Abstract

The proliferation of the e-commerce market has posed challenges to staff safety, product quality, and operational efficiency, especially for cold chain logistics (CCL). Recently, the logistics of vaccine supply under the worldwide COVID-19 pandemic rearouses public attention and calls for innovative solutions to tackle the challenges remaining in CCL. Accordingly, this study proposes a cyber-physical platform framework applying the Internet of Everything (IoE) and Digital Twin (DT) technologies to promote information integration and provide smart services for different stakeholders in the CCL. In the platform, reams of data are generated, gathered, and leveraged to interconnect and digitalize physical things, people, and processes in cyberspace, paving the way for digital servitization. Deep learning techniques are used for accident identification and indoor localization based on Bluetooth Low Energy (BLE) to actualize real-time staff safety supervision in the cold warehouse. Both algorithms are designed to take advantage of the IoE infrastructure to achieve online self-adapting in response to surrounding evolutions. Besides, with the help of mobile and desktop applications, paperless operation for shipment, remote temperature and humidity (T&H) monitoring, anomaly detection and warning, and customer interaction are enabled. Thus, information traceability and visibility are highly fortified in this way. Finally, a real-life case study is conducted in a pharmaceutical distribution center to demonstrate the feasibility and practicality of the proposed platform and methods. The dedicated hardware and software are developed and deployed on site. As a result, the effectiveness of staff safety management, operational informatization, product quality assurance, and stakeholder loyalty maintenance shows a noticeable improvement. The insights and lessons harvested in this study may spark new ideas for researchers and inspire practitioners to meet similar needs in the industry.

Keywords: Service platform, Internet of everything, Digital twin, Cold chain logistics, Abnormal stationary detection, Indoor positioning

1. Introduction

Recent years have witnessed a thriving growth in cold chain logistics (CCL) that bolsters the supply of perishable and medical products. It has been revealed that the CCL market in China has risen 15% per year since 2013 and might attain 80 billion dollars in 2024 [1]. The ever-increasing demand challenges product quality assurance, staff safety supervision, and operational efficiency enhancement. Under this circumstance, CCL service providers endeavor to pursue innovative solutions to tackle these issues.

First, since the efficacy and safety of products in CCL are strictly susceptible to temperature and humidity (T&H), most applications focus on the monitoring via data loggers or IoT sensors. Under the worldwide COVID-19 pandemic, the storage condition of vaccines challenges the logistics. Some vaccines need to be stored at −80 °C – −60 °C while some at 2 °C – 8 °C [2]. Note that both higher and lower degrees could compromise efficacy or even be life-threatening. In August 2020, it was reported that 28 people died of coronavirus vaccination in Korea, and 0.48 million doses of vaccines were recalled [3]. The experts indicated that the refrigeration system in a truck would be responsible for the tragedy due to its breakdown without attention. In this case, it manifested the importance of proactive and timely monitoring on storage conditions throughout the vaccine's lifecycle. However, the use of relevant technologies, information systems, and other forms of technical assistance still remains immature in practice.

Second, in addition to concerns about product quality, operators working in refrigerated and enclosed rooms envisage potential risks. A real-life accident occurred in an air cargo cold storage in Hong Kong. An operator fell on the ground for five hours and turned out frozen to death [4]. Supervisors stayed in a remote office and failed to perceive this accident in time. The news engendered deep grief and, meanwhile, served as a wake-up call for effective staff safety management within CCL. For problem-solving, it is suggested to integrate an active detection on abnormal human motion status and a real-time indoor positioning system to facilitate quick response and handling.

Third, the lack of sufficient data and analytics hampers operation improvement and optimization in traditional CCL. The data collection mainly relies on forms filling on paper by human beings, which is time-consuming and prone to error. Also, most sensors having been deployed only store data locally without real-time upload. The information delay and incompleteness would erode system timeliness and traceability. As a result, the asynchrony between physical and cyber spaces devalues the information assembled.

Overall, three specific research questions are identified in this study. First, how to timely detect abnormal human stationary and accurately locate people in cold rooms? Second, how to fulfill cyber-physical connectivity and synchronization for the digitalization of resources and processes in effect? Third, how to integrate the virtual assets to serve different stakeholders in the CCL, regarding product quality assurance, staff safety management, and operational informatization? It entails a systematic solution that leverages advanced digital technologies to make operation conduction and management safer and more efficient.

Accordingly, an architecture of Internet of Everything (IoE)- and digital twin (DT)-enabled service platform for cold chain logistics (ID-SCCL) is proposed to address these questions. The IoE, which fosters linkages among people, things, processes, and data rather than single things (IoT) [5], is intended to gather a myriad of data and reinforce hyper-connectivity between physical objects as well as cyber-physical spaces. Besides, DT technology is used to map digital representations to physical resources and digitalize processes with seamless cyber-physical synchronicity and interoperability, paving the way for intelligent services provision [6]. The platform applies cloud and edge computing to elevate system responsiveness and storage utility. The software-as-a-service (SaaS) plays a vital role in real-time decision-making, information integration and sharing, and practical operation conduction.

Specifically, three scenarios in CCL are mainly concerned here. First, operators are working in a cold storage warehouse, with motion and location tracked in a timely fashion. Deep learning approaches will be used to identify the unusual static status of people and sense their locations based on Bluetooth Low Energy (BLE) technology. A dynamic tracking map visualizes the latest condition of humans to boost spatial-temporal visibility for supervision. Second, multiple objects are involved in the outbound shipment, including customer orders, products, packages, trucks, and drivers. A casual pairing mechanism is designed to link them up in the digital world and conducted by mobile applications to eliminate paper-based operations and make planning and execution more flexible. Furthermore, it helps attain information traceability and operational accountability. Third, a big concern relates to the storage condition of products during transportation, considering the delivery of unqualified goods would cause a huge loss in both cost and reputation. The BLE tags and IoT gateways will be configured to achieve remote T&H monitoring in a real-time manner. Once an out-of-range is detected in transit, the system automatically raises warnings to persons in charge via multiple ways for product recall. In addition, customers could readily access the entire historical data on T&H in a chart using mobile applications for preliminary product quality confirmation. Finally, a real-life case study has been carried out in a pharmaceutical distribution center to validate the feasibility and rationality of the proposed platform and methods. The case company assumes the responsibility of dispatching vaccines across Hong Kong. The insights and lessons harvested here may spark new ideas for scholars and inspire practitioners to embark on similar projects.

The remainder of this article is organized as follows. Section 2 reviews related work and figures out research gaps. The architecture of the ID-SCCL platform is introduced in Section 3. Section 4 presents the abnormal stationary detection and indoor positioning algorithm in mathematics. Section 5 elaborates on the implementation of the platform and discusses the outcomes. The final section concludes the overall work, with future work also addressed.

