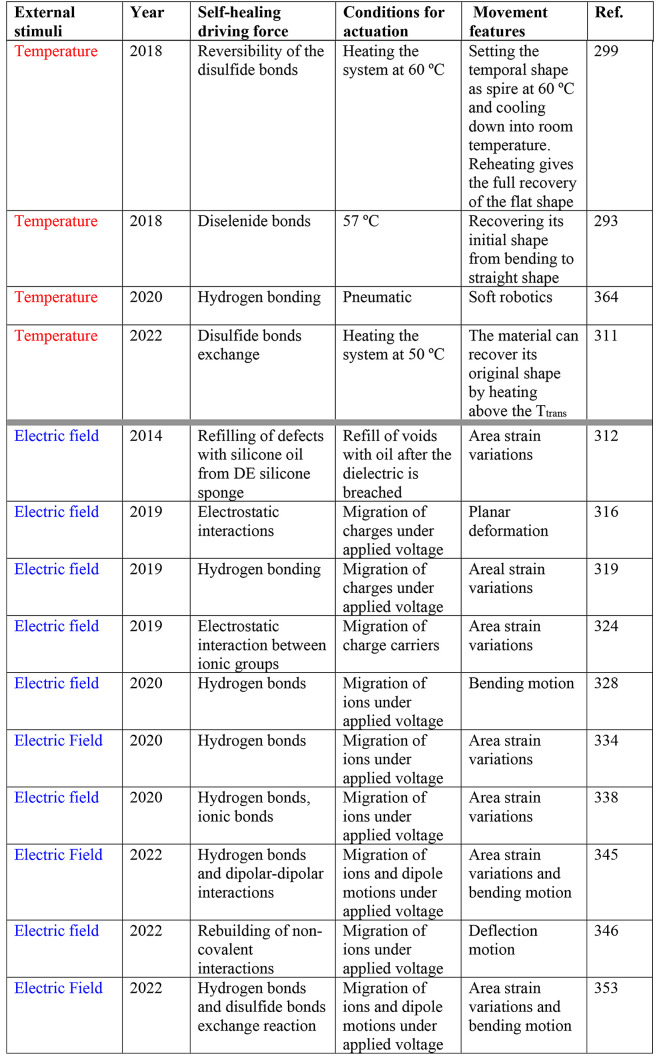

Abstract

Natural evolution has provided multicellular organisms with sophisticated functionalities and repair mechanisms for surviving and preserve their functions after an injury and/or infection. In this context, biological systems have inspired material scientists over decades to design and fabricate both self-healing polymeric materials and soft actuators with remarkable performance. The latter are capable of modifying their shape in response to environmental changes, such as temperature, pH, light, electrical/magnetic field, chemical additives, etc. In this review, we focus on the fusion of both types of materials, affording new systems with the potential to revolutionize almost every aspect of our modern life, from healthcare to environmental remediation and energy. The integration of stimuli-triggered self-healing properties into polymeric soft actuators endow environmental friendliness, cost-saving, enhanced safety, and lifespan of functional materials. We discuss the details of the most remarkable examples of self-healing soft actuators that display a macroscopic movement under specific stimuli. The discussion includes key experimental data, potential limitations, and mechanistic insights. Finally, we include a general table providing at first glance information about the nature of the external stimuli, conditions for self-healing and actuation, key information about the driving forces behind both phenomena, and the most important features of the achieved movement.

1. Introduction

1.1. Self-Healing Soft Materials

Over millions of years of evolution, multicellular organisms have developed different repair mechanisms to survive in a specific ecosystem and preserve their functions after an injury and/or infection.1−4 The large biological diversity in the animal and plant kingdoms has resulted in astoundingly diverse types of healing processes found in nature.2,5−7 In general, the biological complexity of living systems is matched by complexity in the healing mechanism. Although plants and animals share some key aspects of healing processes, their differences in need and biology generate also unique pathways, such as clotting in animals and damage containment (i.e., process of discarding infected/damaged tissue) in plants.1 Some of the most appealing examples of biological healing include, just to mention a few, the muscle contraction and extension through the transformation of chemical to mechanical energy,8−10 adaptive camouflage through muscle control,11 both innate and adaptative immune response of animals and plants,12 the regeneration of nervous systems by maintaining the homeostatic environment surrounding the nerves,13,14 the healing of hard11,15 and soft tissues8,16,17 in both vertebrate and invertebrates through a complex set of cellular signals and humoral responses, the release of special secretion cells or vascular networks to release healing molecular fluid when an injury breaks the cell walls of some plants,1 and the self-healing process of the human skin via an inflammatory response of cells below the dermis by increasing collagen production.18

What seems to be clear is that the self-healing processes found in living systems involves a complex cascade of physical events and chemical reactions, however, the exact chemistries of which are far from understood in many cases even though scientists continue to seek inspiration in biological systems to design new and more reliable self-healing materials. In materials, the presence of local regions with lower performance than that of the surrounding areas is referred as damage.19 Thus, the challenge in the design of self-healing materials is centered in the fabrication of new systems, in most cases composites, with an autonomous or externally stimulated damage healing ability in order to extend their useful life in a given application. Therefore, the incorporation of, for instance, self-healing agents in a material would likely modify its properties. Hence, it is of utmost importance to monitor those changes in order to assess the performance of the new material, which ideally should be at least equal to that of the unmodified system. From a practical point of view, we should consider that in most cases the ability of self-healing materials to recuperate, autonomously20 or externally assisted, their initial properties is mainly affected by the selection of the healing agents. As a matter of fact, a large variety of self-healing agents have been extensively studied to meet the highly demanding requirements of smart materials for high-tech applications.

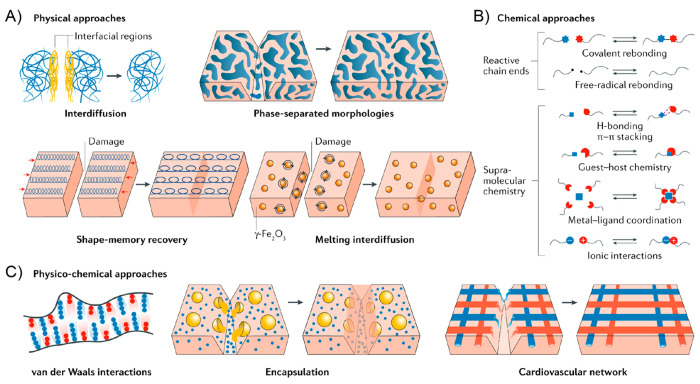

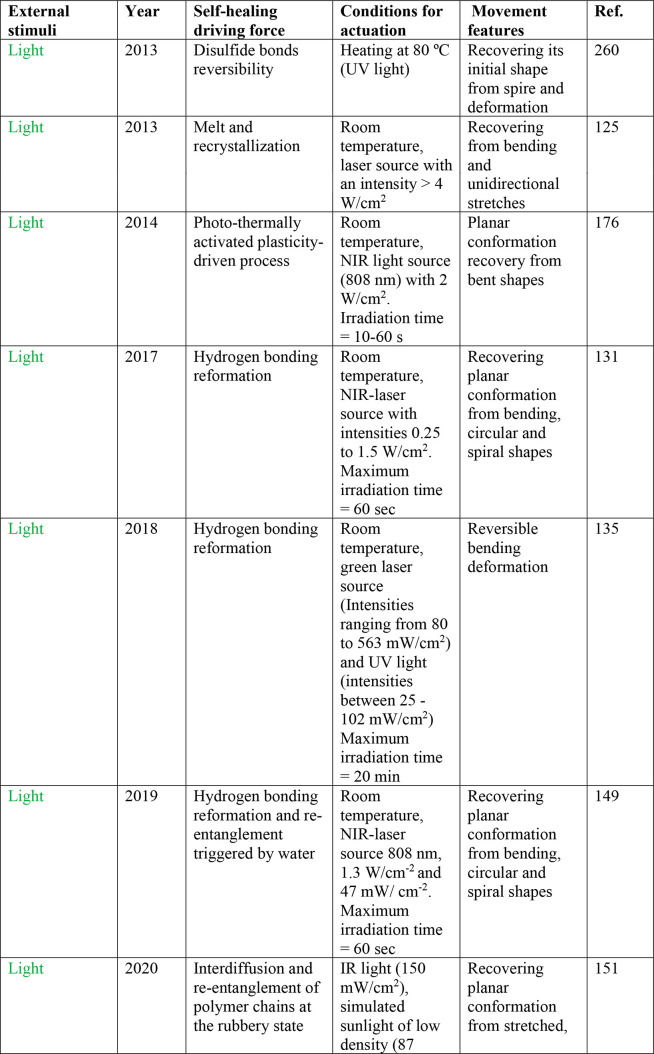

Within this context, the principal strategies for the synthesis of self-healable polymers involve either physical or chemical occurrences at the molecular level, although an overlap between the two approaches results are evident when looking at the self-healing phenomenon as a whole.21,22 As shown in Figure 1, the most common examples of physical self-healing processes involve interchain diffusion,23 phase-separated morphologies,24,25 shape-memory effects,26,27 and the incorporation of superparamagnetic nanoparticles.28 On the other hand, chemical self-healing processes comprise mainly the integration of covalent,29−31 free-radical,32,33 or supramolecular25,34−36 dynamic bonds into the material.37 As mentioned, the combination of physical and chemical events constitutes also a versatile strategy for fine-tuning the healing process of the materials with multiscale complexity such as interdigitated copolymer morphologies20 and cardiovascular networks.38

Figure 1.

Self-healing mechanisms. (A) Physical processes to realize self-healing include interdiffusion of polymer chains, the introduction of phase-separated morphologies, shape-memory effects, and the introduction of active nanoparticles into a polymer matrix. (B) Chemical processes to facilitate self-healing involve either introducing reactive chain ends or supramolecular chemistries. (C) Physical and chemical processes can be combined to realize self-healing. Self-healing is achieved by incorporating enhanced van der Waals interactions, or encapsulating nanocapsules or microcapsules containing reactive liquids to heal a wound, or by mimicking cardiovascular architectures composed of hollow fibers filled with reactive chemicals to heal a polymer matrix. Reproduced with permission from ref (21). Copyright 2020 Nature Publishing Group.

Based on the publications and patents reported during the last decades on this vast field, intrinsic (i.e., without external input), capsule-based, and vascular methods constitute probably the main approaches used in order to impart self-healing capability to different materials. In the case of intrinsic self-healing materials, such as the pioneering epoxy systems,31 repair is achieved through the inherent reversibility of bonding in the polymer matrix phase. Furthermore, among a significant number of reversible reactions,39−41 the thermal Diels–Alder (DA) reaction for cross-linking linear polymers42−45 and disulfide bond formation,46 together with the usage of host–guest interactions47 have been widely explored for the fabrication of self-healing composites capable of multiple healing.48 Furthermore, a promising chemical strategy combining reversible covalent linkages through imine bond formation with noncovalent interactions through hydrogen bonds has been also reported.49 Alternatively, microcapsule-based self-healing materials were first proposed by White et al.20 and nowadays are highly extended due to their ease of applicability and their potential for mass production. These microcapsules, embedded in the polymer matrix, contain the specific healing agent that will be delivered to the damaged zone upon physical rupture of the capsule.50,51 In particular, capsule-based self-healing coatings have been studied by many research groups during the past few years due to the increased importance of preserving the potential of protection of the underlying substrate.52−60 Finally, similar to blood vessels, vascular self-healing materials incorporate healing agents into a polymer matrix through well-defined microchannels, an idea originally proposed by Toohey et al.61 Vascular self-healing materials have been extensively reported during the past decade due to their healing versatility and the large scale of damage that can be healed with this method.62−72 With all this in mind, the possibility of providing self-healing capability not only to static materials but also to stimuli-responsive dynamic systems (i.e., actuators) has been a focus of attention in both academia and industry.

1.2. Polymeric Actuators

Polymer actuators constitute a very important class of materials capable of modifying their shape in response to changes in the environment, such as temperature, pH, light, electrical/magnetic field, and/or chemical additives, among others.73−75 A key challenge in this field is to develop robust actuators with programmable motion and high strain density.76−81 Such materials would be easy to produce, mold, cut, and three-dimensional (3D) print while generating large macroscopic actuation at relatively low energy input. Similar to self-healing materials, many polymeric actuators resemble biological soft actuators that display a diversity of motion.82 Indeed, both plants and animals possess complex actuation systems controlled mainly by two types of actuators, muscle cells for animals83 and turgor-driven cells for plants,84 that transform chemical energy into mechanical output. The muscle cells contract or stiffen when activated, while the turgor cells undergo volume expansion or shrinkage by autonomous or voluntary excitation. Although these actuators are controlled by the nervous systems or signaling molecules, there are some examples in plants where the motion depends on the passive deformation of hygroscopic materials at different humidity conditions.85 Along this line, another sophisticated natural process is the opening of a pinecone to release seeds at low humidity conditions.86 These systems consist of two macroscopic layers of tissues with different degrees of hygroscopic swelling, the scales of pinecone bend outward as the outer layer shrinks greater under decreasing humidity. The swelling ability of the two layers is controlled at the cellular level through a specific arrangement of cellulose microfibrils. It is very important to realize that cell-level actuators are shaped, assembled, and structures well-arranged in a hierarchical manner, which govern their macroscopic actuation efficiency.85 From the mechanical standpoint, the actuation is controlled by the stress and strain distribution at various structural levels of well-organized components within the corresponding supporting matrices.

Within this scenario, many researchers are continually looking for inspiration in biological systems to create new generations of automaton soft actuators (also referred as soft robotics) with high degrees of freedom and mechanical properties closer to natural actuators compared to conventional rigid actuators (e.g., electric motors). The advantages of lightweight soft actuators include, among others, flexibility, safety in interaction with humans (e.g., healthcare applications), availability of a wide range of materials and mechanical properties, and use of various stimuli for the actuation. Due to their softness and compliance, soft actuators are widely used in different applications such as packing, food processing, microfabrication, robotics, lab-on-a-chip systems, etc.74,87,88 Since the pioneering work reporting an aircraft electric actuator in 1944,89 more than 150 000 scientific papers have been dedicated to the study of actuators, which proves the great interest aroused by these materials.

