Abstract

This research aimed to examine the need of adding hot water blanching pre-treatment on the drying of ginger rhizomes using a hybrid solar-dryer with paraffin liquid as thermal storage infused into a copper tube to form a compact heat exchanger. Blanching duration quickened the drying rate of the ginger rhizomes and the average drying rate for blanching at 90 s, 60 s, 30 s and un-blanched ginger varied between 0.0147 kg/h to 0.0245 kg/h at a sensible heat ratio of 4.12 × 10−5 to 2.53 × 10−3. The optimal drying rate varied from 0.01161 kg/h to 0.0263 kg/h for all treatment at a collector temperature range of 39.5 °C–40.5 °C and collector efficiency range of 14.3%–30%. The logarithmic model better predicted the drying kinetics of un-blanched and blanching for 30 s with an R2 value of 0.9875 and 0.97247 respectively while the modified Henderson and Pabis model better predicted drying of blanched ginger rhizomes at 60 s and 90 s with R2 values of 0.96252 and 0.98188 respectively. Using the hybrid solar dryer instead of artificial dryers with fossil energy sources can save about $75.731 to $757.31 of the running cost as the usage increased from 10 to 100%. The payback period decreased from 2.88 years to 0.31 years as the rate of usage increased from 10 to 100%. Using the presented solar dryer instead of coal, diesel or grid base electricity can prevent 15.96 to 186, 7.62 tones of CO2 from entering the atmosphere. The earned carbon credit if the dryer is to be powered by coal, diesel or grid base electricity were $ $6245364, $27080.52, and $231.45 per year respectively which can be used to compensate other non-renewable energy sources deployed within an energy enterprise.

Keywords: Agricultural products, Decarbonisation, Drying kinetics, Hot water blanching, Solar thermal storage

1. Introduction

Ginger (Zingiber officinale) is both a medicinal and spice cash crop used by many in different countries of the world [[1], [2], [3], [4]]. Markam and Bajpai [5] confirmed the effectiveness of ginger nanoparticles with chitosan in the treatment and handling of inflammatory bowel disease. In addition, the polysaccharide-derived particles of which ginger nano-particles is a sub particle has served as carriers and provided the required healing power with a robust boost in the system's immunity against inflammation [5]. Furthermore, ginger can be used as a flavour additive for some drinks [6].

According to the Nigeria Ministry of Agriculture, Nigeria produces about 31 million metric tons of ginger annually with a local demand of 65 million metric tonnes [[7], [8], [9]]. This puts Nigeria as the third largest producer of ginger after China and India. However, due to their aroma, oleoresins content, pungency and high oil content Nigerian ginger rhizomes are highly regarded and sort after at both the local and international markets [8,10]. Farmers, therefore, sell ginger rhizomes products in different forms which include ginger powder, juice, and dried ginger roots [4]. Thus drying the ginger rhizomes is among the first unit operation in the primary processing of ginger rhizomes. This is because, in fresh form, the initial moisture content of freshly harvested ginger rhizome can reach 82.6–95.12% wb [4,11,12]. Therefore, it must be dried to extend its shelf life by limiting bacterial growth and preparing it for further uses [13]. Apart from preparing the ginger for further processing, drying reduces the cost of packaging the product, storage, and even transportation [14]. Before drying, most of the biomaterials undergo pre-treatment to activate some enzymes which hasten the drying process and modify the product quality. These include blanching, saline immersion, laser treatment etc. This pre-treatment modifies the properties of the product which affects the drying mechanism.

Traditionally in Africa, open sun drying is mostly used by farmers due to availability and cost [15]. However, this requires the farmer to be around the product to avoid product re-wetting in the case of rainfall or to prevent birds and rodents from attacking the product [15]. Therefore the farmer must always be available which will affect his time to accomplish other tasks. Thus there is a need for an alternative and secured drying system which is cheap, energy efficient and also clean because of global concern about greenhouse gas emissions by artificial dryers powered by fossil energy sources. Solar drying system, therefore, addresses these challenges of open sun drying using a solar collector covered with transparent glass and a drying cabinet. This provides a clean and healthy environment for the product being dried and perfectly harnesses the solar radiant energy for improved quality of dried products [16]. Research has also shown that solar drying can improve some aspects of a product in terms of quality, flavour, colour, and appearance which projects the product's marketability and allows for improved financial opportunities for the farmers [17]. A review of the literature has shown that solar dryer is preferred over the traditional method of open-air sun drying by crop processors [18,19]. In terms of environmental protection, Ricci et al. [20] have shown that using solar energy for food production has provided substantial non-polluting tendencies in the subtropical and tropical regions of the world.

The operation of solar dryers depends entirely on solar energy and ambient air affecting pressure gradients that naturally promote vertical airflow within a drying chamber. Based on their unique mode of operation, solar dryers are typically classified into three groups: direct solar dryers, indirect solar dryers, and hybrid solar dryers (or hybrid operations) [21]. For the direct solar dryers, the collector and the drying chamber form a single unit. While, for the indirect solar dryers, the sun irradiation is trapped by a fluid (air) reservoir that provides hot moving fluid into the drying chamber. Mixed-mode solar dryers combine the drying mechanism of both the direct and indirect drying system, where drying is done concurrently by both direct exposures of the food produce to solar irradiation and passing heated air from the solar collector to the produce in the drying chamber [22]. However, due to the challenges posed by weather, solar irradiation is intermittent. In the absence of solar irradiation, there is the possibility of re-wetting the product; which will prolong the drying time and leads to product decay [[23], [24], [25]]. Therefore hybrid dryers are developed to assist the drying during the off-sunshine period. This hybrid dryer design is found to produce a faster drying rate in comparison with other solar dryer types due to combined heat sources [26,27]. The design includes the use of an electric heater, biomass gasifier, or thermal storage material as supplementary heat [25,28]. Thermal storage material captures the heat from solar radiation and stores them. This stored energy is released as the product cools during the off-sunshine period. Most of the common thermal storage materials used in literature include stones, gravel and phase change materials like paraffin wax or liquid, glycerine, desiccants etc. with very high latent heat which it gives out as it changes from one phase to another. Liquid thermal storage material like paraffin poses a challenge as it is capable of splashing and coming in contact with the dried product when placed in a bowl inside the dryer. This is because in some cases the bowl containing the liquid thermal storage material is kept in the collector box to absorb heat and moved into the drying chamber during the off-sunshine periods to continue the drying process as they release the stored heat [23]. Therefore integrating them in a tubular heat exchanger as a compact composite from the collector to the drying chamber will be a novel solar dryer design and the drying mechanism based on this design need to be evaluated with agricultural products.

Knowledge of the drying parameters for agricultural products aids engineers to design and improve on the existing drying equipment by determining the energy requirements for the process, study the properties of water adsorbed, evaluate the microstructure of the food and study the physical phenomena that take place at the material surface [29]. Therefore, the study of drying kinetics of agricultural products provides adequate information on the heat and mass transfer that occur between the biological material and that of the drying element (mostly heated or non-heated atmospheric air), which is important for the design, operation and simulation of drying systems [29]. Optimal drying rates at different temperatures and collector efficiency will also provide information for the simulation of the drying process [29]. This aspect of the study is lacking on hybrid solar-dried ginger rhizome slices especially in the West African sub-region since solar drying data is environmentally specific. Therefore this research seeks to close this knowledge gap.

