Abstract

An extremely reduced loss tangent while retaining ultrahigh dielectric permittivity can be successfully obtained in La1.9Sr0.1NiO4 ceramics by doping with Mg2+ ions. A single phase of La1.9Sr0.1NiO4 was detected in all the sintered ceramics, while the lattice parameters increased with increasing doping concentration, indicating that Mg2+ ions can enter the Ni2+ sites. A highly dense microstructure is achieved. Microstructural analysis revealed that Mg2+ ions disperse well in the microstructure of La1.9Sr0.1NiO4 ceramics. Interestingly, ultra–high dielectric permittivity of approximately 8.11 × 105 at 1 kHz is achieved in the La1.9Sr0.1Ni0.6Mg0.4O4 ceramic, while the loss tangent is significantly reduced by two orders of magnitude compared to the undoped La1.9Sr0.1NiO4 ceramic. The DC conductivity significantly decreased by three orders of magnitude. The giant dielectric responses are described by Maxwell–Wagner polarization and small polaron hopping mechanisms. Thus, the significant reduction in the loss tangent can be attributed to the significantly enhanced resistance of the grain boundaries.

Keywords: Nickelate, Giant dielectric properties, Loss tangent, DC conduction, Maxwell−Wagner polarization

1. Introduction

Giant dielectric permittivity materials such as CaCu3Ti4O12 (CCTO) and isostructural ACu3Ti4O12-oxides [[1], [2], [3], [4], [5], [6], [7], [8], [9], [10]], CuO [11], co-doped NiO-based oxides [12,13], AFe1/2B1/2O3 (A = Ca, Sr, Ba; B = Sb, Ta, Nb) [14], co-doped TiO2-based oxides [[15], [16], [17], [18], [19], [20], [21], [22]], co-doped SrTiO3-based oxides [23], and Ln2-xSrxNiO4 (Ln = La, Nd, and Sm) (LnSNO) ceramics [[24], [25], [26], [27], [28], [29], [30]], have been widely investigated in recent years. These giant dielectric materials (or colossal-permittivity materials) can exhibit extreme values of dielectric permittivity (ε′) of approximately 104–106 compared to those of ferroelectric materials (e.g., BaTiO3-based oxides), which are currently used in multilayer ceramic capacitors (MLCCs). In addition to MLCCs, these newly discovered giant dielectric materials have high potential for use in high-energy-density storage devices when some important material parameters can be improved [31].

LnSNO is a promising giant dielectric oxide. LnSNO ceramics exhibited extremely large ε′ ≈ 105–106 in the radio frequency range, while a high ε′ ≈ 104 was retained in the GHz region [25]. By considering the aspects of materials science coupled with resource strategies and resource management, LnSNO has been judged to be potentially critical in the future compared to CCTO and BaTiO3 ceramics [32]. Unfortunately, the great questions on which practical applications of LnSNO ceramics can be developed remain. First, the low–frequency loss tangent of all LnSNO ceramics is generally very large (tanδ ≈ 102–103) among all giant dielectric–permittivity materials [[25], [26], [27], [28],33]. Second, besides the N2−annealed Nd2NiO4+δ ceramic [34], ε′ the values in all frequency ranges were strongly dependent on temperature, especially in the high-temperature range [[35], [36], [37], [38]].

The giant dielectric response (GDR) in LnSNO has been explained to be the extrinsic or intrinsic effect, that is, the sample–electrode effect [39] or small polaronic hopping mechanism [25,33,38,40]. Most recently, we have clearly shown that the GDR in La1.7Sr0.3NiO4 results from a combination of the non-Ohmic contact between the sample−electrode interface and small polaronic hopping effects [24]. The GDRs resulting from these two effects are usually accompanied by a large DC conductivity, and hence, the tanδ value [41]. We have experimentally demonstrated that the dominant electrode effect in La1.7Sr0.3NiO4 ceramics can be significantly reduced (or perhaps concealed) by enhancing the grain boundary resistance, which can be achieved by doping with Mg2+ ions with Ni2+ sites [24]. This experimental result was consistent with the theoretical prediction proposed by Li et al. [42]. As a result, the DC conductivity and tanδ of the La1.7Sr0.3NiO4 ceramics decreased significantly. Furthermore, a significantly reduced tanδ with excellent temperature stability of ε′ (at 1 MHz) in the temperature range of 250–450 K was obtained in La1.5Sr0.5NiO4 (LSNO)–xSiO2 composites, which was attributed to the formation of insulating grain boundaries [28]. Thus, it is reasonable to expect that the greatly enhanced resistance of the grain boundary can improve the dielectric properties of giant dielectric oxides [6,15,24,[43], [44], [45]]. Unfortunately, in both cases, the DC conductivities and related tanδ values for the La1.5Sr0.5NiO4–0.8SiO2 and Mg2+−doped La1.7Sr0.3NiO4 ceramics were still too large. This may be due to the large number of Sr2+ ions, which can induce Ni2+ to Ni3+ ions due to charge compensation. The polaronic concentration is directly dependent on the Sr2+ content.

Therefore, the aim of this work is to provide a new route to simultaneously reduce the low-frequency tanδ value of La1.9Sr0.1NiO4 ceramics and improve the temperature stability ε′ without any significant effect on very large ε′ values (≈8.1 × 105 at 1 kHz). Enhancement of the insulating grain boundary resistivity is the primary cause of the decrease in tanδ of La1.9Sr0.1NiO4 ceramics by doping with Mg2+ ions. A new strategy for the improvement of the temperature dependence of ε′ is also proposed by means of an enlarged polaronic size by reducing the Sr2+ content (x = 0.1 for La2-xSrxNiO4) to shorten the long–range motion of free charge carriers (holes) and/or confining them inside an individual grain.

2. Experimental details

La1.9Sr0.1Ni1-xMgxO4 (x = 0, 0.3, 0.4, and 0.5) materials were prepared using a chemical combustion route and sintered at 1375 °C for 6 h in air. The details of the chemical combustion method for preparing La1.9Sr0.1Ni1-xMgxO4 materials are provided elsewhere [24,29]. The sintered La19Sr01NiO4, La19Sr01Ni0.7Mg0.3O4, La19Sr01Ni0.6Mg0.4O4, and La19Sr01Ni0.5Mg0.5O4 were abbreviated as the LSNO, LSNO_Mg03, LSNO_Mg04, and LSNO_Mg05 ceramics, respectively.

