Abstract

Achievement of better comfort properties in station suits of fire fighters without compromising flame retardancy is an utmost necessity. Inherently fire-resistant fibers play vital role in this scope. In this work twenty-three plain single jersey knitted fabric samples were developed by using five inherently fire-resistant fibers. The fibers used were meta-aramid Nomex, fire resistant (FR-Viscose, modacrylic (Protex), FR-polyester (Recron) and carbon fibers. All the fibers were blended in different blend ratios. Vertical flammability test was performed to investigate the flammability properties. Thermal characterization of the samples was done using thermogravimetric analysis (TGA). Thermophysiological and wearing comfort properties of all samples were evaluated. Scanning electron microscopy (SEM) was carried out for the evaluation of surface morphology of the fibers after charring. Results of vertical flammability test revealed that sample containing 100% Nomex fibers produced minimum char length. Nomex and carbon fiber blended fabric provided better moisture management along with better flame retardant behavior. Statistical tool named as Principal Component Analysis (PCA) was utilized for the optimization of all responses. All the samples were ranked as per principal component analysis. Sample containing 50/50 FR-polyester and FR-viscose fibers was found to be the top ranked, as this sample provided optimum flammability and comfort related performance.

Keywords: Inherently fire-resistant fibers, Fire fighter suits, Flammability, Thermogravimetric analysis (TGA), Principal component analysis (PCA)

1. Introduction

Safety is always the top priority in the working environment of any walk of life. Fire resistant fabrics provide the essential protection from fire, but obvious issue is the deficiency of comfort related properties. Thermo-physiological comfort and wear comfort is an essential requirement in such clothing which requires intensive research for better solutions. A significant amount of research has been carried out to enhance the fire resistance properties of protective fabrics [1]. Flame retardant non-woven fabrics were produced using uniform blend of polyamide fibers and alginate fibers. The flammability of the fabric was tested by vertical flame test and it was found that addition of 50% alginate fibers resulted in self-extinguishing fabric without any melting and dripping [2]. Comparison among inherently FR fibers was done using TGA and DSC and it was observed that at 450 °C all cellulosic fibers were burnt, and FR Viscose showed good heat protection [3]. Marl like yarns were developed which were composed of blend of cotton and meta-aramid fibers. It was concluded that aramid fibers act as a fire barrier and lower down the flammability of cotton fiber [4]. Blend of wool and para-aramid fibers were used to increase the flame resistance. The materials showed improvement in thermal stability and FR performance [5].

The fire resistance properties of four types of nonwoven fabrics developed from fire resistant fibers such as PBI/FR/FR PA6 was compared. After analyzing the flammability properties, it was concluded that FR PA6 blends exhibited self-extinguishing property as compared to pure PA6. All the nonwoven fabrics decomposed at 300 °C [6]. The flame retardancy and pyrolysis mechanism of polyimide fibers was investigated using cone calorimeter, SEM and TGA. Results concluded that polyimide retains excellent thermal stability and flame resistance. It was also observed that knitted fabric was easier to become thermally thick as compared to woven fabrics [7]. In another study different protective fabrics were studied by convective source and calorimeter measured the heat transferred from FR cotton, Rayon and wool, Glass, ceramic etc. Results suggests that due to variable thickness and density all fire-resistant fabrics behaved distinctly [8].

Different FR fabrics such as sateen decorating fabrics, duvetyn fabrics and vinyl sheeting fabrics were studied and concluded that taffeta embossed vinyl sheeting material is the best fire-resistant material which doesn't catch fire even by sparking with match box [9]. Researchers investigated the enhanced fire-retardant properties of cellulosic fibers by incorporating magnesium oxide macro capsules by blend wet spinning. Flammability of modified cellulosic fibers was investigated by cone calorimeter, TGA and LOI. Results showed that the minimum LOI value for modified cellulosic fibers was 35 which is much higher than unmodified cellulosic fibers [10]. The flame resistance properties of cotton fabric were increased by treating with juice of spinach leaves which is a natural product. The spinach juice was made alkaline and applied on mercerized cotton fabrics. The flammability of fibers was analyzed by vertical flammability test, LOI and radiant heat testing. Results showed that LOI of cotton increased from 18 to 26. Treated fabrics also showed lower radiant heat passage and increased time for raising the temperature [11]. The flame retardancy and anti-dripping properties of 100% polyethylene terephthalate (PET) knitted fabrics was improved by layer-by-layer assembly of branched polyethylenimine (BPEI). Result showed that layer by layer assembly treatment significantly improves the LOI, flame retardancy and anti-dripping behavior [12]. Inherently fire-resistant nanocomposites were formed via melt spinning of Nylon 6 which was infused with nano-clay and additives. Micro scale combustion calorimetry showed significant reduction of heat release capacity and obvious enhancement of flame retardant performance [13]. It was concluded that by using different halogen free FR additives fire resistance can be achieved in natural fibers. It was also mentioned that FR intumescent layers can be introduced into the textile fabrics by micro-encapsulation or by incorporation into protective coatings [14]. This fabric is worn under the turnout gear. This will provide additional layers to the wearer. Knitwear fabrics are ultimate choice of consumers because of their easiness in wearing, simplicity, comfort, stretch to fit etc. properties. As knitted fabrics are more comfortable to wear, so commercially such suits are made in knitted form (Dupont fire fighter suits).

On the basis of available literature, it is concluded that there are different approaches to improve fire resistance properties of fabrics. It can be achieved by using FR additives on the fabrics which is not so durable. On the other hand, use of inherently fire-retardant fibers to impart fire retardant behavior in fabrics is a promising alternative. Common challenge encountered in fire retardant fabrics is lack of comfort properties. The aim of this study is to identify/classify the flame resistance and comfort properties of blended knitted fabric for fire fighters’ application. The flame resistance tests along with LOI, TGA, SEM were performed. In addition, the thermo-physiological comfort performance e.g., air permeability, thermal resistance and over all moisture management capacity (OMMC) were studied. Tactile comfort properties e.g., smoothness and softness were evaluated by using Phabrometer. Statistical tool e.g., Principal component analysis (PCA) was employed in order to determine the best blend for the enhancement of comfort properties without compromising with the fire resistance performance.

2. Materials and methods

2.1. Materials

In this research, five types of inherently fire-resistant fibers namely FR-polyester (Recron), FR modacrylic (Protex), FR meta-aramid (Nomex), FR-viscose (China) and carbon/Pyron (Zoltek) were used. Recron FR-polyester is known for excellent breathability and abrasion resistance. It has permanent fire resistance properties and does not need any additional finish to maintain its FR properties. It also offers easy washing and drying properties [15]. Protex is inherently fire-resistant modacrylic fiber of Kanecaron family which offers a soft touch. It does not melt and form droplets which causes skin injury during burning. Rather Protex forms char barrier, which stops the flame and make it self-extinguishing. It is easily blendable and it forms intimate blends with cotton, polyester and other fibers and enhances the flame retardancy. Nomex belongs to family of aromatic polyamide (aramid fibers). Nomex is one of the firstly developed inherently fire-resistant fibers by DuPont. Nomex does not melt, or drip and it also prevents the combustion in air. The unique feature of Nomex is its carbonization behavior due to which it becomes thicker upon exposure to high heat [16]. FR-viscose is a sustainably produced inherently flame-resistant cellulosic fiber. It is commonly blended with other high-performance fibers to produce unique protective solutions for a variety of industrial applications. It typically contributes both protective qualities and enhanced comfort to these fabric blends. Pyron is an oxidized polyacrylonitrile (OPAN) carbon fiber and preferred for high-performance fire and heat resistant applications. This fiber is designed for cost-effective, flame and heat resistant solutions for the textile, industrial, aircraft and automotive.

