Abstract

Protective gloves can affect hand performance indicators (HPIs) like manual dexterity and hand grip. The present study was conducted to comprehensively and comparatively investigate several types of protective gloves and HPI assessment tools. Seventeen healthy men participated in this study. Four types of protective gloves, two structural firefighting and two general protective gloves, were investigated using four different dexterity tests and the bulb dynamometer. Structural firefighting gloves were significantly different in terms of dexterity, while there was no significant difference between general protective gloves. In contrast, firefighting gloves were not significantly different in terms of hand grip strength, while general protective gloves were significantly different in this regard. Among the four investigated tests, the hand tool dexterity test had the highest discrimination power. The negative effects of structural firefighting gloves on HPIs were higher than those of general protective gloves. A trade-off between safety requirements and hand performance is needed.

Keywords: Gloves, Performance, Design, Discrimination power

1. Introduction

Human hands have a rather complex anatomical structure and are the main limbs in performing occupational and non-occupational activities. The physical and tactile capabilities of hands enable us to perform a variety of tasks and motions such as delicate and fast manipulations, power gripping, force exertion, and repetitive motions with high accuracy [1,2]. Dexterity is a term used for explaining the ability of hands and fingers in manipulating objects with various shapes and sizes. Dexterity is mainly affected by the motion range of fingers, hand, forearm, and arm. It is also influenced by nerves, muscles, and tendons of hands and fingers [3,4]. Hand grip strength refers to the amount of force transmitted to an object when it is grasped by hand and fingers. Dexterity and hand grip strength are two main factors determining the ability of an individual in performing a wide range of manipulative tasks such as writing, holding hand tools, using screwdrivers for fastening a screw, using a wrench for unscrewing a bolt, using a hammer for driving a nail, using shovels for digging, and so on [[5], [6], [7], [8]].

As many occupational activities are performed by hand, occupational hand injuries are widespread [9,10]. Therefore, hands must be protected against a wide range of mechanical (abrasion, compression, cutting, fracture, puncture, and so on), thermal (cold and hot surfaces), radiation (ultraviolet, infrared, X, gamma, so on), chemical (corrosives, irritants, sensitizers, and so on), biological (infectious agents), and electrical hazards at workplaces [[11], [12], [13]]. Workers use various types of gloves to prevent their hands from being injured by these hazards [14]. There are many types of protective gloves available in the market designed to protect hands and fingers in various ways. It should be always taken into account that each type of safety glove is designed and made to provide protection against a particular set of hazards and it would not be effective in protecting hands against other hazards. The type of hazards, the tools to be used, duration of the task, and parts of hands, fingers, and forearm that need to be protected are important factors to be considered in designing, manufacturing, or selecting appropriate safety gloves [15]. Various materials are used in manufacturing protective gloves based on the type and degree of required protection. Leather, plastic, tarpaulin, nylon, and Kollar are some commonplace materials used in this regard. Some types of gloves may have an additional coating layer which is normally made of polyvinyl chloride, nitrile, and vinyl, while some others such as those used in butchery are strengthened using metal mesh to manage cutting forces. In addition to construction materials, glove thickness is another important design parameter. The glove thickness should be selected based on the required level of protection. For example, thicker electrical protective gloves are required when higher voltage is dealt with [16]. A main problem related to protective gloves is that they can negatively affect dexterity and hand grip strength, making it difficult for workers to perform their tasks while wearing gloves. In such a situation, some individuals may prefer to not wear their safety gloves, making their hands unprotected against occupational hazards and prone to injuries [15].

Increase in the glove thickness and number of layers can negatively affect manual dexterity [4,17]. The flexibility of gloves is a function of both their thickness and construction materials. Inflexible gloves have a higher negative effect on dexterity, therefore a tradeoff between these two design parameters should be taken into account [17]. Gloves can negatively affect grip strength. Most previous studies demonstrated that wearing any type of gloves has a negative effect on grip strength, for example Wimer et al. [18], Ramadan [19], and Zhao et al. [20]. However, the reducing effect of wearing gloves on grip strength is not supported by all studies. In the other words, there are some studies reporting contradictory results. In this regard Shih et al. [21] demonstrated that wearing multilayer latex gloves could even increase grip strength or Hamouda et al. [22] reported that anti-vibration leather gloves do not affect grip strength significantly. Therefore, the negative effect of gloves on grip strength is a function of its design and can be reduced to a minimum possible value. Manufacturers should design and manufacture gloves with the least possible negative effect on all hand performance indicators, particularly grip strength and dexterity. Construction materials, glove thickness, and gloves fitting are some important design parameters affecting dexterity and hand grip strength [18].

There are several tools and techniques available for measuring dexterity and hand grip strength of hands while wearing gloves. Purdue Pegboard test, O'Connor Dexterity test, and Bennett hand tool dexterity test are some well-known dexterity tests. These tests are also very useful in assessing gloves design. However, it should be noted that a particular type of dexterity test is not appropriate for all purposes. Some of these tests make attempts at simulating intricate hands and fingers motions, while some others are appropriate for less intricate movements of hands and fingers [4,6]. A question to be answered here is which test is appropriate for a particular purpose.

Jamar dynamometer is the most commonly used tool in measuring hand tool strength [23]. However, in recent years other types of dynamometers were also developed, such as the squeeze (bulb) dynamometer. Previous studies have shown the excellent reliability of this tool in measuring hand grip strength [24]. Moreover, the bulb dynamometer is less painful and more comfortable to use than the Jamar dynamometer [25]. People with big hands may struggle to use conventional Jamar dynamometer, while there is no such a problem when the bulb dynamometer is used. Moreover, the bulb dynamometer is less expensive compared to the Jamar dynamometer [23,24]. So far, few studies have used this dynamometer for measuring hand power strength while wearing gloves. In this study, we used the bulb dynamometer instead of the traditional Jamar dynamometer to measure hand grip strength while various types of gloves are worn.

