Abstract

Comprehensive knowledge regarding Saccharomyces cerevisiae has accumulated over time, and today S. cerevisiae serves as a widley used biotechnological production organism as well as a eukaryotic model system. The high transformation efficiency, in addition to the availability of the complete yeast genome sequence, has facilitated genetic manipulation of this microorganism, and new approaches are constantly being taken to metabolicially engineer this organism in order to suit specific needs. In this paper, strategies and concepts for metabolic engineering are discussed and several examples based upon selected studies involving S. cerevisiae are reviewed. The many different studies of metabolic engineering using this organism illustrate all the categories of this multidisciplinary field: extension of substrate range, improvements of producitivity and yield, elimination of byproduct formation, improvement of process performance, improvements of cellular properties, and extension of product range including heterologous protein production.

Saccharomyces cerevisiae is the most thoroughly investigated eukaryotic microorganism, which aids our understanding of the biology of the eukaryotic cell and hence, ultimately, human biology. For several centuries, S. cerevisiae has been used in the production of food and alcoholic beverages, and today this organism is also used in a number of different processes within the pharmaceutical industry. S. cerevisiae is a very attractive organism to work with since it is nonpathogenic, and due to its long history of application in the production of consumable products such as ethanol and baker's yeast, it has been classified as a GRAS organism (generally regarded as safe). Also, the well-established fermentation and process technology for large-scale production with S. cerevisiae make this organism attractive for several biotechnological purposes, as illustrated in this review. Another important reason for the applicability of S. cerevisiae within the field of biotechnology is its susceptibility to genetic modifications by recombinant DNA technology, which has been even further facilitated by the availability of the complete genome sequence of S. cerevisiae, published in 1996 (35).

Strain improvement of baker's and brewer's yeasts has traditionally relied on random mutagenesis or classical breeding and genetic crossing of two strains followed by screening for mutants exhibiting enhanced properties of interest. Recent developments of sophisticated methods in the field of recombinant DNA technology has enabled us to manipulate a given pathway of interest and hence to improve the cell by a more directed approach. Thus, it is now possible to introduce specific genetic perturbations in terms of modifying the promoter strength of a given gene, to perform gene deletions, or to introduce whole new genes or pathways into the cell. Directed improvements of the cellular properties achieved from the interplay of theoretical analysis, relying on biochemical information, and the application of genetic engineering has been referred to as metabolic engineering (4, 130). This approach roughly consists of two important parts: (i) the analytical side of metabolic engineering, which deals with the analysis of the cells in order to identify the most promising target(s) for genetic manipulation, and (ii) genetic engineering of the cells, where the cell with the genetic modifications is constructed.

One way of grouping the different targets for metabolic engineering is as follows: extension of substrate range; improvements of productivity and yield; elimination of by-products; improvement of process performance; improvements of cellular properties; and extension of product range including heterologous protein production. In this paper, the above examples are used to demonstrate these categories of metabolic engineering of S. cerevisiae and to illustrate the major achievements obtained with this organism. Even though most of the examples in the literature on metabolic engineering of S. cerevisiae fall into one of these categories, there are other instructive examples of metabolic engineering of S. cerevisiae (and also some illustrative examples not involving S. cerevisiae). Some of these examples describing metabolite production are listed in Table 1, and we also refer to recent reviews (13, 130). Before we turn to a review of the work grouped in the different categories mentioned above, we will discuss some overall strategies and concepts of metabolic engineering.

TABLE 1.

Metabolite production by various microorganismsa

| Organism | Property or product | Achievements | Reference(s) |

|---|---|---|---|

| Aspergillus nidulans | Enhanced growth rate | Overproduction of glyceraldehyde-3-phosphate dehydrogenase increased the specific growth rate on both acetate and glucose in comparison with the parental strain | 41 |

| Chlostridium acetobutylicum | Acetone and butanol production | Overexpression of acetoacetate decarboxylase (adc) and phosphotransbutyrylase (ptb) by introducing a Bacillus subtilis/C. acetobutylicum shuttle vector into C. acetobutylicum by an improved electrotransformation protocol, which resulted in acetone and butanol formation | 88 |

| Corynebacterium | Amino acid biosynthesis | Isolation of amino acid biosynthetic genes that enables enhanced enzyme activities or removal of feedback regulation in order to improve the production strains | 54 |

| Escherichia coli | Ethanol production | Integration of pyruvate decarboxylase and alcohol dehydrogenase II from Zymomonas mobilis onto the chromosome of E. coli improved the stability of the genes over the plasmid-based system, and the ethanol yield was near the maximum theoretical yield on 10% glucose and 8% xylose | 48, 98 |

| Escherichia coli | 1,3-Propanediol production | Introduction of genes from the Klebsiella pneumoniae dha regulon into E. coli revealed 1,3-butanediol production | 145 |

| Penicillium chrysogenum | 7-ACA and 7-ADCA | Production 7-ACA and 7-ADCA from new fermentation processes was obtained by transformation of the expandase of Cephalosporin acremonium into P. chrysogenum | 19 |

| Saccharomyces cerevisiae | Lactic acid production | A muscle bovine lactate dehydrogenase gene (LDH-A) was expressed in S. cerevisiae, and lactic acid was produced in titers of 20 g/liter with productivities of 11 g/liter/h; due to the acid tolerance of S. cerevisiae this organism may serve as an alternative for substitution of bacteria for lactic acid production | 108 |

| Saccharomyces cerevisiae | Xylitol production | 95% xylitol conversion from xylose was obtained by transforming the XYL1 gene of Pichia stipitis encoding a xylose reductase into S. cerevisiae, making this organism an efficient host for the production of xylitol, which serves as an attractive sweetener in the food industry | 39 |

7-ACA, 7-aminocephalosporanic acid; 7-ADCA, 7-aminodeacetoxycephalosporanic acid.

STRATEGIES AND CONCEPTS OF METABOLIC ENGINEERING

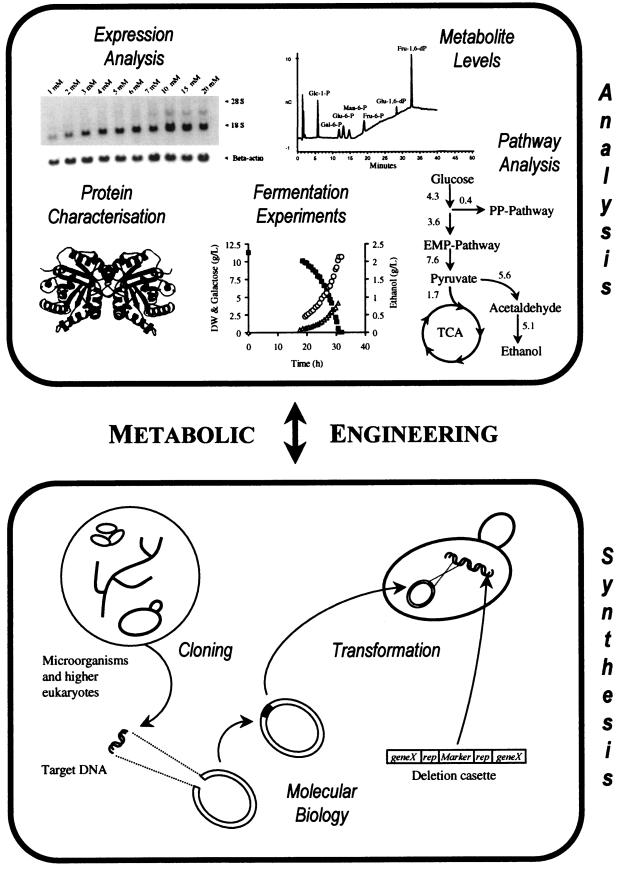

As mentioned in the Introduction, metabolic engineering involves a directed approach to the application of recombinant DNA technology for strain improvement, and it has been defined as follows (130): “The directed improvement of product formation or cellular properties through the modification of specific biochemical reaction(s) or the introduction of new one(s) with the use of recombinant DNA technology.” In this definition, the term “biochemical reaction(s)” should be interpreted in its broadest sense; i.e., signal transduction pathways are also included. What distinguishes metabolic engineering from classical applied molecular biology is the use of the directed approach. This implies that it is necessary to have solid knowledge of the system being used, and as mentioned in the Introduction, metabolic engineering therefore consists of two parts: careful analysis of the cellular system (the analysis part) and construction of the recombinant strain (the synthesis part). This is illustrated in Fig. 1. In some cases the synthesis part precedes the analysis part, e.g., if the substrate range needs to be extended through expression of a heterologous enzyme, but in all cases it is important that the analysis and the synthesis parts go hand in hand.

FIG. 1.

Various aspects of metabolic engineering, divided into an analytic part and a synthetic part. It is important to stress the integrated approach of metabolic engineering, where different disciplines of analysis support suitable targets for the synthetic part. Consequently, metabolic engineering is an iterative process that shifts between analysis and synthesis to keep improving the recombinant microorganism for a given purpose. The three-dimensional structure of triosephosphate isomerase of S. cerevisiae is shown to emphasize the rapid development within the field of protein engineering and protein characterization, which in some cases play an important role in metabolic engineering. The picture of triosephosphate isomerase was downloaded on 22 October 1999 from http://genome-www.stanford.edu/Sacch3D/images/7tim.html. TCA, tricarboxylic acid; EMP, Embden-Meyerhoff-Parnas.