Most soft actuators are made of synthetic polymers mainly due to their great tunability, as they can be soft and hard depending on their chemical and physical structure.90,91 Furthermore, the large variety of different physical and chemical inputs enables a broad range of strain, stress, and conformations compared to traditional ceramic or metallic based actuators.92 In terms of the fabrication techniques,77 they usually begin from the liquid form such as melts or solutions, followed by solidification through cooling, solvent evaporation, and/or curing (i.e., cross-linking). In general, one-dimensional (1D), two-dimensional (2D), and 3D structures can be fabricated by extrusion, casting, and various molding techniques, with a range of structural characteristics and features from nano to macro levels. Moreover, more complex shapes such as hollow inner structures can be achieved in one single step by 3D printing.

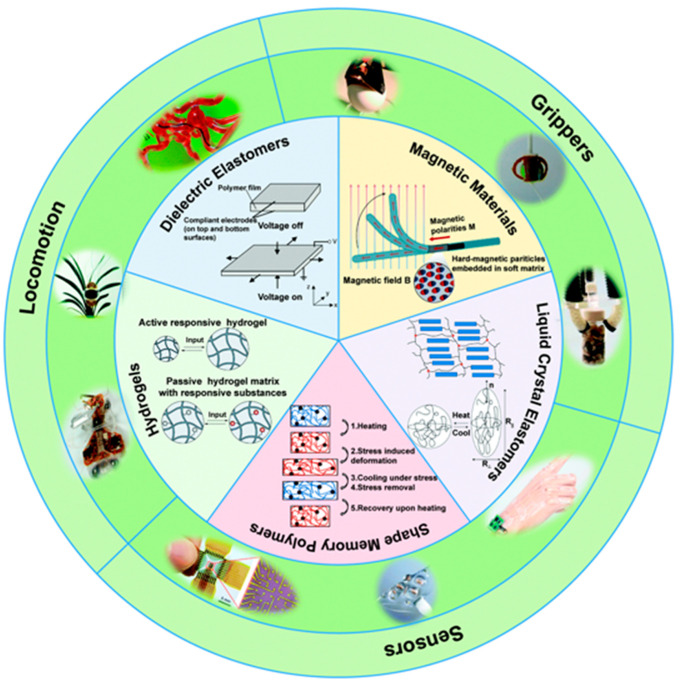

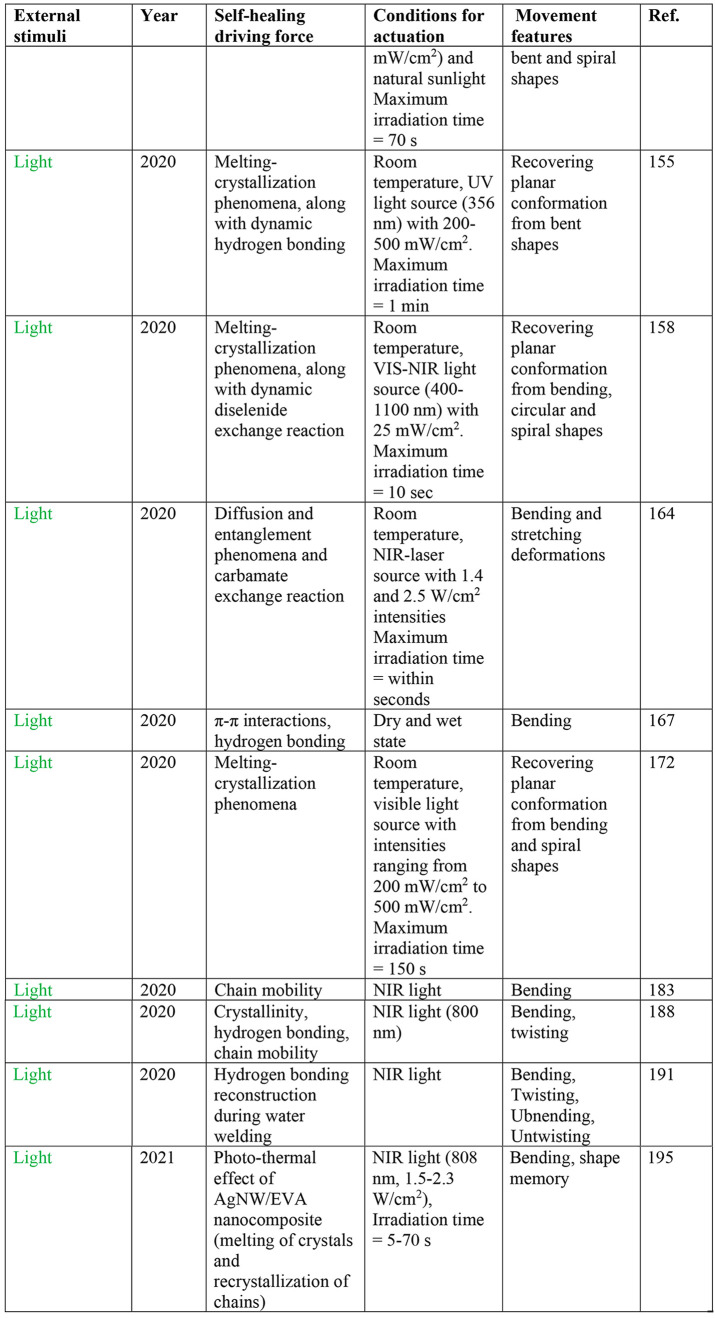

Exploring the literature over the last decades, there are a large number of examples of soft actuators93 based on shape-memory polymers94−97 and electro-/magneto-active1,98−104 polymers, dielectric elastomers,76,105−109 liquid crystal elastomers,110−113 and hydrogels,114−118 among others119 (Figure 2). In this sense, electric field, magnetic field, light, and temperature are the most common stimuli employed for the actuation.120,121

Figure 2.

General overview of typical stimuli-responsive materials and their applications for soft robotics. Reproduced with permission from ref (93). Copyright 2020 Royal Society of Chemistry.

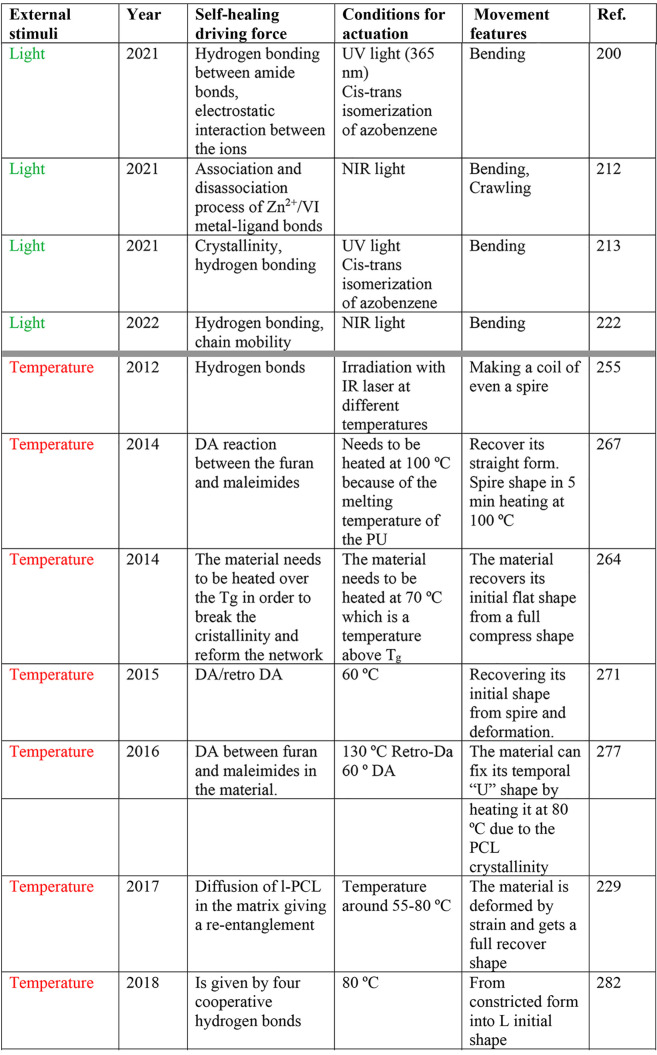

1.3. Scope of This Review

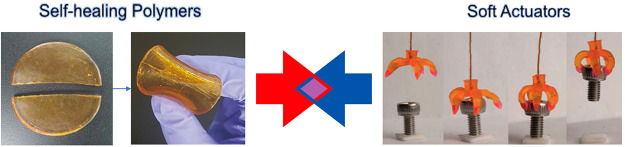

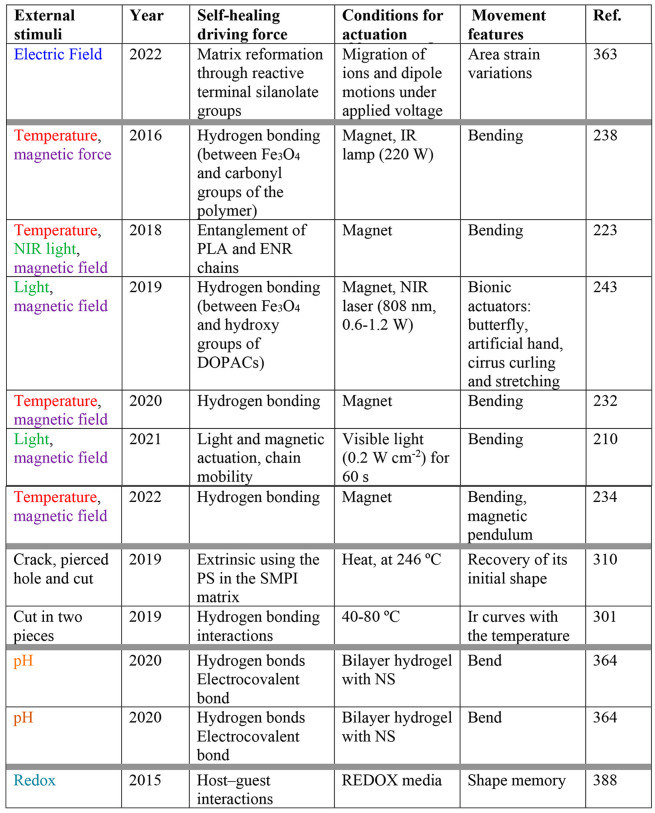

Despite all OF the advantages of soft materials, they are more prone to damage, especially in dynamic and arbitrary circumstances. Thus, their common limited lifespan may lead to unsustainable future applications.122 Thus, in an attempt to increase the reliability of soft actuators for practical applications, it would be extremely useful to provide polymeric soft actuators with self-repairing capabilities to continue operating with unchanged performance after a damage or breakdown. Thus, with this review we focus on a marriage of convenience between the best of the two worlds, self-healing polymers and soft actuators (Figure 3), which should also endow the final materials with environmental friendliness, cost-saving, enhanced safety, and life prolonging by maintaining structure and functionality after a damage. In order to better define the scope of this review, we have concentrated our efforts toward the identification of self-healing soft actuators that display a macroscopic movement under certain environmental conditions. Thus, those examples of self-healing polymers without visual movement or soft actuators without self-healing capacity are out of the scope of this review. Representative literature for those examples is distributed in the previous introductory sections. In addition, typical swelling/deswelling behavior of hydrogels (e.g., used for drug delivery applications) was not considered within the macroscopic actuation. Regarding the use of external stimuli associated with the functionality of the materials, a large part of the review is centered in photo, magnetic, thermal, and electric actuators, those being examples clearly the most abundant in the literature. A few additional instances dealing with pH-, mechanical-, and redox-based actuation are also included in the last section. In order to provide a temporal context to the field, we have provided a chronological discussion of the development of the different materials within each section based on the external stimuli employed. We present a discussion of the major achievements by discussing the key experimental details that are critical for a given system, potential limitations, and mechanistic insights for both the self-healing and the actuation processes. Finally, we have compiled the contributions in a general table, providing at first glance the nature of the external stimuli, conditions for self-healing and actuation, key information about the driving forces for both phenomena, and the most important features of the achieved movement. We believe this table will be very useful for all researchers interested in soft actuators with self-healing capacity.

Figure 3.

Scope of this review: Merging self-healing polymers with soft actuators. (left) Adapted with permission from ref (123). Copyright 2018 John Wiley and Sons. (right) Adapted with permission from ref (124). Copyright 2016 Authors, Springer Nature.