According to mentioned issues, all types of safety gloves are not equal in terms of their effects on dexterity and grip strength. Further, the available dexterity tests are different in terms of their ability to discriminate against various types of gloves. In other words, the discrimination power of dexterity tests is not the same. Moreover, to the best of our knowledge, no study has compared general safety gloves and firefighting gloves in respect to their effects on hand performance indicators. Consequently, the present study had several objectives: 1) to compare various types of safety gloves in terms of dexterity using various types of dexterity tests, 2) to compare various types of safety gloves in terms of hand grip strength measured by the bulb dynamometer, 3) to compare several types of dexterity tests in terms of their ability in discriminating safety gloves, 4) to assess the level of perceived comfort while wearing various types of safety gloves, and 5) to assess the effect of glove thickness on the hand dexterity and power grip strength. To the best of our knowledge, this study is the first on comparing firefighting gloves with general safety gloves.

2. Material and methods

2.1. Participants

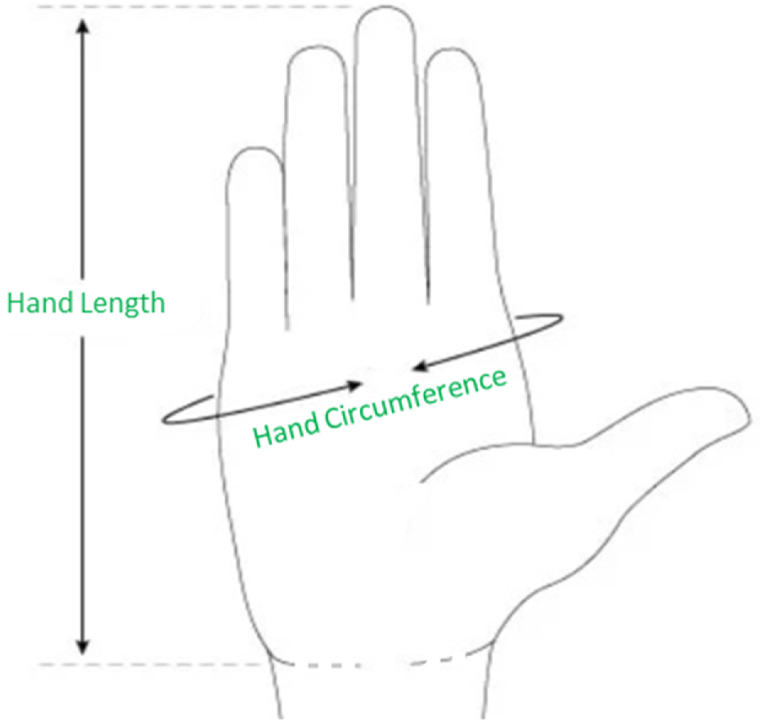

Seventeen men between the ages of 20 and 36 participated in the study voluntarily. All participants were men because only men can be a firefighter in Iran. Their mean age and BMI were 27.4 (±5.4) years and 23.6 (±5.3), respectively. All the participants were right-handed, they had no history of musculoskeletal disorders and no experience in using protective gloves. The hand anthropometric dimensions of the participants were measured in accordance with EN 420 standard. The standard provides a sizing system, which is based on the hand circumference and the hand length (Fig. 1). The glove can have a size between 6 and 11. We included just those participants whose hand dimensions matched size 8 to eliminate effects of hand anthropometric dimensions. Accordingly, participants had hand circumference between 203 and 229 cm and hand length between 180 and 184 cm. People whose hand size was not within this range were excluded from the study. It should be noted that this study was reviewed and approved by the ethics committee of Hamadan University of medical sciences (ethics code: IR.UMSHA.REC.1398.917). Moreover, all participants read and signed an informed consent form and they were allowed to leave the study whenever they tended to.

Fig. 1.

Hand anthropometric dimensions for the glove sizing.

2.2. Protective gloves

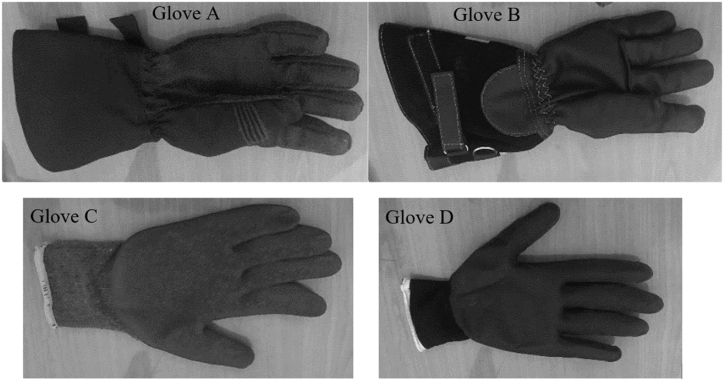

In this study, four different types of protective gloves, including two types used in the structural firefighting and two types used for general safety purposes, were investigated. These gloves are the most commonly used ones in Iranian industries. Illustrated in Table 1 and Fig. 2 are the characteristics of these gloves. The thickness of the gloves was measured using a caliper.

Table 1.

The characteristics of the gloves demonstrated in Fig. 2.

| Glove | Application | Main Materials | Thickness at Palm (mm) |

|---|---|---|---|

| Glove A | Structural firefighting | Kevlar, Nomex, and Silicone-Carbon Coating | 2.8 |

| Glove B | Structural firefighting | Cow-nappa leather, Kevlar, Para-aramid Filament | 2 |

| Glove C | Safety gloves for general applications | Cotton with a latex coating | 1.4 |

| Glove D | Safety gloves for general applications | Cotton with a nitrile coating | 0.9 |

Fig. 2.

Four gloves investigated in this study (Glove A and Glove B are two types of structural firefighting gloves, and Glove C and Glove D are two types safety gloves used in general tasks).