This is well illustrated in attempts to extend the substrate range. Here the first step is clearly to introduce heterologous genes that enable metabolism of the substrate of interest, and for this purpose it is relevant to consider two different strategies: (i) introduction of a gene encoding a membrane-bound protein that transports the given substrate into the cell in addition to a gene encoding a protein responsible for cleavage of the substrate if necessary; and (ii) introduction of a gene encoding a protein that is secreted into the extracellular medium, whereby the substrate of interest is converted or cleaved into substrates that may be directly assimilated by the host organism. Independent of which strategy is chosen, it is important to ensure that the heterologous gene(s) is sufficiently expressed in the new host system. This may involve consideration of possible posttranslational modifications that may diminish or eliminate the activity of the desired enzyme, and this requires careful analysis of the recombinant strain. Once a recombinant organism that may use the substrate has been constructed, it often exhibits low uptake rates and low overall yields of product on the relevant substrate. To identify the underlying problem and direct the next synthesis step, it is necessary to perform a detailed analysis of the cell physiology. This is clearly illustrated in the attempt to convert xylose to ethanol by anaerobic fermentation of S. cerevisiae (reviewed in detail below). Thus, metabolic engineering will almost always involve a close interaction between the synthesis and analysis parts, and often several rounds of strain construction are needed before an optimal recombinant strain is obtained.

In metabolic engineering of S. cerevisiae, the synthesis part is relatively straightforward—at least if the genes to be expressed are available—and it is often the analysis part that is limiting. This is due to the complexity of the cellular metabolism, i.e., the metabolite levels may interact with gene expression and, conversely, gene expression might determine the metabolite levels via the enzyme concentrations. Furthermore, in many cases multiple modifications are required, and for each modification there may be unexpected changes in the cellular metabolism. The analysis part has classically been referred to as physiology; in recent years a number of very powerful techniques have been developed that enable a far more in-depth analysis of the cellular physiology. These include DNA array technology for transcriptome analysis (simultaneous quantification of all gene transcripts in a cell), two-dimensional gel electrophoresis for proteome analysis (simultaneous quantification of a large number of proteins in a cell), gas chromatography-mass spectrometry (GC-MS), and liquid chromatography-mass spectrometry (LC-MS) methods for metabolome analysis (analysis of the intracellular metabolite levels), 13C-labelling experiments for metabolic network analysis, advanced fermentation experiments with on-line monitoring of important cultivation variables, and bioinformatics (including mathematical models for analysis of pathway structures and control of pathway fluxes). In the following section, we will briefly discuss the role of some of these techniques in the analysis part of metabolic engineering.

Transcriptome and Proteome Analysis

The application of DNA arrays to transcriptome analysis is still a new technique, and there are presently no examples of how this technique has been used in the field of metabolic engineering. However, since many challenges in metabolic engineering involve multiple genetic changes, transcriptome analysis will be very important for metabolic engineering in the future, since this approach enables a study of the expression pattern of many genes. Furthermore, it is often found that a single mutation (disruption or overexpression of a certain gene) results in a completely different expression pattern, and DNA array technology will therefore be a very powerful technique for analysis of the consequences of the individual genetic changes.

As well as transcriptome analysis, proteome analysis is important in metabolic engineering. Often the pathway activity is directly correlated with the protein concentration, and when gene expression and/or protein-protein interactions are subjugated to metabolic regulation, it is important to quantify the protein levels in the different recombinant strains constructed. Clearly, a detailed proteome analysis may be valuable, but often it is sufficient to measure the levels of the proteins involved in the pathway studied and perhaps some of the regulatory proteins affecting the expression of the relevant genes.

Pathway Analysis

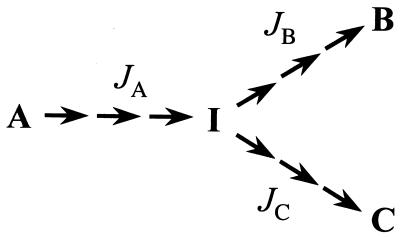

“Pathway analysis” is often used to describe the application of metabolic flux analysis (MFA) and metabolic control analysis. Pathway analysis has proven successful as a guiding tool for the analytical part of metabolic engineering (130). MFA is a “global” cellular approach, where the complete network of intracellular reactions is considered and the fluxes, through the individual branches of the network, are quantified. The metabolic fluxes can be estimated from metabolite balances and measurements of a few fluxes, but introduction of 13C-labelled substrates followed by measurement of the labelling distribution in intracellular metabolites are often used today, which serves as a far more powerful tool for quantification of the fluxes. In this case nuclear magnetic resonance spectroscopy or GC-MS (82, 83, 120) can be used to measure the labelling pattern of the precursor metabolites. The application of labelled substrates allows for flux determination of reversible reactions and for quantification of flux ratios between biosynthetic pathways leading to the same metabolite. Comparison of flux distributions obtained under different physiological conditions may provide valuable knowledge about the interactions between different pathways or may help to identify potential biochemical reactions not previously discovered in a certain microorganism (16). Thus, MFA may be used to choose an appropriate strategy for metabolic engineering, but it may also be used as a tool for physiological characterization of a strain which has been manipulated to introduce a new or altered property to the cell. One area where MFA is especially interesting is in the improvement of yield and productivity. This is illustrated by Fig. 2, which depicts a very simple pathway where substrate A is converted to product B with the formation of by-product C. Substrate A could be glucose, product B could be ethanol, and by-product C could be glycerol. The overall yield of product on the substrate is given by the ratio of the fluxes JB and JA, whereas the productivity is given by the flux JB. The intermediate I cannot accumulate within the cell, and the flux into this metabolite will therefore equal the flux out of this metabolite pool. The fluxes are therefore constrained, i.e., JA = JB + JC, and one can therefore calculate one of the fluxes if the two others are measured. This is the concept of metabolite balancing mentioned above. A clear strategy to improve the overall yield is to reduce or eliminate the flux JC and hence direct more carbon toward the product. However, the formation of C often plays an important role in the overall cellular metabolism, and elimination of JC by a specific gene deletion will therefore be lethal to the cell or lead to auxotrophy. In some cases the fluxes may be determined by additional constraints, e.g., if cofactors like NAD(P)H are involved in the different branches. Modulation of the flux distribution around the branch point metabolite I therefore normally requires analysis of the complete metabolic network, and here the concept of MFA is very important. MFA is generally most useful in cases where a relatively large fraction of the carbon is directed toward the product, i.e., in the production of primary metabolites. Nevertheless, the concepts of MFA may also contribute to an understanding of how the production of secondary metabolites or heterologous proteins is related to the central carbon metabolism through the drain of precursor metabolites (43, 61, 103).

FIG. 2.

Simplified metabolic network illustrating the fluxes JA, JB, and JC around intermediate I, which is a precursor of metabolite B and C.

MFA also plays an important role in metabolic branch point classification. Through analysis of different mutants, it is possible to obtain information about the regulation of the different fluxes, i.e., whether a given pathway branch point is flexible or rigid (129). For a rigid branch point, the enzymes around the branch point metabolite I in Fig. 2 may be tightly regulated by allosteric regulation. Thus, enhancement of the enzyme activity of one of the enzymes in the cascade of reactions from intermediate I to the product B may not result in an increase in the flux JB, and consequently the overall yield is not increased.

This points to another important aspect of pathway analysis, namely, the identification of which enzyme(s) exerts flux control in a given metabolic pathway. Actually, the question of where to target the genome to obtain an increase of flux through a given pathway is related to all of the categories of metabolic engineering mentioned in the Introduction, as illustrated in many examples in this review. The analysis of flux control is an examination on a “local” cellular basis often involving only a single metabolic pathway, in contrast to MFA, where the whole cellular metabolism is considered. The study of flux control examines the effects of perturbations in the enzymatic activities on the systemic metabolic behavior in order to identify the best enzymatic target(s) for genetic manipulation. It is of interest to overexpress the specific gene(s) encoding the enzyme(s) that exerts the greatest control over flux through a pathway, since overexpression of a whole pathway may be very laborious and is often not possible because overexpression of several genes may have some negative metabolic consequences to the cell. One may impose a protein burden on the cell by doing so, and this may affect the maximum specific growth rate or another important design parameter, making the overall process nonbeneficial. For examination of flux control over a given metabolic pathway, the framework of metabolic control analysis as defined by Kacser and Burns (62) and Heinrich and Rapoport (42) may serve as a useful tool (see reference 130 for examples). For determination of the so-called flux control coefficients, which designate the relative increase in flux due to a relative increase in enzymatic activity of the individual enzymes, a variety of methods exist. The flux control coefficients may be determined either directly or via the use of a kinetic model describing the dynamics of the enzymatic behavior with respect to substrates, inhibitors, and activators of the individual enzyme (130). Furthermore, to be successful when performing pathway analysis of a specific metabolic route, it is also important to notice whether any of the intermediates may take part in specific metabolic mechanisms that are toxic to the cell under certain conditions. Additionally, it is important to know whether a given pathway intermediate is involved in a signal transduction pathway that regulates the flux through the metabolic route of interest either by specific protein-protein interactions or by influence at the transcriptional level. Hence, information about the intracellular metabolite levels is an important input parameter for metabolic engineering in order to elucidate certain aspects of cellular metabolism. A fast sampling technique for in vivo measurements in combination with thorough kinetic modelling is a valuable approach to pathway analysis in order to improve the understanding of the dynamics between extracellular metabolites, glycolytic intermediates, and cometabolites of the glucose metabolism in S. cerevisiae (113, 142).

