Highlights

-

•

Hot-air, far-infrared and vacuum-freeze drying were investigated on mango slices.

-

•

FIRD had the relative low energy consumption and high product quality.

-

•

Page model described the most satisfactory drying behavior of mango slices in FIRD.

Keywords: Drying kinetics, Temperatures, Slice thicknesses, Far-infrared drying

Abstract

Mangoes have a short shelf life because of their high-water content. This study aimed to compare the effect of three drying methods (HAD, FIRD and VFD) on mango slices to improve product quality and reduce costs. Mangoes were dried at various temperatures (50, 60, 70 °C) with different slice thicknesses (3, 5, 7, 10 mm). Results indicated that FIRD was the most cost-effective with the dried mango containing the highest sugar-acid ratio, and when the mango slices thickness was 7 mm and drying at 70 °C, the ascorbic acid content, rehydration ratio, sugar-acid ratio, and energy consumption per unit volume reached 56.84 ± 2.38 mg/100 g, 2.41 ± 0.05, 83.87 ± 2.14, and 0.53 kWh/L. Among three mathematical models, the Page model described the most satisfactory drying behaviour of mango slices in FIRD. This study provides useful information in mango processing industry and FIRD is supposed to be a promising drying method.

1. Introduction

Mango (Mangifera indica L.) cultivation has become an important characteristic agricultural industry in tropical regions. Mango is rich in fibre and high content of vitamin A and vitamin C, but low in calories (Yao, Fan, & Duan, 2020). Besides extrinsic factors, such as storage time and temperature, intrinsic factors, such as food composition, may lead to different chemical reactions in mango occurring during shelf-life (Wibowo, Buvé, Hendrickx, Van Loey, & Grauwet, 2018). Ripened mangoes are perishable and fresh mangoes are very sensitive to microbial deterioration because of their high-water content. These lead to their short shelf life, and it is a considerable economical and factual issue (Dereje et al., 2020, Sehrawat et al., 2018). Therefore, deep processing and preservation methods have been extensively pursued to expand the storage and consumption of fresh mangoes.

Drying is one of the most typical and economic processing methods applied to reduce post-harvest product loss and increase the shelf life of products. This inhibits bacterial growth and hinders putrefaction reactions mainly attributed to the reduced moisture content (Dereje et al., 2020, Kumar et al., 2014, Macedo et al., 2020). Traditional drying methods include drying in the sun or shade, which are time-consuming. Nowadays, many drying methods have emerged, such as hot-air drying (HAD), far-infrared drying (FIRD), vacuum-freeze drying (VFD) and microwave drying (Kaveh, Abbaspour-Gilandeh, Fatemi, & Chen, 2021). Product quality and energy consumption are two important aspects should be considered during drying (Kumar et al., 2014, Sehrawat et al., 2018). The quality of dried agricultural production is closely related to drying conditions such as drying temperature, duration and slice thickness. Rashidi, M. et al. (Rashidi, Amiri Chayjan, Ghasemi, & Ershadi, 2021) reported that the concentration of ascorbic acid is inversely related to drying temperature. Mugodo, K. and T.S. Workneh (Mugodo & Workneh, 2021) indicated that mango slices with a thinner thickness (3 mm) showed better performance in retaining quality and structure due to the shorter exposure time in the air. On the other hand, the biggest obstacles to restricting the application and promotion of new drying methods in production practice are cost input and energy consumption (Huang & Zhang, 2015). Kaveh, M. et al. (Kaveh et al., 2021) dried agriculture production with seven drying methods (freeze, hot air-infrared, microwave, sun drying, etc.). It was observed that although freeze drying was the best way to preserve nutrients, its energy consumption was the highest due to the long drying duration. Akther et al. (Akther et al., 2021) determined the effects of different drying methods on the physicochemical properties of mango powder and observed that spray drying powder and cabinet drying powder are preferable in terms of producing high-quality products compared to other drying methods. The drying of mango-based pulps and the rehydration properties of the resulting powders produced by cast-tape drying, freeze drying, and spray drying were also evaluated (Zotarelli, Durigon, da Silva, Hubinger, & Laurindo, 2022).

Drying kinetics is to study the relationship between the amount of dehumidification and various factors in the drying process. They are influenced by the processing conditions such as drying temperature and duration, as well as the properties of the products such as thickness. One of the essential keys in drying method is the modelling of the drying process (Türkmen Erol, 2021). Drying kinetics evaluation helps to estimate the drying rate, as well as to optimise drying parameters. Lewis, Page, Henderson, and other models have been used to predict the drying process of fruits and vegetables (Babalis, Papanicolaou, Kyriakis, & Belessiotis, 2006). Based on the model analysis, drying behaviour of various agricultural products, such as potatoes (Türkmen Erol, 2021), onions (Compaore et al., 2019), daylily (Wang, Yang, et al., 2021), bananas (Macedo et al., 2020) and persimmons (Zhao, Ameer, & Eun, 2021), has been studied extensively. However, there are few studies on optimising the drying conditions of mango by detecting its quality, energy consumption, and establishing the corresponding drying kinetics.

Globally, several studies on mango drying have been conducted (Dereje et al., 2020, Malaikritsanachalee et al., 2020, Mugodo and Workneh, 2021, Sehrawat et al., 2018). However, this study is specific to certain drying conditions and has established the drying kinetics of certain drying methods. No literature compares how these methods (HAD, FIRD, VFD) affect the quality of the dried mango and established drying kinetics on the best drying method. This study aims to fill this current knowledge gap. The findings in the current work contribute to a better understanding of the effects of different drying conditions on product quality, energy consumption, and microstructure of mango, which is necessary for selecting suitable drying methods for mango drying. The results would guide practical application and useful information for mango process industry.

