Abstract

Progressively and projected integration of rare earth metals (REMs) in modern technologies, especially in the clean energy, consumer electronics, aerospace, automotive, and defense sectors, place REMs as critical raw materials in the supply chain and strategic metal from the fourth industrial revolution perspective. Current REM production from the primary mineral resources in the supply chain versus industrial demand is at a bottleneck. Alternatively, REM-bearing anthropogenic wastes are pertinent and potent to addressing the critical supply chain bottleneck. Although secondary REM resources are prudent to address the critical supply chain bottleneck, the absence of effective and efficient technologies to recover these REMs from anthropogenic waste imposes challenges and provides opportunities. Hence, this review analyses and discusses the significance of anthropogenic wastes for REM recovery, the status of recycling technologies for sustainable valorization of REMs, challenges, and opportunities. The current review covers the potential quantitative REM wealth locked in various anthropogenic waste like (i) spent rare earth permanent magnets, (ii) spent batteries, (iii) spent tri-band REM phosphors, (iv) bauxite industry residue red mud, (v) blast furnace slag and (v) coal mines, and coal byproducts and status of valorization technologies for circularizing the REMs. In industrial waste like red mud, steelmaking slag, blast furnace slag, and coal fly ash typically 109,000, 2000, 39,000, and 354,000 tons of REM get scrapped, respectively, in a conservative estimation. In the years 2020 and 2021, respectively, 240,000 and 280,000 tons of REM were produced by mine production in contrast to 504,000 tons of REM that were scrapped with REM-bearing industrial waste. This review revealed that total REM currently getting scrapped with anthropogenic waste versus projected REM demand for the years 2022, 2023, 2024, and 2025 could be standing at 2.66, 2.51, 2.37, and 2.23, respectively. Our investigation revealed that efficient recovery of REMs from anthropogenic waste is significant and promising but associated with challenges like lack of industrial-scale valorization process, lack of a clear strategy, road map, policy, effort, funding, and diversified research.

Keywords: Rare earth metal, Valorizations, Anthropogenic waste, Sustainability

Introduction

Rare earth metals (REMs) are progressively being integrated into modern technologies, especially in the clean energy, consumer electronics, sectors, aerospace, automotive, and defense. The REMs are not only getting integrated into various industrial technologies but also accelerating supply chain criticality driven by the fourth industrial revolution (4IR), clean energy demand, and environmental regulations. The 4IR is very much driven by data associated with connected devices, faster wireless internet, big data, and artificial intelligence which needs core technologies like connectivity, IT hardware, and software, enabling technologies for domains like consumer goods, services, vehicles, healthcare, industrial, home, infrastructure, and agriculture (https://www.epo.org/, 2020; David et al. 2022). Demand for REMs in each of these sectors is expanding and in some industries the growth is exponential, hence, the supply chain constantly getting bottlenecked. Current REM production from the primary mineral resources in the supply chain versus industrial demand is at a bottleneck and places REM as critical raw material in the supply chain and strategic metal from the fourth industrial revolution perspective.

China is monopolizing the global REM supply chain as the single most producer of these critical raw materials (CRMs) which accounts for 58% and 60% for the years 2020 and 2021, respectively (Gambogi 2021; Cordier 2022). China is not only a global leader in REM mine production but also REM reserve in China accounts for 37% of worldwide REM mine reserves (Gambogi 2021). Currently, the entire demand for REMs by various industries is mainly met by mine production as hardly less than 1% of REM is being recycled (Graedel et al. 2011). Progressive demands and lack of good distribution of resources around world-leading not only to supply chain discrepancies but also potentially put various industries and countries at a competitive disadvantage position. Considering all these factors the European Commission (EC) in its critical raw materials strategy continuously in the first (2011), second (2014), and third (2017) reports have identified REMs as critical raw materials (CRMs) with the highest risk of the supply chain (Commision 2017). Similarly, the US Department of Energy (DOE) (Energy 2011) and the American physical society (APS) (Jaffe et al. 2011) in the strategic metal report have emphasized REM as CRM for green energy and emerging technologies.

Challenges associated with REM-like strategic importance, industrial irreplaceability, sustainable alternative green energy, environmental carbon footprint control, geopolitical scenario, and REM supply chain monopoly; can be decisively addressed through circularizing REM from various anthropogenic waste. Hence, technological advancement for the sustainable valorization of REM from anthropogenic waste should be the panacea.

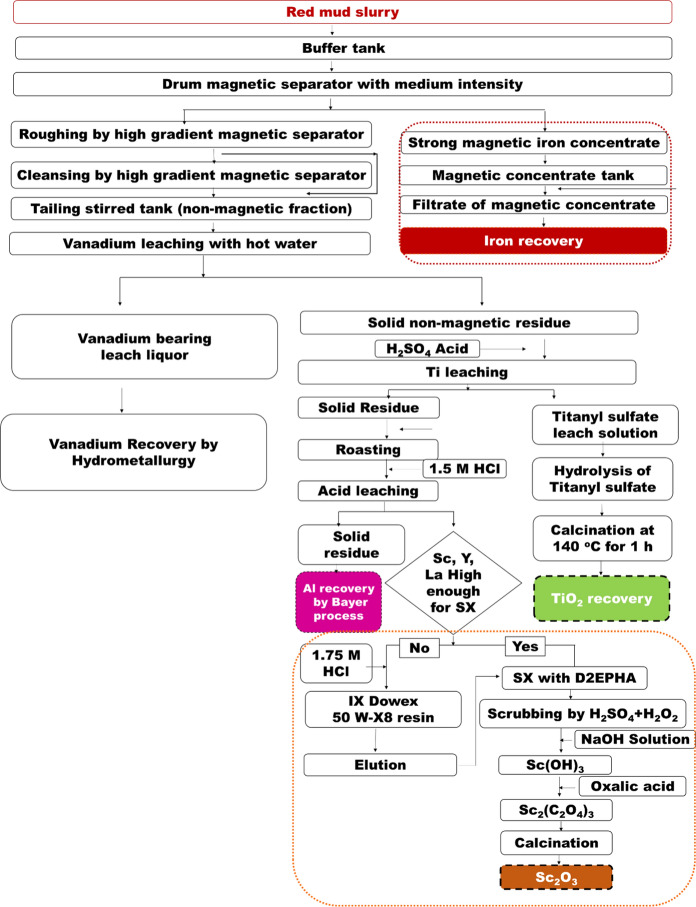

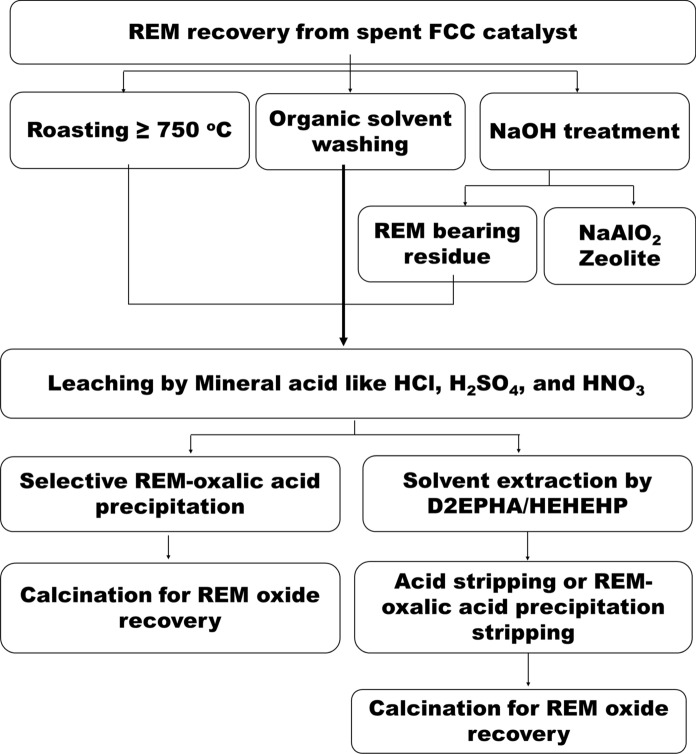

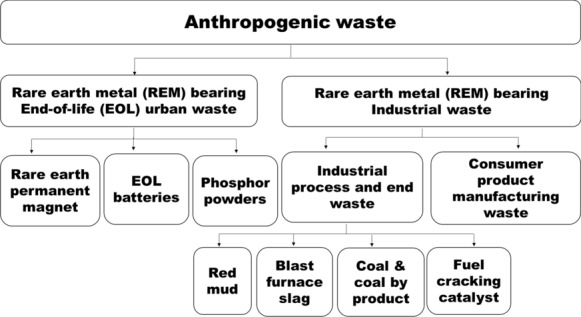

Anthropogenic waste, in general, can be divided into two parts, i.e., (i) end-of-life (EOL) urban waste and (ii) industrial waste. Detailed classification of the REM bearing anthropogenic waste is presented in Fig. 1. As exhibited in Fig. 1, the context of REM bearing anthropogenic waste broadly can be divided into EOL urban waste and REM bearing industrial waste. REM bearing EOL products like electronic waste, waste catalysts, optical lenses, and rare earth permanent magnets (REPM) from various equipment can be classified as EOL urban waste. REM bearing industrial waste is also classified into two types, depending upon the generation process, i.e., (i) industrial process and end waste, and (ii) consumer product manufacturing waste. During the manufacturing of various consumer products for end uses, various process waste gets generated, which can be considered as consumer product manufacturing waste. The REM-bearing waste produced during rare earth permanent magnets (REPM) production, REM refining plant wastewater, and REM mines wastewater can also be classified as manufacturing waste. Similarly, in general, during the industrial metallurgical process, power generation process, and catalytic cracking process, REM bearing process waste gets generated as a by-product, or end waste products can be classified as industrial process and end waste. Spent fluid catalytic cracking catalysts (FCC) which are extremely important in the modern petroleum refining industry use REM mainly made from La and Ce zeolite because of its high activity, selectivity, thermal stability, hydrothermal stability, and toxicity resistance (Palos et al. 2018; Lu et al. 2020). The spent FCC contains about 3% REMs oxide (Lu et al. 2020). REM-bearing alumina industry waste red mud, iron, and steel industry waste blast furnace slag (BFS), coal mines wastewater, and coal byproducts can be classified as industrial process and end waste. Considering the similarity of EOL urban waste and consumer product manufacturing waste, in the current review sustainable valorization of rare earth metal from anthropogenic waste focusing on EOL urban waste and industrial process and end waste has been reviewed.

