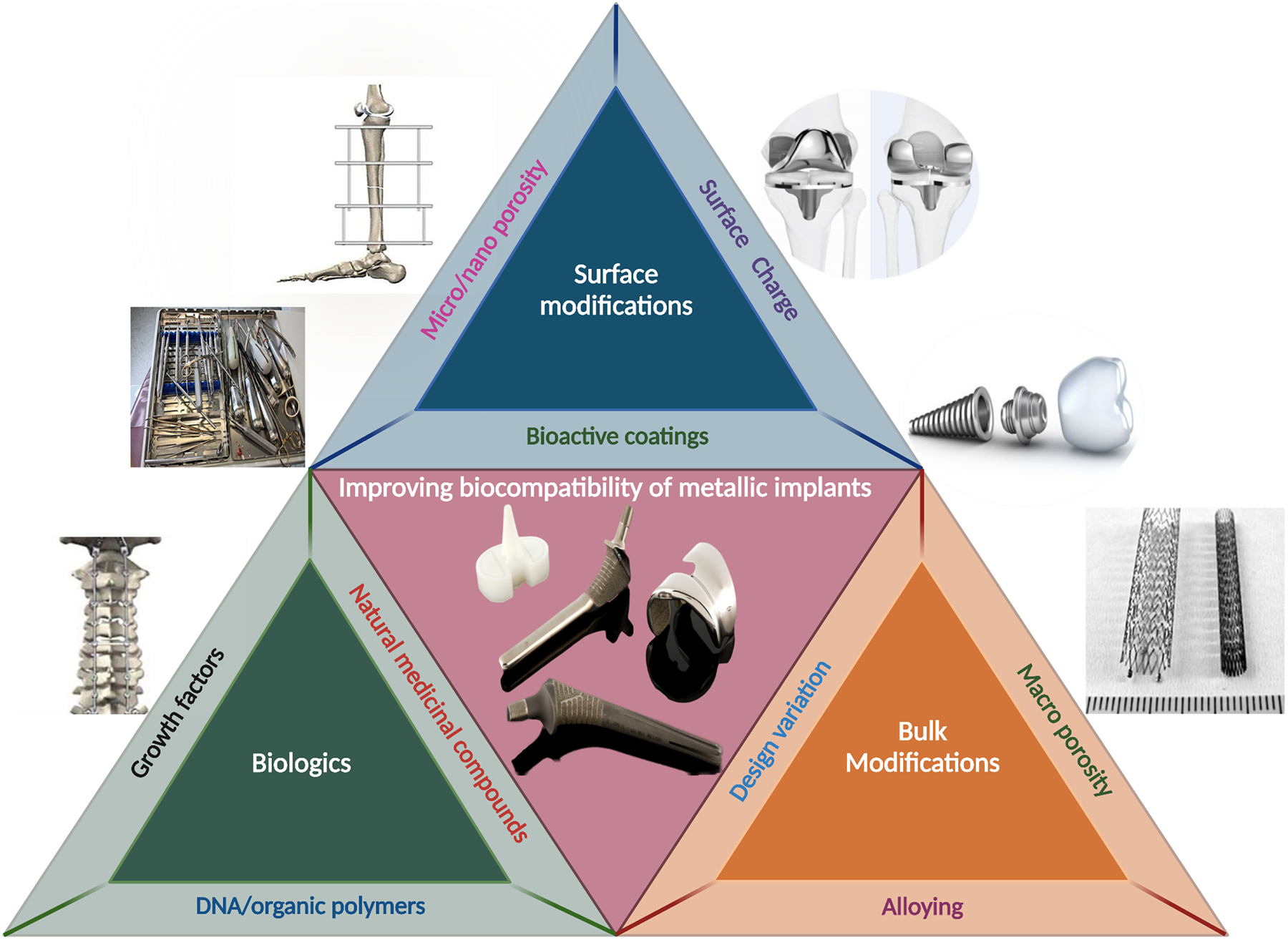

Figure 1.

Interdependence of bulk modification and surface modification of metallic biomedical materials towards comprehensively improving biocompatibility. Representation of the current generation of some metallic implants used in the biomedical devices industry.

2.1. Metallic implants for load-bearing applications

Load-bearing implants such as total hip and knee arthroplasties are constructed out of metals with a high strength-to-weight ratio, good mechanical compatibility with bone, and excellent fatigue and fracture resistance for withstanding constant multi-axial loads. Therefore, the intrinsic mechanical properties of the bulk metals are a critical consideration for load-bearing applications. Young’s modulus, ultimate tensile strength, and fracture toughness define load-bearing implants’ mechanical compatibility. Additionally, the measure of fatigue strength in this context is equally paramount and serves as the baseline for design engineers’ fall on the historical success of forged Ti6Al4V or cast CoCrMo alloys to design new implants industry. Although fatigue strength is an intrinsic property, implants could be designed to have much lower fatigue resistance. The implication that only an increase in cross-section could successfully address the bio-mechanical loads and convince Regulatory bodies to deem these implants as safe based on just mechanical tests renders this parameter unwarranted to be used as a baseline. One of the primary reasons that the majority of the industry has chosen to stay with known alloys is the unknown risk of introducing new materials, proven by the limited examples in support of non-titanium based alloy in orthopedic except a few such as Oxinium (Zirconium Niobium alloy from Smith and Nephew), Roxolid (15 % zirconium and 85 % titanium).

CoCrMo, stainless steel, and titanium alloys have much higher Young’s modulus than the cortical bone. The significant difference in Young’s modulus may result in the implant bearing most of the load-bearing hip or knee implant load. Due to unbalanced load distribution, the surrounding bone bears less load, leading to adverse biological responses such as atrophy and cracks around the implant site, commonly known as the “stress-shielding effect.” Furthermore, bone degeneration at the surgery site may result in implant loosening, which may require revision surgery. Naturally, metallic load-bearing implants are desired to have a closer modulus to human cortical bone. Extensive research has been undertaken to remedy this difference or “mismatch” in modulus to fabricate metallic implants with lower modulus to enhance osseointegration and better load distribution in vivo. Among different options, introducing porosity in the bulk implant structure has been studied the most to lower effective Young’s modulus3–11. Additionally, alloying high-modulus metals like CoCrMo and Ti to reduce Young’s modulus has also been studied by various research groups12–18. Many examples of beta titanium alloys may be biocompatible and much lower Young’s Modulus. Unfortunately, though there has been some research on these13,14,19–23, adoption in clinical use is relatively low or scarce.

2.2. Metallic implants for articulating surfaces

Implants customized for load-bearing articulating surfaces are fabricated primarily focusing on their wear and corrosion resistance, maintaining a low friction coefficient. However, adverse tissue reactions, including implant loosening, remained a primary concern due to bio-tribo-corrosion and related metal ion release in vivo. Although exact reasons behind such aseptic loosening have not yet been fully understood, research and surveys show micro-particulate byproducts from corrosion and wear-induced damage in an artificial joint are of significant concern24–26. The initial performance efficiency of joint replacement devices is measured as a function of their potential for osseointegration, bone healing, and particle leaching susceptibility due to corrosion and severe wear. This initiates the body’s natural defense mechanism through macrophages to eliminate the foreign material27. The biological byproducts, substances, and cellular debris released during this inflammatory reaction contribute to bone erosion surrounding the implant, potentially resulting in implant loosening. Therefore, to address the problems related to corrosion and wear resistance of metallic implants, a significant reduction in the use of older CoCrMo femoral heads or conventional polyethylene liners is seen in recent years, which are replaced by novel bearings such as highly cross-linked polyethylene, ceramic femoral heads, and ceramic-on-ceramic articulations28,29. An implant’s longevity in the human body is primarily determined by fatigue strength, corrosion resistance, and wear properties. However, corrosion and wear debris cause severe adverse responses from the articulating surfaces of large joint implants, which gets further complicated due to the issue of fretting corrosion on modular implants – whether it is the issue of CoCrMo head on the taper junction on Ti6Al4V hip stem or the junction of proximal body of the Ti6Al4V hip stem with the distal section of the Ti6Al4V stem. These taper junctions are mechanically mated during surgery – though machined to a very high finish and tolerance, there is always a certain amount of micromotion leading to fretting corrosion and the unavoidable crevice where crevice corrosion can start, therefore guaranteeing revision surgeries.

2.3. Metallic implants in dentistry

Everyday dental health and hygiene challenges are periodontal diseases and trauma, leading to partial or complete edentulism’s unfortunate predicament. Traditionally these problems were dealt with indirectly or by directly fixed restorations of crowns and bridges or a removable prosthesis with a mixture of precision attachments and other innovative designs. However, some of these solutions were either very invasive and/or cumbersome, like the ‘three-unit bridge’ where a significant loss of dental material for the middle tooth. Some of these remedies were challenging to work with as there was little to no soft and hard tissue support to make these feasible for daily activities like eating a regular meal. Naturally, this led to developing a new idea to try and create a means to improve upon the dental prosthetic’s retention and function for the patient. These new endosseous dental implants were fabricated with metals with excellent corrosion resistance and quickly stabilized at the implantation site. Such properties are essential for these implants because the local environment is exposed to enzymes and acids from food, which corrode the implant’s surface. Moreover, quick stabilization is required to ensure faster patient healing and rehabilitation. The innovations in dental implantology were primarily from a material design perspective. The metal structures’ surface was either machined or textured using 1) acid or laser etching, 2) blasted to form titanium oxide, and 3) hydroxyapatite-coated, sintered, or porous titanium plasma sprayed.

