Abstract

Laccase is a multi-copper enzyme widely expressed in fungi, higher plants, and bacteria which facilitates the direct reduction of molecular oxygen to water (without hydrogen peroxide production) accompanied by the oxidation of an electron donor. Laccase has attracted attention in biotechnological applications due to its non-specificity and use of molecular oxygen as secondary substrate. This review discusses different applications of laccase in various sectors of food, paper and pulp, waste water treatment, pharmaceuticals, sensors, and fuel cells. Despite the many advantages of laccase, challenges such as high cost due to its non-reusability, instability in harsh environmental conditions, and proteolysis are often encountered in its application. One of the approaches used to minimize these challenges is immobilization. The various methods used to immobilize laccase and the different supports used are further extensively discussed in this review.

Keywords: Laccase, Applications, Immobilization

1. Introduction

Laccase (EC 1.10.3:2) is a multi-copper enzyme that was first discovered in the discharge of Rhus Verniciflua by Yoshida in 1883 and later characterized as a fungal enzyme (metal containing oxidase) by Bertrand in 1985 [1,2]. The enzyme has been widely identified in fungi and higher plants, however it was only recently (1993) isolated in bacteria with the first bacterial laccase identified from Azospirillum lipoferum [3, 4]. All the laccases described to date are glycoproteins (monomeric, dimeric, and tetrameric) that show a great deal of divergence [5]. Although the catalytic site is conserved, diversity is observed in the rest of the molecule structure and sugar moiety [6].

Laccase catalyses direct reduction of molecular oxygen to water, through a one electron oxidation of aromatic substrates without formation of hydrogen peroxide intermediate, by one electron abstraction [7, 8, 9]. Molecules containing an aromatic ring substituted with an electron withdrawing groups such as phenols, cresols, chlorophenols, aryldiamines, aromatic amines, and polymethoxybenzenes all undergo oxidation in the presence of laccase [10, 11]. Upon oxidation, free cationic radicals are formed that further undergo catalysed oxidation to form quinones or non-enzymatic reactions such as hydration and polymerization occur to form high molecular weight insoluble components such as dimers, oligomers, or polymers [12, 13, 14, 15]. Thus, laccase shows broad specificity of its substrates and has gained popularity in detoxification processes of aquatic and xenobiotics, industrial effluents, and biotechnological industrial applications [16, 17].

Physical methods such as circular dichroism and Electron paramagnetic resonance (EPR) have been used to study laccase structure. It has been observed that the metallic centres are relatively stable but the secondary structures differ due to varying amino acid sequence and/or composition of the carbohydrate moiety [6]. Due to the diversity in the enzyme secondary structures, the substrates oxidized by laccase vary from one laccase to another ranging from inorganic or organic metal complexes, ferrocyanides, anilines, benzenethiols, and phenols to other redox inorganic, organic, or biological compounds [18, 19]. For example Xu et al. [20], demonstrated that the catalytic properties of laccase from the fungi Rhizoctonia sp. and Myceliophthora thermophile as well their inhibition were altered by type 1 copper site directed mutagenesis.

Laccase catalytic reactions occur in ambient temperatures, use molecular oxygen as the secondary substrate reducing it by a four electron mediator-less mechanism, do not require any other cofactors and only water is produced as the by-product [21, 22]. Due to their extracellular nature, laccases can tolerate high pollutant concentrations in substrates [23]. These advantages and the ability to produce laccase by simple and inexpensive methods make it desirable in various industrial and environmental applications including organic synthesis, degradation of toxic organic compounds, biosensors, and immunoassays [24, 25, 26]. As a result, it has attracted research interest in order to understand its mechanism and obtain a scientific basis for its employment in biotechnological applications [27].

However, with all the advantages of using laccase, it has its own shortcomings including very low stability in harsh conditions and non-recoverability which limits its application at an industrial scale [28]. Recently, attention has been placed on the enzyme immobilization in a confined space or on a support to improve and optimize its performance for commercial use as a biocatalyst and facilitate its reuse [28, 29]. This review explores the various sources of laccase in nature, its structures and proposed mechanisms of catalytic activity, its roles in nature, and its industrial and environmental applications. The immobilization techniques that have been employed over the years to improve its stability and reusability as well as the various immobilization supports are also extensively discussed. The various sections discussed in this review about laccase enzyme are schematically represented in Figure 1.

Figure 1.

A schematic representation of what is covered in this review about laccase enzyme.

2. Structure and reaction mechanism of laccase enzyme

Laccase is a blue oxidase glycoprotein (monomeric, dimeric, or tetrameric) with an amino acid chain over 500 amino acids and carbohydrate moiety of 10–45% of the protein molecule by weight [28, 30]. Different carbohydrates including glucose, hexose amine, mannose, galactose, fructose, xylose and arabinose make up the carbohydrate moiety (glycans), are bound to the polypeptide of the enzyme through an N-linkage and vary depending on the source of the enzyme [31, 32]. The binding of the carbohydrate moieties to the enzyme defines the structure of the enzyme through a specific folding which provides protection against proteolytic and elevated temperature degradations [32].

More than one laccase are often identified in a single fungus with different molecular weights, pH optima, sugar moiety, and substrate specificity [6]. For example, Kim et al. [33] discovered a second extracellular laccase from Crypthonectria parasitica by deleting laccase 1 using recombinant DNA techniques and growing the mutant strain in tannic acid. Wahleithner et al. [34] identified four distinct laccase genes in the fungus Rhizoctonia solani and three of which had been expressed in another fungus Aspergillus oryzae. Marbach et al. [35], identified two molecular forms of laccase induced by different phenolics from Botrytis cinera with different sugar content, isoelectric focusing pattern, amino acid composition, and molecular weight. The enzyme induced by grape juice had a molecular weight of 38,000 and 80% sugar while that induced by gallic acid had molecular weight of 36,000 and 70% sugar. Fukushima and Kirk [36] identified two laccases from the fungus Ceriporiopsis subvermispora with two isoelectric points (3.4 and 4.8), molecular masses of 71 and 68 kDa, half-lives of 120 and 50 min at 60 °C, and carbohydrate content of 15 and 10%, respectively.

The active holoenzyme form of laccase consists of four copper atoms that are classified into three types depending on the features of their surroundings, their accessibility to solvents, and characteristic electron paramagnetic resonance (EPR) signals [37, 38]. The copper atoms are classified into type 1 (blue), type 2 (normal) and type 3 (coupled binuclear) copper with two copper atoms belonging to the type 3 site [30, 39]. Type 1 and type 2 copper have strong electronic adsorption and well characterized EPR signals and type 3 copper atoms are antiferromagnetically coupled through a binding ligand which makes the EPR signal undetectable but give a weak absorbance in the near UV region at 330 nm [30, 40]. Type 1 copper is responsible for the intense blue colour of the enzyme due to a ligand-to-metal charge transfer absorption of the copper cysteine-bond [41, 42]. It is further available to interact freely with solvents (water inclusive), can be removed from the enzyme molecule by various copper complexes, and can displaced by mercury or cobalt with a great loss in activity [30]. Type 2 copper coordinates two Histidine (His)-N and an oxygen atom as OH− while each copper of type 3 coordinates three His residues [43, 44]. The type 1 and type 2/3 copper are bridged by a His-cysteine (Cys)-His tripeptide bridge that acts as an intramolecular electron transfer highway [45].

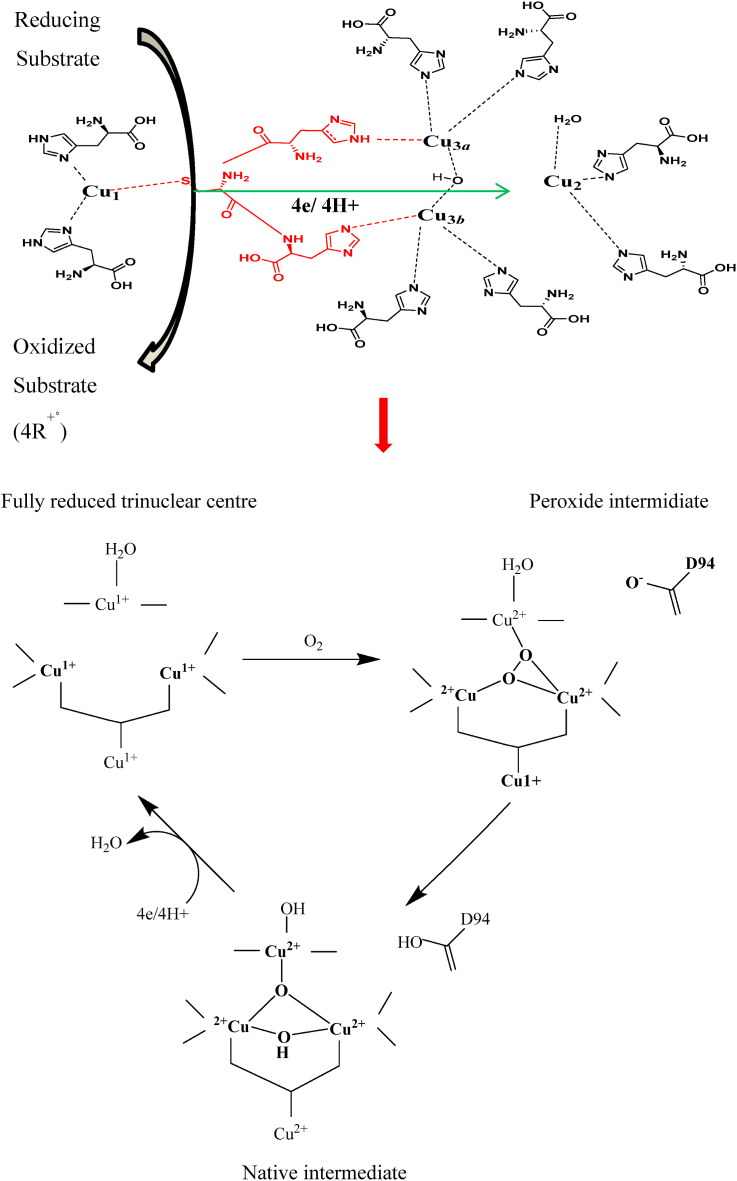

Substrates attach to the binding site of laccase by hydrophobic interaction and all the copper ions are presumed to be involved in the catalytic mechanism [46, 47]. As demonstrated in Figure 2, Type 1 and 2 are presumed to participate in electron capture and transfer while type 2 and 3 are involved in binding with oxygen or oxygen uptake [38, 48]. The catalysis process of laccase comprises of type 1 copper reduction by the reducing substrate, internal electron transfer from type 1 to type 2 and 3 trinuclear structure, and ultimate activation and reduction of oxygen to water at the type 2 and 3 copper trinuclear structure (Figure 2) [42, 49, 50]. The O2 molecule binds to the trinuclear cluster for asymmetric activation and it is presumed that the O2 binding compartment restricts access of other oxidizing agents other than oxygen [30, 49].

