Abstract

Estimating the number of COVID-19 cases in 2020 exacerbated the food contamination and food supply issues. These problems make consumers more concerned about food and the need to access accurate information on food quality. One of the main methods for preserving the quality of food commodities for export, storage, and finished products is food packaging itself. In the food industry, food packaging has a significant role in the food supply which acts as a barrier against unwanted substances and preserves the quality of the food. Meanwhile, packaging waste can also harm the environment; namely, it can become waste in waterways or become garbage that accumulates because it is nonrenewable and nonbiodegradable. The problem of contaminated food caused by product packaging is also severe. Therefore, to overcome these challenges of safety, environmental impact, and sustainability, the role of food packaging becomes very important and urgent. In this review, the authors will discuss in more detail about new technologies applied in the food industry related to packaging issues to advance the utilization of Smart Packaging and Active Packaging.

Keywords: Active packaging, Food packaging, Food security, Smart packaging, Quality monitoring

Introduction

Humans cannot live without one of their most fundamental needs, which is food. However, estimating the number of COVID-19 cases in 2020 exacerbated the food contamination and food supply issues. These problems make consumers more concerned about food and the need to access accurate information on food quality. To protect the interests and rights of consumers, as well as standardize the food market system, it is crucial to provide an efficient way of determining food safety and quality in the food supply process. In the food industry, food packaging has a significant role in the food supply which acts as a barrier against unwanted substances and preserves the quality of the food [2].

The use of proper packaging can help reduce food loss and waste as well as maintain product quality and safety. However, packaging waste can harm the environment; namely, it can become waste in waterways or become garbage that accumulates because it is nonrenewable and nonbiodegradable. The problem of contaminated food caused by product packaging is also severe. The reason is that, according to the World Health Organization (WHO) in 2017, more than 600 million occurrences of disease and 420,000 deaths are caused by food contamination every year [4]. Therefore, to overcome these challenges of safety, environmental impact, and sustainability, the role of food packaging becomes very important and urgent.

One of the main methods for preserving the quality of food commodities for export, storage, and finished products is food packaging itself [1, 3]. In addition, today's changing consumer lifestyles increase the need for hygiene, excellent, fresh, and ready-to-eat products that have more life span, creating urgency and the demand for the present technology [1, 2]. While some initial indicators, such as color, odor, and texture parameters, are usually considered when evaluating food quality before packaging, it is still quite difficult to evaluate food quality after packaging because of outliers. In such a scenario, the latest food packaging technology is absolutely necessary to enable consumers and packaged foods to communicate with each other through active packaging and smart packaging in real time [65].

Recent advances such as biotechnology, nanotechnology, and material science offer new opportunities within the industry. One of them, Abdus Sobhan et al. (2021) analyze the concept of smart food packaging based on biosensors and biopolymer-based nanocomposites (bionanocomposites) that has piqued the interest of the industrial community in an ever-increasing way [65]. This offer is made to develop packaging materials including product safety and quality, environmental impact, and sustainable packaging. In this review, the author will discuss more details about new technologies applied in the food industry related to packaging issues, which is intelligent packaging (IP) and active packaging (AP).

Food security

Food security is defined by Food and Agriculture Organization (FAO) as “A situation that exists when all people at all times have physical, social, and economic access to sufficient, safe, and nutritious food to meet dietary needs and food preferences for an active and healthy life.” According to this definition, the four main pillars of food security are: availability, access, usage, and stability [5]. However, food security is a multidimensional concept that not only includes the four pillars of food security but also relates to food safety, healthy nutrition, and sustainable food [6].

At first, the concept of food security prioritized availability. There are concerns about the global food crisis caused by increasing hunger because food prices rose sharply in the global market. Although if we look at the history of food security, access, as well as stability, has been prioritized from the start, there is an understanding that the level of food consumption is influenced by market fluctuations which indicates access and stability are important in food security. This is reinforced by the presence of 3 main elements in food security, namely availability, access, and stability mentioned in the FAO Director General's report in 1982. When the necessity of nutrition was recognized, the idea of utilization developed. The ability to use the nutrients in food, such as high-quality protein and micronutrients, has evolved into one of the concepts of food security known as utilization, even though nutrition adequacy remains the foundation of food security [7].

Sustainability in food security refers to the application of a food system where the food demands of the current generation are fulfilled without affecting future needs. Currently, sustainability has become a global concern, where sustainability in food security is influenced by agriculture, alternative food sources, and public policies. Activities related to agriculture contribute to 71% of global water use, of which 15–35% is considered unsustainable. In addition, more than a metric billion tons of food is wasted each year [8, 9].

Active packaging

The term "active packaging" refers to packaging in which additional constituents have been purposefully incorporated into the packaging material. Active packaging improves the system’s performance by discharging compounds or absorbing spoiling agents present in or around the food [10, 11]. The types of AP that are often encountered are scavengers (oxygen scavenger, ethylene scavenger, moisture absorber) and diffusion systems (ethanol emitters, sulfur dioxide emitters, carbon dioxide emitters) [1, 12]. Several studies regarding active packaging can be seen in Table 1.

Table 1.

Various smart devices for Active packaging with principles, applications, and results

| Smart devices | Principle/reagents | Information given | Application | Time/Temperature | Results | References |

|---|---|---|---|---|---|---|

| Added to the Sensor | Garlic extract | Meat shelf-life | Meat products (fresh beef) | 24 h at room temperature (28 ± 2 °C) | Can extend the shelf-life of meat by 4 h longer when using high concentrations of garlic extract. This demonstrates that garlic extract acts as an antimicrobial agent that can help delay the spoilage of packaged beef | [65] |

| Vacuum Packaging | Immersion in 5 g/L Ascorbic Acid | Storage conditions | Fresh-cut potatoes | 5 days | Reduce levels of respiration and ethylene production, maintain firmness, prevent weight loss and the formation of reactive oxygen species and malondialdehyde, reduce PMB and TPC, slow down the growth of glucose, fructose, and sucrose content, maintain its flavor and taste parameters | [66] |

| HiOx-MAP packaging | Grape Seed Extract (GSE) | Meat color and premature browning (PMB) | Ground meat patties (85% beef and 15% pork back fat) | Over 10-day storage at 4 °C | Improve the color stability (P < 0.05) and significantly slow down the oxidation of lipids and myoglobin in raw patties from day 5 to day 10, but GSE has no effect on TVC (P > 0.05). When cooked to 66 °C, patties containing 0.50 and 0.75 g kg–1 GSE has greater interior redness than the control (P < 0.05). Could enhance the color of fresh meat and reduce PMB during late storage | [67] |

| Chitosan-SEO (Sandalwood/Santalum album Essential Oil) film | Malic Acid | Lipid oxidation activity | Butter | 90 days at 4 °C | The inclusion of SEO enhance the films' antioxidant properties and the films' UV-barrier, produce significant variations in the samples' transparency and color. Thiobarbituric acid reactive substances decrease significantly and lipid oxidation decrease by 36% compared to unpackaged butter after 3 months of storage. After use, the films can be easily removed from foodstuffs without producing solid waste because they are completely soluble in water | [68] |

| Gelatin film | Silver-Kaolinite (Ag-Kln) | Quality and microbial growth | Meat products (beef) | 13 days at 4 °C | Posses no adverse effects on the beef samples' pH or color. On day 13, beef meat packaged in active films lost more weight (P < 0.05) than meat packaged without active films. Demonstrate potential as antibacterial films and to extend the shelf-life of food products. However, additional research is required to determine the rate at which silver is released from packaging films and to examine the effectiveness of these materials under a variety of storage conditions | [69] |

| Gelatin/κ-carrageenan films | Anthocyanin-and TiO2 nanoparticles | The properties of biopolymer films | Fish | 30 days | The anthocyanin molecules and crystalline TiO2 particles were distributed fairly evenly throughout the amorphous biopolymer films. The optical, mechanical strength, and barrier properties of the biopolymer films were enhanced by the addition of TiO2 and anthocyanins. They provide antioxidant and antimicrobial properties that ought to extend packaged food shelf-life. The films rapidly degrade under simulated environmental conditions, suggesting that they may have a lower environmental impact than standard plastic packaging materials | [74] |

| Smart alginate-based coatings | Aloe Vera (AV) and Garlic Oil (GO) | Film properties | Tomatoes | 16 days | The presence of AV and GO improve mechanical and thermal properties and reduce WVP (P < 0.05), but not significantly affect the transparency of alginate film. The addition of AV and GO significantly enhance the prepared films' antimicrobial properties. When tomatoes (Solanum lycopersicum L.) were coated with the alginate film containing AV and GO, their shelf-life was extended | [82] |

| Cocrystal-based active food packaging | Cocrystallization of microbiologically active compounds present in essential oils, i.e., carvacrol, thymol and cinnamaldehyde | Antimicrobial activity | Grapes | 14 days | Cocrystallization proved to be an effective method for achieving a minimum of 14-day prolonged release of EOs' active compounds. The obtained results demonstrated the superior efficacy of the proposed pack in regulating the growth of the investigated strains, both with and without the need for direct contact with the culture medium. Fresh fruit storage improved both the organoleptic properties and the total mesophilic charge of the developed material, demonstrating its reliability | [87] |

Scavengers

Oxygen scavenger

In food packaging, the existence of O2 accelerates product degradation and the oxidation of dietary vitamins and fats by stimulating microbial activity. Poor taste, bad odor, discoloration, and nutrient degradation are some of its consequences on food. The main methods of oxygen scavenging are iron-, platinum-, and palladium-based metals, tocopherols, unsaturated hydrocarbons, ascorbic acid, enzyme-based scavengers, and microorganisms.