Furthermore, to elevate renewable energy systems in the energy mix, it is advisable to show the cost-benefit and greenhouse mitigation potential in the energy mix. These will assist in convincing the end users and policymakers to adopt the system. Hence, the present research will determine the economic potential of the hybrid dryer and assess the CO2 mitigation potential using different energy sources scenario. Thus the objective of the Study is to (1) present a novel solar dryer design with a liquid thermal storage material infused in a copper tube to form a composite heat exchanger (2) determine the drying kinetics (drying rates, moisture ratio, diffusivity etc.) of pre-treated ginger dried with the solar dryer (3) presents the decarbonisation potential of the dryer in terms of earned carbon credit and economic potential and payback periods of using the solar dryer.

2. Methodology

2.1. Dryer description

The solar dryer used for the drying of the pre-treated ginger rhizomes is presented in Fig. 1. The solar dryer is a natural convection batch dryer made up of the solar collector (1), the drying chamber (2), the collector transparent glass cover (3), the chimney (4), the drying trays (5), the tubular copper heat exchanger (6) and the stand (7). The design specifications and materials used for each component are presented in Table 1. The solar collector is made up of a black-painted aluminium absorber force-fitted into a 0.14 m2 cuboid-shaped wooden cabinet box and covered with transparent glass. The transparent glass cover allows for easy solar radiation heat absorption by the solar collector absorber. The solar collector opens into the drying chamber at an angle of 15.47o. The ambient air flows into the collector by natural convection through a 0.0015 m2 square-shaped opening provided at the southern end. The air absorbs heat from the collector before flowing into the drying chamber. The drying chamber is fitted with two drying trays separated at a distance of 0.22 m for the placement of ginger rhizomes.

Fig. 1.

Schematics of the solar dryer showing the layout of the copper tubes from the collector to the drying chamber and the instrumentations used for data collections.

Table 1.

Design specifications of the natural convection solar dryer.

| Units | Specifications |

|---|---|

| Solar collector | Plywood, tilted 15.47°N, dimension: 0.79 m × 0.18 m x 0.16 m |

| Absorber | Black painted aluminium sheet, 0.79 m × 0.18 m x 0.002 m |

| Glazing | Transparent glass, dimension: 0.78 m × 0.18 m x 0.004 m |

| Drying Chamber | Plywood. Dimension: 0.66 m × 0.43 m x 0.43 m |

| Drying trays | Hardwood skeleton, plastic wire mesh, dimension: 0.30 m × 0.35 m, |

| Chimney | Plywood, 0.15 m high |

| Copper tubing | φ 15.8 mm |

During drying the product absorbs heat, leading to moisture evaporation. The surrounding air absorbs this evaporated moisture and exits through the 0.15 m high chimney. A copper tube coil was laid directly on the base of the absorber plate in two cycles before passing it to the side walls of the drying chamber. The tube served as a heat exchanger as well as the thermal storage carrier. The copper tube was filled manually with paraffin liquid (2.18 L) which served as the thermal storage before sealing at both ends to prevent the paraffin from splashing out or getting in contact with the dried product. The copper tube and paraffin liquid (thermal conductivity 213–244 W/m K) were used due to their relatively high heat conductivity.

2.2. Experimental procedure

2.2.1. Ginger preparation and pre-treatment

Fresh yellow ginger rhizomes (UG1) were purchased from the National Root Crop Research Institute Umudike, South Eastern Nigeria. The ginger rhizomes were sorted and cleaned of sand and other debris. The rhizomes were peeled and cut manually, after which it was further diced into cuboids of dimensions 12 mm × 10 mm x 5 mm using a cuboid-shaped metal pipe for uniform sizes. The ginger cuboids were grouped into four. The first group were un-blanched which served as the control while the second group were blanched for 30 s. The remaining two groups were blanched for 60 s and 90 s respectively. The method presented by Hoque et al. [30], was used for the blanching of the ginger. Blanching was done by dipping ginger rhizomes in water at 100 °C with a 1 mm sieve inside a water bath for the required durations after which it was removed and rapidly cooled in cold water at room temperature.

2.2.2 Experimental set-up.

The developed hybrid solar dryer was set up at Umudike on latitude 5.530 N, and longitude 7.490 E. The typical metrological data of Umudike is presented in Table 2. A mass of 0.2 kg of the sliced ginger rhizomes was placed on the drying trays. Drying of the ginger rhizome slices begins at 9. A.M. local time when the sky is clear. However, it has been noted that at this period, the solar intensity is not high to cause moisture loss but it is hot enough to warm up the solar dryer. Drying continues until the sun sets at around 6. P.M. local time. The mass of ginger rhizomes was measured every 1 h interval until the equilibrium moisture content is attained at three consecutive moisture content of 8.7 ± 2.04% d.b.

Table 2.

Typical Meteorological data of Umudike [31].

| Months | Rainfall (mm) | Temperature (°C) | Evaporation (mm) | Relative Humidity (%) | Sunshine (h) | |||

|---|---|---|---|---|---|---|---|---|

| amount | day | max | min | – | – | – | – | |

| Jan | 0.0 | 0 | 32 | 23 | 0.22 | 72 | 45 | 6.4 |

| Feb | 88.2 | 7 | 35 | 22 | 0.46 | 73 | 50 | 6.3 |

| Mar | 57.0 | 3 | 35 | 23 | 0.50 | 77 | 53 | 3.9 |

| April | 142.0 | 17 | 33 | 24 | 0.82 | 76 | 59 | 6.1 |

| May | 233.7 | 16 | 32 | 24 | 4.70 | 84 | 70 | 5.0 |

| Jun | 213.0 | 14 | 31 | 23 | 9.25 | 87 | 77 | 3.2 |

| July | 362.0 | 24 | 30 | 23 | 10.55 | 86 | 75 | 3.4 |

| Aug | 161.8 | 19 | 30 | 24 | 6.10 | 88 | 78 | 2.2 |

| Sept | 349.0 | 25 | 30 | 24 | 8.80 | 59 | 75 | 2.9 |

| Oct | 244.6 | 16 | 31 | 24 | 4.80 | 86 | 78 | 2.9 |

| Nov | 58.5 | 6 | 33 | 25 | 0.31 | 97 | 70 | 4.1 |

| Dec | 0.0 | 0 | 32 | 21 | 0.20 | 75 | 49 | 4.9 |

The temperatures of the air and humidity in the collector were measured with a temperature and humidity clock (DTH-82; TLX, Guandong China). In addition, the temperatures of the drying chamber, product, and thermal storage material were measured using EXTECH Multi-thermometer attached to a digital UEi thermometer probe (PDT650 made in china). The solar irradiation was measured with an APOGEE pyrometer (Model mp.200, serial number hash 1250 with an accuracy of ±1 W/m2/day). The weights of the ginger were recorded using a weight scale (KERRO model, accuracy of ±0.01 g). The wind direction and velocity were recorded using a dual wind vane (AM-4826; Landesk, Guangzhou, China, an accuracy of ±2% of velocity). The instrumentation layout is presented in Fig. 1.

2.3. Experimental uncertainties

The uncertainties for the experiment were calculated with equation (1) as follows [28].

| 1 |

y1, y2 and yn are the uncertainty in the independent variables x1, x2 and xn. For the evaluated moisture contents, moisture ratios, collector efficiency and sensible heat transfer ratio, the obtained uncertainties were ±0.021, ±0.031, ±0.015 and ±0.00018.