The prepared ceramic samples were characterized by scanning electron microscopy (SEM) (LEO 1450VP, UK). For SEM observation, the surface of the as-sintered samples was polished and thermally etched at 1100 °C for 0.5 h. The density was measured using the Archimedes’ method. The presence of each type of ion in the La1.9Sr0.1Ni1-xMgxO ceramics was confirmed by energy-dispersive X-ray spectroscopy (EDS, HITACHI SU8030, Japan). The structure and phase composition were confirmed using X-ray diffraction (XRD) spectroscopy (PANalytical, EMPYREAN). X-ray photoelectron spectroscopy (XPS) was used to demonstrate the presence of Ni2+ and Ni3+ ions in the sintered La1.9Sr0.1Ni1−xMgxO4 ceramics. XPS spectra were collected using a PHI5000 VersaProbe II (ULVAC-PHI, Japan). The PHI MultiPak XPS software and Gaussian−Lorentzian lines were used to obtain the Ni3+/Ni2+ ratio.

For the electrical and dielectric measurements, the surfaces of the sintered ceramics were polished smoothly. The Au electrode was fabricated by sputtering onto polished surfaces using a Polaron SC500 sputter−coating unit. The dielectric properties of the La1.9Sr0.1Ni1−xMgxO ceramics as a function of frequency (102−106 Hz) and temperature (−70 to 150 °C) were investigated using a KEYSIGHT E4990A impedance analyzer. The ac conductivity (σac) was calculated using the equation σac = ωεoε′′, where ω = 2πf, εo is the permittivity of free space (8.854 × 10−12 F/m), and ε′′ is the imaginary part of the complex dielectric permittivity, which was calculated by ε′′ = ε′ × tanδ. At a low−frequency range, if σac is dependent on frequency, σac is approximately equal to the dc conductivity (σdc).

3. Results and discussion

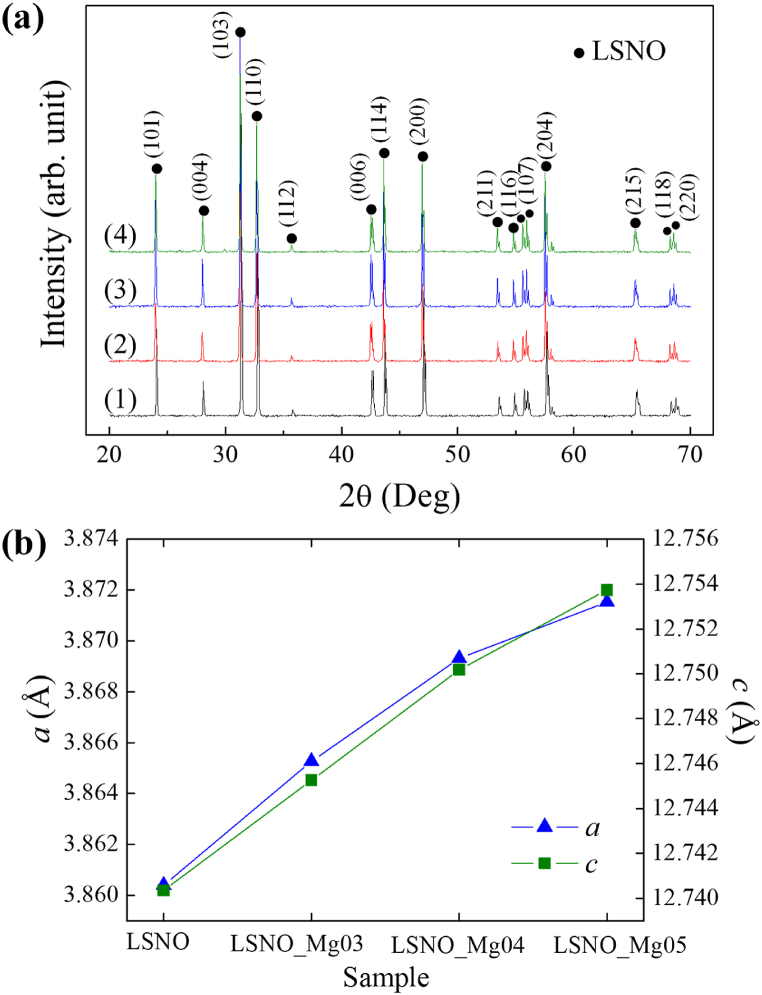

The tetragonal structure of La1.9Sr0.1Ni1-xMgxO4 (JCPDS 32-1241) was confirmed using XRD, as shown in Fig. 1(a). These XRD patterns are similar to those reported in literature [24,29,33,36]. A single phase of LSNO was observed without any impurities. The combustion method was successfully used to produce La1.9Sr0.1Ni1−xMgxO4 ceramics. The lattice parameters (a and c) of all ceramic samples are shown in Fig. 1(b). Obviously, the cell parameters of the La1.9Sr0.1Ni1−xMgxO4 ceramics increased with increasing Mg2+ doping ions. This indicates that Mg2+ ions can be substituted into the lattice structure of the LSNO. The enlargement of the cell parameters results from the different ionic radii between the Ni2+ host ions (r4 = 0.55 Å) and Mg2+ doping ions (r4 = 0.57 Å) [46].

Fig. 1.

(a) XRD patterns of (1) LSNO, (2) LSNO_Mg03, (3) LSNO_Mg04, and (4) LSNO_Mg05. (b) Lattice parameters (a and c) of all the sintered ceramics.

