Abstract

International trade connections with COVID-19 impeding the development of the logistics industry in express delivery, the world has become an inseparable part of daily life. To improve protection competency, there is a need for effective research on logistics warehouse fire accident alarms. The goal of this study is to create a novel fire risk evaluation method for fire safety managers in logistics warehouses. The Gustav method is used to convert a plane model to a stereoscopic model. Hazards to construction, hazards to life, and fire rescue competency are all taken into account. The empirical study used JingDong Gu’an logistics park as a case study, and the evaluation results revealed differences in fire risk levels between the two warehouses. The results show that the transmit warehouse had a higher fire risk level than the sorting warehouse. The method describes the total risk of a warehouse fire. It is appropriate for the various types and processes found in modern logistics warehouses. The results of the developed 3D-Dynamic method demonstrate the model’s feasibility and practicability even to laypeople with limited professional knowledge.

Keywords: Logistics warehouse, 3-Dimension model, Emergency resilience, Fire risk level, Semi-quantitative evaluation, Fire safety management

Introduction

COVID-19 has increased demand for the logistics industry, which benefits human society economically. Various news outlets, however, show that logistics warehouse fires generally result in greater economic losses and casualties. In 2016, the Jindong Gu’an logistics warehouse fire accident [1], in Hebei province, China, lost at least 1 billion RMB (more than $15 million). In 2017, Amazon UK logistics warehouse (BHX1) fire accident [2] destroyed more than 1.7 million kinds of goods in one night. In 2018, a transportation logistics warehouse located at Yokosuka, Kanagawa Prefecture, Japan, fired more than 13 thousand square meters [3]. In 2021, Amazon American logistics center warehouse (TEB6), the largest building in New Jersey, drowned in flames [4]. In 3 months later, 38 lives were lost in the fire accident of an underground logistics warehouse in Icheon, Gyeonggi Province, Korea [5]. The growing number of fires in logistics warehouses has prompted people to consider how to improve fire protection competency more quickly.

Modern Logistics Warehouses and Their Fire Risk

Why and what causes frequent fires in logistic infrastructure? The reasons should be considered from both explicit and implicit risks, which correspond to specific fire sources. The characteristics of the logistics industry and fire accidents may indicate the former.

Characteristics of Logistics Industry

Storage, transfer, sorting, processing, and distribution are all components of modern logistics. Logistics warehouses are larger and higher than traditional ones to meet the urgent demand for express deliveries, heavier load-capacity, multi-functional, and automatic to meet the requirements of ‘light-speed delivery’ and ‘zero storage’. Using statistical data, some Japanese scholars compared the fire load density of all construction categories. Table 1 showed that fire loads in warehouses ranked first, with modern logistics warehouse characteristics contributing to an increase in fire probability.

Table 1.

Comparison of Fire Loads Density in Different Constructions in Japan [6]

| Occupation | Density of fire load (MJ/m2) | Maximum value (MJ/m2) |

|---|---|---|

| Resident building | 644–662 | 1104 |

| Hotel | 276–552 | 552 |

| Meeting room | 368–644 | 644 |

| Designing room | 552–2208 | 2760 |

| Library | 1840–4600 | 4600 |

| Warehouse | 3680–18,400 | – |

| Shopping mall | – | 1840–3680 |

Hazards of Logistics Warehouse Fires

Fire features are the clues of fire risks. We summarized fire features according to fire accidents happened from 2005 to 2020, collecting with their complete information and investigation reports. Fire accidents of logistics warehouses generally destroyed large areas, produced poisonous gases, spread rapidly, and led to the collapse of the warehouses.

Research Review of Fire Protection

The logistics industry began in 1965, when Japan built the first logistics park. However, a fire occurred several months later, killing 19 firefighters and injuring 89 others [7]. The processing plant of a logistics park in southern Germany exploded in 1978, causing the most serious fire accident in Germany in the previous decade. During the early years of the logistics industry, fires heightened awareness of the importance of fire protection in logistics warehouses.

The Fire Protection Planning of Logistics Park

Scientific fire safety construction distance was considered as a possible way to decrease fire risk at first. Melendez et al. [8], Dai [9], Shea [10] and Shanfeng [11] suggested the different optimization plans. Expanding the distance from one warehouse to another one was an efficient method to avoid external fire spread at the original developing stage of logistics warehouses. However, only scientific construction distance is not enough to prevent the warehouse fire from occurring with the various functions of modern logistics warehouses.

Standards for Fire Protection

Countries published laws or regulations to standardize the fire protection design for logistics warehouses. For example, the NFPA 230 Standard for the Fire Protection of Storage [12] ruled how to store the inflammable substance outside. The American Building Code [13] classified logistics warehouses into two levels, while the Canadian National Building Code [14] into three. In China, there are special regulations for logistics parks and warehouses, the Classification and Requirement of Logistics Park (GB/T 24,358–2008) [15] as an example. But the regulations hysteric the development of warehouses. Wenhui Ju [16] chose nine typical logistics warehouses in China and studied on the contradictions between standards and demands and optimized fire protection investment strategy. As a result, in order to adapt to the development of the logistics industry, performance-based fire protection designs, rather than the prescriptive approach, became prevalent in order to meet the overall goal of the fire protection requirement.

Performance-Based Design and Insurance

How to balance the fire safe and development? Performance-based design and economic compensation worked it. Performance-based design (PBD) stimulates the development of logistics industry to some extent, as the key to achieve an appropriate level of safety under the type of operations running there. Yumin Tian [17] used methods from the economics of fire protection [18], such as cost–benefit model, to study the optimized Performance-based design (PBD). However, some owners only focus on the fixed fire extinguishing equipment such as fire hydrant system and automatic fire alarm system, ignoring the fire risk management such as firefighting training and rescue drills. It was necessary to develop a fire risk assessment method with management parameters.

Some scholars [19, 20] also studied on risk management, such as fire insurance, to evaluate risk exposure and diversify fire risk. However, insurance is not a cure-all. Fire results in a loss for either stakeholders or the social-economic system. Meanwhile, no insurer is willing to underwrite a risky subject. The cognition and management of fire risk became a significant issue.

Performance-based design isn’t a matter, but the ignoration of the fire risk management, such as firefighting training and rescue drills, also implicitly increases the probability of fire. Therefore, it was necessary to develop a fire risk assessment method containing management parameters.

Fire Risk Evaluation and the Gustav Method

How to value the fire risk of the logistics warehouse? The intuition drove researchers to study on fire risk factors [21, 22] and fire risk characteristics [23]. With comprehensive risk analysis, fire risk evaluation is a common way to value the hazards. There are various assessment methods, including the Fire Risk Model (FRM) [24], J-value [25], index systems [26, 27], and fuzzy comprehensive method [28–30].

Comparing the evaluation components between different methods, the Gustav method includes both property and life hazards, which is consistent with the fire characteristics of logistics warehouses. The application of the Gustav method is multiple, approximately classified into three ways that combination of evaluation methods [31, 32], changing parameters [33], or algorithm [33, 34]. However, these methods put out a stationary fire risk level, overlapping the extreme values, underestimating, or overestimating the cost of fire economics. Therefore, a dynamic fire evaluation method of logistics warehouse is needed.

Research Structure

The studies we reviewed, as promising as they are, necessitate further investigation. While existing fire risk evaluation methods can produce accurate but stationary results, it remains to be seen whether dynamic risk parameters have a significant impact on the fluctuation of fire risk. Notwithstanding these concerns, the literature review indicates that fire risk evaluation is still an efficient way to cognit and distinguish fire risks in logistics warehouse. Although the practices of the Gustav method are not quite suitable to evaluate the dynamic fire risk, its superior characteristics, simple procedures and results, still attract us.

Considering research goals and available resources, we chose the Gustav method in the end. The research goal is to develop a concise method for grassroots safety managers to describe the fluctuation of fire risk, focusing less on how accurate the outcome, because users pay more attention to whether the probability of fire risk is 0.1 or 0.8, not 0.8 or 0.823. And the lack of logistics fire data excludes quantitative methods, because of the early stage of the logistics industry in China. Also, because of the flexible combination of fire risk factors, the Gustav method may realize the image of dynamic fire risk evaluation for logistics warehouses.

The structure is illustrated as follows, as is shown in Fig. 1. Section 1 mainly illustrates the research background and research review, as what you have read. Section 2 is the fire risk analysis, including the fire risk cognition, extraction of dynamic parameters and weighing parameters in the fire risk evaluation index system. Section 3 introduces the 3D-Dynamic fire risk assessment method from four subsections, modified Gustav method, formula, classification of risk level, and instruction. Section 4 shows the empirical study, and we chose two different logistics warehouse types and evaluated their dynamic fire risk. Section 5 concludes this the research. Reference and appendixes will follow.

