Abstract

Purpose

In the context of the food industry, this research investigates the impact of green supply chain management (GSCM) on environmental health. This helps the practitioners and policy makers in mitigation of the supply chain (SC) risks and enhance the environmental health level.

Design/methodology/approach

The study's model was structured using GSC risk factors of green purchasing, environmental cooperation, reverse logistics, eco design, internal environmental management, and investment recovery. A questionnaire-based survey was used to examine the proposed model; 102 data from the senior managers of food firms in Lebanon were collected. Using SPSS and AMOS statistical software, an exploratory factor analysis (EFA), a confirmatory factor analysis (CFA), and multiple regressions have been applied.

Findings

The outcome of structural equation modeling (SEM) revealed that four of six GSC risk factors were significantly related to environmental health. The study findings can be applied to the external level through many green practices in cooperation with suppliers and customers like the collaboration with them on environmentally friendly design, purchasing, production, packaging and using less energy. This can increase the level of environmental health by decreasing the impact of SCM risks. Regarding the internal level, many procedures and decisions may lead to an environmentally friendly ambience in the firms like the commitment of GSCM practices from the management and the implementation of internal eco-performance evaluation system. This may enhance the environmental health provisions by setting up an action plan to mitigate the GSC risk and address the sustainable health objectives.

Originality

The paper's distinctiveness comes from the fact that it fills a gap in the literature regarding the few numbers of studies that treat the green supply chain management GSCM as mitigation solution for the risks of SCM. In addition, there were no studies explain the relationship between GSCM and environmental health; this will be the first time the assess the impacts of GSCM practices on environmental health in the food industry.

Keywords: Green supply chain risk management, Environmental health, Food industry sector

Abbreviations: GSCM, Green Supply Chain Management; ED, Eco-Design; IEM, Internal Environmental Management; IR, Investment Recovery; GP, Green Purchasing; EC, Environmental Cooperation; RL, Reverse Logistics; NRBV, Natural Resource-Based View

1. Introduction

Concerns regarding the preservation of natural resources and the avoidance of unrecoverable costs on the earth are increasing. These costs are incurred and augmented as a consequence of environmental impacts, societal hazards and economical failures. Sustainable goals can be reached by adopting a green supply chain management (GSCM) scheme from an early stage of production to consumption by the final user [1].

One of the most main industries that face considerable environmental concerns is the food industry. This is because food safety, manufacturing processes, environmental factors like deforestation, climate change, and energy use are receiving the world attention [2,3]. Accordingly, the improvements in supply chain interactions that strive for high environmental performance are typical concerns of the food industry [2]. In addition, the environmental impact of food supply chains has come under scrutiny due to globalization, technological innovations and the use of agrochemicals [4,5], as changes at one level in a supply chain will have pull effects on other levels throughout the chain [5].

This study is applied on the food industry in Lebanon, where this sector is the most important among manufacturing activities. According to the Ministry of Industry, the activity has the most industrial establishments, with 1219 producers accounting for 18.2% of all industrial firms. 450 of these firms are registered members of one of the four chambers: 280 (more than half of the manufacturers) in the Beirut and Mount Lebanon Chamber, 137 in the Zahle Chamber, 86 in the Saida Chamber, and 71 in the Tripoli Chamber. According to the Ministry of Industry's most recent census, "The Lebanese Industrial Sector" (2017), the following activities dominate the industrial sector on six counts:

-

•

It provides the greatest proportion of the industrial labor force (24.9%);

-

•

It accounts for the largest share of manufacturing capacity (25.7%);

-

•

It accounts for the major chunk of advanced manufacturing value added (26.9%);

-

•

Its tangible resources are the industrial sector's largest, accounting for 13.9% of the total;

-

•

Its investment spending is the sector's highest, budgeting for 30.5% of the total; and its exports account for 18% of the country's total exports in 2017, second only to jewelry exports, which reimburse their first place to precious-metal composition of high value

Lebanese customers are growing more conscious of the need of ethical and sustainable production. They aim to ensure that F&B manufacturers use best practices at every stage of the production process, from raw materials to final product delivery. Many clients want to ensure that the items they are buying meet international standards (HACCP; GMP; ISO certified). Customers also appreciate hearing that food manufacturers have a corporate social responsibility policy, are altruistic, and give back to their community.

Until now, GSCM literature has concentrated on the automotive, electronics and manufacturing industries [6]. The previous studies aimed at identifying the linkage between GSCM and sustainable development, GSCM and the circular economy, or GSCM and other topics, including environmental, economic, operational, social or green innovation performances [7]. However, the major contribution of this study is to test the linkage between GSCM risk factors and environmental health in the context of the food industry. Several studies in the literature addressed GSCM application in food organization performance [8], developing green management in restaurants [9,10], in farming and agribusiness to the urban supply point [11].

The main motivation of this research was to fill the gap regarding the linkage between GSCM and environmental health. This study is concerned with large production and consumption of hazardous and wasteful food which cause growing environment and health problems. These problems were behind the risk of increasing in preventable diseases, early deaths, and environmental disasters through the entire world [12].

Accordingly, this study is important since it has a significant contribution by bridging the food supply chain and environmental health. Recently, the imposition of risk on people's health and contagious have become known due to unhealthy production and consumption. Last but not least, GSCM adopts efficient methods to tackle with shortages, resource scarcity and food insecurity.

Therefore, this research suggests an action plan to mitigate the risks of supply chain management (SCM) with the intention of identifying and refuting the environmental health risk through the application of GSCM. . The main question of the study is that could it be possible to consider the GSCM as solution to mitigate the SCM risk in the context of food industry?

2. Literature review

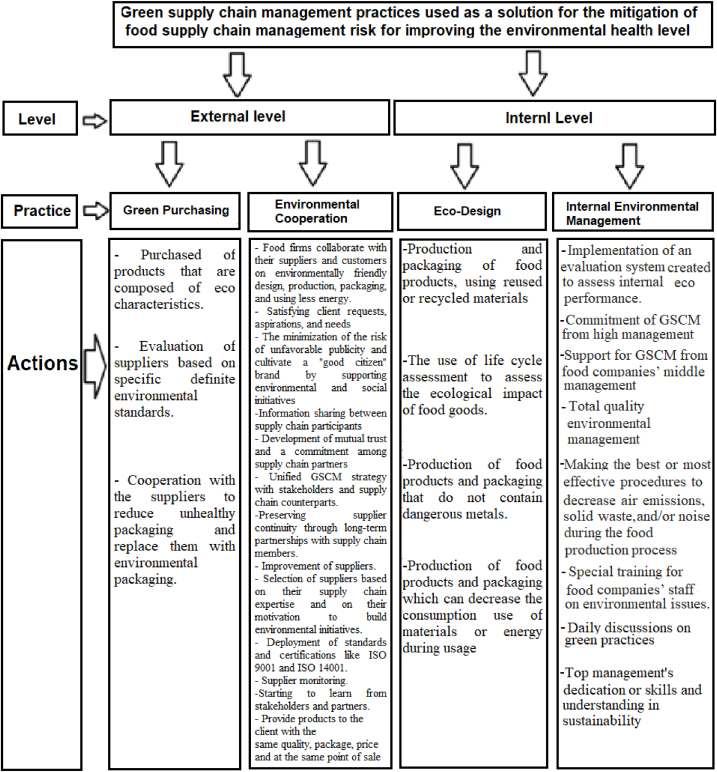

In this section, as cleared in Fig. 1, the authors will extract from the previous studies what is the meaning of GSCM, the concept of environmental health, then the risks of the SCM on the environmental health and their management, how can the GSCM be a solution for eliminate the risks of SCM on the environmental health and finally, describe the theory used in this study.

-

-

Green supply chain management (GSCM):

Fig. 1.

Relationship between SCM risks, environmental health and GSCM.

The concept of supply chain management is the collection of tasks conducted in an organization to enhance management of its supply chain [13]. On the other hand, the GSCM, considered as expansion of the known supply chain, includes activities that lead to the decreasing of the environmental risks of a product during its whole life cycle. There are several activities related to GSCM, including green design, saving of resources, harmful material reducing, recycling or reusing of product [14] reverse logistics, green packaging, green manufacturing and green purchasing [15]. Accordingly, GSCM is an innovative and creative solution to increase a company's production and competence, including manufacturing organizations in the food sector, and to achieve sustainability [16].