Advanced Fermentation Experiments

Even though the above-mentioned techniques are extremely powerful for analysis of cellular physiology, it is important to ensure that the environmental conditions of the cells are very reproducible. This can be achieved through the use of advanced bioreactor systems, where the important cultivation variables are monitored on-line. With these bioreactor systems, it is possible to study the influence of a single medium component on cellular function while keeping all other factors constant. By changing the feed rate of medium to a continuous bioreactor system, it is possible to change the dilution rate, which equals the specific growth rate under steady-state conditions. Furthermore, these systems allow us to study cellular behavior under very well controlled dynamic conditions, e.g., when the cells are suddenly exposed to a high glucose concentration or via a step change in dilution rate and hence a dynamic change in the specific growth rate.

Taking the above considerations together, it is obvious that successful performance of metabolic engineering is a multidisciplinary field that requires inputs from several specialists. Clearly, geneticists and molecular biologists are the drivers in implementing the appropriate genetic modifications, but analytical chemists, biochemists, and biochemical engineers also play important roles in the analysis part of metabolic engineering. Thus, to support the analytical side of metabolic engineering, which includes the theoretical tools mentioned above, analytical chemistry contributes methods necessary for quantifying the extra- and intracellular metabolite levels and biochemistry provides valuable information about pathway regulation and enzyme kinetics. Additionally, biochemical engineering is needed to integrate the information obtained by the different analytical techniques and, based on this, to define appropriate strategies for manipulation of the cell.

EXTENSION OF SUBSTRATE RANGE: STARCH, LACTOSE, MELIBIOSE, AND XYLOSE CONSUMPTION

The extension of the substrate range of S. cerevisiae serves as an important option in utilization of new raw materials, e.g., agricultural waste products, for large-scale production of several biotechnological products as well as in decreasing the biological content in the waste stream of an industrial process. Many examples of substrate range extension are described in the literature, and some of these fall into more than a single category of metabolic engineering as defined in the Introduction, since redirection of the flux to obtain an improved yield of a given product, e.g., ethanol, becomes important immediately after the substrate range has been extended to include the desired substrate. The utilization of starch, lactose, melibiose, and xylose is reviewed in the following sections, and selected examples from these sections, in addition to examples describing the utilization of malate and β-glucans, are summarized in Table 2.

TABLE 2.

Examples illustrating an extension of the substrate range in S. cerevisiae

| Substrate extension | Comments | Reference(s) |

|---|---|---|

| β-Glucans | An extended substrate range was obtained by introduction of a β-glucanase gene of Trichoderma reesei into brewer's yeast. The recombinant strain was able to utilize β-glucans, which resulted in improved filterability. | 105 |

| Lactose | The genes encoding lactose permease and β-galactosidase of Kluyveromyces marxianus were introduced into S. cerevisiae. The recombinant strain efficiently converted lactose into ethanol when fermented in a continuous bioreactor setup. | 24, 25 |

| Lactose | A thermostable β-galactosidase encoded by lacA from Aspergillus niger was expressed from an ADH1 promoter in S. cerevisiae. Of the total β-galactosidase activity, 40% was secreted to the extracellular medium, and the recombinant strain grew on whey permeate with a specific growth rate of 0.43 h−1. | 75 |

| Malate | Malate degradation is essential for deacidification of grapes when producing wine. Due to the lack of malate permease and the low malate affinity of the malic enzyme of S. cerevisiae, this organism was metabolically engineered for efficient malate utilization. The Schizosaccharomyces pombe malate permease (MAE1) and the gene encoding malic enzyme of S. pombe (MAE2) or malic enzyme of Lactococcus lactis (mleS) were expressed in S. cerevisiae, and malate degradation was successfully achieved. | 154 |

| Melibiose | Melibiase-producing baker's yeast strains were successfully constructed by introduction of the MEL1 gene into S. cerevisiae by genetic engineering or by classical breeding and mating. To overcome glucose repression exerted on the galactose metabolism, partial glucose derepressed strains were constructed. | 102, 117, 153 |

| Starch and dextrins | Starch assimilation of 99% was achieved by coexpression of the STA2 gene of Saccharomyces diastaticus, the AMY1 gene of Bacillus amyloliquefaciens, and the pulA gene of Klebsiella pneumoniae encoding a glucoamylase, an α-amylase, and a pullulanase, respectively. | 50 |

| Starch and dextrins | Improvements of baker's and brewer's yeasts were obtained by expressing the α-amylase (AMY1) and the glucoamylase (GAM1) genes of the yeast Schwanniomyces occidentalis in S. cerevisiae. | 46 |

| Xylose | The XYL1 gene and the XYL2 gene of Pichia stipitis encoding a xylose reductase and a xylitol dehydrogenase, respectively, were transformed into S. cerevisiae. When the XKS1 gene encoding the S. cerevisiae xylulokinase was overexpressed in this transformant strain, xylose was successfully utilized and converted into ethanol, with an overall yield of 63% of the maximum theoretical yield. | 45 |

Starch Utilization

Starch is the storage carbohydrate in plants, and it serves as an important energy and carbon source in biotechnological processes. Starch is made up of long chains of glucose units joined by α-1,4 linkages and joined at branch points by α-1,6 linkages. Many microorganisms, including S. cerevisiae, are not able to degrade starch since they do not produce starch-decomposing enzymes such as α-amylase (which cleaves α-1,4-glycosidic bonds), β-amylase (which cleaves maltose units from the nonreducing end of starch), pullulanase or isoamylase (debranching enzymes that hydrolyze α-1,6-glycosidic bonds), and glucoamylase (which hydrolyzes glucose units from the nonreducing end of starch). Hence, it is necessary either to add starch-decomposing enzymes to the starch before fermentation or to use a recombinant strain that produces starch-decomposing enzymes in order to utilize this carbon source. In the baking industry, it is advantageous to use a certain recombinant strain that does not require α-amylase-enriched flour. For production of low-calorie beer in the brewing industry, it is of interest to use a recombinant strain of S. cerevisiae that secretes a glucoamylase whereby the larger oligomers (dextrins), which are formed from the partial hydrolysis of barley starch, are decomposed. Expression of a glucoamylase gene from Aspergillus awamori and secretion of the heterologous protein from S. cerevisiae were successfully demonstrated, but the transformed strain grew on dextrins at a lower rate than observed when glucoamylase was added externally to the medium (49). Coexpression of the STA2 gene of Saccharomyces diastaticus encoding a glucoamylase and an AMY1 gene encoding an α-amylase of Bacillus amyloliquefaciens was demonstrated to synergistically enhance starch degradation (131). When the pulA gene of Klebsiella pneumoniae, encoding a pullulanase, was introduced into this transformant strain containing the STA2 gene and the AMY1 gene and secreted using the yeast mating pheromone α-factor, an even higher starch hydrolysis rate was obtained compared with the parental strain and almost complete assimilation (99%) of starch was achieved (50). This illustrates that it may be necessary to introduce several different starch-degrading enzymes in order to obtain an efficient starch utilization. Hollenberg and Strasser (46) also succeeded in constructing a S. cerevisiae strain that is able to hydrolyze starch by introduction of both the GAM1 gene and the AMY1 gene, which encode a glucoamylase and an α-amylase, respectively, both originating from the yeast Schwanniomyces occidentalis. The transformed strain of S. cerevisiae showed an ethanol productivity equal to that observed when a conventional strain was used together with decomposing enzymes added prior to the fermentation.

Lactose Utilization

Lactose is abundant in milk and is a major constituent of cheese whey, which is a by-product of cheese production. Only half of the cheese whey production is used for different purposes, including production of biogas, ethanol, and single-cell protein, whereas the other half is discarded as effluent (125). Thus, cheese whey causes a major environmental problem due to its high biological oxygen demand and the high chemical oxygen demand, primarily as a result of its high lactose content (84). S. cerevisiae does not have a lactose permease system, and hence lactose cannot be transported across the cell membrane; it also does not encode a β-galactosidase that cleaves the β-1,4-bond of lactose into a glucose residue and a galactose residue. Since S. cerevisiae is a good choice for ethanol production (see “Xylose utilization” below), it may be advantageous to introduce heterologous genes that enable S. cerevisiae to utilize lactose. For this reason, the genes that code for lactose permease and β-galactosidase of Kluyveromyces lactis were introduced into S. cerevisiae (53, 128) and protoplast fusions resulting in hybrids of K. lactis and S. cerevisiae were also employed (28). Unfortunately, these attempts resulted in low specific growth rates on lactose, genetic instability, and low ethanol yields when fermented in an immobilized yeast membrane bioreactor (53). Recently a flocculating S. cerevisiae strain containing genes encoding the lactose permease and the β-galactosidase of Kluyveromyces marxianus was constructed (25). An improved flocculation capacity and strain stability, as well as complete lactose consumption resulting in an ethanol yield of 80% of the theoretical value, were obtained when this strain was fermented in a continuous bioreactor setup (24). Hence, the possibility is presented of ethanol production from whey, which also contributes to solving the environmental problem referred to above. Another strategy to metabolically engineer S. cerevisiae in order to enable it to utilize whey has been successfully demonstrated by introduction of an extracellular β-galactosidase (75). A thermostable β-galactosidase gene of Aspergillus niger (lacA) was expressed from an ADH1 promoter in S. cerevisiae, and 40% of the recombinant protein was secreted to the extracellular medium, whereby the cells grew with a specific growth rate of 0.43 h−1 (equal to a doubling time of 1.6 h) on whey permeate containing 4% (wt/vol) lactose.