2. Self-Healing Polymeric Actuators

2.1. Self-Healing Photo-Actuators

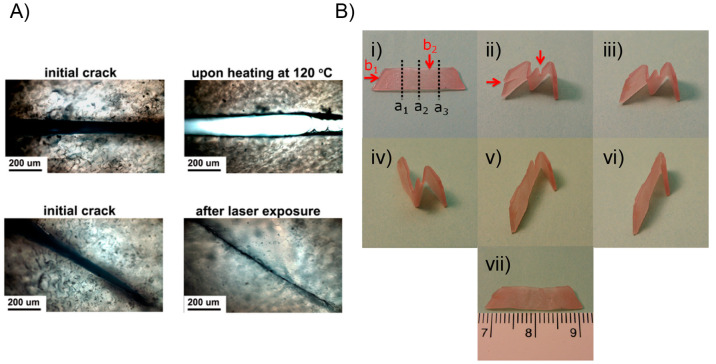

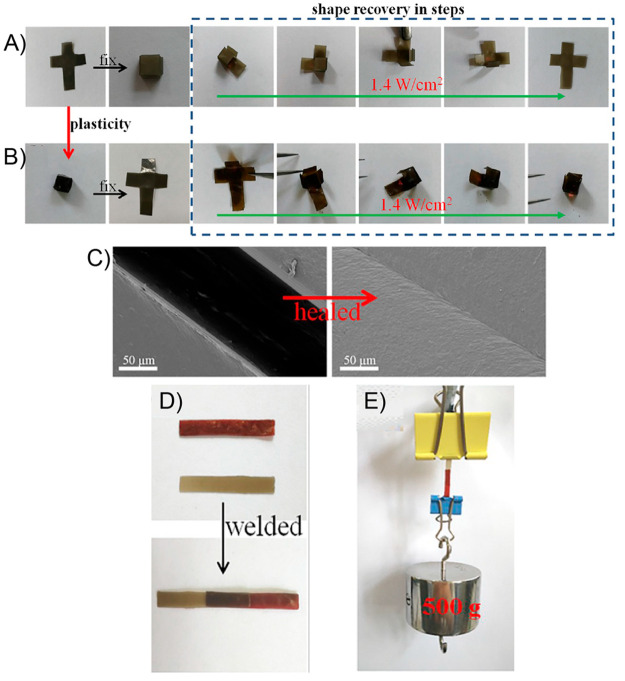

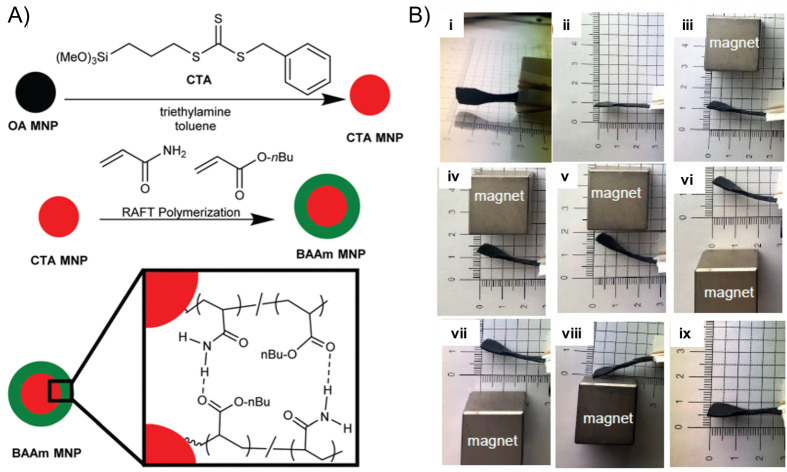

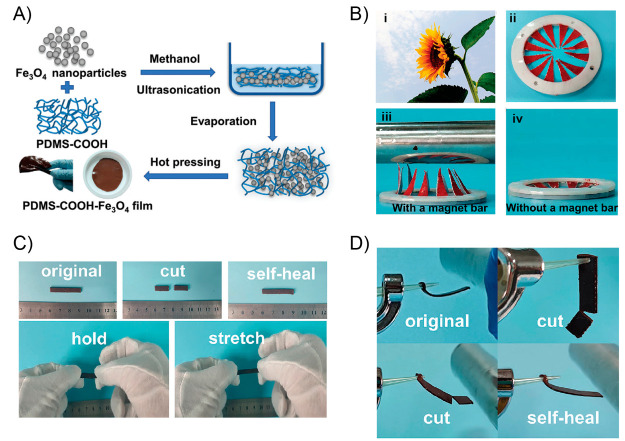

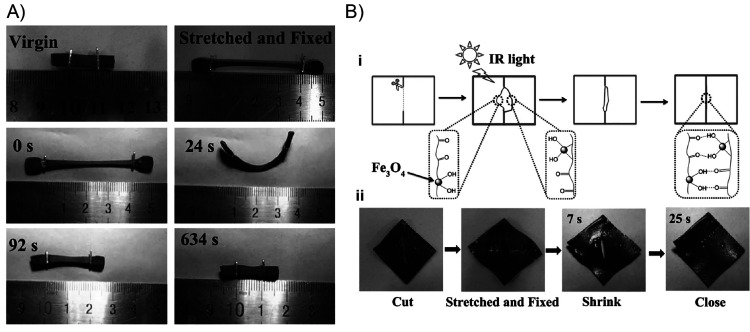

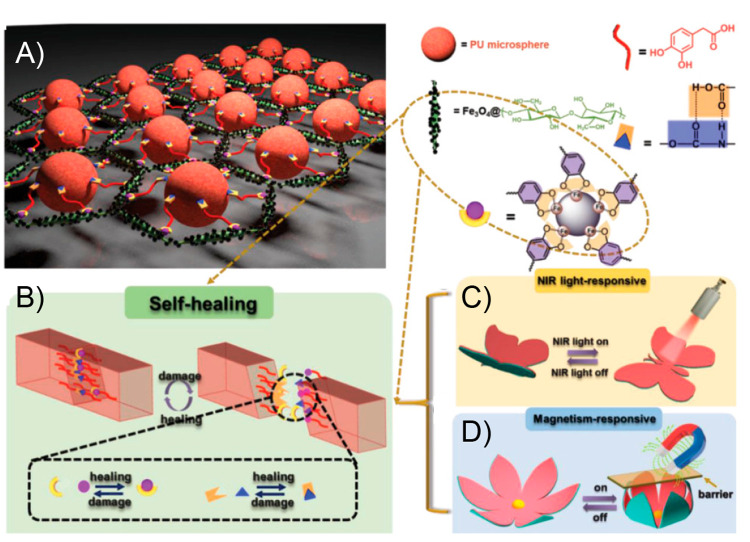

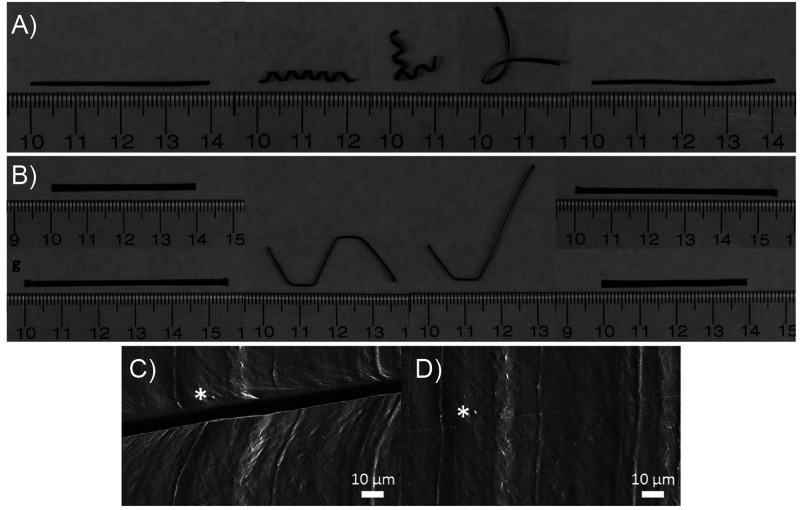

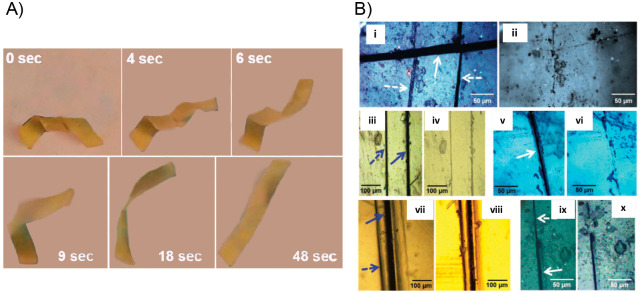

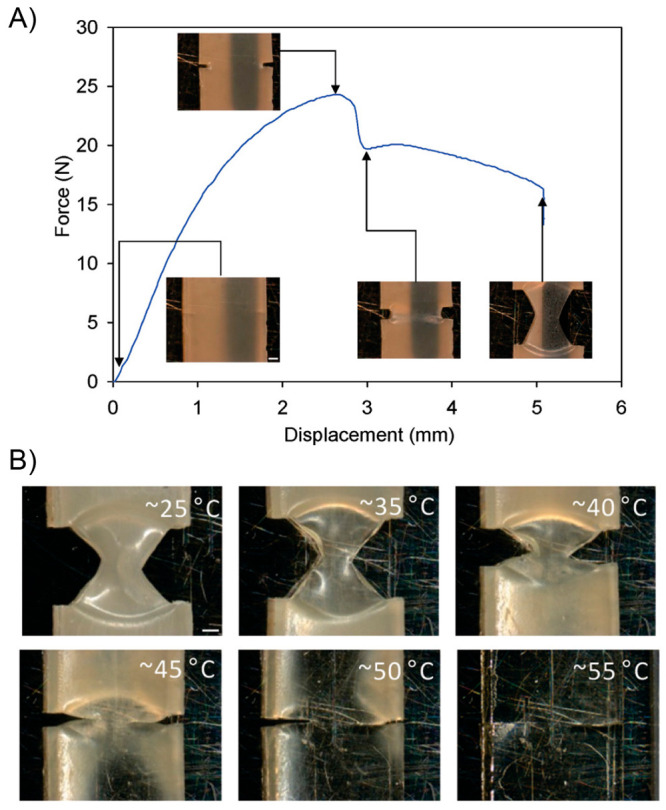

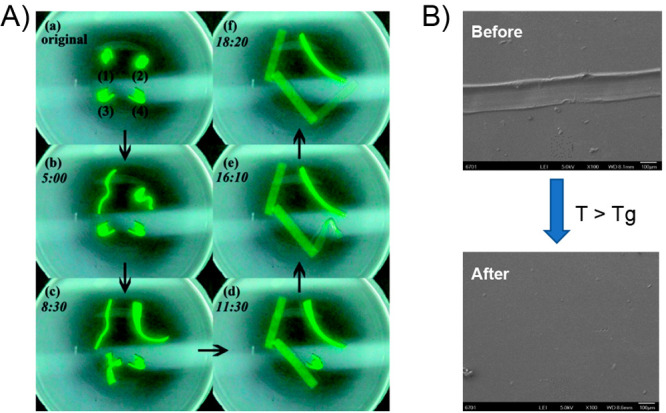

In 2013, Zhang and Zhao reported the first polymer-based nanocomposite exhibiting both shape-memory and self-healing properties triggered by light stimuli which, in addition, can be activated independently and sequentially in the same material.125 This material, under light irradiation, was able to recover its initial shape in a fast-manner after suffering folds or unidirectional stretches, as well as heal from cut-through cracks. Experimentally, the design of the material involved the inclusion of small amounts of Au nanoparticles (AuNPs) (0.003 wt % (wt %)) into chemically cross-linked poly(ethylene oxide) (PEO) matrices, presenting crystalline domains capable of performing reversible melting phenomena. To achieve a good nanoparticle dispersion, AuNPs with an average diameter of 10 nm were decorated superficially with PEO brushes and added into a mixture of APS, N,N,N′,N′-tetramethylethylenediamine (TMEDA), and a linear PEO derivative with both ends modified with acrylate structures. Films of reticulated PEO/AuNP were prepared by exposing the above mixture to a curing process performed at room temperature and 60 °C, consecutively, for a total time of 4 days. The authors devised the inclusion of AuNPs motivated by the photothermal effect that arises from the surface plasmon resonance phenomenon that these entities experience under light irradiation.126−129 Thereby, during light irradiation, local heat is generated at the surroundings of AuNPs, which is later dissipated through the polymer matrix allowing the tuning of the local temperature with respect to the melting temperature of the semicrystalline reticulated material. Therefore, by inducing melting and recrystallization processes inside the material, both shape recovery and healing phenomena can be activated. In terms of the light-controlled shape-memory property, the achieved material was able to completely recover from a 400% stretch deformation. The initial material was stretched unidirectionally at 80 °C (temperature (T) > melting temperature (Tm)) and rapidly cooled at room temperature to fix the temporary shape. Then, using a laser source (530 nm, 7 W/cm2) and irradiating different areas of the material, it was possible to return it to its initial dimensions. Moreover, authors were able to demonstrate the on–off behavior of this process, along with its dependence on the laser intensity which turns out to be directly related to the local temperature generated. Regarding the self-healing capability triggered by light, the material showed an outstanding ability to recover from a cut-through crack created with a razor blade (Figure 4A). Surprisingly, by exposing the damaged area to a laser (13 W/cm2) during 3 s at room temperature, a single piece was obtained which was able to stand >14000 times its own weight, ensuring a correct and efficient healing property. As a complement to the above, tensile tests were carried out, showing that healed samples gained about 62% of its original tensile strength. Authors explained the healing process through a mechanism where polymer chains present in the melted portion of the material can re-entangle between each other and then fix their positions during the recrystallization of the material. However, based on the above, the authors found an unexpected result when they tried to carry out the healing process exposing the bulk material to temperatures above Tm, finding that the obtained samples broke easily in the damaged area, and therefore, indicating the absence of healing capacity. This allowed them to corroborate the importance of the localized heat generated around AuNPs under light irradiation to achieve a successful self-healing property. The above because when the whole sample is heated, the thermal expansion experienced by the bulk material results in an expansion outward that prevents the contact between the fractured surfaces hindering the polymer chain interdiffusion.130 Additionally, it is worth noting that neither shape-memory nor self-healing properties activated by light were observed in materials without presence of AuNPs. Finally, the authors corroborated the independence of both phenomena by inducing, in an alternate manner, the healing of cuts and reshaping of folds exerted on a poly(ethylene glycol) (PEG)/AuNP film (Figure 4B). In this sense, shape-memory and self-healing processes were individually and sequentially triggered within the same material depending on where the light source was focused. Furthermore, light irradiation would activate both processes if the crack is positioned in a bent region. The excellent results reported by this work served as a basis for the beginning of the development of new photoactuators also exhibiting light-driven self-healing ability. Regarding the above, the authors left open the possibility of complementing their results by evaluating the effect of nanoparticles’ size, morphology, and nature on the photothermal effect and, therefore, on the actuation and healing properties. In addition, the substitution of photothermal agents based on noble metals with other less expensive materials would be attractive from an economic point of view.

