Abstract

In this study, the influence of ultrasound-assisted resting at different power on the rheological properties, water distribution and structural characteristics of dough with 50 % surimi as well as the texture, cooking and microstructure characteristics of the surimi-wheat noodles were investigated. Compared with the fermentation control (FC) noodles, the microstructure, cooking and texture characteristics of noodles (≤24.00 W/L) were significantly (p < 0.05) improved after ultrasonic treating. As the increasing of ultrasonic power, compared to FC, the creep strain, recovery strain, semi-bound water, and free sulfhydryl (SH) contents of surimi-wheat dough decreased at first and then increased significantly (p < 0.05). The α-helix and β-turn content of dough increased at first and then decreased after ultrasonic treatment, while the β-sheet was reversed. The surimi-wheat dough network structure was improved by ultrasonic treatment, with the densest and continuous pore size in 21.33 W/L, but the dough structure was broken and loose (>21.33 W/L), which consisted of the hardness, elasticity, chewiness, resistant and cooked quality of surimi-wheat noodles. This work elucidated the effect of ultrasonic power on the performance of surimi-wheat dough, and the optimal ultrasound power was obtained, thereby improving the nutritional properties and the quality of surimi-wheat noodles.

Abbreviations: FITC, fluorescein isothiocyanate; SS, disulfide; SH, sulfhydryl; FT-IR, fourier transform infrared spectrometer; LF-NMR, low field nuclear magnetic resonance; DSC, differential scanning calorimeter; SEM, scanning electron microscope; CLSM, confocal laser scanning microscope; T2, transverse relaxation time; FC, fermentation control; TCA, trichloroacetic acid solution

Keywords: Surimi, Noodles, Dough, Ultrasound treatment, Resting

1. Introduction

In China, the fundamental ingredients for noodles were flour, salt, and water. It has a lengthy history and is well-liked by peoples due to its straightforward prepared, affordable raw material costs, and delicious flavor [1]. Consumer demand for new noodles is rising as the food business develops, particularly for noodles with low levels of wheat gluten protein and other high-value elements. According to studies, low-gluten dough is of poor quality, but its noodle products are healthier [2]. Adding other nutrients to the dough can reduce the gluten content of wheat and improve the high nutritional value. Therefore, grains with high nutrients and surimi that are rich in protein and unsaturated fatty acids were added to wheat flour, which was a feasible way to solve the nutritional problem of noodles [3], [4].

Fish surimi is the primary ingredient of simulated foods such as fish balls, crab sticks and surimi-wheat noodles are enjoyed worldwide as good sources of magnesium, protein, vitamin B12, phosphorus, and selenium due to their unique textural properties and high nutritional value [3], [5]. So, it is possible to increase the nutritional content of noodles by adding surimi. However, after adding a high ratio of surimi, the quality of noodles substantially declined, which resulted in poor quality and formation. The high substitution of surimi gives food technologists a major technological challenge, as gluten is an essential structure-building protein, playing a significant role in the quality of wheat products [6]. Therefore, it is important to find the appropriate processing methods to ensure that noodles with high surimi content have a higher nutritional value and fewer negative effects on other aspects of the noodles.

Resting is usually one of the critical steps in dough production and could have a significant impact on noodle quality [7]. According to Liu, et al. [8], resting was more beneficial to forming an effective gluten network. Resting allows the internal stress, was eliminated by resting for redistributing water within the dough system and improved the quality of dough and noodles [7]. The use of rest and other physical techniques (vacuum [9], alternating current electric fields [10], ultrasound [7], et al.) in combination with wheat composite dough products has not been extensively researched [11].

Ultrasound technology has been widely used in the food industry as a new non-thermal physical processing technology. Since bubbles were created when ultrasound was used in liquid–solid systems, this can result in acoustic cavitation, which can significantly influence the structure and quality of ingredients in food, resulting in changes in food texture, water distribution and microstructure [2], [4], [14]. Dough and product properties could be influenced by ultrasound. Li, et al. [7] found that the quality of fresh wet noodles improved ultrasound-assisted dough resting. Ultrasonic treatment could be used to reduce the resting time of whole wheat dough sheets and improve the gluten network formation of high moisture wheat dough and the texture properties of noodles [12], [13]. Zhang, et al. [4] found that ultrasound at an intensity of 22.5 W/L was used to assist dough fermentation to prepare steamed bread with 50 % sweet potato pulp, which had good quality and sensory characteristics. However, a few people have explored the combination of resting and ultrasound to improve the quality of noodles with high surimi content.

In consequence, this paper studied the influence of ultrasound-assisted resting at different power on surimi-wheat noodles quality and also explored the mechanism of ultrasonic power on the surimi-wheat dough and noodles. First, the influences of ultrasonic at different power on the physicochemical properties and structure of surimi-wheat dough, including rheological properties, secondary structure, disulfide bond content and microstructure were investigated. Then, the cooking quality, texture quality and microstructure of surimi-wheat noodles were analyzed. In brief, the objectives of this study were to (i) investigate the effects of ultrasonic-assisted resting at different power on the quality of the surimi-wheat dough, and (ii) select the best conditions for noodle production.

2. Materials and methods

2.1. Materials

The COFCO International Beijing Company Ltd., (Beijing, China), Guangzhou Branch (Guangzhou, China) provided wheat flour. China National Salt Industry Group Co., Ltd., (Beijing, China) provided salt. The company Hubei Honghu Jingli Aquatic Food Co., Ltd., (Honghu, China) supplied the frozen Long-finned herring surimi (water content: 74.5 %, protein content: 9.06 %). The konjac powder (KGM content: 90 %, water solubility: 75 %, transparency: 55 % viscosity: 32,000 mPa·s) was provided by Zhejiang Yinuo Biotechnology Co., Ltd., (Lanxi, China). All chemicals are analytical reagent grade.

2.2. Preparation of surimi-wheat dough and the cooked noodles

The dough had the following composition: 25 g of deionized water, 1 g of edible salt, 100 g of defrosted surimi, and 100 g of wheat flours by substituting 3 % of the comparable wheat flour with konjac powder, wheat flour was blended. After thawing at 4 °C for 12 h, the frozen surimi was chopped for 5 min. It was chopped into a pulp for 2 min with deionized water and 5 min with edible salt. Wheat flour and chopped surimi were combined in a kneader and blended for 5 min at medium speed to make the surimi-wheat dough. The dough was physically shaped into a circular cake shape. The dough rested for 30 min at 37 °C and 80 % relative humidity as FC in a fermentation tank (TF-16, Thunderbird Food Machinery Co., Ltd., Vencouver, Canada).