Figure 2.

A schematic representation of the different amino acids that coordinate with the copper at the laccase site and the reaction mechanism for the laccase catalytic activity.

Laccase-like enzymes that lack typical absorption at 600 nm have been identified. For example, Palmeri et al. [41], reported a white laccase from P. ostreatus that contained one copper, two zinc, and one iron atoms per mole of enzyme and did not have an absorbance at 600 nm hence the classification of white laccase. The enzyme is considered a laccase due to its identical structure to other laccases and the fact that it uses oxygen as the oxidizing substrate [51]. Leotievsky et al. [52], identified yellow laccase from solid-state culture of ligninolytic fungi as a result of binding lignin-derived molecules by the enzyme protein. The yellow laccases show high homology with the blue laccases when their N-terminal amino acids sequences are compared. They have similar copper content to the typical blue laccase but don't maintain their copper centres in the oxidized state under anaerobic conditions, that is, the copper in the yellow laccase appears in the reduced form. The change in this enzyme property is attributed to binding of low molecular mass phenolic material arising from lignin degradation or heterogeneity induced by glycosylation [51].

Laccases are inhibited by metal ions such as Hg2+, Fe2+, Ag+, Li+ and Pb2+ [53, 54, 55], humic acid [56], cationic quaternary ammonium detergents and small anions like halides [57, 58, 59], azide [60, 61], and hydroxyl [62]. The inhibition process involves amino acid residue modification, copper chelation or conformational changes, and binding of small anions on type 2 and 3 copper hence interrupting internal electron transfer [58, 59]. Enzyme inhibition due to organic solvents occurs as a result of hydrophobic interactions between the solvent and non-polar groups of laccase and substitution of hydration water within the enzyme with the organic solvent. This happens because the binding site of the organic substrate in the enzyme is close to the surface of enzyme globule hence readily accessible for the solvent [63, 64]. Halides bind to the type 2 and 3 copper of the enzyme and inhibit electron transfer from type 1 copper to the trinuclear structure thus leading to enzyme catalytic decay [65]. Metal ions competitively inhibit laccase due to their strong affinity to thiol groups in laccase but have no impact on the enzyme active centre [66]. Interestingly, the presence of divalent metal ions has shown to improve laccase activity due to their competition with Cu2+ in the electron transport system which improves the enzyme-substrate relationship [67].

With the wide range of substrates that can be oxidized by laccase, addition of mediators such as 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) ABTS [68, 69], N-hydroxybenzotriazole (HOBT) [70], and 2,2,5,5-tetramethyl-4-piperidin-1-oxyl radical (TEMPO) [71, 72] to a specific laccase enzyme can further increase the substrate range to include non-phenolic compounds. Mediators are low-molecular-weight organic compounds that are oxidized by laccase to form highly active cation radicals which oxidize the non-phenolic compounds that are usually resistant or impervious to laccase oxidation through the normal shuttling of electrons from the substrate to the enzyme [73, 74, 75]. For example, Peralta-Zamora et al. [76], used HOBT as a mediator in the decolourisation of azo and indigo dyes (usually not laccase substrates) using free laccase and laccase immobilized on silica modified with imidazole. No decolourisation was detected in the absence of HOBT but achieved 30% and 45% decolourisation efficiency for free and immobilized laccase respectively within 30 min after adding 0.4 mL of HOBT. Dodor et al. [77], used T. versicolor laccase immobilized on kaolinite for the catalytic oxidation of anthracene and benzo [a]pyrene in the presence of ABTS as a mediator. Between 17% and 19% oxidation were achieved without a mediator, but after addition of ABTS the oxidation efficiency increased to 80% and 85% for anthracene and benzo [a]pyrene respectively. Gu et al. [78], covalently immobilized laccase on ABTS-encapsulated cellulose beads for indole degradation. While free laccase hardly degrades indole, the biocatalyst achieved a degradation rate of up to 99.7%. Reyes et al. [79], demonstrated that the number of decolourised dyes by laccase increased from 13 to 26 out of 38 dyes when 1 mM HOBT was added as a mediator and increased rate of decolourisation was observed. Laccase immobilized on concanavalin A-activated Fe3O4 nanoparticles demonstrated an exponential increase in the rate of removal of sulfonamide antibiotics when syringic acid was used as a mediator [80].

However, the benefits of mediators are sometimes negated by their disadvantages such as toxicity, cost, and the ability of radical species from mediator compounds to undergo chemical reactions with aromatic side-chains of laccase thereby inactivating the enzyme [81, 82]. For example, Skoronski et al. [83], observed that it was impossible to reuse Aspergillus sp. laccase immobilized on chitosan during syringaldazine bioconversion. More so, the approach used in introducing a mediator has an impact on the performance of the biocatalyst. For example, when laccase and acetylacetone (mediator) were co-immobilized through initiated polymerization into a hydrogel, the biocatalyst displayed a high substrate conversion of malachite green as compared to the sole immobilized laccase and immobilized laccase with an external mediator [84]. Therefore, factors such as good laccase substrate with high redox potential intermediate and with stable reduced and oxidized forms that do not inhibit enzymatic reaction should be considered when selecting a redox mediator [85].

3. Role of laccase in nature

Due to the large amounts of laccase produced by lignin degrading (wood rotting) fungi, it has been presumed that the main role of laccase in nature is the polymerization and degradation of lignin [63, 86]. Laccase mediated degradation of lignin starts with the loss of an electron from the phenolic hydroxyl groups of lignin to produce phenoxy radicals which spontaneously re-organizes to aid either α-carbon oxidation or Cα-Cβ bond cleavage of alkyl side chains of the polymer to produce low molecular weight and/or polymeric products due to polymerizing activity of the enzyme [30, 87]. Fungal laccases are argued to be involved in the regeneration of tobacco protoplasts [88], lignification of cell walls [6, 89], morphogenesis of rhizomorphs [37], sclerotization and melanogenesis processes in insects [90, 91, 92], fungal virulence, sporulation and plant pathogenesis [49, 93].

Laccase has been suggested to play a role in humus synthesis. Laccase catalyses the cleavage of lignin and non-lignin macromolecules into their monomeric structural units which react with other compounds to form humic substances of varying complexity [49, 94]. Additionally, laccase catalyzes coupling reactions between phenolic compounds and humic acids leading to the binding of pollutants on organic matter of soil hence reducing their bioavailability and toxicity [11, 32]. Because of this, laccases have been investigated for applications in detoxification of pollutants in soil environments. Polluted soils can be cleaned up by laccase-mediated incorporation of pollutants into humus through catalytic coupling of xenobiotic compounds and derivatives to humic substance or humic like compounds [49].

4. Sources and production of laccase

Laccases have been identified in fungi [13, 95], higher plants [96, 97], bacteria [49, 98], and insects [99, 100]. The laccases extracted from the various sources have shown different biochemical properties dependent on the source due to the different roles they play in these organisms [101]. In plants laccases aid in lignin polymer formation, in fungi morphogenesis, stress defence, and lignin degradation, while in insects it participates in stress defence, the biosynthesis of brown melanin like pigment, and protection from UV light and hydrogen peroxide [102]. The laccase from plants and fungi is mainly extracellular while that from bacteria is mostly intracellularly localized [103]. Laccases from fungi have lower optimum pH, ranging from 3.6 – 5.2, than plant laccases that have optimum pH in the range 6.8–7.4. The low optimum pH of fungal laccases is due to their adaptability to grow under acidic conditions, while the plant laccase being intracellular have their pH optima nearer to the physiological range. As a result, the functions of laccases obtained from these sources differ in that fungal laccases mainly degrade toxic phenolic compounds while plant laccases are mainly involved in synthetic process such as lignin formation [5].

Different fungi have been used for the production of laccase including Agaricus sp. [93], Trametes sp. [104, 105], Cerrena unicolor [106, 107], Dichomitus squalens [108], Aspergillus oryzae [109, 110], Pleurotus ostreatus [111, 112], Coriolus hirsitus [113], Coriolopsis sp. [114, 115], Rigidoporus lignosus [116], Neurospa crassa [31], Pleurotus florida [117], Cyathus bulleri [118], Ganoderma lucidum [119], Funalia trogii [120], Paraconiothyrium variabile [121] and Trichoderma harzianum [122]. Laccase producing fungi are mainly from three genera, that is, ascomycetes [14], deuteromycetes [123] and basidiomycetes [13]. The basidiomycetes class includes various wood and litter decomposing and soil inhabiting fungi that have been broadly used to produce laccases with variable induction mechanisms, degrees of polymorphism, and physiochemical and kinetic properties due to their efficiency in lignin degradation [108, 112].

