Abstract

The jackfruit seed has excellent nutritional food value which can help to produce healthy and nutritious food products. In this study, wheat flour was partially replaced by jackfruit seed flour (JSF) for the formulation of waffle ice cream cones. The amount of wheat flour added in the batter on the basis of amount of added JSF. The JSF was added after optimization using response surface methodology in a batter formulation for waffle ice cream cones. The waffle ice cream cone was made from 100% wheat flour, was considered as control, and used to compare JSF supplemented waffle ice cream cones. Substitution of wheat flour with JSF has affected the nutritional and sensorial attributes of waffle ice cream cone. In regard to its protein content, ice cream permeability hardness, crispness, and overall acceptability. The protein content was increased (14.55%) after the addition of jackfruit seed flour up to 80% from control. The cone was supplemented with 60% of JSF resulted to the higher values of crispiness and overall acceptability as compared to other waffle ice cream cones. As the JSF have high value in water/oil absorption capacities, therefore it could be utilized into other value-added food products as whole or partial replacement of wheat flour.

Keywords: Jackfruit seed, Value addition, Hardness, Sensory

1. Introduction

Jackfruit (Artocarpous heterophyllous) belongs to family Moraceae, (native of Western Ghats of India) and it is considered as a world's largest fruit. Commonly jackfruit is grown in Asian and other countries including India [1]. It is a composite type of fruit and the whole fruit is composed of inner rind, rachis, flesh (yellow, golden or white), and seed (up to 500 in single fruit) [2]. Seeds show about 10–15% of total fruit weight and considered as rich source of carbohydrate (mainly starch) and protein [3]. Nutritional composition showed that jackfruit seed contains moisture 21.10–71.92%; fibre 1.56–3.96%; ash 2.12–0.89%; protein 10.09–18.12%; fat 4.29% and carbohydrate content 7.89% [4,5,6]. Jacalin, is the main protein present in jackfruit seed which is useful in the boosting up the immune system of human body [7]. Jackfruit seed contains other secondary metabolites like saponins, phytonutrients, lignins, isoflavone, that is helpful in preventing cancer, hypertension, aging, ulcer, and many more due to antioxidant behaviors [8]. It is believed that jackfruit seeds itself have no industrial applications so far and being discarded or steamed or dried or sometimes used in local dishes at household level as snacks and curry [3,9]. By nature, seeds are recalcitrant, and germinate rapidly as fruit reaching to the maturity. Therefore, seeds have a very short shelf life because of their high carbohydrate (specially starch, 60–80%, on dry basis) and protein content which could be used as culturing by the microorganism [3,10]. Consequently, seeds cannot be stored fresh not more than one week and get spoiled which increases the post-harvest loss [7]. Therefore, they needed processing to increase their storability and usage and milling is one of them. The flour from milling of jackfruit seeds has great potential and used as an alternative to or as value addition in various food. According to Ref. [11] the jackfruit seeds flour could be act as an alternative to wheat flour for the development of bread, chapatti, pancake cake, buttered biscuit, and noodles. Praveenasri et al. [12] studied for incorporation of jackfruit seeds flour in the extruded products like snacks, noodles, vada, and vermicelli. Low gluten bread was made after the substitution of wheat flour with 5, 10 and 20% levels of jackfruit seeds flour by Ref. [3]. Similarly, Butool and Butool and Meethal et al. [13,14] also replaced wheat flour with various proportions (10–30%) of jackfruit seeds flour in bread cookies and snack bar respectively.

A cone or bowl shaped waffled textured wafer made from refined wheat flour known as ice cream cone which facilitate the holding of ice cream without an actual bowl. The first ice cream cone/wafer was developed by Italo Marchiony in 1896 [15,16]. There are two basic type of ice cream cone are available based on their making process. First is the rolled cone, which is a waffle baked in a pan and rolled in cone shape just after baking it. The other type of cone is a molded one where, the batter is poured in a various shaped mold/preferably cone shaped mold and being baked till crisp texture [17]. Some other variations of ice-cream cones are also available which include wafer, waffle cone, sugar cone, pretzel and chocolate-coated cones.

For the first time, we are using jackfruit seed flour which comprises jacalin that considered as immunity booster and other components like dietary fibre, carbohydrate, minerals, B-complex vitamins and bioactive components, which is essential for human health. As jackfruit seeds are rich in resistant starches, which controls blood sugar and keeps the gut healthy. These properties make it far more better for the replacement of wheat flour. Definitely, the proposed jackfruit seed flour ice-cream waffle cone will be more health beneficiary as compared to wheat flour, which will reduce the nutrition deficiency. Therefore, we have focused on development of waffle cone for ice-cream using jackfruit seed flour to replace wheat flour to get more nutritious cone (protein rich-low gluten) along with minimizing the postharvest loss.

2. Materials and methods

2.1. Plant material

Jackfruits (Artocarpus heterophyllus Lam.) were collected from an orchard in Khusroobagh (under the Department of Horticulture and Food Processing, Uttar Pradesh Government) Prayagraj, India from May to July 2017 during 10–12 weeks after anthesis. Seeds from cultivars Hadiyava were selected for the present study. Fruits were cut and opened for collection of seeds.

2.2. Flour preparation

Jackfruit seed flour (JSF) was prepared by slight variation the method described by Ref. [18]. Seeds were isolated from ripe fruit and washed and cleaned and the upper white layer was removed manually. Seeds were then lye peeled (2.5% NaOH and 2.5% citric acid solution), washed with distilled water to remove the traces of chemicals. After washing seeds were cut into slices, and dried in oven at 45 °C for <13% moisture content. Dried seeds were ground using a laboratory grinder and sieved using a 300 mesh size sieve to obtain flour which was stored in airtight containers for further applications. While wheat flour was purchased from local market of Allahabad and sieved using a 300 mesh size sieve to get even flour.