2.3. Dexterity tests

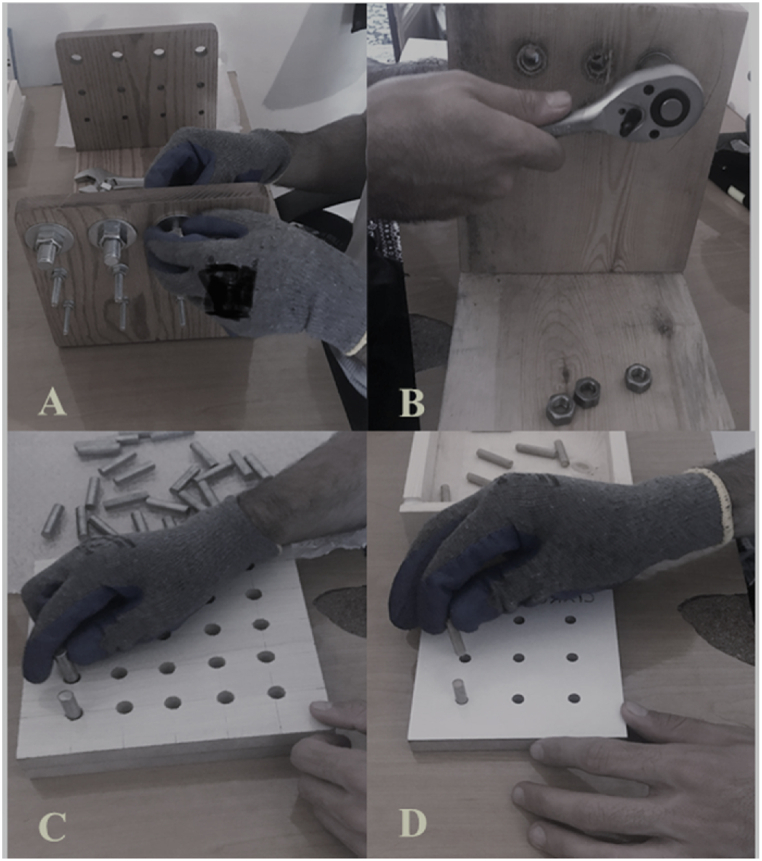

Four different tests were employed for assessing the dexterity of hands and fingers while wearing various types of protective gloves; the modified tool dexterity test (MTDT) [26], the hand tool dexterity test (HTDT) [27], ASTM F2010 test (ASTMF) [28], and the 9-hole Peg test (NHPT) [29]. MTDT and HTDT tests are aimed at assessing the dexterity of hands and fingers as a whole, while ASTMF and NHPT mainly assess the ability of fingers in performing intricate tasks such as manipulating small objects. These tests are among the most common ones used by researchers and we employed all these tests to determine whether their results are different or not. A brief description of each test is presented in the following sections.

HTDT is used when the aim is to assess the dexterity of whole hands and fingers. HTDT (Fig. 3A) includes a wooden frame on which three rows of holes with three different sizes are created [26]. bolts should be loosened with a wrench, second, the bolts and washers should be unscrewed and completely opened by hands and fingers, third, the bolts and washers should again be placed in the holes, firth, the bolts should be firmly fastened by a wrench. The loosening and unscrewing bolts and washers should be started from the uppermost row of holes, while the fastening process should be started from the holes located in the bottommost row. The time taken to complete this four step is regarded as an indicator of the dexterity.

Fig. 3.

Manual dexterity tests (A: the modified tool dexterity test (MTDT), B: the hand tool dexterity test (HTDT), C: ASTM F2010 test (ASTMF) and D: the 9-hole Peg test (NHPT)).

MTDT has been developed to assess the dexterity of hands and fingers while wearing firefighting gloves. National Fire Protection Association (NFPA) recommends to use this test instead of Bennet dexterity test [30,31]. It is composed of a set of bolts, nuts, washers, and a vertical board as demonstrated (Fig. 3B). The participants are asked to locate a pack of bolts, nuts, and washers into the holes and fasten them. For completing this test, the subject begins by picking up the first of four bolt/washer assemblies with the left hand and inserting the bolt/washer into the holes on the top row of the vertical board. The time to assemble all bolt and washers on the board is indicative of dexterity.

ASTMF is used to assess the dexterity of the thumb and index finger while wearing gloves. The test consists of a board with 25 holes and 25 steel pins (Fig. 3C). The pins are randomly dispersed on the right side of the participants and in the vicinity of the board before starting the test. Then, the participant is asked to pick a pin up by his/her right hand and locate it in the hole located on the top left of the board. The order of locating pins is from left to right and top to bottom. Similar to previous tests, the time taken to complete the test is regarded as an indicator of the dexterity.

NHPT test is commonly used by occupational therapists for fast assessment of fingers dexterity. Compared with HTDT and MTDT, this test is both cheaper and less time-consuming. Therefore, the use of NHPT is more widespread than HTDT and MTDT. Some studies have used NHPT for assessing the dexterity of hands and fingers while wearing gloves. NHPT includes a square board with nine holes and a container containing nine pines (Fig. 3D). To administer the test, the board and the container are placed in front of subjects. The container should be on the side of the hand which is to be assessed. In the next step, the participant is asked to place pins in the holes one by one and then placing them back in the container. Similar to HTDT and MTDT, the time taken to complete the test is regarded as the indicator of dexterity.

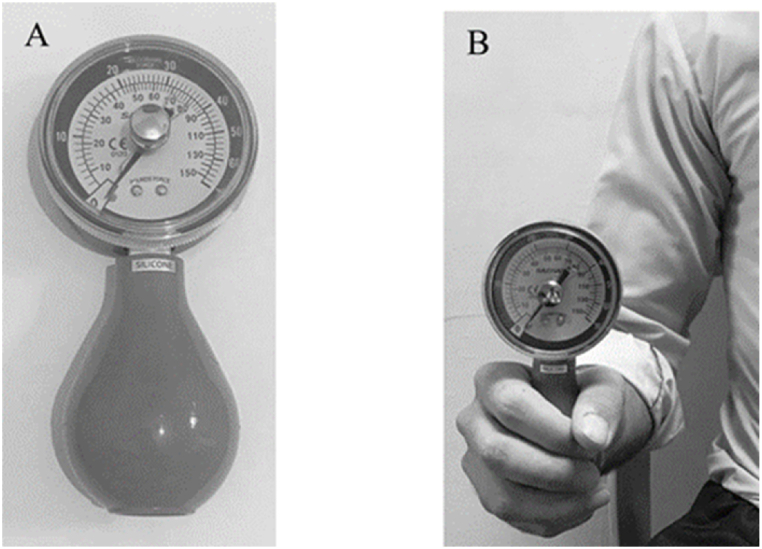

2.4. Hand grip strength

In order to assess the effect of wearing gloves on power grip, the squeeze (bulb) dynamometer (Fig. 4A) in accordance with the protocol recommended by the American Society of Hand Therapists (ASHT) was employed [32]. For measuring power grip, the participants were asked to sit on a chair with an adjustable height. The height of the chair was adjusted in the manner that feet were located on the ground, the knees flexed in the right angle, shoulders were in a natural position, and elbows were also the right angle. For ensuring consistency of measurements, the examiner placed the dynamometer in the hand of the participant in a way that he was unable to see the gauge, as demonstrated in Fig. 4B. In this position, the participant was asked to squeeze the balloon of the dynamometer as strongly as he could. The test was repeated three times and the highest score was recorded as the hand grip strength of that participant.