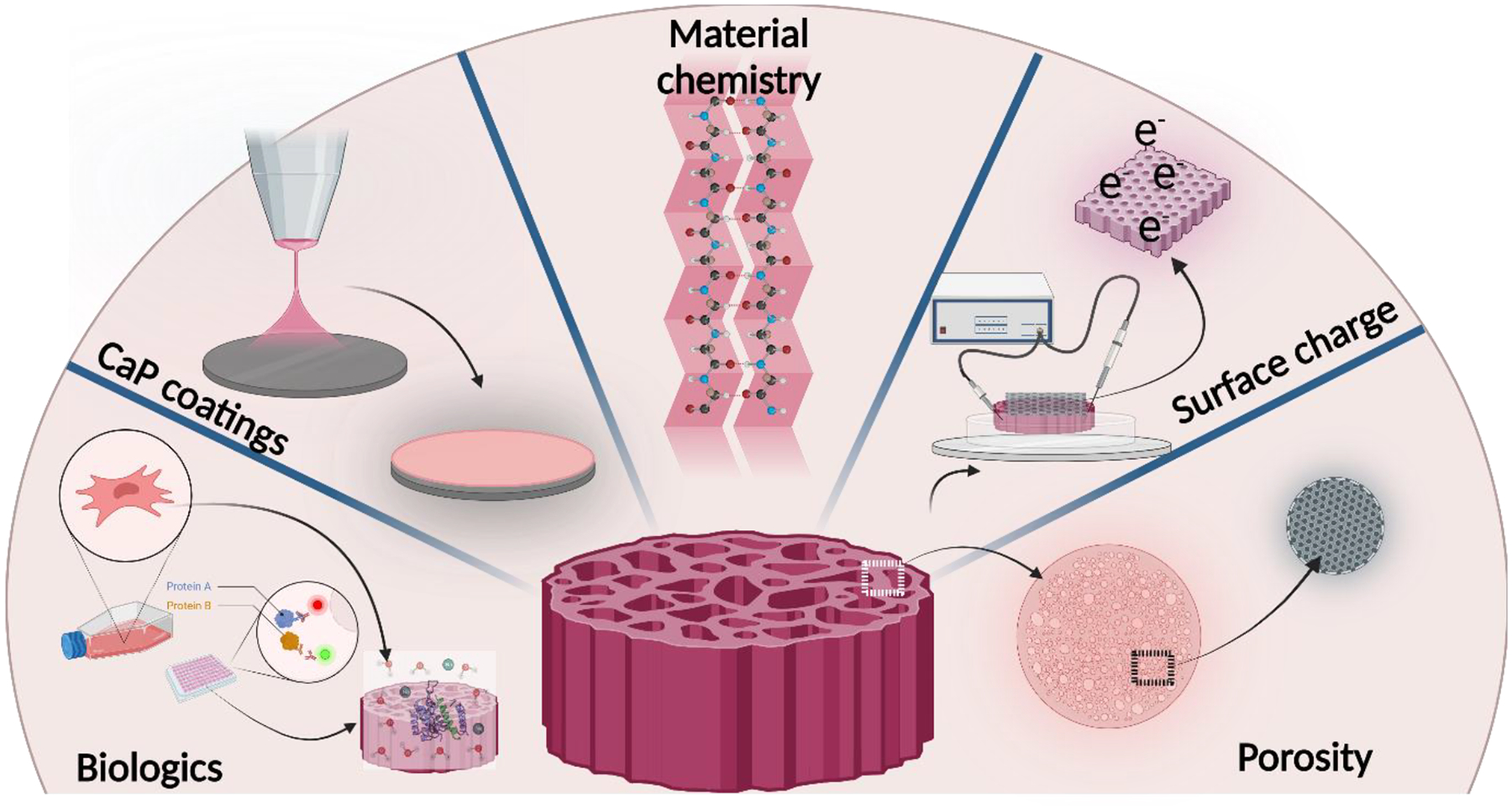

For decades, these metals have been used in clinical applications with bulk and surface modifications to elicit a favorable biological response and their mechanical compatibility. However, most of these metals have been historically borrowed from the aerospace industry for their favorable mechanical properties that align with the biomedical industry’s demands. Figure 2 represents some critical structural and functional modifications employed on metallic biomedical devices to enhance their biocompatibility. Namely, those modifications include – (1) addition of porosity for better biological fixation in vivo; (2) addition of surface charge for faster healing; (3) modification of bulk materials chemistry to reduce modulus and/or improve inherent biocompatibility of the alloy; (4) addition of bioactive calcium phosphate coatings to improve implant-tissue integration in vivo and (5) addition of biologics on the surface of the metallic implants for faster healing. The following sections of this review will focus on those modifications that improve metallic devices’ biocompatibility in greater detail.

Figure 2.

Common bulk and surface modification approach of metallic implants to improve biocompatibility.

3.0. Addition of porosity to improve the biocompatibility of metallic biomaterials

It is generally accepted that implants’ porosity has an essential role in biological fixation during the early stages of osseointegration. Historically, the industry made use of sintered beads or wire mesh pads on the implant surface. These structures were inherently smooth to both the touch and likely to osteoblasts. Further, sintering on titanium alloys resulted in grain growth and notches due to point contacts of the beads or line contact of the wire pads. Though these implants’ clinical success, there have been multiple beads shedding examples in clinical use. This was countered by spraying Ti on Ti implants to create a random porous structure. The substrate was kept metallurgically cool to prevent grain growth. The presence of interconnected three-dimensional (3D) pores in the implant helps promote cell adhesion, mechanical interlocking between host tissue and scaffold via bone ingrowth, and transport of nutrients and metabolic waste. However, porous structures must also have sufficient strength to withstand in vivo stresses at the application site until newly formed bone shows ingrowth into the porous volume, creating mechanical interlocking with the implant surface. Pore size, volume fraction porosity, pore-pore interconnectivity, and pore shape strongly influence implants’ mechanical properties. Figure 3 shows some commercially available porous metal implants and their real-world application in the orthopaedic industry.

Figure 3.

Commercially available porous metallic orthopedic devices. A. Arcam designed hip cup using electron beam melting (EBM) technology44, B. Lattice-structured implant prototype, additively manufactured by Imperial College London45, C. Alphaform produced 3D printed titanium alloy bone-implant using EOSINT M 280 for the reconstruction of the hip bone for a cancer patient in 201446.

3.1. Processing porous metal implants

One of the primary characteristics of metallic orthopedic implants is their structure and shape correlation with the patients’ defect site or the target bone. Porous implants are better suited for such a role due to the advantage of good bone in-growth through the implants’ open porous geometry, which leads to faster osseointegration and healing. Until recently, fabrication of orthopaedic implant structures was accomplished using Computer Numerical Control (CNC) based methods that employed powder metallurgy principles in processes such as gas foaming47–51, plasma spraying52–55, sintering56–58, vapor deposition59–61, combustion synthesis62–64, and fiber mesh structures65–67. However, these conventional methods only allowed for the fabrication of implants with moderately complex geometry. To achieve higher efficiency in the design and fabrication of complicated parts where patient-customization is important, additive manufacturing (AM) methods based on computed tomography (CT) or magnetic resonance imaging (MRI) images became popular in designing individual implants68,69. In contrast to conventional methods, additive manufacturing technologies allow the fabrication of complex-shaped parts with predefined and customizable external shapes and internal architectures in a highly efficient way70,71 in addition to high degrees of geometric flexibility, low production times, high material utilization rates, and true near-net-shape capability, enabling the production of complex-shaped parts which cannot be readily fabricated through conventional manufacturing techniques72. AM has experienced over 20 years of development and is now one of the most quickly developing advanced manufacturing technologies in the world73.

In porous metallic orthopaedic implants and scaffolds, additive manufacturing has been believed to be driving the recent advances in this field. Numerous additive manufacturing technologies (described in Table 3) have been researched and commercially implemented to fabricate patient-specific orthopaedic load-bearing porous metallic implants.74–76 In other orthopaedic applications, such as scaffolds to facilitate bone tissue engineering, considerable advancements have been made by additive manufacturing technology. Porous Ti scaffolds with surface modifications to improve bioactivity, porous Mg scaffolds have shown promising, and much desired, biodegradable properties, etc., have been researched to a great extent77,78.

Table 3.

enlists the primary manufacturing methods, pore characteristics, and key findings in porous metals in orthopedic applications

| Manufacturing method | Materials | Pore architecture | Key Findings |

|---|---|---|---|

| 3D fabrication | Ti6Al4V | Cross patterned hatching |

|

| Electron Beam Melting (EBM) | Ti6Al4V | Variation in shapes of the unit-cell | |

| Selective Laser Melting (SLM) | Ti6Al4V |

|

|

| EBM | Cobalt-chrome alloys | Variation in shapes of the unit-cell |

|

| SLM | Nitinol | Unit-cell variation along with gyroid cross-hatching |

|

| Liquid metal dealloying | TiZr alloys | Removal of magnesium after dealloying using etchants |

|

| Titanium wire space holder approach (TWSH) | Porous magnesium | Immersion of TWSH into molten magnesium followed by etching to remove Ti |

|

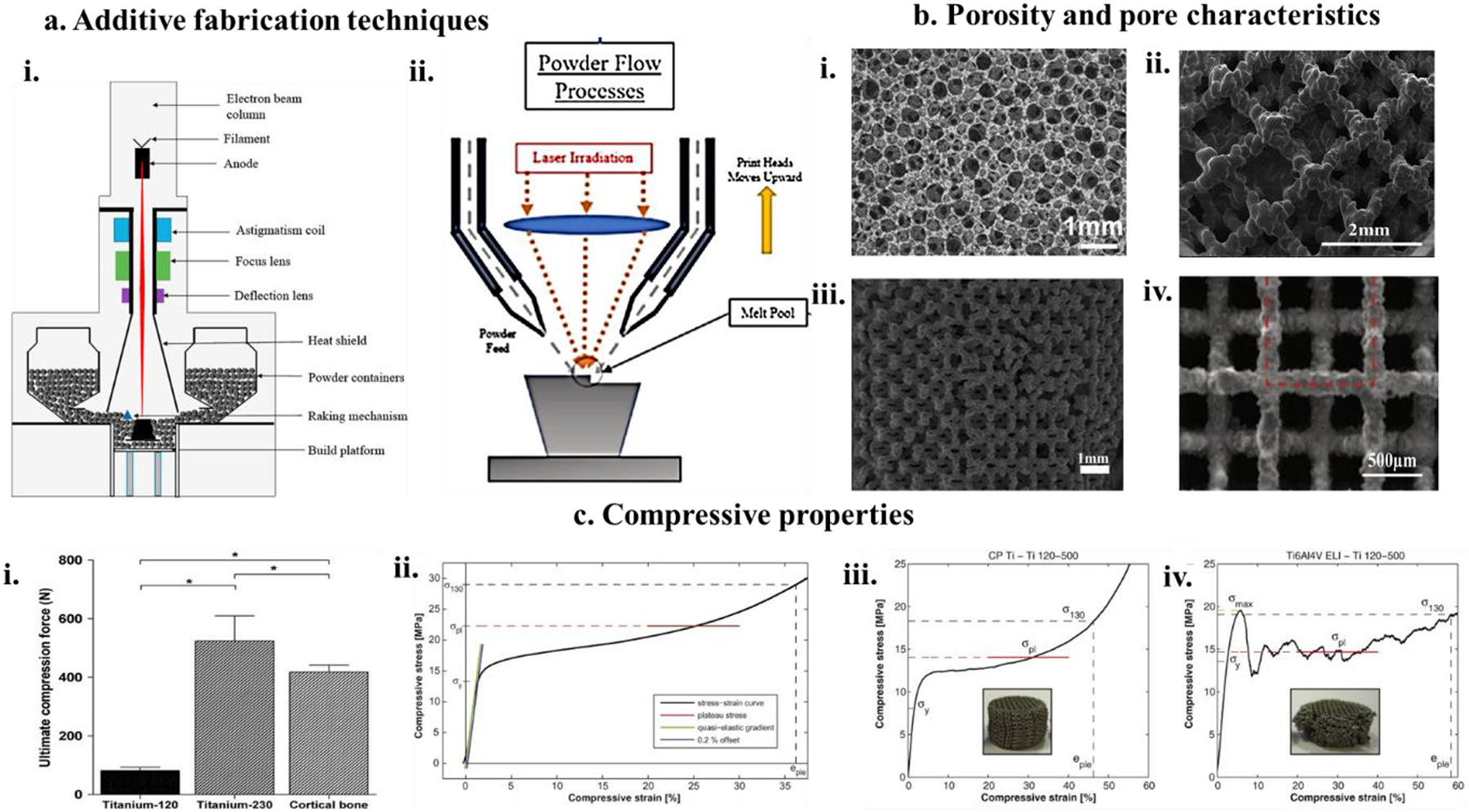

Broadly, additive manufacturing of porous metal structures could be accomplished using powder-bed-based or direct energy-based methods. Powder-bed-based methods could be further classified into Binder-jetting based and powder-fusion-based processes (Fig 4. a. i), and the directed energy deposition-based methods could either be used for metal powders or filaments (Fig. 4. a. ii). The porosity of the structures made of either process could be tailored to obtain up to 80% porous structures. The microstructure and the mechanical properties of either process could be altered by altering the process parameters such as distance from the substrate, energy input, size of the part to be built, orientation, and location. The SEM image of the microstructure of the porous Ti alloy structures built using SLM and EBM is shown in (Fig. 4. b. ii, iii, and iv). The SEM images of surface microstructures from either method indicate small spherical metal particles from unmolten metal particles sintered at the surface.79,80