2.3. Formulation of waffle ice cream cone

The recipe used was according to waffle ice cream cone, 100 g wheat flour, 40 g maize starch, 28 g powdered sugar, 5 mL oil, 20 g soya lecithin, 4 g sodium bicarbonate, 1 g salt, 40 g milk powder, and 250 mL water. The wheat flour in the waffle ice cream cone recipe was replaced with JSF and other ingredients were remained as such. All the ingredients were weighed and then butter (5.0 g) and water were added, and mixing was done using a hand mixer until all ingredients were mixed properly at room temperature and well baked cone was achieved using a cone maker at 200 °C [15]. Value addition of cone was done with JSF and amount of jackfruit seed was added by using response surface methodology (RSM) given in Table 1. Cultivar Hadiyava was selected for the partial replacement of wheat flour from waffle ice cream cone due to its high nutritional values as compared to other starches.

Table 1.

Experimental ranges and levels of independent variables used in RSM in terms of actual and coded factors.

| Run | JSF (g) X1 |

Water content (mL) X2 |

Measured Responses |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Protein (%) | Hardness (N) | Crispiness (Force drops/mm) | Ice-cream Permeability (min) | OAA*** | |||||

| Actual | A* | Actual | B** | ||||||

| C^ | 100.00 (WF) | – | 250.00 | – | 8.06 | 8.13 | 0.51 | 31.47 | 8.01 |

| 1 | 60.00 | 0 | 250.00 | 0 | 11.47 | 15.71 | 1.98 | 39.31 | 7.81 |

| 2 | 40.00 | −1 | 300.00 | +1 | 9.49 | 13.41 | 2.26 | 30.21 | 6.81 |

| 3 | 31.72 | -α | 250.00 | 0 | 10.39 | 17.42 | 2.02 | 39.66 | 7.31 |

| 4 | 80.00 | +1 | 200.00 | −1 | 12.2 | 10.47 | 1.91 | 45.21 | 5.91 |

| 5 | 60.00 | 0 | 250.00 | 0 | 11.01 | 20.27 | 2.41 | 39.31 | 7.00 |

| 6 | 60.00 | 0 | 179.29 | - α | 11.47 | 16.34 | 1.95 | 46.80 | 5.01 |

| 7 | 60.00 | 0 | 250.00 | 0 | 11.46 | 15.77 | 2.22 | 40.20 | 7.11 |

| 8 | 60.00 | 0 | 250.00 | 0 | 11.96 | 16.08 | 2.05 | 39.66 | 7.51 |

| 9 | 80.00 | +1 | 300.00 | +1 | 12.31 | 8.28 | 0.92 | 39.5 | 8.50 |

| 10 | 40.00 | −1 | 200.00 | −1 | 10.32 | 21.66 | 2.30 | 41.22 | 6.90 |

| 11 | 60.00 | 0 | 320.71 | +α | 11.07 | 15.65 | 1.63 | 30.60 | 7.61 |

| 12 | 60.00 | 0 | 250.00 | 0 | 11.68 | 15.83 | 2.04 | 35.50 | 7.52 |

| 13 | 88.28 | +α | 250.00 | 0 | 14.55 | 10.34 | 1.81 | 42.45 | 6.20 |

*Coded value of JSF, **Coded value of Water content C^ = Control, OAA*** = Overall acceptability.

2.3.1. Experimental design

Response surface methodology was employed to determine the optimal combination of seed flour replacement for the development of waffle ice cream cone. The independent variables that were optimized are: JSF (X1; 40–80 g), and water content (X2; 200–300 mL). The amount of these 2 independent variables were taken after laboratory trial basis. The effect of all two independent variables X1 (amount of seed flour), and X2 (amount of water added to form a mix), on protein content, crispness, ice cream permeability, hardness, and overall acceptability (OAA) (dependent variable) were investigated using central composite rotatable design. A total of 20 experiments were performed and 5 points repeated at central point. The data were analyzed using Design-Expert software (7.0.0 version) and generalized second degree polynomial using the method of least squares.

| Y = β0 + β1x1 + β2x2 + β11x12 + β22x22 + β12x1x2 C | (1) |

The coefficients of the polynomial models were constant term depicted as β0; linear terms as β1, and β2; quadratic terms as β11, and β22; and interactive term as β 12 (Eq. (1)). The predicted values were analyzed for coefficient of determination (R2), standard error (SE), lack of fit, F-value. Response surface was used to determine the interaction between two independent variables on responses. Different constraints were set for independent and dependent variables along with their relative importance. A desirability function was used for the optimization of the fitted polynomials. The optimal condition was tested and compared by performing the experiments at predicted values of variables [19].

2.4. Proximate composition of the flours

The jackfruit seed and wheat flour were analyzed for moisture, crude fiber, protein, fat, and ash content using methods given in Association of Official Analytical Chemists [20]. Protein content of waffle ice cream cone was determined using of the Association of Official Analytical Chemists [20].

2.5. Texture analysis

2.5.1. Determination of mechanical hardness

The texture properties of the waffle ice cream cone prepared with different concentration of seed flour was measured by force in compression using a Texture Analyzer (TA-XT2 texture analyzer) with 50 mm diameter cylinder aluminium probe. The load cell was 50 kg and the crosshead speed was 10 mm/min The peak force which is required to compress waffle ice cream cone was recorded in Newton's (N). Texture measurements were performed in triplicates and average values were reported. A special wedge piece was fabricated that could hold the cone perpendicular to the tool. Cones were placed onto the wedge and the tool allowed touching the cone for the test to be carried out. Results were automatically read off from an attached computer [21].