3. Methods

3.1. Yarns and fabrics preparation

Ring spun yarns of 20 Tex were prepared on a sample machine, Ring lab 535 model available in laboratory with different blend ratios of fibers. Details of all blends are given in Table 1. In total 23 samples with different blends of fibers were developed based on design of experiment (DoE). All the samples were produced in plain single jersey knitted structure on laboratory knitting machine with diameter 10 cm and 210 needles. Knitting parameters e.g., stitch length, stitch density, tightness factor and input tension were kept at a constant level for all the samples.

Table 1.

Design of experiment.

| Sample ID | Fiber 1 | Fiber 2 | Sample ID | Fiber 1 | Fiber 2 |

|---|---|---|---|---|---|

| S1 | Nomex | 100% | S13 | Nomex 50% | Carbon 50% |

| S2 | FR-Polyester | 100% | S14 | Protex 50% | Carbon 50% |

| S3 | Protex | 100% | S15 | FR-Polyester 50% | Carbon 50% |

| S4 | FR-Viscose rayon | 100% | S16 | Protex 70% | FR-Polyester 30% |

| S5 | Carbon | 100% | S17 | FR-Polyester 70% | Nomex 30% |

| S6 | FR-Polyester 50% | FR-Viscose rayon 50% | S18 | Protex 70% | Nomex 30% |

| S7 | FR-Polyester 50% | Nomex 50% | S19 | FR-Viscose rayon 70% | Nomex 30% |

| S8 | Nomex 50% | Protex 50% | S20 | Nomex 70% | FR-Polyester 30% |

| S9 | Protex 50% | Viscose 50% | S21 | Nomex 70% | FR-Viscose rayon 30% |

| S10 | FR-Polyester 50% | Protex 50% | S22 | Nomex 70% | Carbon 30% |

| S11 | Nomex 50% | FR-Viscose rayon 50% | S23 | Carbon 70% | Nomex 30% |

| S12 | FR-Viscose rayon 50% | Carbon 50% |

3.2. Wet processing

After the development of fabric samples on knitting machine, all the samples were stitched end to end and wet processing was carried out. Wet processing of all the knitted samples was done using standard techniques. It comprised of scouring and bleaching which was done using MINI JET dyeing machine (Japan). Samples were processed at 60 °C. Scouring and bleaching was done using standard bleaching agent SDC reference detergent 2408 ECE. Non-phosphate detergent was procured from SDC Enterprises, Lahore, Pakistan. Recipe of bleaching consisted of H2O2 and Calcium carbonate and wetting agent. After processing, the sample fabrics were dried and relaxed for 48 h to achieve dry relaxed state. The fiber properties were not affected with these processes as advised in the literature and the supplier guidelines.

4. Testing

4.1. Physical parameters

Physical parameters of all the samples were tested according to standard test methods and lab devices. Fabric thickness was measured using digital fabric thickness tester following standard method ASTM-D-1777. Course and wale density of all knitted samples was counted using magnifying glass. Areal density (g/m2) of samples was measured using GSM cutter according to standard test method of ASTM D3776.

4.2. Flammability

Vertical flammability test was performed to analyze the burning behavior, melting, and dripping behavior of specimens. The test was performed on vertical flammability tester model number M233B. The vertical flammability tests were performed using standard test method ASTM D 6413. This is standard test method to analyze the fire resistance of textiles. In this test burning behavior, char length, after flame time and afterglow time is measured. All the specimens were prepared in standard size mentioned in the test method (300 m × 80 mm) and flammability was measured under controlled laboratory conditions. Flame height was kept at 3.9 cm and for 12 s. The flammability testing set up is shown in Fig. 1(a). Fig. 1(b) shows a sample before flame test and Fig. 1(c) shows the same sample after flame test.

Fig. 1.

Flame testing (a) test set up, (b) sample before test, (c) samples after test.

4.2.1. Limiting oxygen index (LOI)

Limiting oxygen index (LOI) of the fibers were tested according to the standard test method ASTM D 2863. The test was performed on the instrument named as Digital Oxygen Index apparatus YZS-100A.

4.2.2. Thermogravimetric analysis (TGA)

TGA was carried out to perform comparative analysis of fibers based on their thermal degradation behavior. The mass change % and residual mass after burning at high temperatures was measured. TGA tests were performed using instrument TG 209 F1 Libra according to standard test method ASTM D 3850. All the samples were heated from room temperature to 600 °C at the rate of 10 °C/min [17].

4.2.2.1. Scanning electron microscopy (SEM)

Scanning electron microscopy (SEM) was carried out for the samples after burning. The samples were prepared with Quorum Q150R ES, which is a sputter and uses gold-plating with argon gas atmosphere. The thickness of gold plating was kept at 2 nm using a current of 20 mA. The scanning electron microscope MIRA 3 TESCAN was used for this purpose. The samples were visualized in nitrogen atmosphere with SE (secondary electron) detector, using acceleration voltage of 10 kV. The working distance was maintained at 16–32 mm with scan mode. The 100 × magnification was used for all the samples.

4.3. Thermo-physiological comfort properties

Air permeability plays a vital role in determining comfort of fabrics. The air permeability was tested using air permeability tester SDL ATLAS model M021A following the standard method ASTM-D-737. Thermal resistance tests were carried out on Alambeta tester according to standard method ISO-11092. Overall moisture management capacity analyzes the management and transport of liquid moisture. It was tested on moisture management tester MMT SDL ATLAS. Test was performed following the standard test method AATCC-195. Wetting time, absorption rate, maximum wetted radius, spreading speed and one way transport index was measured in the OMMC test.

4.4. Tactile comfort

Hand/tactile comfort properties were tested on Phabrometer-3 fabric evaluation system according to standard test method AATCC TM 202:2014. It is one of the most recently developed instruments for the evaluation of sensorial comfort. 100% Nomex was used as control sample and all other samples were compared with it.

4.5. Statistical analysis

To determine the best blends among all the 23 samples principal component Analysis (PCA) was performed. The principal component analysis is an approach used for multi-variate analysis in which samples were analyzed by keeping some responses as higher the better and some responses were kept as lower the better. Statistical analysis was done using Minitab 21.1.0 software.

5. Results and discussion

5.1. Physical testing

Knitting parameters of all samples developed were kept at a constant level, such as stitch length 0.35 cm, tightness factor at 14 and input tension 25 N. As the samples were developed using different fibers or blends, there is variation in GSM of samples before and after wet processing. In some cases, the GSM increases while in some others the GSM decreases or remains the same after wet processing. It was observed that sample S20 containing 70% FR-Polyester and 30% Protex has highest areal density 176 g/m2 and sample S11 containing 50% FR-viscose and 50% Nomex has the lowest GSM value of 90. Most of the samples have GSM around 120. Thickness was measured for all the samples. Sample containing 100% carbon fibers has highest thickness because of bulkiness of yarn and the air gaps. Air trapped in the yarn and fabric, increases the thickness of fabric. The carbon fiber is stiffer as compared to other fibers used. The fiber stiffness is responsible for having a bulkier fiber bundle/yarn and a thicker fabric. This is well known in the textile field and available literature [[17], [18], [19], [20]].

5.2. Vertical flammability test

Table 2 shows results of vertical flammability testing.

Table 2.