Figure 4. a. Schematic representation of metal implant additive manufacturing techniques,

i) Powder Bed Fusion (PBF) implant fabrication involves the use of an electron beam or high energy laser to melt powder particles on a metal powder bed to fabricate the desired shape and structure of implants81, ii) Directed Energy Deposition (DED) fabrication involves metal powder flow through multiple nozzles and simultaneously being exposed to a high energy laser beam which forms a metal melt pool on the substrate gradually taking shape through layer-wise deposition of molten metal and rapid cooling81. b. Pore properties of fabricated metal structures, i) SEM micrograph of 80% porous Ti sponge sheet fabricated using slurry foaming showing similar pore characteristics as cancellous bone82. ii) Shows the interconnected pore structure of a Ti metal cage 3D printed using electron beam melting technology with a trabecular pore diameter of 413 ± 78 μm. Pores > 300 μm are suitable for bone ingrowth and fusion with metal cage83, iii) Selective laser molten (SLM) porous Ti structures with 230 μm strut size and 500 μm pore size84, iv) SLM fabricated 80% porous Ta implants85. c. Compressive properties of additively manufactured porous metal structures for biomedical applications i) porous Ti with 230 μm strut size and 68% porosity86, ii) Ta structures with 80% porosity85, iii and iv) CpTi and Ti6al4V-ELI structures with 120 μm and 500 μm pore size, respectively87.

On the other hand, porosity could be introduced in 2 ways, individually or together: using optimized process parameters to introduce inter-particle porosity or using appropriate tool paths to introduce porosity. Thus, very high control over the porosity and the pore morphology could be attained by Directed Energy deposition techniques (DED). The total energy input to the melt pool could be determined by altering the process parameters, which facilitates partial melting of the metal particles, and these surface melted particles join at the particle-particle interface leaving some inter-particle porosity. The toolpath-based porosity is because of the altering thickness of and the gap between the metal rods. Introducing porosity produces parts with functionally graded porosity or the porosity’s exact internal architecture. The schematic for the fabrication of porous parts using DED has been shown in (Fig 4. a. ii). Additionally, additive fabrication of porous structures gives precision control over pore size, shape, and geometry and provides the flexibility of mechanical property alteration such as compressive stress, compressive strain, and elastic modulus. Fig. 4. c. i–iv shows examples of volume fraction porosity and strut size dependence of porous metal implants’ compressive properties.

3.2. Biological response of porous metal structures

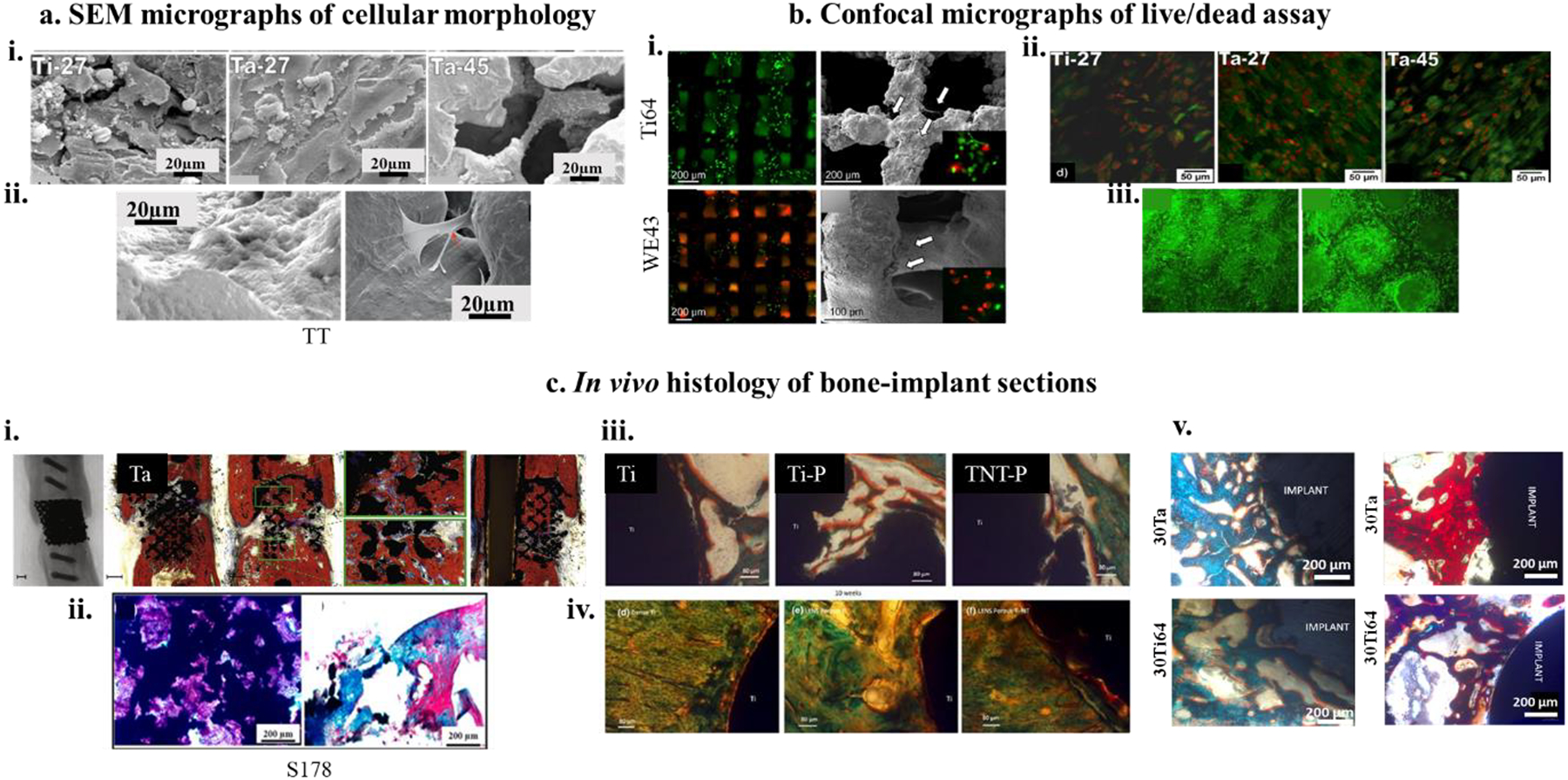

Biological response as a measure of biocompatibility of porous metal structures is based on mainly two types of physiological response, cytocompatibility evaluation in a static in vitro cell culture medium where the cells are directly grown and proliferated on the surface of the implants and biological response from a more dynamic in vivo living animal model. Both these characterization techniques are equally important in determining the biocompatibility of any biomaterial qualitatively and quantitatively. Researchers have studied in vitro response of porous metallic implants in various ways. Cellular growth, proliferation, morphology, and viability depend on the chemistry of the sample’s surface, pore size, morphology, interconnectivity, and pore distribution. However, the literature on in vitro and in vivo cellular response of porous metal implants is primarily divided into evaluations based on volume fraction porosity and pore geometry. 27% volume fraction porosity in Ti and 27% and 45% volume fraction in porosity Ta have been shown to exhibit a considerable growth and adhesion of osteoblasts (OB) implant surface at day 11 of culture (Fig. 5. a. i). Ti surfaces showed more rounded OB morphology and underdeveloped filopodia than Ta at early stages4. However, Ta’s difference in volume fraction porosity did not contribute to cell viability, which was corroborated through focal adhesion measurement using vinculin immunostaining assay (Fig. 5. b. ii and iii). In addition to volume fraction porosity, it is believed that higher surface area due to smaller pores and rough morphology of pores are beneficial for cell growth and better cell attachment favoring bone tissue ingrowth in vitro52,97. However, contradictory results have also been concluded in several studies showing smaller pores (~100μm) lead to favorable chondrocyte attachment to the surface under hypoxic conditions as opposed to direct inset of osteoblastogenesis in larger pores (<300 μm). In contrast, in an in vivo study, a porous Ti plate with pore sizes of 50 to 125 μm implantation in the rabbit femur concluded that bone ingrowth in porous metallic structures is independent of pore size under non-load-bearing conditions. However, this study involved assessing osteonal structures ingrown into the implant’s pores. Osteons are bone structures typically structurally ranging in nanoscale, which can be a potential reason for the unbiased observation of pore size dependency98. The effect of porosity on cell growth’s vitality after a 14-day culture on laser-formed porous Ti6Al4V alloy99 and live/dead cell assay showed that the vital cells had extensively grown throughout the sample with minimal isolated disrupted individuals. The direct laser forming process for the fabrication of porous Ti6Al4V samples did not introduce any undesirable biological properties100–102. Selective laser melting (SLM)-based fabrication of metallic structures showed pore shape and size’s contribution to the proliferation and morphology of human periosteum-derived cells (hPDC)103. The porosities for the study were designed in variations based on geometrical shapes (triangular (T), hexagonal (H), and rectangular (R)) as well as sizes (pores with 500μm and 1000 μm diameters). Overall, the DNA observed on the samples with 500μm pores was higher than that on the 1000μm samples compared to structures with lower porosities based on cell-growth media. Pore shape was a determining factor, with hexagonal pores showing higher cell bridging efficiency than triangular and rectangle-shaped pores based on the surface area. However, studies have refuted the pore shape dependency of cell attachment based on physical phenomena such as surface tension104,105. The surface tension of a curved pore is lower than that of pores with sharp edges, which has been deemed the primary reason for higher cellular affinity. Previously reported in vitro observations on porous Ta structures revealed a similar pore size effect on cell migration and growth4. Furthermore, human adipose-derived stem cells (hADSCs) were found to attach to porous Trabecular Titanium (TT) surface and subsequently proliferated and differentiated to acquire an osteoblast-like phenotype (Fig. 5. b. ii). These cells were further analyzed to produce proteins such as fibronectin, osteocalcin, osteonectin, and decorin, which are unique protein expressions indicating ECM formation. These results suggested the potential implementation of porous TT scaffolds in bone regeneration106,107.