Fig. 4.

A: the squeeze (bulb) dynamometer used for measuring hand grip strength and B: holding the dynamometer for measuring handgrip strength.

2.5. Subjective assessment

For assessing the perceived comfort of gloves while performing dexterity tests, a 9-point Likert scale ranging from score 1 (totally discomfort) to score 9 (totally comfort) was used [33].

2.6. Study procedure

First, all participants were given a pamphlet in which the tests, the way that they should be carried out, and the objectives of the study were explained. Second, the examiner practically explained how the tests should be carried out. Participants were informed that they are free to leave the study at any stage. It took almost 4 h for participants to complete all tests, which have been conducted in two 2-h sessions. A, B, C and D dexterity tests were placed on a table in order. The participant wore one of the gloves and performed the tests in order. Rest time between tests was 2 min. The comfort assessment was carried out immediately after the completion of each test. Since the last test was finished, participants were given a 5-min rest and then they performed the grip test. In the first day, the participants performed the tests once with glove C and once with glove D, and in the second day, gloves A and B were evaluated. Eight of the participants performed dexterity tests in order from A to D and nine from D to A. All tests were conducted between 8:00 a.m. between 12:30 p.m. in a room with a normal condition (temperature: 21c° and relative humidity: 45%). Moreover, all participants asked to sit on an adjustable chair while performing tasks. They were allowed to adjust the chair height so that they could comfortably manipulate objects on the table. Worth mentioning, each test was repeated three times and the average value was regarded as the test result for an individual.

2.7. Statistical analyses

First, the normally of the data was evaluated using the Shapiro-Wilk test. The Repeated Measure ANOVA test was used for comparing the times spent to complete various dexterity tests with various types of gloves. For making pair-wise comparisons among these times the Post hoc Bonferroni test was used. The mixed linear regression test was used for determining the relationship between the glove thickness and the time spent to complete each dexterity test. Discriminant analysis is used to describe the differences between groups and to explore those differences in allocating (classifying) observations of unknown group membership to the groups. There are many discrimination methods such as linear discriminant analysis (LDA). Using discrimination methods to classifying unknown observations faced several problems. Some researchers such as Rencher and Christensen [34] reserve discriminant analysis for descriptive discriminant analysis and use the label classification for predictive discriminant analysis. In this study, we used candisc canonical linear discriminant analysis which is the classical form of LDA. This method computes the same thing as LDA, but with output tailored for the descriptive aspects of the discrimination [35].

3. Results

3.1. The effect of wearing gloves on dexterity and power grip strength

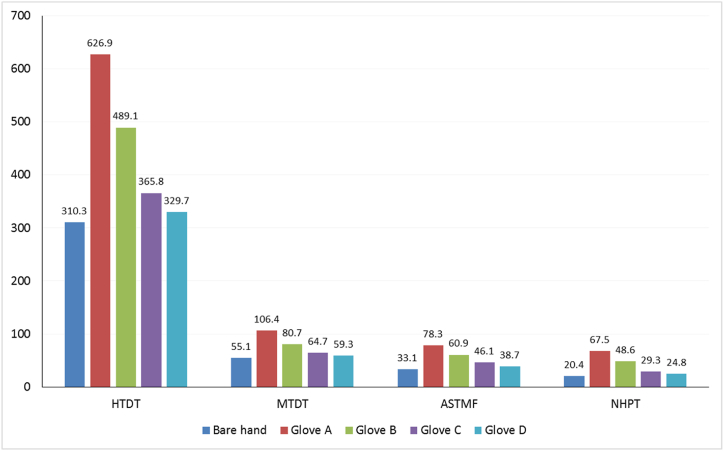

The times spent to complete dexterity tests with various gloves are presented in Fig. 5. As expected, the time spent was lowest when participants carried out the test with the bare hands. Moreover, the same trend can be seen in this figure for all tests: the time spent to complete all dexterity tests was highest when participants wore Glove A, followed by Glove B, Glove C, and Glove D, demonstrating that the negative effect of Glove A on dexterity was higher than those of Glove B, Glove C, and Glove D.

Fig. 5.

The time spent to complete dexterity tests with various gloves (in seconds).

According to the repeated measure ANOVA test, there was a significant difference among the gloves in all dexterity experiments (p < 0.05). The results of the Bonferroni test, used for pair wise comparisons of gloves, are presented in Table 2. Accordingly, there was a significant difference between bare hand and Glove A, bare hand and Glove B, Glove A and Glove B, Glove A and Glove C, Glove A and Glove D, Glove B and Glove C, and Glove B and Glove D in all dexterity tests. In contrast, there was no significant difference between bare hand and Glove D in all dexterity tests. Similarly, the difference between Glove C and Glove D was not significant in all tests.

Table 2.

Pair wise comparisons of gloves in terms of the time spent to complete various dexterity tests.

| Pair wise comparisons | Dexterity test |

|||

|---|---|---|---|---|

| HTDT | MTDT | ASTMF | NHPT | |

| Bare hand vs. Glove A | ** | ** | ** | ** |

| Bare hand vs. Glove B | ** | ** | ** | ** |

| Bare hand vs. Glove C | ** | – | * | * |

| Bare hand vs. Glove D | – | – | – | – |

| Glove A vs. Glove B | ** | ** | ** | ** |

| Glove A vs. Glove C | ** | ** | ** | ** |

| Glove A vs. Glove D | ** | ** | ** | ** |

| Glove B vs. Glove C | ** | ** | ** | ** |

| Glove B vs. Glove D | ** | ** | ** | ** |

| Glove C vs. Glove D | – | – | – | – |

** Significant at 0.01, significant at *, and – non-significant relationship.

Therefore, according to the results of this set of experiments, all types of protective gloves had a significant negative effect on dexterity. The negative effects of structural firefighting gloves were higher than those of general protective gloves. Structural firefighting gloves were significantly different in terms of their effects on dexterity, while there was no significant difference between general protective gloves in this respect.