Figure 4.

(A) Difference between bulk heating and light-induced local heating on the healing performance. (B) Sequentially triggering the optical healing and the light-controlled shape recovery process for a film of cross-linked PEO/AuNP. (i) Original film with the permanent shape; (ii) temporary shape obtained by folding the film along the lines a1, a2, a3 at 80 °C followed by cooling to room temperature, then two cuts were made as indicated by red arrows (b1 and b2 in photo (i); (iii) the b1 cut was healed by exposing the crack to laser (12 W/cm2) for 5 s; (iv) the first unbending after 10 s laser scanning along the fold a1 at a power of 6 W/cm2, followed by the second unbending under the same condition along the fold a2; (v) the other cut b2 remained in the film of an intermediate temporary shape; (vi) the cut b2 was optically healed under the same condition as for the cut b1; (vii) the third light-triggered unbending along the fold a3 completed the permanent shape recovery. Adapted with permission from ref (125). Copyright 2013 American Chemical Society.

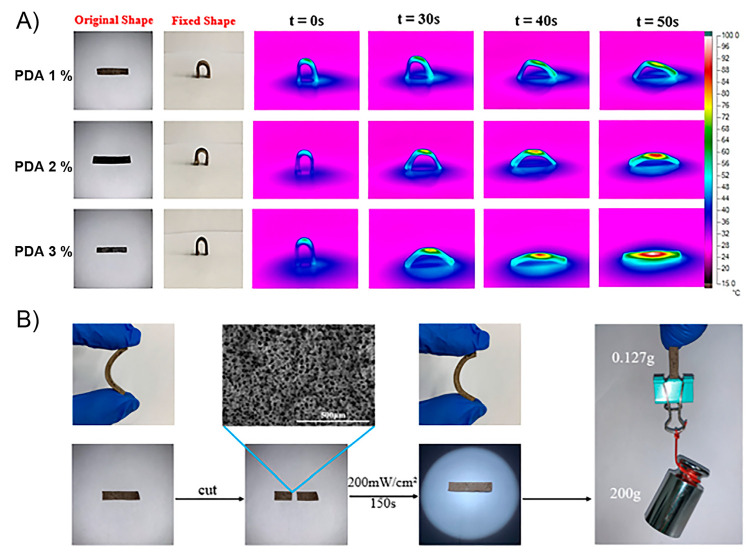

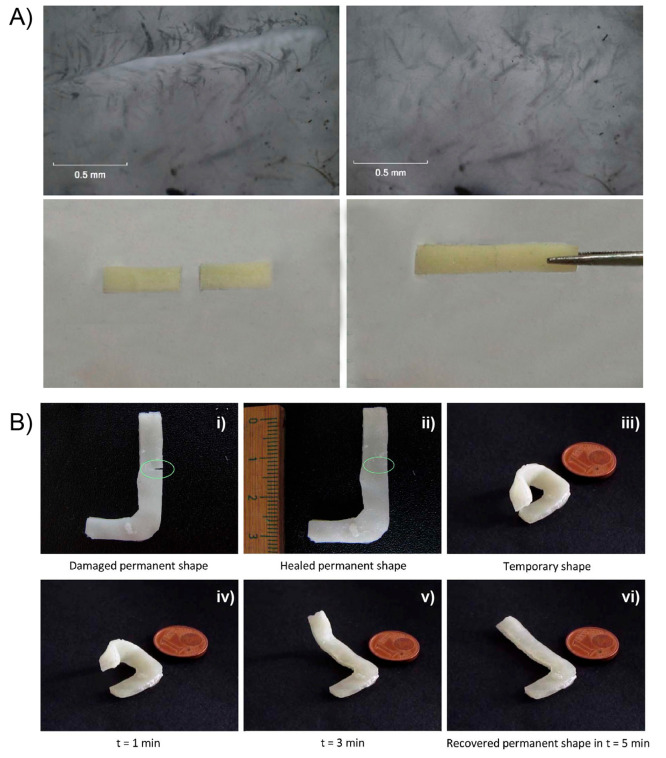

The self-healable photoactuator field had to wait around four years for its development to continue, where, in 2017, Yang and co-workers prepared a hydrogel based on poly(vinyl alcohol) (PVA) and polydopamine particles (PDAPs), which, under near-infrared light (NIR), exhibited ultrafast shape-memory and self-healing properties.131 The rapid light-responsiveness showed by this material was attributed to the photothermal effect induced by PDAPs.132,133 In addition, this material stood out by its excellent mechanical properties and biocompatibility, having outstanding potential in biomedical applications such as tissue engineering, artificial skin and arthrodial cartilage. By following an easy and straightforward protocol, authors were able to synthesize microsized PDAPs through the oxidative polymerization of dopamine.134 Then, the as-prepared spherical PDAPs with an average diameter size of 330 nm were included and well-dispersed into PVA solutions. Lastly, PVA–PDAPs hydrogels from above mixtures were obtained after several freezing/thawing cycles. Two different processes contributed to the physical cross-linking within the PVA–PDAP hydrogels; the first one, reversible in character, was assigned to PVA crystalline domains, while the second was attributed to hydrogen bonding occurring between PVA and PDAPs which act as a fixed phase. Indeed, thanks to the existence of hydrogen bonds between both parts, an adequate dispersion of PDAPs was achieved inside hydrogels, affording a notable enhancement of the mechanical properties of the final material. Regarding the above, and compared to a neat PVA hydrogel, authors demonstrated that the addition of a small amount of PDAP particles (2 wt %) allowed an abrupt increase of the Young’s modulus (from 0.47 to 0.83 MPa), the elongation at break (from 322% to 452%), and the tensile strength (by about 4.3 times) of the material. Therefore, PDAP entities not only allow the light-driven shape-memory and self-healing processes but also contribute to the stability of the cross-linked network. Due to the cross-linked nature of PVA–PDAP hydrogels, these materials exhibited shape-memory response. First, the authors tested this property without light stimuli by stretching a sample up to 100% elongation deformation. Then, they perform freezing/thawing cycles, maintaining the strain to induce the PVA crystallization and form a new crystalline phase that fixed the shape of the sample (corroborated by differential scanning calorimetry (DSC) and X-ray diffraction (XRD) measurements). The elongated material exhibited a complete shape recover ratio of around ≈100% when it was exposed to temperatures above the Tm of PVA (50–60 °C). The above encouraged to authors to test the shape-memory property of the material but now under NIR irradiation, where PDAP particles exhibit photothermal effect. Surprisingly, authors found that samples even with a low content of PDAP (0.5 wt %) and under a very low NIR light source (808 nm, 0.25 W/cm2) showed a notable photothermal effect evidenced by an ultrafast temperature rise. In this sense, samples containing a 2 wt % of PDAP reached temperatures as high as 140 °C in around 20 s during their irradiation with a NIR source of 1.5 W/cm2 power intensity, corroborating that under these conditions the Tm of PVA is easily surpassed. Therefore, the NIR-activated shape-memory property of PVA–PDAP hydrogels was successfully corroborated by showing that samples fully recover their initial shapes after being deformed by simple bending (Figure 5A) or also molded into more complex structures such as circles and spirals (Figure 5B). The above experiments were carried out by irradiating samples with a NIR-light source with an intensity of 0.75 W/cm2 during 60 s, allowing the shape recovery process to be considered as fast. In addition, authors also demonstrated that the recovery ratio increases with increasing the NIR intensity from 0.25 to 1.5 W/cm2 and the on–off nature of the process because the process was completely stopped once the irradiation was halted. The mechanism involved in the shape-memory process is attributed to the melting-crystallization phenomena occurring within the material during NIR irradiation. The ability of PDAPs to convert NIR light into heat, and its subsequent dissipation along the matrix, allows the sample temperature to be rapidly increased above its Tm. Thus, after achieving the fusion of the crystal lattice, the hydrogel recovers its initial shape by releasing the excess energy stored in the form of structural tension. This mechanism was corroborated by the authors by performing XRD measurements to samples before and after being irradiated, where after 10 s of irradiation (0.75 W/cm2) samples did not show peaks associated with PVA crystalline phases. The above demonstrates that the shape-memory ability showed by these hydrogels is due to the melting of crystalline PVA phases. On the other hand, these materials also showed self-healing capacity attributed to the existence of hydrogen bonds between PVA and PDAPs. This property was studied by cutting a sample in two pieces and bringing them together to then being irradiated during 30 s using a NIR source (0.75 W/cm2). The healing process, qualitatively, was successfully observed by optical microscopy (Figure 5C), however, in order to study this process from a more quantitative perspective, the authors evaluated the self-healing property of samples by means of tensile tests. Healing efficiencies were calculated from the ratio of strength at the break of healed and original samples. Regarding the above, after being irradiated for 30 s, PVA–PDAP hydrogels containing 2 wt % of PDAPs revealed a healing efficiency of 94%. This value is notably higher than the one calculated for a sample healed at 37 °C during 36 h (24%). From the above, it corroborated the importance of the NIR light conversion into heat by PDAP, which would allow the local rise of temperature around the damaged region, promoting the thermally activated PVA chains motions and the reformation of hydrogen bonds. In addition, authors also checked the healing efficiency of samples after multiple damage-healing cycles, showing that materials can be repeatedly healed exhibiting healing capacity values above 85% even after fourth cycles. Finally, aiming to introduce this type of systems into biomedical fields, biocompatibility assays were performed in terms of cytotoxicity evaluation, where no significant difference were found between bare PVA, PVA–PDAP hydrogels, and the control experiment, indicating that PVA–PDAP does not inhibit the cell growth.

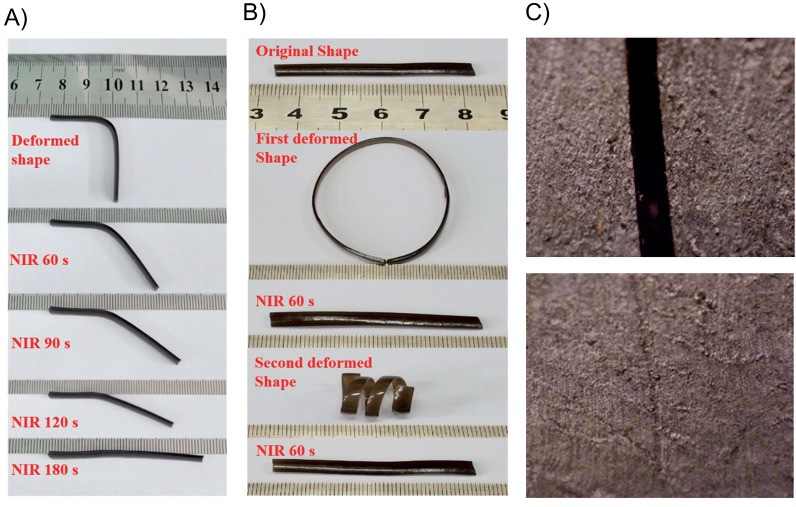

Figure 5.

(A,B) Photos showing the shape recovery behavior of the PVA–PDAP hydrogel under NIR irradiation (0.75 W/cm2). (C) Optical microscopy photos of the cut surface before (up) and after (bottom) NIR irradiation (output power: 0.75 W/cm2, irradiation time: 30 s). Adapted with permission from ref (131). Copyright 2017 John Wiley and Sons.

