Abstract

Piezoelectric layers coupled to micromechanical resonators serve as the basis for sensors to detect a variety of different physical quantities. In contrast to passive sensors, actively operated sensors exploit a detuning of the resonance frequency caused by the signal to be measured. To detect the time-varying resonance frequency, the piezoelectric resonator is resonantly excited by a voltage, with this signal being modulated in both amplitude and phase by the signal to be measured. At the same time, the sensor signal is impaired by amplitude noise and phase noise caused by sensor-intrinsic noise sources that limit the reachable detectivities. This leads to the question of the optimum excitation frequency and the optimum readout type for such sensors. In this article, based on the fundamental properties of micromechanical resonators, a detailed analysis of the performance of piezoelectric resonators in amplitude mode and phase mode is presented. In particular, the sensitivities, the noise behavior, and the resulting limits of detection (LOD) are considered and analytical expressions are derived. For the first time, not only the influence of a static measurand is analyzed, but also the dynamic operation, i.e., physical quantities to be detected that quickly change over time. Accordingly, frequency-dependent limits of detection can be derived in the form of amplitude spectral densities. It is shown that the low-frequency LOD in phase mode is always about 6 dB better than the LOD in amplitude mode. In addition, the bandwidth, in terms of detectivity, is generally significantly larger in phase mode and never worse compared with the amplitude mode.

Keywords: AM, amplitude noise, cantilever, detectivity, limit of detection, magnetic field sensor, magnetoelastic delta-E effect, phase noise, PM, resonator, sensitivity

1. Introduction

Micromechanical cantilevers are among the simplest micromechanical resonators and are utilized to detect a variety of physical quantities. Generally, a microcantilever’s surface can adsorb molecules that generate surface stress where the adsorption of specific molecules can be achieved by coating one surface with a thin layer of a material that shows an affinity to certain molecules in the environment [1]. Instead of that adsorption mechanism, a functional layer can also be utilized to introduce surface stress (e.g., by utilizing a magnetostrictive layer) by way of nonmolecular quantities such as, e.g., magnetic fields [2]. The induced surface stress, in turn, affects the resonance frequency of the micromechanical resonator [3], the evaluation of which allows conclusions to be drawn about the respective physical quantity being measured (measurand). Among many other applications, resonant cantilever sensors for the detection of, e.g., humidity [3], heat [4], biomolecules [5,6], volatile organic compounds [7], explosives [8], magnetic fields [9,10,11,12,13,14], and atomic forces (atomic force microscopy, AFM) [15,16] have been presented.

Regardless of the physical quantity to be detected, the essential task of such measuring systems is to reconstruct the measurand by continuously detecting changes in the resonance frequency. One possibility, widely used in AFM, is to excite the cantilever in the vicinity of its resonance frequency utilizing a piezoelectric actuator while detecting the mechanical motion of the cantilever’s tip using a laser beam and a photosensitive detector ([17] p. 196). Concerning the signal-to-noise ratio (SNR), the optical beam deflection method is equivalent to the Michelson interferometer [18]. However, to eliminate the optical displacement sensor that occupies most of the space in such systems, piezoresistive [19], capacitive [20], and piezoelectric [21] readout schemes have been presented [22].

Micromechanical cantilevers combined with a piezoelectric layer offer the great advantage that the piezoelectric material can be used to drive the resonator, as well as to detect its state. Although more sophisticated structures have been presented [23], most piezoelectric cantilevers have two electrodes, so the cantilever can be interpreted as a simple electrical two-pole (one-port) with a lumped-element equivalent electrical circuit in accordance with Figure 1. Based on the analogies between mechanical and electromechanical systems [24], the electromechanical resonator can be modeled as an electrical series resonance circuit with the motional resistance , the motional capacitance , and the motional inductance [25]. The capacitance results from the two electrodes that typically form a plate capacitor around the piezoelectric layer. Its dielectric losses are covered by the resistance .

Figure 1.

Lumped-element equivalent electrical circuit of a piezoelectric resonator.

Apart from pulse mode operation, the two common continuous operation modes are often referred to as impedance-based measurement and oscillator-based measurement, respectively [25]. A closed-loop oscillator-based system contains a positive feedback network and generates an oscillating signal that is frequency-modulated (FM) by the measurand, while the signal’s amplitude is usually constant. On the contrary, open-loop impedance-based systems are characterized by amplitude-modulated (AM) and phase-modulated (PM) signals. Apart from practical differences between closed-loop and open-loop operation, FM and PM sensor systems are fully equivalent in terms of the minimum reachable limit of detection [26,27]. For open-loop operation, from previous studies it is known that the maximum sensitivity in AM mode is achieved by driving the resonator at a certain frequency [28] that is not equal to the frequency for which the sensitivity in PM mode is at its maximum [29]. However, a comprehensive analysis of the differences between AM and PM modes, especially with respect to the reachable frequency-dependent limits of detection, has not previously been performed and is presented in this article.

This article is organized as follows: Section 2 presents some fundamental characteristics of electromechanical resonators and introduces the properties of a magnetoelastic cantilever-type magnetic field sensor that is exemplarily utilized to illustrate the deduced relations. Section 3 presents the considered readout system utilized to reconstruct the time-varying physical quantity being measured. Both expressions for the frequency-dependent sensitivities, as well as frequency-dependent amplitude noise and phase noise, are deduced in Section 4 and Section 5, respectively. Based on these, Section 6 presents the resulting limits of detection. This article finishes with a summary of the findings in Section 7.