2.4. Drying kinetics of the pre-treated ginger

The moisture loss of the ginger rhizomes cubes was calculated with equation (2) as follows

| 2 |

where Mt is the moisture content (%w.b) at time t (h), wi is the initial weight of ginger, it is the weight (kg) at time t.

The drying rate is determined with equation (3) as follows

| 3 |

The optimum drying rate at different collector temperatures and collector efficiency was also obtained using the response surface optimization method for each blanching period. Design expert 13 software using factorial design and desirability factor to obtain the optimum drying rate.

The effective moisture diffusivity (De) of the pre-treated ginger rhizomes was determined with the method of slopes by plotting the graph of the negative natural logarithm of the moisture ratio (MR) against the drying time t (s). The slope (k) is obtained with equation (4) as follows

| 4 |

where L is the thickness of the ginger rhizome cubes,

Equation (5) was used to determine the moisture ratio as follows

| 5 |

where Me is the equilibrium moisture content of the ginger cubes obtained at three constant weight measurements.

To obtain the best fitting equation for predicting the drying curve, a series of thin layer equations available in the literature was used to test the moisture ratio to choose the best model under the drying scenario for both the solar dryer and sun drying. The selected equations are presented in Table 3. The best-fit equation was chosen by comparing the R2, RMSE and chi-square (χ2) values as presented in equations 6, 7, 8 respectively. The curve with the highest R2, lowest RMSE and chi-square (χ2) was selected as the best-fit equation for predicting the drying curve of ginger at the given pre-treatment using the solar dryer. Fittings were done using the Curve expert software.

Table 3.

| 6 |

| 7 |

| 8 |

2.5. Earned carbon credit

Solar dryers elevate the importance of renewable energy over fossil-based energy sources in the energy mix by cutting down greenhouse gas emissions. However, this advantage can be quantified in direct economic terms by evaluating the carbon credit values. Carbon credits are a unit of measurement which denotes the total emission cap of organizations which must not be exceeded [32]. Therefore an organization that employs both renewable and non-renewable sources of energy in their production mix can use the carbon credit generated by the renewable energy system to purchase or cancel out that aspect of the production process that emission output exceeds the emission cap of the organization. Therefore, the earned carbon credit shows the decarbonisation potential of renewable energy systems. Thus it is used in most cases for an indicative purpose. To calculate the earned carbon credit for the solar dryer we choose coal, diesel and electricity-generated power as a source of a baseline for the carbon credit because research has shown that these energy sources are the most common energy sources for artificial dryers [33,34]. Consequently, the carbon credit rate for the solar dryer is given by Yousef and Hassan [35], as presented in equation (9) as follows

| 9 |

Where ƶCO2 is the price of CO2 globally, given as $ 14.5 per ton [35], is the yearly mass of carbon emission (ton). For electric, diesel and coal-powered dryers, the is calculated with equations 10, 11, 12 respectively as obtained from Alic et al. [32], and Ndukwu et al. [28] as follows

| 10 |

| 11 |

| 12 |

Where k is the CO2 emission rate of electricity given as 0.4392 kg/kWh for Nigeria, n is the total hourly period of sunshine (h) per year sunshine hour. In the southern part of Nigeria, the average daily sunshine hours are 4.5 h per day [24] which will give an average yearly hourly sunshine of 4.5 × 365 (1277.5) h per annum, kf, kd and ηd, , , and are given by Ould-Amrouche et al. [36] as 2.63 kg/l, 10.08 kWh/l, 30%, , , .0 and respectively, Qd is the mass of product dried (kg), The total energy utilized (Qu) by the solar dryer to dry the ginger is determined with equation (13) as follows

| 13 |

where Ac, is the total area of the solar dryer collector (m2), t is the total drying time (h), τ is the transmittance of the glazing cover, Tc is the collector temperature (oC), Ta is the inlet air temperature (oC), I is the solar radiation intensity (W/m2), Uo is the heat loss coefficient (W/m2 oC) deduced from Duffie and Beckman [37], according to equation (14) as follows

| 14 |

where.

FR is the heat removal factor obtained with equation (15) as follows

| 15 |

Where is the absorptivity of the black surface of the collector taken as 0.90, Cp, a is the specific heat capacity of air (kJ/kg/K), ηth is the thermal/collector efficiency of the solar dryer, calculated with equation (16) as follows

| 16 |

To determine the energy input by the paraffin thermal storage (QT), researchers have assumed that paraffin is a phase change material with three temperature transitions (initial, transition and final sensible temperature) when heated. Therefore the energy input of phase change material under solar heating can be calculated with equation (17) as follows [23].

| 17 |

where mp is the mass of paraffin, Cp,p is the specific heat capacity of paraffin, Tm is the transition temperature, Ti is the initial temperature, and To is the final sensible temperature of the paraffin. However, during the experiment it was found that there was no change in phase as the paraffin was liquid throughout the experiment; therefore equation (13) was reduced as presented in equation (18) as follows

| 18 |

The energy input from the copper tubes is calculated as a sensible heat as presented in equation (19) as follows

| 19 |

where Tic is the initial temperature of the copper tubes, Tf is the final temperature.

2.6. Sensible heat ratio

The sensible heat ratio can be used to show the effectiveness of energy utilization during drying. It is the ratio of sensible heat added to the dried product for the evaporation of moisture from the product to occur. The ratio of sensible heat added to dried ginger for moisture loss to occur can be determined with equation (20) as follows

| 20 |

where mp and mw are the mass (kg) of ginger dried (0.2 kg) and water respectively, Cp is the specific heat capacity of ginger (2.026 kJ/kg oC, Olaoye and ogunleye, 2018), ΔT is the temperature change, and L is the latent heat of vaporization of water.

2.7. Cost analysis based on energy utilization

The payback period (PBP), which is the period to recover the capital invested capital [38] is determined based on the rate at which the solar dryer is utilized. It has been agreed that solar dryer is environmentally specific and might not work all through the year. Therefore, the payback period was graduated from 10 to 100% rate of usage. The savings that could be made in that period based on utilization is determined with equation (21) as follows [39].

| 21 |

where β is the degree of utilization which can be expressed from 0.1 to 1.0 (10–100%), the energy cost (Eprice) per kWh is taken as N38.53 (0.087$) per kWh for businesses in Nigeria as of November 2022. Thus the total energy consumed (Ecyr) per kWh per year is given in equation (22) [39].

| 22 |

where d is the likely total number of days the solar dryer can be deployed in a month (in Nigeria, working days exclude Saturdays, Sundays and half a day on Fridays, therefore the total working day per month is taken as 20). Ec is the total energy consumed (Qu) for drying in KWh given in equation (13).