The literature discusses a variety of GSCM practices, which share the same primary goal that is the enhancement of supply chain environmental performance [17].

The area of GSCM practices application extends from green purchasing to incorporated implementation of the supply chains. GSCM overlays all steps of the life cycle of a product starting from planning, fabrication, and selling steps to the last consumer's consumption of products and their final disposal [18].

The linkage between GSCM and organizational environmental performance has been tested by multiple studies. We can benefit from these studies’ outcomes in order to have a look on the relationship between the GSCM and environmental dimension from which the environmental health is derived.

Concerning the impact of GSCM on the environmental dimension, organizations have to broaden environmental management practices outside the internal limitations. This environmental management should coordinate suppliers and customers to maintain ecological responsibility in their operations [19]. GSCM is considered as a tool of successful strategic management that enhances the environmental performance of industrial companies [20,21]. As result, GSCM practices positively affect environmental performance, leading to environmental improvements [22,23].

This study used the most relevant GSCM practices based on previous studies. The table below summarizes the most used GSCM practices in the previous studies with their resources:

The most used practices of Green Purchasing, Environmental Cooperation, Reverse Logistics, Eco-Design, Internal Environmental Management, and Investment Recovery are considered as risk factors that may affect negatively the level of environmental health if they are not applied by the food industry firms.

-

-

Environmental health:

As for the concept of environment, it encompasses a physical environment having external circumstances and encirclement that influence people's, animals', and plants' living conditions. In turn, the physical environment is divided into two categories: built environment that includes constructions, spaces, and transportation infrastructure constructed or modified by humans, and natural environments which are not caused by human intervention [24].

Studying the human's health and well-being, as part of the environmental health, is the first phase towards understanding the population's essential demands. This recognition facilitates an efficient health and social policy solutions [25]. On the other hand, environmental health cannot be restricted to public health. There is a great tension for ameliorating public and environmental health through cooperation with the social sciences [26]. Therefore, environmental health is “dynamic and complex, with an interdependence of the environment and health within the socioeconomic structure” [27]. The relationships between social factors, human welfare and the physical environment will participate in providing long-term environmental sustainability [28].

The interventions and practices of Environmental health are significant for effective disaster response in communities in several ways. First, they can reduce vulnerability to hazards, increase the ability to respond successfully to disruption, and assist in rapid recovery. Second, they encourage organizational collaboration on danger identification and risk estimation. Third, they improve everyday services to lessen the impact of emergencies and disasters on people's health. Fourth, they consider the environmental health factors of safe water quantity and quality, sanitation, and waste management, and other factors such as food security, infectious diseases, transmission issues, or mass assemblage [29].

-

-

Risks of the SCM on the environmental health:

The food industry is at the heart of many of the United Nations' Sustainable Development Goals (SDGs). One of the SDG tied to food production and consumption is the goal of good health and well-being [30]. The realization of this goal is important for the increasing of the environmental health level.

The food supply chain is formed of connected entities working in the fabrication and selling of predetermined foods from raw materials to end-of-chain transmission, to fulfill consumer demand. Efficient management of this supply chain should increase sales while reducing costs and should profit from the full advantages of business such as quality, safety and hygiene that ought to be underpinned throughout the process [31].

On the other hand, the supply chain disturbances are mainly brought on by both internal and external factors. The internal factors include accidents, theft, contamination, and sabotage, while the external factors include strikes, legal conflicts, and natural disasters [[32], [33], [34]].

Producing enough food to feed a growing population while addressing negative environmental implications is considered as a major challenge that faces the food companies [35]. Therefore, the food industry is one of the world's largest sectors that has a significant ecological footprint [36]. For example, the consumption of food products leads to environmental risks through the land-use and the air emissions. To face these risks, an adequate policy instruments is needed by executing strong and timely statistics at sectorial, regional, and global levels (United Nations Sustainable Development solution Network [30].

Although food is necessary for good health and well-being; emissions from food production have indirect effects on human health due to the exposure to harmful food industry toxins generation [37]. This is why food safety and security are critical issues around the world. Food and agricultural products are closely tied to public health; yet the literature has not fully looked into it. Consequently, researches that interpret the main links between society, environment, and public health are urgently needed. Many actions are needed to interpret the societal, health and environmental constraints that we confront [27]. Yet, there are no researches in literature testing the effect of food GSCM on environmental health.

In its statistics, the World Health Organization found that 24% of worldwide deaths are related to the environment. In 2016, about 13.7 million deaths (around 25% of total worldwide deaths) were related to unhealthy environmental factors [38]. In addition, and according to UNSDSN, EU's food consumption contributes in 5% of the EU's total CO2 consumption-based footprint, 9% of the total NOX footprint, 16% of the total PM footprint, 6% of the total SO2 footprint, 46% of the total land-use footprint, 13% of the total employment footprint, and 5% of the total income footprint (United Nations Sustainable Development solution Network [30]. About third of the global greenhouse gas emissions are generated by the food systems [39]. The production of the main food components and the food processing and transportation, waste management, and industrial processes are responsible for these emissions [39,40].

-

-

The management of supply chain risks:

International supply networks and concerns regarding sustainability are becoming more widespread across numerous industries, so it is essential to present a full picture of supply chain sustainability risk. This will enable managers and stakeholders to take informed decisions for enhancing supply chain sustainability and mitigating supply chain sustainability risk [41]. One of the elements of supply chain risk management is the incorporating of the risk-mitigation strategies that includes many mitigation practices like the application of standards and certifications, the surveillance of supply chain members, and the involvement of stakeholders [2,42]. Therefore, the supply chain sustainability risk, in particular, refers to a probable sustainability-related issue or circumstance that can lead to unpleasant stakeholder reactions within the supply chain [43]. Accordingly, the range of supply chain risk management is extended by integrating supply chain risk factors related to social and environmental sustainability [41].

The SCM risk factors fall under multiple categories, including internal and external types [[44], [45], [46]]. The assessing of the risk to the supply chain's stability and effectiveness from both internal and external variables is a crucial part of supply chain management [47,48].

There are three phases of supply chain risk management (SCRM); the first phase is the recognition of the different risk types to which a company is exposed, the second is the risk assessment, and the third is the development of effective mitigation strategies. The risk assessment must be comprehensive in order for risk mitigation attempts to be successful. This includes knowing the type of risk, the factors influencing it, and any potential supply chain effects [49]. Therefore, companies invest in a broad range of risk mitigation techniques depending on the kinds of recognized risks and estimations of their likelihood and effects. Some of the well-known mitigation techniques or actions are the preserving of safety stock, using different supply sources, various modes of transport, supplier certification, variable pricing, controlling interruptions, emergency planning, and variety planning [32,50].

[51] divide these actions into two categories: buffering actions, that are firms’ internal procedures to reduce risk of supply chain members, and bridging actions, which cross firm borders to involve supply chain stakeholders in minimizing risk. While [52] have divided different risk mitigation strategies into proactive and reactive risk management techniques. Reactive risk mitigation aims to reduce the harmful effects of the risk occurrence, whereas preventive risk mitigation aims to lower the likelihood of risk occurrence. Both proactive and reactive risk management strategies are developed in advance of a risk occurrence. Proactive risk management strategies typically have effect before the risk happens, whereas proactive risk management strategies are applicable after the risk event has already occurred [52].

On the other hand, reliability experts advise preventative and periodic maintenance as an efficient way to minimize disruptions for internal process risks [53]. Appropriate safety practices are encouraged by design safety professionals to prevent production accidents that may harm the environment and lead to disrupting the consumer services [54].

Therefore, risk assessment is a crucial component of supply chain risk management since it aids in developing the best possible risk mitigation measures and has a significant effect on those measures [49]. In our study, risk assessment is measured in terms of the probability of the influence of the risk factors used in this study on the environmental health under the food industry sector.