All expressions are given as a function of the two basic parameters of a resonator, the resonance frequency and the quality factor Q. However, please note that several simplifying assumptions are made. It is assumed that the quality factor is independent of the measurand, and , which allows us to neglect a resonance detuning due to mechanical losses. All given results apply not only to cantilever-type sensors but to all types of micromechanical resonators that can be described by a damped harmonic oscillator.

2. Sensor

2.1. Electromechanical Resonator

An oscillating cantilever with the quality factor Q, the angular resonance frequency , and the angular driving frequency can be described by the differential equation of motion of a damped driven harmonic oscillator

| (1) |

where is the time-varying position of the cantilever tip and is the deflection amplitude [30] (p. 454). Solving for the differential equation’s steady state results in the well-known solution in the form of the complex-valued unitless frequency response of a damped driven harmonic oscillator [30] (p. 454) [31] (p. 427) [32]

| (2) |

where is the imaginary number. For low-loss electromechanical resonators () that are operated in the vicinity of their resonance frequency, the expression for the frequency response can be simplified, yielding

| (3) |

with the amplitude frequency response

| (4) |

and the phase frequency response

| (5) |

Although the simplified frequency response (Equation (3)) is not a good approximation of the original frequency response (Equation (2)) far outside the resonance frequency, both the amplitude frequency response and the phase frequency response are well reproduced in the vicinity of the resonance frequency, as shown in Figure 2 for the exemplary cantilever that is described in more detail below in Section 2.3.

Figure 2.

Comparison of amplitude (a) and phase frequency responses (b) between the original expression for the frequency response of a damped harmonic oscillator (Equation (2)) and the simplified expression according to Equation (3). In the vicinity of the resonance frequency, the simplified frequency response is a good approximation for quality factors . The depicted frequency responses are based on the parameters specified in Table 1.

2.2. Sensor Admittance

The lumped-element equivalent electrical circuit of the electromechanical resonator has been introduced above and is depicted in Figure 1. Based on that network, the sensor’s admittance is simply given by

| (6) |

where the resistance covering for the dielectric losses is frequency-dependent and defined by the dielectric loss factor [33] (p. 568). However, in good approximation, can be considered constant if the sensor is operated in the vicinity of the resonance frequency. With both the resonance frequency and the quality factor as functions of the motional element’s values [33] (p. 402), the motional admittance

| (7) |

can be expressed as a function of the frequency response of a damped harmonic oscillator (Equation (2)). In the vicinity of the resonance frequency and for , the motional admittance simplifies to

| (8) |

Thus, a simplified expression for the sensor’s overall admittance yields

| (9) |

2.3. Exemplary Sensor

To illustrate the expressions derived in this article, the properties of an exemplary cantilever-type sensor are referred to. The micromechanical cantilever is designed for the detection of low-frequency magnetic fields ( Hz) in the picotesla regime. It is based on a polysilicon cantilever of 3 mm length, 1 mm width, and 50 μm thickness. The bottom side is coated with 2 μm of magnetostrictive metal ((Fe90Co10)78Si2B10) that affects the cantilever’s resonance frequency by inducing an additional strain depending on an ambient magnetic field. On the top side, a film of 2 μm aluminum-nitride (AlN) piezoelectric material, surrounded by two electrodes, is deposited.

Further details about this sensor [10,11] with a focus on the MEMS fabrication process [34], the magnetic properties [35,36], and the readout and noise behavior [12,29,37,38] can be found in the literature. All electromechanical and magnetic properties required here are summarized in Table 1, where defines the constant magnetic operating point, and thus, the resonator’s initial state. This bias is used to maximize the magnetically induced resonance shift, i.e., the magnetic sensitivity .

Table 1.

Electromechanical and magnetic properties of the exemplary magnetic field sensor referred to in this article.

| Property | Value |

|---|---|

| Static capacitance | |

| Loss factor | |

| Loss resistance | |

| Resonance frequency | |

| Quality factor | |

| Motional resistance | |

| Motional capacitance | |

| Motional inductance | |

| Magnetic operating point | |

| Magnetic sensitivity |

3. Sensor System

For operating the cantilever-type sensor, an electrical system as depicted in Figure 3 is considered [29]. The basic principle is based on driving both the sensor and a capacitive branch to neutralize the parallel resonance due to the cantilever’s static capacitance . For this, a differential input transimpedance/charge amplifier is utilized. Please note that the figure depicts a simplified illustration of such an amplifier. Refer to [39] for further details on differential input charge amplifiers. The excitation signal with the excitation amplitude and the excitation frequency leads to currents through the sensor and through the neutralization branch that, in the frequency domain, can be described by and where is the amplitude spectrum of .

Figure 3.

Electrical readout system for the measurement of a physical quantity (here, a magnetic flux density) that affects the resonance frequency of an electromechanical resonator. The sensor is driven in the vicinity of its resonance frequency by an electrical excitation signal , leading to an amplitude-modulated and phase-modulated signal at the output of a differential input transimpedance amplifier. A subsequent quadrature detector performs both the amplitude demodulation and the phase demodulation.