Melibiose Utilization

Molasses, which is used for ethanol and baker's yeast production, contains mainly glucose, fructose, and sucrose, but the trisaccharide raffinose is also present to some extent (118). Invertase, encoded by the SUC2 gene, decomposes raffinose into fructose and the disaccharide melibiose, which also contains a glucose residue and galactose residue similar to lactose, but the glucose and galactose moieties of melibiose are linked by an α-1,6-bond. Only a few strains of S. cerevisiae are able to assimilate melibiose, and many strains are not able to cleave the α-1,6-linkage of melibiose since they are missing one of the MEL1 to MEL11 genes, all encoding melibiase (α-galactosidase), which is secreted to the medium outside the cell (93). Baker's yeast strains able to utilize melibiose by expressing the MEL1 gene have been constructed by genetic engineering and classical breeding (117, 153; S. Ostergaard, C. Roca, B. Rønnow, J. Nielsen, and L. Olsson, submitted for publication). Thus, industrial use of these strains makes it possible to reduce the biological oxygen demand of an industrial waste stream and improve the overall yield of either biomass or ethanol produced from molasses. Since both glucose and galactose are formed from hydrolysis of melibiose, melibiase-producing strains partly relieved of glucose control over galactose metabolism were constructed (102, 117). When these strains were examined in aerobic batch cultivations, the melibiose hydrolysis rate was in the range of 0.9 to 6.8 g/g (dry weight)/h, which qualitatively correlated with the respective number of copies of the MEL1 gene within the different strains (102). Furthermore, a low melibiose hydrolysis rate resulted in a high biomass yield, and a high ethanol yield was observed for the strain exhibiting the highest melibiose hydrolysis, which was a result of respirofermentative metabolism, i.e., the Crabtree effect. This demonstrated the importance of an integrated approach to metabolic engineering of S. cerevisiae for melibiose utilization, where melibiase activity was introduced and glucose repression was alleviated. If only substrate extension was considered important, consumption of the galactose residue resulting from melibiose hydrolysis would be delayed as a result of glucose repression exerted on the galactose metabolism (56, 77).

Xylose Utilization

d-Xylose is the second most abundant sugar in nature (after d-glucose) and is present in plant material as part of the heterogeneous polymer hemicellulose, which is one of the main constituents of the low-cost carbohydrate lignocellulose. Lignocellulose is renewable, and due to its abundance in nature in some areas of the world, this carbohydrate is potentially attractive for production of value-added products. Production of ethanol to be used as a liquid fuel is a well-described example of this (5, 7, 37, 51, 76, 100). This is an attractive application from an environmental point of view, since no net carbon dioxide is released from combustion of this carbon source (38, 81). To design an economically viable process, the ethanol yield should be close to the maximum theoretical yield (0.51 g of ethanol per g of xylose or glucose). To maximize the ethanol yield, the production organism should be capable of utilizing all pentoses and hexoses present in the lignocellulose, and, furthermore, it is important that the production organism has a high inhibitor tolerance, since the lignocellulose hydrolysates contain inhibitory substances. Dependent on the nature of the inhibitors, the toxicity may be removed by the use of a variety of detoxification methods, but doing so will greatly increase the cost of operation (11, 29, 31, 114, 151, 163). Furthermore, for ethanol production, a high product concentration diminishes the cost involved in ethanol recovery, which means that a high ethanol tolerance is preferred. Among yeasts and bacteria, S. cerevisiae fulfils the above criteria the best and has the ability to produce high ethanol concentrations rapidly but with the disadvantage of not being able to utilize xylose. Expansion of the substrate spectrum to enable xylose consumption by S. cerevisiae seems to be a good approach in the development of a process for large-scale ethanol production from hemicellulose.

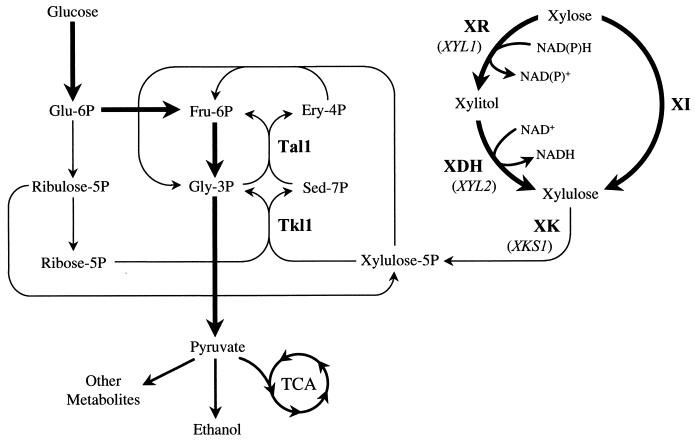

Two tasks are prerequisites for the synthesis of a S. cerevisiae strain that efficiently converts xylose to ethanol: (i) expression of heterologous genes should enable S. cerevisiae to convert xylose to xylulose; and (ii) consumption of xylulose should be improved since S. cerevisiae grows on xylulose with a maximum specific growth rate 10 times lower than that on glucose (123). Xylulose enters the pentose phosphate (PP) pathway after phosphorylation by xylulokinase (XK), encoded by the XKS1 gene, which is naturally present in S. cerevisiae, and consequently a high capacity of the PP pathway is required. A number of steps may contribute to control xylose consumption: the uptake of xylose, the conversion of xylose to xylulose, the phosphorylation of xylulose to xylulose-5-phosphate, and the conversion of xylulose-5-phosphate through the PP pathway followed by subsequent conversion to ethanol from pyruvate after glycolysis (Fig. 3).

FIG. 3.

Overview of metabolic pathways for glucose and xylose metabolism. The Embden-Meyerhof-Parnas pathway and the xylose utilization pathway are illustrated by thick lines. The PP pathway is indicated by thin lines. Abbreviations: TCA, tricarboxylic acid cycle; Tkl1, transketolase; Tal1, transaldolase; Glu-6P, glucose-6-phosphate; Fru-6P, fructose-6-phosphate; Gly-3P, glyceraldehyde-3-phosphate; Ery-4P, erythrose-4-phosphate; Sed-7P; sedoheptulose-7-phosphate. Genes are depicted in parentheses.

The major strategy used in an attempt to metabolically engineer S. cerevisiae for xylose consumption involved the introduction of XYL1 and XYL2 originating from yeasts able to utilize xylose, e.g., Candida shehatae, Pachysolen tannophilus, and Pichia stipitis (36, 51). The XYL1 gene encoding xylose reductase (XR) reduces xylose to xylitol with the consumption of NAD(P)H. Further conversion of xylitol to xylulose at the expense of NAD+ is obtained by the gene product of the XYL2 gene, xylitol dehydrogenase (XDH) (Fig. 3).

The strategy of introducing XYL1 and XYL2 from P. stipitis into S. cerevisiae has not proven successful for ethanol production due to limited growth on xylose and the excretion of xylitol (73, 86, 137, 138, 155). Under aerobic growth conditions, xylose is converted mainly to biomass but a small amount of xylitol is also produced (155). As the yeast is grown under more pronounced oxygen-limited conditions, growth is slower, ethanol production is lower, and increasing xylitol production is observed (137, 138, 155). This could be a result of a redox imbalance of the NAD+/NADH ratio. Accumulation of NADH, and thereby xylitol excretion, may occur since NADH cannot be reoxidized sufficiently to NAD+ under oxygen-limited conditions, since XR of P. stipitis preferably uses NADPH for the conversion of xylose to xylitol (87, 152).

Another explanation for the xylitol formation has been ascribed to the thermodynamic equilibrium of the XR and the XDH reactions that favor xylitol formation, since the equilibrium constants have been estimated to be 6 × 109 M−1 and 7 × 10−11 M for the XR reaction and the XDH reaction, respectively (111, 112). Metabolically engineered S. cerevisiae strains with an altered XR/XDH ratio in favor of enhanced XDH activity were able to eliminate xylitol formation, but only a slightly higher ethanol concentration was achieved (157).

The low rate of xylose consumption by recombinant S. cerevisiae has also been suggested to implicate limitations of the PP pathway (18, 124). The transketolase (Tkl1) catalyzing the formation of sedoheptulose-7-phosphate and glyceraldehyde-3-phosphate from xylulose-5-phosphate and ribose-5-phosphate (Fig. 3), do not control the flux through the PP pathway, since xylose consumption was not improved by enhancing the expression of the TKL1 gene in a strain harboring the XYL1 and XYL2 genes (155). The same study showed that overexpression of the TAL1 gene, encoding transaldolase, which converts the products of the transketolase reactions to erythrose-4-phosphate and fructose-6-phosphate, resulted in a considerably enhanced growth on xylose. The biomass yield on xylose was improved, and xylitol production was increased, but no more ethanol was produced by the TAL1 overexpression compared with that produced by the XYL1/XYL2 strain.