Recently, some bacteria have been used as sources of laccase e.g. B. subtillis [124, 125], γ-Proteobacterium JB commonly found in industrial waste water [126], Streptomyces coelicolor [127], Thermus thermophilus [27], Weissella viridescens [128], Shewanella putrefaciens [103], Alcaligenes faecalis [129], Sphingobacterium ksn-11 [130], Brevibacterium halotolerans N11 [131], and E. coli [27]. Laccases obtained from bacteria have unique characteristics compared to the fungal and higher plant laccases which gives them greater advantages in terms of industrial applications. For example, the laccase obtained from T. thermophilus demonstrated a very high optimal reaction temperature of 92 °C and a half-life of thermal inactivation at 80 °C of over 14 h, making it the most thermophilic laccase reported thus far [27]. Endospore laccases from bacteria serve microorganisms to survive harsh conditions hence the enzyme is expected to withstand harsh conditions such as high temperature, extreme pH, and presence of ionic salts which is beneficial for industrial applications [130, 132].

In plants, laccases have been obtained from maize seeds [133], Rhus vernicifera [25], papaya (Carica papaya) leaves [67], Sycamore Maple (Acer pseudoplatanus) [96], and vegetables such as cabbages, turnip, potatoes, pears, and apples [5, 30]. For example, Bailey et al. [133], extracted laccase from maize seeds. A portion of the extractable laccases was in an inactive form and was activated by treatment with copper and chloride.

Laccase is obtained through fermentation of laccase producing organisms. However, the enzyme is usually produced in small amounts and its productivity is increased by introduction of inducers or altering cultivation conditions [134]. The two most critical components of nutritional medium are nitrogen and carbon [42]. Presence or absence of inducers, induction time, nature and composition of culture medium, carbon to nitrogen ratio, type of culture conditions (pH, temperature, aeration), and genetic manipulation determine the amount and type of laccase to be obtained [135, 136]. Inducers such as 2,5-xylidine [135], benzyl alcohol [49], or xylan [93], their chemical nature, quantity and time of their addition influence laccase production to a great extent. For example, when Osiadacz et al. [18], added 10 μM pyrogallol as inducer on the fourth day to the submerged culture, there was a three-fold increase in laccase production from Trametes versicolor. Therefore, medium optimization is an important factor to ensure maximum enzyme yield with minimal production costs.

Industrial and agricultural byproducts such as corn cobs [137], olive oil mill waste [138], oak dust [139], banana peel [140], pistachio shell [141], tea residues [142], spent coffee, rice straw, and wheat bran [143] have been used as excellent substrates in the fermentation process due to their complex composition of carbon, nitrogen, and mineral supplies suitable for the growth of microorganisms. They also possess natural polymers including cellulose, lignin, pectin, and starch which provide suitable substrates during the fermentation process [144, 145, 146]. In fact, fermentation of some white-rot fungi in the presence of lignocellulosic residues significantly stimulated laccase secretion without any supplementation with inducers [147]. For example, laccase was produced by cultivation of T. versicolor on barley husks and egg shells in solid state conditions without the need for additional carbon and nitrogen sources or mineral compounds [66]. The eggshells acted as supports for microorganism growth and improved the porosity of nutrient media which enabled more oxygen to diffuse deeper inside the reaction mixture. More so, the egg shells were a source of calcium which acted as a laccase inducer. Production of laccase from various sources has been extensively reviewed elsewhere [148].

5. Applications of laccase

Laccases have attracted attention as biocatalysts in a wide range of biotechnological applications due to their non-specificity and their use of molecular oxygen as an electron acceptor [32, 149]. They have been used as biocatalysts in wastewater treatment of textile, paper and pulp, petrochemical effluents, food industries, medical diagnosis and manufacturing, lignin modification, and as a bioremediation agent for herbicides and pesticides [150, 151]. Laccases are one of the most promising enzymes for decontamination of phenol polluted systems and biotechnological applications, they have been explored in the removal of toxic compounds from aquatic and terrestrial systems [87], production treatment of beverages [152], region-specific bio-transformations [153], aerobic oxidation of benzyl alcohols [154], analytical tools and biosensors [49], and commercial polymerization of lignosulfates for further applications as surfactants, dispersants and plasticizers in the cement and concrete industry [26]. In this section the various applications of laccase enzyme in waste water treatment, biosensors, paper and pulp industry, food industry, biofuel cells, and pharmaceutical industry are represented in Figure 3 and further discussed.

Figure 3.

Applications of laccase enzyme.

5.1. Waste water treatment

Enzymatic bioconversion technologies have attracted growing interests in the field of wastewater treatment due to their ability to eliminate toxic compounds at mild conditions with less biodegradation by-products [155]. The use of enzymes for wastewater treatment is advantageous due to the substrate specificity of enzymes, reduced susceptibility of the biocatalyst to shock-loading effects, high rates of reaction, efficient use of oxidants, and effective treatment at low substrate concentrations [156]. The removal of phenolic compounds from industrial effluents and the environment is of great importance as these compounds are highly toxic to aquatic organisms and account for the biggest percentage of organic pollutants [157, 158]. Phenolic compounds form a significant percentage of industrial effluents due to their wide use in many industrial processes such as manufacture of plastics and resins, wood preservation, petroleum refining, paper, dyes, pesticides, textiles, drugs, and anti-oxidants [159, 160, 161]. Majority of these compounds are not removed from the liquid portion by waste water treatment plants and they are transferred into the sludge. More so, they are not degraded by the active sludge in treatment plants hence end up in the environment via waste water effluents and in bio-solids through agricultural applications [162, 163]. These compounds have been related to health problems and environmental pollution due to their inherent toxicity [164]. Consequently, the need to degrade or transform these compounds into degradable or non-toxic ones using enzymes is of great interest [165].

The ability of laccase to degrade a variety of phenolic compounds without harsh side effects has attracted attention in detoxification of polluted waste waters [166, 167]. The enzyme doesn't require exotic co-substrates, uses readily available oxygen as electron acceptor, and the free radicals formed by laccase oxidation bypass the steps involved in formation of carcinogenic amines [168]. Mostly insoluble products are formed when phenol derivatives are oxidized by laccase and can easily be removed by filtration or sedimentation [157, 169]. Laccase has proved to oxidize recalcitrant chemicals from the environment which are difficult to degrade to more bioavailable or harmless and stable water insoluble polymers [29, 83]. For example, High-performance liquid chromatography (HPLC) indicated that the main product of anthracene oxidation by laccase was 9,10-anthraquinone which is less toxic than its precursor [170]. As a result, laccase has been widely used in decontamination and restoration of hazardous chemical-contaminated waters [83, 114]. The mechanisms of free and immobilized laccase in detoxification of phenolic compounds have been reviewed elsewhere [171].

Laccase has been utilized in decolourisation of effluents from olive oil mills [116, 172], molasses wastewaters and baker's yeast effluents [173], and textile, paper and pulp effluents [174]. Degradation of pharmaceutically active compounds such as Diclofenac [175, 176], Tetracycline [177], Sulfamethoxazole [178, 179], Chlortetracycline [180], and carbamazepine [181, 182] from the environment using laccase has been reported. A number of researchers have reported successful laccase mediated degradation of endocrine disrupting chemicals such as bisphenols [114, 183, 184, 185], alkylphenols [186], Polycyclic aromatic hydrocarbons (PAHs) [187, 188, 189], benzidine-based dyes [190], and synthetic estrogenic compounds [156]. Herbicides, pesticides, and insecticides such as 2,4-dichlorophenol [191], Chlorpyrifos [192, 193], lindane [23], pirimicarb [194], triclosan [195], pentachlorophenol [196], as well as other phenolic compounds like naphthalene [17], phenol, p-chlorophenol, and catechol [197, 198, 199] have also been successfully degraded by laccase (Table S1). The application of laccase in waste water treatment and detection of harmful pollutants in the environment has been reviewed elsewhere [200, 201, 202, 203, 204].

Figure 4 shows the different drugs, pesticides, and organic pollutants that have been studied for possible degradation by laccase immobilized on various supports. Different drugs such as tetracycline [177, 205, 206], diclofenac [176, 207], estrogens including estrone, 17β-estradiol, 17α-ethinylestradiol [208, 209], sulfa drugs including sulfamethoxazide, sulfadiazine, sulfamethazine and sulfathiazole [80, 210, 211], and carbamazepine [181, 182, 212]. Among other drugs explored are paracetamol [163, 213], hydroquinone [214] and antibiotics such as ampicillin, erythromycin [177], amoxicillin and ciproflaxin [215]. Laccase immobilized on nanoparticles (NPs), nanocomposites (NCs) and metal organic frameworks (MOFs) show the highest degradation efficiencies of over 80% even with short incubation time (0–6 h) as compared to other supports like polymers, silica, and clay. This could be due the high surface area to volume ratios provided by the NPs and NCs which enhances the catalysis of the enzyme [216]. Also immobilization of the enzyme on MOFs is usually by entrapment based on enzyme-MOF affinity which has minimal enzyme denaturation and high enzyme loading hence facilitating high enzyme activity [217].

Figure 4.

A graph showing the percentage degradation of various drugs, pesticides, herbicides and other organic pollutants that have been degraded using laccase enzyme immobilized on various supports with different times of exposure, that is, 0–6 h, 6–24 h and over 24 h.

However, the degradation rate of carbamazepine is low (less than 60%) regardless of reaction time or immobilization support used. Degradation in presence of mediators in the drug solution or co-immobilized on the support can be explored to improve the degradability of this drug since the degradation has been studied exclusively at room temperature in stirred reactors systems [155, 181, 218].