By means of the transimpedance both currents are transformed into the two voltage spectra

| (10) |

and

| (11) |

yielding a differential output voltage spectrum of

| (12) |

if the neutralization capacitance is matched to the sensor’s static capacitance . The dielectric losses taken into account by are important for the noise analysis in Section 5 below. However, due to its high resistance (compare Table 1), the impact of can be neglected here, yielding

| (13) |

This spectrum corresponds with the time domain signal

| (14) |

when considering that the resonator, i.e., (Equation (3)), is affected by an ambient magnetic flux density that consists of the constant bias to set the sensor’s magnetic operating point (initial state) and a time-dependent magnetic signal to be measured. Both the magnitude

| (15) |

and the phase

| (16) |

of the resonator’s frequency response can be described by a sum of a static term, defined by , and a (fractional) dynamic term that changes with . The coefficients of the dynamic terms are referred to as sensitivities in amplitude mode () and phase mode (), respectively. Expressions are given, and more details are discussed, in Section 4. Considering additional random fractional amplitude fluctuations and random phase fluctuations [40] (p. 3), the total differential voltage is given by

| (17) |

| (18) |

As depicted in Figure 3, the modulated signal is demodulated employing a quadrature detector, yielding the amplitude-demodulated voltage

| (19) |

and the phase-demodulated signal

| (20) |

if assuming that the two low-pass filters (LPF) ideally suppress the frequency components around .

4. Sensitivity

The sensitivity of resonant micromechanical sensors is composed of several partial sensitivities, which are described and derived below.

4.1. Functional Sensitivity

The functional sensitivity covers the relationship between the physical measurand to be detected and the frequency detuning of the micromechanical resonator. In the case of the magnetic field sensor used in this article to illustrate the results, the functional sensitivity is referred to as the magnetic sensitivity

| (21) |

with the physical dimension Hz/T. For other types of resonant sensors, the functional sensitivity could have, for example, the physical dimensions of Hz/K (temperature sensor), Hz/N (force sensor), or Hz/kg (mass sensor). Note that the functional sensitivity only depends on the sensor’s initial state, here set by the constant magnetic bias .

4.2. Electrical Sensitivity

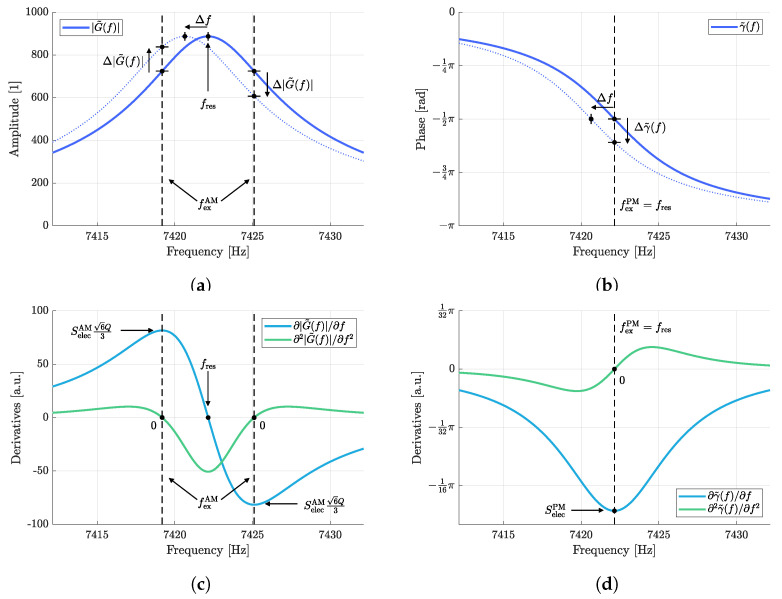

In addition to the influence of the physical measurand on the sensor’s resonance frequency, an additional sensitivity is required to characterize how the frequency detuning changes the sensor signal. Two sensitivities are required for this purpose, one covering the influence on the amplitude and the other the influence on the phase, where the two sensitivities are referred to as electrical sensitivities. The Figure 4a and Figure 4b illustrate the change in amplitude and in phase due to a detuned resonance frequency by . To determine the optimal excitation frequencies and the resulting sensitivities, the two first derivatives

| (22) |

and

| (23) |

as well as the two second derivatives

| (24) |

and

| (25) |

of the amplitude frequency response (Equation (4)) and the phase frequency response (Equation (5)), respectively, are required. These derivatives are depicted in Figure 4c,d and visualize that the maximum influence on the signal, i.e., the highest sensitivity, is given by the corresponding first derivative at those frequencies at which the second derivatives are zero. These frequencies are referred to as the optimum excitation frequencies.

Figure 4.

Illustration of the relations between shifted amplitude (a) and phase (b) frequency responses due to a detuned resonance frequency and the corresponding electrical sensitivities. Highest sensitivities are given by the corresponding first derivative at those frequencies at which the second derivatives are zero (c,d). These frequencies are referred to as the optimum excitation frequencies. The plots are based on the sensor parameters specified in Table 1.

Determining the roots of the second derivatives by solving for f and for f, respectively, yields the two optimum excitation frequencies for the amplitude mode

| (26) |

that agree with reported results in [28] and the optimum excitation frequency for the phase mode

| (27) |

At these optimum excitation frequencies, the values of the electrical sensitivities are given by

| (28) |

and

| (29) |

4.3. Dynamic Sensitivity

The functional sensitivity combined with the electrical sensitivity already gives the sensor’s total sensitivity with regard to static measurands, i.e., for a constant magnetic flux density. However, for dynamic measurements, i.e., if the signal to be measured is of the general form , the sensor’s sensitivity decreases for higher frequencies as shown in measurements [12]. This effect is taken into account by the so-called dynamic sensitivity. In normalized form, the dynamic sensitivity, which typically exhibits a low-pass behavior, can be calculated according to

| (30) |

where denotes a complex conjugate [41]. Because the optimum excitation frequencies differ in amplitude mode (Equation (26)) and in phase mode (Equation (26)), the AM dynamic sensitivity

| (31) |

also differs from the PM dynamic sensitivity

| (32) |

For both operation modes, the amplitude frequency responses and the phase frequency responses are depicted in Figure 5. The dB cutoff frequencies of

| (33) |

and

| (34) |

are almost identical. However, the amplitude response above the cutoff frequency decreases proportional to ( dB/decade) for AM, whereas the decrease for PM is only proportional to ( dB/decade).

