Abstract

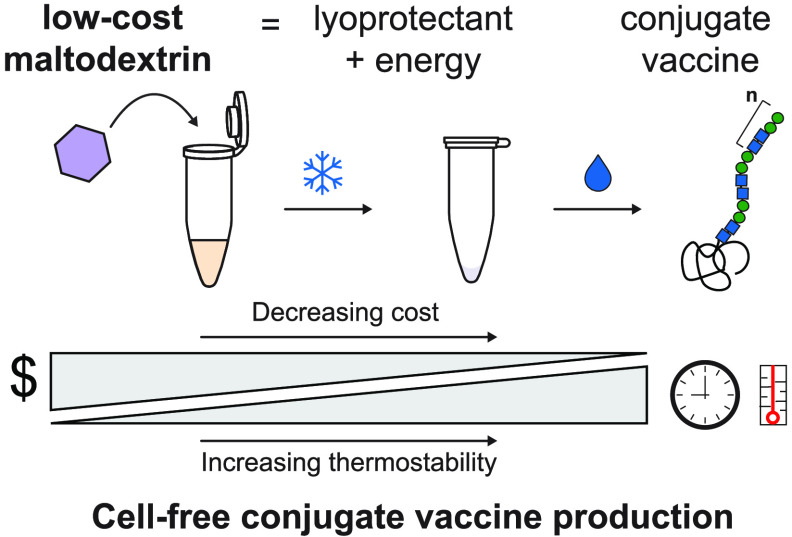

Cell-free protein synthesis systems that can be lyophilized for long-term, non-refrigerated storage and transportation have the potential to enable decentralized biomanufacturing. However, increased thermostability and decreased reaction cost are necessary for further technology adoption. Here, we identify maltodextrin as an additive to cell-free reactions that can act as both a lyoprotectant to increase thermostability and a low-cost energy substrate. As a model, we apply optimized formulations to produce conjugate vaccines for ∼$0.50 per dose after storage at room temperature (∼22 °C) or 37 °C for up to 4 weeks, and ∼$1.00 per dose after storage at 50 °C for up to 4 weeks, with costs based on raw materials purchased at the laboratory scale. We show that these conjugate vaccines generate bactericidal antibodies against enterotoxigenic Escherichia coli (ETEC) O78 O-polysaccharide, a pathogen responsible for diarrheal disease, in immunized mice. We anticipate that our low-cost, thermostable cell-free glycoprotein synthesis system will enable new models of medicine biosynthesis and distribution that bypass cold-chain requirements.

Keywords: cell-free protein synthesis, glycosylation, conjugate vaccine, lyophilization, lyoprotectant, decentralized biomanufacturing

Introduction

Synthetic biology promises to transform planet and societal health by producing energy, materials, fuels, foods, medicines, and more.1−3 Unfortunately, current state-of-the-art biomanufacturing practices require expensive, centralized facilities to grow cells used to make bioproducts, tend to be inflexible because of the cost of customization, and can require cold-chain for distribution (e.g., mRNA vaccines).4,5

Cell-free gene expression (CFE) systems have recently matured as an approach to address these limitations.6−14 The foundational principle is that biological processes (e.g., protein biosynthesis, metabolism) can be conducted outside of living cells in crude cell-free lysates.15,16 Key features of CFE systems include that they are (i) distributable through freeze drying,17 which allows simple distribution before rehydration at the point of use,12,13,18−24 (ii) scalable from 1 nL to 100 L,25,26 which accelerates process development, and (iii) do not require unique production cell lines for each product, which facilitates rapid customization and product switching.10,12 Taken together, these features have the potential to advance new paradigms in decentralized manufacturing. For example, lyophilized cell-free systems have already been used to manufacture a variety of products in a manner suitable for portable biomanufacturing (e.g., conjugate vaccines,13 erythropoietin,10 and granulocyte-macrophage colony-stimulating factor11).

While recent breakthroughs in freeze-dried CFE systems have set the stage for creating a disruptive, distributed protein biosynthesis technology, adoption of CFE systems remains limited by cost and thermostability. For example, we recently developed a modular, in vitro conjugate vaccine expression (iVAX) platform that can be freeze-dried and rehydrated for decentralized production of conjugate vaccines.13 However, lyophilized iVAX reactions cost on the order of ∼$5.00 per reaction in raw materials and are not stable at elevated temperatures, making them infeasible for distribution and use in resource-limited settings. The Meningitis Vaccine Project recently benchmarked parameters for conjugate vaccine distribution in remote settings with the WHO approval of the MenAfriVac vaccine for controlled temperature chain storage for 4 days at up to 40 °C with a cost of <$0.50 per dose.27,28 Adjusting CFE reaction formulations could address these challenges in our cell-free conjugate vaccine production platform. However, to date, CFE optimizations have typically sought to address either cost29−32 or thermostability33−35 rather than considering both formulation properties together.

In this work, we set out to address both the cost and stability of CFE reactions together, to identify a low-cost and thermostable formulation for decentralized manufacturing. As a model, we selected the production of conjugate vaccines, which are among the most effective methods for preventing bacterial infections that are predicted to threaten up to 10 million lives by 2050.36−40 First, we screened sugar additives that could potentially serve as both lyoprotectants and energy systems. We identified maltodextrin as the best lyoprotectant. We then optimized the formulation to also use maltodextrin as a low-cost energy substrate, reducing the reaction cost ∼4-fold and providing thermostability of lyophilized reactions after 4 weeks of storage at room temperature, 37 and 50 °C. Finally, we demonstrated that cell-free glycoprotein synthesis machinery is still active in all formulations under these storage conditions by producing relevant and effective antidiarrheal conjugate vaccine molecules (ETEC O78 O-antigen conjugated to the approved carrier protein D (PD)) for as low as ∼$0.50 per dose based on raw materials purchased at the laboratory scale.

Results and Discussion

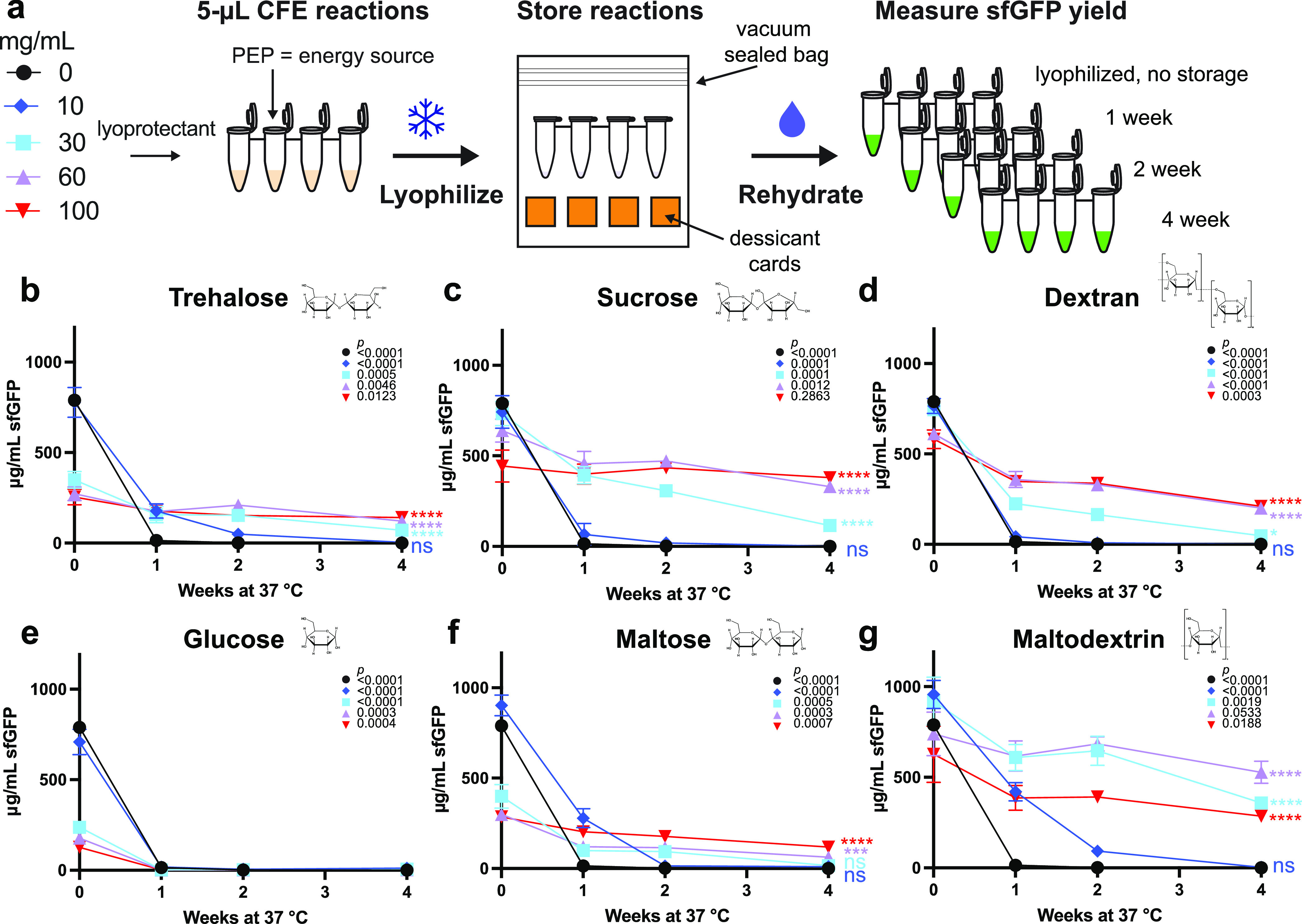

Maltodextrin Enhances the Thermostability of CFE Reactions

With the goal of decreasing the cost and increasing the stability of CFE reactions, we first benchmarked the thermostability of our CFE formulation using a common protein expression lysate derived from BL21 Star (DE3) cells. We lyophilized 5 μL CFE reactions containing all reagents for the PANOx-SP-based system,41 which uses the phosphorylated secondary energy substrate phosphoenolpyruvate (PEP), supplemented with DNA encoding superfolder green fluorescent protein (sfGFP). Then, after 1, 2, and 4 weeks of storage at 37 °C in vacuum-sealed bags with desiccant cards, we rehydrated lyophilized reactions with 5 μL of water and measured sfGFP concentrations via fluorescence (Figure 1A). Rehydrated controls (0-week timepoint) produced protein comparable to controls that were never lyophilized (fresh) (Figure S1), but lyophilized CFE reactions with no lyoprotectant additives did not produce sfGFP after 1 week of storage at 37 °C (Figure 1B; black circles). Consistent with previous studies,35 these data indicated that lyophilized one-pot CFE reactions are not stable at elevated temperatures.

Figure 1.