Nano-iron in humid conditions as well as anhydrous environments can lower oxygen concentration from 20.95 vol% to 9.45 vol% in a day. In this case, palladium plays a vital role that changes oxygen into water in the presence of hydrogen. On the other hand, this system is used for an altered atmospheric environment with the existence of hydrogen in it. This system has a high scavenging rate, i.e., the oxygen concentration decreases from 2 vol% to 0.47 vol% in 2 minutes. Unsaturated hydrocarbon scavengers are a very suitable choice for dried food. However, the creation of by-products like ketones, aldehydes, or organic acids will degrade the food's sensory quality. The solution to this issue is the introduction of a protective layer that must be activated by UV light or transition metal catalysts in order to avoid the transfer of by-products.

Tocopherols, ascorbic acid, microorganisms, and enzymes are several scavenger systems that have a slow scavenging rate. As alternatives to nano-iron, tocopherols and ascorbic acids are natural forms of vitamins E and C that are applicable for food packaging. However, they must be activated by UV light, light, or transition metals and are more expensive than nano-iron. The enzyme catalase is needed to change the hydrogen peroxide produced by the enzyme-based system into water. However, when exposed to temperature changes, acidic conditions, or storage, these systems are very likely to get denatured. Additionally, microorganisms are also temperature labile, but microorganisms can be properly immobilized to counteract this. Primary application of oxygen scavengers is controlling mold growth and food products frequently use oxygen scavengers to absorb extra oxygen [1, 13].

Ethylene scavenger

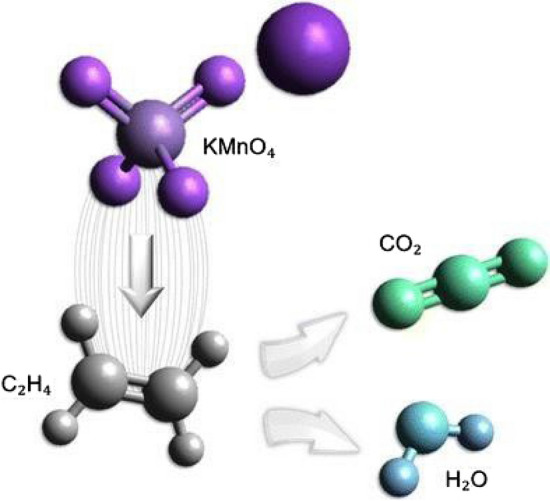

Fruit and vegetables discharge ethylene, which is related to the growth, ripening, and germination processes [14, 15]. The nature of the fruit, the state of ripeness, and the degree of exposure of the fruit to ethylene govern the specific role played by ethylene. Although ethylene plays a role in accelerating fruit ripening, this ripening can be excessive or even lead to spoilage. This is certainly a disadvantage such as reduced shelf-life, demands for long-term food quality maintenance, and increased food spoilage. Therefore, post-harvest utilization to slow fruit and vegetables ripening can utilize ethylene synthesis inhibitors or scavengers [16]. Potassium permanganate (KMnO4) is the basis of the most commonly used ethylene scavenger system through the oxidation process to access ethylene (C2H4). Immobilized KMnO4 on silica gel or alumina is applied in several scavenging systems. Alumina serves as a permanganate carrier as well as an absorbent layer that retains ethylene molecules. Ethylene (C2H4) is oxidized by KMnO4 to produce carbon dioxide (CO2), water (H2O), manganese dioxide (MnO2), and potassium hydroxide (KOH) [17]. The general stoichiometry of the ethylene oxidation reaction is:

Indian scientists (Raje et al., 1997), respectively, used Ethysord to extend mango shelf-life to 32–36 days, proving that it was effective in preserving mango color and flavor of mangoes up to 16 days. To inhibit the hormonal action of ethylene by competing with ethylene for ethylene receptors, 1-methylcyclopropene (1-MCP) is commonly used endogenous ethylene inhibitor, mainly by inhibiting the synthesis of ethylene in fruit [10].

Several methods, such as low temperature [15, 18], controlled atmosphere storage [19, 20], usage of hydrogen sulfide [21], pickering emulsion coating [22], and LED lighting [23], have advanced in various ways to preserve post-harvest goods from the consequences of ethylene. Several other types of ethylene scavenger are activated carbon, zeolite, ZSM, etc. Recently, there has been an increasing demand for new ethylene scavenging materials for use in the manufacture of plastic films for packaging fresh produce. When selecting ethylene sequestration materials, the capacity, stability, safety, and price of the fresh produce packaging system must be considered (Table 2). Concerns include migration of packaging materials into food products, tearing of sachets, and transfer or leakage of scavenger material from sachets and subsequent contamination of food. Besides issues challenging the use of this system (marketability, environmental safety issues, and consumer acceptance), appropriate cost benefit considerations also become very important [24]. Further research is needed to address the above issues and problems in the field of ethylene scavenging packaging materials to offer a safer and more cost-effective packaging system without compromising food shelf-life extension [1, 16].

Table 2.

Some Active Packaging techniques available commercially

| Scavenger | Commercial product |

|---|---|

| Oxygen | ATCO® |

| Bioka | |

| ActiTUF™ | |

| Ageless® | |

| OMAC® | |

| FreshPax® | |

| Cryovac® OS2000 | |

| Celox™ | |

| Shelfplus® | |

| OxyRx® | |

| OxyGuard® | |

| OxyCatch® | |

| Ethylene | Retarder® |

| Profresh | |

| PEAKfresh® | |

| Bi-On® O2 | |

| Ethysorb | |

| Bio-fresh |

Moisture absorber

One of the most damaging factors in food problems and harmful effects is the presence of moisture, where this will affect the storage of raw materials and products; for example, the water activity contained in food is high enough to accelerate the growth of fungi and bacteria, which in turn reduces the quality of the food and the nutrient content in it [25]. On the other hand, there are several main causes that can accelerate the spoilage of food products such as the nature of the product itself (oxygen content, moisture content, water activity, pH, composition, nutritional composition), process conditions, storage conditions, packaging properties (carrier gasses, UV carrier, thermal stability, antioxidant, mechanical properties, antimicrobial activity).

Diffusion systems

Ethanol emitter

Ethanol emitters release ethanol vapor into the package headspace to inhibit the growth of the mold. As an antimicrobial, ethanol will reduce spoilage and extend the vegetables and fruits shelf-life during handling, storage, and retail. Known as a traditional preservative with strong antimicrobial activity, it can be directly sprayed onto the product or inside the packaging in the form of an ethanol emitter [26]. Several commercial ethanol release systems are available that are made by direct adsorption of ethanol onto adsorbents such as silica. Ethanol is usually used in liquid form, which has a high and uncontrolled evaporation rate. In Japan, ethanol production is commonly used in baked products because it can slow down the mold growth process, which in turn increases shelf-life, such as breads, cakes, pastries, and pizza dough [27].

Ethicap® is one example of an ethanol emitter, a heat-sealed sachet composed of food-grade alcohol adsorbed onto silica powder. It has several advantages: (1) no chemical preservative required; (2) in sachet form, easy to make; (3) there is no need to spray the ethanol solution directly onto the product to generate ethanol vapor; (4) it is not expensive [28]. One of the main disadvantages of using them as an active form of packaging is their uncontrolled release rate of and high volatility, which quickly leads to low consumer acceptance [2, 29].

Sulfur dioxide emitter

In general, the emission of SO2 works according to the mechanism of hydrolysis of metabisulfite and the reaction of calcium sulfite with water vapor [27]. The addition of sulfurdioxide (SO2) has been observed beneficial in stopping the shelf-existence of a huge variety of agricultural products such as walnuts, coconut, cabbage, peppers, squash, tomatoes, peas, beans, carrots, and potatoes. In addition, sulfur dioxide emitters have been used on wine packaging to prevent the growth of mold. Two different SO2-release films were used to package white and purple wines to study their impact on wine spoilage and quality. After 4 days of storage at 21 °C, it was observed that the sulfite content in purple grapes was lower than in white wine, although SO2 was higher. A polymer for the controlled release of SO2 must be used here in order to achieve inactivation of fungi without adverse effects on food [2, 27].

Carbon dioxide emitter

Carbon dioxide (CO2) is a gas molecule dissolves in the water phase and fet phase of food, producing carbonic acid and food acidification at the same time. CO2 is well known for its antimicrobial properties and is widely used in the food industry for food preservation and shelf-life extension. It interacts through a complex series of reactions that include changes in bacterial cell membranes, inhibition of bacterial enzymes, and changes in cytoplasmic pH [30]. This leads to a prolongation of the lag phase and inhibition of bacterial spoilage [27]. The optimal ratio in the modified atmosphere packaging (MAP) between the product volume and headspace (g/p ratio) is 2/1 or 3/1. The high amount of CO2 allows for effective diffusion of the gas with the product and prevents deformation of the packaging (due to the absorption of CO2). However, a high g/p ratio causes a large package size, resulting in reduced distribution efficiency, an increase in packaging materials and packaging gasses which cause environmental pollution [12]. Also in the form of sachets, CO2 emitters are mainly used for packaged fish, fresh meats, and vegetables [31].

The commonly used CO2 release technology involves two active substances, namely organic acids (citric acid) and sodium bicarbonate (NaHCO3) [30]. The reaction starts when the liquid (of the food) comes into contact with the active substance and dissolves it. The acid lowers the pH of the system to a level where the sodium bicarbonate buffering system shifts to the formation of carbonic acid and undissociated carbon dioxide. Le Chatelier's principle states that when a liquid is introduced into the system, the pH drops and carbon dioxide production begins.