Figure 5.

Illustrations of the dynamic sensitivities for amplitude mode and phase mode. The dB cutoff frequencies are almost identical, whereas the slopes of the amplitude frequency responses differ. The plots are based on the sensor parameters specified in Table 1. (a) amplitude frequency responses, (b) phase frequency responses.

4.4. Overall Sensitivity

For a certain operating point of the sensor, defined by the constant bias , the overall sensitivities are given by the products of the individual sensitivities and yield

| (35) |

| (36) |

and

| (37) |

| (38) |

for amplitude mode operation and phase mode operation, respectively.

5. Noise

A micromechanical sensor comprises several loss mechanisms which, according to the fluctuation–dissipation theorem [42], correspond with noise. In general, such losses can be taken into account in an electrical equivalent circuit in the form of dissipative elements, i.e., by electrical resistors. For piezoelectric resonators, and in accordance with the two resistors in the sensor’s electrical equivalent circuit in Figure 1, the loss mechanisms can be divided into two types.

Dielectric losses are affiliated with the sensor’s capacitor-like structure, i.e., to the piezoelectric material acting as the dielectric medium. These dielectric losses are considered by the loss factor with reported values for thin-film piezoelectric materials as low as, e.g., (aluminum-nitride, AlN) [43], (aluminum-scandium-nitride, AlScN) [44], and (lead-zirconate-titanate, PZT) [45]. The exemplary sensor referred to in this article exhibits a value of , thus resulting in a resistance in parallel to the static capacitance with a value in the vicinity of the resonance frequency of .

The predominant loss mechanism of micromechanical cantilevers under atmospheric pressure is usually air damping, commonly referred to as viscous damping. In addition, e.g., thermoelastic friction intrinsic to the solid structure, support losses, surface losses, and mounting losses may further attenuate the cantilever’s deflection, also expressed by its quality factor Q [46]. In the electrical equivalent circuit model, these losses are taken into account by the motional resistance .

In addition to these standard loss mechanisms, depending on the type of sensor, the special functional layer may introduce additional dominant losses, e.g., in the case of magnetostrictive films [29,38]. Such losses and the associated noise are not considered here. However, they can be taken into account using the same approach as shown below if necessary. Furthermore, the noise of the electronics is also neglected at this point, because corresponding amplifiers can generally be realized with very low noise [47], and likewise, at least the phase noise of the generator can be sufficiently suppressed [48].

5.1. Voltage Noise

Both the thermal electrical Johnson–Nyquist noise of the piezoelectric material acting as the capacitor’s dielectric and the thermal mechanical noise of the micromechanical resonator can be accurately predicted [38,47,49] based on the sensor’s electrical impedance. For the sensor readout system as depicted in Figure 3, the thermal voltage noise contributions related to the output of the differential input transimpedance amplifier are given by

| (39) |

and

| (40) |

if, as above, and are assumed as constant in the vicinity of the resonance frequency, where is the Boltzmann constant and the room temperature [29]. As expected, the thermal mechanical noise of the resonator is weighted by the magnitude of the frequency response of the damped harmonic oscillator, whereas the thermal electrical noise of the piezoelectric material is independent of the frequency [49]. Both statistically independent voltage noise densities of the sensor add up to

| (41) |

and are depicted in Figure 6 for the exemplary sensor without any excitation signal ().

Figure 6.

Noise contributions of the sensor to the overall voltage noise density at the output of the differential input transimpedance amplifier for the exemplary sensor described in Table 1, for feedback capacitances of , and without any excitation signal. Near the resonance frequency, the total noise is dominated by the thermal mechanical noise , whereas the thermal electrical noise becomes relevant only at some distance from .

5.2. Amplitude Noise and Phase Noise

To determine the relationship between the introduced voltage noise densities and the power spectral densities (PSD) and of the random amplitude fluctuations and random phase fluctuations , respectively, Equation (18) is written as

| (42) |

in which the measurement signal and the static phase offset, which are both irrelevant to the noise, are neglected. In this equation, one amplitude noise component and one phase noise component , both at the frequency , represent other spectral components that can be taken into account by linear superposition. Based on basic trigonometric identities, Equation (42) can be rearranged into

| (43) |

| (44) |

| (45) |

revealing the typical structures of an amplitude-modulated signal and a narrow-band small-signal phase-modulated signal, respectively, with a carrier at and symmetrical sidebands at . Following the concept of noise sidebands [50] (p. 243), both carrier-to-noise sideband ratios

| (46) |

are equal to the carrier-to-voltage noise ratio where the additional factor transforms the voltage noise density into an effective voltage noise in the bandwidth . Equation (46) directly yields the PSD of random amplitude fluctuations

| (47) |

in units of 1/Hz and the PSD of random phase fluctuations

| (48) |

in units of . Each PSD is composed of a constant component due to the thermal electrical noise of the piezoelectric material

| (49) |

| (50) |

and a frequency-dependent component

| (51) |

| (52) |

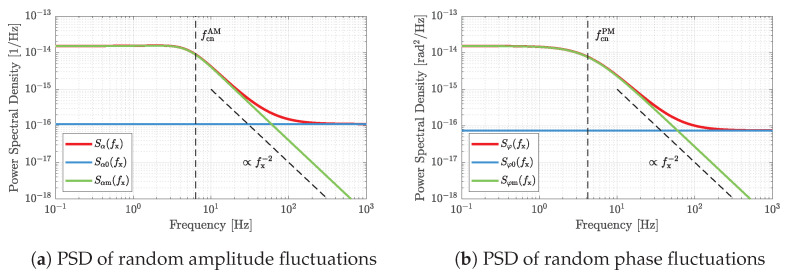

due to the thermal mechanical noise of the resonator. As illustrated in Figure 7, and decrease with 20 dB/decade for frequencies above the respective dB cutoff frequency of and . In contrast to parametric noise, all four noise components involved here are additive noise. Such noise is characterized by the fact that it can be reduced by increasing the excitation amplitude .