Therefore the payback period is deduced with equation (23), considering the input parameters from equations 21, 22) as follows

| 23 |

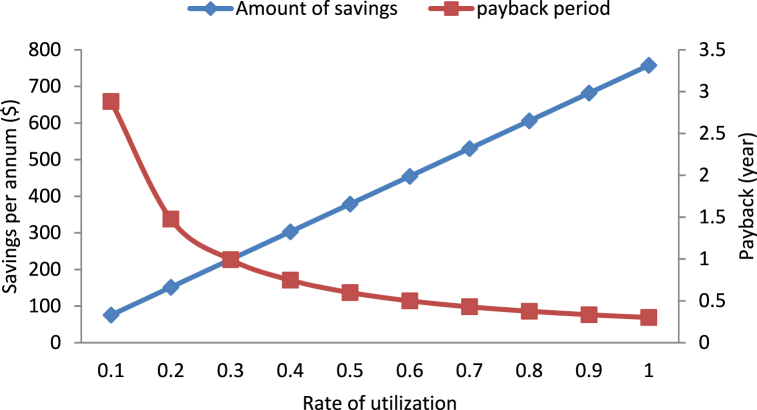

where Cc is the capital cost of the dryer ($220), S1 is savings during the first year of the dryer (equation (21)), d is the rate of interest on long-term investment taken as 11.5% for Nigeria and i is the rate of inflation taken as 15.70% for Nigeria as at May 2022 [40] (see Fig. 3).

Fig. 3.

Ambient condition and paraffin temperature variations during the drying period.

3. Results and discussion

3.1. Eco-thermal effects on drying evolution of the pre-treated ginger

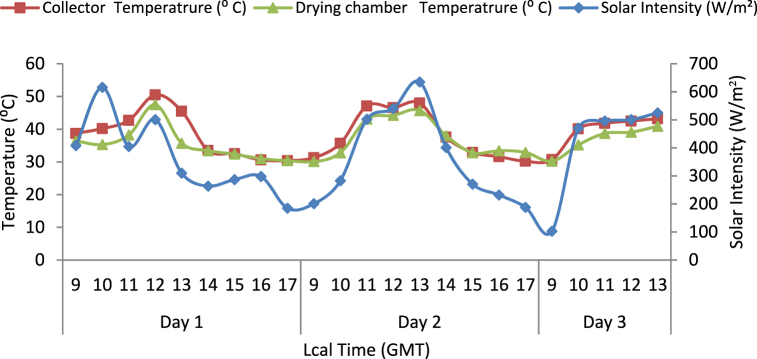

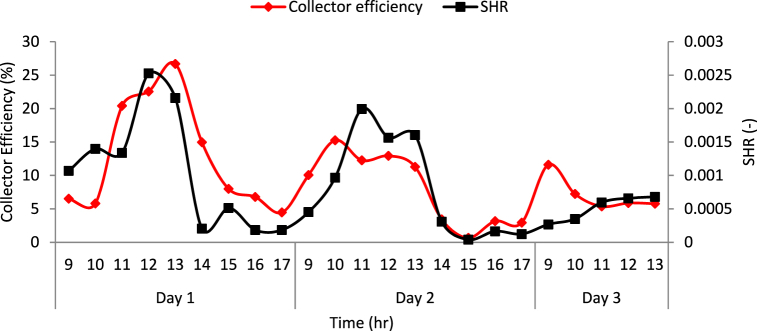

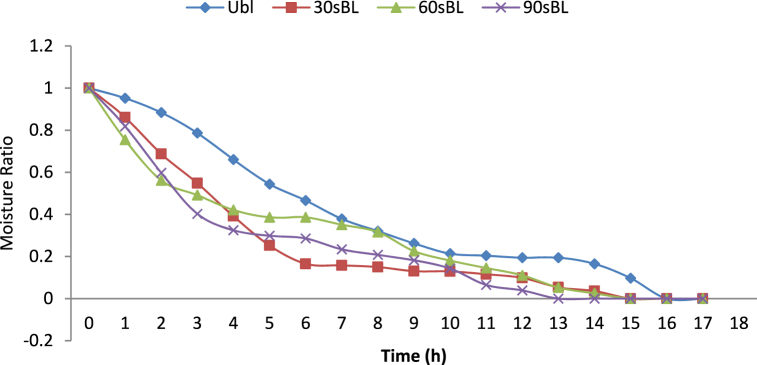

Fig. 2, Fig. 3 show the temperature and relative humidity evolution of both the ambient and the hybrid composite solar dryer as the ginger rhizomes dry. The solar radiation intensity varied from 103 to 616 W/m2 with an average value of 374.87 W/m2. The peak solar radiation value is lower than 1013 W/m2 obtained by Lamrani et al. [41] in Morocco but the average value is higher than 368.38 and 303.6 W/m2 recorded by Ndukwu et al. [31,42] respectively in this area. These showed that the study location is a low solar intensity area which most time results in a longer period of drying using the solar dryer when compared to areas like Morocco. This justifies the use of supplementary thermal energy storage material to boast the thermal process to avoid product rewetting during the low-temperature period. Within this period, the ambient temperature and relative humidity ranged from 21.9 to 40.2 °C and 25–90% respectively with average values of 34.33 °C and 46.3%. This resulted in a temperature difference of 0.5–12.3 °C and 0.3–9.3 °C between the collector and drying chamber temperatures respectively with the ambient temperature. Similarly, the paraffin temperature ranged from 30 to 47 °C. These ranges of temperatures and relative humidity were enough to cause moisture reduction for the ginger rhizomes. However, at a very low-temperature difference range, it has been established that moisture loss might not occur but Bennamoun and Benghari [43] stated that this range of temperature will serve as warm-up periods for the solar dryer. The effectiveness of solar energy conversion and energy utilization is embodied in the collector efficiency and the sensible heat ratio shown in Fig. 4. These values ranged from 0.68 to 26.7% and 4.12 × 10−5 to 2.53 × 10−3 with an average value of 10% and 8.5 × 10−4 respectively. The two parameters increased in the afternoon as the solar radiation intensity increased and decreases in the evening as the sun sets. The average value of collector efficiency is lower than 24.7% obtained by Isaac and Sam [44] but they are within the range of 10–15% for the thermal efficiency of natural convection solar dryers as proposed by Brenndorfer et al. [45]. The rate of moisture extraction depends on the fraction of sensible heat in the drying chamber. This fraction of available heat for moisture extraction is analyzed in terms of the sensible heat transfer ratio (SHR). The higher the SHR, the steeper the drying curve of the product. These values increased or decreased with the moisture loss. Hence it took between 13 and 16 h for the pre-treated ginger to reach the equilibrium moisture content of 8.26 ± 008%w.b for all the pre-treatment, though drying continued until 18 h as shown in Fig. 5.

Fig. 2.

Solar dryer temperature and solar radiation evolution.

Fig. 4.

Evolution of the collector efficiency and sensible heat ratio evolutions for the solar dryer.

Fig. 5.

Moisture Ratio evolution of the product.

