Abstract

Background

A disposable lunch box is an important cause of “white pollution”. Many people consider that the disposable polylactic acid (PLA) lunch box is more environmentally friendly than the disposable paper pulp lunch box and can substitute for the latter.

Objective

We can determine whether PLA tableware is more environmentally friendly than paper tableware by analyzing the product life cycle of two tableware types. At the same time, as a continuous compound, carbon dioxide has significant commercial value. Carbon dioxide materials' applications range from beverages to cosmetics and building materials. The future application of carbon dioxide in the field of lunch boxes is discussed in this paper.

Methods

In this paper, the production stages of the two types of disposable lunch boxes were compared and surveyed using the life cycle assessment (LCA) method.

Conclusion

The results reveal that the main impact of the two types of lunch boxes is resource damage; the PLA lunch box is not better than the paper type; the production stage of the disposable PLA lunch box poses greater damage to the environment in all aspects than the paper type.

Discussion

Against the background of carbon neutrality and based on the constantly mature carbon dioxide conversion technology, the author explored the possibility of making products from carbon dioxide and proposed to make product designs based on carbon dioxide.

Keywords: Life cycle assessment (LCA), Disposable lunch box, Conversion of carbon dioxide, Sustainability

1. Introduction

As Victor Papanek mentioned in the Design for the Real World, if disposable goods can be used continuously without damage to the environment, there will be quite abundant goods, tools, and artifacts available for random selection [1]. This view is also correct, even in the current social environment. Nowadays, people are facing a severe eco-crisis. The environmental problem caused by disposable goods is extremely urgent. Furthermore, the takeaway lunch box at the restaurant accounts for a large proportion of disposable goods. Relevant data statistics show that in 2020, 17 billion orders were made in China's takeaway market, where 3.44 lunch boxes were required in each order on average, and plastic lunch boxes accounted for nearly 70%. In addition, about 90% of the orders required plastic bags. Only in 2020, 1.6 million tons of plastic waste was produced in China's takeaway industry [2]. Without a doubt, the takeaway industry has the major demand for disposable lunch boxes. It causes environmental pollution while providing convenience.

The development of new products has attracted global attention. With the constant growth in the global population, resources are consumed at an astonishing speed, resulting in an unsustainable ecosystem [3]. Facing the “white pollution” caused by disposable plastics, biodegradable plastic is often regarded as the main solution; meanwhile, the government, enterprises, and universities are seeking more feasible solutions. Biodegradable plastic accounts for approximately 1% of the total global plastic production (370 million tons) [4]. Under the control of applicable environmental protection policies, paper and polylactic acid (PLA) are the most popular degradable materials on the current market. Molded pulp tableware with low production cost is an optimum substitute for common plastics such as polypropylene (PP) [5]. However, consumers generally report that paper tableware has a poor user experience. Especially when drinking, its poor waterproofness will be exposed. Hence, PLA straw with high degradability is increasingly being selected by catering merchants and gradually takes the place of disposable paper tableware. Fig. 1 exhibits the change in the materials. However, was the PLA type greener than the paper type indeed?

Fig. 1.

The change in the materials of economically available disposable tableware.

“For the first time, microplastic particles are found in the blood and shit of human beings.” Recently, a research team published an article on the Science of the Total Environment, reporting that they discovered microplastic particles in the lung tissue of a living human body [6]. Most of the existing mainstream products are made of plastics such as polypropylene (PP), polyethylene (PE), Polyethylene Terephthalate (PET), acrylonitrile-butadiene-styrene (ABS), and polystyrene (PS). Such products exist in every aspect of our lives since they can be easily and economically recycled. However, the harm of microplastics has been reported endlessly in recent years, and each event has attracted great attention at the social level. Therefore, the contradiction between the advantages and disadvantages of plastic tableware drives the search for new degradable materials. Recently, a report from China published in the Science published stated that researchers from Tianjin Institute of Industrial Biotechnology, Chinese Academy of Sciences, had successfully synthesized industrial starch from carbon dioxide [7]. As we all know, starch is a widely used industrial raw material. According to the General Requirement of Plastic Disposable Tableware (GB18006.1–2009), the starch content in disposable degradable tableware should be above 40%. Meanwhile, the content of food starch in some tableware has reached 80%, showing the possibility of “carbon conversion”. Against a series of global problems such as climate warming and food crisis, the achievements in converting carbon dioxide into starch are significant for maintaining food safety and promoting carbon neutrality-oriented biological, economic development. The success of the ‘carbon conversion’ experiment indicates that a more reasonable concept of carbon reduction is that “waste is a resource placed in the wrong place”; carbon dioxide should not be treated as a ferocious thing to be eliminated, but should be made the best use of. As people says, “for us, it is impossible to not burn a little coal and gas”. Therefore, it is necessary to develop new technologies to convert carbon dioxide into useful materials rationally.