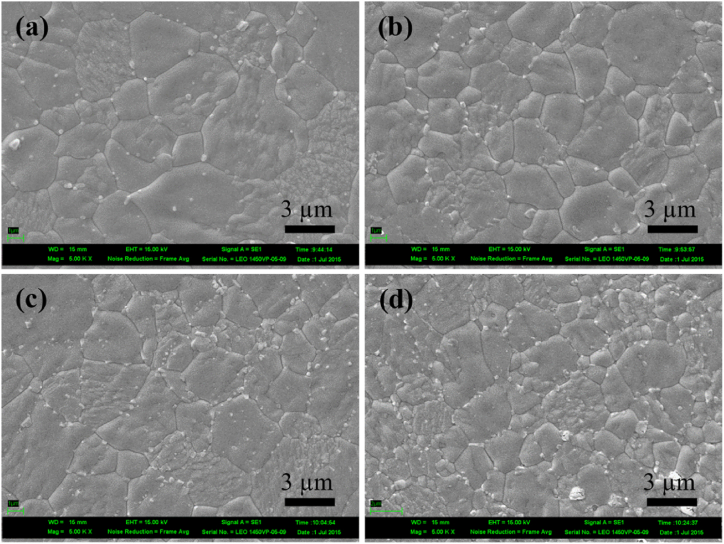

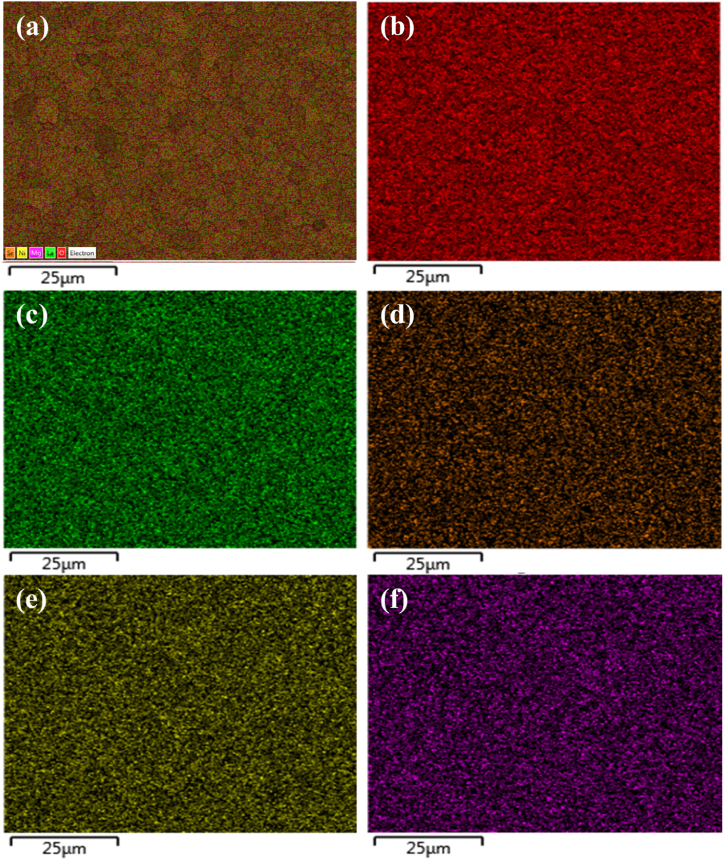

Fig. 2(a–d) shows the morphologies of all the sintered ceramics. A highly dense microstructure without porosity was achieved in all sintered ceramics. The relative density of all samples was ∼98%. The mean grain size tended to decrease when Mg2+ increased, indicating that Mg2+ doping inhibited the grain growth rate of the La1.9Sr0.1Ni1−xMgxO4 ceramics [47]. The suppressed grain growth found in the La1.9Sr0.1Ni1−xMgxO4 ceramics because of Mg2+ is similar to that observed in Mg2+-doped CCTO and ACu3Ti4O12 ceramics [48,49]. Fig. 3(a–f) shows the microstructure analysis of the LSNO_Mg04 ceramic using the SEM−mapping technique. The Mg dopant and the major elements (La, Sr, Ni, and O) were well dispersed in the microstructure. No segregation of the Mg dopant at the grain boundaries or other regions was observed. This result supports the XRD result because Mg2+ ions can likely be substituted into the LSNO structure without the formation of a new phase, the second phase. It was also observed that some white points appeared on the SEM images (Fig. 2), whereas they cannot be detected by the SEM-mapping technique. These particles may be an impurity phase, which was segregated during the sintering process.

Fig. 2.

SEM images of (a) LSNO, (b) LSNO_Mg03, (c) LSNO_Mg04, and (d) LSNO_Mg05 ceramics.

Fig. 3.

SEM mapping images of LSNO_Mg04 ceramics; (a) all elements, (b) O, (c) La, (d) Sr, (e) Ni, and (f) Mg.

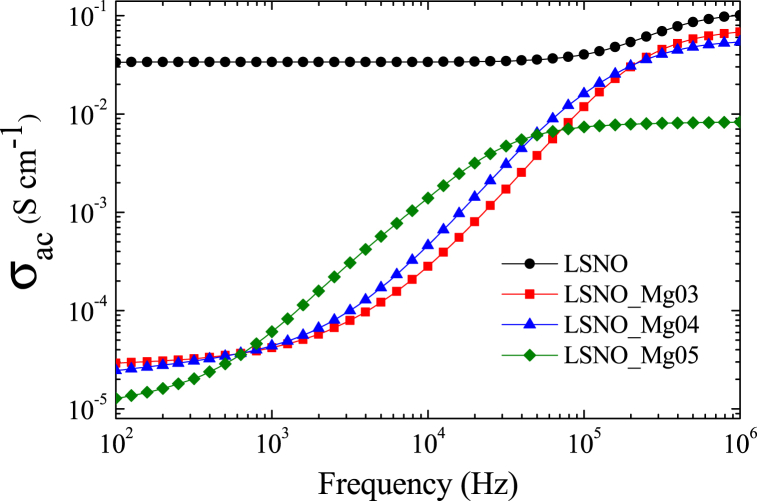

The AC conductivities (σac) of the La1.9Sr0.1Ni1−xMgxO4 ceramics are shown in Fig. 4. The σac in a low-frequency range is independent of the frequency, which is usually estimated to be the DC conductivity (σdc) [50]. The σdc value was estimated from the σac at 102 Hz. As clearly seen, σ the dc of the LSNO ceramics was significantly reduced by three orders of magnitude after doping with Mg2+ ions. The σdc values of the LSNO, LSNO_Mg03, LSNO_Mg04, and LSNO_Mg05 ceramics were 3.4 × 10−2, 4.2 × 10−5, 4.4 × 10−5, and 6.1 × 10−5 S cm−1, respectively. This indicates that doping LSNO with Mg2+ ions can enhance the total resistivity, which is significantly affected by the insulating grain boundaries. Therefore, doping LSNO with Mg2+ may reduce the long–range motion of free charge carriers (i.e., holes) and/or confining them inside an individual grain.