The concept commonly used is to apply dry powder of baking soda and citric acid in a specific amount and ratio to a liquid absorbent pad. The pads are placed under the food product and serve as a liquid absorber and CO2 generator. In practice, this process is easy to apply in production and often does not require any additional steps in industrial packaging. The advantage of this CO2 emission system is the flexibility to adjust the ratio between the active ingredients to provide a pH of, which corresponds to the pH of a specific food product [12]. Another CO2-emitting system is a combination of ascorbic acid and sodium bicarbonate. Ascorbic acid is known for reducing properties and is thought to have a dual role in this system, as an acidifier, promoting the formation of CO2 and also as an O2 scavenger. The antioxidant effects of ascorbic acid may also be beneficial in the packaging of high-fat foods as it slows down lipid oxidation and the development of rancid taste and odor, resulting in quality degradation [30].

Commercial CO2 emitters based on citric acid and sodium bicarbonate currently on the market are CO2 Pad (Cellcomb AB, Säffle, Sweden), Superfresh (Vartdal Plastindustri USA, Vartdal, Norway), and CO2 Freshpads (CO2 Technologies, Iowa, USA). The combination of ascorbic acid and sodium bicarbonate can be found in VerifraisTM (SARL Codimer, Paris, France) CO2 emitters [30].

Smart packaging

The concept of smart packaging has become an exciting topic in the food packaging industry. In general, smart packaging increases the safety and quality of the food by adding one or more intelligent agents (such as detectors, sensors, or trackers) to transmit food quality information and make decisions to extend shelf-life, gather information, and also warn of food problems using various intelligent techniques [32–34]. TTI (time-temperature indicator), repeat index, freshness indicator, coloring indicator, barcode, and radio frequency identification (RFID) are key components of smart packaging on the market [65]. Several studies regarding smart packaging can be seen in Table 3.

Table 3.

Various smart devices for Intelligent or Smart food packaging with principles, applications, and results

| Smart Devices | Principle/Reagents | Information given | Application | Time/Temperature | Results | References |

|---|---|---|---|---|---|---|

| Sensor | Bacterial Cellulose ofAcetobacter xylinum | Food freshness by detecting color changes using BTB (pH 2,75) | Meat products (fresh beef) | 24 h at room temperature (28 ± 2 °C) | The BTB indicator solution changes color from orange to dark green, indicating that the quality of the beef has changed from fresh to rotten | [65] |

| Anthocyanin-based film | Polysaccharide or protein polymers | Food freshness | Aquatic products (Fish and shrimp), Meat products (Pork and beef), Dairy products (Cheese and yogurt) | 4–30 °C | Highly sensitive to pH, capable of serving as a real-time indicator, safe, nontoxic, biodegradable, excellent antioxidant and antimicrobial properties. However, food deterioration could result from the anthocyanin-based films' vulnerability to oxygen permeation, light, thermal degradation, and water vapor. Also, the films can't keep track of how fresh food is because anthocyanins degrade over time | [70] |

| Biopolymer-based edible film (Cassava starch) | Natural plant extracts from Pomegranate Peel Powder (PPP) | Food freshness | Meat products (Lamb) | 72 h at 25 °C | The mechanical properties of the starch films were significantly altered, the films' color got darker and more red, the TPC and antioxidant activity of the produced films increased as a result of the PPP levels being raised (P < 0.05). The packaging changed color from red to green while being stored at 25 °C, indicated the amount of TVB-N in the meat | [71] |

| Gelatin/CNF-based film | Shikonin (Natural pigment extracted fromLithospermum erythrorhizon root) | Food freshness | Shrimp | 48 h | Good pH-responsive color changes and volatile gas sensing properties, excellent antioxidant and antibacterial activity, high tensile strength (> 80 MPa), excellent UV light barrier properties. In the presence of shikonin, the film's hydrodynamic properties slightly altered, but its thermal stability and WVP remained unaffected. The shrimp's freshness and spoilage after 48 h of storage are also clearly visible | [72] |

| Sensor | D-π-A luminogen | Food spoilage | Fish | 8 days in refrigerator temperature at 3.5 °C | The present D-π-A compound was made into a cellulose film with a colorimetric and fluorometric dual-channel as a response to amine vapors from fish samples. It is simple to transform into smart labels and encase it in food bags, resulting in an intelligent food package | [73] |

| Polypropylene (PP) film | Two composite films (Polypropylene/Octadecane and Polypropylene/Octadecane/Zeolite) | Food quality | Cherry tomatoes | 10 days and 23 °C | It showed significantly higher temperature dependence. The cherry tomatoes in the composite film pouches maintained their quality because of the higher gas permeability, which resulted in improved firmness, color, and total soluble solid content. Can reduce the effects of temperature on the quality of agricultural products and extend their shelf-life | [77] |

| Smart color-changing paper packaging sensors | Anthraquinone and Azo chromophores | Food freshness | Cooked crabs | 4 h | The color-changing patterns printed with two visible pH-sensitive dyes were developed to respond to acid-alkaline environmental conditions. The cooked fresh crabs began to deteriorate after 1.5 h and completely deteriorated after 4 h | [78] |

| Smart biodegradable Chitosan (CS)/ Methylcellulose (MC) film | Phyllanthus reticulatus (PR) ripen fruit anthocyanin | Food freshness | Fish fillet | 4 h at room temperature | The smart films displayed strong antioxidant and antibacterial activity against common foodborne pathogens like S. aureus, P. aeruginosa, and E. coli, and displayed pink coloration in acidic pH solution and yellowish coloration in basic pH solution | [79] |

| ClO2 self-release encapsulated antimicrobial agent | HNT–NaClO2 | Food spoilage | Cherry tomatoes | 20 days | Depending on the amount of releasing materials in the packaging, different concentrations of ClO2 were found in the headspace. Higher concentrations of ClO2 prevented microbial growth and thus extended the shelf-life of cherry tomatoes | [80] |

| Bilayer pH-sensitive colorimetric films | GG-MBA/GN-ZnO | Food spoilage | Fish | 9 days | The illumination stability of the bilayer film was significantly enhanced by the addition of ZnO nanoparticles, but there was no interference with the films' NH3-sensing capabilities. With the crucian spoilage, the bilayer colorimetric films showed visible color changes, and the patterns written on the films were well-maintained | [81] |

| Colorimetric pH sensoring packaging films | Sugarcane wax/agar integrated with butterfly pea (BF) flower extract | Food freshness | Shrimp | 24 h | At pH ranges 2–12, BF extracts have shown a gradual shift from red to blue and green. When ammonia vapor is present, the colorimetric film appears green. Light transmission has fundamentally changed, reducing visible light and preventing UV–VIS. In addition, among the films used to determine shrimp freshness, color changes and a connection between TVB-N and pH were observed | [83] |

| Smart colorimetric sensing films | Cellulose and naphthoquinone dyes extracted from Arnebia euchroma (AENDs) | Food freshness | Shrimp and Pork | 5 days | The sensing film changed clearly from rose-red to purple, then bluish violet, according to visual observation. This was a good sign of spoilage, and it was well correlated with the TVBN and TVC content of shrimp and pork measured using standard lab procedures | [84] |

| Halochromic smart films | Immobilizing red cabbage anthocyanins into chitosan/oxidized-chitin nanocrystals composites | Food freshness | Hairtail and shrimp | 48 h at 25 °C | Within short time intervals, the smart films showed distinct color changes to ammonia vapor and an acidic or alkaline environment that were clear to the naked eye. During the storage period, the film's color changed significantly, and three stages of product freshness—fresh, medium fresh, and spoiled—were successfully distinguished | [85] |

| Smart fluorescent tag | Green fluorescent fluorescein as an indicator and red fluorescent carbon quantum dots (RQDs) with aggregation-induced emission property as an internal reference | Food freshness | Seafood | 5 days | The fluorescent membrane changed color in different ways under different UV light. Under 254 nm UV light, the membrane's fluorescence changed from pink to off-white, green, and then back to pink after being exposed to varying concentrations of biogenic amine vapor. The membrane's fluorescence changed from pink to light pink, yellow, and green when exposed to UV light at 365 nm. Because of the significant color change, biogenic amines can be seen with the naked eye in real time and accurately | [86] |

| Cellulose/chitosan pH-responsive film | Integrated with anthocyanins of black carrot (ABC) | Food spoilage | Pasteurized milk | 48 h | Chitosan-cellulose paper's swelling and water solubility were enhanced by the ABC. The manufactured indicator completely distinguish fresh pasteurized milk from spoiled milk based on the color changes from blue to violet rose color that could be seen in the indicator by the naked eye. The indicator shows different responses to pH buffers and the highest color changes when exposed to an acidic pH | [88] |

| Extruded low density polyethylene-curcumin sensor film | Low density polyethylene (LDPE) and curcumin | Ammonia activity | Silver carp and beef | 7 days | A lower relative humidity facilitate the LDPE-curcumin film's sensitivity to NH3. When beef and silver carp were stored at 4 °C, the LDPE-curcumin film changed from a yellow to a brown color. Because the film is safe, cheap, and good for industrial production, it could be used in smart food packaging | [89] |

| Nanocellulose hydrogel | Sugarcane bagasse | Food spoilage | Chicken breast | 7 days | When the packed chicken was kept at 4 °C for three days, the indicator hydrogel change optically from green to bright red. A high level of CO2 detected at this turning point, which correspond to the growth of microorganisms beyond the limit of food safety. There are also remarkable changes in volatile components that could be distinguish using electronic nose testing | [90] |

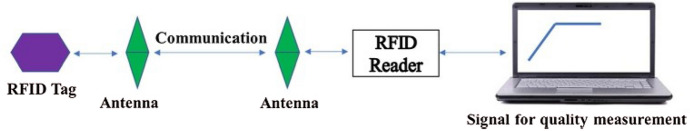

TTIs and RFID are two well-known components among these parts. Temperature and time profile can be used to measure changes in food's physical properties with TTIs. The TTI devices can only be used in frozen food products, so their application is limited. RFID is one of the smart packaging materials that monitors wireless communication between tags, readers, and computer systems in the packaging of products. RFID is preferable to barcodes because it allows for remote control so that multiple items can be monitored simultaneously without requiring line of sight [65].