At present, most studies on “carbon conversion” concentrate on the collection and conversion of carbon dioxide and on how to convert carbon dioxide into a high-value-added compound. Few studies explore whether carbon dioxide can be produced into daily necessities indirectly or not. In this study, two types of mainstream tableware available economically (the PLA type and the food-level degradable type, the so-called paper tableware) were compared and surveyed using the life cycle assessment (LCA) method. The impact of their production on the environment was analyzed. Furthermore, the possibility of indirectly converting carbon dioxide into products was discussed to provide some scientific basis for the development of materials for disposable tableware and relevant environmental protection.

2. Methodology

2.1. Life cycle assessment

Life cycle assessment (LCA) ranges from the initial extraction and processing of the raw material to the final disposal method, namely “from cradle to grave”. As denoted in the name, LCA is a method of assessing the environmental impact of a product or service and has been accepted most widely [8]. However, it cannot be a clear-cut solution for many cases because some problems will arise when comparing products made of completely different ecological materials. For example, as revealed by the evaluation, although a PS cup occupies more land resources in the landfill than a paper cup, the manufacture of the latter requires electric energy 36 times the former and discharges wastewater 580 times the former. What is worse, the paper cup, when being sent for landfilling, may undergo anaerobic decomposition and finally produce methane [9]. This further shows that the change in some product materials does not necessarily protect the environment. At the same time, the public has some misunderstandings about PLA tableware. Many consumers believe they are substitutes for paper tableware, are more environmentally friendly than paper materials, and vigorously promote their development.

LCAs of the two types of disposable tableware were completed with the support of SimaPro9.0, one of the leading LCA software solutions in the world. This software was developed by PRé Sustainability of the Netherlands, aiming to become the source of science-based information and provide a completely transparent and reliable operation [10]. It can help LCA personnel collect, analyze and assess the environmental information of a product or service, simulate and analyze the complex life cycle of the product or service systematically and transparently according to the ISO14040 series of standards. Most importantly, this software can integrate different data banks and save resources from different sources in categories, hence its practicability and confidentiality.

2.2. Determining the objective, scope and functional unit of the LCA

The purpose of this work is to compare the Cradle-to-gate environmental impacts of a disposable paper lunch box and a disposable PLA lunch box in their production and to survey their data. Through an analysis of their environmental impacts in their life cycles, parts with the most significant environmental impact in their life cycles can be found to theoretically judge whether the disposable PLA lunch box is more environmentally friendly.

To ensure the rationality of the comparison, the tableware with a specification of 1 kg was selected, and the functional unit was producing 1 kg of tableware.

The system boundary is raw material collection, raw material production, and tableware production (from cradle to gate) (Fig. 2). The life cycle assessment of the two types of disposable tableware was carried out Cradle-to-gate, and the following stages were identified by the study objectives and the ISO 14041 standard: Cradle-to-gate, Gate-to-gate, and Gate-to-grave (Fig. 3) [11]. Disposable tableware does not produce pollution during use, and the environmental impact of the use phase is also minimal. Therefore, the use phase of both types of tableware is ignored in the study. At the same time, for disposable food containers, the environmental impact of the post-use to recycling stage is relatively small and difficult to simulate in various ways, so the Gate-to-grave stage is ignored.

Fig. 2.

System boundary.

Fig. 3.

Life cycle of two types of meal boxes.

2.3. Source of the data in the life cycle list

The data of tableware in the production stage of its life cycle was mainly sourced from the Environmental Impact List of the Disposable Degradable Plastic Tableware Production Project of Wuhu Lvkang Environmental Protection Technology Co., Ltd. published by the People's Government of Wanzhi District and the Production Project of Disposable Degradable Plastic Tableware issued by Shantou Yuhe Environmental Technology Co., Ltd. The author surveyed the stages of production of the two types of tableware, collected the following lists and analyzed partial data as required (Tables 1 and 2).

Table 1.

Environmental-friendly disposable paper tableware list.

| Product | Environmental-friendly disposable paper tableware | 3w | t/a | |||

|---|---|---|---|---|---|---|

| Input | Quantity | Unit | Type of pollutant | Output substance | Quantity | Unit |

| Sugarcane bagasse board | 25000 | t | Wastewater | COD | 5.8 | t |

| Bamboo paddle board | 5000 | t | NH3–N | 0.48 | t | |

| Waterproof agent | 500 | t | Waste gas | Non-methane hydrocarbon | 0.089 | t |

| Oil-proofing agent | 250 | t | SO2 | 1.66 | t | |

| Wood paddle board | 200 | t | NOx | 1.26 | t | |

| Glue | 19.1 | t | PM | 0.0066 | t | |

| Lubricating oil | 0.3 | t | ||||

| Heat transfer oil | 35 | t | ||||

| Tap water | 46,200 | t | ||||

| Electric power | 4,000,000 | kWh | ||||

| Natural gas | 4,136,000 | m3 | ||||

Table 2.