Fig. 4.

Frequency dependence of AC conductivity (σac) for sintered ceramics at room temperature.

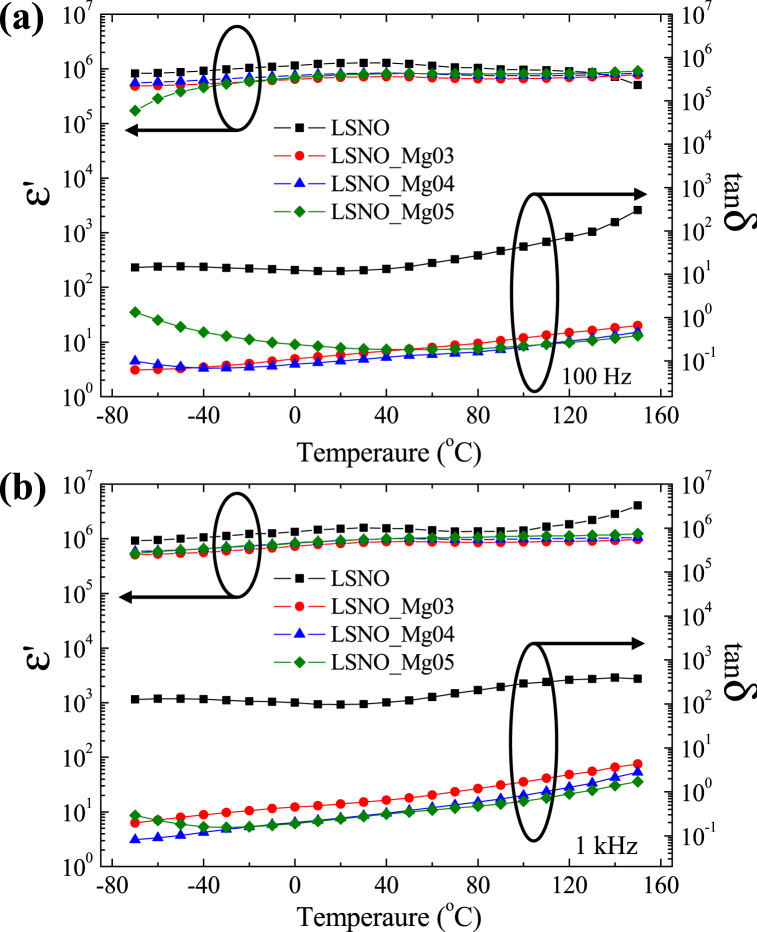

The GDR at different temperatures (−70 to 150 °C) at 100 Hz and 1 kHz for the sintered La1.9Sr0.1Ni1−xMgxO4 are displayed in Fig. 5(a and b), respectively. All the samples showed large ε′ values on the order of 105−106 over the measured temperature range. The ε′ of the La1.9Sr0.1Ni1−xMgxO4 ceramics changed slightly with the doping concentration. Furthermore, ε′ of all La1.9Sr0.1Ni1−xMgxO4 ceramics is slightly dependent on the temperature compared to that of the undoped ceramic. Surprisingly, tanδ of the LSNO ceramics was significantly reduced by at least two orders of magnitude after doping with Mg2+ ions. The ε′ values at 1 kHz and 20 °C of the LSNO_Mg03, LSNO_Mg04, and LSNO_Mg05 ceramics were 12.6 × 105, 6.96 × 105, 8.11 × 105, and 7.68 × 105, respectively, while the tanδ values were 11.76, 0.138, 0.099, and 0.200, respectively.

Fig. 5.

Temperature dependence of dielectric permittivity (ε′) and loss tangent (tanδ) for ceramics sintered at (a) 100 Hz and (b) 1 kHz.

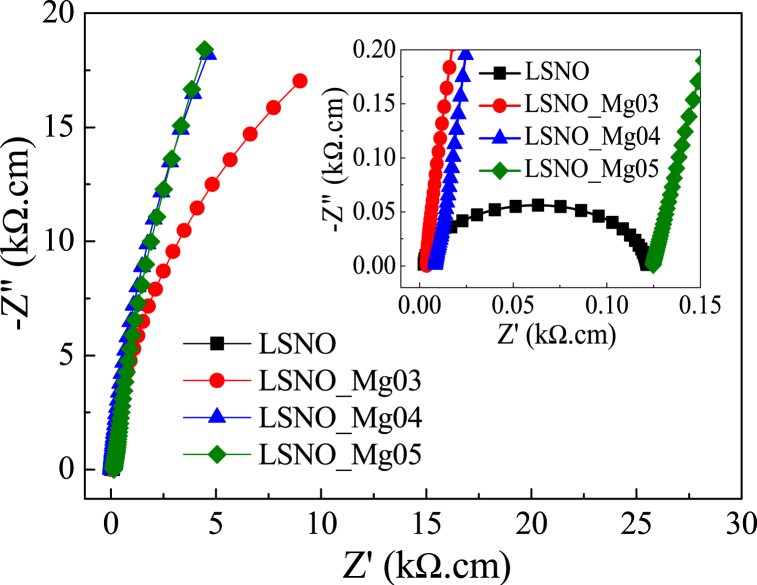

As clearly demonstrated in Fig. 6 and the inset, the resistance of the grain boundary (Rgb) of the LSNO ceramics was greatly increased by doping with Mg2+ ions, while the grain resistance (Rg) increased. It should be noted that the Rgb of the undoped LSNO was very low (∼125 Ω cm), as shown in the inset of Fig. 6. The origin of the GDR in LSNO ceramics was described by the small polaron hopping and sample−electrode contact effect [25,38,39]. This was due to the very low Rgb value of LSNO. However, upon doping LSNO with Mg2+, the Rgb values increased significantly. Therefore, the origin of the observed dielectric properties of the LSNO_Mg03, LSNO_Mg04, and LSNO_Mg05 ceramics should be primarily attributed to Maxwell–Wagner polarization. The significant reduction in tanδ in the La1.9Sr0.1Ni1-xMgxO4 ceramics can be explained by the extremely high Rgb value. It is worth noting that the dielectric properties of many giant dielectric oxides can be controlled by the electrical properties of the grain boundary such as CCTO [[51], [52], [53], [54]] and related compounds [55]. Furthermore, the defect dipoles is one of the important key factors that can contribute the giant dielectric response and temperature stability of ε′, which has widely been reported in TiO2 [17,19,20], SrTiO3 [23], NiO [56], CCTO [57], and BaTiO3-based materials [58,59].