2. Literature review

This section reviews techniques for accident detection and indoor positioning in the industry. In addition, the applications of IoE and DT technologies to CCL are also presented. Finally, the difference and significance of this research will be clarified.

2.1. Deep anomaly detection

In effect, detecting accidents in an intelligent environment is likened to identifying anomalies from the deal of real-time data collected. A novelty or outlier refers to a single dataset deviating from major datasets distinctly. A body of research focuses on anomaly detection for different application scenarios like traffic accidents, network security, and financial auditing [7], [8], [9]. Recently, a growing number of studies have highlighted the viability and superiority of deep learning techniques applied to anomaly detection, namely deep anomaly detection (DAD) [10], [11], [12]. Amid, four types of DAD approaches are mainly concerned. First, predictability modeling is designed to forecast current data instances based on the representations of previous instances within a time window by feature learning [13,14]. The advantage of this method is to dispose of expressive temporally-dependent low-dimensional representations, whereas the weakness is to consume a mass of computation and easily fall into a suboptimal. Second, the aim of generative adversarial networks (GAN) is to extract intrinsic normality from data instances in a latent feature space [15,16]. Realistic instances can be generated, especially for image data, but model training is exposed to a big issue. Third, the features of normality can be learned by the self-supervised classification model, and the data inconsistent with the model would be regarded as an outlier [17,18]. It is good at discriminating anomalies from expressive low-dimensional representations but only for image data. Fourth, auto-encoder (AE), by comparison, shows the advantage of dealing with different types of data in a set [19], [20], [21]. Importantly, AE approaches are simple for deployment, thus fitting the industrial context well. To the best of our knowledge, this study is the first attempt to apply the AE method to fulfill abnormal stationary detection in an air cargo cold storage.

2.2. Indoor positioning

Solutions to indoor positioning have been studied for decades as the global positioning system (GPS) that dominates the outdoor location has the limitation of penetrating walls. Specifically, radio frequency-related technologies gain popularity in academia and industry [22]. Each technology collaborated with different localization techniques owns strengths and weaknesses. For example, applying the proximity technique to the radio frequency identification (RFID) technology shows the advantage of simplicity but suffers from short range and low precision [23]. A combination of WiFi and fingerprinting technique can realize higher location accuracy, and pervasive infrastructures can be leveraged to reduce the investment. However, this solution is faced with the problems of excessive energy consumption and potential network congestion [24]. An ultra-wideband (UWB) system using the trilateration technique performs the best in terms of location accuracy as it can attain nearly 10-centimeter error [25], but what hinders its further application should be the high cost and low scalability. In contrast, BLE technology sparks the public's interest due to its high location accuracy, low energy consumption, low cost, and high scalability [26]. Thus, it will be used for staff tracking in this work. Nevertheless, the difficulty it faces is concerned with the signal fading intensified by a mass of environmental noises, thereby challenging the fingerprinting accuracy. Deep neural network is such a promising method to handle this issue and make the fingerprinting-based indoor localization more accurate [27]. Many studies have probed into multi-layer feedforward neural networks (FNN) to harvest good results, whereas using this structure to process sequential data remained limited [28,29]. Convolutional neural network (CNN) and recurrent neural network (RNN) were effective in processing time-series data and thus applied to cope with signal noises [[30], [31], [32]]. However, most studies were carried out in labs or educational buildings where the environments were less sophisticated than those in the industry. Therefore, this paper attempts to explore a proper solution to indoor localization in the industrial context using deep neural networks based on BLE technology.

2.3. IoE in cold chain logistics

The advent of Industry 4.0 urges smart logistics systems to satisfy expanded demands. IoT technologies are indeed the core impetus to make a network of machines and devices capable of sensing and interacting with other things and systems over the Internet, thus facilitating cyber-physical interconnectivity, big data acquisition, and intelligent decision-making [33]. Besides, not only can things be reached in the network, but everything is expected to be involved for more extensive and close ties [34,35]. Accordingly, the Cisco Internet Business Solutions Group (2013) gave birth to the IoE, which expanded to four dimensions: things, people, processes, and data [5]. People could serve as data sources or users with smart devices. For example, IoE technologies are beneficial to space optimization [36], environment monitoring [37], and process management [38] for smart warehousing. In addition, to timely capture and integrate the information on vehicles, cargoes and driver situations during transportation could effectively enhance the efficiency, ensure the quality and reduce the cost [39].

Specifically, IoE has been applied to serve the CCL characterized by dealing with environmentally sensitive products [40]. Tsang et al. [41] proposed an IoT-based cargo monitoring system for frozen food to capture any environmental changes in a cold warehouse and make storage condition suggestions in line with specific products using fuzzy logic and case-based reasoning techniques. A technical architecture aimed at timely circulations of operational information and a conceptual model for the supply chain of perishable food were designed on the basis of IoTs by Zhang et al. [42] to guarantee safe and economical transportation. Product quality evaluation also drew much attention to take advantage of the massive sensing data acquired. Afreen and Imran [43] sensed gas luminosity and concentration, altogether with T&H, and developed an artificial neural network to classify the status of fruits and vegetables. However, the spotlight of major work was shone on things per se, with rare on human or human-related operations, which are also crucial to overall revenues and multi-level stakeholders’ loyalty. Tsang et al. [44] attempted to devise an IoE-based risk monitoring system to evaluate occupational safety risk using a fuzzy logic approach in consideration of personal health status in different cold chain parties. Except for risk prediction, measures of first aid when accidents occur are significant to staff safeguard as well, which necessitates real-time motional and spatial-temporal information [45]. Overall, the servitization of IoE for the smart logistics is far from enough, thus requiring more exploratory studies.

3. Overview of the ID-SCCL platform

The CCL, featuring condition-sensitive, risk-inherent, and surveillance-blind, exposes high demand for remote and timely monitoring and raised information traceability and visibility to promote overall performance. In this case, the ID-SCCL platform is devised to synchronize cyber and physical spaces and servitize the digitalized assets for product quality assurance, staff safety management, and operational informatization. As Fig. 1 shows, a particular four-layer platform architecture is proposed, involving perception, interoperation, synchronization, and application (PISA). Each layer will be elaborated on in the following paragraphs.

Fig. 1.

The overview of the IoE and DT-enabled service platform for cold chain logistics (ID-SCCL).

At the perception layer are physical objects in CCL, including refrigerated trucks, cold boxes, and workers. Those objects would be equipped with IoT tags to become capable of sensing and communicating. One cold box holds one beacon tag that incorporates T&H sensors to monitor environmental conditions and broadcast messages proactively and periodically. The optimal mounting position in the box for tags can refer to the experimental work [46]. When entering cold rooms, warehouse operators must embed card-sized beacon tags that adopt the BLE protocol into their cardholders for real-time indoor tracking. The accelerometer is involved in the beacon tag for abnormal stationary detection during operations.

