Abstract

We performed a market basket survey of plant-based milk alternatives (PBMAs) from the US market for vitamin A, vitamin D, calcium, and potassium to identify the amount and variability of these micronutrients across various PBMAs. The PBMA types included in this analysis were almond, cashew, coconut, hemp, oat, pea, rice, and soy (n=90 total product units). Analyses for vitamin A (as retinyl palmitate), vitamin D2/D3, and minerals were performed using high-performance liquid chromatography, liquid chromatography-tandem mass spectrometry, and inductively coupled plasma-mass spectrometry, respectively. A majority of PBMA types had significant differences (P<0.05) in the amounts of target micronutrients across brands. The coefficient of variation (%CV) for micronutrient concentrations within one lot of a single brand ranged from 4.1–42.2% for vitamin A, 1.5–44.1% for vitamin D, 1.7%−37.6% for calcium, and 0.7%−39.0% for potassium. The variability of these micronutrients should be taken into account when considering the nutritional value of PBMAs.

Keywords: Cholecalciferol, dairy, ergocalciferol, elemental analysis, mass spectrometry, minerals, plant-based beverages, retinol, vegetarian

Graphical Abstract

INTRODUCTION

Vitamin A, vitamin D, calcium, and potassium are micronutrients with important biological roles, such as maintaining immune function, bone health, and intracellular fluid volume.1–3 The National Academy of Medicine has established a recommended dietary allowance (RDA) for vitamin A, vitamin D, and calcium, and an adequate intake (AI) level for potassium.1–3 Because vitamin A can be obtained through various food sources, including plant (as provitamin A carotenoids) and animal foods (as preformed vitamin A), a deficiency of this vitamin is uncommon in the US. Vitamin D is typically found in animal foods or foods fortified with vitamin D, with animal sources generally containing vitamin D in the form of cholecalciferol (D3) and plant sources as ergocalciferol (D2). Foods from both plant and animal sources contain the minerals calcium and potassium.

Despite their nutritional importance, diets in the US and throughout the world generally contain vitamin D, calcium, and potassium below recommended amounts.4–6 With the update to the Nutrition Facts label in 2016 by the US Food and Drug Administration (FDA), the vitamin D and potassium content of a product are required to appear on the product’s package labeling.7 In addition, calcium continues to be required on the updated label. Although vitamins A and D, calcium, and potassium can be obtained in the diet through various foods, these are all key nutrients provided by dairy products.8

While bovine fluid milk (hereafter referred to as “milk”) consumption has been steadily declining in the US, there has been a corresponding increase in including plant-based milk alternatives (PBMAs) in the American diet.9, 10 Some of the potential factors driving PBMA consumption include an allergy to milk protein, consumer perception of the environmental impact of the dairy industry, religious reasons, and adherence to a diet that eliminates or reduces animal-derived foods (e.g., vegan or certain types of vegetarian diets).11–15 Because consumers may use PBMAs as a substitute for milk, some manufacturers formulate these beverages with added micronutrients (e.g., vitamins A and D, and calcium) to mimic amounts found in milk with added vitamins A and D.13, 16, 17

Information on the vitamin A, vitamin D, calcium, and potassium content of PBMAs is necessary when comparing key micronutrients in milk to PBMAs, but publicly available analytical data on the amounts of these compounds in PBMAs are limited. Indeed, a large number of studies examining the nutritional content of PBMAs rely on the values declared on the product’s Nutrition Facts label or information from publicly available databases, such as the US Department of Agriculture’s (USDA) FoodData Central.15, 18–21 These sources have been previously noted to be limited because the FoodData Central currently does not contain sufficient information on the increasingly large variety of PBMAs available on the market,22 and the Nutrition Facts label does not necessarily reflect the product’s potential micronutrient variability. Due to the increased consumption of PBMAs, it is crucial to measure the micronutrient content in a variety of PBMA types to allow for further understanding of how consumption of these products affects population micronutrient intake.

In the present study, we conducted a market basket analysis of commercially available PBMAs and milk (as a comparison) to measure the content of vitamins A and D, calcium, and potassium. The eight different types of PBMAs selected for the study were almond, cashew, coconut, hemp, oat, pea, rice, and soy. Samples were analyzed for vitamin A using high performance liquid chromatography with diode array detection (HPLC-DAD), vitamin D using liquid chromatography-tandem mass spectrometry (LC-MS/MS), and for calcium and potassium using inductively coupled plasma-mass spectrometry (ICP-MS). The variability of target nutrients was compared across PBMA types and brands, and, for almond PBMAs, across lots within a brand. Finally, the micronutrient analysis results were compared to values declared on the product’s Nutrition Facts label and to the amounts measured in milk.

MATERIALS AND METHODS

Chemicals, standards, and reference material

Chemicals obtained from Thermo Fisher Scientific (Waltham, MA, USA) were Optima grade acetonitrile, acetone, methanol, formic acid, and concentrated nitric acid; HPLC grade isooctane, methyl-t-butyl ether and absolute ethanol; reagent grade 4-phenyl-1,2,4-triazoline-3,5-dione (PTAD), potassium hydroxide, sodium acetate, hydroquinone, papain, glacial acetic acid, hydrochloric acid (36%), and pyrogallol; electronic grade 2-propanol; and retinyl palmitate standard (vitamin A palmitate). Vitamin D2 (ergocalciferol), vitamin D3 (cholecalciferol), d6-vitamin D2 (26,26,26,27,27,27-d6 ergocalciferol) and d6-vitamin D3 (26,26,26,27,27,27-d6 cholecalciferol) standards were purchased from Sigma-Aldrich (St. Louis, MO, USA). Stock standard containing Ca2+ and K+ was from Inorganic Ventures (Blacksburg, VA, USA). Internal standard mix for ICP-MS was purchased from Agilent Technologies (Santa Clara, CA, USA).

Deionized (DI) water (18.2 MΩ cm at 25 °C) was obtained from a Milli-Q system (Millipore-Sigma; Burlington, MA, USA). Standard Reference Material (SRM) 1869 (Infant/Adult Nutritional Formula II; milk/whey/soy-based) was procured from the National Institute of Standards and Technology (NIST; Gaithersburg, MD, USA).

Sampling and storage of PBMAs and milk

The eight different PBMA types in this study were made from almond, cashew, coconut, hemp, oat, rice, pea, and soy, as described by the product packaging label. These product types were selected based on the most commonly consumed PBMAs in the US as of September 2020.10 Locations of sample purchase were selected from a comprehensive list of retail food markets within a 50-mile radius of the Institute for Food Safety and Health (Bedford Park, IL, USA). Sampling was done by first identifying whether a specified PBMA product type with the required number of replicates was in stock at the selected retail market. Any products not in stock were then marked for selection at another market. This process was repeated until all samples were procured. Sampling for the majority of products was conducted at a total of 10 retail markets during Fall of 2020. Certain samples were not available at the local retail markets, so two PBMA brands (one brand each of rice and pea PBMA) were purchased from an online retailer.

Two to three brands of each PBMA type, and at least two replicate product units within the same production lot were obtained. Samples were from a total of 19 brands. In addition, one almond PBMA brand was selected to capture the variability of target micronutrients across production lots, due to almond PBMAs currently being the most consumed PBMA type in the US. Thus, three unique lots of one brand of an almond PBMA were sampled for analysis. In total, 85–90 unique PBMA product units were used for the analysis (see Table 1).

Table 1.

Summary of the 8 different types of PBMAs and number of products sampled for vitamin and mineral analysis.

| Type | Code | Brands, n | Number of product units for vitamin A analysis, n | Number of product units for vitamin D analysis, n | Number of product units for mineral analysis, n |

|---|---|---|---|---|---|

| Almond | A | 3 | 18 | 17 | 18 |

| Cashew | CW | 2 | 9 | 9 | 9 |

| Coconut | CT | 2 | 9 | 9 | 9 |

| Hemp | H | 2 | 10 | 10 | 8 |

| Oat | O | 3 | 14 | 14 | 12 |

| Pea | P | 2 | 9 | 10 | 8 |

| Rice | R | 2 | 8 | 8 | 8 |

| Soy | S | 3 | 13 | 13 | 13 |

| Total | 90 | 90 | 85 |

According to the product’s Nutrition Facts label, the majority of PBMA brands (16/19) were formulated by the manufacturer with added vitamin A, vitamin D, and calcium (see Tables 2, 3 and 4), except for one brand of cashew, hemp, and rice PBMAs (CW1, H1, and R2). The PBMA ingredient list indicated that CW1 contained added calcium, but no added vitamin A or vitamin D. Hemp brand H1 contained no added vitamin A. Rice brand R2 was formulated with no added vitamin A, vitamin D, or calcium. Eight PBMA brands were formulated with potassium-containing ingredients (e.g., potassium citrate), but it is important to note that these ingredients can be added as buffering agents.23 Milk obtained from a local retail market (3.25% milkfat) contained added vitamin A and vitamin D3.24, 25

Table 2.

