Abstract

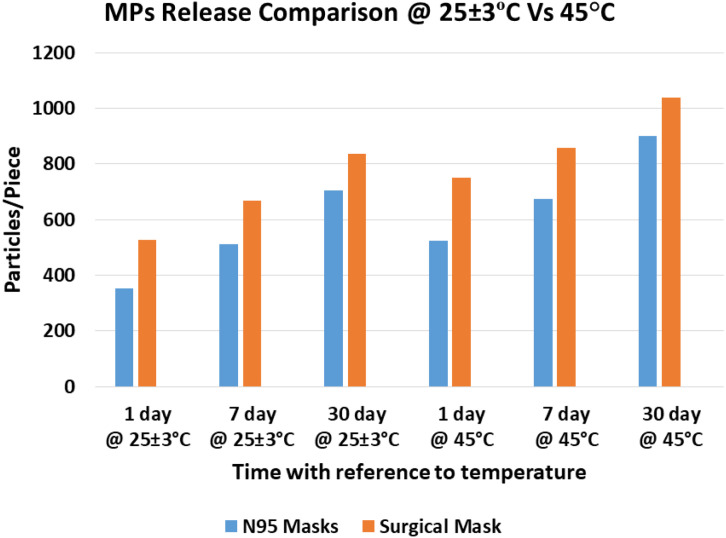

Outbreak of COVID 19 has caused an abrupt surge in the consumption of disposable face masks around the world. WHO has stated that wearing a face mask in public reduces the chances of being exposed to COVID 19 virus. With unchecked disposal of these used masks, a new kind of pollutant has emerged in the environment. Since these masks are generally made of polypropylene and polyurethane material, they can be considered as a potential source of microplastics (MPs) in the environment. In this study, we have evaluated the release of MPs particles from these face masks (namely from N95 and surgical masks) in deionized (DI) water and tap water over the span of 1 to 180 days. More specifically, a systematic study has been carried out to see the effect of temperature on release of MPs in water. MPs particles released in tap water (837 ± 113 particles/piece in 30 days) were significantly higher than that in DI water (564 ± 37 particles/piece in 30 days). When these masks were kept at a constant temperature of 45 °C for 30 Days, highest amount of MPs release (N95 899 ± 65 particles, Surgical 1038 ± 65 particles/piece) was observed as compared to other conditions. Most of the MPs particles released were polypropylene which were transparent and white in case of N95 while for surgical mask they were found to be of blue and white colour. With the aging of masks in water, quantity of MPs release was increased with simultaneous reduction in their size. Our study indicates that these disposable face masks are emerging to be a prominent source of MPs release in the environment and more hazardous for the tropical climate.

Keywords: Microplastics, Face mask, COVID 19, Freshwater, Toxicological effects

Abbreviations

- PU

Polyurethane

- PC

Polycarbonate

- PS

Polystyrene

- PE

Polyethylene

- PP

Polypropylene

- PVC

Polyvinyl Chloride

- PET

Polyethylene Terephthalate

- PA

Polyamide (nylon)

- PPE

Personal Protective Equipment

- MPs

Microplastics

- DI

Deionized

1. Introduction

MPs are the plastic particles having size to 5 mm. These can be categorized into two categories: Primary and secondary (Pico et al., 2019). Primary MPs are the already manufactured synthetic polymers (with size less than 5 mm) for the use in cosmetic industry, pharmaceutical industry, sandblasting, 3D printing etc. (Silva et al., 2018). Secondary MPs are a result of degradation from larger plastic particles due to any external natural force (Li et al., 2018). Hidalgo-Ruz et al. (2012) have classified MPs based on their type: Pellets, plastic films, plastic fragment, granules, filaments, Styrofoam and foamed plastic. Rodríguez-Seijo and Pereira (2017) categorized MPs based on their shape: fragments, fibres and microspheres/micro beads. Another method of categorization is by their chemical composition: PE, PET, PA, PP, PU,PC, PS, PVC (Silva et al., 2018). MPs have been observed in various conditions like marine environment (Thompson et al., 2004), freshwater environment (Gupta et al., 2022), bottled water (Akhbarizadeh et al., 2020b), influent and effluent of wastewater treatment plants (Takdastan et al., 2021), in soil (Akdogan and Guven, 2019), indoor dust (Kashfi et al., 2022), leachates of landfill sites (Mohammadi et al., 2022), urban runoff (Hajiouni et al., 2022) and Canned Fish (Akhbarizadeh et al., 2020a). Akhbarizadeh et al. (2021a) studied the relationship between fine particulate matter (PM), MPs and polycyclic aromatic hydrocarbons (PAHs). They observed that the PM acts as a carrier for the airborne MPs and PAHs. It was also observed that the airborne MPs movement is highly dependent on the surrounding atmospheric conditions. Dobaradaran et al. (2018) observed that a large number of plastic particles enters in the marine environment from the waste generated at the beaches adding more MPs for ingestion by marine organisms. In a recent study by Li et al. (2020) variation in MPs release have been observed in the PP infant feeding bottle when exposed to DI water with temperature ranging from 25 °C to 95 °C. They concluded that MPs abundance increases with increase in the temperature of DI water. Previous studies have also suggested that washing of polymer based fabric at higher temperature may result in an increased amount of MPs released per unit square of fabric being statically significant (Yang et al., 2019, Zambrano et al., 2019).

Global plastic production is estimated to reach 34 billion tons by 2050 from 9.2 billion tons in 2017 (Geyer, 2020). With the rise in production, plastic accumulation is rapidly increasing in the environment due to its unsustainable use, disposal and low degradation rate. The degradation of plastic also leads to the production of micro and Nano plastic. In 2010, 4.8 to 12.7 million tons of plastic waste have entered in the marine environment worldwide and it is increasing exponentially. To reduce this growth there is an urgent need to reduce the virgin plastic production and to achieve increased rate of plastic recycling which is less than 10% currently (Geyer, 2020).

With the emergence of a novel coronavirus in Wuhan, China, World Health Organization (WHO), announced a Public Health Emergency of International Concern on January 30, 2020. Later on March 11, 2020 COVID-19 was announced to be a pandemic (WHO, 2020). As of June 27, 2022, more than 502 million cases have been reported across the world causing more than 6.32 million deaths (Mathieu et al., 2020). This Coronavirus pandemic has influenced the production of plastic positively due to the high demand of testing equipment, gloves, medical devices, ventilators, PPE kits, surgical trays, syringes, medical bags and masks. All these products are manufactured with plastic as raw material. The use of masks has now become a regular practice all over the world. Various countries and organizations like US Centres for Disease Control and Prevention (CDC), recommended that wearing the mask in public was the only primary tool against this pandemic of COVID 19. Various countries (like India, China, South Korea, Japan, Taiwan) had passed legislation mandating the use of mask in public (Allison et al., 2021). In the beginning of year 2022 majority of the countries had halted the mandate of wearing masks in public but COVID cases are still being reported in different parts around the world, especially in China. Though use of masks was the demand of situation but improper disposal of these masks has led to severe MPs pollution.