2.5.2. Determination of crispness

By applying a force on the edible cone with the Texture analyzer with 11.3 mm diameter ball as a probe, micro-fractures occur until the wafer can no longer be crushed. Each time a micro-fracture occurs, a force drop is noted. The number of forces drop per mm and the magnitude of the force drops were calculated and expressed as the crispness of the cone. Force drops greater or equal to 2 N in magnitude were considered for the analysis [21].

2.6. Icecream permeability

Ice cream permeability of waffle cone was measured method given by Ref. [21] as the time taken for ice cream to permeate through cone. The ice cream cones were set on the racks and soft ice cream was added. After that the time taken for the ice cream to permeate to the outside of the cone was recorded (min) and recorded ice cream permeability.

2.7. Sensory analysis

The sensory properties of the developed product samples were evaluated by 9-point hedonic method described by Ref. [22]. A semi-trained panel of 20 judges selected from amongst the researchers and teaching staff members of the Centre of Food Technology, University of Allahabad, U.P. India. The consent was obtained from all participants before the sensory analysis. The sensory analysis was approved by the Food and Development committee (members of 7 panellists), University of Allahabad, U.P. India. A sensory score sheet specially designed for waffle ice cream cones overall acceptability (OAA) was given to each judge. A structured 9-point hedonic scale ranging from ‘like extremely’ rated 9 points, to ‘dislike extremely’ rated 1 point was used to arithmetically explain the sensory attributes of the waffle ice cream cones (Supplementary material 1). During the test, participants were presented five samples with one sample serving as a “Control”. Panellists received only one sample at a time to reduce the likelihood of inter-sample comparison. Samples were encoded in a random three-digit number, and each sample was portioned to a uniform mass of 20 ± 1 g.

2.8. Statistical analysis

The experiments were performed in triplicate and the mean value was used for statistical analysis. The data of analysis was analyzed using one way analysis of variance (ANOVA) by statistical software SPSS.16 for finding elements causing difference between the samples. For optimization design Design-Expert version 7.0.0 Stat-Ease, USA was applied.

3. Results and discussion

3.1. Proximate composition of flours

The wheat flour and JSF contained 11.27 and 6.82% moisture, 11.27 and 15.69% protein, 1.33 and 0.66% fat, 0.71 and 2.85% ash and 1.85 and 3.04% crude fiber.

3.2. Optimization of JSF and water content for the development of waffle ice cream cones

The aim of the study was to develop waffle ice cream cones (Fig. 1) using JSF with the help of response surface methodology (RSM). Table 1 showed the actual and coded value of independent variable used for the experimental design along with experimental combination and effect of the two selected independent variables i.e., JSF and water content on the dependent variables like protein content, hardness, crispiness, ice cream permeability and overall acceptability. The response variables were fitted with the quadratic models. The second order polynomial equation was used to model the efficient correlation between the process variables (independent variables) and the responses (dependent variables). Table 2 showed the regression coefficient which represents the relationship between the responses and the process variables. It is important to analyse the significance of the data which is done by analysis of variance (ANOVA). The model for all the responses was found to be fit as the coefficient of determination (R2) varied between 75.50 and 98.97% and the lack of fit was found to be non-significant for all five responses (Table 3). The observed data showed comparability with the second order regression model supporting the high value of R2 and confirmed normal distribution of all errors. The adjusted coefficient of determination (adjusted R2) was also high ranging between 58.01 and 98.24% showed that the developed model was significant. The predicted R2 is the measure of amount of variation in new data explained by the model. The sufficient variability of the model is explained by the linear term, square term, and interaction term. The three-dimensional surface representation was plotted to study the interaction among two process factors and to predict the combined effects of factors i.e., JSF (X1) and water content (X2) on the responses of the cones.

Fig. 1.

Waffle ice cream cone.

Table 2.

Regression coefficients for second-order polynomial equation representing the relationship between the responses and process variables.

| Hardness (N) |

Crispness (force drops/mm) |

Protein (%) |

Ice-cream Permeability (min) |

Overall Acceptability |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coefficient | p value | Coefficient | p value | Coefficient | p value | Coefficient | P value | Coefficient | P value | |

| Variables | 16.73 | 0.0253 | 2.14 | 0.0420 | 11.52 | 0.0028 | 38.80 | 0.0032 | 7.38 | 0.0150 |

| X1 | −3.29 | 0.0046 | −0.26 | 0.0225 | 1.32 | 0.0002 | 2.15 | 0.0235 | −0.11 | 0.5566 |

| X2 | −1.43 | 0.1196 | −0.19 | 0.0697 | −0.16 | 0.4132 | −4.95 | 0.0003 | 0.77 | 0.0032 |

| X12 | −1.80 | 0.0760 | −0.12 | 0.2615 | 0.28 | 0.2012 | 0.92 | 0.2888 | −0.19 | 0.3476 |

| X22 | −0.74 | 0.4202 | −0.18 | 0.1014 | −0.32 | 0.1498 | −0.26 | 0.7561 | −0.41 | 0.0652 |

| X1 X2 | 1.51 | 0.2250 | 0.24 | 0.0918 | 0.23 | 0.3983 | 1.32 | 0.2498 | 0.67 | 0.0311 |

Table 3.

