Abstract

In this work, the CO2 adsorption performance of metal–organic frameworks (MOFs) impregnated with ionic liquids (ILs) was studied using quartz crystal microbalance (QCM) at the temperature of 298.15 K and pressures up to 5 bar. The hybrid composites consist of aluminum terephthalate metal–organic framework (AlTp) impregnated of 1-butyl-4-methyl pyridinium and 1-butyl-3-methylimidazolium–based ionic liquids (ILs) with different anions, viz. tetrafluoroborate ([BF4]−), thiocyanate ([SCN]−), chloride ([Cl]−), and bromide ([Br]−). ILs-impregnated AlTp synthesized was characterized using scanning electron microscopy (SEM), X-ray diffraction analysis (XRD), the thermogravimetry analysis (TGA) and Fourier transform infrared (FTIR) spectroscopy. CO2 adsorption isotherms of the IL/AlTp composites and AlTp were measured to evaluate the ILs effect on the CO2 adsorption of the AlTp. Comparison of CO2 adsorption in ILs/AlTp with different anion ([Cl]−, [Br]−, [SCN]−, [BF4]−) reveals that CO2 adsorption in ILs/AlTp was increased in the order as: [BF4]− < [SCN]− < [Br]− < [Cl]−. The results show that [BMPyr][Cl]/AlTp the highest CO2 adsorption capacity, 2.6 times higher than that of AlTp at 5 bar and 298.15 K which helps to guide the logical design of new mixtures for gas separation applications. Also, adsorption/desorption test show that regeneration performance of [BMPyr][Cl]/AlTp is 96.53% after five consecutive cycles adsorption/desorption.

Subject terms: Energy science and technology, Carbon capture and storage

Introduction

Climate change is one of the most significant challenges ago for countries around the world; preventing and modifying it received widespread attention1. Rising global temperatures pose an urgent threat to the planet, with an increase of approximately 2 °C by the end of this century2. The increase in the average temperature of the earth can be attributed to a group of greenhouse gases, of which carbon dioxide (CO2) accounts for more than 70% of the total3,4. To overcome these troubles, the capture potential and storage concept (CCS) for CO2 was offered to control the CO2 amount in the atmosphere5. Different CO2 capture technologies are presently accessible containing absorption (physical and chemical absorptions), cryogenic separation, adsorption, and membrane technologies. Among these technologies, the chemical absorption of amine scrubbing is used as an efficient technique for the chemical adsorption of CO2 in industries6,7. Although the usage of the amine method can reduce CO2 by up to 98%, this technique is inefficient with a large number of absorber requirements, high energy consumption, corrosions, etc. As a result, solid adsorption processes have been studied to reduce these problems8. A significant category of porous materials has been investigated as adsorbents, such as activated carbon, zeolites, aluminophosphates, silica gel, carbon nanotubes, polymeric resins, and porous metal–organic frameworks9,10.

Among the mentioned adsorbents, porous metal–organic frameworks (MOFs) have received the attention of many researchers owing to their high adsorption capacity and significant selectivity for the past two decades. Metal–organic frameworks (MOFs) are a category of porous materials, which their structure is composed of metal ions networks or metal ion clusters and organic linkers connected through coordination bonds11. MOFs own a high internal surface area, tunable multifunctional pores, adaptable porosity, and high thermal and chemical stabilities12,13. MOF structure and properties can be tuned using selecting the appropriate linker metal pair for a purpose application14, such as the adsorption of specific gas species15,16. Improving the pore characteristics of MOFs with different active sites, among which creation of incorporation of carboxylate oxygen atoms/–NH2 or uncoordinated nitrogen/ and or adjustment of pore space partition, and unsaturated metal centers (UMCs), can increase preferential interactions between the frameworks and CO217,18. Recently, MOFs have been modified using functional molecules impregnation and chemical functionalization to further enhance their CO2 uptake performance. Because of the complex manipulation of chemical function, physical modification is a convenient alternative by introducing functional molecules in metal–organic frameworks that show a lot of tendency for CO2. Recent investigations have focused on improving the CO2 adsorption performance of MOFs using the impregnation of ionic liquids (ILs) on the porous frameworks.

Ionic liquids are molten solvent having melting point below 373 K, and considered as green solvents, have potential as a possible replacement candidate for conventional solvents especially in the area of green chemistry and have been described as potential environmentally in a variety of applications19,20. Their unique properties include low volatility, high thermal stability, and recyclability21. The possibility to design their physicochemical properties by tuning the anion or cation in their structure makes them unique compared to other organic solvents22–24. Azevedo et al.25 studied the adsorption of pure methane, carbon dioxide, nitrogen, and typical mixtures found in natural gas and flue gases in mesoporous MOF MIL-100(Fe) impregnated with ILs [Bmim][Tf2N] and [Bmim][PF6] using molecular simulations. Vicent-Luna et al. 26 analyzed the adsorption and diffusion of gases such as CO2, N2, and CH4 in metal–organic frameworks (MOFs) consisting of IRMOF-1, HMOF-1, MIL-47, and MOF-1 impregnated of 1-ethyl-3-methylimidazolium thiocyanate. They have suggested that the increase the gas adsorption and controlling the pore sizes of the structures to further selective adsorption. Gupta et al. 27,28 investigated CO2 capture in IRMOF-1 supported four IL including cation 1-n-butyl-3-methylimidazolium [BMIM]+ with various anions: tetrafluoroborate [BF4]−, hexafluorophosphate [PF6]−, thiocyanate [SCN]−, and bis(trifluoromethylsulfonyl)imide [Tf2N]− by molecular simulation and indicated that the [BMIM][SCN]/IRMOF-1 to be the most favorable site for CO2 adsorption. However the use of ILs impregnated on MOF for CO2 adsorption study is still limited. In this research, ILs-impregnated AlTp was synthesized for CO2 adsorption. The CO2 adsorption in these ILs-impregnated AlTp was measured using quartz crystal microbalance (QCM) at the temperature of 298.15 K and pressures up to 5 bar. A novel hybrid model has been offered for correlating CO2 isotherm, which resulted in good agreement with the experimental data. The efficacy of the type of anion and cation in the ionic liquid on the CO2 adsorption was investigated.

Experimental section

Materials

N-Methylimidazole (> 99%), 4-Methylpyridine (> 98%), Potassium thiocyanate (> 98%), sodium tetrafluoroborate (> 98%), 1-Chlorobutane (> 99%), and 1-Bromobutane (> 99%) were obtained from Sigma–Aldrich. Ethyl acetate (> 99%), Toluene (> 99%), Ethanol (> 99%) and were obtained from Merck. Aluminum nitrate (Al(NO3)3·9H2O) (> 99%), and Terephthalic acid (> 98%) were purchased from Merck products. CO2 gas (> 99%) was used in gas absorption tests.