Figure 5. a. Cell-materials interaction as a function of cellular morphology investigation,

i) SEM micrographs of hFOB morphology on DED processed 27% porous Ti and Ta and 45% porous Ta at day 11, showing Ta-27 has the most optimized surface for cell-material interaction with cellular confluence as well as excellent proliferation4 ii) shows highly efficient focal adhesion of human adipose-derived stem cells (hADCs) on trabecular tantalum (TT) surface106. b) Fluorescence assay of dead and living cells on biocompatible metal surfaces. i) (Top left and bottom left) show fluorescence micrographs of Ti64 and Mg alloy (WE43) at 4h after seeding MG-63 osteoblast-like cells as compared to 24h fluorescence images (Top right and bottom right113) ii and iii) ALP protein expression for hFOB cells on 27% porous Ti and Ta and 45% porous Ta has shown through fluorescence micrographs. In contrast to SEM micrographs, Ta-27 did not show strong ALP expression at day 114. c) In vivo bone formation and osseointegration analyses, i) X-ray and histological images of open porous SLM-processed Ta revealing a fair amount of osseous growth for both the porous Ta specimens with almost 100% bridging of the defect85, ii) H&E (left) and Masson-Goldner (right) stained bone sections after 12 weeks of implantation of Ti64 implants with 178 μm pore size showing new bone formation around the porous metal implant,122 iii and iv) Photomicrograph showing the histology images after 4 weeks (top row) and 10 weeks (bottom row) for Ti, porous Ti (Ti-P) and porous Ti with nanotube surface (TNT-P) where signs of osteoid like new bone formation could be seen in orange/red color. Modified Masson Goldner’s trichrome staining method was used143,v) In vivo biological response from tantalum parts fabricated using direct energy deposition (DED) showing early-stage osseointegration at 5 weeks (left column) as a function of designed porosities and extended new bone formation at 12 weeks (right column)37.

A prominent metallic shape memory alloy in clinical practice for over two decades now is nickel-titanium, also known as nitinol (NiTi). NiTi has seen the most prolonged and most extensive history of application in dentistry. However, other clinical applications such as orthopedics, maxillofacial, and cardiovascular have also developed the use of NiTi in recent times108–110. Recent research to explore the field of porous NiTi in the light of in vitro biological response. Evaluation of cellular behavior of fibroblasts L-929 on porous NiTi (pore size – 400μm–900μm) showed healthy cell growth within the pores of the specimens and around the edges111.

The degradation of a porous metallic sample in the biological environment is significant as porosity on the sample increases the total surface area and increases the risks of metal ion leaching. Moreover, the chemistry of the surface oxides and the possible reactions with the physiological fluids significantly impact the porous structure’s applicability as a load-bearing implant. For example, porous magnesium’s in vitro degradation behavior was observed through the tendency to degrade at a controlled rate depending on their porosity with the non-toxic degradation product MgCl2112. However, cell-material interaction between OB and the degradable magnesium surface did not depend on degradation rates; instead, it showed favorable and enhanced cellular activity104,113. Thus, such materials could find an application at sites where a biodegradable implant structure with considerable mechanical strength is beneficial, such as bone defects, bone, and cartilage tissue engineering, substituting materials of lower mechanical strength such as hydroxyapatite (HA), natural polymers such as collagen and chitin, etc.114–116. Porosity plays an essential role by increasing the specimen’s surface area for higher protein adsorption, leading to enhanced corrosion resistance. Porous Mg surfaces can aid increased cell adhesion and proliferation and be a good candidate for biodegradable metallic bone implants. In vitro cytotoxicity assay with MG-63 osteoblast-like cells on porous Mg scaffolds (WE43) and Ti64 exhibited the scaffolds’ initial toxicity compared to Ti64 specimens. On direct contact with untreated Mg surfaces, cell lysis was observed in the first 4h. However, after 48h treatment of immersion in physiological serum, both surfaces showed cellular viability even after 24h of direct contact (Fig. 5. b. i).

In the case of in vivo studies, implants are manufactured and surgically placed into mice, rabbits, cats, dogs, pigs, etc. After a specific time interval, implants are harvested and subjected to histological examinations using different staining methods unique to structures such as osteoid, trabecular bone, collagen, etc. The morphology of new bone formation and interface integration is typically studied using optical or confocal or scanning electron microscopy (SEM), tomography, or radiography to learn about layer-wise bone formation in a 3D plane117–122. In vivo studies help reveal bone tissue development into and around the implants in live subjects, a more accurate evaluation of implant structures’ performance, particularly for longer-term applications. Characterizing the onset and rate of bone-remodeling in vivo can help develop the next generation of implants with higher integrity, mechanical compatibility, and enhanced tissue-material interactions123.

Ti6Al4V implants with a pore size of 178 μm (S178) have shown that the lamellar bone formation also increased with an increase in porosity, characterized by the depth of bone penetration into the implant. Highly porous implants are beneficial for faster healing in vivo; for example, at 4 weeks post-implantation, S178 and S279 specimens exhibited 26.8% and 31.5% bone volume/defect volume, respectively (Fig. 5. c. ii). In vivo bone formation in porous Ti mesh with 70 volume% porosity with three different pore sizes 188, 313, and 390 μm showed a much-pronounced porosity towards bone ingrowth at 12 weeks. Several in vitro studies have investigated the dependency of pore size of bone formation onto and into an implant, concluding that pore sizes ranging between 100–500 μm can aid in in vivo osteoinduction97,124,125. Within this range, pore sizes between 300–400 μm are optimal for osteoblast proliferation, differentiation as well as neo-vascularization within the pores of the implants; 200 μm pores to aid in early osseointegration, and pores >300 μm can aid in oxygen diffusion and nutrient transport that is needed for enhanced vascularization and new bone ingrowth97,126,127. A similar trend was observed with porous Ti implants with pore sizes 300, 600, and 900 μm (P300, P600, and P900 implants)128. With increased porosity in the P600 and P900 specimens, vascularization significantly increased, which led to enhanced bone ingrowth. This was attributed to the positive effect of increased curvature and surface area of larger pores. SLM fabricated porous Ti64 with different strut sizes, 120 μm, and 230 μm, resulting in different volume fraction porosities of 88% and 68% revealing bone growth adjacent to the bony implant proliferation into the pores in general86. The titanium-120 and titanium-230 specimens showed enhanced bone fixation compared to the empty controls, which exhibited reduced bridging of the defects and loss of fixation. In contrast, Bandyopadhyay et al.129 optimized volume porosity in porous Ti6Al4V implants to 23–32% and showed Young’s modulus to vary between 7 and 60GPa. The modulus of the LENS™ processed implants was observed to be close to that of cortical bone. Specimens with 25% porosity exhibited higher calcium content in vivo after 6 weeks of implantation. In addition, 25% porous specimens also revealed the highest bone tissue formation and surface bonding with the implants (Fig. 5. c. iii and iv).

Even though Ta has been used as a biomaterial since the 1940s, its use has been limited and compartmentalized. However, porous tantalum implants have shown better and quicker bone tissue in-growth and higher shear strength for in vivo implantation into distal femurs of dogs for 52 weeks130–136; it was observed that regardless of the pore size, the new bone tissue in growth rates has been consistently high, and it was observed that samples with large pore sizes had more significant initial bone ingrowth with implants of smaller pore sizes showing complete ingrowth. In contrast, in vivo bone ingrowth ability of porous Ta implants fabricated using the SLM technique with 500μm pore size and ~80% porosity137 revealed significant osseous growth for both the porous Ta specimens at 12 -weeks in Wistar rats. A detailed evaluation of individual longitudinal cross-sections showed better bone ingrowth for specimen 2, with almost 100% bridging of the critical-sized defect (Fig. 5. c. i). In vivo efficacy of orthopaedic implants also depends on the implant and host bone tissue’s initial surface reactions. These biochemical interactions depend on the implant’s surface characteristics such as roughness, hydrophilicity, pH dependency, and microstructure138–142.

Any physical alteration of the implant surface based on these factors can largely expedite bone binding to the implant surface. One of these techniques is rendering Ti implants’ surface with a nanoarchitecture in titania nanotubes138,144–146 to overcome the bioinert nature of Ti147. Such nanoarchitectured surfaces, in addition to customized complex porous geometry fabrication, using additive manufacturing cumulatively led to better bone-bonding due to a combinatory effect of biological fixation of bone into the pores and a bioactive fixation at the surface at both 5- and 10-weeks post-implantation (Fig. 5. c. iii and iv)143. A similar synergistic effect of inducing porosity in metallic bone implants combined with nanotubes resulting in enhanced osteoconductivity and improved interfacial mechanical properties for clinical use was reported based on a comparative study between 30% porous Ti64 and Ta implants66 (Fig. 5. c. v).

Overall pore geometry, pore size, and characteristics govern the mechanical and biological properties of orthopedic implants. It cannot be determined if cell-material interactions follow a singular trend or pattern based on pore characteristics. For example, osteoblastic precursor cells require at least 200μm pores for effective bone ingrowth and bonding.52. Cellular growth and cell morphology show characteristic dependence on pore sizes above and below 500 μm with the observed bridging of pores<500 μm and increasing along the strut of 3D printed Ti6Al4V structures > 700 μm99. None of these extensive studies were able to determine the extent of cell growth into the pores. These findings suggest that pore geometry and pore size are critical factors that play a crucial role in the cellular bridging of pores and inward cell migration proving the pivotal function of good scaffold design in additive bone-implant fabrication. While it is crucial to describe the osteoblastic activity, vascularization into the porous structure is another avenue well explored toward determining metals’ biocompatibility in biomedical applications148–151. Vascularization is essential as the porous structure’s depth increases (especially as research moves into AM-based implant design and manufacture). If there is no or limited vasculature, the advancing front of the bone cells could stop and recede. Therefore, this review presents a comprehensive table 5 enlisting a broader classification of porous materials, based on pore characteristics and fabrication methods, commonly employed in porous implant fabrications and their mechanical and biological response in vitro and in vivo for a better comparative understanding.