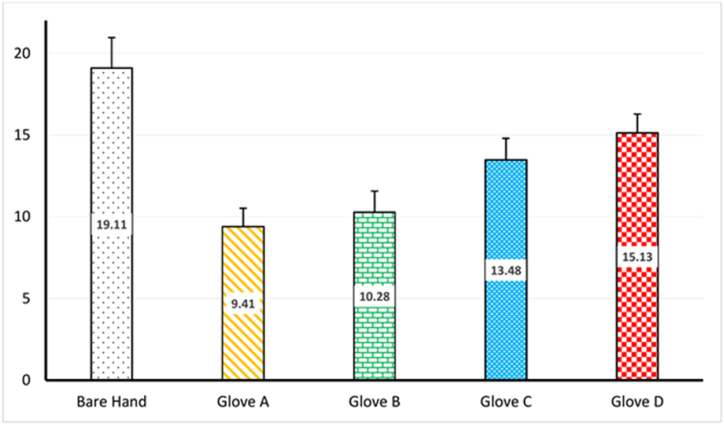

Fig. 6 demonstrates the results of power grip experiments. As expected, the highest level of power grip strength was associated with the bare hand (mean value = 19.1 N and SD = 1.8) and wearing any type of gloves significantly reduced this HPI (P < 0.01). Among the gloves, the highest level of power grip strength was associated with Glove D (mean value = 15 N and SD = 1.1), followed by Glove C (mean value = 13.5 N and SD = 1.3), Glove B (mean value = 10.3 N and SD = 1.3), and Glove A (mean value = 9.4 N and SD = 1.1). The repeated measures ANOVA test revealed a significant difference among the gloves in terms of power grip strength. The Bonferroni post-hoc test also demonstrated that there was a significant difference between Glove A and Glove C (p < 0.01), Glove A and Glove D (p < 0.01), Glove B and Glove C (p < 0.01), Glove B and Glove D (p < 0.01), and Glove C and Glove D (p = 0.011). In Contrast, there was no significant difference between Glove A and Glove B (p = 0.781). Therefore, firefighting gloves were not significantly different in terms of hand grip strength, while general protective gloves were significantly different in this regard.

Fig. 6.

The power grip strength with various types of gloves (Kg).

3.2. The effect of glove thickness on dexterity and power grip strength

The effect of glove thickness on the time spent to complete dexterity tests and power grip strength were investigated using the multivariate regression test and the results are presented in Table 3. The effects of age and BMI as the possible confounding variables were adjusted. As evident, glove thickness is the only variable affecting the time spent to complete all dexterity tests. Moreover, 1 mm increase in the glove thickness resulted in 116.95, 18.38, 16.64, and 17.42 s increase in the time spent to complete HTDT, MTDT, ASTMF, and NHPT, respectively. Likewise, the glove thickness was the only variable that affected power grip strength so that 1 mm increase in the glove thickness resulted in 3.61 kg decrease in the power grip strength.

Table 3.

The results of multiple regression test conducted to assess effects of various variables on the hand dexterity and power grip strength.

| Variable | Coefficient (95% CI) |

||||

|---|---|---|---|---|---|

| HTDT | MTDT | ASTMF | NHPT | Power grip | |

| Glove thickness | 116.95** (104.31–129.58) | 18.38** (15.82–20.94) | 16.64** (14.45–18.83) | 17.42** (15.43–19.41) | −3.61** (−3.84 to −3.37) |

| BMI | 1.67 (−7.40–10.75) | 0.35 (−2.38 – 3.09) | −0.71 (−3.09 – 1.66) | 0.52 (−0.90 – 1.93) | 0.18 (−0.15 – 0.51) |

| Age | 1.13 (−2.02-4.28) | 0.53 (−0.42 – 1.48) | 0.54 (−0.28 – 1.37) | 0.42 (−0.07 – 0.91) | −0.06 (−0.17 – 0.05) |

| Constant | 187.75 (−16.14–391.65) | 24.21 (−37.05–85.47) | 29.76 (−23.43–82.96) | −10.37 (−42.23–21.48) | 16.11** (8.73–23.48) |

HTDT= Hand Tool Dexterity Test; MTDT = Modified Tool Dexterity Test; ASTMF = ASTM F2010 Test; NHPT= Nine-Hole Peg Test.

*p < 0.05, **p < 0.01.

3.3. Discrimination power analysis

The results of discriminant power analyses are presented in Table 4. When all dexterity tests were compared to each other, the highest discriminant coefficient belonged to HTDT (coefficient = 1.03), followed by NHPT (coefficient = 0.91), MTDT (coefficient = −0.11), and ASTMF (coefficient = −0.87), suggesting that HTDT and ASTMF had the highest and lowest discrimination power, respectively. When the power of dexterity tests in discriminating structural firefighting gloves, i.e. Glove A and Glove B, was investigated, the higher discriminant power coefficient was associated with HTDT, demonstrating that HTDT is the most appropriate test for comparing structural firefighting gloves in terms of dexterity. When the power of these tests in discriminating general safety gloves, i.e. Glove C and Glove D, was scrutinized the highest coefficient was associated with ASTMF, indicating that this test is the best one for examining and comparing general safety gloves.

Table 4.

The discrimination power coefficients of various dexterity tests.

| Dexterity test | All gloves | Glove A and Glove B | Glove C and Glove D |

|---|---|---|---|

| HTDT | 1.03 | 1.09 | 0.45 |

| MTDT | −0.11 | 0.19 | −0.71 |

| ASTMF | −0.87 | −0.79 | 0.95 |

| NHPT | 0.91 | 0.88 | 0.24 |

HTDT= Hand Tool Dexterity Test; MTDT = Modified Tool Dexterity Test; ASTMF = ASTM F2010 Test; NHPT= Nine-Hole Peg Test.