Figure 7.

Illustrations of the power spectral densities (PSD) of random amplitude fluctuations (a) and random phase fluctuations (b). Both are composed of a constant component due to the thermal electrical noise of the dielectric and a frequency-dependent component due to the thermal mechanical noise. The plots are based on the sensor parameters summarized in Table 1.

6. Detectivity

The frequency-dependent noise floor of a sensor system is usually given by a spectral density that is related to the unit of the physical quantity to be detected. For a physical quantity with the arbitrary unit , the representation of the sensor system’s noise floor could be given as a PSD of the fluctuations of the arbitrary quantity in units of . However, in general, it is more common to use the amplitude spectral density (ASD) of the fluctuations of the arbitrary quantity in units of , referred to as the limit of detection (LOD) or detectivity [26]. For the magnetic field sensor system considered in this article, the LOD is given in units of ; thus, it is also referred to as equivalent magnetic noise floor.

Depending on the operation mode, the LOD is given by the ratio of the ASD of random amplitude fluctuations and the overall amplitude sensitivity

| (53) |

or by the ratio of the ASD of random phase fluctuations and the overall phase sensitivity

| (54) |

In each case, the detectivity is limited by the same two physical noise sources. The limit due to the thermal electrical noise of the dielectric material yields

| (55) |

and

| (56) |

whereas the limit due to the thermal mechanical noise of the resonator is given by

| (57) |

and

| (58) |

Because both noise sources are additive noise (see above), the LOD can be improved in each case by increasing the excitation voltage . Figure 8 illustrates the detectivities for the exemplary magnetic field sensor considered in this article. For both operation modes, and in agreement with the previous noise analysis (see Figure 7), the low-frequency detectivities are limited by the thermal mechanical noise of the micromechanical resonator and are constant with the frequency. On the contrary, at higher frequencies and for both operating modes, the thermal electrical noise due to the piezoelectric layer limits the detectivity. While the detectivity in AM mode deteriorates with an increasing frequency proportional to , the detectivity in PM mode increases only proportional to (compare the slopes of the associated dynamic sensitivities in Figure 5). In addition, the different dynamic sensitivities lead to significantly different cutoff frequencies at which the initially frequency-independent detectivities increase or deteriorate. These +3 dB cutoff frequencies can be considered as the bandwidths of the sensor system and are given by

| (59) |

in AM mode and by

| (60) |

in PM mode, respectively. It can be shown that ; thus, the bandwidth in terms of the limit of detection can never be higher in AM mode than in PM mode. With regard to the minimum achievable limit of detection inside the bandwidth, a distinction should be made between limitations by the different noise sources. If the detectivity is limited by the thermal electrical noise of the dielectric material, a low-frequency ratio of

| (61) |

is obtained. For practical this relation approaches a value of . Similarly, if the detectivity is limited by the thermal mechanical noise of the resonator, the ratio is given by

| (62) |

which, also for quality factors , approaches a value of . Thus, independent of the dominant type of noise, the detectivity in PM mode is always more than 6 dB better compared with an operation in AM mode.

Figure 8.

Illustrations of the limits of detection in AM mode (a) and in PM mode (b). For both types of operation, the low-frequency detectivity is limited by the thermal mechanical noise of the resonator. The bandwidth in which the detectivity is constant with frequency is significantly higher in PM mode. In general, the bandwidth can never be higher in AM mode than in PM mode. In addition, independent of the dominant type of noise, the detectivity in PM mode is always more than 6 dB better compared with an operation in AM mode. The plots are based on the sensor parameters given in Table 1.

7. Conclusions

In this article, the performance of quasi-resonantly driven piezoelectric sensors operated in amplitude mode and phase mode has been investigated. Regardless of the physical quantity that a micromechanical sensor with a piezoelectric layer is designed to detect, changes in its resonance frequency result in both amplitude (AM) and phase modulation (PM) of the sensor signal if the sensor is operated in an open-loop configuration. The degree of the respective modulation is essentially determined by the frequency of the signal used to electrically excite the sensor.

The objective of the analysis presented here was to evaluate the respective performance in terms of the minimum reachable limit of detection (LOD) as a function of the frequency of the physical signal to be measured. Thus, based on the fundamental properties of micromechanical resonators, comprehensive analyses of the frequency-dependent sensitivities, as well as the frequency-dependent amplitude noise and phase noise, were performed and respective analytical expressions were derived. Different optimal excitation frequencies result for the two types of operation, and these also lead to different limits of detection. It has been shown that the low-frequency LOD in phase mode is always about 6 dB better than the LOD in amplitude mode. In addition, the bandwidth in terms of detectivity is generally significantly larger, and never worse, in phase mode compared with amplitude mode. Accordingly, an evaluation of the sensor signal’s phase with appropriate excitation of the sensor is generally preferable to an evaluation of the sensor signal’s amplitude.

To illustrate all the analytical relationships in this article, an exemplary piezoelectric magnetic field sensor was considered. In Table 2, all electromechanical parameters of this sensor, and further parameters of the employed sensor system, as well as various numerical values for the derived equations, are summarized.

Table 2.