2. Materials and methods

2.1. Materials and reagents

Twenty fresh fruits of Keitt mango were harvested from Sichuan Province, China, in October 2021. Standard compounds of ascorbic acid (purity ≥ 99.0 %) were obtained from Solarbio, China. Standard compounds of D-(+)-glucose (purity ≥ 99.5 %) were obtained from Sigma-Aldrich, United States, and all the other reagents were of analytical grade.

2.2. Sample pretreatment and drying processing

The mangoes were cut into small slices after washing and peeling, and the slices with uniform length and width but in different thicknesses (3, 5, 7 and 10 mm) were selected for the following experiments. Mango slices with different thicknesses were dried using vacuum-freeze dryer (12 L vertical freeze dryer, Labconco company, American), hot-air drying oven (M53 blast drying oven, BINDER company, German), or far-infrared drying oven (DIR631C far-infrared heating furnace, Yamato company, American), respectively, under different drying temperatures (50, 60, and 70 °C). Dry processing was stopped when the moisture content reached 15 %.

The ascorbic acid content, retention of soluble sugar content, sugar-acid ratio, rehydration ratio of the dried mango was detected at the condition that slice thickness was 3, 5, 7 and 10 mm.

2.3. Determination of ascorbic acid Content, soluble sugar content and Sugar-Acid ratio

Ascorbic acid was determined by the HPLC method reported by Silva, F.O. (Silva, 2005) with slight modification. Dried samples were added with 0.5 mL of 0.1 mM HCl, followed by adjusting the volume to 10 mL, sonicating in an ultrasonic cleaner (SK7200BT, Shanghai Kedao, China) at 350 W, 35 kHz for 15 min, and centrifuging in a low-speed centrifuge (DL-5C, Shanghai Anting Scientific Instrument Factory, China) at 4,500 rpm, for 10 min. Then the supernatant was collected as the sample extracts. Different concentrations of ascorbic acid standard solution (0.88–12.50, μg/mL, the number of calibration points was 5) and sample extracts were filtered through a 0.45 μm membrane before HPLC analysis (Agilent 1260, Agilent company, American). A Diamonsil C18(2) column (250 × 4.6 mm i.d., 5 µm particle size, Dikma, China) was used for chromatographic separation at the temperature of 30 °C. The mobile phase was a mixture of 0.1 mol/L ammonium formate aqueous solution and methanol (75:25, v/v), and the flow rate was 1.0 mL/min and aliquots of 10 µL were injected. The UV detection was operated at 254 nm (the calibration curve was y = 96.437x-24.403 R2 = 0.9999). All injections were repeated three times to ensure reproducibility.

The soluble sugar content of mango slices before and after drying was determined by 3,5-dinitrosalicylic acid colorimetric method (Yu et al., 2020). The samples were hydrolysed with 1.0 mL of 6 M HCl at 80 °C for 10 min. After cooling, the pH of all samples was neutralised with 6 M NaOH then distilled water for constant volume. The sample solution (1.0 mL) was mixed with 3,5-dinitrosalicylic acid reagent. The mixture was heated for 5 min in a boiling water bath, and the absorbance was measured at 540 nm (the number of calibration points was 7 and the calibration curve was y = 0.9192x-0.0444 R2 = 0.9999). The soluble sugar content retention was calculated as the ratio of the soluble sugar content of fresh mango to dried mango slices. Titratable acid content was determined by acid-base indicator titration (Macedo et al., 2020). Sugar-acid ratio was calculated as the ratio of soluble sugar content to titratable acid content.

2.4. Determination of rehydration ratio

The rehydration ratio was determined based on the method reported by Joseph Bassey, E. et al. (Joseph Bassey, Cheng, & Sun, 2022) with slight modifications. Briefly, 1 g of dried mango slices were immersed in 50 mL distilled water maintained at a temperature of 50 °C for 50 min.

2.5. Scanning electron microscopy (SEM) observation

The microstructure of dried mango slices was observed using a scanning electron microscope (JEOL, JSM-5800, Hitachi, Japan) following the procedure described by Wang et al. (Wang, Han, Huang, and Shi, 2021). The samples of different drying methods were fixed on the aluminium specimen holder with double graphite tapes. The films were sputtered with gold particles and observed under SEM, and XT Microscope Control software was used to collect a map with a magnification of 2000×.

2.6. Drying kinetics

2.6.1. Determination of moisture content and moisture ratio

Drying kinetics was analyzed based on the change in moisture ratio with time, which was an estimation of moisture loss per unit time. For the drying processing of the sample to establish drying kinetics, the thickness of mango slices was 3, 5, 7, and 10 mm, respectively, and mango slices of uniform size were used for the experiments. The samples were dried in a hot-air drying oven and a far-infrared drying oven (drying temperature was 50, 60, 70 °C). The weight of the sample was measured at 20, 40, 60, 80, 100, 120, 150, 180 min, etc., respectively. And vacuum-freeze dried samples were taken out at 12, 24, 36, 48, 60, 72 h, respectively.

The moisture content was calculated according to Eq. (1). Moisture ratio (MR) was calculated according to Eq. (2) (Diamante & Munro, 1993). Equilibrium moisture content (Ce) was the status of neither absorbing nor losing moisture, compared to the initial moisture content (C0) and instantaneous moisture content (Ct). So, Eq. (2) could be simplified to Eq. (3).

| (1) |

| (2) |

| (3) |

mt was the mass of the sample at time t.m was the mass of dry matter.

2.6.2. Drying kinetic model

Three mathematical models (Henderson and Pabis model, Newton model, Page model) (Kaur et al., 2022, Macedo et al., 2020, Türkmen Erol, 2021) for the optimal drying method were conducted to predict the drying characteristics. Three drying kinetic models were tested as follows (Babalis et al., 2006):

| (4) |

| (5) |

| (6) |

Where t was drying duration; a, k, n were undetermined coefficients.