The IoT gateway dominates the interoperation layer as a bridge for cyber-physical connectivity and synchronicity. The sensing devices contain diversified wireless communication and networking (WC&N) protocols to establish linkages with the physical and digital world, such as BLE and broadband cellular networks. Besides, a suite of software services is designed primarily with defining, configuring, executing, and interacting functions, termed gateway operating systems (GOS). Concretely, it defines data transmission flow with heterogeneous devices and the cloud, configures basic setups and relevant parameters, executes data refinement and decision-making, and interacts with other layers via streams of information. The data analytics capability actuates edge computing to mitigate cloud computing burdens and attain rational storage space allocation. It should be highlighted that there are two types of IoT gateways, static and mobile. The static one acts as a micro-computer fixed at spots, while the mobile one represents smart devices, like smartphones and tablets, that can install proprietary applications to function. It not only supplements data collection channels and utilizes the ubiquity of those devices to save investment but, importantly, involves people in the network to play a core role in information integration and interpretation.

The third layer, synchronization layer, maps the digital world to the physical and enables intelligent decision-making, assisted by the cloud. It mainly consists of two modules. First, the Docker engine manages all the functional software packages running in isolated containers to prevent interference. Amid, cyber-physical agent resembles a cyber gate for data gathering and instructions issuing. The centered database connects with other modules, copes with massive data, and preserves essential information. Models, algorithms, and rules are implemented in data analytics engine to process data and make decisions, which ties closely with the cyber-physical agent and database. The intent of the application server is to maintain services in support of different applications, like web and Android applications. Second, DT models are built to construct digital representations for things, people, and processes, which are highly interconnected. Each element is also labeled with a chain of attributes so that, when one object is retrieved or changed, it would be easy to capture the holistic relation map or make a corresponding alteration on the whole, respectively. It benefits seamless cyber-physical synchronization and intelligent services provision.

Towards the application layer, different services are authorized to different stakeholders. For example, a dashboard depicts each cold box's T&H condition in a timely manner for visible supervision. Once the value exceeds the prescribed range, the system would trigger a warning in special symbols and sounds via applications. The T&H monitoring application is open to operators and external customers. A QR barcode is attached to the box's surface, which involves a link to access the basic information and historical T&H data regarding the cold box. At the arrival of delivery, customers can scan the code to grasp the overall condition of products for initial quality confirmation. In addition, a dynamic tracking map visualizes staff location and differentiates motion status in colors, leading to reinforced spatial-temporal visibility and quick response to an emergency. Managers take charge of the entire process and thus tend to leverage anomaly alarms and the tracking map for risk management. Mobile applications replace paper-based operations with automatic shipment recording, thereby increasing operational flexibility and reducing human-made errors. Object and process twins can be readily traced and retrieved via desktop applications to empower more efficient operation management and optimization. These applications can be used by warehouse workers, on-duty directors, and drivers to conduct operations in a handy way. The traceable retrieval is also a helpful tool for directors to gain reliable evidence of happened affairs.

Overall, this platform intends to tackle three main problems using advanced technologies. First, operators’ safety and location can be supervised proactively and vividly when they work in cold storage, which elevates the responsiveness of emergency handling. Second, the digitalization of outbound shipments is realized, thus alleviating the reliance on paper and enhancing traceability and accountability. Third, the storage condition of medical products can be monitored remotely in real-time throughout their lifecycle so that their quality can be assured when delivered to customers.

4. Methodology

The motionless status of operators in a cold room is a dangerous signal implying a potential accident might be happening. Hence, to timely identify an abnormal idle state is necessary for staff safety supervision. Besides, the synchronized spatial-temporal information of staff at the workplace plays a vital role in launching a responsive and precise rescue, which entails a real-time indoor positioning system as a base. Accordingly, the mechanism of abnormal stationary detection and indoor tracking algorithm based on deep learning approaches are designed to take advantage of the technical infrastructure built above. The mathematical models are expressed in the following subsections.

4.1. SAE-enabled abnormal stationary detection

Auto-encoder is an unsupervised neural network that encompasses encoding and decoding stages. The input data will be compressed into lower dimensions at the encoding stage and then restored to the original for decoding. With regard to anomaly detection, a big difference between the input and output would be recognized as an outlier. In this study, the stacked auto-encoder (SAE) is applied, which comprises several layers of sparse AEs, as portrayed in Fig. 2 . Note that the input data also works as a label for unsupervised model training.

Fig. 2.

The structure of stacked auto-encoders.

In terms of the input, two major factors are concerned for abnormal stationary identification, namely distance and acceleration. Operators are always expected to take motions in a cold environment, so the tri-axial accelerations should remain to fluctuate. A special situation is when people may move at a constant speed. In this case, distance shift should be considered to expand the difference for distinguishing. It needs to normalize the input vector before learning so as to even the effect of every factor involved.

The hidden neural layers are composed of encoder, code, and decoder parts. Neighbor layers are fully connected in the encoder and decoder. Also, a symmetric scheme is implemented upon these two parts, as expressed in the following two formulas.

| (1) |

| (2) |

Hereinto, the represents a vector of neural values in the k th layer. The and stand for weight matrix and bias in the k th layer for encoding, respectively. Correspondingly, the and contribute to decoding. and are activation functions yielding the output of each neuron. Our network selects the rectified linear units (ReLU) as a default, which turns negative values into zeros and keeps positive ones the same as before. Exceptionally, the sigmoid function is adopted at the end for classification, which is presented as:

| (3) |

Subsequently, the objective function for model training is set as the mean squared error (MSE), which calculates the average of differences between the predicted and actual values that also come from the input vector here. The learning process aims at minimizing the error, as denoted below.

| (4) |

Then, the acquisition of the optimal solution is achieved by the adaptive moment estimation (Adam) algorithm based on the backpropagation of gradients. This algorithm performs robustly in the face of any initialization of hyper-parameters. It engenders iterative updates for the entire model parameters, denoted as , in the direction of gradient descent at an adaptive learning rate. If the training dataset is divided into m mini-batches, the gradient matrice can be obtained as follows:

| (5) |

The computes each parameter's partial derivatives regarding the MSE. Next, the first-order () and second-order () moment at the t th state in the Adam can be revamped by:

| (6) |

| (7) |

The and are exponential decay rates in the moment estimation, both close to but less than one. The connotes a Hadamard product that multiplies by elements. The learning rate controls the speed of gradient regeneration with a decay rate for precise tuning, as given by:

| (8) |

Now, the model parameters can be updated as follows.

| (9) |

The optimal solution is reached after epochs of iterative training, with early stopping applied to prevent overfitting. The mean absolute error (MAE) is computed for anomaly detection. Compared with MSE, MAE can amplify the difference between the output and input, which is presented below.

| (10) |

Under this condition, a threshold is needed to enable the classification, which depends on trials and errors on site. At the early stage, several iBeacon tags will be mounted somewhere in the cold storage for model initialization and later used for calibration. In this case, normal data learned by the model would be actually on behalf of abnormal stationary.