Vertical flammability test results.

| Sample ID | Weight difference (%) | Char length (cm) | After flame time (s) | After glow time (s) | Dripping | Smoke |

|---|---|---|---|---|---|---|

| S1 | 1.54 | 6 | 1 | 7 | No | |

| S2 | 0.24 | 13 | 0 | 1 | Yes | |

| S3 | 1.43 | 17 | 0 | 0 | No | * |

| S4 | 52.1 | Full Burn | 3 | 7 | No | ** |

| S5 | 0.00 | 13 | 0 | 0 | No | |

| S6 | 34.87 | 15 | 1 | 3 | No | * |

| S7 | 2.24 | 12 | 1 | 9 | No | * |

| S8 | 29.07 | Full Burn | 6 | 4 | No | * |

| S9 | 1.30 | 7 | 1 | 2 | No | * |

| S10 | 1.52 | 18 | 0 | 0 | No | * |

| S11 | 42.6 | Full Burn | 7 | 2 | No | ** |

| S12 | 2.55 | 12 | 1 | 6 | No | * |

| S13 | 4.59 | Full Burn | 25 | 2 | No | ** |

| S14 | 30.82 | Full Burn | 40 | 2 | No | ** |

| S15 | 32.74 | Full Burn | 6 | 1 | No | |

| S16 | 4.40 | 14 | 3 | 2 | No | * |

| S17 | 2.43 | 14 | 1 | 7 | No | ** |

| S18 | 2.00 | 10 | 1 | 2 | No | * |

| S19 | 5.22 | 10 | 3 | 0 | No | * |

| S20 | 30.55 | Full Burn | 34 | 2 | Yes | ** |

| S21 | 2.05 | 9 | 1 | 8 | No | ** |

| S22 | 32.16 | Full Burn | 4 | 2 | No | * |

| S23 | 26.12 | Full Burn | 17 | 1 | No |

It can be observed that sample S10 containing 50% FR-polyester and 50% Protex shows char length of 18 cm. Sample S1 containing 100% Nomex produces lowest char length of 6 cm due to the fire retardance nature of Nomex which provides necessary protection and resistance to flammability as reported in previous research [19]. It was noted earlier that char length of Nomex increases with increase in weight change. A minor weight change was observed with respect to the other samples. Sample S9 consisting of 50% Carbon and 50% Nomex produced 7 cm char length. These two samples showed minimum char length due to presence of Nomex fiber in the blend. It was also previously noted that Nomex produces minimal char length [20]. Maximum weight loss was observed in sample S4 containing 100% FR-viscose fibers. This can also be attributed to the lowest limiting oxygen index of FR-viscose fibers. Char forming indicates excellent barrier properties if non-thermoplastic fibers are used.

It was observed that sample S2 consisting of 100% FR-Polyester and sample S20 consisting of 70% FR-polyester and 30% Nomex showed dripping behavior. This is because of thermoplastic nature of FR-polyester which causes the dripping and melting during burning [[21], [22], [23], [24]].

Highest after flame time (40s) was observed in sample S14 containing 50% Protex and 50% Carbon. Samples S2, S3, S5 and S9 showed 0s while S7 showed highest afterglow time 9s. According to standard ASTM F1506, maximum char length is 15 cm while NFPA 2112 demands maximum 10 cm char length is acceptable. 15 cm char length is universally accepted.

5.2.1. Limiting oxygen index

Generally, textiles having LOI values greater than oxygen level (21%) tend to be considered flame retardant fibers. Higher LOI value give the indication how harder for the material to catch fire. LOI tests were performed only for the samples comprising 100% or 50/50 ratio of component fibers in the blend. The results are shown in Table 3. The purpose was to test the individual limiting oxygen and flammability behavior of fibers while in 50/50 blends the aim was to investigate the combined effect of both fibers to increase/decrease flame retardancy.

Table 3.

Limiting oxygen index.

| Sample ID | Composition | LOI |

|---|---|---|

| S1 | Nomex 100% | 31.3 |

| S2 | FR-Polyester 100% | 22.5 |

| S3 | Protex 100% | 22.4 |

| S4 | FR-Viscose 100% | 17.4 |

| S5 | Carbon 100% | 28.0 |

| S6 | FR-Polyester 50%/FR-Viscose 50% | 20.9 |

| S7 | Nomex 50%/FR-Polyester 50% | 25.8 |

| S8 | Protex 50%/Nomex 50% | 25.2 |

| S9 | Protex 50%/FR-Viscose 50% | 24.5 |

| S10 | Protex 50%/FR-Polyester 50% | 21.5 |

| S11 | FR-Viscose 50%/Nomex 50% | 20.9 |

| S12 | FR-Viscose 50%/Carbon 50% | 18.7 |

| S13 | Carbon 50%/Nomex50% | 26.0 |

| S14 | Protex 50%/Carbon 50% | 27.1 |

| S15 | FR-Polyester 50%/Carbon 50% | 30.5 |

Nomex fiber shows the highest LOI value as meta-aramids are inherently flame resistant. The higher the LOI value, the higher the non-flammability. The higher the hydrogen to carbon ratio in the polymer, the greater is the tendency to burning (other factors being constant). Presence of benzene rings and hydrogen bonded molecules in polymer chains tends to increase the flame resistance and LOI. FR-Viscose is a cellulose-based fiber which was found to be minimum flame resistant. During synthesis of fire-resistant cellulose, the polymer solution is mixed with fire retardant agent to impart flame resistance. In general, high flammability is the inherent behavior of all cellulosic materials. When FR-viscose fibers were blended with other high flame-resistant fibers like Nomex, carbon and FR-polyester it tends to decrease the overall LOI values.

It was observed that in the blend containing 50% Protex fiber and 50% Nomex fiber, the Nomex tends to enhance the LOI value of the blended sample. In case of 50/50 blended carbon and Protex fibers sample S14, the overall LOI of the sample decreased as compared to the individual LOI of carbon fibers. Thus, it can be inferred that Protex fibers tend to decrease the LOI. The highest LOI among the blended samples was achieved in the blend comprising 50% Polyester fiber and 50% carbon fibers (S15). It means that combination of Nomex fibers helps in enhancing the overall LOI value of Protex, FR-viscose rayon and Polyester.

5.3. Thermogravimetric analysis

TGA was performed to analyze the thermal stability of 15 samples which contain 100% and 50/50 blends of fibers so that the effect of the fiber composition on thermal stability could be analyzed. In thermogravimetric analysis, mass of material was measured and change in mass was recorded as the function of temperature. All the samples were subjected to high temperature up to 600 °C. The samples behaved differently, and variable mass degradation was observed. The TGA curves of samples with 100% and 50/50% composition are shown in Fig. 2(a). DTGA curves of samples with 100% and 50/50% composition are shown in Fig. 2(b).

Fig. 2.

Thermogravimetric analysis, (a) TGA curves of samples with 100% and 50/50% composition, (b) DTGA curves of samples with 100% and 50/50% composition.

The results suggest that sample S2 containing 100% FR-polyester fibers showed very good thermal stability as minimum mass degradation and highest residual mass (84.12%) was obtained at temperature of 600 °C. Sample S5 consisting of 100% carbon fibers showed residual mass of 64.52%. Sample S4 containing 100% FR-viscose showed minimum thermal stability as it was observed that maximum mass was decomposed and only 19.79% was residual mass at 600 °C. TGA results also showed that very small amount of residual mass (20.79%) was observed in sample S10 containing 50% FR-polyester and 50% Protex fibers.

For the sample S1 containing 100% Nomex, only 2% of mass change occurred for first 100 °C which was due to evaporation of moisture absorbed in the fibers. The moisture regain of meta-aramid is only 0.5%. In the 2nd stage up to 300 °C, only 3% mass decomposed because the pyrolysis starts at this temperature range. This small mass loss can be due to release of water caused by the breaking of hydrogen bonds. Small amount of heat also causes change in crystalline nature of fibers which is reported in previous research [[25], [26], [27], [28]]. In the 3rd stage, with an increase of 300 °C up to temperature of 600 °C, maximum mass change (41%) occurs. The combustion temperature of meta-aramids is around 500 °C when the degradation starts. Total mass decomposition of Nomex samples is estimated as 46%. Charring starts at around 400 °C and then with the increasing temperature, Nomex burns into the residual mass, it doesn't melt or drip. In the last stage the decrease in slope suggests the condensation reactions which cause the yield of polyaromatic compounds. In this phase, the C N bonds break frequently and then followed by C O. By increasing the temperature further, gases like CH4 are formed and this increases the pyrolysis energy [[29], [30], [31], [32]].