An RFID tag is made up of a tiny transponder and antenna with a unique number or alphanumeric order in a basic RFID system; a reader uses radio waves to get the data from the RFID tag. The data are then sent to a host computer, which might be more connected to the local network or the internet, where it is analyzed and a real-time database server makes decisions. The fact that RFID tags cannot be reused, make them unprofitable for the food industry, and that their market prices are significantly higher make them unsuitable for commercial use in food packaging applications. As a result, research is urgently required to develop less expensive and reusable smart food packaging components and to increase market opportunities [65].

Data carrier indicator

Sensors

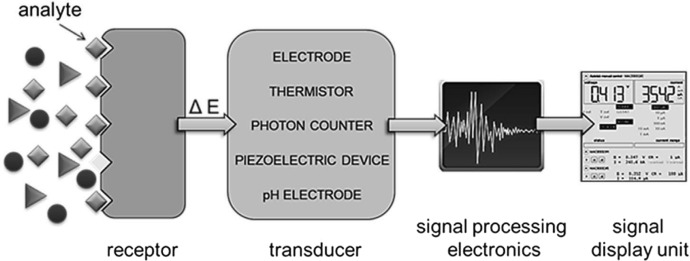

Sensors are electronic devices that collect information from an object and convert it from one signal form to another usable form using a converter [2, 35]. The sensor device consists of control and processing electronics along with an interconnected network and software that provide signals to detect or measure physical or chemical properties to which the device responds. Sensors can detect, localize, or measure energy or matter [36]. In general, a sensor includes 3 purposeful parts, a sensing component, accompanied through a sign conditioning component (sign processing component), and subsequently an interface component that shows the measured residences. The first component factories bodily or chemical residences and commonly converts them into electric signals. The sign conditioning unit methods the ensuing sign. In this unit, the sign is amplified, linearized, and scaled. The remaining components may be adapters, easy mechanical connectors, Wi-Fi sensors, and others. Electronic gadgets are used withinside the remaining sections in maximum of the cases [37]. For example, in chemical sensors, the sensor component is commonly covered with a chemical layer. If there may be a chemical alternate on this layer because of dissolution with a substance or different substances, the residences of the sensor component alternate. In other words, upon a pH alternate, the sign processing phase gets the power alternate from the sensing phase and converts it right into a beneficial electric sign. Then the remaining phase shows the changes [1].

Sensors and markers are capable of degree physical, chemical, or organic variables, and among them, fueloline sensors and biosensors, and chemical sensors are broadly applied withinside the meals packaging industry. The structures used on this sort of packaging are used withinside the shape of labeling, including packaging materials, or printing on meals and permit clients to manipulate quality, song important points, and acquire records approximately the packaging [36]. Sensors are taken into consideration to be the maximum promising generation for the improvement and development of destiny clever packaging structures [1].

Biosensor

A biosensor is a tool able to detect a particular organic evaluation and change its presence or awareness into diverse optical, thermal, electric or different alerts that may be without difficulty analyzed [2]. Biosensors consist of biologically identifiable elements such as antibodies, enzymes, hormones, antigens, nucleic acids, phages, and signal transduction elements such as acoustic, optical amperometry, and electrochemical sensors that are linked to data acquisition and monitoring systems. Biosensors are used to capture, record, and transmit records of approximately organic reactions. Biosensors encompass bioreceptors and transducers.

Commercial biosensors for meal pathogens were developed. Certain antibodies bind to biosensor receptors and are capable of discovering microbes and organic retailers in meals packaging [39–41]. In the food packaging industry, particularly in the fish and meat industry, biosensors are implemented to pathogen detection and protection systems. For example, there is a biosensor developed by toxin alert called toxin guard. It is based on antimicrobial antibodies that are integrated directly into the plastic packaging in which food is packaged. Contaminants bind to detector antibodies and are detected by visual signals, allowing detection of pathogens such as Listeria, Salmonella, Campylobacter, and E. coli [33, 36].

Fresh foods are those that haven't been spoiled and preserved yet. This term refers to fresh foods that have just been harvested and treated in the case of fruits and vegetables; the freshness of food indicates that it was recently slaughtered and butchered in the case of meat; freshness in food refers to fish that has just been caught or chopped and kept cold. The target metabolites produced by food spoilage are being monitored by the biosensor, which is intended to evaluate food freshness [65].

Chemical sensor

In chemical sensors, the receptor is a selective chemical capable of detecting the presence, activity, composition, and concentration of chemical particles or gaseous analytes. The sensor undergoes chemical interactions between the substrate and the analyte molecules, which are further used for sensing/detecting applications. When the presence of a chemical is confirmed, the transducer converts it into a signal. The active and passive transducers rely upon the outside power required for measurement [42]. Chemical sensors that may be used consist of carbon nanomaterials together with graphene, nanoparticles, nanofibers, and nanotubes due to their extraordinary mechanical and electric properties. In their application, those chemical sensors are used to hit upon pathogens, spoilage, chemical contaminants, and meals fraud [2, 33] (Figs. 1 and 2).

Fig. 1.

Ethylene oxidation reaction by KMnO4 [17]

Fig. 2.

Representation of the functional principle and the components of the sensor [38]

Gas sensor

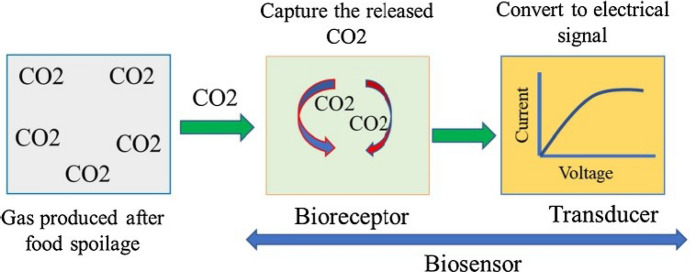

Gas sensors are designed to detect and indicate the presence of volatile gasses or compounds such as oxygen, carbon dioxide, amines, and other particular gasses. The gas sensor must always be in contact with the food and atmosphere in the package. Studies on the production of CO2 sensitive smart packaging films have recently been carried out [43–45]. As the level of CO2 gas in the headspace of the package increases, the color of the film will change to provide a visual indication of the quality of the packaged food. So these indicators can closely monitor changes in food quality that are not visible to consumers to produce visible changes. The three parts of a gas sensor are: a sensing electrode that is also a working, counter, and reference electrode all at once. A reference electrode is used to keep the working electrode's potential constant, and the counter electrode is separated from the working electrode by a thin layer of electrode. First, gas comes into contact with the working electrode after passing through the hydrophobic barrier. A gas sensing component in the working electrode responds to the desired gas and generates an electrochemical signal. The sensing electrode is used to measure the level of CO2 gas using carbon dioxide sensors, one type of gas sensor. Figure 3 depicts the gas sensor's concept for detecting CO2 materials within food packages. Gas sensors are superior to conventional sensing techniques because they can be used in a hazardous area, are specific to the gas molecules being targeted, and are unaffected by electromagnetic interferences [65].

Fig. 3.

The fundamental principle of a gas sensor for detecting CO2 (gas) after food spoilage [65]

Carbon dioxide is the primary product from microbial metabolism. Food spoilage and fermentation sometimes occur because of fluctuations within the external environment. Changes in food quality are among the assembly of CO2 by the expansion of microorganisms. Once selecting fruits and vegetables, the respiration rate of fruits and vegetables suddenly increases, which releases massive amounts of carbon dioxide, particularly in the amount between growth and aging. Therefore, the freshness of some foods depends on the carbon dioxide concentration in the packaging [46]. Volatile alkaline nitrogen is a more suitable type of indicator to indicate the freshness of aquatic products than meat products because less acid is produced in aquatic products and microbial growth is more favorable for enzymatic autolysis because it is more susceptible to decay to produce volatile alkaline nitrogen properties.

When poultry meat, some fruits, and vegetables are decayed, it produces large amounts of sulfide, which can be used as an indicator of freshness due to the physical and chemical properties of sulfides [47, 48]. During the decomposition of chicken meat, hydrogen sulfide is produced through Pseudomonas which binds to myoglobin in the meat to form green pigment sulfur protein, sodium phosphate as a buffer, and agarose gel as a buffer. The released hydrogen sulfide causes the color of the indicator placed on the top of the chicken package to change color from brown to green [47].