The most promising results for ethanol production from xylose by S. cerevisiae were reported recently (45). Expression of the XYL1 and XYL2 genes from P. stipitis, in addition to overexpression of the XKS1 gene of S. cerevisiae, was shown to give an ethanol yield of 0.32 g of ethanol per g of xylose and a xylitol yield of 0.10 g of xylitol per g of xylose. Hence, XK, phosphorylating xylulose, seems to exert a considerable control over flux through this biochemical route. Although a relatively high ethanol yield has been obtained, further research should pursue the maximum theoretical yield of 0.51 g of ethanol per g of xylose.

Endowing S. cerevisiae with this expanded substrate range has also been attempted by introducing a bacterial xylose isomerase (XI), which converts xylose into xylulose (2, 91, 119, 156) (Fig. 3). Only the gene product of the xylA gene of Thermus thermolyticus, encoding XI, was shown to be active in S. cerevisiae, but with an optimum activity at 85°C (156). Unfortunately, a yield of 0.13 g of ethanol per g of xylose, far from the maximum theoretical yield of 0.51 g/g, was obtained, and xylitol formation was not avoided (0.38 g of xylitol per g of xylose) due to the presence of an unspecific NADPH-dependent aldo-keto reductase in S. cerevisiae (74). Deletion of the gene encoding this aldo-keto reductase and mutagenesis of the xylA gene to lower the temperature optimum of the XI may serve as potential strategies for increasing the ethanol yield from xylose. Nonetheless, metabolic engineering has proven successful in endowing S. cerevisiae with the ability to consume xylose and to direct the resulting carbon flux to ethanol production.

IMPROVEMENTS OF PRODUCTIVITY AND YIELD, AND ELIMINATION OF BY-PRODUCTS IN BREWERS', DISTILLERS', AND WINE YEASTS

Traditionally, S. cerevisiae has been used in beer, wine, and bread production, and the yeast has been designated baker's, brewer's, distiller's, or wine yeast dependent on the use of the specific strain. Distiller's yeast is applied in large-scale ethanol production where the overall yield obtained by the individual strain constitutes the most important parameter in obtaining a profitable process. This does not account for brewer's yeast strains used for beer production, where a balanced flavor giving the desired taste is of utmost importance. Improved strains of both brewer's and distiller's yeasts have traditionally been obtained by classical breeding and mating and by screening for high-yield strains, but with the genetic engineering tools available today, it is possible to perform directed genetic changes to improve the production strains of brewer's and distiller's yeasts.

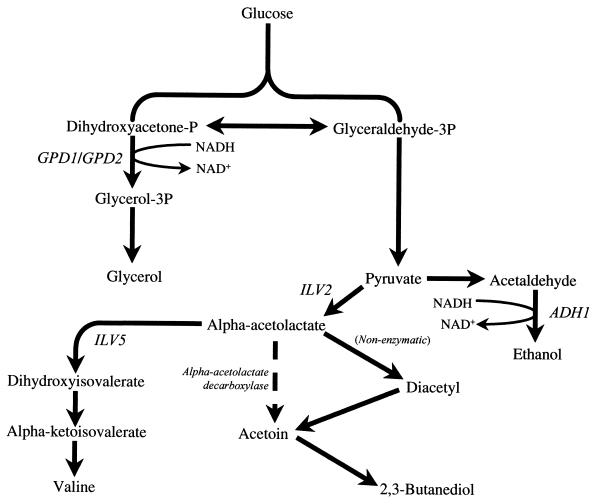

Various aspects of genetically engineered brewer's yeasts were thoroughly reviewed a few years ago (40). It is possible to introduce favorable properties into brewer's yeast by a strong interplay between the analytical side of metabolic engineering and genetic manipulation of the cell to help the brewing process become more profitable. One of the main reasons for the requirement of a long period of lagering beer is the nonenzymatic and slow conversion of α-acetolactate to the unpleasant off-flavor compound diacetyl, which is enzymatically converted to acetoin and subsequently to 2,3-butanediol (Fig. 4). Diacetyl is involved in amino acid metabolism, and the taste threshold of this compound is much lower than that of acetoin. One way to avoid the off-flavor caused by diacetyl is to introduce an alternative route of degradation of α-acetolactate that bypasses diacetyl formation. Thus, genetic modifications of brewer's yeast by introduction of a heterologous α-acetolactate decarboxylase enabled the transformed strains to produce acetoin directly from α-acetolactate, which accelerates the brewing process by diminishing the time of lagering from weeks to hours (Fig. 4). The α-acetolactate decarboxylase successfully expressed in yeast originated from Klebsiella terrigena, Enterobacter aerogenes, and Acetobacter xylinum (8, 136, 162). Other attempts to minimize diacetyl formation in brewer's yeast have succeeded by screening for specific mutants and overexpression of specific genes encoding enzymes involved in the biosynthesis of valine (Fig. 4). Screening for mutants resistant to the herbicide sulfometuron methyl and exhibiting slow growth on isoleucine- and valine-deficient medium revealed strains with low acetolactate synthase (Ilv2) activities and thus a low carbon flux directed toward α-acetolactate formation. Only half the amount of diacetyl was produced by some of these strains in comparison with the parental strain (33). Another successful strategy was to increase the flux through the valine biosynthetic pathway for the purpose of bypassing diacetyl formation. By overexpressing the ILV5 gene encoding acetolactate reductoisomerase, which converts α-acetolactate to dihydroxyisovalerate, either by transformation of a multicopy vector bearing the ILV5 gene (33) or by integration of multiple ILV5 copies into the genome (90), a twofold reduction in diacetyl formation was achieved.

FIG. 4.

Overview of the biochemical routes leading to glycerol, pyruvate, and ethanol. Furthermore, valine biosynthesis and diacetyl formation are shown, which may be bypassed by introduction of a heterologous α-acetolactate decarboxylase that directly converts α-acetolactate to acetoin. GPD1 and GPD2, glycerol dehydrogenases 1 and 2; ADH1, alcohol dehydrogenase I; ILV2, acetolactate synthase; ILV5, acetolactate reductoisomerase.

Manipulation of the central metabolism pathway of S. cerevisiae has been used to increase ethanol yield and productivity in order to examine different strategies to improve distiller's yeast. When eight different enzymes of glycolysis were expressed separately on multicopy vectors, none of the transformed strains exhibited a higher ethanol formation rate than the wild-type strain (121). Not even overexpression of the enzymes catalyzing irreversible reactions, such as hexokinase, phosphofructokinase, and pyruvate kinase, had an effect on the ethanol productivity, and neither did pairwise overexpression of the last two enzymes or pairwise overexpression of pyruvate decarboxylase and alcohol dehydrogenase. These results illustrate the rigidity in the control of the flux through the central carbon metabolism in S. cerevisiae. However, another study reported that overexpression of phophofructokinase improved the ethanol productivity in the case of immobilized resting cells grown aerobically but not anaerobically (21).

A major problem in connection with ethanol production by anaerobic fermentation of S. cerevisiae is a substantial formation of glycerol as a by-product. Under aerobic growth conditions, cytosolic NADH formed from biomass formation may be reconverted to NAD+ via glycerol formation, in addition to the mitochondrial external NADH dehydrogenases encoded by the NDE1 and NDE2 genes and alternatively via unknown metabolic systems (80). Anaerobically, oxidation of cytosolic NADH can occur only via glycerol formation since the oxidative phosphorylation is not functioning under this condition. Two genes, GPD1 and GPD2, both encode glycerol-3-phosphate dehydrogenase, which regenerates NAD+ from NADH while converting dihydroxyacetone-phosphate to glycerol-3-phosphate, but the isoenzyme encoded by the GPD2 gene has been demonstrated as being the more important of the two under anaerobic conditions (26, 96). The overall conversion of glucose to ethanol is redox neutral, since NADH is formed by glyceraldehyde-3-phosphate dehydrogenase and since the conversion of acetaldehyde to ethanol includes regeneration of NAD+ from NADH by alcohol dehydrogenase I (encoded by ADH1) (Fig. 4). Thus, the formation of glycerol is important for maintenance of the cytosolic redox balance to reoxidize the NADH formed. A possible strategy to optimize ethanol production could be to deduce glycerol formation by redirecting the carbon flux via manipulation of the redox metabolism. When a gpd2 mutant was grown under anaerobic conditions, a higher ethanol yield of 8% in addition to a 40% reduction of the glycerol yield (relative to the amount of substrate consumed) was obtained but the maximum specific growth rate was reduced by 45% compared with the wild-type strain, W303-1A (148). Similar results were obtained with a gpd2 mutant of another wild-type background (2T3D derived from CBS 8066), where the ethanol yield increased only 4.7% and a fivefold reduction of the maximum specific growth rate was observed, which precludes the industrial use of a gpd2 mutant for ethanol production (96). Since a double gpd1 gpd2 deletion mutant strain is unable to grow under anaerobic conditions, introduction of a new pathway to regenerate NAD+ was attempted by expressing a bacterial transhydrogenase (catalyzing NADH + NADP+ ⇌ NAD+ + NADPH) of Azotobacter vinelandii in a double gpd1 gpd2 mutant strain. Unfortunately, the NAD+ pool became limiting for biomass synthesis before the transhydrogenase was able to support the synthesis of NAD+, and consequently no growth was observed under anaerobic conditions (96). When a plasma membrane-bound transhydrogenase of Escherichia coli was transformed into S. cerevisiae, a functional protein was synthesised that presumably accumulated in the rough endoplasmic reticulum (ER). Unfortunately, this transhydrogenase favored NADH and NADP+ formation, and hence an increased glycerol yield and a decreased ethanol yield were observed (3).