Mean concentration of vitamin A and associated variability in market basket analysis of eight different types of PBMAs and milk.a

| PBMA Type/Brand Code | Number of Product Units, n | Mean concentration (μg/100 g portion) | %CV | Nutrition Facts Label Value (μg/100 g portion) | % Difference from Nutrition Facts Label Value | % Difference from Milk |

|---|---|---|---|---|---|---|

| Milk | 2 | 33.7 | 10.0 | 37.5 | −10.1 | - |

| Almond | ||||||

| Almond/A1 | 10 | 54.2 | 21.0 | 62.5 | −13.3 | +60.8 |

| Almond/A2 | 3 | 44.3 | 36.1 | 62.5 | −29.1 | +31.5 |

| Almond/A3 | 5 | 58.5 | 12.2 | 55.4 | +5.6 | +73.6 |

| Cashew | ||||||

| Cashew/CW1 | 5 | <LOQ | - | “Not a significant source of vitamin A” | - | - |

| Cashew/CW2 | 4 | 51.9 | 22.1 | 62.5 | −17.0 | +54.0 |

| Coconut | ||||||

| Coconut/CT1 | 4 | 91.4 | 42.2 | 75 | +21.9 | +171.2 |

| Coconut/CT2 | 5 | 94.6 | 37.7 | 62.5 | +51.4 | +180.7 |

| Hemp | ||||||

| Hemp/H1 | 5 | <LOQ | - | “Not a significant source of vitamin A” | - | - |

| Hemp/H2 | 5 | 63.9 | 21.5 | 37.5 | +70.4 | +89.6 |

| Oat | ||||||

| Oat/O1 | 5 | 56.8 | 13.4 | 75 | −24.3 | +68.5 |

| Oat/O2 | 5 | 54.3 | 7.1 | 56.3 | −3.6 | +61.1 |

| Oat/O3 | 4 | 77.7 | 22.3 | 66.7 | +16.5 | +130.6 |

| Pea | ||||||

| Pea/P1 | 4 | 44.6 | 28.4 | 57.2 | −22.0 | +32.3 |

| Pea/P2 | 5 | 30.6 | 30.2 | 37.5 | −18.4 | −9.2 |

| Rice | ||||||

| Rice/R1 | 3 | 144 | 4.1 | 41.7 | +246.3 | +328.5 |

| Rice/R2 | 5 | <LOQ | - | “Not a significant source of vitamin A” | - | - |

| Soy | ||||||

| Soy/S1 | 5 | 55.5 | 21.2 | 62.5 | −11.2 | +64.7 |

| Soy/S2 | 5 | 58.5 | 8.9 | 62.5 | −6.4 | +73.6 |

| Soy/S3 | 3 | 94.6 | 29.6 | 62.5 | +51.4 | +180.7 |

All Nutrition Facts labels declared vitamin A palmitate as the form of vitamin A added to the product, except for PBMA brands O2 and P2 (none specified). No vitamin A was added to brands CW1, H1, and R2.

Table 3.

Mean concentration of vitamin D (vitamin D2 and D3) and associated variability in a market basket of eight different types of PBMAs and milk.a

| PBMA Type/Brand Code | Number of Product Units, n | Mean Concentration (μg/100 g portion) | %CV | Nutrition Facts Label Value (μg/100 g portion) | % Difference from Nutrition Facts Label Value | % Difference from Milk |

|---|---|---|---|---|---|---|

| Milk | 2 | 2.08 | 3.7 | 2.1 | −1.0 | - |

| Almond | ||||||

| Almond/A1 | 9 | 2.23 | 31.7 | 2.1 | +6.2 | +7.2 |

| Almond/A2 | 3 | 2.54 | 17.0 | 1.0 | +154.0 | +22.1 |

| Almond/A3 | 5 | 0.77 | 15.5 | 2.1 | −63.3 | −63.0 |

| Cashew | ||||||

| Cashew/CW1 | 5 | <LOQ | - | “Not a significant source of vitamin D” | - | - |

| Cashew/CW2 | 4 | 1.62 | 44.1 | 1.0 | +62.0 | −22.1 |

| Coconut | ||||||

| Coconut/CT1 | 4 | 1.67 | 30.6 | 0.8 | +108.8 | −19.7 |

| Coconut/CT2 | 5 | 1.28 | 24.4 | 1.0 | +28.0 | −38.5 |

| Hemp | ||||||

| Hemp/H1 | 5 | 0.96 | 22.4 | 0.8 | +20.0 | −53.9 |

| Hemp/H2 | 5 | 1.30 | 23.5 | 1.2 | +8.3 | −37.5 |

| Oat | ||||||

| Oat/O1 | 5 | 1.89 | 4.6 | 1.7 | +11.2 | −9.1 |

| Oat/O2 | 5 | 1.59 | 14.4 | 1.3 | +22.3 | −23.6 |

| Oat/O3 | 4 | 2.60 | 2.1 | 1.5 | +73.3 | +25.0 |

| Pea | ||||||

| Pea/P1 | 5 | Not determined | - | 0.8 | - | - |

| Pea/P2 | 5 | 3.06 | 29.0 | 2.1 | +45.7 | +47.1 |

| Rice | ||||||

| Rice/R1 | 3 | 11.5 | 1.5 | 2.1 | +447.6 | +452.9 |

| Rice/R2 | 5 | <LOQ | - | “Not a significant source of vitamin D” | - | - |

| Soy | ||||||

| Soy/S1 | 5 | 3.90 | 27.4 | 2.5 | +56.0 | +87.5 |

| Soy/S2 | 5 | 3.40 | 26.4 | 2.5 | +36.0 | +63.5 |

| Soy/S3 | 3 | 2.35 | 8.3 | 1.3 | +80.8 | +13.0 |

All Nutrition Facts labels declared PBMA brands and milk contained added vitamin D, except for CW1 and R2. Vitamin D2 was detected in all PBMAs brands with added vitamin D, except for O2 and P2, which contained vitamin D3. Vitamin D3 was detected in milk samples.

Table 4.

Mean concentration of calcium and associated variability in a market basket of eight different types of PBMAs and milk.

| PBMA Type/Brand Code | Number of Product Units, n | Mean Concentration (mg/100 g portion) | %CV | Nutrition Facts Label Value (mg/100 g portion) | % Difference from Nutrition Facts Label Value | % Difference from Milk | Calcium Ingredient(s) on Label |

|---|---|---|---|---|---|---|---|

| Milk | 2 | 106 | 2.6 | 117 | −9.4 | - | - |

| Almond | |||||||

| Almond/A1 | 10 | 205 | 4.3 | 188 | +9.0 | +93.4 | Calcium carbonate |

| Almond/A2 | 3 | 209 | 3.9 | 188 | +11.2 | +97.2 | Calcium carbonate |

| Almond/A3 | 5 | 43.1 | 4.8 | 54 | −20.2 | −59.3 | Calcium carbonate |

| Cashew | |||||||

| Cashew/CW1 | 5 | 18.2 | 7.0 | 17 | +7.1 | −82.8 | Tricalcium phosphate |

| Cashew/CW2 | 4 | 199 | 8.4 | 188 | +5.9 | +87.7 | Calcium carbonate |

| Coconut | |||||||

| Coconut/CT1 | 4 | 196 | 5.2 | 192 | +2.1 | +84.9 | Calcium carbonate |

| Coconut/CT2 | 5 | 168 | 4.8 | 188 | −10.6 | +58.5 | Calcium carbonate |

| Hemp | |||||||

| Hemp/H1 | 3 | 117 | 3.3 | 113 | +3.5 | +10.4 | Tricalcium phosphate |

| Hemp/H2 | 5 | 17.6 | 22.0 | 163 | −89.2 | −83.4 | Tricalcium phosphate |

| Oat | |||||||

| Oat/O1 | 5 | 158 | 3.4 | 146 | +8.2 | +49.1 | Calcium carbonate |

| Oat/O2 | 5 | 149 | 6.3 | 130 | +14.6 | +40.6 | Calcium carbonate; Tricalcium phosphate |

| Oat/O3 | 2 | 153 | 14.3 | 146 | +4.8 | +44.3 | Calcium carbonate; Tricalcium phosphate |

| Pea | |||||||

| Pea/P1 | 4 | 212 | 1.7 | 219 | −3.2 | +100 | Tricalcium phosphate |

| Pea/P2 | 4 | 28.2 | 15.6 | 140 | −79.9 | −73.4 | Calcium carbonate |

| Rice | |||||||

| Rice/R1 | 3 | 99.2 | 37.6 | 162 | −38.8 | −6.4 | Tricalcium phosphate |

| Rice/R2 | 5 | 9.1 | 8.6 | “Not a significant source of calcium” | - | −91.4 | - |

| Soy | |||||||

| Soy/S1 | 5 | 111 | 20.3 | 125 | −11.2 | +4.7 | Calcium carbonate |

| Soy/S2 | 5 | 124 | 9.2 | 125 | −0.8 | +17.0 | Calcium carbonate |

| Soy/S3 | 3 | 191 | 4.4 | 188 | +1.6 | +80.2 | Calcium carbonate; Tricalcium phosphate |

Each product unit was thoroughly mixed before being dispensed into 15 mL amber polypropylene tubes (Chemglass Life Sciences; Vineland, NJ, USA) under blue-light shielded lamps. The samples were stored at −20 °C until analysis. Samples were extracted and analyzed in randomized order.