The ultrasound-assisted dough manufacturing followed the same pattern as the control. A plastic wrap was used to contain the prepared dough. Afterward, stop outside moisture from penetrating. The dough bag was placed in an ultrasonic bath (KQ-500DE, Kunshan Ultrasonic Instrument Co., Ltd., Kunshan, China) for a 30 min ultrasonic. The power of the ultrasonic was 16.00, 18.67, 21.33, 24.00, and 26.67 W/L. By the literature [4], the bag was situated 3 cm from the bottom and 7 cm below the water surface. Under the iron basket of the ultrasonic water tank was where the bag was found. A cooling water circulation system kept the water in the ultrasonic tank at a temperature of 35 °C.

The production of surimi-wheat noodles was carried out using an extruder (HX-03, Zhongshan COMAHEART INTELLIGENT Technology Co., Ltd., Zhongshan, China) and a circular die with holes with a diameter of 2.8 mm. Extruded dough weighing around 100 g was cooked for 150 s in 500 mL of boiling deionized water. The cooked noodles were then immediately poured into 500 mL of deionized water and allowed to cool to 25 °C. The noodles were then placed on filter paper, drained from the surface and tested within 10 min.

2.3. Rheological behavior

The rheological behavior of the dough was determined by model DHR-2 rotational rheometer (DHR-2, TA Instruments-Waters LLC, New Castle, USA) with parallel plate geometry (40 mm diameter) and a 2 mm gap. The dough was trimmed along the geometric parallel plate and coated with silicone oil. The sample was then rested for 6 min to allow residual tensions to dissipate. The surimi-wheat dough was then given a 6 min rest period to let tensions release. The frequency sweep measurement's linear viscoelastic range (0.10 % strain) was used in 1–10 Hz. The creep was carried out at a constant stress (τ = 50 pa) for 220 s and recovered after stress removal for 330 s. The creep strain (maximum creep strain) and recovery strain were measured according to Wang, et al. [15].

2.4. Water distribution characterization

The water distribution of the dough and magnetic resonance imaging of cooked noodles were determined by LF NMR (MesoMR, Suzhou Niumag Analytical Instrument Co., Ltd., Shanghai, China) [16]. Dough wrapped about 30 g in cling film measuring 5 × 5 cm.

The specific experimental parameters were as follows: Echo count = 4000, TD = 2000, Echo time = 44 μs, SW = 100 kHz, NS = 8, and TW = 2000 ms. T2 transversal relaxation curves were collected using the Carr-Purcell-Meiboom-Gill sequence (CPMG), with 90° and 180° pulses of 32 and 64 μs, respectively.

The T2-weighted images of the noodles were obtained using spin-echo (SE) MRI sequences after absorbing water from the surface of the noodles (0.4 g) with filter paper and placing them on an MRI bed. The parameters are set as follows: Average = 4, RG = 20 dB. Echo time (TE) and repetition time (TR) of T2 weighted image were 20 ms and 500 ms.

2.5. Disulfide-sulfhydryl analysis

The number of free sulfhydryl and total free sulfhydryl in dough was measured using a method that was previously described Cao et al. [16] with minor modifications.

Free sulfhydryl: the freeze-dried power of dough (75 mg) was combined with 1 mL (86 mmol/L Tris-Glycine buffer solution, 90 mmol/L Glycine, 4 mmol/L EDTA, and 4.7 g of guanidine hydrochloride). The mixture was immediately agitated for 30 min after diluting with 10 mL of Tris-Glycine buffer solution. The combined liquid was centrifuged for 10 min at 13600 rpm. A mixture of 5 mL of urea solution (8 mol/L urea, designed with Tris-Glycine buffer) and 0.04 mL of Ellman’s solution (4 mg/ml DTNB (Dithiobis-2-nitrobenzoic acid), also configured with Tris-Glycine buffer), were added to the supernatant (1 mL).

Total free sulfhydryl: the 1.0 mL sample mixture was mixed with 0.05 mL β-mercaptoethanol and 4 mL urea guanidine hydrochloride solution. The mixed solution was rested for 60 min at 25 °C. The sample mixtures were mixed with 10 mL trichloroacetic acid solution (TCA, 12 % W/V). The centrifuged at 4, 000 rpm for 10 min place at 25 °C, pour out the supernatant, add 5 mL of trichloroacetic acid to wash and precipitate twice, and then add 10 mL of urea solution (8 mol/L urea, designed with Tris-Glycine buffer). Add 0.04 mL of Ellman reagent, and measure the absorbance at 412 nm.

At least three measurements for each sample

where: A412 is the absorbance at 412 nm; D is the extinction coefficient, free sulfhydryl Dfree = 5.02, Dtotel = 10; C is the concentration of dough sample (mg /mL); M1 is the content of free thiol group; M2 is the content of total sulfhydryl.

2.6. Secondary structure analysis of dough

Using a Nicolet NEXUS 470 FT-IR spectrometer (Thermo Nicolet Co., Waltham, USA), the surimi-wheat dough of the secondary structure was captured. The sample of freeze-dried dough was precisely weighed, and KBr was added at a ratio of 1:10. The mixture was pressed into transparent slices after being reduced to fine powders. At 4 cm−1 intervals, FT-IR spectra between 4000 and 400 cm−1 wavelengths were captured. Peakfit 4.12 software was used to carry out the structural analysis of the amide I band (1600–1700 cm−1) using the technique described by Hu et al. [18].

2.7. Confocal laser scanning microscope (CLSM) analysis of noodles

By using a CLSM (LSM880, Carl Zeiss Jena Group, Oberkochen, Germany), the microstructure of the surimi wheat protein network of noodles was evaluated [16]. About 1 cm of noodle was wrapped in Leica glue before being sliced into 10 m pieces with a freezing microtome (CM1950, Leica Microsystems, Wetzlar, Germany). Dough sections were stained with Rhodamine B (0.025 %, W/W) to reveal proteins. Following dyeing, the sample was briefly rinsed with deionized water and then dried using filter paper. It was shown that the vascular tool (Angio Tool) can quantitatively analyze surimi-gluten networks.

2.8. Textural characteristics of the noodles

Using the texture analyzer (TA-XT2i; Stable Micro Systems Ltd., Godalming, UK) [16], the resistance and texture profile analysis of the noodles was evaluated. A cooked noodle was fixed to the SH-LS02 probe for the tensile test, which was then conducted with gradually increasing tensile load until the noodle broke. Pre-test, mid-test, and post-test speeds were set at 1 mm/s, with a 70 mm probe travel distance. Three parallel rows of the cooked noodles were set up on the testing platform for texture profile analysis (TPA). Texture parameters were set as pretest speed = 2.0 mm/s; test speed = 0.8 mm/s; posttest speed = 0.8 mm/s and compressed to 50 % of the original height using the probe P50. All the above tests were repeated three times.