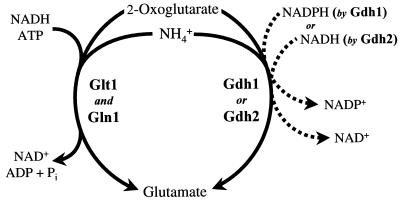

In another approach involving metabolic engineering to enhance the ethanol yield by S. cerevisiae, the redox metabolism was engineered by changing the cofactor requirements associated with ammonium assimilation (97). Ammonium assimilation by S. cerevisiae is outlined in Fig. 5. Ammonium and 2-oxoglutarate can be converted into glutamate by different isoenzymes of glutamate dehydrogenase, using either NADPH (Gdh1) or NADH (Gdh2) as cofactors. Ammonium can also be assimilated by glutamine synthetase (Gln1) with the formation of glutamine, which is converted into glutamate by the action of glutamate synthase (Glt1); the sum of the two reactions of Gln1 and Glt1 is shown in Fig. 5. These two coupled reactions use NADH and ATP, and hence if glutamate formation occurs via this route only, the strategy was to reduce the surplus NADH formed in association with biomass synthesis in combination with the production of an increased ATP consumption, which would reduce the requirement for glycerol formation and increase the ethanol formation. Deletion of GDH1 resulted in an increased ethanol yield of 8% and a decreased glycerol yield, but the maximum specific growth rate was halved compared with that of the wild-type strain due to a reduction in the glutamate synthesis rate. By deletion of GDH1 and overexpression of GLN1 and GLT1 from PGK promoters, the ethanol yield was even further enhanced by 3% compared with the gdh1 mutant strain, and overexpression of these two genes rescued the maximum specific growth rate to 90% of the wild-type strain. When GDH2 was overexpressed from a PGK promoter in a gdh1 mutant strain, the maximum specific growth rate was essentially equal to that of the wild-type strain; however, the observed decrease in glycerol formation resulted not in a considerably increase in ethanol yield but, rather, in an increased biomass yield. Thus, metabolic engineering that diminishes glycerol formation by imposing a higher rate of NADH reoxidation onto the cell does not necessarily lead to an increased ethanol yield. To serve this purpose, a reduction of surplus NADH should be combined with a higher consumption of ATP in biomass formation, whereby the cell compensates for the higher energetic demand by increasing the flux toward ethanol. This present example illustrates how improved flux through one pathway can be obtained by engineering of a completely different pathway and shows that it is important to consider the whole metabolic network. In addition to the example mentioned above, an increase in the conversion rate of ATP to ADP may be obtained by introduction of an uncoupled ATPase activity to a given cell, whereby the production of a desired product may be improved. Recently, various applications of this approach were described (52).

FIG. 5.

Ammonium assimilation in S. cerevisiae, where 2-oxoglutarate and NH4+ are converted into glutamate in two different ways. The sum of the two reactions catalyzed by glutamine synthetase (Gln1) and glutamate synthase (Glt1) is shown on the left. The other side shows glutamate formation by the two isoenzymes of glutamate dehydrogenase, using either NADPH (Gdh1) or NADH (Gdh2) as cofactors.

In contrast to distiller's yeast, it is of interest to direct the carbon flux toward glycerol during ethanol formation in wine yeast, since glycerol may improve the wine quality by giving body to the wine. In an attempt to attain this objective, overexpression of GPD1 resulted in a substantial increase in glycerol yield at the expense of a reduced ethanol yield (89, 95, 109). Nevertheless, when redirecting the carbon flux by changing the redox metabolism, one should be aware of substantial changes in the by-product pattern of certain metabolites such as acetate and acetoin, which may affect the quality of wine (89, 109).

IMPROVEMENT OF PROCESS PERFORMANCE

To improve the large-scale production of biotechnological products, it is very important to keep focusing on engineering disciplines dealing with bioreactor design and optimization of fermentation technology, which may lead to an improved process performance giving higher overall yields and productivities. Nevertheless, one should not only focus on developing appropriate methods and new hardware to improve certain unit operations of a given process but also shed light on the capabilities of S. cerevisiae itself for improvement of process performance. An appropriate example of this is the ability of certain S. cerevisiae strains to undergo pseudohyphal growth, where the yeast cells form clumps by flocculation (134, 140); this property is usually ascribed to brewer's yeast. A suitable brewer's yeast strain should be able to flocculate, since this property provides the most cost-effective method of clearing beer in comparison with other conventional methods such as filtration and centrifugation.

Various studies dealing with flocculation have generated a large amount of data, but unfortunately comparison of these is restricted due to differences in test and growth conditions and the various genetic backgrounds examined. Two entirely distinct mechanisms of flocculation have so far been observed: the NewFlo phenotype, found in many brewer's yeast strains, and the Flo1 phenotype, found mainly in flocculating laboratory strains (132, 133). The two phenotypes differ remarkably in their onset of flocculation. The Flo1 phenotype exhibits constitutive flocculation throughout growth, regardless of environmental signals such as nutrient limitation, whereas flocculation of the NewFlo phenotype seems to be triggered at the end of exponential growth when glucose (127), nitrogen (126), or oxygen limitation (135) is present. The late onset of flocculation in the NewFlo phenotype is an obvious advantage to the brewing industry in helping separate the yeast from the brew, but the genetics behind the NewFlo phenotype remains to be discovered. Although further work is also needed to give a complete picture of the genes involved with the Flo1 phenotype, more genetic knowledge is available than for the NewFlo phenotype. The Flo1 phenotype contains one or more of the dominant flocculation genes, of which the FLO1 gene is the best studied (6, 139, 160). FLO1 encodes a cell surface protein that plays a direct role in the flocculation process. The Flo1 protein is anchored in the cell wall, where the N-terminal end is exposed to the medium, and during flocculation this end may bind to neighboring cell wall mannoproteins (140). The FLO1 gene has successfully been integrated into the genome of a nonflocculent brewer's yeast strain, whereby a stable constitutive flocculating strain was produced (159). Flocculation throughout the fermentation causes lower cell counts, increasing the overall fermentation time, and hence it is of interest to control flocculation in the Flo1 phenotype. The FLO1 gene in strains with a Flo1 phenotype seems to be regulated at the transcriptional level, where an increase in the FLO1 transcript correlates with an increase in flocculation. Constitutive flocculation was observed in all stages of growth, but it was intensified in the declining and the stationary phases of growth (141). To introduce flocculence to a nonflocculent host, it would be of interest to establish a genetic system that expresses the flocculation genes only toward the end of fermentation. Thus, metabolic engineering should focus on establishing a certain genetic system that contains one or more of the dominant flocculation genes subject to the still unknown control mechanism that is responsible for triggering flocculation at nutrient limitation, as seems to be the case in strains with the NewFlo phenotype.

Although introduction of flocculence to brewer's yeast is a convenient method of separating the yeast from the brew, beer filtration is still an important separation technique in the brewing industry. The presence of β-glucans in barley impedes beer filtration due to their high viscosity (S. cerevisiae cannot cleave the β-1,4 linkages of β-glucans), and addition of commercial enzyme preparations is therefore necessary. Alternatively, a heterologous gene encoding β-glucanase could be introduced into brewer's yeast. The latter option serves as an obvious task for metabolic engineering whereby the substrate range is extended to include β-glucans, and consequently the process performance of beer production may be improved. β-Glucanases of Bacillus subtilis (14), Trichoderma reesei (104, 105), and barley (99) have successfully been expressed in S. cerevisiae, and active enzymes were secreted. The production of β-glucanase did not affect beer quality, and, furthermore, the β-glucans were efficiently degraded, resulting in an improved filterability (105). An improved process performance is often accomplished in association with other aims, such as was demonstrated in the last example, where an extended substrate range also was obtained.