Synthesis of components

Synthesis of AlTp

AlTp was synthesized using the hydrothermal technique as described in the literature29. To synthesize AlTp, 16.71 g (45 mmol) of aluminum nitrate (Al(NO3)3·9H2O), 3.74 g (22.5 mmol) terephthalic acid, and deionized water (50 mL) were put in autoclave at 493 K for about 72 h. The pH of the composition should be in the range of 2–3; otherwise, HNO3 is added to achieve the desired pH. The synthesized AlTp with a structural unit of Al(OH)[O2C–C6H4–CO2].[HO2C6H4–CO2H]x was filtered and washed several times with deionized water to ensure the elimination of unreacted materials and dried in a vacuum for 2 h. The product was calcined for 72 h at 633 K under air for removing terephthalic acid and water molecules trapped inside its cavities.

Synthesis of the ionic liquids

The ionic liquids, 1-butyl-3-methylimidazolium ionic liquids, ([BMIm][X], and 1-butyl-4-methyl pyridinium ionic liquids, [BMPyr][X] where X = , ,, and were synthesized with a reported method in the literature30–32. The procedure to synthesize and purify the ionic liquids was similar to that described previously33–35. The water amount of the ionic liquids was evaluated by a Karl-Fischer titrator (720-KSS-Metrohm Herisau, Switzerland). The 1H NMR and the spectra of FT-IR of the synthesized ionic liquids are displayed in Figs. S1–S7 (Supporting Information).

Synthesis of IL-impregnated on MOF

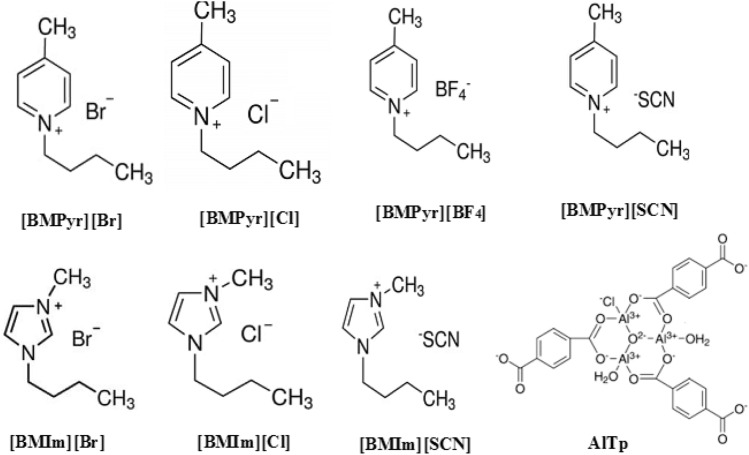

AlTp was impregnated by the ILs solution with a ratio of 1:1 wt/vol using a vacuum impregnation method; hence, obtaining 5% ILs on AlTp. The slurry obtained was dried using an oven at 378 K for 24 h. The structures of AlTp and ILs are shown in Fig. 1.

Figure 1.

Structures of AlTp and ILs.

Characterization of MOF

FTIR spectra were obtained by PerkinElmer (Spectrom RXI). The thermogravimetry analysis (TGA) curve has been determined using a TGA instrument, (TGA-DAT, perkin elmer pyris diamond). A rate of 10 °C/min was used together with nitrogen purging. Furthermore, the BET surface area of the AlTp was also obtained by measuring the nitrogen adsorption at 77 K by a BET (Chem BET-3000) system. The morphology of synthesized MOF was investigated using providing SEM images through LEO 1430VP. X-ray diffraction (XRD) patterns were determined by Philips (X-Pro) in the scan range of 2θ = 5°–70°.

Gas adsorption apparatus

QCM sensor was applied for gas adsorption measurement. The cell of adsorption entails an 8 MHz AT-cut quartz crystal applied in the electrical oscillator circuit. Adsorption apparatus performance has been mentioned in the prior papers by authors in detail36–38. The adsorption capacity of adsorbent, () was computed as follows:

| 1 |

where difference between the coated and the uncoated crystal frequencies. is the difference between the frequencies ILs/AlTp coated crystal under vacuum and the ILs/AlTp coated crystal after CO2 adsorption.

Thermodynamic model

To achieve the isotherm diagrams, the adsorbed gases' amounts and their corresponding equilibrium pressure of adsorption were modeled. The two-parameter models such as Langmuir39, Tempkin 40, and Freundlich41, and three parameters such as Khan 42, Redlich-Peterson 43, and Sips 44 are offered to model the experimental data. Among these isotherm models, the three-parameter Khan model was applied to correlate the data of CO2 adsorption on AlTp. In this study, to correlate the experimental data of CO2 solubility in IL-impregnated on MOF are used a hybrid law of Henry and Khan Model as below:

| 2 |

where is the partial pressure of CO2, H is the CO2 Henry’s law constant, n is the dimensionless adsorbent parameter, qs and b are also parameters of the Khan model. The first term in Eq. (2) is Henry law and indicates absorption gas in the confinement IL in the pores of adsorbent. The second term in Eq. (2) is Khan Model indicates adsorption gas in the surface of adsorbent.

Results and discussion

Characterization

FT-IR spectra

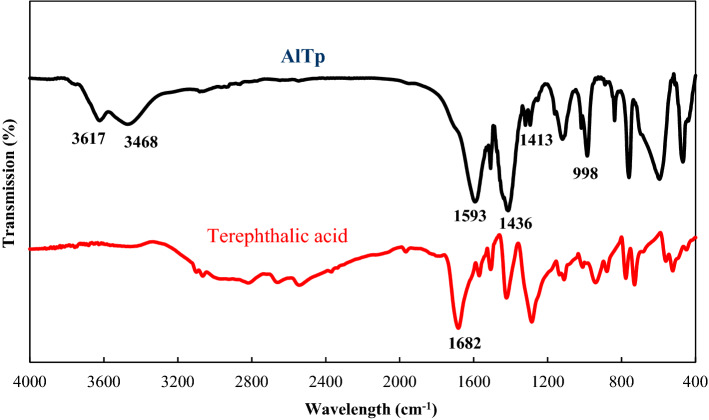

The FT-IR spectra of the terephthalic acid and AlTp are shown in Fig. 2. As seen in the AlTp spectrum, the broad signals at around 3600–3400 cm−1 correspond to the stretching vibration of water molecules poached in the cavities of AlTp. The observed peaks at around 1508 and 1593 cm−1 are attributed to C=O asymmetric stretching. These peaks are consistent with the presence of CO2 groups that are coordinated to Al. The peaks of the symmetric stretching vibration of –CO2 are indicated at 1413 and 1436 cm−1 in the AlTp spectrum45,46. Moreover, the presence of the Al–O bond (C=O of terephthalate with Al ions) in the AlTp structure was corroborated by the observed signal at 998 cm−1. As is presented in Fig. 2 the peak at 1682 cm−1 is attributed to the stretching vibration of free carboxylic acids in the terephthalic acid which this peak is eliminated in the spectrum of AlTp. This shows that the terephthalic acids enclosed in AlTp cavities were removed in sample calcinations47,48.