For the convenience of analysis, the logarithm of the Henderson and Pabis model, the Newton model, and the Page model was taken respectively to obtain a linear model, as shown in Eq. (7), Eq. (8), and Eq. (9).

| (7) |

| (8) |

| (9) |

Therefore, the -ln MR ∼ t relationship curves and the ln (-ln MR) ∼ ln t relationship curves of different mango slice thicknesses and drying temperatures were plotted respectively. The slope n and intercept ln k of the fitted would be calculated by the fitted curve according to Eqs. (10), (11), respectively.

| (10) |

| (11) |

where H was the thickness of mango slices; T was drying temperature; a, b, c, d, e, f, g, h, i, j were undetermined coefficients.

The model was evaluated by RSS (residual sum of squares), TSS (total sum of squares), RMSE (root mean square error), R2 and χ2 (chi-square).

| (12) |

| (13) |

| (14) |

| (15) |

| (16) |

2.7. Statistical analysis

All data were expressed as mean ± standard deviation with triple measurements, and they were analyzed by ANOVA and Duncan’s multiple-range test using SPSS statistics software (version 25). Origin software (version 9.0) was used for graphic drawing. Model fitting was analyzed with MATLAB (version 2018a). Statistical significance for differences was tested at 5 % probability level (p < 0.05).

3. Results and discussion

3.1. Changes in the ascorbic acid content of mango slices

Drying temperature had a significant effect on the ascorbic acid content of mango slices in the same slice thickness (Table 1). From the result of FIRD with a slice thickness of 7 mm, the ascorbic acid content of the drying temperature at 50, 60, 70 °C was 69.03 ± 3.47, 62.18 ± 1.60, 56.84 ± 2.38 (mg/100 g), respectively, significantly decreased with increasing drying temperature. It was acknowledged that ascorbic acid was sensitive to environmental conditions, such as oxygen, temperature, light. A similar finding was shown using HAD, indicating that ascorbic acid was heat-sensitive and degraded in aerobic conditions easily (Senem et al., 2015), which was consist with the findings reported by Rashidi et al. (Rashidi et al., 2021). According to the report of Smuda and Glomb (Smuda & Glomb, 2013), around 75 % of the Maillard induced decomposition of the ascorbic acid.

Table 1.

The ascorbic acid content of different mango slices at different drying temperatures.

| Slice thickness/mm | Drying temperature/oC | ascorbic acid content/mg/100 g |

||

|---|---|---|---|---|

| FIRD | HAD | VFD | ||

| 3 | 70 | 42.68 ± 1.35c | 36.85 ± 1.34b | 91.04 ± 4.90a |

| 5 | 70 | 49.49 ± 2.41b | 45.83 ± 3.37a | 80.56 ± 1.79a |

| 7 | 50 | 69.03 ± 3.47A | 57.48 ± 2.30A | 86.54 ± 13.60a |

| 60 | 62.18 ± 1.60B | 50.80 ± 4.11B | ||

| 70 | 56.84 ± 2.38aC | 43.73 ± 1.06aC | ||

| 10 | 70 | 56.93 ± 2.22a | 46.24 ± 2.48a | 79.34 ± 2.81a |

Note: Data were expressed as the mean ± standard deviation (n = 3). Different capital letters (A, B, C) in the same column indicated ascorbic acid content had a significant difference at different drying temperatures (p < 0.05). Different lowercase letters (a, b, c) in the same column indicate ascorbic acid content had a significant difference with different slice thicknesses (p < 0.05).

Meanwhile, the ascorbic acid level was also compared over different slice thicknesses. Under FIRD with mango slices thickness was 3, 5, 7, 10 mm and dried at 70 °C, ascorbic acid content was 42.68 ± 1.35, 49.49 ± 2.41, 56.84 ± 2.38, 56.93 ± 2.22 (mg/100 g), respectively (Table 1). This indicated that mango slice thickness was positively related to the ascorbic acid content of the mango. A similar trend was also observed using HAD. This may be because the thinner mango slice thickness was, the specific surface area was higher, and thus lose more ascorbic acid (Qadri & Srivastava, 2017). For VFD, no significant (p > 0.05) difference between the mango slice thickness and ascorbic acid content was observed, this may be attributed to this processing operated under relatively low temperatures.

Different drying techniques also had a significant effect on the ascorbic acid (p < 0.05). The ascorbic acid dried by VFD had greater retention than FIRD or HAD. The ascorbic acid content of the mango dried by HAD slumped about 13 mg/100 g and 42 mg/100 g compared with those dried by FIRD and VFD with a slice thickness of 7 mm at the temperature of 70 °C. These results may be attributed to the fact that the mango slices dried by FIRD had a higher drying efficiency than HAD at similar drying conditions resulting in less contact with oxygen in the air (Stuart & Wills, 2003).

3.2. Changes in the retention of soluble sugar content and sugar-acid ratio of mango slices

Sugars and acids of mango were extremely significant compounds, which had a great impact on the overall organoleptic quality of the mango (Li et al., 2021). The soluble sugar content of mango slices at 50 °C was significantly higher (p < 0.05) than those at 60 °C and 70 °C in both FIRD and HAD (Table S1). This was probably because Maillard reaction between reducing sugar, such as glucose and fructose, and amino acids or protein during food processing may take place, and thus resulted in macronutrients loss especially at a high temperature for a long time (Abano et al., 2019, Lyu et al., 2017). The titratable acid content of mango slices showed the same result (Table S1). The acid in mango slices could be volatile and even undergo oxidative degradation at a high temperature during the drying process (Stuart & Wills, 2003). The rise noted in the soluble sugar content retention might be attributed to the hydrolysis of carbohydrates by the acids (Grohmann et al., 1995, Mesa et al., 2016). The sugar-acid ratio was calculated and found using HAD and FIRD, that the sugar-acid ratio at 50 °C was lower than 60 °C or 70 °C with a mango slice thickness of 7 mm (Table 2).

