Abstract

Gasification and pyrolysis are thermal processes for converting carbonaceous substances into tar, ash, coke, char, and gas. Pyrolysis produces products such as char, tar, and gas, while gasification transforms carbon-containing products (e.g., the products from pyrolysis) into a primarily gaseous product. The composition of the products and their relative quantities are highly dependent on the configuration of the overall process and on the input fuel. Although in gasification, pyrolysis processes also occur in many cases (yet prior to the gasification processes), gasification is a common description for the overall technology. Pyrolysis, on the other hand, can be used without going through the gasification process. The current study evaluates the most common waste plastics valorization routes for producing gaseous and liquid products, as well as the key process specifications that affected the end final products. The reactor type, temperatures, residence time, pressure, the fluidizing gas type, the flow rate, and catalysts were all investigated in this study. Pyrolysis and waste gasification, on the other hand, are expected to become more common in the future. One explanation for this is that public opinion on the incineration of waste in some countries is a main impediment to the development of new incineration capacity. However, an exceptional capability of gasification and pyrolysis over incineration to conserve waste chemical energy is also essential.

Keywords: gasification, pyrolysis, plastic waste, valorization, chemistry

1 Introduction

Plastics are adaptable, flexible, and lightweight, allowing them to be used in a wide variety of applications. In recent years, the political agenda has focused on the economic, environmental, and social influences of plastics, with an emphasis on sustainable manufacturing and the decoupling of negative ecological outcomes from waste generation. Waste plastics disposal has become a significant global environmental issue. Around 55 million tons of postconsumer plastic waste are produced annually in the United States, Japan, and Europe (Sun et al., 2021). Previously, these waste products were discarded in landfills, which was an unsustainable and environmentally unsound practice. Furthermore, the number of landfill sites and their capabilities are steadily declining, and landfill regulation is becoming more stringent in most countries. Recycling is being considered as another option for managing plastic waste in order to reduce its disposal in landfills. Because of the restrictions on water pollution and insufficient separation prior to recycling, which is labor intensive, recycling plastic has proved difficult and expensive (Jaafar et al., 2022). Since plastics come in a variety of colors, resin compounds, and transparencies, separation is required. Plastics that are pigmented or dyed typically have a lower market value. Manufacturers choose clear transparent plastics because they can be colored and turned into new goods, giving them more flexibility (Thompson, 2022). Recycling plastic has become difficult in recent years due to the strict requirements for obtaining high-value products.

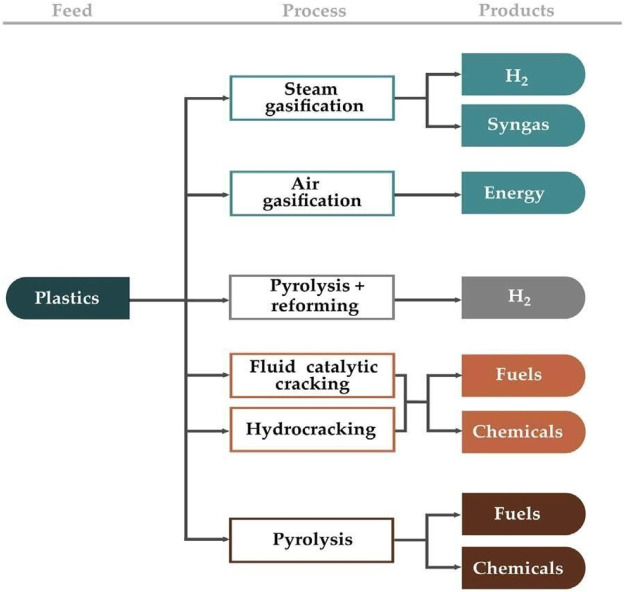

The disposal of plastic waste presents a significant problem that must be tackled immediately. As a result, plastics’ low degradability poses significant ecological issues, particularly in marine environments (de Sousa, 2021). Furthermore, insufficient waste plastics management contributes to environmental concerns due to the depletion of essential and limited resources obtained from petroleum. As a result, in recent years, public policies aimed at strengthening waste plastics management have been promoted. In fact, in Europe over the last decade, the quantity of plastic waste disposed of in landfills has decreased by 38% while the fraction of waste plastics used for energy valorization and recycling has increased by 46% and 64%, respectively (Plastics, 2016). Although the situation with waste plastics management in developed countries is slowly improving, it is still far from satisfactory, and in developed countries, plastics management is obviously less promising. Different methods, such as reuse, recycling, energy recovery, and waste minimization are being considered with the goal of minimizing the volume of waste that is disposed of in landfills. However, neither minimization nor reuse has been extensively utilized in the case of waste plastics (Aguado et al., 2008). Combustion is a viable valorization route due to the high calorific value of plastics, but it is hampered by the emissions generated (Thimoteo et al., 2022). Chemical recycling routes have been the best chance of being implemented on a wide scale because these permit the formation of syngas/hydrogen, chemicals, and fuels from plastic waste. Figure 1 depicts the major chemical valorization pathways for waste plastics. Pyrolysis of waste plastics is widely recognized as the most efficient method for producing chemicals and fuels from plastic waste (Aguado et al., 2008), (Al-Salem et al., 2009; Al-Salem et al., 2010; Butler et al., 2011; Wong et al., 2015; Anuar Sharuddin et al., 2016; Kunwar et al., 2016; Ma et al., 2016; Yu et al., 2016; Lopez et al., 2017).

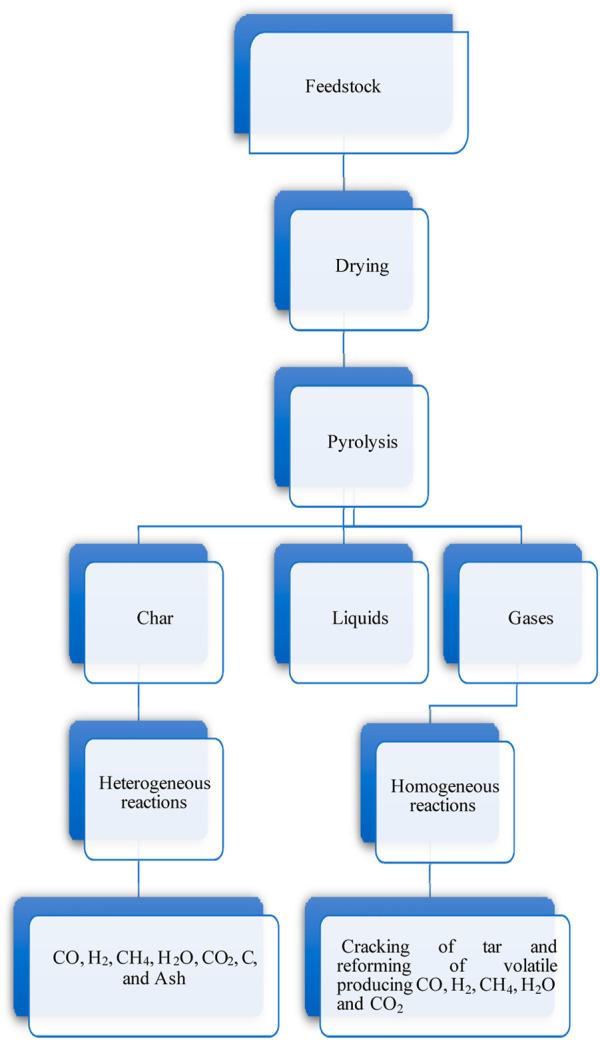

FIGURE 1.

Primary chemical routes for plastic waste valorization.

The solid waste incineration is an attractive technology for thermal energy generation and reducing the volume of landfill waste. However, municipal waste incineration involves climate-relevant emissions (CO2, SOx, NOx, and N2O). One tonne incineration of municipal waste generates about 0.7–1.7 tonnes of CO2, thus making significant greenhouse effect contribution. When compared to other conventional plastic recycling techniques (such as gasification and pyrolysis), the energy produced by incineration has significantly high emissions of greenhouse gases (340 g CO2 eq per kWh). Therefore, waste incineration is not an environmentally friendly alterative due to subsequent greenhouse gas emissions.

Various plastic pyrolysis processes have been developed for the selective processing of waxes (Berrueco et al., 2002; Arabiourrutia et al., 2012a; Yansaneh and Zein, 2022), light olefins (Milne et al., 1999; Mastral et al., 2006a; Hernandez et al., 2007; Elordi et al., 2011; Artetxe et al., 2013a), and monomers (Achilias et al., 2007; Mo et al., 2014). Furthermore, in recent years, plastic waste and biomass co-pyrolysis have gained a lot of attention (Xue et al., 2015; Zhang et al., 2016a). Despite the growing interest in plastic waste pyrolysis, it is still in the developmental stages of implementation (Butler et al., 2011). Waste plastics and their derivatives, such as pyrolysis wax oil products, can also be fed into traditional refinery units to produce fuels (Arandes et al., 1997; Lopez et al., 2017; Lovás et al., 2017; Palos et al., 2022a).

Numerous studies have been conducted on the potential of different plastic types for gasification and pyrolysis procedures to produce gas and liquid products. It is important to note that the setup parameters have a significant impact on product quality and yield. Therefore, this review concentrates on the various plastic gasification and pyrolysis processes that have been investigated along with the key factors that affect these processes and those that require attention in order to maximize the production of gas and liquid oil and improve the quality of the final product. The primary parameters include pressure, residence time, the reactor type, temperature, the use of various catalysts, and the type and flow rate of the fluidizing gas. The obtained results from various valorization methodologies have been compared, and their potential values have been discussed critically. Furthermore, this study also presents some important discussion concerning product yield optimization.

2 Gasification

By partial oxidation with a gasification agent, gasification refers to the chemical and thermal conversion of carbon-based materials into a primarily gaseous output (usually air, oxygen, or steam). If gasification is preceded by pyrolysis, the pyrolysis outputs (gas, tar, and char) can be improved further by partial oxidation of the more complex hydrocarbons, particularly those found in the char and tar.

Temperature range from 800 to 1,100°C when using air as an oxidant, and up to 1,500°C when using oxygen. While most gasification processes are exothermal, that is, they generate heat, some of the associated reactions are endothermal and require heat, which could be provided by steam as the gasification agent. In general, the products of gasification are

Solid: non-volatile metals and other inorganic elements are found in ashes. Solids may account for 30–50% of the input weight.

Liquid: smaller amounts of oil and tar, about 10–20% by weight of the input, are used in some conditions.

Gas: same as pyrolysis gas but with higher CO2 fractions. The heating value varies depending on the gasification agent, but it is usually 3–12 MJ/Nm3 with oxygen as the gasification agent. By weight of the supply, the gas yield can range from 30 to 60% (Belgiorno et al., 2003; Hu et al., 2021; Tezer et al., 2022).

Like pyrolysis products, gasification products are strongly influenced by the temperature, waste input, and overall process framework. The waste input, in particular, is often underrepresented in the literature, and the waste is frequently composed of distinct industrial segments instead of mixed MSW. The heating value for the gas output can therefore be considered as the upper limit for MSW. Char and tar formed by pyrolysis reactions are further converted to CO2, CO, CH4, and H2 by heating to higher temperatures than pyrolysis and adding a gasification agent. The gasification agent used has a considerable impact on the processed gas composition, and “dilution” from the gasification agent has a substantial impact on the gas heating value, again contingent on the agent (medium) used. For example, air gasification is less expensive than using pure oxygen as a gasification agent but produces a gas that contains up to 60% nitrogen (Tezer et al., 2022).