Figure 2.

FTIR spectra of the synthesized AlTp.

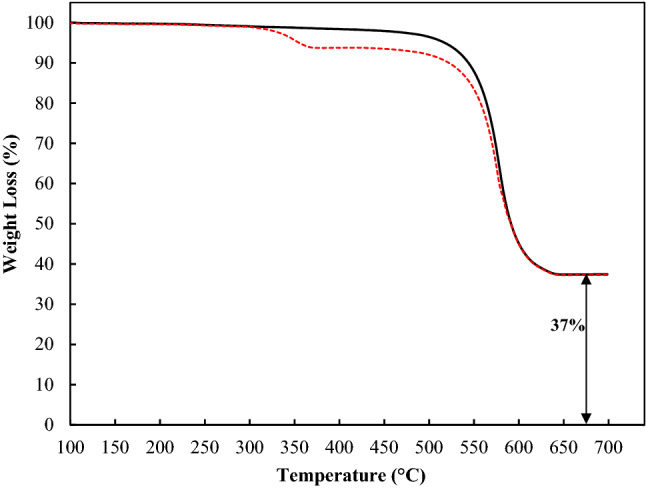

Thermogravimetric analysis

Thermogravimetric analysis (TGA) was performed to evaluate the thermal stability of the AlTp and [BMPyr][Cl]/AlTp. The TGA curve for the AlTp and [BMPyr][Cl]/AlTp are shown in Fig. 3. According to Fig. 3, The AlTp structure is stable up to 500 °C, finally collapses with the motion of the bound terephthalic acid. The temperature of 700 °C is related to the amorphous form of Al2O3 which is in good agreement with reported data49. Thermogravimetric (TG) analysis of [BMPyr][Cl]/AlTp shown in Fig. 3 confirmed that the thermal stabilities is stable up to 300 °C. From 300 to 400 °C, it loses about 5% of its weight, which is related to the destruction of the ILs-impregnated, which indicates that 5% of the ionic liquid has been impregnated.

Figure 3.

Thermogravimetry analysis (TGA) curve for (dashed line) [BMPyr][Cl]/AlTp and (straight line) AlTp.

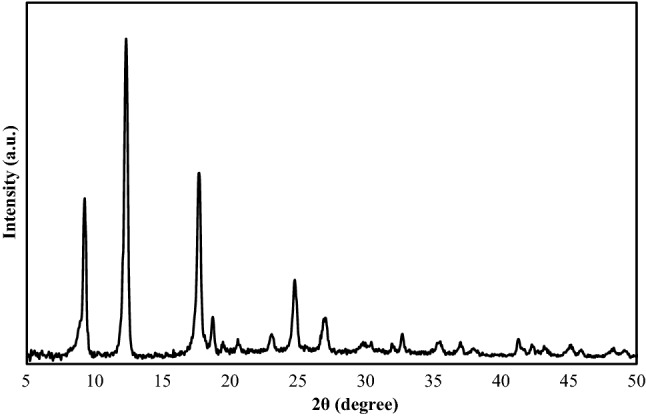

XRD pattern

XRD pattern of the AlTp is illustrated in Fig. 4. The crystalline structures of AlTp demonstrate the main diffraction peaks of the AlTp at 2θ = 9.48°, 12.55°, 17.92°, 23.32°, 25.12°, and 27.28°.

Figure 4.

XRD patterns of the synthesized AlTp.

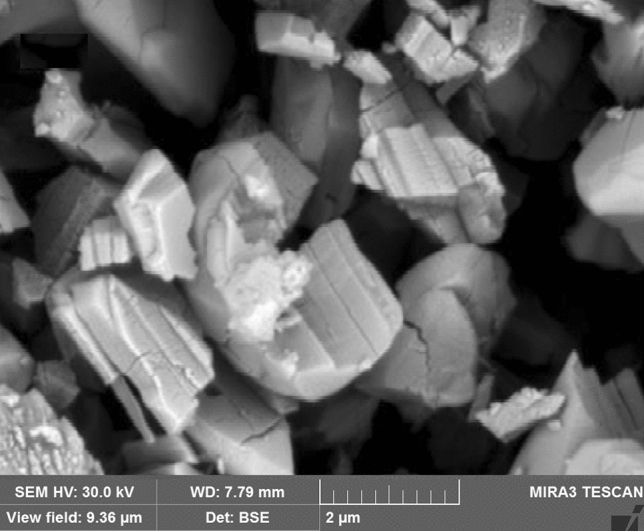

Scanning electron microscopy

Scanning Electron Microscopy (SEM) was used to determine crystal morphology and size of the products. The SEM image of the AlTp is shown in Fig. 5. As seen in the SEM image, the AlTp species is seen as layered cubes with small pores.

Figure 5.

SEM image of the synthesized AlTp.

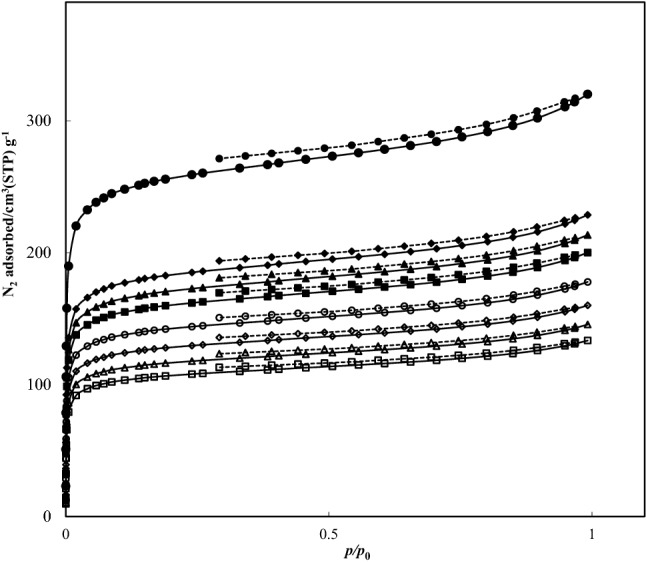

BET analysis

Nitrogen adsorption isotherms displayed for AlTp and ILs/AlTp at 77 K in Fig. 6. The results obtained from BET analysis were also presented in Table 1. According to the results plotted in Fig. 5, the amount of adsorbed N2 by ILs/AlTp was significantly less than that AlTp. Moreover, the specific surface area (ABET) and total pore volume (VP) of ILs/AlTp were lower than those of AlTp. The micropore volume and surface area of MOF is comparable with values reported in the literature50. The textural properties indicated that the impregnation procedure decreased the values of micropore volume, specific surface area and total pore volume relative to the original AlTp sample. This behavior reveals that ILs molecules were incorporated in the pores of AlTp because of the impregnation process.