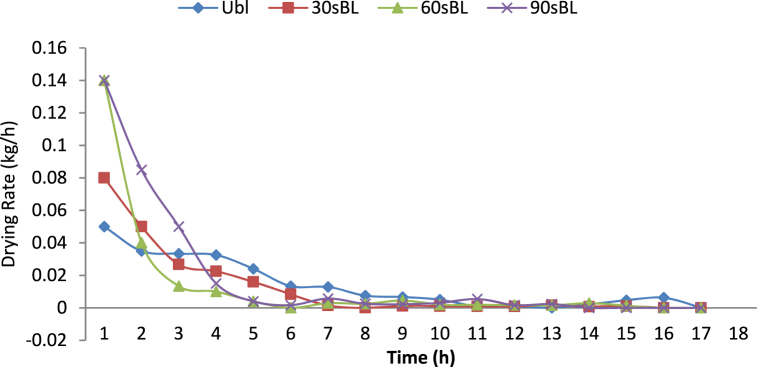

From Fig. 5, it is obvious that blanching time affected the duration of drying. It took 13 h to attain the equilibrium moisture content for blanching for the 90s; while it took 15 h for blanching for 30 and 60s. However, it took 16 h to reach the equilibrium moisture content for the un-blanched sample. This is reflected in the drying rate in Fig. 6. Blanching at 90 s dried faster with an average drying rate of 0.0245 kg/h followed by 60 s with an average drying rate of 0.0162233 kg/h. Similarly, the average drying rate of 30 s blanching and un-blanched ginger rhizomes were 0.016179 kg/h and 0.0147 kg/h respectively. This agrees with the previous work of Hawa et al. [46] and Ndukwu et al. [25], that blanching time affects the drying period of crops. Blanching the product increased the drying rate of the product during the first 2 h compared to the un-blanched sample, producing an initial steeper curve compared to un-blanched ginger. According to Pandey et al. [47], blanched samples always have a speed-up drying rate at the beginning of drying. This is because blanching softens the texture of the product which leads to a reduction in water flux resistance, thus accelerating the moisture transfer to the surface during drying [48]. Furthermore, blanching the product also opens the pore spaces which facilitate faster moisture transfer to the surface for evaporation to occur. Thus increasing the blanching time increased the drying rate and shortens the drying duration. This is similar to the results obtained in drying blanched potatoes [25] and Cabaya fruits [46].

Fig. 6.

Drying rate of the product.

A factorial response surface optimization at a 95% confidence limit was carried out to determine the various responses of drying rate to varying collector temperature and collector (thermal) efficiency of the hybrid composite solar dryer. The constraints were based on maximizing the drying rate and collector efficiency (decimal) while minimizing the drying temperature and choosing the highest desirability factor using the Design Expert 13 software. This method has been used by Ihediwa et al. [49] in the optimization of drying parameters for agricultural products. The results of the surface plot for the four treatment scenarios for the ginger rhizomes are presented in Fig. 7. The surface plot showed a non-linear relationship for the three parameters, however, the optimum equations within the study conditions for the un-blanched, blanching for 302, 60 s and 90 s are presented in equations 24, 25, 26, 27) with an optimum yield of collector Temperature of 39.93 °C, collector efficiency of 30% and drying rate of 0.0263 kg/h for un-blanched ginger rhizome while blanching for 30 s gave collector Temperature (T) of 40.4 °C, collector efficiency(η) of 14.3% and drying rate (dr) of 01621 kg/h. Similarly, blanching for 60 s and 90 s gave a collector Temperature of 40.5 °C, collector efficiency of 15.3%, the drying rate of 0.0214 kg/h and collector Temperature of 40.5 °C, collector efficiency of 15.3% and drying rate of 0.01161 kg/h respectively.

| 24 |

| 25 |

| 26 |

| 27 |

where η is the collector or thermal efficiency (decimal), T is collector temperature (oC).

Fig. 7.

Surface plot of drying rate response to collector temperature and thermal efficiency variations.

The average moisture diffusivity for Un-blanched, 30 s, 60 s and 90 s blanched are 1.9059 × 10−9 m2/s, 2.6637 × 10−9 m2/s, 2.6639 × 10−9 m2/s and 2.8948 × 10−9 m2/s respectively as shown in Table 4. These values of moisture diffusivity are above 2.807 × 10−10 to 6.977 × 10−10 m2/s presented by Akpinar et al. [50] for drying ginger slices between 40 and 70 °C under convective drying but below 1.31–1.91 × 10−7 m2/s presented by Jayashree et al. [51] for convective drying of ginger which Deshmukh et al. [52] stated that it is out of range while stating that the moisture diffusivity of ginger should fall within and m/s2. The moisture diffusivity gives information on moisture migration from the internal structure of the material to the surface where drying takes place.

Table 4.

Average Effective moisture diffusivity.

| Pre-Treatment | 30 s.BL | 60s.BL | 90S.BL | Unblanched |

|---|---|---|---|---|

| Moisture Diffusivity | 2.66E-09 | 2.66E-09 | 2.89E-09 | 1.91E-09 |

3.2. Mathematical modelling

The drying curve of ginger rhizomes using the hybrid composite dryer was depicted with moisture ratio using equation (5). The obtained moisture ratio for each pre-treatment was fitted into the kinetic models in Table 3 to choose the best-fitting equation for each pre-treatment. The result of the coefficients and statistical parameters is presented in Table 5. From the table, all the models showed a good fit for all the treatments, however, looking at the values of the statistical data showed that the logarithmic model better predicted the drying kinetics of un-blanched and blanching for 30 s while the modified Henderson and Pabis model better predicted drying 60 s and 90 s blanched ginger rhizomes. Fig. 8 (A-D) showed the predicted and experimental moisture ratio at different blanching time duration while equation (28) -31 showed the moisture ratio expression equation for the best fitting models for un-blanched, 30 s blanched, 60 s blanched and 90s blanched respectively.

| 28 |

| 29 |

| 30 |

| 31 |

Table 5.

Results of model fitting and statistical parameters.