Maltodextrin enhances the stability of cell-free gene expression (CFE) reactions stored at 37 °C. (A) Schematic of CFE reaction setup and lyophilization for the screening of lyoprotectants. The impact of (B) trehalose, (C) sucrose, (D) dextran, (E) glucose, (F) maltose, and (G) maltodextrin at concentrations of 0 mg/mL in black circles, 10 mg/mL in blue diamonds, 30 mg/mL in light blue squares, 60 mg/mL in purple triangles, and 100 mg/mL in inverted red triangles on the amount of sfGFP produced by lyophilized CFE reactions after storage was measured. Reactions were rehydrated with 5 μL of water and incubated at 30 °C for 20 h after 1, 2, and 4 weeks of storage at 37 °C. Error bars represent the standard deviation of three CFE reactions (n = 3). Unpaired two-tailed t-tests were used to compare the 0- and 4-week timepoint for each condition. P values showing the significance of the change in sfGFP yield for each condition between 0 and 4 weeks of storage at 37 °C are inset on the top right of each graph with the corresponding shape for each condition. An ordinary one-way ANOVA (95% confidence interval) with Dunnett’s multiple comparisons test was performed to determine the significance of the yields after 4 weeks of storage for each condition compared to the no lyoprotectant control. Significance (adjusted p value <0.0001 is denoted by ****, 0.0001 to 0.001 by ***, 0.001 to 0.01 by **, 0.01 to 0.05 by *, and ≥0.05 by ns) is reported to the right of the 4-week timepoint marker for each condition.

We next sought to identify low-cost lyoprotectant additives that could confer storage stability at elevated temperatures (37 °C). Specifically, we explored the use of trehalose,34,42 sucrose,43 and dextran,35 which have previously been shown to enhance lyophilized reaction stability (Figure 1B–D). In addition, we wanted to test whether sugars that have been demonstrated as low-cost, secondary energy sources in CFE systems, such as glucose,31,44,45 maltose,46,47 and maltodextrin,46−50 could also protect or stabilize reactions during lyophilization and storage (Figure 1E–G).

We supplemented CFE reactions with 0–100 mg/mL of each lyoprotectant individually prior to lyophilization. No significant loss in activity was observed from the lyophilization process, although some lyoprotectants (e.g., trehalose) were detrimental to protein yields (Figure S1). Then, after 1, 2, and 4 weeks of storage, we rehydrated lyophilized reactions with 5 μL of water and measured sfGFP concentrations after 20 h via fluorescence. The addition of trehalose, glucose, and maltose, at concentrations greater than 10 mg/mL, each significantly (p < 0.0001) decreased protein expression compared to the no lyoprotectant control in fresh and lyophilized reactions (Figures S1 and1B,E,F). After 4 weeks of storage, reactions protected with sucrose, dextran, and maltodextrin resulted in the highest-yielding reactions, leading us to compare the best concentration from each group (sucrose at 100 mg/mL, dextran at 100 mg/mL and maltodextrin at 60 mg/mL). While supplementing reactions with 100 mg/mL dextran caused a significant (p = 0.0003) loss of activity over the course of 4 weeks, retaining only ∼36% of the freshly lyophilized reaction activity (0-week timepoint), reactions supplemented with sucrose at 100 mg/mL or maltodextrin at 60 mg/mL did not lose significant (p = 0.2863, 0.0533, respectively) activity over the course of 4 weeks, maintaining ∼85 and ∼71% of freshly lyophilized reaction activity, respectively (Figure 1C,D,G). However, adding just 60 mg/mL maltodextrin achieved significantly (p > 0.05) higher overall protein yields after 4 weeks of storage (528 ± 61 μg/mL sfGFP) than sucrose-protected reactions compared with an unpaired, two-tailed t-test (Figure 1G). Of note, adding maltodextrin protects CFE reactions without any additional costly additives such as DMSO or stabilizers,35 resulting in a simplified and cost-effective solution.

Maltodextrin Can Be Used as a Low-Cost CFE Lyoprotectant and Energy Source

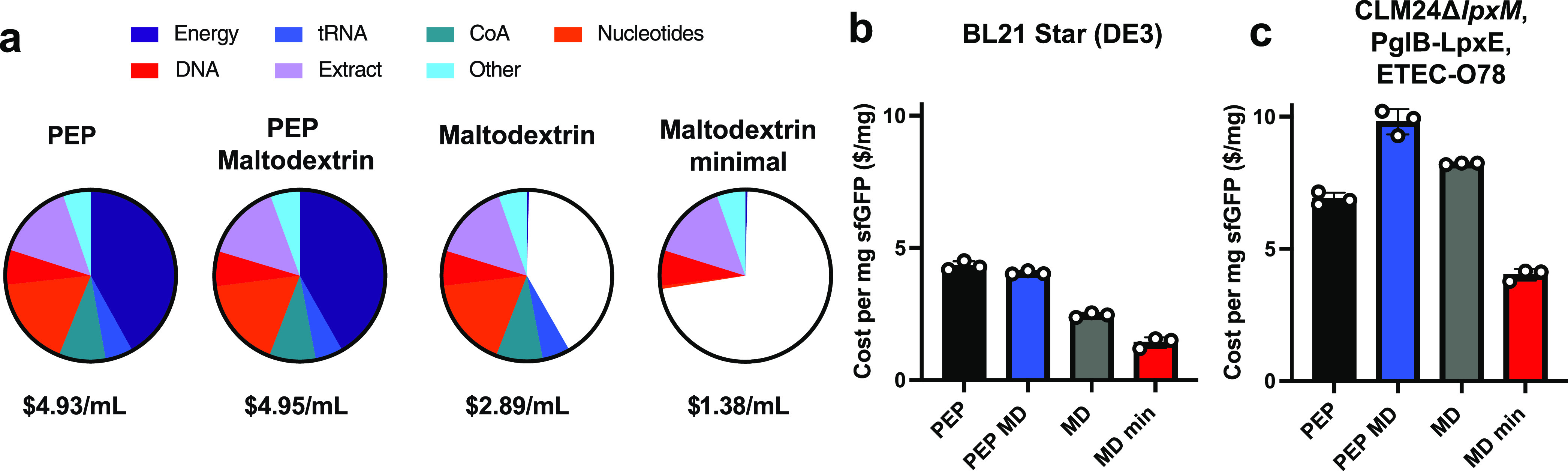

After identifying that maltodextrin could be used as an effective lyoprotectant, we wanted to explore whether this polysaccharide could simultaneously preserve the reaction and act as an energy source for CFE reactions. Maltodextrin, a non-phosphorylated substrate, with the addition of exogenous phosphate, can be broken down into early glycolytic intermediates and used to fuel protein synthesis.47−50 By having a dual-use for maltodextrin (∼$0.02 per mL reaction with 60 mg/mL maltodextrin) and replacing PEP in the PANOx-SP system, we could potentially reduce the cost of CFE reagent formulation from ∼$4.93 per mL reaction to ∼$2.89 per mL of reaction (a 59% reduction) (Tables S1–S3 and Figure 2A). Further, replacing nucleotide triphosphates (NTPs) with nucleotide monophosphates (NMPs), which can be phosphorylated in the cell-free reaction, and removing nonessential additives like tRNA and CoA29−31 could yield a minimal formulation (MD min) costing ∼$1.38 per mL of CFE reaction, a quarter of the cost per mL of the PANOx-SP CFE system.

Figure 2.

Maltodextrin can be effectively used as both an energy source and lyoprotectant for low-cost CFE. (A) Cost per mL CFE reaction was calculated for each formulation: PEP with no lyoprotectant, PEP with maltodextrin supplemented as a lyoprotectant (PEP MD), maltodextrin as an both energy source and a lyoprotectant (MD), and maltodextrin without CoA, tRNA, and replacing NTPs with NMPs (MD min). Costs are based only on raw materials included in the reaction purchased at laboratory scale using calculations in Supporting Tables S1–S3. (B) Cost per milligram sfGFP in CFE reactions using BL21 Star (DE3) extract in all four formulations. (C) Cost per milligram sfGFP in CFE reactions using CLM24 ΔlpxM extract in all four formulations. Error bars represent the standard deviation of three CFE reactions (n = 3).

To test whether these low-cost maltodextrin formulations could work in practice, we assembled these formulations and evaluated their ability to produce protein. Specifically, we tested four formulations (PEP, PEP + MD, MD, and MD min; Table S4) using extracts from BL21 Star (DE3) and a specialized iVAX production strain (CLM24 ΔlpxM) harboring glycosylation machinery (Table S5)13 for the synthesis of sfGFP in fresh reactions. We first optimized the addition of exogenous phosphate necessary for energy regeneration in the form of potassium phosphate dibasic (75 mM) and buffer (Bis-Tris or HEPES) in maltodextrin-based reactions. For BL21 Star (DE3) extracts, 57 mM Bis-Tris buffer (pH 10) was optimal and maintained higher final reaction pH (Figure S2).31,44 Notably, all formulations with these extracts produced roughly the same amount of sfGFP (∼1000 μg/mL), indicating that the removal of reagents did not significantly impact protein yields (Figures S3A and S4). Interestingly, the CLM24 ΔlpxM extracts performed better with the HEPES buffer (pH 7.2) (Figure S5) and 60 mg/mL maltodextrin appeared to have a detrimental impact on sfGFP yields with ∼70% protein produced in the PEP MD formulation and ∼50% protein produced in both the MD and MD min formulations compared to the original (PEP) formulation (Figure S3B). Despite this difference, the MD min formulation has a lower cost per milligram sfGFP in extracts derived from both strains (Figure 2B,C) and enables protein yields sufficient for glycoconjugate vaccine production (∼100 μg/mL),51 with a maximum yield of ∼350 μg/mL sfGFP in the iVAX strain.

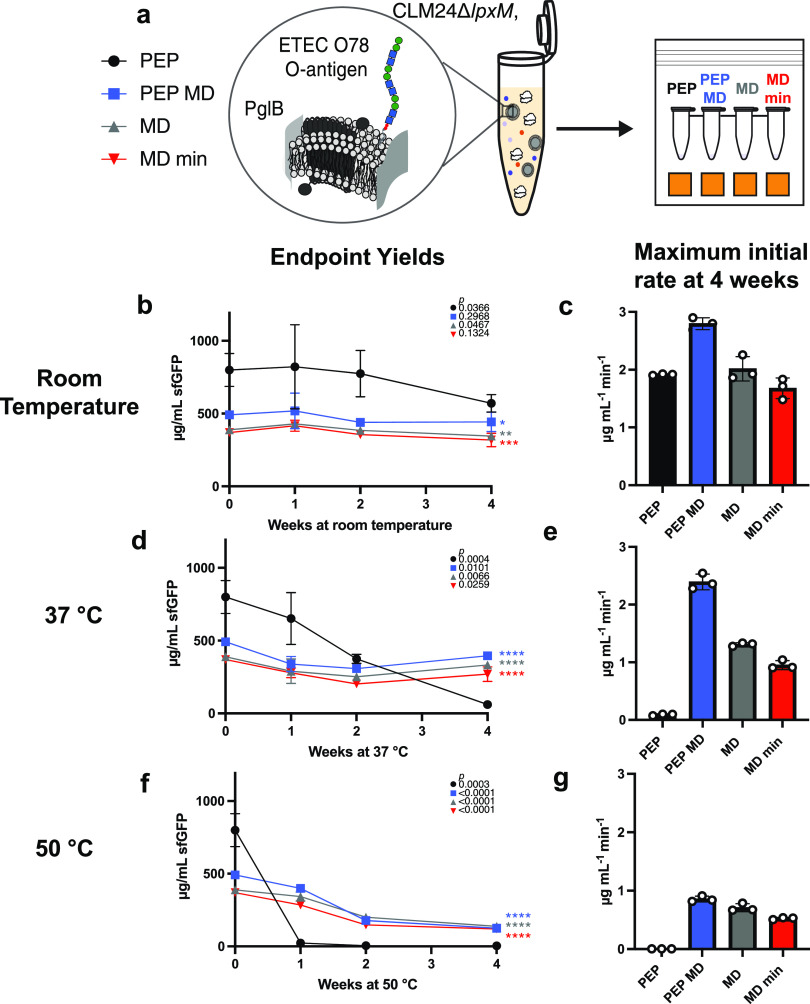

Low-Cost CFE Formulations Retain Activity When Stored at up to 50 °C

We next sought to evaluate the thermostability of the optimized, low-cost CFE formulations after lyophilization. We lyophilized all four formulations using CLM24 ΔlpxM extracts and stored each at room temperature (∼22 °C), 37 °C and 50 °C, for 4 weeks (Figure 3A). We rehydrated samples with 5 μL of water and measured maximum initial rates over the first ninety minutes (Figures 3C,E,G and S6) as well as endpoint sfGFP concentrations after 20 h of incubation (Figure 3B,D,F). Lyophilization did not reduce activity compared to fresh controls (Figure S7), but we found that the supplementation of purified T7 RNA polymerase required for transcription (often stored in glycerol) must be dialyzed to remove glycerol (into S30 buffer, see Materials and Methods) to maintain activity (Figure S8).