Vitamin A analysis using HPLC-DAD

The samples were analyzed for vitamin A as retinyl palmitate using AOAC Official Method 2012.10.26 Briefly, after the frozen samples were thawed and thoroughly mixed, 5.0 g of each sample was dispensed into an amber 50 mL polypropylene tube (Chemglass Life Sciences; Vineland, NJ, USA). This was followed by the addition of 5 mL of enzymatic digestion solution (papain:sodium acetate:hydroquinone; 20 g/L:40 mg/mL:1.0 mg/mL). Samples were incubated in a 37 °C water bath for 25 min. After the samples were cooled to room temperature, 20 mL of acidified methanol (20 mL acetic acid + 1 L methanol) was added to each sample and then samples were shaken for 10 min using a GenoGrinder automated shaker (SPEX SamplePrep; Metuchen, NJ, USA). Each sample was mixed with iso-octane (10 mL) and then placed in the shaker for an additional 10 min. The samples were centrifuged for 10 min (Sorvall Legend X1R; Thermo Fisher Scientific, Waltham, MA, USA), and approximately 1 mL of the organic layer from each sample was transferred to an amber LC vial (Waters Co., Bedford, MA, USA) for analysis.

Retinyl palmitate was quantified using an Agilent 1260 Infinity HPLC equipped with a DAD. Separations were achieved using a Zorbax NH2 column (150 × 4.6 mm, 5 μm; Agilent Technologies, Santa Clara, CA, USA) with the column oven set to 40 °C. Gradient elution mode was used with mobile phase A as n-hexane and mobile phase B as n-hexane:methyl-t-butyl ether:methanol (750:250:3). The flow rate was set to 1.5 mL/min. Sample injection volume was 50 μL, and both cis- and trans-retinyl palmitate isomers were monitored at 325 nm.

In order to assess method performance, samples of SRM 1869 (n=3) were extracted and analyzed for retinyl palmitate and compared to the reference values provided by NIST. Intraday and interday variabilities were determined by analyzing replicate SRM 1869 samples within a day (n=3) and across five days (n=5), respectively. Quality control measures for analysis included validating each analytical sequence by analyzing a sample of SRM 1869. The method limit of detection (LOD) was 15 μg vitamin A palmitate/100 g sample.

Vitamin D analysis using LC-MS/MS

Vitamin D2 and D3 analysis was completed using AOAC First Action Method 2016.05.27 All steps during the extraction were performed under UV-shielded lighting. Briefly, after the frozen samples were thawed and thoroughly mixed, 10 mL of each sample was dispensed into an amber 50 mL polypropylene tube (Chemglass Life Sciences; Vineland, NJ, USA), followed by addition of 10 mL ethanolic pyrogallol solution (1%, w:v), 0.5 mL of internal standard solution containing 1.0 μg/mL d6-vitamin D2 and d6-vitamin D3, and 2 mL of 50% potassium hydroxide solution (w:v). Samples were saponified for 1 h, and lipid-soluble compounds were extracted using isooctane. Vitamin D was derivatized with 75 μL PTAD solution (10 mg/mL). The derivatized sample was mixed with acetonitrile (1 mL), and then centrifuged. The lower layer was collected and mixed with 167 μL DI water. The filtered sample was dispensed into an LC-MS vial (Waters Co., Bedford, MA, USA) for analysis.

Vitamins D2 and D3 were quantified using a Waters Acquity UPLC in line with a TQD triple quadrupole mass spectrometer. Separations were achieved using a CORTECS C18 core-shell column (2.1 × 50 mm, 2.6 μm; Waters Co., Bedford, MA, USA) with the column oven set to 40 °C. Gradient elution mode was used with aqueous 0.1% v/v formic acid as mobile phase A and methanol as mobile phase B. The flow rate was set to 0.6 mL/min. Sample injection volume was 3 μL. The TQD mass spectrometer used an electrospray ionization (ESI) probe operated in positive ionization mode. The mass transition for vitamin D2 quantification was m/z 572.2 → 298.0, and the mass transition for vitamin D3 quantification was m/z 560.2 → 298.0. For the internal standards, the mass transition for d6-vitamin D2 quantification was m/z 578.2 → 298.0 and m/z 566.2 → 298.0 for d6-vitamin D3 quantification.

In order to assess method performance, three samples of SRM 1869 were extracted and analyzed for vitamins D2 and D3 by LC-MS/MS and compared to the reference values provided by NIST. Intraday and interday variabilities were determined by analyzing replicate SRM 1869 samples within a day (n=3) and across five days (n=5), respectively. Quality control measures for analysis included validating each analytical sequence by analyzing a sample of SRM 1869. The method LOD for vitamin D was 0.04 μg/100 g.

Calcium and potassium analysis using ICP-MS

Samples were analyzed for total calcium (Ca2+) and potassium (K+) content using microwave-assisted digestion followed by ICP-MS, according to a method adapted from the FDA’s Elemental Analysis Manual 4.7.28 Briefly, 4 g of PBMA sample was placed in a digestion vessel with 10 mL of nitric acid and subjected to microwave-assisted digestion using a Discover SP-D microwave digestion system (CEM Corporation; Matthew, NC, USA). After digestion, each sample was diluted to 100 g with DI water in trace metal quality plastic tubes (SCP Sciences; Champlain, NY). Samples were further diluted 20-fold with 5% (v:v) nitric acid. An Agilent 8800 ICP-MS (Santa Clara, CA, USA) was set in single quadrupole mode with research grade helium (99.999%) from Airgas (Radnor, PA) as the collision gas. Internal Standard Mix (Agilent Technologies) was prepared in aqueous nitric acid:2-propanol (5:20; v:v), with the internal standard for both Ca2+ and K+ set as scandium (45Sc). For Ca2+, both 43Ca and 44Ca isotopes were monitored and is reported as 44Ca; data for K+ is reported as 39K.

To assess method performance, three independent replicates of SRM 1869 were analyzed and the resulting data was compared to the certified values provided by NIST. Quality control measures for analysis included validating each analytical sequence by analyzing SRM 1869, in addition to analyzing a Ca2+ and K+ calibration verification standard every 10 samples. The method LOD was 6.5 mg/100 g for Ca2+ and 1.2 mg/100 g for K+.

Data processing and statistics

Vitamin A data was processed using ChemStation version C.01.05 (Agilent Technologies; Santa Clara, CA, USA). Vitamin A results are expressed as retinol activity equivalents (RAE), which was calculated by multiplying the results for retinyl palmitate (the sum of cis and trans isomers) by 0.55.26 Data processing for vitamin D results were conducted using MassLynx workstation software version 4.1 (Waters Co.; Bedford, MA, USA). Mineral data processing was conducted using MassHunter Workstation software version 4.6 (Agilent Technologies; Santa Clara, CA, USA) with results exported as Excel worksheets (Microsoft Office, Microsoft Co., Redmond, WA).

One to two subsamples per PBMA product unit underwent extraction or acid digestion for vitamin and minerals analyses, respectively. Statistical analysis was performed using JMP 16 (SAS Institute, Cary, NC, USA). One-way ANOVA followed by pairwise mean comparisons using Tukey’s honest significant difference (HSD) post-hoc correction determined significant differences (P < 0.05) between groups. Data presented as box-and-whisker plots were generated using Microsoft Excel (Redmond, WA, USA). Additional data for figures are displayed as means±SD. For statistical purposes and for generating the box plots, data below the LOD was imputed a value of the analyte’s LOD/2. The percent coefficient of variation (%CV) was calculated as SD/mean*100%.

RESULTS

Method performance for quantification of vitamin A, vitamin D, calcium, and potassium

The recovery of vitamin A (as retinyl palmitate) from SRM 1869 (n=3) was determined to be 98.4 ± 3.1% of the NIST reference value. The intraday %CV (n=3) for vitamin A was 0.9% and the interday %CV across five days (n=5) was 2.7%.

The recovery of vitamins D2 and D3 from SRM 1869 (n=3) was found to be 92.7 ± 1.4% and 102 ± 4%, respectively. The intraday %CV (n=3) for vitamin D2 was 1.5% and for vitamin D3 was 4.2%. The interday %CV (n=5) for analysis of samples was 10.0% and 4.5% for vitamin D2 and vitamin D3, respectively.

Calcium and potassium recoveries from SRM 1869 (n=3) were 104 ± 2% and 100 ± 0% of the NIST certified values for calcium and potassium, respectively.