Environmental-friendly disposable PLA tableware list.

| Product |

Environmental-friendly disposable PLA tableware |

300 |

t/a |

||||

|---|---|---|---|---|---|---|---|

| Input | Quantity | Unit | Output substance | Quantity | Unit | ||

| Polylactic acid (PLA) | 212.28 | t/a | Waste gas | Organic waste gas (Non-methane hydrocarbon) | 0.292 | t/a | |

| Bamboo powder masterbatch | 32.26 | t/a | Wastewater | Domestic wastewater | 324 | m3 | |

| Starch masterbatch | 62.27 | t/a | COD | 0.065 | t/a | ||

| Packing material | 1 | t/a | BOD | 0.032 | t/a | ||

| SS | 0.0065 | t/a | |||||

| Electric power | 10w | kwh | Ammonia nitrogen | 0.0065 | t/a | ||

| Water | 840 | m3 | Solid waste | Household waste | 4.5 | t/a | |

| General industrial solid waste | Waste leftover bits and pieces | 6 | t/a | ||||

| Packing material | 1 | t/a | |||||

| Hazardous waste | Spent activated carbon | 2.36 | t/a | ||||

| Spent UV lamp | 0.02 | t/a | |||||

2.4. Life cycle impact assessment

Life cycle impact assessment (LCIA) is the third stage and also the core of LCA. According to the ISO 14040 series of standards, LCIA aims to assess the environmental impact of a product system [12]. It qualitatively and quantitatively characterizes and evaluates the environmental impact recognized from the list of a product system and determines the impact of the substance energy exchange of the production system on the external environment (mainly, including the ecosystem and human health). This study was carried out using the Eco-indicator99 impact assessment model provided by SimaPro. Practices have shown that Eco-indicator99 and SimaPro are useful in sustainable design and can greatly reduce the design cost and shorten the green design cycle [13]. The Eco-indicator99 impact assessment model is widely used internationally and is mainly divided into the following steps: characterization, damage assessment, normalization, and weighted assessment.

2.4.1. Characterization

Characterization is to multiply the same impact category of substance with the corresponding Eigenfactor. The Eigenfactor represents the relative contribution of different substances. In the Eco-indicator99 impact assessment model, there are 11 categories of environmental impacts: carcinogens, respiratory organics, respiratory inorganics, climate change, radiation, destruction of the ozone layer, ecotoxicity, acidification/eutrophication, land use, minerals, and fossil fuels.

As found by a comparison between 1 kg of environmentally friendly disposable food level tableware (excluding oil proofing agent and heat transfer oil) and PLA tableware (Table 3 and Fig. 4), among the 11 categories of environmental impacts: (1) PLA tableware has a greater environmental impact than food level tableware; (2) in the aspect of land use, the two types of tableware have the maximum difference between their environmental impacts during the life cycle, where the impact of food level tableware is only 25% of PLA tableware's; (3) from the perspective of respiratory organics, the two types of tableware have the minimum difference, where the respiratory organics produced by the food level tableware is 60% of that produced by PLA tableware.

Table 3.

Numerical values of the life cycle environmental impact categories of the two different types of tableware.

| Environmental impact category | Unit | PLA | Environmental-friendly material | |

|---|---|---|---|---|

| Carcinogens | DALY | 1.03E-06 | 4.45E-07 | |

| Resp. organics | DALY | 4.79E-09 | 2.89E-09 | |

| Resp. inorganics | DALY | 2.91E-06 | 1.66E-06 | |

| Climate change | DALY | 5.89E-07 | 2.98E-07 | |

| Radiation | DALY | 4.71E-09 | 1.97E-09 | |

| Ozone layer | DALY | 1.82E-10 | 8.48E-11 | |

| Ecotoxicity | PAF*m2yr | 1.09E+00 | 4.72E-01 | |

| Acidification/Eutrophication | PDF*m2yr | 7.74E-02 | 3.15E-02 | |

| Land use | PDF*m2yr | 8.43E-01 | 2.11E-01 | |

| Minerals | MJ surplus | 4.75E-02 | 1.68E-02 | |

| Fossil fuels | MJ surplus | 2.89E+00 | 1.05E+00 | |

Fig. 4.

Comparison between the life cycle environmental impact categories of the two different types of tableware.

2.4.2. Damage assessment

In the Eco-indicator99 impact assessment model, the data obtained by the analysis of the product list were divided into different categories of environmental problems according to a certain environmental mechanism, normalized, and finally merged into three categories of damage: human health, ecosystem, and resource. Further, by adding up their weight coefficients, the ecological index of the product was obtained [14].

The resource refers to the remaining energy source of mineral resource and the exploitation of the mineral resource for future use and surely includes the land use.

Human health damage is defined as the reduction in the lifetime of people due to diseases and abnormal deaths caused by various environmental problems, such as extreme weather, air pollution, and various radiations.

The damage of ecosystems mainly considers the damage to biodiversity in nature, including the damage caused by biological toxic materials, acid rain, eutrophication, land use, and other environmental problems.