-

-

GSCM as a solution for mitigate the risks of SCM on the environmental health:

With the rise of global awareness about environmental protection and health, GSCM plays a primordial and significant role in the modern management of industrial firms. Green supply chain management (GSCM) studies were carried out to serve as guidance for increasing organizations’ environmental performance [55]. Latterly, governments and industries have begun realizing the importance of GSCM implementation in supply chains [56].

[31] concluded that GSCM has not been fully surveyed in various sectors and conditions. A few studies with a focus on GSCM in the food industry have been carried out [57,58]. Several studies have examined supplier selection [55] and eco-labeling [59]. Due to growing concern about the preservation of natural resources across the world, GSCM has formed with the concept of environmental reasoning in supply chain management.

Many studies evidenced that the food quality and flavor motivate consumers to increase their health awareness [60]. High demand for best quality and nutritious foods is resulting in stakeholders inspiriting food-processing firms to help improve the supply chain's sustainability performance [55].

The fast food systems burdens cost on both the environment and human health. Diets that are green and nutritious strive to support healthy lifestyle and a low influence on the environment [61].

Finally, two types of GSCM risk mitigation factors are used in this study; the internal risk mitigation factors of eco design, internal environmental management, and investment recovery and the external risk mitigation factors of green purchasing, environmental cooperation and reverse logistics.

-

-

Theoretical framework

The natural resource-based view (NRBV) is the perspective that this study was derived from Refs. [22,62]. The environmental issues, green supply chain, and performance linkages are hypothesized. Because both theories, the NRBV and the stakeholder theory, state that environmental direction assists enterprises in strengthening their capacities of green supply chain, the NRBV and the stakeholder theory are applied simultaneously [62]. The natural resource-based view (NRBV) is the extension of the resource-based view (RBV), which underlines how much businesses depend on the environment and natural resources to retain a competitive edge.

Based on NRBV [63], stated that by investing in environmental protection and product stewardship strategies, a corporation can be profiting on both internal and external levels. As shown in Fig. 2 below, the components of NRBV and the practices of GSCM are interconnected to each other.

Fig. 2.

Interconnection between the components of NRBV theory and GSCM practices.

3. Statement of the problem

In this section, the hypotheses of the conceptual model are formulated and discussed. Independent variables are categorized as external and internal risk factors. Green Purchasing, Environmental Cooperation, and Reverse Logistics are the external GSCM risk factors while Eco Design, Internal Environmental Management, and Investment Recovery are the internal GSCM risk factors.

3.1. GSCM risk factor of green purchasing and environmental health

The procurement function is the first phase and an important component of GSCM [22]. Green Purchasing (GP) is the action that aims to assure that purchased goods and services fit the environmental goals, which are intended to reduce waste by encouraging recycling, reuse and replacement of materials.

Green purchasing, defined as buying environmentally friendly products and avoiding the purchasing of environmentally harmful products, is an inclusive concept in terms of actions toward environmental management, particularly in the food production [31].

The success of GP depends on integrating environmental efforts and objectives with the purchasing activities of the firm [64].

This paper proposes the following hypothesis:

Hypothesis 1

The Green Purchasing will help in the mitigation of the SCM risks that may affect the environmental health.

3.2. GSCM risk factor of environmental cooperation and environmental health

Several studies used Environmental Cooperation (EC) as a GSCM practice. EC was indicated either in the downstream side with customers or in the upstream side with suppliers [19]. EC with customers contains firms' activities that aim to increase customers’ environmental awareness levels and motivate them to be more eco-friendly. This can be done by presenting the positive characteristics of green products and their low impact on the environment. While the EC with suppliers aims to cooperate with suppliers and motivate them to be interested in environmental subjects, to assess their ecological procedures and stimulate them to obtain ISO 14001 certification, and to design their products according to environmental needs [19].

In this regards, businesses invest in processes that determine different sustainability-related risks at the suppliers' side, evaluating them, and building suppliers' capacities in sustainability-related measures in order to assure that suppliers adhere to environmentally friendly practices. These initiatives throughout time assist suppliers in raising awareness and enhancing sustainable practices, which empowers them to provide high-quality items that are compliant with all environmental requirements [33].

This is a significant necessity for clients because research indicates that suppliers who are using toxic substances, chemicals that cause cancer, and high carbon pollution practices in their activities of manufacturing and distribution risk not only going to harm their customers' image and moreover create disrupting procedures and causing product recalls [65,66], that will therefore raise the risk in the supply chain.

Businesses could minimize their entire supply chain risk by incorporating the knowledge acquired from improving suppliers' ecological procedures to strengthen the trustworthiness and robustness of their internal and external operations. For businesses to gain a durable competitiveness, the supply chain must be less risky because any disturbance to business operation can negatively affect a company's performance [67].

The layout and structuring of the supply chain network is referred to as supply chain continuity to promote effective association between supply chain participants. Long-term partnerships with supply chain partners, partner capacity building, and partner selection are essential features [2,68,69].

Cooperation in the supply chain entails the planning and administration of supply chain operations as well as the development and preservation of lifelong partnerships. Collaboration between supply chain actors enable cooperative development, technical and logistical synergy, better communication, and knowledge and information exchange [2,70,71].

Since a good SCM needs trust, commitment and a long-term relationship with suppliers, EC with suppliers would be more effective if those needs were satisfied.

This paper proposes the following hypothesis:

Hypothesis 2

The Environmental Cooperation will help in the mitigation of the SCM risks that may affect the environmental health.

3.3. GSCM risk factor of reverse logistics and environmental health

Reverse Logistics (RL) is considered as the most frequently applied GSCM risk factors in previous studies. It could be applied by customers returning unused or no-longer useful products and materials to reincorporate them into the supply chain through reusing, recycling, repairing remanufacturing, and disposing of the products and materials [72]. These practices are applicable to final products, as well as their elements and packaging materials [73]. Accordingly, RL leads the firms to be more efficient by recycling, reusing and remanufacturing products and materials, which creates cost savings and decreases the consumption of raw materials, and then leads to a positive impact of the green supply chain management on the environmental health.

This study proposes the following hypothesis:

Hypothesis 3

The Reverse Logistics will help in the mitigation of the SCM risks that may affect the environmental health.

3.4. GSCM risk factor of eco-design and environmental health

The practice of Eco-Design (ED) is divided into two sections, one for product design and the other for packaging design. The use of recyclable and reusable components in production is very important [74]. ED is a task of product planning phase aimed at decreasing the influence of the product on the environment through its entire life cycle. This life cycle starts with acquiring the raw materials, continues through production and use, and ends with final disposal, without harming other main product specifications, like the performance and cost []. ED and environmental health are linked to each other throughout environmental risk management, product safety, pollution reduction, resource saving and waste treatment [75].

This paper proposes the following hypothesis:

Hypothesis 4

The Eco-Design will help in the mitigation of the SCM risks that may affect the environmental health.

3.5. Internal environmental management risk factor and environmental health

Internal Environmental Management (IEM) is a set of inter-organizational policies and goals that are intended to protect the environment as much as possible. The scope of IEM is identified as actions by top and middle management that point at supporting environmental practices and collaboration between departments [76].

This paper proposes the following hypothesis:

Hypothesis 5

The Internal Environmental management will help in the mitigation of the SCM risks that may affect the environmental health.

3.6. GSCM risk factor of investment recovery and environmental health

Investment Recovery (IR) is considered as the process of reselling of unused inventories and materials or reselling of scrap of used materials. IR is considered as one of the most commonly studied practices in GSCM researches [22]. Basically, IR may positively affect environmental health.

This paper proposes the following hypothesis:

Hypothesis 6

The Investment Recovery will help in the mitigation of the SCM risks that may affect the environmental health.

The study's conceptual model is shown in Fig. 3 where, as discussed before, the three external risk factors of Green Purchasing, Environmental Cooperation, and Reverse Logistics, and the three internal risk factors of Eco Design, Internal Environmental Management, and Investment Recovery are hypothesized to affect the environmental health.

Fig. 3.

Conceptual model, relationship between GSCM practices and Environmental health.

4. Methods

4.1. Sampling and data collection

The proposed model was tested using a questionnaire-based survey via two modes, face to face and emails, using a plant survey of senior managers from 102 food companies in Lebanon. SPSS and AMOS statistical software were used to analyze the data. An unrestricted (exploratory) factor analysis (EFA), a confirmatory (restricted) factor analysis (CFA), and multiple regressions were applied.