Fig. 6.

Impedance complex plane plots of the ceramics sintered at 20 °C; the inset shows an expanded view of the high-frequency data close to the origin.

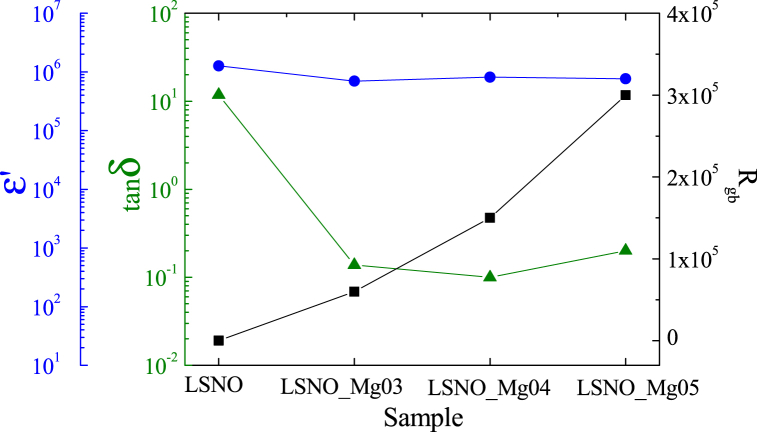

The overall dielectric and electrical properties of the La1.9Sr0.1Ni1-xMgxO4 ceramics are shown in Fig. 7. The ε′ values at 1 kHz for the La1.9Sr0.1Ni1-xMgxO4 ceramics changed slightly as the concentration of Mg2+ increased. A correlation between tanδ (at 1 kHz) and Rgb was clearly observed. The extreme decrease in tanδ was attributed to the significant increase in Rgb [15,24,45]. The activation energies of all sintered ceramics were 0.109, 0.294, 0.383, and 0.404 eV for the LSNO, LSNO_Mg03, LSNO_Mg04, and LSNO_Mg05 ceramics, respectively. Thus, the increased Rgb value of the La1.9Sr0.1Ni1−xMgxO4 ceramics was due to the grain boundary properties caused by Mg2+ substitution.

Fig. 7.

ε′, tanδ, and Rgb values of ceramics sintered at 20 °C.

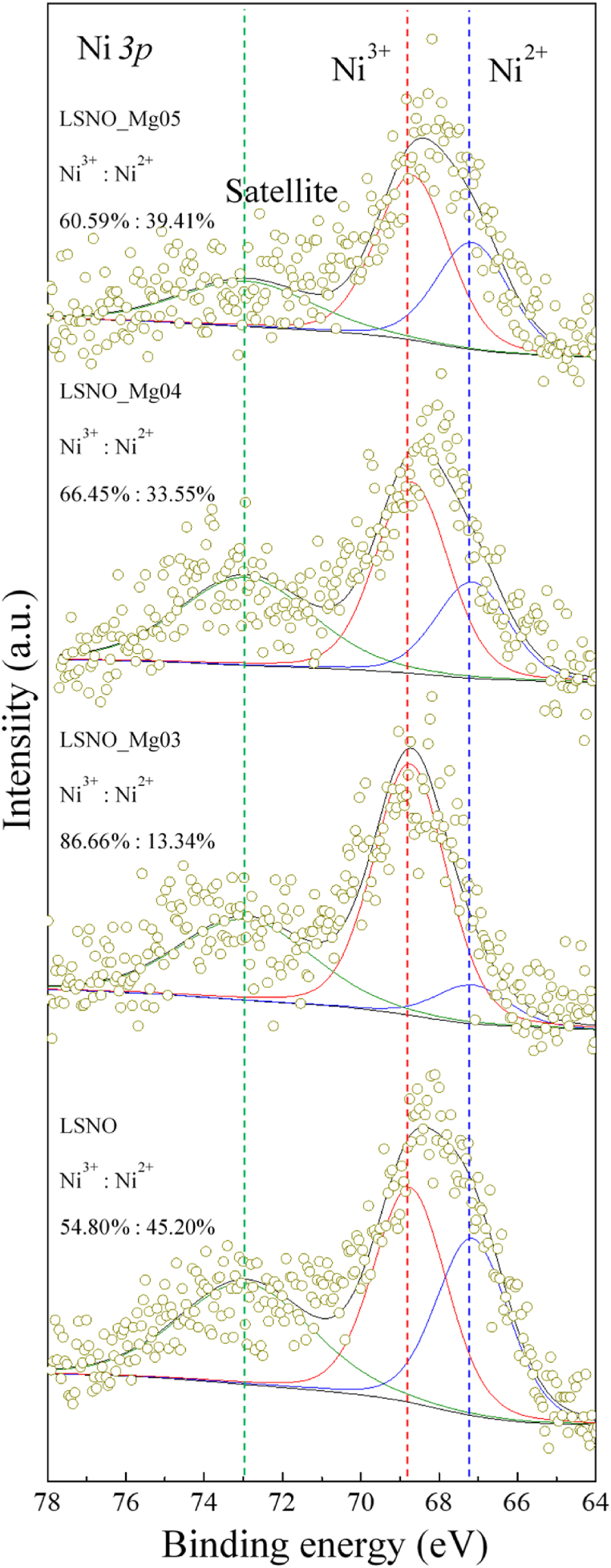

Fig. 8 shows the XPS spectra of all sintered ceramics, confirming the existence of induced Ni3+ ions due to the partial replacement of La3+ by Sr2+ and oxygen ion enrichment. However, the concentration of Ni3+ ions was reduced in the LSNO_Mg03, LSNO_Mg04, and LSNO_Mg05 ceramics compared to that in the undoped LSNO ceramic. This may be due to the substitution of Mg2+ into the Ni3+ sites and/or the reduced enrichment of oxygen ions in the structure. The GDR cannot be described by small polaron hopping only because the value of ε′ is not correlated with the ratio of Ni3+/Ni2+ ions. Another important factor is interfacial polarization at the grain boundaries. This can also cause an increase in the dielectric response of LSNO ceramics.