Fig. 1.

Systematic classification of anthropogenic waste

USGS reported, globally driven by demand REM oxide production from primary resources continuously increased year by year and during the last five years, respectively, 147, 190, 210, 240, and 280 thousand tons of REM oxide were produced in the year 2017, 2018, 2019, 2020, and 2021, from primary resources (Gambogi 2020; 2021; Cordier 2022). In the year 2020, worldwide REM consumption for various end uses was 38%, 23%, 13%, 8%, 9%, 5%, and 3% respectively for REPM, catalysts, glass polishing powder, and additives, metallurgy and alloy, battery alloy, ceramic and pigments, and phosphorus (https://www.nrcan.gc.ca/2020).

REPM is mainly used in information technology devices and battery alloy main used in electrical vehicles that are mainly driven by consumer demand and those consumer goods are also associated with rapid up-gradation and diversification. As majoring of REM are being used for consumer goods, considering the EOL of the respective product, all those REMs or REM bearing scraps enter the waste stream after a certain year(s) of time lag. The time lag depends upon which device/consumer good and how long it is being used. Hence, all these REM bearing urban scrap can be rich secondary resources. Similarly, Swain et. al has reported globally that 4 billion tons of red mud which contains 0.5–1.7 kg/ton of REMs have been stockpiled by 2020 (Swain et al. 2020b), and the same red mud being generated, annually between 120–150 million tons worldwide mainly goes for stockpiling. Kasina and Michalik have reported each ton of BFS could contain 0.12–14 kg/ton of REMs (Kasina and Michalik 2016). To put in perspective, quantitative estimation of REM gets slagged with BFS can be calculated from worldwide iron and steel production data. USGS reported in the year 2020, that worldwide 310–380 million tons of iron slag and 180–270 million tons of steel slag were generated (Ober 2021). USGS also reported in the year 2021 global iron slag and steel slag production was estimated to be 340–410 million tons and 190–280 million tons, respectively (Tuck 2022). The combination of the information above is indicative of plausible BFS as secondary resources for REM. Harris et al. have reported, that in the year 2017 worldwide 1.1 billion tons of coal combustion product that safely can consider coal fly ash was generated (Harris and Feuerborn 2020). Franus et al. have reported each ton of coal fly ash could contain 0.1–54 kg/ton of REMs (Franus et al. 2015). Ferella et al. have reported worldwide FCC supply is estimated at 840,000 tons/year (Ferella et al. 2016; Ye et al. 2017). Lu et al. have reported modern petroleum refining industries are crapping 210,000 tons of FCC annually (Ye et al. 2017; Lu et al. 2020). All the explained data suggest that efficient recovery of CRMs like REMs from anthropogenic waste is much more important and promising but associated with challenges like lack of industrial-scale valorization process, lack of a clear strategy, road map, policy, effort, funding, and diversified research. The significance, novelty, and objective of the review are described in the significance and novelty section below.

Significance and novelty of review over REM valorization from anthropogenic waste

The EOL waste material contains a higher REM concentration compared to primary resources whence a significant volume of industrial waste is generated with a moderate or small amount of REM content. The volume of industrial waste and concentrated resources from urban mining provides significant opportunities for addressing the REM supply chain bottleneck. Simultaneously, REM valorization through urban mining and REM recovery from industrial waste also imposes significant challenges. For techno-economic industrial recovery of REM from EOL scrap, the volume of raw material is very important for the efficient circular economy, hence, efficient waste management and collection play a vital role. Although waste management policies and resource recycling policies for EOL scrap are available in some developed countries, the same is not true for the majority of the countries around the world (Domenech and Bahn-Walkowiak 2019; Ferronato and Torretta 2019). Every other nation consumes but the nonexistence of REM waste management processes and policies in most parts of the world also imposes substantial challenges despite the rich resources of REM. Hence, from waste to wealth vision and to achieve sustainable development goals, starting from policy development to process development, understanding the current state of REM bearing anthropogenic waste generation is essential and the current review addresses those fundamental aspects. The current review revealed that industrial-scale, efficient recovery economically feasible technology hardly available for EOL scraps hinders the valorization of REM for the circular economy. Also. the review indicated that laboratory-scale technology development may not be completely neglected and still not in a significantly advanced state that can fill the gap between lab-scale investigation and industrial-scale REM recovery from EOL waste (Ilankoon et al. 2022). As the volume of EOL waste as raw material is limited and technology for economic feasibility is rarely available, hardly grabs the attention of the metallurgical industry, unlike primary resources. Hence, sustainable REM waste management and recycling process technology for EOL scrap need of the hour and need to be developed.

Unlike EOL scrap, industrial waste like red mud, blast furnace slag, coal mines, and coal byproducts volume or input raw material are not scarce but the efficient industrial-grade technology for REM recovery (Deng et al. 2022). Not only technology but also the scarcity of precise data regarding REM content in the above industrial waste product, the exact volume of waste generation, and the lack of country-wide data accelerated the concern. The current review also highlights the abundance of REM wealth in the industrial waste whence, relevant data like REM content on individual industrial waste, the volume of waste being generated, and the fate of generated waste are hardly available which is the rudimentary stage for the policy or process development. Though some of the researchers report plausible economic feasibility, an equally opposite conclusion also hinders industrial recovery interest (Innocenzi et al. 2016b; Joseph et al. 2019; Deng et al. 2020; Ilankoon et al. 2022). Through, dedicated research and precise data on the context of industrial-scale REM recovery and economic impact can address the concern. The current investigation also reviewed the reported review literature, and the details are summarized in Table 1. Investigation of the literature and reported review (Table 1) indicated that extensive research on the integrated sustainable valorization of REM from anthropogenic waste lacks the following aspect, i.e., (i) quantitative estimation of volume waste generated, (ii) discussion on the prudent potential of anthropogenic waste for addressing CRMs issue, (iii) possible recommendation for bridging the gap among industry requirement and policy deficit, and (iv) lack of recommendation addressing research development and real-life REM criticality issue. The significance and objective of the current review are highlighted below.

Table 1.

Summary of reviews covering the REM bearing waste over literature

| REM bearing waste and issues addressed | The focus of the reported review | Significance of the review | Weakness of the review | Reference |

|---|---|---|---|---|

|

Phosphogypsum Red mud Mine tailings, Coal ash and incinerator ash Metallurgical slags |

Waste specific investigation, rather REM selective Zero waste discharge has significantly been focused |

Discussion on the importance of the zero-waste valorization of REM-bearing waste The concept for zero-waste valorization is specific to industrial waste like phosphogypsum, red mud, mine tailings, coal ash, incinerator ash, metallurgical slags Extensively discussed on |

EOL like REM-bearing waste has not been taken into consideration Lack of quantitative estimation of REM bearing waste industrial waste generation The precise content of REM in those wastes has hardly been considered |

Binnemans et al. (2015) |

|

EOL REPM Ni-MH batteries Phosphorous powder, CRT phosphors Glass polishing powders, FCC Optical glass |

Waste-specific investigation, rather REM selective Life cycle assessment and the possibility of REM recycling have been discussed |

Extensive discussion on EOL REPM by all possible techniques like pyrometallurgy, hydrometallurgy, and gas-phase extraction Discussed (but not extensively) Ni-MH batteries, phosphorous powder, CRT phosphors, Glass polishing powders, FCC, and optical glass |

Unlike EOL REPM discussion over Ni-MH batteries, phosphorous powder, CRT phosphors, Glass polishing powders, FCC, and optical glass are not extensive Life cycle assessment and potential of REM recycling are introductory only Lack of quantitative estimation for potential substitute of primary resources |

Binnemans et al. (2013) |

|

NdFeB magnets Ni-MH batteries Lighting Catalysts |

Light REM only, rather than REM in general addressed | Review over published literature related to light REM recovery | Quantitative data, policy, and environmental aspects have hardly been discussed | (Omodara et al. 2019) |

|

Application of the hydrometallurgical process for recovery of REM from REM-bearing waste Significance of pretreatment before the hydrometallurgical process for recovery of REM |

Discussed only process-specific approach rather than REM focused though application intended for REM recovery |

Various process for REM recovery from secondary resources recycling has been discussed Mainly discussion covers possible laboratory-scale REM recovery processes |

Lack of data-based estimation, policy, and environmental aspects not addressed The review focused on separation and recovery only |

(Swain and Mishra 2019) |

|

Critically of supply chain Waste management challenges Global supply and demand scenario |

Complexity REM separation and purification Lack of large-scale research and development to develop High operational costs and Supply chain pressures |

Highlighted practical problems industries are encountering Discussion on supply chain criticality, policy, and process Highlighted lack of research and development Discussion over irreplaceability of REM in the industry |

No discussed on specific industrial requirements and recycling prospects Hardly recommended how the industry could get attracted Hardly discussed supply chain mitigation and role of industry |

Ilankoon et al. (2022) |

|

Spent NiMH battery Coal ash Spent fluorescent lamp Phosphogypsum Red mud |

Focussed waste specific rather than REM selective |

Focussed on hydrometallurgy process used REM recovery only Explored possibility of REM extraction and separation chemistry in hydrometallurgical recovery Review over basically two reviews reported elsewhere by Binnemans et al. (2013, 2018) The importance of Korean resources circulation society has been highlighted |

Policy aspect of global resources circulation society has not been discussed but only focused on Korea Number of articles published discussed rather challenges, opportunities and quantitative estimation of waste and REM wealth locked in those waste Very similar discussion to review reported by Binnemans et al. (2013, 2018) |

Jyothi et al. (2020) |

|

Spent fluorescent lamp NiMH batteries Spent CFL Red mud Phosphogypsum Magnetite ore slag |

Focussed primarily on REM recovery by hydrometallurgy |

Focussed mostly on leaching and solvent extraction process used for REM recovery only Explored possible REM extraction and separation chemistry in hydrometallurgical recovery |

Though entitled as REM recovery from consumer electronics scrap but also covers different secondary resources Other process like pyrometallurgical and chemical metallurgy process hardly been discussed |

Akcil et al. (2021) |

| Both primary and secondary resources discussed very briefly |

Focussed on bioleaching of REM from primary and secondary resources Discussed bioleaching mechanism and process |

Extensively discussed bioleaching and bioleaching process for REM recovery rather specific waste | Lack discussion on diversified process and technique rather absolutely focused on bioleaching only | Rasoulnia et al. (2020) |

-

(i)

Reviews published elsewhere (Binnemans et al. 2013, 2018) in the field are almost a decade old, considering rapid waste generation and sustainable development an update in the information is essential, hence, reviewed over recent and if any advances developments.