3 Chemical reactors for gasification of plastic waste

Plastic waste gasification processes are exactly the same as those used to gasify other feedstocks such as coal and biomass. However, the unique properties of plastic wastes, particularly their high volatility and high thermal resistivity; sticky, viscous, and adhesive nature; and exceptional tar production, obstruct their processing in traditional gasification technologies and pose a significant challenge for process realization. As a result, an adequate gasifier design for plastic handling must incorporate the following characteristics: it should 1) be capable of providing high rates of heat transfer aiming to facilitate rapid depolymerization of plastic waste, 2) evade operative issues caused by the sticky and adhesive behavior of plastics by maintaining a tight control over the operating parameters and conditions, 3) have adequate residence time dispensation to favor the cracking of tar and enable the use of primary (fundamental) catalyst in situ while maintaining virtuous contact with the catalyst.

Traditional waste gasification systems are fixed bed, entrained flow, downdraft, updraft, fluidized bed, plasma reactor, and rotary kiln (Heidenreich and Foscolo, 2015; Ahmad et al., 2016; Mahinpey and Gomez, 2016; Molino et al., 2016; Ud Din and Zainal, 2016; Sansaniwal et al., 2017). However, because of the complexities of waste plastics, some of these technologies have been limited in their application. Each gasification system is available in a number of basic configurations, each with benefits for a specific product or feedstock applications. Each system type’s basic design revolves around the reaction chamber with feedstock insertion, but each has a unique air entry, heating mechanism, and syngas removal area.

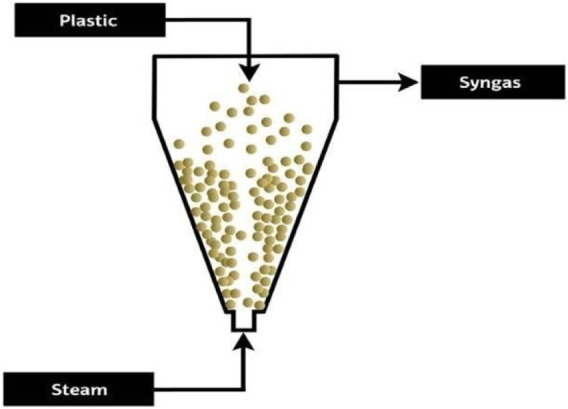

3.1 Spouted conical bed gasifier

Conical spouted reactors are a substitute for heterogeneous fluidized beds (FBRs) for waste valorization processes due to their unique characteristics. As a result, these reactors have high mass and heat transfer rates, appropriate fluidization, and excellent solid mixing (Makibar et al., 2011). Furthermore, their dynamic solid cyclic circulation eliminates agglomeration and de-fluidization issues and facilitates the manipulation of irregular and discrete particulates, particles with a wide distribution size, and adhesive substances. In gasification processes, the primary drawbacks are the volatiles’ short residence (stay) time, which impedes the cracking tar reactions (Erkiaga et al., 2014). In bench-scale units, this technology is extensively applied in the pyrolysis of various solid wastes (Lopez et al., 2009; Lopez et al., 2010; Amutio et al., 2012; Artetxe et al., 2013a; Alvarez et al., 2015). Furthermore, the biomass pyrolysis process has been effectively generalized up to 25 kg/h (Fernandez-Akarregi et al., 2013; Makibar et al., 2015). The first time the spouted beds were used in the gasification processes, coal was used as the feedstock (Foong et al., 1981; Teo and Watkinson, 1986; Sueaquan et al., 1995; Fernandez et al., 2022). Gasification of different feedstocks (raw materials) has recently been added to this technology, such as waste plastics and biomass (Erkiaga et al., 2013a; Erkiaga et al., 2013b; Bernocco et al., 2013; Erkiaga et al., 2014; Lopez et al., 2015a; McCullough et al., 2015). To decrease the content of tar and improve the efficiency of the process in the gaseous product, various primary (fundamental) catalysts have been investigated in situ (Erkiaga et al., 2013a; Erkiaga et al., 2013b), or in a second reactor, secondary catalysts have been utilized (Lopez et al., 2015b). Figure 2 depicts a spouted conical bed gasifier design.

FIGURE 2.

Spouted conical bed gasifier.

3.2 Fixed (packed) bed reactor

Packed bed reactors are used in the gasification of plastic because of the ease in their operation and design, and their low investment cost, with the key problem being scaling up, limited gas–solid contact, continuous operation, and a low heat transfer rate. There are many different designs of fixed-bed reactors, but they all have one thing in common: they are used in small-scale units (Ahmed and Gupta, 2009; Wu and Williams, 2010a; Wu and Williams, 2010b; Wu and Williams, 2010c; Friengfung et al., 2014; Parparita et al., 2015; Baloch et al., 2016). Usually, plastic waste gasification (Ponzio et al., 2006; HeMXiao et al., 2009a; Wang et al., 2012; Lee et al., 2014; Ongen, 2016) or their coprocessing with biomass and coal (Straka and Bicáková, 2014a; Akkache et al., 2016; Singh et al., 2022) in fixed-bed reactors has received little attention. Ahmed and Gupta (2009) used a laboratory-scale fixed-bed (packed) reactor operating in the batch mode for steam co-gasification of polystyrene and plastic–wood samples (Singh et al., 2022). Moreover, experiments were performed in a bench-scale fixed-bed reactor designed by HeMXiao et al. (2009b) at a plastic continuous feed rate of 0.3 kg/h, and the impact of utilizing reforming in situ Ni/Al2O3 catalyst was investigated. Li et al. (2012) also developed a similar continuous-mode experimental setup for MSW steam gasification. Lee et al.( 2014) conducted their research in a semi-batch laboratory-scale reactor with a steam (condensation) atmosphere. Guo et al. (2015, 2016) investigated polyurethane air gasification by utilizing various in situ catalysts in a laboratory-scale fixed-bed (packed) reactor.

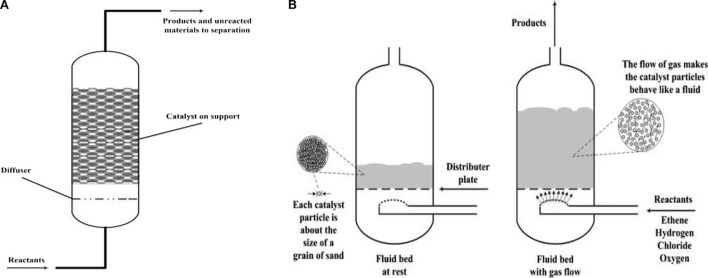

3.3 Fluidized bed reactors

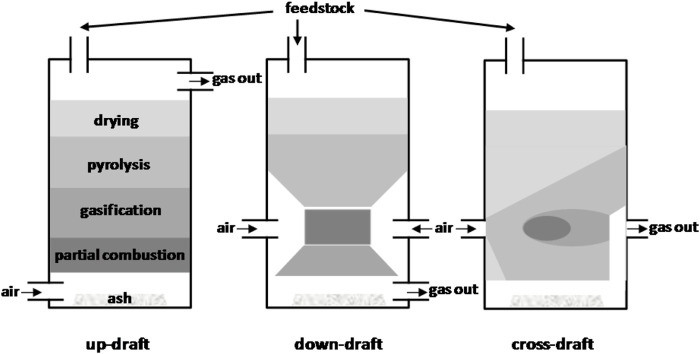

In gasification processes, two classes of fluidized bed reactors have traditionally been utilized: circulating fluidized beds (CFBs) and bubbling fluidized beds (BFBs) (Mahinpey and Gomez, 2016; Molino et al., 2016). Despite the intriguing characteristics of CFBs for the gasification of plastic waste operations, particularly the ability to achieve low tar and high conversion yields (McKendry, 2002), plastic gasification research has been limited to BFBs. The primary benefits of BFBs are their excellent gas–solid contact, high mass and heat transfer rates, good temperature control and flexibility, and good solid-mixing regime. Their primary drawbacks are their limitations in particle size both in feed and bed, high investment cost, unreacted material entrainment, and defluidization issues (Molino et al., 2016). These reactors run in a continuous mode and have a high scale and development degree, with various research being conducted in pilot plant scale units (Arena et al., 2010; Arena et al., 2011; Ruoppolo et al., 2012; Martínez-Lera et al., 2013a; Wilk and Hofbauer, 2013; Arena and Di Gregorio, 2014; Brachi et al., 2014; Narobe et al., 2014). In the co-gasification with coal and biomass or in plastic waste gasification, these are generally used with air as the gasifying medium (Sancho et al., 2008; Kim et al., 2011; Toledo et al., 2011; Ruoppolo et al., 2012; Cho et al., 2013a; Martínez-Lera et al., 2013b; Martínez-Lera et al., 2013c; Arena and Di Gregorio, 2014; Brachi et al., 2014). Despite the low gas heating value obtained, this approach offers functional benefits like lesser content of tar in the product gas and autothermal process (Gil et al., 1999; Devi et al., 2003). Mastellone and Arena (2008), Arena et al. (2009), and Arena et al. (2010) conducted research with continuous feed rates in a pilot plant up to 100 kg/h, while gasifiers have been employed by other researchers with feed rates of plastic ranging from 1 to 4 kg/h, running in a continuous mode (Xiao et al., 2007; Sancho et al., 2008; Toledo et al., 2011). Because steam gasification is considerably endothermic, it has high requirements of energy that are resolved in biomass gasification by utilizing dual fluidized bed (DFB) reactors, which combine a fast fluidized bed puffed with air with a steam-blown fluidized bed, where the residual char is burned (Goransson et al., 2011; Schneider et al., 2022). The research group led by Prof. Hofbauer used this operating methodology to gasify waste plastics in a pilot plant with a capacity of 15 kg/h (Martínez-Lera et al., 2013a; Narobe et al., 2014). However, as a result of the low yield of char and the problem in maintaining the heat balance between the combustion and gasification operations, issues may arise. Figure 3 depicts various types of gasifier schemes.

FIGURE 3.

Gasification system types.

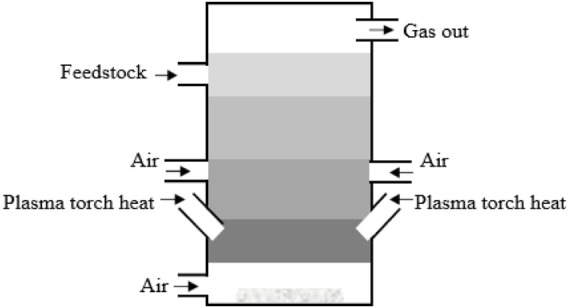

3.4 Plasma gasification reactors

The primarily use of plasma gasification is in industries where hazardous waste is disposed of at relatively high temperatures. The plasma torch in the gasifier (Figure 4) generates high temperatures (up to 10,000°F). There are two plasma gasification arrangements available depending on where the plasma torch is used in the gasification process. The first is plasma-assisted gasification, and the second is plasma-assisted gasification combined with traditional thermal gasification. This methodology has been utilized sparingly for the gasification of plastic waste, and studies have usually been conducted on a small scale (Tang and Huang, 2007; Rutberg et al., 2013a; Gibadullina et al., 2015; VishwajeetPawlak-Kruczek et al., 2022). However, the level of development achieved by Hlina et al. (2014) in their gasification unit, which works in a continuous mode with 11 kg/h plastic feed rate, is remarkable. Park et al. (2016) proposed combining continuous pyrolysis processes with 1.3 kg/h feed rate in a plasma reactor with gasification–pyrolysis (in-line) of volatiles.