Figure 3.

Low-cost formulations preserve CFE reactions with iVAX extract when stored at up to 50 °C. (A) Schematic of CFE reaction storage conditions. After 4 weeks of storage at room temperature (∼22 °C) (B, C), 37 °C (D, E), and 50 °C (F, G), lyophilized CFE reactions were rehydrated with 5 μL of water and incubated at 30 °C for 20 h and endpoint sfGFP yields and maximum initial protein synthesis rates were measured. Error bars represent the standard deviation of three CFE reactions. Unpaired two-tailed t-tests were used to compare the 0-week and 4-week timepoint for each condition. P values showing the significance of the change in sfGFP yield for each condition between 0 and 4 weeks of storage are inset on the top right of each graph with the corresponding shape for each condition. An ordinary one-way ANOVA (95% confidence interval) with Dunnett’s multiple comparisons test was performed to determine the significance of the yields after 4 weeks of storage for each condition compared to the PEP formulation. Significance (adjusted p value <0.0001 is denoted by ****, 0.0001 to 0.001 by ***, 0.001 to 0.01 by **, 0.01 to 0.05 by *, and ≥0.05 by ns) is reported to the right of the 4-week timepoint marker for each condition.

After 4 weeks of storage at room temperature (∼22 °C), all formulations retained activity using CLM24 ΔlpxM extracts and the PEP formulation still produced significantly (p < 0.05) higher yields than the formulations containing maltodextrin (Figure 3B). However, at elevated temperatures, the PEP-only formulation lost activity after 4 weeks of storage at 37 °C (Figure 3D) and after 1 week of storage at 50 °C (Figure 3F), while the maltodextrin-containing formulations retained significantly higher endpoint yields after 4 weeks than PEP (p < 0.0001), despite losing activity over time (Figure 3D,F). Interestingly, reactions that use maltodextrin as the sole energy source have slower initial protein production rates than the PEP MD formulation despite similar endpoint yields, suggesting that maltodextrin is more slowly metabolized (Figure 3C,E,G). While lyophilized maltodextrin-based formulations have been shown to be stable at ambient conditions,49 this work demonstrates the first instance, to our knowledge, of high-temperature storage (50 °C) and stability of assembled CFE reactions where the energy substrate is also acting as the lyoprotectant.

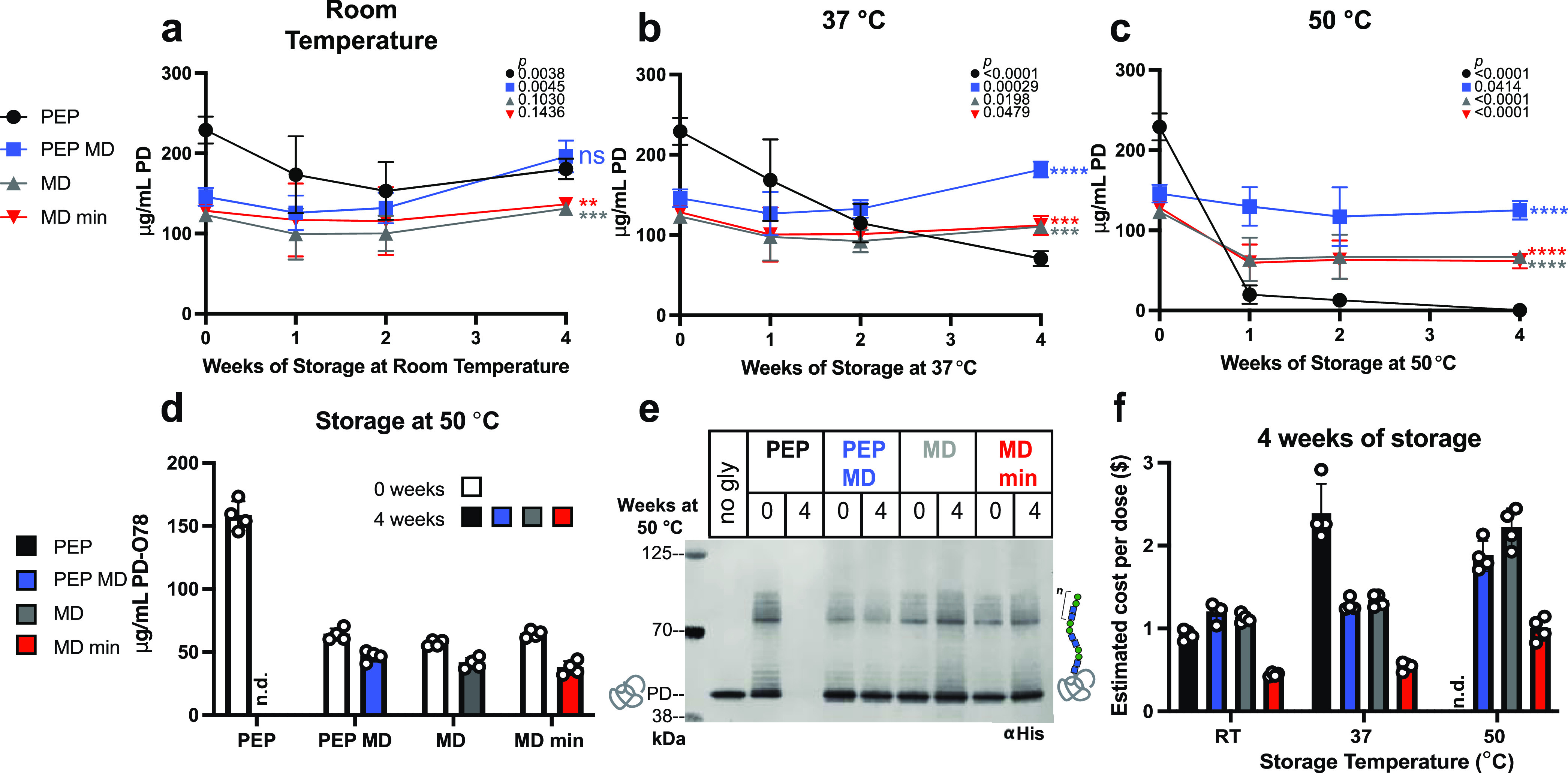

Low-Cost, Thermostable CFE Enables Conjugate Vaccine Production and Storage

With a low-cost, thermostable formulation at hand, we wanted to produce and store conjugate vaccines as a potential use case. We have previously shown that coupled CFE and glycosylation (i.e., iVAX) reactions are stable at room temperature (∼22 °C) for up to 3 months,13 but higher temperatures are likely encountered during distribution without cold-chain temperature control. To test elevated temperatures on storage of iVAX reactions, we considered a model conjugate vaccine for distribution in resource-limited settings composed of the O-antigen from enterotoxigenic Escherichia coli ETEC O78, a strain of enterotoxigenic E. coli responsible for diarrheal disease, conjugated to the licensed carrier protein D (PD) from Haemophilus influenzae.(52−54) We lyophilized iVAX reactions with CLM24 ΔlpxM extracts containing the necessary glycosylation machinery and the new CFE formulations. After storage at room temperature (∼22 °C) (Figure 4A), 37 °C (Figure 4B), and 50 °C (Figure 4C) for 1, 2, and 4 weeks, we measured PD produced via 14C-labeled leucine incorporation. Lyophilized reactions behaved similarly under elevated temperatures when producing PD (Figure 4A–C) and the maltodextrin-containing formulations retained significantly higher endpoint yields (p < 0.001) than the PEP formulation at both 37 °C (Figure 4B), and 50 °C (Figure 4C) storage conditions after 4 weeks. Interestingly, after 4 weeks of storage at room temperature (∼22 °C) or 37 °C, we observed a slight increase in PD produced by the PEP MD formulation (Figure 4A,B); however, we are unsure what is causing this result.

Figure 4.

Maltodextrin-based formulations with iVAX extract enable production of conjugate vaccine molecules at low cost after high-temperature storage. Yields of carrier protein (PD) were measured from lyophilized 15 μL of reactions stored for up to 4 weeks at (A) room temperature (∼22 °C), (B) 37 °C, and (C) 50 °C. Unpaired two-tailed t-tests were used to compare the 0-week and 4-week timepoint for each condition in (A)–(C). P values showing the significance of the change in sfGFP yield for each condition between 0 and 4 weeks of storage are inset on the top right of each graph with the corresponding shape for each condition. An ordinary one-way ANOVA (95% confidence interval) with Dunnett’s multiple comparisons test was performed to determine the significance of the yields after 4 weeks of storage for each condition compared to the PEP formulation. Significance (adjusted p value <0.0001 is denoted by ****, 0.0001 to 0.001 by ***, 0.001 to 0.01 by **, 0.01 to 0.05 by *, and ≥0.05 by ns) is reported to the right of the 4-week timepoint marker for each condition in (A)–(C). CFE reactions were rehydrated with 15 μL of water and incubated at 30 °C for 4 h, then glycosylation was initiated, and samples were incubated for an additional 16 h at 30 °C. Yields of glycosylated carrier protein (PD) with a C-terminal glycosylation tag followed by a 6x-His tag were measured (D) and observed via anti-His Western blot (E) for reactions that were stored at 50 °C. (F) Estimated cost per dose of conjugate vaccines produced by CFE reactions stored for 4 weeks at each tested temperature. Error bars represent the standard deviation of four CFE reactions (n = 4).

Glycosylation was initiated after 4 h of protein synthesis (ca. 100–200 μg/mL carrier protein produced) (Figure S9A), yielding >57 μg/mL glycosylated PD in all conditions before storage.51 The glycosylation activity is retained in all formulations before storage (Figure S10A) and preserved after 4 weeks of storage at 50 °C (Figure 4E, Figure S10C (uncropped blot image)). Each formulation with protein produced can efficiently glycosylate PD as seen by the characteristic O-antigen banding pattern (varying number of repeated monomers) on the anti-His Western blot (Figure 4E). The glycoprotein produced is also cross-reactive with an antibody specific for the ETEC O78 O-antigen (Figure S10B).