The surveyed respondents were randomly selected from top-level managers of food companies located in the Beirut, Bekaa, and Tripoli regions of Lebanon. The food industry sector was used because it has been traditionally accompanied by resource utilization, waste reproduction, and execution of environmental management operations above the average which may cause risks on the environmental health. Moreover, due to rising awareness of traceability in food production and supply, there is a growing need to study the GSCRM in the food industry.

Thus, the primary data were collected by distributing questionnaires to the top-level manager of each food company. All respondents held plant-level management positions [22] in a food production firm, specifically CEOs, quality managers, SCM managers, financial managers, and production managers.

According to Ref. [77] formula, the sample study has to be at least 85 companies from a total population of 450 registered food companies. However, the questionnaires were sent to 450 companies, and during the following week a date was set by telephone to collect the completed questionnaires in person. Consequently, 102 questionnaires were filled and deemed appropriate to be utilized to test the study hypotheses.

The participants were split into two groups for the non-response bias test, each group consisting of fifty-one response data. The first group included the participants who answered promptly to the questionnaires and the second group included the participants those who answered later. The two groups were compared using the homogeneity of variance test. There was no statistical difference when comparing the data from the earlier time of the first group with the data from the later time of the second group.

4.2. Measurement

This research adopted the most used and relevant GSCM risk factors based on previous studies. Table 1, shows the GSCM practices used by the previous studies. Green Purchasing, Environmental Cooperation, Reverse Logistics, Eco-Design, Internal Environmental Management, and Investment Recovery, among the most commonly utilized GSCM practices, were considered as risk factors and used to analyze structural relationships with environmental health.

Table 1.

Most used GSCM practices in the previous studies.

| Author | GSCM practices |

|---|---|

| Carter and Carter (1998) | green packaging |

| Zhu et al. (2005) | * green packaging * sale of excess inventory, * sale of scrap and used material, * environmental auditing programs, * commitment from senior managers * and total quality environment management |

| Carter and Carter (1998) | green packaging |

| Zhu et al. (2005) | * green packaging * sale of excess inventory, * sale of scrap and used material, * environmental auditing programs, * commitment from senior managers * and total quality environment management |

| [42] | * internal practices * and external practices |

| Large and Thomsen (2011) | green packaging |

| Tritos et al. (2013) | * Pro-active practices include: green purchasing practices, eco-design practices, reverse logistics practices; and * Re-active practice include: legislation and regulation. |

| [75] | * green purchasing, * eco-design, * environmental cooperation * and reverse logistics |

| [22] | * green purchasing, * green manufacturing, * green distribution and packaging, * green marketing, * Internal environmental management * environmental education * Investment Recovery |

To measure each of these risk factors and test their correlation with the environmental health, sixty-one questions were included in the questionnaire. The survey questionnaire were translated into Arabic. The measurement items related to GSCM practices and environmental health are appended in Table 3,. A five-point Likert scale was used to assess all of the items. (1-Strongly Agree, 2-Agree, 3-Neutral, 4-Disagree, 5-Strongly Disagree).

Table 3.

Measurement items related to GSCM practices and Environmental Health.

| Items | Source | |

|---|---|---|

| Green Purchasing | Provides design specifications to suppliers that include environmental requirements for purchased items. | [78] [79] [80] [72] Zhu and Sarkis (2005) [75] [81] [74] |

| Requires your suppliers to develop and maintain an environmental management system (EMS). | [78] [79] [74] |

|

| Requires your suppliers to have a certified EMS such as ISO 14001. | [78] [79] [80] [72] [74] |

|

| Uses a questionnaire to collect information about your suppliers' environmental aspects, activities and/or management systems. | [78] [79] [74] |

|

| Makes sure that your purchased products must contain green attributes such as recycled or reusable items. | [78] [79] [74] |

|

| Makes sure that your purchased products must not contain environmentally undesirable items such as lead or other hazardous or toxic materials. | [78] [79] [81] [74] [75] |

|

| Evaluates your suppliers based on specific environmental criteria. | [78] [79] [72] Zhu and Sarkis (2005) [75] [81] [74] |

|

| Evaluates the environmental aspects of your suppliers. | [78] [79] [74] |

|

| Makes sure that your suppliers meet its environmental objectives. | [78] [79] [80] [72] [74] |

|

| Second-tier supplier environmentally friendly practice evaluation | [80] [72] [75] [81] [74] |

|

| Eco labeling of products | [82] Zhu and Sarkis (2004) |

|

| Environmental audit for suppliers' internal management | Zhu and Sarkis (2007) [75] |

|

| Adopting just-in-timelogisticssystem | [72] Zhu and Sarkis (2005) |

|

| Cooperating with supplier to reduce packaging | [72] Zhu and Sarkis (2005) |

|

| Require supplierstouse environmental packaging (degradable and non-hazardous) | [72] [75] [81] [74] |

|

| Eco Design | Produces products that have reused or recycled materials in their contents such as recycled plastics and glass. | [78] Tritos et al. (2013) [74] [83] |

| Uses life cycle assessment to evaluate the environmental load of your products. | [78] Zhu and Sarkis (2007) [83] [81] [74] |

|

| Produces products that are free from hazardous substances such as lead, mercury, chromium, and cadmium. | [78] [79] [80] [72] [75] [81] [74] |

|

| Produces products that reduce the consumption of materials or energy during use. | [78] [80] [72] [75] [81] [74] |

|

| Makes sure that product's packaging has recyclable contents. | [78] [79] [83] [74] |

|

| Makes sure that product's packaging is reusable. | [78] [83] [74] [75] |

|

| Minimizes the use of materials in product's packaging. | [78] [79] [83] [74] |

|

| Avoids or reduces the use of hazardous materials in product's packaging. | [78] [83] [74] |

|

| Design for remanufacturing (a design that facilitates repair, rework, and refurbishment activities aiming at returning the product to the new and better condition) | [80] | |

| Design for recycling (a design that facilitates disassembly of the waste product, separation of parts according to material, and reprocessing of the material) | [78] [80] [72] [75] [81] [74] |

|

| Design for reuse (a design that facilitates reuse of a product or part of it) | [80] | |

| Design of processes for minimization of waste | [72] Zhu and Sarkis (2005) [75] |

|

| Internal Environmental Management | Commitment of GSCM from senior managers | [80] [72] [81] |

| Support for GSCM from mid-level managers | [80] [72] [81] |

|

| Cross-functional cooperation for environmental improvements | [80] [72] [81] |

|

| Total quality environmental management | [80] [72] [81] |

|

| Environmental compliance and auditing programs | [80] Zhu and Sarkis (2007) |

|

| ISO 14000 certification | [72] [80] |

|

| Eco-labeling of products | [72] [80] Zhu and Sarkis (2005) |

|

| Environmental Management Systems exist (IEM7) | Zhu and Sarkis (2007) Zhu and Sarkis (2004) |

|

| In the past two years, to what extent did your firm engage in the following IEM activities? | Pietro De Giovanni (2010) [84] |

|

| Environmentally friendly raw materials | Pietro De Giovanni (2010) [84] |

|

| Substitution of environmentally questionable materials | Pietro De Giovanni (2010) [84] |

|

| Taking environmental criteria into consideration | Pietro De Giovanni (2010) [84] |

|

| Optimization of processes to reduce air emissions, water use, solid waste, and/or noise | Pietro De Giovanni (2010) Rao (2002) |

|

| Use of cleaner technology process to make savings (IEM5) | Pietro De Giovanni (2010) [84] |

|

| Special training for workers on environmental issues | [72] Zhu and Sarkis (2005) |

|

| Existence of Pollution Prevention Programs | [72] Zhu and Sarkis (2005) |

|

| The internal performance evaluation system incorporates environmental factors | [81] [72] |

|

| Generate environmental reports for internal evaluation | [81] [72] |

|

| Environmental Cooperation | Cooperation with customer for eco-design | [80] [72] [75] [71] [81] |