2.9. Cooking property

Noodles cooking characteristics were assessed using a modified version of the AACC method [17]. 500 L of boiling, deionized water was used for cooking 10 g of noodles (H1) for 2.5 min. The cooked noodles (H2) water was then collected and diluted with deionized water to a volume of 500 mL. Finally, 100 mL of the solution was put into a beaker (N2) that had already been dried to help remove the majority of the water before being baked at 105 °C for a constant mass (N3).

2.10. Microstructure of dough and noodles

Variation in surimi-gluten structure of dough and cooked noodles were observed using a JSM-7800F SEM (SU-8100, Hitachi, Ltd., Tokyo, Japan). Samples were freeze-dried, broken up, and then covered in gold before being inspected at a 5.0 kV accelerating voltage.

2.11. Statistical analyses

The values were shown as means ± standard after each measurement was made independently-three times. The average value was deemed significant when p < 0.05 in a statistical analysis using IBM SPSS Statistics 24 (SPSS Inc., Chicago, USA).

3. Results and discussion

3.1. Rheological properties

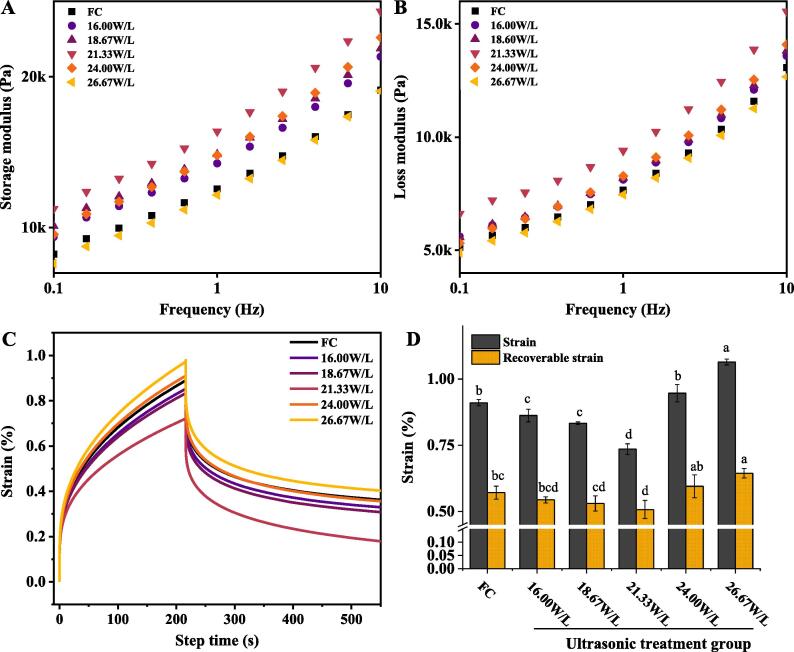

The rheological characteristics of the dough, which ultimately influence the attributes of the dough and product, were intimately tied to the viscoelastic behavior associated with the structure of the gluten network. [19]. Fig. 1A and Fig. 1B shown the variations in G′ and G″ with frequency of dough with 50 % surimi treated by various ultrasonic power. For all of the dough samples, the G′ was greater than G″ (G′ > G″) in 0–10 Hz, showing that the elastic modulus predominated. In actuality, one study found that surimi was added to the wheat dough, which decreased the amount of gluten protein present, and ultimately caused the G′ and G″ to decrease significantly in dough [20]. However, G′ and G″ of dough with ultrasonic power raised (≤21.33 W/L) compared with the control, which showed that ultrasonic could increase the frequency dependence of dough. Using ultrasound during the fermentation of dough with 50 % sweet potato pulp homogenized the dough structure and improved its rheological characteristics [4]. That study also claimed that following ultrasonic, a better gluten network structure was produced, the free sulfhydryl content of the dough dropped, the elongation properties increased, and the quality of steamed bread improved. Furthermore, the G′ and G″ value of dough treated with the ultrasonic power of 21.33 W/L was highest in the dough with ultrasonic [7]. However, when ultrasonic power increased over 21.33 W/L, G′ and G″ values dramatically decreased, showing negative impact on dough rheology of ultrasonic-assisted resting with high power. Because of this, strong ultrasonic fields may cause the wheat glutenin molecule to unravel, impair the link between glutenin and gliadin, and break like polar hydrogen bonds and SS bonds between stable protein molecules [14].

Fig. 1.

The rheological properties of dough in the frequency range of 0.1–10 Hz (A: the storage (G′) moduli, B: loss (G″) moduli) and in the time range of 0–550 s (C: the strain, D: the recovery strain). Different letters superscripted on the columns indicate have a significant difference (p < 0.05).

As shown in Fig. 1C and D, the creep and recovery were the two stages that made up the creep recovery curve of the dough [21]. During the creep stage, the surimi-wheat dough strain grew over time before stabilizing under constant stress. The steady load vanished during the recovery phase, and the dough strain was partially restored with time [15]. The creep strain of the surimi-wheat dough reduced with the raising of ultrasonic power, and it could be considered that ultrasonic treatment improved the hardness of surimi-wheat dough. When the ultrasonic power was increased to 21.33 W/L, the creep strain of the dough decreased by 20.88 %. However, during the recovery phase, the creep strain of the dough increased significantly (p < 0.05) with the persistent increase of ultrasonic power (>21.33 W/L), and the dough with extensive deformation (surimi-wheat network structure is damaged) was difficult to restore to its original state.

During the relaxation stage, although the recovery strain of the dough decreased with increasing ultrasonic power, the recovery rate had contrary trend, which meant that ultrasonic treatment strengthened the rigidity properties of the surimi-wheat dough [15]. Interestingly, when the ultrasonic power was 21.33 W/L, the dough recovery rate reached the highest value of 68.39 %.A previous study indicated that high intensity ultrasound could cause hydrolysis and destruction of protein and polypeptide, and eventually lead to their thermal aggregation [22]. Thus, it is inferred that these effects of ultrasound on the individual components of the dough will result in increasing recovery strain and high ultrasonic power damaged the surimi-gluten network structure and negatively impacted its viscoelasticity [14].

3.2. Water properties

For the manufacturing of noodles, water is a necessary and important element. According to the distribution of the transverse relaxation times, water distributions are designated T21, T22, and T23 in the dough, but it only has T21 and T22 in noodles (Table 1). T21 represents water that was tightly bound to the flour composite, T22 represents semi-bound water, and T23 represents free water [16], [18]. As shown in Table 1, the T22, T23, A21 and A23 of the surimi-wheat dough decreased first and then increased with increasing ultrasonic power, approaching the minimum values at 21.33 W/L, which decreased by 26.09 %, 37.08 %, 33.40 % and 3.95 % with dough as compared with the control, respectively. However, the A22 of surimi-wheat dough had reversed this trend. Interestingly enough, during the ultrasonic-assisted resting power for 21.33 W/L, the internal structure of the dough transformed from chaotic entanglement to orderly unfolding, with the participation of the binding water between starch molecules [7]. This forms an ordered and dense network of gluten molecules. Therefore the A22 of dough was increased and the T22 decreased. Ultrasonic at a certain power had caused rearrangement of molecules, increased bound-water content in dough and reinforce hydrogen bonding between water molecules [23]. Meanwhile, the intermolecular semi-bound water of starch and myofibrils can be converted into bound water involved in the formation of gluten network. In the process of stacking and extending ordered structure of gluten and extension of the ordered structure, part of the water will be discharged, leading to a basic unchanged or slightly reduced the A23 contents [24]. Furthermore, an excessively high power treatment may cause the surimi-wheat gluten network to be destroyed and the water retention capacity to diminish [2].