For the case of pesticides and other organic pollutants, bisphenols (A,B and F) [183, 219, 220], chlorophenols [22, 221, 222], triclosan [64, 147, 195], anthracene [77, 223, 224], and other phenolic compounds such as naphthalene [17], catechol [225], phenol [226], and aminophenols [227]. Other pesticides explored include pyrometryn, atrazine [228], indole [223] and chlorpyrifos [192]. As compared to drugs, laccase shows generally higher degradation efficiency for pesticides and other organics regardless of immobilization support or reaction time. This could be due to the phenolic structure of these compounds that provide wonderful substrates for the catalytic activity of the enzyme [10, 11]. It is evident that increasing reaction time from 0-6 h to 6–24 h increases the overall performance of the enzyme in degrading pesticides from below 60% to above 60% with majority above 80% efficiency in degradation. Increasing reaction time above 24 h has limited effect on the performance of the biocatalyst and other options such as use of mediators should be explored.

5.2. Dye degradation

Synthetic dyes have gained popularity in the textile, paper, cosmetics, leather dyeing, colour photography, pharmaceutical, and food industries due to their low cost, ease of synthesis, and colour variety [111, 162]. They are classified according to chemical structure of the chromophore (molecule responsible for their colour) groups as azo, anthraquinone, heterocyclic, triphenylmethane, xanthene, acridine, or phthalocyanine [229]. Azo dyes constitute of the largest percentage accounting for 60–70% of all the dyes in the textile industry [230, 231] followed by the anthraquinones [232]. Since the dyes are designed to meet various colouring requirements, they have very stable chemical structures that are difficult to degrade hence causing serious environmental pollution [198, 233]. They are obstinate to microbial degradation and conventional treatment methods, affecting water transparency and gas solubility leading to reduced dissolved oxygen and may be transformed to carcinogenic compounds under anaerobic conditions [234, 235, 236].

The textile and dye industry is the major source of water pollution with its effluents containing 10–30% of the initial dyestuffs that are difficult to treat due to their non-biodegradable nature and complex molecular structures [168, 237]. The most crucial step in dye degradation by laccases is the cleavage of their chromophores which renders the dye fragments more susceptible to biodegradation by other less specialized biocatalysts [111, 234]. The chemical structure and type of substitute group such as azo, nitro, and sulfo groups of the reactive dye molecule determine the dye decolourisation rate [235, 237]. Biological treatment processes of effluent dye are inefficient because the dyes are highly resistant to biological oxidation and they poorly adsorb on activated sludge [66]. Decolourisation using physical or chemical methods such as adsorption, precipitation, chemical degradation, and photo-degradation has financial and methodological disadvantages, is time-consuming, and mostly ineffective [238]. With the stringent regulations and restrictions established for effluent discharge into the ecosystem, a number of studies have focused on microorganisms, which are able to decolourise and biodegrade these dyes [239, 240, 241, 242]. Enzymatic treatment of dye effluents has gained attention because of the mild reaction conditions involved without generating any secondary pollution like toxic sludge [243, 244].

Laccases have emerged as an attractive enzyme for dye degradation because of their ability to mediate coupling reactions which form a basis for dye removal [43]. Most of the commercially relevant dyes have similar structures to lignin substructures which likely enables the enzyme to act on the compounds chromophore hence decolourising a wide range of synthetic and organic dyes even at environmentally relevant concentrations [245, 246]. Laccases have decolourised a wide spectrum of dyes (Table S1) including Malachite green (MG) [247, 248], Congo red [249], Crystal violet dye [244], Direct blue [250], Procion red MX-5B [231], Reactive red [198, 251], reactive blue [252], Phenol red [253], Acid blue [241], Acid orange [121], Remazol brilliant blue R [232], Reactive green, Reactive brown, Cibacron blue [254], bromaminic acid [255], Direct green [256], Bismark brown R, and Lanaset grey G [115]. The application of laccase enzyme in degradation dyes has been extensively reviewed elsewhere [51, 257, 258, 259].

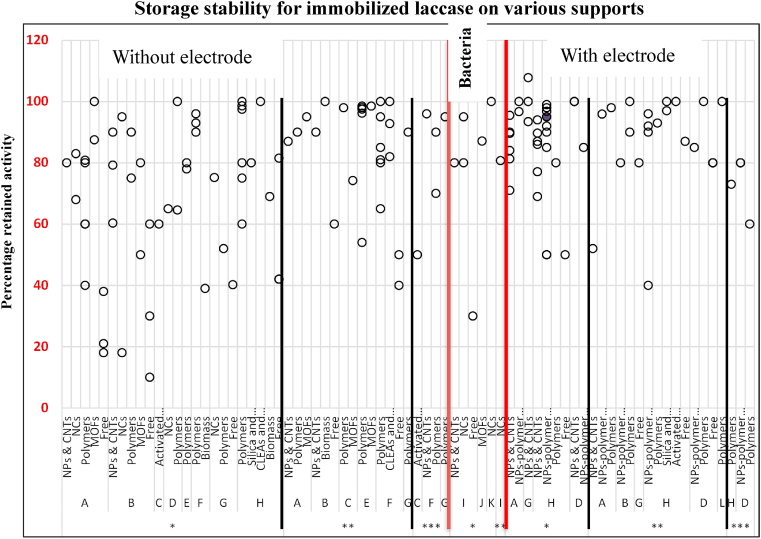

Although bacterial laccase has not been widely explored, they demonstrate overall high degradation efficiencies of over 60% regardless of the immobilization support and reaction time (Figure 5). Amongst the fungi, Aspergillus sp., M. thermophilia, and Cerrena sp. laccases show higher degradation on all the supports except for biomass immobilized that give less than 40% efficiency. The most explored fungus for laccase production is Trametes sp. and their laccases provide desirable degradation rates overall for dyes and industrial effluents in the free and immobilized state.

Figure 5.

A graph showing laccase immobilized on various supports and its efficiency in degrading synthetic dyes, textile effluents, olive mill waste water and paper industry effluents at different hours of exposure, that is, 0–6 h, 6–24 h and over 24 h.

Even though laccase-NPs/NCs biocatalysts showed high degradation rates for drugs and pesticides at in short incubation times, a longer time (6–24 h) is needed for them to achieve higher degradation efficiencies in dyes and industrial effluents (Figure 5). Polymers have been the most extensively used supports for laccase immobilization and subsequently its application in waste water treatment and their biocatalysts show desirable degradation efficiencies. As observed earlier, increasing reaction or contact time of polymer-laccase biocatalyst with waste water beyond 24 h has no impact on the improvement of the performance of the biocatalyst. In fact, their degradation capacities decrease and degradation efficiencies of below 40% have been recorded for over 24 h incubation. Other supports such as clay, silica, alumina, zeolite and glass provide desirable platforms for the catalytic performance of laccase. Addition of mediators and degradation at laccase optimum pH and temperature can be utilized to improve and facilitate complete degradation of dyes and industrial effluents by laccase. The different supports used to immobilize laccase from various sources and their efficiency in degradation of dyes, paper and textile effluents and olive mill waste water have been showed in Figure 5.

5.3. Paper and pulp industry

Laccase is used in the pulp and paper industry for lignin degradation, deinking, pitch control, effluent detoxification, bio-pulping, and grafting on fibres to improve the physical, chemical, and mechanical properties of paper [260]. In order to obtain high quality paper, structurally embedded lignin responsible for the dark colour should be removed after cooking. This is traditionally done by bleaching with chlorine based chemical agents which results in production of various chloro-organic derivatives that are toxic once released in the environment [261]. Laccase offers a green alternative in bioleaching of pulp to conventional and environment non-friendly chlorine and chlorine based bleaching and has no reductive effect on the final yield of pulp as compared to other enzymes (xylanases and mannanases) [262]. Use of laccase in the pulp industry has showed improved pulp properties, reasonable decrease in kappa number (residual lignin content), increased paper brightness, and reduced chlorine consumption [102]. Laccase has also been used in lignin removal from biomass such as kraft pulp [234] and olive pomace [226] to help in its recycling and enhance the efficiency of cellulose extraction and hydrolysis. The applications of laccase in the paper and pulp industry have been extensively reviewed elsewhere [263, 264, 265].

5.4. Food and pharmaceutical industries

Laccase has found application in food industry as a food additive for stabilization of beverages, wines and beers [266, 267, 268], clarification of fruit juices [269, 270, 271], baking [272, 273, 274, 275], sugar beet pectin gelation [276], and improvement of food sensory parameters [277]. It is also used in the detection of phenolic compounds in beverages, wines and beers [278], as well as bioremediation of food industry waste water. The application of laccase in the food industry has been extensively reviewed elsewhere [277, 279, 280].

Laccase has been used to mediate coupling reactions for synthesis and modification of pharmaceutical products and food supplements such as Trans-Resveratrol [281], degradation of pharmaceuticals from waste water (Figure 4) [218, 282] and catalytic synthesis of anti-cancer drugs and antimicrobial applications [283]. For example, Sampaio et al. [284], used entrapped M. thermophila laccase in bacterial nanocellulose membrane (from Gluconacetobacter xylinum) in wound dressing application. The bioconjugate demonstrated cytotoxicity acceptable for wound dressing applications and 92% and 28% antimicrobial activity against gram positive and gram negative bacteria respectively. The antimicrobial activity of laccase against gram positive and gram negative bacteria was attributed to the electrochemical mode of action to penetrate cell wall of the microorganisms, thereby causing leakage of essential metabolites and physically disrupting other microbial key cell functions.

5.5. Biofuel cells

The fascinating character of direct four electron reduction of oxygen to water by laccase at high electrode potentials has promoted its application in the cathode compartment of biofuel cells [285, 286, 287]. Compared to metallic catalysts, laccase has unique advantages such as catalytic efficiency at high redox potentials, clean oxygen reduction without the formation of hydrogen peroxide intermediate, and relatively low cost [65, 288]. The effective immobilization of laccase and its mediator on electrodes as required is the key step in construction of biofuel cells [289]. Efficient electron transfer between the active site of laccase and the electrode and efficient supply of laccase with oxygen are the prerequisites for high performance of the biofuel cell [285].