Figure 6.

Nitrogen desorption–adsorption BET isotherms at 77 K: in (filled circle) AlTp; (filled diamond) [BMIm][Cl]/AlTp; (filled triangle)[BMIm][Br]/AlTp; (filled square)[BMIm][SCN]/AlTp; (open circle)[BMPyr][Cl]/AlTp; (open diamond)[BMPyr][Br]/AlTp; (open triangle) [BMPyr][SCN]/AlTp; and (open square)[BMPyr][BF4]/AlTp; (straight line) N2 adsorption and (dotted line) N2 desorption.

Table 1.

Textural characteristics of the samples.

| ILs/AlTp | ABET (m2·g−1) | VP (cm3·g−1) |

|---|---|---|

| AlTp | 985.72 | 0.49 |

| [BMIm][Cl]/AlTp | 780.45 | 0.45 |

| [BMIm][Br]/AlTp | 725.65 | 0.44 |

| [BMIm][SCN]/AlTp | 664.56 | 0.37 |

| [BMPyr][Cl]/AlTp | 578.35 | 0.35 |

| [BMPyr][Br]/AlTp | 534.80 | 0.33 |

| [BMPyr][SCN]/AlTp | 496.35 | 0.29 |

| [BMPyr][BF4]/AlTp | 420.38 | 0.27 |

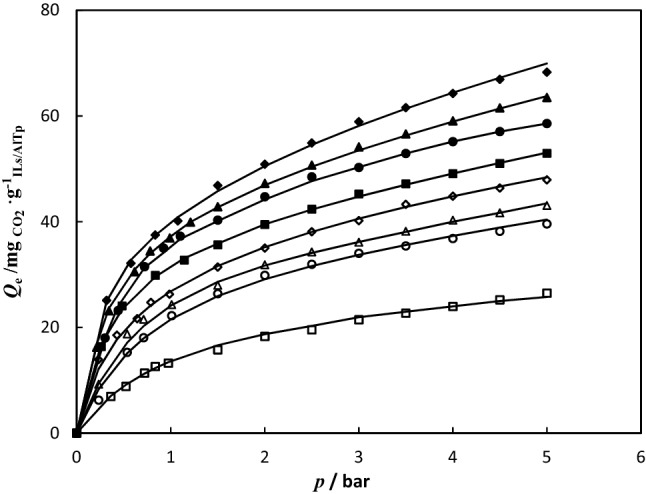

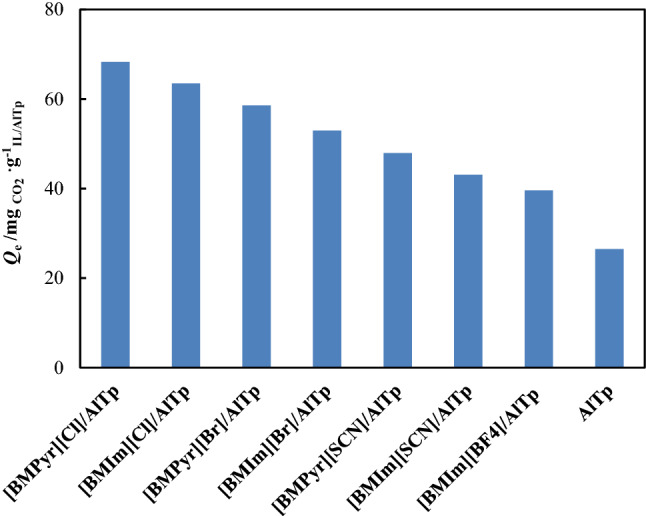

Adsorption isotherms

CO2 adsorption in ILs-impregnated AlTp MOF was measured at a temperature of 298.15 K and pressure of up to 5 bar. The CO2 adsorption data are tabulated in Table 2. The experimental data of CO2 solubility in IL-impregnated on AlTp is correlated by the hybrid model (Eq. 2). The parameters of the Khan Model, Henry’s law constant, and absolute average relative deviation (AARD) for experimental adsorption data for CO2 on the synthesized ILs/AlTp are reported in Table 3. The absolute average relative deviation is lower than 0.02, which implies to suitable capability of the proposed model. According to the data, the modification of AlTp MOF with ILs increases the CO2 adsorption capacity. At pressure of 5 bar, AlTp has a CO2 adsorption capacity of 26.46 , while ILs-impregnated AlTp [BMPyr][Cl]/AlTp, [BMIm][Cl]/AlTp, [BMPyr][Br]/AlTp, [BMIm][Br]/AlTp, [BMPyr][SCN]/AlTp, [BMIm][SCN]/AlTp, and [BMPyr][BF4]/AlTp had adsorption capacities of ca. 68.27, 63.48, 58.56, 52.93, 47.91, 43.05 and 39.58 , respectively. The CO2 adsorption isotherm in ILs-impregnated AlTp was illustrated at a temperature of 298.15 K and pressure of up to 5 bar in Fig. 7. In AlTp main interaction between CO2 and AlTp arises from carboxylate oxygen atoms and unsaturated metal centers (UMCs), can increase preferential interactions between the frameworks and CO2. In the MOF impregnated with ILs, at low pressure gas adsorption take placed on the immobilized ILs on surface of MOF; whereas at high pressure gas adsorption take placed on the confinement ILs on pores of MOF. According Fig. 7, the CO2 adsorption in [BMPyr][SCN]/AlTp, [BMPyr][Cl]/AlTp, and [BMPyr][Br]/AlTp is more than the CO2 adsorption in [BMIm][SCN]/AlTp, [BMIm][Cl]/AlTp, and [BMIm][Br]/AlTp. This behavior may be attributed to the stabilization of charge distribution in cation of ILs. The cation in pyridinium-based ionic liquids has a hexagonal ring whereas the cation in imidazolium-based ionic liquids has a pentagonal ring; therefore stabilization of charge distribution in cation of pyridinium-based ionic liquids is done better than that the cation in imidazolium-based ionic liquids. This behavior causes weak interactions between cation and anion in pyridinium-based ionic liquids and the consequence increases the interactions between CO2 and IL; therefore this leads to an increment in the CO2 solubility. Also, the comparison of CO2 adsorption in ILs/AlTp with different anion of ILs, viz. chloride ([Cl]−), bromide ([Br]−), thiocyanate ([SCN]−), and tetrafluoroborate [BF4]− in Fig. 8 depicts CO2 adsorption in ILs/AlTp was increased with different anion of ILs in the order as: [BF4]− < [SCN]− < [Br]− < [Cl]−. This trend implies that anion acts a main role in the CO2 adsorption in ILs/AlTp. In the MOF impregnated with ILs, gas adsorption arises from two factor; first factor is ILs which confinement in pores and second factor is ILs which immobilized in the surface of pores. In the ILs with large size anion possibility of confinement in pores reduced. Therefore in ILs with halide anion gas adsorption take placed due to confinement and immobilized ILs in pores but in the ILs with [BF4]− anion gas adsorption take placed only due to immobilized ILs. Therefore adsorption capacity in MOF impregnated with halide anion is higher than [BF4]−, nevertheless CO2 adsorption in pure [BF4]− ILs higher than halides.