FIGURE 4.

Plasma gasification (Oliveira et al. 2022).

4 Temperature and heating rate

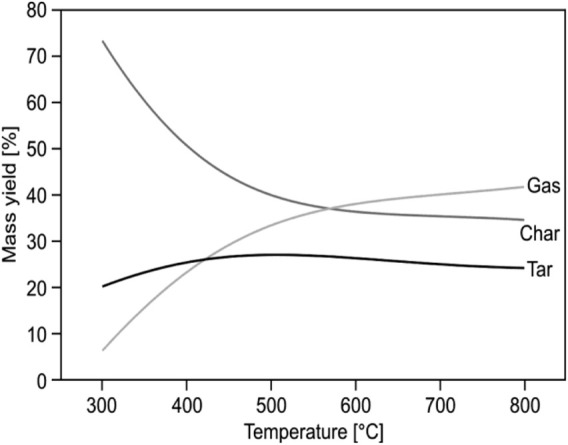

The temperature reached in the reactor is critical because temperature changes affect the majority of the chemical reactions for waste conversion. Higher temperatures, in general, alleviate lower tar content and higher carbon conversion in the waste in the gas phase, but in the case of gasification, a lower heating value of the gas may also result. In pyrolysis, higher temperatures produce more gas, while lower temperatures produce more liquid. Figure 5 depicts a relationship between temperature and output products, demonstrating that temperature is a very important factor and that uniform distribution of temperature across the reactor is crucial.

FIGURE 5.

Reactor temperature (°C; RT) and mass yields (wt%, MY) correlation (Tezer et al., 2022).

Another factor that affects the outputs significantly is the heating rate (Hu et al., 2021). Char generation is increased by slow heating rates combined with relatively low final temperatures (e.g., slow heating at relatively low temperatures is required for the production of charcoal from wood). Mild heating rates up to mild temperatures give a more even weight distribution of pyrolysis outputs. High heating rates to high temperatures, possibly accompanied by rapid quenching, are commonly referred to as flash pyrolysis and can result primarily in a liquid product; however, the oils can be further broken down to enhance the gas output, if quenching is evading. Slow heating rates to high final temperatures typically result in a primarily gaseous product.

Some gasification processes use steam as the gasification agent and operate at high pressures (up to about 20 bar). High pressure favors the gas yield, though these processes may be circumscribed in their use with fuel as waste.

5 Gasification mechanism

The plastics gasification aims for the highest possible conversion to a syngas or gas product, with char and tar being the most unwanted derivatives. Gasification is a complex process and consists of many chemical reactions. Figure 6 depicts these steps. The importance of these steps in terms of kinetics and process performance is determined by the gasification conditions and feedstock properties. The main steps of gasification are

• Drying: around temperatures between 20 and 100°C, moisture is converted into steam. The feedstock is not decomposed, and no chemical reaction occurs at these temperatures. The predominant part of the gasification system is feedstock with a moisture content ranging from 10 to 20% for a high calorific value of produced gas.

• Pyrolysis: is devolatilization (thermal degradation), at temperatures between 150 and 700°C in the absence of oxygen, of the dry feedstock, liberating the volatile elements and a residue consisting of ash and char. The produced volatiles are a mixture of hydrogen, CO2, tar, CO, water vapor, and light hydrocarbons.

• Oxidation: in a gasification scenario, various oxidation chemical reactions occur, liberating the heat required for endothermic reactions. Carbon dioxide is produced due to the reaction between oxygen and char. Water is produced by oxidizing the hydrogen in the feedstock. Substoichiometric amounts of oxygen are present; partial oxidation of carbon may transpire, ensuing carbon monoxide production.

• Reduction: due to the consumption of oxygen in oxidation reactions, several chemical reactions, primarily endothermic ones occur in the absence of O2. CH4, CO, and H2 are the reduction reactions' main products.

FIGURE 6.

Potential gasification routes (Aguado et al., 2008).

The following is a list of the most important chemical reactions that take place during the gasification process:

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

Shift reaction

| (9) |

| (10) |

| (11) |

| (12) |

Steam reforming reaction

| (13) |

| (14) |

The gasification process, as far as can be determined, is globally endothermic, with the required heat obtained in one of the two ways: direct (autothermal) gasification occurs when heat is generated inside the reactor as a result of exothermic reactions, while indirect (allothermal) gasification occurs when the required heat is generated outside of the reactor (Milhé et al., 2013).

6 Processes involved in gasification of plastic waste

Valorization of waste plastics through gasification processes has been considered using a variety of schemes, with the goal of producing syngas of various compositions and potential applications. Research on the gasification of waste plastics is still in its early stages, and the number of studies is restricted. On the other hand, investigations on biomass and coal co-gasification have been conducted.

Due to process simplification, air gasification is the most widely used process as there are no external energy prerequisites. Moreover, as compared with steam gasification, tar content is typically lower in the gas products (Gil et al., 1999). As a result, this gas is primarily used in the production of energy (Arena et al., 2010; Arena, 2012). Steam gasification produces an H2-rich syngas with high ratios of H2/CO, which is more suitable for chemical synthesis applications than direct air gasification syngas (Erkiaga et al., 2013a). The main difficulty with this alternative is the amount of heat that must be introduced into the reactor in order to perpetrate the endothermic steam reforming reactions.

Direct air gasification is the utmost investigated of these, compassing a gas product with a comparatively low heating value because of the diluting result of nitrogen.

Gasification with pure O2 is an alternative to air and steam that combines the benefits of both gasifying agents. Although, due to the operating costs and high capital assets for air separation, this choice is more expensive and complex for medium-size utilizations in particular (Xiao et al., 2007). Recently, pyrolysis–reforming (in-line) of pyrolysis volatiles has been intended as a favorable waste plastics H2 production valorization route (Czernik and French, 2006; Wu and Williams, 2010a; Park et al., 2010; Namioka et al., 2011; Barbarias et al., 2016a; Barbarias et al., 2016b). Furthermore, this alternative makes use of highly active reforming catalysts, which enable the production of tar-free syngas, overcoming the key problem in standard gasification of plastics.

6.1 Steam gasification

Plastic steam gasification has received little attention in the literature. In contrast to air gasification studies, which have almost entirely been conducted in fluidized bed reactors, plastics waste steam gasification has been investigated in various reactor types (Table 1), such as fluidized beds (FBRs) (Martínez-Lera et al., 2013a), fixed (packed) bed (HeMXiao et al., 2009a; Wang et al., 2012; Friengfung et al., 2014; Lee et al., 2014), and conical spouted beds reactors (CSBRs) (Erkiaga et al., 2013a; Lopez et al., 2015b). Heat requirement and the content of tar in the product gas are the challenges that steam gasification faces. To overcome this limitation, Wilk and Hofbauer (2013) investigated steam gasification of various plastics in a dual fluidized bed reactor, with a 100-kW pilot plant. At 850°C, the gasification reactor runs an in situ primary catalyst of olivine with an S/P ratio of 2.

TABLE 1.

Different gas compositions obtained by authors in steam plastics waste gasification.

| Plastic type | Reactor | Reaction conditions | Bed material | Composition of gas (% vol) | Gas produced (m3/kg) | LHV (MJ/m3) | Tar content (g/m3) | References |

|---|---|---|---|---|---|---|---|---|

| Waste plastics | Plasma reactor | Gasifying agent: steam/O2 T: 1,200 | — | CO: 34, H2: 62, CH4: –, CO2: – | 3.5 | 10.1 | — | Rutberg et al. (2013b) |

| PE | Spouted bed reactor (0.1 kg h−1) | T: 900, S/P: 1 | Olivine | CO: 27, H2: 58, CH4: 7, CO2: 3 | 3.2 | 16.2 | 15 | Erkiaga et al. (2013a) |

| PE | Spouted bed reactor | T: 900, S/P: 1 | γ-Alumina | CO: 26, H2: 59, CH4: 8, CO2: 2 | 3.3 | 16.2 | 16.1 | Erkiaga et al. (2013a) |

| PE | Two steps: Spouted bed plus packed bed reactor (0.1 kg h−1) | T: 900/600–700, S/P: 1 | Olivine/NiCa-Al2O4 | CO: 8–12, H2: 71–73, CH4: 3–0.3, CO2: 17–15 | 4.4–5.6 | — | 0 | Lopez et al. (2015b) |

| PET | Semi-batch and fixed (packed) bed reactor | T: 1,000 | — | CO: 6, H2: 61, CH4: 2, CO2: 12 | — | 7.8 | — | Lee et al. (2014) |

| PS + PE | Fluidized bed (dual) (15 kg h−1) | T: 850, S/P: 1.8 | Olivine | CO: 24, H2: 52, CH4: 12, CO2: 7 | 1.4 | 17 | 110 | Martínez-Lera et al. (2013a) |

| PET + PE | Fluidized bed (dual) (15 kg h−1) | T: 850, S/P: 1.2 | Olivine | CO: 20, H2: 27, CH4: 15, CO2: 29 | 1 | 16.4 | 160 | Martínez-Lera et al. (2013a) |

| PE + PP | Fluidized bed (dual) (15 kg h−1) | T: 850, S/P: 2.0 | Olivine | CO: 22, H2: 46, CH4: 16, CO2: 5 | 2.1 | 19.4 | 30 | Martínez-Lera et al. (2013a) |

| PP | Fluidized bed (dual) (15 kg h−1) | T: 850, S/P: 2.0 | Olivine | CO: 4, H2: 34, CH4: 40, CO2: 8 | 1 | 27.2 | 180 | Martínez-Lera et al. (2013a) |

| PE | Fluidized bed (dual) (15 kg h−1) | T: 850, S/P: 2.0 | Olivine | CO: 7, H2: 38, CH4: 30, CO2: 8 | 1.2 | 25.8 | 190 | Martínez-Lera et al. (2013a) |

| HDPE | Fixed (packed) batch bed (0.1 g) | Gasifying agent: steam/O2 1:1, T: 850 | Ni-dolomite | CO: 43, H2: 35, CH4: 11, CO2: 10 | 2.4 | — | 17 | Friengfung et al. (2014) |

| PS | Fixed (packed) batch bed (0.1 g) | Gasifying agent: steam/O2 1:1, T: 850 | Ni-dolomite | CO: 43, H2: 29, CH4: 1.7, CO2: 26 | 1.3 | — | 290 | Friengfung et al. (2014) |

| PP | Fixed (packed) batch bed (0.1 g) | Gasifying agent: steam/O2 1:1, T: 850 | Ni-dolomite | CO: 45, H2: 38, CH4: 9, CO2: 8 | 1.9 | — | 140 | Friengfung et al. (2014) |

| Plastic waste | Fixed (packed) batch bed (0.1 g) | T: 850 (15 °C/min) | — | CO: 19, H2: 44, CH4: 20, CO2: 13 | — | 20.4 | — | Akkache et al. (2016) |

| Plastic waste and refuse paper | Fixed (packed) batch bed (0.1 g) | T: 900 | — | CO: 22, H2: 38, CH4: 12, CO2: 17 | 0.9 | 17.9 | — | Hwang et al. (2014) |

| PW waste | Fixed (packed) bed (0.3 kg h−1) | T: 700–900, S/P: 1.33 | Ni/γ-Al2O3 | CO: 20–27, H2: 17–37, CH4: 21–10, CO2: 35–21 | 1.22–2.04 | 12.4–11.3 | 106–13 | HeMXiao et al. (2009a) |