4.2. ResNet-based indoor positioning

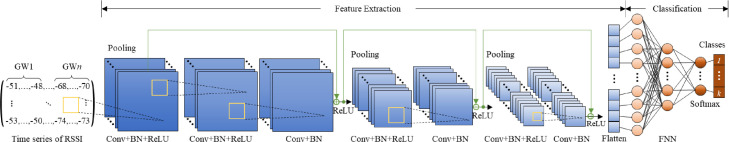

The real-time spatial-temporal information can help enable a quick response when an anomaly occurs. Here, the principle of fingerprinting based on the received signal strength indicator (RSSI) of BLE is applied to realize indoor localization, instead of the range-based technique that calculates distances via signal propagation models, which is hard to keep pace with the constant change in the industrial environment [47]. The fingerprinting technique incorporates offline and online stages. The RSSI pattern of each location partitioned, similar to a unique fingerprint, is weaved at the offline stage to set up a location database for online estimation. Deep neural networks manifested an improved performance on the relation mapping so as to attain higher locating accuracy. Specifically, the CNN is proven to cope with time-series data and images efficiently due to its automatic detection on key features. Besides, the deeper layers the network contains, the better it performs. Nonetheless, the gradient vanishes in the process of weight updating, thus causing accumulated training errors. Accordingly, the residual neural network (ResNet) is born from CNN, featuring short-cut connections, to retain features and accelerate convergence. Hence, we devise a ResNet to realize fingerprinting-based indoor localization in this work. Note that several calibration points inside cold rooms are configured to make the model fulfill online self-adapting in a timely response to surrounding transitions. The following parts will outline the ResNet framework and the learning process.

The entire network architecture consists of feature extraction and classification phases, as schematized in Fig. 3 . In terms of feature extraction, once IoT gateways receive messages from an iBeacon tag, an exclusive RSSI matrix can be formed immediately. Within a short period , one location's signal fingerprint could be represented by:

| (11) |

Fig. 3.

The architecture of the residual network (ResNet).

Amid, the denotes the n th RSSI value from the p th gateway. Note that the number of RSSI values acquired by gateways within the same timespan may not be identical because the start time to broadcast is hard to be synchronized for all the tags, and a long distance may make the communication unstable. Moreover, the number of gateways in the fingerprint also varies from location to location, thus causing difficulties in model training. Under this circumstance, this study proposes a particular feature selection method to pose a filtration on raw data. Two steps are needed. The first step intends to pick out the four nearest gateways by comparing the averaged signal strength. A bigger RSSI value indicates the distance is closer. Then, the maximum, mean, and minimum (MMM) values are computed to represent the series of RSSIs in line with the nearest gateways. Thus, the fingerprint of a location can be updated as:

| (12) |

The final input to the neural network should be constituted by several continuous periods of , like triple or quadruple, to attain higher location accuracy but sacrifice a little responsiveness. For example, the input matrix could be given by:

| (13) |

After the construction of the input tensor, a small matrix of values working as a kernel or filter, denoted as K, traverses the input tensor and initiates a convolutional transformation for data refinement. A certain number (p) of kernels are devised to conduct feature pooling. The indexes of rows and columns for the updated tensor U are marked by m and n, respectively, which complies with the following equation.

| (14) |

Given the mini-batch training applied in the optimization, a batch normalization (BN) layer is added to accelerate gradient descent and prevent overfitting. Next, the normalized output will be fed to an activation function, namely ReLU. Subsequent layers follow these three steps in the same order to deepen feature extraction. It should be highlighted that the ReLU is enforced after the additional layer that incorporates a skip connection with the early layer to refrain from gradient degeneration. After a chain of identical residual blocks follows a flatten layer to unfold outputs. Whereafter, the classification phase comprises a fully-connected FNN with the softmax activation at the final output layer. The n th output at the l th layer satisfies the following formula.

| (15) |

The and represent the weighting and bias matrix for the n th output, respectively. The softmax function is formulated by:

| (16) |

The number of values in the output vector that only involves one and zero equals the entire location classes to be distinguished. The target class is assigned with one while zero for the rest. With the establishment of the ResNet network, the next step is to resolve the optimal parameters by training.

At first, the categorical cross-entropy loss is set as the optimization objective due to the softmax applied. The expected value of the i th output is denoted as , while the corresponding actual output is . Hence, the loss function can be expressed as:

| (17) |

The Stochastic Gradient Descent (SGD) method is used to enable the backpropagation of gradients. The whole parameters to be learned in the model are denoted as . The gradient is computed as follows.

| (18) |

The represents partial derivatives of the loss towards each parameter. The Adam algorithm approaches the optimal solution with an adaptive learning rate. The procedure can be referred to in the previous subsection. Finally, the model learned at the offline stage attains parametric initialization, assigned with a timestamp. These parameters will keep updating online according to calibration points to effectuate long-term accuracy.

5. Case study

To verify the effectiveness of the developed ID-SCCL framework and relevant algorithms, the holistic solution has been deployed in a pharmaceutical distribution center in Hong Kong. The case company offers a comprehensive package of services across the entire value chain, from registration to marketing, promotion, and distribution. Their products reach a wide range of customers, including hospitals, clinics, pharmacies, doctors, and drugstores. The center is highly incentivized to adopt state-of-the-art technologies to provide intelligent services and promote operational efficiency. Specifically, they endeavor to realize the digitalization of assets and processes to enhance cyber-physical traceability and visibility and maintain long-term sustainability.

5.1. Operation reengineering

Warehousing operations feature intensive labor and equipment for a deal of material handling under time pressure, which increases safety risk, especially in a potentially-dangerous workplace like cold storage. The boomed demands on CCL have aggravated this situation. Hence, it will be of paramount importance to effectively implement staff safety management throughout the operations. A real-time detection system to identify their abnormal status and recognize the whereabouts becomes helpful. Besides, most operations for outbound shipments are still based on paper, like the driver taking order lists to pick up goods and noting down the loading information, which are time-consuming, tedious, and prone to errors. Accordingly, smart device-assisted operations are anticipated to improve the efficiency and reduce mistakes, further propelling process digitalization and data mining. Else, ensuring the quality of pharmaceuticals when delivered to customers is vital, since damaged products may contaminate supplier reputation and increase reverse logistics costs. Thus, it would be necessary to remotely monitor the surrounding T&H of products in real-time for quality control. Once the out-of-range condition occurs in transit, directors can contact drivers to cancel the dispatch ahead of time.