While maltodextrin-containing reactions reduce glycosylation efficiency, with ∼50% glycosylation when MD is present compared to ∼70% for the PEP formulation (Figure S10D), these reactions produce more protein after storage at elevated temperatures, yielding higher concentrations of glycosylated product than the PEP formulation (Figure 4D). At 24 μg of conjugate vaccine per dose, we estimated that the MD min formulation could synthesize conjugate vaccines for ∼$0.50 per dose after storage at 37 °C for 4 weeks and ∼$1.00 per dose after storage at 50 °C for 4 weeks (Figure 4F), making it the most cost-effective, thermostable cell-free glycoprotein synthesis formulation. Even before storage, the MD min formulation still has a cost benefit due to the significantly cheaper cost of raw materials in the reactions (Figure S9B). These developments reduce the cost of iVAX reactions capable of synthesizing conjugate vaccines and enable activity after weeks of storage at elevated temperatures that could be encountered during distribution without cold-chain temperature control.28

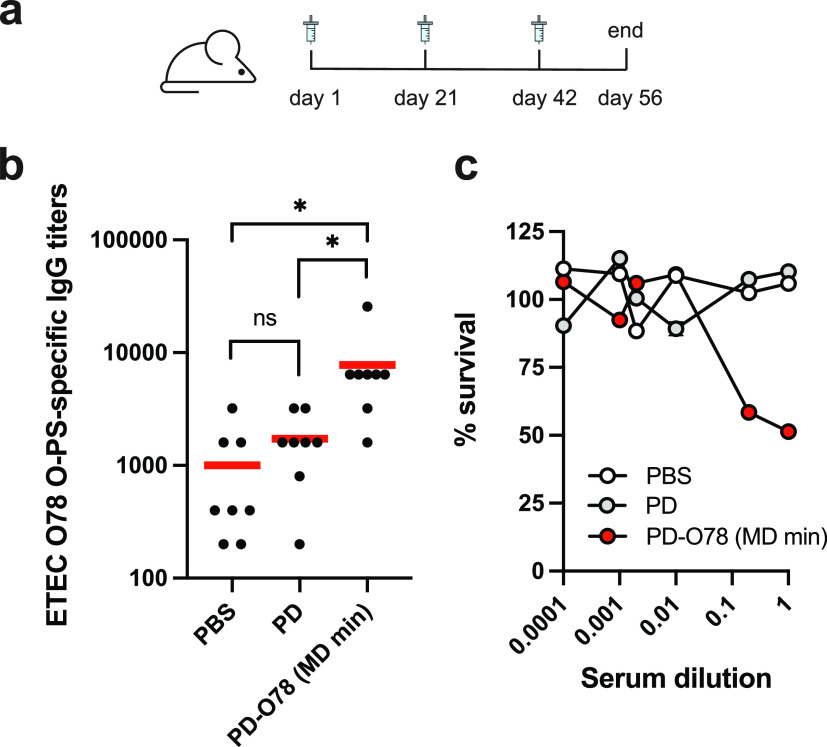

Conjugate Vaccines Produced Using the MD min Formulation Elicit Bactericidal Antibodies

Finally, we tested the effectiveness of lyophilized PD-O78 conjugates synthesized using the MD min CFE formulation. We scaled up production, purified conjugates, and immunized 8 BALB/c mice with ∼24 μg of conjugate or negative control (aglycosylated PD) (Figure S11). Mice were then boosted with 24 μg of conjugate on days 21 and 42, with serum collected on day 56 at the end of the trial (Figure 5A). ETEC O78 O-polysaccharide (O-PS)-specific antibodies were generated in mice that received purified conjugate derived from lyophilized MD min CFE reactions that was significant over both negative controls tested (Figure 5B). We also tested the bactericidal activity of the sera collected from mice that received conjugate vaccines and observed 51.4 ± 1.91% survival of ETEC O78 strain H10407 cells treated with undiluted serum and 58.4 ± 0.20% survival of ETEC O78 strain H10407 cells treated with serum at a five-fold dilution compared to inactivated complement controls (Figure 5C). In comparison, sera derived from mice who received the control treatment (PD) resulted in 110.3 ± 0.92 and 107.5 ± 0.18% survival of ETEC O78 strain H10407 cells compared to inactivated complement controls at undiluted and five-fold serum dilutions, respectively (Figure 5C). Together these data show that conjugates derived from our new cost-effective, stable, MD min formulation are effective at eliciting bactericidal antibodies against ETEC O78 O-PS. As demonstrated by the robust glycosylation profile observed in our cell-free glycosylation reactions after storage at a variety of temperatures (Figure 4E), we expect that conjugate vaccines derived from reactions stored at elevated temperature conditions will remain effective.

Figure 5.

Conjugate vaccines produced using the MD min CFE formulation elicit antibodies that are bactericidal. (A) Lyophilized MD min CFE reactions using iVAX extracts were used to synthesize anti-ETEC O78 conjugate vaccines for immunization studies. Groups of BALB/c mice were immunized subcutaneously with a 1:1 mixture of adjuvant and PBS or ∼24 μg of the following cell-free-derived immunogens: unconjugated protein D (PD), or PD modified with O78 O-PS from a minimal iVAX reaction (PD-O78 (MD min)). Each group was composed of eight mice. Mice were boosted on days 21 and 42 with identical doses of antigen. (B) ETEC O78 O-PS-specific IgG titers were measured by enzyme-linked immunosorbent assay (ELISA) in endpoint (day 56) serum of individual mice (black dots) with recombinant O-PS immobilized as antigen. Mean titers of each group are also shown (red lines). Statistical significance was calculated by unpaired two-tailed t-test with a single asterisk (*) indicating p-value <0.05 and ns indicating not significant. (C) Bacterial killing activity of serum antibodies corresponding to the same groups as in (B). Survival data were derived from a standard serum bactericidal assay (SBA) where dilutions of pooled sera from immunized mice were tested against ETEC O78 strain H10407 in the presence of human complement. Values for % survival were determined from the colony forming units (CFUs) counted at each individual serum dilution. Data in (C) represent average error bars for two independent samples (n = 2).

Discussion

Cost and stability of CFE reactions are key barriers to point-of-need use, such as iVAX for glycoconjugate vaccine production. Here, we identify a low-cost, thermostable CFE reaction formulation. A key innovation of this work is the use of maltodextrin to simultaneously stabilize lyophilized reactions at high temperatures and reduce reaction costs. To build on previous work demonstrating that maltodextrin can be used as a low-cost energy source for CFE reactions,49,50 we show that it can also be used as a lyoprotectant without extensive optimization. To our knowledge, this is the first characterization of CFE reactions using a nonphosphorylated energy substrate at elevated temperatures. We were further able to reduce the cost of the reaction to ∼25% of the original, by identifying a maltodextrin minimal (MD min) formulation that is economically beneficial for multiple extract source strains tested and is still capable of synthesizing protein after storage for 4 weeks at 50 °C. This formulation supports protein synthesis in extracts produced from the common high-yielding strain BL21 Star (DE3) as well as a specialized iVAX strain tailored to produce complex glycosylated products. A similar workflow could be used for future investigation into the combinatorial impacts of lyoprotectants that enhance long-term stability.

Successful conjugate vaccine distribution as determined by the MenAfriVac campaign achieved <$0.50 per dose and tolerated high storage temperatures (40 °C).27,28 We show that our low-cost CFE formulations are in line with these metrics and can synthesize effective model conjugate vaccine molecules against ETEC O78 after storage for up to 4 weeks at 37 °C at this price point. Additionally, the formulation is still active after storage at up to 50 °C, although the price increases to $1.00 per dose. In fact, our maltodextrin minimal (MD min) system is capable of synthesizing ∼40 μg/mL glycoconjugate vaccine molecule after storage at all conditions after 4 weeks, higher than previously reported concentrations for this molecule in a CFE system.13 Importantly, all formulations with maltodextrin retain protein synthesis activity after high-temperature storage, while the activity of the original formulation (PEP) declines (37 °C) or disappears (50 °C).

Our formulations achieved <$1.00 per dose for all storage temperatures tested, and the MD min formulation stored at room temperature (∼22 °C) was as low as ∼$0.40 per dose. These cost estimates were determined based on raw materials purchased at the laboratory scale to highlight the cost improvements in the materials required for each formulation.15 Labor and capital equipment costs are dependent on production scale and product demand and were therefore not included at this stage. The next main targets to further reduce cost will be to increase glycosylation efficiency and protein titers in the minimal formulation to therefore increase conjugate vaccine yields. We anticipate this work and the continued interest in CFE systems will lead to additional metrics to more accurately predict CFE cost at a variety of scales, formal large-scale economic analyses,55 and further optimization of cell-free glycoprotein synthesis reaction formulations to improve commercial feasibility of cell-free conjugate vaccine production.

Looking forward, our work provides an important step in the implementation of CFE reactions for decentralized manufacturing and builds on past work by taking advantage of the multiple properties of maltodextrin as a reaction component. We envision that the bulk distribution of freeze-dried CFE reaction material will be facilitated by this work, enabling scaled-down point-of-care manufacturing. To make this possible, scaled production (greater than lab scale) coupled with innovations in downstream purification and quality control processes will be required for adoption and increased access. Importantly, glycosylated products now join other highly sought-after molecules that can be produced in lyophilized CFE systems following a range of storage conditions.35 Taken together, the generation of effective ETEC O78 conjugate vaccines in a low-cost, thermostable formulation advances the iVAX platform and increases the accessibility of the technology that can be used to synthesize glycoprotein vaccines in low-resource settings.

Materials and Methods

Statistical Analysis

Statistical significance was determined using GraphPad Prism 9 for MacOS (Version 9.4.1 or 9.2.0). Unpaired two-tailed t-tests were used to compare the 0-week and 4-week timepoint for each condition in Figures 1B–G, 3B,D,F and 4A–C. Unpaired two-tailed t-tests were also used to compare yields after 4 weeks of PEP reactions with either 100 mg/mL sucrose or 60 mg/mL maltodextrin added as lyoprotectants (Figure 1) and in Figure 5B to compare ETEC O78 O-PS-specific IgG titers. Ordinary one-way ANOVA (95% confidence interval) with Dunnett’s multiple comparisons test was performed to determine the significance of the yields from fresh reactions, lyophilized/0-week reactions, and reactions stored for 4 weeks at 37 °C (displayed in figure), for each condition compared to the no lyoprotectant condition of the respective reaction type in Figure 1B–G. This method was also used to determine the significance of the yields after 4 weeks of storage for each condition compared to the PEP formulation in Figures 3B,D,F and 4A–C. Adjusted p value <0.0001 is denoted by ****, 0.0001 to 0.001 by ***, 0.001 to 0.01 by **, 0.01 to 0.05 by *, and ≥0.05 by ns.

Extract Preparation

Cells were grown in shake flasks at the 1 L scale or in a Sartorius Stedim BIOSTAT Cplus bioreactor at the 10 L scale. BL21 Star (DE3) cells were inoculated at an optical density at 600 nm (OD600) = 0.08 and grown in 2xYTPG at pH 7.2 at 37 °C. Cells were induced at OD600 = 0.6 with 0.5 mM IPTG for T7 RNA polymerase expression and harvested at OD600 = 3. CLM24 ΔlpxM cells transformed with plasmids pSF-PglB-LpxE13 and pMW07-O7813,56,57 were inoculated at OD600 = 0.08 and grown at 37 °C in 2xYTP with no glucose and carbenicillin at 100 μg/mL and chloramphenicol at 34 μg/mL supplemented. Cells were induced at OD600 = 0.8–1 with 0.02% arabinose to induce expression of PglB and the ETEC O78 O-antigen and harvested at OD600 = 3. All subsequent steps were performed on ice unless otherwise stated. Cells were harvested by centrifugation at 5000g for 15 min and then washed three times with S30 buffer (10 mM Tris acetate pH 8.2, 14 mM magnesium acetate, and 60 mM potassium acetate). Following washing, cells were pelleted at 7000g for 10 min, then either flash-frozen and stored at −80 °C, or directly resuspended for lysis.