Table 2.

CO2 adsorption capacity () of ILs/AlTp at 298.15 K and pressures up to 5 bar.

| T = 298.15 K | T = 298.15 K | T = 298.15 K | T = 298.15 K | ||||

|---|---|---|---|---|---|---|---|

| p (bar) | () | p (bar) | () | p (bar) | () | p (bar) | () |

| AlTp | [BMPyr][Cl]/AlTp | [BMIm][Cl]/AlTp | [BMPyr][Br]/AlTp | ||||

| 0.362 | 6.931 | 0.318 | 25.112 | 0.212 | 16.240 | 0.302 | 18.000 |

| 0.524 | 8.822 | 0.576 | 32.129 | 0.343 | 23.130 | 0.441 | 23.189 |

| 0.722 | 11.342 | 0.836 | 37.483 | 0.615 | 30.512 | 0.722 | 31.486 |

| 0.836 | 12.602 | 1.076 | 40.161 | 0.781 | 34.449 | 0.924 | 35.005 |

| 0.975 | 13.233 | 1.500 | 46.854 | 0.990 | 36.925 | 1.102 | 37.264 |

| 1.500 | 15.753 | 2.000 | 50.870 | 1.210 | 39.894 | 1.500 | 40.302 |

| 2.000 | 18.273 | 2.500 | 54.886 | 1.500 | 42.815 | 2.000 | 44.710 |

| 2.500 | 19.534 | 3.000 | 58.902 | 2.000 | 47.244 | 2.500 | 48.489 |

| 3.000 | 21.424 | 3.500 | 61.580 | 2.500 | 50.689 | 3.000 | 50.256 |

| 3.500 | 22.684 | 4.000 | 64.257 | 3.000 | 54.134 | 3.500 | 52.897 |

| 4.000 | 23.945 | 4.500 | 66.934 | 3.500 | 56.594 | 4.000 | 55.156 |

| 4.500 | 25.205 | 5.000 | 68.273 | 4.000 | 59.055 | 4.500 | 57.048 |

| 5.000 | 26.465 | 4.500 | 61.516 | 5.000 | 58.564 | ||

| 5.000 | 63.484 | ||||||

| [BMIm][Br]/AlTp | [BMPyr][SCN]/AlTp | [BMIm][SCN]/AlTp | [BMPyr][BF4]/AlTp | ||||

|---|---|---|---|---|---|---|---|

| 0.261 | 16.362 | 0.231 | 7.728 | 0.234 | 4.861 | 0.234 | 4.861 |

| 0.483 | 24.062 | 0.428 | 12.365 | 0.537 | 10.417 | 0.537 | 8.333 |

| 0.836 | 29.836 | 0.643 | 15.456 | 0.713 | 13.194 | 0.713 | 10.417 |

| 1.144 | 32.724 | 0.789 | 18.547 | 1.010 | 15.972 | 1.010 | 12.500 |

| 1.500 | 35.611 | 0.986 | 20.093 | 1.500 | 19.444 | 1.500 | 15.972 |

| 2.000 | 39.461 | 1.500 | 24.730 | 2.000 | 22.917 | 2.000 | 18.056 |

| 2.500 | 42.348 | 2.000 | 27.821 | 2.500 | 25.694 | 2.500 | 20.139 |

| 3.000 | 45.236 | 2.500 | 30.912 | 3.000 | 27.778 | 3.000 | 22.222 |

| 3.500 | 47.161 | 3.000 | 32.458 | 3.500 | 29.861 | 3.500 | 23.611 |

| 4.000 | 49.086 | 3.500 | 35.549 | 4.000 | 31.944 | 4.000 | 25.000 |

| 4.500 | 51.011 | 4.000 | 37.094 | 4.500 | 33.333 | 4.500 | 26.389 |

| 5.000 | 52.936 | 4.500 | 38.640 | 5.000 | 34.722 | 5.000 | 27.778 |

| 5.000 | 40.185 | ||||||

Standard uncertainties are u () = 0.001, u(T) = 0.05 K, and u (p) = 0.001.

Table 3.

Henry’s law constant (H), and b are also parameters of the Khan model, the dimensionless adsorbent parameter (n), the correlation coefficient (R2) and absolute average relative deviation (AARD) for CO2 adsorption ILs/AlTp at 298.15 K.

| ILs/AlTp | T (Ka) | H (bar) | () | b () | n | R2 | bAARD% |

|---|---|---|---|---|---|---|---|

| AlTp | 298.15 | – | 26.553 | 0.966 | 0.938 | 0.99845 | 1.62 |

| [BMPyr][Cl]/AlTp | 298.15 | 0.434 | 21.138 | 11.789 | 0.741 | 0.99858 | 1.90 |

| [BMIm][Cl]/AlTp | 298.15 | 0.449 | 32.039 | 3.582 | 0.806 | 0.99924 | 1.05 |

| [BMPyr][Br]/AlTp | 298.15 | 0.482 | 26.716 | 6.039 | 0.81 | 0.99938 | 0.99 |

| [BMIm][Br]/AlTp | 298.15 | 0.537 | 33.278 | 4.476 | 0.902 | 0.99961 | 0.78 |

| [BMPyr][SCN]/AlTp | 298.15 | 0.561 | 24.121 | 3.626 | 0.847 | 0.99897 | 1.38 |

| [BMIm][SCN]/AlTp | 298.15 | 0.566 | 28.119 | 0.659 | 0.915 | 0.99909 | 1.27 |

| [BMPyr][BF4]/AlTp | 298.15 | 0.626 | 39.282 | 1.074 | 0.875 | 0.99925 | 1.09 |

aStandard uncertainty is u(T) = 0.05 K.

b.