In this case, aided by IoE and DT technologies, dedicated software has been developed as a service to address these concerns. Correspondingly, relevant operations should be adjusted and reengineered, as depicted in Fig. 4 . The principle to comply with for the design is that it is supposed to reserve original operations to the utmost in order to minimize the effort and impact. For instance, operators just place beacon tags into their cardholders for motion detection and indoor localization when entering cold rooms, without any changes in their daily operations. The cardholder is hanged around the neck, and its effectiveness for motion detection has also been testified. As for shipment digitalization, six key elements are involved and intertwined, drivers, orders, cold boxes, BLE tags, gateways, and trucks. Elements need to be paired to form a correlated information chain for tracking and tracing. In terms of the pairing work, some are realized by scanning QR barcodes that contain unique identification via applications, and some by physical aggregation or wireless communication. It should be highlighted that those jobs can be carried out in advance or on the spot thanks to the seamless synchronization between cyber-physical spaces, thus augmenting operational flexibility. Mobile applications installed in smart devices can help operators accomplish all the outbound tasks and make planning and execution more agile. Explicitly, drivers assume the responsibility of placing products into cold boxes in line with customer orders assigned by directors via the system. When the cold box, paired with a BLE tag, is loaded to a truck that is paired with a gateway, a linkage between them can be set up automatically as the electronic tag can proactively broadcast messages to the gateway. As a result, the T&H of the cold box's inner chamber can be monitored remotely and real-timely. To promote customer-centric services, customers can scan the QR barcode stuck to the cold box surface to grasp the present and historical in-transit condition of products and confirm the quality preliminarily when the delivery arrives. It diminishes the drug failure rate and promotes customer satisfaction.

Fig. 4.

The reengineered operations for pharmaceutical logistics.

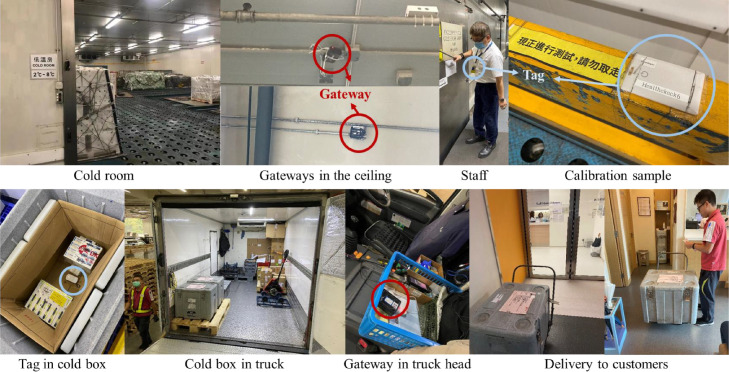

5.2. System deployment

In the light of reengineered operations, the ID-SCCL platform is implemented in the cold warehouse to enable digital services. This subsection focuses on presenting the practical deployment of IoE hardware and system software.

Fig. 5 displays actual scenes of hardware installation and related operations. In a cold storage covering nearly 2000 m2, gateways are mounted in the ceiling and powered by Ethernet, having the advantage of plug-and-play. They interact with the IoT tags carried by workers for motion monitoring and location tracking. In effect, each room or corridor installs one gateway but may be partitioned into several subzones as location units for fingerprinting. Specially, the refrigerated room ranging from −25 to −15 ° and the second buffer room are sealed tightly enough to block signal transmission, so no subzones are divided there. The pseudo-codes to realize unsupervised learning for the SAE model and supervised learning for the ResNet are displayed in Algorithms 1 and 2, respectively.

Fig. 5.

The hardware deployment and relevant operations.

Algorithm 1.

The SAE model for anomaly detection.

| Input: Raw sensor data | |

| Output: SAE model | |

| 1 | Set the initial value of learning rate (= 0.001), and exponential decay rates(= 0.9), (= 0.999) |

| 2 | Set time window size (= 10 s) |

| 3 | Initialize the parameter matrix with random values in the range (−1, 1) |

| 4 | for every time window: |

| 5 | |

| 6 | Normalize the vector |

| 7 | Integrate the vector to the training dataset |

| 8 | end for |

| 9 | Construct the SAE neural network (4–64–32–64–4) |

| 10 | for epochs with a batch size (m = 5): |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | end for |

| 17 | return SAE model |

Algorithm 2.

The ResNet with MMM for indoor positioning.

| Input: RSSI datasets R | |

| Output: ResNet model | |

| 1 | Set the initial value of timewindow and hyperparameters (see Table 1) |

| 2 | forTstart to end in a step of timewindowdo |

| 3 | for each tTagsdo |

| 4 | forTk to Tk + 1 in a step of mini-spando |

| 5 | for each gGatewaysdo |

| 6 | |

| 7 | end for |

| 8 | Pn [I1, …, Ig] |

| 9 | end for |

| 10 | Form input matrix across time IM [P1, …, Pn] with a label l |

| 11 | end for |

| 12 | end for |

| 13 | Randomly split matrices for training, validation and testing |

| 14 | Construct ResNet structure (three blocks of skip connection) |

| 15 | for epochs with a batch size (m = 10): |

| 16 | |

| 17 | Adam algorithm (Same as Algorithm 1) |

| 18 | end for |

| 19 | return ResNet model |

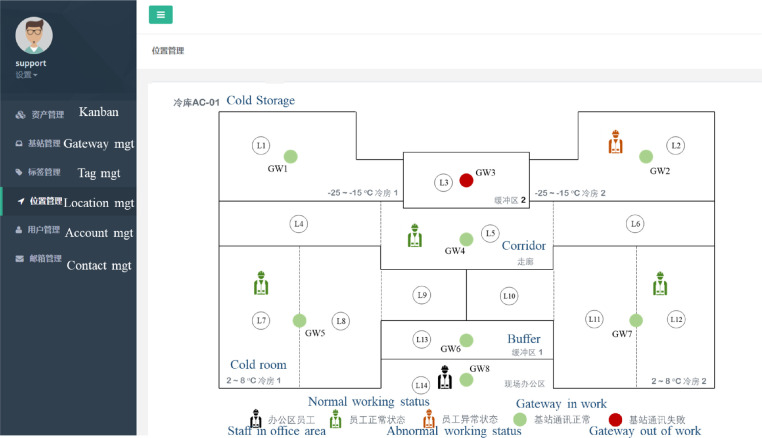

The real-time location and working status of humans, together with gateway layout and operating status, are twined and visualized in a tracking map, as demonstrated in Fig. 6 . This dynamic map is helpful for directors to monitor staff safety and locate people efficiently. Once an abnormal idle state is perceived, the system would provoke alarms to the persons in charge (PIC) via applications, e-mail, and short message services (SMS) for a prompt response. To sense environmental evolution and actualize self-adaptive learning in the long term for the neural network, eight tags are fixed at scattered spots to serve as calibration samples.