BL21 Star (DE3) cells were resuspended in 1 mL/g S30 buffer. Cells were then lysed using a Q125 Sonicator (Qsonica, Newtown, CT) with a 3.175 mm diameter probe at a frequency of 20 kHz and 50% amplitude. Energy was delivered to cells in pulses of 10 s followed by 1 s off until 640 J was delivered to each 1 mL aliquot of resuspended cells. Following lysis, cells were centrifuged at 12,000g for 10 min. The supernatant was then collected, flash-frozen, and stored at −80 °C as the final extract.

CLM24 ΔlpxM cells were resuspended in 1 mL/g S30 buffer. Cells were then homogenized using an EmulsiFlex-B15 (1 L scale) or an EmulsiFlex-C3 (10 L scale) high-pressure homogenizer (Avestin, Inc. Ottawa, ON, Canada) with 1 pass at a pressure of ∼21,000 psig. Following lysis, cells were centrifuged at 12,000g for 10 min. The supernatant was then collected and incubated at 37 °C for 1 h in a runoff reaction. Cells were then centrifuged once more at 10,000g for 10 min and then the supernatant was flash-frozen and stored at −80 °C as the final extract. Reagents involved in extract preparation are included in Table S2.

Plasmids

All plasmids used in this study are listed in Table S5. No new plasmids were cloned in this study, and all appropriate references are cited.

CFPS Reactions

Reactions were run at the 5 μL scale in PCR tubes in a qPCR instrument set to 30 °C incubation or at the 15 μL scale in 1.5 mL microcentrifuge tubes in a 30 °C incubator (Axygen). CFPS reactions were not agitated. Reactions were run for 20 h when synthesizing sfGFP. Reactions containing lyoprotectants were supplemented with trehalose (Sigma, T0167), sucrose (Sigma, S0389), Dextran 70 (TCI chemicals, D1449), glucose (Sigma, G8270), maltose (Sigma, M9171), or maltodextrin-dextrose equivalent 4.0–7.0 (Sigma, 419672), at the appropriate final concentrations (10–100 mg/mL) as described in the text. A stock solution of 300 mg/mL maltodextrin was prepared fresh before reactions were set up and added to CFPS reactions at the appropriate concentration. All other lyoprotectants were prepared and stored at −20 °C.

Reactions for each formulation were prepared as described below and in Table S4:

PEP

Each reaction was prepared as described previously51 unless otherwise noted, to contain 13.33 ng/μL plasmid, 30% (vol/vol %) S12 extract, and the following: 10 mM magnesium glutamate (Sigma, 49605), 10 mM ammonium glutamate (Biosynth, FG28929), 130 mM potassium glutamate (Sigma, G1501), 1.2 mM adenosine triphosphate (Sigma A2383), 0.85 mM guanosine triphosphate (Sigma, G8877), 0.85 mM uridine triphosphate (Sigma U6625), 0.85 mM cytidine triphosphate (Sigma, C1506), 0.034 mg/mL folinic acid, 0.171 mg/mL E. coli tRNA (Roche 10108294001), 2 mM each of 20 amino acids, 30 mM phosphoenolpyruvate (PEP, Roche 10108294001), 0.4 mM nicotinamide adenine dinucleotide (Sigma N8535-15VL), 0.27 mM coenzyme-A (Sigma C3144), 4 mM oxalic acid (Sigma, PO963), 1 mM putrescine (Sigma, P5780), 1.5 mM spermidine (Sigma, S2626), and 57 mM HEPES (Sigma, H3375). T7 was supplemented to reactions at a final concentration of 15–20 μg/mL when using the iVAX extract either in 50% glycerol or dialyzed into S30 buffer supplemented with 2 mM DTT.

PEP MD

Maltodextrin at a final concentration of 60 mg/mL was supplemented to the PEP reaction formulation described above. See Table S4 for more details.

MD

Maltodextrin at a final concentration of 60 mg/mL was supplemented with the PEP reaction formulation described above, and PEP was removed. Potassium phosphate dibasic was supplemented to the PEP reaction formulation at a final concentration of 75 mM unless otherwise noted. Potassium phosphate dibasic (Sigma, 60353) was prepared and pH was adjusted to 7.2 with acetic acid. For BL21 Star (DE3) extract-based reactions, Bis-Tris (Sigma, B9754) with unadjusted pH was added at a concentration of 57 mM and HEPES was removed. See Table S4 for more details.

MD min

Reactions were prepared according to the MD reaction formulation described above with the removal of tRNA and CoA. NTPs were also replaced by equal concentration of NMPs (CMP: Sigma C1006, UMP: Sigma U6375, AMP: Sigma 01930, GMP: Sigma G8377). NMPs were prepared at a stock concentration of 0.5 M by dissolving in nuclease-free water and pH was adjusted to 7.2 with acetic acid. See Table S4 for more details.

Lyophilization and Packaging

CFPS reactions were set up as described in the CFPS Reactions section. Reactions were set up on ice and aliquoted into PCR strip tubes with 1 hole in the lid created by an 18-gauge needle. Samples were kept on ice in aluminum blocks (Cole-Parmer 6361504) and then samples (in blocks) were flash-frozen in liquid nitrogen. Frozen samples in blocks were then transferred to a multitainer manifold adapter on a VirTis Benchtop Pro Lyophilizer (SP scientific). Lyophilization was performed at 100 mT, and a condenser was set to −80 °C. Samples were lyophilized overnight for 16–20 h. Following lyophilization, the samples were packaged (all replicates stored together for each tested time and temperature condition) in a FoodSaver bag with 2–4 Dri-Card desiccant cards and then vacuum-sealed under ambient conditions with a FoodSaver vacuum sealer. Packaged samples were then stored at room temperature at the bench (∼22 °C), or in incubators set to either 37 or 50 °C as indicated for the appropriate storage time. Lyophilized controls were rehydrated immediately after removal from the lyophilizer and not stored or packaged in a vacuum-sealed bag.

Cell-Free Glycoprotein Synthesis

For PD synthesis and glycosylation, 15 μL reactions were rehydrated with nuclease-free water (Ambion) supplemented with 200 ng of pJl1-PD-4xDQNAT and 10 μM C14 Leucine for a total volume of 15 μL added to the reactions. After rehydration, reactions were incubated for 4 h at 30 °C. After 4 h, a final concentration of 0.1% (wt/vol) DDM and 25 mM MnCl2 was added to each reaction to initiate glycosylation and incubated at 30 °C for an additional 16 h. Before analysis, samples were centrifuged at 16,000g for 15 min and the soluble fraction was removed. The soluble fraction of each reaction was used to measure yields of the accepter protein PD-4xDQNAT by radioactive counting and to load on western blot to verify glycosylation.

Protein Quantification

For sfGFP measurement

CFPS reaction (2 μL) was diluted with 48 μL of nanopure water in a black costar 96-well plate. Fluorescence was read on a plate reader and converted to μg/mL sfGFP using a standard curve with sfGFP measured by C14 incorporation.

For Initial sfGFP Synthesis Rate Measurements

Fluorescence was measured every 5 min by the qPCR machine. Initial rates were calculated by taking the maximum slope over the first 90 min of the cell-free protein synthesis reaction. Using a standard curve, relative fluorescence units measured by the qPCR were converted to μg/mL sfGFP. To calculate the maximum initial slope over the first 90 min, a sliding window of five time points was used. For each window, the slope was determined based on a regression line fitting the five time points. This was repeated over the 90 min, advancing the starting timepoint of the window by 1 each time. The maximum initial slope was determined independently for each of the three replicates, which were then averaged together to determine the overall average maximum initial slope. This process was completed for each individual reaction condition.

For PD Synthesis

Reactions (15 μL) containing all reagents except the DNA template were lyophilized and then rehydrated with 15 μL of nuclease-free water containing 200 ng of PD-4xDQNAT (or no DNA in control reactions) and 10 μM C14 Leucine (PerkinElmer). Samples were incubated for 4 h at 30 °C, then glycosylation was initiated, and reactions were incubated at 30 °C for an additional 16 h. Following centrifugation at 16,000g for 15 min, 5 μL of the soluble fraction of each reaction was treated with 5 μL of 0.5 M KOH for 20 min at 37 °C. Following incubation, 4 μL of the sample was added to two filtermats (PerkinElmer Printer Filtermat A 1450-421). After the filtermat dried, one filtermat was washed three times for 15 min with 5% w/v TCA at 4 °C and once with Ethanol for 10 min at room temperature. After the washed filtermat dried, scintillation wax (PerkinElmer MeltiLex A 1450-441) was melted on both mats and counts were measured using a Microbeta2 scintillation counter (PerkinElmer). Background radioactivity was measured in CFGpS reactions with no template DNA and subtracted before calculating protein yields. The fraction of incorporated leucine (washed/unwashed counts) was multiped by the overall leucine concentration in the reaction and the molecular weight of pJL1-PD-4xDQNAT (Table S5). The amount of protein produced was determined by dividing this value by the number of leucines present in the protein.

Western Blotting

Samples were loaded on 4–12% Bis-Tris gels and run with SDS-MOPS running buffer supplemented with NuPAGE antioxidant. Samples were then transferred to Immobilon-P-poly(vinylidene difluoride) (PVDF) 0.45 μm membranes (Millipore) for 55 min at 80 mA per blot using a semidry transfer cell. Membranes were blocked for 1 h at room temperature or overnight at 4 °C in Intercept Blocking Buffer (Licor). The primary antibodies, anti-His (Abcam, ab1187) at 1:7500 dilution or anti-ETEC O78 antigen (Abcam, ab78826) at 1:2500 dilution, were diluted in Intercept blocking buffer with 0.2% Tween20 and were incubated for 1 h at room temperature or overnight at 4 °C. A fluorescent goat, anti-rabbit antibody GAR-680RD (Licor, 926-68071) was used as the secondary antibody at 1:10,000 dilution in Intercept blocking buffer, 0.2% Tween20 and 0.1% SDS for both anti-His and anti-O78 glycan blots. Blots were washed six times for 5 min after each blocking, primary, and secondary antibody incubation using 1x PBST. Blots were imaged with Licor Image Studio and analyzed by densitometry using Licor Image Studio Lite. The fluorescence background was subtracted from each membrane before densitometry was performed.

Cost Analysis

The cost of each CFPS reaction formulation was estimated using lab-scale quantities of reagents from vendors utilized in this study (Table S3). Labor and equipment costs are not considered in these estimations. For extract cost estimations, it is assumed that 4 mL of the extract is produced per liter of cell culture and 30% v/v extract is added to CFE reactions. A “base” extract cost of only the components added to the culture for all strains is considered to make cost estimates more generalizable. The cost of variable components such as inducers and antibiotics are approximately the same for both strains used in this study and are dependent on strain and plasmid used to make extract and are thus neglected (Table S2). Glycosylation cofactors are included in the vaccine cost estimates. Vaccine cost estimates assume a 24 μg conjugate vaccine dose and take into account the glycosylation efficiency (amount of PD successfully glycosylated) determined in Figure S10D. Supporting Tables 1–4 include references, assumptions, and detailed cost calculations for each reaction component.