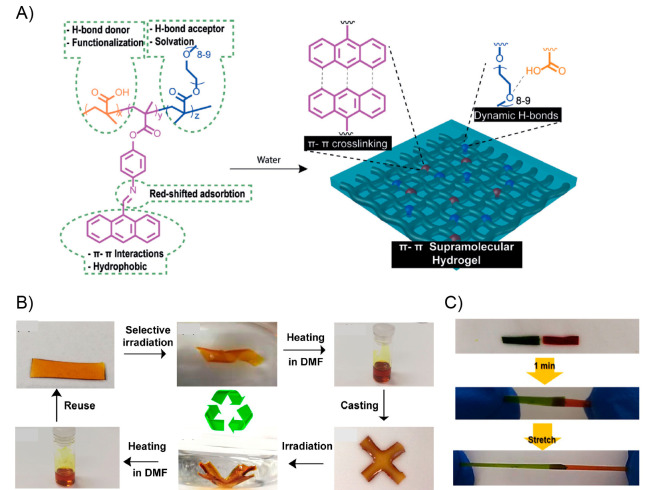

A year later, Si and collaborators achieved the preparation of a photoresponsive supramolecular polymer-based system exhibiting both light-induced actuation and self-healing ability.135 This work can be considered as the first report in which the above-mentioned photoactuation property is not ascribed to photothermal effect but to the well-known light-triggered trans–cis isomerization of azo structures.136 Due to the above, the obtained material can be considered a “truly” light-stimulated system showing a controllable and reversible shape-memory property, along with a fast self-healing capability. Furthermore, on the basis of the excellent optical-actuation performance shown, the authors were able to successively grab and release an object using this material in an “arm” configuration, expanding the scope of work into the field of advanced microrobotics. First, authors carried out the synthesis of a poly(acrylic acid) (PAA) graft copolymer bearing 2-ureido-4[1H]-pyrimidinone (UPy) units as pendant groups (PAA-u), which then was dissolved together with 3,3′,5,5-azobenzenetetracarboxylic acid (t-Azo). This mixture was successively heated, cooled at room temperature, and stirred overnight before being deposited, through the dip-coating technique over a glass substrate. The above system was irradiated under ultraviolet (UV) light during 48 h, after which a PAA-u/t-Azo film was peeled off from the substrate. The structural stability of this material was attributed to the presence of multiple hydrogen bonds serving as cross-linking points within the polymer matrix. In this regard, the system can be considered a supramolecular assembly. The authors successfully corroborate the presence of this type of interaction by means of Fourier transform infrared spectroscopy (FTIR) and DSC analysis, while the higher mechanical strength exhibited by PAA-u/t-Azo, compared to PAA and PAA-u films, served also as indirect evidence of its cross-linked structure. Nonetheless, authors declared that hydrogen bonds not only are responsible of the structural stability of the material, but also allow stabilization of the azo Z-isomers formed during the irradiation process.137 It has been reported that the photoactuation property of azo-polymers depends largely on the ratio of E/Z isomers (usually dominated by the E-isomer).12,138,139 In this sense, the increase of the Z-isomer population inside the material has been adopted as a viable strategy to improve its light-actuation property. The above was the primary motivation to conduct the materiaĺs formation under UV light, inducing the E to Z isomerization process of t-Azo entities, which then, thanks to H-bonds, some of them would find a suitable environment to preserve their Z conformation. The success of the strategy was demonstrated by ultraviolet–visible (UV–vis) spectroscopy by tracking the changes of the band assigned to π–π transitions of t-Azo moieties, from which a 25% of Z-isomers in the final material was calculated. This value was 10% higher than the one obtained for the pristine t-Azo. The efficient stabilization of Z-isomers in the PAA-u/t-Azo assembly was also demonstrated by their notable half-life values (120 h in dark), being longer than in many previous studies.140−148 Surprisingly, the authors demonstrated the high reversibility of the photoisomerization process by carrying out up to 100 irradiation cycles alternating green and UV light, without observing deterioration of the property. Regarding the above, the Z-to-E isomerization induced by green light irradiation allowed reduction from 25% to 12% the amount of Z-isomerin 60 s, whereas the E-to-Z isomerization using UV light achieved an increase up to 27% in around 240 s. After ascertaining the E/Z isomerization in the PAA-u/t-Azo film, its light-driven actuation property was evaluated. To achieve this, a strip of film was exposed to a green laser, successfully achieving a controlled photoinduced bending-like motion. This optically conducted bending allowed the deformation of the material into different shapes that remained stable after the cessation of irradiation. The magnitude of the bending deformation was highly dependent on the irradiation time, while the rate of the process was efficiently modulated by varying the intensity of the light source. The bent film did not recover its initial form even after 480 h, ascribing this result to the high stability of the E-isomer within the assembly matrix. Then, using ultraviolet light, the initial shape of the strip was recovered by inducing bending deformations in the opposite directions to those achieved with green light. The photobending property displayed by the films was tested over 100 consecutive cycles, revealing excellent reversibility as well as demonstrating the robustness of the photoactuator. The observed deformation would be induced by intrinsic stretching and contraction forces arising from the isomerization of t-Azo units. Based on the above, when the material is exposed to light irradiation, those azo entities present on the irradiated surface are more available to carry out light absorption than the ones present on the back surface. Considering this, during the irradiation process, t-Azo units in the illuminated surface should exhibit a faster and higher degree of isomerization than those at the back, thereby the unequal Z-to-E isomerization rate along the material would generate stretching forces causing the material’s deformation. The same explanation can be applied to the shape recovery achieved under UV light irradiation, where the E-to-Z isomerization process would generate contraction forces along the material. Interestingly, the authors devised a method to measure these stretching and contraction driving forces exerted by the material. The stretching driving forces, emerged under green light irradiation, fall between the range of 3.2 × 10–6 to 1.7 × 10–5 N, where the greatest values were obtained under higher irradiation intensities. Similarly, the contraction forces achieved by UV irradiation exhibited values between 1.6 × 10–6 and 1.1 × 10–5 N. Motivated by the above results, the authors successfully attempted to fabricate a photoactuated manipulator arm using two strips of PAA-u/t-Azo film disposed into a cross shape, simulating a “hand” configuration (Figure 6A). Then, each strip (“finger”) was consecutively irradiated with a green laser stimulating its bending process. The bent configuration was able to grab an object which afterward was lifted and maintained for a period of 480 h. After that, using a UV light source, the release of the object was induced by recovering the initial shape of the “fingers”. The authors demonstrated the reversibility of the process by performing 40 successively grab–release cycles alternating between green and UV irradiation. Additionally, PAA-u/t-Azo films exhibited an outstanding light triggered self-healing property, which was developed during the bending process activated under green laser irradiation. Before activating the bending motion, the strip was damaged with a scratch using a razor blade. Initially, the self-healing process was monitored by optical microscopy in which after 20 s of green light irradiation (310 mW/cm–2) the scratch disappeared completely (Figure 6B). However, a more in-depth investigation regarding the healing ability of the material was carried out by performing stress–strain tests for the original sample and its healed counterpart. These experiments revealed that the healing property increases with the light exposition time, recovering up to 98% of the tensile strength after 20 s of irradiation (25.5 and 25 MPa for the original and healed sample, respectively). The light-induced self-healing process was further investigated by inducing more severe damage to the sample, that is, cutting it in two. In this case, the initially bisected sample recovers around 94–97% of its original tensile strength after being irradiated with green light. In addition, the authors demonstrated that the healing ability can be notably improved by irradiating the sample with higher intensities or longer times. The excellent and rapid self-healing property exhibited by PAA-u/t-Azo has been attributed to the multiple hydrogen bonds, reversible in nature, existing within the structure. During irradiation, besides inducing the bending of the material, the local temperature of the illuminated area increases to around 72 °C according to the obtained high-resolution infrarred image. On the other hand, by means of FTIR spectra recorded at different temperatures, the authors demonstrated that hydrogen bonds in the sample are weakened as temperature increases while they are efficiently reformed during the cooling process. Therefore, the proposed light-induced self-healing mechanism for this material would be associated with the local heating of the damaged zone due to irradiation, prompting the temporal dissociation of H-bonds that later could be reformed by connecting areas separated by the fissure. In addition, the light-induced bending actuation could also be involved by facilitating the contact between the damaged areas. It is important to mention that most of the supramolecular polymer assemblies exhibit thermally induced self-healing properties, activated after being heated above their glass transition temperature (Tg). In those cases, the healing mechanism mainly consists of the interpenetration and re-entanglement of polymeric chains facilitated by their increased mobility. However, because the temperature achieved in PAA-u/t-Azo (65–80 °C) did not surpass its Tg value (106 °C), the mechanism would be mostly attributed to H-bond reformation. Lastly, the self-healing performance revealed by PAA-u/t-Azo films was notably superior to most of the previously reported polymer-based systems in terms of healing efficiency, temperature requirements, and healing time.

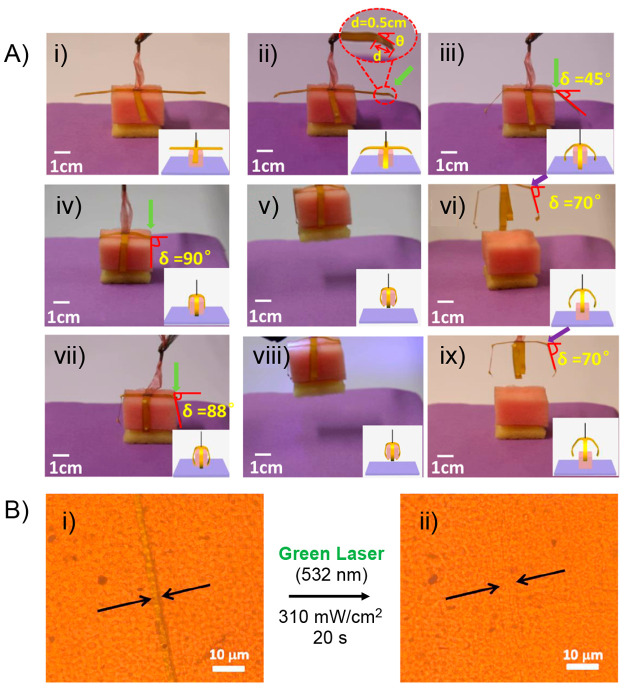

Figure 6.

(A) Photographs showing the cyclic process of grabbing and releasing an object by the optically actuated manipulator arms. (i) Manipulator arms crossed at the center were held vertically with their center tied with a rope. (ii–iv) Finger bends with a knuckle induced by the green light. (v) The object grabbed by the finger is lifted. (vi) Fingers releases the object induced by UV light. (vii–ix) The above process is repeated. (B) Optical microscopic images of a scratched sample before (i) and after (ii) the exposure to a green laser. Adapted with permission from ref (135). Copyright 2018 American Chemical Society.

Within the field of self-healing photoactuators, the material designed by Si et al. is undoubtedly one of the best exponents but also unique in terms of design. In reference to the above, the lack of reports related to the development of self-healing photoactuators, whose actuation is achieved by the isomerization of molecular entities is not a coincidence. Indeed, the development and understanding of these types of systems is usually more challenging in terms of synthetic nd characterization procedures. Due to the above, the current literature reveals that this field has been widely dominated by materials whose actuating motions and self-healing capabilities are triggered by the photothermal effect. This could be attributed to the greater simplicity with which these types of systems can be prepared and studied. Notwithstanding the above, the use and implication of other types of isomerizable structures, aiming to replace the already widely studied azo compounds, should be the next step in the area.

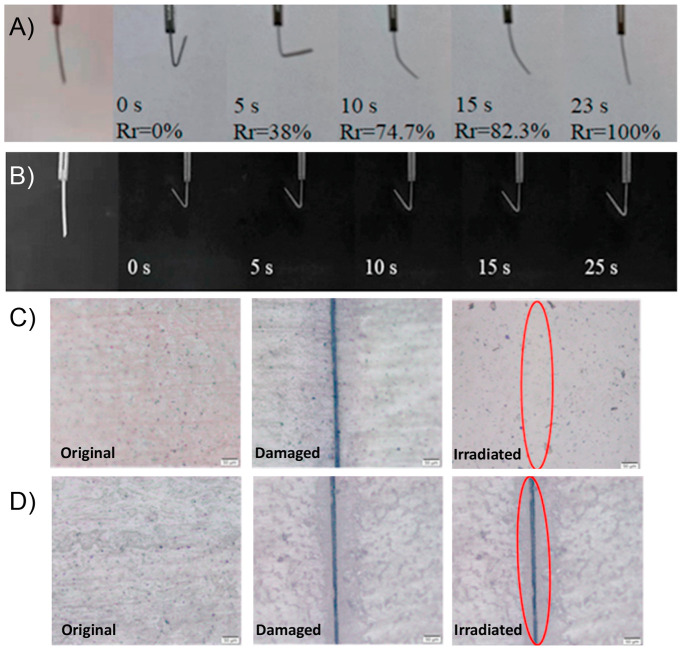

Regarding the preparation of novel photothermal actuators, at the beginning of 2019, by dispersing poly(acrylic acid)-grafted graphene oxide (PAA-GO) into PVA matrix, Li and collaborators carried out the preparation of a robust polymer network stabilized by multiple hydrogen bonds, exhibiting an excellent NIR-light-induced shape-memory property, attributed to the photothermal effect caused by the presence of GO.149 In addition, due to the reversible nature of hydrogen bonding,150 PVA/PAA-GO films displayed an outstanding self-healing property assisted by water, which also endowed this material with the ability to repair the fatigue shape-memory function. Based on the obtained results, the authors aimed this material to be potentially used as actuators in biomedical devices and flexible electronics, among others. In the first place, the authors carried out the preparation of PAA-GO thought redox-initiated graft polymerization of PAA onto GO nanosheets in aqueous media. The success of the polymerization was corroborated by means of Raman spectroscopy, while the content of PAA in PAA-GO (≈ 28%) was determined by thermogravimetric analysis (TGA). Then, PVA/PAA-GOx% films containing 1, 2, 3, and 4 wt % of PAA-GO were prepared through the solvent-casting technique from PVA/PAA-GO aqueous mixtures. Uniform films were obtained thanks to the improved dispersibility exhibited by PAA-GO. FTIR spectra recorded at different temperatures allow demonstration that hydrogen bonds between carbonyls of PAA and hydroxyl groups from PVA would be the main type of interactions taking place within the polymer matrix. Stress–strain curves measured for PVA/PAA-GOx% samples revealed a similar behavior to pristine PVA, however, the yield stress and fracture stress values were dramatically increased after the addition of PAA-GO, while the opposite trend was observed for the elongation at break values. Overall, the presence of PAA-GO in PVA matrix significantly increases the mechanical strength of samples, permitting them to be repeatedly deformed without evidence of crack formation. Therefore, the thermally induced shape-memory of these samples was first evaluated by deforming a flat film strip at temperatures well above its glass transition temperature (Tg + 20 °C), followed by cooling to room temperature in order to fix the new temporary shape. Because the Tg of the material is considerably higher than room temperature, samples were able to maintain their temporary shape at ambient conditions. Then, when the deformed strip was heated again above Tg, a complete recovering of the original shape was afforded in 30 s, corroborating the thermally induced shape-memory property. The shape recovery ratio (Rr,t) of pristine PVA films decreases from 97.5 ± 0.4% to 80.2 ± 0.3% after 15 consecutive folding/recovery cycles. Surprisingly, after being exposed to the same mechanical stress, Rr,t values for PVA/PAA-GOx% containing 1, 2, 3, and 4% went from 98.2 ± 0.2, 98.6 ± 0.3, 99.6 ± 0.4, and 99.7 ± 0.2% to 87.4 ± 0.4, 88.6 ± 0.2, 90.6 ± 0.4, and 90.7 ± 0.3%, respectively. Authors argued that the greater drop of the Rr,t for the PVA film should be ascribed to a higher disentangling and glissade of polymer chains during bent/unbent cycles. Conversely, thanks to the formation of hydrogen bonds between PAA-GO and PVA, the disentanglement and/or slippering of polymer chains would be diminishing, avoiding the abrupt decrease of Rr,t values. Afterward, the NIR-triggered shape-memory ability of PVA/PAA-GO3% sample was evaluated, first, by elongating a strip under heating and then fixing this temporary shape by cooling to room temperature. Figure 7A shows that this sample was able to completely recover its original shape in 35 s of NIR-light irradiation (808 nm, 1.3 W/cm–2) thanks to the outstanding photothermal property provided by GO, which allowed the sample to increase its temperature up to 75.4 °C (Tg + 21.4 °C) in only 5 s. It is worth noting that no shape-memory property was observed for a pristine PVA film after being exposed to the same experimental protocol (Figure 7B). Moreover, an initially flat strip sample, deformed into a W-shape, was able to recover its original shape by sequentially irradiating different areas of the film with NIR-light (Figure 7C). The authors went further by testing the shape-memory property on samples arranged in more complicated structures, in this case, a petal-shaped PVA/PAA-GO3% film (Figure 7D). This sample, initially configured as an open flower, was deformed into a bud at 74 °C and fixed after cooling at room temperature. Then, after 1 min of NIR irradiation (47 mW cm–1), the sample emulated the bloom motion (Figure 7E). PVA/PAA-GO3% samples also exhibited the ability to heal in environments with high relative humidity (RH). A film strip was cut into two pieces, after which several drops of water were deposited on the damaged surfaces. Then, the two pieces were brought together to start the healing process. The authors observed an optimal adhesion between the parts at 5 min of initiated the contact and an evident heal of the cut after 5 h. However, the scar of the damaged remained visible under SEM observation. Stress–strain curves of the healed sample showed a similar value for the yield stress regarding the original sample (71.4 MPa), while lower values for the fracture stress (61.2 MPa) and elongation at break (152.4%) were obtained after the healing process. However, to demonstrate the efficiency of the healing, an additional sample, purely consisting of PVA and GO, were exposed to the same damage and healing protocol, giving as a result a sample that easily fractures in the affected zone during bending. The above result corroborated the importance of PAA in the self-healing ability displayed by these materials. Because the healing property was activated by the presence of water, authors argued that one of the main functions of PAA was to increase the water absorption (swelling ability) of the material. In this sense, after water adsorption, it is expected that hydrogen bonds within the matrix would be weakened, resulting in a less restricted environment for the polymer chains mobility, which, after inducing the contact between the fractured fragments, the re-entanglement and reformation of interactions between PVA and PAA-GO would allow the healing of the material. More importantly, in this work, authors demonstrate that the self-healing ability is not only limited to healing mechanical damage but also healing the fatigued shape-memory function. Regarding the above, when a piece of PVA/PAA-GO3% was exposed to 12 folding/recovery cycles its Rr,t value was calculated as 92.9 ± 0.4%, however, after being healed for 6 h under 90% RH conditions, this value notably increased up to 99.5 ± 0.3%. Repeating the above experiment, but now after 60 folding/recovery cycles, the Rr,t value jumped from 92.6 ± 0.2 to 99.8 ± 0.3%. Authors explained that a possible mechanism for the healing process of the fatigued shape-memory function could be, again, addressed to the absorbed water thanks to the hygroscopic nature of PAA, where water can act as plasticizer enhancing the chains mobility inside the matrix, facilitating the transition from a high-energy stretched configuration to a more relaxed coiled state. Author also evidenced that the crystallinity degree of PVA in PVA/PAA-GO after being exposed to 90% RH conditions was lower than in a PVA film, serving as additional argument to support the idea of a higher chain mobility in PVA/PAA-GO.