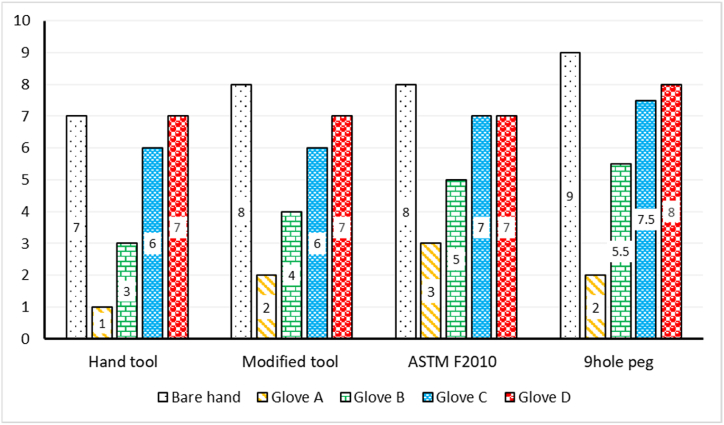

3.4. Subjective assessment

Demonstrated in Fig. 7 are the results of perceived comfort after completing each dexterity test. As seen in this figure, the trends of perceived comfort are consistent throughout all dexterity tests. The highest score of perceived comfort was associated with the bare hand, followed by Glove D, and Glove C. In contrast, the lowest score of perceived comfort was observed to be associated with Glove A. As expected, the score of perceived comfort for general safety gloves (Glove C and Glove D) was much higher than structural firefighting gloves (Glove A and Glove D).

Fig. 7.

Perceived comfort after completing dexterity tests with various types of safety gloves.

4. Discussion

The present study was set to meet several objectives. Four different types of protective gloves, including two types of structural firefighting gloves and two types of general protective gloves, were investigated and compared in terms of their effects on dexterity and hand grip strength.

Various tests have been proposed to be used in assessing the effect of wearing gloves on hand dexterity. In this study, four well-known and popular dexterity tests were applied: HTDT, MTDT, ASTMF, and NHPT. According to the results of the present study, all dexterity tests demonstrated that wearing structural firefighting gloves significantly reduced the hand and fingers dexterity. However, according to the results of four dexterity tests, there was no significant difference between the bare hands and hands with Glove D in terms of dexterity. MTDT was the only test that did not differentiate Glove C and Glove D, suggesting that this test is not sensitive enough to be used in assessing general protective gloves. These results are in line with those of previous studies such as Bensel [36], Yao et al. [4], Dianat et al. [6] Irzmańska and Okrasa [37]. Therefore, it always is a necessity for manufacturers to avoid making gloves with an unnecessary degree of thickness. In fact, a trade-off between safety and performance is always needed. The use of newly-developed nanomaterials which provide a higher level of protection at lower thickness is recommended [38,39]. However, it should be noted that glove thickness is not the only factor that affects dexterity. Construction materials are also important in this regard. The surface friction coefficient and flexibility are a function of construction material. Too low and too high friction coefficients both intensify the negative effect of gloves on dexterity. Too low friction coefficient lets the objects slip out of the hand and fingers, while too high friction coefficient makes the successive picking up and dropping objects difficult. This can be another reason why the dexterity performance of Glove B was better than that of Glove A, as its surface seemed to be more pleasant in terms of friction coefficient.

According to the canonical linear discriminant analysis, HTDT is the most appropriate test for assessing the dexterity of the whole hand and fingers. NFPA 1971 introduces this test as the best one for assessing structural firefighting gloves in terms of their effects on dexterity. However, some research explained that this test suffers from serious drawbacks such as the lengthy time required to complete the test and uncertainty regarding how tight the bolts should be fastened. As a result, MTDT has been recommended to be used for accomplishing this purpose [26,40]. The results of the present study revealed that MTDT had a lower discrimination power than HTDT which is in contradiction with the results of the study carried out by Barker et al. [31]. This contradiction can be attributed to the low sample size of Barker's study or the different types of gloves investigated in these two studies.

Among all the dexterity tests, HTDT had the highest discrimination power. Among the finger dexterity tests, the discrimination power of ASTMF was higher than NHPT. This finding is in line with the study carried out by Yao et al. [4] in which anti-vibration gloves were investigated. Among the tests used for investigating the dexterity of hands and fingers, i.e. HTDT and MTDT, HTDT had a higher discrimination power and among the tests used for investigating the dexterity of fingers, i.e. ASTMF and NHPT, NHPT had a higher discrimination power. Therefore, it is recommended to use HTDT for assessing structural firefighting gloves and NHPT for general protective gloves.

None of the dexterity tests was able to differentiate Glove C and Glove D. In other words, these two types of gloves seemed to be similar in terms of dexterity. These gloves were made of cotton with a coating of latex (Glove C) and nitrile (Glove D). The coating layer makes the gloves both impermeable to fluids such as water and oil and more resistant against mechanical impacts. Moreover, these materials provide gloves with better surface friction, resulting in better performance when objects are grasped and manipulated. Latex and nitrile are two popular construction materials used in manufacturing medical gloves. The effect of latex and nitrile medical gloves on dexterity has long been a source of contention. Few studies have reported that there is no significant difference between these gloves [41], while most studies have found a better dexterity performance for latex gloves [[42], [43], [44]]. Therefore, based on previous studies, it can be assumed that the negative effect of nitrile on dexterity is higher than that of latex, this higher negative effect could be compromised by the lesser glove thickness. This explanation can be a reason why we did not observe a significant difference between Glove C and Glove D in terms of dexterity as Glove D had a lower thickness.

Hand grip strength is another important hand performance indicator [45]. There is a variety of dynamometers using which handgrip strength can be measured. The bulb dynamometer utilized in this study is cheap, easy-to-use, and as reliable as the Jamar dynamometer [23]. Moreover, a study recommended the bulb dynamometer to be used for measuring handgrip strength of young and adolescent individuals as an alternative to the Jamar dynamometer [24]. This was the first study in which the bulb dynamometer was used for assessing the effect of wearing gloves on hand grip strength. In this study, we found that the use of any type of gloves resulted in the reduction of hand grip strength which is consistent with previous studies [18,46,47]. The reduction was more salient in the structural firefighting gloves, i.e. Glove A and Glove B. In contrast to dexterity, there was no significant difference between these two types of gloves.