Erkiaga et al. (2013a) investigated the HDPE steam gasification in a spouted bed conical continuous bench scale reactor (0.1 kg/h) operating at temperatures ranging from 800 to 900°C. Operating at temperatures above 850°C and with an S/P of 1, the product stream H2 content was slightly higher than 60%, accounting for an 18 wt% production. Because of the decrease in hydrocarbon content, the gas heating value decreased from 19.3 to 15.4 MJ/m3 as the gasification temperature was raised. At the highest temperature investigated for an inert sand bed, a minimal tar content of 16.8 g/m3 was obtained, and this tar was interestingly composed primarily of single-ring aromatics. In the syngas, the tar content was slightly reduced and had little effect on the gas composition, by utilizing γ-alumina and olivine as the primary catalysts. The same authors used Ni reforming commercial catalyst with a fixed-bed (packed) reactor connected in-line with the spouted conical bed gasifier in a subsequent study (Lopez et al., 2015b). The operating temperature of the fixed bed is between 600 and 700°C with gasification experimental parameters being the same as those used in a previous study. The production of H2 increased up to 36.5 wt% by the addition of a catalytic reforming step and also enabled the full reforming of tar and hydrocarbons.

The gasification of PP and PE generates syngas with up to 40% H2 concentration, accordingly with 4–3 wt% of H2 production rates (gH2 100 g/plastic). However, the most notable aspect of the composition gas product were the high concentrations of CH4 (40% and 30%, respectively) and C2H4 (11% and 15%) in the PP and PE gasification. The heating value of the produced gas up to 25 MJ/m3 due to high hydrocarbon content. However, the high concentration of light hydrocarbons and methane as previously investigated by other authors is a clear indication for the presence of tar (Pohorelyl et al., 2006; Mastellone and Arena, 2008; Pinto et al., 2009a; Mastellone et al., 2010a), and for both plastics, the values of tar content were higher than 120 g/m3, with naphthalene as the prevailing compound. In utilizing the same experimental parameters in biomass gasification, lower tar values have been reported by the same authors (Schneider et al., 2022).

Using an Ni-Al2O3 catalyst, HeMXiao et al. (2009a) investigated the PE gasification (0.3 kg/h) with 1.33 S/P ratio between 700 and 900°C in a fixed (packed) bed reactor. The production and concentration of H2 improved significantly to 3.7 and 6.6 wt%; conversion of plastic improved with temperature increase; and at 900 C, gases' yield reached 2.04 m3/kg. On steaming after 3 h time, no deactivation was evident by reforming the (Ni-based) catalyst. The gas product heating value ranged from 12.3 to 11.4 MJ/m3, at the lowest temperature, with the highest value being obtained.

Dou et al. (2016) recently conceived a laboratory-scale continuous reaction system consisting of a fluidized bed (FBR) gasifier followed by CO2/steam reforming adsorption in a moving bed reactor. The combination of steam reforming on CO2 retention on CaO and a Ni-Al2O3 catalyst resulted in the high production of H2; however, they discovered that below 700°C, adsorption of CO2 was only effective.

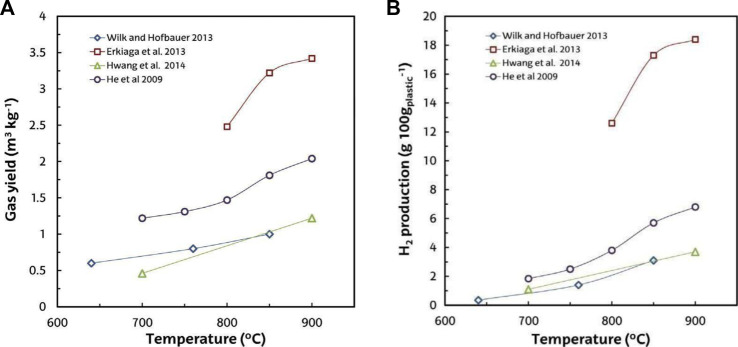

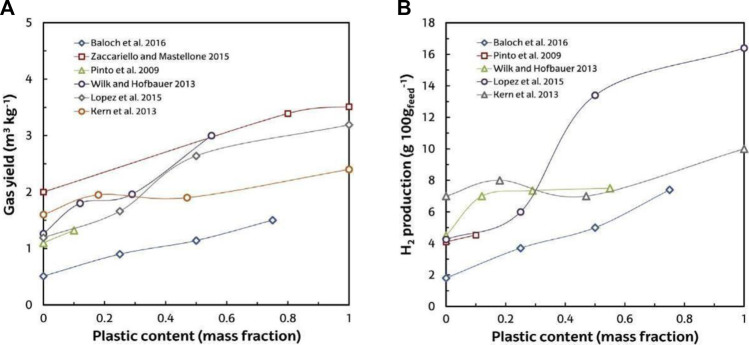

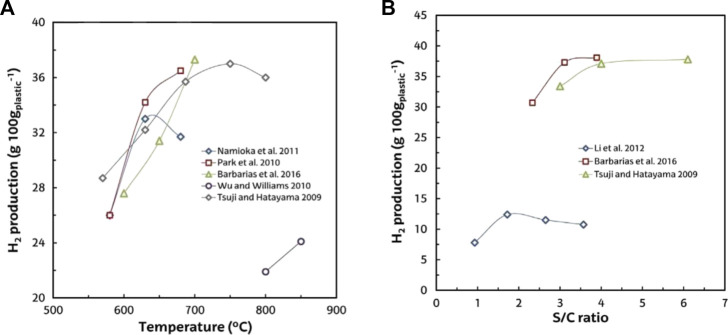

In the literature, the values of H2 production with high concentrations of H2 vary between 3 and 18 wt% (g 100 g/plastic) of polyolefins steam gasification (HeMXiao et al., 2009a; Erkiaga et al., 2013a; Martínez-Lera et al., 2013a). Furthermore, the syngas obtained is suitable for the synthesis of various fuels (methanol, DME, and hydrocarbons) (Zhang, 2010). Temperature is the most critical and important parameter in the steam gasification of plastics. Its increase facilitates the cracking and reforming of endothermic reactions that include tar and light hydrocarbons, which facilitates the yield of both gas (Figure 7A) and H2 (Figure 7B). However, for synthesis applications in the gaseous stream, the tar content must be considerably decreased to achieve stringent tar content constraints (Devi et al., 2003). Steam gasification of plastic waste, as previously reported, results in high concentrations of tar in the gas product, even exceeding 100 g/m3 (HeMXiao et al., 2009a; Martínez-Lera et al., 2013a). In fact, it is widely acknowledged that air gasification results in less tar than that obtained through steam gasification (Gil et al., 1999; Devi et al., 2003), and as compared with the gasification of biomass and coal, the gasification of plastic waste yields more tar (Pinto et al., 2009b; Mastellone et al., 2010b; Martínez-Lera et al., 2013a).

FIGURE 7.

(A) Temperature effect on yield of gas in steam plastic waste gasification. (B) Temperature effect on H2 production.

By using fixed-bed batch reactor, Friengfung et al. (2014) studied the laboratory-scale gasification of steam/O2 (0.1 g of sample) of various plastics. By utilizing (Ni-impregnated) dolomite and dolomite at 850°C, the experiments were carried out without a catalyst. In all cases, the tar production was higher (more than 80 wt%) and the results obtained without a catalyst with various polyolefins, PP, LDPE, and HDPE were poor. In the HDPE case, promising results were achieved by utilizing Ni-impregnated dolomite catalyst for which a tar production of 10 wt% or below was achieved. The gasification efficiency is enhanced by utilizing a dolomite catalyst, but the tar production was on the higher side (more than 50 wt%). For full-scale development, steam gasification faces considerable challenges due to its high process heat requirement, however N2 absence improves the gas heating value over 15 MJ/m3 (Erkiaga et al., 2013a; Martínez-Lera et al., 2013a; Hwang et al., 2014). In fact, the well-designed dual fluidized beds scheme is also scarce by the low fixed carbon of waste plastics, which impedes the heat balance closure process (Wilk and Hofbauer, 2013; Schneider et al., 2022). Generally, steam gasification of waste plastics has received little attention and development and is not as advanced and promising when compared to air gasification.

6.2 Air gasification

The main challenge of gasification of plastic processes, regardless of the gasifying agent utilized, is the yield of the gas product tar, though when O2 or air is utilized in the place of steam, the tar yield is lower (Gil et al., 1999; Devi et al., 2003). Thus, the content of tar must be less than 10 mg N/m3 for the utilization of syngas for the production of energy in turbines and engines but much lower for synthesis applications (Devi et al., 2003). Deposition in the process equipments, especially in heat exchangers, and the characteristics of tar, mainly its dew point, play a vital role in the problems that it causes (Guan et al., 2016). The dew point is determined by the amount of tar present, and its composition, since single-ring aromatic hydrocarbons are non-condensable even at concentrations of 10 g N/m3. At the concentration of just 1 mg N/m3, polyaromatics with more than four rings condense, resulting in serious operational problems (Anis and Zainal, 2011).

Air gasification studies on plastic waste have primarily been conducted in fluidized bed reactors (FBRs), with substantial advancement in experimental units, especially the bench scale or pilot plants functioning in a continuous mode. Table 2 summarizes the important outcomes in air gasification of plastic waste. Air gasification has been broadly examined by the research group of Prof. Arena. They used plastic mixtures and different plastics in a pilot plant fluidized bubbling bed with a surmised capacity between 30 and 100 kg/h (Mastellone and Arena, 2008; Arena et al., 2009; Arena et al., 2010; Arena et al., 2011; Arena and Di Gregorio, 2014). Their early research focused on PE waste gasification with equivalence ratios (ERs) in between 0.21 and 0.33 at 850°C to investigate the role of olivine as the main catalyst for tar diminution (Mastellone and Arena, 2008; Arena et al., 2009). The gasification process efficiency improved significantly with the use of olivine, resulting in significant tar content reduction in the product gas. This result is linked not only to direct tar cracking but also to the removal of its promoters, i.e., light olefins. By improving the reforming reactions, the composition of the gas was also improved, resulting in a significant increase in H2 content. Thus, in experiments using inert silica powder, the content of tar in the product gas was about 100 g N/m3, while when calcined olivine was utilized in situ as the catalyst, the tar was almost completely removed. The efficiency of carbon conversion, or the fraction of carbon in the feed that is altered into products in the stream outlet, has been shown to increase the overall process output when olivine is used. At low ERs, this parameter increased by 60%–66%, while at high ERs, it increased by 70%–82%. In the gas product, the increase in equivalence ratio had a positive impact on the content of tar yield. However, the dilution effect due to the increased gas output for high ER values may also be a factor. The same authors have equated the gasification efficiency of various plastic waste mixtures retrieved from MSW and postconsumer packaging in a subsequent study (Arena et al., 2010). The in situ waste gasification of a mixture of polyolefin with olivine yields a gas fraction composition, process efficiency, and tar yield that are close to those which have result with pure PE, demonstrating the versatility of this valorization path. Poor results however have been obtained in the case of complex plastic mixture gasification with low process efficiencies and high tar yields. This is due to the reduction in the performance of the primary olivine catalyst.