Mouse Immunizations

Glycoconjugate Production

Cell-free glycoprotein synthesis reactions were run as described above using the MD min CFE reaction formulation and were scaled up to 5 mL in 50 mL falcon tubes. Reactions were lyophilized overnight for 16–20 h and then rehydrated with 5 mL of nuclease-free water and incubated at 30 °C for 1 h. Following 1 h of protein synthesis, glycosylation was initiated and reactions were incubated at 30 °C overnight. The unglycosylated PD negative control was synthesized using the PEP CFE formulation in S30 iVAX extract without the ETEC O78 pathway overexpressed.13

Glycoconjugate Purification

CFGpS reactions were centrifuged at 20,000g for 10 min. The supernatant was then mixed with 0.5 mL of Ni-NTA Agarose resin (Qiagen); equilibrated with 50 mM NaH2PO4, 300 mM NaCl, and 10 mM imidazole, per 1 mL of CFE reaction; and incubated with agitation for 2–4 h at 4 °C. Purification of His-tagged carrier protein (glycosylated and aglycosylated) was carried out according to manufacturer’s protocol as follows. Following incubation with resin, CFE reaction and resin slurry were loaded onto polypropylene columns (Bio-Rad) and washed two times with six column volumes of buffer containing 50 mM NaH2PO4, 300 mM NaCl, and 20 mM imidazole. Protein was eluted with 50 mM NaH2PO4, 300 mM NaCl, and 300 mM imidazole. The most concentrated elution fractions were pooled and concentrated to ∼2 mg/mL, then dialyzed into sterile endotoxin-free PBS and stored at 4 °C. Purification elution fractions were analyzed on an SDS-PAGE gel and Coomassie stained (Figure S11). Densitometry (Licor Image Studio) of carrier protein/total protein from SDS-PAGE was used to account for percent purity of the aglycosylated carrier protein (PD) and then multiplied by total protein concentration as measured by absorbance (A280) with a nanodrop. (Total protein A280* (PD aglycosylated/total protein) = concentration of PD aglycosylated). This method was used to determine the concentration of PD from reactions that produced aglycosylated PD for the control group. For the glycosylated conjugate group, the same method was used, and it was assumed that aglycosylated PD ≅ glycosylated PD in the sample based on the approximate glycosylation efficiency of the MD min CFE reactions (∼50%).

Mouse immunizations

Groups of eight 6-week-old female BALB/c mice (Harlan Sprague Dawley) were immunized with 50 μL of sterile PBS (pH 7.4, Fisher Scientific) or formulations containing unconjugated nonacylated protein D (PD) from H. influenzae made using the PEP CFE formulation in S30 iVAX extract without the ETEC O78 pathway overexpressed, or PD modified with ETEC O78 O-PS made using the MD min CFE formulation (PD-O78 (MD min)). The amount of antigen in each preparation was normalized to ensure that ∼24 μg of unmodified protein or conjugate was administered per injection. Purified protein groups formulated in PBS were mixed with an equal volume of Adju-Phos aluminum phosphate adjuvant (InvivoGen) before injection. Each group of mice was immunized subcutaneously with vaccine candidates or controls, then boosted 21 and 42 days after the initial immunization. For antibody titering, blood was obtained on days 0, 35, and 49 via submandibular collection, and at study termination on day 56 via cardiac puncture. For bacterial killing assays, final blood collections for all of the mice within each group were pooled. All procedures were carried out in accordance with protocol 2012-0132 approved by the Cornell University Institutional Animal Care and Use Committee.

Enzyme-Linked Immunosorbent Assay (ELISA)

The plasmid pMW07-O78 encoding the pathway for E. coli ETEC O78 O-antigen biosynthesis was used to transform E. coli JC8031 competent cells. The resulting cells were used to prepare O78 LPS antigen in house by hot phenol water extraction after DNase I (Sigma) and proteinase K (Invitrogen) treatment, as described elsewhere.58 Extracted LPS was purified using a PD-10 desalting column packed with Sephadex G-25 resin (Cytiva), and concentration was determined using a purpald assay;59 96-well plates (MaxiSorp; Nunc Nalgene) were incubated with 0.5 μg/mL purified O78 LPS diluted in PBS, pH 7.4, 25 μL/well, at 4 °C overnight. Plates were blocked in blocking buffer overnight at 4 °C with 5% (w/v) nonfat dry milk (Carnation) in PBS, then washed three times with 200 μL of PBS-T (PBS, 0.05% Tween20) per well. Serum samples isolated from the collected blood draws of immunized mice were appropriately serially diluted in triplicate in blocking buffer and added to the plates for 2 h at 37 °C. Plates were washed three times with PBS-T (+0.03% BSA (w/v)), then incubated for 1 h at 37 °C in the presence of a horseradish peroxidase–conjugated antibody, goat anti-mouse IgG (Abcam, 1:25,000 dilution). After three PBS-T + 0.3% BSA washes, 50 μL of 3,3′-5,5′-tetramethylbenzidine substrate (1-Step Ultra TMB-ELISA; Thermo Fisher Scientific) was added to each well, and the plates were incubated at room temperature in the dark for 30 min. The reaction was stopped by adding 50 μL of 2 M H2SO4, and absorbance was measured at a wavelength of 450 nm using a FilterMax F5 microplate spectrophotometer (Agilent). Serum antibody titers were determined by measuring the lowest dilution that resulted in signals that were 3 standard deviations above the background controls of no serum. Statistical significance was determined in GraphPad Prism 9 for MacOS (Version 9.2.0) using an unpaired two-tailed t-test.

Serum Bactericidal Assay (SBA)

A modified version of a previously described SBA method was followed.56 ETEC H10407 cells were grown overnight from a frozen glycerol stock, then seeded 1:20 in Luria Bertani (LB) medium. Log-phase grown bacteria were harvested, adjusted to an OD600 of 0.1, then further diluted 1:5000 in Hanks’ Balanced Salt Solution with 0.5% bovine serum albumin (BSA) (Sigma-Aldrich). Assay mixtures were prepared in 96-well microtiter plates by combining 20 μL of serially diluted heat-inactivated test serum (with dilutions ranging from 1–104), and 10 μL of diluted bacterial suspension. After incubation with shaking for 60 min at 37 °C, 10 μL of active or inactive complement source was added to each well, to a final volume percent of 25%. Heat-inactivated complement was prepared by thawing an aliquot of active pooled human complement serum (Innovative Research, ICSER1ML), incubating in a 56 °C water bath for 30 min, and cooling at room temperature. Assay plates were incubated with shaking at 37 °C for 60–90 min, then 10 μL was plated from each well (diluted to 50 μL in LB) on LB agar plates. Serum samples were tested and plated in duplicate, and colonies were counted (Promega Colony Counter) after 16–18 h of incubation at 30 °C. Colony forming units (CFUs) were counted for each individual serum dilution, and SBA titers were determined by calculating percent survival at various serum dilutions. Data were plotted as percentage survival versus serum dilution.

Acknowledgments

The authors acknowledge Jessica Stark and Jasmine Hershewe for helpful discussions and contribution of cell-free reagents used in this work and Kosuke Seki for the development of the code used for maximum initial rate calculations. This work was supported by the Bill and Melinda Gates Foundation (OPP1217652 to M.P.D. and M.C.J.), Defense Threat Reduction Agency (HDTRA1-15-10052 and HDTRA1-20-10004 to M.P.D. and M.C.J.), Army Contracting Command (W52P1J-21-9-3023), and National Science Foundation (CBET-1936823 to M.P.D. and CBET-1936789 to M.P.D. and M.C.J.). K.F.W acknowledges the National Defense Science and Engineering (NDSEG) Fellowship Program (ND-CEN-013-096) sponsored by the Army Research Office. M.C.J. thanks the David and Lucile Packard Foundation. A.W. acknowledges support from the Cornell Postdoctoral Scholars Program. D.A.W. acknowledges support from the National Science Foundation Graduate Research Fellowship under grant no. DGE-1842165. S.E.S. acknowledges support from the Murphy Scholars Program of the Robert R. McCormick School of Engineering and Applied Science and the Office of Undergraduate Research at Northwestern University.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acssynbio.2c00392.

Impact of lyoprotectant additives on fresh (un-lyophilized) and lyophilized (un-stored/0-week timepoint) CFE PEP formulation reactions using BL21 Star (DE3) extract (Figure S1); optimization of CFE reagents in fresh (un-lyophilized) reactions for MD formulation in BL21 Star (DE3) extract (Figure S2); sfGFP yields of four formulations in fresh (un-lyophilized) CFE reactions using different extracts (Figure S3); sfGFP yields in fresh (un-lyophilized) CFE reactions using BL21 Star (DE3) extract showing the impact of the formulation changes made to the MD formulation to arrive at the MD min formulation (Figure S4); optimization of CFE reagents for fresh (un-lyophilized) CFE reactions with the MD formulation in iVAX extract (CLM24 ΔipxM with overexpression of glycosylation machinery from pSF-PglB-LpxE and pMW07-O78 plasmids) (Figure S5); rates of sfGFP synthesis in all formulations using the iVAX extract (Figure S6); sfGFP yields of fresh (un-lyophilized) and lyophilized (un-stored/0-week timepoint) controls of all CFE reaction formulations with the iVAX extract (Figure S7); impact of glycerol (contained in purified T7) on MD formulation (Figure S8); PD yields and estimated cost per conjugate vaccine dose of fresh (un-lyophilized) and lyophilized (un-stored) controls of all CFE reaction formulations with the iVAX extract (Figure S9); glycosylation of PD with ETEC O78 O-antigen in iVAX reactions (Figure S10); analysis of purified cell-free-derived protein for mouse study (Figure S11); cost breakdown of the CFE reaction formulations used in this work (Table S1); cost breakdown of cell extract (Table S2); information on all reagents added to the CFE reaction (Table S3); components of the CFE reaction formulations used in this work (Table S4); and strains and plasmids used in this study (Table S5) (PDF)

Author Contributions

All of the authors designed the research; K.F.W., A.W., D.A.W., S.E.S., P.D., and J.L. performed research; K.F.W., A.W., D.A.W., and S.E.S. analyzed data; Y.F.-C., M.P.D., and M.C.J. directed research; and K.F.W., A.S.K., and M.C.J. wrote the paper. All authors reviewed and edited the paper.

The authors declare the following competing financial interest(s): M.P.D. has a financial interest in Gauntlet, Inc., Glycobia, Inc., SwiftScale Biologics, Inc., Versatope, Inc., Gauntlet Bio, and UbiquiTx, Inc. M.C.J. has a financial interest in SwiftScale Biologics, Gauntlet Bio, Pearl Bio, Inc., Design Pharmaceutics, and Stemloop Inc. M.P.D.s and M.C.J.s interests are reviewed and managed by Cornell University and Northwestern University, respectively, in accordance with their competing interest policies. All other authors declare no competing interests.