-

(ii)

Fundamental difference and classification of waste in term of REM-bearing EOL and industrial waste has been introduced, and the broader characteristics of waste from REM content and the amount of waste generation which has been lacking in the literature has been discussed.

-

(iii)

Essentially potential of each waste in the ideal circular economy scenario has been highlighted and their possible contribution to resolving the supply chain criticality of REM has been analyzed.

-

(iv)

Status of technology and drawback associated with efficient management of REM bearing waste and constraint for REM circular economy has been discussed.

Sustainable valorization of REM from anthropogenic waste: challenges

To learn well challenges and opportunities associated with sustainable valorization of REM from anthropogenic waste, three important aspects of REM, i.e., (i) production of REM from primary resources, mineral reserve, and its distribution, (ii) current demand, estimated future demand for REM and its distribution according to end-use and (iii) possible substitute from a technology efficiency perspective and status of recycling of each category need to be well understood. All the explained aspects are discussed below individually.

Global mine production, reserve, and distribution

Detailed analysis of REM oxide worldwide mine production during 2010–2020, country-wise production for the year 2020, and country-wise reserve data known by the year 2020 is presented in Fig. 2. From the U.S. Geological Survey (USGS) data on the global mine production of REM oxide for the year 2010–2020 is summarized in Fig. 2a and indicates 130, 130, 110, 110, 123, 124, 129, 130, 190, 220, and 240 thousand tons respectively (Gambogi 2020; 2021). The same USGS also reported global REM oxide mines production data for the years 2015–1920 were 124, 129, 130, 190, 220, and 240 thousand tons, respectively (Gambogi 2018). The mass of countrywide REM oxide mine production depicted in Fig. 2b for the year 2020, indicates China is the largest producer of REM oxide production accounting for 58% of world mine production amounting to 140 thousand tons.

Fig. 2.

a Global REM oxide mine production during the 2011–2021 decade, b Countrywide REM oxide production during the year 2020, and c Country-wide REM oxide reserve distribution known by the year 2020 (Gambogi 2020; 2021)

The same Fig. 2b indicates from a supply chain perspective worldwide 58, 15.5, 12.3, and 7% of REM were produced by China, the USA, Myanmar, and Australia, respectively (https://www.nrcan.gc.ca/2021), accounting for 140, 38, 30, and 17 thousand tons. The data presented in Fig. 2b indicates not only does China monopolize the REM oxide production but also approximately 93% of worldwide REM oxide production is concentrated in those four countries only. Global REM oxide reserve data known by the year 2020 presented in Fig. 2c indicates Chinese primary resources REM oxide reserve is 44 million tons accounting for 38% of worldwide REM oxide reserve. The next four major REM oxide reserve-holding countries are Brazil, Vietnam, Russia, and India accounting for 19%, 18%, 10%, and 6% respectively. The major reserve of REM oxide accosting 91% of the worldwide reserve is concentrated in the above five countries only. The rate of global REM oxide production for the 2011–2020 decades and projected demand for the near-term future between the year 2021–25 indicates REMs are at a critical metal bottleneck in the global supply chain. The dominance and monopoly of China on reserve, production, import, and utilization of value-added products put global competitiveness and better business incentives in jeopardy (Wübbeke 2013; Golev et al. 2014).

REM current, future demand, and its distribution according to end-use

Detailed analysis of projected REM oxide demands for the years 2021–2025, distribution of REM oxide consumption by the end uses of the year 2019, and distribution of projected REM oxide consumption by the end uses by the year 2018 has been analyzed and depicted in Fig. 3. REM oxide consumption and distribution of projected REM oxide data were collected from web references of https://www.statista.com/ (Garside 2020; 2021), and https://www.nrcan.gc.ca/ (https://www.nrcan.gc.ca/2020). Although when the manuscript was revised the REM oxide consumption data has been updated but reported values are different and observed discrepancies mainly because of Coronavirus disease (COVID-19) related interruption during the year 2020. Because the COVID 19 is a one-of-its-kind disruption it may not reflect the usual trend hence, the updated data has not been considered for the current analysis. Projected REM oxide demand presented in Fig. 3a for the years 2021–25 are 242, 256, 271, 287, and 305 thousand tons, respectively (Garside 2020). REM oxide demand data indicates the exponential rate of growth between the year 2016–2025. Figure 3b depicts the distribution of REM oxide consumption by end uses for the year 2019. The figure indicated that in the year 2019, 38% of global REM production was used for manufacturing rare earth permanent magnets (REPM) signifies the single largest consumption (Garside 2020; 2021). Followed by REPM, catalyst, glass polishing industry, metallurgical industry, battery manufacturing, and phosphors producing industry consumed 23, 13, 8, 9, and 4% REM oxide of global production. The same was 5% for ceramic, pigment, and glaze manufacturing.

Fig. 3.

a Projected global REM oxide demand for the year 2022–2025, b Distribution of REM consumption in the year 2019, and c projected sector-wise REM oxide distribution by the year 2028 (Garside 2021; https://www.nrcan.gc.ca/, 2021, 2022; https://www.statista.com/)

Figure 3c depicts the forecasted distribution of REM oxide consumption by end uses for the year 2028. The forecasted consumption indicates the market share of REM oxide for REPM could reach 68% of global REM oxide production, which is 79% growth only for REPM just in 8–9 years (https://www.statista.com/2022). All other applications like the catalyst, glass polishing industry, metallurgical industry, battery manufacturer, and phosphors producing industry consumption could be only 21%. On the contrary, the replaceability of REM oxide with other materials either compromises desired functional characteristics or is expensive, hence, industrial substitution in the near-term future is hardly an option. Hence, the valorization of REM oxide-bearing secondary resources like anthropogenic waste could be a sustainable and much-needed alternative. The forecasted exponential growth of REM oxide consumption is mainly driven by rare earth permanent magnets (REPM). Among all (end users) EOL REM bearing products such as permanent magnets, fuel cracking catalysts (FCC), battery alloy, metallurgical alloy, and phosphorous, are fundamentally feasible for valorization. Other (end users) EOL REM bearing products like glass polishing and ceramics may be hard for valorization. Permanent magnet production not only consumes the largest share of global REM oxide produced but also progressively going to consume a higher % and the largest share of global REM oxide to be produced.

REM bearing anthological waste and status of recycling

A detailed list of REMs bearing EOL urban waste has been summarized in Table 2. Table 2 shows in a vast range of products REMs are being used for their superior functionality. The table also indicated most of the REM bearing EOL urban waste is mainly associated with electronics waste (e-waste). The recent report on the global e-waste monitor 2020 reported in the year 2019 is mainly 17.4 Mt of small equipment, 13.1 Mt of large equipment, 6.7 Mt of screens and monitors, 4.7 Mt of small IT and telecommunication equipment, and 0.9 Mt of lamps were scrapped (Forti et al. 2020). The same report also indicated that from 2014 to 2019, e-waste comprising large equipment, and lamps and small equipment increased by 5%, and 4%, respectively (Forti et al. 2020). Global distribution for that e-waste generated per capita for the year 2019 across the content is as follows; 13.3 kg in the Americas, 16.3 kg in Europe, 16.1 kg in Oceania, 5.6 kg in Asia, and 2.5 kg in Africa (Forti et al. 2020). In the absence of REM bearing EOL waste data in particular from the above four sets of information, i.e., Table 2, amount of e-waste generated, rate of increasing e-waste generation, and per capita e-waste generation around the globe, massive EOL waste generation is indicated. All the information on e-waste together suggests that the EOL life waste is not only an environmental problem but also a prudent secondary resource for the various metal in general and REM in particular. From the listed urban waste in Table 2, it can be reasonably concluded that through proper waste management like collection strategy, segregation, and transportation strategy followed by valorization, the REMs being scrapped along with EOL life products can be brought back to the material flow stream. From an economy and process development perspective, a quantitative understanding of REM content on the listed EOL product is essential.

Table 2.