Electromechanical properties of the exemplary magnetic field sensor referred to in this article and resulting numerical values for the derived equations.

| Property | Value for AM | Value for PM |

|---|---|---|

| Static capacitance | ||

| Loss factor | ||

| Loss resistance | ||

| Resonance frequency | ||

| Quality factor | ||

| Motional resistance | ||

| Motional capacitance | ||

| Motional inductance | ||

| Magnetic operating point | ||

| Magnetic sensitivity | ||

| Excitation amplitude | ||

| Feedback capacitance | ||

| Transimpedance | ||

| Excitation frequency | ||

| Electrical sensitivity | ||

| Sensitivity cutoff frequency () | ||

| Overall sensitivity | ||

| Thermal electrical voltage noise density | ||

| Thermal mechanical voltage noise density | ||

| Overall noise power spectral density | ||

| Noise cutoff frequency () | ||

| Overall detectivity | ||

| Overall detectivity cutoff frequency () | ||

Even if the exemplary sensor is a magnetic field sensor, all derived equations have general validity for all micromechanical sensors which can be described by the differential equation of motion of a damped driven harmonic oscillator (Equation (1)).

Several directions exist for the future continuation of the work presented here. First, confirmation of the theory developed here on the basis of measurements is advisable. Provided that the parasitic capacitance of the sensor is compensated as presented here, PM operation would always be preferred. However, it would also be interesting to compare AM and PM operation modes without neutralization, because the effective impedance leading to the electrical sensitivity can take a significantly different form. Due to the asymmetry caused by the additional parallel resonance, however, the calculations are considerably complicated, meaning that numerical simulation would possibly be more appropriate in this case.

Author Contributions

Conceptualization: P.D., Methodology: P.D., Software: P.D., Validation, P.D. and M.H., Formal analysis: P.D. and M.H., Investigation: P.D., Writing—original draft: P.D., Writing—review & editing: P.D. and M.H., Visualization: P.D. and M.H., Supervision: M.H., Project administration: M.H., Funding acquisition: M.H. All authors have read and agreed to the published version of the manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Funding Statement

This work was funded by the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG) through the Collaborative Research Centre CRC 1261 Magnetoelectric Sensors: From Composite Materials to Biomagnetic Diagnostics.

Footnotes

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

References

- 1.Lang H.P., Gerber C. Topics in Current Chemistry. Volume 285. Springer; Berlin/Heidelberg, Germany: 2008. Microcantilever Sensors; pp. 1–27. [DOI] [PubMed] [Google Scholar]

- 2.du Trémolet de Lacheisserie E., Peuzin J. Magnetostriction and internal stresses in thin films: The cantilever method revisited. J. Magn. Magn. Mater. 1994;136:189–196. doi: 10.1016/0304-8853(94)90464-2. [DOI] [Google Scholar]

- 3.Chen G.Y., Thundat T., Wachter E.A., Warmack R.J. Adsorption-induced surface stress and its effects on resonance frequency of microcantilevers. J. Appl. Phys. 1995;77:3618–3622. doi: 10.1063/1.359562. [DOI] [Google Scholar]

- 4.Barnes J.R., Stephenson R.J., Welland M.E., Gerber C., Gimzewski J.K. Photothermal spectroscopy with femtojoule sensitivity using a micromechanical device. Nature. 1994;372:79–81. doi: 10.1038/372079a0. [DOI] [Google Scholar]

- 5.Ziegler C. Cantilever-based biosensors. Anal. Bioanal. Chem. 2004;379:946–959. doi: 10.1007/s00216-004-2694-y. [DOI] [PubMed] [Google Scholar]

- 6.Lee J.H., Hwang K.S., Park J., Yoon K.H., Yoon D.S., Kim T.S. Immunoassay of prostate-specific antigen (PSA) using resonant frequency shift of piezoelectric nanomechanical microcantilever. Biosens. Bioelectron. 2005;20:2157–2162. doi: 10.1016/j.bios.2004.09.024. [DOI] [PubMed] [Google Scholar]

- 7.Kilinc N., Cakmak O., Kosemen A., Ermek E., Ozturk S., Yerli Y., Ozturk Z.Z., Urey H. Fabrication of 1D ZnO nanostructures on MEMS cantilever for VOC sensor application. Sensors Actuators Chem. 2014;202:357–364. doi: 10.1016/j.snb.2014.05.078. [DOI] [Google Scholar]

- 8.Yinon J. Peer Reviewed: Detection of Explosives by Electronic Noses. Anal. Chem. 2003;75:98 A–105 A. doi: 10.1021/ac0312460. [DOI] [Google Scholar]

- 9.Osiander R., Ecelberger S.A., Givens R.B., Wickenden D.K., Murphy J.C., Kistenmacher T.J. A microelectromechanical-based magnetostrictive magnetometer. Appl. Phys. Lett. 1996;69:2930–2931. doi: 10.1063/1.117327. [DOI] [Google Scholar]

- 10.Gojdka B., Jahns R., Meurisch K., Greve H., Adelung R., Quandt E., Knöchel R., Faupel F. Fully integrable magnetic field sensor based on delta-E effect. Appl. Phys. Lett. 2011;99:223502. doi: 10.1063/1.3664135. [DOI] [Google Scholar]

- 11.Jahns R., Zabel S., Marauska S., Gojdka B., Wagner B., Knöchel R., Adelung R., Faupel F. Microelectromechanical magnetic field sensor based on Δ E effect. Appl. Phys. Lett. 2014;105:052414. doi: 10.1063/1.4891540. [DOI] [Google Scholar]