| Model | Un-blanched | Bl30s | Bl60s | Bl90s |

|---|---|---|---|---|

| Page | ||||

| k | 0.0932 | 0.1974 | 0.14781 | 0.15647 |

| R2 | 0.9269 | 0.9026 | 0.93578 | 0.95534 |

| RMSE | 0.1047 | 0.125 | 0.08075 | 0.0504 |

| χ2 | 0.0062 | 0.0096 | 0.00475 | 0.00315 |

| Henderson and Pabis | ||||

| a | 1.1629 | 1.38459 | 1.14182 | 1.12129 |

| k | 0.11084 | 0.27078 | 0.1705 | 0.17695 |

| R2 | 0.95692 | 0.97041 | 0.94832 | 0.96516 |

| RMSE | 0.05812 | 0.03503 | 0.06117 | 0.03686 |

| χ2 | 0.00363 | 0.00292 | 0.00382 | 0.00246 |

| Logarithmic | ||||

| a | 2.1392 | 1.40041 | 1.1735 | 1.14523 |

| c | −1.0935 | 0.04542 | 0.0992 | 0.09121 |

| k | 0.0347 | 0.30874 | 0.2425 | 0.24416 |

| R2 | 0.9875 | 0.97247 | 0.9623 | 0.97667 |

| RMSE | 0.0158 | 0.02988 | 0.0419 | 0.02304 |

| χ2 | 0.0011 | 0.00262 | 0.0028 | 0.00165 |

| Wang and Singh | ||||

| a | −0.0628 | −0.15816 | −0.12049 | −0.12477 |

| b | 0.0005 | 0.00673 | 0.00409 | 0.00432 |

| R2 | 0.9863 | 0.92718 | 0.91899 | 0.93943 |

| RMSE | 0.0185 | 0.08623 | 0.0905 | 0.06409 |

| χ2 | 0.0012 | 0.00719 | 0.00603 | 0.00427 |

| Verma et al. | ||||

| a | 83.44287 | 1.57742 | 1.14462 | 1.1212 |

| k | 0.19509 | 0.29795 | 0.17059 | 0.17693 |

| g | 0.19725 | 1.42631 | 625.400 | 9.394E11 |

| R2 | 0.97386 | 0.97218 | 0.94649 | 0.96267 |

| RMSE | 0.03306 | 0.02994 | 0.05964 | 0.03686 |

| χ2 | 0.0022 | 0.00269 | 0.00398 | 0.00263 |

| Modified page | ||||

| k | 0.03013 | 0.0791 | 0.13087 | 0.14209 |

| n | 1.48741 | 1.56161 | 1.06098 | 1.0495 |

| R2 | 0.97925 | 0.94825 | 0.93342 | 0.9535 |

| RMSE | 0.02799 | 0.06128 | 0.0788 | 0.0492 |

| χ2 | 0.00175 | 0.00511 | 0.00493 | 0.00328 |

| Modified Henderson and Pabis | ||||

| a | 0.38765 | 0.46153 | 0.3872 | 0.3554 |

| k | 0.11079 | 0.27078 | 0.47307 | 0.12061 |

| b | 0.38765 | 0.46153 | 0.40767 | 0.72289 |

| g | 0.11083 | 0.27078 | 0.47309 | 0.56386 |

| c | 0.38765 | 0.46153 | 0.6162 | 0.33379 |

| h | 0.11093 | 0.27078 | 0.1056 | 0.12059 |

| R2 | 0.94256 | 0.95562 | 0.96252 | 0.98188 |

| RMSE | 0.05812 | 0.03503 | 0.03327 | 0.01406 |

| χ2 | 0.00484 | 0.00438 | 0.00277 | 0.00128 |

| Two Term | ||||

| a | 1.03748 | 1.13131 | 0.9761 | 0.96256 |

| ko | −0.03582 | −0.09063 | −0.06439 | −0.06732 |

| b | 0.32663 | 0.52482 | 0.40621 | 0.41239 |

| k1 | 0.32663 | 0.52482 | 0.40621 | 0.41239 |

| R2 | 0.98674 | 0.94058 | 0.89236 | 0.91379 |

| RMSE | 0.01566 | 0.05863 | 0.11148 | 0.07905 |

| χ2 | 0.00112 | 0.00586 | 0.00796 | 0.00608 |

| Two-term exponential | ||||

| a | 1.95668 | 2.24341 | 0.70307 | 0.99738 |

| k | 0.14883 | 0.3566 | 0.16464 | 0.15647 |

| R2 | 0.97337 | 0.97075 | 0.93186 | 0.95236 |

| RMSE | 0.03593 | 0.03463 | 0.08064 | 0.0504 |

| χ2 | 0.00225 | 0.00289 | 0.00504 | 0.00336 |

Fig. 8.

Experimental and predicted moisture ratio for different blanching durations (A) 90 s (B) 60 s (C) 30 s (D) un-blanched ginger rhizomes.

3.3. Earned carbon credit and mass f carbon mitigated

The earned carbon credit imposes a limit on carbon emissions from industries. It gives an overview of the cost impact of carbon emissions [53]. Therefore when a renewable energy system is deployed, this carbon credit could compensate for the deployment of non-renewable energy resources in the energy loop. Various kinds of energy sources are used to power different dryers. Therefore, the carbon emission generated by these dryers differs and attracts a different level of carbon credit which shows the level of the decarbonisation potential of the solar dryer in comparison with these energy sources. In this case, we considered coal, diesel and grid-based electricity as an alternative to power the dryer instead of solar dryers and compare the energy utilization from which the mass of carbon mitigated is calculated. Table 6 presented the results of earned carbon credit. From the table, the mass of carbon mitigated showed that solar dryer instead of fossil-based coal as energy input will limit 430,714.76tonnes of CO2 per year into the atmosphere while using a diesel-powered dryer will mitigate 186,7.62 tonnes of CO2 per year. Additionally, using grid-based electricity will mitigate the lowest amount of CO2 at about 15.96 tonnes of CO2 per year. Thus when this CO2 is quantified in terms of cost, the amount of carbon credit deduced if the dryer is to be powered by coal, diesel or grid base electricity were $ 6245364, $27080.52, and $231.45 per year respectively which is what could be saved if the evaluated solar dryer is used instead of coal, diesel or electric-powered dry. The results showed coal as the worst emitter while electricity powered dryer is the least comparatively. The obtained result is for the indicative purpose to give an overview of the positive environmental impact of using natural convection solar dryers instead of other energy sources to dry.

Table 6.

Earned carbon credit and mass of CO2 mitigated.

| Energy source | Diesel | Coal | Grid Electricity |

|---|---|---|---|

| Mass of carbon (tons) per year | 186,7.62 | 430,714.76 | 15.96 |

| Earned Carbon credit ($) per annum | 27080.52 | 6245364 | 231.45 |

3.4. Economic assessment of using the hybrid solar dryer

Solar dryers have little or no negative environmental impact as well as low running costs. To buttress this potential savings that can accrue from using the solar dryer to dry the ginger rhizomes instead of fossil energy sources were carried out. The calculation was based on a different level of utilization with belief that the sunshine duration varies from one location to another [54,55]. Therefore the cost is determined based on a 10% level of usage to a 100% level of usage. Based on this, the payback period of the solar dryer which is an important decision-making tool is also presented in Fig. 9. It has been found that the lower the payback period the greater the projected liquid, thereby lessening the risk involved [56]. Fig. 9 showed that as the level of utilization increases, the payback period decreases. The calculated amount of money that can be saved in using the natural convection solar dryer increased from $75.731 to $757.31 as the usage increased from 10 to 100%. At this cost savings, the payback period decreased from 2.88 years to 0.31 years. With most solar dryers running for over 10 years, it means that if the useful life of the dryer goes beyond 3 years, no matter the rate of use the solar dryer will operate almost free of running cost.

Fig. 9.

Payback periods and savings per annum due to the percentage rate of usage for the solar dryer.

4. Conclusion

The Assessment of the drying kinetics and thermo-economic analysis of a hybrid composite heat exchanger solar dried hot water blanched ginger rhizomes was carried out. Drying of the various pre-treated ginger rhizomes cubes in the solar dryer took 13–16 h to attain the desired moisture content under the drying conditions. Blanching duration quickened the drying rate of the ginger rhizomes, as the effective moisture diffusivity increased from 1.9059 × 10−9 for un-blanched ginger rhizomes to 2.8948 × 10−9 m2/s for blanching from 90 s. The optimal drying rate for the four pre-treatment adopted varied from 0.01161 kg/h to 0.0263 kg/h at a collector temperature range of 39.5 °C–40.5 °C and collector efficiency range of 14.3%–30%. The economic analysis showed that at a maximum rate of usage (100% usage) the hybrid composite solar dryer could save up to $757.31 of running cost per annum with a payback period of 0.31 years. Using the presented solar dryer instead of coal, diesel or grid base electricity can prevent 15.96 to 186, 7.62 tones of CO2 from entering the atmosphere. The earned carbon credit if the dryer is to be powered by coal, diesel or grid base electricity were $ 6245364, $27080.52, and $231.45 per year respectively which can be used to compensate other non-renewable energy sources deployed within an enterprise.

Author contribution statement

Macmanus Chinenye Ndukwu: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper. Augustine Edet Ben: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper. Ugwu Elijah, Mathew Imagwuike Ibeh, Ekop Inemesit, Akpan Godwin, Anietie Effiong Udo, Ihediwa V. E, Leonard Akuwueke, Mbanasor Jude, Abam Fidelis: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interest's statement

The authors declare no conflict of interest.