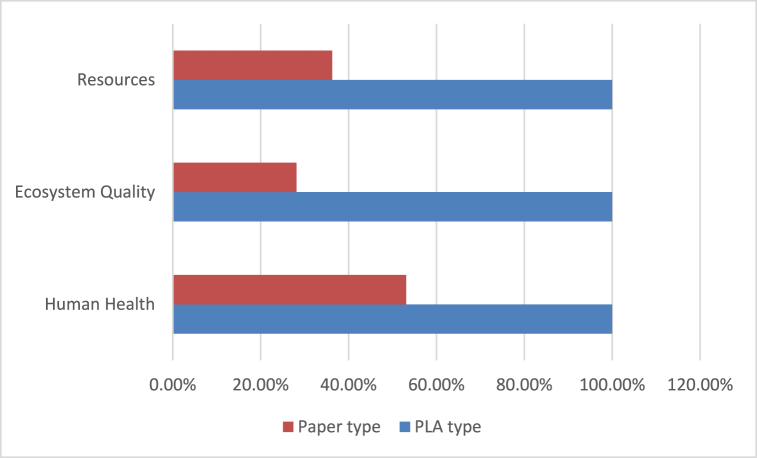

The damage assessment results (Table 4 and Fig. 5) reveal as follows: among the three categories of damage, resource damage is the largest, followed by ecosystem damage, and then human health damage. The three categories of damage to disposable paper tableware are about 60% smaller than those of PLA type.

Table 4.

The human health, ecosystem, and resource data of the two types of tableware.

| Damage assessment | |||

|---|---|---|---|

| Damage category | Unit | PLA | Environmental-friendly material |

| Human Health | DALY | 4.53E-06 | 2.41E-06 |

| Ecosystem Quality | PDF*m2yr | 1.03E+00 | 2.90E-01 |

| Resources | MJ surplus | 2.94E+00 | 1.07E+00 |

Fig. 5.

Comparison between the human health, ecosystem, and resource data of the two types of tableware.

2.4.3. Weighted assessment

The weighting element in the LCA is always controversial [15], partly because this element should be incorporated with social, political and ethical values. Value is involved not only in the selection of the weighting factor and weighting method but also in judging whether to use the weighting method or not. Despite the controversy, weighting is widely applied in practice. It is crucial to strictly check the method and the data used. However, it is difficult to assess the weighting method, since the values involved are difficult to identify and assess. Fortunately, all weighting methods adopt different scientific disciplines of data and methods that can and should be assessed and can identify and clarify value selection [16].

As found by a weighted assessment of the two types of tableware (Fig. 6, Fig. 7), the environmentally friendly disposable paper tableware is plainly superior to the PLA type.

Fig. 6.

The weighted results of deposable PLA tableware.

Fig. 7.

The weighted results of deposable paper tableware.

2.5. Uncertainty sensitivity analysis

To provide additional improvements in interpreting the results, uncertainty sensitivity analysis investigates the environmental impact of all input parameters with uncertainty on cutlery during the life cycle phase of PLA Tableware and paper tableware. More consistent data collection on input parameters can boost the credibility of the evaluation results. Nonetheless, the large number of input parameters in commonly constructed life cycle evaluation models makes enhancing the data for each data item inefficient. Sensitivity analysis can calculate each parameter's contribution to the uncertainty of the output results and focus on improving the quality of the parameters of the more significant variables, reducing the workload of data improvement and increasing the reliability of the evaluation results—environmental impact.