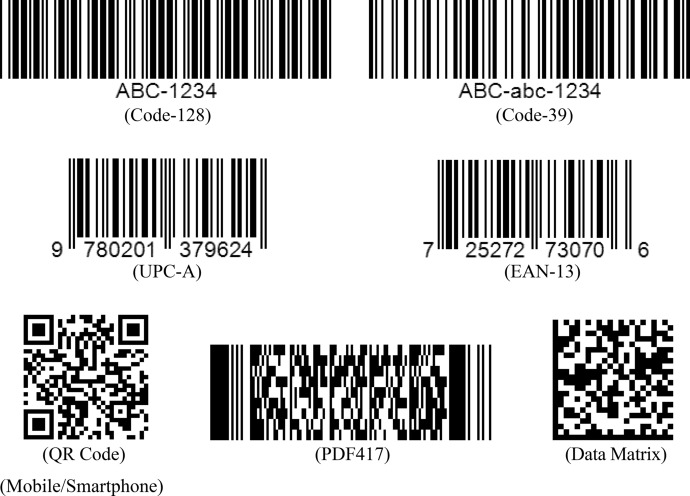

Barcode

The barcode is an optical symbol in the form of numbers and characters in the form of a barcode that can be read by an optical barcode scanner and then sent to a central system. Barcodes can be divided into two types, namely linear one-dimensional barcodes and two-dimensional barcodes. Conventional (one-dimensional) barcodes that are commonly found are in the form of black vertical bars printed on a white background with the size and spacing of the barcodes being wide and narrow. How to measure it is to record the width of the line per mile as well as the blank distance left and right of the barcode character to ensure the authenticity of the barcode reading. The one-dimensional formats European Article Numbering (EAN), Universal Product Code (UPC), Code 99, and Code 128 are well known in all supermarket products (US barcodes and RFID reports). One-dimensional food barcodes typically consist of 13 digits, with the first three digits representing the country where the barcode is manufactured [49]. Barcodes were first invented in the seventh decade of the last century by large retail and grocery stores to manage their products. The use of barcodes in the modern era has often been encountered because the cost is very small and its use is very simple.

Over time, the need to store more information in the barcode was finally found in the two-dimensional barcode format [50]. This two-dimensional barcode format was first introduced in 1988 by the Intermec company (Everett, Washington, USA) with a code structure consisting of a collection of black and white boxes. The difference between one-dimensional and two-dimensional barcode formats, apart from their shape, is in the information stored in them. In a one-dimensional barcode, the information stored is only about 2953 bytes or about 10–13 characters. The two-dimensional barcode can store information of 4296 alphanumeric characters and 7089 numeric characters. Two-dimensional barcodes that we often encounter are QR code formats, PDF 417, and data matrix.

For example, in the problem of detecting spoilage in chickens. A series of color-based sensors made of silica beads has been further developed and modified as bar codes with the help of three dyes. The three dyes, namely Nile Red, methyl red, and zinc tetraphenylporphyrin in three different geometric shapes. The detection is based on the separation of red, green, and blue dyes and can be read out by the integrated application on the smartphone. The approach is inexpensive, and the manufacturing process is simple [51]. If pathogenic bacteria grow on the packaging during the storage period, the barcode can detect this, discolors, and makes the barcode illegible [35] (Fig. 4).

Fig. 4.

Some barcode models in general (All codes are created by the author, https://barcode.tec-it.com/en)

Radio frequency identification (RFID)

RFID tag is an advanced technology in the form of a chip that can identify electronic information on the package that contains an antenna for data retrieval, a reader for data transmission and analysis, and a responder for responding to data information [52]. RFID tags have several advantages such as noncontact ability, data collection through nonmetallic materials, large data storage capacity, rapid identification of multiple products, traceability, cost-effectiveness, can monitor food freshness by measuring moisture and corruption products, noncontact capability, line of sight to collect real-time data, promote quality and safety, and much more so that RFID tags are often applied to food packaging or can be combined with other intelligent technologies [40, 53]. A simple illustration of the RFID system can be seen in Fig. 5.

Fig. 5.

A standard RFID system parts [65]

When compared to barcodes, RFID costs are more expensive and also requires a stronger network. However, RFID has a larger operating range and the reader can also read RFID tags at the same time. To read and write data remotely, the RFID system uses electromagnetic and electronic signals [54]. The frequency ranges used by RFID technology are low frequency (9 to 135 kHz), high frequency (13,553 to 15,567 MHz), amateur radio band (430 to 440 MHz), ultra-high frequency (860 to 930 MHz), and microwave frequencies (2.45 and 5.8 GHz) [55]. RFID tags have three different modes: active, passive, and semi-passive. Battery powered active tags have the advantages of longer range and higher operating frequency. On the one hand, however, it has a downside, which is the high price, which ranges from $20 to $100, large size by battery, and short battery life. While the passive tag works without power supply, it uses the signal received from the reader as power supply. Therefore, the reader must send a strong signal and the tag must send a weak signal to the reader. However, they only send a signal when they are in the field of the reader. Passive tags have the advantage of being cheaper (10 cents), smaller, and much more durable than active tags. However, passive labels are more expensive than 1 cent barcode labels. Semi-passive tags behave in the same way as passive tags when transmitting signals, but only use battery power to operate the microchip circuitry.

There are classifications of RFID tags from another perspective, namely read-many (WORM), read-only, electronic erasable programmable read-only memory (EEPROM), read-write and write-once, tags based on the ability to read and write [55, 56]. Consequently, the RFID system consists of two basic components: transponders (tags or contactless cards) and readers depending on the technology used, may be read-write devices or read-only devices [57]. In the food and retail industry, simple devices (RFID tags) are attached to food products. This device communicates with the RFID reader using a wireless signal. Readers can receive information from several nearby tags. More specifically, the interrogation signal generated by the reader is transmitted from the antenna to the environment. This signal beats the tag, which includes every other antenna linked to a unique digital circuit that consists of facts approximately the product in a unique memory. In reaction to the reader's sign, the tag generates a reaction sign that consists of product facts despatched with the aid of using the reader and obtained back [58].

Chen et al. [30] proposed a scheme of application of the device as a food qualification system which may be visible withinside the example in Fig. 6. Chen et al. [30] also suggested including colorimetric dyes that can detect other antennas connected to special electronic circuits that keep statistics approximately the product in a unique memory. In reaction to the reader's sign, the tag generates a reaction sign containing product statistics that are dispatched, returned, and acquired through the reader. To system and alternate records transmitted among the reader and the tag, the reader is normally linked to a number laptop, community laptop, or microcontroller.

Fig. 6.

Device application scheme as a food qualification system [59]

The largest technical task of RFID generation is the shortage of reliability withinside the retail market. Due to the interference of the high water content material in the human body, it is very difficult to read the ultra-high-frequency label near the participant [60]. It is not clean to study labels packaged on foodstuffs with massive quantities of liquid or in steel boxes due to the fact that steel displays signals. The loss of a worldwide trendy frequency prevents using RFID generation for diverse applications. RFID tags are much more high priced than barcode tags, so this hassle makes it uneconomical to put in force this generation of objects on the market to the public. With the emergence of the latest production technology withinside the future, the very last fee will now no longer be reduced, as a way to guide the good-sized adoption of RFID generation [60]. Recycling and pollutants issues, in addition to protection issues, are different demanding situations in enforcing this generation. For example, nonpublic data consisting of stock and delivery information may be stolen via means of unauthorized vendors who can experiment tags for access.

Time–temperature indicator

Time–temperature indicator is an easy and cheaper tool placed on consumer packages or packages that aims to determine changes that occur depending on temperature over the years alongside the meal delivery chain from packaging to consumption [2, 38, 40]. The simple working precept of TTI is primarily based totally on irreversible mechanical, chemical, enzymatic, or microbiological adjustments of meal merchandise beneath neath better temperatures. These adjustments are generally expressed as a seen reaction withinside the shape of mechanical deformation, color improvement, or color movement. The bodily or chemical reaction via means of TTI is the end result of bodily adjustments or chemical reactions, inclusive of fusion, polymerization, acid-base reactions, etc., while the organic reaction is primarily based totally on adjustments in organic activity, inclusive of microorganisms, spores, or enzymes over the years or adjustments in temperature. Since the charge of organic alternate is time-temperature dependent, the cumulative seen TTI reaction displays the time-temperature records of the accompanying product [36].

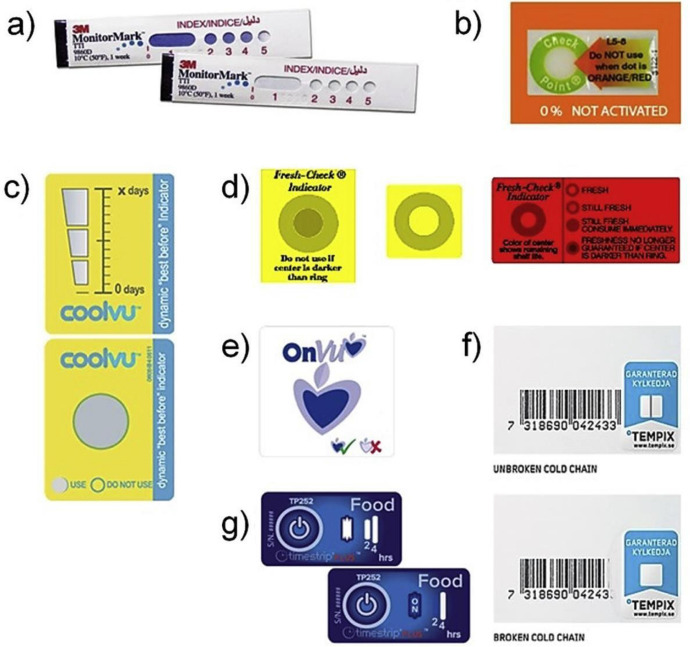

TTI is currently the most commonly used system in packaging as it is easy and the reaction does now no longer rely upon the character of the meals or the attention of chemical materials however on positive temperature versions whose facts can be understood by consumers regarding food quality [38, 59]. In its application, TTI has been developed and applied to dairy products, fish and other seafood products, frozen foods, and cold meats [35]. Currently, few examples of TTIs on the market are 3M™ MonitorMark™ (USA), Fresh-Check® (USA), CoolVu™ (Switzerland), CheckPoint (Sweden), Tempix® (Sweden), ColdSNAP Temperature Recorders, ShockWatch, ThermRF Logger, Timestrip® (UK), VarioSens®, and WarmMark Time-Temp Tag, etc [38, 40] (Fig. 7).