| Cooperation with customers for cleaner production | [80] [72] [81] [75] |

|

| Cooperation with customers for green packaging | [80] [72] [75] [81] |

|

| Cooperation with customers for using less energy during product transportation | [80] [72] [75] [81] |

|

| Adopting third-party-logistics | [72] Zhu and Sarkis (2004) |

|

| Cooperation with customers for product take back | [72] Zhu and Sarkis (2004) |

|

| Cooperation with customers for reverse logistics relationships | [72] Zhu and Sarkis (2004) |

|

| Developing a mutual understanding of responsibilities regarding environmental performance | [75] [71] |

|

| Working together to reduce environmental impact of our activities | [75] [71] |

|

| Conducting joint planning to anticipate and resolve environmental-related problems | [75] [71] [81] |

|

| Making joint decisions with other supply chain members about ways to reduce overall environmental impact of our products | [75] [81] |

|

| Investment Recovery | Investment recovery (sale) of excess inventories/material | [80] [72] |

| Sale of scrap and used materials | [80] [72] |

|

| Sale of excess capital equipment | [80] [72] |

|

| Collecting and recycling end-of-life products and materials | [72] Zhu and Sarkis (2005) |

|

| Establishing a recycling system for used and defective products | [72] Zhu and Sarkis (2005) |

|

| Reverse Logistics | Collects back used products from customers for recycling, reclamation of materials, or reuse. | [78] Rogers and Tibben-Lembke (2001) [74] |

| Collects back used packaging from customers reuse or recycling. | [78] [74] |

|

| Requires suppliers to collect back their packaging materials. | [78] [74] |

|

| Returns back its products to suppliers for retaining of materials, or remanufacturing. | [78] [74] |

|

| Returns back its packaging to suppliers for reuse and recycling. | [78] [74] |

|

| Returns back the products from customers for safe refill | [78] [74] |

|

| Reuse (the process of collecting used products, and distributing or selling them) | [80] | |

| Remanufacturing (the process of collecting a used product and replacing defective or outdated parts with new or renovated parts) | [80] [81] [75] |

|

| Recycling (the process of collecting, disassembling, separating, and processing used products into recycled products and materials) | [80] | |

| D5. Collects used packaging from customers for recycling | [74] [81] [75] |

|

| Use of remanufacturing | [75] [15] |

|

| Recovery of the company's end-of-life products | [81] [75] |

|

| Environmental Health | Reduction of air emission. | [78] [72] [75] [81] [74] |

| Reduction of solid/liquid wastes | [78] [72] [75] [81] [74] |

|

| Decrease of consumption for hazardous/harmful/toxic materials. | [78] [72] [75] [74] |

|

| Decrease of frequency for environmental accidents. | [78] | |

| Improvement of a firm's environmental situation. | [78] | |

| Reduction of amount of energy used | Pietro De Giovanni, 2010 | |

| Improved compliance to environmental standards | [74] | |

| Reduction in material usage | [74] |

4.3. Data analysis

Before conducting the main survey, a pilot survey was conducted from seventeen respondents to evaluate the reliability of the questions. As a result of Cronbach's Alpha test, twelve items with low correlations were eliminated and the questionnaire was finalized with 49 questions.

After collecting the 102 questionnaires, the level of reliability of each GSCRM scale, as well as environmental health, were tested [85]. As reported in Table 2 the reliability level of the questions was acceptable [86].

Table 2.

Reliability test result.

| Reliability Statistics | |

|---|---|

| Cronbach's Alpha | N of Items |

| .942 | 49 |

a. Listwise deletion based on all variables in the procedure.

Moreover, an EFA and a CFA were carried out. The EFA was carried out using principal component extraction with a varimax rotation to test the factors' unidimensionality. The results revealed that out of thirteen factors of GSCM, seven of them had suppressing loadings less than 0.5, and the other six factors had suppressing loadings greater than 0.5.

Accordingly, the six practices of GSCM are accepted. The result of EFA showed that all the questions had acceptable factor loads, accordingly, no need to remove questions from the questionnaire. As a result the EFA there were no questions with low factor loads, and thus nothing to be eliminated from the questionnaire. This result is confirmed with the outcome of Cronbach's Alpha test.

The researchers used structural equation modeling to test the proposed hypothesis. The research model was tested using the software AMOS. The fit indices ratio of chi-square to degree of freedom, root-mean-square error of approximation (RMSEA), and comparative fit index (CFI) were utilized in this study. The following are the model fit results: Chi-square/df of 1.803; CFI = 0.951; RMSEA = 0.3.

Accordingly, the fit indices and CFA results were at an acceptable level [22].

5. Results and discussion

The tested sample of 102 companies is characterized as follow:

First, the type of industry, 37.3% of the sample is composed of food material producers while 62.7% of the sample is composed of roastaries, sweet, restaurants, dairy products and others. Second, the age of the firms in the sample, 41.2% are working from less than 15 years and 58.8% from more than 15 years. Third, the number of employees, 86.3% has less than 100 employees and 13.7% have more than 100 employees. Fourth, the type of products, 84.3% produce consuming product, while 15.7% produce industrial products. Fifth, the sources of material, 67.6% are domestic resources, 16.7% are regional sources and 15.7% are global sources. And sixth, the green participations, 60.8% have such participations and 39.2% don't have.

Table 4 summarizes the findings of structural equation modeling of the relationship between GSCM risk factors and environmental health.

Hypothesis 1

The Green Purchasing will help in the mitigation of the SCM risks that may affect the environmental health.

In Table 4, the relationship between Green Purchasing (GP) and Environmental Health was presented: GP (p = 0.562); this relationship is significant and positive. The result implies that:

- -

There are food companies whose purchased products are composed of eco characteristics like recycled or reusable components [74,78,79],

- -

And where environmentally undesirable materials such as lead and other harmful or poisonous materials are not contained in their purchased products [75,74,78,79,81].

- -

In addition many food companies are evaluating their suppliers based on specific definite environmental standards, ensuring that environmental objectives are met [75,72,74,78,79,81].

- -

Cooperation with their suppliers is vital to reduce unhealthy packaging and replace them with environmental packaging (e.g., degradable and non-hazardous) [75,72,74,81].

Therefore, these results can support Hypothesis 1.

Hypothesis 2

The Environmental Cooperation will help in the mitigation of the SCM risks that may affect the environmental health.

Environmental Cooperation (EC) and environmental health have a positive and significant relationship: EC (p = 0.586). This finding may occur because:

- -

Food firms collaborate with their suppliers and customers on environmentally friendly design, green production, and eco-packaging, as well as using less energy during product shipping, enhancing product take-back, and developing reverse logistics relationships. Cooperation with other supply chain participants to reduce product environmental impacts can be an important reason for this positive relationship [75,71,72,80,81].

- -

One of the most commonly main factors for the execution of GSCM is satisfying client requests, aspirations, and needs [17,45,87]. It is generally recognized that customers are the stakeholders that have the greatest impact on the performance of a company by choosing to purchase or refuse a certain product [88]. Customers who want ecologically friendly goods and services, are ready to pay more to satisfy their requirement. Companies risk client boycotts if they do not adhere to this particular demand [89].

- -

The minimization of the risk of unfavorable publicity is one of the reputation-critical factors linked to company name and reputation. Brand image and reputation and eco-branding developments are significantly correlated [90].

- -

Companies cultivate a "good citizen" brand by supporting environmental and social initiatives throughout their supply chain. This brand will enhance the access to important resources and the credibility [17].

- -

One of the most fundamental drivers of the implementation of GSCM practices has been identified as information sharing [[91], [92], [93]].

[94] stated that sharing of information facilitates cooperation all across the supply chain as well as the formulation of innovative environmental concepts. In the food industry Information sharing between supply chain participants is considered as a new type of traceability and is associated with increased supply chain performance [69].

- -

Food safety and social sustainability are supported by product traceability [95]. On the other side, the lack of information and transparency on concerns related to the environment has an adverse impact on the adoption of GSCM [92,96].

- -

One of the essential components for applying GSCM in the food industry is the development of mutual trust and a commitment among supply chain partners [17].

Nevertheless [97], emphasize that one of the most frequent risky factors is the weak commitment between SC partners. This lack of trust and commitment between supply chain members is a major barrier, particularly when suppliers are audited by the customers [46].