Summary of major EOL urban waste bearing REMs, data borrowed from U.S. Department of Energy report on REMs (Scott and Kolker 2019)

| REMs | Major EOL urban waste |

|---|---|

| Scandium | TVs, fluorescent and energy-saving lamps |

| Lanthanum | Hybrid engines, metal alloys |

| Cerium | Catalysts, metal alloys |

| Praseodymium | Magnets |

| Neodymium | Catalysts, hard drives in laptops, headphones, hybrid engines |

| Promethium | Watches, pacemakers |

| Samarium | Magnets |

| Europium | Red color for television, computer screens |

| Terbium | Phosphors, permanent magnets |

| Dysprosium | Permanent magnets, hybrid engines |

| Erbium | Phosphors |

| Yttrium | Red color, fluorescent lamps, ceramics, metal alloy agent |

| Holmium | Glass coloring, lasers |

| Thulium | Medical x-ray units |

| Lutetium | Petroleum catalysts (FCC) |

| Ytterbium | Lasers, steel alloys |

| Gadolinium | Magnets |

Table 3 lists the content of REMs in the various anthropogenic waste. Table 3 exhibits, individual REM in industrial waste varies significantly, which is purely contributed by the geological origin of the minerals and mining products for either metal production purposes or energy production purposes. The same table also indicates that the red mud, iron, and steel industry slag, coal mines, and coal ash scraps reasonably fair amount of REM in the context of the critical nature of REMs in the supply chain. REM content is summarized in Table 3 from various resources reasonably concluded that red mud, steel making slag (SMS), BFS, electric arc furnace dust (EAF), ladle furnace slag (LFS), coal mines, and coal fly ash scraps 0.5–1.7 kg/ton, 12.14–11.94 kg/ton, 127–145 kg/ton, 41.56 kg/ton, 62.31 kg/ton, 0.29–1134 kg/ton of REM respectively. Literature investigation indicated that globally that 4 billion tons of red mud have been stockpiled by 2020 and the same is being generated, annually between 120 and 150 million tons worldwide that mainly get stockpiled (Swain et al. 2020b). USGS has reported in the year 2020, globally 310–380 million tons of iron slag and 180–270 million tons of steel slag were generated (Ober 2021). USGS also reported in the year 2021 global iron slag and steel slag production was estimated to be 340–410 million tons and 190–280 million tons, respectively (Tuck 2022). Similarly, Harris et al. have reported, that in the year 2017 worldwide 1.1 billion tons of coal combustion products that are reasonable can be considered as coal fly ash was generated (Harris and Feuerborn 2020). Table 3 indicates from a quantitative REM content perspective the REM bearing EOL urban waste and industrial waste poses two different sets of challenges for REM value recovery. In the EOL urban waste usually, REM content is at a higher concentration side, and only selective REM elements are present. Selective REM present could be relatively easier for separation and purification and efficient valorization. Whence, in industrial waste usually REM content is at the lower concentration side and contains the whole range of REM at varying concentrations. Because of similarities in chemical properties of REM, when present all together in the industrial waste, the recycling process needs significant technological effort for the separation and purification of individual REM in the valorization process. Table 3 indicates both kinds of waste pose two distinct sets of challenges for the valorization of REM bearing anthropogenic waste.

Table 3.

Rare earth metal content in various anthropogenic waste (adapted for typical studies reported in the literature elsewhere)

| REMs | REM wt % | REM mg/kg−1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| REPM Magnet NdFeB (Zhang et al. 2020b) |

Battery (Lie and Liu 2021) |

FCC Catalyst (Zhao et al. 2017; Sposato et al. 2021) | Phosphorous (Yurramendi et al. 2019) | Red Mud (Swain et al. 2020b) | Slags (Kasina and Michalik 2016) | Coal Mine (Zheng et al. 2017) | Coal Fly Ash (Franus et al. 2015) | ||||

| Steel Making Slag (SMS) | Blast Furnace Slag (BFS) | Electric arc furnace dust (EAF) | Ladle furnace slag (LFS) | ||||||||

| Sc | – | – | – | 121 ± 10 | 1.0 | 9–11 | 1.0 | 3.0 | – | 7–45 | |

| Y | – | – | – | 6.29 | 75.7 ± 9.6 | 3.9–4.2 | 34.8–36.6 | 4.1 | 13.8 | 0.2–575 | 17.9–73.2 |

| La | 0–1.58 | 8.96 | 1.5–1.92 | 0.90 | 114 ± 15 | 2.8–3.8 | 24.5–25.9 | 9.4 | 12.7 | 0.2–32.9 | 15.5–81.7 |

| Ce | – | 2.7 | 0–0.29 | 0.74 | 368 + 68 | 4.4–3.8 | 50.3–58.2 | 18.1 | 26.3 | 0.13–255 | 30.7–172.5 |

| Pr | 0.07–7.1 | – | – | – | 28.0 ± 3.9 | 0.61–0.54 | 5.98–6.71 | 2 | 3.4 | 0.005–16.7 | 3.3–20.51 |

| Nd | 10–31 | 2.7 | – | – | 98.6 ± 7.0 | 2.3–2 | 23.1–27.1 | 8.4 | 12.4 | 0.05–86.2 | 12.7–81.3 |

| Sm | 0–0.77 | – | – | – | 21.3 ± 2.3 | 0.4–0.32 | 4.7–5.35 | 0.9 | 1.8 | 0.1–28.9 | 2.8–17.0 |

| Eu | – | – | – | 0.43 | 5.0 ± 0.9 | 0.07–0.08 | 1.44–1.57 | 0.15 | 0.31 | 0.003–8.16 | 0.56–3.81 |

| Gd | 0.02–1.51 | – | – | 0.14 | 22.0 ± 1.9 | 0.42–0.41 | 4.75–5.35 | 0.8 | 1.6 | 0.02–42.1 | 2.85–14.65 |

| Tb | 0–0.41 | – | – | 0.32 | 3.5 ± 0.6 | 0.06–0.07 | 0.82–0.9 | 0.1 | 0.2 | 0.003–3.52 | 0.45–2.4 |

| Dy | – | – | – | – | 16.7 ± 0.7 | 0.4–0.31 | 4.86–5.26 | 0.9 | 1.6 | 0.01–37.3 | 2.61–12.18 |

| Ho | – | – | – | – | 3.9 ± 0.6 | 0.08–0.09 | 0.91–1.03 | 0.1 | 0.3 | 0.003–7.31 | 0.59–2.58 |

| Er | – | – | – | – | 13.5 ± 1.8 | 0.27–0.24 | 2.98–3.2 | 0.5 | 0.8 | 0.02–19.4 | 1.79–7.41 |

| Tm | – | – | – | – | 1.9 ± 0.3 | 0.03 | 0.45–0.5 | – | 0.1 | 0.001–2.24 | 0.27–1.07 |

| Yb | – | – | – | – | 14.0 ± 1.9 | 0.26–0.21 | 2.76–3.09 | 0.3 | 0.7 | 0.0112.9 | 1.80–6.74 |

| Lu | – | – | – | – | 2.4 ± 0.3 | 0.04 | 0.41–0.46 | – | 0.1 | 0.002–1.84 | 3–1.03 |

| Total | 10.09–42.37 | 14.36 | 1.5–2.21 | 8.82 | 909.3 | 12.14–11.94 | 127–145 | 41.56 | 62.31 | 0.29–1134 | 101–543 |

Valorization of REM bearing anthological waste: Challenges

Despite explained importance and significance, the current global REM recovery status, resources recycling policy, and REM bearing anthropogenic waste exploitation scenario are purely miserable and neglected. Graedel et al. have reported that < 1% of REM-bearing waste is recycled, and even after decades, the rate of recycling for REM or REM valorization from secondary resources stands at no charge (Graedel et al. 2011). A recent report by U.S. Geological survey on Mineral commodity summarizes the recycling rate for REMs are limited (Cordier 2023). Chinwego et al. have reported a maximum REM recycling rate of 20% could be accomplished after a decade provided efficient recovery and a continuous growth trend could be achieved (Chinwego et al. 2022). Though the thousand tons of REM oxide flows to EOL and apparently to the waste stream, in the absence of technology, policy, and process, the critical REM gets scrapped. The amount of REM in EOL scraps could provide the opportunity to overcome the REM critical supply chain bottlenecks through proper valorization. Currently, valorization REM bearing EOL scrap is associated with several challenges like, (i) technology for recovery from EOL scrap is not well developed, (ii) Collection of urban waste and its management is not well organized and streamlined, (iii) several nations does not have a policy in place for recycling, and (iv) scarcity of data for the material flow of REM bearing EOL scrap. From the report of Graedel et al., it can reasonably be concluded that most of the REM bearing waste mainly follows the cradle (mines) to grave approach, rather than the cradle-to-cradle waste management and valorization approach (Graedel et al. 2011). Challenges for REM bearing EOL urban waste and industrial waste are not the same or similar, rather district and different. Challenges associated with valorization and the circular economy of REM from anthropogenic waste are summarized below.

-

(i)

Lack of precise data regarding the material flow of REM bearing EOL urban waste, collection strategy, segregation, and transportation strategy as a raw material for the recycling industry, and policy direction to bring back a certain amount or % of REM from EOL scrap. On the contrary industrial waste, collection, segregation, and transportation do not as issues as those that are readily available at the production site abundantly. Industrial waste faces precise assessment and data mining challenges for REM content in waste, the volume of REM bearing waste generation, and policy issues.

-

(ii)

The lack of industrial-scale process for selective recovery of REM or REM valorization, Lack of strategy for bringing back the REM from either waste to raw material stream or circular economy is equally challenging for both the waste.

-

(iii)

Available information, regarding waste generation, stockpiled, and REM content in respective waste are haphazard and literature reports are quite speculative and rather precise. The absence of waste-wide, country-wise, and industry-wide accurate and precise quantitative data related to REM bearing waste generation makes it more tedious to understand the REM worth in the anthropogenic waste.

-

(iv)

Serious efforts for REM value recovery on an industrial scale from anthropogenic waste. The literature on REM recovery from anthropogenic waste is limited which is not only counterproductive for REM but also a huge challenge for massive solid waste management challenges posed by this anthropogenic waste.

-

(v)

Bench-scale to industrial-scale REM recovery from anthropogenic waste is the biggest challenge needed not only to be addressed to CRMs supply chain issue but also challenges posed by these solid waste management issues.