Table 2.

The retention of soluble sugar content and the sugar-acid ratio of different mango slices at different drying temperatures.

| Slice Thickness/mm | Drying Temperature/oC | retention of soluble sugar content/% |

sugar-acid ratio |

||||

|---|---|---|---|---|---|---|---|

| FIRD | HAD | VFD | FIRD | HAD | VFD | ||

| 3 | 70 | 72.82 ± 0.02b | 70.21 ± 0.02b | 93.15 ± 0.00a | 62.98 ± 1.60c | 62.34 ± 1.62c | 45.38 ± 0.44a |

| 5 | 70 | 78.50 ± 0.01a | 76.60 ± 0.02a | 89.58 ± 0.02a | 73.13 ± 0.70b | 67.65 ± 1.58c | 44.43 ± 0.81a |

| 7 | 50 | 82.75 ± 0.02A | 79.43 ± 0.02A | 82.82 ± 0.04b | 73.81 ± 1.59B | 71.75 ± 1.99B | 42.30 ± 0.41b |

| 60 | 78.30 ± 0.01B | 74.11 ± 0.00B | 83.11 ± 0.81A | 80.14 ± 0.40A | |||

| 70 | 78.41 ± 0.02aB | 74.36 ± 0.01aB | 83.87 ± 2.14bA | 80.48 ± 1.22bA | |||

| 10 | 70 | 78.23 ± 0.03a | 77.48 ± 0.03a | 76.85 ± 0.04c | 139.70 ± 6.23a | 131.83 ± 4.28a | 40.99 ± 0.87c |

Note: Data were expressed as the mean ± standard deviation (n = 3). Different capital letters (A, B, C) in the same column indicated the retention of soluble sugar content had a significant difference at different drying temperatures (p < 0.05). Different lowercase letters (a, b, c) in the same column indicate the retention of soluble sugar content had a significant difference with different slice thicknesses (p < 0.05).

In this study, the soluble sugar level was also observed over the slice thickness of mango. The soluble sugar content of mango increased with slice thickness, while its titratable acid content decreased (Table S2). Under FIRD with a mango slice thickness of 3, 5, 7, 10 mm and dried at 70 °C, the retention of soluble sugar content was 72.82 ± 0.02, 78.50 ± 0.01, 78.41 ± 0.02, 78.23 ± 0.03(%), respectively (Table 2), positively associated with the slice thickness. The sugar-acid ratio was calculated and it could be seen that the sugar-acid ratio using HAD or FIRD with thicker slice thickness was higher (Table 2). It was speculated that the thinner thickness of mango slices, the higher probability of CO2 in the air may be reacted with the mango during drying (Amoriello et al., 2018, Coenye et al., 2020).

In addition, soluble sugars were also found to be affected by different drying methods (p < 0.05), with VFD having higher soluble sugar content than FIRD or HAD. The titratable acid using VFD was also higher than FIRD or HAD at the same drying condition. This was probably due to the thermal decomposition of heat-sensitive compounds when using FIRD or HAD (Kayacan et al., 2020). However, it was interesting to note that, using FIRD, sugar-acid ratio was the highest compared with HAD or VFD (Table 2). The lowest titratable acid of FIRD mango could be the reason for these changes.

3.3. Comparison of rehydration ratio

The rehydration ratio represents the damage to the internal cell structure of mango slices under different drying conditions (Sehrawat et al., 2018). The results of mango slices rehydration ratio in different dry temperatures and slice thicknesses were summarised in Table 3. The rehydration ratios were significantly higher (p < 0.05) at 50 °C than at 60 °C or 70 °C. This was probably because as the drying temperature decreased, the matrix structure in the mango slices was better maintained, and thus this promoted water reabsorption. For mangos dried by FIRD, HAD and VFD in different slice thicknesses (3, 5, 7, 10 mm) at 70 °C, the rehydration ratios varied from 2.20 ± 0.02 to 2.41 ± 0.07, 2.00 ± 0.02 to 2.36 ± 0.16 and 2.86 ± 0.09 to 2.88 ± 0.11, also showed a positive correlation with slice thickness between 3, 5 mm and 7, 9 mm in FIRD and HAD, respectively. It was also observed that the rehydration using VFD was significantly higher (p < 0.05) than those for mangoes using HAD or FIRD. This was probably because VFD would maintain mango slices a well internal cell structure (Kaur, Kumar, Gupta, & Kumar, 2017). FIRD dried mango achieved a higher rehydration capacity than HAD, which could be attributed to sealed surface capillaries caused by long drying duration (Xu et al., 2020).

Table 3.

The rehydration ratio of different mango slices at different drying temperatures.

| Slice Thickness/mm | Drying Temperature/oC | FIRD | HAD | VFD |

|---|---|---|---|---|

| 3 | 70 | 2.20 ± 0.02b | 2.00 ± 0.02b | 2.88 ± 0.04a |

| 5 | 70 | 2.22 ± 0.01b | 2.12 ± 0.04b | 2.86 ± 0.18a |

| 7 | 50 | 2.78 ± 0.05A | 2.63 ± 0.04A | 2.86 ± 0.09a |

| 60 | 2.49 ± 0.10B | 2.34 ± 0.11B | ||

| 70 | 2.41 ± 0.05aB | 2.34 ± 0.12aB | ||

| 10 | 70 | 2.41 ± 0.07a | 2.36 ± 0.16a | 2.88 ± 0.11a |

Note: Data were expressed as the mean ± standard deviation (n = 3). Different capital letters (A, B, C) in the same column indicated rehydration ratio had a significant difference at different drying temperatures (p < 0.05). Different lowercase letters (a, b, c) in the same column indicate rehydration ratio had a significant difference with different slice thicknesses (p < 0.05).