Overall distribution and variability of target micronutrients in PBMAs and milk

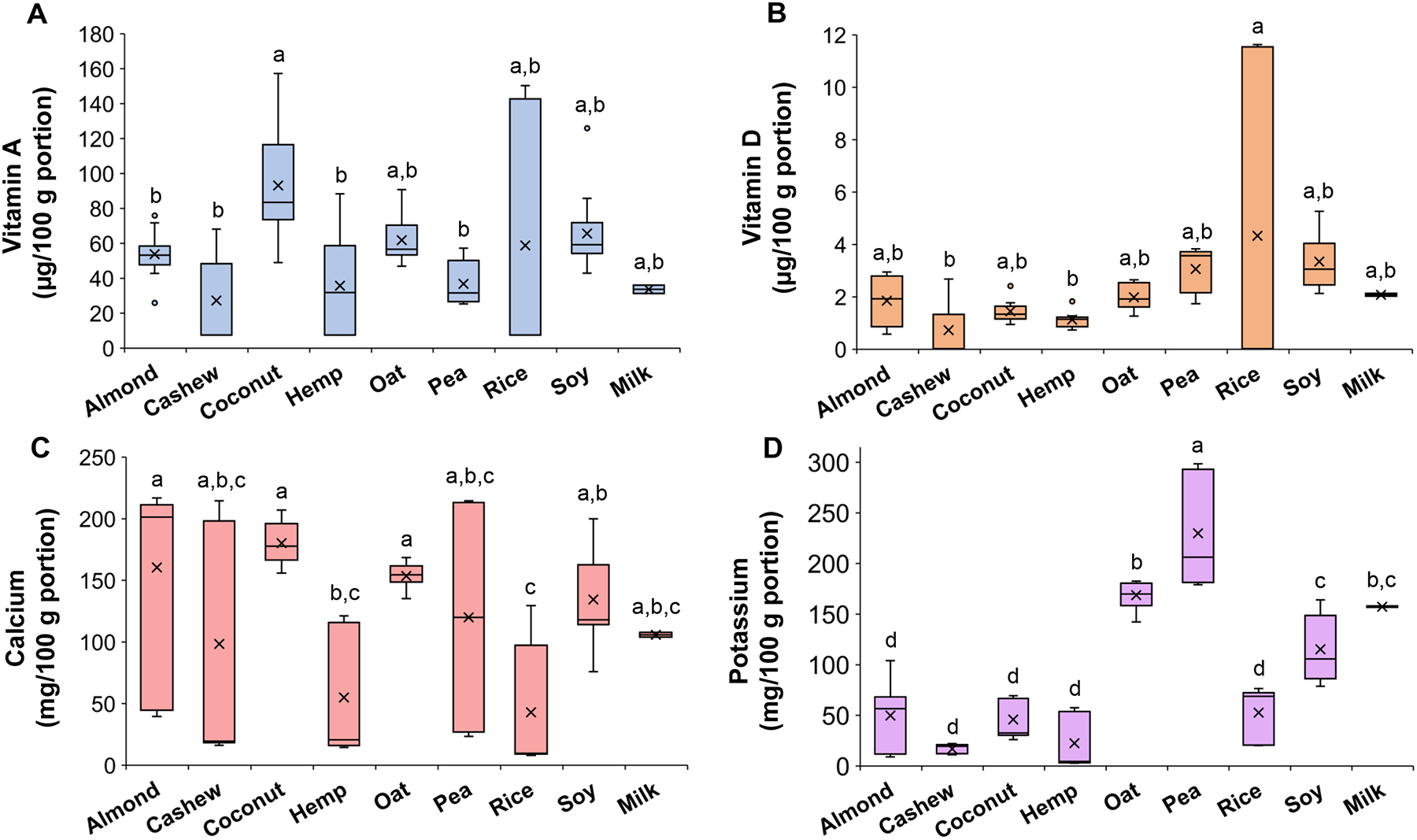

Figure 1 shows a boxplot with the overall distribution and variability of the measured vitamin A, vitamin D, calcium, and potassium amounts across the eight PBMA types with milk as a comparison. The highest mean vitamin A value (expressed as RAE) was in coconut PBMAs (93.2 μg vitamin A/100 g) and the lowest was in cashew PBMAs (27.2 μg/100 g) (Figure 1A). Milk vitamin A concentrations (mean: 33.7 μg vitamin A/100 g) were not statistically different (P>0.05) from any PBMA type.

Figure 1. Box plot of the concentrations of target micronutrients in a market basket analysis of eight different types of PBMAs and milk.

(A) vitamin A (expressed as RAE), (B) vitamin D, (C) calcium and (D) potassium. Information on the number of samples per PBMA type are found in Tables 1–4. Vitamin A in samples was detected as retinyl palmitate. Samples with quantifiable amounts of vitamin D contained only vitamin D2 except for O2, P2, and milk, which contained only vitamin D3. Values not sharing the same letter within PBMA type are significantly different (P<0.05) as determined by Tukey’s HSD post hoc test.

Figure 1B displays the overall distribution of vitamin D (inclusive of vitamin D2 and D3) concentrations across PBMA types and milk. Vitamin D concentrations varied across PBMA type, with the highest value being in rice PBMAs (mean: 4.33 μg vitamin D/100 g) and the lowest in cashew (mean: 0.73 μg/100 g). Mean vitamin D concentrations in milk (2.08 μg vitamin D/100 g) were not significantly different (P>0.05) from any PBMA type.

The highest mean concentration of calcium (Figure 1C) was in coconut PBMAs (180 mg/100 g) and the lowest in rice PBMAs (42.9 mg/100 g). Mean concentrations of calcium in any PBMA type were not statistically different from the amount found in milk (mean: 106 mg/100 g).

For potassium content in PBMAs, Figure 1D shows that the highest mean concentration was in pea PBMAs (230 mg/100 g) and the lowest in cashew PBMAs (16.9 mg/100 g). Pea PBMA contained significantly higher (P<0.05) concentrations of potassium compared to milk (157 mg/100 g), while rice, almond, coconut, hemp, and cashew PBMAs had significantly lower concentrations of potassium compared to milk.

Variability of vitamin A across PBMA brands and comparison to milk

In Figure 2, the vitamin A content for each PBMA type is displayed according to brand. Vitamin A was found at quantifiable concentrations in all samples with a vitamin A value declared on the Nutrition Facts label. Considering only PBMA brands with vitamin A amounts above the LOD, only oat and soy PBMAs showed significant differences (P<0.05) in vitamin A concentrations between brands. There were no significant differences in vitamin A concentrations between the brands of almond, coconut and pea PBMAs.

Figure 2. Vitamin A variability across different brands of PBMAs. Vitamin A in samples was detected as retinyl palmitate (expressed as RAE).

Brands with vitamin A below the LOD are labeled as <LOD. Information on the number of samples per PBMA type are found in Table 1. Values are shown as mean ± SD. Brands not sharing the same letter within a PBMA type are significantly different (P<0.05) as determined by Tukey’s HSD post hoc test. LOD, limit of detection; NS, not significant.

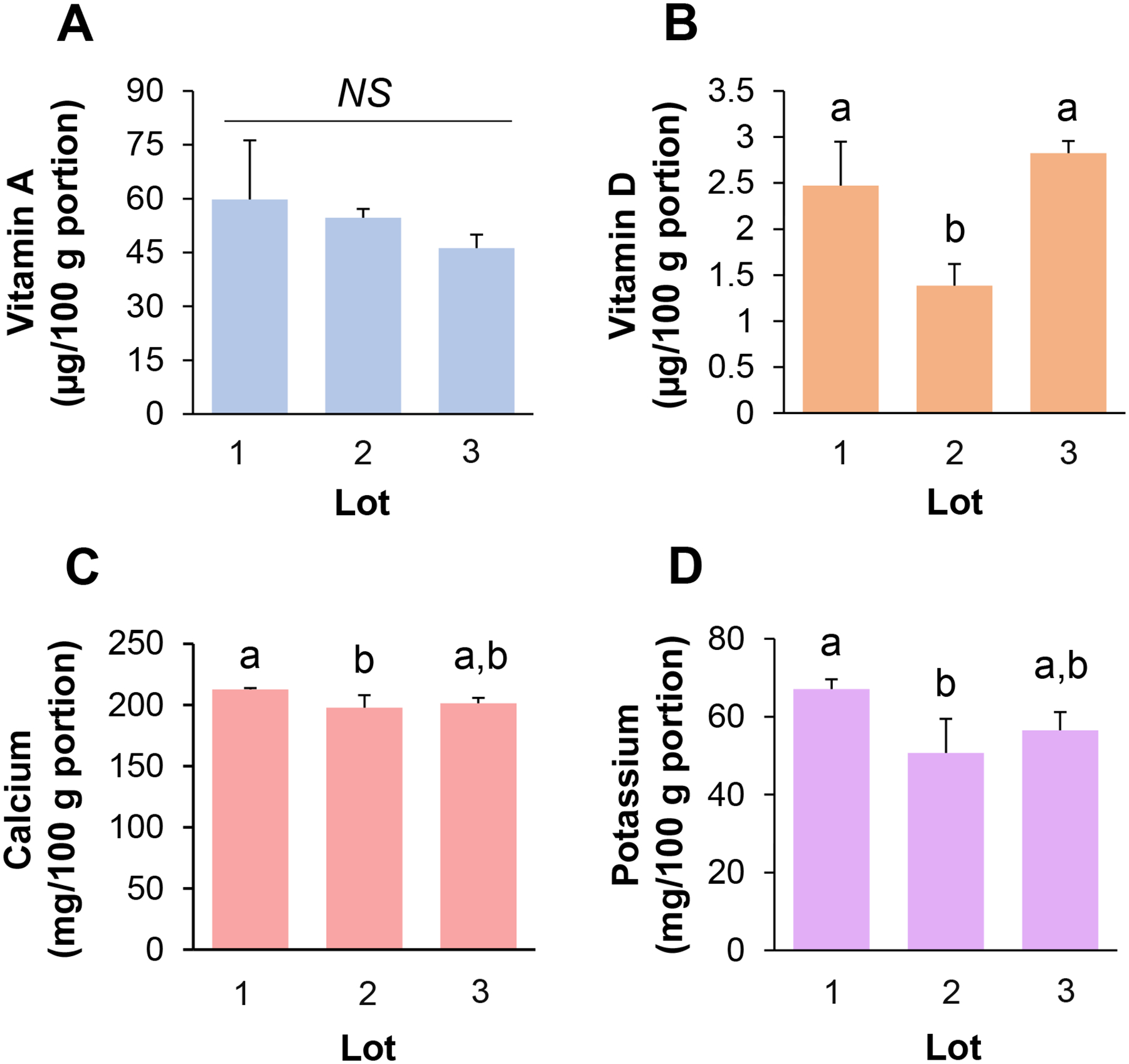

Table 2 displays the %CV of vitamin A within each PBMA brand, in addition to the difference between the vitamin A amount declared on the product’s Nutrition Facts label and the measured results. Of note is coconut PBMA brand CT1, which had the greatest variability of vitamin A concentrations at 42.2%, while rice PBMA brand R1 was the lowest at 4.1%. Out of the 19 brands tested, 8 brands contained analytical results within 20% of the amount declared on the Nutrition Facts label. The vitamin A concentrations in a majority of PBMA brands (9/16) were below the amount declared on the Nutrition Facts label. PBMA brand R1 contained the highest concentration of vitamin A compared to the declared amount (246% higher). Although the number of milk samples were limited, variation in milk (10.0%) was less than the variation in most of the PBMA brands. Vitamin A amounts did not vary significantly (P>0.05) across lots of almond A1 (Figure 3A).