Analysis of variance (ANOVA) data for the responses.

| Source of variations | Df | Hardness (N) |

Crispness (Force drops/mm) |

Protein (%) |

Ice-cream Permeability (min) |

OAA |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean square | F | Mean square | F | Mean square | F | Mean Square | F | Mean Square | F | ||

| Regression | 5 | 27.28 | 5.26 | 0.26 | 4.28 | 15.87 | 11.63 | 49.46 | 11.09 | 1.60 | 6.43 |

| Linear | 2 | 102.97 | 19.86 | 0.80 | 13.07 | 14.21 | 52.03 | 233.41 | 52.35 | 4.865 | 19.60 |

| Square | 2 | 26.25 | 5.06 | 0.322 | 5.04 | 1.25 | 4.61 | 6.34 | 1.42 | 1.43 | 5.78 |

| Interaction | 1 | 9.18 | 1.77 | 0.24 | 3.81 | 0.22 | 0.81 | 7.02 | 1.58 | 1.80 | 7.24 |

| Lack of Fit | 3 | 6.85 | 1.74 | 0.10 | 3.35 | 0.48 | 3.92 | 5.70 | 1.62 | 0.44 | 4.12 |

| Pure error | 4 | 3.93 | 0.031 | 0.12 | 3.53 | 0.11 | |||||

| Total | 12 | 176.46 | 1.753 | 32.15 | 305.46 | 10.245 | |||||

| R2 (%) | 79.01 | 75.36 | 89.25 | 88.79 | 82.12 | ||||||

| R2 (Adj) (%) | 64.01 | 57.75 | 81.57 | 80.79 | 69.34 | ||||||

3.3. Response surface methodology

The effect of jackfruit seed flour, and amount of water on hardness, crispness, protein, ice-cream permeability and overall acceptability (OAA) of waffle ice cream cone is shown in Table 3.

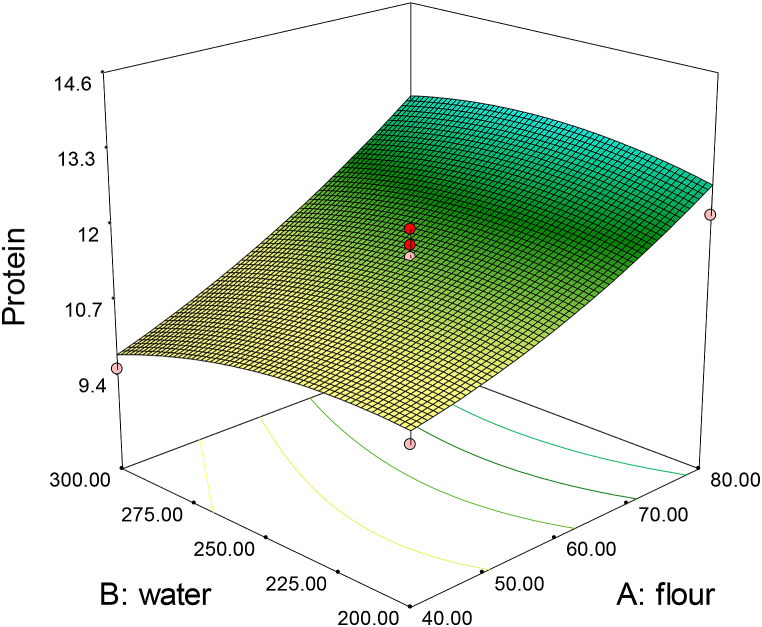

3.3.1. Effect of independent variables on protein content of waffle ice cream cones

In food products, the proteins act as emulsifying agents, foaming agents, gelling agents etc. The regression coefficients for second-order polynomial equation represent the relationship between the process variables and responses (Table 2). It shows that the linear, square and interaction effects of independent variables on the responses. The magnitude of p-value implies that the linear terms i.e., JSF (X1) and water content (X2); and the square term of seed flour (X22) have significant effect (p < 0.05) on the protein content of waffle ice cream cone. This clearly indicated that the increase in the protein content was basically due to the increase in the amount of seed flour and this increase of protein content was desirable. Which was expected, since JSF has over higher proteins than WF. As WF is deficient in amino acids like lysine, threonine, and methionine. Jackfruit seed flour has high amount of and at the same time jackfruit seed flour has enough concentration of these amino acids. Therefore, addition of JSF in WF help to complete all the essential amino acids required by the body [23]. The highest protein content was found in the experiment no. 6 where JSF (X1) was 88.28 g and water content (X2) were 250.00. The magnitude of coefficients (β) values showed that the linear term of variables had positive effect on the protein content.

The seed flour has positive effect (β2 = 11.52) and water content has negative effect (β1 = −0.16). The interaction term (β12 = 0.23) as well as the square term (β12 = 0.28) also showed positive effect on the protein content while another square term (β22 = −0.32) showed a negative effect. The response surface quadratic model showed F-value of 11.63 and the model is significant at p < 0.05 (Table 3). The “Lack of Fit F-value” of 3.92 indicated that the Lack of Fit is not significant in relation to the pure error. The model is significant as lack of fit is non-significant. The coefficient of determination (R2) is 0.8925, which showed that 89.25% of the variation was explained by the model. The adjusted R2 was 0.8157 which indicates that 81.57% of the variation as explained by the model. The multiple regression equation (Eq. (2)) of the model was obtained for the protein content (in terms of actual factors) is as follows:

| Protein = +6.37888–0.076455X1 + 0.04679X2 + 2.35000E−004X1*X2 + 6.98750E−004X12 − 1.28200E−004 X22 | (2) |

The regression equation was graphically represented by the 3D response plot (Fig. 2) in which the curve lines represent the line of the responses and the effect of two factors on the responses can be visualized at one time. The plot showed that an increase in the jackfruit seed flour cause enhancement in the protein content. The protein content of the seed flour is high, and it is shown by the contour line that as the seed flour increase the appreciable increase of protein content was found in cones.

Fig. 2.

Response surfaces plot showing effect of JSF (g) and water content (mL) on protein content of cone.