Table 1.

The spin–spin relaxation time and areas proportion of various peak of surimi-wheat dough and noodles with different ultrasonic power.

| Ultrasonic power (W/L) | T21/ms | T22/ms | T23/ms | A21 | A22 | A23 | |

|---|---|---|---|---|---|---|---|

| Dough | FC | 0.02 ± 0.00a | 2.53 ± 0.10a | 186.89 ± 7.40ab | 9.88 ± 0.30a | 87.59 ± 0.33e | 2.53 ± 0.03a |

| 16.00 | 0.02 ± 0.00a | 2.41 ± 0.00a | 196.05 ± 15.34a | 9.39 ± 0.16b | 87.99 ± 0.22e | 2.62 ± 0.08a | |

| 18.67 | 0.02 ± 0.00a | 2.20 ± 0.09b | 191.16 ± 0.00ab | 8.55 ± 0.18c | 88.92 ± 0.07d | 2.53 ± 0.12a | |

| 21.33 | 0.02 ± 0.00a | 1.87 ± 0.08c | 117.59 ± 0.00c | 6.58 ± 0.22e | 90.99 ± 0.27a | 2.43 ± 0.05a | |

| 24.00 | 0.02 ± 0.00a | 2.00 ± 0.08c | 178.34 ± 0.00b | 7.03 ± 0.36e | 90.51 ± 0.21b | 2.46 ± 0.16a | |

| 26.67 | 0.02 ± 0.00a | 2.20 ± 0.09b | 186.89 ± 7.40ab | 7.90 ± 0.11d | 89.47 ± 0.08c | 2.63 ± 0.07a | |

| Noodles | FC | 0.02 ± 0.00b | 10.87 ± 0.89a | – | 13.04 ± 1.28bc | 86.96 ± 1.28ab | – |

| 16.00 | 0.02 ± 0.00b | 7.84 ± 0.00bc | – | 11.32 ± 2.37c | 88.67 ± 2.41a | – | |

| 18.67 | 0.02 ± 0.00b | 6.84 ± 0.47c | – | 12.68 ± 0.32bc | 87.32 ± 0.32ab | – | |

| 21.33 | 0.02 ± 0.00b | 5.81 ± 0.23a | – | 17.10 ± 0.90a | 82.90 ± 0.90c | – | |

| 24.00 | 0.02 ± 0.02b | 7.84 ± 0.00bc | – | 15.94 ± 2.50ab | 84.04 ± 2.47bc | – | |

| 26.67 | 0.12 ± 0.10a | 8.22 ± 0.33b | – | 11.65 ± 1.39c | 88.35 ± 1.39a | – | |

Different superscript letters in the same line are significant difference (p < 0.05).

3.3. Secondary structure and free sulfhydryl of gluten surimi-wheat dough

The three-dimensional helix structure of proteins were stabilized by the disulfide bonds, which were involved in gluten protein formation [25]. The free SH content decreased by 53.28 %, and the content of SS bonds increased by 28.92 % after ultrasonic-assisted resting (Table 2). Due to the addition of surimi, which dilutes the structure of the gluten network and further decreases dough stability, the free SH concents in the surimi-wheat dough were considerably lower than those in the FC (p < 0.05), but can improve the quality of dough by ultrasonic-assisted resting. First, the amount of free SH in the dough decreased, and then it rose, and the contents of SS bonds increased and then decreased with the increase in ultrasonic power. In addition, the free SH contents reduced to 0.85 μmol/g and the content of SS bonds increased significantly (p < 0.05) to 6.70 μmol/g compared with the control at the ultrasonic power of 21.33 W/L. Because low ultrasonic power could improve protein–protein interactions and orderly glutenin cross-linking, which reduces the amount of free SH required for gluten protein cross-linking and eventually increased SS bonds amounts. Additionally, the cavitation action of ultrasonic waves in water can produce hydroxyl radicals that can oxidize free SH into SS bonds, enhancing the network structure of the gluten protein [26]. The free SH contents increased when the ultrasonic power was above 21.33 W/L. The cavitation effect of ultrasound causes the free SH content inside the protein fold to be exposed to the outside, which further leads to an increased the content of the free SH [4]. Therefore, the SS bonds could be destroyed to generate SH by the cavitation effect, and the gluten spatial structure could be destroyed at higher ultrasonic power [27].

Table 2.

The secondary structure, SS bonds and free SH contents of surimi-wheat dough treated with different ultrasonic power.

| Ultrasonic power (W/L) | β-sheet (%) | α-helical (%) | β-turn (%) | Free SH contents (μmol/g) | SS bonds contents (μmol/g) |

|---|---|---|---|---|---|

| FC | 29.19 ± 0.77c | 33.48 ± 0.12e | 37.34 ± 0.87a | 2.44 ± 0.01b | 4.08 ± 0.24e |

| 16.00 | 28.96 ± 0.10c | 37.92 ± 0.01b | 33.11 ± 0.11b | 1.14 ± 0.03c | 5.26 ± 0.16d |

| 18.67 | 29.24 ± 0.00c | 37.80 ± 0.00c | 32.96 ± 0.00b | 1.02 ± 0.01d | 5.75 ± 0.06c |

| 21.33 | 38.58 ± 0.05a | 28.03 ± 0.09f | 33.39 ± 0.05b | 0.85 ± 0.01e | 6.70 ± 0.04a |

| 24.00 | 30.72 ± 0.55b | 36.07 ± 0.00d | 33.21 ± 0.00b | 1.12 ± 0.08c | 6.07 ± 0.07b |

| 26.67 | 28.66 ± 0.07c | 38.15 ± 0.03a | 33.19 ± 0.04b | 3.15 ± 0.04a | 3.13 ± 0.10f |

Different superscript letters in the same line are significant difference (p < 0.05).