TABLE 2.

Gas compositions achieved by various researchers in air gasification of plastics waste.

| Plastic type | Reactor | Reaction Conditions (°C) | Bed material | Composition of gas (% vol) | Gas produced (m3/ kg) | LHV (MJ/m3) | Tar Yield (g/m3) | References |

|---|---|---|---|---|---|---|---|---|

| Plastic waste | Fixed (packed) bed (0.06 kg/h) | T:700–900, ER: 0.4 | - | CO: 0.2–4, H2: 0–2, CH4: 21–20, CO2: 5–7 | - | 7.8–8 | 18–12 | Kaewpengkrow et al. (2012) |

| Mixture of waste plastic | Moving grate * fueled with pure O2 (80 kg/h) | T:700–900, ER: 0.15–0.6 | - | CO: 22–33, H2: 41–29, CH4: 4.3–10, CO2: 8.2–22 | 1.2-1.5 | 9.0–11.8 | - | Lee et al. (2013) |

| PE | Bubbling fluidized (aggregative) bed (100 kg/h) | T: 845–897, ER: 0.20–0.31 | Sand | CO: 2.8–2.2, H2: 9.1–9.5, CH4: 10.4–7.1, CO2:9.1–10.4 | 3–4.3 | 7.9–6.3 | 160–81 | Arena et al., (2010) |

| PE | Bubbling fluidized (aggregative) bed (100 kg/h) | T: 807–850, ER: 0.2–0.29 | olivine | CO: 18.4–20.9, H2: 30.1–29.1, CH4: 3.4–1.5, CO2:1.6–1.2, | 4.2-6.2 | 7.6–6.3 | 0 | Arena et al., (2010) |

| Mixture of waste plastic | Bubbling fluidized (aggregative) bed (100 kg/h) | T: 869–914, ER: 0.22–0.31 | Olivine | CO: 3.7–4.8, H2: 6.8–6.6, CH4: 7.3–6.3, CO2: 11.1–11.6 | 2.5-3.2 | 6.8–5.2 | 99-56 | Arena et al., (2010) |

| Mixed waste (polyolefins) | Bubbling fluidized (aggregative) bed (100 kg/h) | T: 887, ER: 0.25 | Olivine | CO: 4.5, H2: 5.9, CH4: 6.6, CO2: 10.3 | 3.3 | 6.6 | 59 | Arena and Di Gregorio, 2014 |

| Mixed cellulosic and plastic waste | Bubbling fluidized (aggregative) bed (100 kg/h) | T: 869, ER: 0.24 | Olivine | CO: 6.6, H2: 6.0, CH4: 6.5, CO2: 12.7 | 2.73 | 7.4 | 34 | Arena and Di Gregorio, 2014 |

| Recycled plastic waste from packaging | Bubbling fluidized (aggregative) bed (5 kg/h) | T: 887, ER: 0.25 | Silica sand | CO: 6.6, H2: 6.0, CH4: 6.5, CO2: 12.7 | 3.5 | 7.9 | 46 | Zaccariello and Mastellone, 2015 |

| PP | Fluidized bed (FBR) (1/kg h) | T: 850, ER: 0.32–0.36 | Sand | CO: 5, H2: 5, CH4: 3, CO2: 12 | 4.5 | 2.9 | 17 | Sancho et al. (2008) |

| PP | Fluidized bed (FBR) (1/kg h) | T: 850, ER: 0.32–0.36 | 70% sand−30% dolomite | CO: 7, H2: 6, CH4: 8, CO2: 16 | 5.3 | 7.4 | 1.5 | Sancho et al. (2008) |

| PP | Fluidized bed (FBR) (1/kg h) | T: 850, ER: 0.32–0.36 | 70% sand−30% olivine | CO: 4, H2: 5, CH4: 7, CO2: 14 | 2.9 | 5.8 | 10 | Sancho et al. (2008) |

| PP | Fluidized bed (FBR) (1/kg h) | T: 850, ER: 0.32–0.36 | olivine | CO: 8, H2: 10, CH4: 7, CO2: 11 | 6 | 6 | 2 | Sancho et al. (2008) |

| PP | Fluidized bed (FBR) (4/kg h) | T: 690–950, ER: 0.2–0.45 | bottom ash | CO: 20–15, H2: 4–5, CH4: 6–4, CO2: 9–15 | 2-3.8 | 11.3–5.2 | 40-1.3 | Xiao et al. (2007) |

| Mixture of plastic waste | Fluidized bed plus fixed bed (0.5 kg/h) | T: 800/830, ER: 0.2 | olivine/active carbon | CO: 6.7, H2: 27.1, CH4: 6.4, CO2: 8.5 | - | 5.8 | - | Cho et al. (2013b) |

| Mixture of plastic waste | Fluidized bed plus fixed bed (0.5 kg/h) | T: 800/800, ER: 0.2 | silica sand/dolomite | CO: 6.6, H2: 14.2, CH4: 15.7, CO2: 4.0 | - | 13.4 | - | Kim et al. (2011) |

| Mixture of plastic waste | Fluidized bed plus fixed bed (0.5 kg/h) | T: 800/800, ER: 0.2 | silica sand/active carbon | CO: 6.7, H2: 15.2, CH4: 14.8, CO2: 4.5 | - | 13.2 | - | Kim et al. (2011) |

| PE | Bubbling fluidized (aggregative) bed (1 kg/h) | T: 750, ER: 0.3 | silica sand | CO: 6.1, H2: 2.7, CH4: 7.0, CO2: 8.8 | 3.6 | 3.9 | 128 | Martínez-Lera et al. (2013b) |

| Polyolefins waste | Bubbling fluidized (aggregative) bed (1 kg/h) | T: 750, ER: 0.25–0.35 | silica sand | CO: 8.5–10, H2: 3, CH4: 8.5-10, CO2: 7.8–6.5 | 3.2–4.4 | 4.9–5.7 | 150-55 | Martínez-Lera et al. (2013b) |

| PE waste | Bubbling fluidized (aggregative) bed (1 kg/h) | T: 750, ER: 0.3 | silica sand | CO: 8.7, H2: 3, CH4: 8.7, CO2: 7.4 | 3.7 | 4.9 | 102 | Martínez-Lera et al. (2013b) |

In a bench scale two-step unit, Kim et al. (2011) investigated air gasification with a continuous feed rate of 0.50 kg/h of plastic waste mixture composed of polyolefins and other waste plastics (PET, PVC, and PS). Both phases were conducted at about 800°C in fluidized bed reactors, with the first containing sand, followed by the second, i.e., tar cracking catalysts. Dolomite and activated carbon were among the catalysts investigated, with activated carbon proving to be a better option for tar removal. Apart from reducing the tar content, the utilization of activated carbon as a primary catalyst significantly improved the content of H2 in gas products. Based on experimental parameters, the tar yields ranged from 3 to 7 wt% with the impact of catalytic bed mass being particularly noticeable. The same authors suggested a similar approach in a subsequent study conducted under similar conditions, but they substituted sand with olivine in the first bed and dolomite as the primary cracking catalyst (Cho et al., 2013a; Cho et al., 2013b). The fraction of gas composition improved significantly with the utilization of dolomite. Furthermore, combining both these catalysts in the first bed with active carbon in the second bed provided a tar yield of less than 2 wt%. In bubbling fluidized bed gasifier (4 kg/h bench scale), Xiao et al. (2007) investigated the impact of various operating variables like equivalence ratio, gas velocity, and residence time on PP air gasification. The presence of Fe, Al, Mg, and Ca caused tar cracking activity in the bottom ash from a boiler. The most important variable analyzed was ER, which induced a substantial increase in the temperature of the gasifier from 705 to 917 °C when ER was increased from 0.23 to 0.47. Furthermore, in the ER range investigated, the gas product tar content decreased from 40.3 to 0.25 g N/m3. A higher yield of gas and the high temperature were both responsible for this reduction. For high ER values, the authors found that the equivalence ratio should be thoroughly calibrated to prevent a decrease in the heating value of the gas product.

At 850°C, Sancho et al. (2008) studied PP air gasification in a continuous fluidized bed reactor (bench scale) with an equivalence ratio of about 0.35 at 1 kg/h. This study evaluated the catalytic efficiency of dolomite and olivine as the primary catalysts and compared the findings to those procured with inert sand. They found that the use of dolomite is restricted by its low physical ability, which drives it to be ejected from the gasifier. Moreover, olivine has material characteristics that make it ideal for use in fluidized beds, with a catalytic activity that is just marginally lower than dolomite. As a result of the use of olivine, the content of tar in the product gas was decreased from 17 g N/m3 achieved with sand to 2 g N/m3. Furthermore, olivine facilitates reforming hydrocarbon reactions, which increases the amount of hydrogen in the syngas. The same authors went on to investigate the use of olivine in PP air gasification, demonstrating olivine permanence over long gasification runs (Toledo et al., 2011). Furthermore, the values of the equivalence ratio were dropped from 0.37 to 0.24 to increase the heating value of the gas product while maintaining the tar content at a low. This was accomplished by raising the gasifier freeboard region temperature up to 915°C by using an external heat source.

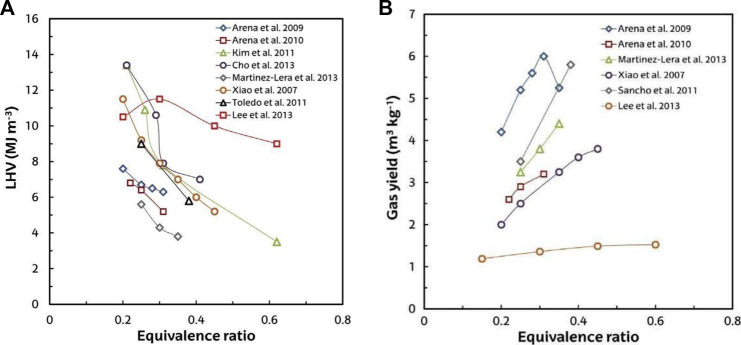

In a moving grate pilot plant gasifier, Lee et al. (2013) studied the gasification of waste plastics with an output of 80 kg/h. The gasifying agent used was pure oxygen. Under these parameters, the ideal equivalence ratio was between 0.30 and 0.45, and the gas yield was from 1.35 to 1.48 m3/kg with the heating value above 10 MJ/m3. Plastic waste air gasification is an intriguing option for producing a gas stream adequate for a variety of energy applications, the most viable one being electricity generation in engines and turbines (Heikkinen et al., 2004). As shown in Figure 8A (ER 0.2 and 0.45), the heating value is 3–12 MJ/m3 of produced gas. This heating value is primarily influenced by two factors: 1) equivalence ratio and 2) waste plastics composition. In the gasification of plastic waste, the heating value (average) is approximately 6–8 MJ/m3 (Table 2).