Fig. 6.

The dynamic tracking map in explorer.

Regarding vaccine delivery, an IoT tag is placed at the bottom of each cold box's interior chamber, which has been testified as the fit layer reflecting the maximal temperature in the vertical position. Operators just need to bring smartphones to fulfill pairing, planning, and recording jobs. Some mobile application interfaces are exhibited in Fig. 7 . After order-picking, cold boxes are loaded to the truck body, with one gateway powered in the head to gather data from tags in real-time. Fig. 8 shows the application interface that depicts a time series of T&H for all the cold boxes in transit and displays a chain of related information to fortify traceability and visibility. When T&H exceeds the required range in the process, a warning function will pop up in applications to remind PICs one by one to handle this anomaly.

Fig. 7.

The interfaces of mobile applications.

Fig. 8.

The real-time T&H monitoring dashboard for cold boxes in transit.

As shown in Fig. 7, PIC can access the entire T&H trend till the moment and readily contact the driver to double-check the condition and stop the delivery if necessary. It just needs users to click the phone button in the interface, which links with the driver's phone number behind. When boxes are returned to the center, operators use the application to end the monitoring process for lifecycle management.

5.3. Results and analysis

Based on the IoE infrastructure, real-time abnormal stationary detection and indoor location awareness for operators working in cold rooms are conducted. First, to monitor the staff motion status, three operators are involved in doing operations as usual and pretending to faint in different rooms. Fig. 9 portrays accelerations in three axes and amplitudes represented by the size of spheres. Amid, the abnormal status is painted in red, while the normal in green. By on-site testing, an inherent vibration on the ground is discovered due to goods transfer. At the preparation stage, the initial samples used for SAE model training should include the vibration. Hence, some iBeacon tags are mounted at on-site spots without physical movement for sampling. The experimental results indicated that the accuracy of anomaly detection achieved by the SAE could attain 100% in effect.

Fig. 9.

The tri-axial acceleration and overall amplitude for abnormal motionless detection.

Second, for the BLE-based indoor tracking, each location's RSSI fingerprint matching with the four nearest gateways has been constructed. Apart from the refrigerated rooms, the initial signal map of other locations where IoT tags can interact with at least two gateways is depicted in Fig. 10 . One type of color represents one gateway. It illustrates that the differentiation of signal fingerprints for each position could lay a fundamental base for deep learning-based classification.

Fig. 10.

The initial signal fingerprints for partitioned locations.

At the offline training stage, the residual network of CNN is generated to extract features from a time series of RSSI data and structure the mapping relation between signal fingerprints and realistic locations. Table 1 lists the values of all the hyperparameters in this network for the optimal solution approaching, which are decided by previous experience or trial and error.

Table 1.

The hyper-parameters in the ResNet.

| Symbol | Description | Value |

|---|---|---|

| K | Kernel matrix | |

| p | Number of kernels in convolutional layers | 32 |

| b | Mini-batch size | 10 |

| Initial value of learning rate | 0.001 | |

| The decay rate of learning rate | 0.0002 | |

| Initial value of the first-order moment | 0 | |

| Initial value of the second-order moment | 0 | |

| The exponential decay rate of the first-order moment estimation | 0.9 | |

| The exponential decay rate of the second-order moment estimation | 0.999 | |

| A minimum value close to zero |

By virtue of the massive data acquired, the hold-out method is applied to evaluate the model. We adopt stratified sampling to create training, evaluation, and testing datasets to eliminate biases. Fig. 11 displays the optimization process in consideration of accuracy and loss for training and evaluation, which demonstrates the rapid convergence benefiting from the skipped connections in ResNet. The average accuracy of testing could come to 99.67%. As a result, the optimal model parameters obtained in this stage would be stamped by a moment and work as the initiator for online estimation. Attributing to calibration samples fixed at onsite spots, the neural network can automatically adapt to surrounding variations in a periodic manner.

Fig. 11.

The learning process regarding accuracy and loss for training and validation datasets.

The deployment of the ID-SCCL platform enables intelligent services to enhance staff safety, product quality, operational efficiency, and service level. The IoE devices produce a vast amount of real-time data and establish close connections among things, people and processes. With edge and cloud computing applied, digital twins can seamlessly mirror physical resources and processes, leading to valid cyber-physical synchronization. On the ground of the platform, the abnormal stationary detection approach and ResNet-based tracking algorithm can facilitate the supervision of workers’ health status during operations and realize prompt responses to accidents. Besides, mobile and desktop applications are developed to assist paperless operations conduction and elevate information traceability and visibility for more efficient operations. Workers can take a smartphone to fulfill order-picking and loading tasks for shipment informatization, giving rise to agile pairing. In addition, the T&H of cold boxes is remotely monitored to ensure vaccine quality throughout the lifecycle. Once an anomaly is detected, the system triggers alarms to PICs to handle the issue immediately and prevent further loss. Customers are in favor of the service that allows them to access a holistic picture of cold box conditions over time by scanning the QR barcode on the box. As a consequence, the feasibility and effectiveness of the platform can be validated.

6. Conclusion

With the surge of demands on cold chain logistics, especially under the new normal of post-pandemic, state-of-the-art technologies and solutions are desired to strengthen product quality assurance, staff safety management, and operational efficiency improvement. Accordingly, this paper proposes a platform architecture based on IoE and DT technologies to provide intelligent services for different stakeholders in CCL. Deep learning techniques have been applied to fully leverage the mass of data generated and gathered by the platform to enable the servitization.

The main contributions of this research can be summarized in three aspects. First, the platform of ID-SCCL is proposed to offer services to both internal staff and external customers in CCL, including accident detection and location tracking in a warehouse for staff safety supervision, using smart applications for operation informatization, and real-time monitoring on storage conditions for product quality assurance. IoE and DT technologies are harnessed to digitalize and interconnect physical things, people, processes and data to promote cyber-physical synchronicity, traceability and visibility. Second, the SAE-based algorithm for abnormal stationary detection and the ResNet-based indoor positioning algorithm with the MMM feature selection method are designed to real-timely track and monitor operators working in cold storage. Both take advantage of the IoE infrastructure to fulfill online self-adapting so as to keep pace with surrounding evolutions in the long term. Third, the proposed system and methods are deployed in a pharmaceutical distribution center to demonstrate the viability and rationality, with dedicated hardware and software developed. The holistic platform framework and detail of implementation can work as a reference for reproduction to meet similar industrial needs or spark new ideas for practitioners and researchers.