Different categories of face mask are (i) cloth or fabric mask, (ii) surgical mask, (iii) NIOSH filter masks like N95, KN95 Mask. US CDC has recommended the use of any of the above category masks. Healthcare professionals have prioritized the use of N95 or surgical mask which are most effective against the virus (MacIntyre et al., 2017). The monthly global usage of disposable masks has reached up to 129 billion (Prata et al., 2020).

Generally, any mask is made up of three or five layers in which outer layer is hydrophobic, central layer is for melt-blown filters and supports and inner layer is hydrophilic in order to absorb the moisture from the user. All these layers may be manufactured from different synthetic polymers like PP, PE, PU, polyester, PC, or PS (Pu et al., 2018). De-la-Torre et al. (2022c) studied the FTIR spectra of the discarded PPEs and observed that most of the PPEs are made of PP, PET, PA and polyester. Most of the masks are single use and non-recyclable. Pizarro-Ortega et al. (2022) observed that the face masks being the most abundant PPE is a significant source of MPs release in the environment because of its fibrous microstructure. They further observed that the environmental exposure of face masks leads to the physical changes (like fracture and braking of microfibres) in its fabric and these single use masks are generating a new kind of MPs waste in the environment. PPE density of 6.6 × 10−4 PPE/m2, 5.6 × 10−3 PPE/m2 and 2.79 × 10−4 PPE/m2 has been observed in the coastal area of Peru, Argentina and Morocco respectively (De-la-Torre et al., 2022c, Haddad et al., 2021). The surgical masks are becoming an emergent source of MPs pollution in littering and water environment (Aragaw, 2020). Akhbarizadeh et al. (2021b) estimated the rate of PPEs disposal to be 350 items/day and 127,750 item annually on the Bushehr port, Persian Gulf. The reusable masks may release the MPs in the domestic sewage upon washing (Shruti et al., 2020).

Previous studies have reported the release of MPs by various disposable face masks in the water (Aragaw, 2020, Chen et al., 2021, Liang et al., 2022). Chen and group (Chen et al., 2021) studied and compared the release of MPs from fresh and used disposable face masks in 24 h duration. Liang et al. (2022) carried out 24 h release test on various disposable face masks and analysed the kinetic release using parabolic diffusion, power function and Elovich equations. It has been observed that release of MPs from synthetic polymer based fabric is directly proportional to the temperature (Periyasamy, 2021). Jiang et al. (2022) studied the environmental effects (such as temperature up to 40 °C), incubation time of 1 to 7 days and wearing time on MPs release from face mask based on the regression analysis. Sun et al. (2021) investigated the kinetic release of PP surgical masks in marine environment and its toxicological effects on marine copepod. Zuri et al. (2022) evaluated the release of MPs and phthalates from face mask to water using migration study. Liu et al. (2022) studied the release of MPs from single layer face masks under the simulated UV light irradiation in 28 days at a constant temperature of 22 ± 3 °C. Rathinamoorthy and Balasaraswathi (2022) studied the MPs release in freshwater in a static immersion condition for a duration of 10 h. De-la-Torre et al. (2022a) observed the degradation of different PPE items in seawater and distilled water for the release of MPs and chemical contaminants in the time span of 1,10,30, and 60 days in presence of simulated environmental conditions. However, these studies are still limited, for example temperature of different continents are different and this may affect the release of MPs from masks since thermoplastic materials are highly susceptible to temperature (Tripathi, 2002).

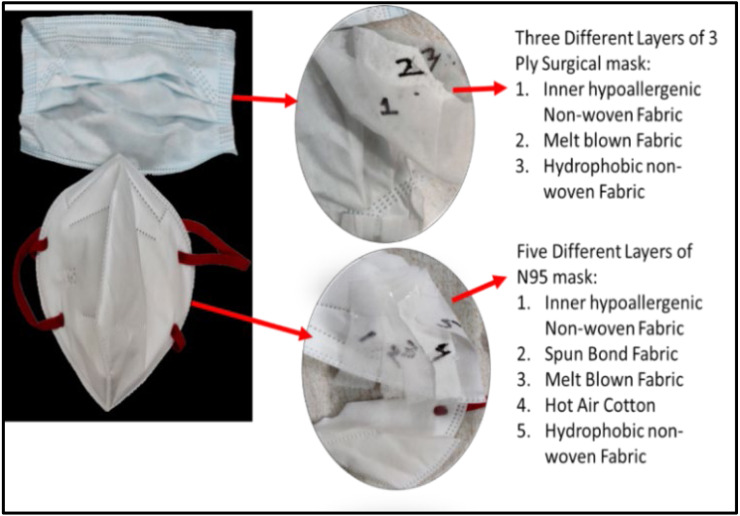

In this study we have taken two types of disposable masks, one is N95 mask with five layers and another is surgical mask with three layers (Fig. 1). We have quantified the release of MPs from each of them with reference to time and temperature. To the best of our information, this is the first study where time based release of MPs has been noted with reference to interaction of masks with the water for a longer duration (for more than 100 days) and where the masks are left undisturbed in the water with no other external force has been carried out, However De-la-Torre et al. (2022b) have studied the release of MPs from surgical face masks and gloves in the span of 60 days in presence of seawater and DI water under the influence of sunlight. In present study, the effect of temperature in controlled conditions (with oven at temperature higher than 40 °C) has been studied for the first time. This study has been conducted to study the release of MPs from the face masks in the aquatic environment where temperature reaches around 45 °C (tropical countries like India, Australia, Egypt, China, African countries, south American countries), when masks have settled in the floors of waterbodies, banks of ponds and isolated lakes with nearly zero water movement.

Fig. 1.

Showing different layers of a. Surgical mask, b. N95 mask used in this study.

2. Experimental setup

2.1. Materials and methods

N95 and disposable surgical masks were purchased from local market in Bhopal city of India. Single type of manufacturer was used for each type of mask. Masks without respirators were purchased and all the masks were as per the implementation standards for surgical and N95 face masks in India. All masks were new, unbroken and unused. No accessories like nose bridges were removed from the masks.

Both types of masks were put through different types of conditions as per Table 1 in triplicate form to analyse the release of MPs from masks in environmental conditions. At every condition, masks were kept in 500 ml water in beaker and the same were sealed with the aluminium foil. After the selected duration, the water was stirred thoroughly and masks were removed from water. Water was filtered on a 0. cellulose filter membrane. This filter membrane was dried and stored in the petri dish for further analysis.

Table 1.