- 12.Zabel S., Kirchhof C., Yarar E., Meyners D., Quandt E., Faupel F. Phase modulated magnetoelectric delta-E effect sensor for sub-nano tesla magnetic fields. Appl. Phys. Lett. 2015;107:152402. doi: 10.1063/1.4932575. [DOI] [Google Scholar]

- 13.Park Y., Lee E., Kouh T. Field-Dependent Resonant Behavior of Thin Nickel Film-Coated Microcantilever. Micromachines. 2017;8:109. doi: 10.3390/mi8040109. [DOI] [Google Scholar]

- 14.Zhang Z., Wu H., Sang L., Takahashi Y.K., Huang J., Wang L., Toda M., Akita I.M., Koide Y., Koizumi S., et al. Enhancing Delta E Effect at High Temperatures of Galfenol-Ti-Single Crystal Diamond Resonators for Magnetic Sensing. ACS Appl. Mater. Interfaces. 2020;12:23155–23164. doi: 10.1021/acsami.0c06593. [DOI] [PubMed] [Google Scholar]

- 15.Giessibl F.J. Advances in atomic force microscopy. Rev. Mod. Phys. 2003;75:949–983. doi: 10.1103/RevModPhys.75.949. [DOI] [Google Scholar]

- 16.Butt H.J., Cappella B., Kappl M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005;59:1–152. doi: 10.1016/j.surfrep.2005.08.003. [DOI] [Google Scholar]

- 17.Voigtlander B. Scanning Probe Microscopy. Springer; Berlin/Heidelberg, Germany: 2015. NanoScience and Technology. [Google Scholar]

- 18.Putman C.A.J., De Grooth B.G., Van Hulst N.F., Greve J. A detailed analysis of the optical beam deflection technique for use in atomic force microscopy. J. Appl. Phys. 1992;72:6–12. doi: 10.1063/1.352149. [DOI] [Google Scholar]

- 19.Tortonese M., Barrett R.C., Quate C.F. Atomic resolution with an atomic force microscope using piezoresistive detection. Appl. Phys. Lett. 1993;62:834–836. doi: 10.1063/1.108593. [DOI] [Google Scholar]

- 20.Göddenhenrich T., Lemke H., Hartmann U., Heiden C. Force microscope with capacitive displacement detection. J. Vac. Sci. Technol. Vac. Surfaces Film. 1990;8:383–387. doi: 10.1116/1.576401. [DOI] [Google Scholar]

- 21.Itoh T., Suga T. Development of a force sensor for atomic force microscopy using piezoelectric thin films. Nanotechnology. 1993;4:218–224. doi: 10.1088/0957-4484/4/4/007. [DOI] [Google Scholar]

- 22.Lee C. Development of a piezoelectric self-excitation and self-detection mechanism in PZT microcantilevers for dynamic scanning force microscopy in liquid. J. Vac. Sci. Technol. Microelectron. Nanometer Struct. 1997;15:1559. doi: 10.1116/1.589400. [DOI] [Google Scholar]

- 23.Mahdavi M., Coskun M.B., Moheimani S.O.R. High Dynamic Range AFM Cantilever With a Collocated Piezoelectric Actuator-Sensor Pair. J. Microelectromechanical Syst. 2020;29:260–267. doi: 10.1109/JMEMS.2020.2967794. [DOI] [Google Scholar]

- 24.Bloch A. Electromechanical analogies and their use for the analysis of mechanical and electromechanical systems. J. Inst. Electr. Eng. Part Gen. 1945;92:157–169. doi: 10.1049/ji-1.1945.0039. [DOI] [Google Scholar]

- 25.Park J.Y., Choi J.W. Review—Electronic Circuit Systems for Piezoelectric Resonance Sensors. J. Electrochem. Soc. 2020;167:037560. doi: 10.1149/1945-7111/ab6cf7. [DOI] [Google Scholar]

- 26.Durdaut P., Höft M., Friedt J.M., Rubiola E. Equivalence of Open-Loop and Closed-Loop Operation of SAW Resonators and Delay Lines. Sensors. 2019;19:185. doi: 10.3390/s19010185. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Durdaut P., Kittmann A., Rubiola E., Friedt J.M., Quandt E., Knöchel R., Höft M. Noise Analysis and Comparison of Phase- and Frequency-Detecting Readout Systems: Application to SAW Delay Line Magnetic Field Sensor. IEEE Sens. J. 2019;19:8000–8008. doi: 10.1109/JSEN.2019.2914965. [DOI] [Google Scholar]

- 28.Martin Y., Williams C.C., Wickramasinghe H.K. Atomic force microscope–orce mapping and profiling on a sub 100-Å scale. J. Appl. Phys. 1987;61:4723–4729. doi: 10.1063/1.338807. [DOI] [Google Scholar]

- 29.Durdaut P., Rubiola E., Friedt J.M., Müller C., Spetzler B., Kirchhof C., Meyners D., Quandt E., Faupel F., McCord J., et al. Fundamental Noise Limits and Sensitivity of Piezoelectrically Driven Magnetoelastic Cantilevers. J. Microelectromechanical Syst. 2020;29:1347–1361. doi: 10.1109/JMEMS.2020.3014402. [DOI] [Google Scholar]

- 30.Bhushan B., editor. Springer Handbook of Nanotechnology. Springer; Berlin/Heidelberg, Germany: 2004. [Google Scholar]

- 31.Heer C.V. Statistical Mechanics, Kinetic Theory, and Stochastic Processes. Academic Press; New York, NY, USA: 1972. [Google Scholar]