Figure 3. Variability of target micronutrients across three lots of brand A1 almond PBMA.

(A) vitamin A (expressed as RAE), (B) vitamin D, (C) calcium, and (D) potassium. Values are shown as mean ± SD. Values not sharing the same letter are significantly different (P<0.05) as determined by Tukey’s HSD post hoc test. NS, not significant.

In comparison to milk, almost all brands with added vitamin A (except for P2) contained measured vitamin A amounts at least those found in milk (Table 2). PBMA brand P2 contained vitamin A at amounts ~10% lower than milk. The three brands with no added vitamin A (CW1, H1, and R2) contained no detectable amounts of this vitamin.

Variability of vitamin D across PBMA brands and comparison to milk

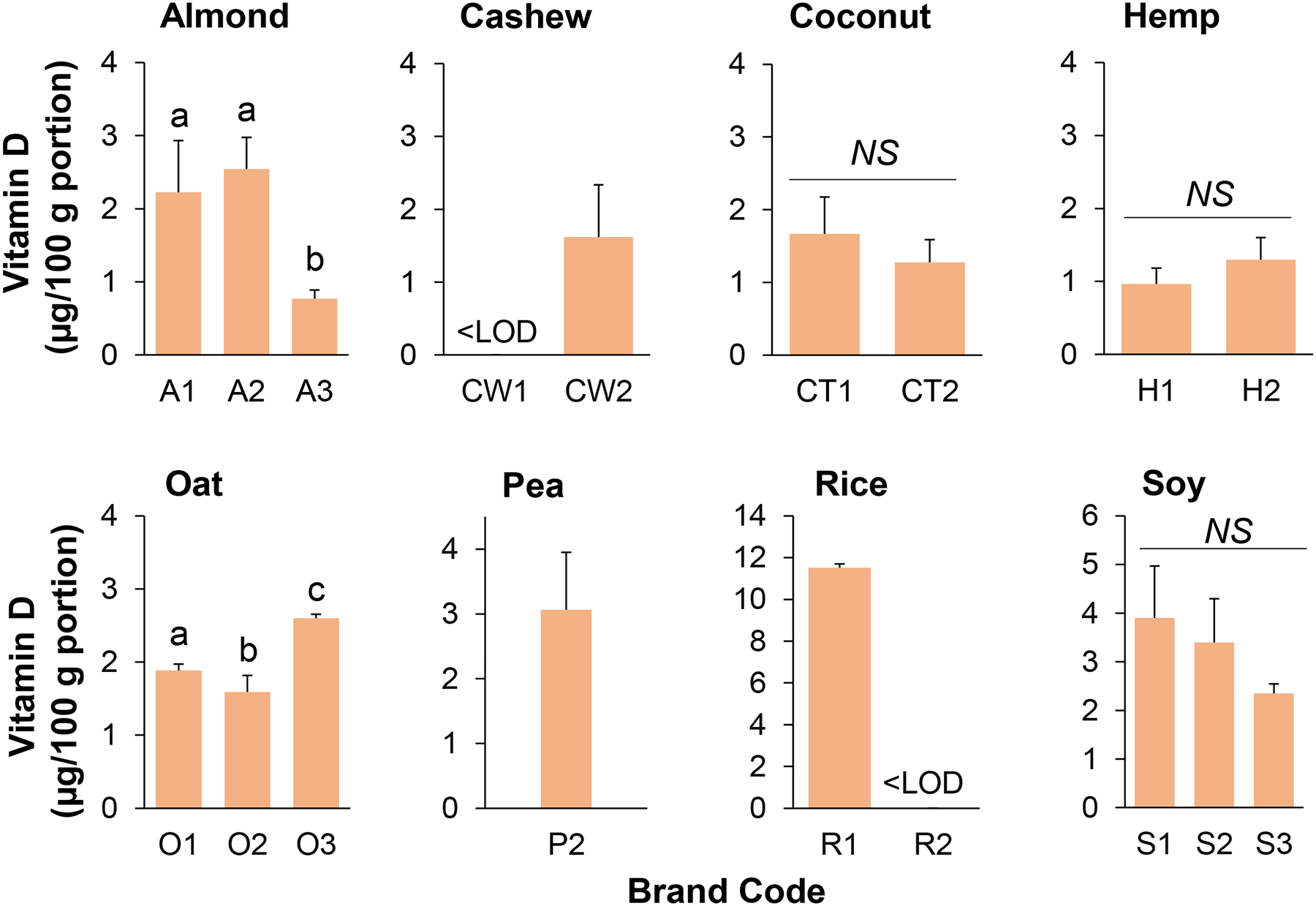

The vitamin D content for each PBMA type is displayed according to brand in Figure 4. Vitamin D in the form of D2 was detected in all PBMAs brands except for one brand of oat PBMA (O2) and one brand of pea PBMA (P2), which both contained vitamin D3. Vitamin D3 was detected in the milk samples. The results for one brand of pea PBMA (P1) were not included in the presented data because the sample extraction was deemed inadequate based on the internal standard response being less than the LOD. Out of the seven PBMA types where more than one brand was analyzed, four types showed significant differences (P<0.05) in vitamin D concentrations between brands. There were no significant differences in vitamin D concentrations between the brands of coconut, hemp, and soy PBMAs.

Figure 4. Vitamin D (D2 and D3) variability across different brands of PBMAs.

All beverage types with quantifiable amounts of vitamin D contained only vitamin D2 except for O2 and P2 which contained only vitamin D3. Brands with vitamin D concentration below the LOD are labeled as <LOD. Sample P1 was analyzed but vitamin D could not be determined due to poor analyte recovery. Information on the number of samples per PBMA type are found in Table 2. Values are shown as mean ± SD. Brands not sharing the same letter within a PBMA type are significantly different (P<0.05) as determined by Tukey’s HSD post hoc test. LOD, limit of quantitation; NS, not significant.

Table 3 displays the variability (%CV) of vitamin D within a PBMA brand. Additionally, it shows the vitamin D amount declared on the product’s Nutrition Facts label and the calculated percent difference compared to the analytical results. Of note is cashew brand CW2, which had the greatest variability of vitamin D concentrations (44.1%), while rice brand R1 had the lowest (1.5%). Out of the 19 brands tested, four brands (A1, H1, H2, O1) contained measured vitamin D amounts within 20% of the value declared on the Nutrition Facts label. The majority of vitamin D concentrations were above the amount on the Nutrition Facts label, with A3 being the exception (63.4% less than the declared amount). Rice R1 contained the highest concentrations of vitamin D compared to the declared amount (448% higher). The vitamin D variation in milk (3.7%) was less than the majority of the variation found in PBMA brands. Vitamin D varied significantly (P<0.05) across three different lots of almond PBMA brand A1, with the greatest difference being 1.44 μg vitamin D/100 g (Figure 3B).

Of the PBMA brands with added vitamin D, half of the brands (8/16) contained measured vitamin D concentrations at least those found in milk (Table 3). Of the six brands with declared amounts of vitamin D to be at least those of milk, the measured value in five of the brands met the label claim. There was no detectable vitamin D in the two brands with no added amounts of this micronutrient (CW1 and R2).