Figure 1.

Research structure

Fire Risk Analysis of Modern Logistics Warehouses

Modern logistics warehouses are not the traditional ones, the implicit fire risks are more complex. Because logistics warehouses derived various types defined by height, location, and occupation, the hidden fire risks depend on special context, like types and functions of logistics warehouses. Meanwhile, dynamic factors implicit extreme risk values which may cause the ‘Black Swan Event’. However, not all dynamic factors affect fire risk, for example, the weather. Therefore, it’s necessary to extract dynamic parameters then, as well as weigh them.

Heterogenous Analysis of Fire Risk

We chose three classic warehouse types, including storage warehouse, sorting center warehouse, and transmit warehouse, consistent with three main functions of the logistics chain. And the heterogenous analysis was summarized in Table 2.

Table 2.

The Heterogenous Analysis of Fire Risks in Three Warehouse Types

| Type | Function | Transportation period | Fire risks | Reasons |

|---|---|---|---|---|

| Storing warehouse | Storage | More than one week | Large fire loads | •••The capacity of logistics warehouses is 5–10 times that of normal warehouses to satisfy the express need |

| Various combustibles | •••Besides general commodities, there are plastic, cotton, linen, rubber products and even lubricating oil | |||

| Dynamic contributions of goods | •••The high frequency of goods flow makes some combustibles accumulate heat out of control | |||

| Hidden ignition points | •••The height of shelves is over the efficient detect distance of automatic fire detectors and sprayers, especially when detecting the corner ignition points | |||

| Electrical failures | •••The electrical or batteries failures are larger proportions of fire reasons | |||

| Sorting center warehouse | Storage, Sorting & Manufacturing | 2–4 h | Unpredictable fire loads | •••The residence period of goods depends on orders, making it difficult to accurately predict the amplitude of the fluctuation values of fire loads |

| High-frequency electrical failure | •••The large-scale automatic equipment leads to an unbalanced contribution of electricity. And electrical failure is the highest fire reason | |||

| High-temperature processing conditions | •••The goods processed by thermoplastic have high-temperature external surfaces, which ignite the combustibles near | |||

| Transmit warehouse | Storage & Sorting | Two days or one week | Reduced vigilance | •••The middle storing period relax the vigilance of workers and elevates the group loafing |

| Inevitable unsafety behaviors | •••As the fast flow of workers makes the security check loose, arsons or smokers may fire the warehouse easily |

Some regulations cover or shall cover this fire risk if properly applied. Why do these risks exist? Most of these problems are because of the failure of risk management.

For example, a modern logistics warehouse should be built with a proper sprinkler design according to the Code for design of sprinkler system (GB 50,084–2017), including ceiling sprinklers and in-rack sprinklers. However, investigations and fire accident reports of several modern logistics warehouses in China showed that it was quite difficult to detect the lowest corner ignition points, such as the ‘Hidden ignition points’.

The fire detection failure of sprinkler systems mainly results from the risk management failure separated into two cases. One is the failure of automatic fire detectors and sprayers. Owners don’t want to spend more on fire protection once passing the fire audit and inspection. Therefore, fire safety managers don’t inspect or maintain the fire protection systems promptly [35]. Sprayers, near the ignition point, cannot detect fire signals.

The other one is the incorrect placement of goods. To realize the maximum cost–benefit value of the operation, users or workers would like to store as many interests as possible per square, which leads to overload. Some inflammable goods, such as cotton and fiber, smolder easily, especially when stored crowdedly in the corner [36]. These ignition points are too hidden to be detected as soon as possible.

In addition, the regulations always lag behind the development of logistics warehouses even though they standardize fire protection design and cover most fire risks. For example, the Code for design of sprinkler system (GB 50,084–2017) only requires the efficient detect distance of automatic fire detectors and sprayers, as well as the rules of storing categories, but no requirement of store location or strategy.

As the essential function in the modern logistics supply chain, storage still occupies most of the construction area, whichever the warehouse-type is, as is shown in Fig. 2a. The sorting center warehouse is also called the ‘Zero storage’ warehouse, the popular type in logistics park, selecting goods from address A to transport to address B with high flow speed. And it is multi-functional, including storing and sorting while the store function is auxiliary. Sorting not only classify goods but produce, for example, packing, unpacking, and thermal process. Generally, besides storing, the sorting center warehouse includes the sorting area and manufacturing area, as is shown in Fig. 2b and c respectively. Transmit warehouse has a longer transportation period than the sorting center warehouse, as is shown in Fig. 2d, while its sorting function is auxiliary on the contrary.

Figure 2.

The insight of modern logistics warehouse. (a) storing warehouse; (b) sorting area of the sorting center warehouse; (c) manufacturing area of the sorting center; (d) transit warehouse

We analyzed the special characteristics using fire accidents, Event Tree Analysis (ETA), and Fault Tree Analysis (FTA). Wenhui Ju [37] innovated the Event and Fault Tree Analysis method (EFTA) to explore the fire spread mechanism of various cotton logistics warehouses and obtained straightly the reducing or protection factors.

Dynamic Parameters Analysis

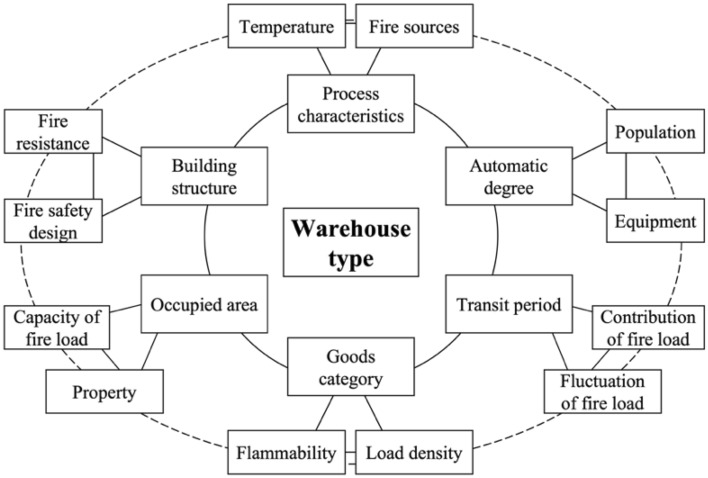

The analyses of explicit risks in Sect. 1 and implicit ones above extract the dynamic fire risk parameters, as shown in Fig. 3. We also found that some parameters in the original formulas of the Gustav method were parts of dynamic ones.

Figure 3.

Dynamic parameters in logistics warehouses and their correlations

There are two circles. The circle inside includes the main dynamic factors depending on warehouse type, and the ellipse shows the dynamic sub-factors depending on specific factors. We should mention that the correlations between factors and sub-factors are not fixed or unique. The figure describes that some dynamic sub-factors are significant in a factor.

Fire Risk Evaluation Index System

A thorough fire risk analysis provided a solid foundation for developing a fire risk evaluation method. However, the investigation was not conducted in a systematic manner. Furthermore, the judgment of fire risk status quo and evaluation of each parameter from different assessors would make a big noise to the assessment of fire risk level. And the noise might magnify the stochastic error. Index system is an efficient tool to integrate risk parameters and reduce the error.

Wenhui et al. [38] constructed an index system of fire risk evaluation for modern logistics warehouse with four parameters in first level, 10 in second level, and 32 in third level with four noteworthy points (B2, C27, B5, and C32), as is shown in Fig. 4. They also weighted parameters by the AHP method and the Delphi method. We use these weighted values as the coefficients of risk parameters in this novel fire risk evaluation method, and more details are listed in Appendix 1.

Figure 4.

The fire risk evaluation index system of modernized logistics warehouses [38]

The 3D-Dynamic Fire Risk Evaluation Method

According to the fixable result of the fire risk level, the traditional Gustav method provides assessors with simple and feasible fire protection plans. Based on the current state of modern logistics warehouses and fire risk characteristics, the traditional version must be modified to be a flexible evaluation method for calculating dynamic fire risks.

The Construction of 3D Gustav Method

The Gustav method, a half-quantitative fire assessment method, classifies fire risk factors into two aspects, the risk to construction’s destroys donated as GR, and the risk to the properties and lives donated as IR. Each point in a rectangular coordinate system composes of GR as the x-axis and IR as the y-axis can determine the fire risk of one building. The planar defined by the original Gustav method is separated into four parts, suggesting four fire protection ways respectively for the users, including the zone without fire protection measure, the zone with automatic firefighting measures, the zone with automatic fire alarm system, and the zone with automatic fire alarm and firefighting measures, as is shown in Fig. 5.

Figure 5.

The fire risk zones in the original Gustav method

The Gustav method has a series of value principles for risk parameters. The evaluator could calculate the values of two axis and determine the position of fire risk in the rectangular coordinate system. The Gustav method provides owners with feasible and reasonable fire protection strategies according to the fire risk level located in the planar.