3.4. Energy consumption

Energy consumption was one of the critical factors for the selection of suitable drying methods as it was linked to the cost of drying. As listed in Table 4, the energy consumption per unit volume was from 0.05 to 0.34 kWh/L, 0.24 to 1.57 kWh/L and 4.0 to 20.0 kWh/L using HAD, FIRD and VFD, respectively. The rise of the drying temperature or decrease in mango slice thickness would reduce the energy consumption due to shorter drying time when moisture content reached about 15 % (Motevali & Tabatabaee Koloor, 2017). Compared with the three drying methods, HAD consumed the lowest energy consumption per unit volume, and VFD was the highest. This was because HAD or FIRD increased the thermal gradient and accelerated moisture removal from the mangoes, thus resulting in shorter drying time and lower consumption of energy (Saifullah, McCullum, McCluskey, & Vuong, 2019).

Table 4.

Energy consumption of different drying methods.

| Energy consumption parameters | Power/kW | Effective Volume/L | Drying temperature /oC |

Slice thickness/mm | Drying duration/h | Energy consumption per unit volume/kWh/L * |

|---|---|---|---|---|---|---|

| Far-Infrared Drying Oven | 10 | 70 | 50 | 3 | 3.2 | 0.46 |

| 5 | 4.5 | 0.64 | ||||

| 7 | 8.0 | 1.17 | ||||

| 10 | 11.0 | 1.57 | ||||

| 60 | 3 | 2.0 | 0.29 | |||

| 5 | 3.7 | 0.53 | ||||

| 7 | 5.0 | 0.71 | ||||

| 10 | 6.5 | 0.93 | ||||

| 70 | 3 | 1.7 | 0.24 | |||

| 5 | 2.3 | 0.33 | ||||

| 7 | 3.7 | 0.53 | ||||

| 10 | 5.3 | 0.76 | ||||

| Hot-Air Drying Oven | 1.2 | 53 | 50 | 3 | 6.0 | 0.14 |

| 5 | 9.0 | 0.20 | ||||

| 7 | 12.0 | 0.27 | ||||

| 10 | 15.0 | 0.34 | ||||

| 60 | 3 | 2.5 | 0.06 | |||

| 5 | 4.5 | 0.10 | ||||

| 7 | 7.0 | 0.17 | ||||

| 10 | 9.0 | 0.20 | ||||

| 70 | 3 | 2.2 | 0.05 | |||

| 5 | 3.5 | 0.08 | ||||

| 7 | 4.5 | 0.10 | ||||

| 10 | 6.0 | 0.14 | ||||

| Vacuum-Freeze Dryer | 2 | 6 | / | 3 | 12.0 | 4.0 |

| 5 | 24.0 | 8.0 | ||||

| 7 | 48.0 | 16.0 | ||||

| 10 | 60.0 | 20.0 |

*Energy consumption per unit volume was the ratio of the product of the power and drying duration to the effective volume with every drying method.

/VFD had no temperature change.

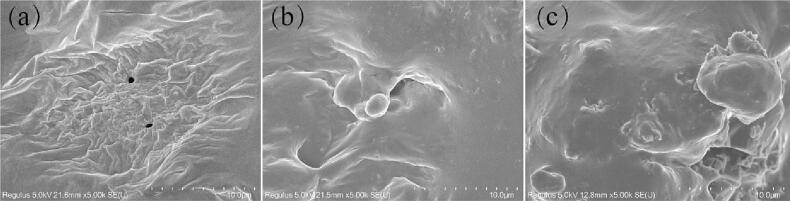

3.5. Microstructure analysis

The effect of various drying methods on the microstructure of dried mango slices was examined by SEM. The microstructure was an important aspect reflecting the performance of the drying method in understanding the underlying cellular mechanisms (Karunasena et al., 2014), and specific degrees of damage to mango tissue could also be indicated by SEM (Mugodo & Workneh, 2021). From Fig. 1, two small and neat pore holes were observed in VFD samples. Such massive and tiny pores caused a high specific surface area, loose and porous structure, which could be attributed to a large vapor pressure between the frozen mango slices and the surrounding environment in vacuum drying conditions (Carmen, Vaclav, José Gerardo, Galal, & Karim, 2014). HAD mango slices were dried under a high temperature and need a long drying duration, so their texture showed more compact to a greater extent, which was consist with reported by Deng et al. (Deng et al., 2017). FIRD samples were shown as smooth surfaces with some irregular pores. This might be due to the much higher evaporation rate of internal water than that of the water migrating from the interior to the exterior, leading to a more compact layer close to the surface of the dried samples (Khampakool et al., 2019, Yao et al., 2020).

Fig. 1.

Appearance of three drying methods (The images were VFD(a), FIRD(b), HAD(c) mango slices, which drying temperature of FIRD and HAD was 70 °C and slice thickness was 7 mm; the magnification was 2000X).