FIGURE 8.

(A) ER effect on gas LHV product in air plastic waste gasification. (B) ER effect on the yield of gas by Lee et al. (2013).

The air gasification of pure PP, PE, and PE waste has been studied by Martínez-Lera et al. (2013c) in a bubbling fluidized bed bench-scale gasifier with a capacity of 1 kg/h. The bed was composed of inert silica sand with an equivalence ratio of 0.25–0.35, and the experiments were carried out at 750°C. Pure PP and PE gasification produced similar gas compositions and yields. However, waste PE gasification produced better results than pure polyolefins gasification. As a result, the gas yield achieved with PE waste was 92.7%, while that of pure PE was 90.6%, with the tar content difference being more substantial. The tar content obtained from pure PE and waste plastics was 127 g N/m3 and 103 g N/m3. Despite the fact that the ER was only changed to a small degree (0.25–0.35), it had a significant impact on the process efficiency, especially tar yield. As a result, it was lower from around 150 g N/m3 to below 60 g N/m3 in the case of PE waste. A semiempirical model was developed by Martínez-Lera and Pallarés Ranz (2017) for polyolefin in FBR gasification, with the model predictions confirmed by previously described findings and others from the literature.

The equivalence ratio is undoubtedly the most significant parameter in terms of impact on air gasification operating conditions since it specifies the composition and yield of the gas (Xiao et al., 2007; Martínez-Lera et al., 2013c). Increased ER contributes to higher gas production, but it also reduces the gas heating value (Figure 8B). In the gas product, the presence of N2 increases with an increase in ER value, and the combustion of CH4, CO, and H2 and the resulting increase in CO2. An increase in the ER usually reduces the gas product tar content, which not only increases the gasifier temperature but also the volumetric gas yield.

The gasifier’s design is also essential for improving tar removal quality. To favor the cracking of tar in FBRs, an increase in temperature and residence time in the freeboard area is typically sought (Toledo et al., 2011; Martínez-Lera et al., 2013b). In fluidized bed gasifiers, the feed location also affects the tar yield (Wilk et al., 2013; Brachi et al., 2014). Secondary air injections in the gasifier’s free board are another popular technique for improving tar cracking and increasing the temperature in this region (Narváez et al., 1996; Pan et al., 1999). In a plastic waste air gasification, the amount of tar in the gas produced by different researchers varies greatly and depends on various factors, i.e., catalyst utilization, design of the reactor, the composition of plastics, and experimental parameters, in particular residence time, temperature, and equivalence ratio (Table 2). In general, the contents of tar are higher than biomass gasification (Pinto et al., 2009b; Mastellone et al., 2010b; Pinto et al., 2016), whose average value in the FBR reactors is 10 g/m3 (Anis and Zainal, 2011).

Since the content of tar has a significant impact on the direct use of the gas generated, various strategies for eliminating or reducing it have been suggested. As a result, using a primary catalyst in situ reduces the tar content of the gas component substantially (Sancho et al., 2008; Arena et al., 2009; Toledo et al., 2011). While in tar cracking, dolomite is more effective than olivine (Rapagna et al., 2000; Corella et al., 2004; Sancho et al., 2008; de Andres et al., 2011). In FBR reactors, olivine is the more commonly utilized catalyst because of its refined mechanical characteristics (Sancho et al., 2008; Arena et al., 2010; Toledo et al., 2011; Arena and Di Gregorio, 2014). The olivine catalytic function is generally linked to the content of iron (II) oxide (Kumar and Singh, 2011), with interest stemming from not only the enhanced removal of tar promoters but also the ability of the catalyst in the direct cracking of tar, preventing further formation of tar in the gasification system (Arena et al., 2010; Schneider et al., 2022). Different catalysts, like active carbon (Kim et al., 2011; Cho et al., 2013a; Cho et al., 2013b), zeolite (Cho et al., 2014), dolomite (Kim et al., 2011; Cho et al., 2013b), and active carbon filled with Ni (Cho et al., 2015), have been proposed for catalytic cracking of tar in secondary beds. Furthermore, for the removal of tar from the gas product, electrostatic precipitators and filters have been recommended (Kim et al., 2011; Cho et al., 2013a).

6.3 Co-gasification

The degree to which the product distribution is dependent on the composition of the feed is a notable differentiation between gasification and pyrolysis processes. As a result, the yield and composition of the products derived from pyrolysis of various solid wastes are extremely different. Moreover, the variations in gasification of various feed materials are limited to the composition of gas and small byproduct yields such as char and tar. The analysis of waste plastics co-gasification has been aided by the flexibility of the gasification process, and the higher advancement level of the gasification of biomass and coal.

Pinto et al. (2003) used a fluidized bed gasifier (5.5 kg/h) to investigate coal air/steam co-gasification with lower concentrations of PE and biomass (20% each). Plastic co-feeding increased the hydrocarbon content in the product gas; however, this result could be prevented by working at higher ERs or temperatures. A similar pattern was observed in the formation of tar. In order to achieve an appropriate performance for each mixture of feedstock, they found that the gasifier operating parameters had to be thoroughly calibrated. The same authors were able to fully eliminate tar by using two secondary fixed-bed (packed) tar cracking reactors, the first of which used dolomite and the second of which used Ni-Al2O3 (Pinto et al., 2009b). Surprisingly, holding unwanted halogen and sulfur mixtures in the dolomite bed bettered the durability and performance of the Ni-based catalyst. Pinto et al. recently investigated rice husk co-gasification (80%)/PE (20%) in a fluidized bed gasifier utilizing various gasifying agents, such as air, pure oxygen, steam, and mixtures of these agents (Kaewpengkrow et al., 2012; Pinto et al., 2016). The findings show that working with steam and pure oxygen produces the best gas, but that the usage of pure oxygen is restricted due to high oxygen production cost, thereby considering enriched air as a viable alternative.

Pinto et al. (2002) investigated the PE/biomass mixture steam gasification (continuous) in an FBR. The PE maximum content studied (60%) resulted in effective conversion, as demonstrated by a particular gas yield and a heating value, i.e., 1.96 kg/m3 and 18.3 MJ/m3. Furthermore, an increase in PE feed resulted in an increase in methane concentrations and H2 (to 52%) on the one side, but a decrease in CO2 and CO concentrations on the other.

Despite the fact that plastic waste has mostly been co-gasified with biomass (Pinto et al., 2002; Wilk and Hofbauer, 2013; Alvarez et al., 2014; Narobe et al., 2014; Lopez et al., 2015a; Zaccariello and Mastellone, 2015; Arena and Di Gregorio, 2016; Singh et al., 2022), it has also been co-processed with ternary mixtures (Ahmed and Gupta, 2011; Jung et al., 2013; Lopez et al., 2016) and coal (Mastellone et al., 2010b; Kriz and Bicakova, 2011; Straka and Bicáková, 2014b). Steam, air, or their mixtures were used as the gasifying agent in these experiments. Table 3 summarizes the key findings in the co-gasification of plastic waste.

TABLE 3.

Gas compositions obtained by authors in the plastics waste co-gasification.

| Plastic type | Reactor | Bed material | Gasifying agent | Reaction Conditions (°C, -) | Composition of gas (% vol) | Gas yield (m3/kg) | LHV (MJ/m3) | Tar yield (g/m3) | Reference |

|---|---|---|---|---|---|---|---|---|---|

| PE(0.3)/wood pellets (0.7) | Fluidized bed (dual) (15 kg/h) | olivine | steam | S/F: 1.6, T: 850 | CO: 23, H2: 41, CH4: 14, CO2: 16 | 1.9 | 16 | 47 | Wilk and Hofbauer, (2013) |

| MSW plastic(0.5)/wood pellets (0.5) | Fluidized bed (dual) (15 kg/h) | olivine | steam | S/F: 0.94, T: 850 | CO: 24, H2: 35, CH4: 6, CO2: 19 | 1.1 | 16 | 39 | Wilk and Hofbauer, (2013) |

| PE(0.33)/lignite (0.66) | Fluidized bed (dual) (15 kg/h) | olivine | steam | S/F: 0.90, T: 850 | CO: 24, H2: 45, CH4: 8, CO2: 10 | - | 13 | 9 | Kern et al. (2013) |

| Wood (0.2)/recycled plastic (0.8) | Bubbling Fluidized (aggregative) bed (5 kg/h) | SiO2 | air | T: 872, ER: 0.25 | CO: 7, H2: 10, CH4: 8, CO2: 11 | 3.4 | 7 | 34 | Zaccariello and Mastellone, (2015) |

| wood (0.2)/Recycled plastic (0.3)/ coal (0.5) | Bubbling Fluidized (aggregative) bed (5 kg/h) | SiO2 | air | T: 868, ER: 0.25 | CO: 13, H2: 14, CH4: 2, CO2: 14 | 2.7 | 6 | 41 | Zaccariello and Mastellone, (2015) |

| Wood(0.5)/HDPE(0.5)/PE (0.5) | Spouted (conical) bed reactor (0.1 kg/h) | olivine | steam | S//F: 1.00, T: 900, | CO: 27, H2: 57, CH4: 6, CO2: 7 | 2.64 | - | 9.7 | Lopez et al. (2015a) |

| PE(0.5)/coconut shell (0.5) | Fluidized bed/fixed (packed) bed (2/kg) | Commercial Ni catalyst/dolomite | steam | S/F: 2, T: 800/600 | CO: 9, H2: 82, CH4: 7, CO2: 2 | 2.7 | 12.4 | 0 | Alipour Moghadam Esfahani et al. (2017) |

| PE (0.5)/rice straw (0.5) | Fixed (packed) bed | - | steam | T: 900 | CO: 30, H2: 46, CH4 :12 CO2: 12, | 1.1 | 13.9 | - | Baloch et al. (2016) |

| Wood and biomass paper fiber(0.45)/ waste polyolefins (0.55) | Updraft (60kg/h) | - | air | ER: 0.19-0.24, T: 800–930 | CO: 15–14, H2: 10–15, CH4: 6-5, CO2: 8 | 2.6-3.4 | 9.5-79 | 22-11.2 | Ponzio et al. (2006) |

| Biomass (0.5)/PP (0.5) | Dual Fixed bed (0.04g) | Fe-CeO2 | steam | T: 850/700 | CO: 5, H2: 40, CH4: 6, CO2: 16 | 2.55 | 35.5 | - | Parparita et al. (2015) |

| PET (0.5)/wood (0.5) | Fluidized (heterogeneous) bed reactor | olivine | air | ER: 0.19-0.31, T: 725-875 | CO: 13-9, H2: 4.3-5.4, CH4: 3-2.7, CO2: 17 | - | 4.5-3.5 | 145-63 | Robinson et al. 2016 |

| PE(0.2)/ rice husk (0.8) | Fluidized (heterogeneous) bed reactor (0.3 kg/h) | - | oxygen | ER:0.20, T:850 | CO: 12, H2: 38, CH4: 12, CO2: 37 | 1 | 13 | 12 | Pinto et al. (2016) |