References

- 1.Ebru K.A., Seda T. 2015. Determination of Drying Kinetics and Convective Heat Transfer Coefficients of Ginger Slices. [Google Scholar]

- 2.Schweiggert U., Hofmann S., Reichel M., Schieber A., Carle R. Enzyme-assisted liquefaction of ginger rhizomes (Zingiber officinale Rosc.) for the production of spray-dried and paste-like ginger condiments. J. Food Eng. 2008;84:28–38. [Google Scholar]

- 3.Gizanna R., Lindmark L., Frondoza C. Ginger a Merbal medicinal product with broad anti-inflammatory actions. J. Med. Food. 2005;8(2):125–162. doi: 10.1089/jmf.2005.8.125. [DOI] [PubMed] [Google Scholar]

- 4.Phoungchandang S., Saentaweesuk S. Effect of two-stage, tray and heat pump assisted-dehumidified drying on drying characteristics and qualities of dried ginger. Food Bioprod. Process. 2011;89:429–437. [Google Scholar]

- 5.Markam R., Bajpai A.K. Functionalization of ginger derived nanoparticles with chitosan to design drug delivery system for controlled release of 5-amino salicylic acid (5-ASA) in treatment of inflammatory bowel diseases: an in vitro study. React. Funct. Polym. 2020 doi: 10.1016/j.reactfunctpolym.202. [DOI] [Google Scholar]

- 6.Onwuka G.L., Nwokoha G.U., Asumugha G.N. Evaluation of processing methods for the production of ginger drinks. Vol. 26. 2002. pp. 58–61. [Google Scholar]

- 7.Ginger statistics production in Nigeria, Hectare. Medium (2021), 1-8, available online: https://medium.com/thrive-agric/ginger-production-in-nigeria-c8af56c737c1 (accessed 15 December 2022).

- 8.Eze J.I., Agbo K. Comparative studies of the sun and solar drying of peeled and unpeeled ginger. Am. J. Sci. Ind. Res. 2011;2(2):136–143. [Google Scholar]

- 9.Okafor G.I. TWAS-CSRI postdoctoral fellowship research report; CFTRI, India: 2002. Processing and Utilization of Ginger: Effect of Processing Methods on Product Quality, and its Application in Fruit and Bakery Products; p. 32. [Google Scholar]

- 10.Njoku B.O., Mbanaso E.N., Asumugha G.N. Dolf madi publishers; Owerri: 1995. Ginger Production by Conventional and Tissue Culture Techniques; pp. 13–14. [Google Scholar]

- 11.Famurewa A.V., Enuekele P.O., Jaiyeoba K.F. Effect of drying and size reduction on the chemical and volatile oil contents of ginger (Zingiberofficnale) J. Med. Plants Res. 2011;5(14):2941–2944. http://www.academijournals.org 18 July 2011. [Google Scholar]

- 12.Gan H., Charters E., Driscoll R., Srzednicki G. Effects of drying and blanching on the retention of bioactive compounds in ginger and Turmeric. Horticulturae. 2017;3(1):13. [Google Scholar]

- 13.Olaoye O.S., Ogunleye A.J. Experimental study of drying parameters of ginger at different temperature and moisture content. EJERS, European J. Eng. Res. Sci. 2018;3(No. 9):34–39. doi: 10.24018/ejers.2018.3.9.901. [DOI] [Google Scholar]

- 14.Chaudhri S., Kothari S., Panwar N.L. Performance evaluation of exhaust air recirculation system of mixed mode solar dryer for drying onion flakes. Int. J. Renew. Energy Technol. 2009;1(1):29–41. [Google Scholar]

- 15.Hossain M.A. Mymensingh; Bangladesh: 2003. Forced Convection Solar Drying of Chilli. PhD Thesis. Bangladesh Agricultural University.https://www.linquip.com/blog/efficiency-of-heat-exchanger/ [Google Scholar]

- 16.Azaizia Z., Kooli S., Elkhadraoui A., Hamdi I., Guizani A. Investigation of a new solar greenhouse drying system for peppers. Int. J. Hydrogen Energy. 2017;42(13):8818–8826. doi: 10.1016/j.ijhydene.2016.11.180. [DOI] [Google Scholar]

- 17.Chen C.R., Sharma A., Lam H.X. SOLARIS, Third Intl. Conf.; New Delhi, India: Anamaya Publishers: 2007. Experimental Thermal Performance Studies of a Forced Flow Solar Dryer; pp. 293–297. [Google Scholar]

- 18.El-Sebaii A., Shalaby S. Solar drying of agricultural products: a review. Renew. Sustain. Energy Rev. 2012;16(1):37–43. [Google Scholar]

- 19.Jairaj K.S., Singh S.P., Srikant K. A review of solar dryers developed for grape drying. Sol. Energy. 2009;83(9):1698–1712. doi: 10.1016/j.solener.2009.06.008. [DOI] [Google Scholar]

- 20.Ricci M.R., Battisti J., de F., Schmidt C.A.P. Secador solar: Processo de desidratação de frutas com diferentes tratamentos osmóticos. Cadernos de Agroecologia. 2012;7(1):1–4. [Google Scholar]

- 21.Kumar M., Sansaniwal S.K., Khatak P. Progress in solar dryers for drying various commodities. Renew. Sustain. Energy Rev. 2016;55:346–360. doi: 10.1016/j.rser.2015.10.158. [DOI] [Google Scholar]

- 22.Fudholi A., Sopian K., Ruslan M.H., Alghoul M., Sulaiman M. Review of solar dryers for agricultural and marine products. Renew. Sustain. Energy Rev. 2010;14(1):1–30. [Google Scholar]

- 23.Ndukwu M.C., Bennamoun L., Abam F.I., Eke A.B., Ukoha D. Energy and exergy analysis of a solar dryer integrated with sodium sulphate decahydrate and sodium chloride as a thermal storage medium. Renew. Energy. 2017;113:1182–1192. [Google Scholar]

- 24.Ndukwu M.C., Bennamoun L., Abam F.I. Experience of solar drying in Africa: presentation of designs, operations, and models. Food Eng. Rev. 2018;10:211–244. [Google Scholar]

- 25.Ndukwu M.C., Onyenwigwe D.I., Abam F., Lamrani B., Simo-Tagne M., Bekkioui N., Bennamoun L., Said Z. Influence of hot water blanching and saline immersion period on the thermal effusivity and the drying kinetics of hybrid solar drying of sweet potato chips. Sol. Energy. 2022;240(2022):176–192. [Google Scholar]

- 26.Simate I. Optimization of mixed-mode and indirect-mode natural convection solar dryers. Renew. Energy. 2003;28(3):435–453. [Google Scholar]

- 27.Singh S., Kumar S. Testing method for a thermal performance-based rating of various solar dryer designs. Sol. Energy. 2012;86(1):87–98. [Google Scholar]

- 28.Ndukwu M.C., Onyenwigwe D., Abam F.I., Eke A.B., Dirioha C. Development of a low-cost wind-powered active solar dryer integrated with glycerol as thermal storage. Renew. Energy. 2020;154:553–568. [Google Scholar]

- 29.Corrêa P.C., Oliveira G.H.H., Botelho F.M., Goneli A.L.D., Carvalho F.M. Mathematical modelling and determination of the thermodynamic properties of coffee (Coffea arabica L.) during the drying process. Rev. Ceres. 2010;57:595–601. [Google Scholar]