Table 5.

enlists the mechanical properties and biological response of common metallic orthopedic materials based on pore characteristics and processing.

| Porosity | Materials | Pore Characteristics | Processing & Mechanical properties | Key Findings | Remarks | |

|---|---|---|---|---|---|---|

| In vitro | In vivo | |||||

| MICROPOROSITY | CpTi Intervertebral cage82 |

80% v/v porosity and 300 μm pore diameter | Slurry foaming method Compressive strength=19.4Mpa Young’s Modulus=3.2GPa |

In vivo The direct bone-bonding ability of porous Ti cage with sheep lumbar spine. Circumvents the use of bone grafts |

The sample size was less considering a large animal model. The study period was 4 months, which is insufficient to determine the quality of bone growth and long-term effect |

|

| Ti6Al4V interference screw152 |

15.4% residual porosity | Powder bed direct laser sintering |

In vivo Better bone-tendon-implant integration Higher ultimate failure load |

Long term significance is not presented The study period should include early and late time points for more dynamic understanding. |

||

| CpTi porous scaffolds153 |

70% v/v porosity 500 μm pore size |

Metal laser melting Compressive yield stress ranged between 257MPa-395MPa based on the shape of the unit cell Young’s modulus ranged from 4.5GPa-5.4GPa. |

In vitro Human bone marrow mesenchymal stem cells showed good cytocompatibility on the scaffold surface Cellular differentiation and mineralization were observed after 7 and 21 days, respectively. In vivo Diamond crystal lattice showed better osteogenesis in vivo at 8 weeks Overall porous structure performed better under push-out force than solid scaffolds |

Comprehensive assessment of biomechanical functions of porous scaffolds It can be a bone graft substitute due to different topological designs |

||

| Ti lumbar spine implants154 |

57% porosity 200 μm pore size |

Powder metallurgy route with the space holder Interconnected porosity yield strength~60 MPa maximum strength~170 MPa 30 % of strain up to fracture |

In vitro Apatite formation on porous Ti surfaces In vivo Higher osseointegration with bone formation up to 64% for porous structures |

In vitro is not presented, which could provide important information on cellular morphologies based on pore size. | ||

| 3D printed porous Ti cage83 | Pore size ~600μm | EBM fabrication Young’s modulus ~20 GPa compressive strength ~38 GPa |

In vivo Sheep cervical implantation At 6 months bone contact rate was 58% |

Porous cage structure effectively avoids micromotion in vivo Long-term fusion effects are lacking. |

||

| Ti Templates155 |

Pore size~90 μm Interpore distance~ 200 μm Subsurface porosity~9 μm |

Regenerative amplified Ti: sapphire laser at 800nm 90 μm surface exhibited contact angle of ~88° 9 μm pore surface-displayed~84° Surfaces had high hydrophobicity |

In vitro Human skeletal stem cells were seeded 90 μm pore surfaces showed not only pore bridging but also cells penetrating up to 25 μm depth of the 100 μm conical pores early osteogenic differentiation was also reported |

Early differentiation resulted in interrupted proliferation and migration Long-term in vivo efficacy can be hindered Overall, microporous and micro rough surfaces can be used as peri-implant wound healing |

||

4.0. Influence of electrical charge on the biocompatibility of metals

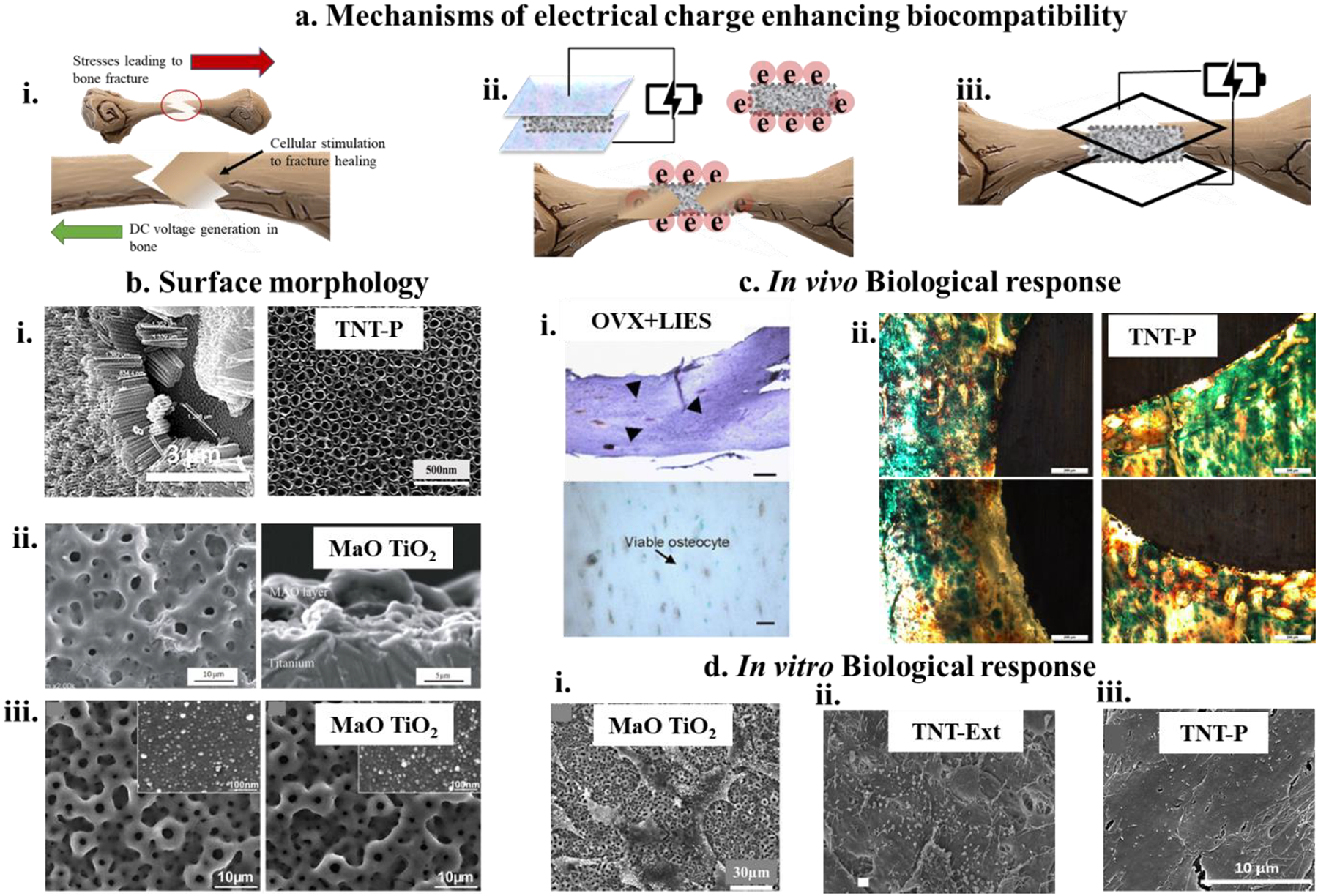

Localized charge distribution at the electrostatic surface of a biomaterial defines biological interactions depending on surface charge polarity. Different surfaces exhibit the variable extent of cellular adsorption depending on individual predisposition towards cell-binding proteins and physiological ions, which lead to discrete cellular response and bone bonding. The biomedical device’s surface polarity often works with human bone’s innate biological direct current (DC) potential. Development of bone bio-potential can be either mechanistically driven under stress from a mechanical load or strain-related potential.

4.1. Biological potential of natural bone

Natural bone’s biological potential, also known as bio-potential, is an endogenous electrical potential in tissue structures that moderate cells’ normal growth and cellular structures156,157. Endogenous electrical potentials are classified into two categories: Strain-related potentials (SRP) and bio-potential (BP). SRPs stem from the piezoelectric properties of specific osseous structures such as collagen, which result in ion migration between tissues through the characteristic porosities of cancellous bone. On the other hand, BP results from the continuous remodeling of osseous structures vis-à-vis potential that develops across newly formed membranes in osteoid tissues, extracellular matrix formation, and osteoclast resorption leading to ionization release158,159. As mentioned above, these electrical signals work in tandem toward natural bone’s physical development but can be interrupted due to trauma or injury. Significant modifications of endogenous potentials have been observed under extraneous injury, where injury potential takes over the injured tissue’s normal bio-potential. There is often a spike in DC potential in such conditions, which lasts longer than usual until the wound is healed. DC potential in natural bone results from ion migration between the injured tissue and the intact surrounding tissue, which results in the current generation spanning over hundreds of microns. Voltage differences of 10–100 mV/cm have been measured in injured soft tissues, spanning hundreds of microns160–162. Studies have shown how injury potentials can differ based on the specific injury’s characteristics leaning towards a selective healing process based on either SRP or BP or a parallel functioning. Zhao et al. studied the activation of specific cell signaling pathways, such as the Src pathway associated with epithelial cell migration, and determining wound healing in a rat cornea163. They have also found that specific mechanistic cues such as nanoarchitecture surfaces and external electric fields164 can drive epithelial cell growth in bovine eyes by activating biological pathways. This is a befitting example of how SRP and BP can initiate unique wound healing mechanisms and work together, leading to a synergistic outcome.

More elaborately, it is possible to determine the exact characteristics or driving characteristics of the endogenous electrical potential for both SRPs and BPs. As discussed earlier, bone remodeling mainly depends on mechanical forces, generally the outcomes of extraneous stress or mechanical load165,166. It has been observed that bone tissue under stress is inclined to grow and multiply, whereas its absence leads to untimely resorption167. Due to trauma and injury, the stress applied to bone tissue has been characterized as negative polarity, leading to bone growth. In contrast, the bone under resorption has been evaluated to have an overall positive polarity. On a cellular level, bone tissue fronts with a high level of osteoblast activity and proliferation show negative polarization, while osteoclast resorption fronts have been observed to have an overall positive polarization170. Therefore, when it comes to electrical stimulation for bone growth, a natural biological feedback mechanism comes into play168,169. Of note, owing to similar chemical properties like bone, calcium phosphates have been researched for their piezoelectric properties171–173. This is particularly beneficial in hydroxyapatite-coated metallic implants under stress conditions that influence the charge toward bone-building cellular response. Additionally, external charge storage in hydroxyapatite has been explored in a similar context174–176.

4.2. Surface charge storage and corrosion potential

Over the years, several significant types of research have been driven by the influence of electrical stimulation on bone growth. Studies evaluating the electrical potential applied to repair bone trauma or stimulating selective cell differentiation pathways have proven successful177–180. Some studies have reported enhancing bone morphogenetic proteins (BMP-2,4,5,6) and higher calcium deposition in the extracellular matrix on the application of electrical stimuli177,178,181,182. These studies were based on the knowledge of induced polarities at specific locations in the bone due to trauma/ injury (as discussed earlier). Even though an overall constructive outcome has been suggested in several studies in terms of faster healing or accelerated osseointegration, there is still a significant knowledge gap in the evidential understanding of molecular pathways that play a role under electrical stimuli. However, recently, there have been several attempts to enhance the biological response of osseous tissue by storing electrical charge on the surface of metallic implants either through surface modification followed by electrical polarization or through corrosion of the implant in surface potential. Of course, there is also the possibility to apply an electrical voltage at the implant surface. In fact, there are commercially available implants to assist with bone fusion that make use of electrical stimuli183.

Development oxide surfaces on Ti implants have been extensively shown to reduce water contact angles and enhance surface hydrophilicity. However, recent research on polarizing these oxide layers has successfully stored negative charge on the surface through space-charge polarization. Yamazaki et al. have shown that electrical polarization of micro-arc oxidized Ti surfaces can store negative charges (~ 2.7μC/cm2) through ion migration of oxygen vacancies, which significantly reduces de-ionized water contact angles surface more hydrophilic for favorable biological response184. The dielectric properties of TiO2 at room temperature are 63.72, which is close to that of water (i.e., 80), giving Ti an added advantage from the perspective of cell-material interaction, meaning other than a physiological solution that interacts with the metallic implant, it is proteins that interface with the implant. Protein conformation on the implant’s surface determines the signal to cells and cellular interaction. Furthermore, these surfaces were tested against osteoblast-like MG63 cells, which enhanced cellular attachment, growth, and proliferation on the negatively polarized surfaces185. More recently, Bandyopadhyay et al. reported charge storage in nanotube-modified titanium oxide surfaces by novel bridging of nanostructures’ enhanced efficiency in storing capacitive charge with the higher surface to volume ratio imparted by nanotubes on the surface186. They have reported a negative surface charge of ~ 37mC/cm2, which was a magnitude higher than other values reported in the literature and attributed to the nanostructured surfaces’ effect. These nanotubes modified Ti implants were evaluated in vivo in a rat distal femur model and exhibited a 92% increase in newly formed bone area compared to the control commercially pure Ti surfaces.