Review of REM valorization technologies from anthropogenic waste

Several research reports have indicated that anthropogenic waste like spent REPM, spent batteries, phosphor powders, red mud, BFS, coal mines, and coal byproducts can be a sustainable alternative to primary resources. Hence, the current investigation reviews over challenges and opportunities for the sustainable valorization of REM from anthropogenic waste like (i) spent REPM, (ii) spent batteries, (iii) spent tri-band REM phosphors, (iv) alumina industry residue red mud, (v) BFS and (v) coal mines, and coal byproducts. Various aspect of sustainable valorization of REM from anthropogenic waste and associated challenges and opportunities has been discussed thoroughly in the below sections.

REM valorization through urban mining

REM recovery from EOL permanent magnets

Rare earth permanent magnet (REPM) materials can generally categorize into two types, i.e., high-performance permanent magnets mainly made from magnetic material based on Sm2(Co, Cu, Fe, Zr)17 otherwise called SmCo magnet and NdFeB permanent magnets primarily made from (Nd, Pr)2Fe14B (Goll and Kronmüller 2000; Wang et al. 2020). The NdFeB permanent magnet contains 30–40% REMs, of which 15–30% is Nd along with 2–5% Dy, Tb, and Gd, and the rest are Fe and B. In the NdFeB permanent magnet, Fe and B constitute up to 60–70 where B hardly up to 1% (Önal et al. 2015; Yang et al. 2016). Similarly, high-performance permanent magnets contain mainly Sm and with an atomic ratio of 1:5 or 2:17 depending on the requirement of magnetic property and operating temperature (Zhang et al. 2018; Palasyuk et al. 2021). Worldwide demand for NdFeB permanent magnet from 2018 to 2022 was 6.7 kt, 6.8 kt, 8.35 kt, 11.73 kt, and 16.14 kt, respectively (https://www.statista.com/2023). Worldwide production of NdFeB permanent magnet production in the year 2017 was 170 kt which includes high-performance permanent magnets. In the same year, the high-performance permanent magnet worldwide production was 60 kt. Out of worldwide 170 kt production, ~ 90% of NdFeB permanent magnet production had come from China alone which is 150 kt. Globally, TDK, Hitachi Metals, Shin-Etsu Chemical, and VAC are the leading producer of high-performance NdFeB permanent magnet accounts, with 50% of the market share (Markets June 2018). Although mid or low-performance permanent magnets dominate the consumer market emerging applications of permanent magnets for various applications in new energy vehicles, robots, and energy-saving household appliances projected demand more for high-performance NdFeB permanent magnets (Matizamhuka 2018). Whereas globally, China is the largest REPM producer owing to its availability of primary resources and as well as superiority production facilities. In the year 2017, China had produced 150kt of NdFeB permanent magnets mainly in the mid and low-end products segment, which account for 90% of (Markets June 2018) global productions (https://www.stanfordmagnets.com/).

Considering resource scarcity, and Chinese monopoly over REM, to develop the competitive advantage of the REM consuming industry, REM recovery from the end of life (EOL) REPM can be a lucrative option that can address the above issues simultaneously. This EOL REPM is a rich source of REMs such as Nd, Sm, and other REM although comparatively smaller content than Nd, and Sm. Besides, in the REPM manufacturing process, about 20–30% of process waste is generated and rejected as industrial sludge (Bian et al. 2015; Li et al. 2021). In the REPM manufacturing process, the aforesaid 20–30% get rejected during sequential vacuum melting, atomization, and quenching process which are difficult to reutilize under the given process design. These REPM manufacturing industrial sludge can also be rich secondary resources for REM recovery. Considering the criticality of supply chain scarcity, various REM valorization technique from REPM has been reported. The valorization REPM process commonly follows dismantling, physical separation for accessing the REPM from various discarded equipment, and a pretreatment process followed by the valorization process.

Physical separation of REPM is the primary difficulty that has been successfully addressed by Hitachi, Ltd., Tokyo, Japan. Hitachi, Ltd., has developed a complete integrated physical separation process for the separation of HDDs and compressors of air conditioners from discarded equipment. In the reported process by Hitachi, Ltd., before the pretreatment, for physical separation of REPM, the automated mechanical dismantling of the components from hard disks and compressors motors/ generators has been employed. A similar, valorization approach for recovery REM from MRI (magnetic resonance imaging equipment) has also been outlined (Haque et al. 2014). Hitachi has also developed a process to recover the NdFeB-based magnets from HDDs and compressors of air conditioners using a combination of vibration, demagnetization, and manual collection. Satio et al. have reported valorization of Nd from EOL NdFeB magnets through glass slag formation where the EOL NdFeB magnets melted with BO3 in an induction furnace where Nd gets completely slagged. From the Nd bearing slag, recovery of Nd through sequential sulfuric acid leaching followed by precipitation using sodium sulfate has been proposed (Saito et al. 2003, 2006). The same author also reported Sm recovery from Sm–Co magnets through glass slag formation with 99% efficacy (Tetsuji Saito et al. 2003; Saito et al. 2005). Takeda et al. have reported a scrap-to-scrap integration recovery process where Nd was recovered from NdFeB magnet through alloying with Mg at high temperature followed by hydrothermal treatment (Takeda et al. 2006). Effectively, Nd from the NdFeB magnet was alloyed with Mg as Nd-Mg followed by hydrothermal treatment using NaOH, H3PO4, HCl, and H2SO4 using both high temperature and pressure (Itakura et al. 2006). As reported above though pyro-metallurgical processes have been used dominatingly, still, pyro-metallurgical processes use subsequent processes like hydrogenation, oxidation, chlorination, liquid molten extraction, and electrolysis downstream. Though various pyro-metallurgical processes have been reported, none is fully developed for commercial exploitation. Alternatively, hydrometallurgical processes for the valorization of REPM have been reported in the literature (Binnemans et al. 2013; Sinha et al. 2017). Sinha et al. have reported the recycling of Sm–Co magnet by hydrometallurgical route, where a sequentially demagnetization-mineral acid leaching-purification process was followed (Sinha et al. 2017). In the reported process by Sinha et al., the magnet was demagnetized by roasting at 1123 K followed by leaching at the optimized conditions using 4 M HCl, and 100 g/L pulp density. Quantitative leaching of Sm and Co has been achieved (Sinha et al. 2017). Sn/Co from the leach liquor was separated by solvent extraction with Cyanex 572. Despite several developments, direct re-use of the magnets or alloys seems impossible, and substantial technological challenges exist for REMs recovery (Binnemans et al. 2013). Kaya et al. have reported NdFeB permanent magnet recycling by an alternate route sequential griding, sieving, acid baking, calcination, water leaching to recover Fe2O3 and purify REM and finally REM recovery by ultrasonic spray pyrolysis (Kaya et al. 2021). Chowdhury et al. analyzed the sustainable recycling aspect of NdFeB permanent magnet from a techno-economical-environment perspective (Chowdhury et al. 2021). Chowdhury et al. have investigated the techno-economical aspect of REM recovery by sequential acid-free Cu(NO3)2 leaching followed by REM recovery as REM oxalate and finally REM oxide valorization by calcination. Apart from process development studies for REM recovery from EOL permanent magnets, several authors also reported fundamental and lab-scale investigation by various techniques has been summarized in Table 4 below. Our literature investigation indicated recycling of NdFeB permanent magnets by hydrometallurgical route relatively extensive though pyrometallurgical and chemical metallurgy route is extensive and diversified. Table 4 represents comprehensive discussion only as it has limited implication on current review rather fundamental investigation. As extensive discussion over fundamental studies for REPM recycling is not scope of the study, it has been kept comprehensive rather extensive and focused on hydrometallurgical route.

Table 4.

Summary of the various reported fundamental and lab-scale investigations by various techniques in the open literature

| Sources/type of EOL Permanent Magnet | Lixiviant used | Process lowed by leaching to recover REM | Advantages | Disadvantages | Reference |

|---|---|---|---|---|---|

| Automotive industry | H2SO4 | Disk milling → ball milling → oxidative roasting → selective acid leaching → Pure REE product | Mechano-chemical process, simple route for getting 98% REM | High-temperature process, not selective for individual REM | Önal et al. (2015) |

| NdFeB permanent magnet | CH3COOH | Pulverization → Organic acid leaching → leaching kinetic | Organic acid utilization and leaching kinetic can provide insight for further studies | Limited to leaching kinetic only, up to 80% leaching achieved | Behera and Parhi (2016) |

| NdFeB permanent magnet | CH3COOH | Demagnetized through roasting → Crushing and grinding → Organic acid leaching → Fe selective precipitation → REE oxalate recovery | Organic acid utilization and leaching kinetic can provide insight. Simple leaching and precipitation route | Limited to systematic leaching kinetic and Fe precipitation, limited with REM precipitation study | Niskanen et al. (2022) |

| NdFeB permanent magnet | HCl | Pulverization → corrosion induced by NaCl → HCl Leaching for selectivity of REM → REM purification by NH4Cl and Cyphos IL 101 | Close look process, ionic liquid utilization | Only mg scale investigation, Corrosion induces take 1 week | Kitagawa and Uemura (2017) |

| NdFeB magnet swarf | HCl, H2SO4 | Crushing and grinding → leaching with HCl → solvent extraction with Cyanex302 → acid stripping | Nd-DY separation, stripping efficiency | Poor selectivity for REM stripping, Limited investigation | Padhan et al. (2017) |

| NdFeB magnet | HNO3 |

Demagnetization → crushing → acid leaching → Hollow Fibre Membrane (HFM) non-dispersive solvent extraction |