- 30.Hoque M.A., Bala B.K., Hossan M.A., Uddin M.B. Drying kinetics of ginger rhizome. Bangladesh J. Agril.Res. 2013;38(2):31–319. June 2013. ISSN 0258-7122. [Google Scholar]

- 31.Ndukwu M.C., Ibeh M., mEkop I., Abada U., Etim P., Bennamoun L., Abam F., Simo-Tagne M., Gupta A. Analysis of the heat transfer coefficient, thermal effusivity and mathematical modelling of drying kinetics of a partitioned single pass low-cost solar drying of cocoyam chips with economic assessments. Energies. 2022;15:4457. doi: 10.3390/en15124457. [DOI] [Google Scholar]

- 32.Alic E., Das Mehmet, Ebru Kavak Akpinar Design, manufacturing, numerical analysis and environmental effects of single-pass forced convection solar air collector. J. Clean. Prod. 2021;311(2021) [Google Scholar]

- 33.Ndukwu M.C., Ibeh M.I., Etim P., Augustine C.U., Ekop I.E., Leonard A., Oriaku L., Abam F., Lamrani B., Simo-Tagne M., Bennamoun L. Assessment of eco-thermal sustainability potential of a cluster of low-cost solar dryer designs based on exergetic sustainability indicators and earned carbon credit. Cleaner Energy Systems. 2022;3(2022) [Google Scholar]

- 34.Ndukwu M.C., Ibehb M.I., Ugwu E., Ekop I., Etim P., Igbojionu D., Abam F., Lamrani B., Simo-Tagne M., Bennamoun L. Environmental sustainability and exergy return on investment of selected solar dryer designs based on standard and extended exergy approaches. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 2022. 2022;44(No. 4) doi: 10.1080/15567036.2022.2156636. 10647–10664. [DOI] [Google Scholar]

- 35.Yousef M.S., Hassan H. Energy payback time, exergo-economic and enviro-economic analyses of using thermal energy storage system with a solar desalination system: an experimental study. J. Clean. Prod. 2020;270 doi: 10.1016/j.jclepro.2020.122082. [DOI] [Google Scholar]

- 36.Ould-Amrouche O., Rekioua D., Hamidat A. Modelling photovoltaic water pumping systems and evaluation of their CO2 emissions mitigation potential. Appl. Energy. 2010;87:3451–3459. doi: 10.1016/j.apenergy.2010.05.021. [DOI] [Google Scholar]

- 37.Duffie J.A., Beckman W.A. Wiley; New York: 2006. Solar Engineering of Thermal Process. [Google Scholar]

- 38.Nigeria G.P.P. Electricity prices. Global Petrol Prices. 2021:1–5. www.globalpetrolprices.com/Nigeria/electricity_prices/ Available online: accessed on 15 May 2022. [Google Scholar]

- 39.Herez A., Khaled M., Murr R., Haddad A., Elhage H., Ramadan M. Using geothermal energy for cooling—parametric study. Energy Procedia. 2017;119:783–791. [Google Scholar]

- 40.Kirian D.R. Elsevier Inc.; Amsterdam, The Netherlands: 2022. Principles of Economics and Management for Manufacturing Engineering. [Google Scholar]

- 41.Lamrani L., Elmrabet Y., Ibeh M., Bekkioui N., Etim P., l Chahboun A., Draoui A., Ndukwu M.C. Energy, economic analysis and mathematical modelling of mixed-mode solar drying of potato slices with thermal storage loaded V-groove collector: application to Maghreb region. Renew. Energy. 2022;200(2022):48–58. [Google Scholar]

- 42.Ndukwu M.C., Simo-Tagne M., Bennamoun L. Solar drying research of medicinal and aromatic plants: an African experience with assessment of the economic and environmental impact. Afr. J. Sci. Technol. Innov. Dev. 2021;13:247–260. [Google Scholar]

- 43.Bennamoun L., Belhamri A. Design and simulation of a solar dryer for agriculture products. J. Food Eng. 2003;59:259–266. [Google Scholar]

- 44.Isaac N.S., Sam C. Design and testing of a natural convection solar Tunnel dryer for mango. J. Solar Energy. 2017 doi: 10.1155/2017/4525141. [DOI] [Google Scholar]

- 45.Brenndorfer B., Kennedy L., Mrema G. Commonwealth Secretariat Publishers, Malborough House; London: 1987. Solar dryers: their role in post-harvest processing; pp. 1–282. [Google Scholar]

- 46.Hawa L.C., Ubaidillah U., Mardiyani S.A., Laily A.N., Yosika N.I.W., Afifah F.N. Drying kinetics of cabya (Piper retrofractum Vahl) fruit as affected by hot water blanching under indirect forced convection solar dryer. Sol. Energy. 2021;214:588–598. [Google Scholar]

- 47.Pandey O.P., Mishra B.K., Misra A. Comparative study of green peas using blanching and without blanching techniques. Inform. Process. Agric. 2019;6(2):285–296. [Google Scholar]

- 48.Deng L.Z., Pan Z., Mujumdar A.S., Zhao J.H., Zheng Z.A., Gao Z.J., Xiao H.W. High-humidity hot air impingement blanching (HHAIB) enhances the drying quality of apricots by inactivating the enzymes, reducing drying time and altering the cellular structure. Food Control. 2019;96:104–111. [Google Scholar]

- 49.Ihediwa V.E., Akpan G.E., Akuwueke L., Oriaku L., O Ndubuisi C., Mbanasor J., Ndukwu M.C. Thermal dehydration of some forage grasses for livestock feeding: effect of different methods on moisture diffusivity and the quality of dried leaves. Energy Nexus. 2022;8(2022) [Google Scholar]

- 50.Akpinar E.K., Toraman S. Determination of drying kinetics and convective heat transfer coefficients of ginger slices. Heat Mass Tran. 2015;52(10):2271–2281. [Google Scholar]

- 51.Jayashree E., Viswanathan R. Studies on thin layer drying characteristics of ginger (Zingiber officinale) in a mechanical tray drier journal of plantation crops. J Spices Aromat Crops. 2013;41(1):86–90. [Google Scholar]

- 52.Deshmukh A.W., Varma M.N., Yoo C.K., Wasewar K.L. Investigation of solar drying of ginger (Zingiber officinale): empirical modelling, drying characteristics, and quality study. Chinese J. Eng. 2014:1. doi: 10.1155/2014/305823. [DOI] [Google Scholar]

- 53.Rao V.V., Datta S.P. A feasibility assessment of single to multi/hybrid evaporative coolers for building air-conditioning across diverse climates in India. Appl. Therm. Eng. 2020;168(2020) [Google Scholar]

- 54.Ndukwu M.C., Simo-Tagne M., Abam F.I., Onwuka O.S., Prince S., Bennamoun L. Exergetic sustainability and economic analysis of hybrid solar-biomass dryer integrated with copper tubing as a heat exchanger. Heliyon. 2020;6(2) doi: 10.1016/j.heliyon.2020.e03401. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Ndukwu M.C., Bennamoun L. Potential of integrating Na2SO4 · 10H2O pellets in the solar drying system. Dry. Technol. 2017;36(9):1017–1030. doi: 10.1080/07373937.2017.1366506. [DOI] [Google Scholar]

- 56.Ndukwu M.C., Manuwa S.I. A techno-economic assessment for the viability of some waste as cooling pads in evaporative cooling system. Int. J. Agric. Biol. Eng. 2015;8(2):151–158. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.