3.3.2. Effect of independent variables on hardness of waffle ice cream cone

Hardness is an important factor in bakery products and is strongly related with the consumer's perception of bakery products freshness. The product hardness is a crucial texture attributes of bakery and confectionary food products. The effect of JSF (X1) and water content (X2) on the hardness of waffle ice cream cones is presented in Fig. 3. The hardness of the samples ranged from 8.28 to 21.66 N (Table 1) depends on the amount of independent factors is utilized for the cone development. The hardness, as predicted by the regression model (Table 2), was significantly (p < 0.05) affected by the linear term is JSF (X1) and water content (X2) and quadratic square terms of them. The coefficients of the first-order term in the equation with these coded variables depicts that the hardness of the cone increased with increased amount of seed flour and when less quantity of water added in the mix. Water content in combination with other variable could have aggravated an increase in the cone hardness probably due to the moisture loss and thickening of the mix [24,25]. The final equation (Eq. (3)) in terms of actual factors is given below:

| Hardness = +21.81887–4.34145E−003 + 0.028385X2 + 1.51500E−003X1*X2 − 4.49156E−003X12 − 2.95650E−004X22 | (3) |

Fig. 3.

Response surfaces plot showing effect of JSF (g) and water content (mL) on hardness of Waffle ice cream cone.

The magnitude of β coefficients showed that linear term of JSF has the maximum negative effect (β = −3.29) as compared to water content (β = −1.43) on the cone hardness strength (Table 2). Similar trends are also shown by response surface plot (Fig. 3). As seed flour increased hardness increased and as water content increases the hardness decreased. This may be due to the presence of sugar compounds other than sucrose. There could be one more explanation for increased hardness of cones with high amount of flour is their starch content. As starches from jackfruit seed has high retrograded starch which makes them hard to brake. Hardness is also corelated to tannins and phytonutrients of the flour [26]. Akesowan [27] also reported similar findings in sucralose-erythritol mixture based chiffon cake. Similar results were reported by Ref. [28] in the sweet potato peel flour cone.

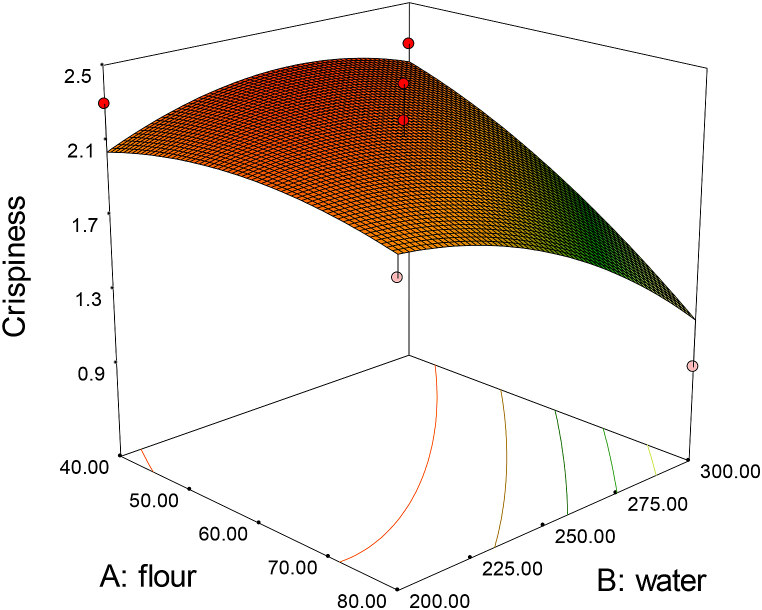

3.3.3. Effect of independent variables on crispness of waffle ice cream cone

According to Ref. [29]; in the consumer enjoyment of foods, the perception of crispness is equal in importance to freshness. The effect of JSF (X1) and water content (X2) on the crispness of waffle ice cream cones is presented in Fig. 4. The crispness of the samples ranged from 0.92 to 2.41 force drops/mm dependent on the quantity of independent factor is used for the cone preparation (Table 1). The crispness, as predicted by the regression model (Table 2), was significantly (p < 0.05) affected by the linear term is JSF (X1) and water content (X2) and quadratic square terms of them. Table 3 showed that the response surface quadratic model showed F-value of 4.28 and the model is significant at p < 0.05. The “Lack of Fit F-value” of 3.35 indicated that the Lack of Fit is not significant in relation to the pure error. The model is significant as lack of fit is non-significant. The R2 is 0.7536, which indicates that 75.36% of the variation was explained by the model. The adjusted R2 of 0.5775 which indicates that 57.75% of the variation was explained by the model. The coefficients of the first-order term in the equation with independent variables which depicts that increment in the crispness value of the cone with the quantity of jackfruit seed flour as well as water content. Jackfruit seed flour has more fiber and protein than wheat flour; therefore, liquid is necessary to get a good mix for cone, and the cone prepared from high-absorption end to be hard and ultimately crispier [30]. This statement was supported by Ref. [31] that crispness is reliant to gelatinization of starch during baking which finally depend on the water availability during baking, so along with flour increment water should be higher for crispness. The final equation (Eq. (4)) in terms of actual factors is given below:

| Crispness = −5.26329 + 0.082331X1 + 0.046294X2 − 2.42500E−004X1*X2 − 2.87500E004X12 − 7.10000E − 005X22 | (4) |

Fig. 4.

Response surface plots showing interaction effect of variables on crispness of Waffle ice cream cone.

The magnitude of β-coefficients showed a linear term of seed flour has the maximum negative effect (β = −0.26) as compared to water content (β = −0.19) on the cone crispness (Table 2). Similar trend is also shown by response surface plot (Fig. 4). As seed flour and water content increased crispness was maximum at middle concentrations of both X1 and X2. The properties might be due to the high composition of fiber in the seed flour. High fiber content increased the texture of the cone to become crispy. Similar results were reported by Ref. [28] in the cone prepared using sweet potato.