The infrared spectroscopy could reveal the structural changes of lyophilized dough powder [28]. The structure changes of surimi-wheat dough had been shown in Table 3, with the highest percentage of β-turn, followed by β-sheet and α-helix. The results illustrated that ultrasound could change the structural conformation of surimi-wheat dough, unraveling the structure changes of the gluten and surimi protein and fracturing a part of the hydrogen bonds, which led to first decreased and then increased in α-helical content and conversion to β-sheet and β-turn. Within ultrasonic power of 16.00 W/L, the percentage of α-helix significantly increased to 37.92 % compared with the control (p < 0.05), the percentage of β-sheet and β-turn was lower than that of FC. The α-helix reduced content was helpful to the unfolding of the gluten protein [29]. A hydrogen bond formed between two chains of a protein results in the formation of α-helix, whereas an inter-chain hydrogen bond results in the formation of β-sheet. This might be attributed to ultrasound produced the high pressure and mechanical forces, and encouraged the formation of hydrogen bonds. According to Li et al. [30], who studied the secondary protein structure of noodles, an increase in α-helix was associated with dough elasticity. According to the aforementioned results, it may be concluded that the α-helix content of decreased and β-sheet content of increased were caused by ultrasound-assisted resting of high power. These changes in protein structures are in agreement with RincónAguirre, et al. [31], they indicated that the formation of intermolecular β-sheets and β-turns accompanied by the reduction of α-helical structures at 30–45 °C.

Table 3.

Texture and cooking properties of surimi-wheat cooked noodles with different ultrasonic power.

| Ultrasonic power (W/L) | Texture properties |

Cooking properties |

||||||

|---|---|---|---|---|---|---|---|---|

| Hardness (g) | Elasticity | Chewiness | Resistant (g) | Extensibility (cm) | Water absorption (%) | Cooking loss (%) | Turbidity | |

| FC | 2495.53 ± 88.34e | 0.91 ± 0.03a | 1670.58 ± 46.00b | 0.19 ± 0.00e | 23.50 ± 1.15d | 33.66 ± 0.64b | 4.94 ± 0.42ab | 0.35 ± 0.02b |

| 16.00 | 2639.69 ± 33.11d | 0.90 ± 0.03a | 1698.41 ± 88.64b | 0.22 ± 0.00d | 25.03 ± 0.51 cd | 32.28 ± 2.89b | 3.14 ± 0.47 cd | 0.37 ± 0.01b |

| 18.67 | 2927.77 ± 43.94c | 0.86 ± 0.04a | 1698.08 ± 114.94b | 0.25 ± 0.00c | 27.86 ± 1.10c | 33.91 ± 0.72b | 3.89 ± 0.93bc | 0.22 ± 0.00c |

| 21.33 | 3395.08 ± 40.88a | 0.87 ± 0.02a | 1933.58 ± 81.47a | 0.32 ± 0.01a | 50.23 ± 1.20a | 39.55 ± 0.45a | 2.36 ± 0.20d | 0.19 ± 0.00d |

| 24.00 | 3167.70 ± 17.29b | 0.84 ± 0.03a | 1741.30 ± 57.92ab | 0.29 ± 0.01b | 34.63 ± 3.85b | 38.20 ± 2.53a | 3.39 ± 0.33 cd | 0.37 ± 0.00b |

| 26.67 | 2322.37 ± 16.77f | 0.86 ± 0.07a | 1346.98 ± 191.01c | 0.17 ± 0.01f | 16.40 ± 2.26e | 32.38 ± 2.40b | 5.20 ± 0.81a | 0.44 ± 0.01a |

Different superscript letters in the same line are significant difference (p < 0.05).

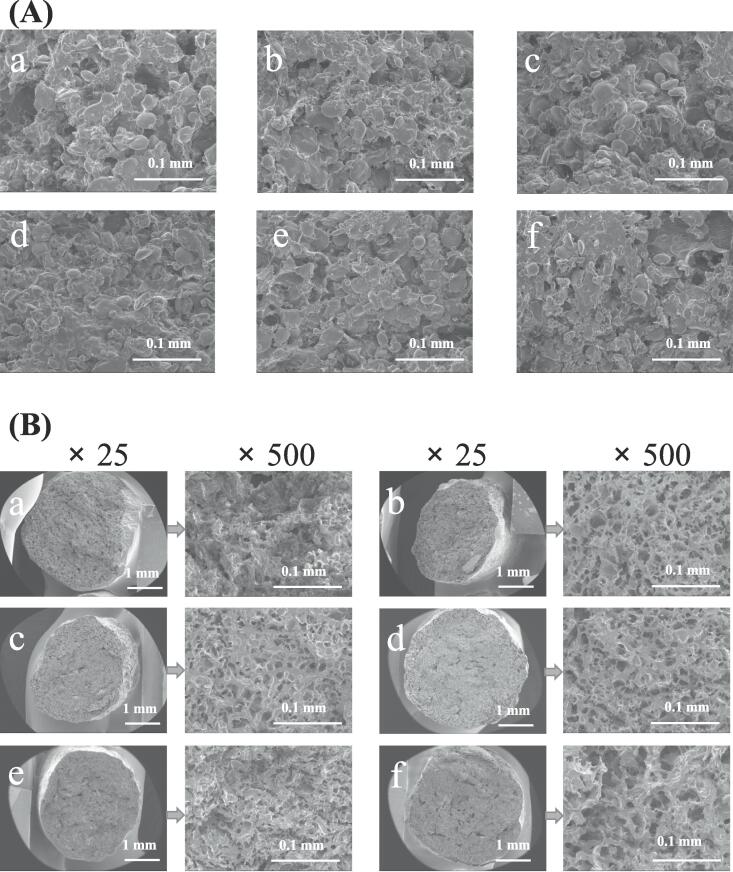

3.4. Microstructures of surimi-wheat dough

The microstructure of dough with ultrasonic-assisted resting in different power was observed by SEM (Fig. 4A). Surimi addition decreased the amount of gluten present, which hindered the development of the protein network structure and finally damaged the uniformity and completeness of the surimi-wheat dough structure. Some of the starch granules in FC were left and exposed since they could not be enveloped by the gluten network (Fig. 4A-a). However, compared to the FC, sonication considerably enhanced the consistency of the gluten network structure, allowing surimi and starch granules to be uniformly incorporated into the gluten matrix. The improvement of dough quality by ultrasonic-assisited resting, disruption of gluten network structure due to addition of surimi. Additionally, with an ultrasonic power of 21.33 W/L, the starch and surimi granules were spread the most evenly in the surimi-wheat dough (Fig. 4B, d). When the treatment power was higher than 21.33 W/L, the dough improving effect started to wane, the protein phase was broken up into huge cracks, and starch granules were plainly visible. This phenomenon might be destroyed the SS and hydrogen bonds of gluten because of high ultrasonic power and ultimately led to the reduction of gluten network in dough [4]. Furthermore, the internal hydrogen bonds between gulten and surimi protein molecules may be destroyed by high temperature and pressure of sonication, weakening the tertiary and quaternary structures of protein, and leading to a loose network structure of surimi-gluten [14].