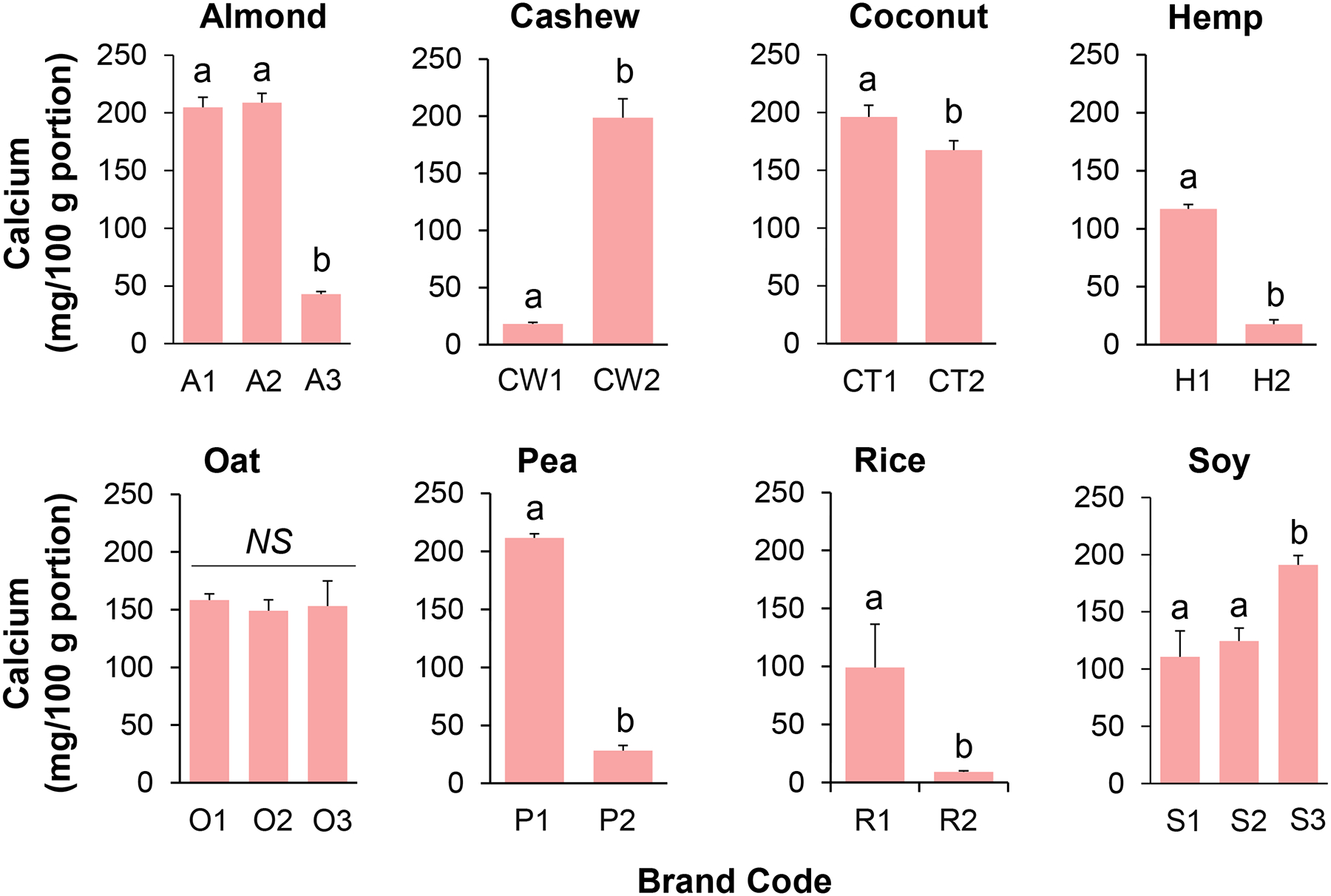

Variability of calcium across PBMA brands and comparison to milk

Calcium concentrations were significantly different (P<0.05) across the majority of PBMA brands within a PBMA type (Figure 5). Of the eight PBMA types, only oat PBMAs did not exhibit significant differences (P>0.05) in calcium concentrations across any brand. Pea PBMAs showed the greatest absolute difference in calcium concentrations (183 mg/100 g) between the two brands analyzed.

Figure 5. Calcium variability across different brands of PBMAs.

Details on the number of samples per PBMA type are found in Table 3. Values are shown as mean ± SD. Brands not sharing the same letter within a PBMA type are significantly different (P<0.05) as determined by Tukey’s HSD post hoc test. NS, not significant.

Table 4 displays the variability (%CV) of calcium within a single PBMA brand. It also shows the calcium amount declared on the product’s Nutrition Facts label, the calculated percent difference compared to the analytical results, and any calcium-containing ingredient listed on the label. The PBMA brand with the highest calcium variability was rice R1 (37.6%), but most PBMA brands (16/19 brands) had a %CV of less than 20%. The majority of PBMA brands (16/19 brands) were within 20% of the amount of calcium declared on the Nutrition Facts label. One brand of pea PBMA (P2) and hemp PBMA (H2) both had approximately 80–90% lower calcium concentrations compared to the amount declared on the Nutrition Facts label. Overall calcium variation within a PBMA brand was low, but variation in milk (2.6%) was still lower than a majority of PBMA brands. As shown in Figure 3C, there was a significant difference (P<0.05) in calcium concentrations across lots of almond PBMA brand A1. Although statistically significant, the greatest absolute difference in calcium concentrations was only 15 mg/100 g.

All brands except for R1 contained added calcium, and all brands contained detectable levels of this element (Table 4). Compared to milk, a majority of brands (13/18 brands) with added calcium contained measured amounts at least those found in milk. Of the 15 brands with a declared calcium amount to be at least that of milk, 13 contained sufficient calcium to meet this claim.

Variability of potassium across PBMA brands and comparison to milk

Potassium concentrations for each PBMA type are displayed according to brand in Figure 6. Of the eight PBMA types, six showed significant differences (P<0.05) across brands. The pea PBMAs showed the greatest absolute difference in potassium concentrations (94 mg/100 g).

Figure 6. Potassium variability across different brands of PBMAs.

Details on the number of samples per PBMA type are found in Table 4. Values are shown as mean ± SD. Brands not sharing the same letter within a PBMA type are significantly different (P<0.05) as determined by Tukey’s HSD post hoc test. NS, not significant.

Table 5 displays the potassium variation (%CV) within a single PBMA brand. This table also displays the potassium declared on the Nutrition Facts label, the percent difference compared to the measured value, and any potassium-containing ingredient included on the label. The vast majority of PBMAs (16/19) had a %CV of less than 20%. Of the 16 products with a potassium amount declared on the label, 14 were within 20% of the value. Of note was hemp PBMA H2, which contained approximately 90% less potassium than the declared value. The variation in milk (0.6%) was lower than all PBMA brands. Figure 3D shows that although there was a significant difference (P<0.05) in potassium content across three lots of almond PBMA brand A1, the absolute value was 16 mg/100 g.

Table 5.

Mean concentration of potassium and associated variability in a market basket of eight different types of PBMAs and milk.

| PBMA Type/Brand Code | Number of Product Units, n | Mean Concentration (mg/100 g portion) | %CV | Nutrition Facts Label Value (mg/100 g portion) | % Difference from Nutrition Facts Label Value | % Difference from Milk | Potassium Ingredient on Label |

|---|---|---|---|---|---|---|---|

| Milk | 2 | 157 | 0.6 | 158 | −0.6 | - | - |

| Almond | |||||||

| Almond/A1 | 10 | 59.0 | 15.0 | 67 | −11.9 | −62.4 | Potassium citrate |

| Almond/A2 | 3 | 83.6 | 21.3 | 71 | +17.7 | −46.8 | - |

| Almond/A3 | 5 | 11.0 | 11.0 | 11 | 0.0 | −93.0 | - |

| Cashew | |||||||

| Cashew/CW1 | 5 | 20.8 | 4.4 | “Not a significant source of potassium” | - | −86.8 | - |

| Cashew/CW2 | 4 | 12.1 | 7.0 | 0 | - | −92.3 | - |

| Coconut | |||||||

| Coconut/CT1 | 4 | 65.4 | 7.8 | 71 | −7.9 | −58.3 | Dipotassium phosphate |

| Coconut/CT2 | 5 | 30.2 | 9.2 | 23 | +31.3 | −80.8 | - |

| Hemp | |||||||

| Hemp/H1 | 3 | 53.8 | 9.6 | 58 | −7.2 | −65.7 | - |

| Hemp/H2 | 5 | 3.8 | 21.9 | 42 | −91.0 | −97.6 | - |

| Oat | |||||||

| Oat/O1 | 5 | 159 | 6.4 | 167 | −4.8 | +1.3 | Dipotassium phosphate |

| Oat/O2 | 5 | 174 | 6.4 | 150 | +16.0 | +10.8 | Dipotassium phosphate |

| Oat/O3 | 2 | 182 | 0.7 | 163 | +11.7 | +15.9 | Potassium phosphate |

| Pea | |||||||

| Pea/P1 | 4 | 182 | 1.7 | 191 | −4.7 | +15.9 | Dipotassium phosphate |

| Pea/P2 | 4 | 278 | 12.4 | 313 | −11.2 | +77.1 | Dipotassium phosphate |

| Rice | |||||||

| Rice/R1 | 3 | 20.7 | 4.2 | - | - | −86.8 | - |

| Rice/R2 | 5 | 71.7 | 4.4 | 83 | −13.6 | −54.3 | Potassium citrate |

| Soy | |||||||

| Soy/S1 | 5 | 113 | 39.0 | 108 | +4.6 | −28.0 | - |

| Soy/S2 | 5 | 102 | 8.5 | 108 | −5.6 | −35.0 | - |

| Soy/S3 | 3 | 142 | 8.8 | 158 | −10.1 | −9.6 | - |

In comparison to milk, all PBMA brands from types oat and pea contained higher potassium amounts than milk (Table 5). Although both these PBMA types were formulated with potassium-containing ingredients, other PBMA brands also made with these ingredients (i,e., A1, CT1, R2) had potassium amounts lower than milk. Four out of five PBMA brands with declared potassium amounts at least those of milk contained measured amounts to meet this claim (O1, O3, P1, P2).

DISCUSSION

Due to the limited publicly available analytical data on micronutrients in PBMAs, various researchers who assessed the nutritional value of these beverages have generally relied on information provided by the values declared on the product’s Nutrition Facts label or from FoodData Central.15, 16 Indeed, the only publicly available analytical data on vitamin A and D concentrations in PBMAs we were able to use for comparison purposes was from the Foundation Foods database within FoodData Central, with information on micronutrients in almond (unsweetened, plain, shelf stable), soy (unsweetened, plain, shelf stable), and oat (unsweetened, plain, refrigerated) PBMA types. In the database, the mean vitamin A content was 41 μg/100 g, 58 μg/100 g, and 85 μg/100 g for almond, soy, and oat PBMAs, respectively. Our results found overall mean vitamin A concentrations of 54 μg/100 g, 66 μg/100 g, and 62 μg/100 g, for almond, soy, and oat PBMAs, respectively, indicating comparable amounts of this vitamin between the current results and with FoodData Central.

