Abstract

The whole world has been affected by the COVID-19 pandemic and oxygen demand is greater than ever, but the supply is expectedly short. People in need of this oxygen are not able to receive it, especially those who cannot afford it. In addition to these issues, the oxygen from production plants is not getting delivered to hospitals on a timely basis due to insufficient availability of tankers and cylinders. It is therefore crucial to enable access of oxygen beds and cylinders to the public by developing economical methods for medical oxygen generation. Conventional methods like oxygen concentrators, the Pressure Swing Adsorption (PSA) Technique and Air Separation Units (ASUs) are either too expensive, energy intensive or feasible only on a small scale. This indicates the need to exploit methods that have not been utilized fully yet, such as Integrated Energy Systems (IES). However, reducing the cost of a process is not enough. It needs to be scaled up to have a real impact on the situation at hand. Ion Transport Membranes (ITM) are promising in this aspect as they can produce large volumes of extremely high-purity oxygen at low costs. All these methods along with their economic aspects have been discussed and then compared to identify the most feasible one.

Keywords: COVID-19, Medical Oxygen, Oxygen Concentrators, Pressure Swing Adsorption (PSA), Air Separation Units (ASUs), Integrated Energy Systems (IES)

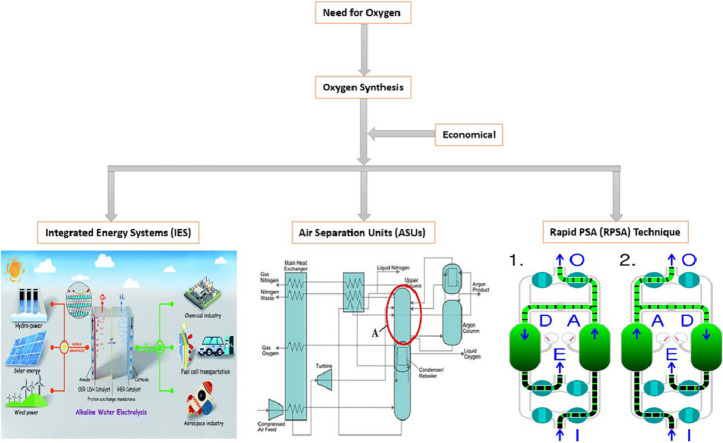

Graphical abstract

1. Introduction

The COVID-19 pandemic has drastically affected the entire world's health and economy. It is a global emergency and we are facing it with limited information from published data (Pravda et al., 2020). The corona virus has indeed impacted the world in unimaginable ways and can be identified by some common symptoms which include headache, respiratory problems, fatigue, cough, fever and anosmia. The organs affected the most are the lungs, especially the alveoli, causing major complications such as pneumonia, acute respiratory distress syndrome and sepsis, which reduce the oxygen intake and might ultimately lead to organ failure itself. To combat these issues, oxygen cylinders are used to increase the oxygen level as an attempt to improve the condition and aid the recovery of a patient.

Medical oxygen is essential in the treatment of people suffering from respiratory problems, whether at home or in hospitals. That being said, it is clear that oxygen therapy signifies a central focus of emergency care (Karlis et al., 2020). An uninterrupted oxygen supply is a critical hospital need (Paul et al., 2020). However, with the rise in cases, the demand for this oxygen has escalated so much that there is a growing scarcity, especially for those who cannot afford oxygen beds in hospitals. In addition to this, the oxygen produced at plants is not getting delivered to where it needs to be due to the shortage of tankers and cylinders.

As stated by the World Health Organization (WHO), one in five people struggling with COVID-19 needs medical oxygen to guarantee that the oxygen level in their blood is adequate. In order to enable access of these oxygen beds and cylinders to the public, economical methods of synthesis must be adapted. Liquid Medical Oxygen (LMO) is highly pure oxygen and has several advantages. It can be stored in large volumes and is also portable when compared to other systems such as concentrators (Su et al., 2014).

Medical oxygen (either in liquid or gaseous state) is an oxidizing agent which can cause fires or explosions if handled improperly. To avoid catastrophic mishaps in the event of failure, careful planning is required. It also requires the use of sophisticated equipment as well as accessories for measuring and dispensing medication. All of these necessitate instruction on how to operate them as well as routine maintenance.