Different conditions for MPs release.

| S. No. | Water type | Temperature | Mask type | Duration (in Days) |

Nomenclature | Layers in masks |

|---|---|---|---|---|---|---|

| 1 | DI water | 25 ± 3 °C | N95 | 1 | N | 5 Layer |

| 7 | N | |||||

| 30 | N | |||||

| 90 | N | |||||

| 180 | N | |||||

| 2 | DI water | 25 ± 3 °C | Surgical | 1 | S | |

| 7 | S | |||||

| 30 | S | |||||

| 90 | S | |||||

| 180 | S | |||||

| 3 | Tap water | 25 ± 3 °C | N95 | 1 | N | |

| 7 | N | |||||

| 30 | N | |||||

| 90 | N | |||||

| 180 | N | |||||

| 4 | Tap water | 25 ± 3 °C | Surgical | 1 | S | |

| 7 | S | |||||

| 30 | S | |||||

| 90 | S | |||||

| 180 | S | |||||

| 5 | Tap water | 45 °C | N95 | 1 | N()1 | |

| 7 | N()7 | |||||

| 30 | N()30 | |||||

| 6 | Tap water | 45 °C | Surgical | 1 | S()1 | |

| 7 | S()7 | |||||

| 30 | S()30 |

2.2. Quantification and identification

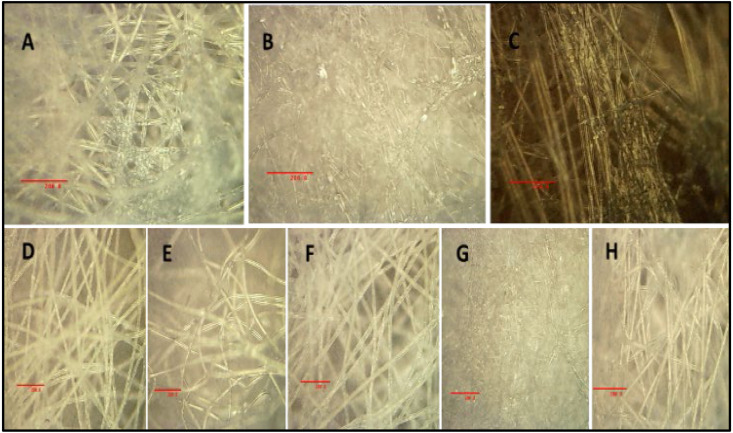

MPs retained on filter paper were observed under a metallurgical microscope and images were captured using a 3 Megapixel camera equipped with the metallurgical microscope. MPs were assessed visually based on their shape and size. Different layers of masks (Fig. 1) were analysed using FTIR spectroscopy for its basic material signature. The layers of both the masks were also observed under the same microscope (Fig. 2). Typical MPs released from the face masks were identified using a IndiRam CTR 300 Raman spectrometer. Raman spectra were recorded from 300 to 4000 cm−1 with a laser excitation wavelength of 570 nm. Polymer types were identified based on the similarity to the spectra of standards. The resulted spectra were compared with the spectra of standard and the type of polymer used in the manufacturing of each layer was identified.

Fig. 2.

Microscopic images showing (a) inner layer (b) middle layer (c) outer layer of fresh Surgical Mask and (d) inner layer, (e) spun bond fabric, (f) melt blown fabric, (g) hot air cotton, (h) outer hydrophobic layer of fresh N95 Mask.

2.3. Quality control and quality assurance

For avoiding the contamination in the experiment, all the equipment used during the process were prewashed using the DI water and were kept in desiccator after covering with aluminium foil. Use of plastic accessories was avoided during the entire process, for this purpose the cotton mask, cotton laboratory coats were used. Clean gloves were used during the entire process. All the surfaces were properly sanitized at every stage of the process. One blank sample analysis was done to minimize the statistical error at any stage.

2.4. Data analysis

The sample results were statically analysed by one-way ANOVA followed by Tukey’s test and paired sample t-test for mean comparison between MPs abundance from N-95 and surgical masks for different duration. A significant level of 0.05 was used.

2.5. Raman and FTIR analysis

After disassembling different layers of surgical and N95 masks, layers were put into 150-ml clean dried pre-heated (500 C) glass vessels. 100 ml of water (DI or tap water) was added to the glass vessel and the vessels were left as such for certain period of time followed by filtration on cellulose membrane then the leachate was filtered onto a 0. cellulose filter membrane. This process was repeated for at least 5 times for different layers of mask. The particles obtained were dried and then characterized using Bruker alpha FTIR under attenuated total reflection mode (ATR). For this, dried sample was kept on ATR diamond crystal holder followed by applying pressure of 80 kPa. An average of 64 scans were recorded for each of the sample. In case of Raman spectrophotometer, the particles were exposed to laser of wavelength of 570 nm using an IndiRam CTR 300 Raman spectrometer.

3. Results and discussions

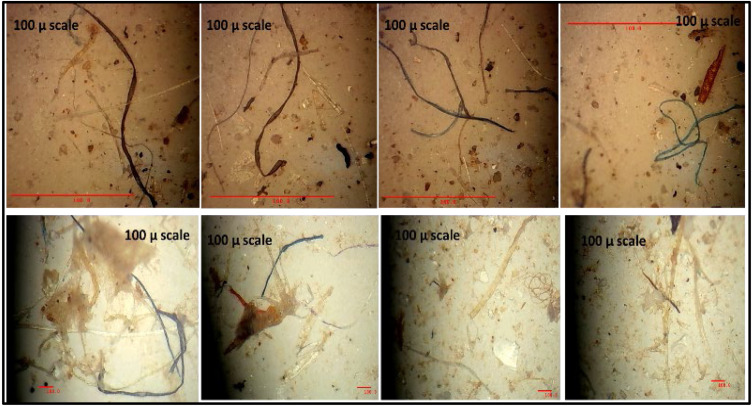

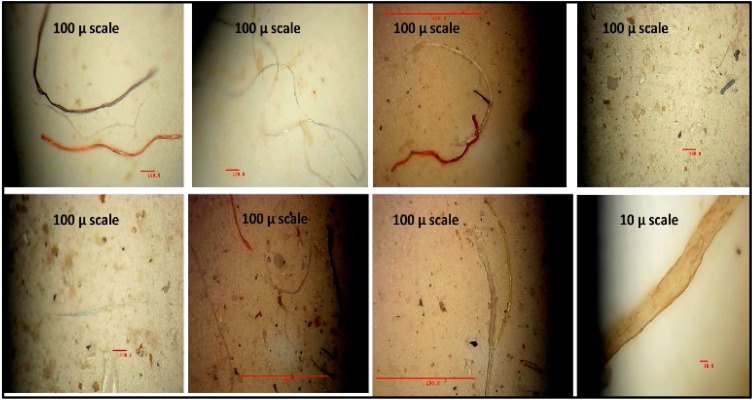

Release of MP fibres were found in all the samples regardless of type of mask used or the type of water used (Fig. 3, Fig. 4). Previous reports (Aragaw, 2020, Fadare and Okoffo, 2020, Shruti et al., 2020) have also suggested that the disposable face masks are a potential source of MPs and some other studies (Li et al., 2021, Liang et al., 2022, Saliu et al., 2021, Shen et al., 2021) have presented the results from the release of MPs from short term interaction in the environment. It has been observed that PPE aging may lead to the release of MPs and contaminants in the environment (De-la-Torre et al., 2022c). Wang et al. (2021) investigated the effects of UV radiation exposure on release of MPs from face masks and weathered masks. They reported that UV radiation exposure results in decreased mechanical strength of mask layers thereby enhancing the release of MPs from weathered masks by 3 times as compared to new masks . It has been observed that MPs release from face masks is highly influenced by shear stress (Morgana et al., 2021).

Fig. 3.

Microscopic images of MPs fibre released from surgical mask on a 100 scale.

Fig. 4.

Microscopic images of MPs fibre released from N95 mask on a 100 and 10 scale.