Fig. 4.

The SEM micrographs of dough (A, ×500) and noodles (B, ×25 and ×500) with ultrasonic-assisted resting at different power. A and B (a: fermentation control (FC); b: 16.00 W/L; c: 18.67 W/L; d: 21.33 W/L; e: 24.00 W/L; f: 26.67 W/L).

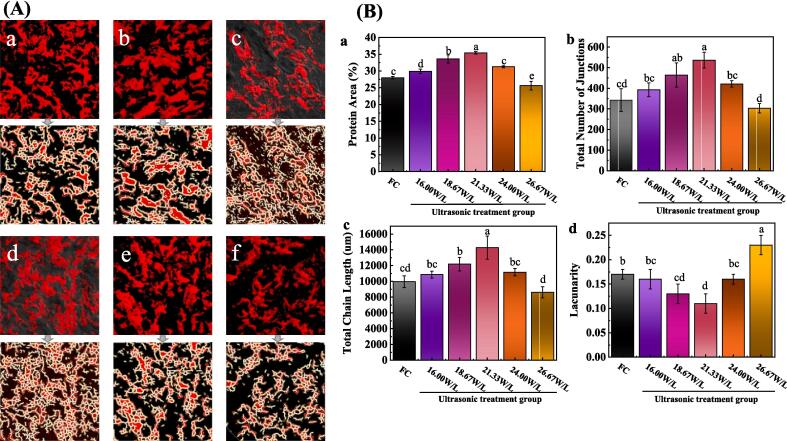

3.5. Microstructure of noodles

By using a CLSM, the structure of the surimi wheat protein network was evaluated. As shown in Fig. 3A, the surimi-gluten matrix of the cooked noodles all presented a honeycomb-like structure. As the proportion of ultrasonic power increased from 18.67 to 21.33 W/L, the surimi-gluten matrix network appeared uniformed distribution, no-collapsed and became lower roughness (Fig. 3A-b and -c). When the ultrasonic power was adjusted to 21.33 W/L (Fig. 3A-d), the most apparent improved behavior appeared on matrix networks, and black void area decreased in the gluten-surimi network. The protein network was loose and discontinuous, resulting in many holes when ultrasonic power exceeded to 21.33 W/L (Fig. 3A-e and -f). Furthermore, the differences in the surimi-gluten protein network were quantified by protein area, the total number of junctions, total chain length, and lacunarity (Fig. 3 B) [32]. As the ultrasonic power increased, the protein percentage area, the total number of junctions, and total chain length increased first and then decreased, while the lacunarity showed a reversed trend. When the ultrasonic power was 21.33 W/L, the cooked surimi-wheat noodles had extremum value (Fig. 3A-d). Consistent with dough rheological properties, ultrasonic-assisted treatment made the surimi-gluten network more strengthen and improved the microstructure of the dough. However, high ultrasonic power of the dough may result in excessive heating, protein spatial structure unfolding, and a further step in the collapse of the surimi-gluten structure [4]. After the ultrasonic-assisted, the components of the dough could be easier hydrated, which was promoted to the formation of gluten network [7].

Fig. 3.

CLSM of gluten-surimi networks of noodles and their fitted graphs (A) and the analysis results of the CLSM micrographs (B). A-a: fermentation control (FC); A-b: 16.00 W/L; A-c: 18.67 W/L; A-d: 21.33 W/L; A-e: 24.00 W/L; A-f: 26.67 W/L. B-a, proteins area (%); B-b, the total number of junctions; B-c, total chain length; B-d: lacunarity.

Noodle cross-sectional structures were displayed in Fig. 4B. Noodle cross-sectional pores in the control group (FC) were rough, big, and uneven. However, noodles were more regular and equally distributed following ultrasonic-assisted resting. Fewer irregular pores and a more continuous structure were seen as ultrasonic power increased. Large amounts of surimi in the sample disrupted the gluten network, but surimi protein interacted with the gluten to produce a linear after cooking, resistant frame that could bind the soluble ingredients in the cooked noodles and result in a compact structure. Li, et al. [7] found that ultrasonic treatment could improve the quality of fresh wet noodles.

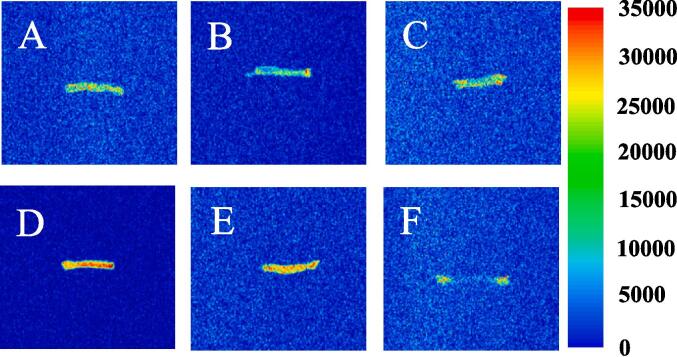

3.6. Noodle properties

As shown in Fig. 2, the colour from red to blue represents high to low proton density after cooking. With the increase of ultrasonic power, the signal intensity of red colour of cooked noodles in 21.33 W/L became stronger than others samples. As shown in Table 1, the T22 and A22 of surimi-wheat noodles decreased first and then increased with increasing ultrasonic power, reaching the minimum at 21.33 W/L, which decreased by 46.55 %, 4.67 % as compared with the control, respectively. However, the A21 of noodles had reversed trend. The pseudo-colour diagram of Fig. 2 D to E showed a large red area with high water content after ultrasonic power for 21.33 W/L. Interestingly enough that ultrasonic treatment enables spatial protein structure to develop, further to increase water binding capacity [7]. Ultrasound transferred pressure waves which may, to some extent, unfold the protein structure, then form crosslinks. And water is confined inside the polymer matrix, which caused the together of bound-water and the reduction of relaxation time [23], [24]. According to Liang et al. [24], the construction of a regular and ordered network structure was encouraged while protein cross-linking and aggregation were strengthened when ultrasonic and microwave technology were combined with water bath heating.

Fig. 2.

The MRI images of cooked noodles with ultrasonic-assisted resting at different power. A: fermentation control (FC); B: 16.00 W/L; C: 18.67 W/L; D: 21.33 W/L; E: 24.00 W/L; F: 26.67 W/L.