Scholars modified the original Gustav method into different versions for various assessed subjects, comparisons among modifications listed in Tables 3 and 4.

Table 3.

The modifications of Gustav method

| Version | Origin [32] | Modified parameters [28] | Modified algorithm [29] | ||

|---|---|---|---|---|---|

| Empirical formulas | Considered risk of large-scale processing equipment | Considered parameters of fire spread | |||

| Separated firefighting competency into two aspects, firefighters and fire protection systems | Extracted firefighting competency | ||||

| Changed the value principles of parameters through establishing an index system with parameter weights | Deleted hazards to properties | ||||

| Added the number of people to consider hazards to life | |||||

| None | None | None | Defined a new risk evaluation aspect, ‘Competency of fire-controlling’ | ||

| Risk value | The Risk Profile | The Risk Profile | No change | The Risk Profile | Deleted transition region |

| Visualization risk value in a rectangular coordinate system | Visualization risk value in a rectangular coordinate system | No change | Comprehensive Risk Value | ||

| Application | All contributions | E-commerce Logistics Warehouses | Shopping Mall | ||

Table 4.

The Meaning of Variables in Formulas

| Variable | Meaning | Variable | Meaning | Variable | Meaning |

|---|---|---|---|---|---|

| Mobile fire loads | Parameters of decreasing fire risk | Firefighting competency parameter of fire brigade | |||

| Stationary fire loads | The feature parameter of people | Firefighting competency parameter of fire protection system | |||

| Flammable parameter of | The parameter of gas | The parameter of population | |||

| Square meters of the constructions | Hazard parameter of life | The parameter of firefighting competency of a fire brigade | |||

| Parameter of firefighting competency | The destroy risk parameter of property | The distance parameter of firefighting | |||

| Fire resistance parameter | Hazard parameter of equipment | The height parameter of the building | |||

| Parameters of decreasing fire risk | Fire-controlling competency parameter of the construction | The effect parameter of outdoor firefighting systems |

The existed modifications of the Gustav method exhibited some drawbacks. On one hand, all the modified versions of empirical formula included rescue parameters into GR but didn’t make fire rescue powers independent of fire risk resources, which couldn’t quantify the effect of the effort of firefighting. On the other hand, the outcome of Gustav’s method is too simple to describe the fluctuation of the relative fire risk levels.

We separated the firefighting effort by defining a new empirical formula, named Control ability of fire protection (CA). In this way, Gustav’s method can modify from 2 to 3 dimensions, as shown in Fig. 6. We established a spatial rectangular coordinate system, defining GR as X-axis, IR as Y-axis, and CA as Z-axis. CA contains the fire rescue parameters, including firefighting facilities inside or outside, fire brigades, fire safety management. Each axis will be illustrated in detail below.

Figure 6.

Spatial diagram of the 3D Gustav method

The Formula of GR

Compared to the original formula in Gustav’s method, the modified GR alternates L, the parameter of firefighting power, to P and T, to distinguish the special characteristics of fire risk between technic processes. The modified expression of GR is formula (1):

| 1 |

, mobile fire loads; , stationary fire loads; , flammable parameter of ; S, square meters of logistics warehouse; P, district parameter of fire loads; T, the characteristics of technic process; W, the fire resistance parameter; , the parameters of decreasing fire risk.

is the main dynamic parameter, depending on the transit period of a specific logistics warehouse, while changes with its fluctuation. Gustav method uses the isothermal value of standard wood, , to value . Normally, can be valued by formula (2) [39]:

| 2 |

While is the density of fire loads. So, we need to make sure the value of . And the density of fire loads can be calculated by formula (3) [39]:

| 3 |

While is the density of fire loads, MJ/m2; , the mass of each good, kg; , the available heating value of the good, MJ/kg; , the occupied area of the good.

It should be emphasized that the fluctuation of the density of fire loads is affected by the transit period of the logistics warehouse. We considered the effect to classify the transit period into three kinds, less than 2 days (like ‘zero storage’ warehouses), between 2 and 7 days (like transmit warehouses), and more than 7 days (like traditional warehouses).

The Formula of IR

The modified expression of IR is formula (4) [38]:

| 4 |

While F is the parameter of toxic gas; H, hazard parameter of life; , the number of people; D, the destroyed risk parameter of property.

Compared to the original formula in Gustav’s method, the modified GR pays attention to the change of people’s amount in specific technic process of a logistics warehouse. To make a balance between the maximum value in different axis, the result is calculated value multiplied by 0.1.

The Formula of CA

Control ability of fire protection (CA) refers to the comprehensive competency from fire protection equipment, workers, and firefighters to fire risk control in either daily safety management or fire accident, the sum of these three kinds of sub-competency. The expression of CA is formula (5):

| 5 |

Each ingredient represents the extinguishing capacity respectively comes from firefighters, fire protection equipment indoor (), and early fire extinguishing behaviors of workers in order. In the first ingredient, represents the firefighting capacity parameter of the fire brigade, represents the distance parameter of arriving fire accident site, represents the height parameter of logistics warehouse, and E represents the extinguish capacity parameter of fire equipment outdoor. And is the number of available fire brigader.

For , the fire scale positively correlates with the distance between fire site and fire brigade when the arriving speed is stationary. According to Gustav’s method, is calculated by formula (6):

| 6 |

While d is the driving distance, m; is the driving speed, m/s.

Gustav considered the effect of the logistics warehouse height to fire rescue. And the height of the building won’t affect the fire rescue if the elevating high of a fire engine is taller than the building, vis versa. For , it remains the original empirical formula in Gustav’s method but improves the available elevating high of the fire engine considering the technical development of the fire engine. can be calculated by formula (7) [33]:

| 7 |

While is the building height, m; is the elevating high of the fire engine, m.

Based on the principle of the parameter values in Gustav method [39], we referenced the empirical value from renowned fire safety experts to discuss the values to each parameter, listed in Appendix 2. In this way, we can calculate both values of axis.

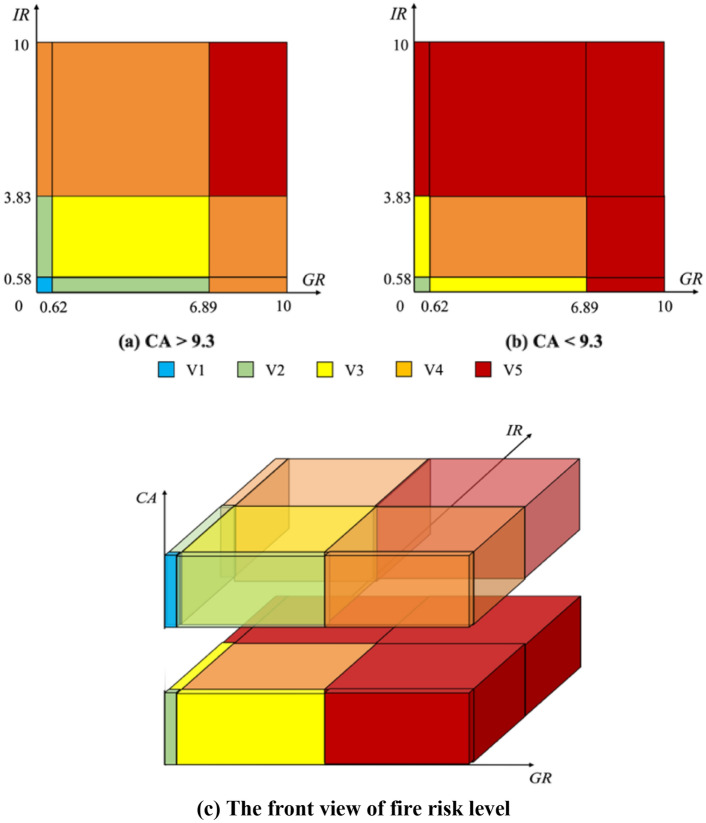

The Classification of Fire Risk Levels

Points in the spatial rectangular coordinates system are defined as the fire risk values. However, no user wants to gain a pile of figures, which doesn’t make sense, and even experts couldn’t judge straightly whether the fire risk is serious using these figures.

In extreme scenarios, the maximum of each axis can be calculated by specifying the best or worst conditions. We use cubes to classify the fire risk level, similar to how the original Gustav method distinguished fire risk levels. The X-axis, like the Y-axis, is divided into three intervals, while the Z-axis is divided into two intervals. As a result, the spatial rectangular coordinated system is made up of 18 cubes. And, in accordance with the international classification principle, these 18 cubes were classified into five risk levels. The 5-level evaluation set of fire risk levels is represented by the formula (8):

| 8 |

While the fire risk level grows up with the increase of the number.