Figure 7.

The CO2 adsorption in (filled diamond) [BMPyr][Cl]/AlTp; (filled triangle) [BMIm][Cl]/AlTp; (filled circle) [BMPyr][Br]/AlTp; (filled square) [BMIm][Br]/AlTp; (open diamond) [BMPyr][SCN]/AlTp; (open triangle) [BMIm][SCN]/AlTp; (open circle)[BMPyr][BF4]/AlTp at temperature 298.15 K; (straight line) Fitting results by Eq. (2).

Figure 8.

Graphical comparison of CO2 adsorption capacity in the different IL/AlTp systems at temperature 298.15 K and pressure 5 bar.

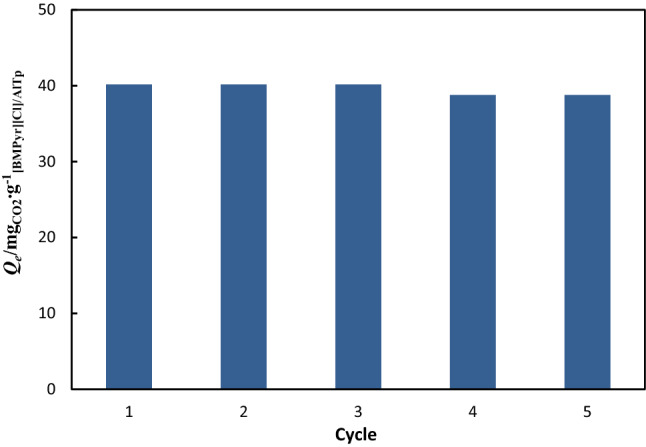

Regeneration efficiency of IL/AlTp

Regeneration efficiency was calculated to estimate the desorption performance of the CO2 adsorbent in ILs/AlTp. To evaluate reuse capacity, five cycles of CO2 adsorption/desorption test [BMPyr][Cl]/AlTp are illustrated in Fig. 9. For the regeneration test, CO2 adsorption has tested at 298.15 K and 1 bar and, vacuum desorption at 298.15 K and 90 min for CO2 elimination. The value of absorption/desorption shows that CO2 is entirely eliminated in 90 min and the amount of adsorption is constant in five cycles. The CO2 adsorption capacity reduction in the regenerated [BMPyr][Cl]/AlTp compared to the fresh sample was estimated at about 1% in 5 cycles. This trend confirms that the ILs/AlTp is stable and regenerable under the practical condition of regeneration. The values of CO2 adsorption [BMPyr][Cl]/AlTp are calculated 40.161, 40.161, 39.547, 38.770, and 38.770 in five consecutive cycles of adsorption/desorption and regeneration performance of [BMPyr][Cl]/AlTp is 96.53% after five consecutive cycles adsorption/desorption.

Figure 9.

The CO2 absorption capacity of [BMPyr][Cl]/AlTp at p = 1 bar and T = 298.15 K in five regeneration cycles.

Conclusions

Aluminum terephthalate metal–organic framework (AlTp) impregnated of 1-butyl-4-methyl pyridinium and 1-butyl-3-methylimidazolium–based ionic liquids with different anions, tetrafluoroborate ([BF4]-), thiocyanate ([SCN]-), chloride ([Cl]-), and bromide ([Br]-) were synthesized and characterized by SEM, FT-IR, XRD, TGA and BET techniques. CO2 adsorption in AlTp impregnated with ILs was studied at 298.15 K and pressures up to 5 bar using QCM. The hybrid law of Henry and Khan Model has been applied to evaluate CO2 absorption in the AlTp impregnated of ILs. Comparison of CO2 adsorption in ILs/ AlTp with different anion ([Cl]−, [Br]−, [SCN]−, [BF4]−) reveals anion play importance role in CO2 adsorption. The results show that [BMPyr][Cl]/AlTp had the highest CO2 adsorption capacity among the studied systems. Also, after several adsorption/desorption test regeneration efficiency slightly reduced; therefore it can be concluded that these system were reusable and logical for gas separation applications.

Supplementary Information

Author contributions

N.N.: Data duration, Writing-Original draft preparation, Visualization, Investigation. A.M.: Conceptualization, Methodology, Validation, Writing-Reviewing and Editing.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The online version contains supplementary material available at 10.1038/s41598-023-30267-x.

References

- 1.Kang S, Chung YG, Kang JH, Song H. CO2 absorption characteristics of amino group functionalized imidazolium-based amino acid ionic liquids. J. Mol. Liq. 2020;297:111825. doi: 10.1016/j.molliq.2019.111825. [DOI] [Google Scholar]

- 2.Krishnan A, Gopinath KP, Vo DVN, Malolan R, Nagarajan VM, Arun J. Ionic liquids, deep eutectic solvents and liquid polymers as green solvents in carbon capture technologies: a review. Environ. Chem. Lett. 2020;18:2031–2054. doi: 10.1007/s10311-020-01057-y. [DOI] [Google Scholar]

- 3.Anderson TR, Hawkins E, Jones PD. CO2, the greenhouse effect and global warming: From the pioneering work of Arrhenius and Callendar to today’s Earth system models. Endeavour. 2016;40:178–187. doi: 10.1016/j.endeavour.2016.07.002. [DOI] [PubMed] [Google Scholar]

- 4.Davis SJ, Caldeira K, Matthews HD. Future CO2 emissions and climate change from existing energy infrastructure. Science. 2010;329:1330–1333. doi: 10.1126/science.1188566. [DOI] [PubMed] [Google Scholar]

- 5.U. S. Department of Energy. CarbonCapture,Utilization,andStorage:ClimateChange,EconomicCompetitiveness,andEnergySecurity. Vol. 12 (2016).

- 6.Jones CW. CO2 capture from dilute gases as a component of modern global carbon management. Annu. Rev. Chem. Biomol. Eng. 2011;2:31–52. doi: 10.1146/annurev-chembioeng-061010-114252. [DOI] [PubMed] [Google Scholar]

- 7.Torralba-Calleja, E., Skinner, J., Gutierrez-Tauste, D., CO2 capture in ionic liquids: a review of solubilities and experimental methods. J.Chem. (2013) (articleID473584).