- -

Another vital supply chain factor is having a unified GSCM strategy [17]. Companies that declare sustainability objectives to their stakeholders and supply chain counterparts are more likely to cooperate with them to create a shared GSCM strategy. By creating a unified GSCM strategy, the supply chain partners may all strive to achieve the same strategic objective [93]. It was noted that setting mutual goals and sharing policies were a key step in the execution of SSCM practices like environmental collaboration [98].

- -

On the other hand, the structure and configuration of the supply chain system have an effect on supply chain continuity [2]. One of the main sustainable supply chain management principles is preserving supplier continuity [17].

Long-term partnerships with supply chain members, the advancement of supply chain partners, and partner selection are the key components of supply chain continuity [17]. Long-term partnerships facilitate information sharing [99] and improve cooperative product or process design [98] through building confidence and commitment among supply chain participants [69].

Companies that promote supply chain continuity are working to make sure that all members of their chain not only remain in service, but do so in a way that enables them to prosper, invest, innovate, and develop [69].

- -

The supplier growth is the process of enhancing a supplier's social and environmental footprint [69]. The improvement of suppliers is one of the best techniques in regular supply chain management [100], which also links to environment using mentorship techniques [101].

- -

The selection of suppliers is dependent on their supply chain expertise [102] and on their motivation to build environmental initiatives [103]. For the purpose of maintaining supplier continuity, it's critical to concentrate on initiatives that improve clarity, traceability, and supplier certification [69].

- -

The most frequent risk management approach identified in the literature is the deployment of standards and certifications [2]. This is because standards and certifications like ISO 9001 and ISO 14001 can be employed in a wide range of fields and maintained by outside experts who improve the levels of credibility [104].

- -

Another activity categorized under risk management is the surveillance of particular suppliers in order to assess their interests and measure their progress on particular targets [105]. According to Ref. [2]; traceability is essential for ensuring ecological sustainability in food supply chain along with personal supplier monitoring which is extremely significant.

- -

Another essential factor of GSCM is the starting to learn from stakeholders and partners. The main feature of learning is the acquiring of new knowledge. Firms can increase knowledge from their supply chain associates, surrounding communities, NGOs, the authorities and scientists [17].

- -

One of the main external factors for implementing GSCM procedures is the risk of modifying quality of the product after manufacturing. As noted, a firm is sustaining if supply products with the same quality, package, price and at the same point of sale [17].

Therefore, these results can support Hypothesis 2.

Hypothesis 3

The Reverse Logistics will help in the mitigation of the SCM risks that may affect the environmental health.

Furthermore, the relationship between Reverse Logistics (RL) and environmental health is not strong: RL (p = 0.470).

This may be because of the nature of food products; Collecting used products from customers for recycling, material reclamation, or reuse is challenging.

Accordingly, these results do not support Hypothesis 3.

Hypothesis 4

The Eco-Design will help in the mitigation of the SCM risks that may affect the environmental health.

Eco-Design (ED) risk factor and environmental health have a positive and significant relationship: ED (p = 0.574). This can be elucidated in terms of:

- -

Production and packaging of food products, using reused or recycled materials like recyclable components such as recyclable plastics and glass [78]; Tritos et al., 2013; [74,83].

- -

The use of life cycle assessment to assess the ecological impact of food goods [74,78,[81], [82], [83]].

- -

Production of food products and packaging that do not contain dangerous metals like lead, mercury, chromium and cadmium [75,74,[78], [79], [80], [81], [82]].

- -

Production of food products and packaging which can decrease the consumption use of materials or energy during usage [75,74,78,80].

Therefore, these results can approve Hypothesis 4.

Hypothesis 5

The Internal Environmental management will help in the mitigation of the SCM risks that may affect the environmental health.

Internal Environmental Management (IEM) and environmental health have a positive and significant relationship: IEM (p = 0.582). Possible explanations for this positive relationship can be as follows:

- -

The implementation by food companies of an evaluation system created to assess internal eco performance in addition of the producing of environmental reports to be used in the internal evaluation [72,81].

- -

Commitment of GSCM from high management in the food companies; the most firm level critical factor is considered to be the commitment and support from senior management [45,91,93]. [106] emphasize that top management is in charge of managing green initiatives. Moreover [107], found that the perspective of top corporate management should ensure environmental management at the plant level.

Environmental activities and green supply management are driven by top management [87]. However, many studies stated that poor or inadequate top management commitment is an obstacle to the successful application of GSCM [46,97].

- -

Support for GSCM from food companies' middle management [72,80,81].

- -

Total quality environmental management in the food industry sector [72,80,81].

- -

Making the best or most effective procedures to decrease air emissions, solid waste, and/or noise during the food production process [84,108].

- -

Special training for food companies' staff on environmental issues; companies can facilitate the adoption of GSCM practices by investing in human capital with specialized knowledge and skills on environmental concerns [94]. In the same line [90], believed that the growth of GSCM is hampered by a lack of awareness of sustainability issues.

One of the most important firm-level critical factor that is directly tied to environmental performance is the capacity building of the employees. Learning and capacity building in sustainability enhances job performance improvement in environmental concerns and aids businesses in reducing waste and making mistakes [94]. On the other hand, the risk of weakness in learning and training prevent the effective application of GSCM [97].

- -

Every decision-making process involves daily discussions on green practices so that every employee takes the social and/or environmental effects of their actions into account [17]. Basically, environment issues being discussed on daily basis is a sign of good management orientation [69].

- -

Top management's dedication or skills and understanding in sustainability are considered to be crucial firm-level important factors for GSCM [17]. The growth of GSCM is hampered by the lack of support and commitment from senior management [45,97].

Therefore, these results can support Hypothesis 5.

Hypothesis 6

The Investment Recovery will help in the mitigation of the SCM risks that may affect the environmental health.

Finally, the variables Investment Recovery (IR) and environmental health did not have a promising relationship: IR (p = 0.316).

This may be because food products have an expiration time, and it is difficult to sell the resulting scrap and used materials, or excess inventories and material.

Accordingly, these results do not support Hypothesis 6.

Table 4.

Correlation between GSCM practices and Environmental health.

| Correlations | ||||||||

|---|---|---|---|---|---|---|---|---|

| GreenPurchase | EcoDesign | InEnvMan | EnvCoop | InvetRecov | ReverseLog | Environmental Health | ||

| GreenPurchase | Pearson Correlation | 1 | .550** | .788** | .650** | .351** | .660** | .562** |

| Sig. (1-tailed) | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| N | 102 | 102 | 102 | 102 | 102 | 102 | 102 | |

| EcoDesign | Pearson Correlation | .550** | 1 | .570** | .431** | .298** | .484** | .547** |

| Sig. (1-tailed) | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | ||

| N | 102 | 102 | 102 | 102 | 102 | 102 | 102 | |

| IntEnvMan | Pearson Correlation | .788** | .570** | 1 | .642** | .305** | .600** | .582** |

| Sig. (1-tailed) | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | ||

| N | 102 | 102 | 102 | 102 | 102 | 102 | 102 | |

| EnvCoop | Pearson Correlation | .650** | .431** | .642** | 1 | .346** | .481** | .586** |

| Sig. (1-tailed) | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| N | 102 | 102 | 102 | 102 | 102 | 102 | 102 | |

| InvetRecov | Pearson Correlation | .351** | .298** | .305** | .346** | 1 | .523** | .316** |

| Sig. (1-tailed) | 0.000 | 0.001 | 0.001 | 0.000 | 0.000 | 0.001 | ||

| N | 102 | 102 | 102 | 102 | 102 | 102 | 102 | |

| ReverseLog | Pearson Correlation | .660** | .484** | .600** | .586** | .523** | 1 | .470** |

| Sig. (1-tailed) | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | ||

| N | 102 | 102 | 102 | 102 | 102 | 102 | 102 | |

| EnvironmentalHealth | Pearson Correlation | .562** | .547** | .582** | .481** | .316** | .470** | 1 |

| Sig. (1-tailed) | 0.000 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | ||

| N | 102 | 102 | 102 | 102 | 102 | 102 | 102 | |

**. Correlation is significant at the 0.01 level (1-tailed).

6. Conclusions and implications

The objective of this study therefore is to examine the ability of GSCM to serve as solution for the mitigation of the SCM risks that may affect the environmental health. In the academic literature, to the best of our knowledge, this study can be considered as a first in examining the impacts of GSCM on environmental health especially in the context of food industry.