The original Gustav method provides managers with reasonable fire protection measurements by dividing the axis into three areas, safety, transition, and danger. And the X-axis and Y-axis in modification also follow this separating way. But for Z-axis, it is different. On the one hand, the emergency capacity is changeable every day because many parameters depend on human behaviors. It is enough to judge the relativity of CA. On the other hand, it makes no sense to divide too many cubes, classified into five levels in the end.

For GR and IR, each parameter is classified into three levels, safety, transition, and danger. Then the results are naturally divided into three intervals. The interval nodes of GR are 0.62 and 6.89, while those of IR are 0.58 and 3.83. For CA, 9.3, the half of the maximum, is the interval node. The corresponding relations between 18 cubes and 5 fire risk levels are shown in Fig. 7.

Figure 7.

The spatial schematic diagram of fire risk level contribution. (a) The vertical view of fire risk level when CA > 9.3. There are five fire risk level, consistent with the upper part in (c). (b) The vertical view of fire risk level when CA < 9.3. There are four fire risk level, consistent with the down part in (c). (c) The front view of the 3D-Dynamic fire risk evaluation model

Compared with GR and IR, CA has the opposite mechanism of fire risk expression. The fire risk increases when the value of GR and IR goes up, while the higher value of CA illustrates maximum safety. The meaning of each fire risk level lists in Table 5.

Table 5.

The 5-Level Evaluation Set of Fire Risk Levels in Logistics Warehouse

| Fire risk level | Meaning |

|---|---|

| V1 | Scenario A. The warehouse, property, and people all have less exposure to fire risks, and the fire-controlling competency of construction is strong |

| V2 | Scenario B. With the high fire-controlling competency, hazards to the logistics warehouse, or hazards to people and property are small |

| Scenario C. The warehouse, property, and people have less exposure to fire risks although the fire-controlling competency of construction is weak | |

| V3 | Scenario D. With the high fire-controlling competency, hazards to the warehouse, property, and people are middle |

| Scenario E. Although the fire-controlling competency of construction is weak, hazards to the warehouse, property, and people are below the average level | |

| V4 | Scenario F. The fire-controlling competency of construction is strong, but either hazards to the warehouse or hazards to property and people are bigger than the average level |

| Scenario G. Although hazards to the warehouse, property, and people are below the average level, the fire-controlling competency of construction is weak | |

| V5 | Scenario H. The warehouse, property, and people all have more exposure to fire risks, while the fire-controlling competency of construction is strong |

| Scenario I. Only if hazards to the warehouse, or hazards to property and people is big, adding the weak fire-controlling competency of the logistics warehouse |

Application Instruction

Combining the above researches, we develop a 3D-Dynamic fire risk assessment method of logistics warehouses. The instruction can conclude into ‘5C’, Collection, Calculation, Curve tracing, Classification, and Correction in order.

Collect data of the assessed logistics warehouse. Users can gain fixable data through investigating the status quo of the assessed subject, including construction quo (area, layer), operation quo (function, goods category, transit period), fire protection quo (fire resistance class, firefighting equipment, fire load), and other aspects listed in the index system. For dynamic data, users need to record the values of dynamic risk parameters during more than one transit period without maximum limitation.

Calculate the values of risk parameters in empirical formulas. Determining the value of each risk parameter according to the collected data, users put values into the empirical formulas of the 3D Gustav’s method and gain the outcome of three axes.

Tracing the curve into the spatial rectangular coordinate system. A series of spatial points, describing GR, IR, and CA, can be drawn in the spatial rectangular coordinate system, while the curve reveals the temporal fluctuation of the fire risk.

There are five steps to model them.

Firstly, the user should collect data from the assessed logistics warehouse. Basic data, such as construction area, layers, operation function, goods category, etc., corresponding to in the index system, are easy to collect. For fire protection factors, such as fire protection design, fire safety management, and fire emergency strategy, corresponding to in the index system, users need to check one by one, and gain the score of each parameter. For example, if the automatic sprinkler system in the assessed logistics warehouse is available and in perfect condition, the value of the automatic sprinkler system, one of the parameters of I, is 100 according to Table 24. And for dynamic parameters, such as fire loads, populations, transit period, etc., users need to record the values of dynamic risk parameters during more than one transit period without maximum limitation.

Table 24.

The Value Principle of I

| Fire protection measures | Values in different levels | |||

|---|---|---|---|---|

| 10 | 40 | 60 | 100 | |

| Automatic fire alarm system1 | None | Regional control | Centralized control | Controller control |

| Fire power supply | Not qualified | Partially qualified | Mostly qualified | Qualified2 |

| Electrical fire protection | Poor | Qualified | Good | Excellent |

| Fire hydrant system indoor | Not qualified | Partially qualified | Mostly qualified | Qualified |

| Automatic sprinkler system | Not qualified | Partially qualified | Mostly qualified | Qualified |

| Smoke control system | Not qualified | Partially qualified | Mostly qualified | Qualified |

| Fire curtain at firewall | Breakdown | – | – | Normal |

| Fire curtain near conveyor belts | Breakdown | – | – | Normal |

| Fire compartment | Not qualified | – | – | Qualified |

1. There are three types of automatic fire alarm system in Fire Code, respectively suiting to different building levels.

2. ‘Qualified’ means that the measure reaches the standard of the relevant codes.

Secondly, the collected value of each parameter multiplies the corresponding weight in the index system (Table 8 in Appendix 1), and the results are the value of parameters in empirical formulas. For example, if each fire protection factor of scores 100, then the value of I will be:

Table 8.

The Weights of Fire Risk Parameters in Index System

| First level index | Second level index | Third level index | Comprehensive weight | |||

|---|---|---|---|---|---|---|

| Parameter | Weight | Parameter | Weight | Parameter | Weight | |

| A1 | 0.5349 | B1 | 0.8333 | C10 | 0.2000 | 0.0892 |

| C11 | 0.8000 | 0.3566 | ||||

| B2 | 0.1667 | C12 | 0.5414 | 0.0483 | ||

| C13 | 0.2313 | 0.0206 | ||||

| C14 | 0.0751 | 0.0067 | ||||

| C15 | 0.1522 | 0.0136 | ||||

| A2 | 0.1504 | B3 | 0.5000 | C20 | 0.4434 | 0.0333 |

| C21 | 0.1443 | 0.0109 | ||||

| C22 | 0.2223 | 0.0167 | ||||

| C23 | 0.0391 | 0.0029 | ||||

| C24 | 0.0919 | 0.0069 | ||||

| C25 | 0.589 | 0.0044 | ||||

| B4 | 0.5000 | C26 | 0.5318 | 0.0400 | ||

| C27 | 0.1221 | 0.0092 | ||||

| C28 | 0.0760 | 0.0057 | ||||

| C29 | 0.2702 | 0.0203 | ||||

| A3 | 0.2456 | B5 | 0.75000 | C30 | 0.4723 | 0.0870 |

| C31 | 0.2854 | 0.0526 | ||||

| C32 | 0.1697 | 0.0313 | ||||

| C33 | 0.0725 | 0.0134 | ||||

| B6 | 0.25000 | C34 | 0.2500 | 0.0154 | ||

| C35 | 0.7500 | 0.0461 | ||||

| A4 | 0.0691 | B7 | 0.0837 | C40 | 0.6667 | 0.0039 |

| C41 | 0.3333 | 0.0019 | ||||

| B8 | 0.5450 | C42 | 0.6483 | 0.0244 | ||

| C43 | 0.1220 | 0.0046 | ||||

| C44 | 0.2297 | 0.0086 | ||||

| B9 | 0.1385 | C45 | 0.3333 | 0.0032 | ||

| C46 | 0.6667 | 0.0064 | ||||

| B10 | 0.2329 | C47 | 0.2297 | 0.0037 | ||

| C48 | 0.6483 | 0.0104 | ||||

| C49 | 0.1220 | 0.0020 | ||||

Thirdly, determining the value of each risk parameter according to the collected data, users put values into the empirical formulas of the 3D Gustav’s method and gain the outcome of three axes.

Fourthly, tracing the curve into the spatial rectangular coordinate system. A series of spatial points, describing GR, IR, and CA, can be drawn in the spatial rectangular coordinate system, while the curve reveals the temporal fluctuation of the fire risk.

Lastly, users can evaluate the fire risk level of the assessed logistics warehouse according to the 3D graph. The spatial rectangular coordinated system is made up of 18 cubes, while the X-axis and the Y-axis are both divided into three intervals while the Z-axis is divided into two intervals. And following the international classification principle, these 18 cubes were classified into five risk levels, as shown in Fig. 7. For classifying the fire risk level, the curve by which the cube penetrate through is what the fire risk level is at one specific period. It is clear to summarize the fluctuation of fire risk level.