For sample S2 containing 100% FR-polyester fibers, there was only 4.5% mass change in first stage of 100 °C. In 2nd stage up to 300 °C, again 4.5% mass degradation occurred. In the 3rd stage up to maximum range of temperature from 300 °C to 600 °C, there was 12% mass change. As melting point of polyester is about 250 °C, the fibers start melting, and the fabric shrinks. The FR-polyester (Recron) sample shows the smallest mass change due to highly crystalline nature of the FR-polyester fiber. Pyrolysis temperature of FR-polyester is 420 °C which is higher than others. That is why FR-polyester fibers burnt at higher temperature and a smaller mass change occurred [33,34]. Thermal degradation of FR-polyester is usually done by the random chain breakages which cause significant mass loss [35].

In the sample S3 consisting of 100% modacrylic (Protex), there was only 1% mass change in first stage of 100 °C. This is due to very low moisture regain of modacrylic fibers which is 0.3–0.4% [34]. Also up to 200 °C only 1% mass degradation was observed. In the 2nd stage, with temperature increase of up to 300 °C, there was suddenly 50% mass degradation. This is confirmed by the previous research in which modacrylic fibers showed similar decomposition behavior [36].

In case of sample S4 containing 100% FR-viscose fibers, there was 10% mass change in the first stage of temperature rise to 100 °C. This is because of higher moisture regain of FR-viscose fibers (10–11%). In the 2nd stage of temperature rise by further 100 °C, there was only 1% mass change. There are numerous reactions happening successively, various volatile compounds are released from the samples. The third stage denotes an increase of 400 °C, from 200 °C to 600 °C. During this phase the maximum mass change of 70% occurred due to degradation of cellulosic polymer.

FR-Viscose fiber showed highest mass reduction as it decomposed completely. In the earlier works, it was reported that only 14% mass was left as residual upon a temperature of 600 °C [[37], [38], [39], [40], [41], [42]]. The excessive mass loss in FR-viscose occurs due to dehydration and decarboxylation reactions which causes the emission of combustible gases like aldehydes, ketones, ethers, etc. Weight loss of fire-retardant FR-viscose fiber corresponds to the dehydration of polysilicic acid. The dehydration of polysilicic acid provides a flame and facilitates the emission of combustible gases generated from FR-viscose fiber [[41], [42], [43]].

Sample S5 which consists of 100% carbon fibers, showed a mass loss of 8% in the first stage when temperature rises to 100 °C. In the 2nd stage, when temperature increased from 100 °C to 300 °C, there was even smaller mass change of 6%. In the 3rd stage up to 600 °C, 17% mass degradation occurred. In PAN based carbon fibers, the mass loss happens due to dehydrogenation and chain rupture. The dehydrogenation is due to oxidation and evolves H2O. As heating rate increases, there is more and more chain rupture. Heating at the rate 10 °C per minute causes lower oxygen uptake to polymers chains. Mass loss in nitrogen is significant because of no mass gain due to oxygen introduction [44]. Mass reduction above 250 °C is due to thermal shrinkage caused by the cyclization in PAN based carbon fibers. At higher temperatures, significant amount of mass loss is observed. The previous findings reported the decomposition of carbon fibers results in emission of various products including H2O, CO, CO2 and CH4 [45].

The 50:50 blended samples of the constituent fibers exhibited mass loss based on rule of mixture and the behavior was intermediate based on the fiber composition. The charred samples were analyzed with SEM. The microscopic images of fibers which have not lost their different inherent structure are presented in Fig. 3. Fig. 3(a) shows FR-Polyester fibers, (b) shows Protex fibers, (c) shows Nomex fibers, (d) shows FR-Viscose fibers, and (e) shows Carbon fibers, which are unchanged even after burning of the sample.

Fig. 3.

Charred surface morphologies of FR-fibers which have not lost their different inherent structure (a) FR-Polyester fibers, (b) Protex fibers, (c) Nomex fibers, (d) FR-Viscose fibers, and (e) Carbon fibers.

The SEM images show that the samples are not completely decomposed or charred at 600 °C. This is indication of thermal resistance performance in the fabrics developed from the inherently flame-resistant fibers.

6. Thermo-physiological comfort properties

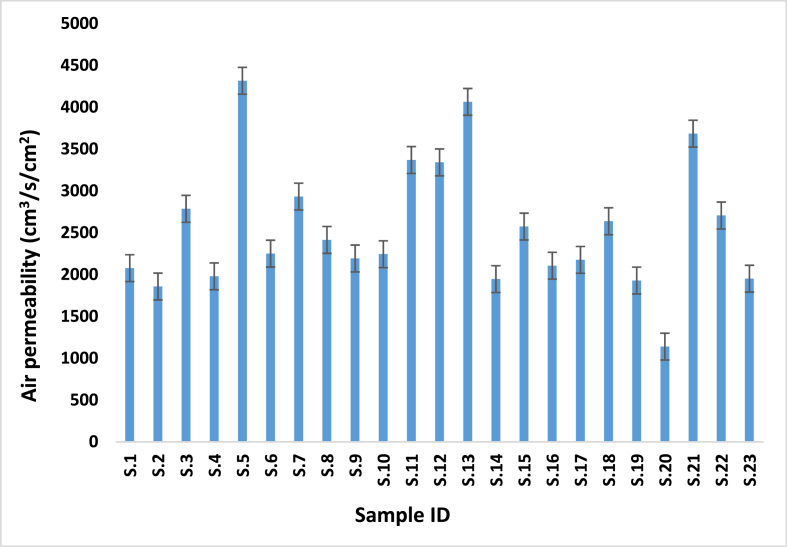

6.1. Air permeability

Results presented in Fig. 4 demonstrate that sample having 100% carbon fibers shows highest value of air permeability due to open knitted structure resulting from the fiber stiffness. Areal density of the sample was 100 g/m2, wales density 10/cm and 12 twists/cm in the yarn. It was also demonstrated in the previous research reported that plain knitted fabrics with lower yarn twist results in higher air permeability [45]. It was observed that sample S20 containing 30% FR-polyester and 70% Nomex fibers shows the lowest air permeability. This sample has the highest areal density of 176 g/m2. It was obvious from the results that compact fabric sample has lowest air permeability. This sample also has 2nd highest thickness and course density. It was suggested in earlier research that fabric thickness and porosity significantly influences the air permeability of knitted fabrics [45].

Fig. 4.

Air permeability of fire-resistant fabrics.

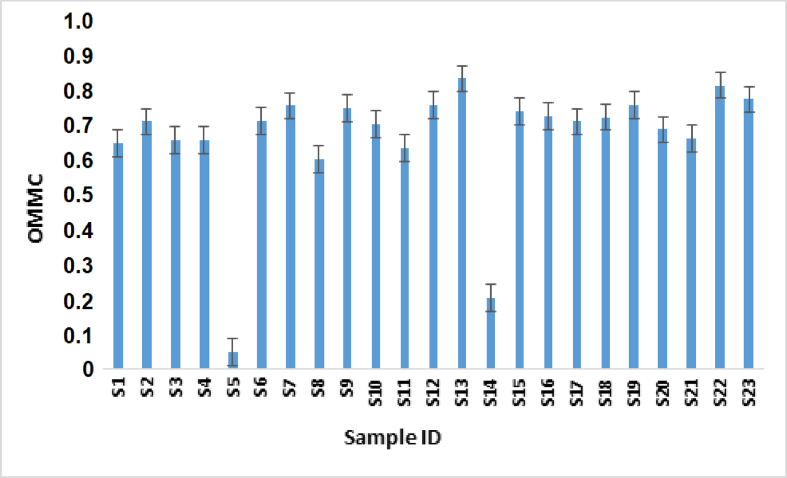

6.1.1. Overall moisture management capacity (OMMC)

Tests were performed to analyze the moisture management capacity of fire-resistant fabrics. In this test wetting time, absorption rate, maximum wetted radius, spreading speed, accumulated one way transport etc. were measured. Results of OMMC tests (Fig. 5) revealed that sample S13 shows highest value of overall moisture management capacity. This behavior in textile structures depends on moisture regain of the constituent fibers as well as the capillary action in the yarn and fabric structure. The hygroscopic nature of fiber favors good absorption rate, short wetting time, large maximum wetted radius, rapid absorption and fast drying properties, which makes it comfortable to wear. FR-Viscose is a cellulose based regenerated fiber which should show higher absorption abilities as compared to other fibers [[24], [25], [26]]. However, the blends of FR-viscose did not perform as expected. The blend of modacrylic (Protex) with carbon also did not show that high moisture management as other blends. This is result of lower porosity and poorer capillary action in the fabric despite hygroscopic behavior of the Protex fibers. It was also interesting to note that sample containing 100% carbon fibers have the lowest value of OMMC. This is due to poor moisture regain of carbon fibers [27]. On the other hand, carbon and Nomex blended fabrics showed excellent moisture management capacity. These observations indicate that in case of fire-retardant fabrics, the porosity in the yarn and fabric structure which is responsible for capillary action is more dominant to decide the overall moisture management rather than the moisture regain and hygroscopicity of the fiber itself. This can be the reason why the blends of relatively rigid fibers have resulted in superior overall moisture management capacity. This is a promising feature of such fire-resistant suits for the comfortable wear of the fire fighters.