The food consumption is necessary for the human wellbeing, human health, and for the environmental health since it assures the food substances needed for the human body like the vitamins, mineral and other essential materials. However, on the other side, food production has a negative risk on the environmental health when generating wastes and toxins. To mitigate this potential risk exposure, supply chain risk management approaches are to be adopted [42]. Accordingly, in order to meet the goal of this research, an action plan is proposed in Fig. 4 to help the practitioners and policy makers in the implementation of the GSCM risk factors to enhance the environmental health level.

Fig. 4.

Proposed action plan, how tp mitigate the risk of SCM on environmental health by applying the GSCM.

6.1. Theoretical implications

SPSS and AMOS statistical programs were used to analyze the data collected via a questionnaire-based survey. Multiple regressions, unrestricted (exploratory) factor analysis, and confirmatory (restricted) factor analysis have been applied. Structural equation modeling revealed that, in the context of the food industry, the GSCM risk factors of Environmental Cooperation (external), Green Purchasing (external), Eco-Design (internal), and Internal Environmental Management (internal) each had a significant positive relationship with environmental health, while the relationships between Reverse Logistics (external) and Investment Recovery (internal) with environmental health were not strong.

The study suggests that, regarding the external GSCM level, encouragement of green purchasing is needed. This issue could be realized by, for example, providing the suppliers with design features that incorporate environmental specifications for purchased materials [75,81], and by contracting with suppliers who are certified for Environmental Management Systems such as ISO 14001, [78]; Diabat and Govindan, 2011).

In addition, food industry suppliers would be required to ensure that procured products contained green specifications in terms of recycled or reusable components, with no environmentally harmful components materials such as lead or even other dangerous or poisonous components [75,74,81]. Eco-labeling of products [82], and cooperating with suppliers and customers is essential for reducing the risk of packaging on the environmental health by using environmental friendly packaging (non-hazardous and biodegradable) [75,72,81]. These activities may increase the level of environmental health by reducing the risks of SCM of the companies working in the food industry sector.

Regarding internal GSCM levels, some activities may lead to an ambiance of environmentally friendly procedures in the firms. One of these activities is internal environmental management that is required to enhance the environmental health conditions. This can be done by reinforcing the commitment to GSCM from the high management, with support for GSCM from middle management (Diabat and Govindan, 2011; [81]. The adopt of a cleaner technology approach is recommended to make savings on clean production and packaging [108]. Providing special training for workers on environmental issues [72], and optimizing processes are vital in order to decrease air emissions, water consumption, solid waste, and noise [108], which will reduce the risk of SCM on the environmental health by enhancing the Internal environmental management. This may be followed up by activating an internal performance evaluation system and generating an internal environmental report process [72,81].

In addition, and based on the findings, enhancing Eco-Design as an internal GSCM risk factor to ameliorate environmental health is required. This enhancement would be implemented by designing products incorporating reused or recycled items like recycled plastics and glass into the products, designing products that do not contain hazardous components like lead, mercury, chromium and cadmium, and reducing the utilization of materials or energy during manufacture (Abdullah and Yaakub, 2014; [81].

Moreover, each of the design for remanufacturing, recycling and reuse, working with the design of processes that minimize the use of materials and the creation of waste, are important activities that lead to the improvement of eco-design practices (Diabat and Govindan, 2011 [75,81]; and then to enhance the environmental health by reducing the risks of the SCM.

6.2. Managerial implications

When GSCM is applied by a company's management, a balance between the goal of profit maximization and environmental health responsibility needs to be determined. In addition, the actions that may enhance or may affect negatively the environmental health need to be highlighted and implemented carefully. However, the decisions related to such matters are not easy to make. Company management may need to weigh the advantages and disadvantages of every decision relating to the idea of not doing harm to society or the environment.

This research lays out practical results for both practitioners in the industry context and policymakers. Every producer's priority is to maximize profit and minimize the cost of production by avoiding risks. However, firms whose aim is to pursue short-term profits by ignoring the environmental and societal impacts cannot be sustained in the pursuit of long-term success.

7. Limitations

We encountered limitations during the data collection in Lebanon in terms of a low response rate. The outbreak of COVID-19 and the 2020 Beirut port explosion exacerbated the condition, which limited communication and transportation. Over the last year, many businesses were frequently closed because of lockdowns and quarantine policies. Due to safety and political issues, some of the sampled firms’ managers were reluctant to participate in the survey and complete the questionnaire.

8. Future studies

This study opens many areas for future analyses on GSCM and customer behavior, governance, social responsibility, and the decision making process. In addition, further studies can be conducted to test if there is a linkage between GSCM and environmental health in sectors other than the sector of food producers.

Author contribution statement

Mohamad Saad El Ayoubi, M. D: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.Mehrshad Radmehr, Assist Prof: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Footnotes

Supplementary data to this article can be found online at 10.1016/j.heliyon.2023.e13264.

Contributor Information

Mohamad Saad El Ayoubi, Email: moayouby@gmail.com.

Mehrshad Radmehr, Email: mradmehr@ciu.edu.tr.

Appendix A. Supplementary data

The following is the Supplementary data to this article:

References

- 1.Hervani A.A., Joseph S., Marilyn M.H. Environmental goods valuations for social sustainability: a conceptual framework. Technol. Forecast. Soc. Change. 2017;125(December 2017):137–153. doi: 10.1016/j.techfore.2017.07.015. [DOI] [Google Scholar]

- 2.Beske P., Land A., Seuring S. Sustainable supply chain management practices and dynamic capabilities in the food industry: a critical analysis of the literature. Int. J. Prod. Econ. 2014;152:131–143. doi: 10.1016/j.ijpe.2013.12.026. [DOI] [Google Scholar]

- 3.Carter C.R., Kale R., Grimm C.M. Environmental purchasing and firm performance: an empirical investigation. Transport. Res. E Logist. Transport. Rev. 2000;36(3):219–228. doi: 10.1016/S1366-5545(99)00034-4. [DOI] [Google Scholar]

- 4.McNeely J.A., Scherr S.J. Island Press; Washington, DC, USA: 2003. Ecoagriculture: Strategies to Feed the World and Save Wild Biodiversity. [Google Scholar]

- 5.Yakovleva N. Measuring the sustainability of the food supply chain: a case study of the UK. J. Environ. Pol. Plann. 2007;9:75–100. doi: 10.1080/15239080701255005. [DOI] [Google Scholar]

- 6.Al-Ghwayeen W.S., Abdallah A.B. Green supply chain management and export performance: the mediating role of environmental performance. J. Manuf. Technol. Manag. 2018;29(7):1233–1252. [Google Scholar]

- 7.Bhatia M.S., Gangwani K.K. Green supply chain management: scientometric review and analysis of empirical research. J. Clean. Prod. 2021;284(15 February 2021) doi: 10.1016/j.jclepro.2020.124722. [DOI] [Google Scholar]

- 8.Diab S.M., Al-Bourini F.A., Abu-Rumman A.H. The impact of green supply chain management practices on organizational performance: a study of Jordanian food industries. J. Mgmt. Sustain. 2015;5:149. [Google Scholar]

- 9.Tahhan S.A. The drivers and barriers of implementing green supply chain management in Lebanese restaurants-the case of Besten. Manag. Sustain.: An Arab Review. 2022 (ahead-of-print) [Google Scholar]

- 10.Wang Y.F., Chen S.P., Lee Y.C., Tsai C.T.S. Developing green management standards for restaurants: an application of green supply chain management. Int. J. Hospit. Manag. 2013;34:263–273. [Google Scholar]

- 11.Rajabion L., Khorraminia M., Andjomshoaa A., Ghafouri-Azar M., Molavi H. A new model for assessing the impact of the urban intelligent transportation system, farmers' knowledge and business processes on the success of green supply chain management system for urban distribution of agricultural products. J. Retailing Consum. Serv. 2019;50:154–162. [Google Scholar]