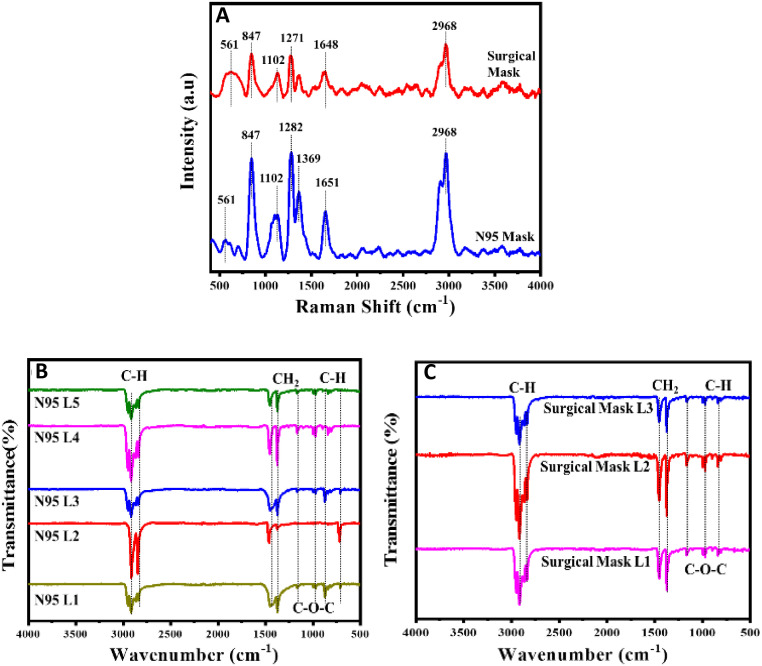

Raman spectra and FTIR spectra further confirmed the presence of PP in the form of fibres (Fig. 5). Polypropylene’s simple structure, a methyl group on every other backbone carbon is confirmed with help of FTIR data. Spectra were measured between 400 and 4000 cm−1, using 64 scans. A band at 2914 and 2843 cm−1 corresponds to the C—H stretching vibrations. Similarly, band at 1458 and 1373 cm−1 corresponds to CH2 and C—H bending vibrations while a band at 1160 cm−1 corresponds to C—O—C asymmetric stretching. Vibration bands at 970 and 880 cm−1 shows strong C—H bending. Similarly, Raman peak at 2968 cm−1 is assigned to the asymmetric CH2 stretching. The band at 1651 and 1648 cm−1 are located to the stretching of C—H. The symmetric stretching mode of C—H is assigned at 1369 and 1282 cm−1. A band at 1102 cm−1 corresponds to C—O bonding while the band at 847 cm−1 is assigned to the CH2, and 561 cm−1 can be assigned to C—C stretching mode. Both Raman and FTIR spectroscopic analysis show the characteristic pattern of PP, suggesting that PP fibres are major source of MP from these masks.

Fig. 5.

(A) Raman Spectra of MP particles released by different masks. (B and C) FTIR spectra of different layers of (a) N95 Masks (b) Surgical Mask.

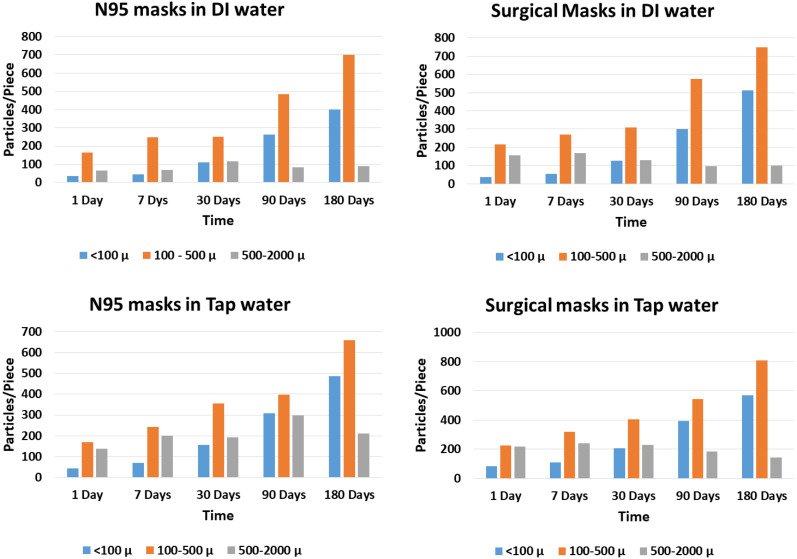

The average amount of MP released by the N95 mask in DI water has varied from 266 ± 70 particles/piece in one-day interval to 1188 ± 97 particles/piece in 180 days interval and in case of surgical mask with the same sets of conditions, the variation was 408 ± 25 particles/piece in one day interval to 1359 ± 78 particles/piece in 180 days interval. The amount of particles released from surgical masks are slightly higher than the N95 masks. The 24 h results of this experiment are similar to the study conducted by Chen et al. (2021) who firstly confirmed the MPs release from the disposable face masks. They compared the MPs release from new and old disposable face masks by keeping the masks in DI water on rotatory shaker for 24 h. The average abundance varied from 183.00 ± 78.42 particles/piece for new masks to 1246.62 ± 403.50 particles/piece for old masks. Jiang et al. (2022) observed the MPs release from activated carbon mask, medical mask and N-95 mask in presence of ultrapure water after 24 h duration. The MPs abundance was observed in the range of 1600 ± 237 items per piece/day, 1447 ± 218 and 1339 ± 166 respectively for activated carbon mask, medical mask and N-95 mask. In this study longer incubation time has been considered, since Julienne et al. (2019) suggested that with passage of time fibres breaks into smaller pieces in presence of water. Zuri et al. (2022) assessed the MPs release from face masks using migration study. They cut all the masks in to small pieces of size 0.5 cm2 including all the layers and the same were kept in pyrex tubes with HPCL water on an orbital shaker for 10 days at 20 °C. They estimated the potential release of MPs may vary from 2040 MPs/mask to 4716 MPs/mask in the duration of 10 days. As compared to our study these results are 4 to 10 times higher which may be because of cutting the masks into pieces and due to placing the sample in the orbital shaker resulting in the mechanical abrasion and breaking of polymer particles.