IMPROVEMENTS OF CELLULAR PROPERTIES: ALLEVIATION OF GLUCOSE CONTROL ON SUCROSE AND MALTOSE METABOLISM

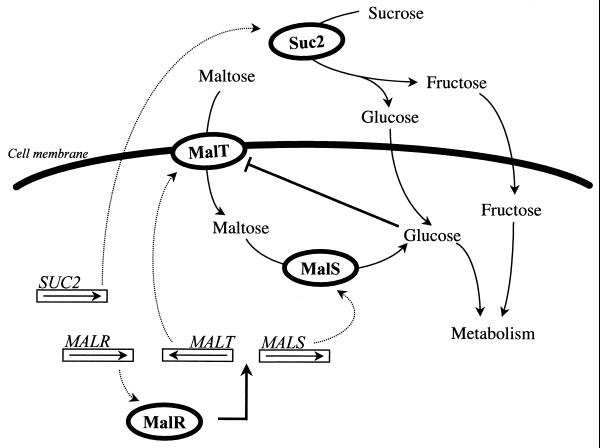

Much effort has been made to improve already existing properties of S. cerevisiae related to the industrial exploitation of this organism. Here we describe some of the work carried out to obtain a reduction in glucose repression exerted on the consumption of sucrose and maltose, which are present in sugar mixtures of industrial media that are naturally metabolized by S. cerevisiae. Baker's yeast is produced aerobically from molasses, which contains 40 to 50% (wt/wt) sucrose. Ethanol production and bread-making are large-scale anaerobic processes where S. cerevisiae metabolizes sugar mixtures. All-malt brewer's wort used for ethanol production contains 50 to 60% (wt/wt) maltose (27), and the starch present in the dough for bread-making is continuously decomposed into oligosaccharides and the disaccharide maltose by the action of amylases. S. cerevisiae hydrolyzes sucrose extracellularly and maltose intracellularly by the action of invertase (Suc2) and maltase (MalS), respectively (Fig. 6). The maltose transporter (MalT) plays an essential role in the expression of the MAL genes, since maltose is needed as an inducer of these genes, in contrast to the expression of the SUC2 gene, which does not require an inducer. The MAL genes also comprise the MALR gene, which encodes a regulatory protein responsible for the induction of the MALT gene and the MALS gene.

FIG. 6.

Sucrose metabolism and maltose metabolism in addition to the respective genes. Suc2, invertase; MalT, maltose permease; MalS, maltase; MalR, regulatory protein responsible for the induction of the MALS gene and the MALT gene.

When maltose or sucrose is present in the medium together with glucose, intermittent lag phases exist between the depletion of glucose and the initial consumption of sucrose or maltose, a phenomenon designated glucose control (70). This regulatory mechanism may have a costly impact on the above-mentioned processes due to the extended process time required when using a production strain severely subject to glucose control. The regulatory system that ensures consumption of glucose before other sugars has been studied mainly at the transcriptional level, i.e., the level of glucose repression. Glucose repression, mediated by the zinc finger protein Mig1, controls the expression of both the SUC2 gene and the MAL genes (47, 94). The molecular mechanism of Mig1-mediated glucose repression is a complicated regulatory cascade that eventually involves a protein complex containing Ssn6, Tup1, and Mig1, where Mig1 directs the complex to a specific consensus motif on the promoters of the target genes (58, 63, 146). The target genes of Mig1 are limited not only to genes encoding proteins involved in the peripheral functions of the cell, such as the SUC2 gene, the MAL genes, and the GAL genes (encoding the enzymes responsible for galactose utilization [regulation of the GAL genes is reviewed in references 56 and 77]), but also to genes of the central carbon metabolism (reviewed in references 32, 56, 70, 116 and 147).

To overcome the glucose repression exerted on the SUC2 gene, deletion of MIG1 in a haploid laboratory strain (W303-1A) has proven successful since a ninefold increase in SUC2 expression was obtained when the cells were grown on glucose (94). Furthermore, alleviation of glucose control was observed when growing two mig1 mutants derived from another haploid laboratory strain (X2180-1A) and a polyploid industrial strain (DGI 342), respectively, on sucrose-glucose mixtures (68, 101). Another recently identified zinc finger protein, Mig2, also contributes to controlling the expression of the SUC2 gene (79). Additional deletion of MIG2 in a mig1 mutant strain revealed further derepression of SUC2 expression (79). Physiological studies of the mig1 mig2 deletion strain indicated that the disruption of MIG2 led to a further alleviation of glucose control and to an increase in the respiratory activity; furthermore, a 12% increase of the specific growth rate on glucose was obtained compared with the wild-type strain (CEN.PK 113-7D) (72). Hence, concomitant deletion of MIG1 and MIG2 has proven to be very successful for the production of baker's yeast since glucose control is alleviated with respect to the sucrose metabolism; the glucose feeding rate used in the industrial fed-batch process may be increased without onset of the Crabtree effect; and the specific growth rate, which serves as an important design parameters for baker's yeast production, is enhanced by this approach.

Successful strategies for metabolic engineering of the MAL genes to diminish the extent of glucose control exerted on these genes differed from the above strategy. Disruption of the MIG1 gene in the haploid wild-type strain B224 slightly alleviated glucose control exerted on the MAL genes; however, this effect could not be obtained with mig1 mutants derived from the haploid strain CEN.PK 113-7D and the polyploid industrial strain DGI 342 (68, 72). The mig1 mutant strains derived from the last two wild-type strains started to consume maltose at lower glucose concentrations, when cultivated in glucose-maltose mixtures, compared with their parental strains; this was concluded to be due to a more stringent catabolite inactivation of the maltose permease (68). Additional disruption of the MIG2 gene in the mig1 mutant derived from the CEN.PK 113-7D wild-type strain revealed a slightly more repressed phenotype than in the mig1 mutant without disruption. Disruption of MIG1 (and MIG2) may derepress certain proteins involved in the glucose signaling cascade (for details, see references 55 and 158), and these proteins mediate inactivation of the maltose permease. Several reports indicate that catabolite inactivation of the maltose permease has a major impact on the maltose metabolism (78, 85, 110), and metabolic control analysis also indicated that maltose permease limits the maltose metabolism (71).

Instead of targeting regulatory genes such as MIG1 and MIG2, improved maltose consumption in glucose-maltose mixtures was obtained by constitutive expression of the structural MAL genes. Constitutive expression of MALT and MALS in the mig1 mutant derived from the wild-type strain B224 revealed a simultaneous uptake of glucose and maltose. When MALT and MALS were overexpressed in the wild-type strain, maltose was utilized slightly preferentially over glucose (69). Presumably overexpression of the MALT gene completely counteracted the effect of carbon catabolite inactivation of the maltose transporter. In addition to alleviation of glucose control, overexpression of the two structural MAL genes increased the specific growth rates by 0.03 h−1 on both glucose and maltose compared with that of the wild-type strain. Hence, this strategy seems attractive for the alleviation of glucose control on the maltose metabolism in brewer's yeast, which reduces the overall ethanol production time. The alleviated glucose control also reveals a shorter process time for bread production, which is further shortened because the dough may leaven even faster as a result of the increased specific growth rate.

Deletion of genes encoding transcriptional repressor proteins or overexpression of genes coding for positive transcriptional activators may be a successful strategy for metabolic engineering in some metabolic systems. This strategy may result in overexpression of several genes that are all subject to transcriptional control involving the deleted repressor protein or the amplified activator protein. In some cases this approach will be favorable in comparison with overexpression of the genes encoding some or all of the enzymes of a given metabolic route, since this somewhat tedious approach may impose some negative constraints onto the cell, such as a plasmid or protein burden. Nonetheless, when targeting genes coding for regulatory proteins, one may observe some inappropriate consequences of the cellular metabolism, since transcription factors may be involved in the regulation of other genes.

EXTENSION OF PRODUCT RANGE: HETEROLOGOUS PROTEIN PRODUCTION

Thorough studies of the physiological behavior of S. cerevisiae, as well as the important ability of this yeast to express foreign genes in conjunction with its secretory apparatus, makes S. cerevisiae an attractive host organism for production of certain heterologous proteins. A number of heterologous proteins that have been used for diagnostic purposes and as human therapeutic agents and vaccines were successfully produced by S. cerevisiae (34). Human interferon was the first recombinant protein produced by S. cerevisiae, in 1981 (44), and in the following year, the hepatitis B surface antigen was produced and was the first genetically engineered vaccine (149). The production of the peptide hormone insulin by S. cerevisiae covers approximately half of the insulin needed by the 154 million diabetics throughout the world (http://www.who.int/ncd/dia/dia_est.htm). In recent years, secretion of insulin by S. cerevisiae has been improved by protein engineering of the leader sequence, and the improvements achieved may benefit not only insulin production but also the potential of S. cerevisiae as a host organism for production of other heterologous proteins.

S. cerevisiae has a multicomponent secretory pathway and hence is capable of performing posttranslational modifications of the heterologous protein such as proteolytic maturation of prohormones, N- and O-linked glycosylation, and disulfide bond formation (122). These features resemble those of mammalian cells, and some biologically active mammalian proteins may therefore be successfully expressed and secreted by S. cerevisiae. Furthermore, the ease of transforming S. cerevisiae with foreign DNA and the well-established fermentation technology devoted to this organism make S. cerevisiae a good host for heterologous-protein production. Nevertheless, S. cerevisiae exhibits some disadvantages when used for the production of certain recombinant heterologous proteins. Scale-up problems have been observed as a result of plasmid instability (20), and hyperglycosylation of secreted heterologous protein has been reported, which may cause undesired immunogenic effects (92, 150). To overcome some of these undesired modulations of the recombinant protein of interest, alternative yeasts have been investigated for use as host organisms, which has been reviewed elsewhere (12, 115).