Biofuel cells using enzymes as biocatalysts are emerging as the new non-polluting and renewable electricity sources that respect the standards of “green energy’’ [124]. Enzymatic biofuel cells take advantage of selectivity of enzymes to oxidize specific substrate and reduce oxygen in order to obtain power output from physiological fluids [290, 291]. Due to the selectivity of enzymes, separation of electrodes in an enzymatic biofuel cell is not required hence the anode and cathode can all be immersed in one membrane containing the fuel and oxidant. This allows for fabrication of miniaturized fuel cells as small as the micrometre scale [292]. For example, Barrière et al. [293], used an osmium-based redox polymer for laccase-mediated reduction of oxygen coupled to glucose oxidase-mediated oxidation of glucose to form a membrane-less biofuel cell. At the biocathode, laccase is wired on to an electrode surface to achieve oxygen reduction through either mediated electron transfer (MET) or direct electron transfer (DET) [290]. MET involves integration of redox mediators that shuttle electrons between the active sites of the enzyme and the electrode while DET allows electron transfer between laccase and electrode via fast tunnelling in absence of a mediator [45, 294].

In MET, the mediator (e.g. Dopamine [295] and ABTS [291]) is either free in solution or immobilized with the enzyme on the electrode [296]. For example, laccase was immobilized on three-dimensional graphene networks (3D-GNs) functionalized with dopamine and 3,4,9,10-perylene tetra carboxylic acid (PTCA) which acted as mediator and spacer respectively on the GCE. The modified electrode was used as a cathode in a glucose/O2 biofuel cell with a maximum power density of 112 μWcm-2 and a short circuit current of 0.96 mAcm-2 [289]. Barrière et al. [297], fabricated a biofuel cell consisting of a glucose-oxidase based anode and laccase based cathode. The enzymes were immobilized on graphite electrodes using osmium-based redox polymers as mediators and the biofuel cell gave maximum power density of 16 μW/cm2 at a cell voltage of 0.25 V. The redox mediators should have excellent reversible electron transfer properties, potentials close to the redox potential of the enzyme active site, and ensure sufficient driving force to optimize bioelectrocatalytic activity [285]. Even though utilization of redox mediators results in higher current densities, MET-based systems often experience mediator leaching, oxygen sensitivity of the mediators, and loss of open-circuit potential [45, 298]. As a result DET-based systems are preferred for high power biofuel cells that can be used in portable power applications [298].

In DET-based cell, the reduction of oxygen relies on the close proximity (within 1.5 nm) of the enzyme active site and the electrode surface [45, 299]. Electron transfer occurs during catalytic transformation of the substrate and its kinetics is determined by the orientation of the enzyme on the electrode surface, potential difference, and distance between the enzyme active site and the electrode surface [298, 300]. DET is optimized when active site of the enzyme molecules are most exposed to the electrode surface and can be improved by modifying the electrode surface with conductive nano-elements like carbon nanotubes and metal and metal oxide nanoparticles [301]. Electrode surfaces modified with nanoparticles such as nano-Gold (nAu) provide a microenvironment similar to that of redox-enzymes in native systems and allow freedom in enzyme orientation since electron transfer proceeds through the conducting tunnels of the nanoparticles [302]. DET is preferred because the biofuel cell voltage is maximized since enzymatic catalysis is performed at apparent redox potentials of the enzymes at the cathode and anode. Also the absence of redox mediators simplifies the fabrication process of the cell, increases cell stability, and minimizes toxicity issues that could arise from the leaching of mediators [285, 303]. Gellet et al. [298], used Rhus vernificera laccase to develop an air-breathing biocathode that employed DET for application in a proton exchange membrane hydrogen/air fuel cell and a direct methanol fuel cell (DMFC) with an anion exchange membrane. The biocatalyst provided high operational current density of 50 mA/cm2, maximum power density of 8.5 mW/cm2, and a lifetime of 290 h in a 40% methanol DMFC. A stable current for 350 discontinuous h when operated for 8 h daily was achieved in the hydrogen/air fuel cell.

5.6. Biosensors

The release of phenolic compounds by a large number of industries necessitates their detection and quantification in the environment. Since these compounds are toxic and persistent in the environment, their quantification is important when evaluating the total toxicity of an environmental sample [304, 305]. Phenolic compounds are also present in fruits and vegetables and their products such as juices and wines. The polyphenol content in juices and wines affects their quality in terms of colour, flavour, stability, and aging behaviour hence the need for their quantification [306]. Most analytical methods used to qualitatively and quantitatively determine polyphenols are expensive, time consuming, and require several operation steps, costly reagents, and separation steps with large amounts of environmentally unfriendly effluents [304, 307].

Biosensors modified with laccase have been developed for detection of laccase electron donors (phenolic compounds) [116, 308] and monitoring oxygen and laccase inhibitors [24]. The construction of laccase-based biosensors is relatively simple as it doesn't require hydrogen peroxide as a co-substrate or any other co-factor for its catalytic activity [164, 309]. The biosensors are based on the principle of reduction of oxygen by laccase to water hence monitor the consumption of oxygen during oxidation of the analyte [43, 308]. The response time is dependent on the enzymatic reaction kinetics, the diffusion and solubility of the substrates at the electrode, and the electrochemical reduction of the oxidized mediator at the electrode surface [310].

Laccase-based biosensors have been fabricated for detection of various compounds including Catechol and its derivatives [164, 305, 311], guaiacol [302], hydroquinone [312], adrenaline [296], Methyldopa [313], Rutin (flavonoid) in pharmaceutical formulations [314], methomyl (insetcide) in vegetable extracts [109], azo-dye tartrazine [15], and industrial kraft lignin [315] as demonstrated in Table 1. For example, Jarosz-Wilkotazka et al. [308], immobilized C. unicolor laccase on the surface of graphite electrode by physical adsorption and the electrode was inserted into a flow-injection system to serve as a biosensor for detection of polyphenols including flavonoids. The biosensor was more sensitive to bulky highly polymerized polyphenolic structures. The laccase biosensors demonstrate great stability in reusability and storage over long periods. For example, laccase/Nafion biosensor demonstrated 92% activity after 98 days storage [1] and a carbon/laccase biosensor for catechol retained 100% after 90 days storage at room temperature and after 25 assays [316]. Chawla et al. [317], for detection of guaiacol, reported retained activity of 85% on a laccase/NiNPs/MWCNTs/PANI/Au biosensor in a space of 4 months and 80% after 300 assays over 7 months for laccase/CuNPs/CS/MWCNTs/PANI/Au biosensor [318]. Similarly, Cadorin-Fernandes et al. [109], reported 100% after 450 assays over 2 months for laccase/sol-gel/carbon ceramic electrode for detection of methomyl.

Table 1.

Application of laccase in fabrication of biosensors for detection of organic pollutants.

| Laccase source | Immobilization support | Electrode used | Analyte | Detection range (μM) | LOD (μM) | Response time (s) | Storage stability and reusability | Ref |

|---|---|---|---|---|---|---|---|---|

| A. oryzae | AuNPs/poly (allylamine hydrochloride) (PAH) | Carbon paste | Dopamine | 0.49–23.0 | 0.26 | [319] | ||

| - | AuNPs-MoS2 | Glassy carbon electrode (GCE) | Catechol | 2 to 2000 | 2 | 100 | 90% activity after 30 days, 97% after 10 cycles and RSD of 1.2% and 0.7% for 10 assays and 5 electrodes | [320] |

| A. oryzae | PEI-AuNPs | GCE | Catechol | 0.36–11.00 | 0.03 | 80% after 90 days and 150 assays | [302] | |

| Guaiacol | 0.79–17.42 | 0.03 | ||||||

| Pyrogallol | 1.74–19.60 | 0.14 | ||||||

| Hydroquinone | 2.90–22.00 | 0.21 | ||||||

| C. unicolor | poly (N-isopropylacrylamide) gel | Indium Tin Oxide (ITO) | Oxygen in solutions | Reduction signals of 0.79 V and 0.38 V at T1 and T2 respectively | [321] | |||

| T. Versicolor | poly (ethyleneimine) (PEI) microcapsules with p-phenylenediamine (PPD) mediator | GCE | Oxygen in solutions | 73% after 6 months of storage | [322] | |||

| T. versicolor | Fe3O4@Au nanoparticles | Catechol | 5.0–70.0 | 2 | 2400 | [199] | ||

| Au/Mxene NPs | GCE | Catechol | 0.05–0.15 | 0.05 | 10.98 | 89.6% after 15 days of storage and RSD of 2.21% for 9 assays | [323] | |

| T. versicolor | Bacterial cellulose-AuNPs | GCE | Hydroquinone | 0.03–0.1 | 0.00571 | 96% after 3 months storage, RSD of 2.65% for 3 electrodes and 3.17% for 3 assays | [324] | |

| R.vernicifera sp. | TiO2–CuC NFs | GCE | Hydroquinone | 1–89.8 | 3.65 | 5 | 107.8% after 1 week and 93.45% after 1 month. RSD of 2.69% and 1% for 3 biosensors and 9 assays respectively | [312] |

| T. versicolor | MnONPs-graphene nanoplates nanocomposite | Caffeic acid | 5–320 | 1.9 | 77.1% after 1 week, RSD of 3.97% and 1.84% for 10 biosensors and 3 assays | [325] | ||

| Cu/C NFs | GCE | Catechol | 9.95–9760 | 1.18 | 5 | 100% and 95.9% after 4 and 22 days, RSD of 4.35% for 3 assays | [326] | |

| T. versicolor | Nafion | DROPSENS cells screen printed electrodes | Catechol | 1.2–120 | 0.43 | 100 | 92% after 98 days, RSD 6.08% for 9 electrodes | [327] |