Supplementary Material

References

- Scown C. D.; Keasling J. D. Sustainable Manufacturing with Synthetic Biology. Nat. Biotechnol. 2022, 40, 304–307. 10.1038/s41587-022-01248-8. [DOI] [PubMed] [Google Scholar]

- Khalil A. S.; Collins J. J. Synthetic Biology: Applications Come of Age. Nat. Rev. Genet. 2010, 11, 367–379. 10.1038/nrg2775. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Clomburg J. M.; Crumbley A. M.; Gonzalez R. Industrial Biomanufacturing: The Future of Chemical Production. Science 2017, 355, aag0804 10.1126/science.aag0804. [DOI] [PubMed] [Google Scholar]

- Acharya K. P.; Ghimire T. R.; Subramanya S. H. Access to and Equitable Distribution of COVID-19 Vaccine in Low-Income Countries. npj Vaccines 2021, 6, 54 10.1038/s41541-021-00323-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tinafar A.; Jaenes K.; Pardee K. Synthetic Biology Goes Cell-Free. BMC Biol. 2019, 17, 64 10.1186/s12915-019-0685-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Karim A. S.; Dudley Q. M.; Juminaga A.; Yuan Y.; Crowe S. A.; Heggestad J. T.; Garg S.; Abdalla T.; Grubbe W. S.; Rasor B. J.; Coar D. N.; Torculas M.; Krein M.; Liew F. E.; Quattlebaum A.; Jensen R. O.; Stuart J. A.; Simpson S. D.; Köpke M.; Jewett M. C. In Vitro Prototyping and Rapid Optimization of Biosynthetic Enzymes for Cell Design. Nat. Chem. Biol. 2020, 16, 912–919. 10.1038/s41589-020-0559-0. [DOI] [PubMed] [Google Scholar]

- Rasor B. J.; Yi X.; Brown H.; Alper H. S.; Jewett M. C. An Integrated in Vivo/in Vitro Framework to Enhance Cell-Free Biosynthesis with Metabolically Rewired Yeast Extracts. Nat. Commun. 2021, 12, 5139 10.1038/s41467-021-25233-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hunt A. C.; Case J. B.; Park Y.-J.; Cao L.; Wu K.; Walls A. C.; Liu Z.; Bowen J. E.; Yeh H.-W.; Saini S.; Helms L.; Zhao Y. T.; Hsiang T.-Y.; Starr T. N.; Goreshnik I.; Kozodoy L.; Carter L.; Ravichandran R.; Green L. B.; Matochko W. L.; Thomson C. A.; Vögeli B.; Krüger A.; VanBlargan L. A.; Chen R. E.; Ying B.; Bailey A. L.; Kafai N. M.; Boyken S. E.; Ljubetič A.; Edman N.; Ueda G.; Chow C. M.; Johnson M.; Addetia A.; Navarro M.-J.; Panpradist N.; Gale M. Jr; Freedman B. S.; Bloom J. D.; Ruohola-Baker H.; Whelan S. P. J.; Stewart L.; Diamond M. S.; Veesler D.; Jewett M. C.; Baker D. Multivalent Designed Proteins Neutralize SARS-CoV-2 Variants of Concern and Confer Protection against Infection in Mice. Sci. Transl. Med. 2022, 14, eabn1252 10.1126/scitranslmed.abn1252. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bundy B. C.; Hunt J. P.; Jewett M. C.; Swartz J. R.; Wood D. W.; Frey D. D.; Rao G. Cell-Free Biomanufacturing. Curr. Opin. Chem. Eng. 2018, 22, 177–183. 10.1016/j.coche.2018.10.003. [DOI] [Google Scholar]

- Adiga R.; Al-Adhami M.; Andar A.; Borhani S.; Brown S.; Burgenson D.; Cooper M. A.; Deldari S.; Frey D. D.; Ge X.; Guo H.; Gurramkonda C.; Jensen P.; Kostov Y.; LaCourse W.; Liu Y.; Moreira A.; Mupparapu K.; Peñalber-Johnstone C.; Pilli M.; Punshon-Smith B.; Rao A.; Rao G.; Rauniyar P.; Snovida S.; Taurani K.; Tilahun D.; Tolosa L.; Tolosa M.; Tran K.; Vattem K.; Veeraraghavan S.; Wagner B.; Wilhide J.; Wood D. W.; Zuber A. Point-of-Care Production of Therapeutic Proteins of Good-Manufacturing-Practice Quality. Nat. Biomed. Eng. 2018, 2, 675–686. 10.1038/s41551-018-0259-1. [DOI] [PubMed] [Google Scholar]

- Sullivan C. J.; Pendleton E. D.; Sasmor H. H.; Hicks W. L.; Farnum J. B.; Muto M.; Amendt E. M.; Schoborg J. A.; Martin R. W.; Clark L. G.; Anderson M. J.; Choudhury A.; Fior R.; Lo Y.-H.; Griffey R. H.; Chappell S. A.; Jewett M. C.; Mauro V. P.; Dresios J. A Cell-Free Expression and Purification Process for Rapid Production of Protein Biologics. Biotechnol. J. 2016, 11, 238–248. 10.1002/biot.201500214. [DOI] [PubMed] [Google Scholar]

- Pardee K.; Slomovic S.; Nguyen P. Q.; Lee J. W.; Donghia N.; Burrill D.; Ferrante T.; McSorley F. R.; Furuta Y.; Vernet A.; Lewandowski M.; Boddy C. N.; Joshi N. S.; Collins J. J. Portable, On-Demand Biomolecular Manufacturing. Cell 2016, 167, 248–259.e12. 10.1016/j.cell.2016.09.013. [DOI] [PubMed] [Google Scholar]

- Stark J. C.; Jaroentomeechai T.; Moeller T. D.; Hershewe J. M.; Warfel K. F.; Moricz B. S.; Martini A. M.; Dubner R. S.; Hsu K. J.; Stevenson T. C.; Jones B. D.; DeLisa M. P.; Jewett M. C. On-Demand Biomanufacturing of Protective Conjugate Vaccines. Sci. Adv. 2021, 7, abe9444 10.1126/sciadv.abe9444. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim D.-M.; Swartz J. R. Efficient Production of a Bioactive, Multiple Disulfide-Bonded Protein Using Modified Extracts of Escherichia Coli. Biotechnol. Bioeng. 2004, 85, 122–129. 10.1002/bit.10865. [DOI] [PubMed] [Google Scholar]

- Silverman A. D.; Karim A. S.; Jewett M. C. Cell-Free Gene Expression: An Expanded Repertoire of Applications. Nat. Rev. Genet. 2020, 21, 151–170. 10.1038/s41576-019-0186-3. [DOI] [PubMed] [Google Scholar]

- Carlson E. D.; Gan R.; Hodgman C. E.; Jewett M. C. Cell-Free Protein Synthesis: Applications Come of Age. Biotechnol. Adv. 2012, 30, 1185–1194. 10.1016/j.biotechadv.2011.09.016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hunt J. P.; Yang S. O.; Wilding K. M.; Bundy B. C. The Growing Impact of Lyophilized Cell-Free Protein Expression Systems. Bioengineered 2017, 8, 325–330. 10.1080/21655979.2016.1241925. [DOI] [PMC free article] [PubMed] [Google Scholar]

- McNerney M. P.; Zhang Y.; Steppe P.; Silverman A. D.; Jewett M. C.; Styczynski M. P. Point-of-Care Biomarker Quantification Enabled by Sample-Specific Calibration. Sci. Adv. 2019, 5, eaax4473 10.1126/sciadv.aax4473. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu X.; Silverman A. D.; Alam K. K.; Iverson E.; Lucks J. B.; Jewett M. C.; Raman S. Design of a Transcriptional Biosensor for the Portable, On-Demand Detection of Cyanuric Acid. ACS Synth. Biol. 2020, 9, 84–94. 10.1021/acssynbio.9b00348. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Thavarajah W.; Silverman A. D.; Verosloff M. S.; Kelley-Loughnane N.; Jewett M. C.; Lucks J. B. Point-of-Use Detection of Environmental Fluoride via a Cell-Free Riboswitch-Based Biosensor. ACS Synth. Biol. 2020, 9, 10–18. 10.1021/acssynbio.9b00347. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pardee K.; Green A. A.; Takahashi M. K.; Braff D.; Lambert G.; Lee J. W.; Ferrante T.; Ma D.; Donghia N.; Fan M.; Daringer N. M.; Bosch I.; Dudley D. M.; O’Connor D. H.; Gehrke L.; Collins J. J. Rapid, Low-Cost Detection of Zika Virus Using Programmable Biomolecular Components. Cell 2016, 165, 1255–1266. 10.1016/j.cell.2016.04.059. [DOI] [PubMed] [Google Scholar]

- Jung J. K.; Alam K. K.; Verosloff M. S.; Capdevila D. A.; Desmau M.; Clauer P. R.; Lee J. W.; Nguyen P. Q.; Pastén P. A.; Matiasek S. J.; Gaillard J.-F.; Giedroc D. P.; Collins J. J.; Lucks J. B. Cell-Free Biosensors for Rapid Detection of Water Contaminants. Nat. Biotechnol. 2020, 38, 1451–1459. 10.1038/s41587-020-0571-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nguyen P. Q.; Soenksen L. R.; Donghia N. M.; Angenent-Mari N. M.; de Puig H.; Huang A.; Lee R.; Slomovic S.; Galbersanini T.; Lansberry G.; Sallum H. M.; Zhao E. M.; Niemi J. B.; Collins J. J. Wearable Materials with Embedded Synthetic Biology Sensors for Biomolecule Detection. Nat. Biotechnol. 2021, 39, 1366–1374. 10.1038/s41587-021-00950-3. [DOI] [PubMed] [Google Scholar]

- Salehi A. S. M.; Smith M. T.; Bennett A. M.; Williams J. B.; Pitt W. G.; Bundy B. C. Cell-Free Protein Synthesis of a Cytotoxic Cancer Therapeutic: Onconase Production and a Just-Add-Water Cell-Free System. Biotechnol. J. 2016, 11, 274–281. 10.1002/biot.201500237. [DOI] [PubMed] [Google Scholar]

- Hunt A. C.; Vögeli B.; Kightlinger W. K.; Yoesep D. J.. et al. A High-Throughput, Automated, Cell-Free Expression and Screening Platform for Antibody Discovery bioRxiv, 2021. [DOI] [PMC free article] [PubMed]

- Zawada J. F.; Yin G.; Steiner A. R.; Yang J.; Naresh A.; Roy S. M.; Gold D. S.; Heinsohn H. G.; Murray C. J. Microscale to Manufacturing Scale-up of Cell-Free Cytokine Production--a New Approach for Shortening Protein Production Development Timelines. Biotechnol. Bioeng. 2011, 108, 1570–1578. 10.1002/bit.23103. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tiffay K.; Jodar L.; Kieny M.-P.; Socquet M.; LaForce F. M. The Evolution of the Meningitis Vaccine Project. Clin. Infect. Dis. 2015, 61, S396–S403. 10.1093/cid/civ594. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zipursky S.; Djingarey M. H.; Lodjo J.-C.; Olodo L.; Tiendrebeogo S.; Ronveaux O. Benefits of Using Vaccines out of the Cold Chain: Delivering Meningitis A Vaccine in a Controlled Temperature Chain during the Mass Immunization Campaign in Benin. Vaccine 2014, 32, 1431–1435. 10.1016/j.vaccine.2014.01.038. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cai Q.; Hanson J. A.; Steiner A. R.; Tran C.; Masikat M. R.; Chen R.; Zawada J. F.; Sato A. K.; Hallam T. J.; Yin G. A Simplified and Robust Protocol for Immunoglobulin Expression in Escherichia Coli Cell-Free Protein Synthesis Systems. Biotechnol. Prog. 2015, 31, 823–831. 10.1002/btpr.2082. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim T.-W.; Keum J.-W.; Oh I.-S.; Choi C.-Y.; Kim H.-C.; Kim D.-M. An Economical and Highly Productive Cell-Free Protein Synthesis System Utilizing Fructose-1,6-Bisphosphate as an Energy Source. J. Biotechnol. 2007, 130, 389–393. 10.1016/j.jbiotec.2007.05.002. [DOI] [PubMed] [Google Scholar]