- 8.Rochelle GT. Amine scrubbing for CO2 capture. Science. 2009;325:1652–1654. doi: 10.1126/science.1176731. [DOI] [PubMed] [Google Scholar]

- 9.Keskin S, Sholl DS. Selecting metal organic frameworks as enabling materials in mixed matrix membranes for high efficiency natural gas purification. Energy Environ. Sci. 2010;3:343–351. doi: 10.1039/b923980b. [DOI] [Google Scholar]

- 10.Mason JA, McDonald TM, Bae TH, Bachman JE, Sumida K, Dutton JJ, Kaye SS, Long JR. Application of a high-throughput analyzer in evaluating solid adsorbents for post-combustion carbon capture via multicomponent adsorption of CO2, N2, and H2O. J. Am. Chem. Soc. 2015;137:4787–4803. doi: 10.1021/jacs.5b00838. [DOI] [PubMed] [Google Scholar]

- 11.Zhou HC, Long JR, Yaghi OM. Introduction to metal–organic frameworks. Chem. Rev. 2012;112:673–674. doi: 10.1021/cr300014x. [DOI] [PubMed] [Google Scholar]

- 12.Sumida K, Rogow DL, Mason JA, McDonald TM, Bloch ED, Herm ZR, Bae TH. Carbon dioxide capture in metal–organic frameworks, J. R. Long. Chem. Rev. 2012;112:724–781. doi: 10.1021/cr2003272. [DOI] [PubMed] [Google Scholar]

- 13.Nugent P, Giannopoulou EG, Burd SD, Elemento O, Giannopoulou EG, Forrest K, Pham T, Ma S, Space B, Wojtas L, Eddaoudi M, Zaworotko MJ. Porous materials with optimal adsorption thermodynamics and kinetics for CO2 separation. Nature. 2013;49:80–84. doi: 10.1038/nature11893. [DOI] [PubMed] [Google Scholar]

- 14.Lee JY, Tang CY, Huo F. Fabrication of porous matrix membrane (PMM) using metal-organic framework as green template for water treatment. Sci. Rep. 2014;4:1–5. doi: 10.1038/srep03740. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.EruÅar I, Yılmaz G, Keskin S. Recent advances in metal–organic framework-based mixed matrix membranes. Chem. Asian J. 2013;8:1692–1704. doi: 10.1002/asia.201300084. [DOI] [PubMed] [Google Scholar]

- 16.Li H, Wang K, Sun Y, Lollar CT, Li J, Zhou HC. Recent advances in gas storage and separation using metal–organic frameworks. Mater. Today. 2018;21:108–121. doi: 10.1016/j.mattod.2017.07.006. [DOI] [Google Scholar]

- 17.Foo ML, Horike S, Fukushima T, Hijikata Y, Kubota Y, Takata M, Kitagawa S. Ligand-based solid solution approach to stabilisation of sulphonic acid groups in porous coordination polymer Zr6O4(OH)4(BDC)6 (UiO-66) Dalton Trans. 2012;41:13791–13794. doi: 10.1039/c2dt31195j. [DOI] [PubMed] [Google Scholar]

- 18.Parshamoni S, Sanda S, Jena HS, Konar S. Tuning CO2 uptake and reversible iodine adsorption in two isoreticular MOFs through ligand functionalization. Chem. Asian J. 2015;10(10):653–660. doi: 10.1002/asia.201403123. [DOI] [PubMed] [Google Scholar]

- 19.Sarwono A, Man Z, Idris A, Khan AS, Muhammad N, Wilfred CD. Optimization of ionic liquid assisted sugar conversion and nanofiltration membrane separation for 5-hydroxymethylfurfural. J. Ind. Eng. Chem. 2019;69:171–178. doi: 10.1016/j.jiec.2018.09.020. [DOI] [Google Scholar]

- 20.Iqbal J, Muhammad N, Rahim A, Khan AS, Ullah Z, Gonfa G, Ahmad P. COSMO-RS predictions, hydrogen bond basicity values and experimental evaluation of amino acid-based ionic liquids for lignocellulosic biomass dissolution. J. Mol. Liq. 2019;273:215–221. doi: 10.1016/j.molliq.2018.10.044. [DOI] [Google Scholar]

- 21.Ullah Z, Bustam MA, Man Z, Khan AS. Thermal stability and kinetic study of benzimidazolium based ionic liquid. Proc. Eng. 2016;148:215–222. doi: 10.1016/j.proeng.2016.06.577. [DOI] [Google Scholar]

- 22.Cui GK, Wang JJ, Zhang SJ. Active chemisorption sites in functionalized ionic liquids for carbon capture. Chem. Soc. Rev. 2016;45:4307–4339. doi: 10.1039/C5CS00462D. [DOI] [PubMed] [Google Scholar]

- 23.Earle MJ, Esperanca J, Gilea MA, Lopes JNC, Rebelo LPN, Magee JW, Seddon KR, Widegren JA. The distillation and volatility of ionic liquids. Nature. 2006;439:831–834. doi: 10.1038/nature04451. [DOI] [PubMed] [Google Scholar]

- 24.MacDowell N, Florin N, Buchard A, Hallett J, Galindo A, Jackson G, Adji-man CS, Williams CK, Shah N, Fennell P. An overview of CO2 capture technologies. Energy Environ. Sci. 2010;3:1645–1669. doi: 10.1039/c004106h. [DOI] [Google Scholar]

- 25.Oliveira LT, Gonçalves RV, Gonçalves DV, de Azevedo DCS, Lucena SMP. Superior performance of mesoporous MOF MIL-100 (Fe) impregnated with ionic liquids for CO2 adsorption. J. Chem. Eng. Data. 2019;64(5):2221–2228. doi: 10.1021/acs.jced.8b01177. [DOI] [Google Scholar]

- 26.Vicent-Luna JM, Gutiérrez-Sevillano JJ, Hamad S, Anta JA, Calero S. Role of ionic liquid [EMIM]+[SCN]− in the adsorption and diffusion of gases in metal-organic frameworks. ACS Appl. Mater. Interfaces. 2018;10(35):29694–29704. doi: 10.1021/acsami.8b11842. [DOI] [PubMed] [Google Scholar]

- 27.Gupta KM, Chen Y, Jiang J. Ionic liquid membranes supported by hydrophobic and hydrophilic metal−organic frameworks for CO2 capture. J. Phys. Chem. C. 2013;117:5792–5799. doi: 10.1021/jp312404k. [DOI] [Google Scholar]

- 28.Gupta KM, Chen YZ, Hu Z, Jiang J. Metal–organic framework supported ionic liquid membranes for CO2 capture: Anion effects. Phys. Chem. Chem. Phys. 2012;14:5785–5794. doi: 10.1039/c2cp23972h. [DOI] [PubMed] [Google Scholar]