| PE(0.2)/ rice husk (0.8) | Fluidized (heterogeneous) bed reactor (0.3 kg/h) | - | air | ER:0.20, T:850 | CO: 24, H2: 19, CH4: 13, CO2: 33 | 1.3 | 8 | 12 | Pinto et al. (2016) |

| PE(0.2)/ rice husk (0.8) | Fluidized (heterogeneous) bed reactor (0.3 kg/h) | - | steam | S/F: 1, T:850 | CO: 15, H2: 41, CH4: 11, CO2: 24 | 0.35 | 13 | 15 | Pinto et al. (2016) |

| PE (0.1)/ pine wood (0.9) | Fluidized (heterogeneous) bed reactor (0.75 kg/h) | - | steam | S/F: 0.8, T: 740–880 | CO: 34–31, H2: 25–44, CH4: 15–10, CO2: 14–9, | 0.63–1.28 | 21–15 | - | Pinto et al. (2002) |

| PE (0.1)/ coal (0.9) | Fluidized (heterogeneous) bed reactor (6 kg/h) | - | steam/air | S/F: 0.85, ER: 0.2, T: 850 | CO: 17, H2: 40, CH4: 17, CO2: 16 | 1.3 | - | 19 | Pinto et al. (2009b) |

| PE (0.2)/pine wood (0.2)/coal (0.6) | Fluidized (heterogeneous) bed reactor (5.5 kg/h) | - | steam/air | Air/ F: 1.14, S/F: 1, T: 740–880 | CO: 18–17, H2: 25–40, CH4: 18–15, CO2: 24–20, | 0.6–1.35 | 24–18 | - | Pinto et al. (2003) |

| PE (0.2)/ pine wood(0.8) | Fluidized (heterogeneous) bed reactor (5 kg/h) | quartz sand | air | ER: 0.23, T: 780 | CO: 16, H2: 17, CH4: 12, CO2: 15 | - | 7.3 | 60 | Ruoppolo et al. (2012) |

| PE (0.2)/ pine wood(0.8) | Fluidized (heterogeneous) bed reactor (5 kg/h) | Ni-γAl2O3 | air | ER: 0.23, T: 780 | CO: 14, H2: 30, CH4: 3 CO2: 10 | - | 6.5 | 27 | Ruoppolo et al. (2012) |

| Polyolefins waste (0.4)/ coal (0.6) | Fluidized (heterogeneous) bed reactor (4 kg/h) | sand-dolomite | air | ER: 0.36, T: 850 | CO: 22, H2: 40, CH4: 5.5, CO2: 16 | 2.9 | 8.3 | 1.3 | Aznar et al. (2006) |

| biomass (0.2)/ polyolefins waste (0.2)/coal (0.6) | Fluidized (heterogeneous) bed reactor (4 kg/h) | sand-dolomite | air | ER: 0.36, T: 850 | CO: 12, H2: 11, CH4: 2, CO2: 14 | 3 | 5.5 | 1 | Aznar et al. (2006) |

| PET (0.25)/ olive husk (0.75) | Fluidized (heterogeneous) bed reactor (5 kg/h) | γ-Al2O3 | steam/air | S/F: 0.76, ER: 0.1, T: 752 | CO: 13, H2: 33, CH4: 9, CO2: 19 | 1.3 | 10.2 | 90 | Brachi et al. (2014) |

| PET (0.25)/ olive husk (0.75) | Fluidized (heterogeneous) bed reactor (5 kg/h) | Ni-γAl2O3 | steam/air | S/F: 0.62, ER: 0.1, T: 845 | CO: 22, H2: 40, CH4: 5.5 CO2: 16 | 1.4 | 9 | 29 | Brachi et al. (2014) |

At 900°C in a laboratory fixed-bed batch reactor, Ahmed and Gupta (2011) studied PE steam co-gasification and wood chips. In the co-processing of biomass and plastics, they also discussed the synergistic impact on gas yields, hydrocarbons, and hydrogen, as well as on thermal performance. Furthermore, in the feed, the optimized content of plastic was found to be within 65 and 80%. Lopez et al. (2015a) confirmed the previously recorded synergistic effects in a spouted bed conical gasifier (0.1 kg/h) using biomass and PE co-gasification. This effect is particularly noticeable at a 1/1 blending ratio.

The gas product tar content of a 1/1 mixture of biomass and PE gasification was decreased to 9.5 N/m3 with an S/F ratio of 1, by utilizing a primary olivine catalyst operating at 900 °C. Furthermore, while the gas yield (2.67 kg/m3) was close to the theoretical value predicted in accordance with the results achieved for biomass and PE particular feeds, a synergistic impact on the char yield reduction and H2 content in the syngas was observed.

By utilizing olivine as the bed material in the dual fluidized bed gasifier (15 kg/h), Wilk and Hofbauer (2013) investigated biomass pellets steam co-gasification with various waste plastics types and their mixtures (such as PE). Thus, a 16 MJ/m3 LHV value of 1.6 m3/kg gas yield was reported for 1/1 ratio of blended HDPE/biomass, which is significantly less than that obtained with pure plastic. Moreover, when plastics and biomass were co-gasified, a synergistic effect on the formation of tar was observed, with the tar contents being less than that predicted based on their particular gasification. Furthermore, tar composition was also affected by an increase in the content of plastic in the feed thus lowering furan and phenol while enhancing naphthalene content. Similarly, by utilizing different blending ratios, non-linear patterns were perceived, and the composition of the gas product cannot be directly evaluated from the outcomes achieved with particular feedstocks. The impact of lignite co-feeding in the PE steam gasification was investigated by the same authors (Kern et al., 2013). Furthermore, lignite co-feeding was found to have a synergistic impact on cold gas efficacy, and lignite co-feeding also enabled a reduction in the content of tar when contrasting with those results from pure plastic.

In a fluidized bed pilot scale gasifier, Ruoppolo et al. (2012) explored pellets gasification containing 20% PE and 80% wood, and correlated the results to those from pure biomass. Ni-Al2O3 and inert quartzite catalyst were utilized as bed materials. Mixtures of air and air/steam were utilized as gasifying agents, and they discovered that by improving the reforming reactions, air/steam mixtures resulted in a higher hydrogen concentration and a lower content of tar. The high concentration of H2 obtained during PE pellets gasification was the most promising result (30% vol.). Despite their utilization of comparatively low Ni-Al2O3 catalyst and the content of plastic in the pellets, the tar content as compared with biomass (below 30 g N/m3) was significantly higher (around 46 g N/m3). Therefore, the above synergies in steam gasification were apparently less pronounced when air was used as the gasifying agent. The same authors investigated gasification of pellets composed of olive PET (25%) and husk (75%) with mixtures of steam/air, but with low ERs to increase syngas efficiency (Brachi et al., 2014). When a nickel-based catalyst (Ni-Al2O3) was compared with an Al2O3 catalyst, the former produced better gas composition and tar content. Furthermore, when the effects of feeding from a bed middle point were compared to those from the top bed feeding, a substantial increase in gasifier efficiency was observed.

A two-step gasification framework was developed by Park et al. (2016) that included oxidative pyrolysis at 526°C and a plasma thermal reactor operating at 626°C. Different mixing ratios and equivalence ratios were used to investigate the biomass and HDPE co-gasification. With an ER of 0.46 and 70% biomass in the feed, the best results were achieved.

In a fluidized bed pre-pilot gasifier, Mastellone et al. (2010b), Mastellone et al. (2012), and Zaccariello and Mastellone (2015) investigated the air gasification of ternary mixtures composed of biomass, coal along with plastic mixtures, and coal. Because of the higher light hydrocarbon content, the key result of plastics co-feeding was an improvement in heating value and gas yield. When plastics were used in the feed, they found a rise in tar formation and a decrease in H2 concentration, i.e., for various ERs (0.21–0.31), the co-gasification of coal/plastics tar contents ranged from 26 to 48 gm−3. Surprisingly, biomass had the opposite effect than that predicted, which is tar formation reduction. As a result, the authors assessed that by promoting synergistic effects in the feed by using appropriate component proportions, the process’ viability can be increased.

Moghadam et al. (2014) and Alipour Moghadam Esfahani et al. (2017) proposed a two-stage method for HDPE steam gasification and a palm kernel shell/coconut shell mixture between 660 and 880°C in FBR using in situ Ni catalyst (powder), followed by cracking of tar in an FBR dolomite reactor at 600 °C. This method produces syngas with high H2 content and allows for effective tar removal. Hence, at the maximum gasification (880 °C) temperature, a hydrogen yield of 29.4 wt% was recorded, with an 87% concentration (by vol).

Furthermore, plastics in the feed had a positive effect on the content of tar and gas heating value; but on tar formation, this effect was found to be the opposite of that stated by other authors (Ruoppolo et al., 2012; Wilk and Hofbauer, 2013; Zaccariello and Mastellone, 2015). Thus, for binary and ternary mixtures, very low contents of tar (1.35 gm−3) were achieved by operating at 850°C, utilizing dolomite as the primary catalyst and with an ER of 0.36, with heating values in the range of 5–8 MJ/m3 due to the high equivalence ratio used.

Aznar et al. (2006) studied air co-gasification of binary and ternary mixtures in a fluidized bed reactor. The mixtures were made up of plastic waste, i.e., PP and PE, biomass, and coal. In binary mixtures, the content of plastics was comparatively high (40%), while in ternary mixtures, the content was low (10–20%). The concentration of hydrocarbon in the gas production increased due to the presence of plastics in the feed while lowering H2, CO2, and CO.

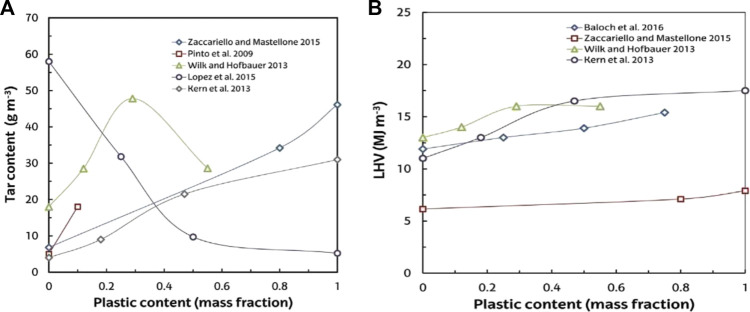

According to these results, plastic waste co-gasification with various feedstocks produces fascinating synergies, highlighting the strategy’s utility (Wilk and Hofbauer, 2013; Lopez et al., 2015a; Singh et al., 2022). The reciprocations between product polymer degradation and biomass chars are usually due to these synergies (Antelava et al., 2021), with a positive correlation in their thermal joint degradation being well established (Zhang et al., 2016b; Lopez et al., 2017). As shown in Figures 9A,B, increasing the content of plastics in its co-gasification with coal and biomass increases both H2 concentration and gas yield. These outputs are explicated by the higher content of carbon and H2 in waste plastics when compared to coal and biomass, as well as the lower or non-existent char yield. An increase in the formation of tar is the key plastics co-feeding disadvantage as shown in Figure 10A. The higher gas heating value generated when compared to that in the gasification of biomass, as shown in Figure 10B, also facilitates the plastic co-feeding benefit (Pinto et al., 2016). Another benefit of co-gasification of plastic and biomass is that this reduces plastics gasification operational issues, such as formation of fine char particulates and reactor feeding (Pinto et al., 2002).