This paper probes into new valuable services in the context of CCL, which are supported by IoE and DT technologies. However, there are still some limitations. For one thing, the positioning scenario only considers the cold rooms on the same floor, while multiple floors may trouble the localization due to different patterns of signal interference, especially for neighboring floors. For another, the large volume of data assembled by the platform is not fully made use of, and the intelligent services designed here are still few, with only a logistics service provider concerned. Accordingly, certain possibilities for future research can be clarified as follows. Firstly, the influence on indoor positioning under the industrial environment, caused by the signal propagation between multiple floors in the vertical direction, could be tested and analyzed. Secondly, it deserves deeper data mining for statistics, decision-making, troubleshooting, and risk prediction. More stakeholders along the CCL could be involved, like suppliers, manufacturers, and retailers, which entails more smart services to improve efficiency and sustainability for the supply chain as a whole. Thirdly, not just limited to the applications in CCL, IoE and DT technologies could bring benefits to other fields like intelligent manufacturing and smart construction. Therefore, more meaningful applications wait to be discovered.

CRediT authorship contribution statement

Wei Wu: Writing – original draft, Investigation, Methodology, Visualization. Leidi Shen: Software, Data curation, Project administration. Zhiheng Zhao: Writing – review & editing, Supervision. Arjun Rachana Harish: Formal analysis. Ray Y. Zhong: Writing – review & editing. George Q. Huang: Conceptualization.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work is partially supported by grants from RGC HK TRS (Project No.: T32-707-22-N).

Data availability

The data that has been used is confidential.

References

- 1.Dai J., Che W., Lim J.J., Shou Y. Service innovation of cold chain logistics service providers: a multiple-case study in China. Ind. Mark. Manag. 2020;89:143–156. doi: 10.1016/j.indmarman.2019.08.002. [DOI] [Google Scholar]

- 2.Bottani E., Montanari R. RFID and real time localization systems for warehouse management: a model for technical and economic evaluation. Int. J. RF Technol. 2013;4(3–4):209–245. doi: 10.3233/RFT-130046. [DOI] [Google Scholar]

- 3.Seco F., Jimenez A.R., Xufei Z. 2016 International Conference on Indoor Positioning and Indoor Navigation (IPIN) 2016. RFID-based centralized cooperative localization in indoor environments; pp. 1–7. [Google Scholar]

- 4.H. Ai, W. Huang, Y. Yang, and L. Liao, "The BLE fingerprint map fast construction method for indoor localization," In International Conference on Algorithms and Architectures for Parallel Processing, vol. 11337, pp. 326–340, 2018.

- 5.Miraz M.H., Ali M., Excell P.S., Picking R. 2015 Internet Technologies and Applications (ITA) 2017. A review on Internet of Things (IoT), Internet of Everything (IoE) and Internet of Nano Things (IoNT) [Google Scholar]

- 6.Jiang Z., Guo Y., Wang Z. Digital twin to improve the virtual-real integration of industrial IoT. J. Ind. Inf. Integr. 2021;22 [Google Scholar]

- 7.Yan X., Xu Y., Xing X., Cui B., Guo Z., Guo T. Trustworthy network anomaly detection based on an adaptive learning rate and momentum in IIoT. IEEE Trans. Ind. Inf. 2020;16(9):6182–6192. doi: 10.1109/TII.2020.2975227. [DOI] [Google Scholar]

- 8.Zhao H., et al. Anomaly detection for medical images using self-supervised and translation-consistent features. IEEE Trans. Med. Imaging. 2021;40(12):3641–3651. doi: 10.1109/TMI.2021.3093883. [DOI] [PubMed] [Google Scholar]

- 9.Ahmed M., Mahmood A.N., Islam M.R. A survey of anomaly detection techniques in financial domain. Future Gener. Comput. Syst. 2016;55:278–288. doi: 10.1016/j.future.2015.01.001. [DOI] [Google Scholar]

- 10.Pustokhina I.V., Pustokhin D.A., Vaiyapuri T., Gupta D., Kumar S., Shankar K. An automated deep learning based anomaly detection in pedestrian walkways for vulnerable road users safety. Saf. Sci. 2021;142 doi: 10.1016/j.ssci.2021.105356. [DOI] [Google Scholar]

- 11.Wang R., Nie K., Wang T., Yang Y., Long B. Proceedings of the 13th International Conference on Web Search and Data Mining. 2020. Deep learning for anomaly detection; pp. 894–896. [Google Scholar]

- 12.R. Chalapathy and S. Chawla, "Deep learning for anomaly detection: a survey," arXiv preprint arXiv:1901.03407, 2019.

- 13.Ye M., Peng X., Gan W., Wu W., Qiao Y. International Multimedia Conference. 2019. AnoPCN: video anomaly detection via deep predictive coding network; pp. 1805–1813. [DOI] [Google Scholar]

- 14.Liu W., Luo W., Lian D., Gao S. Proceedings of the IEEE Conference on Computer Vision And Pattern Recognition. 2017. Future frame prediction for anomaly detection – a new baseline. [Google Scholar]

- 15.Jang J., Lee H.H., Park J.-.A., Kim H. Unsupervised anomaly detection using generative adversarial networks in 1H-MRS of the brain. J. Magn. Reson. 2021;325 doi: 10.1016/j.jmr.2021.106936. [DOI] [PubMed] [Google Scholar]

- 16.D. Li, D. Chen, J. Goh, and S.-k. Ng, "Anomaly detection with generative adversarial networks for multivariate time series," arXiv preprint arXiv:1809.04758, 2018.

- 17.Li C.-.L., Sohn K., Yoon J., Pfister T. Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition. 2021. CutPaste: self-supervised learning for anomaly detection and localization; pp. 9664–9674. [Google Scholar]

- 18.R. Giri, S.V. Tenneti, F. Cheng, K. Helwani, U. Isik, and A. Krishnaswamy, "Unsupervised anomalous sound detection using self-supervised classification and group masked autoencoder for density estimation," Challenge on Detection and Classification of Acoustic Scenes and Events (DCASE 2020 Challenge), Tech. Rep, 2020.