Figure 7.

(A) NIR-light induced shape recovery of the PVA/PAA-GO3% and (B) PVA film. (C) Sequential shape recovery of the W-shaped PVA/PAA-GO3% film induced by NIR light irradiation. (D) Fabrication process of the PVA/PAA-GO3% flower that can bloom under NIR light irradiation. (E) Time-sequence images of the PVA/PAA-GO3% flower that is blooming under NIR light irradiation. The scale bars in all panels are 1 cm. Adapted with permission from ref (149). Copyright 2019 American Chemical Society.

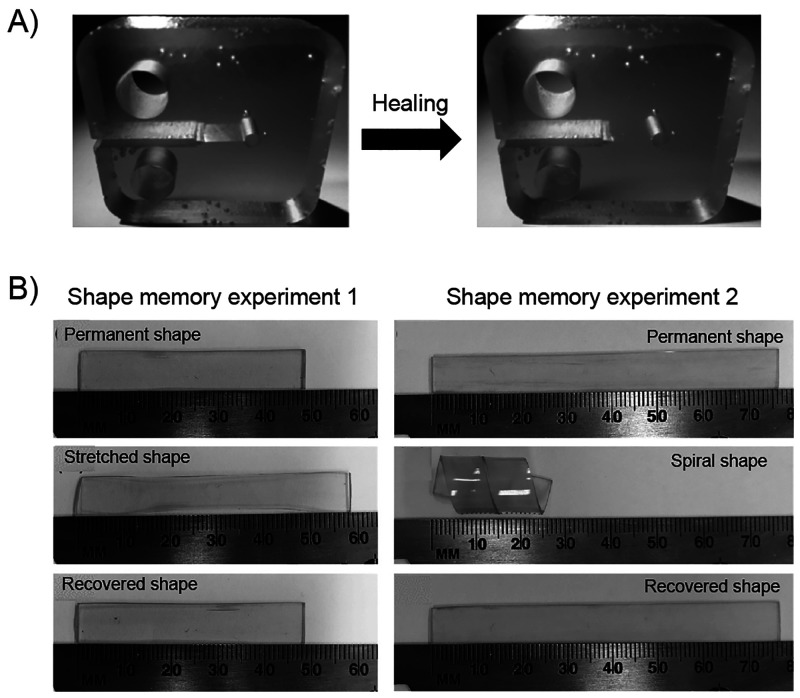

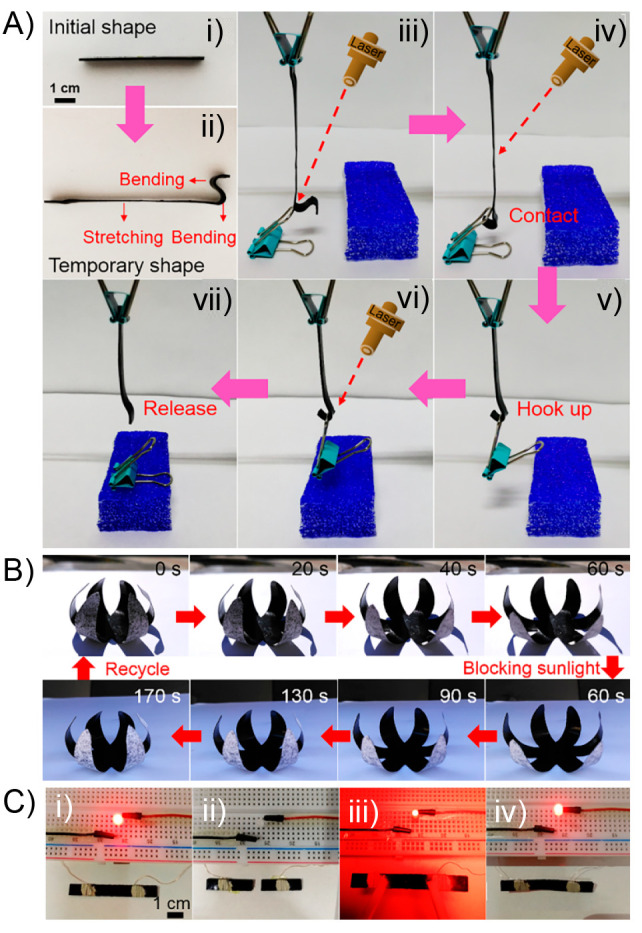

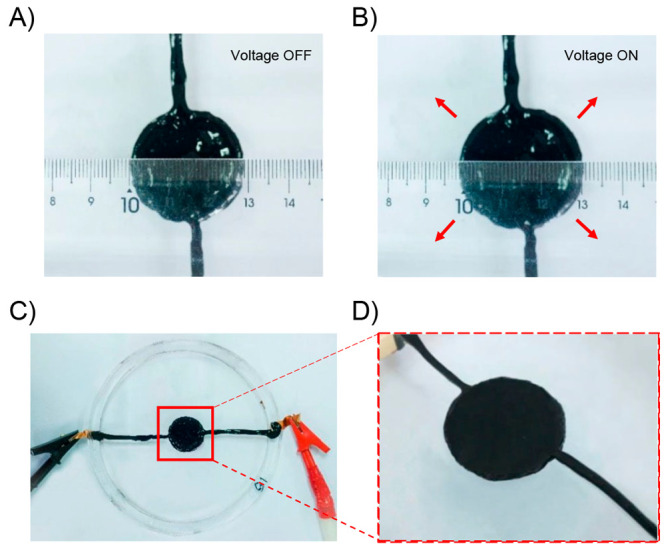

A few months later, Cui and co-workers developed a light-actuated nanocomposite exhibiting a fast light-induced self-healing property.151 This material, comprised of multiwalled carbon nanotubes (MWCNTs) dispersed inside chlorinated poly(propylene carbonate) (CPPC), exhibited an outstanding shape-memory property activated by IR light, simulated sunlight, and also by natural sunlight, giving way to a fast and strong response that can be remotely and sequentially activated. Experimentally, MWCNTs/CPPC nanocomposites were fabricated by melt blending and molded into sheets through a hot-press process conducted at 140 °C and 10 MPa. Following the same above protocol, the authors also prepared a sample consisting of pure CPPC for comparison purposes. In the case of nanocomposites, four different amounts of MWCNTs were used (1, 2, 3, and 4 wt %). SEM analysis showed a uniform distribution of MWCNTs within the polymer matrix, even when through conductivity measurements a percolation threshold around 1.5 wt % was estimated. In addition, the mechanical properties of obtained samples showed that both the Young’s modulus and the tensile strength values increased with the MWCNTs load, revealing that these entities would help to reinforce the internal network of the material. Prior to studying the light-actuated properties, the authors analyzed the thermally induced shape-memory function of pure CPPC. They found that this polymer exhibited an excellent shape-memory property when heated at 60 °C, above its glass transition temperature (Tg = 36.2 °C), achieving full recovery from stretched or bent initial configurations. Then, aiming to obtain a more quantitative information about this property, through DMA measurements the shape fixing ratio (Rf) and the shape recovery ratio (Rr) were calculated. It is important to keep in mind that Rf is related to the crystalline phase of the material, whereas Rr corresponds to the amorphous portion. Values of 100% and 85.5% were calculated for Rf and Rr, respectively, corroborating that CPPC is an excellent thermally driven shape-memory material. Due to the above, because MWCNTs exhibit a remarkably photothermal effect,152,153 the inclusion of these entities into CPPC resulted in an attractive strategy to search for synergic effects during the fabrication of light-responsive materials. Indeed, under IR irradiation (150 mW/cm2), the authors evidenced a much more rapid increment of the surface temperature in nanocomposites than in pure CPPC. In this sense, while pure CPPC reached a temperature of 41.7 °C after 60 s of IR illumination, the nanocomposite containing the lowest amount of MWCNTs (1 wt %) was able to reach temperatures above the Tg of the system (46.0 °C) in only 10 s. Later, to test the light-triggered shape-memory function of these materials, a flat sheet of MWCNTs/CPPC (1 wt %) was heated up to 60 °C, deformed (stretched, bended, or twisted), and finally cooled to room temperature in order to fix the new temporary shape. As an example of the above, a sheet deformed into a “U” shape was able to rapidly recover its original flat shape (Rr = 100%) after 40 s of IR irradiation (150 mW/cm2), whereas the same experiment performed on a pure CPPC strip required about 160 s of illumination. Aiming to demonstrate the potential application of these MWCNTs/CPPC nanocomposites in high-tech fields, the authors prepared a light-actuated hook that can be remotely controlled (Figure 8A). The hook’s temporary shape was achieved from a flat MWCNTs/CPPC (1 wt %) sheet, which was subjected to a stretching process (200% strain) followed by two bending deformations at one of its ends. Then, by sequentially irradiating different zones of the sample, its original shape could be recovered, and during this process, the hook was able to grab an object, lift it, and place it in another position of higher altitude. Surprisingly, the contraction force exerted by the sample with 200% strain was 2.6 ± 0.2 N, meaning that a MWCNTs/CPPC (1 wt %) sheet can lift 550 times its own weight. Another critical fact resolved by the authors of this work was the dependence of the shape recovery time on the thickness of the sample, going from 40 to 7 s of IR light irradiation when the thickness falls from 1.0 mm to 0.2 mm. The same phenomenon was observed using simulated sunlight of low density (87 mW/cm2), achieving a rapid photoactuation property in samples having low thickness, thereby opening the possibility of using the abundant solar energy to trigger shape changes. Motivated by the sunlight-induced shape-memory property of these materials and taking as inspiration the heliophile flowers, the authors prepared an artificial flower by assembling petals fabricated from MWCNTs/CPPC films. The closed state was chosen to be the temporary form of the flower, which was achieved by heating the system up to 60 °C and rapidly cooling it to room temperature. Then, under IR light irradiation, the petals gradually open into a fully bloom state within 70 s. Additionally, by decreasing from 1.0 to 0.2 mm the thickness of petals, the bloom state was reached under natural sunlight in only 39 s. However, unlike a real heliophilous flower, this system could not perform reversible opening and closing movements. To emulate this situation, the authors assembled a new flower but using petals fabricated from a bilayered material comprised of a MWCNTs/CPPC film hot-pressed onto paper (Figure 8B). The above idea emerged from the much lower thermal expansion coefficient that paper has compared to CPPC;154 thereby, because the paper layer is more likely to remain bent, a new force driving the shape change from the open state to the close state will remain once the light source is removed. Thus, under IR or natural sunlight illumination, the MWCNTs/CPPC layer will tend to reach its stretched configuration, creating a driving force that dominates the process, however, when the light source is turned off, the driving force caused by the paper will induce the petals bent again. In this way, by alternating light and dark conditions, the system was able to achieve these photoactuated motions in a cyclic manner. On the other hand, MWCNTs/CPPC nanocomposites also exhibited a fast and efficient light-induced self-healing capability, ascribed to the excellent photothermal effect displayed by MWCNTs, allowing the temperature of the system to increase rapidly above its Tg. Regarding the above, due to the greater mobility of the polymer matrix at the rubbery state, the proposed self-healing mechanism would involve the interdiffusion and re-entanglement of the polymer chains along the damaged area. The authors evaluated the efficiency of the healing process, first, by comparing the mechanical properties between the original and the healed samples obtained after 3 min of IR irradiation, demonstrating that healed nanocomposites maintain robust mechanical properties in terms of Young’s modulus, tensile strength, and elongation at break. As a proof of this, a healed sample was able to sustain a weight of 1000 g. In a complementary way, the authors studied the efficiency of the healing process through the evolution of the conductive properties of the material under light irradiation (Figure 8C). After being cut into two halves, the resistance of the sample showed an abrupt increase ascribed to the disruption of the inner MWCNTs network. However, after inducing the contact between both pieces, the resistance value started to decrease rapidly after 5 s of IR light irradiation. This was ascribed to the reconstruction of the MWCNTs conductive network promoted by the interdiffusion and re-entanglement of CPPC polymer chains. Interestingly, the resistance value gradually decreases up to reach a value close to the measured resistance before the damage. Moreover, the robustness of the healing process was successfully demonstrated by consecutive cutting–healing cycles. Conversely, when visible light was used instead of IR irradiation, the healing process was not achieved completely, possibly related to the greater penetration of IR light. This is a relevant factor to be solved if we want to improve the performance of the new generation of self-healable actuators, searching to maximize their functions by using conditions provided by nature.