For vitamin D concentrations, FoodData Central reported means of 0.9 μg/100 g, 0.7 μg/100 g, and 1.7 μg/100 g for almond, soy, and oat PBMAs, respectively. The overall vitamin D amounts we measured in almond and soy PBMAs (1.9 μg/100 g and 3.4 μg/100 g, respectively) were notably higher than the database’s values. In contrast, vitamin D values in FoodData Central for oat PBMAs were similar to our measured amount (mean: 2.0 μg/100 mg). Because PBMAs are often formulated with varying amounts of added vitamin D, these differences in measured amounts may be reflective of the level of vitamin D added by the manufacturer. Additionally, the analytical method for determination of vitamin D used by FoodData Central for almond and soy PBMAs (HPLC-UV) and the current method (LC-MS/MS) may partly be a reason for observed differences.

Another factor potentially influencing variation in vitamin A and D concentrations is the effect of thermal processing and subsequent storage of PBMAs on micronutrient stability. Manufactures will typically increase micronutrients added to a product by a certain amount over target levels (“overage”) due to degradation that may occur during thermal processing and storage. For example, one recommendation is an overage of 20–30% for vitamins A and D added to milk undergoing pasteurization or ultra-high temperature (UHT) treatment to compensate for degradation during the thermal processing.29 Several studies have explored retention of vitamins A and D through processing and subsequent storage in dairy, but limited data are available on the stability of such micronutrients in PBMAs.30, 31 We froze the samples soon after procurement to prevent any further micronutrient degradation of the samples. However, it is possible that these micronutrients could be found at lower concentrations if they were analyzed at the end of the PBMA product’s shelf life.

Overall, the results for the calcium and potassium contents were comparable to data obtained from FoodData Central. The range of calcium concentrations in almond, soy, and oat PBMAs reported in our analysis (135–161 mg/100 g) were similar to those reported by FoodData Central (101–173 mg/100 g). However, the mean of our data obscures that two of the almond PBMA brands contained ~210 mg/100 g, while the third brand contained 43.1 mg/100 g (Figure 5). Samples from studies done in Germany, Greece, New Zealand, Spain, and Turkey have typically found the calcium content in PBMAs in the range of 30–70 mg calcium/100 g, but some have reported values as high as 100 mg/100 g.32–36

According to the Nutrition Facts label of the PBMA samples we analyzed, almost all of the products contained added calcium. Rice PBMAs were the only PBMA type with brands formulated with or without added calcium. The calcium concentration in the PBMA without added calcium was ~9 mg/100 g, while the product with added calcium was approximately an order of magnitude higher (100 mg calcium/100 g). In a study done in Brazil, the researchers analyzed various types of commercial PBMAs for calcium and found that, while cashew, coconut, oat, and rice PBMAs formulated without additional calcium contained concentrations that ranged from ~1–14 mg calcium/100 g, those with added calcium were ~50–170 mg/100 g.37

A report from Italy that performed elemental analysis on seven types of PBMAs (almond, cashew, coconut, hemp, oat, rice, and soy) is useful to compare our results for potassium concentrations.38 The authors reported potassium in soy PBMAs (~100 mg/100 g) comparable to the present study (overall mean: 115 mg/100 g), but there were notable differences for oat PBMAs. The concentrations we observed in oat PBMAs (mean: ~170 mg/100 g) was more than 4-fold higher than those reported by Astolfi et al. (~40 mg/100 g). These differences may be due to the formulation or natural variability in the potassium content of the oats used to produce the PBMAs. Data for the mean potassium concentrations reported in FoodData Central were similar for both almond (50 mg/100 g vs. 31 mg/100 g; present study vs. FoodData Central), soy (115 mg/100 g vs. 158 mg/100 g; present study vs. FoodData Central) and oat PBMAs (169 mg/100 g vs. 148 mg/100 g; present study vs. FoodData Central). There were potassium-containing ingredients on the label of some PBMAs, including potassium citrate, and dipotassium phosphate (see Table 5). However, these ingredients are typically added to beverages to act as a pH buffer or stabilizer,23 and thus likely do not add potassium in substantial amounts to the product.

A majority of PBMA types were not significantly different from milk with respect to vitamin A, vitamin D, and calcium concentrations, while most PBMA types were lower in potassium compared to milk. Still, it is important to consider the amounts of micronutrients according to PBMA brand because of potential variation in formulation between products. For instance, at least one brand within PBMA types cashew and rice did not contain any added vitamin A or vitamin D. Some of the PBMA product packaging claimed to contain at least the concentrations of vitamin A, vitamin D, and calcium found in milk, but none appeared to make a similar claim for potassium. This is likely reflective of consumer preferences that PBMAs contain added vitamin A, vitamin D, and calcium.39

There are a few limitations of this study that should be mentioned. Except for the few samples obtained from an online retailer, our sampling was confined to one geographical region in the Midwestern US. It is possible that analysis of samples from different regions could alter the observed micronutrient value distributions by including brand types only available in certain locations.

It is also important to note that although the purpose of this study was limited to analyzing concentrations of target micronutrients in PBMAs, we did not consider the bioavailability of these micronutrients. There is ongoing research into how product formulation can affect micronutrient bioavailability, and some studies using in vitro models indicate that increasing calcium content can subsequently decrease the bioaccessibility of vitamin D in PBMAs.40 The food matrix is well known to affect micronutrients bioavailability. It is important to conduct further work into the effect of PBMA formulation on the bioavailability of micronutrients in PMBAs and how it compares to milk.41

Vitamin D analysis was not able to be completed on one pea PBMA brand (P1) due to poor analyte recovery. Because we were able to successfully quantify vitamin D in another pea PBMA sample (P2), the presence of stabilizer additives (i.e., guar gum and gellan gum) and the higher protein content in brand P1 (3 g/100 g vs. 1 g/100 g; P1 vs. P2) may be a contributing factor to the poor extraction efficiency. This suggests that additional work should be done to perform method matrix extensions to the growing number of PBMA products for micronutrient analyses.

In sum, we performed a market basket analysis of eight types of PBMAs for the micronutrients vitamin A, vitamin D, calcium, and potassium. Overall, the results indicated that PBMA type and brand are important factors that are related to micronutrient concentrations. For almond PBMAs, the measured amounts of vitamin D, calcium, and potassium all varied significantly across lots of a single brand. In the majority of brands formulated with added vitamins A and D, the measured amounts of these vitamins differed by greater than 20% compared to the amounts declared on the Nutrition Facts label. In contrast, nearly all brands contained calcium and potassium concentrations within 20% of the value declared on the Nutrition Facts label.

The addition of micronutrients in the PBMA formulation appeared to be a major driver of the nutritional content. In PBMA brands formulated to contain vitamin A, vitamin D, and calcium at amounts at least those of milk (with added vitamins A and D), the vast majority of brands contained measured amounts of these micronutrient at concentrations equal to or greater than the claim declaration. Of the PBMA brands with a claim to contain potassium at concentrations at least those of milk, nearly all contained measured amounts to meet the claim. In contrast, brands with no added vitamin A or D contained undetectable amounts of these micronutrients. Only one PBMA brand (a rice PBMA) was not formulated with added calcium, and this product contained approximately 90% less calcium than milk.

This study provides one of the largest publicly available datasets on the measured amounts of vitamin A, vitamin D, calcium, and potassium in PBMAs. These results are significant from a nutritional standpoint because researchers use such data to assess the impact of how incorporating PBMAs into the diet affects micronutrient intake. The high variability of certain micronutrients across PBMA type and brand underscore the importance of publicly available data on the nutritional content of PBMAs. These results also highlight that commercial PBMAs are being formulated with micronutrients amounts similar to those in milk, and, as such, can be important for consumers seeking PBMAs containing certain key micronutrients similar to that of milk.

Acknowledgments

The authors would like to thank Lillian Wang (Illinois Institute of Technology) and Supriya Pandey (Illinois Institute of Technology) for providing technical assistance for sample analysis. The research described in this publication is supported by the Food and Drug Administration (FDA) of the U.S. Department of Health and Human Services (HHS) as part of an award totaling $4,148,332 with 0% financed with non-governmental sources. The contents are those of the authors and do not necessarily represent the official views of, nor an endorsement, by FDA, HHS, or the U.S. Government. For more information, please visit FDA.gov.

Footnotes

Declaration of interest

The authors have no competing interests.