Fig. 5.

Overall moisture management capacity of fire-resistant fabrics.

6.1.2. Thermal resistance

The results of thermal resistance shown in Fig. 6 depict that sample containing 70% Protex and 30% Nomex has highest thermal resistance. The thermal resistance of the samples is a function of porosity and thickness of the fabric. The thermal conductivity of the fibers also plays an important role. The blend of Protex and Nomex fibers results in a highly porous and bulky fabric composed from inherently thermally resistant elements. The lowest thermal resistance was observed in the sample containing 100% FR-Viscose fibers as these fibers have inherently low thermal resistance. The sample is relatively compact and contains minimum volume of air. The 50:50 blend of FR-viscose and Nomex also results is relatively better thermal insulation as compared to the rest of the samples. This is attributed to a combined effect of these two fibers which results in a porous fabric. All other samples show relatively smaller thermal resistance. The carbon fiber samples fail to provide sufficient thermal resistance despite high bulk and porosity of the samples. This is result of very high thermal conductivity of the carbon fibers.

Fig. 6.

Thermal resistance of fire-resistant fabrics.

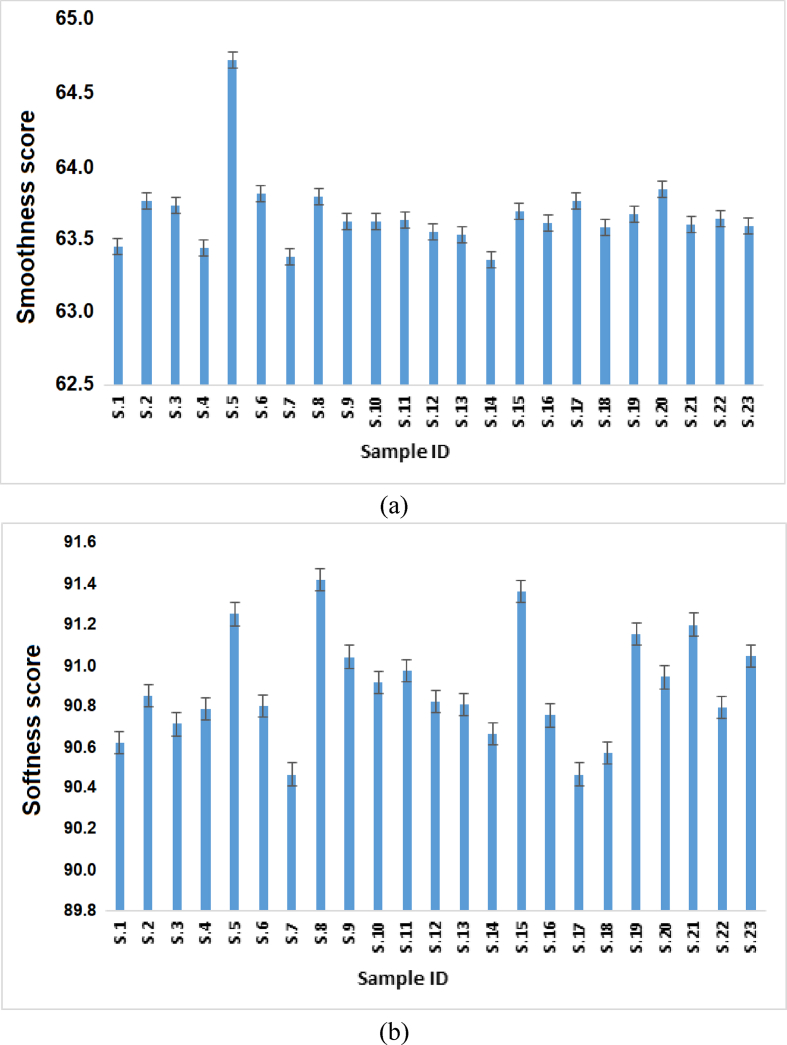

6.2. Tactile comfort properties

Tactile comfort properties were measured to analyze the sensorial properties of all samples. Relative hand value (RHV), wrinkle recovery rate, drape index, smoothness score, softness score and resilience score were considered in this test presented in Table 4.

Table 4.

Comfort properties of the samples.

| Sample ID | Relative Hand Value (RHV) | Resilience Score | Softness Score | Smoothness Score | Drape index | Wrinkle Recovery Rate (%) |