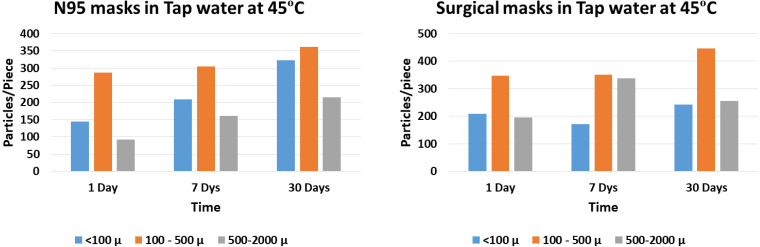

When the water was changed from DI to tap water, the MP released by N95 mask showed a variation of 351 ± 58 in one day to 1357 ± 42 particles/piece in 180 days interval and the surgical mask showed a variation of 527 ± 48 particles/piece in one day to 1522 ± 31 particles/ piece in 30 days interval (Fig. 6, Fig. 8). The results observed from the statistical analysis shows that there was no correlation in between the MPs abundance from N95 and surgical masks (p 0.05). On moving from DI to tap water, nothing changes except the presence of additional ions, whose effect was found negligible on release of MP from the mask. Also, the type of mask used has no impact on release of MP as confirmed by previous studies (Chen et al., 2021). It has been observed that the initial release rate of MPs from face mask is rapid and becomes slow with passage of time (Liang et al., 2022). They measured the MPs release from N-95, surgical and normal medical masks in the duration of 24 h and continued to analyse its release kinetics for 7 days. The MPs (PP origin) abundance ranged from 801 ± 71 to 2667 ± 97 particles per piece per day for N-95 mask, 1034 ± 119 to 2547 ± 185 particles per piece per day for normal medical mask and 1136 ± 87 to 2343 ± 168 particles per piece per day for surgical mask. De-la-Torre et al. (2022a) observed that the direct exposure of sun on the polymeric material may lead to changes in its crystallinity. This may also result in the possible changes in mechanical properties and thermal stability of polymeric material. Rathinamoorthy and Balasaraswathi (2022) studied the MPs release from newly purchased facemasks in presence of freshwater under static immersion for 10 h duration without any external agitation. They reported an average abundance of 2171.40 ± 292.46 fibres/mask which is approximately 4 times higher as compared to this study. This may be due to the difference in the material quality of masks which can vary with the manufacturer. De-la-Torre et al. (2022b) in their study (with exposure duration of 1, 10, 30, and 60 days) observed the MPs abundance of 46.3 ± 10.5 MPs/PPE with median of 21.5 MPs/PPE in DI water and 8.8 ± 11.6 MPs/PPE with median of 36.2 MPs/PPE in seawater with sunlight exposure. They conducted their study on used face masks by collecting them from various sandy and rocky beaches of Bushehr port, Iran. We have conducted a similar study but for a higher exposure time with controlled conditions and in presence of tap water/fresh water in place of seawater. In some studies MPs abundance has been measured after every 24 h duration for up to 7 days (Jiang et al., 2022, Liang et al., 2022) while in this study different samples were used for different incubation time. Sun et al. (2021) compared the release of MPs from new and old surgical masks in the presence of artificial seawater on day 1, 3, 5, 7 and 9 day from the same mask sample at 25 °C. The sample was kept on mechanical shaker for 9 days continuously to create artificial marine environment. Whereas in this study different samples for different time duration were prepared and mechanical shaking was not opted since we have considered the case of isolated pond and lakes where very less water movement is observed throughout the year (except rainy season).

Fig. 6.

MP abundance in different mask samples at room temperature (25 ± 3 °C).

Fig. 8.

Comparison of MPs abundance in DI vs. Tap water.

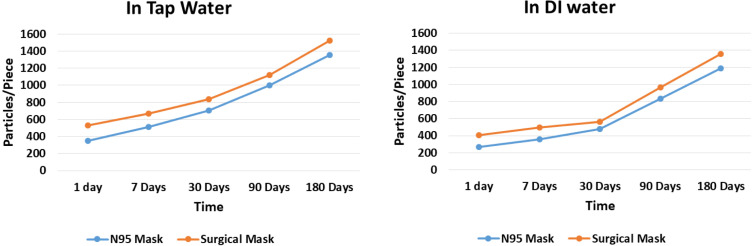

Covid-19 pandemic has affected the whole world significantly. Different regions of world have different geography, demography etc. Along with this the climatic conditions vary significantly. In India itself, the climatic conditions; particularly the temperature varies significantly across whole country. In certain parts of the country, summer temperatures touches 45–48 C, this prompted us to study the effect of increased temperature on release of MPs. Further Jiang et al. (2022) considered temperature to be one of the crucial driving factor for MPs release in the environment. They studied the release of MPs from 8 h worn mask in a temperature controlled lab. The MPs abundance ranged from 1043 ± 155 to 2940 ± 392 items per piece/day as the temperature varied from 15 °C to 40 °C. They observed that MPs abundance increased to 3.5 times when temperature increased from 15 °C to 40 °C.

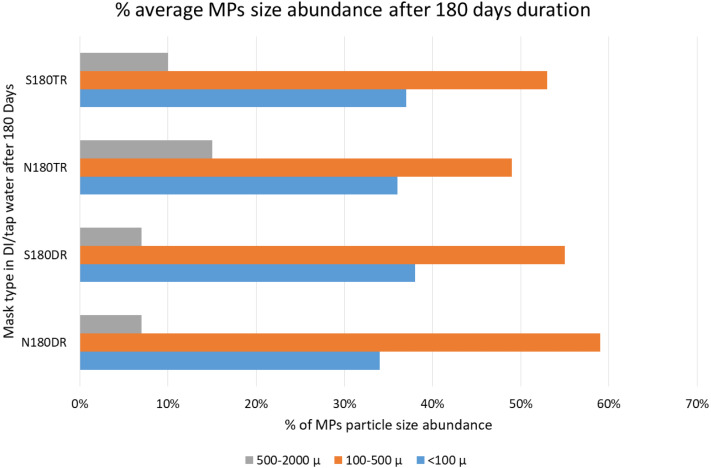

Present study was carried out in the tap water samples maintaining constant temperature of 45 °C for 1 Day to 30 Days. The average MP release for N95 mask was 525 ± 40 particles/piece in one day to 899 ± 65 particles/piece in 30 days and for surgical mask was 751 ± 87 particles/piece to 1038 ± 65 particles/piece in 30 days (Fig. 7). Li et al. (2020) studied the influence of hot water on the release of MPs in PP feeding bottles and concluded that the MPs release from PP feeding bottles is highly influenced by temperature. In Present study MPs in the size range of (100–500 ) were dominant in both the case of masks and in all types of water samples. A bar chart having the percentage particle abundance after 180 days in both types of masks is shown in Fig. 10. These results show that temperature plays a significant effect on release of MP in water and thus tropical countries (like India, Australia, Egypt, China, African countries, south American countries) having relatively high temperature are more susceptible to the masks led MPs pollution (Fig. 9). Release of MPs from synthetic polymer based fabric during washing at higher temperature (30 to 60 °C) in alkaline medium can be attributed to the surface hydrolysis characteristic of the fabric (Periyasamy, 2021).

Fig. 7.

MPs abundance in different mask samples at 45 °C.

Fig. 10.

Percentage release of MPs particle size from both types of masks after 180 days.

Fig. 9.

Comparison of MP abundance at room temperature (25 ± 3 °C) vs. 45 °C in tap water.

Disposable face masks (both N95 and surgical mask) are made up of 5 layers while surgical mask has three layers as shown in Fig. 1, however the MP release is almost similar quantitatively as well as qualitatively from both the masks. All the layers of both types of masks were observed under microscope (Fig. 2) and are made from PP fabrics as observed with the FTIR spectra (Fig. 5). We believe that the middle layer of the made of melt blown fabric is major route to release of MPs in water. This is attributed to the difference in methodology for obtaining the melt blown fabrics and spun bond fabrics. To synthesize melt blown fabric, a liner die having orifices of small diameter is used for extrusion of thermoplastic fibres, which are then subjected to blown by high velocity air and are collected on conveyor leading to formation of web of fibres having size range of 0.5 to 10 m (Geus, 2016). For the formation of spun bond fibres, the thermoplastic first undergo extrusion followed by collection on conveyor in form of random web like structure which are chemically, thermally or mechanically bonded (Hutten, 2007). In later process, during synthesis whole fibre come across the hot air while in former process hot air converged along the fibre as it passed through the orifices of die leading to formation of very fine and non-continuous fibre (Geus, 2016, Hutten, 2007). This former process of formation of ultrafine filament can lead to the production of lots of MPs and therefore is considered as major source of MPs in water.