Fig. 7.

Examples of time–temperature indicators: a Monitor Mark™ by 3 M (USA) (http://3m.com); b Fresh-Check® by Lifelines Technologies Inc. (USA) (http://fresh-check.com/); c CoolVu™ by Freshpoint (Switzerland) (http://www.freshpoint-tti.com/product/coolvu.aspx); d Checkpoint® by Vitsab International AB (Sweden) (http://vitsab.com/index.php/tti-label/); e OnVu™ by Freshpoint (Switzerland) (http://www.freshpoint-tti.com/links/default.aspx); f Tempix® by Tempix AB (Sweden) (http://tempix.com/the-indicator/); and g Timestrip® by Timestrip Plc (UK) (http://timestrip.com)

Natural color formulation indicator

The changes in food quality can be monitored in real time using natural pH-responsive indicator films, which are typically utilized in smart packaging. The natural-based pH-responsive colorimetric indicator films have a growing population and good pH sensitivity, indicating food quality in a safe and environmentally friendly manner. Natural pigments and polymer carriers have recently shown great promise for pH-responsive indicator-based smart packaging. Natural pH-sensitive indicator films, which are one of the most important components of smart packaging, can be made using natural pigments and polymer carriers extracted from waste peels, seeds, roots, and even pulps. The compositions and properties of pH-responsive colorimetric indicator films are depicted in Fig. 8.

Fig. 8.

Advantages and composition of pH-responsive colorimetric indicator films [116]

Natural pigments have gradually replaced synthetic chemical pigments with pH-sensitive properties due to their negative effects on the environment and toxicity. Most of the time, natural pigments like anthocyanins, carotenoids, chlorophylls, and other natural pigments are used as food indicators. These natural pigments can not only show changes in a food's quality but also improve certain characteristics of the food, like its ability to fight bacteria and protect against free radicals. To meet the requirements of pH-responsive food packaging, natural pigment dye penetration, and color rendering range as food indicators need to be improved. Due to the advantages of degradability and renewability, there has also been an increase in research into natural polymer carriers like starch, gum, and chitosan to replace petroleum-based polymers. However, the natural polymers still had a few flaws, such as their low suitability, high brittleness, low toughness, and high sensitivity to water. To enhance the properties of the film, plasticizers or nanomaterials must be added in addition to pigments and polymer carriers [116, 117].

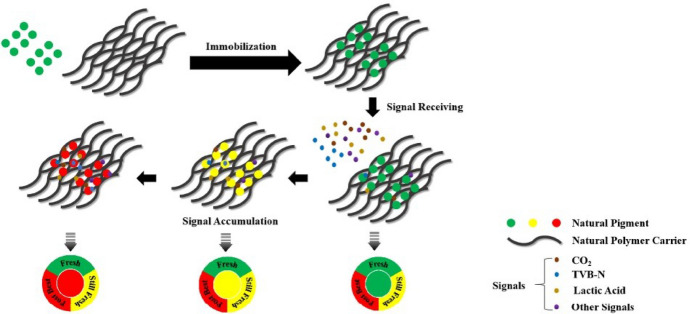

Natural pigments are frequently utilized in intelligent packaging, particularly for monitoring food freshness because of their abundant source, accessibility, safety, wide indicating range, and favorable pH response, among other benefits. As depicted in Fig. 9, the idea is that the color of the natural pigment is related to the quality of the food because of changes in the concentration of certain gasses (like CO2 and ethylene) in fruits and vegetables or volatile substances (like TVB-N and H2S) in meat products during storage, which can give consumers information about how fresh the food is. This is due to the fact that as food deteriorates, the accumulation of these gasses or volatile substances causes the packaging environment's pH to change, affecting the color of pH-responsive pigments and indicating food quality [116, 118, 119].

Fig. 9.

The illustration of the natural pH-responsive colorimetric indicator film as a schematic [116]

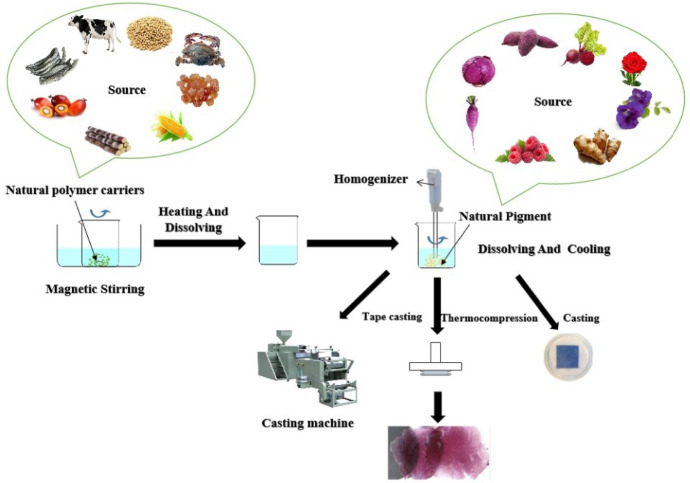

Natural pigments' characteristics, storage conditions (light and heat), and appearance of indicator films are just a few of the other considerations that must be made before using them effectively. Due to their unique pH sensitivity, low stability, and varying solubility, natural pigments' characteristics are generally regarded as limited. The most common categories for natural pigments are anthocyanins, carotenoids, betalains, chlorophyll, and curcumin [120]. In smart packaging, the pH-responsive colorimetric indicator film plays a crucial role in displaying color changes that are irreversible and easy to see and indicate changes in the storage environment or food quality. As depicted in Fig. 10, tape casting, thermocompression, or casting are the most common methods for preparing pH-responsive films. The pigment is combined with the polymer carrier to form a film-forming solution after it is dissolved in a suitable solvent. The film-forming solution is directly poured onto a flat plate during the casting process to ensure uniform solvent evaporation. Film-forming solution is heated and extruded into a shape for thermocompression. In terms of tape casting, the process involves directing the film-forming solution through a casting machine. The thermocompression method and tape casting are both suitable for industrial production, but both are limited by the negative impact of heat treatment on pigment activity [35, 121, 122].

Fig. 10.

Natural pH-responsive colorimetric indicator film preparation process [116]

Initially, paper materials or plastic films were used as indicators to measure the freshness of food because they contain natural pigments. Natural pigments are getting more attention because they have advantages, namely in terms of safety and their effects on the environment [61]. However, this material still has drawbacks; namely, sometimes harmful substances are still found in it. To overcome this problem, several materials that have met the qualifications of a good freshness indicator are able to overcome this problem, namely materials that have been prepared with natural polymer as a carrier.

All materials that have met the qualifications of a good freshness indicator are biodegradable and also safe when in direct contact with food. Natural polymer carriers such as these usually contain protein carriers, polysaccharide carriers, and composite membrane carriers [62, 63]. Natural polymer materials containing polysaccharide carriers are commonly used because of their relatively low-cost, long storage time, chemical stability, and also the availability of abundant sources. Due to their strong gel action, polysaccharide carriers can also form films with loose network structures through their hydrogen intermolecular bonds [64].

The films were characterized for purposes of physicochemical analysis, morphological structure, thermal and barrier properties, antioxidant activity, and color change at different pHs. With that in mind, the color variation of smart films is completely pH dependent [76]. For example, anthocyanin extract was used to prepare intelligent gelatin films, which were prepared using the casting method from gelatin extract, glycerol, butterfly pea anthocyanin (BPA), or resazurin, at pH 6. The results showed that the gelatin film prepared with BPA extract had a dark blue color, while the film with resazurin is violet/purple in color [75].

The use of polymer in smart packaging

Biocompatible and biodegradable polymers, including natural and synthetic polymers, are thought to be viable options aimed for food packaging materials given the growing concern about food security and food quality [91, 92]. The development of active food packaging materials attracted significant interest in a number of natural biopolymers and synthetic polymers. In conclusion, polysaccharides including starch, pullulan, alginate, chitosan, cellulose, and cyclodextrin as well as protein-based polymers like gelatin, zein, silk fibroin, wheat, whey, and marine sources proteins are frequently used in food packaging (Table 4). Additionally, the bacterial biopolymer (3-hydroxybutyrate-co-3-hydroxyvalerate, or PHBV) is a common material used to create packaging nanofibers [93]. However, the poor mechanical qualities and unstable physiological circumstances of natural polymers limited their use. Contrarily, synthetic polymers such as poly (vinyl alcohol) (PVA), poly (ethylene oxide) (PEO), poly (vinyl pyrrolidone) (PVP), poly (ε-caprolactone) (PCL), poly L-lactic acid (PLLA), and poly (lactic acid)-(glycolic acid) (PLGA) are the most widely used polymers for electrospinning due to their feasible tunability, good spinnability, and mechanical properties. As a result, the synthetic polymers can compensate for the shortcomings of natural polymers applied for electrospinning. A simple way to modify the physicochemical characteristics of nanofibers and give them multipurpose capabilities is to blend polymers. For example, the blending of chitosan with synthetic PVA polymers improved the spinnability of chitosan, mechanical, and thermal properties [94]; the blending of protein and carbohydrates can overcome the limitations of poor mechanical properties and permeability, as well as avoid the usage of cross-linkers [95].