|---|---|---|---|---|---|---|

| S1 | 0.00 | −1.83 | 90.47 | 63.38 | 1.25 | 53.60 |

| S2 | 1.43 | −4.10 | 90.77 | 63.42 | 2.45 | 63.09 |

| S3 | 1.16 | −3.66 | 90.75 | 63.46 | 2.19 | 74.06 |

| S4 | 1.64 | −4.43 | 90.89 | 63.44 | 2.64 | 35.92 |

| S5 | 0.77 | −1.07 | 91.22 | 64.30 | 0.52 | 78.29 |

| S6 | 1.39 | −4.02 | 90.91 | 63.55 | 2.38 | 59.34 |

| S7 | 2.43 | −5.70 | 90.66 | 63.10 | 3.46 | 64.36 |

| S8 | 2.22 | −5.32 | 91.11 | 63.49 | 3.17 | 0.00 |

| S9 | 0.81 | −2.93 | 91.06 | 63.89 | 1.68 | 77.07 |

| S10 | 2.41 | −5.65 | 90.94 | 63.34 | 3.39 | 91.62 |

| S11 | 1.66 | −4.44 | 90.95 | 63.48 | 2.64 | 62.99 |

| S12 | 0.84 | −3.11 | 90.83 | 63.65 | 1.84 | 78.44 |

| S13 | 1.28 | −3.84 | 90.85 | 63.47 | 2.28 | 80.40 |

| S14 | 1.73 | −4.57 | 90.89 | 63.46 | 2.72 | 62.30 |

| S15 | 0.93 | −3.05 | 91.22 | 63.96 | 1.73 | 75.65 |

| S16 | 1.28 | −3.84 | 90.85 | 63.47 | 2.28 | 80.40 |

| S17 | 0.23 | −1.75 | 90.75 | 63.75 | 1.07 | 58.10 |

| S18 | 0.74 | −2.99 | 90.71 | 63.45 | 1.80 | 50.36 |

| S19 | 1.33 | −3.83 | 91.13 | 63.77 | 2.24 | 81.35 |

| S20 | 0.52 | −2.37 | 90.99 | 63.89 | 1.35 | 86.27 |

| S21 | 1.25 | −3.73 | 91.05 | 63.76 | 2.19 | 90.15 |

| S22 | 1.24 | −3.75 | 90.95 | 63.68 | 2.21 | 72.27 |

| S23 | 1.46 | −4.08 | 91.04 | 63.68 | 2.40 | 63.95 |

Results showed that sample comprising 50% Protex and 50% Nomex exhibited highest relative hand value (RHV) [41]. It is because of modacrylic fibers which have soft and smooth tactile properties. It is resilient, wrinkle resistant, shrinkage resistant and offers a soft feeling [42]. Sample containing 70% Nomex and 30% Protex shows 0.23 RHV value. It was also noted that sample consisting of 50% Protex and 50% Nomex has the highest drape index of 3.46 because of the stiffness and sample containing 100% carbon fibers has lowest value of 0.52 due to easy bending of the fabric. Sample with 50% FR-polyester and 50% Protex has highest wrinkle recovery rate of 91.62% while lowest wrinkle recovery rate of 35.92% was observed in sample consisting of 100% FR-viscose. This tendency is typical for cellulosic fibers which have higher amorphous regions which offer poor resilience. 100% carbon sample has highest softness score and smoothness score of 91.22 and 64.30 respectively. This is because PAN based carbon fibers have good compressive strength and orientation of crystallites in carbon fibers microstructure [42]. The overall bulk of the carbon fabric offers a gentle feel and smooth surface. It can be inferred that; the fabric tactile properties are not a straightforward prediction based on the fiber properties. The yarn and fabric structure, thickness, porosity, bulkiness, and surface smoothness can be dramatically changed by combination of FR fibers which themselves do not seem to be comfortable to wear. Softness and smoothness scores are considered as most important parameters since the fabrics will come in contact with the skin of the wearer. Fig. 7(a) shows a comparative account of the relative smoothness scores and Fig. 7(b) shows the scores for softness.

Fig. 7.

Tactile comfort properties of fire-resistant fabrics, (a) Smoothness and (b) Softness.

6.2.1. Optimization using principal component analysis (PCA)

For the selection of optimum blend among the 23 samples on the basis of multiple responses, principal component analysis (PCA) was done. The samples are ranked according to the modified reference point index (MRPI) values which were gained from signal to noise (S/N) ratios and normalized S/N ratios. The principal component analysis was performed according to the stepwise procedure explained in literature [[46], [47], [48], [49], [50]]. It takes into account all the factors and their importance. The stepwise procedure for application of PCA is given below.

Step 1

Transformation of the original data into S/N ratios with the help of Taguchi experiment for response by utilizing using the appropriate formula depends upon the characteristics of responses either higher the better or lower the better.

Responses such as air permeability, thermal resistance, OMMC, softness and smoothness were considered as higher the better. The S/N ratio for higher-the-better is calculated using following equation.

S/N = −10*log (1/nΣ(1/Y2ij)) (1) where Yij is the ith replicate of jth response and n is the number of replicates.

Other responses e.g. char length, after flame time, after glow time, weight difference etc. were kept as lower the better where the S/N ratio for lower-the-better is calculated using the following equation.

S/N = −10*log(1/nΣY2)) (2)

Step 2

The S/N ratios were normalized.

Step 3

The normalized S/N ratio values corresponding to each response were considered to be the initial input for Factor Analysis. Factor analysis was performed using statistical software MINITAB.

Step 4

Insignificant principal components which have eigenvalues less than one were eliminated.

Step 5

The principal component values with eigenvalue greater than one corresponding to each response were considered for further analysis.

Step 6

Modified reference point index (MRPI) values were calculated using principal components obtained by factor analysis.

Z1 = ¼ (P1Y1 + P1Y2) (3)

Z2 = ¼ (P2Y1 + P2Y2) (4)

MRPI = ¼ (W1Z1 + W2Z2) (5) Where W1 and W2 are the weightages of respective principal components.

Step 7

The optimal factor and its level combination was determined. The higher performance index implies the better product quality, therefore, on the basis of the performance index, the factors (þ) and their effect were estimated and the optimal level for each controllable factor was determined. The effect, E, was calculated as:

Ei = ¼ Max MRPI (ðþmin) × MRPI (ðþ) (6) The probability plots shown in Fig. 8 provides the evidence of the normality of the data.

The S/N ratios and MRPI values along with sample rankings are given in Table 5, Table 6 respectively.

The sample S6 which is a 50:50 blend of FR-polyester (Recron) and FR-viscose is ranked as the best, taking into consideration the flame resistance, LOI, thermo-physiological and tactile comfort properties. This behavior is attributed to the fact that both the components are produced in bulk for applications in clothing materials. Therefore, with inherent flame-retardance, FR-polyester and FR-viscose combination still performs the best according to overall product quality. The samples S3 and S7 are judged with 2nd and 3rd rankings. Nomex is a relatively more crystalline fiber with higher stiffness, which resulted in relatively lower comfort of wearing. Further, it exhibited lower moisture management capability, and could not top the ratings. Among the worst performers are samples S14, S16 and S10, they are all blends of Protex. It may be inferred that blends of FR modacrylic with carbon or FR-polyester are not preferrable as fire fighters’ suits with respect to overall flame-retardant and comfort related performance.

Fig. 8.

Probability plots of MRPI values from PCA.

Table 5.

S/N ratios for the flame-resistant fabric samples.

| Sample No. | Thermal Resistance | OMMC | Air Permeability | Smoothness | Softness | Char length | After flame time | After glow Time | Weight Difference |

|---|---|---|---|---|---|---|---|---|---|

| S1 | −33.6272 | −3.68735 | 66.33425 | 36.04953 | 39.14506 | −15.6427 | −3.0103 | −16.5909 | 27.46581 |

| S2 | −34.3403 | −2.97376 | 65.35617 | 36.09212 | 39.16712 | 21.54505 | −120 | 2.480939 | −38.9345 |

| S3 | −36.4444 | −3.59055 | 68.89236 | 36.08808 | 39.15365 | 22.86602 | −120 | −120 | −28.7961 |

| S4 | −39.4554 | −3.59055 | 65.92313 | 36.04807 | 39.16073 | 40 | 10.58452 | 17.01339 | 1.573942 |

| S5 | −34.7796 | −95.2288 | 72.63596 | 36.22226 | 39.20521 | 22.07 | −120 | −120 | −120 |

| S6 | −37.4729 | −3.00885 | 67.02783 | 36.09811 | 39.16196 | 23.88739 | 3.432277 | 9.542425 | −0.08818 |

| S7 | −35.2474 | −2.43735 | 69.30903 | 36.03874 | 39.13006 | 20.104 | 3.432277 | 19.08056 | −22.8959 |

| S8 | −36.323 | −19.7491 | 67.64995 | 36.09535 | 39.22125 | 40 | 14.05035 | 11.93288 | −3.57865 |

| S9 | −33.739 | −2.57528 | 66.80929 | 36.07237 | 39.18528 | 17.92466 | 1.526102 | 5.822202 | −26.4805 |

| S10 | −34.8256 | −3.29916 | 66.99296 | 36.07256 | 39.17318 | 24.87549 | −120 | −120 | −26.3752 |

| S11 | −34.3762 | −4.20134 | 70.54159 | 36.0732 | 39.17892 | 40 | 16.40834 | 5.582206 | 1.517779 |

| S12 | −34.9775 | −2.69825 | 70.43361 | 36.06262 | 39.16426 | 19.64311 | 1.526102 | 15.20175 | −25.2494 |

| S13 | −35.1695 | −1.53096 | 72.17504 | 36.06041 | 39.16299 | 40 | 27.32322 | 5.454374 | −21.0812 |

| S14 | −34.0133 | −95.272 | 65.70235 | 36.03712 | 39.1487 | 40 | 31.95541 | 6.221814 | 2.007405 |

| S15 | −35.2551 | −2.58398 | 68.19635 | 36.08135 | 39.21573 | 40 | 16.2476 | −0.35689 | −0.41542 |

| S16 | −33.9576 | −2.9337 | 66.40002 | 36.07086 | 39.15788 | 22.74286 | 8.029748 | 6.454516 | −19.1174 |

| S17 | −34.5851 | −2.97376 | 66.74905 | 36.0923 | 39.12998 | 22.92256 | 1.526102 | 16.78871 | −23.8031 |

| S18 | −33.2022 | −2.98463 | 68.41855 | 36.06727 | 39.13991 | 20.104 | 1.249387 | 6.454516 | −26.3163 |

| S19 | −33.9068 | −2.69825 | 65.69698 | 36.07866 | 39.19578 | 19.25366 | 10.227 | −120 | −15.7491 |

| S20 | −34.1256 | −3.20215 | 61.11473 | 36.10321 | 39.17573 | 40 | 30.54141 | 5.981948 | 3.019184 |

| S21 | −34.9543 | −3.5883 | 71.31904 | 36.0691 | 39.20022 | 19.91279 | 0.774122 | 17.92695 | −23.8276 |

| S22 | −37.1092 | −1.76291 | 68.22571 | 36.07456 | 39.16162 | 40 | 12.35618 | 6.356917 | −0.91195 |

| S23 | −35.6144 | −2.3756 | 65.80029 | 36.06759 | 39.18559 | 40 | 24.85367 | 0.104001 | −0.72456 |

Table 6.