Correct dangerous parameters and decrease the fire risk level. Users can distinguish periods with the high-risk level and analyze why they are so high. Then they can take reasonable mitigation to correct the state quo of hazards and decline the fire risk. In this way, safety managers needn’t treat all warehouses without discrimination but pays more attention to dangerous buildings in specific periods. And the efficiency of management will naturally improve.

Furthermore, the modified version still inherits the original intention of Gustav’s method, which is to provide users with a feasible suggestion to improve safety level instead of quantum of changeable numbers.

Case Study

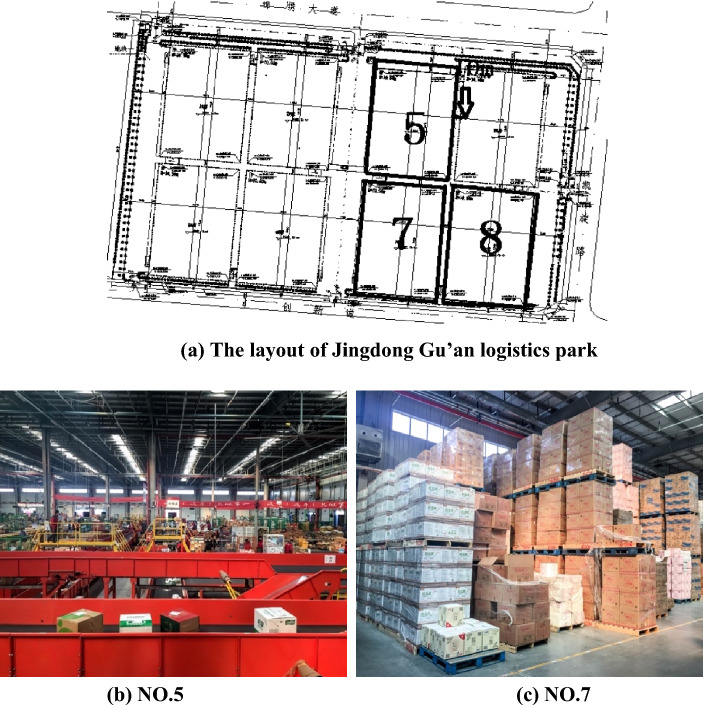

The manager of Jingdong Gu’an logistics park provided us with two logistics warehouses, a sorting center warehouse, and a transit warehouse in the second construction of the logistics park, to do an empirical study. This logistics park had a fire accident in 2016, causing more than 1 billion in insurance compensation, which woke the fire safety consciousness.

The layout of the logistics park is shown in Fig. 8. The sorting center warehouse is NO. 5, and the transit warehouse is NO. 7. Two warehouses are not independent, while NO. 7 selects goods according to the orders and transit to NO. 5 to pack and transport to the destination. And we follow the ‘5C’ procedures to assess the fire risks of these warehouses.

Figure 8.

The basic situation of the empirical subjects

All constructions in Jingdong Gu’an logistics park should be designed according to the relevant fire safe regulations. For negative fire protection measures, each warehouse was designed with proper fire compartmentations, fire resistances according to Code for fire protection design of buildings (GB 50,016–2014). For positive fire protection measures, each warehouse installed fire hydrant system indoor and outdoor, sprinkler system, automatic fire alarm system, according to the Technical code for fire protection water supply and hydrant systems (GB 50,974–2014), the Code for design of sprinkler system (GB 50,084–2017), the Code for design of automatic fire alarm system (GB 50,116–2013). And the logistics park satisfied the fire safety requirements in the General rules for fire safety management of storage occupancies (GA 1131–2014).

Both NO. 5 and 7 installed automatic fire protection systems, including fire hydrant system indoor and outdoor, sprinkler system, automatic fire alarm system, fire water tank etc.

Fire Risk Evaluation of Sorting Center Warehouse (NO. 5)

NO. 5 is 20762.28 m2 with three fire compartments, and it is used to pack, sort, and distribute goods. Automatic sorting equipment, the conveyor belts of which lay across each other, occupies almost all areas.

The categories and amount of goods in NO. 5 depends on the orders. Besides the goods from NO. 7, the goods also come from other warehouses or trucks to make accurate prediction impossible. Generally, most of the goods include small electrical appliances, office supplies, mobile phones or computers, followed by daily necessities and wine.

Field investigation revealed the current state of fire risk, as shown in Fig. 9. The goods in the sorting area were disorganized due to insufficient sorting. Goods or cartons were used to cover the fire engine road outside and the fire hydrants inside. The security guards at the entrance were strict about who came in and out, but there were no monitors in the loading and unloading area, where people could come and go as they pleased.

Figure 9.

The fire safety status quo of NO. 5. (a) The goods in the sorting area were disordered (left picture), even the cotton goods were above the lubricating oil. (b) The fire engine road outdoor and the fire hydrants indoor were covered by goods or cartons (right picture)

NO.5 operates from 7 to 2 am the next day and should have zero mobile fire loads when it closes. We chose the worktime to record the data of dynamic parameters. The mobile fire loads were recorded each half-hour during the work time. There are 135 workers on average and up to 200 in shopping festivals, while half of the workers rest at lunch or dinner. The parameters of NO.5 are listed in Table 6. The curve tracing is shown in Fig. 10.

Table 6.

Values of Fire Risk Parameters in Sorting Center Warehouse (NO. 5)

| Factor | Value | Factor | Value | Factor | Value | Factor | Value | Factor | Value | Factor | Value |

|---|---|---|---|---|---|---|---|---|---|---|---|

| α | 1.6 | B | 1.4 | T | 0.0206 | D | 3 | Li | 1 | I | 7.127 |

| Qi | 0 | W | 1.6 | F | 1.2 | φ | 3or2 | hi | 1 | P | 6.73 |

| S | 4 | Ri | 1.3 | H | 1.5 | Xi | 4.192 | E | 0.741 | – | – |

Figure 10.

The curve tracing of fire risk value in NO. 5

The fire risk curve showed that NO. 5 stays at V2, the safe state, from 7 to 8:30 am and after 1 am, while other operating time is at V3, the middle fire risk level. Above all, the sorting center warehouse (NO. 5) is relatively safe though the mobile loads go up and down every moment. That is because of the strict requirement of zero fire load when there are no workers.

Fire Risk Evaluation of Transmit Warehouse (NO.7)

NO. 7 is just 200 m2 bigger than NO. 5 but with six fire compartments because of its storage function. It composes high-layer shelves and general shelves. The conveyor belts were around the warehouse to conveniently transit goods to NO. 5. The firewalls between the two warehouses were crossed by conveyor belts many times so that the owner could install many fire-roller shutters at the holes.

Field investigation disclosed fire risk state quo, as is shown in Fig. 11. According to the building codes, NO. 7 belongs to Class C in the warehouse category, limited to storing flammable goods. However, we found aerosols deposited with yoga mats. And some goods were deposited below the conveyor belts, even some below the fire roller shutters.

Figure 11.

The fire safety status quo of NO. 7. (a) The goods below the conveyor belts (left picture). When the goods ignite, the fire will spread to another warehouse from the holes in the firewall. (b) The goods below the fire roller shutter (right picture). It makes the fire roller shutter no sense because the goods hinder the operation of the fire roller shutter

NO. 7 transits goods about 2 to 3 days, depending on the orders. We recorded the fire loads by retrieving order documents for the past 2 weeks. NO. 7 operates all day and needs 45 workers in the daytime (7 am to 5 pm), 25 workers at night (5 pm to 7 am the next day). The parameters of NO. 7 are listed in Table 7. The curve tracing is shown in Fig. 12.

Table 7.

Values of Fire Risk Parameters in Transmit Warehouse (NO. 7)

| Factor | Value | Factor | Value | Factor | Value | Factor | Value | Factor | Value | Factor | Value |

|---|---|---|---|---|---|---|---|---|---|---|---|

| α | 2.0 | B | 1.8 | T | 0.0136 | D | 1/3/4 | Li | 1 | I | 7.127 |

| Qi | 0 | W | 2 | F | 1.5 | φ | 1 | hi | 1 | P | 6.73 |

| S | 4 | Ri | 1.0 | H | 1.2 | Xi | 4.192 | E | 0.741 | – | – |

Figure 12.

The curve tracing of fire risk value in NO. 7

The fire risk curve showed that the transit warehouse (NO. 7) contains V2 or a higher fire risk level. However, the fluctuation of the fire risk is significant. From the top view, the fire risk level of NO. 7 revolves around V2 to V3, which should be contributed to fire protection equipment and mitigations because the CA stayed at the ‘good’ interval.