Considering our results, in India around 1 billion disposable face masks could have released around 4.39 × 1011 MPs particles in 24 h (considering average results of this study in tap water: 351 for N95 and 527 for surgical masks for 1 billion disposable face masks) during the pandemic of COVID 19 and this may have increased manifolds with the passage of time spent by masks in the environment. These results are in line with a similar study for 24 h by Sun et al. (2021) who estimated around 396 billion of daily release of MPs from surgical masks and approximately 1370 trillion MPs might have been released in the coastal marine environment in the year 2020.

Our samples were kept in the undisturbed scenario and in the absence of sunlight but once disposed in the environment, there are other factors such as weathering due to flow pressure, UV radiation, abrasion and disintegration due to longer exposure to the environment (Khaled et al., 2018, Song et al., 2017, ter Halle et al., 2016). During the pandemic, due to the shortage of masks, it was a regular practice to wash these disposable mask which may have released the MP in a similar manner as mentioned in other reports on the release of MPs from washing of cloths in the households (Hernandez et al., 2017, Kelly et al., 2019, Shruti et al., 2020).

As the disposable face masks comes under the category of medical waste, it should not be discarded casually in the environment. The disposal of face mask should be managed and controlled in a very scientific manner similar to any other medical waste. This will be beneficial not only in controlling the pandemic but controlling the release of MPs in the environment. A proper medical waste collection system should be developed by the government followed by the strict suggestion to the citizens to collect the face mask and to be disposed only via the medical waste collection system. As the face masks are vital in controlling the pandemic and with very limited supply in some parts of the world, an extended use of face mask without washing might result in a reduced release of MP in the environment.

4. Study limitations and future scope

This study has been conducted for the release of MPs from face masks in controlled conditions at 45 °C for 30 days duration. However, further study may be conducted for the impact of cyclic temperature variation for a longer time duration (minimum 180 days) for the release of MPs from face masks, since in countries like India there is a huge temperature variation with the passage of time. It has been observed that release of MPs from face masks increases as the time passes. The face masks may have very high toxicological effects on the aquatic organism, however further research is required in this direction. Being a highly populated country, India’s disposable face mask production has reached 10 million units per month during the COVID −19 pandemic. Therefore, implementation of an effective disposal management/policy for reducing the dumping of face masks and PPEs into the environment will not only help in reducing the spread of COVID 19 but also it will reduce the extent of MPs release in the environment.

5. Conclusions

Recently, MPs have emerged as one of the major environmental pollutants. There are limited studies which have reported the release of MPs from face masks taking into account longer time duration. Face masks are manufactured using the plastic polymers in the form of different layers, which makes them a prominent source of MP release in the environment. In this study, we have evaluated the release of MPs in water samples from N95 and surgical face masks with reference to the aging, temperature and time. It was observed that quantity of MPs particles release increased with aging, increase in temperature and size of fibres was reduced which may be because of the age, rise in temperature and degradation. It can be concluded that disposal of these masks in tropical climate is more hazardous for the environment as the release of MPs is highest with reference to increase in temperature. It is further recommended that the government bodies should guide public for the effective management and disposal of these face masks.

CRediT authorship contribution statement

Dinesh Kumar Gupta: Visualization, Methodology, Investigation, Software, Validation, Writing – original draft. Amit Vishwakarma: Supervision. Archana Singh: Conceptualization, Data curation, Supervision, Writing – review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

Authors acknowledges Dr. Santanu Talukder, Asst. Professor, Department of Electrical Engineering and Computer Science, Indian Institute of Science Education and Research Bhopal for his assistance in accessing his microscope facilities. Archana Singh acknowledges the Department of Science and Technology, Govt. of India grant No. WTI/2K19/EWFH/2019/397 for financial assistance.

Data availability

No data was used for the research described in the article.

References

- Akdogan Z., Guven B. Microplastics in the environment: A critical review of current understanding and identification of future research needs. Environ. Pollut. 2019;254 doi: 10.1016/j.envpol.2019.113011. [DOI] [PubMed] [Google Scholar]

- Akhbarizadeh R., Dobaradaran S., Amouei Torkmahalleh M., Saeedi R., Aibaghi R., Faraji Ghasemi F. Suspended fine particulate matter (PM2.5), microplastics (MPs), and polycyclic aromatic hydrocarbons (PAHs) in air: Their possible relationships and health implications. Environ. Res. 2021;192 doi: 10.1016/j.envres.2020.110339. [DOI] [PubMed] [Google Scholar]

- Akhbarizadeh R., Dobaradaran S., Nabipour I., Tajbakhsh S., Darabi A.H., Spitz J. Abundance, composition, and potential intake of microplastics in canned fish. Mar. Pollut. Bull. 2020;160 doi: 10.1016/j.marpolbul.2020.111633. [DOI] [PubMed] [Google Scholar]

- Akhbarizadeh R., Dobaradaran S., Nabipour I., Tangestani M., Abedi D., Javanfekr F., Jeddi F., Zendehboodi A. Abandoned Covid-19 personal protective equipment along the Bushehr shores, the Persian Gulf: An emerging source of secondary microplastics in coastlines. Mar. Pollut. Bull. 2021;168 doi: 10.1016/j.marpolbul.2021.112386. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Akhbarizadeh R., Dobaradaran S., Schmidt T.C., Nabipour I., Spitz J. Worldwide bottled water occurrence of emerging contaminants: A review of the recent scientific literature. J. Hazard. Mater. 2020;392 doi: 10.1016/j.jhazmat.2020.122271. [DOI] [PubMed] [Google Scholar]

- Allison A., Ambrose-Dempster E., Aparsi T., Bawn M., Arredondo M., Chau C., Chandler K., Dobrijevic D., Hailes H., Lettieri P., Liu C., Medda F., Michie S., Miodownik M., Munro B., Purkiss D., Ward J. 2021. The impact and effectiveness of the general public wearing masks to reduce the spread of pandemics in the UK: a multidisciplinary comparison of single-use masks versus reusable face masks. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020:159. doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen Xianchuan, Chen Xiaofei, Liu Q., Zhao Q., Xiong X., Wu C. Used disposable face masks are significant sources of microplastics to environment. Environ. Pollut. 2021;285 doi: 10.1016/j.envpol.2021.117485. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Dioses-Salinas D.C., Dobaradaran S., Spitz J., Keshtkar M., Akhbarizadeh R., Abedi D., Tavakolian A. Physical and chemical degradation of littered personal protective equipment (PPE) under simulated environmental conditions. Mar. Pollut. Bull. 2022;178 doi: 10.1016/j.marpolbul.2022.113587. [DOI] [PubMed] [Google Scholar]