- 19.Nguyen H.D., Tran K.P., Thomassey S., Hamad M. Forecasting and anomaly detection approaches using LSTM and LSTM autoencoder techniques with the applications in supply chain management. Int. J. Inf. Manag. 2021;57 doi: 10.1016/j.ijinfomgt.2020.102282. [DOI] [Google Scholar]

- 20.Chow J.K., Su Z., Wu J., Tan P.S., Mao X., Wang Y.H. Anomaly detection of defects on concrete structures with the convolutional autoencoder. Adv. Eng. Inf. 2020;45 doi: 10.1016/j.aei.2020.101105. [DOI] [Google Scholar]

- 21.Luo T., Nagarajan S.G. 2018 IEEE International Conference on Communications (ICC) 2018. Distributed anomaly detection using autoencoder neural networks in WSN for IoT. [DOI] [Google Scholar]

- 22.Wu W., Shen L., Zhao Z., Li M. Industrial IoT and Long Short-Term Memory Network Enabled Genetic Indoor Tracking for Factory Logistics. IEEE Trans. Industr. Inform. 2022;18(11):7537–7548. [Google Scholar]

- 23.Kunhoth J., Karkar A., Al-Maadeed S., Al-Ali A. Indoor positioning and wayfinding systems: a survey. Human-centric Comput. Inf. Sci. 2020;10(1):1–41. [Google Scholar]

- 24.Roy P., Chowdhury C. A survey on ubiquitous WiFi-based indoor localization system for smartphone users from implementation perspectives. CCF Trans. Pervasive Comput. Interact. 2022:1–21. [Google Scholar]

- 25.Obeidat H., Shuaieb W., Obeidat O., Abd-Alhameed R. A review of indoor localization techniques and wireless technologies. Wirel. Pers. Commun. 2021;119(1):289–327. [Google Scholar]

- 26.Wu W., Shen L., Zhao Z., Li M., Huang G.Q. Industrial IoT and long short-term memory network enabled genetic indoor tracking for factory logistics. IEEE Trans. Ind. Inf. 2022:1. doi: 10.1109/TII.2022.3146598. -1. [DOI] [Google Scholar]

- 27.Alhomayani F., Mahoor M.H. Deep learning methods for fingerprint-based indoor positioning: a review. J. Locat. Based Serv. 2020;14(3):129–200. [Google Scholar]

- 28.Cui W., et al. Received signal strength based indoor positioning using a random vector functional link network. IEEE Trans. Ind. Inf. 2018;14(5):1846–1855. doi: 10.1109/TII.2017.2760915. [DOI] [Google Scholar]

- 29.Zhang W., Liu K., Zhang W., Zhang Y., Gu J. Deep neural networks for wireless localization in indoor and outdoor environments. Neurocomputing. 2016;194:279–287. doi: 10.1016/j.neucom.2016.02.055. [DOI] [Google Scholar]

- 30.Sun D., Wei E., Yang L., Xu S. Improving fingerprint indoor localization using convolutional neural networks. IEEE Access. 2020;8:193396–193411. [Google Scholar]

- 31.Abid M., Compagnon P., Lefebvre G. 2021 International Conference on Indoor Positioning and Indoor Navigation (IPIN) IEEE; 2021. Improved CNN-based magnetic indoor positioning system using attention mechanism; pp. 1–8. [Google Scholar]

- 32.Zhang Y., Qu C., Wang Y. An indoor positioning method based on CSI by using features optimization mechanism with LSTM. IEEE Sensors J. 2020;20(9):4868–4878. [Google Scholar]

- 33.Gubbi J., Buyya R., Marusic S., Palaniswami M. Internet of Things (IoT): a vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013;29(7):1645–1660. doi: 10.1016/j.future.2013.01.010. [DOI] [Google Scholar]

- 34.Zhang M., Feng H., Luo H., Li Z., Zhang X. Comfort and health evaluation of live mutton sheep during the transportation based on wearable multi-sensor system. Comput. Electron. Agric. 2020;176 [Google Scholar]

- 35.Zhang M., Wang X., Feng H., Huang Q., Xiao X., Zhang X. Wearable Internet of Things enabled precision livestock farming in smart farms: a review of technical solutions for precise perception, biocompatibility, and sustainability monitoring. J. Clean. Prod. 2021;312 [Google Scholar]

- 36.Trab S., Bajic E., Zouinkhi A., Abdelkrim M.N., Chekir H. RFID IoT-enabled warehouse for safety management using product class-based storage and potential fields methods. Int. J. Embedded Syst. 2018;10(1):71–88. [Google Scholar]

- 37.Chihana S., Phiri J., Kunda D. An IoT based warehouse intrusion detection (E-Perimeter) and grain tracking model for food reserve agency. Int. J. Adv. Comput. Sci. Appl. 2018;9(9) [Google Scholar]

- 38.Zhao Z., Zhang M., Yang C., Fang J., Huang G.Q. Distributed and collaborative proactive tandem location tracking of vehicle products for warehouse operations. Comput. Ind. Eng. 2018;125:637–648. [Google Scholar]

- 39.Song Y., Yu F.R., Zhou L., Yang X., He Z. Applications of the Internet of things (IoT) in smart logistics: a comprehensive survey. IEEE Internet Things J. 2020;8(6):4250–4274. [Google Scholar]

- 40.Golpîra H., Khan S.A.R., Safaeipour S. A review of logistics internet-of-things: current trends and scope for future research. J. Ind. Inf. Integr. 2021 [Google Scholar]

- 41.Tsang Y.P., Choy K.L., Wu C.H., Ho G.T.S., Lam H.Y., Koo P.S. An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment. Int. J. Eng. Bus. Manag. 2017;9 doi: 10.1177/1847979017749063. [DOI] [Google Scholar]

- 42.Zhang Y., Zhao L., Qian C. Modeling of an IoT-enabled supply chain for perishable food with two-echelon supply hubs. Ind. Manag. Data Syst. 2017;117(9):1890–1905. doi: 10.1108/IMDS-10-2016-0456. [DOI] [Google Scholar]

- 43.Afreen H., Bajwa I.S. An IoT-based real-time intelligent monitoring and notification system of cold storage. IEEE Access. 2021;9:38236–38253. doi: 10.1109/ACCESS.2021.3056672. [DOI] [Google Scholar]

- 44.Tsang Y.P., Choy K.L., Wu C.H., Ho G.T.S., Lam C.H.Y., Koo P.S. An Internet of Things (IoT)-based risk monitoring system for managing cold supply chain risks. Ind. Manag. Data Syst. 2018;118(7):1432–1462. doi: 10.1108/IMDS-09-2017-0384. [DOI] [Google Scholar]

- 45.Wu W., et al. Just trolley: implementation of industrial IoT and digital twin-enabled spatial-temporal traceability and visibility for finished goods logistics. Adv. Eng. Inf. 2022;52 doi: 10.1016/j.aei.2022.101571. [DOI] [Google Scholar]

- 46.Wu W., Zhao F., Ma C., Huang G.Q. 2020 IEEE 16th International Conference on Automation Science and Engineering (CASE) IEEE; 2020. Experimental investigation of a real-time monitoring system for cold chain logistics; pp. 1201–1206. [Google Scholar]

- 47.Martins P., Abbasi M., Sá F., Cecílio J., Morgado F., Caldeira F. Improving bluetooth beacon-based indoor location and fingerprinting. J. Ambient Intell. Humaniz. Comput. 2019 doi: 10.1007/s12652-019-01626-2. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data that has been used is confidential.