Implementation of HFM non-dispersive solvent extraction | REM selectivity is still challenging | Yadav et al. (2018) |

| NdFeB Magnet | Glycolic, Maleic, and Ascorbic Acids | Hydrogen decrepitated → roasting → sieving → organic acid leaching → solvent extraction (TBP, D2EHPA, Cyanex 272, and 923 → acid stripping | Organic acid leaching, 95% leaching by organic acid, Efficient extraction by commercial extractant D2EHPA | Selective isolation of REM not addressed | Gergoric et al. (2019) |

| NdFeB Magnet | HCl + NH4Cl | HCl + NH4Cl leaching → Fe precipitation → ionic liquid extraction (trihexyl (tetradecyl) phosphonium chloride) → Oxalic acid precipitation | Simple route, only three stage process | Purity aspect not addressed, studied using only few grams in lab-scale | Vander Hoogerstraete et al. 2014) |

| NdFeB Magnet | Co-Chlorination and water | Chlorination roasting → Water leaching → Fe precipitation → REM purification | Simple roasting and water leaching | Limited to water leaching and Fe precipitation | Wu et al. (2023) |

| NdFeB Magnet | HF | HF leaching → selective precipitation of REM → electrodeposition of iron | No waste generation | Hydrofluoric acid was highly toxic and environmentally unfriendly | Yang et al. (2020) |

From a review of the literature and discussion in the current inferred that recycling of permanent magnets usually follows the following stages, i.e., (i) demagnetization of REPM, (ii) size reduction by crushing, (iii) pulverization for getting a superior surface area that accelerates subsequent leaching, (iv) roasting or oxidative roasting, (v) mineral acid or organic acid leaching, (vi) solvent extraction by conventional solvent extraction using commercial extractant or solvent extraction by ionic liquids, (vii) REM recovery either by direct precipitation stripping using oxalic acid or mineral acid stripping followed by precipitation by oxalic acid and (viii) Finally, REM materialization as REM oxide (RE2O3) from REM oxalate. In some cases, further value addition of recovered REM oxalate or REM oxide by subsequent investigations has also been reported.

The leaching chemistry for NdFeB permanent magnet by oxidation roasting, mineral acids, and organic acid can be explained using the Equations given below. The chemistry associated with oxidative roasting NdFeB permanent magnet followed by commonly used mineral acids (H2SO4, HCl, and HNO3) leaching can be explained using Eqs. 1 to 4 given bellow (Emil-Kaya et al. 2023). Leaching chemistry for NdFeB permanent magnet with commonly used mineral acids (H2SO4, HCl, and HNO3) without roasting can be explained using Eqs. 5 to 7 given bellow. Similarly, leaching chemistry for NdFeB permanent magnet using Organic acids like, Acetic acid, Ascorbic acids, Glycolic acids, and Maleic acid can be explained using chemical Eqs. 8–9 given below (Liu et al. 2019).

| 1 |

| 2 |

| 3 |

| 4 |

| 5 |

| 6 |

| 7 |

| 8 |

| 9 |

In the above Eqs. 8–9, the OrgH and Org− are the organic component and cationic organic component, respectively.

The generalized process flowsheet represented in Fig. 4 implies that different mineral acids (H2SO4, HCl, and HNO3) have been employed for REPM leaching and followed by mineral acids (H2SO4, HCl and HNO3) leach liquor, the REM has been recovered by different commercial extractants like D2EPHA, PC 88A, and Cyanex 272. Hence, more generalized solvent extraction chemistry for REM recovery from sulfate, chloride, and nitrate media, respectively, using commonly used commercial extractant D2EPHA, PC 88A, and Cyanex 272 can be explained using the Eqs. 10–12 given below (Swain and Otu 2011).

| 10 |

| 11 |

| 12 |

Fig. 4.

Generalized flow sheet employed for REM recovery from rare earth permanent magnet (Saito et al. 2003, 2005; Takeda et al. 2006)

In Eqs. 10–12, the double over bar on (HL)2 and single over bar on L− species represent dimeric HL and monomeric L− species, respectively. The HL represents cation exchange solvents such as D2EPHA, PC 88A, and Cyanex 272.

To make it straightforward and for easier understanding, more simplified solvent extraction chemistry for REM from sulfate, chloride, and nitrate media, respectively, using commonly used commercial extractant Cyanex 272 (for representative case only) can be explained using the Eqs. 13–15 given below. In Eqs. 13–15, the double over bar and single over bar represents the dimeric Cyanex 272 and monomeric Cyanex 272 species, respectively. In Eq. 13–15, the Cyanex 272 can be replaced with other extractants like D2EPHA and PC 88A.

| 13 |

| 14 |

| 15 |

Precipitation stripping of REM from explained loaded extractants in Eqs. 10–12 using oxalic acid and further valorization of REM oxalate to REM oxide can be explained using Chemical Eqs. 16–17 given below.

| 16 |

| 17 |

Based on the above studies the entire REPM recycling process flow diagram can be summarized as presented in Fig. 4. In the REPM reclining process like other e-waste recycling processes, the physical separation of EOL equipment is essential for the initial separation of metal, nonmetal, and reusable and to access the target material for recycling. Followed by the isolation, the isolated REPM can be recycled either by hydrometallurgical process or pyrometallurgical process. The generalized process flowsheet presented in Fig. 4 indicates the employed processes are mainly hybrid processes. Whereas several authors interpret the hybrid process either as a pure pyrometallurgical process or a pre-hydrometallurgical process, can be interpreted as inaccurate.

Based on Fig. 4, rather the process flowsheet should be classified as pyrometallurgy dominated hybrid process and as hydrometallurgy dominated hybrid process. In the pyrometallurgical-dominated hybrid process, the isolated REPM is either glass slagged or alloyed using various reagents, then the glass slag or alloy passes through the hydrometallurgical process. Similarly, In the hydrometallurgical dominated hybrid process, the isolated REPM is roasted or calcinated for demagnetization followed by the hydrometallurgical process being followed. In either process after glass slagging or alloying or demagnetizing the processed material gets leached mainly using mineral acids like HCl, HNO3, or H2SO4. Then the leached metal from leach liquor was purified mainly through solvent extraction using a selective extractant. Finally, from purified/separated metal solution either metal salt or metals recovered through precipitation or metallization, respectively.

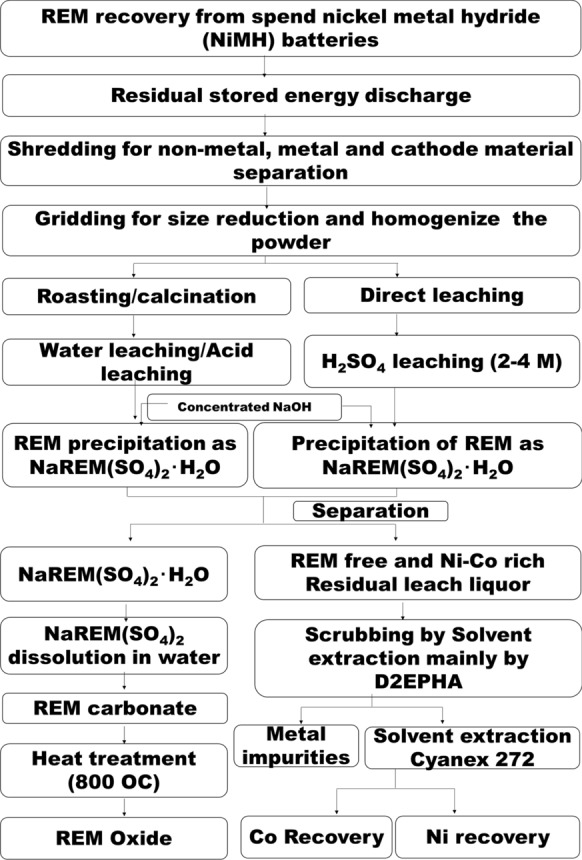

REM recovery from EOL batteries

With the emergence of the lithium-ion battery, although the use of nickel-metal hydride (NiMH) batteries has gradually decreased, currently the NiMH batteries are being used in hybrid electric vehicles (HEV) significantly (http://www3.cec.org/2015). Driven by demand, stringent policies against fossil fuel-powered (internal combustion engine) automotive, and policy supports for hybrid electric vehicle (HEV) and electric vehicles (EV), the HEV and EV revolution getting accelerated. Though HEV and EV have their inherent advantages and disadvantages, considering the requirement either of higher power density or energy density, batteries like the lithium-ion battery or NiMH get selected for the purpose. HEVs are taking advantage of batteries with a higher power density and the gasoline rechargeable option and use preferably NiMH batteries (http://www3.cec.org/2015). The use of HEV continues to increase due to the higher demand and hence NiMH batteries attract attention for the efficient and cost-effective recycling process. Secondary portable nickel-metal hydride (NiMH) batteries contain a significant amount of REM, which varies in the range of 7–18% depending upon the type of cells. REM content in different types of NiMH batteries is summarized in Table 5 (Rodrigues and Mansur 2010). The anode material of NiMH batteries uses REM in the form of metal hydride (MH). In the anode material of NiMH batteries, the REMs are present either as A2B7 (LaCePrNdNiCoMnAl) or AB5 (LaCePrNdNiCoMnAl) or as AB2 (VTiZr-NiCrCoMnAlSn). Where the 'ABx' represents the ratio of the A metals (LaCePrNd or TiZr) to B metals (VNiCrCoMnAlSn) (Ruetschi et al. 1995).

Table 5.