- De-la-Torre G.E., Dioses-Salinas D.C., Dobaradaran S., Spitz J., Nabipour I., Keshtkar M., Akhbarizadeh R., Tangestani M., Abedi D., Javanfekr F. Release of phthalate esters (PAEs) and microplastics (MPs) from face masks and gloves during the COVID-19 pandemic. Environ. Res. 2022;215 doi: 10.1016/j.envres.2022.114337. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De-la-Torre G.E., Dioses-Salinas D.C., Pizarro-Ortega C.I., Fernández Severini M.D., Forero López A.D., Mansilla R., Ayala F., Castillo L.M.J., Castillo-Paico E., Torres D.A., Mendoza-Castilla L.M., Meza-Chuquizuta C., Vizcarra J.K., Mejía M., De La Gala J.J.V., Ninaja E.A.S., Calisaya D.L.S., Flores-Miranda W.E., Rosillo J.L.E., Espinoza-Morriberón D., Gonzales K.N., Torres F.G., Rimondino G.N., Ben-Haddad M., Dobaradaran S., Aragaw T.A., Santillán L. Binational survey of personal protective equipment (PPE) pollution driven by the COVID-19 pandemic in coastal environments: Abundance, distribution, and analytical characterization. J. Hazard. Mater. 2022;426 doi: 10.1016/j.jhazmat.2021.128070. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dobaradaran S., Schmidt T.C., Nabipour I., Khajeahmadi N., Tajbakhsh S., Saeedi R., Javad Mohammadi M., Keshtkar M., Khorsand M., Faraji Ghasemi F. Characterization of plastic debris and association of metals with microplastics in coastline sediment along the Persian Gulf. Waste Manage. 2018;78:649–658. doi: 10.1016/j.wasman.2018.06.037. [DOI] [PubMed] [Google Scholar]

- Fadare O.O., Okoffo E.D. Covid-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Geus H.-G. In: Woodhead Publishing Series in Textiles. Kellie G.B.T.-A. in T.N., editor. Woodhead Publishing; 2016. 5 - Developments in manufacturing techniques for technical nonwovens; pp. 133–153. [DOI] [Google Scholar]

- Geyer R. 2020. Production, use, and fate of synthetic polymers; pp. 13–32. [DOI] [Google Scholar]

- Gupta D.K., Choudhary D., Vishwakarma A., Mudgal M., Srivastava A.K., Singh A. Microplastics in freshwater environment: occurrence, analysis, impact, control measures and challenges. Int. J. Environ. Sci. Technol. 2022 doi: 10.1007/s13762-022-04139-2. [DOI] [Google Scholar]

- Haddad M. Ben, De-la Torre G.E., Abelouah M.R., Hajji S., Alla A.A. Personal protective equipment (PPE) pollution associated with the COVID-19 pandemic along the coastline of Agadir, Morocco. Sci. Total Environ. 2021;798 doi: 10.1016/j.scitotenv.2021.149282. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hajiouni S., Mohammadi A., Ramavandi B., Arfaeinia H., De-la Torre G.E., Tekle-Röttering A., Dobaradaran S. Occurrence of microplastics and phthalate esters in urban runoff: A focus on the Persian Gulf coastline. Sci. Total Environ. 2022;806 doi: 10.1016/j.scitotenv.2021.150559. [DOI] [PubMed] [Google Scholar]

- Hernandez E., Nowack B., Mitrano D.M. Polyester textiles as a source of microplastics from households: A mechanistic study to understand microfiber release during washing. Environ. Sci. Technol. 2017;51:7036–7046. doi: 10.1021/acs.est.7b01750. [DOI] [PubMed] [Google Scholar]

- Hidalgo-Ruz V., Gutow L., Thompson R.C., Thiel M. Microplastics in the marine environment: A review of the methods used for identification and quantification. Environ. Sci. Technol. 2012;46:3060–3075. doi: 10.1021/es2031505. [DOI] [PubMed] [Google Scholar]

- Hutten I.M. Butterworth-Heinemann; Oxford: 2007. CHAPTER 5 - Processes for Nonwoven Filter Media; pp. 195–244. [DOI] [Google Scholar]

- Jiang H., Su J., Zhang Y., Bian K., Wang Z., Wang H., Wang C. Insight into the microplastics release from disposable face mask: Simulated environment and removal strategy. Chemosphere. 2022;309 doi: 10.1016/j.chemosphere.2022.136748. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Julienne F., Delorme N., Lagarde F. From macroplastics to microplastics: Role of water in the fragmentation of polyethylene. Chemosphere. 2019;236 doi: 10.1016/j.chemosphere.2019.124409. [DOI] [PubMed] [Google Scholar]

- Kashfi F.S., Ramavandi B., Arfaeinia H., Mohammadi A., Saeedi R., De-la Torre G.E., Dobaradaran S. Occurrence and exposure assessment of microplastics in indoor dusts of buildings with different applications in Bushehr and Shiraz cities, Iran. Sci. Total Environ. 2022;829 doi: 10.1016/j.scitotenv.2022.154651. [DOI] [PubMed] [Google Scholar]

- Kelly M.R., Lant N.J., Kurr M., Burgess J.G. Importance of water-volume on the release of microplastic fibers from laundry. Environ. Sci. Technol. 2019;53:11735–11744. doi: 10.1021/acs.est.9b03022. [DOI] [PubMed] [Google Scholar]

- Khaled A., Rivaton A., Richard C., Jaber F., Sleiman M. Phototransformation of plastic containing brominated flame retardants: Enhanced fragmentation and release of photoproducts to water and air. Environ. Sci. Technol. 2018;52:11123–11131. doi: 10.1021/acs.est.8b03172. [DOI] [PubMed] [Google Scholar]

- Li J., Liu H., PaulChen J. Microplastics in freshwater systems: A review on occurrence, environmental effects, and methods for microplastics detection. Water Res. 2018;137:362–374. doi: 10.1016/j.watres.2017.12.056. [DOI] [PubMed] [Google Scholar]

- Li D., Shi Y., Yang L., Xiao L., Kehoe D.K., Gun’ko Y.K., Boland .J.J., Wang J.J. Microplastic release from the degradation of polypropylene feeding bottles during infant formula preparation. Nat. Food. 2020;1:746–754. doi: 10.1038/s43016-020-00171-y. [DOI] [PubMed] [Google Scholar]

- Li L., Zhao X., Li Z., Song K. COVID-19: Performance study of microplastic inhalation risk posed by wearing masks. J. Hazard. Mater. 2021;411 doi: 10.1016/j.jhazmat.2020.124955. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liang H., Ji Y., Ge W., Wu J., Song N., Yin Z., Chai C. Release kinetics of microplastics from disposable face masks into the aqueous environment. Sci. Total Environ. 2022:816. doi: 10.1016/j.scitotenv.2021.151650. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu, C., Li, S., Ma, Q., Liu, L., Wang, Y., Chen, J., Zhu, L., Zhong, H., 2022. Fate of Microplastics Released by Discarded Disposable Masks 31, 4197–4204 10.15244/pjoes/149410. [DOI]

- MacIntyre C.R., Chughtai A.A., Rahman B., Peng Y., Zhang Y., Seale H., Wang X., Wang Q. The efficacy of medical masks and respirators against respiratory infection in healthcare workers. Influenza Other Respir. Viruses. 2017;11:511–517. doi: 10.1111/irv.12474. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mathieu Edouard, Ritchie Hannah, Rodés-Guirao Lucas, Appel Cameron, Beltekian Diana, Giattino Charlie, Ortiz-Ospina Esteban, Hasell Joe, Macdonald Bobbie, Roser Max. Coronavirus pandemic (COVID-19) [WWW Document] Our World Data. 2020 [Google Scholar]