- 29.Mirzayi B, Basharnavaz H, Babapoor A, Kamali H, Khodayari A, Sohrabnezhad Sh. Effects of aluminum terephthalate metal–organic framework and its nanocomposites on the corrosion of AM60B magnesium alloy in ethylene glycol solution containing chloride ions. Mater. Chem. Phys. 2021;272:125056. doi: 10.1016/j.matchemphys.2021.125056. [DOI] [Google Scholar]

- 30.Shekaari H, Mehrdad A, Noorani N. Effect of some imidazolium based ionic liquids on the electrical conductivity of L(+)-lactic acid in aqueous solutions of poly(ethylene glycol) Fluid Phase Equilib. 2017;451:1–11. doi: 10.1016/j.fluid.2017.08.003. [DOI] [Google Scholar]

- 31.Mehrdad A, Shekaari H, Noorani N. Effect of 1-butyl-4-methylpyridinium and 1-butyl-3-methylimidazolium halide ionic liquids on the interactions of lactic acid in the aqueous solutions of polyethylene glycol. J. Chem. Thermodyn. 2017;112:188–195. doi: 10.1016/j.jct.2017.05.007. [DOI] [Google Scholar]

- 32.Holbrey JD, Seddon KR. The phase behaviour of 1-alkyl-3-methylimidazolium tetrafluoroborates; ionic liquids and ionic liquid crystals. J. Chem. Soc. Dalton Trans. 1999;213:2133–2140. doi: 10.1039/a902818h. [DOI] [Google Scholar]

- 33.Mehrdad A, Shekaari H, Noorani N. Density, speed of sound, and viscosity of aqueous solutions containing 1-alkyl-4-methylpyridinium bromide, lactic acid, and polyethylene glycol. J. Chem. Eng. Data. 2017;62:2021. doi: 10.1021/acs.jced.7b00033. [DOI] [Google Scholar]

- 34.Noorani N, Mehrdad A, Ahadzadeh I. CO2 absorption in amino acid-based ionic liquids: Experimental and theoretical studies. Fluid Phase Equilib. 2021;547:113185. doi: 10.1016/j.fluid.2021.113185. [DOI] [Google Scholar]

- 35.Noorani N, Mehrdad A, Chakhmaghi F. Thermodynamic study on carbon dioxide and methane permeability in polyvinylchloride/ionic liquid blends. Chem. Thermodyn. 2020;145:106094. doi: 10.1016/j.jct.2020.106094. [DOI] [Google Scholar]

- 36.Noorani N, Mehrdad A. Experimental and theoretical study of CO2 sorption in biocompatible and biodegradable cholinium-based ionic liquids. Sep. Purif. Technol. 2021;254:117609. doi: 10.1016/j.seppur.2020.117609. [DOI] [Google Scholar]

- 37.Noorani N, Mehrdad A. Cholinium-amino acid ionic liquids as biocompatible agents for carbon dioxide absorption. J. Mol. Liq. 2022;357:119078. doi: 10.1016/j.molliq.2022.119078. [DOI] [Google Scholar]

- 38.Noorani N, Mehrdad A, Zareidiznab R. Thermodynamic study on carbon dioxide absorption in vinyl imidazolium–amino acid ionic liquids. Fluid Phase Equilib. 2022;557:113433. doi: 10.1016/j.fluid.2022.113433. [DOI] [Google Scholar]

- 39.Langmuir I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918;40:1361–1403. doi: 10.1021/ja02242a004. [DOI] [Google Scholar]

- 40.Tempkin M, Pyzhev V. Kinetics of ammonia synthesis on promoted iron catalyst. Acta Phys. Chim. USSR. 1940;12:327. [Google Scholar]

- 41.Freundlich H. Over the adsorption in solution. J. Phys. Chem. 1906;57:1100–1107. [Google Scholar]

- 42.Khan AR, Al-Waheab I, Al-Haddad A. A generalized equation for adsorption isotherms for multi-component organic pollutants in dilute aqueous solution. Environ. Technol. 1996;17:13–23. doi: 10.1080/09593331708616356. [DOI] [Google Scholar]

- 43.Redlich O, Peterson DL. A useful adsorption isotherm. J. Phys. Chem. 1959;63(1024):1024–1024. doi: 10.1021/j150576a611. [DOI] [Google Scholar]

- 44.Sips R. On the structure of a catalyst surface. J. Chem. Phys. 1948;16:490–495. doi: 10.1063/1.1746922. [DOI] [Google Scholar]

- 45.Seoane B, Téllez C, Coronas J, Staudt C. NH2-MIL-53(Al) andNH2-MIL-101(Al) insulfur-containing copolyimide mixed matrix membranes for gas separation. Sep. Purif. Technol. 2013;111:72–81. doi: 10.1016/j.seppur.2013.03.034. [DOI] [Google Scholar]

- 46.Vimont A, Travert A, Bazin P, Lavalley JC, Daturi M, Serre C, Ferey G, Bourrelly S, Llewellyn PL. Evidence of CO2 molecule acting as an electron acceptor on a nanoporous metal–organic-framework MIL-53 or Cr3+(OH)(O2C–C6H4–CO2) Chem. Commun. 2007;21:3291–3293. doi: 10.1039/b703468g. [DOI] [PubMed] [Google Scholar]

- 47.Chowdhury T, Zhang L, Zhang J, Aggarwal S. Removal of arsenic (III) from aqueous solution using metal organic framework-graphene oxide nanocomposite. Nanomaterials. 2018;8:1062. doi: 10.3390/nano8121062. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Ramkumar T, Selvakumar M, Mohanraj M, Chandramohan P, Narayanasamy P. Microstructure and corrosion behavior of ZnO-Mg coating on AISI 4140 steel fabricated by spray coating. J. Mater. Eng. Perform. 2020;29:5796–5806. doi: 10.1007/s11665-020-05099-9. [DOI] [Google Scholar]

- 49.Loiseau T, Serre Ch, Huguenard C, Fink G, Taulelle F, Henry M, Bataille Th, Fÿrey G. A rationale for the large breathing of the porous aluminum terephthalate (MIL-53) upon hydration. Chem. Eur. J. 2004;10:1373–1382. doi: 10.1002/chem.200305413. [DOI] [PubMed] [Google Scholar]

- 50.Abedini R, Omidkhah MR, Dorosti F. Highly permeable poly(4-methyl-1-pentyne)/NH2-MIL 53 (Al) mixed matrix membrane for CO2/CH4 separation. RSC Adv. 2014;4:36522–36537. doi: 10.1039/C4RA07030E. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.