REFERENCES

- 1.Institute of Medicine, Dietary Reference Intakes for Calcium and Vitamin D. National Academies Press: Washington DC, 2011. [PubMed] [Google Scholar]

- 2.National Academy of Medicine, Dietary Reference Intakes for Sodium and Potassium. National Academies Press: Washington DC, 2019. [PubMed] [Google Scholar]

- 3.Institute of Medicine, Dietary Reference Intakes for Vitamin A, Vitamin K, Arsenic, Boron, Chromium, Copper, Iodine, Iron, Manganese, Molybdenum, Nickel, Silicon, Vanadium, and Zinc. National Academy Press: Washington DC, 2001. [PubMed] [Google Scholar]

- 4.Kimball SM; Holick MF, Official Recommendations for Vitamin D through the Life Stages in Developed Countries. Eur J Clin Nutr 2020, 74 (11), 1514–1518. [DOI] [PubMed] [Google Scholar]

- 5.Drewnowski A; Rehm CD; Maillot M; Mendoza A; Monsivais P, The Feasibility of Meeting the WHO Guidelines for Sodium and Potassium: a Cross-national Comparison Study. BMJ Open 2015, 5 (3), e006625. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Cormick G; Betrán AP; Metz F; Palacios C; Beltrán-Velazquez F; García-Casal M. d. l. N.; Peña-Rosas JP; Hofmeyr GJ; Belizán JM, Regulatory and Policy-related Aspects of Calcium Fortification of Foods. Implications for Implementing National Strategies of Calcium Fortification. Nutrients 2020, 12 (4), 1022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.US Food and Drug Administration Changes to the Nutrition Facts Label. https://www.fda.gov/food/food-labeling-nutrition/changes-nutrition-facts-label (accessed 14JAN2022).

- 8.US Department of Agriculture and US Department of Health and Human Services, Dietary Guidelines for Americans 2015–2020. 8th ed.; Government Printing Office: Washington, DC, 2015. [Google Scholar]

- 9.Stewart H; Kuchler F; Cessna J; Hahn W, Are Plant-based Analogues Replacing Cow’s Milk in the American Diet? J Agric Appl Econ 2020, 52 (4), 562–579. [Google Scholar]

- 10.Watson E Oatmilk Edges Past Soymilk for #2 slot in US Plant-based Milk Retail Market https://www.foodnavigator-usa.com/Article/2020/09/25/Oatmilk-edges-past-soymilk-for-2-slot-in-US-plant-based-milk-retail-market-as-almondmilk-continues-to-drive-category-sales (accessed 2021 FEB 24).

- 11.Auclair O; Han Y; Burgos SA, Consumption of Milk and Alternatives and their Contribution to Nutrient Intakes among Canadian Adults: Evidence from the 2015 Canadian Community Health Survey—Nutrition. Nutrients 2019, 11 (8), 1948. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Haas R; Schnepps A; Pichler A; Meixner O, Cow Milk Versus Plant-based Milk Substitutes: A Comparison of Product Image and Motivational Structure of Consumption. Sustainability 2019, 11 (18), 5046. [Google Scholar]

- 13.Rizzo P; Harwood W; Drake M, Consumer Desires and Perceptions of Lactose-free Milk. J Dairy Sci 2020, 103 (8), 6950–6966. [DOI] [PubMed] [Google Scholar]

- 14.Paul AA; Kumar S; Kumar V; Sharma R, Milk analog: Plant Based Alternatives to Conventional Milk, Production, Potential, and Health Concerns. Crit Rev Food Sci Nutr 2020, 60 (18), 3005–3023. [DOI] [PubMed] [Google Scholar]

- 15.Chalupa-Krebzdak S; Long CJ; Bohrer BM, Nutrient Density and Nutritional Value of Milk and Plant-based Milk Alternatives. Int Dairy J 2018, 87, 84–92. [Google Scholar]

- 16.Singhal S; Baker RD; Baker SS, A Comparison of the Nutritional Value of Cow’s Milk and Nondairy Beverages. J Pediatr Gastroenterol Nutr 2017, 64 (5), 799–805. [DOI] [PubMed] [Google Scholar]

- 17.Hodges JK; Cao S; Cladis DP; Weaver CM, Lactose Intolerance and Bone Health: the Challenge of Ensuring Adequate Calcium Intake. Nutrients 2019, 11 (4), 718. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Drewnowski A, Plant-based milk Alternatives in the USDA Branded Food Products Database would Benefit from Nutrient Density Standards. Nat Food 2021, 2 (8), 567–569. [DOI] [PubMed] [Google Scholar]

- 19.Craig WJ; Fresán U, International Analysis of the Nutritional Content and a Review of Health Benefits of Non-Dairy Plant-Based Beverages. Nutrients 2021, 13 (3), 842. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Drewnowski A; Henry CJ; Dwyer JT, Proposed Nutrient Standards for Plant-based Beverages Intended as Milk Alternatives. Front Nutr 2021, 8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Clegg ME; Ribes AT; Reynolds R; Kliem K; Stergiadis S, A Comparative Assessment of the Nutritional Composition of Dairy and Plant-based Dairy Alternatives Available for Sale in the UK and the Implications for Consumers’ Dietary Intakes. Food Res Int 2021, 148, 110586. [DOI] [PubMed] [Google Scholar]

- 22.US Food and Drug Administration, Use of the Names of Dairy Foods in the Labeling of Plant-Based Products. Federal Register: Washington DC, 2018; Vol. 83, pp 49103–49107. [Google Scholar]

- 23.Cargill Inc. Potassium Citrate. https://www.cargill.com/food-bev/na/potassium-citrate (accessed 28 JAN 2022).

- 24.US Food and Drug Administration. Milk, 21 CFR § 131.110

- 25.US Public Health Service/Food and Drug Administration, Grade” A” Pasteurized Milk Ordinance. 2017.

- 26.McMahon A, Determination of Vitamin E and Vitamin A in Infant Formula and Adult Nutritionals by Normal-phase High-performance Liquid Chromatography: Collaborative Study, Final Action 2012.10. J AOAC Int 2016, 99 (1), 223–241. [DOI] [PubMed] [Google Scholar]

- 27.Gill BD; Indyk HE, Analysis of Vitamin D2 and Vitamin D3 in Infant and Adult Nutritional Formulas by Liquid Chromatography-tandem Mass Spectrometry: A Multilaboratory Testing Study. J AOAC Int 2018, 101 (1), 256–263. [DOI] [PubMed] [Google Scholar]

- 28.Gray PJ; Cunningham W, Inductively Coupled Plasma Collision Cell Quadrupole Mass Spectrometric Determination of Extractible Arsenic, Cadmium, Chromium, Lead, Mercury, and other Elements in Food using Microwave-assisted Digestion: Results from an FDA Interlaboratory Study. J AOAC Int 2019, 102 (2), 590–604. [DOI] [PubMed] [Google Scholar]

- 29.DSM Nutritional Products Fortification Basics; 2017.

- 30.Kaushik R; Sachdeva B; Arora S, Vitamin D2 Stability in Milk during Processing, Packaging and Storage. LWT - Food Sci Technol 2014, 56 (2), 421–426. [Google Scholar]

- 31.McCarthy D; Kakuda Y; Arnott D, Vitamin A Stability in Ultra-high Temperature Processed Milk. J Dairy Sci 1986, 69 (8), 2045–2051. [Google Scholar]

- 32.Karasakal A, Determination of Trace and Major Elements in Vegan Milk and Oils by ICP-OES after Microwave Digestion. Biol Trace Elem Res 2020, 197 (2), 683–693. [DOI] [PubMed] [Google Scholar]

- 33.Manousi N; Zachariadis G, A Simple and Rapid Analytical Method for the Determination of Nutrient and Toxic Elements in Nut-based Milk Alternative Beverages by ICP-OES. Food Anal Methods 2021, 1–7. [Google Scholar]

- 34.Marquès M; Correig E; Capdevila E; Gargallo E; González N; Nadal M; Domingo JL, Essential and Non-essential Trace Elements in Milks and Plant-based Drinks. Biol Trace Elem Res 2022, 200, 4524–4533. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Pointke M; Albrecht EH; Geburt K; Gerken M; Traulsen I; Pawelzik E, A Comparative Analysis of Plant-based Milk Alternatives Part 1: Composition, Sensory, and Nutritional Value. Sustainability 2022, 14 (13), 7996. [Google Scholar]

- 36.Smith NW; Dave AC; Hill JP; McNabb WC, Nutritional Assessment of Plant-based Beverages in Comparison to Bovine Milk. Front Nutr 2022, 9, 957486–957486. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Silva JGS; Rebellato AP; dos Santos Carames ET; Greiner R; Pallone JAL, In vitro Digestion Effect on Mineral Bioaccessibility and Antioxidant Bioactive Compounds of Plant-based Beverages. Food Res Int 2020, 130, 108993. [DOI] [PubMed] [Google Scholar]

- 38.Astolfi ML; Marconi E; Protano C; Canepari S, Comparative Elemental Analysis of Dairy Milk and Plant-based Milk Alternatives. Food Control 2020, 116, 107327. [Google Scholar]

- 39.McCarthy K; Parker M; Ameerally A; Drake S; Drake M, Drivers of Choice for Fluid Milk Versus Plant-based Alternatives: What are Consumer Perceptions of Fluid Milk? J Dairy Sci 2017, 100 (8), 6125–6138. [DOI] [PubMed] [Google Scholar]

- 40.Zhou H; Zheng B; Zhang Z; Zhang R; He L; McClements DJ, Fortification of Plant-based Milk with Calcium may Reduce Vitamin D Bioaccessibility: An In Vitro Digestion Study. J Agric Food Chem 2021, 69 (14), 4223–4233. [DOI] [PubMed] [Google Scholar]

- 41.Aguilera JM, The Food Matrix: Implications in Processing, Nutrition and Health. Crit Rev Food Sci Nutr 2019, 59 (22), 3612–3629. [DOI] [PubMed] [Google Scholar]