Fig. 8.

XPS spectra of all sintered La1.9Sr0.1Ni1−xMgxO4 ceramics.

4. Conclusions

In conclusion, an extremely reduced loss tangent with ultrahigh ε′ can be successfully obtained in LSNO ceramics by doping with Mg2+ ions. A single phase of LSNO was detected in all the sintered ceramics, while the lattice parameters increased with increasing doping concentration, indicating that Mg2+ ions can enter the Ni2+ sites. A highly dense microstructure is achieved. Microstructural analysis revealed that Mg2+ ions disperse well in the microstructure of LSNO ceramics. Interestingly, ultra–high ε′ of approximately 8.11 × 105 at 1 kHz is achieved in the La1.9Sr0.1Ni0.6Mg0.4O4 ceramic, while the tanδ is significantly reduced by two orders of magnitude compared to the undoped LSNO ceramic. The DC conductivity significantly decreased by three orders of magnitude. The GDRs are described by Maxwell–Wagner polarization and small polaron hopping mechanisms. Thus, the significant reduction in the tanδ can be attributed to the significantly enhanced Rgb.

Author contribution statement

Keerati Meeporn: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Narong Chanlek, Pornjuk Srepusharawoot: Performed the experiments; Analyzed and interpreted the data.

Prasit Thongbai: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by National Research Council of Thailand (NRCT) (N41A640084), Thailand Research Fund under the Royal Golden Jubilee (PHD/0191/2556) and by Research and Graduate Studies, Khon Kaen University.

Data availability statement

Data will be made available on request.

Declaration of interest's statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Kotb H.M., Ahmad M.M., Alshoaibi A., Yamada K. Dielectric response and structural analysis of (A3+, Nb5+) cosubstituted CaCu3Ti4O12 ceramics (A: Al and Bi) Materials. 2020;13:5822. doi: 10.3390/ma13245822. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Xue R., Chen Y., Li T., Liu D., Chen S., Chen H., Cui M. Effects of Lu3+ doping on microstructures and electrical properties of CaCu3Ti4O12 ceramics. J. Supercond. Nov. Magnetism. 2021;34:3297–3309. [Google Scholar]

- 3.Chinnathambi M., Sakthisabarimoorthi A., Jose M., Robert R. Study of the Electrical and Dielectric behaviour of selenium doped CCTO ceramics prepared by a facile sol-gel route. Mater. Chem. Phys. 2021;272 [Google Scholar]

- 4.Li Y., Li W., Du G., Chen N. Low temperature preparation of CaCu3Ti4O12 ceramics with high permittivity and low dielectric loss. Ceram. Int. 2017;43:9178–9183. [Google Scholar]

- 5.Peng Z., Wang J., Lei X., Zhu J., Xu S., Liang P., Wei L., Wu D., Wang J., Chao X., Yang Z. Colossal dielectric response in CdAlxCu3−xTi4O12 perovskite ceramics. Mater. Chem. Phys. 2021;258 [Google Scholar]

- 6.Peng Z., Zhou X., Wang J., Zhu J., Liang P., Chao X., Yang Z. Origin of colossal permittivity and low dielectric loss in Na1/3Cd1/3Y1/3Cu3Ti4O12 ceramics. Ceram. Int. 2020;46:11154–11159. [Google Scholar]

- 7.Du G., Wei F., Li W., Chen N. Co-doping effects of A-site Y3+ and B-site Al3+ on the microstructures and dielectric properties of CaCu3Ti4O12 ceramics. J. Eur. Ceram. Soc. 2017;37:4653–4659. [Google Scholar]

- 8.Peng Z., Wang J., Zhou X., Zhu J., Lei X., Liang P., Chao X., Yang Z. Grain engineering inducing high energy storage in CdCu3Ti4O12 ceramics. Ceram. Int. 2020;46:14425–14430. [Google Scholar]

- 9.Miao G., Yin M., Li P., Hao J., Li W., Du J., Li G., Wang C., Fu P. Effect of Cr addition on the structure and electrical properties of CaCu3Ti4O12 NTC thermistor. J. Alloys Compd. 2021;884 [Google Scholar]

- 10.Mao P., Wang J., Xiao P., Zhang L., Kang F., Gong H. Colossal dielectric response and relaxation behavior in novel system of Zr4+ and Nb5+ co-substituted CaCu3Ti4O12 ceramics. Ceram. Int. 2021;47:111–120. [Google Scholar]

- 11.Prakash T., Murty B.S., Kaskhedikar A.R., Peshwe P.D. Crystallite size effect on voltage tunable giant dielectric permittivity of nanocrystalline CuO. Electron. Mater. Lett. 2013;9:59–62. [Google Scholar]

- 12.Tangwancharoen S., Thongbai P., Yamwong T., Maensiri S. Dielectric and electrical properties of giant dielectric (Li, Al)-doped NiO ceramics. Mater. Chem. Phys. 2009;115:585–589. [Google Scholar]

- 13.Liu Y., Wang W., Huang J., Zhu C., Wang C., Cao Y. High dielectric permittivity of Li and Sc co-doped NiO ceramics. J. Mater. Sci. Mater. Electron. 2014;25:1298–1302. [Google Scholar]

- 14.Huang Y., Shi D., Liu L., Li G., Zheng S., Fang L. High-temperature impedance spectroscopy of BaFe0.5Nb0.5O3 ceramics doped with Bi0.5Na0.5TiO3. Appl. Phys. A. 2014;114:891–896. [Google Scholar]