Current methods of oxygen synthesis include oxygen concentrators, the Pressure Swing Adsorption (PSA) Technique and Air Separation Units (ASUs) that use the process of cryogenic fractional distillation (Frank, 2006). However, these methods are rather expensive and high maintenance. A more reliable and economical method would be Integrated Energy Systems (IES), which has not been exploited to its full potential yet (Ding et al., 2020). Ion Transport Membranes (ITM) can also produce large volumes of high – purity oxygen (> 99.5%) at low costs (Sudhakar and Kadam, 2021).

On-site production of medical oxygen should also be encouraged if delivery from production plants is to be avoided. The requirement for an on-site oxygen generating system was discovered through consumer research in the market area. This kind of device could furnish enormous amounts of medical-grade oxygen needed for everyday operations to a hospital. It would also reduce the reliance on gas suppliers and the associated troubles of transportation and acquiring of bulk oxygen on a regular basis (Frank, 2006). Considering all these factors and improving the existing systems would help resolve issues and eventually lead to higher production rates and lower costs to meet the current demand. This paper reviews the various medical oxygen synthesis and storage methods along with their economic aspects.

2. Oxygen cylinders

Oxygen cylinders are containers made of metal that hold compressed gasses at high pressures. They range in size from small portable ambulatory cylinders to huge static cylinders when filled with oxygen. A central bank of oxygen cylinders, on the other hand, can be built by setting up a series connection to provide the hospital with piped gas having acceptable backup. They are the most prevalent sources of oxygen, and can be found even in small towns (Paul et al., 2020). These cylinders, however, are not as effective as liquid oxygen cylinders.

Liquid oxygen cylinders are vacuum-sealed, double-walled liquid storage containers composed of high-quality insulating material that hold cryogenic liquid oxygen to reduce evaporation losses. Prior to a patient obtaining oxygen into the nostrils by means of tubes through a nasal cannula, the LMO is required to be evaporated first to a compressed gas and then warmed at ambient or room temperature inside the apparatus. 1 L (liter) of liquid oxygen expands to about 860 L of oxygen gas when evaporated (Madaan et al., 2021). Liquid oxygen is preferred in most large hospitals due to its purity, cost-effectiveness, and vast capacity. Other advantages include portability, continuous flow capabilities, low weight, and long duration. The disadvantage is that it may be delivered from remote locations, increasing transportation costs while also posing a supply problem during natural disasters (Paul et al., 2020).

3. Oxygen synthesis/production methods

3.1. Pressure swing adsorption (PSA) technique

PSA is based on gasses being adsorbed under high pressure. The greater the pressure, the greater the quantity of gas that is adsorbed. An air compressor, drier, filters, dual separation chambers, a reservoir, and controls are the typical parts of the oxygen generation plant (Organization WH 2020).