| Caffeic acid | 3–15 | 2.5 | ||||||

| Chlorogenic acid | 3–15 | 2.8 | ||||||

| Gallic acid | 2–7 | 1.55 | ||||||

| Rosmarinic acid | 3–15 | 2.4 | ||||||

| T. versicolor | Mg-MCM-41/PVA | Gold | Catechol | 0.94–10.23 | 0.00531 | 14 | 90% after 30 days, RSD 5.2% and 4.6% for 10 electrodes and 30 assays | [328] |

| T. versicolor | PANI/CMC/cellulose | GCE | Catechol | 0.497–2270 | 0.374 | 8 | 98% after 2 weeks, RSD of 2.23% and 3.03% for 5 assays and 5 electrodes | [329] |

| T. versicolor | PANI | Screen printed electrode (SPE) | Bisphenol A | 0.004–4 | 0.004 | 100 | [330] | |

| MWCNTs-Ag@ZnO nanocomposites | Carbon SPE | Bisphenol A | 0.5–2.99 | 0.6 | 25 | 71.02% after 10 days, RSD of 0.86% for 3 assays | [331] | |

| T. versicolor | Carbon black | Carbon SPE | Catechol | 2.5–50 | 2 | 0.5 | 100% after 90 days storage at roomtemperature, 100% after 25 assays | [316] |

| T. versicolor | MWCNTs | Carbon SPE | Bisphenol A | 0.84–12 | 0.84 | 87% after 1 month, RSD 5.3% for 3 electrodes | [185] | |

| Coriolus hirsuta | MWCNTs | Carbon SPE | Catechol | 0.0–0.102 | 5 | 100% after 20 days storage, 77% after 10 cycles | [332] | |

| T. versicolor | CS/silica-magnetic MWCNT | Carbon paste | Catechol | 0.1–165 | 0.034 | 50 | 90% after 45 days, RSD 3.01% for 35 assays over 29 days | [333] |

| T. versicolor | CS-MWCNTs nanocomposite | GCE | Catechol | 0.1–50 | 0.02 | 92% and 85% after 1 week and 1 month respectively. RSD 3.03% for 20 assays | [334] | |

| Ganoderma lucidium | NiNPs/cMWCNTs/PANI | Gold | Guaiacol | 0.1–500 | 0.05 | 8 | 85% after 200 cycles in a space of 120 days | [317] |

| T. versicolor | MWCNT-COOH/AuNPs-SDBS-PEDOT | GCE | Catechol | 0.1–0.5 | 0.11 | [335] | ||

| 11.99–94.11 | 12.26 | |||||||

| T. versicolor | MWCNTs | Carbon paste | Pirimicarb | 0.99–11.5 | 0.18 | 1200 | [194] | |

| P. ostreatus | SWCNT/C-quantum dots | GCE | 17a-ethynylestradiol | 0.05–7 | 0.004 | 96.8% after 10 cycles | [336] | |

| Reduced GO (rGO)- Sb2O5 | Estriol | 0.025–1.03 | 0.011 | 4 | 84% and 52% after 1 and 2 months storage. RSD of 2.84% and 4.37% for 10 assays and 5 electrodes | [337] | ||

| Magnetic graphene/PANI (PANI/MG) | GCE | Hydroquinone | 0.4–337.2 | 2.94 | 5 | 96.7% after 2 weeks storage. RSD of 4.3% and 1.95 for 3 electrodes and 20 assays | [338] | |

| T. versicolor | Graphene-Cellulose Microfiber | Carbon SPE | Catechol | 0.2–209.7 | 0.085 | 2 | 96.8% after 132 h. RSD 2.6% for 5 electrodes | [339] |

| R. vernicifera | AuNPs-graphene nanoplates | Carbon SPE | Hydroquinone | 4–130 | 1.5 | 100% after 5 days. RSD of 2% and 3% for 5 assays and electrodes respectively | [278] | |

| T. versicolor | ∗Mercury | 49.9–600 | 74.8 | [55] | ||||

| T. versicolor | rGO | GCE | Dopamine | 0.0–3 | 0.091 | 89.7% after 30 days storage, RSD 2.1% for 3 electrodes | [340] | |

| T. versicolor | N-doped carbon hollow spheres (NCHS)/CS composite film | GCE | Calcium lignosulfonate (lignin in kraft effluent) | 370–19000 | 120 | 95% after 1 week storage | [315] | |

| T. versicolor | polyazetidine prepolymer (PAP)/MWCNTs | SPE | Catechol | 0.64–20.73 | 0.18 | 10 | [341] | |

| T. versicolor | Nafion/MWCNTs | SPE | Catechol | 1.36–65.45 | 0.45 | 10 | [341] | |

| T. versicolor | MWCNTs | SPE | Catechol | 2.36–134.73 | 0.73 | 10 | [341] | |

| Agaricus bisporus | AuNPs | Gold disk electrode (GDE) | Dopamine | 0.5–13.0 | 0.029 | 100% after 1 week, RSD 2.7% and 3.2% for 7 assays and 5 electrodes | [101] | |

| 47.0–430.0 | ||||||||

| AuNPs | Carbon SPE | Tartrazine | 0.2–14 | 0.04 | 120 | 95.5% and 81.3% after 10 days and 1 month. RSD of 2.37% and 8.54% for 5 assays and electrodes respectively | [15] | |

| Montmorillonite | GCE | Catechol | 1–10 | 0.89 | 10 | RSD of 3.58% for 10 assays | [342] | |

| T. versicolor | 3,3′-Dithiodipropionic acid di (Nsuccinimidyl ester) (DTSP) | Gold | Hydroquinone | 3–15 | 0.89 | 50 | 96% and 93% after 50 cycles and 6 weeks storage. RSD of 3.1% for 5 electrodes | [343] |

| T. versicolor | (3-mercaptopropyl)-trimethoxysilane (MPTS) | Gold | Hydroquinone | 0.9–20 | 0.25 | 50 | 99% and 97% after 50 cycles and 6 weeks storage. RSD of 3.0% for 5 electrodes | [343] |

| T. versicolor | Gold | Hydroquinone | 3–15 | 0.91 | 50 | 89% and 87% after 50 cycles and 6 weeks storage. RSD of 2.6% for 5 electrodes | [343] | |

| T. versicolor | PANI | GCE | Catechol | 3.2–19.6 | 2.07 | [311] | ||

| T. versicolor | MWCNTs-silica spheres | SPE | Dopamine | 1.3–85.5 | 0.42 | 91% and 86% after 10 and 30 days storage. RSD of 4.7% for 5 assays | [344] | |

| T. versicolor | Titania NPs | Graphite | Catechol | 0.75–150 | 0.75 | 60 | 94% and 69% after 7 and 22 days. RSd of 7% for 6 assays | [164] |

| T. versicolor | polyazetidine prepolymer (PAP)-MWCNTs nanocomposite | SPE | Dopamine | 0.80–4.13 | 0.24 | 50% after 6 days | [310] | |

| Catechol | 0.07–2.28 | 0.02 | ||||||

| Gallic acid | 1.07–49.16 | 0.32 | ||||||

| Caffeic acid | 0.03–0.79 | 0.01 | ||||||

| T. hirsuta | polyazetidine prepolymer (PAP)-MWCNTs nanocomposite | SPE | Dopamine | 0.03–6.00 | 0.008 | 50% after 6 days | [310] | |

| Catechol | 0.01–0.95 | 0.003 | ||||||

| Gallic acid | 0.79–19.9 | 0.24 | ||||||

| Caffeic acid | 0.03–0.60 | 0.01 | ||||||

| T. versicolor | GCE | Gallic acid | 0.24–117.6 | 0.24 | 100 | 50% fater 5 days. RSD of 2.8% for 5 assays | [306] | |

| Caffeic acid | 0.0056–0.56 | 0.56 | ||||||

| Ganoderma sp. | CuNPs/CS/MWCNTs/PANI | Gold | Guaiacol | 1–500 | 0.156 | 4 | 80% after 300 assays over 7 months. RSD of 2.6% for 6 assays | [318] |

| T. versicolor | Mesoporous silica | GCE | Catechol | 2.0–100 | 2 | 120 | 100% after 50 days storage | [305] |

| T. versicolor | CS-MWCNTs film | Gold | Rosmarinic acid | 0.91–12.1 | 0.233 | 120 | 90% after 15 cycles. RSD of 5.62% for 10 assays | [345] |

| Caffeic acid | 0.735–10.5 | 0.151 | ||||||

| Chlorogenic acid | 0.793–6.71 | 0.161 | ||||||

| Gallic acid | 0.79–2.1 | 0.79 | ||||||

| Pycnoporus sanguineus | CuTAPc-Fe3O4 NPs | Sensor head with oxygen sensing membrane | Adrenaline | 0.2–0.9 | 0.01 | 30 | 85% after 1 month storage | [296] |

| 0.01–0.09 | ||||||||

| A. oryzae | Sol-gel | Carbon ceramic electrode (CCE) | Methomyl | 0.5–12.2 | 0.2 | 100% for 450 assays over 2 months. RSD of 5.7% and 4.3% for 10 assays and 5 electrodes | [109] | |

| A. oryzae | CS-tripolyphosphate microspheres | Carbon paste | Rutin | 0.6–3.92 | 0.0623 | 930 assays over 320 days | [314] | |

| 5.83–13.1 | 0.712 | RSD 3.1% for 9 assays | ||||||

| A. oryzae | Cellulose acetate | Carbon paste | Methyldopa | 34.8–370.3 | 5.5 | 90% after 60 days. RSD of 1.5% and 4.3% for 6 assays and 5 electrodes | [313] | |

| T. versicolor | Cu-ordered mesoporous carbon/CS | Gold | Catechol | 0.67–15.75 | 0.67 | 99% and 95% after 15 and 30 days storage. RSD 2.01% for 6 assays | [307] | |