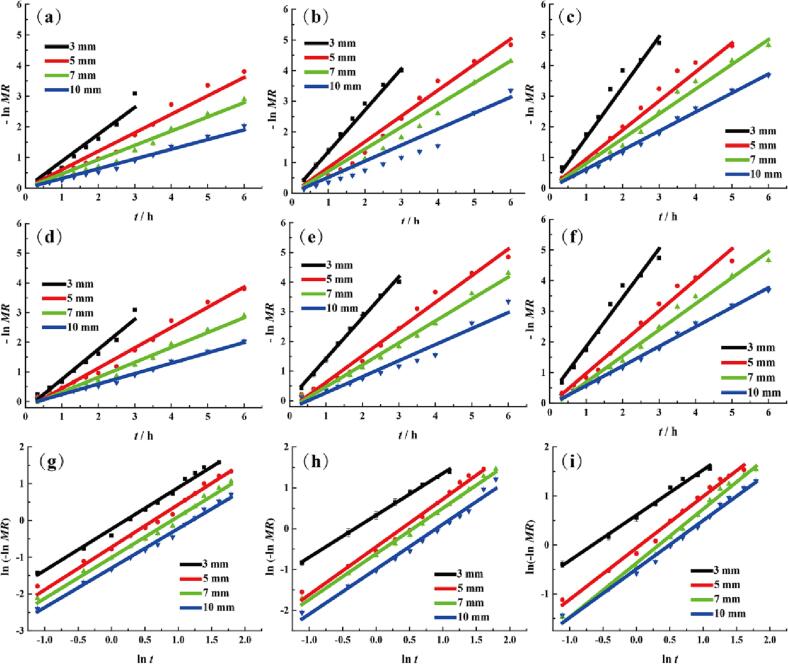

3.6. Drying kinetics

Developing a drying model was crucial to predicting drying process parameters and researching the variation law of drying. Taking both mango overall quality and energy consumption into consideration, FIRD was selected to further evaluate the drying kinetics of mango slices in terms of drying temperature, drying duration and mango slice thickness.

The -ln MR ∼ t curves and ln (-ln MR) ∼ ln t curves of different slice thicknesses and different drying temperatures were calculated. From Fig. 2 and Table S3, the R2 of ln (-ln MR) ∼ ln t curves were higher than the corresponding R2 of -ln MR ∼ t curves, indicating a higher fit for each drying temperature and slice thickness in the ln (-ln MR) ∼ ln t curves. Three different mathematical models, Henderson and Pabis, Newton and Page model were used to describe the drying behaviour of mango samples using the non-linear regression analysis method, and a regression equation was obtained by using MATLAB software. As shown in Table S4, among the three mathematical models, Page model equations represented the drying kinetics of mango with high R2 (>0.980), TSS values (>23.958) and lower RSS (<0.468), χ2(<0.036) and RMSE (<0.060) values. Therefore, the Page model was selected as not only the most appropriate model to describe the drying process of mango slices but also could accurately reflect the FIRD processing between slice thicknesses and drying temperatures.

Fig. 2.

The relationship between the -ln MR and t (the intercept was zero) of dried mango slices with different slice thicknesses with FIRD temperature were set as 50 °C (a), 60 °C (b), 70 °C (c); the relationship between the -ln MR and t of dried mango slices with different slice thickness with FIRD temperature was set as 50 °C (d), 60 °C (e), 70 °C (f) and the relationship between the ln (-ln MR) and ln t of dried mango slices with different slice thickness with FIRD temperature was 50 °C (g), 60 °C (h), 70 °C (i).

4. Conclusion

Considering mango quality and production efficiency, FIRD appears to be a better alternative for drying mango slices on a large-scale. Drying temperature of 70 °C and slice thickness of 7 mm showed higher retention of sugar acid ratio and energy consumption per unit volume. Three drying kinetics, the Henderson and Pabis model, Newton model and Page model of FIRD were developed, and the Page model was the best-fitted theoretical model to reflect the drying behaviour of mango slices. The current findings provide a better understanding of choosing appropriate drying conditions for mango to tackle the problem of postharvest loss and seasonal availability. Future studies can focus on extending FIRD applications to other foods, applying the drying kinetic to the drying process, and scaling up laboratory results for industrial applications. With further research and developments, it is hoped that the technology should become one of the dominant drying methods for the food industry in the future.

CRediT authorship contribution statement

Qiongni Lin: Methodology, Software, Investigation, Data curation, Writing – original draft. Xinyan Zong: Methodology, Software, Data curation. Huixia Lin: Resources. Xiaojun Huang: Supervision, Writing – review & editing. Junqiao Wang: Supervision, Validation, Writing – review & editing. Shaoping Nie: Project administration, Conceptualization, Resources, Supervision, Validation, Writing – review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the Central Government Guide Local Special Fund Project for Scientific and Technological Development of Jiangxi Province (20221ZDD02001) and Open Project Program of State Key Laboratory of Food Science and Technology, Nanchang University (No. SKLF-KF-202013).

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.fochx.2023.100600.

Appendix A. Supplementary data

The following are the Supplementary data to this article:

Data availability

Data will be made available on request.

References

- Abano E.E., Amoah R.S., Opoku E.K. Temperature, microwave power and pomace thickness impact on the drying kinetics and quality of carrot pomace. Journal of Agricultural Engineering. 2019;50(1):28–37. doi: 10.4081/jae.2019.872. [DOI] [Google Scholar]

- Akther S., Sultana A., Badsha M.R., Rahman M.M., Alim M.A., Amin A.M. Physicochemical properties of mango (Amropali cultivar) powder and its reconstituted product as affected by drying methods. International Journal of Food Properties. 2021;23(1):2201–2216. doi: 10.1080/10942912.2020.1849278. [DOI] [Google Scholar]

- Amoriello T., Ciccoritti R., Paliotta M., Carbone K. Classification and prediction of early-to-late ripening apricot quality using spectroscopic techniques combined with chemometric tools. Scientia Horticulturae. 2018;240:310–317. doi: 10.1016/j.scienta.2018.06.031. [DOI] [Google Scholar]

- Babalis S.J., Papanicolaou E., Kyriakis N., Belessiotis V.G. Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficus carica) Journal of Food Engineering. 2006;75(2):205–214. doi: 10.1016/j.jfoodeng.2005.04.008. [DOI] [Google Scholar]

- Carmen T.-P., Vaclav S., José Gerardo M.-G., Galal A., Karim A. Impact of swell-drying process on water activity and drying kinetics of moroccan pepper (Capsicum annum) Drying Technology. 2014;33(2):131–142. doi: 10.1080/07373937.2014.936556. [DOI] [Google Scholar]