Table 3 showed the texture and cooking properties of noodles sample. Noodles of high quality should have greater water absorption, and low cooking losses [33]. Except for no-ultrasonic resting, the resistant of the noodles was significantly (p < 0.05) higher than that of the control after ultrasonic (≤24.00 W/L). At 21.33 W/L, the resistant reached the maximum value, and increased significantly (p < 0.05) by 68.42 % compared with the control. The increase of ultrasonic power could increase the resistant and the extensibility distance of surimi-wheat noodles. The resistance distances of the noodles was significantly (p < 0.05)less than that of the control at 26.67 W/L. When the ultrasonic power was over high, the components of the dough could be over hydrated, which was damaged to the formation of gluten network [7]. With ultrasonic power increasing, the structure of surimi-wheat gluten network became stronger and the noodles became more extensibility. Positive relationships existed between the noodles of extensibility and resistance distances, which both increased initially before declining. Tan, et al. [34] also revealed that cake batter mixed by ultrasound produced a high quality of cake with higher springiness, cohesiveness and resilience. The hardness and chewiness of dough increased first and then declined with the increased of the ultrasonic power. The gluten network was continuously improved, and when dough increases to a certain point, there was not be any noticeable increases or even much weakening, which will reduce the resistance, hardness, and chewiness of the noodles [7]. Noodles can absorb water at a substantially higher rate at 21.33 and 24.00 W/L. On the one hand, the development of the gluten network can be blamed for the rise in water absorption. On the other hand, it might be connected to the roughness of the surfaces of big molecules like starch. However, due to the increased ultrasonic power, more starch granules from the gluten network were exposed to the surface of the noodles, where were easily peeled off, increasing the noodles of cooking loss. The turbidity of noodles soup was an important evaluation index for noodles, the lower the soup turbidity the better the noodles qualities. The turbidity of soup noodles first decreased to the minimum value of 0.19, and then increased. When surimi-wheat noodles had treated with appropriate ultrasonic power, the extra amount of surimi-gluten network could further wrap starch swelling and reduced spontaneous rupture [4], so the turbidity of noodles soup decreased. And the ultrasonic power of 21.33 W/L could obtain a better quality of noodles with the lowest turbidity.

4. Conclusion

The qualities of dough and noodles containing 50 % surimi were significantly improved by ultrasonic-assisted resting. Results demonstrated that the optimum attribute of surimi-wheat dough and noodles were obtained under the ultrasonic power of 21.33 W/L. Ultrasonic at low power treatment (≤21.33 W/L) could reduce the content of free SH in dough, and significantly improve the formation of SS bonds, which resulted in an improvement in the rheological properties of dough and the quality characteristics of noodles. The bound-water of the dough was transferred to semi-bound water after sonication. The dough and noodles with sonication had better continuity surimi-gluten-starch matrix evenly filled with the starch and surimi particles, which made the gluten network structure more compact. Compared with the FC, ultrasound treatment (≤21.33 W/L) had a remarkable impact on the hardness, chewiness, resistant and extensibility of surimi-wheat noodles (p < 0.05). Moreover, the cooking properties of surimi-wheat noodles were improved by ultrasonic-assisted resting treatment. This paper lacks in-depth research on starch, and hopes to supplement it later. However, this study provided a new reference scheme for the development of noodles with high addition of surimi, further enriched the theoretical system of ultrasonic modification of flour products, and provided a theoretical basis for the application of ultrasonic technology in noodles preparation.

CRediT authorship contribution statement

Geng Cao: Investigation, Writing – original draft. Xueting Chen: Investigation, Formal analysis. Bingbing Hu: Methodology, Formal analysis. Zuoqian Yang: Methodology, Formal analysis. Man Wang: Methodology, Formal analysis. Shuang Song: Supervision, Resources. Lei Wang: Methodology, Formal analysis. Chengrong Wen: Supervision, Funding acquisition, Writing – review & editing, Project administration.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by Natural Science Foundation of Liaoning Province (No. 2022-MS-348) and National Key R&D Program of China (No. 2022YFF1100503). The authors are grateful to the testing center of Dalian Polytechnic University for the access to the facility and analytical devices.

References

- 1.Xu M., Wu Y., Hou G.G., Du X.F. Evaluation of different tea extracts on dough, textural, and functional properties of dry Chinese white salted noodle. LWT-Food Sci. Technol. 2019;101:456–462. [Google Scholar]

- 2.Zhang H.X., Chen G.J., Liu M., Mei X.F., Yu Q.Q., Kan J.Q. Effects of multi-frequency ultrasound on physicochemical properties, structural characteristics of gluten protein and the quality of noodle. Ultrason. Sonochem. 2020;67 doi: 10.1016/j.ultsonch.2020.105135. [DOI] [PubMed] [Google Scholar]

- 3.Li T., Niu L.H., Li X.H., Wang F.X., Hang Y.Q., Liu Y.L. Formation of advanced glycation end-products in silver carp (Hypophthalmichthys molitrix) surimi products during heat treatment as affected by freezing-thawing cycles. Food Chem. 2022;395 doi: 10.1016/j.foodchem.2022.133612. [DOI] [PubMed] [Google Scholar]

- 4.Zhang M., Deng Y.X., Jiang L.J., Qi M.M., Liu Y., Li L.X., Wang C.J., Zheng H., Li H.J. Effect of ultrasound-assisted dough fermentation on the quality of dough and steamed bread with 50% sweet potato pulp. Ultrason. Sonochem. 2022;82 doi: 10.1016/j.ultsonch.2022.105912. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Wu Y.S., Lin Y., Wang S.Y., Lin D.Q., Chen J., Chen Y.C. Effects of washing step and salt-addition levels on textural and quality properties in the chicken-surimi products. Poultry Sci. 2022;101 doi: 10.1016/j.psj.2022.101885. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Diego A.S.N., Yamul K. Effect of hydrocolloids on structural and functional properties of wheat/potato (50/50) flour dough. Food Struct. 2020;24 [Google Scholar]

- 7.Li S., Tang D., Liu S., Qin S., Chen Y.e. Improvement of noodle quality: The effect of ultrasonic on noodles resting. J. Cereal Sci. 2020;96:103089. [Google Scholar]

- 8.Liu S.Y., Liu Q., Li X., Obadi M., Jiang S., Li S.Y., Xu B. Effects of dough resting time on the development of gluten network in different sheeting directions and the textural properties of noodle dough. LWT-Food Sci. Technol. 2021;141 [Google Scholar]

- 9.Bozkurt S., Görgüç A., Gençdağ E., Elmas F., Koç M., Yılmaz F.M. Principles and recent applications of vacuum technology in the processing of dough-based cereal products: A comprehensive review. Food Chem. 2023;403:134443. doi: 10.1016/j.foodchem.2022.134443. [DOI] [PubMed] [Google Scholar]

- 10.Brandner S., Becker T., Jekle M. Instantaneous wheat dough relaxation by alternating current electric fields. J. Food Eng. 2022;315 [Google Scholar]

- 11.Jha P.K., Chevallier S., Cheio J., Rawson A., LeBail A. Impact of resting time between mixing and shaping on the dough porosity and final cell distribution in sandwich bread. J. Food Eng. 2017;194:15–23. [Google Scholar]