Table 4.

Electrospinning nanofibers from natural biopolymers and their applications in food packaging [96]

| Polymer matrix | Active agents | Food packaging applications | References |

|---|---|---|---|

| Zein | GA | The heat-cured zein nanofibers reduced the release of gallic acid and offered potential application of protein-based nanofibers for food packaging | [97] |

| Zein/γ-CD | Thymol | The γ-CD/thymol inclusion complex was electrospun into zein nanofibers and obviously improved the stability of thymol for antibacterial food packaging | [98] |

| Gelatin | PO or CO | Two kinds of essential oils were encapsulated into gelatin nanofibers with improved antioxidant and antibacterial properties and provided potential application for edible packaging | [99] |

| Silk fibroin | TO | The TO/SF nanofibers fabricated by electrospinning process and cold-plasma treatment to improve the release of TO, which was applied for the preservation of poultry meat | [100] |

| KGM/zein | Cur | The KGM/zein/Cur composite biopolymer nanofibril film with antioxidant and antibacterial properties, which has a potential application in food packaging | [101] |

| Gelatin, β-CD | TEO, ε-polylysine | The TEO/β-CD/ε-polylysine nanoparticles (TCNPs) were embedded into gelatin nanofibers via electrospinning for meat preservation | [102] |

| Zein/ethyl cellulose | CEO | This hybrid nanofibers encapsulated with CEO to improve the water resistance and maintained the firmness of Agaricus bisporus | [103] |

| Zein/KC | ZnONPs/RE | This biocompatible nanofiber incorporated with ZnONPs as nanofillers to improve the mechanical property and loaded with RE to improve antibacterial and antioxidant activities in active food packaging | [104] |

| Zein | Ag NPs/TA | The TA/zein nanofibers were immersed in silver nitrate solution to form AgNPs in situ, which possess synergistic antibacterial, antioxidant and catalytic properties and can be applied as a candidate for active food packaging | [105] |

| HPβCD, MβCD, HPγCD | Thymol | Thymol was electrospun into cyclodextrin nanofibers for food, pharmaceutics and oral- care applications with improved antioxidant property, water solubility and thermal stability | [106] |

| Potato starch | Carvacrol | The soluble potato starch was applied to encapsulate carvacrol by electrospinning and this nontoxic starch nanofibers are promising edible materials for active food packaging | [107] |

| Chitosan/gelatin | – | This composite edible nanofiber film was fabricated for edible packaging films | [108] |

| PULL | MMT | The montmorillonite was incorporated into pullulan nanofibers as a nanofiller to improve the mechanical property | [109] |

| Pullulan/β-cyclodextrin | Perillaldehyde | This edible nanofibrous film was used for humidity-controlled release of aroma compounds and have a potential application for enhancing the safety of foods | [110] |

| PUL/CMC | TP | This nanofibrous film was used for preservation of strawberries and significantly improved the quality of strawberries | [111] |

| WPI/pullulan | – | This composite nanofibrous film has potential application in encapsulation of bioactives, development of coating formulations with specific functions and production of biopolymer materials | [112] |

| Pullulan/alginate | CaCl2 | The water-based edible nanofibers can be used as active food packaging components and food-grade bioactive delivery systems | [113] |

| API/PUL | Nisin | This nanofiber was applied to encapsulate nisin for inhibit microorganism of apple juice and fresh cheese | [114] |

| Chitosan/pullulan | – | This composite nanofiber with improved mechanical and thermal properties fabricated by two green crosslinking methods can be used for active food packaging | [115] |

Conclusions and future prospects

Customers' choices are significantly influenced by both product quality and packaging, according to a number of studies. The market is presented with new opportunities by innovative packaging technologies that offer numerous advantages to both the industry and consumers. Customers have been interested in active and smart packaging, such as bio-nanocomposites and biosensors. Due to its potential to extend a product's shelf-life and improve food safety, active packaging, such as antimicrobial packaging and MAP, has received a lot of attention. From a business standpoint, active packaging technology is utilized extensively in the home meal industry, whereas intelligent packaging technology is gradually expanding in cold chains that handle chilled and deep-frozen food. In order to create a packaging technology of the next generation, other related trends must be taken into account and incorporated. As modern consumers seek to lessen their overall impact on the environment, recent global environmental issues like marine pollution and climate change have pushed the packaging industry toward the use of eco-friendly, recyclable, and biodegradable materials. The recent market has been energized by the emergence of printed electronics and applications for smartphones. A smart tag on the packaging allows customers to obtain useful digital data, such as the nutritional value, shelf-life, and real-time quality of the product. A touchless environment and emerging technologies like QR codes, drone delivery, and robotic systems, for example, have the potential to boost consumer confidence in purchasing. The food manufacturers can use these technologies as marketing tools and differentiate their brands in addition to the benefits they provide to customers. Continuous research and development can contribute to a wider adoption of these technologies in the near future, despite the main constraints of cost and technology integration.

Declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Firouz MS, Mohi-Alden K, Omid M. A critical review on intelligent and active packaging in the food industry: research and development. Food Res Int. 2021;141:110113. doi: 10.1016/j.foodres.2021.110113. [DOI] [PubMed] [Google Scholar]

- 2.Shao P, Liu L, Yu J, Lin Y, Gao H, Chen H, Sun P. An overview of intelligent freshness indicator packaging for food quality and safety monitoring. Trends Food Sci Technol. 2021;118:285–296. doi: 10.1016/j.tifs.2021.10.012. [DOI] [Google Scholar]

- 3.Kiryukhina MV, Laua HH, Goha SH, Teh C, Korzhb V, Sadovoya A. A membrane film sensor with encapsulated fluorescent dyes towards express freshness monitoring of packaged food. Talanta. 2018;182:187–192. doi: 10.1016/j.talanta.2018.01.085. [DOI] [PubMed] [Google Scholar]

- 4.World Health Organization (2017) World health statistics 2017: Monitoring health for the SDGs, Sustainable Development Goals

- 5.Walls H, Baker P, Chirwa E, Hawkins B. Food security, food safety & healthy nutrition: Are they compatible? Global Food Secur. 2019;21:69–71. doi: 10.1016/j.gfs.2019.05.005. [DOI] [Google Scholar]

- 6.Guiné RDPF, Pato MLDJ, Costa CAD, Costa DDVTAD, Silva PBCD, Martinho VJPD. Food security and sustainability: discussing the four pillars to encompass other dimensions. Foods. 2021;10:27–33. doi: 10.3390/foods10112732. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Clapp J, Moseley WG, Burlingame B, Termine P. Viewpoint: the case for a six-dimensional food security framework. Food Policy. 2022;106:102164. doi: 10.1016/j.foodpol.2021.102164. [DOI] [Google Scholar]

- 8.Fan S, Brzeska J. Sustainable food security and nutrition: Demystifying conventional beliefs. Global Food Secur. 2016;11:11–16. doi: 10.1016/j.gfs.2016.03.005. [DOI] [Google Scholar]

- 9.Wang Y, Yuan Z, Tang Y. Enhancing food security and environmental sustainability: a critical review of food loss and waste management. Res Environ Sustain. 2021;4:100023. [Google Scholar]

- 10.Janjarasskul T, Suppakul P. Active and intelligent packaging: The indication of quality and safety. Crit Rev Food Sci Nutr. 2018;58:808–831. doi: 10.1080/10408398.2016.1225278. [DOI] [PubMed] [Google Scholar]

- 11.Monção ÉDC, Grisi CVB, Fernandes JDM, Souza PS, Souza ALD. Active packaging for lipid foods and development challenges for marketing. Food Biosci. 2022;45:101370. doi: 10.1016/j.fbio.2021.101370. [DOI] [Google Scholar]

- 12.Vilela C, Kurek M, Hayouka Z, Röcker B, Yildirim S, Antunes MDC, Nilsen Nygaard J, Pettersen MK, Freire CSR. A concise guide to active agents for active food packaging. Trends Food Sci Technol. 2018;80:212–222. doi: 10.1016/j.tifs.2018.08.006. [DOI] [Google Scholar]

- 13.Dey A, Neogi S. Oxygen scavengers for food packaging applications: a review. Trends Food Sci Technol. 2019;90:26–34. doi: 10.1016/j.tifs.2019.05.013. [DOI] [Google Scholar]

- 14.Dan M, Huang M, Liao F, Qin R, Liang X, Zhang E, Huang M, Huang ZG, He Q. Identification of ethylene responsive miRNAs and their targets from newly harvested banana fruits using high-throughput sequencing. Agric Food Chem. 2018;66:10628–10639. doi: 10.1021/acs.jafc.8b01844. [DOI] [PubMed] [Google Scholar]

- 15.Sun M, Yang X, Zhang Y, Wang S, Wong MW, Ni R, Huang D. Rapid and visual detection and quantitation of ethylene released from ripening fruits: the new use of grubbs catalyst. Agric Food Chem. 2019;67:507–513. doi: 10.1021/acs.jafc.8b05874. [DOI] [PubMed] [Google Scholar]

- 16.Wei H, Seidia F, Zhang T, Jin Y, Xiao H. Ethylene scavengers for the preservation of fruits and vegetables: a review. Food Chem. 2021;337:127750. doi: 10.1016/j.foodchem.2020.127750. [DOI] [PubMed] [Google Scholar]