- Coenye T., Wei C., Qiao J., Tang X., Yan Q., Tang L.…Huang H. Effect of bagging on the content of sugar and acid in postharvest “Jinhuang” mango fruit. E3S Web of Conferences. 2020;145:01032. doi: 10.1051/e3sconf/202014501032. [DOI] [Google Scholar]

- Compaore A., Putranto A., Dissa A.O., Ouoba S., Remond R., Rogaume Y.…Koulidiati J. Convective drying of onion: Modeling of drying kinetics parameters. Journal of Food Science and Technology. 2019;56(7):3347–3354. doi: 10.1007/s13197-019-03817-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Deng L.-Z., Yang X.-H., Mujumdar A.S., Zhao J.-H., Wang D., Zhang Q.…Xiao H.-W. Red pepper (Capsicum annuum L.) drying: Effects of different drying methods on drying kinetics, physicochemical properties, antioxidant capacity, and microstructure. Drying Technology. 2017;36(8):893–907. doi: 10.1080/07373937.2017.1361439. [DOI] [Google Scholar]

- Dereje B., Abera S., Yildiz F. Effect of some pretreatments before drying on microbial load and sensory acceptability of dried mango slices during storage periods. Cogent Food & Agriculture. 2020;6(1):1807225. doi: 10.1080/23311932.2020.1807225. [DOI] [Google Scholar]

- Diamante L.M., Munro P.A. Mathematical modelling of the thin layer solar drying of sweet potato slices. Solar Energy. 1993;51(4):271–276. doi: 10.1016/0038-092x(93)90122-5. [DOI] [Google Scholar]

- Grohmann K., Cameron R.G., Buslig B.S. Fractionation and pretreatment of orange peel by dilute acid hydrolysis. Bioresource Technology. 1995;54(2):129–141. doi: 10.1016/0960-8524(95)00121-2. [DOI] [Google Scholar]

- Huang J., Zhang M. Effect of three drying methods on the drying characteristics and quality of okra. Drying Technology. 2015;34(8):900–911. doi: 10.1080/07373937.2015.1086367. [DOI] [Google Scholar]

- Joseph Bassey E., Cheng J.-H., Sun D.-W. Improving drying kinetics, physicochemical properties and bioactive compounds of red dragon fruit (Hylocereus species) by novel infrared drying. Food Chemistry. 2022;375 doi: 10.1016/j.foodchem.2021.131886. [DOI] [PubMed] [Google Scholar]

- Karunasena H.C.P., Hesami P., Senadeera W., Gu Y.T., Brown R.J., Oloyede A. Scanning electron microscopic study of microstructure of gala apples during hot air drying. Drying Technology. 2014;32(4):455–468. doi: 10.1080/07373937.2013.837479. [DOI] [Google Scholar]

- Kaur R., Kaur K., Sidhu J.S. Drying kinetics, chemical, and bioactive compounds of yellow sweet pepper as affected by processing conditions. Journal of Food Processing and Preservation. 2022;46(3):e16330. [Google Scholar]

- Kaur R., Kumar M., Gupta O.P., Kumar S. Drying characteristics of mango and development of computer simulated model. Agricultural Research Journal. 2017;54(1):76. doi: 10.5958/2395-146X.2017.00013.8. [DOI] [Google Scholar]

- Kaveh M., Abbaspour-Gilandeh Y., Fatemi H., Chen G. Impact of different drying methods on the drying time, energy, and quality of green peas. Journal of Food Processing and Preservation. 2021;45(6):15503. doi: 10.1111/jfpp.15503. [DOI] [Google Scholar]

- Kayacan S., Karasu S., Akman P.K., Goktas H., Doymaz I., Sagdic O. Effect of different drying methods on total bioactive compounds, phenolic profile, in vitro bioaccessibility of phenolic and HMF formation of persimmon. Lwt. 2020;118:e108830. [Google Scholar]

- Khampakool A., Soisungwan S., Park S.H. Potential application of infrared assisted freeze drying (IRAFD) for banana snacks: Drying kinetics, energy consumption, and texture. Lwt. 2019;99:355–363. doi: 10.1016/j.lwt.2018.09.081. [DOI] [Google Scholar]

- Kumar C., Karim M.A., Joardder M.U.H. Intermittent drying of food products: A critical review. Journal of Food Engineering. 2014;121:48–57. doi: 10.1016/j.jfoodeng.2013.08.014. [DOI] [Google Scholar]

- Stuart D.L., Wills R.B.H. Effect of drying temperature on alkylamide and cichoric acid concentrations of Echinacea purpurea. Journal of Agricultural and Food Chemistry. 2003;51(6):1608–1610. doi: 10.1021/jf026213k. [DOI] [PubMed] [Google Scholar]

- Li Y., Sun H., Li J., Qin S., Yang W., Ma X.…Yang B. Effects of genetic background and altitude on sugars, malic acid and ascorbic acid in fruits of wild and cultivated apples (Malus sp.) Foods. 2021;10(12):2950. doi: 10.3390/foods10122950. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lyu J., Yi J., Bi J., Chen Q., Zhou L., Liu X. Effect of sucrose concentration of osmotic dehydration pretreatment on drying characteristics and texture of peach chips dried by infrared drying coupled with explosion puffing drying. Drying Technology. 2017;35(15):1887–1896. doi: 10.1080/07373937.2017.1286670. [DOI] [Google Scholar]

- Macedo L.L., Vimercati W.C., Araújo C., Saraiva S.H., Teixeira L.J.Q. Effect of drying air temperature on drying kinetics and physicochemical characteristics of dried banana. Journal of Food Process Engineering. 2020;43(9):13451. doi: 10.1111/jfpe.13451. [DOI] [Google Scholar]