This study, both sensitivity and uncertainty analyses were conducted. The characterization and normalization results of LCIA are obtained through Simapro 9.0 software. A sensitivity analysis was performed to determine which inputs are the most influential to the overall environmental impact. An uncertainty analysis was performed to quantify the uncertainty of the model outputs as a function of the uncertainty of the model inputs, in order to quantify the uncertainty inherent in the inventory dataset that is used. For both tableware, the uncertainty analysis was completed using Monte Carlo simulations. For the sensitivity analysis, to conclude which inputs were the most sensitive, there was a 20% increase to the mass of each input separately and the impact was analyzed to see if it was lower, higher, or the same as 20%. If the impact equaled to 20%, the input was not as sensitive; if the impact changes by less than 20%, the input was somewhat sensitive; if the impact changed by more than 20%, the input was determined to be sensitive. According to the diagram in the (Supplementary information file), the paper tableware, Sensitivity analysis (Fig. S4): in Characterization, the amount of various inputs increases by 20%, resulting in the percentage of total impact change. Comparison with initial data (Fig. S1), the results show that the sensitivity of the Fibreboard is the largest, followed by organizations, Minerals increase, and Radiation. When the input of Fibreboard increases by 20%, the organizations increase by 18.53%, the Minerals increase by 16.74%, and the Radiation increase by 16.22%. On the contrary, Land use decreases by 12.17%. Glue and Glass cullet had the lowest sensitivity. In the Damage Assessment (Fig. S5) and Normalization (Fig. S6), the number of variable inputs increased by 20%, resulting in the percentage of total impact change. Comparison with initial data (Fig. S2 and Fig. S3), the results show that the sensitivity of the Fibreboard is the largest. When the input of the Fiber Board increases by 20%, Human Health and Resources increase by 15.74% and 14.29%, respectively, and Ecosystem Quality decreases by 21.14%. PLA Tableware, Sensitivity analysis (Fig. S10): in Characterization, the number of various inputs increased by 20%, resulting in the percentage of total impact change. Comparison with initial data (Fig. S7), the results show that Polyline and Maize starch are the most sensitive, followed by Land use, Fossil fuels, and the ozone layer. When the input of Polyline and Maize starch increases by 20%, Land use increases by 20.05%, Fossil fuels increases by 17.82%, and the ozone layer increases by 17.42%. Carcinogens have a minor percentage change, increasing by 13.58%. In the Damage Assessment (Fig. S11) and Normalization (Fig. S12), the number of variable inputs increased by 20%, resulting in the percentage of total impact change. Comparison with initial data (Fig. S8 and Fig. S9), the results show that Polyline and Maize starch has the highest sensitivity. When the input of Polyline and Maize increases by 20%, Human Health, Ecosystem Quality, and Resources increase by 15.58%, 19.26%, and 17.78 respectively. The minor changes are Waste incineration of plastics and Glass cullet. Uncertainty analysis: SD, SEM, and other indicators are obtained based on the Monte Carlo method, and the results are shown in (Fig. S13 and Fig. S14).

3. Results

By analysis, the following points were obtained: first, from the perspective of the production stage in the LCA, the environmental friendly disposable paper tableware is significantly superior to the PLA type in all aspects; second, among the three categories of damage (human health, ecosystem, and resource), resource damage is the maximum in the production stages of both the two types of tableware, followed by ecosystem damage and then human health damage; third, by LCA analysis, even the well-known environmental friendly materials are also found to be somewhat harmful to the ecosystem and human health. In the human-oriented social life, priority is given to human health instead of the other two categories. Only when human's essential issue is completely guaranteed can the development in other directions be considered. In this regard, both types of tableware have large development spaces; the PLA type can be used as an alternative to the paper type, but it is not more environmentally friendly than the latter.

The two types of tableware were analyzed mainly on the basis of the data in the production stage of their LCA, not involving the life cycle of other products. Under the guidance and constraints of the policy for plastic prohibition and restriction, more environmentally friendly disposable tableware will be an inevitable selection in the development of the catering industry; hence the recent increasingly unblocked popularization of PLA tableware in the markets. PLA is made primarily from starch (the raw material) as extracted from reproducible plant resources, such as maize. With good compatibility and biodegradation performance, this material is suitable for the production of disposable tableware. In contrast, disposable paper tableware is more environmentally friendly than PLA type. After use, these two types of tableware can be degraded by microorganisms in nature and form carbon dioxide and water, which are then directly absorbed by plants or enter the organic substance of the soil. Whereas in the production stage, paper tableware has much less human health damage, ecosystem damage, and resource damage than PLA type. According to the LCIA result, the priority of the paper type is higher than that of the PLA type. However, they still have certain impacts on the ecosystem and human health. Moreover, the shortcomings of paper tableware have come out constantly in recent years. For consumers, (Table 5), the largest shortcoming is the poor user experience of paper tableware. Consumers often smell the taste of paper when eating hot food or drinking milky tea filled with paper tableware because paper tableware is less waterproof and heat resistant due to its intrinsic material characteristics. For the merchant, paper tableware costs much more than plastic tableware (the former's cost of the former is triple the latter's), which is also a problem of the type of PLA. In addition, in the early years, whether paper cups were environmental-friendly or not was discussed. Because the coating inside the paper cup can hardly be separated from the paper for recycling, the traditional recycling practice is incineration, while the plastic waste produced is still harmful to the environment [17].

Table 5.

Comparison of three types of tableware.

| Comparison of three types of tableware | |

|---|---|

| User experience | Plastic PP type ≥ PLA type > paper type, mainly regarding the sense of touch and unpleasant odor |

| Resistance to high temperature | Plastic PP type > paper type > PLA type; most PLA straws cannot resist high temperature |

| Waterproofness | Plastic PP type ≥ PLA type > paper type; paper straw softens seriously |

| Price | PLA type > paper type > Plastic PP type; the PLA type costs the highest |

| Environmental protection performance | paper type ≥ PLA type > Plastic PP type |

4. Discussion and outlook

4.1. Discussion

On the background of carbon conversion, can carbon dioxide be used to produce daily necessities?