Results and Discussion

Analysis of the Evaluation Results

Comparing the fire risk level interval, two modern logistics warehouses seemed equal. However, if we compare the amplitudes of fire risk fluctuation, we may find that the fire risk fluctuation in NO. 5 is larger than that in NO. 7. The fire risk in NO. 5 is significantly affected by GR, while GR and IR contribute to the fire risk level in NO. 7 together. And we also noticed that the fire risk level in NO. 7 intensively stays at the higher level. And more specific-context factors should be considered. For example, the working time of NO. 7 is 24 h while NO. 5 just opens 18 h, and there should be zero mobile fire loads when workers in NO. 5 work off. Above all, the fire risk level of NO. 7 may be higher than that of NO. 5, although the time unit of record in the two logistics warehouses is different.

Practical Application

The research goal doesn’t just calculate the fire risk level or the amplitude of fire risk fluctuation but describes how fire risk changes and improves the vigilance when fire risk increases. This method suits to fire risk evaluation of modern logistics warehouses, especially storing warehouses, sorting center warehouses, and transit warehouses. With the increasing demands of logistics, advanced technologies, and transportation capacity, new logistics warehouses type will be developed, such as the automatic modernized logistics warehouses with a clearance height of over 14 m. This fire risk evaluation method needs to be improved following the development of the logistics industry to cover as many risk factors as possible.

For different kind of logistics warehouses, there are various mitigation measures. For example, the evaluation result of NO. 7 shows that the fire risk level will increase when most of the goods stay in storing phase. At that time, safety managers should limit the input amount of goods to control the fire risk level at the safe interval or increase patrol intensity with higher vigilance.

This new fire risk evaluation method of modern logistics warehouses is superior in five aspects by comparing with other existing methods. Compared with the Safety Checklist method (SCL) listing some rough risk exposures for managers to check, this 3D-Dynamic Gustav method evaluates fire risk more accurately. Compared with the general AHP method, this 3D-Dynamic Gustav method uses a new index system of fire risk evaluation for modern logistics warehouses, considering the risk of various process characteristics (B2), the risk of different fire shutters (C27, C28), garbage materials (C32), and adjusting traditional weight of the evacuation factors. Compared with the original Gustav method, this 3D-Dynamic Gustav method can assess fire risk dynamically in three-dimensional view. Users input changeable values of each fire risk parameter in real-time and this method outputs dynamic fluctuation of fire risk level time-dependently. Compared with the fuzzy analytical method, this 3D-Dynamic Gustav method is more practical for grassroots safety managers. Compared with other methods, this 3D-Dynamic Gustav method is popular. We invited fire safety managers working at JingDong Logistics Park to experience this 3D-Dynamic Gustav method. Users’ feedback improved that the new method is feasible and practical even for laypeople with little professional knowledge because of its spatial view and concise procedures.

Conclusion

The study creates a 3D-Dynamic fire risk evaluation method for logistics warehouse grassroots safety managers based on the Gustav method.

Following a review of fire accidents and fire protection research, the majority of existing fire risk evaluation methods for logistics warehouses result in a stationary fire risk value for a specific warehouse. Among the various fire risk evaluation methods, the Gustav method meets the needs of the end-users. However, neither the original Gustav method nor its modifications place a premium on emergency fire control, which may result in unnecessary economic costs.

Considering the drawbacks of previous studies, we extracted parameters correlating fire protection to define the control ability of fire protection as CA, also defined as the Z-axis at the same time. In this way, the planar rectangular coordinate system established by the Gustav method extends to the spatial one. The parameters in empirical formulas are composed of stationary ones and dynamic ones. Each parameter determines by multiplying experienced value and weight, the former component obeys the value principles in the Gustav method while the latter one is determined by the fire risk evaluation index system of logistics warehouses. Fire protection factors are scored according to the value principle tables and field investigation, and calculated final value through using score multiplies the weight in the fire risk index system. The spatial points defined as fire risk values are separated into 18 cubes classifying five fire risk levels.

The empirical study above identified the novel method as a necessary tool for fire risk evaluation of logistics warehouse, but there are still limitations. The recording period in the empirical study is at a singular time. The interviewed workers reflected that the management was disordered when the shopping festivals came, marking the peak value of fire risk. Moreover, the government supervising officers suggested that the end-users of the assessment method shouldn’t only include safety managers. When the mitigations of fire risks conflict the benefits of the company, safety managers may ignore the fire risk. If supervising officers record the fluctuation of fire risk at the same frequency, cheating behaviors will be reduced to minimum.

And the quantitative evaluation is challenging. Big data technology can make up for the lack of data. IoT is prevalent in transmitting subject-to-subject information. With the support of logistics IoT platforms, the weights and values of risk parameters in empirical formulas can be calculated quantitatively. Meanwhile, insurance for logistics warehouse fire accidents combing fire risk evaluation is also a significant research direction.

Appendix 1 The weights of fire risk parameters in index system

Combined Delphi Method and Analytic hierarchy process (AHP) method, the weights of parameters could be calculated, as is shown in Table 8. And the result of consistency test of judgement matrix is well.

See Table 8.

Appendix 2 The value principles of fire risk parameters

See Tables 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25.

Table 9.

The Value Correlations Between Qm and ω and

| , kg/m2 | 0–100 | 101–200 | 201–500 | 501–1000 | 1001–1600 | ≥ 1601 |

|---|---|---|---|---|---|---|

| Q m | 0–10 | 11–20 | 21–30 | 31–40 | 41–50 | 60 |

Table 10.

The Value Correlations Between Combustibles’ Category and α

| Combustibles’ category | |

|---|---|

| Food and agricultural products | 0.8 |

| Decoration materials (including wooden beams and columns, ceiling, floor, etc.) | 1.0 |

| Fiberboard, cotton-free products, polyester mattresses | 1.2 |

| Plastic products (including household appliances, office supplies) | 1.4 |

| Daily textiles (including yoga mat, cotton towel, hemp products, chemical fiber, etc.) | 1.6 |

| Cotton crops (raw or seed cotton) and food crops | 1.8 |

| Chemicals (including daily chemical products, oil, aerosols, etc.) | 2.0 |

Table 11.

Judgement Rule of Multiple Categories of Combustibles [34]

| The proportion of combustible category with higher-risk level | Judgement rule |

|---|---|

| < 10% | The combustible category depends on which mass proportion is over 90% |

| 10–25% | The combustible category depends on which mass proportion is over 75% |

| > 25–50% | The combustible category depends on the higher-risk-level combustible which mass proportion is over 25% |

Table 12.

The Value Principle of Qi

| Density of the combustible (kg/m2) | Material of the structural support | Material of the ceiling | Material of the wall | |

|---|---|---|---|---|

| 0–20 | Concrete, brick, or steel | Concrete or steel | Concrete, brick, or steel | 0 |

| 21–45 | Steel | Wood | Concrete or steel | 2 |

| 46–70 | Wood or steel | Wood | Concrete or brick | 4 |

| 71–100 | Wood | Wood | Tile, wood, or iron | 6 |

Table 13.

The Value Principle of S

| Construction area, m2 | Construction area, m2 | Construction area, m2 | |||

|---|---|---|---|---|---|

| 4000–8000 | 0–1 | 20,001–24,000 | 4–5 | 36,001–40,000 | 8–9 |

| 8001–12,000 | 1–2 | 24,001–28,000 | 5–6 | > 40,000 | 9–10 |

| 12,001–16,000 | 2–3 | 28,001–32,000 | 6–7 | – | – |

| 16,001–20,000 | 3–4 | 32,001–36,000 | 7–8 | – | – |

Table 14.

The Value Principle of B

| Level | Ignition area | ||||

|---|---|---|---|---|---|

| Occupation | Height | Layer | Fire compartment | ||

| 1 | Office area | < 8 m | Single layer | < 1500 m2 | 1.0 |

| 2 | Loading and unloading area | 8–14 m | Single layer | 1500–2000 m2 | 1.2 |

| 3 | Sorting center | 8–14 m | Multiple layer | 2000–2500 m2 | 1.4 |

| 4 | Manufacturing area | > 14 m | Multiple layer | 2500–3500 m2 | 1.6 |

| 5 | Storing area | > 14 m | Multiple layer | > 3500 m2 | 1.8 |

| 6 | Elevated warehouse | > 20 m | Multiple layer | > 3500 m2 | 2.0 |

Table 15.

The Value Principle of T

| Process characteristics | Thermoplastic and manufacturing | Sorting and packing | Loading and transportation | storing |

|---|---|---|---|---|

| T | 0.0483 | 0.0206 | 0.0067 | 0.0136 |

Table 16.

The Value Principle of W

| Fire resistance level | First level | Second level | Third level |

|---|---|---|---|

| W | 2 | 1.6 | 1.2 |

Table 17.