| Ganoderma sp | Epoxy resin membrane | Platinum | Guaiacol | 0.5–50 | 0.3 | 30 | 60% after 200 assays in 10 months. RSD | [304] |

| Polyphenols in fruit juices | 0.81–1.92 | |||||||

| Polyphenols in alcoholic beverages | 1.9–3.0 | |||||||

| Rigidoporus lignosus | Hydrophilic matrix | GCE | Hydroquinone | 0–500 | 60 | 100% after 100 working days | [116] | |

| Catechol | 0–500 | |||||||

| Caffeic acid | 0–500 | |||||||

| Catechin | 0–100 | |||||||

| Quercetin | 0–100 | |||||||

| Guaiacol | 0–500 | |||||||

| Vanillic acid | 0–500 | |||||||

| Pyrogallol | 0–500 | |||||||

| Gallic acid (in olive oil mill waste water) | 0–500 | |||||||

| T. versicolor | Methylene blue-mesoporous silica | Gold | Catechol | 4–87.98 | 0.331 | 4 | [346] | |

| Ganoderma sp | AgNPs/MWCNTs/PANI | Gold | Phenolic content in tea, alcoholic beverages and pharmaceutical formulations | 0.1–500 | 0.1 | 6 | 80% after 200 assays in 4 months. RSD of 2.3% for 5 assays | [347] |

| γ-Proteobacterium JB | Nitrocellulose membrane | Catechol | 40–90 | 100% after 3 months | ||||

| Catechin | 40–60 | |||||||

| L-methyl DOPA | 30–70 | |||||||

| T. versicolor | Zn–Cr–ABTS | GCE | Dissolved oxygen | 0.06–4 | 0.06 | RSD 8% for 6 assays | [24] | |

| T. versicolor | Polytetrafluoroethylene membranes | Oxygen electrode | Guaiacol | 91.3–400 | 91.3 | 40% and 40% after 50 assays and 20 days | [160] | |

| 3-methyl2-benzothiazolinone hydrazone (MBTH) films | Catechol | 500–8000 | 330 | 600 | 98% after 2 months storage. RSD 5.3% for 8 electrodes | [348] | ||

| Denilite | Platinum | Hydroquinone | 0.2–35 | 0.05 | 2 | 80% after 60 days. RSD 3.1% for 7 assays | [349] | |

| Homogentisic acid | 1–50 | 0.3 | ||||||

| T. versicolor | PVP-CLECs | Gold | Phenols | 50–1000 | 120 | 40% after 30 cycles | [309] | |

| T. versicolor | PANI | Platinum | Phenol | 0.4–6 | 0.4 | 300 | [159] | |

| Catechol | 0.2–1 | 0.2 | ||||||

| L-DOPA | 2–20 | 2 | ||||||

| A. niger | PANI | Platinum | Phenol | 0.4–4 | 0.4 | 300 | [159] | |

| Catechol | 0.4–15 | |||||||

| L-DOPA | 0.4–6 | |||||||

| Agaricus bisporus | PANI | Platinum | Phenol | 1–10 | 1 | 300 | [159] | |

| Catechol | 0.4–1.6 | 0.4 | ||||||

| L-DOPA | 1–10 | 1 | ||||||

| T. versicolor | Graphite | Catechol | 1–10 | 0.23 | RSD 1% and 11% for 12 assays and 6 electrodes | [87] | ||

| R. vernicifera | Platinum | ABTS | 0.5–15 | 0.5 | 3 | 80% after 2 months | [86] | |

| p-phenylenediamine | 0.5–20 | 0.05 | ||||||

| T. hirsute | Nafion | GCE | Hydroquinone | 0.1–3 | 0.035 | 87 | 80% after 5 days | [350] |

| Denilite | Platinum | p-phenylenediamine | 0.14–29 | 0.045 | 2 | 80% after 2 months. RSD for 2.8% and 2.6% for 7 assays for PPD and PAP respectively | [46] | |

| p-aminophenol (PAP) | 0.12–22 | 0.04 | ||||||

| C. unicolor | Graphite | Caffeic acid | 1–10 | 0.56 | [308] | |||

| Prodelphinidin B3 | 1–10 | 0.43 | ||||||

| Epicatechin gallate | 1–10 | 0.54 | ||||||

| Catechin | 4–40 | 4.36 | ||||||

| Epicatechin | 2–60 | 2.44 | ||||||

| Denilite | GCE | PPD | 0.15–30 | 0.04 | 2 | 80% after 2 months | [351] | |

| Botryris cinerea | Gelatin | O2 sensing electrode | Hydroquinone | 0–8000 | 96% after 500 assays | [352] |

used UV-Vis spectroscopy using Caffeic acid as an electron donor.

In order to improve the biosensor characteristics such as minimize laccase leakage and improve laccase-electrode electron movement, a variety of materials have been co-immobilized with laccase on the electrode either by crosslinking or physical adsorption [164]. For example, Rawal et al. [353], covalently immobilized Ganoderma sp. laccase on a silver nanoparticles (AgNPs)/carboxylated multiwalled carbon nanotubes (cMWCNT)/polyaniline (PANI) layer modified gold (Au) electrode and used it as biosensor for detection of phenolic content in tea, alcoholic beverages, and pharmaceutical formulations. The biosensor gave a linear range, response time, and detection limit of 0.1–500 μM, 6 s, and 0.1 μM, respectively and retained 80% of its activity after 200 reuses for a period of over 4 months. The PANI provided a protective microenvironment that sheltered the enzyme from leakage and the external environment. Wu et al. [354], assembled laccase and ABTS on graphene surface and the bioconjugate was deposited on a GCE for detection of extracellular oxygen released from human erythrocytes. The GC/rGO/Lac biosensor was applied to the detection of dopamine in synthetic urine and plasmatic serum samples, achieving a detection limit of 91.0 nmol L−1 [340]. Jabbari et al. [355], covalently immobilized laccase on surface plasmon resonance (SPR) carboxymethyldextran chip to promote its activity towards syringaldazine while at the same time making it inert to ABTS. This showed that the specificity and activity of laccase can be enhanced towards a target metabolite. Applications of laccase in biosensors has been extensively reviewed elsewhere [356, 357, 358].

6. Immobilization of laccase

Despite the many advantages associated with using laccase in industrial settings, limitations such as enzyme instability in varying environmental conditions like pH, ionic strength and temperature, proteolysis, inactivation by inhibitors, and the difficulty to separate the enzyme from the reaction mixture limits its further use in industrial applications [215, 359, 360]. Moreover the high cost of continually discarding the enzyme with treated solutions may be particularly prohibitive [361]. For the potential use of laccase to be increased and its reuse and stability in harsh conditions to be achieved, immobilization is necessary [362, 363]. It is the key to optimizing the operational performance of laccase in industrial processes and especially in non-aqueous media [364]. Immobilized enzymes mimic their natural mode in living cells where they are mostly attached to organelle structures, membranes, and cellular cytoskeleton there by improving their stability [115, 365]. The extent of stabilization depends on the enzyme structure, the immobilization methods, and type of support [366].

Enzyme immobilization limits its freedom to undergo drastic conformational changes which equips it with characteristics such as resistance to thermal and pH changes, improved activity, prolonged half-life, greater variety of bioreactor designs, ease of separation from reaction medium, and reusability for longer periods of time hence reduced cost [367, 368, 369, 370]. For example, When Mukhopadhyay et al. [371], immobilized laccase from a psychrophilic bacteria on Cu2O nanoparticles (CuONPs), the enzyme retained high activity at 4 °C which is lower than its optimum temperature (10 °C). And when lipid functionalized single walled carbon nanotubes (SWNTs) were attached to the CuONPs, it retained activity in very low (4 °C) and high (80 °C) temperatures and great stability under repeated freeze-thaw cycles. Lloret et al. [208], encapsulated M. thermophilia laccase in a sol-gel matrix based on methyltrimethoxysilane and tetramethoxysilane and the enzyme demonstrated improved pH and thermal stability by 10–30%, increased tolerance to different inactivating agents such as acetone, methanol, zinc chloride, calcium chloride, and sodium nitride by 20–40% and preserved up to 80% activity after 10 cycles. Yinghui et al. [372], immobilized laccase on carboxylated crosslinked PVA particles activated by N-hydroxysuccinimide (NHS) in aqueous solution. The bioconjugate showed increased stability in extreme pH conditions where it retained 95% activity when incubated at pH 2 and 13 for 4 and 1 h respectively as compared to the free enzyme that had an optimum pH of 2.4.

The reuse and ease of separation of enzymes after immobilization allow use of enzymes in continuous bioreactor operations which is useful in the production of fine chemicals and bio-treatment of industrial and agricultural wastes [373, 374]. It also enables recycling and reuse of enzymatically treated effluents which drastically decreases water consumption and reduces pollution [111, 375]. The properties of the immobilized enzyme are determine by the properties of the support (such as hydrophobicity, surface charge, density of binding sites, and level of support activation) and the immobilization procedure while the operational efficiency of any immobilization system depends on the amount of enzyme retained by the system [359, 376, 377]. Also, the stability of an immobilized enzyme upon storage and repeated use determine its effectiveness in continuous processes [237]. It is evident that enzymes lose much of their initial activity after immobilization due to changes in diffusion rate, variations in the microenvironment, and non-biospecific interactions especially when binding takes place at the enzyme active site or its vicinity since maximal activity is associated with protein flexibility [241, 379]. For example, Gutiérrez-Sánchez et al. [380], observed that covalent immobilization of laccase on aminophenyl-modified carbon nanofibers/carbon nanotubes electrode via amide bonds with the aspartic/glutamic carboxylic acid residue close to the type 1 copper site provided unfavourable laccase orientation for DET.