The low-carbon economic transition has become a globally irreversible orientation and a strategic choice for countries to realize the sustainable development of their social economy. Since the signing of the United Nations Framework Convention on Climate Change (UNFCCC) in 1992, the countries have issued a series of energy-saving and emission-reduction policies [18]. Carbon emissions in developing countries are the highest and gradually become the main source of global carbon emissions. For example, carbon emissions in the BRICS (Brazil, Russia, India, China and South Africa) represented 27.35% of global carbon emissions in 2001, which increased to 39.88% in 2014 [19]. At present, China ranks top in the global carbon emission, where the annual carbon emission in recent years was about 10 billion tons, above 1/4 of the global carbon emission. The frequent extreme weathers in recent years practically evoke us the harm of “carbon pollution”. From the early outbreak of extremely high temperature weather in America to the successive occurrence of rare floods in Germany and China, the world has been suffering increasingly severe loss from extreme weather, and the frequency of occurrence is also increasing fast. In most regions of China, carbon emission reduction always concentrates on “development” and “reduction” ineluctably. The “development” is to develop low-carbon industries, while the “reduction” is to reduce high-carbon industries. The two conventional reaction modes trigger problems in practical applications. For example, one-sided emphasis on developing low-carbon industries is likely to cause a herd phenomenon and low-quality competition in the industry. Meanwhile, overemphasis on reducing high-carbon industries may induce deviated understanding of carbon neutrality in some regions and “non-discretionary implementation”, posing negative impacts on enterprises and society.

Apparently, (Fig. 8), the above two modes are not the only solutions for carbon emission reduction. It is necessary to introduce a ‘third option’ that is not a neutralization of the two modes mentioned, but a unique mode of thinking, reminding us of the existence of an innovative road between development and reduction.

Fig. 8.

Two modes of carbon emission reduction.

Above all, disposable PLA tableware as an alternative to disposable paper tableware is not more environmentally friendly than the latter and even has inversely greater environmental damage in the production stage. In terms of disposable tableware, the present academic studies mainly focus on two points: seeking replaceable environmental-friendly materials and finding a recyclable collection mode [20]. Carbon dioxide can be used as the raw material for producing chemicals, which means another feasible method, except for a new opportunity to study catalyst and industrial chemistry. That is, carbon dioxide can be used to produce new materials with cost competitiveness and a small environmental impact. The conversion of carbon dioxide not only contributes to weakening global warming but also helps to reduce the emission and resource depletion of fossil fuels or even create a benign production approach [21].

4.2. Outlook

About 1/4 of greenhouse gas emission is related to the production of products. Although carbon dioxide has been used commercially, (Fig. 9), such as being added in beverages and the chemical industry, the present demand is insufficient to realize significant carbon emission reduction. Therefore, a new method should be explored to change the way of industrial manufacturing from producing carbon dioxide to using carbon dioxide. As all plastics, chemicals, cosmetics, and many other products require a carbon supply, billions of tons of greenhouse gases can be fixed annually if products can be produced using carbon dioxide instead of fossil hydrocarbon.

Fig. 9.

The use of carbon dioxide Image source: Translation drawn from Little Red Book Lo Siu Ha's table program.

To date, The Kingdom of Bhutan and The Republic of Suriname have produced negative emissions of carbon dioxide, that is, their carbon absorption is more than their carbon emission [22]. The direction of carbon dioxide development is to transform it into valuable raw materials, and existing studies focus on ‘carbon collection’ and ‘carbon conversion’. For example, Air Company is a lifestyle brand and technology company in New York, specializing in creating green products with unique carbon conversion technology while seeking solutions to climate change. Its first product is natural vodka without sugar and carbohydrate. In the past, carbon dioxide was mostly used for making wine as it can create an anaerobic environment to prevent the growth of bacteria. Air Company claims that its product is the “world's first carbon-negative vodka” and is directly converted from carbon dioxide. Simultaneously, a German company is producing a special mattress called Cardyon, where 20% of its material is made from carbon dioxide. Considering that the global production of polyurethane (PU) exceeds 15 million tons per year, there will surely be a huge impact if the raw material is substituted with carbon dioxide. A research team at the Chemical Engineering College of the University of New South Wales, Australia, has conceived a new technology to convert carbon dioxide into a product similar to the ‘Lego building block’. By converting carbon dioxide into simple chemical construction units for building “Lego”, scientists can simply have the carbon dioxide emitted from power plants converted into other practical products such as synthetic fuel or plastics [23]. There are also many similar cases.

In 2015, an entrepreneurial firm Twelve was established in America, opening the market category of “carbon conversion”. The company launched a new catalytic unit, “O12” that is powered by wind, water, and other green energies and can decompose carbon dioxide into carbon monoxide and oxygen, which are further produced into polythene, ethyl alcohol, and other raw materials. On this basis, a further extension is also available. Currently, Twelve and other similar companies have cooperated with some traditional enterprises in producing aviation fuel, auto parts, washing powder, sunglasses, hand sanitizer, sports shoes, vodka, and perfume by using carbon dioxide. This way of “carbon conversion” has two advantages: first, recycling the carbon dioxide emitted and reducing the carbon dioxide content in the air; second, reducing the demand for other carbonic materials and further reducing carbon emission. With the constant progress in the studies of “carbon conversion”, more and more products made from carbon dioxide will appear in our lives.