3.3.4. Effect of independent variables on ice-cream permeability of Waffle ice cream cone

Ice cream permeability was measured as the time taken for ice cream to permeate through a given cone. The effect of JSF (X1) and water content (X2) on the permeability of icecream cones is presented in Fig. 5. The permeability of the samples depends upon the level of independent factor is used for the formulation of cone. The permeability, as predicted by the regression model (Table 2), was significantly (p < 0.05) affected by the linear term is JSF (X1) and water content (X2) and quadratic square terms of them. Table 2 showed that the response surface quadratic model showed F-value of 11.09 and the model is significant at p < 0.05. The “Lack of Fit F-value” of 1.62 indicated that the Lack of Fit is not significant in relation to the pure error. The model is significant as lack of fit is non-significant. The coefficient of determination (R2) is 0.8879, which indicates that 88.79% of the variation and the adjusted R2 of 0.8079 which indicates that 80.79% of the variation was explained by the model (Table 3). The results indicated that the ice cream permeability increased with the quantity of jackfruit seed flour and decreased water content. The final equation (Eq. (5)) in terms of actual factors is given below:

| Ice-cream permeability = +78.78454–0.49925X1 − 0.12685X2 + 1.32500E−003X1*X2 + 2.29719E−003X12 − 1.03450E−004X22 | (5) |

Fig. 5.

Response surface plots showing interaction effect of variables on ice cream permeability of Waffle ice cream cone.

The magnitude of β coefficients demonstrated the linear term of flour of jackfruit seed has the maximum positive effect (β = 2.15) and water content has the maximum negative effect (β = −4.95) on the cone permeability (Table 2). The 3D graphical representation of response plot is given in Fig. 5. It can be suggested that the permeability of cone was higher in the cones where less water was used to make the dough mix, due to their hardness and high-water retention capacity as compared to other where high amount of water used for the formulations. Similar results were reported by Ref. [21] that the permeability was higher at low water content and high sorghum flour concentration.

3.3.5. Effect of independent variables on overall acceptability (OAA) of waffle ice cream cone

The effects of JSF and water concentration on the overall acceptability of waffle ice cream cone is given in 3D plots (Fig. 6). Sensory analysis helps defining the product characteristics which are important with respect to customer acceptance of the product [32]. Test on individual parameters depicts that the overall acceptability of the waffle ice cream cone was significantly (p < 0.05) influenced only by the linear term of JSF and water concentration and interaction terms (X12*X22). The results showed that the model is significant, with non-significant lack of fit (Table 3). The values of R2 of 0.8212 and adjusted R2 of 0.6934 also showed significance of the model. A lack of fit value was 4.12 is found to be insignificant relative to pure error. The independent coded variables indicated that the OAA decreased at higher concentration of wheat flour and increased with water amount. The final equation (Eq. (6)) in terms of actual factors is given below:

| OAA = +1.872822−0.1159X1 + 0.057767X2 + 6.70000E−004X1*X2 − 4.75313E−004X12 − 1.65050E−004X22 | (6) |

Fig. 6.

Response surface plots showing interaction effect of variables on OAA of Waffle ice cream cone.

The magnitude of β coefficients (Table 2) revealed that the linear term of jackfruit seed flour content has the negative effect (β = −0.11) and water content has the maximum positive effect (β = +0.77) on the cone OAA. As jackfruit seed flour has high water absorption capacity so it will affect the dough consistency during the preparation of dough mix it can be explained from Table 1. The experiments with high seed flour with low liquid for dough mix preparation has minimum overall acceptability. Similar results were reported by Ref. [26] that the permeability of the cone was higher at low water content and high sorghum flour concentration.

3.3.6. Optimization and characterization

Numerical optimization was done for determining the best possible combination of the independent variables in order to produce the product of desired characteristics. The desired goals (maximize or minimize) for each independent variable and the responses were set as per requirement and importance (+ to +++++) was given to each factor as shown in Table 4. In order to get optimized result, the formulation was done with maximum protein, crispness, permeability, and overall acceptability, while the hardness was set to occur in range. This was obtained by targeting the seed flour to 80 g. The optimized combination of independent variables with the predicted values of responses was obtained by numerical optimization (Table 5). The optimized predicted responses were validated experimentally. The experimental trials were done in triplicate and found to be near to the predicted values within the acceptable limit (Table 5). Optimization was done by using a multiple response method called desirability. Results showed that the Waffle ice cream cone was only reliant on the interaction terms. The predicted values of the responses under optimum condition are hardness 11.72, crispness 1.69, protein 13.30, Ice-cream permeability 40.12 and overall acceptability score 7.74, respectively. The computed desirability of JSF cone was 0.653. The variables concentration was determined to be optimum by the response surface methodology and was used to authenticate it experimentally and they were found to be in close agreement with the predicted values.

Table 4.

Constraints Set for the optimization of Waffle ice cream cone from JSF.

| Variables | Goal | Limits | Importance |

|---|---|---|---|

| JSF | is in range | 40–80 | 3 |

| Water | is in range | 200–300 | 3 |

| Hardness | is in range | 8.29–21.66 | 3 |

| Crispness | is in range | 0.9–2.41 | 3 |

| Protein | is in range | 9.49–14.55 | 5 |

| Ice-Cream permeability | Minimize | 30.21–46.80 | 5 |

| Overall acceptability (OAA) | Maximize | 1.1–8.5 | 5 |

Table 5.