Rare earth metal contents in different classes of NiMH batteries

| NiMH, Battery type | Ce, % | La, % | Nd, % | Pr, % |

|---|---|---|---|---|

| A2B7 | 3.4 | 11.5 | 1.09 | 3.2 |

| AB2 | 6.1 | 5.4 | 3.0 | 0.8 |

| AB5 | 0.4–5.5 | 1.4–6.6 | 1–4.1 | 0.3–1.3 |

The summarized report presented in Table 5 indicated that a significant portion of the anode in NiMH contains REM, hence recycling of REM from EOL NiMH batteries can also address supply chain contraptions. Like other waste valorization processes NiMH battery is also associated with the integration of processes like the removal of labels, the opening of casings, destruction of seals, separation of cathode and anode materials by mechanical cutting chopping/ vacuum milling/ cryo-grinding/ pyrolysis, and metal value recovery through hardcore metallurgy process (Meshram et al. 2019). Spent portable NiMH batteries have often been recycled using high-temperature/pyro-metallurgical processes to recover the Ni and Co. However, the high-temperature processes lead to a metal loss in the slag. Metals like Ni, Cr, and Mn find applications in steel production, whereas other metals like Zn and Cd owed to high temperature, lead to ash/ dust. The pure elements can either be supplied for the re-manufacturing of batteries or any other chemical/ metallurgical applications, and the slag/ash/dust is mostly used for construction purposes. In the pyro-metallurgical processes, only base metal gets recycled whence REMs have rarely been recycled and rather slagged, which is counterproductive in the context of REM scarcity (Binnemans et al. 2013). Considering the disadvantages like; energy-intensive processes, high cost for infrastructure, and negative carbon-footprint processes, pyrometallurgy, in general, is not preferable. Hence, further recovery of REMs from slag generally hydrometallurgy process being employed because of flexibility and versatility preference.

In the reported hydrometallurgy process leaching is the elementary step that uses mineral acid preferably sulfuric acid (Pietrelli et al. 2005; Rodrigues and Mansur 2010; Meshram et al. 2016) or hydrochloric acid (Zhang et al. 1998; Tzanetakis and Scott 2004) to extract metal values including REM from NiMH battery for further purification. Several hydro-metallurgical technologies reported in the literature recover metals from the spent NiMH batteries on a laboratory scale. Inorganic reagents such as hydrochloric acid (Zhang et al. 1998) and sulfuric acid (Pietrelli et al. 2002, 2005) or sulfuric acid with the addition of hydrogen peroxide as a reduction agent (Mantuano et al. 2006) were used for the dissolution of the black mass of the dismantled batteries. Pietrelli et al. have reported extraction of metals values from spent NiMH batteries using 2 M sulfuric acid, pulp density 100 g/L, leaching temperature 20 ℃, and leaching time of 2 h. Followed by REM recovery from the leached solution precipitation REM through pH control has been reported by Pietrelli et al. (Pietrelli et al. 2002). Like Pietrelli et al. process, Luiz et al. also have reported a very similar REM recovery route through sequential sulfuric acid leaching and REM precipitation through PH control using NaOH. Unlike Pietrelli et al. process, Luiz et al. have recovered Co and Ni by the solvent extraction process. After REM precipitation in the solvent extraction process, metal impurities were scrubbed out using di-2-Ethylhexyl phosphoric acid (D2EHPA), then used bis(2,4,4-trimethylpentyl) phosphinic acid (Cyanex 272) to separate Ni/Co from the solution containing Ni and Co (Rodrigues and Mansur 2010). Meshram et al. have reported quantitative leaching of both base battery metal and REMs using 2 M H2SO4 and pulp density of 100 g/L As reported through H2SO4 leaching 98.1% 98.4%, 95.5%, and 89.4% of Nd, Sm, Pr, and Ce has been achieved along with base metal recovery with 90% efficiency (Meshram et al. 2016). Meshram et al. have reported roasting power spent NiMH battery powder material followed by 2 stages of leaching for selective leaching of REMs and base metals. In the first stage REM, Ni, and Zn were selectively water leached with 91–94% efficiency. In the second stage, 74% Mn and 55% Co were leached using NaHSO3 with H2SO4 as lixiviant (Meshram et al. 2017). Abreu et al. and Namil et al. have recovered REM as NaREM(SO4)‧xH2O adding NaOH solution followed REM oxide recovery through metathesis (Abreu and Morais 2010; Um and Hirato 2016). Similar to Abreu et al. and Namil et al. report, Ahn et al. have also reported REM recovery from spent NiMH through sequential H2SO4 leaching followed by REM precipitation as (NaREM(SO4)2‧H2O) using concentrated NaOH (Ahn et al. 2020). Provazi et al. have reported metal value recovery from mixed spend batteries, where through a series of processes like grinding the waste of mixed batteries, reducing, and volatile metals elimination using an electric furnace, acid leaching, selective precipitation, and solvent extraction (Provazi et al. 2011). In their process spent batteries were dismantled and fed into a shredder to separate non-metal, metals, and active battery powder material. The separated black powder was acid leached to extract metal values, then sequentially followed two-stage precipitation and solvent extraction. Though mixed battery clinging through hydrometallurgy was an innovative attempt, an adverse result was observed for REM recovery (Provazi et al. 2011).

Reported research elsewhere (Ahn et al. 2020) indicates in the waste NiMH battery the active material mainly consists of nickel-oxo compound Ni(OH)2, NiO, NiOOH, Ni-REM alloys like Ni7Ce2, Ni7Nd2, and Co3Nd, Co-REM alloy like Co5Nd, and Co3Nd and La2O3. The leaching chemistry of nickel-oxo compound and La2O3 can be expressed using chemical Eqs. 18–21 (Ahn et al. 2019).

| 18 |

| 19 |

| 20 |

| 21 |

Similarly, leaching chemistry for Ni-REM alloys like, Ni7Ce2, Ni7Nd2, and Co3Nd, and Co-REM alloy like Co5Nd, and Co3Nd can be summarized by Eqs. 22 and 23, respectively.

| 22 |

| 23 |

Solvent extraction chemistry using D2EHPA and Cyanex 272 for extraction and purification Co and Ni can be explained using Eqs. 24–25 given below.

| 24 |

| 25 |

where stands for D2EHPA and Cyanex 272 as both exist as a dimer in solution and stands for monomer anion of D2EHPA and Cyanex 272.

Similarly, precipitation reaction chemistry for REM using NaOH can be explained using Eq. 26 below.

| 26 |

From elsewhere reported studies (Ahn et al. 2019, 2020) and based on explained chemistry the entire NiMH recycling process flow diagram can be summarized as presented in Fig. 5. The process follows sheet follows the two-stage process, i.e., (i) mechanical sorting/separation process to access the electrode material, followed by a chemical metallurgy process to recover the metals values from the electrode material. The mechanical process follows: (i) remaining energy discharge, (ii) crushing and calcination, (iii) classification based on metal, non-metal, and electrode material, and finally access to the electrode material. From the electrode, material REM was recovered through a selective sequential chemical metallurgy process as follows(i) mineral acid leaching dominated by H2SO4, (ii) selective precipitation of REM as sulfate salt from Ni/Co sulfate solution (using NaOH), (iii) further dissolution of REM sulfate for carbocation and (iv) REM oxide recovery by calcination. Followed by REM recovery, from leach liquor Co and Ni were recovered by solvent extraction.

Fig. 5.

Flow sheet option for REM recovery from nickel-metal hydride battery (Abreu and Morais 2010; Um and Hirato 2016; Ahn et al. 2020)

REM recovery from phosphor powders

Cathode ray tubes (CRT), fluorescent lamps (FL), and compact Fluorescent Lamps (CFL) contain tri-band REM phosphors which are responsible for white light emission from the lamp (Khazova and O'Hagan 2008; Safari et al. 2015). As CRTs are phased out, the use of CFLs and FLs has risen by > 90% (Tan et al. 2014). The REM content in REM phosphors of CFLs and FLs accounts for 23% amounts to 230 kg/t (Binnemans et al. 2013) (Tan et al. 2014). The REM phosphors are primarily a mixture of red, blue, and green (~ 55% red, 35% green, and 10% blue), though variation exists. Depending on the manufacturer and application requirements, different quantities of REMs are used in different phosphors. Y (mainly) and Eu constitute the red phosphor. The green phosphor contains ~ 10% Tb, and < 5% Eu is in the blue phosphor (Balachandran 2014; Lucas et al. 2015). As the mass of REMs in the phosphors of the waste FLs is high, which may reach up to 30–40 wt %, it is a potential source of REM and inherent potential recycling value. Commonly, the spent FLs/CFLs value recovery follows the separation of individual components of phosphors and the aqueous processing of the material in mineral acid/ alkali. As the scope for pyro-process is limited mainly hydro process being investigated to complete REM value recovery from REM phosphors. Leaching/selective leaching using mineral acid mainly HCl followed by solvent extraction processes using D2EHPA, PC-88A (2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester), or Cyanex 272 are often explored to separate and recover the REMs from REM phosphors.

Although limited, a couple of investigation on REM value recovery from REM phosphors has been reported, mainly of the hydrometallurgical route. Verma et al. have reported a two-stage selective acid leaching process, where 96% and 94% of Eu and Y, respectively, have been leached using 2 M HCl and 30% pulp density. In the second stage La, Ce and Tb have been extracted with 95%, 90%, and 70% efficiency respectively, using 6 M HCl from the first stage residue. The leached metals were subsequently separated by a solvent extraction process using a reagent, Cyanex 272 (Verma et al. 2013). Ippolito et al. have proposed REM recovery from FLs through alkali fusion followed by sulfuric acid leaching to recover REMs (Ippolito et al. 2017). Achievement of 99% of Y and Eu, 80% of Tb, 65% of La, 63% of Ga, and 60% of Ce recovery from the leach liquor by oxalic acid precipitation has been proposed (Ippolito et al. 2017). Tunsu et al. (Tunsu et al. 2016) have studied REM recovery through the leaching solvent extraction route in a bench-scale investigation. In their study, the powder sample of FLs followed an I2/KI leaching process to remove the Hg contaminant before the above-explained acid leaching and solvent extraction route. For Hg leaching, 0.025/0.05 M of I2/KI solution with pulp density of 20 and 40% w/v were employed. Followed by the residual sample was leached using nitric acid and from leach-liquor REM was separated by solvent extraction using Cyanex 923 (Tunsu et al. 2016).