- Mohammadi A., Malakootian M., Dobaradaran S., Hashemi M., Jaafarzadeh N. Occurrence, seasonal distribution, and ecological risk assessment of microplastics and phthalate esters in leachates of a landfill site located near the marine environment: Bushehr port, Iran as a case. Sci. Total Environ. 2022;842 doi: 10.1016/j.scitotenv.2022.156838. [DOI] [PubMed] [Google Scholar]

- Morgana S., Casentini B., Amalfitano S. Uncovering the release of micro/nanoplastics from disposable face masks at times of COVID-19. J. Hazard. Mater. 2021;419 doi: 10.1016/j.jhazmat.2021.126507. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Periyasamy A.P. Evaluation of microfiber release from jeans: the impact of different washing conditions. Environ. Sci. Pollut. Res. 2021;28:58570–58582. doi: 10.1007/s11356-021-14761-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pico Y., Alfarhan A., Barcelo D. Nano- and microplastic analysis: Focus on their occurrence in freshwater ecosystems and remediation technologies. TrAC Trends Anal. Chem. 2019;113:409–425. doi: 10.1016/J.TRAC.2018.08.022. [DOI] [Google Scholar]

- Pizarro-Ortega C.I., Dioses-Salinas D.C., Fernández Severini M.D., Forero López A.D., Rimondino G.N., Benson N.U., Dobaradaran S., De-la Torre G.E. Degradation of plastics associated with the COVID-19 pandemic. Mar. Pollut. Bull. 2022;176 doi: 10.1016/j.marpolbul.2022.113474. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Prata J.C., Silva A.L.P., Walker T.R., Duarte A.C., Rocha-Santos T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Technol. 2020;54:7760–7765. doi: 10.1021/acs.est.0c02178. [DOI] [PubMed] [Google Scholar]

- Pu Y., Zheng J., Chen F., Long Y., Wu H., Li Q., Yu S., Wang X., Ning X. Preparation of polypropylene micro and nanofibers by electrostatic-assisted melt blown and their application. Polymers (Basel) 2018 doi: 10.3390/polym10090959. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rathinamoorthy R., Balasaraswathi S.R. Disposable tri-layer masks and microfiber pollution – An experimental analysis on dry and wet state emission. Sci. Total Environ. 2022;816 doi: 10.1016/j.scitotenv.2021.151562. [DOI] [PubMed] [Google Scholar]

- Rodríguez-Seijo A., Pereira R. In: Characterization and Analysis of Microplastics. Rocha-Santos T.A.P., Duarte A.C.B.T.-C.A.C., editors. Elsevier; 2017. Chapter 3 - morphological and physical characterization of microplastics; pp. 49–66. [DOI] [Google Scholar]

- Saliu F., Veronelli M., Raguso C., Barana D., Galli P., Lasagni M. The release process of microfibers: from surgical face masks into the marine environment. Environ. Adv. 2021;4 doi: 10.1016/j.envadv.2021.100042. [DOI] [Google Scholar]

- Shen M., Zeng Z., Song B., Yi H., Hu T., Zhang Y., Zeng G., Xiao R. Neglected microplastics pollution in global COVID-19: Disposable surgical masks. Sci. Total Environ. 2021;790 doi: 10.1016/j.scitotenv.2021.148130. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shruti V.C., Pérez-Guevara F., Elizalde-Martínez I., Kutralam-Muniasamy G. Reusable masks for COVID-19: A missing piece of the microplastic problem during the global health crisis. Mar. Pollut. Bull. 2020 doi: 10.1016/j.marpolbul.2020.111777. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silva A.B., Bastos A.S., Justino C.I.L., da Costa J.P., Duarte A.C., Rocha-Santos T.A.P. Microplastics in the environment: Challenges in analytical chemistry - A review. Anal. Chim. Acta. 2018;1017:1–19. doi: 10.1016/J.ACA.2018.02.043. [DOI] [PubMed] [Google Scholar]

- Song Y.K., Hong S.H., Jang M., Han G.M., Jung S.W., Shim W.J. Combined effects of UV exposure duration and mechanical abrasion on microplastic fragmentation by polymer type. Environ. Sci. Technol. 2017;51:4368–4376. doi: 10.1021/acs.est.6b06155. [DOI] [PubMed] [Google Scholar]

- Sun J., Yang S., Zhou G.J., Zhang K., Lu Y., Jin Q., Lam P.K.S., Leung K.M.Y., He Y. Release of microplastics from discarded surgical masks and their adverse impacts on the marine copepod Tigriopus japonicus. Environ. Sci. Technol. Lett. 2021;8:1065–1070. doi: 10.1021/acs.estlett.1c00748. [DOI] [Google Scholar]

- Takdastan A., Niari M.H., Babaei A., Dobaradaran S., Jorfi S., Ahmadi M. Occurrence and distribution of microplastic particles and the concentration of di 2-ethyl hexyl phthalate (DEHP) in microplastics and wastewater in the wastewater treatment plant. J. Environ. Manag. 2021;280 doi: 10.1016/j.jenvman.2020.111851. [DOI] [PubMed] [Google Scholar]

- ter Halle A., Ladirat L., Gendre X., Goudouneche D., Pusineri C., Routaboul C., Tenailleau C., Duployer B., Perez E. Understanding the fragmentation pattern of marine plastic debris. Environ. Sci. Technol. 2016;50:5668–5675. doi: 10.1021/acs.est.6b00594. [DOI] [PubMed] [Google Scholar]

- Thompson R.C., Olsen Y., Mitchell R.P., Davis A., Rowland S.J., John A.W.G., Mcgonigle D., Russell A.E. 2004. Lost at sea: Where is all the plastic? p. 304. [DOI] [PubMed] [Google Scholar]

- Tripathi D. ISmithers Rapra Pub; 2002. Practical Guide to Polypropylene. [Google Scholar]

- Wang Z., An C., Chen X., Lee K., Zhang B., Feng Q. Disposable masks release microplastics to the aqueous environment with exacerbation by natural weathering. J. Hazard. Mater. 2021;417 doi: 10.1016/j.jhazmat.2021.126036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- WHO C.O. Coronavirus disease (COVID-19) pandemic. World Health Organ. 2020;2019:2633. [Google Scholar]

- Yang L., Qiao F., Lei K., Li H., Kang Y., Cui S., An L. Microfiber release from different fabrics during washing. Environ. Pollut. 2019;249:136–143. doi: 10.1016/j.envpol.2019.03.011. [DOI] [PubMed] [Google Scholar]

- Zambrano M.C., Pawlak J.J., Daystar J., Ankeny M., Cheng J.J., Venditti R.A. Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar. Pollut. Bull. 2019;142:394–407. doi: 10.1016/j.marpolbul.2019.02.062. [DOI] [PubMed] [Google Scholar]

- Zuri G., Oro-Nolla B., Torres-Agulló A., Karanasiau A., Lacorte S. 2022. Migration of microplastics and phthalates from face masks to water. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.