Predicted and experimental values of responses for Waffle ice cream cone using optimum process parameters.

| Values | Responses variables |

Desirability | ||||

|---|---|---|---|---|---|---|

| Hardness (N) | Crispness (Force drops/mm) | Protein (%) | Icecream permeability (min) | OAA | ||

| Predicted | 11.65 | 1.74 | 13.12 | 41.62 | 7.18 | 0.653 |

| Experimented | 11.72 ± 0.03 | 1.69 ± 0.01 | 13.30 ± 0.28 | 40.12 ± 0.87 | 7.14 ± 0.03 | |

| t-test Statistics for predicted and experimented | 0.07 | 0.18 | 0.08 | 0.17 | 0.19 | |

3.3.7. Model validation

The ratio of JSF and wheat flour for icecream cone was optimized using response surface methodology. A model can be considered as an adequate model, if the predicted values are close to the experimental values observed during the validation tests [33]. The paired t-test was used to model validation, and the results illustrated that the experimental results were not significantly different (p > 0.05) that confirms the validity of the estimated models (Table 5). Similar findings were reported by Ref. [34] for millet–legume blended extrudates.

4. Conclusion

Response surface methodology was effectively employed to evaluate and model effects of two levels of two independent variables (JSF and water content) on the overall acceptability of product. In the preparation of waffle ice cream cone amount of seed flour and water has great effect on the texture and overall acceptability. For the optimization of seed flour and water content used for preparation waffle ice cream cone response surface methodology was found fitted. It is concluded that the cone was supplemented with 60% of JSF resulted to the higher values of crispiness and overall acceptability as compared to other waffle ice cream cones. The model also showed that supplementation levels up to 80 g (JSF) can also be done with slightly higher amount of water. Thus, the JSF can be utilized to value added products by partial/full replacement of wheat flour. This work recommends jackfruit seed flour as a potential substitute for nutritionally enrich with low gluten waffle ice cream cone and also utilization of by-products which reduces the environment burden. Further studies may include detailed analysis of nutritional constituents and functional properties of various value-added food products from jackfruit seed flour.

Author contribution statement

Radha kushwaha: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Ayushi Gupta: Performed the experiments.

Vinti Singh: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Seeratpreet Kaur: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Vinita Puranik: Contributed reagents, materials, analysis tools or data.

Devinder Kaur: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by the University Grant Commission (UGC), New Delhi, India (Ref No. 1608 (OBC) (NET JAN-2017).

Data availability statement

Data will be made available on request.

Declaration of interest's statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors thank the centre of Food Technology University of Allahabad, for providing facilities to carry out the investigation.

Footnotes

Supplementary data related to this article can be found at https://doi.org/10.1016/j.heliyon.2023.e13140.

Appendix A. Supplementary data

The following is the supplementary data related to this article:

References

- 1.Jagtap U.B., Bapat V.A. Artocarpus: a review of its traditional uses, phytochemistry and pharmacology. J. Ethnopharmacol. 2010;129(2):142–166. doi: 10.1016/j.jep.2010.03.031. [DOI] [PubMed] [Google Scholar]

- 2.Menaka T., Nagaraja G., Yogesh D.B., Kumar U.S., Prakash L. Physicochemical properties of flour and isolated starch from jackfruit seeds (Artocarpus heterophyllus Lam) RGUHS J. Pharm. Sci. 2011;1(1):58–60. [Google Scholar]

- 3.Tulyathan V., Tananuwong K., Songjinda P., Jaiboon N. Some physicochemical properties of jackfruit (Artocarpus heterophyllus Lam) seed flour and starch. Sci. Asia. 2002;28(1):37–41. [Google Scholar]

- 4.Samaddar H.N. In: Fruits of India, Tropical and Sub-tropical. Bose T.K., Mitra B., editors. Naya Prakash; Calcutta, India: 1990. Jackfruit; pp. 638–649. [Google Scholar]

- 5.Abedin M.S., Nuruddin M.M., Ahmed K.U., Hossain A. Nutritive compositions of locally available jackfruit seeds (Artocarpus heterophyllus) in Bangladesh. Int. J. Biosci. 2012;2(8):1–7. [Google Scholar]

- 6.Amadi J.A., Ihemeje A., Afam-Anene O.C. Nutrient and phytochemical composition of jackfruit (Artocarpus heterophyllus) pulp, seeds and leaves. Int. J. Innov. Food Nutr. Sustain. Agric. 2018;6(3):27–32. [Google Scholar]

- 7.Deshmukh P.S. College of Agricultural Engineering & Technology, Dr. BSKKV, Dapoli; 2014. Development of Jackfruit Seed Flour by Different Methods. Doctoral Dissertation. [Google Scholar]

- 8.Swami S.B., Thakor N.J., Haldankar P.M., Kalse S.B. Jackfruit and its many functional components as related to human health: a review. Compr. Rev. Food Sci. Food Saf. 2012;11(6):565–576. doi: 10.1111/j.1541-4337.2012.00210.x. [DOI] [Google Scholar]

- 9.Zhang Y., Zhu K., He S., Tan L., Kong X. Characterizations of high purity starches isolated from five different jackfruit cultivars. Food Hydrocolloids. 2016;52:785–794. [Google Scholar]

- 10.Babitha S., Soccol C.R., Pandey A. Solid-state fermentation for the production of Monascus pigments from jackfruit seed. Bioresour. Technol. 2007;98(8):1554–1560. doi: 10.1016/j.biortech.2006.06.005. [DOI] [PubMed] [Google Scholar]

- 11.Hema J. Department of Agro-processing, Bangabandhu Sheikh Mujibur Rahman Agricultural University; 2015. Development of Nutritious Instant Dried Powder by Mixing Bulb and Seeds of the Jackfruit. Doctoral Dissertation, MS Thesis. [Google Scholar]

- 12.Praveenasri B., Priya R., Helen S.A. ICFOST; Hyderabad: 2006. Studies on Incorporation of Jack Fruit Seed Flour on Extruded Products. 66. [Google Scholar]

- 13.Butool S., Butool M. Nutritional quality on value addition to jack fruit seed flour. Int. J. Sci. Res. 2015;4(4):2406–2411. [Google Scholar]