MRPI values and ranking of samples.

| Sample ID | MRPI values | Ranking of sample |

|---|---|---|

| S1 | 0.13812 | 16 |

| S2 | 0.06779 | 19 |

| S3 | 0.98538 | 2 |

| S4 | 0.00601 | 20 |

| S5 | 0.08411 | 18 |

| S6 | 0.98868 | 1 |

| S7 | 0.68259 | 3 |

| S8 | 0.44858 | 6 |

| S9 | 0.57006 | 4 |

| S10 | −0.00783 | 21 |

| S11 | 0.19382 | 14 |

| S12 | 0.25323 | 12 |

| S13 | 0.11717 | 17 |

| S14 | −0.09938 | 23 |

| S15 | 0.31503 | 8 |

| S16 | −0.07331 | 22 |

| S17 | 0.28019 | 10 |

| S18 | 0.14816 | 15 |

| S19 | 0.25178 | 13 |

| S20 | 0.53131 | 5 |

| S21 | 0.28504 | 9 |

| S22 | 0.27726 | 11 |

| S23 | 0.36562 | 7 |

7. Conclusions

Fire resistance properties of inherently fire-retardant fibers and their blends were studied vis-à-vis their comfort related performance. It was concluded that Nomex fibers and their blends show excellent flame resistance as compared to other fibers and their blends investigated. Nomex fibers and their blends with carbon also result in better performance with reference to thermo-physiological comfort properties which are limitation of pure Nomex fabrics. Viscose fiber blends result in inferior comfort properties. Viscose fibers are cellulose based fibers so result in lower fire-resistant properties. Combined effect of Protex and Nomex fibers result in optimum tactile comfort properties along with good fire-resistant properties.

The optimization of flame resistance and comfort properties of fabrics was done by using principal component analysis. The PCA was used to optimize the responses and rank the samples based on the results of air permeability, thermal resistance, OMMC, softness, smoothness, char length, after flame time, after glow time, weight difference etc. It was found that samples comprising 50% FR-Polyester and 50% FR-Viscose ranked 1st as per PCA results. This affirmed the better comfort properties achieved because of combination of cellulose-based FR-viscose and FR-polyester fibers which are blend of fibers whose moisture management and flame-resistant properties are acceptable for station wear/suits. Sample containing 100% Protex fibers was found to be second in ranking which affirmed the better comfort properties of modacrylic (Protex) fibers along with optimum fire-resistant properties. 50% Nomex & 50% FR-polyester blended fabric was ranked in 3rd position as both fibers provide relatively good fire-resistant behavior. Nomex is a relatively more crystalline fiber with higher stiffness, which resulted in relatively lower comfort of wearing. Further, it exhibited lower moisture management capability, and could not top the ratings. Protex in combination with carbon or FR-polyester was ranked among the poorest with regard to overall performance. The fire fighters’ suits should be selected based on optimization of fire-resistance as well as comfort of wearing. Further detailed analysis of the Total Hand Value, shear and bending force, frictional resistance etc. should be carried out to recommend the optimal solution with respect to functionality, performance, protection and wearing comfort of the fire fighters.

Author contribution statement

Hafsa Jamshaid, Rajesh Mishra, Awais Khan, Vijay Chandan, Miroslav Muller: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Petr Valasek: Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by the Internal grant agency of Faculty of Engineering, Czech University of Life Sciences Prague, “Numerical modelling and computational analysis of lightweight composite structures in automotive components”, (no. 2022:31140/1312/3111) and Higher education commission, NRPU-8980, Optimization of performance and comfort properties of fire-resistant knit wear.

Data availability statement

Data will be made available on request.

Declaration of interest’s statement

The authors declare no competing interests.

Acknowledgement

Authors would like to thank University of Engineering & Technology (UET) Lahore, Faisalabad campus, for special assistance for testing. Thanks to Mr. Yousaf Iqbal (TECH Fab International) Pakistan for providing assistance. Special thanks to Bilal Amin and Ekerama Ahmad, for their support for this work.

References

- 1.Osorio A., Fernandez-Pello C., Urban D., Ruff G. Limiting conditions for flame spread in fire resistant fabrics. Proc. Combust. Inst. 2013;34:2691–2697. [Google Scholar]

- 2.Zhang F., Wang B., Xu Y., Li P., Liu Y., Zhu P. Convenient blending of alginate fibers with polyamide fibers for flame-retardant non-woven fabrics. Cellulose. 2020;27:8341–8349. [Google Scholar]

- 3.Varga K., Noisternig M., Griesser U., Aljaz L., Koch T. Thermal and sorption study of flame-resistant fibers. Lenzinger Berichte. 2011;89:50–59. [Google Scholar]

- 4.Feng J., Zhang M., Hua T., Chan K. Study of a newly structuralized meta-aramid/cotton blended yarn for fabrics with enhanced flame-resistance. Textil. Res. J. 2020;90:489–502. [Google Scholar]

- 5.Kozłowski R.M., Muzyczek M. Elsevier; Oxford, london, UK: 2020. Handbook of Natural Fibres II Improving the Flame Retardancy of Natural Fibres. [Google Scholar]

- 6.Yao L., Wu L., Wu H., Krifa M. vol. 2. De Gruyter Open Access; 2019. pp. 49–59. (Design and Characterization of Flame Resistant Blended Nondrip PA6/FR/PBI Fiber Nonwoven Fabrics). [Google Scholar]

- 7.Zhang X., Tang X., Wang R., Wang R., Yan X., Shi M. The fire retardant properties and pyrolysis mechanism of polysulfonamide (PSA) fibers. Textil. Res. J. 2018;88:1299–1307. [Google Scholar]

- 8.Barker R., Carolina N. Analysis of heat transfer characteristits of fabrics in an open flame exposure. Textil. Res. J. 1983;53:475–482. [Google Scholar]

- 9.Pandian P., Ashifa K. Analysis and design of fire resistance cloth in fire works industries. Mater. Today Proc. 2020;33:1032–1037. [Google Scholar]

- 10.Li X., Zhang K., Shi R., Ma X., Tan L., Ji Q., Xia Y. Enhanced flame-retardant properties of cellulose fibers by incorporation of acid-resistant magnesium-oxide microcapsules. Carbohydr. Polym. 2017;176:246–256. doi: 10.1016/j.carbpol.2017.08.096. [DOI] [PubMed] [Google Scholar]

- 11.Taylor P., Basak S., Samanta K., Chattopadhyay S. Fire retardant property of cotton fabric treated with herbal extract. J. Textil. Inst. 2015;106(12):1338–1347. [Google Scholar]

- 12.Fang Y., Liu X., Wang C. Layer-by-layer assembly flame-retardant and anti-dripping treatment of polyethylene terephthalate fabrics. J. Eng. Fiber. Fabric. 2019;14:1–8. [Google Scholar]

- 13.Wu H., Krifa M., Koo J. Inherently flame retardant Nylon 6 nanocomposite fibers. Fibers Polym. 2018;19(7):1500–1512. [Google Scholar]

- 14.Borodulin A., Kalinnikov A., Bazheva R., Beshtoev B. Synthesis and properties of aromatic polyethersulfones. Int. J. Mech. Eng. Technol. 2018;9(13):1109–1116. [Google Scholar]

- 15.https://www.recronfs.com/pdf/brochure.pdf Assessed on 01.08.2022.