Metallic devices for bone applications exposed to ion-rich electrolytes in the physiological system establish a fundamental reaction cell. During electrochemical responses, the progression of ions and electrons can prompt heavy potentials between the metallic electrode and the electrolyte. These currents are commonly used to quantify the reaction pace since they are directly identified with the metal leaching. Thus, small pits form on the surface due to corrosion reactions can affect its mechanical stability, reducing the device’s longevity and causing unexpected failure187–189.

4.3. External electrical stimulation

External electrical stimulation in bone repair is one of the popular treatment methods involving cell growth using external factors because of some non-invasive application methods. However, there is not much literature on these treatment methods since these are not specific to a localized physiological site. Three primary ways of external electrical stimulation for bone repair include applying DC, alternative current (AC) generated capacitive stimuli, and electromagnetically induced electrical field. DC stimulation is one of the exceptions in such therapies since this is an invasive approach. The cells are subjected to DC/faradic stimulation to enhance and accelerate growth directly on the implant’s surface or applied to the cell growth media. Usually, a maximum DC field of 50μA/cm2 is applied, positively affecting the cell-material interaction and enhancing cell proliferation190. Cellular differentiation through an expression of markers specific to osteoblast differentiation has also been reported in the literature due to DC stimulation178. However, most studies have applied the stimuli to the cell culture media instead of directly to the implanted metal device. This establishes a fixed current flow between the applied cathode and the anode, which aids in cell growth in vitro191. Despite the efficacy of such electrical stimulation, the electrode products that get generated due to electrochemical currents have been seen to have enhanced and adverse effects on cell response.

In contrast, capacitive stimulation involves the application of alternating current in a noninvasive over-the-skin approach. These cases mostly use a voltage-frequency combination of a maximum 50V at 60–200,000 Hz, which generates an adequate field strength of 0.1–5 V/m192,193. The capacitive stimulation is primarily applied externally to the body with plates placed at the implantation site externally. However, some studies have reported direct media contact of these electrodes without touching the implant in vitro. This therapy approach has shown effective results both in vitro and in vivo179,181,194,195. However, a significant concern in the capacitive stimulation approach towards bone healing is patient compliance regarding topical irritation due to high voltage and frequency. Additionally, since this approach is non-invasive, specific measurements at the surgery site, such as local current density, cannot be quantified, affecting biological response prediction. Another similar non-invasive therapeutic approach is inductive stimulation, which involves generating an electric field using electromagnets, which have been shown to influence cellular response and expression of genetic markers190. Studies involving osteoblast-like MG63 cells as well as mesenchymal stem cells (MSCs) have reported upregulation of specific osteoinductuve markers such as BMP-2, TGF-β1, osteocalcin as well as collagen synthesis and early onset of osteoblast maturation and differentiation under the influence of the electromagnetic field. However, similar to the capacitive approach, the application of inductive current is a non-specific external therapy that can adversely affect tissues in the surrounding area of the injury site.

5.0. Influence of materials chemistry on the biocompatibility of metals

The chemistry of a material is an essential factor in deciding its biocompatibility. Material chemistry signifies the properties of the metals that influence their interaction with their surroundings. These can range from multiple metals’ influence in an alloy to chemical interactions on a molecular level to some metals’ inherent tendencies to oxidize197.

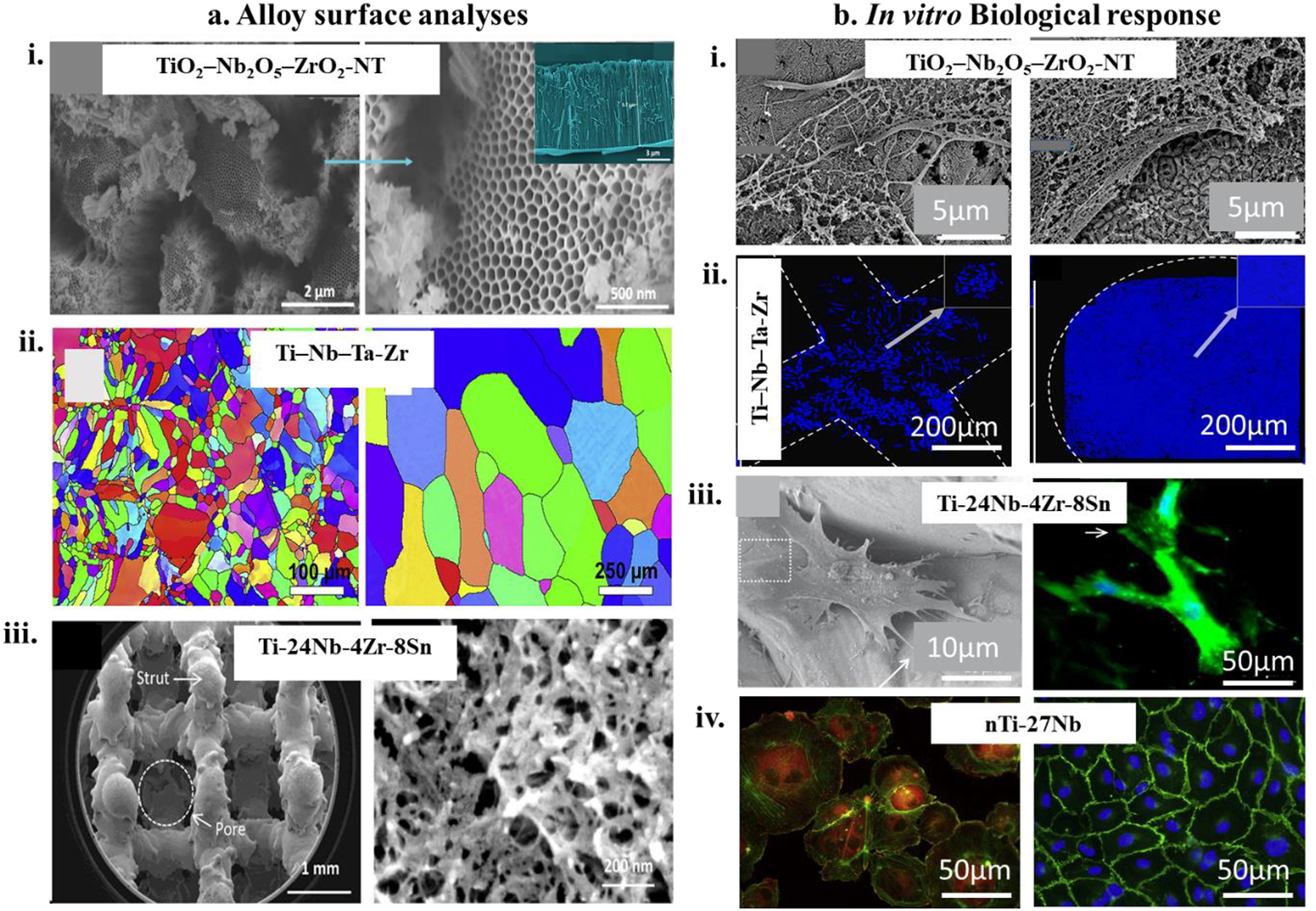

5.1. β-Titanium alloys

As discussed earlier, untreated Ti surfaces are bioinert, meaning that these surfaces in a metallic orthopedic implant are inherently incapable of eliciting any kind of biological response from the host tissue. Therefore, surface modification techniques enhance the implants’ surface bioactivity, which leads to faster bioactive bone fixation. However, these metallic implants’ drawbacks have a large difference in elastic modulus compared to the bone, making them even mechanically unsuitable for orthopedic application. One way of circumventing said drawback is by fabricating phase alloys of the parent metal by introducing phase stabilizing components. For example, Ti metal has two distinct phases α and β, while CpTi is predominantly α-phase Ti, Ti6Al4V on the other hand, has vanadium as a β-phase stabilizer, which makes it a α+β type alloy. The simple introduction of vanadium in Ti enhances mechanical properties such as fatigue resistance, strength, etc. These α+β types of alloys exhibited higher strength and better corrosion properties than α alloys for long-term applications. However, vanadium and aluminum’s introduction was questionable because of their inherent toxicity from free ion leaching to the human body. Aluminum in excessive quantities and continuous exposure have been reported to cause Alzheimer’s disease. Therefore, other α+β alloys emerged in the research community, such as Ti-6Al-7Nb, which exhibited an elastic modulus of 110GPa not significantly different from Ti6Al4V (modulus ~ 112GPa)198,199. There remained a vast difference between the modulus of these metals and human cortical bone (~30GPa). At this point β type Ti alloys were developed and introduced in the orthopedic and dental application field. These alloys had a significant advantage over the dual-phase alloys because the β phase stabilizers that were used in the alloy system, such as molybdenum (Mo), tantalum (Ta), and Zirconium (Zr), were not only non-toxic to the human body but also exhibited lower elastic modulus thereby improving mechanical biocompatibility with bone200,201. For example, the elastic modulus of Ti–24Nb–4Zr–8Sn (46–55 GPa)202is notably lower than that of other Ti alloys, which allows for β-type alloys to have a considerably important position in the biomedical industry. Over the years, various other fabrication routes were implemented for β-type Ti alloys like Ti–15Mo203–206, Ti–Nb–Ta21,207, Ti–24Nb–4Zr–8Sn22,208,209, Ti–35Nb–2Ta–3Zr19,20,210,211, Ti–35Nb–5Ta–7Zr212,213, Ti–30Nb–4Sn214,215, Ti–35Nb216–218, Ti–15Nb–3Mo–3Zr–2Sn219,220, and so on. Therefore, many investigations of processing β-type Ti alloys have focused on improving their properties and tailoring their microstructures. The most recent improvement in the fabrication of β-type Ti alloys has been coupled with designing porous implants to reduce the distinction in elastic modulus and derive better biocompatibility. So far, various fabrication methods for porous materials have been implemented, such as sintering, investment casting, and rapid prototyping221,222. However, two major strategies are often used in porous β-type Ti alloy implant fabrication - powder metallurgy (PM) and additive manufacturing (AM). For porous implants, the PM process requires careful management of pores’ dimension and morphology, influencing biological fixation, osseointegration, and fatigue223,224. In current years, porous Ti alloys are designed by using PM for biomedical applications. Among various PM routes, spark plasma sintering and the space holder approach are generally used for producing porous Ti and Ti alloys. AM techniques have many advantages, including a short manufacturing cycle, easy machining, and better inventory utilization225. On the other hand, AM aids in preparing components with complicated geometry quickly and accurately, which is way more efficient than the ordinary subtractive manufacturing method226,227. Through years of evaluation and study, AM has been determined to produce Ti and Ti alloy implants using laser or electron beam to melt metal powders based on a computer-aided design (CAD). Recently, AM-fabricated porous Ti alloy structures attracted attention; selective laser melting (SLM) and electron beam melting (EBM) are proven to be efficient in producing high-efficiency metal parts228. Usually, α + β-type Ti alloys have toxic adverse effects leading to the development of β-type Ti alloys and their corresponding biocompatibility investigation. For example, comparison of biocompatibility between Ti–26Nb and Ni–49.2Ti, showed that Ti–26Nb is less cytotoxic229. Additionally, Ti–19Zr–10Nb–1Fe alloy has comparable cytocompatibility with the Ni–Ti alloy however higher hemocompatibility230. The enhanced biocompatibility of β-type alloys is due to the absence of toxic alloying elements. Current investigations on biocompatibility of β-type Ti alloys are still nascent.