- Calhoun K. A.; Swartz J. R. An Economical Method for Cell-Free Protein Synthesis Using Glucose and Nucleoside Monophosphates. Biotechnol. Prog. 2008, 21, 1146–1153. 10.1021/bp050052y. [DOI] [PubMed] [Google Scholar]

- Kim H.-C.; Kim T.-W.; Kim D.-M. Prolonged Production of Proteins in a Cell-Free Protein Synthesis System Using Polymeric Carbohydrates as an Energy Source. Process Biochem. 2011, 46, 1366–1369. 10.1016/j.procbio.2011.03.008. [DOI] [Google Scholar]

- Yang J.; Cui Y.; Cao Z.; Ma S.; Lu Y. Strategy Exploration for Developing Robust Lyophilized Cell-Free Systems. Biotechnology Notes 2021, 2, 44–50. 10.1016/j.biotno.2021.08.004. [DOI] [Google Scholar]

- Karig D. K.; Bessling S.; Thielen P.; Zhang S.; Wolfe J. Preservation of Protein Expression Systems at Elevated Temperatures for Portable Therapeutic Production. J. R. Soc. Interface 2017, 14, 20161039 10.1098/rsif.2016.1039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wilding K. M.; Zhao E. L.; Earl C. C.; Bundy B. C. Thermostable Lyoprotectant-Enhanced Cell-Free Protein Synthesis for on-Demand Endotoxin-Free Therapeutic Production. New Biotechnol. 2019, 53, 73–80. 10.1016/j.nbt.2019.07.004. [DOI] [PubMed] [Google Scholar]

- Rappuoli R.; De Gregorio E.; Costantino P. On the Mechanisms of Conjugate Vaccines. Proc. Natl. Acad. Sci. U.S.A. 2019, 116, 14–16. 10.1073/pnas.1819612116. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jin C.; Gibani M. M.; Moore M.; Juel H. B.; Jones E.; Meiring J.; Harris V.; Gardner J.; Nebykova A.; Kerridge S. A.; et al. Efficacy and Immunogenicity of a Vi-Tetanus Toxoid Conjugate Vaccine in the Prevention of Typhoid Fever Using a Controlled Human Infection Model of Salmonella Typhi: A Randomised Controlled, Phase 2b Trial. Lancet 2017, 390, 2472–2480. 10.1016/S0140-6736(17)32149-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Trotter C. L.; McVernon J.; Ramsay M. E.; Whitney C. G.; Mulholland E. K.; Goldblatt D.; Hombach J.; Kieny M.-P.; Optimising the Use of Conjugate Vaccines to Prevent Disease Caused by Haemophilus Influenzae Type b, Neisseria Meningitidis and Streptococcus Pneumoniae. Vaccine 2008, 26, 4434–4445. 10.1016/j.vaccine.2008.05.073. [DOI] [PubMed] [Google Scholar]

- Micoli F.; Costantino P.; Adamo R. Potential Targets for next Generation Antimicrobial Glycoconjugate Vaccines. FEMS Microbiol. Rev. 2018, 42, 388–423. 10.1093/femsre/fuy011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- on Antimicrobial Resistance (London)., R.; Grande-Bretagne. Antimicrobial Resistance: Tackling a Crisis for the Health and Wealth of Nations: December 2014; Review on antimicrobial resistance, 2014.

- Jewett M. C.; Swartz J. R. Mimicking the Escherichia Coli Cytoplasmic Environment Activates Long-Lived and Efficient Cell-Free Protein Synthesis. Biotechnol. Bioeng. 2004, 86, 19–26. 10.1002/bit.20026. [DOI] [PubMed] [Google Scholar]

- Gregorio N. E.; Kao W. Y.; Williams L. C.; Hight C. M.; Patel P.; Watts K. R.; Oza J. P. Unlocking Applications of Cell-Free Biotechnology through Enhanced Shelf Life and Productivity of E. Coli Extracts. ACS Synth. Biol. 2020, 9, 766–778. 10.1021/acssynbio.9b00433. [DOI] [PubMed] [Google Scholar]

- Smith M. T.; Berkheimer S. D.; Werner C. J.; Bundy B. C. Lyophilized Escherichia Coli-Based Cell-Free Systems for Robust, High-Density, Long-Term Storage. Biotechniques 2014, 56, 186–193. 10.2144/000114158. [DOI] [PubMed] [Google Scholar]

- Calhoun K. A.; Swartz J. R. Energizing Cell-Free Protein Synthesis with Glucose Metabolism. Biotechnol. Bioeng. 2005, 90, 606–613. 10.1002/bit.20449. [DOI] [PubMed] [Google Scholar]

- Anderson M. J.; Stark J. C.; Hodgman C. E.; Jewett M. C. Energizing Eukaryotic Cell-Free Protein Synthesis with Glucose Metabolism. FEBS Lett. 2015, 589, 1723–1727. 10.1016/j.febslet.2015.05.045. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Caschera F.; Noireaux V. Synthesis of 2.3 Mg/Ml of Protein with an All Escherichia Coli Cell-Free Transcription–Translation System. Biochimie 2014, 99, 162–168. 10.1016/j.biochi.2013.11.025. [DOI] [PubMed] [Google Scholar]

- Caschera F.; Noireaux V. A Cost-Effective Polyphosphate-Based Metabolism Fuels an All E. Coli Cell-Free Expression System. Metab. Eng. 2015, 27, 29–37. 10.1016/j.ymben.2014.10.007. [DOI] [PubMed] [Google Scholar]

- Wang Y.; Zhang Y.-H. P. Cell-Free Protein Synthesis Energized by Slowly-Metabolized Maltodextrin. BMC Biotechnol. 2009, 9, 58. 10.1186/1472-6750-9-58. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Guzman-Chavez F.; Arce A.; Adhikari A.; Vadhin S.; Pedroza-Garcia J. A.; Gandini C.; Ajioka J. W.; Molloy J.; Sanchez-Nieto S.; Varner J. D.; Federici F.; Haseloff J. Constructing Cell-Free Expression Systems for Low-Cost Access. ACS Synth. Biol. 2022, 11, 1114–1128. 10.1021/acssynbio.1c00342. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Arce A.; Guzman Chavez F.; Gandini C.; Puig J.; Matute T.; Haseloff J.; Dalchau N.; Molloy J.; Pardee K.; Federici F. Decentralizing Cell-Free RNA Sensing With the Use of Low-Cost Cell Extracts. Front Bioeng. Biotechnol. 2021, 9, 727584 10.3389/fbioe.2021.727584. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hershewe J. M.; Warfel K. F.; Iyer S. M.; Peruzzi J. A.; Sullivan C. J.; Roth E. W.; DeLisa M. P.; Kamat N. P.; Jewett M. C. Improving Cell-Free Glycoprotein Synthesis by Characterizing and Enriching Native Membrane Vesicles. Nat. Commun. 2021, 12, 2363 10.1038/s41467-021-22329-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Khalil I.; Walker R.; Porter C. K.; Muhib F.; Chilengi R.; Cravioto A.; Guerrant R.; Svennerholm A.-M.; Qadri F.; Baqar S.; Kosek M.; Kang G.; Lanata C.; Armah G.; Wierzba T.; Hasso-Agopsowicz M.; Giersing B.; Louis Bourgeois A. Enterotoxigenic Escherichia Coli (ETEC) Vaccines: Priority Activities to Enable Product Development, Licensure, and Global Access. Vaccine 2021, 39, 4266–4277. 10.1016/j.vaccine.2021.04.018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- von Mentzer A.; Connor T. R.; Wieler L. H.; Semmler T.; Iguchi A.; Thomson N. R.; Rasko D. A.; Joffre E.; Corander J.; Pickard D.; Wiklund G.; Svennerholm A.-M.; Sjöling Å.; Dougan G. Identification of Enterotoxigenic Escherichia Coli (ETEC) Clades with Long-Term Global Distribution. Nat. Genet. 2014, 46, 1321–1326. 10.1038/ng.3145. [DOI] [PubMed] [Google Scholar]

- Palmu A. A.; Jokinen J.; Borys D.; Nieminen H.; Ruokokoski E.; Siira L.; Puumalainen T.; Lommel P.; Hezareh M.; Moreira M.; Schuerman L.; Kilpi T. M. Effectiveness of the Ten-Valent Pneumococcal Haemophilus Influenzae Protein D Conjugate Vaccine (PHiD-CV10) against Invasive Pneumococcal Disease: A Cluster Randomised Trial. Lancet 2013, 381, 214–222. 10.1016/S0140-6736(12)61854-6. [DOI] [PubMed] [Google Scholar]

- Stamatis C.; Farid S. S. Process Economics Evaluation of Cell-Free Synthesis for the Commercial Manufacture of Antibody Drug Conjugates. Biotechnol. J. 2021, 16, e2000238 10.1002/biot.202000238. [DOI] [PubMed] [Google Scholar]

- Valentine J. L.; Chen L.; Perregaux E. C.; Weyant K. B.; Rosenthal J. A.; Heiss C.; Azadi P.; Fisher A. C.; Putnam D.; Moe G. R.; Merritt J. H.; DeLisa M. P. Immunization with Outer Membrane Vesicles Displaying Designer Glycotopes Yields Class-Switched, Glycan-Specific Antibodies. Cell Chem. Biol. 2016, 23, 655–665. 10.1016/j.chembiol.2016.05.014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Çelik E.; Ollis A. A.; Lasanajak Y.; Fisher A. C.; Gür G.; Smith D. F.; DeLisa M. P. Glycoarrays with Engineered Phages Displaying Structurally Diverse Oligosaccharides Enable High-Throughput Detection of Glycan-Protein Interactions. Biotechnol. J. 2015, 10, 199–209. 10.1002/biot.201400354. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Svennerholm A.-M.; Qadri F.; Lundgren A.; Kaim J.; Rahman Bhuiyan T.; Akhtar M.; Maier N.; Louis Bourgeois A.; Walker R. I. Induction of Mucosal and Systemic Immune Responses against the Common O78 Antigen of an Oral Inactivated ETEC Vaccine in Bangladeshi Children and Infants. Vaccine 2022, 40, 380–389. 10.1016/j.vaccine.2021.10.056. [DOI] [PubMed] [Google Scholar]

- Lee C. H.; Tsai C. M. Quantification of Bacterial Lipopolysaccharides by the Purpald Assay: Measuring Formaldehyde Generated from 2-Keto-3-Deoxyoctonate and Heptose at the Inner Core by Periodate Oxidation. Anal. Biochem. 1999, 267, 161–168. 10.1006/abio.1998.2961. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.