- 16.https://www.dupont.com/content/dam/dupont/amer/us/en/personal-protection/public/documents/en/Nomex(R)%20Aramid%20Fiber%20Laundering%20Guide.pdf Acccessed on 30.07.2022.

- 17.Mishra R., Petru M., Novotna J. Bio-composites reinforced with natural fibers: comparative analysis of thermal, static and dynamic-mechanical properties. Fiber. Polymer. 2020;21(3):619–627. [Google Scholar]

- 18.Sahoo P., Jena D. Synthesis and study of mechanical and fire retardant properties of (carboxymethyl cellulose -g-polyacrylonitrile)/montmorillonite biodegradable nano composite. J. Polym. Res. 2018;25(12):260. [Google Scholar]

- 19.Ogulata R., Mavruz S. Investigation of porosity and air permeability values of plain knitted fabrics. Fibres Text. East. Eur. 2010;18(5):71–75. [Google Scholar]

- 20.Mishra R., Tiwari R., Marsalkova M., Behera B.K. Effect of TiO2 nanoparticles on basalt/polysiloxane composites: mechanical and thermal characterization. J. Text. Inst. 2012;103:1361–1368. [Google Scholar]

- 21.Jamshaid H., Mishra R., Hussain S. Basalt hybrid woven textile materials for advanced thermal applications. Indian J. Fibre Text. Res. 2019;44:56–64. [Google Scholar]

- 22.Özkan E., Kaplangiray B. Investigating thermophysiological comfort properties of polyester knitted fabrics. J. Text. Eng. Fash. Technol. 2019;5(1):50–56. [Google Scholar]

- 23.Cimilli S., Nergis B., Candan C., Özdemir M. A comparative study of some comfort-related properties of socks of different fiber types. Textil. Res. J. 2010;80(10):948–957. [Google Scholar]

- 24.Kim H., Kim S. Flame retardant, anti-static and wear comfort properties of modacrylic/Excel®/anti-static PET blend yarns and their knitted fabrics. J. Textil. Inst. 2019;110(9):1318–1328. [Google Scholar]

- 25.Petrusic S., Onofrei E., Bedek G., Codau C., Dupont D., Soulat D. Moisture management of underwear fabrics and linings of firefighter protective clothing assemblies. J. Textil. Inst. 2015;5000:1270–1281. [Google Scholar]

- 26.Kim H. Tactile hand and wear comfort of polyethylene terephthalate imbedded woven fabrics. Textil. Res. J. 2019;89(21–22):4658–4669. [Google Scholar]

- 27.Qian X., Zhang Y., Wang X., Heng Y., Zhi J. Effect of carbon fiber surface functionality on the moisture absorption behavior of carbon fiber/epoxy resin composites. Surf. Interface Anal. 2016;48(12):1271–1277. [Google Scholar]

- 28.Venkataraman M., Mishra R., Xiong X., Yao J., Zhu G. Electrospun nanofibrous membranes embedded with aerogel for advanced thermal and transport properties. Polym. Adv. Technol. 2018;29(10):2583–2592. [Google Scholar]

- 29.Halim A., Housny H. MSc thesis, New Jersey institute of Technology; New Jersey, USA: 1977. Analysis of Combustion Products of Kynol and Nomex Copyright Warning & Restrictions. [Google Scholar]

- 30.Gu H. Research on thermal properties of Nomex/viscose FR fibre blended fabric. Mater. Des. 2009;30(10):4324–4327. [Google Scholar]

- 31.Fang Y., Liu X., Tao X. Intumescent flame retardant and anti-dripping of PET fabrics through layer-by-layer assembly of chitosan and ammonium polyphosphate. Prog. Org. Coating. 2019;134:162–168. [Google Scholar]

- 32.Villar-Rodil S., Martínez-Alonso A., Tascón J. Studies on pyrolysis of Nomex polyaramid fibers. J. Anal. Appl. Pyrolysis. 2001;58–59:105–115. [Google Scholar]

- 33.https://www.dupont.com/products/nomex-fibers.html Accessed on.

- 34.Jain A., Vijayan K. Thermally induced structural changes in Nomex fibres. Bull. Mater. Sci. 2002;25(4):341–346. [Google Scholar]

- 35.Mishra R., Behera B.K., Bhagti B. Influence of noncellulosic contents on nano scale refinement of waste jute fibers for reinforcement in polylactic acid films. Fibers Polym. 2014;15:1500–1506. [Google Scholar]

- 36.Yin F., Tang C., Wang Q., Liu X., Tang Y. Molecular dynamics simulations on the thermal decomposition of meta-aramid fibers. Polymers. 2018;10:691. doi: 10.3390/polym10070691. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Patnaik A., Mvubu M., Muniyasamy S., Botha A., Anandjiwala R. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build. 2015;92:161–169. [Google Scholar]

- 38.Yang T., Saati F., Horoshenkov K., Xiong X., Mishra R. Study on the sound absorption behavior of multi-component polyester nonwovens: experimental and numerical methods. Textil. Res. J. 2019;89(16):3342–3361. [Google Scholar]

- 39.Moiseev V., Neiman M., Kriukova A. The thermal degradation of polypropylene. Polym. Sci. USSR. 1961;2(1–2):55–62. [Google Scholar]

- 40.Zimniewska M., Kozłowski R. Natural and man-made fibers and their role in creation of physiological state of human body. Mol. Cryst. Liq. Cryst. 2004;418(1):113–130. [Google Scholar]

- 41.Grgac S., Bischof S., Pušić T., Petrinić I. Analytical assessment of the thermal decomposition of cotton-modacryl knitted fabrics. Fibres Text. East. Eur. 2017;25(6):59–67. [Google Scholar]

- 42.Xu Y., Lu Z., Tang R. Structure and thermal properties of bamboo viscose, Tencel and conventional viscose fiber. J. Therm. Anal. Calorim. 2007;89(1):197–201. [Google Scholar]

- 43.Wang X., Li Q., Di Y., Xing G. Preparation and properties of flame-retardant viscose fiber containing phosphazene derivative. Fibers Polym. 2012;13(6):718–723. [Google Scholar]

- 44.Yang T., Xiong X., Mishra R., Novak J. Acoustic evaluation of Struto nonwovens and their relationship with thermal properties. Textil. Res. J. 2018;88(4):426–437. [Google Scholar]

- 45.Wang T., Xu X., Ren Y., Qin S., Sui X., Wang L. Kinetics of thermal degradation of viscose fiber and fire retardant viscose fiber. J. Eng. Fiber. Fabr. 2014;9(2):38–46. [Google Scholar]

- 46.Arbab S., Menczel J. Woodhead Publishing; Cambridge, UK: 2020. Thermal Analysis of Acrylic and Carbon Fibers. [Google Scholar]

- 47.Wu G., Lu C., Ling L., Lu Y. Comparative investigation on the thermal degradation and stabilization of carbon fiber precursors. Polym. Bull. 2009;62(5):667–678. [Google Scholar]

- 48.https://www.primaryinfo.com/industry/acrylic-fiber.htm Accessed on.

- 49.Newcomb B. Processing, structure, and properties of carbon fibers. Compos. Part. A. Appl. Sci. Manuf. 2016;91:262–282. [Google Scholar]

- 50.Umair M., Shaker K., Ahmad N., Hussain M., Jabbar M., Nawab Y. Simultaneous optimization of woven fabric properties using principal component analysis. J. Nat. Fibers. 2017;14(6):846–857. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.