5. Conclusion

With the gradual increase and maturity of the application of life cycle assessment methods, previously ignored problems have attracted the attention of an increasing number of researchers. Nowadays, society is obsessed with the color, material, and shape of a product. As a result, people only see the finished product and do not consider the pollution and destruction of the environment, ecology, and resources that occur during the manufacturing process. As a result, such an LCA concept must be included when manufacturing products. This is due to the fact that the product's colors, materials, shapes, and functions are only phases and not fixed in stone, whether for nature or for mankind's future sustainable living conditions. In the long run, we must consider how to manufacture a product while minimizing its environmental impact and positively impacting the human body, physiology, emotion, and so on. This is what we must consider when dealing with sustainability. A cradle-to-gate comparison of two types of disposable tableware made of different materials reveals that PLA disposable tableware, used as a substitute for disposable paper tableware, is not more environmentally friendly than disposable paper tableware. Meanwhile, use examples to demonstrate the possibility of carbon transforming into products in our lives and to provide a theoretical foundation for product material selection.

5.1. Research limitations

-

(1)

In this study, when collecting the list data of two types of disposable tableware, the primary list data is from the data published by the government. The second data list is mainly obtained from calling database or by literature research and design calculation. The accuracy of the evaluation results largely depends on the accuracy and availability of the data itself. Domestic disposable tableware enterprises lack the list of related materials and energy consumption, and the credibility of the data is reduced.

-

(2)

This research is mainly about the cradle-to-gate stage of the tableware life cycle. For disposable tableware, the recycling method is relatively complex, and it is not easy to conduct calculation research. So, the Gate to the grave stage is ignored, leading to some uncertainty in the results.

-

(3)

This study conducted limited research on the user's experience using tableware. Therefore, when exploring the possibility of making tableware with carbon dioxide, the user's feelings were ignored. When making tableware based on carbon dioxide, various additive materials are added, which often significantly impacts the environment. In this regard, there are still some deficiencies in this study.

Author contribution statement

Xiangyu Zhu: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Ye Tian: Conceived and designed the experiments.

Shuaiqi Wang: Contributed reagents, materials, analysis tools or data.

Funding statement

Ye Tian was supported by the Project of High-level Talent Platform of Kunming University of Science and Technology "Art Intervention in the Development Path and Value Assessment of Yunnan Special Cultural Industry" [KKKP201855006].

Data availability statement

Data will be made available on request.

Declaration of interest’s statement

The authors declare no conflict of interest.

Institutional review board statement

Not applicable.

Informed consent statement

Not applicable.

Acknowledgments

Thanks to Mr Ye Tian for his final guidance. Thanks to Keyan Chen for providing data to help complete the LCA analysis experiment. Thanks to all the authors for their joint efforts.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2023.e13480.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Victor P. CITIC Press; Beijing: 2013. Design for the Real World: Human Ecology and Social Change. [Google Scholar]

- 2.Zhang Y., Wen Z. Mapping the environmental impacts and policy effectiveness of takeaway food industry in China. Sci. Total Environ. 2022;808 doi: 10.1016/j.scitotenv.2021.152023. [DOI] [PubMed] [Google Scholar]

- 3.Correa J.P., Montalvo-Navarrete J.M., Hidalgo-Salazar M.A. Carbon footprint considerations for biocomposite materials for sustainable products: a review. J. Clean. Prod. 2019;208:785–794. doi: 10.1016/j.jclepro.2018.10.099. [DOI] [Google Scholar]

- 4.Moshood T.D., Nawanir G., Mahmud F., Mohamad F., Ahmad M.H., AbdulGhani A. Sustainability of biodegradable plastics: new problem or solution to solve the global plastic pollution? Curr. Res. Green Sust. Chem. 2022 doi: 10.1016/j.crgsc.2022.100273. [DOI] [Google Scholar]

- 5.Liu C., Luan P., Li Q., Cheng Z., Sun X., Cao D., Zhu H. Biodegradable, hygienic, and compostable tableware from hybrid sugarcane and bamboo fibers as plastic alternative. Matter. 2020;3:2066–2079. doi: 10.1016/j.matt.2020.10.004. [DOI] [Google Scholar]

- 6.Jenner L.C., Rotchell J.M., Bennett R.T., Cowen M., Tentzeris V., Sadofsky L.R. Detection of microplastics in human lung tissue using μFTIR spectroscopy. Sci. Total Environ. 2022;831 doi: 10.1016/j.scitotenv.2022.154907. [DOI] [PubMed] [Google Scholar]

- 7.Cai T., Sun H., Qiao J., Zhu L., Zhang F., Zhang J., Tang Z., Wei X., Yang J., Yuan Q. Cell-free chemoenzymatic starch synthesis from carbon dioxide. Science. 2021;373:1523–1527. doi: 10.1126/science.abh4049. [DOI] [PubMed] [Google Scholar]