The Value Principle of Ri

| Num | State | |

|---|---|---|

| 1 | There are large fire loads with the inflammable, large-scale area per layer, delayed waste cleaning, causing fire to spread quickly | 1.0 |

| 2 | There are large fire loads with the combustible, or no consciousness of goods classification, causing fire to spread quickly | 1.3 |

| 3 | There are fire-retardant goods with good ventilation and strict safety management | 1.6 |

| 4 | There are fire-retardant or non-combustible goods with reasonable fire compartments, defending fire to spread | 2.0 |

Table 18.

The Value Principle of F

| Num | The toxicity of combustibles | |

|---|---|---|

| 1 | Timber, grain, cotton, paper, etc | 1.0 |

| 2 | Daily necessities (yoga mat, clothing, chemical fiber fabric) | 1.2 |

| 3 | Oil, aerosols, daily chemicals, etc | 1.5 |

| 4 | Household appliances, synthetic plastics, etc | 1.7 |

| 5 | Steel structure fire retardant coating, rubber, etc | 2.0 |

Table 19.

The Value Principle of H

| Num | The status quo of evacuation system | H |

|---|---|---|

| 1 | When the fire broadcasting, emergency lights, and indication signs work well, the evacuation pathway is unblocked | 1.0 |

| 2 | When the indicating broadcasting and the emergency lights work well, the evacuation pathway is unblocked | 1.2 |

| 3 | When just alarm bells ringing without any signs, the evacuation pathway is not safe | 1.5 |

| 4 | When there is no fire broadcasting, emergency lights, or indication signs, the evacuation pathway is blocked | 2.0 |

Table 20.

The Value Principle of D

| Risk level | Danger level | D |

|---|---|---|

| 1 | The logistics warehouse without large-scale process equipment is in-transit period, and the capacity of goods is low | 1 |

| 2 | The logistics warehouse without large-scale process equipment contains fewer valuable goods | 2 |

| 3 | The logistics warehouse with large-scale process equipment includes sorting center or manufacturing function | 3 |

| 4 | The logistics warehouse with large-scale process equipment attains the capacity peak of goods | 4 |

Table 21.

The Value Principle of φ

| Population | Population | Population | |||

|---|---|---|---|---|---|

| 0–50 | 1 | 151–200 | 4 | 301–350 | 7 |

| 51–100 | 2 | 201–250 | 5 | 351–400 | 8 |

| 101–150 | 3 | 251–300 | 6 | – | – |

Table 22.

The Value Principle of Xi

| Parameter | Value of different levels | |||

|---|---|---|---|---|

| 10 | 40 | 60 | 100 | |

| Fire brigade corresponding time | > 20 min | 15–20 min | 10–15 min | < 10 min |

| Number of firefighters | Serious lack | Insufficient | Enough | Sufficient |

| Quantity and quality of firefighting equipment | Poor | Qualified | Good | Excellent |

| Fire emergency plan | No | Simple | Normal | Comprehensive |

| Field operation plan | No | Unreasonable | Reasonable | Practical |

Table 23.

The Value Principle of E

| Parameters | Values in different levels | |||

|---|---|---|---|---|

| 10 | 40 | 60 | 100 | |

| Fire rescue road | Blocked/Occupied | – | Partially passable | Qualified |

| Fire hydrant system outdoor | Useless | Partially useful | Qualified | – |

| Water source for fire rescue | None | Qualified | Sufficient | – |

Table 25.

The Value Principle of P

| Parameters | Values in different levels | |||

|---|---|---|---|---|

| 10 | 40 | 60 | 100 | |

| Fire safety propaganda | None | Poor | Qualified | Excellent |

| Fire rescue drill | None | Poor | Qualified | Excellent |

| Firefighting training | None | Poor | Qualified | Excellent |

| Fire safety knowledge & skills | None | Poor | Qualified | Excellent |

Appendix 3 The numerical results of the empirical study

Table 26.

The Real-Time Value of Qm in NO. 5

| Time | Time | Time | ||||||

|---|---|---|---|---|---|---|---|---|

| 7:00 | 0.0 | 0 | 14:00 | 9437.5 | 31 | 21:00 | 13,495.7 | 35 |

| 7:30 | 346.7 | 2 | 14:30 | 6734.1 | 26 | 21:30 | 17,834.3 | 38 |

| 8:00 | 683.5 | 4 | 15:00 | 8536.9 | 27 | 22:00 | 20,534.5 | 42 |

| 8:30 | 992.9 | 6 | 15:30 | 12,438.4 | 34 | 22:30 | 13,679.3 | 35 |

| 9:00 | 2591.4 | 14 | 16:00 | 15,289.7 | 36 | 23:00 | 9895.2 | 32 |

| 9:30 | 3478.1 | 17 | 16:30 | 19,478.8 | 42 | 23:30 | 4523.7 | 21 |

| 10:00 | 4850.3 | 22 | 17:00 | 24,489.5 | 45 | 00:00 | 2476.8 | 13 |

| 10:30 | 6940.2 | 26 | 17:30 | 26,894.5 | 47 | 00:30 | 1464.0 | 8 |

| 11:00 | 8980.4 | 29 | 18:00 | 30,100.5 | 60 | 01:00 | 1034.2 | 6 |

| 11:30 | 12,580.6 | 34 | 18:30 | 32,205.6 | 60 | 01:30 | 475.6 | 3 |

| 12:00 | 19,479.2 | 41 | 19:00 | 33,498.1 | 60 | 02:00 | 0.0 | 0 |

| 12:30 | 24,340.0 | 45 | 19:30 | 25,734.6 | 45 | 02:30 | 0.0 | 0 |

| 13:00 | 29,840.5 | 60 | 20:00 | 17,783.3 | 38 | 03:00 | 0.0 | 0 |

| 13:30 | 18,730.6 | 40 | 20:30 | 10,038.9 | 32 | 03:00 | 0.0 | 0 |

Table 27.

The Numerical Results of Three Axis in NO. 5

| Time | GR | IR | CA | Time | GR | IR | CA | Time | GR | IR | CA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 7:00 | 0 | 0 | 16.96 | 14:00 | 2.75 | 1.08 | 16.96 | 21:00 | 3.11 | 2.16 | 16.96 |

| 7:30 | 0.18 | 2.16 | 16.96 | 14:30 | 2.31 | 2.16 | 16.96 | 21:30 | 3.37 | 2.16 | 16.96 |

| 8:00 | 0.35 | 2.16 | 16.96 | 15:00 | 2.40 | 2.16 | 16.96 | 22:00 | 3.73 | 2.16 | 16.96 |

| 8:30 | 0.53 | 2.16 | 16.96 | 15:30 | 3.02 | 2.16 | 16.96 | 22:30 | 3.11 | 2.16 | 16.96 |

| 9:00 | 1.24 | 2.16 | 16.96 | 16:00 | 3.19 | 2.16 | 16.96 | 23:00 | 2.84 | 2.16 | 16.96 |

| 9:30 | 1.51 | 2.16 | 16.96 | 16:30 | 3.73 | 2.16 | 16.96 | 23:30 | 1.86 | 2.16 | 16.96 |

| 10:00 | 1.95 | 2.16 | 16.96 | 17:00 | 3.99 | 2.16 | 16.96 | 00:00 | 1.15 | 2.16 | 16.96 |

| 10:30 | 2.31 | 2.16 | 16.96 | 17:30 | 4.17 | 2.16 | 16.96 | 00:30 | 0.71 | 2.16 | 16.96 |

| 11:00 | 2.57 | 2.16 | 16.96 | 18:00 | 5.32 | 1.08 | 16.96 | 01:00 | 0.53 | 2.16 | 16.96 |

| 11:30 | 3.02 | 2.16 | 16.96 | 18:30 | 5.32 | 1.08 | 16.96 | 01:30 | 0.27 | 2.16 | 16.96 |

| 12:00 | 3.64 | 1.08 | 16.96 | 19:00 | 5.32 | 1.08 | 16.96 | 02:00 | 0 | 0 | 16.96 |

| 12:30 | 3.99 | 1.08 | 16.96 | 19:30 | 3.99 | 1.08 | 16.96 | 02:30 | 0 | 0 | 16.96 |

| 13:00 | 5.32 | 1.08 | 16.96 | 20:00 | 3.37 | 1.08 | 16.96 | 03:00 | 0 | 0 | 16.96 |

| 13:30 | 3.55 | 1.08 | 16.96 | 20:30 | 2.84 | 2.16 | 16.96 | 03:00 | 0 | 0 | 16.96 |

Table 28.