- 12.Zorell C.V. Central persons in sustainable (food) consumption. Int. J. Environ. Res. Publ. Health. 2022;19:3139. doi: 10.3390/ijerph19053139. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Li S., Rao S.S., Ragu-Nathan T., Ragu-Nathan B. Development and validation of a measurement instrument for studying supply chain management practices. J. Oper. Manag. 2005;23:618–641. doi: 10.1016/j.jom.2005.01.002. [DOI] [Google Scholar]

- 14.Paksoy T., Kochan C.G., Ali S.S. CRC Press; 2020. Logistics 4.0: Digital Transformation of Supply Chain Management.https://books.google.com.lb/books?id=sC4PEAAAQBAJ [Google Scholar]

- 15.Rao P.H. Green supply chain management in hotel azure: a case in sustainability. J. Supp. Chain Manag. Sys. 2020;9(2 & 3):28–38. http://52.172.152.24/index.php/jscms/article/view/205816 [Google Scholar]

- 16.Sharma V.K., Chandana P., Bhardwaj A. Critical factors analysis and its ranking for implementation of GSCM in Indian dairy industry. J. Manuf. Technol. Manag. 2015;26(6):911–922. doi: 10.1108/JMTM-03-2014-0023. [DOI] [Google Scholar]

- 17.Mastos T., Gotzamani K. Sustainable supply chain management in the food industry: a conceptual model from a literature review and a case study. Foods. 2022;11:2295. doi: 10.3390/foods11152295. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Alkhuzaim L., Zhu Q., Sarkis J. Evaluating emergy analysis at the nexus of circular economy and sustainable supply chain management. Sustain. Prod. Consum. 2021;25(January 2021) doi: 10.1016/j.spc.2020.11.022. [DOI] [Google Scholar]

- 19.Diabat A., Khodaverdi R., Olfat L. An exploration of green supply chain practices and performances in an automotive industry. Int. J. Adv. Manuf. Technol. 2013;68:949–961. doi: 10.1007/s00170-013-4955-4. [DOI] [Google Scholar]

- 20.Geng R., Mansouri S.A., Aktas E. The relationship between green supply chain management and performance: a meta-analysis of empirical evidences in Asian emerging economies. Int. J. Prod. Econ. 2017;183:245–258. doi: 10.1016/j.ijpe.2016.10.008. Part A(January 2017) [DOI] [Google Scholar]

- 21.Hassan, M. G., H. Ashari and N. Nordin. Environmental stewardship issue among Malaysian manufacturing firms. Int. J. Supply Chain Manag. 5(2), 36–42. https://www.researchgate.net/publication/309257663_Environmental_stewardship_issue_among_Malaysian_manufacturing_firms.

- 22.Çankaya S.Y., Sezen B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019;30(1):98–121. doi: 10.1108/JMTM-03-2018-0099. [DOI] [Google Scholar]

- 23.Vanalle R.M., Ganga G.M.D., Godinho-Filho M., Lucato W.C. Green supply chain management: an investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017;151(10 May 2017):250–259. doi: 10.1016/j.jclepro.2017.03.066. [DOI] [Google Scholar]

- 24.Northridge M.E., Sclar E.D., Biswas P. Sorting out the connections between the built environment and health: a conceptual framework for navigating pathways and planning healthy cities. J. Urban Health. 2003;80(4):556–568. doi: 10.1093/jurban/jtg064. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Grané A., Albarrán I. Editorial on S.I. “Advances in measuring health and wellbeing” in the international journal of environmental research and public health. Int. J. Environ. Res. Publ. Health. 2022;19(9):5103. doi: 10.3390/ijerph19095103. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Cordner A., Poudrier G., DiValli J., Brown P. Combining social science and environmental health research for community engagement. Int. J. Environ. Res. Publ. Health. 2019;16(18):3483. doi: 10.3390/ijerph16183483. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Yang X., Lo K. Environmental health research and the COVID-19 pandemic: a turning point towards sustainability. Environ. Res. 2021;197 doi: 10.1016/j.envres.2021.111157. (June 2021) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Zakianis, Adzania F.H., Fauzia S., Aryati G.P., Mahkota R. Sociodemographic and environmental health risk factor of COVID-19 in Jakarta, Indonesia: an ecological study. One Health. 2021;13(December 2021) doi: 10.1016/j.onehlt.2021.100303. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Rodrigues M.A., Silva M.V., Errett N.A., Davis G., Lynch Z., Dhesi S., Hannelly T., Mitchell G., Dyjack D., Ross K.R. How can environmental health practitioners contribute to ensure population safety and health during the COVID-19 pandemic? Saf. Sci. 2021;136(April 2021) doi: 10.1016/j.ssci.2020.105136. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.United Nations Sustainable Development solution Network (UNSDSN) December 2021. Making Globalisation and Trade Work for People and Planet: International Spillovers Embodied in EU's Food Supply Chains. [Google Scholar]

- 31.Banaeian N., Mobli H., Nielsen I.E., Omid M. Criteria definition and approaches in green supplier selection—a case study for raw material and packaging of the food industry. Produc. Manuf. Res. 2015;3(1):149–168. doi: 10.1080/21693277.2015.1016632. [DOI] [Google Scholar]

- 32.Ivanov D., Dolgui A., Sokolov B., Ivanova M. Literature review on disruption recovery in the supply chain. Int. J. Prod. Res. 2017;55(20):1–17. [Google Scholar]

- 33.Kumar Gouda Sirish, Saranga Haritha. Sustainable supply chains for supply chain sustainability: impact of sustainability efforts on supply chain risk. Int. J. Prod. Res. 2018;56(17):5820–5835. doi: 10.1080/00207543.2018.1456695. [DOI] [Google Scholar]

- 34.Speier C., Whipple J.M., Closs D.J., Voss andM.D. Global supply chain design considerations:mitigating product safety and security risks. J. Oper. Manag. 2011;29(7):721–736. [Google Scholar]

- 35.Van Dijk M., Morley T., Rau M.L., Saghai Y. A meta-analysis of projected global food demand and population at risk of hunger for the period 2010–2050. Nat. Food. 2021;2(7):494–501. doi: 10.1038/s43016-021-00322-9. [DOI] [PubMed] [Google Scholar]

- 36.Grunert K.G., Heike S., Wills J. Sustainability labels on food products: consumer motivation, understanding and use. Food Pol. 2014;44:177–189. (February 2014) [Google Scholar]

- 37.Malley C., Hicks K., Kuylenstierna J., Michalopoulou E., Molotoks A., Slater J., Heaps C., Ulloa S., Veysey J., Shindell D. Integrated assessment of global climate, air pollution, and dietary, malnutrition and obesity health impacts of food production and consumption between 2014 and 2018. Environ. Res. Commun. 2021;3(7) [Google Scholar]

- 38.World Health Organization . 2021. Preventing Disease through Healthy Environments: A Global Assessment of the Burden of Disease from Environmental Risks.https://www.who.int/publications/i/item/9789241565196 [Google Scholar]

- 39.Crippa M., Solazzo E., Guizzardi D., Monforti-Ferrario F., Tubiello F., Leip A. Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food. 2021;2(3):198–209. doi: 10.1038/s43016-021-00225-9. [DOI] [PubMed] [Google Scholar]

- 40.Poore J., Nemecek T. Reducing food's environmental impacts through producers and consumers. Science. 2018;360(6392):987–992. doi: 10.1126/science.aaq0216. [DOI] [PubMed] [Google Scholar]

- 41.Xu Ming, Cui Yuanyuan, Hu Meng, Xu Xinkai, Zhang Zhechi, Liang Sai, Shen Qu. Supply chain sustainability risk and assessment. J. Clean. Prod. 2019;225:857–867. [Google Scholar]

- 42.Seuring S., Müller M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008;15:1699–1710. doi: 10.1016/j.jclepro.2008.04.020. [DOI] [Google Scholar]

- 43.Hofmann H., Busse C., Bode C., Henke M. Sustainability-related supply chain risks: conceptualization and management. Bus. Strat. Environ. 2014;23(3):160e172. [Google Scholar]