The effect of glove thickness, age, and BMI on the hand grip strength was investigated using the multivariate analysis. Results demonstrated that glove thickness is the only factor affecting hand grip strength significantly. The results are consistent with previous studies [19]. This finding highlights the need for making a trade-off between the glove-thickness and glove performance.

This study had some limitations which should be mentioned. In this study, we selected four types of gloves with different thickness to assess the effect of glove thicknesses on dexterity and hand grip strength. However, these gloves were different in construction materials. Construction materials determine the elasticity, hardness, and surface friction of the gloves [48,49]. In this study, we could not assess these parameters because of technical limitations. In order to assess the effect of construction materials on dexterity, it is recommended for future studies to select and investigate gloves with the same thickness but different construction materials. Learning effect is always a problem in such studies. The randomization of the order of experiments is a solution but it cannot totally remove the problem.

5. Conclusion

Wearing any type of gloves would reduce hand dexterity. Structural firefighting gloves were significantly different in terms of dexterity, while there was no significant difference between general protective gloves according to the results of four dexterity tests. In contrast, structural firefighting gloves were not significantly different in terms of hand grip strength, while there was a significant difference between general protective gloves in this respect. Glove thickness is one the most important factor determining the magnitude of negative effect of gloves on dexterity. There are a variety of dexterity tests in the market and each has its own applications. Some of them assess the dexterity of hands while some others assess the dexterity of fingers. Discrimination power refers to the ability of these tests in discriminating gloves in terms of the magnitude of their effects on dexterity. The hand tool dexterity test had the highest discrimination power when various types of gloves were investigated. However, when general protective gloves were compared, the ASTM F2010 test provided better discrimination. The bulb dynamometer can be used as an alternative to the Jamar dynamometer for measuring hand grip strength with various gloves.

Author contribution statement

Payam Khanlari: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper. Fakhradin Ghasemi: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper. Rashid Heidarimoghadam: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

Mr Payam Khanlari was supported by Hamadan University of Medical Sciences [9811018465].

Data availability statement

Data will be made available on request.

Declaration of interest's statement

The authors declare no competing interests.

References

- 1.Imamura R., et al. Manual performance in cold conditions while wearing NBC clothing. Ergonomics. 1998;41(10):1421–1432. doi: 10.1080/001401398186180. [DOI] [PubMed] [Google Scholar]

- 2.Jones L.A., Lederman S.J. Oxford university press; 2006. Human Hand Function. [Google Scholar]

- 3.Wang Y.-C., et al. Assessing manual dexterity: comparing the WorkAbility rate of manipulation test with the Minnesota manual dexterity test. J. Hand Ther. 2018;31(3):339–347. doi: 10.1016/j.jht.2017.03.009. [DOI] [PubMed] [Google Scholar]

- 4.Yao Y., et al. Evaluation of effects of anti-vibration gloves on manual dexterity. Ergonomics. 2018;61(11):1530–1544. doi: 10.1080/00140139.2018.1497208. [DOI] [PubMed] [Google Scholar]

- 5.Bullock I.M. Yale University; 2016. Understanding Human Hand Functionality: Classification, Whole-Hand Usage, and Precision Manipulation. [Google Scholar]

- 6.Dianat I., Haslegrave C.M., Stedmon A.W. Methodology for evaluating gloves in relation to the effects on hand performance capabilities: a literature review. Ergonomics. 2012;55(11):1429–1451. doi: 10.1080/00140139.2012.708058. [DOI] [PubMed] [Google Scholar]

- 7.Dianat I., Haslegrave C.M., Stedmon A.W. Using pliers in assembly work: short and long task duration effects of gloves on hand performance capabilities and subjective assessments of discomfort and ease of tool manipulation. Appl. Ergon. 2012;43(2):413–423. doi: 10.1016/j.apergo.2011.06.016. [DOI] [PubMed] [Google Scholar]

- 8.Martin J.A., et al. Age and grip strength predict hand dexterity in adults. PLoS One. 2015;10(2):e0117598. doi: 10.1371/journal.pone.0117598. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Bicer E.K., et al. Evaluation of the risk factors for acute occupational hand injuries. Chir. Main. 2011;30(5):340–344. doi: 10.1016/j.main.2011.04.003. [DOI] [PubMed] [Google Scholar]

- 10.DavasAksan A., et al. Risk factors for occupational hand injuries: relationship between agency and finger. Am. J. Ind. Med. 2012;55(5):465–473. doi: 10.1002/ajim.22016. [DOI] [PubMed] [Google Scholar]

- 11.Laszlo H.E., Griffin M.J. The transmission of vibration through gloves: effects of push force, vibration magnitude and inter-subject variability. Ergonomics. 2011;54(5):488–496. doi: 10.1080/00140139.2011.562984. [DOI] [PubMed] [Google Scholar]

- 12.Riley M., Cochran D., Schanbacher C. Force capability differences due to gloves. Ergonomics. 1985;28(2):441–447. doi: 10.1080/00140138508963153. [DOI] [PubMed] [Google Scholar]

- 13.Sorock G.S., et al. Glove use and the relative risk of acute hand injury: a case-crossover study. J. Occup. Environ. Hyg. 2004;1(3):182–190. doi: 10.1080/15459620490424500. [DOI] [PubMed] [Google Scholar]

- 14.Batra S., et al. Glove attributes: can they predict performance? Int. J. Ind. Ergon. 1994;14(3):201–209. [Google Scholar]

- 15.Zare Bidaki F., et al. Introduction of protective gloves and their performance evaluation methods. J. Textile Sci. Technol. 2018;7(3):19–28. [Google Scholar]

- 16.Yalamarty A., et al. Effect of electric utility lineman gloves on strength and efficiency. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2009;53(18):1286–1289. [Google Scholar]

- 17.Millard C.E., Vaughan N.P. Assessment of protective gloves for use with airfed suits. Ann. Occup. Hyg. 2015;59(8):1022–1033. doi: 10.1093/annhyg/mev039. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Wimer B., et al. Effects of gloves on the total grip strength applied to cylindrical handles. Int. J. Ind. Ergon. 2010;40(5):574–583. [Google Scholar]