- 12.Wang L., Zhang Y., Xu F., Chen J. Effects of ultrasound-assisted resting on the tensile properties and gluten network formation of wheat noodle dough. J. Food Meas. Charact. 2022;16:4273–4283. [Google Scholar]

- 13.Xing J.-J., Qiao J.-Y., Yang Z., Guo X.-N., Zhu K.-X. Effects of ultrasound-assisted resting on the qualities of whole wheat dough sheets and noodles. Int. J. Food Sci. Technol. 2021;56(11):5609–5618. [Google Scholar]

- 14.Luo D.L., Wu R.Y., Zhang J., Zhang K.Y., Xu B.C., Li P.Y., Yuan Y.X., Li X. Effects of ultrasound assisted dough fermentation on the quality of steamed bread. J. Cereal Sci. 2018;83:147–152. [Google Scholar]

- 15.Wang C.C., Yang Z., Xing J.J., Guo X.N., Zhu K.X. Effects of insoluble dietary fiber and ferulic acid on the rheological properties of dough. Food Hydrocolloids. 2021;121 doi: 10.1016/j.foodchem.2021.130444. [DOI] [PubMed] [Google Scholar]

- 16.Cao G., Chen X.T., Wang N., Tian J., Song S., Wu X.Y., Wang L., Wen C.R. Effect of konjac glucomannan with different viscosities on the quality of surimi-wheat dough and noodles. Int. J. Food Sci. Technol. 2022;221:1228–1237. doi: 10.1016/j.ijbiomac.2022.09.024. [DOI] [PubMed] [Google Scholar]

- 17.AACC. Approved Methods of the American Association of Cereal Chemists (10th ed.), American Association of Cereal Chemists. Inc., St. Paul. Minnesota, USA (2000).

- 18.Hu X.H., Cheng L., Hong Y., Li Z.F., Li C.M., Gu Z.B. Impact of celluloses and pectins restrictions on gluten development and water distribution in potato-wheat flour dough. Int. J. Food Sci. Technol. 2022;206:534–542. doi: 10.1016/j.ijbiomac.2022.02.150. [DOI] [PubMed] [Google Scholar]

- 19.Cao Y.F., Zhang F.J., Guo P., Dong S., Li H.J. Effect of wheat flour substitution with potato pulp on dough rheology, the quality of steamed bread and in vitro starch digestibility. LWT-Food Sci. Technol. 2019;111:527–533. [Google Scholar]

- 20.Nawaz A., Li E.P., Khalifa I., Irshad S., Walayat N., Mohammed H.H.H., Zhang Z.L., Ahmed S., Simirgiotis M.J. Evaluation of fish meat noodles: physical property, dough rheology, chemistry and water distribution properties. Int. J. Food Sci. Technol. 2020;56:1061–1069. [Google Scholar]

- 21.Bonnand-Ducasse M., Della Valle G., Lefebvre J., Saulnier L. Effect of wheat dietary fibres on bread dough development and rheological properties. J. Cereal Sci. 2010;52:200–206. [Google Scholar]

- 22.Arzeni C., Pérez O.E., Pilosof A.M.R. Functionality of egg white proteins as affected by high intensity ultrasound. Food Hydrocolloids. 2012;29:308–316. [Google Scholar]

- 23.Zhang Y.Y., Li Y.L., Wang H.W., Oladejo A.O., Zhang H., Liu X.L. Effects of ultrasound-assisted freezing on the water migration of dough and the structural characteristics of gluten components. J. Cereal Sci. 2020;94 [Google Scholar]

- 24.Liang F., Zhu Y.J., Ye T., Jiang S.T., Lin L., Lu J.F. Effect of ultrasound assisted treatment and microwave combined with water bath heating on gel properties of surimi-crabmeat mixed gels. LWT-Food Sci. Technol. 2020;133 [Google Scholar]

- 25.Bai N., Guo X.N., Xing J.J., Zhu K.X. Effect of freeze-thaw cycles on the physicochemical properties and frying performance of frozen Youtiao dough. Food Chem. 2022;386 doi: 10.1016/j.foodchem.2022.132854. [DOI] [PubMed] [Google Scholar]

- 26.Wen C.T., Zhang J.X., Zhou J., Duan Y.Q., Zhang H.H., Ma H.L. Effects of slit divergent ultrasound and enzymatic treatment on the structure and antioxidant activity of arrowhead protein. Ultrason. Sonochem. 2018;49:294–302. doi: 10.1016/j.ultsonch.2018.08.018. [DOI] [PubMed] [Google Scholar]

- 27.Zhang Y.Y., Wang B.R., Wang W.T., Wang H.W., Liu X.L., Zhang H. Study on the mechanism of ultrasonic treatment impact on the dough’s fermentation capability. J. Cereal Sci. 2021;100 [Google Scholar]

- 28.Kuang J.W., Yang Q., Huang J.R., Cao Y.H., Pu H.Y., Ma W.Y., Min C., Xiong Y.L. Curdlan-induced rheological, thermal and structural property changes of wheat dough components during heat treatment. J. Cereal Sci. 2022;107 [Google Scholar]

- 29.Gülseren İ., Güzey D., Bruce B.D., Weiss J. Structural and functional changes in ultrasonicated bovine serum albumin solutions. Ultrason. Sonochem. 2007;14:173–183. doi: 10.1016/j.ultsonch.2005.07.006. [DOI] [PubMed] [Google Scholar]

- 30.Li M., Zhu K.X., Peng J., Guo X.N., Amza T., Peng W., Zhou H.M. Delineating the protein changes in Asian noodles induced by vacuum mixing. Food Chem. 2014;143:9–16. doi: 10.1016/j.foodchem.2013.07.086. [DOI] [PubMed] [Google Scholar]

- 31.RincónAguirre A., FigueroaCárdenas J.D.D., RamírezWong B., Ibba M.I., Cruz E.M. Nixtamalization of durum wheat and the effect on protein secondary structure, gliadins, dough, and breadmaking quality. J. Cereal Sci. 2022;107 [Google Scholar]

- 32.Cao Z.B., Yu C., Yang Z., Xing J.J., Guo X.N., Zhu K.X. Impact of gluten quality on textural stability of cooked noodles and the underlying mechanism. Food Hydrocolloids. 2021;119 [Google Scholar]

- 33.Yang Y., Guan E., Zhang L., Li M., Bian K. Mechanical action on the development of dough and its influence on rheological properties and protein network structure. Food Res. Int. 2022;158 doi: 10.1016/j.foodres.2022.111495. [DOI] [PubMed] [Google Scholar]

- 34.Tan M.C., Chin N.L., Yusof Y.A. Power ultrasound aided batter mixing for sponge cake batter. J. Food Eng. 2011;104:430–437. [Google Scholar]