- 32.Kobayashi K., Yamada H., Matsushige K. Frequency noise in frequency modulation atomic force microscopy. Rev. Sci. Instrum. 2009;80:043708. doi: 10.1063/1.3120913. [DOI] [PubMed] [Google Scholar]

- 33.Bird J. Electrical Circuit Theory and Technology. 5th ed. Routledge; New York, NY, USA: 2014. [Google Scholar]

- 34.Kirchhof C. Ph.D. Thesis. Kiel University; Kiel, Germany: 2017. Resonante Magnetoelektrische Sensoren zur Detektion Niederfrequenter Magnetfelder. [Google Scholar]

- 35.Urs N.O., Teliban I., Piorra A., Knöchel R., Quandt E., McCord J. Origin of hysteretic magnetoelastic behavior in magnetoelectric 2-2 composites. Appl. Phys. Lett. 2014;105:202406. doi: 10.1063/1.4901948. [DOI] [Google Scholar]

- 36.Urs N.O., Golubeva E., Röbisch V., Toxvaerd S., Deldar S., Knöchel R., Höft M., Quandt E., Meyners D., McCord J. Direct Link between Specific Magnetic Domain Activities and Magnetic Noise in Modulated Magnetoelectric Sensors. Phys. Rev. Appl. 2020;13:024018. doi: 10.1103/PhysRevApplied.13.024018. [DOI] [Google Scholar]

- 37.Reermann J., Zabel S., Kirchhof C., Quandt E., Faupel F., Schmidt G. Adaptive Readout Schemes for Thin-Film Magnetoelectric Sensors Based on the delta-E Effect. IEEE Sens. J. 2016;16:4891–4900. doi: 10.1109/JSEN.2016.2553962. [DOI] [Google Scholar]

- 38.Durdaut P., Reermann J., Zabel S., Kirchhof C., Quandt E., Faupel F., Schmidt G., Knöchel R., Höft M. Modeling and Analysis of Noise Sources for Thin-Film Magnetoelectric Sensors Based on the Delta-E Effect. IEEE Trans. Instrum. Meas. 2017;66:2771–2779. doi: 10.1109/TIM.2017.2709478. [DOI] [Google Scholar]

- 39.Massarotto M., Carlosena A., Lopez-Martin A.J. Two-Stage Differential Charge and Transresistance Amplifiers. IEEE Trans. Instrum. Meas. 2008;57:309–320. doi: 10.1109/TIM.2007.909498. [DOI] [Google Scholar]

- 40.Rubiola E. Phase Noise and Frequency Stability in Oscillators. Cambridge University Press; Cambridge, UK: 2009. [Google Scholar]

- 41.Mertz J., Marti O., Mlynek J. Regulation of a microcantilever response by force feedback. Appl. Phys. Lett. 1993;62:2344–2346. doi: 10.1063/1.109413. [DOI] [Google Scholar]

- 42.Callen H.B., Welton T.A. Irreversibility and Generalized Noise. Phys. Rev. 1951;83:34–40. doi: 10.1103/PhysRev.83.34. [DOI] [Google Scholar]

- 43.Yarar E., Hrkac V., Zamponi C., Piorra A., Kienle L., Quandt E. Low temperature aluminum nitride thin films for sensory applications. AIP Adv. 2016;6:075115. doi: 10.1063/1.4959895. [DOI] [Google Scholar]

- 44.Fichtner S., Wolff N., Krishnamurthy G., Petraru A., Bohse S., Lofink F., Chemnitz S., Kohlstedt H., Kienle L., Wagner B. Identifying and overcoming the interface originating c-axis instability in highly Sc enhanced AlN for piezoelectric micro-electromechanical systems. J. Appl. Phys. 2017;122:035301. doi: 10.1063/1.4993908. [DOI] [Google Scholar]

- 45.Piorra A., Jahns R., Teliban I., Gugat J.L., Gerken M., Knöchel R., Quandt E. Magnetoelectric thin film composites with interdigital electrodes. Appl. Phys. Lett. 2013;103:032902. doi: 10.1063/1.4812706. [DOI] [Google Scholar]

- 46.Weinberg M., Candler R., Chandorkar S., Varsanik J., Kenny T., Duwel A. Energy loss in MEMS resonators and the impact on inertial and RF devices; Proceedings of the 15th International Conference on Solid-State Sensors, Actuators and Microsystems; Kyoto, Japan. 21–25 June 2009; pp. 688–695. [DOI] [Google Scholar]

- 47.Durdaut P., Penner V., Kirchhof C., Quandt E., Knöchel R., Höft M. Noise of a JFET Charge Amplifier for Piezoelectric Sensors. IEEE Sens. J. 2017;17:7364–7371. doi: 10.1109/JSEN.2017.2759000. [DOI] [Google Scholar]

- 48.Durdaut P., Kittmann A., Bahr A., Quandt E., Knöchel R., Höft M. Oscillator Phase Noise Suppression in Surface Acoustic Wave Sensor Systems. IEEE Sens. J. 2018;18:4975–4980. doi: 10.1109/JSEN.2018.2832289. [DOI] [Google Scholar]

- 49.Durdaut P., Salzer S., Reermann J., Hayes P., Meyners D., Quandt E., Schmidt G., Knöchel R., Höft M. Thermal-Mechanical Noise in Resonant Thin-Film Magnetoelectric Sensors. IEEE Sens. J. 2017;17:2338–2348. doi: 10.1109/JSEN.2017.2671442. [DOI] [Google Scholar]

- 50.Lance A.L., Seal W.D., Labaar F. Infrared and Millimeter Waves. Volume 11 Academic Press, Inc.; Orlando, FL, USA: 1984. Phase Noise and AM Noise Measurements in the Frequency Domain. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.