A suitable support matrix with appropriate structural characteristics and an immobilization strategy that maximizes enzyme-matrix interactions for catalytic efficiency should be considered during immobilization for a stable and active biocatalyst [316, 381]. The enzyme-support interaction is significantly influenced by the properties of the enzyme and the support matrix [382]. There is no universal support matrix that can immobilize all kinds of enzymes and the choice of support and immobilization method depends on the specific features of the enzyme and the application it is devoted to [270, 383, 384]. The ideal support for immobilization is expected to be inert, stable, compatible with laccase, and resistant to microbial attack and mechanical force [313, 383, 385]. The morphology, composition, hydrophobicity, specific surface area and functional surface group of the support material determine the immobilization yield and immobilization efficiency of the biocatalyst which in turn affect its performance [256, 386]. For instance, hydrophilic membranes are preferred as immobilization supports for catalysis under isothermal conditions (because they provide a better microenvironment for enzymes) while hydrophobic membranes are preferred for non-isothermal conditions [190]. Also, the charge and charge density on the support surface are important as they can alter the enzyme activity upon immobilization due to electrostatic interaction [387]. Therefore for a successful immobilization, a suitable carrier and immobilization procedure that maximize the catalytic and non-catalytic needs of a biocatalyst have to be considered [379, 388, 389]. For a successful biocatalyst, enzyme loading, activity and stability, specific activity of the bound enzyme, and storage stability have to be maximized [390].

A good immobilization strategy should maximize the catalytic (stability, selectivity, and space time yield) and non-catalytic needs (separation, control, and down-streaming processing) for a given application [391]. This entails selecting a suitable carrier, considering the nature of the enzyme, and conditions of immobilization [392]. For example, Tastan et al. [160], compared immobilization of laccase on polytetrafluoroethylene (PTFE) membranes using entrapment to gelatin and covalent immobilization to the surface using carbodiimide coupling. For covalent immobilization, the functional groups were formed on the PTFE surface by radiofrequency (RF) plasma treatment followed by polymer grafting with polyacrylamide (pAAm) and polyacrylic acid (pAAc) polymers. It was observed that, although the membrane with entrapped enzyme displayed high activity, it had poor mechanical stability, narrow working pH range, and low storage life while the covalently bound membrane showed high stability and reusability. Qiu et al. [393], immobilized laccase on nanoporous gold via three approaches: physical adsorption, electrostatic attraction, and covalent coupling. Physical adsorption gave the best results because of the covalent linkage between the nanoscale gold surface and the amino groups of the residue amino acids of laccase. Adhami et al. [374], compared covalent immobilization of laccase from three different fungi, viz. Cerrena unicolor, Heterobasidion annosum and Trametes versicolor on DEAE-Granocel 500. C. unicolor laccase showed the best binding efficiency to the carrier, good enzyme activity, and thermal and storage stability. On the other hand, T. versicolor laccase immobilized on hexagonal mesoporous silica nanoparticles demonstrated higher activity across a broader pH range as compared to when it was immobilized on Kaolinite under the same conditions [166].

Immobilization sometimes leads to alteration of enzyme properties such as catalytic efficiency and optimum pH and temperature. The enzyme kinetic parameters are altered as well facilitated by changes in affinity of substrate to an enzyme due to steric hindrances, partitioning, and diffusion effects of the substrate and decreased protein flexibility [162, 197, 394]. For example, Lante et al. [395], adsorbed laccase on a spiral-wound asymmetric polyether-sulphone membrane, the optimum pH changed from 6.3 to 6.6 due to the presence of ionized groups on the support. The change in pH activity of the immobilized enzyme is due to electrostatic interactions especially for charged supports which lead to the unequal partitioning of H+ and OH− concentrations between the microenvironment of the immobilized enzyme and the bulk phase [107, 161, 390]. When Abdullah et al. [348], immobilized laccase on chitosan-nafion/sol-gel silicate MBTH and used it as a biosensor for catechol, guaniacol, o-cresol and m-cresol, the sensor was responsive only to catechol and the immobilized enzyme had no catalytic effect on the remaining substrates. The non-reactivity of immobilized laccase is attributed to the hydrophobic hybrid Nafion/sol-gel silicate film used for immobilization which restricts the interaction of the enzymes active site with certain phenolic compounds through steric hindrance and change in stability of the phenoxy radical produced.

However, immobilization may not offer any improvement on the enzyme properties. For example, when Abadulla et al. [104], immobilized T. hirsuta laccase on APTES silanized alumina pellets with GA cross-coupling, immobilization showed insignificant change in enzyme half-life, thermal stability and resistance against inhibitors. In some instances, the immobilization has shown to reduce the enzyme properties. For example, Zille et al. [375], immobilized Thapsia. villosa laccase on APTES silanized alumina spherical pellets with GA crosslinking and used it for decolourisation of industrial dye effluent. It was observed that decolourisation was predominantly due to physical adsorption of the dye on the immobilization support (79%) and not by the catalytic activity of laccase (4%) and the free enzyme demonstrated more stability than the immobilized enzyme. The high amounts of salts (especially sodium chloride) in dyeing effluents enhanced electrostatic coupling of the anionic dyes and the positively charged proteins thereby forming stable dye/enzyme aggregates for free laccase. However, the restricted enzyme structure limited accessibility for interaction of the enzyme with salts and anionic dyes.

Immobilization conditions such as pH, temperature, concentration of crosslinking agent, concentration of enzyme, and type of solvent also affect the activity of the biocatalyst [359]. Different solvents affect the substrate-enzyme interactions and conformational mobility and structure of catalyst [396]. For example, Addition of organic solvents (20% ethanol, acetone and acetonitrile) in laccase solution during laccase immobilization on SWCNTs registered 600%, 400%, and 350% increase in maximum reductive current, respectively, when the biocatalyst was used in mediatorless electro-reduction of oxygen [45]. It was observed that ethanol promoted laccase-SWCNTs contact leading to favourable enzyme orientation on SWNTs. An increase in enzyme concentration during immobilization offers increased bioconjugate activity up to a maximum beyond which increasing the enzyme concentration leads to decreased bioconjugate activity [397, 398]. This is because an increased enzyme concentration leads to increased enzyme loading up to a point beyond which high enzyme loadings produces intermolecular space hindrance of the immobilized enzyme which screens the active site of the enzyme and restrains the dispersion of the enzyme or damages the active sites [359, 399]. This was demonstrated by Fortes et al. [400], where beyond a given enzyme concentration, the enzymatic activity decreased with increases in enzyme concentration. This was attributed to support saturation due to excess enzyme in solution leading to steric hindrance and restrained dispersion of substrate and products. Figure 6 represents the various immobilization techniques and immobilization supports that have been explored for laccase enzyme.

Figure 6.

Various techniques and supports used for immobilization of laccase enzyme.

6.1. Immobilization techniques

There are five major techniques employed in immobilization of laccase namely, physical adsorption, entrapment, encapsulation, covalent bonding, and crosslinking (Figure 6). The techniques are classified as physical (entrapment, encapsulation and adsorption) and chemical (covalent and crosslinking). These methods vary in cost and ease of preparation, stability, catalytic efficiency, and physical properties of the resultant biocatalyst [401]. The different immobilization techniques with their advantages and disadvantages as well as the type and strength of interaction between enzyme and support for each technique have been summarized in Table 2.

Table 2.

Characteristics of the various immobilization techniques.

| Immobilization technique | Type of interaction | Strength of interaction | Advantages | Disadvantages |

|---|---|---|---|---|

| Entrapment | Ionic interactions, hydrophobic interactions, covalent bonds | weak/strong | No enzyme modification, ease of preparation, minimal loss of enzyme activity | Pose diffusion limitations to substrates and products, high enzyme leakage, difficult to implement at industrial level |

| Encapsulation | Ionic interactions, hydrophobic interactions | Weak | No enzyme modification, protection of the enzyme, minimal loss of enzyme activity, minimal enzyme leakage | Pose diffusion limitations to substrates and products, less concentration of enzyme |

| Adsorption | Epoxy groups hydrogen bonds, ionic interactions, hydrophobic interactions | Weak | No enzyme modification, simple and inexpensive reusability of the support, minimal diffusion limitations for substrates and products | May pose enzyme leakage, probable activity loss of enzyme, lower efficacy |

| Covalent binding | covalent bonds | strong | Strong and stable interactions, multipoint attachment, minimal enzyme leakage | Costly to prepare, may pose diffusion limitations for substrates and products, activity loss of enzymes, enzyme once denatured the support and enzyme are discarded |

| Cross-linking | covalent bonds | strong | No support needed, high strength of interactions | Poor stability, structural modification of enzyme by crosslinker leading to activity loss |

Immobilization with physical techniques involves relatively weak and reversible interactions with the support [365]. They offer less disturbance to the enzyme structure and retain enzyme properties to those in solution [19]. However, the weak interactions between the enzyme and support cause enzyme leaching which results in activity loss and contamination of the surrounding media [212]. And since there is no control over the parking density of the enzyme on the support, the activity of the biocatalyst can be reduced due to overcrowding of the enzyme [365].

6.1.1. Entrapment

Entrapment is the physical confinement of an enzyme in the micro-spaces of porous hollow fiber, spun fiber, insoluble gel matrix, and/or a reverse micelle without chemically binding to the support [402]. This approach allows preservation of the enzymes’ three-dimensional conformation and optimum operating parameters since there is no interaction between the enzyme active site and support upon immobilization [245]. It also offers practical convenience of simple regeneration by removal of deactivated enzyme reloading with fresh active catalyst [367]. It is the most preferred technique in industries because it is a mild process, easier to operate, and provides minimal structural changes to the enzyme hence retaining the enzyme activity [200, 403]. For instance, When Makas et al. [367], entrapped laccase in K-carrageenan based semi-interpenetrating polymer networks, the optimum pH and temperature remained unchanged and the enzyme displayed high stability of 82% activity after 42 days of storage and over 50% activity after 10 reuses.