- 8.Suwanmanee U., Varabuntoonvit V., Chaiwutthinan P., Tajan M., Mungcharoen T., Leejarkpai T. Life cycle assessment of single use thermoform boxes made from polystyrene (PS), polylactic acid,(PLA), and PLA/starch: cradle to consumer gate. Int. J. Life Cycle Assess. 2013;18:401–417. doi: 10.1007/s11367-012-0479-7. [DOI] [Google Scholar]

- 9.Bhamra T., Lofthouse V. Gower Publishing, Ltd.; 2007. Design for Sustainability: A Practical Approached. [Google Scholar]

- 10.Herrmann I.T., Moltesen A. Does it matter which Life Cycle Assessment (LCA) tool you choose?–a comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015;86:163–169. doi: 10.1016/j.jclepro.2014.08.004. [DOI] [Google Scholar]

- 11.Li D.X., Ye L., Zhi Z.H., Jin Z.Y., Miao M. Life cycle assessment of three typical disposable plastic takeout boxes. Mod. Food Sci. Techn. 2022;38.01:233–237+28. doi: 10.13982/j.mfst.1673-9078.2022.1.1027. [DOI] [Google Scholar]

- 12.Chen X., Matthews H.S., Griffin W.M. Uncertainty caused by life cycle impact assessment methods: case studies in process-based LCI databases. Resour. Conserv. Recycl. 2021;172 doi: 10.1016/j.resconrec.2021.105678. [DOI] [Google Scholar]

- 13.Luan Z. Environmental attributes assessment of product green design and its application based on the Eco-indicator99. Light Ind. Mach. 2004:8–12. doi: 10.3969/j.issn.1005-2895.2004.02.003. [DOI] [Google Scholar]

- 14.Liu M.Y., Ou-Yang D. 4th International Symposium on Lifetime Engineering of Civil Infrastructure (ISLECI 2009) Changsha; China: 2009. Quantitative assessment of life-cycle environmental impacts of bridges based on eco-indicator 99; pp. 255–260.https://www.zhangqiaokeyan.com/academic-conference-foreign_4th-international-symposium-lifetime-engineering-civil-infrastructure_thesis/020511194717.html [Google Scholar]

- 15.Soares S.R., Toffoletto L., Deschênes L. Development of weighting factors in the context of LCIA. J. Clean. Prod. 2006;14:649–660. doi: 10.1016/j.jclepro.2005.07.018. [DOI] [Google Scholar]

- 16.Finnveden G., Hauschild M.Z., Ekvall T., Guinée J., Heijungs R., Hellweg S., Koehler A., Pennington D., Suh S. Recent developments in life cycle assessment. J. Environ. Manag. 2009;91:1–21. doi: 10.1016/j.jenvman.2009.06.018. [DOI] [PubMed] [Google Scholar]

- 17.Genovesi A., Aversa C., Barletta M., Cappiello G., Gisario A. Comparative life cycle analysis of disposable and reusable tableware: the role of bioplastics. Clean Eng. Technol. 2022;6 doi: 10.1016/j.clet.2022.100419. [DOI] [Google Scholar]

- 18.Bush E.J., Harvey L.D. Joint implementation and the ultimate objective of the united Nations Framework convention on climate change. Global Environ. Change. 1997;7:265–285. doi: 10.1016/S0959-3780(97)00012-5. [DOI] [Google Scholar]

- 19.Xuan D., Ma X., Shang Y. Can China's policy of carbon emission trading promote carbon emission reduction? J. Clean. Prod. 2020;270 doi: 10.1016/j.jclepro.2020.122383. [DOI] [Google Scholar]

- 20.Fan X.B. A review of the research on solving the problem of takeout boxes under the background of green development. Log. Eng. Manag. 2021:166–169. doi: 10.3969/j.issn.1674-4993.2021.07.049. [DOI] [Google Scholar]

- 21.Pacheco K.A., Bresciani A.E., Nascimento C.A., Alves R.M. Assessment of property estimation methods for the thermodynamics of carbon dioxide-based products. Energy Convers. Manag. 2020;211 doi: 10.1016/j.enconman.2020.112756. [DOI] [Google Scholar]

- 22.Zhao X., Ma X., Chen B., Shang Y., Song M. Challenges toward carbon neutrality in China: strategies and countermeasures. Resour. Conserv. Recycl. 2022;176 doi: 10.1016/j.resconrec.2021.105959. [DOI] [Google Scholar]

- 23.Daiyan R., Lovell E.C., Huang B., Zubair M., Leverett J., Zhang Q., Lim S., Horlyck J., Tang J., Lu X. Uncovering atomic‐scale stability and reactivity in engineered zinc oxide electrocatalysts for controllable syngas production. Adv. Energy Mater. 2020;10 doi: 10.1002/aenm.202001381. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.