The entire REM phosphors CRT/FL/CFL recycling process flow diagram can be summarized as presented in Fig. 6a. Like other waste recycling processes, the REM phosphors track process flow as follows, (i) mechanical separation process for accessing REM phosphors, pretreatment, leaching, solvent extraction, and REM recovery process. Figure 6a represents two different routes for REM oxalate recovery from leach liquor. In one process, the leach liquor was directedly precipitated using oxalic acid and further calcinated to get REM oxide. In another process, followed by leaching, the leach liquor gets treated by solvent extraction for better purification and selectivity then REM recovery follows the same REM oxalate precipitating and REM oxide recovery route.

Fig. 6.

a Flowsheet for REM recovery from CRT/CFL/FLs, b Separation of red, blue, and green phosphors (Himanshu and Verma 2013; Tunsu et al. 2016; Ippolito et al. 2017)

Mei et al. (2009) reported an innovative approach for the separation of red, blue, and green phosphors in a two-stage selective solvent extraction process using 2-thenoyltrifluoroacetone (TTA) and chloroform in 1-pentanol (Fig. 6b). In the first stage, TTA is dissolved in heptane to extract the blue powder at alkaline pH. Potassium sodium tartrate (PST) and Na2CO3 were used as regulators. In the second stage, chloroform was used to extract the green phosphor into the organic phase leaving the red phosphor in the aqueous phase. The addition of a small quantity of 1-pentanol improved the separation efficiency. A report regarding the application of novel green extractants such as N, N-dioctyldiglycolamic acid (DODGAA) for recovery of REMs from fluorescent lamps has also been reported (Van Loy et al. 2017).

REM recovery from industrial waste

REM recovery from Red Mud

Red mud is a solid waste produced in Bayer's process of alumina production from bauxite contains major metal oxides like Fe2O3, Al2O3, and TiO2 and minor metals like V, Ga, Cr, P, Mn, Cu, Cd, Ni, Zn, Pb, Mg, Zr, Hf, Nb, U, Th, K, Ba, Sr, and REMs. Red mud contains REMs like La, Ce, Pr, Nd, Sm, Eu, Sc, and Y with a varied ratio depending upon geological origins (Swain et al. 2020b). Bauxite is the principal ore utilized for aluminum production through Bayer’s process, usually generating 4 to 6 tons of red mud for each ton of aluminum production (Kumar et al. 2006; Sinha et al. 2016). It is reasonable to explain here that the Bayer process primarily produces alumina, followed by the produced alumina used for aluminum production(Swain 2022). Red mud is a rich source of poly-metals that include rare elements such as Ti, V, Ga, and REMs such as Sc, La, Ce, Y, and Nd (Zhang et al. 2019). Typical red mud contains 121, 76, 114, 368, 28, 99, 21, 5, 22, 4, 17, 14, 4, 2, 14, and 3 g/ton of REMs like Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Er, Ho, Tm, Yb, and Lu, respectively. In general, typical red mud contains REMs ranging from 500 to 1700 g/ton. Though quantitatively minor, the value perspective of REMs in RM is significant. In comparison to the currently mined bastnäsite (carbonate-fluorides) and monazite (phosphates) ores, where the average REMs contents vary from 3000 to 13,000 g/ton (calculated from Binnemans et al. (Binnemans et al. 2018)). Compared to REM content in mined bastnäsite, the REMs concentrations in red mud are significant, and hardly could be neglected from a comparative quantity perspective. In the absence of efficient technology, most of the red mud remains stockpiled. Global red mud inventory is about 4 billion tons by 2020 and is generated 120–150 million tons per year worldwide. Analysis indicated that industrial-scale valorization could unlock approximately $4.3 trillion worth of REMs from stockpiled red mud (Swain et al. 2020b). A thorough investigation suggests that, currently, a sustainable industrial process for REM value recovery from RM is mostly non-existence though part of the problem is being addressed for base metal only on a laboratory scale.

Literature investigation indicated that several reports for recovery Sc, Y, and La have been reported mainly because of the cost of those metals and content, still, other REMs get any attention. Selective Sc recovery from red mud leach liquor by solvent extraction using D2EHPA (Di-(2-Ethylhexyl) phosphoric acid) has been reported by Wang et al. (Wang et al. 2013). The proposed process by Wang et al. mainly consists of sequential sulfuric acid leaching and then two stages of solvent extraction. As reported after red mud leaching with dilute sulfuric acid, Ti and Zr were separated by solvent extraction using Primene JMT. After Ti and Zr recovery, Fe and Ti were scrubbed using D2EHPA. Finally by controlling pH through NaOH solution, Sc(OH)3 was isolated. The isolated materials were dissolved in an acidic solution and then precipitated as Sc-oxalate. By calcination of Sc-oxalate, Sc2O3 has been recovered (Wang et al. 2013). Ochsenkühn et al. (Ochsenkühn et al. 1995) have also reported Sc as well as Y and La recovery from the red mud leach solution by combination sequential two stages, i.e., (i) ion exchange and (ii) solvent extraction process in lab-scale and then in a pilot scale. The process reported by Ochsenkühn et al. consists of pretreatment, acid leaching, ion exchanges, solvent extraction, and precipitation stripping. Before 1.5 M HCl leaching, the red mud was roasted with a mixture of NaKCO3 and Na2B4O7. From leach liquor, Fe, Al, Ca, Si, Ti and Na were separated by ion-exchange using Dowex 50W-X8 (ion exchange) resin and elution using 1.75 M HCl. In the second stage the loaded Dowex 50W-X8 resin was eluted using 6 M HCl to separate Sc, Y, and La. From elute chloride Sc, Y, and La mixture solution Sc was separated by solvent extraction using D2EPHA. From laded D2EPHA Sc(OH)3 precipitation was stripped by precipitation stripping. Through Ochsenkühn et al. not extended the investigation but taking strength from wang et al. (Wang et al. 2013) investigation, the Sc can be recovered as Sc2O3 from Sc(OH)3 precipitate through the same route. The reported process is quiet about Y and La separation/recovery, but reasonably those could be separated and recovered by solvent extraction as discussed elsewhere (Swain and Otu 2011; Saito et al. 2015; Swain and Tanaka 2018). Ochsenkühn et al. (Ochsenkühn et al. 2002) have also reported a pilot-scale Sc recovery from the red mud through a similar process investigated on the lab scale. The process developed by Ochsenkühn et al. and Wang et al. (2013) has been discussed extensively elsewhere (Swain et al. 2020b). In the context of REM recovery from, focusing on REM recovery from red mud, the process developed by Ochsenkühn et al. and Wang et al. (2013) discussed extensively elsewhere by Swain et al. (2020a) can be modified as presented in Fig. 7. An important drawback of the reported process is, that the process is limited to Sc only, other REM still gets neglected and enters to waste stream. The leaching, solvent extraction, Sc oxalate recovery and Sc oxide valorization chemistry from red mud can also be explained using chemical Eqs. 27–30 given below (Swain et al. 2020a).

| 27 |

| 28 |

| 29 |

| 30 |

| 31 |

| 32 |

Fig. 7.

Flow sheet for recovery of REM from red mud. The flow sheet has been borrowed from Swain et al. (2020a) and modified for the REM recovery perspective

REM recovery from blast furnace slag

In the ironmaking making when iron ore is mixed with flux (limestone and/or dolomite) and fuel (coke) in reducing conditions at a high temperature of more than 1500 °C, molten iron, and molten slag are produced. The molten slag knows as BFS. In the steelmaking process, 20–25% of materials slagged out as BFS. Approximately, 0.4 tons of BFS produced per ton of steel production. Worldwide BFS generation was 320–384 million tons during the year 2019 (Kim and Azimi 2020). Currently, 90% of produced BFS get utilized mainly in cement making and the rest of 10% (32–38 million tons annually) of BFS is disposed of in landfills (Kim and Azimi 2020). Several authors in the literature have reported BFS to contain REM along with other metals like niobium, tantalum, and titanium (Kim and Azimi 2020; 2021). Hence, BFS can be a contributor to REM supply chain scarcity.

Kim et. al. have reported Sc and Nd recovery from BFS by H2SO4 baking-water leaching, where BFS was mixed with concentrated H2SO4, and the mixture was baked. Then the acid-baked sample was water leached where 82.5% and 80.6% of Sc and Nd were extracted from BFS (Kim and Azimi 2020). The same author also reported a sequential carbothermic reduction-acid baking-water leaching process for REM recovery along with other metals (Kim and Azimi 2021). In their investigation, the optimum condition for carbothermic reduction was explored through Carbon to BFS mass ratio variation and temperature variation followed by the above-explained acid baking-water leaching process route were followed (Kim and Azimi 2021). Abhilash et al. have reported hot H2SO4 leaching followed by solvent extraction to extract and purify REMs. La, Ce, Nd, and Er recovery with 92%, 36%, 35%, and 52% efficiency were achieved using 1 M hot (95 °C) H2SO4 for pulp density of 1:5 (w/v) BSF versus H2SO4 from 17, 16, 44 and 4 mg/kg of La, Ce, Nd, and Er, respectively (Abhilash et al. 2017). Bisaka et al. have reported REM recovery from BSF by three classical leaching routes, (i) Caustic crack followed by REM leaching with HCl, (ii) H2SO4 baking followed by a water leaching, and (iii) Direct HCl leaching and compared all three-leaching process. Bisaka et al. have indicated direct HCl leaching was efficient and can leach 94–96% of total REM whence other leaching processes hardly can leach 49% of total REM (Bisaka 2016). Kasina et al. have investigated BSF to find out whether the BFS can be a potential source for REM and indicated the concentrations of REM in BFS could be inadequate for profitable recovery (Kasina and Michalik 2016).

REM recovery from Coal, coal mines, and coal by-products