Figure 8.

(A) Digital images of a remotely controlled light-actuated hook showing its (i) initial shape, (ii) temporary shape, and (iii–vii) the composite hook contacting the binder clip, hooking it up, and releasing it. (B) Cyclic shape changes of a bionic flower made of bilayer composites controlled by natural sunlight. (C) Digital photos of the circuit constructed by MWCNTs/CPPC sheet and a light-emitting-diode (LED) lamp at different states: (i) the LED is lighted at the initial state, (ii) the composite sheet is cut into two parts extinguishing the LED, (iii) the two parts of the sheet are connected under IR light, and (iv) after the healing process of the sheet the LED is lighted up again. Adapted with permission from ref (151). Copyright 2020 Elsevier.

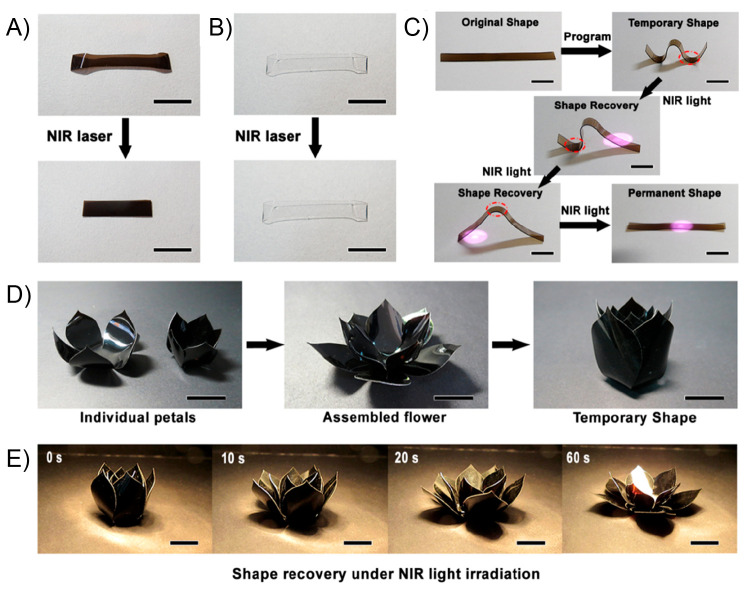

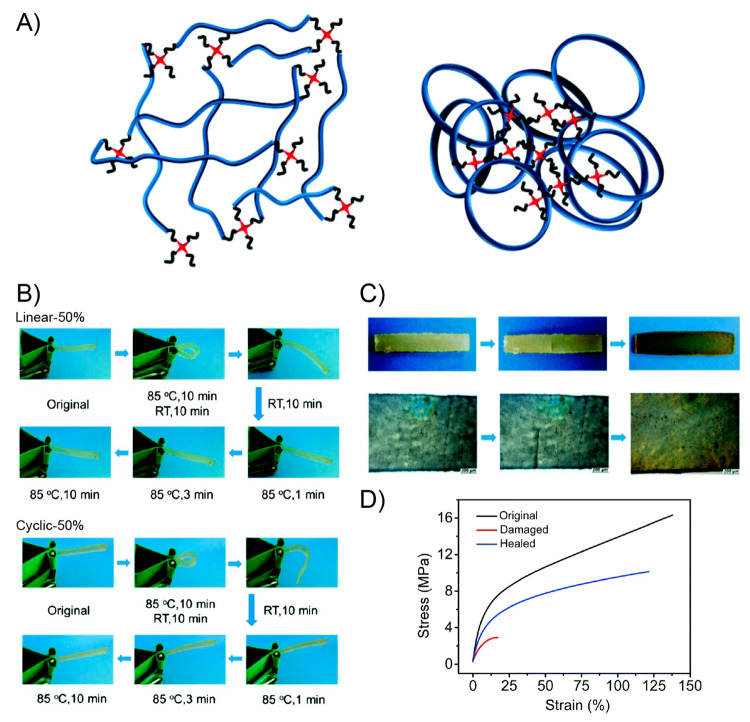

In the same year, Yan and co-workers prepared a polymer-based network standing out by its high toughness and displaying both light-triggered shape-memory and self-healing properties.155 Motivated by the outstanding mechanical properties and the fast and efficient self-healing ability, the authors successfully tested this material as a strain sensor, demonstrating its potential application in wearable electronic devices. By polymerizing methacrylic derivatives of PEG, poly(ε-caprolactone) (PCL), and UPy, a supramolecular network constructed by covalent and transient cross-links was achieved. Based on thermal and mechanical characterizations, the authors concluded that samples containing 10–20% UPy content were able to display efficient shape-memory and healing properties. The material revealed an excellent mechanical performance characterized by tensile stress and toughness values of 7.2 MPa and 25.2 MJ/m3, respectively, attributed to its semicrystalline nature provided by the presence of both PEG and PCL segments and the existence of multiple hydrogen bonding interactions provided by UPy units. On the other hand, DSC measurements showed Tm values in the range of 40–47 °C, corroborating the presence of crystalline domains within the matrix. The shape-memory property shown by these materials was attributed by the authors to reversible melting-crystallization processes, which can be triggered either by external heating (Figure 9A) or by light irradiation (Figure 9B). The latter based on the well-known ability of UPy units to transform ultraviolet light into heat.156,157 Regarding the above, the photothermal property of samples was studied under UV irradiation (365 nm) by varying the intensity of the light source (200–500 mW/cm2), concluding that after 2 min under UV-light irradiation at 500 mW/cm–2 the sample reaches a temperature of ≈63 °C, which is higher than the melting temperature of the network and, thereby, enough to activate the dynamic process of UPy dimers. Thus, the shape-memory property was first evaluated by folding samples at 70 °C (above Tm), followed by a cooling process. All networks were able to maintain their temporary shapes for long periods, characterized by excellent shape fixing ratio values (≈100%). Then, the shape recovery process of bent samples was carried out by using a laser beam as irradiation source (365 nm, 500 mW/cm2). After 10 s of irradiation, samples containing 10 and 20% of UPy content reached shape recovery values of 71% and 47%, respectively, while after 90 s these values increased up to 99% and 92%. The authors attributed the good performance showed by these systems to the photoinduced heat generated in the irradiated area that allows, simultaneously, the melt of crystalline domains and the cleavage of hydrogen bonds existing between UPy units. Due to the above, the strained sample was able to release the stored strain energy by inducing the apparition of restoring forces that triggers the shape recovering process. Regarding the self-healing ability displayed by these systems, after scratching the sample’s surface with a razor blade, the authors evaluated this property by using external heat (10 min at 70 °C) (Figure 9C) and UV light irradiation (365 nm, 500 mW/cm–2, 1 min) (Figure 9D). Interestingly, damaged samples were able to fully close the cracks under both conditions, however, showing evident advantages in terms of time when light was used. The healing efficiency was also evaluated by tensile test, where samples healed under light irradiation showed better restoring of their mechanical properties than those healed under heat. Particularly, the light-healed network having 20% of UPy content reached 86% of the original toughness. In this sense, when the healing process is carried out by temperature the entire sample is affected, inducing the healing of the damaged area but also prompting the disruption between UPy units in undamaged areas. As authors argued, the healing process is assisted by shape-memory motions that help bring together interfaces along the damage area, facilitating the encounter and reformation of UPy hydrogen bonds.

Figure 9.

Heat-induced (A) and light-induced (B) shape-memory behaviors of PEG-PCL-UPy polymers with different UPy contents. Optical micrographs showing scratches of PEG-PCL-UPy polymers before and after healing by heat (C) and light (D) (scale bar = 100 μm). Adapted with permission from ref (155). Copyright 2020 Elsevier.