- 15.Tuichai W., Danwittayakul S., Manyam J., Chanlek N., Takesada M., Thongbai P. Giant dielectric properties of Ga3+-Nb5+Co-doped TiO2 ceramics driven by the internal barrier layer capacitor effect. Materialia. 2021;18 [Google Scholar]

- 16.Youssef A.M., Yakout S.M. Colossal permittivity, electrical conductivity and ferromagnetic properties of pure TiO2: mono and binary doping. Materialia. 2022;21 [Google Scholar]

- 17.Liang P., Zhu J., Wu D., Peng H., Chao X., Yang Z. Good dielectric performance and broadband dielectric polarization in Ag, Nb co-doped TiO2. J. Am. Ceram. Soc. 2021;104:2702–2710. [Google Scholar]

- 18.Zhou X., Liang P., Zhu J., Peng Z., Chao X., Yang Z. Enhanced dielectric performance of (Ag1/4Nb3/4)0.01Ti0.99O2 ceramic prepared by a wet-chemistry method. Ceram. Int. 2020;46:11921–11925. [Google Scholar]

- 19.Peng P., Chen C., Cui B., Li J., Xu D., Tang B. Influence of the electric field on flash-sintered (Zr + Ta) co-doped TiO2 colossal permittivity ceramics. Ceram. Int. 2022;48:6016–6023. [Google Scholar]

- 20.Wang Z., Peng P., Zhang L., Wang N., Tang B., Cui B., Liu J., Xu D. Effect of electric field on the microstructure and electrical properties of (In + Ta) co-doped TiO2 colossal dielectric ceramics. J. Mater. Sci. Mater. Electron. 2022;33:6283–6293. [Google Scholar]

- 21.Chao Y., Xianhua W., Jianhua H. Colossal permittivity in TiO2 co‐doped by donor Nb and isovalent Zr. J. Am. Ceram. Soc. 2018;101:307–315. [Google Scholar]

- 22.Li J., Zeng Y., Fang Y., Chen N., Du G., Zhang A. Synthesis of (La + Nb) co-doped TiO2 rutile nanoparticles and dielectric properties of their derived ceramics composed of submicron-sized grains. Ceram. Int. 2021;47:8859–8867. [Google Scholar]

- 23.Chen Y., Zeng Y., Cao W., Chen N., Du G. Colossal permittivity and low dielectric loss in (Li, Nb) co-doped SrTiO3 ceramics with high frequency and temperature stability. Ceram. Int. 2022;48:36393–36400. [Google Scholar]

- 24.Meeporn K., Chanlek N., Thongbai P. Effects of DC bias on non-ohmic sample-electrode contact and grain boundary responses in giant-permittivity La1.7Sr0.3Ni1−xMgxO4 ceramics. RSC Adv. 2016;6:91377–91385. [Google Scholar]

- 25.Krohns S., Lunkenheimer P., Kant C., Pronin A.V., Brom H.B., Nugroho A.A., Diantoro M., Loidl A. Colossal dielectric constant up to gigahertz at room temperature. Appl. Phys. Lett. 2009;94 [Google Scholar]

- 26.Liu X.Q., Wu Y.J., Chen X.M., Zhu H.Y. Temperature-stable giant dielectric response in orthorhombic samarium strontium nickelate ceramics. J. Appl. Phys. 2009;105 [Google Scholar]

- 27.Meeporn K., Maensiri S., Thongbai P. Abnormally enhanced dielectric permittivity in poly(vinylidene fluoride)/nanosized-La2NiO4−δ films. Appl. Surf. Sci. 2016;380:67–72. [Google Scholar]

- 28.Liu X.Q., Liu G., Ma P.P., Li G.J., Wu J.W., Chen X.M. Giant dielectric response with reduced loss in ceramics with nominal composition of La1.5Sr0.5NiO4-SiO2. J. Electroceram.37. 2016:73–78. [Google Scholar]

- 29.Meeporn K., Yamwong T., Thongbai P. La1.7Sr0.3NiO4 nanocrystalline powders prepared by a combustion method using urea as fuel: preparation, characterization, and their bulk colossal dielectric constants. Jpn. J. Appl. Phys. 2014;53 [Google Scholar]

- 30.Thongbai P., Yamwong T., Maensiri S. Microstructure and modified giant dielectric response in Ga‐doped La1.5Sr0.5NiO4 ceramics. Mater. Lett. 2012;82:244–247. [Google Scholar]

- 31.Wang Y., Jie W., Yang C., Wei X., Hao J. Colossal permittivity materials as superior dielectrics for diverse applications. Adv. Funct. Mater. 2019;29 [Google Scholar]

- 32.Krohns S., Lunkenheimer P., Meissner S., Reller A., Gleich B., Rathgeber A., Gaugler T., Buhl H.U., Sinclair D.C., Loidl A. The route to resource-efficient novel materials. Nat. Mater. 2011;10:899–901. doi: 10.1038/nmat3180. [DOI] [PubMed] [Google Scholar]

- 33.Liu X.Q., Wu Y.J., Chen X.M. Giant dielectric response and polaronic hopping in charge-ordered ceramics. Solid State Commun. 2010;150:1794–1797. [Google Scholar]

- 34.Liu G., Chen T.T., Wang J., Liu X.Q., Chen X.M. Effect of excess oxygen on crystal structures and dielectric responses of Nd2NiO4+δ ceramics. J. Alloys Compd. 2013;579:502–506. [Google Scholar]

- 35.Wen Jia B., Qiang Liu X., Ming Chen X. Structure, magnetic and dielectric properties in Mn-substituted Sm1.5Sr0.5NiO4 ceramics. J. Appl. Phys. 2011;110 [Google Scholar]

- 36.Liu X.Q., Wu S.Y., Chen X.M. Enhanced giant dielectric response in Al-substituted La1.75Sr0.25NiO4 ceramics. J. Alloys Compd. 2010;507:230–235. [Google Scholar]

- 37.Liu X.Q., Jia B.W., Yang W.Z., Cheng J.P., Chen X.M. Dielectric relaxation and polaronic hopping in Al-substituted Sm1.5Sr0.5NiO4 ceramics. J. Phys. D Appl. Phys. 2010;43 [Google Scholar]