- 17.Álvarez-Hernández MH, Artés-Hernández F, Ávalos-Belmontes F, Castillo- Campohermoso MA, Contreras-Esquivel JC, Ventura-Sobrevilla JM, Martínez-Hernández GB. Current scenario of adsorbent materials used in ethylene scavenging systems to extend fruit and vegetable postharvest life. Food Bioproc Technol. 2018;11:511–525. doi: 10.1007/s11947-018-2076-7. [DOI] [Google Scholar]

- 18.Yao M, Zhou X, Zhou Q, Shi F, Wei B, Cheng S. Low temperature conditioning alleviates loss of aroma-related esters of 'Nanguo' pears by regulation of ethylene signal transduction. Food Chem. 2018;264:263–269. doi: 10.1016/j.foodchem.2018.05.024. [DOI] [PubMed] [Google Scholar]

- 19.Thewes FR, Brackmann A, Anese RO, Ludwig V, Schultz EE, Dos Santos LF. Effect of dynamic controlled atmosphere monitored by respiratory quotient and 1- methylcyclopropene on the metabolism and quality of 'Galaxy' apple harvested at three maturity stages. Food Chem. 2017;222:84–93. doi: 10.1016/j.foodchem.2016.12.009. [DOI] [PubMed] [Google Scholar]

- 20.Weber A, Neuwald DA, Kittemann D, Thewes FR, Both V, Brackmann A. Influence of respiratory quotient dynamic controlled atmosphere (DCA - RQ) and ethanol application on softening of Braeburn apples. Food Chem. 2020;303:125346. doi: 10.1016/j.foodchem.2019.125346. [DOI] [PubMed] [Google Scholar]

- 21.Li D, Limwachiranon J, Li L, Du R, Luo Z. Involvement of energy metabolism to chilling tolerance induced by hydrogen sulfide in cold-stored banana fruit. Food Chem. 2016;208:272–278. doi: 10.1016/j.foodchem.2016.03.113. [DOI] [PubMed] [Google Scholar]

- 22.Jung J, Deng Z, Zha Y. Mechanisms and performance of cellulose nanocrystals Pickering emulsion chitosan coatings for reducing ethylene production and physiological disorders in postharvest 'Bartlett' pears (Pyrus communis L.) during cold storage. Food Chem. 2020;309:125693. doi: 10.1016/j.foodchem.2019.125693. [DOI] [PubMed] [Google Scholar]

- 23.Ballester AR, Lafuente MT. LED blue light-induced changes in phenolics and ethylene in citrus fruit: implication in elicited resistance against Penicillium digitatum infection. Food Chem. 2017;218:575–583. doi: 10.1016/j.foodchem.2016.09.089. [DOI] [PubMed] [Google Scholar]

- 24.Gaikwad KK, Singh S, Lee YS. High adsorption of ethylene by alkali treated halloysite nanotubes for food-packaging applications. Environ Chem Lett. 2018;16:1055–1062. doi: 10.1007/s10311-018-0718-7. [DOI] [Google Scholar]

- 25.Ščetar M. Trends in fruit and vegetable packaging – a review. Hrvatski časopis za prehrambenu tehnologiju, biotehnologiju i nutricionizam. 2010;5:69–86. [Google Scholar]

- 26.Pilli TD. Development of a vegetable oil and egg proteins edible film to replace preservatives and primary packaging of sweet baked goods. Food Control. 2020;114:107273. doi: 10.1016/j.foodcont.2020.107273. [DOI] [Google Scholar]

- 27.Bambang Kuswandi J (2020) Mohammed Wasim Siddiqui (Eds), Fresh-Cut Fruits 726 and Vegetables, Academic Press, pp 243–294

- 28.Melini V, Melini F. Strategies to extend bread and GF bread shelf-life: From sourdough to antimicrobial active packaging and nanotechnology. Fermentation. 2018;4:1–18. doi: 10.3390/fermentation4010009. [DOI] [Google Scholar]

- 29.Mu H, Gao H, Chen H, Fang X, Han Q. A novel controlled release ethanol emitter: preparation and effect on some postharvest quality parameters of Chinese bayberry during storage: preparation and application of a novel ethanol emitter. Sci Food Agric. 2017;97:4929–4936. doi: 10.1002/jsfa.8369. [DOI] [PubMed] [Google Scholar]

- 30.Yildirim S, Röcker B, Pettersen MK, Nilsen-Nygaard J, Ayhan Z, Rutkaite R, Radusin T, Suminska P, Marcos B, Coma V. Active packaging applications for food: active packaging applications for food. Compr Rev Food Sci Food Saf. 2018;17(1):165–199. doi: 10.1111/1541-4337.12322. [DOI] [PubMed] [Google Scholar]

- 31.Haghighi-Manesh S, Azizi MH, Haghighi-Manesh S, Azizi MH. Active packaging systems with emphasis on its applications in dairy products. Food Process Eng. 2017;40:e12542. doi: 10.1111/jfpe.12542. [DOI] [Google Scholar]

- 32.Yam K, Takhistov P, Miltz J. Intelligent packaging: concepts and applications. Food Sci. 2005;70:1–10. doi: 10.1111/j.1365-2621.2005.tb09052.x. [DOI] [Google Scholar]

- 33.Pirsa S, Sani IK, Mirtalebi SS. Nano-biocomposite based color sensors: Investigation of structure, function, and applications in intelligent food packaging. Food Packag Shelf Life. 2022;31:100789. doi: 10.1016/j.fpsl.2021.100789. [DOI] [Google Scholar]

- 34.Wyrwa J, Barska A. Packaging as a source of information about food products. Procedia Eng. 2017;82:770–779. doi: 10.1016/j.proeng.2017.03.199. [DOI] [Google Scholar]

- 35.Kalpana S, Priyadarshini SR, Maria Leena M, Moses JA, Anandharamakrishnan C. Intelligent packaging: trends and applications in food systems. Trends Food Sci Technol. 2019;93:145–157. doi: 10.1016/j.tifs.2019.09.008. [DOI] [Google Scholar]

- 36.Chowdhury EU, Morey A. Intelligent packaging for poultry industry. Appl Poultry Res. 2019;28:791–800. doi: 10.3382/japr/pfz098. [DOI] [Google Scholar]

- 37.Korhonen I, Ahola J. Estimating the specific heat capacity and heating of electronic sensors and devices. IEEE Instrum Meas Mag. 2018;21:54–62. doi: 10.1109/MIM.2018.8278813. [DOI] [Google Scholar]

- 38.Ghaani M, Cozzolino CA, Castelli G, Farris S. An overview of the intelligent packaging technologies in the food sector. Trends Food Technol. 2016;51:1–11. doi: 10.1016/j.tifs.2016.02.008. [DOI] [Google Scholar]

- 39.Deng Y, Liu K, Liu Y, Dong H, Li S. An novel acetylcholinesterase biosensor based on nano-porous pseudo carbon paste electrode modified with gold nanoparticles for detection of methyl parathion. Nanosci Nanotechnol. 2016;16:9460–9467. [Google Scholar]

- 40.Fang Z, Zhao Y, Warner RD, Johnson SK. Active and intelligent packaging in meat industry. Trends Food Sci Technol. 2017;61:60–71. doi: 10.1016/j.tifs.2017.01.002. [DOI] [Google Scholar]

- 41.Hsu C-P, Chen P, Wang Y-L (2017) A novel packaging technology for disposable FET-based biosensors with microfluidic channels. In: Proceedings of the 2017 IEEE 12th international conference on nano/micro engineered and molecular systems (NEMS), IEEE, pp 375–378

- 42.Ramon-Marquez T, Medina-Castillo AL, Fernandez-Gutierrez JF. Fernandez Sanchez, Novel optical sensing film based on a functional nonwoven nanofiber mat for an easy, fast and highly selective and sensitive detection of tryptamine in beer. Biosens Bioelectron. 2016;79:600–607. doi: 10.1016/j.bios.2015.12.091. [DOI] [PubMed] [Google Scholar]

- 43.Baek S, Maruthupandy M, Lee K, Kim D, Seo J. Preparation and characterization of a poly (ether-block-amide) film-based CO2 indicator for monitoring kimchi quality. React Funct Polym. 2018;131:75–83. doi: 10.1016/j.reactfunctpolym.2018.07.007. [DOI] [Google Scholar]

- 44.Lee K, Baek S, Kim D, Seo J. A freshness indicator for monitoring chicken breast spoilage using a Tyvek® sheet and RGB color analysis. Food Packag Shelf Life. 2019;19:40–46. doi: 10.1016/j.fpsl.2018.11.016. [DOI] [Google Scholar]

- 45.Lyu JS, Choi I, Hwang KS, Lee JY, Seo J, Kim SY, Han J. Development of a BTB-/TBA+ ion-paired dye-based CO2 indicator and its application in a multilayered intelligent packaging system. Sens Actuators, B Chem. 2019;282:359–365. doi: 10.1016/j.snb.2018.11.073. [DOI] [Google Scholar]

- 46.Puligundla P, Jung J, Ko S. Carbon dioxide sensors for intelligent food packaging applications. Food Control. 2012;25:328–333. doi: 10.1016/j.foodcont.2011.10.043. [DOI] [Google Scholar]

- 47.Egan AF, Shaq BJ, Rogers PJ. Factors affecting the production of hydrogen sulfide byLactobacillus sake L13 growing on vacuum-packaged beef. Appl Bacteriol. 1989;67:255–262. doi: 10.1111/j.1365-2672.1989.tb02493.x. [DOI] [Google Scholar]