- Malaikritsanachalee P., Choosri W., Choosri T. Study on intermittent low-pressure superheated steam drying: Effect on drying kinetics and quality changes in ripe mangoes. Journal of Food Processing and Preservation. 2020;44(9):e14669. [Google Scholar]

- Mesa K., Serra S., Masia A., Gagliardi F., Bucci D., Musacchi S. Seasonal trends of starch and soluble carbohydrates in fruits and leaves of ‘Abbé Fétel’ pear trees and their relationship to fruit quality parameters. Scientia Horticulturae. 2016;211:60–69. doi: 10.1016/j.scienta.2016.08.008. [DOI] [Google Scholar]

- Motevali A., Tabatabaee Koloor R. A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. Journal of Cleaner Production. 2017;154:445–461. doi: 10.1016/j.jclepro.2017.03.219. [DOI] [Google Scholar]

- Mugodo K., Workneh T.S. The kinetics of thin-layer drying and modelling for mango slices and the influence of differing hot-air drying methods on quality. Heliyon. 2021;7(6):e07182. doi: 10.1016/j.heliyon.2021.e07182. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Qadri O.S., Srivastava A.K. Microwave-assisted foam mat drying of guava pulp: Drying kinetics and effect on quality attributes. Journal of Food Process Engineering. 2017;40(1):e12295. [Google Scholar]

- Rashidi M., Amiri Chayjan R., Ghasemi A., Ershadi A. Tomato tablet drying enhancement by intervention of infrared - A response surface strategy for experimental design and optimization. Biosystems Engineering. 2021;208:199–212. doi: 10.1016/j.biosystemseng.2021.06.003. [DOI] [Google Scholar]

- Saifullah M., McCullum R., McCluskey A., Vuong Q. Effects of different drying methods on extractable phenolic compounds and antioxidant properties from lemon myrtle dried leaves. Heliyon. 2019;5(12):e03044. doi: 10.1016/j.heliyon.2019.e03044. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sehrawat R., Nema P.K., Kaur B.P. Quality evaluation and drying characteristics of mango cubes dried using low-pressure superheated steam, vacuum and hot air drying methods. Lwt. 2018;92:548–555. doi: 10.1016/j.lwt.2018.03.012. [DOI] [Google Scholar]

- Senem K., Gamze T., Dilek B., Jules B., Robert D.H., Esra C. A review on the effect of drying on antioxidant potential of fruits and vegetables. Critical Reviews in Food Science and Nutrition. 2015;56(Sup 1):S110–S129. doi: 10.1080/10408398.2015.1045969. [DOI] [PubMed] [Google Scholar]

- Silva F.O. Total ascorbic acid determination in fresh squeezed orange juice by gas chromatography. Food Control. 2005;16(1):55–58. doi: 10.1016/j.foodcont.2003.11.007. [DOI] [Google Scholar]

- Smuda M., Glomb M.A. Maillard degradation pathways of vitamin C. Angewandte Chemie International Edition. 2013;52(18):4887–4891. doi: 10.1002/anie.201300399. [DOI] [PubMed] [Google Scholar]

- Türkmen Erol N. Mathematical modelling of thin layer dried potato and effects of different variables on drying behaviour and quality characteristics. Potato Research. 2021;65(1):65–82. doi: 10.1007/s11540-021-09509-w. [DOI] [Google Scholar]

- Wang N., Yang S., Zhang Y., Jiang L., Zheng X., Jiang P., Chen Y. Drying kinetics and quality characteristics of daylily dried by mid-infrared. International Journal of Food Engineering. 2021;17(12):969–979. doi: 10.1515/ijfe-2021-0137. [DOI] [Google Scholar]

- Wang S.-Y., Han J.-Z., Huang J.-J., Shi X.-D. Physicochemical and functional properties of starches from pachyrhizus erosus with low digestibility. eFood. 2021;2(3):154–161. doi: 10.2991/efood.k.210626.001. [DOI] [Google Scholar]

- Wibowo S., Buvé C., Hendrickx M., Van Loey A., Grauwet T. Integrated science-based approach to study quality changes of shelf-stable food products during storage: A proof of concept on orange and mango juices. Trends in Food Science & Technology. 2018;73:76–86. doi: 10.1016/j.tifs.2018.01.006. [DOI] [Google Scholar]

- Xu Y., Xiao Y., Lagnika C., Li D., Liu C., Jiang N.…Zhang M. A comparative evaluation of nutritional properties, antioxidant capacity and physical characteristics of cabbage (Brassica oleracea var. Capitate var L.) subjected to different drying methods. Food Chemistry. 2020;309 doi: 10.1016/j.foodchem.2019.06.002. [DOI] [PubMed] [Google Scholar]

- Yao L., Fan L., Duan Z. Effect of different pretreatments followed by hot-air and far-infrared drying on the bioactive compounds, physicochemical property and microstructure of mango slices. Food Chemistry. 2020;305 doi: 10.1016/j.foodchem.2019.125477. [DOI] [PubMed] [Google Scholar]

- Yu L., Liao Z., Zhao Y., Zeng X., Yang B., Bai W. Metabolomic analyses of dry lemon slice during storage by NMR. Food Frontiers. 2020;1(2):180–191. doi: 10.1002/fft2.20. [DOI] [Google Scholar]

- Zhao C.-C., Ameer K., Eun J.-B. Effects of various drying conditions and methods on drying kinetics and retention of bioactive compounds in sliced persimmon. Lwt. 2021;143 doi: 10.1016/j.lwt.2021.111149. [DOI] [Google Scholar]

- Zotarelli M.F., Durigon A., da Silva V.M., Hubinger M.D., Laurindo J.B. Rehydration of mango powders produced by cast-tape drying, freeze drying, and spray drying. Drying Technology. 2022;40(1):175–187. doi: 10.1080/07373937.2020.1777562. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data will be made available on request.