- 14.Meethal S.M., Kaur N., Singh J., Gat Y. Effect of addition of jackfruit seed flour on nutrimental, phytochemical and sensory properties of snack bar. Curr. Res. Nutr. Food Sci. 2017;5(2):154–158. doi: 10.12944/CRNFSJ.5.2.12. [DOI] [Google Scholar]

- 15.Kigozi J., Byaruhanga Y., Kaaya A., Banadda N. Development of the production process for sorghum waffle ice cream cones. J. Food Technol. 2011;9(6):143–149. [Google Scholar]

- 16.Manoharan A.P., Saarunikesh G., Ashokkumar C. Quality characterization of casein enriched ice cream wafer cone. Ind. J. Vet. Anim. Sci. Res. 2020;49(5):30–37. [Google Scholar]

- 17.Phuenpipob C., Thomthong D., Sakdumrong T. Applied Mechanics and Materials. Trans Tech Publications Ltd; 2016. Utilization from Okara to replace wheat flour in ice-cream cone; pp. 107–110. vol. 848. [Google Scholar]

- 18.Mukprasirt A., Sajjaanantakul K. Physico‐chemical properties of flour and starch from jackfruit seeds (Artocarpus heterophyllus Lam.) compared with modified starches. Int. J. Food Sci. Technol. 2004;39(3):271–276. doi: 10.1111/j.1365-2621.2004.00781.x. [DOI] [Google Scholar]

- 19.Kushwaha R., Vinti Singh M.P., Kaur D. Traditional sweet: Gulab jamun. Int. J. Curr. Res. Rev. 2017;9(21):45–53. doi: 10.7324/IJCRR.2017.9217. [DOI] [Google Scholar]

- 20.Association of Official Agricultural Chemists. Latimer George W. AOAC International; Rockville, Maryland: 2016. Official Methods of Analysis. [Google Scholar]

- 21.Kigozi J., Banadda N., Byaruhanga Y., Kaaya A., Musoke L. Optimization of texture in sorghum waffle ice cream cone production using sensory analysis. Open Food Sci. J. 2014;8(1):18–21. [Google Scholar]

- 22.Yang M., Li L. Physicochemical, textural and sensory characteristics of probiotic soy yogurt prepared from germinated soybean. Food Technol. Biotechnol. 2010;48(4):490–496. [Google Scholar]

- 23.Miah M.Y., Bhattacharjee S., Sultana A., Bhowmik S., Kumar A., Sarker A.…Zaman A. Evaluation of amino acid profile of jackfruit (Artocarpus heterophyllus) seed and its utilization for development of protein enriched supplementary food. J. Noakhali Sci. Technol. Univ. 2017;1(1):77–84. [Google Scholar]

- 24.Rosell C.M., Rojas J.A., De Barber C.B. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloids. 2001;15(1):75–81. doi: 10.1016/S0268-005X(00)00054-0. [DOI] [Google Scholar]

- 25.Torbica A., Hadnađev M., Dapčević T. Rheological, textural and sensory properties of gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocolloids. 2010;24(6–7):626–632. doi: 10.1016/j.foodhyd.2010.03.004. [DOI] [Google Scholar]

- 26.Kigozi J., Banadda N., Byaruhanga Y., Kaaya A., Lule F. Sorghum waffle ice cream cone texture; correlations between instrumental and sensory analysis. J. Adv. Food Sci. Technol. 2016;3(3):134–145. [Google Scholar]

- 27.Akesowan A. Quality of reduced-fat chiffon cakes prepared with erythritol-sucralose as replacement for sugar. Pakistan J. Nutr. 2009;8(9):1383–1386. [Google Scholar]

- 28.Dom Z.M., Amin N.A.M.Z., kadir Basha R. Sweet potato peel flour applications in the textural quality of waffle waffle ice cream cone and other food products. Adv. Agric. Food Res. J. 2020;1(2) doi: 10.36877/aafrj.a0000150. [DOI] [Google Scholar]

- 29.Szczesniak A.S. Consumer awareness of and attitudes to food texture II. Children and teenagers. J. Texture Stud. 1972;3(2):206–217. doi: 10.1111/j.1745-4603.1972.tb00624.x. [DOI] [PubMed] [Google Scholar]

- 30.de Santana Silva C., Greiner R., Marinho L.Q.M., Alves A.S.B., Cardoso L.A., Maciel L.F., de Almeida D.T. Development of a gluten-free ice cream basket alternative using cowpea flour (Vigna unguiculata (L.) Walp), rice flour (Oryza sativa) and crude palm oil (Elaeis guineensis Jacq.) Int. J. Gastron. Food Sci. 2022;28 doi: 10.1016/j.ijgfs.2021.100431. [DOI] [Google Scholar]

- 31.Hadiyanto, Asselman A., Van Straten G., Boom R.M., Esveld D.C., Van Boxtel A.J.B. Quality prediction of bakery products in the initial phase of process design. Innovat. Food Sci. Emerg. Technol. 2007;8(2):285–298. doi: 10.1016/j.ifset.2007.01.006. [DOI] [Google Scholar]

- 32.Yaakob H., Ahmed N.R., Daud S.K., Malek R.A., Rahman R.A. Optimization of ingredient and processing levels for the production of coconut yogurt using response surface methodology. Food Sci. Biotechnol. 2012;21(4):933–940. doi: 10.1007/s10068-012-0123-0. [DOI] [Google Scholar]

- 33.Madamba P.S. The response surface methodology: an application to optimize dehydration operations of selected agricultural crops. LWT--Food Sci. Technol. 2002;35(7):584–592. doi: 10.1006/fstl.2002.0914. [DOI] [Google Scholar]

- 34.Chakraborty S.K., Singh D.S., Kumbhar B.K., Chakraborty S. Millet–legume blended extrudates characteristics and process optimization using RSM. Food Bioprod. Process. 2011;89(4):492–499. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.