In contrast, due to Ti alloys’ biological inertness, fibrous tissue can form around the implant198. Such a defensive reaction is inevitable for all sorts of bioinert β-type Ti alloys, which are non-toxic, safe, but no longer bioactive. Although β-type Ti alloys are free of toxic alloying elements, enhancing osseointegration is regarded as essential. Generally, surface modification to enhance the bioactivity of Ti alloys is employed, such as alkali coating remedies on Ti–29Nb–13Ta–4.6Zr with the aid of electrochemical, hydrothermal, or blended processes for specific times, and the outcomes have been considered to exhibit regardless of the techniques or parameters, the surface of Ti–29Nb–13Ta–4.6Zr is favorable for mesh-like apatite formation231. Also, sol-gel synthesized calcium phosphate/TiO2 coatings on Ti‒29Nb‒13Ta‒4.6Zr exhibited substantial bioactivity enhancement because calcium phosphate and TiO2 are notably bioactive to bone cells232. Besides inorganic coatings, natural coatings (or layers) have received sizeable attention. Recently, immobilized extracellular matrix (ECM) proteins on CpTi and Ti–6Al–4V showed more significant bioactivity for human mesenchymal cells with similar consequences observed in different coatings233,234. Unfortunately, there is not enough literature about the natural coatings on β-type Ti alloys. However, due to the massive success of natural coatings on other types of Ti alloys, β-type Ti alloys with bioactive coatings are expected to be a future for biomedical Ti alloys.

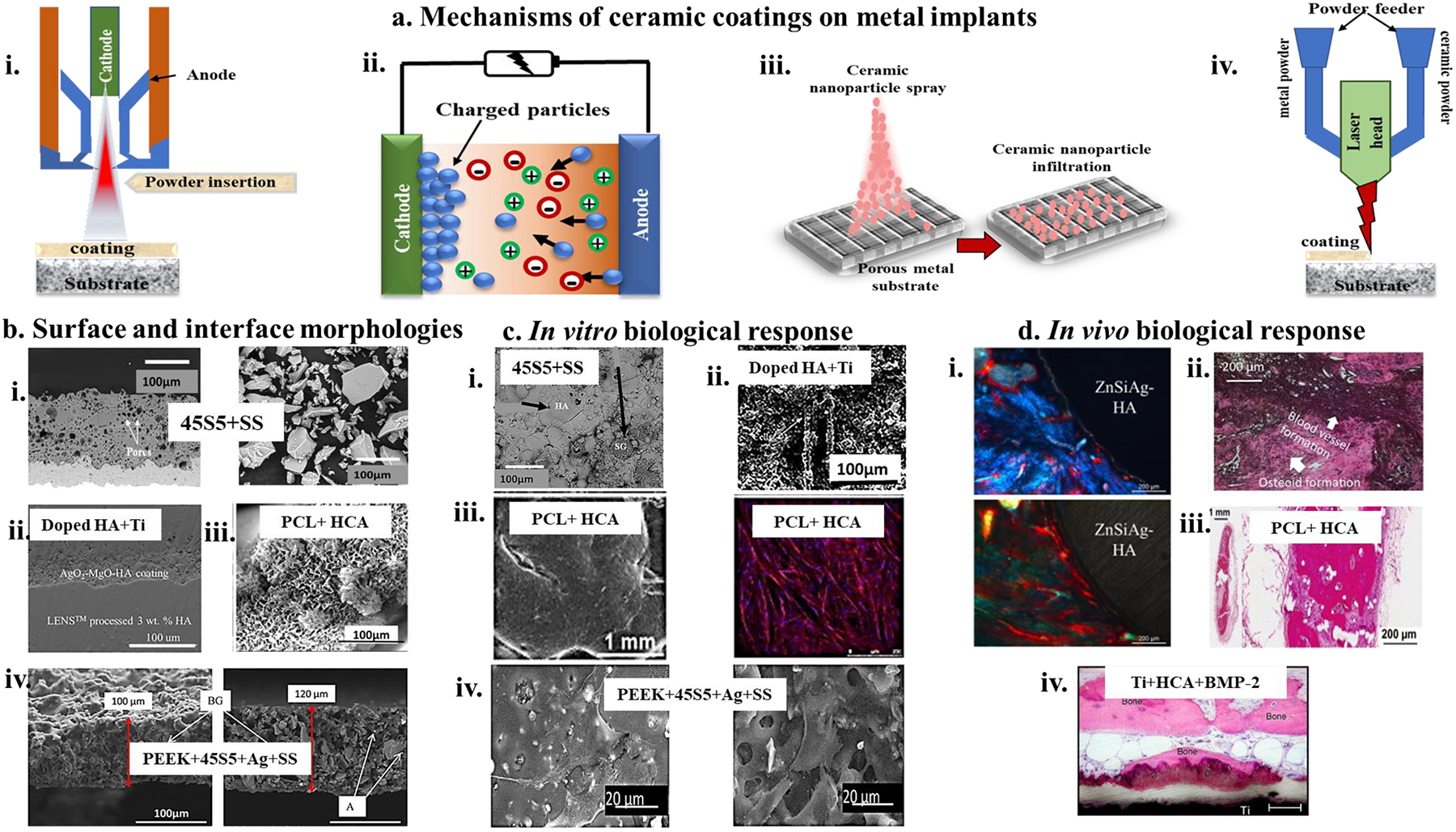

5.2. Tantalum, Tantalum oxide coatings, and Tantalum alloys

Alloys of metals such as tantalum (Ta) can provide better biocompatibility because of Ta chemistry and its inherent tendency to form an oxide layer on the surface. However, studies show that Ta alone does not contribute to any biological response from the body238. In that case, the biocompatibility of Ta is exclusively attributed to its non-cytotoxicity in a physiological environment238. Historically Ta has found its use in secondary medical applications, majorly as an FDA’s class II biomedical device, as mentioned in Table 2. Since then, Ta has been extensively used as a metal coating on metallic devices such as Ti implants and carbon composites36,239,240. Since Ti implants and ceramic coated metal implants are routinely applied in the orthopaedic industry, these form a standard for comparison for any new material that can be potentially introduced into the industry. Therefore, comparing Ta coatings with Ti substrate and hydroxyapatite (HA) coated Ti implants can provide a realistic picture of Ta’s applicability in FDA’s class III medical devices. It has been shown that Ta coatings on Ti implants exhibit 6 times higher osteoblast (OB) response than just Ti surfaces evaluated through living cell density using MTT assays36. The higher cell response is attributed to the increased surface energy due to coating Ta on Ti implant surfaces, making the surface more hydrophilic and favorable for cellular interactions. Additionally,36Balla et al. have also compared the biocompatibility of the same Ta-coated structures fabricated using laser-based additive manufacturing methods with hydroxyapatite (HA) coated Ti surfaces through radio frequency plasma spray coating. While Ta coatings exhibited a 6-fold increase in live OB density than the Ti substrate, OB density was comparable for Ta coatings with HA-coated Ti surfaces. This was further corroborated through confocal microscopy through fluorescence intensity observation for vinculin expression, indicating the Ta coated surfaces’ better biocompatibility than the industry standards. Several studies have evaluated Ta coatings’ biocompatibility from a corrosion resistance perspective. Zhou et al.241 fabricated Ta coated nitinol (NiTi) substrates using plasma immersion ion implantation followed by magnetron deposition (PIIID) technique to form an optimized 3.3micron coating of Ta. Auger electron spectroscopy results showed excellent bonding strength of the Ta coating on NiTi surfaces through the formation of intermetallics. This was concluded to contribute to the enhanced corrosion resistance of the coated substrates. Furthermore, electrochemical analysis through potentiodynamic polarization exhibited a higher passive anodic current, which substantiates their finding of the Ta coatings’ enhanced corrosion resistance. Other studies have examined the corrosion resistance properties of tantalum oxide layers (Ta-O) formed over magnesium and Ti6Al4V substrates. Jin et al.242 observed that a 4.8micron thick layer of Ta-O showed an active anodic current, which was ~500 times smaller than an untreated surface. Moreover, magnesium corrosion products from ZK60 alloys in untreated surfaces in vitro hindered cell proliferation compared to Ta-coated surfaces. They have also concluded that Ta coating moderate pH imbalances in the substrate’s immediate surroundings mainly result from magnesium leaching. Ta-O coatings were also examined by Rahmati et al.243 on Ti6Al4V substrates. The coating was formed using plasma vapor deposition at 100°C to achieve the highest adhesion strength, which was also observed to have increased the surface by 88.5% compared to the same group’s high adhesion strength after thermal treatment at 500°C244. However, both studies concluded that higher adhesion strength and high coating hardness make Ta-O coatings better suited for biomedical implant applications.

Table 2.

enlists the primary metals that are used in the biomedical and orthopaedic industry at present.

| Metallic materials | Application areas | Advantages | Disadvantages | |

|---|---|---|---|---|

| SS 316L 30 | Martensitic | Bone curettes, hemostats, orthodontic pliers, scalpels, root elevators, dental burs | Good short-term corrosion resistance. Low cost of fabrication Easily machinable |

Can corrode in long term application Stress shielding due to high modulus Ni and Cr toxicity leading to allergic reactions and inflammations |

| Ferritic | Solid instrument handles, pins, and fasteners | |||

| Austenitic | Hypodermic needles, sterilizing units, thoracic retractors, canulae | |||

| Duplex | Not used in the biomedical field yet | |||

| CpTi 31 | Mostly non-load bearing applications for their corrosion resistance: Pace-makers Ventricular assist devices Dental implants Maxillofacial and craniofacial implants Screws for spinal applications |

Excellent corrosion resistance for their spontaneous oxide layer formation Excellent biocompatibility Easy to weld and machine Relatively low Young’s modulus |

Heat strengthening is difficult Low strength at ambient temperature Low shear strength |

|

| Ti64 and Ti64-ELI 31 | Total hip arthroplasty (THA) and Total Knee Arthroplasty (TKA) Femoral stems Fracture fixation devices (plates and screws) |

Load bearing application It can be strengthened by heat treatment Relatively low Young’s modulus |

Lower biocompatibility than CpTi Lower corrosion resistance than CpTi. Low wear resistance |

|

| Cobalt-chrome alloys 30,32 | Permanent implants Femoral heads |

Higher long-term corrosion resistance Higher fatigue resistance Higher wear resistance Better castability |