FIGURE 9.

(A) The effect of the feed’s plastic content on the yields of gas in plastics co-gasification with coal and biomass. (B) Plastic content effect in the feed on the production of H2 in plastics co-gasification with coal and biomass.

FIGURE 10.

(A) Plastic content effect in the feed on the content of tar in the produced gas in plastics co-gasification with coal and biomass. (B) Plastic content effect in the feed on the produced gas heating value in plastics co-gasification with coal and biomass.

7 Pyrolysis

Pyrolysis is organic matter thermal decomposition without oxidizing agents like CO2, oxygen, or steam. The temperature for pyrolysis processes is generally inbetween 300 and 850°C, depending on various process parameters. Usually, pyrolysis processes are endothermic, which means that energy is required to proceed with the process. The energy content and composition of pyrolysis products are dependent largely on the input of waste and can differ significantly (Hu et al., 2021; Tezer et al., 2022):

• Solid: a char-like substance that contains residual solid products, such as sand, glass, and metals. The heating values and char content (by weight) are around 10–35 MJ/kg and 20–50%, respectively, which may have substantial content of ash (10–50%).

• Liquid: a complex mixture of hydrocarbons, such as organic acids, phenols, PAHs, and alcohols, made up of water, tar, and oil. The heating values and liquid amount (by weight) are around 5–15 MJ/kg and 30–50%.

• Gas: a mixture of CO, CH4, CO2, H2, and other volatile waste constituents. The heating value and gas yield may be around 3–12 MJ/Nm3 and 20–50%, respectively.

Moisture is released and waste is dried during the pyrolysis process, which involves heating the waste to about 100–120°C. Following this process, a series of complex reactions take place, resulting in the release of volatile compounds and the breakdown of more complex carbon-containing compounds into simpler ones. Gaseous outputs are formed by breaking nitrogen, hydrogen, and oxygen bonds at temperatures ranging from about 200°C to 800 C (see Table 4). The primary reactions are those that result in the production of gas and tar/oil, while the secondary reactions are those that result in the conversion of gas and tar/oil. During gasification, these secondary reactions can also occur. Secondary reactions convert further tar to gases and char, along with the enhancement in the concentrations of CH4 and CO2 in the gas product.

TABLE 4.

Temperature-dependent pyrolysis reactions (Bilitewski et al., 1997).

| Chemical reaction | Temperature range |

|---|---|

| Dehydration, thermal drying | 100–120 |

| Desulfurization, deoxidation, CO2 and H2O molecular splitting, H2S splitting | 250 |

| Aliphatic hydrocarbon bonds breakage, methane and other aliphatic hydrocarbons splitting | 340 |

| Carbonization | 380 |

| C-O and C-N bonds breakage | 400 |

| Bituminous (asphalt) compounds disintegration into low temperature tars and oils | 400–600 |

| Bituminous (asphalt) compounds cracking into thermal resistant elements, aromatic organic compounds formation | 600 |

| Thermal aromatization of ethene to hexanaphthene to C6H6 formation and other volatile aromatic hydrocarbons | >600 |

Pyrolysis product heating values and mass yields differ greatly from one process to another and also depend highly on the composition of the waste input. With well-sorted solid recovered fuel (SRF), automotive shredder residue (ASR), or biomass waste as a process input, the above values can only be considered suggestive and typically representing an upper limit. Mixed plastics generally produce high amounts of inorganic residues and char, whereas high quality plastic waste and rubber promote higher oils and gases ratios.

The amount of water in the waste input has an impact on both the process conditions and outputs, especially on the liquid and gas outputs. Heat is mostly supplied indirectly via the reactor walls, but waste compaction and friction can also lead to waste heating. Pyrolysis takes place in an inert atmosphere, but in practice, it occurs in the pyrolysis gaseous atmosphere that go through various secondary conversion reactions.

8 Pyrolysis of waste plastics

Plastics come in a variety of compositions which are usually stated based on their proximate analysis. The proximate analysis includes the determination of volatile matter, moisture content, fixed carbon, and waste sample ash content. If samples of solid waste are to be utilized as a fuel, all of these characteristics are very significant (Kreith, 1998). The main factors that affect the yield of liquid oil in the pyrolysis process are ash content and volatile matter. A high content of ash decreases the liquid oil yield, while high volatile matter enhances the production of liquid oil (Abnisa and Wan Daud, 2014). The proximate study of various plastics is summarized in Table 5, which shows that all plastics have high volatile matter and low ash content. These properties show that plastics have a high capacity for pyrolysis to produce significant amounts of liquid oil.

TABLE 5.

Proximate analysis of plastics (Abnisa and Wan Daud, 2014).

| Plastics types | Marks on plastics | Volatile (wt%) | Fixed carbon (wt%) | Ash (wt%) | Moisture (wt%) | References |

|---|---|---|---|---|---|---|

| Polyethylene terephthalate (PET) |

|

91.75 | 7.77 | 0.02 | 0.46 | Zannikos et al. (2013) |

| 86.83 | 13.17 | 0 | 0.61 | Heikkinen et al. (2004) | ||

| High-density polyethylene (HDPE) |

|

99.81 | 0.01 | 0.18 | 0 | Ahmad et al. (2013) |

| 98.57 | 0.03 | 1.40 | 0 | Heikkinen et al. (2004) | ||

| Polyvinyl chloride (PVC) |

|

93.70 | 6.30 | 0 | 0.80 | Hong et al. (1999) |

| 94.82 | 5.19 | 0 | 0.74 | Heikkinen et al. (2004) | ||

| Low-density polyethylene (LDPE) |

|

99.70 | 0 | 0 | 0.30 | Park et al. (2012) |

| 99.60 | - | 0.40 | - | Aboulkas et al. (2010) | ||

| Polypropylene (PP) |

|

95.08 | 1.22 | 3.55 | 0.15 | Jung et al. (2010) |

| 97.85 | 0.16 | 1.99 | 0.18 | Heikkinen et al. (2004) | ||

| Polystyrene (PS) |

|

99.63 | 0.12 | 0 | 0.25 | Abnisa et al. (2014) |

| 99.50 | 0.20 | 0 | 0.30 | Park et al. (2012) | ||

| Polyethylene (PE) Acrylonitrile butadiene styrene (ABS) Polyamide (PA) or Nylons Polybutylene terephthalate (PBT) |

|

98.87 | 0.04 | 0.99 | 0.10 | Jung et al. (2010) |

| 97.88 | 1.12 | 1.01 | 0 | Othman et al. (2008) | ||

| 99.78 | 0.69 | 0 | 0 | Othman et al. (2008) | ||

| 97.12 | 2.88 | 0 | 0.16 | Heikkinen et al. (2004) |

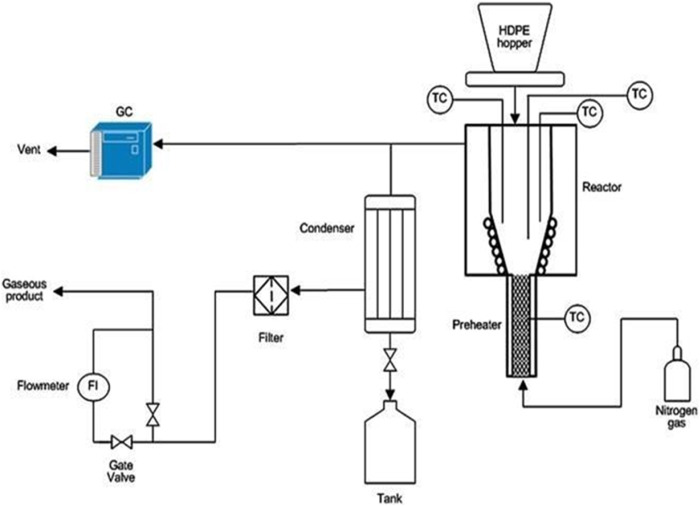

8.1 High-density polyethylene

Polyethylene is the most popular plastic in the world. It is the most basic of all commercial thermoplastics in terms of structure. Its molecules are made up of long-chain carbon atoms joined by two atoms of hydrogen. The straight chain (no branching) is called high-density polyethylene (HDPE) or linear PE, short for high-density polyethylene. Although linear PE is far more durable than branched PE, branched PE is easier to manufacture and less expensive. Its different uses account for 17.6% of the plastic waste group, which is the third most common plastic form of MSW (Michael, 2010). HDPE is therefore suitable for applications like weaving, Raschel knitting, reinforcement applications, and braiding. Many studies on the pyrolysis of HDPE at various operating conditions have been performed to determine the yield of the product.

Using a batch reactor, Marcilla et al. (2009a) explored the pyrolysis of HDPE at 550°C. The gaseous product produced was 16.4 wt% and the yield of liquid oil was 84.8 wt%. The findings showed that at higher temperatures, more liquid oil yield could be produced, but there was also a drawback that should be observed; since the process had reached the utmost thermal decomposition stage, too high temperatures would increase the gaseous product while decreasing the yield of liquid oil. Mastral et al. (2001) studied the pyrolysis of HDPE at 650 °C in an FBR. During experimentation, they noted that the production of the gaseous product was 31.7 wt% and liquid oil yield was 68.3 wt%. They found that when the temperature exceeds 550°C, the liquid further cracks into the gaseous products.

Kumar and Singh (2011) investigated the thermal pyrolysis of HDPE at 400–550°C utilizing a semi-batch reactor. At 550°C, gaseous product (24.73 wt%) and the maximum liquid yield (79.06 wt%) were obtained, while at temperatures of 500–550°C, wax began to dominate the fraction of the product. The pyrolysis produced a dark brownish oil with no clear residue and a boiling point ranging from 83 to 351°C. This indicated that the oil contained a mixture of components of various oils, like diesel, kerosene, and gasoline, which coordinated the characteristics of conventional fuel (see Table 6). In addition, the pyrolytic oil of HDPE had a very low sulfur content (0.018%), making it environmentally friendly.

TABLE 6.

Properties comparability of conventional fuel and pyrolytic HDPE oil.

| Oil type | Properties of conventional fuel (Boundy et al., 2011) | Characteristics of HDPE pyrolysis oil (Kumar and Singh, 2011) | ||

|---|---|---|---|---|

| Boiling point (°C) | Cv (MJ/kg) | Boiling point (°C) | Cv (MJ/kg) | |

| Gasoline | 40–200 | 42.9 | 82–352 | 43.4–46.5 |

| Diesel | 150–390 | 42.8–45.8 | ||

| Kerosene | 150–300 | 43.0–46.2 | ||

In a micro steel reactor, Ahmad et al. (2014) explored the pyrolysis of HDPE by utilizing nitrogen as a fluidizing medium at 5–10°C/min heating rate at 300–400°C. They discovered that the maximum total conversion occurred at 350°C, with liquid yield as the primary product (80.83 wt%). At 300°C, the solid residue was fairly significant (33.07 wt%), but it decreased to 0.53 wt% at the maximum temperature of 400 °C.

8.2 Low-density polyethylene