- 19.Ramadan M.Z. The effects of industrial protective gloves and hand skin temperatures on hand grip strength and discomfort rating. Int. J. Environ. Res. Publ. Health. 2017;14(12):1506. doi: 10.3390/ijerph14121506. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Zhao C., Li K.W., Yi C. Assessments of work gloves in terms of the strengths of hand grip, one-handed carrying, and leg lifting. Appl. Sci. 2021;11(18):8294. [Google Scholar]

- 21.Shih R., et al. The effects of latex gloves on the kinetics of grasping. Int. J. Ind. Ergon. 2001;28(5):265–273. [Google Scholar]

- 22.Hamouda K., et al. Fingers' vibration transmission and grip strength preservation performance of vibration reducing gloves. Appl. Ergon. 2018;66:121–138. doi: 10.1016/j.apergo.2017.08.005. [DOI] [PubMed] [Google Scholar]

- 23.Ward C., Adams J. Comparative study of the test-re-test reliability of four instruments to measure grip strength in a healthy population. Br. J. Hand Ther. 2007;12(2):48–54. [Google Scholar]

- 24.Maher C., et al. Reliability of the bulb dynamometer for assessing grip strength. Open J. Occupat. Therapy. 2018;6(2):10. [Google Scholar]

- 25.Mendonca R., et al. Establishing norms for the bulb dynamometer and evaluating pain and comfort differences between the bulb and jamar dynamometers. Am. J. Occup. Ther. 2018;72(4_Supplement_1) 7211500061pp.1–7211500061p.1. [Google Scholar]

- 26.Watkins J. 2011. Evaluation of Grip and Dexterity Test Methods for Characterization and Improvement to Structural Firefighting Glove Design. [Google Scholar]

- 27.Bennett G.K. Psychological Corporation; 1965. Hand-tool Dexterity Test. [Google Scholar]

- 28.ASTM . ASTM International; 2018. Standard Test Method for Evaluation of Glove Effects on Wearer Finger Dexterity Using a Modified Pegboard Test. [Google Scholar]

- 29.Mathiowetz V., et al. Adult norms for the nine hole peg test of finger dexterity. Occup. Ther. J. Res. 1985;5(1):24–38. [Google Scholar]

- 30.Association N.F.P. National Fire Protection Association; 2018. NFPA 1971: Standard on Protective Ensemble for Structural Fire Fighting and Proximity Fire Fighting 2018 Edition. [Google Scholar]

- 31.Barker R.L., et al. Comparative studies on standard and new test methods for evaluating the effects of structural firefighting gloves on hand dexterity. Textil. Res. J. 2017;87(3):270–284. [Google Scholar]

- 32.Fess E., Moran C. 1981. American Society of Hand Therapists Clinical Assessment Recommendations. [Google Scholar]

- 33.Yu A., et al. The effect of pressure glove tightness on forearm muscle activity and psychophysical responses. Hum. Factors. 2015;57(6):988–1001. doi: 10.1177/0018720815583398. [DOI] [PubMed] [Google Scholar]

- 34.Rencher A.C., Christensen W.F. third ed. Wiley; Hoboken, NJ: 2012. Methods of Multivariate Analysis. [Google Scholar]

- 35.Rencher A.C. vol. 338. Wiley-Interscience; 1998. (Multivariate Statistical Inference and Applications). [Google Scholar]

- 36.Bensel C.K. The effects of various thicknesses of chemical protective gloves on manual dexterity. Ergonomics. 1993;36(6):687–696. doi: 10.1080/00140139308967930. [DOI] [PubMed] [Google Scholar]

- 37.Irzmańska E., Okrasa M. Preliminary study evaluating manual dexterity tests assessing gloves protecting against cuts and stabs by hand knives. Int. J. Ind. Ergon. 2016;56:138–149. [Google Scholar]

- 38.Irzmańska E. Health & Safety International; 2014. August/September. Ergonomic Gloves. The Evolution of Ergonomic Properties; pp. 15–25. [Google Scholar]

- 39.Nayak R., Houshyar S., Padhye R. Recent trends and future scope in the protection and comfort of fire-fighters’ personal protective clothing. Fire Sci. Rev. 2014;3(1):1–19. [Google Scholar]

- 40.Dodgen C.R., et al. ASTM International; 2000. Investigation of a new hand function test aimed at discriminating multi-layer glove dexterity. (Performance of Protective Clothing: Issues and Priorities for the 21 St Century: Seventh Volume). [Google Scholar]

- 41.Mylon P., et al. Evaluation of the effect of medical gloves on dexterity and tactile sensibility using simulated clinical practice tests. Int. J. Ind. Ergon. 2016;53:115–123. [Google Scholar]

- 42.Allahyari T., Khanehshenas F., Khalkhali H. An investigation of the impact of using latex and nitrile gloves on hand dexterity. Int. J. Occup. Hyg. 2015;7(1):22–26. [Google Scholar]

- 43.Mylon P., et al. A study of clinicians' views on medical gloves and their effect on manual performance. Am. J. Infect. Control. 2014;42(1):48–54. doi: 10.1016/j.ajic.2013.07.009. [DOI] [PubMed] [Google Scholar]

- 44.Sawyer J., Bennett A. Comparing the level of dexterity offered by latex and nitrile SafeSkin gloves. Ann. Occup. Hyg. 2006;50(3):289–296. doi: 10.1093/annhyg/mei066. [DOI] [PubMed] [Google Scholar]

- 45.Pedretti L.W., M B. Mosby; St. Louis, MO: 2001. Early, Occupational Therapy: Practice Skills for Physical Dysfunction. [Google Scholar]

- 46.Kovacs K., et al. Grip force and muscle activity differences due to glove type. AIHA J. 2002;63(3):269–274. doi: 10.1080/15428110208984713. [DOI] [PubMed] [Google Scholar]

- 47.Zare A., et al. How do medical gloves affect manual performance? Evaluation of ergonomic indicators. Int. J. Ind. Ergon. 2021;81 [Google Scholar]

- 48.Roberts A., Brackley C. Friction of surgeons' gloves. J. Phys. Appl. Phys. 2000;25:A28. [Google Scholar]

- 49.Moerman F., Partington E. Materials of construction for food processing equipment and services: requirements, strengths and weaknesses. J Hyg Eng Design. 2014;6:10–37. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.