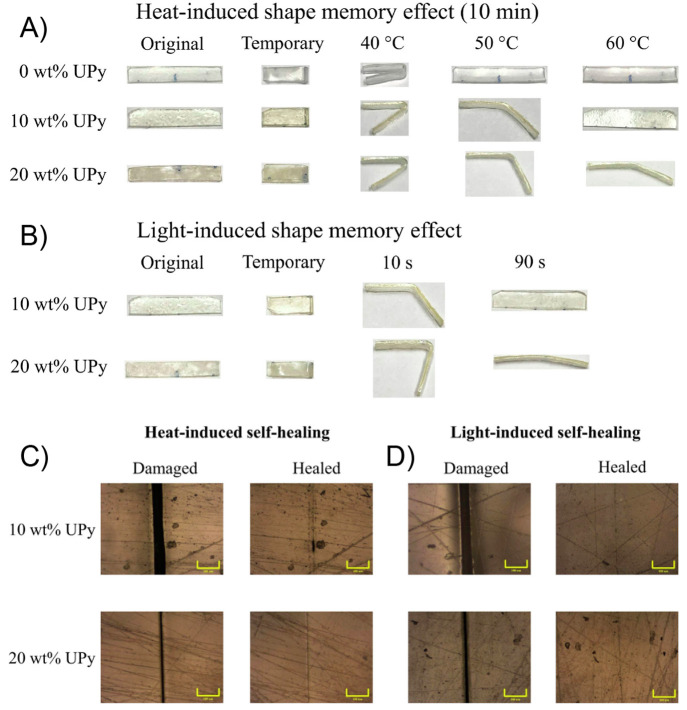

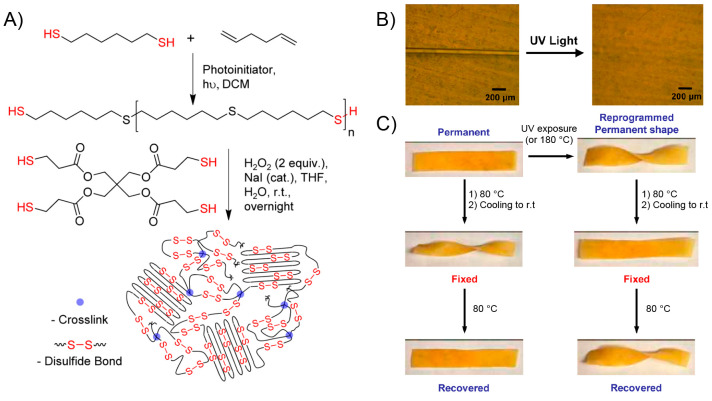

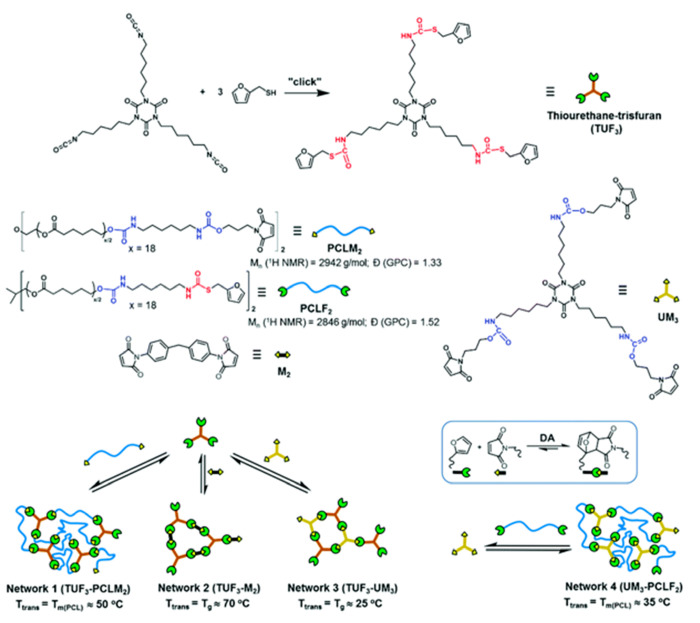

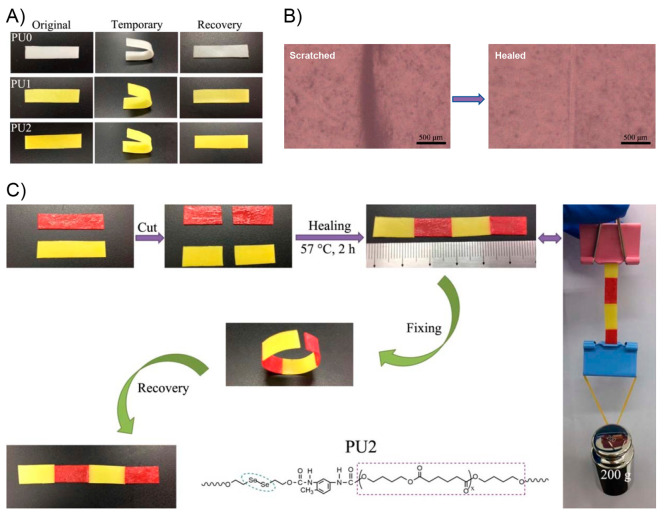

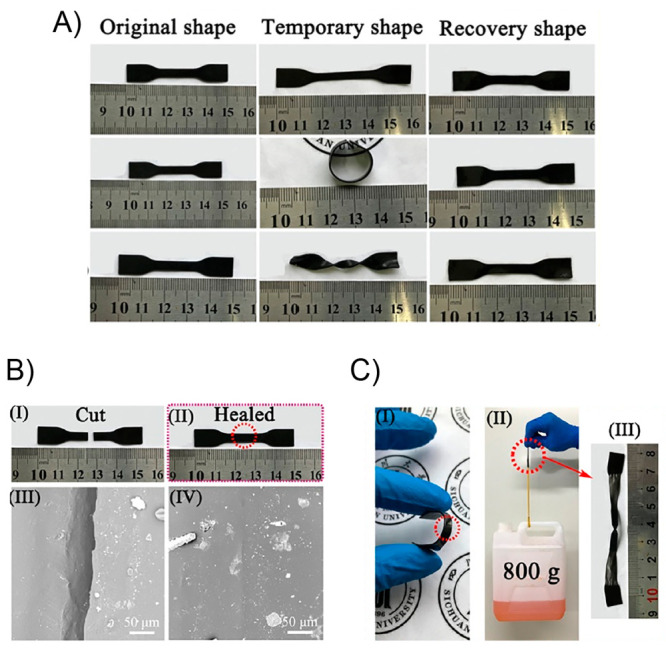

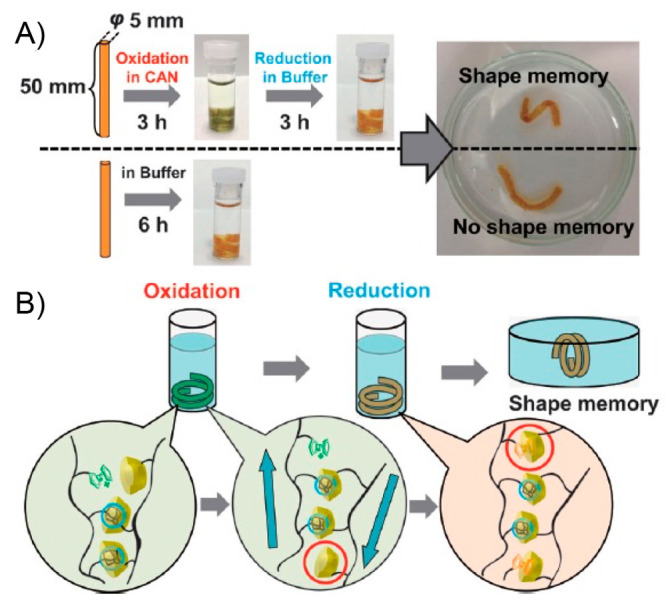

The design of polymeric systems featuring efficient flame retardancy function has become an innovative topic as they are able to reduce fire risks and economic losses in practical applications. Motivated by the above and by the absence of reports on self-healing actuators showing flame retardancy properties, almost parallel to Yan et al.,155 Du et al. devised the preparation of a new polymer-based nanocomposite showing shape-memory and self-healing, both activated by VIS–NIR light (400–1100 nm), achieving an outstanding flame retardant capacity.158 This material was achieved by dispersing multifunctionalized GO entities within a polymer matrix consisting of a polyurethane (PU) containing reversible diselenide bonds. The light-triggered shape-memory property was ascribed to the photothermal effect displayed by these graphene oxide derivatives under VIS–NIR irradiation, while the self-healing ability, also activated by light, was attributed to a combination of the above photothermal effect and the VIS–NIR reversible formation of Se–Se bonds. First, the authors carried out the synthesis of a multifunctionalized GO (mfGO) through the covalent incorporation of nitrogen, phosphorus, and silicon-based molecular units. The N, P, and Si containing structures were poly(ethylenimine) (PEI), 9,10-dihydro-9-oxa-10-phosphaphenanthrene (DOPO), and isocyanatopropyltriethoxysilane (IPTS), respectively, which were selected based on past reports suggesting the adequate fire safety properties exhibited by materials containing these types of substrates.159−161 The preparation of mfGO was corroborated in terms of FT-IR, Raman, TGA, XRD, and scanning electron microscopy–energy dispersive X-ray spectroscopy (SEM-EDS), showing a correct chemical structure, along with important features related to chemical composition and morphological properties. For instance, XRD analyses showed a peak at 2θ = 9.77° (002 reflection) and a d-spacing value of 9.05 Å for GO. In contrast, the 2θ peak was shifted down to 7.42°, and the interlayer spacing was increased to 12.01 Å in the case of mfGO. This increase of the d-spacing was attributed to the intercalation of PEI, DOPO, and IPTS units between the GO sheets. Moreover, in contrast to pristine GO, mfGO displayed a higher thermal stability, supporting its potential application as flame retardant. On the other hand, following well-known solution polymerization protocols, the authors conducted the preparation of a PU from poly(hexylene-adipate) diol (PHA), polytetramethylene ether glycol (PTMG), and 2,4-toluene diisocyanate (TDI). To the above solution, they incorporated mfGO achieving a 2 wt % dispersion followed by the addition of di(1-hydroxyethylene) diselenide as chain extender. Then, the reaction mixture was poured on a Teflon mold and cured at 60 °C for 48 h, obtaining the final nanocomposite coded as dPTD–mfGO (dPTB refers to the polyurethane copolymer containing 1,4-butanediol (BDO)). Similarly, the above process was repeated but using 1,4-butanediol instead of di(1-hydroxyethylene) diselenide, generating a nanocomposite coded as dPTB–mfGO, which was used for comparison purposes. Surprisingly, the authors evidenced a notably better dispersion for mfGO than pristine GO in the polymer matrix, showing no evidence of agglomeration phenomena. This observation, ascribed to an enhancement of compatibility, was attributed to hydrogen bond interactions occurring between PU chains and PEI grafts attached to the surface of mfGO. Following the same argument, the so-obtained dPTD–mfGO nanocomposite exhibited better mechanical properties than pure dPTD PU, demonstrated by an increase of 23% and 16% for the tensile strength and elongation at break values (dPTD refers to the polyurethane copolymer containing di(1-hydroxyethylene)diselenide). The authors explained this result based on a more effective load transfer from the polymer to mfGO sheets under external mechanical stress. In terms of d-spacing, the values of mfGO containing PTB and PTD increased to 12.35 and 12.26 Å, respectively. Such an increase compared to the pristine mfGO (12.01 Å) was ascribed to the strong hydrogen-bonding interactions between mfGO sheets and PU chains. In addition, the DMA analysis showed that both dPTD–mfGO and dPTB–mfGO nanocomposites exhibited higher Young’s modulus values than their counterparts matrices (dPTD and dPTB), suggesting a higher rigidity and toughness of the polymer matrix in the presence of mfGO. The presence of crystalline regions in nanocomposites was confirmed by means of DSC and XRD measurements. All PU and nanocomposites films showed relatively similar melting behavior, characterized by two endothermic processes around ≈24 °C and ≈38 °C assigned to the melting of PHA and PTMG, respectively. However, the enthalpic contribution of the former was notably higher than the one associated with PTMG segments. Thus, the crystalline structure in these samples was mainly related to PHA. Furthermore, measurements revealed that nanocomposites containing mfGO showed an increment in their crystallinity, suggesting that these entities can act as nucleation sites, reinforcing the presence of crystalline domains. The latter found direct relation with the adequate shape fixity exhibited by these samples during shape-memory process. As a first approach to study the shape-memory process, a simple bending test was conducted to evaluate parameters such as the Rf, Rr, and recovery times under VIS–NIR irradiation and also external heating. Regarding Rf, while neat polyurethanes dPTD and dPTB exhibited values of 88.3% and 91.5%, respectively, their counterparts containing mf-GO showed increased values around 95.2% and 96.7%. The same trend was observed for Rr where, again, dPTD–mfGO and dPTB–mfGO nanocomposites showed values of 93.1% and 95.5%, respectively, being higher than those measured for pure polyurethanes. The higher Rf values were related to the increased crystallinity degree and the presence of hydrogen bonding within the polyurethane structure, both attributed to the presence of mfGO. On the other hand, the increment on the Rr values after the incorporation of mfGO would be ascribed to an enhancement of the physically cross-linking process between the attached polymer chains over mfGO and the PU matrix. The authors also prepared two additional samples consisting of dPTD and dPTB polyurethanes containing nonfunctionalized GO. Both samples displayed Rf and Rr values even lower than neat dPTD and dPTB, accusing the importance of achieving a good filler dispersion. Another important parameter measured for all samples was the recovery time, defined as the time required to reach the maximum Rr value. This parameter was evaluated under two modalities: VIS–NIR irradiation and external heat. Recovery times were notably faster under light irradiation than under heating; however, during light experiments, only those samples containing mfGO were able to carry out the recovery process, demonstrating the importance of mfGO. The authors also performed an additional experiment using pristine GO as filler in dPTD and dPTB, obtaining longer recovery times in comparison to dPTD–mfGO and dPTB–mfGO, which, according to authors, this result could be related to the low dispersibility showed by unmodified GO. Notwithstanding the above, the need of mfGO or GO to achieve the shape-memory property under light irradiation was attributed to the well-known photothermal effect displayed by these entities, especially under NIR conditions. The authors also evaluated the repeatability of the shape-memory process, performing consecutive cycles of deformation. Results showed that, while pristine dPTD and dPTB exhibited a noticeable diminishing in their Rf and Rr values, after three cycles, nanocomposites containing mfGO kept both values above 90%. Later, focusing on dPTD–mfGO, the authors demonstrated the ability of this system to recover its initial shape from different type of deformations (Figure 10A). In this sense, dPTD–mfGO samples were initially heated at 45 °C (above its melting temperature) and reshaped into different configurations such as circles and spirals. Subsequently, the system was allowed to cool down to fix the new temporary shape. All dPTD–mfGO samples showing different temporary shapes were able to recover their initial shapes in notably short times under VIS-NIR light. For example, the dPTD–mfGO sample that was deformed into a spiral shape recovery its original configuration within 10 s. The actuation mechanism proposed by authors was based on melting-crystallization phenomena triggered by the photothermal effect. Regarding the above, temporary shapes were successfully achieved after deforming samples heated above their melting temperatures. Then, thanks to the nucleation effect showed by the mfGO entities during PU crystallization, the system maintained the initially induced shape. Then, during light irradiation, the mfGO fillers allowed the transformation of VIS–NIR light into thermal energy, which was transferred through the polymeric matrix inducing the melting of crystalline domains, releasing the stored strain energy, and, thus, triggering the shape recovery process. On the other hand, the authors also evaluated the light-activated self-healing property of these materials by cutting samples into two pieces, brought into contact and irradiating them for 3 min with a VIS–NIR source (400–1100 nm, 25 mW/cm2), after which a one-single piece of material showing no evidence for scars under SEM visualization was obtained (Figure 10B). To achieve this quantitatively, tensile experiments were performed on original and healed samples, reporting the healing efficiency as the ratio of the maximum tensile strength or elongation at break values of the healed and original samples. Evidently, pure dPTB PU showed a poor healing efficiency, characterized by healing efficiencies of 14% and 1% for maximum tensile strength and elongation at break, respectively. Contrary to the above, dPTD revealed a better healing property with healing efficiency values of 31% and 41%. Authors ascribed this to the light-triggered exchange reaction of diselenide bonds present in the polymer backbone.162,163 Surprisingly, the healing efficiencies of dPT–mfGO (39% and 70%) and dPTD–mfGO (80% and 96%) nanocomposites were notably increased after the incorporation of mfGO, demonstrating the importance of the photothermal effect on the healing process. In this sense, by using an infrared digital camera, the authors were able to visualize the rising of the temperature for each sample under VIS–NIR irradiation. Samples containing mfGO achieved temperatures above 45 °C in only 8 s, reaching temperatures as high as ≈55 °C in around 16 s. Conversely, none of the pure PU samples reached temperatures above 30 °C in the same time scale. Therefore, it was clear that nanocomposite samples in short times of irradiation were able to surpass the melting temperature of PU segments, favoring the mobility, diffusion, and re-entanglement of polymer chains across the damage area, promoting the healing process. Notwithstanding the above, it must be pointed out that the healing efficiency of dPTD–mfGO was considerably higher than dPTB–mfGO even when both have a similar photothermal response. Regarding the above, the authors attributed this result to a synergistic effect achieved between the photothermal effect provided by mfGO and diselenide exchange reactions present in dPTD–mfGO. Both light-activated processes would complement each other, allowing a better healing process under VIS–NIR irradiation where, simultaneously, the melt of crystalline domains and the activation of diselenide linkages would promote the interfacial diffusion and re-entanglement of polymer chains across the damaged area. Surprisingly, the healed dPTD–mfGO sample was able to maintain a weight of 800 g and also resist strong bending and stretching deformations without showing signals of fracture at the joint position (Figure 10C). Finally, these photoactuators exhibiting light-triggered self-healing property were successfully tested as flame retardant materials, demonstrating that the multifunctionalization of GO and its incorporation into PU matrices allow the enhancing of the thermal stability and the flame retardancy property.

Figure 10.

(A) Digital photographs of dPTD–mfGO nanocomposites strips showing their initial, temporary, and recovery shapes achieved during the shape-memory process under VIS–NIR irradiation (400–1100 nm). (B) Digital images (I–II) and SEM micrographs (III–IV) of a healed dPTD-mfGO sample. (C) Digital photographs showing the self-healing behavior of the healed dPTD–mfGO2 with different shapes: (I) bending, (II) bearing a weight of 800 g, and (III) after stretching. Adapted with permission from ref (158). Copyright 2020 Elsevier.