Expensive processing due to machining difficulties High modulus leading to stress shielding Ni and Cr toxicity |

|

| Magnesium alloys 33–35 | Cardiovascular stents, Resorbable implants |

Modulus close to human bone ~40GPa Naturally occurring element in the human body Similar resorption kinetics with the healing period Similar tensile strength as human bone. |

Resorbable metal unfit for load-bearing applications Soft and malleable |

|

| Tantalum 4,18,36,37 | Suturing wires for tendons38 Clips for ligation of anastomase39 Staples for abdominal surgery40 Reconstructive craniofacial surgery41 Coating other metals36 |

Excellent corrosion resistance Excellent biocompatibility |

Comparatively heavier metal Soft and ductile metal Evidence of local sarcomas and toxicity to alveolar cells42,43 |

|

Based on its exceptional biocompatibility, there has been a surge of interest in fabricating standalone orthopaedic implants from Ta. However, the intrinsic material properties of Ta pose a hindrance to successful fabrication. Ta is a dense metal (densitŷ 16 g/cc, compared to titanium ~4.2 g/cc and Stellite (CoCr alloy)~ 8.6 g/cc) that is soft and ductile; therefore, a bulk implant fashioned out of Ta might not withstand the patient’s regular activities. It has a very high melting temperature of 3200K, which is nearly impossible to reach in conventional furnaces; therefore, there is a lack of effective processing/fabrication methods. In addition to processing difficulties, there is a price point drawback. Ta is almost 10 times more expensive than an equivalent weight of Ti. Recently, Bandyopadhyay et al.37 fabricated porous Ta implants using Laser Engineered Net Shaping (LENS™), an additive manufacturing method with high-energy laser beams to melt the fine metal powders to form local melt pools and, in turn, form 3D structures layer-wise. Their findings suggested the feasibility of processing pure Ta structures under similar processing parameters as pure Ti. Not only do their results suggest novel, easier processability of Ta structures, but in vivo results also showed exceptional biological performance of Ta over an extended period in terms of osteoid tissue formation around the implant. More recently, Ta has been alloyed with other metals such as Ti and Mo to reduce processing difficulties and modulate mechanical properties to make it better suited for commercial applications16,18,245,246. Such alloying helps elicit an amalgamation of properties that coherently work towards improving metal alloy implants’ biocompatibility.245Zhou et al. compared the mechanical and biological properties of Ti-Ta alloys with that of pure Ti and found that Ta can simultaneously enhance strength and reduce the elastic modulus of Ti alloys. Ta not only provides better corrosion resistance to Ti, which improves its biocompatibility. However, in terms of cellular interaction, Ti-Ta alloys perform comparably to pure Ti. Ta’s contribution towards reducing elastic modulus and increasing strength is based on the weight% of Ta present in the alloy. Interestingly, ZimmerBiomet has Trabecular Metal implants that essentially vapor deposition of Tantalum on carbon scaffold. Such implants have been in clinical use for over 20 years with great clinical success. Table 5 details Ti-Ta alloy processing, material characteristics, and key findings on the biological response.

5.3. Nickel-Titanium (NiTi) alloys

The NiTi alloys classify as shape memory alloys due to their ability to return to their predefined dimensions after elastic deformation under specific external stimuli. The alteration in these alloy systems’ shape/dimension is often reversible and has been termed pseudoelasticity. The shape-memory effect in NiTi alloys was first discovered by Buehler et al. circa 1960. Among other metal alloy systems in the same classification, it was observed that NiTi systems show the best performance as shape-memory alloys due to their superelasticity, stable fatigue performance, and good corrosion resistance. These overall workable qualities make NiTi a desirable candidate in the biomedical performance of shape-memory alloys257. NiTi alloys showed excellent corrosion resistance to brine, which expedited their application in the biomedical field, from orthopaedic clinical trials in the ‘80s to large-scale commercial vascular stent application258,259. Corrosion resistance is one of NiTi alloys’ biocompatibility primary yardsticks since these implants are subjected to various physiological environments. Moreover, these alloys’ shape memory properties depend on temperature, which can accelerate corrosion behavior in metals. Therefore, the analysis of NiTi alloys’ corrosion resistance in different testing conditions provides an extensive understanding of these alloys’ applicability. NiTi alloys were found to have better corrosion resistance than Co-Cr-Mo and SS316L alloys when exposed to Hank’s solution and a 0.9% NaCl solution 37°C260–262. However, NiTi alloys were less corrosion-resistant than Ti when subjected to 0.9% NaCl solution at 37°C263. The corrosion behavior in most of these alloys depends on forming spontaneous oxide films on the surface when exposed to an oxidative environment such as a highly ionic solution. These oxide films on Ti, SS316L and NiTi alloys prevent ions from interacting with the metal implant surface, reducing metal leaching. However, the capacity to form an unreactive passive oxide layer on the surface is completely dependent on the makeup of the material and its chemical compositions. For example, it was found that NiTi releases a higher amount of toxic Ni ions in simulated body fluid (SBF) compared to SS316L (austenitic). Similarly, the passivated film properties formed on NiTi surfaces were inferior to those on Ti6Al4V surfaces264. In addition to corrosion resistance in acellular in vitro conditions, evaluating these properties under in vivo dynamic conditions is essential. Studies in large animal models show that NiTi plates did not result in localized corrosion and systemic organ accumulation of Ni ions when tested in dogs for 17 months265. However, some corrosion was observed in a sheep model study where iliac artery stents were placed in the sheep for more than a year. In this case, the corrosion product was analyzed as an oxide of Ti, which is deemed toxic compared to Ni ions. Moreover, this also served as indirect proof of spontaneous surface passivation in an in vivo physiological environment266.

Studying the corrosion resistance of metal alloys is critical to better understand their influence on cell-material interactions. Therefore, evaluating NiTi alloys’ cellular performance in vitro is necessary to understand their biocompatibility. Although minimal literature on NiTi alloys’ cell-material interaction elicits a response from a wide range of human-derived cells, some reported results are exciting and essential. Human fetal lung fibroblasts responded positively to NiTi alloys compared to SS316L or Co-Cr alloys; however, cell growth was significantly reduced267. On the other hand, L-929 fibroblasts showed cytotoxicity for NiTi and Co-Cr alloys more than SS316L268. It was observed that human peripheral blood lymphocytes showed no cytotoxicity or genotoxic activity when exposed to NiTi alloys, strongly supporting its candidacy as a biologically safe implant material109,269. In orthopaedic implant applications where NiTi alloys were directly in contact with bone cells, it was concluded that this implant material was well tolerated by osteosarcoma ROS-17 cells, osteoblasts, and osteoblast-like MG63 cells with or without surface modifications such as plasma-treatment, oxidation, or nanoscale surface modifications270–274.

The worldwide application of NiTi in practical orthopaedic implantation has been hindered because of a lack of knowledge of the material’s biocompatibility. However, based on the published studies, it can be concluded that NiTi is biocompatible in vitro and in vivo, with special cases such as vascular stents requiring surface modification for long-term applications. The FDA recently approved a biomedical device for bone anchoring, which has a part fashioned out of NiTi, which remains to follow. As the research community advances new alloy formulations, it is imperative to understand that corrosion and ion leaching risks can manifest many years after implantation. Orthopedic device manufacturers would be hesitant to adopt alloys that could show ion release much later as many thousands of patients in the interim would have been implanted with such questionable alloys.

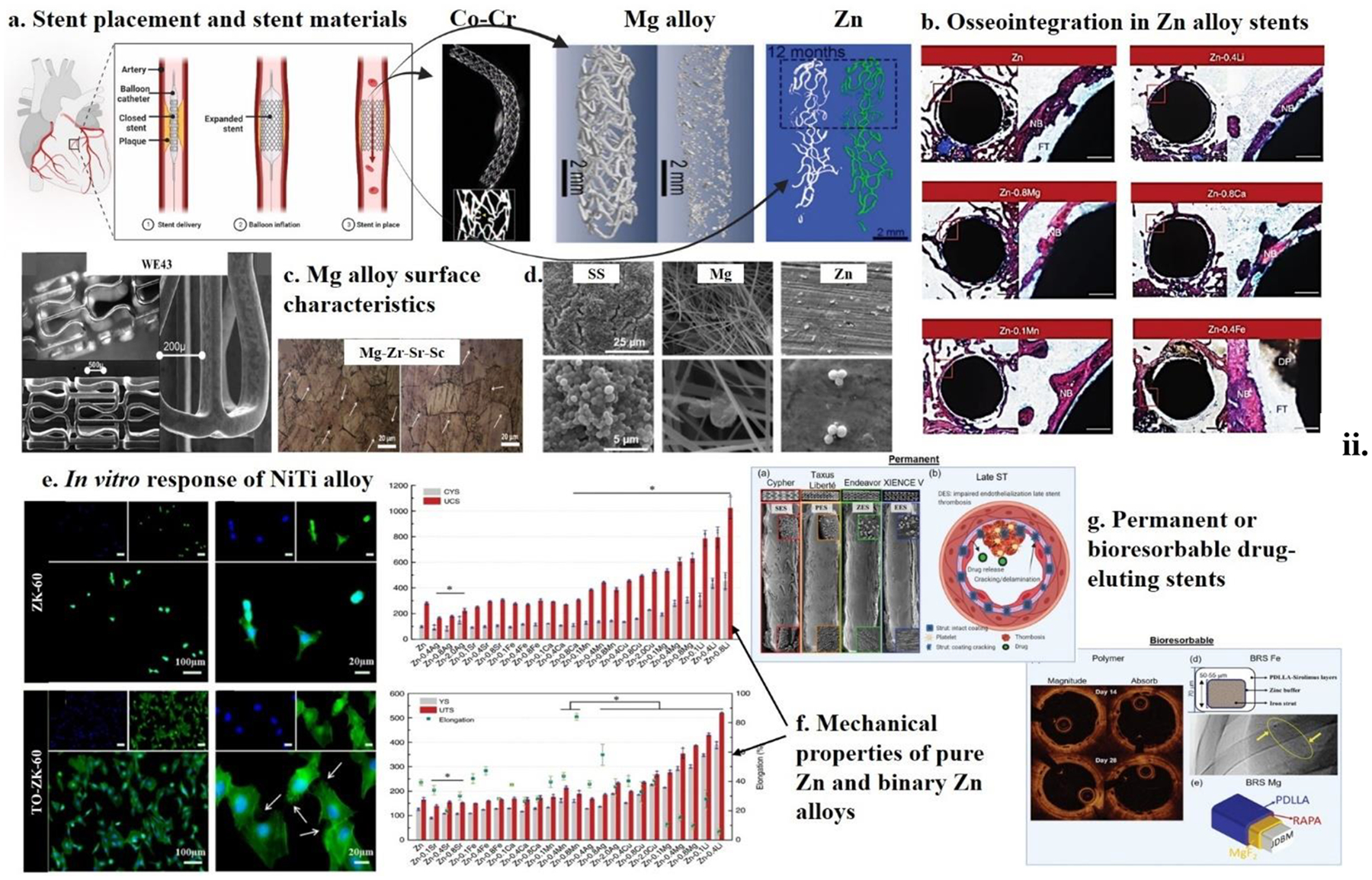

5.4. Metal and alloys in cardiovascular applications