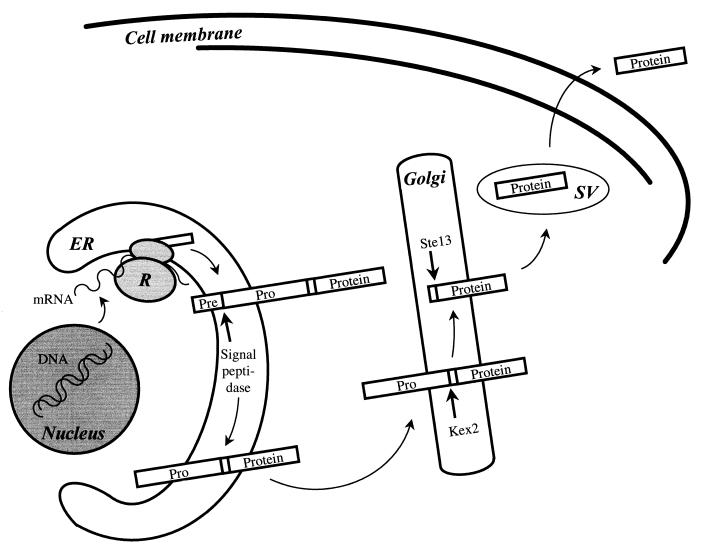

Haploid α-mating-type cells of S. cerevisiae secrete the pheromone α-factor for efficient mating of haploid a and α cells (144). The S. cerevisiae α-factor prepro-leader is most commonly used as the secretory expression system for heterologous proteins in a number of different yeasts including S. cerevisiae (9, 10, 115, 164). Fusion of the prepro-leader sequence to a heterologous gene enables S. cerevisiae to secrete the heterologous protein (Fig. 7), since the leader sequence mediates cotranslational translocation of the fusion protein into the ER. The pre-region of the leader sequence is cleaved by a signal peptidase (115), and in the Golgi apparatus compartment the Kex2 endoprotease cleaves the pro-region on the C-terminal side of the dibasic Kex2 maturation site (Lys-Arg) (1, 60). Before secretion, the peptide spacer on the C-terminal side of the Kex2 maturation site is removed by the action of the dipeptidyl aminopeptidase, encoded by the STE13 gene (59), whereby the heterologous protein is released to the extracellular medium (Fig. 7) (reviewed in reference 10).

FIG. 7.

Secretory pathway of proteins in S. cerevisiae, indicating the cleavage of the pre-region by the signal peptidase, the pro-region by Kex2 endoprotease, and the peptide spacer by dipeptidyl aminopeptidase (Ste13). Abbreviations: R, ribosome; SV, secretory vesicles.

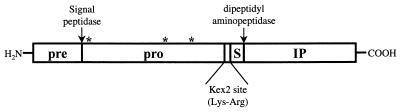

Thorough studies to improve the secretion of insulin by using the α-factor prepro-leader have been carried out. The entire α-factor prepro-leader of S. cerevisiae was used for the initial studies of insulin secretion with a peptide spacer having a Glu-Ala-Glu-Ala sequence, which resulted in the fusion protein shown in Fig. 8 (143). In this study, the peptide spacer was hardly removed by the dipeptidyl aminopeptidase, giving mainly a Glu-Ala-Glu-Ala-insulin precursor, and consequently the spacer was removed by site-directed mutagenesis. This modified α-factor leader sequence successfully revealed the expression and secretion of various insulin precursors (143). Other studies have implied the advantage of a spacer, since an improved Kex2p processing may be achieved (64, 107, 164), which in the case of insulin is desirable since insufficient Kex2 processing may cause hyperglycosylation and a decreased insulin yield (64, 65, 164). When appropriate spacers, designed in such a way that they could be removed by trypsin or by the Achromobacter lyticus Lys-specific protease I, were introduced between the dibasic Kex2 site and the insulin precursor, the yield of insulin precursor was improved more than twofold in comparison with that of the nonextended insulin precursor (64). Not only has the presence of a spacer proven successful for secretion of the α-factor leader sequence fused to the insulin precursor, but also N-linked glycosylation of the two α-factor pro-peptide glycosylation sites localized closest to the insulin precursor (Fig. 8) plays a pivotal role in the secretion process, since the lack of these two glycosylation sites significantly decreased insulin precursor secretion (15, 66).

FIG. 8.

Illustration of the α-factor prepro-leader fused to an insulin precursor. The pre-region, the pro-region, the Kex2 maturation site (Lys-Arg), the peptide spacer (S), and the insulin precursor (IP) are illustrated schematically. The three N-linked glycosylation sites in the pro-region are indicated by asterisks.

Another expression concept recently demonstrated in S. cerevisiae is the design of synthetic prepro-leader sequences obtained by a combination of a rational approach and stepwise optimization (65). If the synthetic leaders were used in the appropriate spacer context, the yield of insulin precursor exceeded the yield obtained with the α-factor prepro-leader, and furthermore the synthetic leaders were able to facilitate the secretion of not only insulin but also other heterologous proteins (65). Pulse-chase experiments showed a prolonged transition time of the synthetic leader/insulin precursor fusion protein in the ER compared with fusion proteins containing the α-factor prepro-leader, which presumably provided additional time for correct folding of the insulin precursor and thus an increased yield. When synthetic prepro-leaders lacking the N-linked glycosylation sites were fused to the insulin precursor protein, a higher yield of correctly folded insulin precursor was obtained compared with the yield obtained with the α-factor leader sequence. Thus, the lack of N-linked glycosylation of the synthetic prepro-leaders did not have an impact on the secretion competence (67), which contrasts with what was reported for the α-factor prepro-leader as mentioned above.

Replacement of the Kex2 maturation site with another enzymatic processing site within the synthetic pro-leaders lacking the N-linked glycosylation sites led to secretion of an unprocessed insulin precursor, and this unprocessed insulin precursor could be purified from the culture medium and matured in vitro by addition of A. lyticus lysyl-specific protease (67). The replacement of the Kex2 maturation site with another proteolytic site may be appropriate for the secretion of heterologous proteins having a Kex2 maturation site within their sequence, since a certain protein may be cleaved by the Kex2 endoprotease, which causes a decreased yield of the heterologous protein. Hence, by choosing a proteolytic enzyme whose processing site is not present in the desired heterologous protein, this protein could be secreted as an unprocessed fusion protein in a kex2 mutant strain, and subsequently, maturation could occur in vitro. Furthermore, secretion of an unprocessed heterologous protein having a synthetic pro-leader could be advantageous compared with secretion of a processed heterologous protein, since this pro-leader may enhance the stability and the solubility of the fusion protein, which is preferable before purification and maturation of the fusion protein are carried out. Thus, an alternative expression system independent of the Kex2 endoprotease was obtained by using protein engineering in the design of modified enzymes, which illustrates the use of protein design in metabolic engineering. The newly developed synthetic prepro-leader sequences were demonstrated to be an extremely powerful tool for expression and secretion of insulin, and these leader sequences may enable the expression and secretion of other heterologous proteins that are not possible with the traditionally used α-factor prepro-leader.

FUTURE DIRECTIONS

The above sections describe recent examples that illustrate the possibilities of designing strains of S. cerevisiae with new or improved properties through pathway engineering and protein engineering. The focus on S. cerevisiae to fulfil several biotechnological purposes is still increasing. Since the sequence of the complete yeast genome is available, targeted genetic changes are easily obtained by recombinant DNA technology, which facilitates and accelerates metabolic engineering. Furthermore, availability of the complete yeast genomic sequence has paved the way for the development of new techniques such as the gene chips, i.e., DNA fragment microarrays or oligonucleotide chips (57), which enable genome-wide expression monitoring (22, 161). A genomic expression pattern obtained when S. cerevisiae was undergoing the metabolic shift from fermentation to respiration conformed with the known regulatory response of yeast, which illustrated the potential of the DNA microarray; additionally, a number of previously unknown responses were identified (22). Also, gene expression during sporulation of S. cerevisiae was elucidated using this technique (17). The gene chips will clearly generate a vast amount of biological information concerning the yeast model system in the future, and this may also be used for further understanding of higher eukaryotic cells like human cells. Within a very short time frame, the expression patterns obtained from the gene chip technology may have an exploratory function in gene regulation, and hence transcriptional activators and repressors may be identified, which may help to define appropriate strategies for metabolic engineering. Extensive information about new “protein pathways” i.e., protein interactions such as signaling transduction pathways, which may be obtained from the two-hybrid system or many other techniques (30, 106) also serves to identify potential targets for gene amplification or gene deletion.

Although the rigidity of S. cerevisiae in terms of alteration of its metabolic functions may limit certain approaches of metabolic engineering, this microorganism certainly has a great potential for pathway engineering. Undoubtedly a number of novel applications based on S. cerevisiae will arise in the future, and these, together with the examples mentioned in this paper, will clearly illustrate the potential of S. cerevisiae as a cell factory in biotechnological processes.

REFERENCES

- 1.Achstetter T, Wolf D H. Hormone processing and membrane-bound proteinases in yeast. EMBO J. 1985;4:173–177. doi: 10.1002/j.1460-2075.1985.tb02333.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Amore R, Wilhelm M, Hollenberg C P. The fermentation of xylose—an analysis of the expression of Bacillus and Antinoplanes xylose isomerase genes in yeast. Appl Microbiol Biotechnol. 1989;30:351–357. [Google Scholar]