The Real-Time Value of Qm in NO. 7

| Time | Time | Time | ||||||

|---|---|---|---|---|---|---|---|---|

| 1.1 | 28,693.8 | 49 | 1.6 | 34,902.7 | 60 | 1.11 | 14,352.2 | 35 |

| 1.2 | 34,982.5 | 60 | 1.7 | 15,843.8 | 36 | 1.12 | 10,354.4 | 32 |

| 1.3 | 35,499.1 | 60 | 1.8 | 28,098.9 | 49 | 1.13 | 25,303.8 | 46 |

| 1.4 | 11,909.4 | 33 | 1.9 | 34,975.4 | 60 | 1.14 | 26,305.5 | 47 |

| 1.5 | 29,674.5 | 50 | 1.10 | 33,424.3 | 60 | 1.15 | 32,339.1 | 60 |

Table 29.

The Numerical Results of Three Axis in NO. 7

| Time | GR | IR | CA | Time | GR | IR | CA | Time | GR | IR | CA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.1 | 4.80 | 0.36 | 16.96 | 1.6 | 6.92 | 1.44 | 16.96 | 1.11 | 3.43 | 0.18 | 16.96 |

| 1.2 | 6.92 | 1.44 | 16.96 | 1.7 | 3.53 | 0.18 | 16.96 | 1.12 | 3.13 | 0.18 | 16.96 |

| 1.3 | 6.92 | 1.44 | 16.96 | 1.8 | 4.80 | 0.36 | 16.96 | 1.13 | 4.50 | 0.36 | 16.96 |

| 1.4 | 3.23 | 0.18 | 16.96 | 1.9 | 6.92 | 1.44 | 16.96 | 1.14 | 4.60 | 0.36 | 16.96 |

| 1.5 | 4.90 | 0.36 | 16.96 | 1.10 | 6.92 | 1.44 | 16.96 | 1.15 | 6.92 | 1.44 | 16.96 |

Declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Wenhui Ju, Email: juwh19@mails.tsinghua.edu.cn.

Guofeng Su, Email: sugf@tsinghua.edu.cn.

References

- 1.Fire accident in Jingdong Gu’an logisitics warehouse. Available online: https://www.sohu.com/a/121949285_516168 (accessed on 19 December 2019)

- 2.Amazon UK logistics warehouse’s (BHX1) fire accident on 4th November. Available online: http://www.jiufanglogistics.cn/news/123 (accessed on 4 November 2017)

- 3.Fire accident in a transportation logistics warehouse located at Yokosuka, Kanagawa Prefecture, Japan. Available online: https://baijiahao.baidu.com/s?id=1606750445007026624&wfr=spider&for=pc (accessed on 23 July 2018)

- 4.Amazon American logistics center warehouse’s (TEB6) fire accident. Available online: http://news.sohu.com/a/507372379_120099883 (accessed on 12 December 2021)

- 5.17 fire accident in logistics center located in Icheon, Gyeonggi Province, Korea. Available online: https://baijiahao.baidu.com/s?id=1702887030877746030&wfr=spider&for=pc (accessed on 18 June 2021)

- 6.A Xidaizhi, Y Tanaka et al. (1982) Introduction to fuzzy system theory. Beijing, China

- 7.Zhang LM. Case introduction and analysis of Japanese firefighters dead in rescue work. Fire Tech Prod Inf. 2014;2:69–70. [Google Scholar]

- 8.Melendez O, Maria F. Bonded logistics zone under the influence of basic traffic construction. J Log Trans Rev. 2001;21:1–4. [Google Scholar]

- 9.Dai M. Study on layout optimization of the regional logistics system master’s thesis. J Bus Log. 2010;11:43–45. [Google Scholar]

- 10.Shea JB. Challenges of emergency logistics management. J Log Trans Rev. 2007;43:655–659. doi: 10.1016/j.tre.2007.01.001. [DOI] [Google Scholar]

- 11.Xia SF (2015) The crowded warehouse on E-commerce logistics layout plan and primary equipment design. Dissertation, Qilu University of Technology

- 12.NFPA (2003) NFPA 230, Standard for the Fire Protection of Storage. American Standard

- 13.IBC (2009) IBC 2009, International Building Code. Australia Standard

- 14.NRCC NRCC 47666, national building code of Canada: 2005. Canada Stand. 2005 doi: 10.4224/40001245. [DOI] [Google Scholar]

- 15.Standardization administration (2017) GB/T 21334-2017. Classification and planning fundamental requirements of logistics park. Chinese Standard

- 16.Ju WH, Liu YF (2017) Study on the economy of modernization logistics warehouse fire engineering construction. Conf. 3rd E-commerce & contemporary economic development 216–21

- 17.Tian YM. Discussion on the interactive mode of fire insurance and fire protection management based on risk assessment. J Catastr. 2013;28:116–180. [Google Scholar]

- 18.Ramachandran G. The economics of fire protection. 1. London: Routledge; 1998. [Google Scholar]

- 19.Harrington SE, Niehaus GR. Risk management and insurance. USA: Irwin/McGraw; 1999. [Google Scholar]

- 20.Sun JH, Zhu GQ, Liu XY (2008) Fire risk and insurance. Beijing, China

- 21.Zang L. The study on the domestic cotton logistics. J Chin Mark Log Manag. 2015;822:19–19. [Google Scholar]

- 22.Jin Y. The study on current situation and countermeasures of cotton logistics. J Chin Process. 2006;5:5–6. [Google Scholar]

- 23.Zhao QL, Guan L, Wu HL, Kang QQ. Study on fire spread at the early stage of cotton warehouse fire. Fire Sci Technol. 2019;38:1397–1041. [Google Scholar]

- 24.Hansen N, Steffensen F, Valkvist M, Jomaas G, Van Coile R. A fire risk assessment model for residential high-rises with a single stairwell. Fire Saf J. 2018;95:160–169. doi: 10.1016/j.firesaf.2017.11.006. [DOI] [Google Scholar]

- 25.Hopkin D, Spearpoint M, Van Coile R. The J-value and its role in evaluating investments in fire safety schemes. Fire Technol. 2018;54:1547–1564. doi: 10.1007/s10694-018-0752-9. [DOI] [Google Scholar]

- 26.Watts JM, Kaplan ME. Fire risk index for historic buildings. Fire Technol. 2001;37:167–180. doi: 10.1023/A:1011649802894. [DOI] [Google Scholar]

- 27.Danzi E, Fiorentini L, Marmo L. FLAME: a parametric fire risk assessment method supporting performance based approaches. Fire Technol. 2021;57:721–765. doi: 10.1007/s10694-020-01014-9. [DOI] [Google Scholar]

- 28.Kong Dp, Lu Sx, Kang Qs, et al. Fuzzy risk assessment for life safety under building fires. Fire Technol. 2014;50:977–991. doi: 10.1007/s10694-011-0223-z. [DOI] [Google Scholar]

- 29.Ramli N, Ghani NA, Ahmad N, et al. Psychological response in fire: a fuzzy Bayesian network approach using expert judgment. Fire Technol. 2021;57:2305–2338. doi: 10.1007/s10694-021-01106-0. [DOI] [Google Scholar]

- 30.Lo SM, Hu BQ, Liu M, et al. On the use of reliability interval method and grey relational model for fire safety ranking of existing buildings. Fire Technol. 2005;41:255–270. doi: 10.1007/s10694-005-3732-9. [DOI] [Google Scholar]

- 31.Fu Q, Zhang HP, Wang H, Xie QY. Study on public buildings fire risk assessment method. Fire Saf Sci. 2007;16:137–143. [Google Scholar]

- 32.Shields TJ, Boyce KE. A study of evacuation from large retail stores. Fire Saf J. 2000;35:25–49. doi: 10.1016/S0379-7112(00)00013-8. [DOI] [Google Scholar]

- 33.Tao YR. Fire risk assessment of large shopping centers based on Gustav’s method. Fire Sci Technol. 2010;29:255–258. [Google Scholar]

- 34.Liren Yang LR, Shang KD, Liu J. An approach to successful application of Gustav’s method to the fire risk assessment of the E-commerce logistics warehouse. J Saf Environ. 2018;18:2120–2125. [Google Scholar]

- 35.Song ZJ. Research on fire protection design and fire supervision management of storage and logistics places. J Fire Protect Today. 2022;7(3):82–84. [Google Scholar]

- 36.Guo JS. Research on fire protection design of logistics building. J Public Utility Design. 2020;21:71–73. [Google Scholar]

- 37.Ju WH. Study on fire risk and disaster reducing factors of cotton logistics warehouse based on event and fault tree analysis. Proc Eng: Conf Ser. 2016;135:417–425. doi: 10.1016/j.proeng.2016.01.150. [DOI] [Google Scholar]

- 38.Ju WH, Su GF, Wu LZ, Wang YG (2021) Study on logistics warehouse dynamic fire risk assessment based on gustav method. J Phys: Conf Ser (in press)

- 39.Fan W.C., Sun J.H., Lu S.X. (2004) Fire risk assessment methodology. Beijing, China