- 38.Liu X.Q., Wu S.Y., Chen X.M., Zhu H.Y. Giant dielectric response in two-dimensional charge-ordered nickelate ceramics. J. Appl. Phys. 2008;104 [Google Scholar]

- 39.Li M., Sinclair D.C. The extrinsic origins of high permittivity and its temperature and frequency dependence in Y0.5Ca0.5MnO3 and La1.5Sr0.5NiO4 ceramics. J. Appl. Phys. 2012;111 [Google Scholar]

- 40.Jia B.W., Yang W.Z., Liu X.Q., Chen X.M. Giant dielectric response in (Sm1−xNdx)1.5Sr0.5NiO4 ceramics: the intrinsic and extrinsic effects. J. Appl. Phys. 2012;112 [Google Scholar]

- 41.Lunkenheimer P., Krohns S., Riegg S., Ebbinghaus S.G., Reller A., Loidl A. Colossal dielectric constants in transition-metal oxides. Eur. Phys. J. Spec. Top. 2010;180:61–89. [Google Scholar]

- 42.Li M., Sinclair D.C., West A.R. Extrinsic origins of the apparent relaxorlike behavior in CaCu3Ti4O12 ceramics at high temperatures: a cautionary tale. J. Appl. Phys. 2011;109 [Google Scholar]

- 43.Siriya P., Pengpad A., Srepusharawoot P., Chanlek N., Thongbai P. Improved microstructure and significantly enhanced dielectric properties of Al3+/Cr3+/Ta5+ triple-doped TiO2 ceramics by Re-balancing charge compensation. RSC Adv. 2022;12:4946–4954. doi: 10.1039/d1ra08847e. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Siriya P., Chanlek N., Srepusharawoot P., Harnchana V., Thongbai P. Triple-doping of (Ga1/2Nb1/2)xTi1-xO2 ceramics with Al3+ for enhanced giant dielectric response with simultaneous decrease in dielectric loss. J. Eur. Ceram. Soc. 2022;42:2798–2803. [Google Scholar]

- 45.Peng Z., Wu D., Liang P., Zhou X., Wang J., Zhu J., Chao X., Yang Z. Grain boundary engineering that induces ultrahigh permittivity and decreased dielectric loss in CdCu3Ti4O12 ceramics. J. Am. Ceram. Soc. 2020;103:1230–1240. [Google Scholar]

- 46.Shannon R.D. Revised effective ionic radii and systematic Studies of interatomie distances in halides and chaleogenides. Acta Crystallogr. 1976;A32:751–767. [Google Scholar]

- 47.Rahaman M.N. second ed. M. Dekker; New York: 2003. Ceramic Processing and Sintering. [Google Scholar]

- 48.Boonlakhorn J., Kidkhunthod P., Thongbai P. A novel approach to achieve high dielectric permittivity and low loss tangent in CaCu3Ti4O12 ceramics by co-doping with Sm3+ and Mg2+ ions. J. Eur. Ceram. Soc. 2015;35:3521–3528. [Google Scholar]

- 49.Peng Z., Wang X., Xu S., Zhang F., Wang J., Wang J., Wu D., Liang P., Wei L., Chao X., Yang Z. Improved grain boundary resistance inducing decreased dielectric loss and colossal permittivity in Y2/3Cu3Ti4O12 ceramics. Mater. Chem. Phys. 2022 [Google Scholar]

- 50.Song C.L., Wu Y.J., Liu X.Q., Chen X.M. Dielectric properties of La1.75Ba0.25NiO4 ceramics prepared by spark plasma sintering. J. Alloys Compd. 2010;490:605–608. [Google Scholar]

- 51.Liu L., Fang L., Huang Y., Li Y., Shi D., Zheng S., Wu S., Hu C. Dielectric and nonlinear current–voltage characteristics of rare–earth doped CaCu3Ti4O12 ceramics. J. Appl. Phys. 2011;110 [Google Scholar]

- 52.Huang Y., Liu L., Shi D., Wu S., Zheng S., Fang L., Hu C., Elouadi B. Giant dielectric permittivity and non-linear electrical behavior in CaCu3Ti4O12 varistors from the molten-salt synthesized powder. Ceram. Int. 2013;39:6063–6068. [Google Scholar]

- 53.Huang Y., Shi D., Li Y., Li G., Wang Q., Liu L., Fang L. Effect of holding time on the dielectric properties and non-ohmic behavior of CaCu3Ti4O12 capacitor-varistors. J. Mater. Sci. Mater. Electron. 2013;24:1994–1999. [Google Scholar]

- 54.Deng J., Sun X., Liu S., Liu L., Yan T., Fang L., Elouadi B. Influence of interface point defect on the dielectric properties of Y doped CaCu3Ti4O12 ceramics. J. Adv. Dielectr. 2016;6 [Google Scholar]

- 55.Li G., Chen Z., Sun X., Liu L., Fang L., Elouadi B. Electrical properties of AC3B4O12-type perovskite ceramics with different cation vacancies. Mater. Res. Bull. 2015;65:260–265. [Google Scholar]

- 56.Li Y., Fang L., Liu L., Huang Y., Hu C. Giant dielectric response and charge compensation of Li- and Co-doped NiO ceramics. Mater. Sci. Eng. B. 2012;177:673–677. [Google Scholar]

- 57.Han F., Ren S., Deng J., Yan T., Ma X., Peng B., Liu L. Dielectric response mechanism and suppressing high-frequency dielectric loss in Y2O3 grafted CaCu3Ti4O12 ceramics. J. Mater. Sci. Mater. Electron. 2017;28:17378–17387. [Google Scholar]

- 58.Meng Y., Liu K., Zhang X., Qiang X., Lei X., Chen J., Li C., Yang Z., Liu L. Compositional modulation and annealing treatment in BaTiO3 to simultaneously achieve colossal permittivity, low dielectric loss, and high thermal stability. Ceram. Int. 2021;47:33912–33916. [Google Scholar]

- 59.Meng Y., Liu K., Zhang X., Lei X., Chen J., Yang Z., Peng B., Long C., Liu L., Li C. Defect engineering in rare-earth-doped BaTiO3 ceramics: route to high-temperature stability of colossal permittivity. J. Am. Ceram. Soc. 2022;105:5725–5737. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.