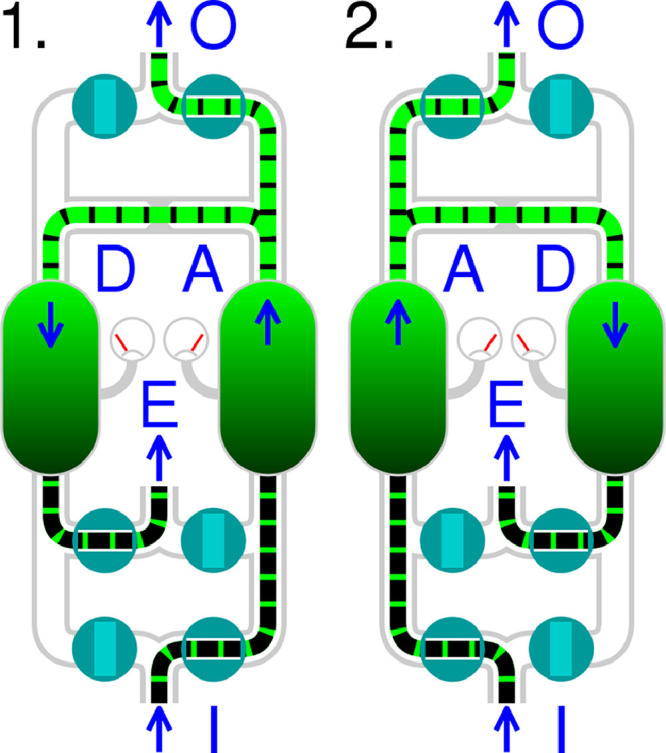

PSA is divided into three subclasses on the basis of the pressure levels in the production and purge steps: Pressure Swing Adsorption, Vacuum Swing Adsorption (VSA), and Vacuum Pressure Swing Adsorption (VPSA) (Arora and Hasan, 2021). PSA is used in Medical Oxygen Concentrators (MOCs). VSA generates oxygen (from air) at high pressures and flows by sending air through a single low-pressure blower and using a valve to reverse its flow. However, this is mainly for industrial use (Madaan et al., 2021). Fig. 1 illustrates the principle of PSA.

Fig. 1.

Principle of PSA (I – air input, O – oxygen output, E – exhaust, A – adsorption, D – desorption. (1) and (2) illustrate alternating adsorption and desorption.) (Wikimedia Commons contributors).

PSA is reliable and generates a stream of 99 mol% pure oxygen because it includes a device that can be utilized even for argon removal from air streams. Because of the similarities between argon and oxygen, the argon removal process is slightly more complicated than the nitrogen removal PSA. A study also looked into argon pressure swing adsorbers to boost the purity of the product stream to 99% (Frank, 2006).

Rapid PSA (RPSA) technique is one where product oxygen is provided to the user on site once the portable unit is attached to an existing compressed air connection. This eliminates the need for an air compressor for the MOC (Rao et al., 2014).

Two-stage PSA techniques combining kinetic and equilibrium separation have also been devised to obtain 99 oxygen from air. A carbon molecular sieve adsorbent removes argon and nitrogen from the air supply kinetically, while a N2/O2 selective zeolite removes the residual nitrogen. Despite this, two-stage procedures, which require more than one compressor or vacuum pump, are frequently complex and energy-intensive. The majority of two-stage units defined in the literature failed to achieve 99.5% oxygen purity until one study showed that the usage of a zeolite AgLiLSX that is selective to argon/oxygen in a two-stage VPSA process can produce an oxygen stream that is 99.5+% pure (Ferreira et al., 2016).

An advantage of VPSA is that it can be done on-site. But the need for multiple compressors/vacuum pumps results in an increase in prices, especially if a larger volume of gas is to be generated. Yet, the total cost of a PSA is substantially lower than that of a liquid oxygen tank. At current market rates, the various PSA constituents and the distribution system would be extremely expensive if all PSA, booster, UPS, generator, and distribution system components, accessories, and maintenance costs for ten years are considered for analysis, making small and medium hospitals self-reliant in providing oxygen at reasonable costs (Madaan et al., 2021).

3.2. Oxygen concentrators

Oxygen concentrators can use different technologies like vacuum swing adsorption, membrane gas separation and PSA process. Membrane gas separation concentrators separate a gas mixture to obtain oxygen using synthetic membranes consisting of polymers like polyamide or cellulose acetate, ceramics, or even nanomaterials. These technologies are more environmentally friendly and require less space, but are very expensive (Madaan et al., 2021).

Idaho National Laboratory (INL) established a model based on a spreadsheet for techno-economic analysis that took into consideration various parameters such as membrane selectivity and permeability, performance conditions and so on to develop understanding of the economical perspective of polymer membrane-based oxygen enrichment in a better way. This cost is lower than PSA and comparable to cryogenic distillation, which achieves its goals only at a considerably higher level (Adhikari et al., 2021). The principal drawback of an oxygen concentrator is the fact that its output could be insufficient to meet oxygen demand during the busiest hours in hospitals, even at maximum flow (Paul et al., 2020).

Portable MOCs have proven to be effective in enabling at-home oxygen therapy for patients infected with COVID-19. A PSA technique with an adsorbent selective to nitrogen is used in the majority of MOCs. WHO states that medical-grade oxygen has 90 to 96% V/V oxygen content, the rest being argon and nitrogen. In order to achieve this high purity, a flexible and modular PSA process is desired. The bed size factor (BSF) and oxygen recovery are very important measures used to evaluate the efficacy of a PSA-based MOC. The BSF is calculated by determining how much adsorbent is required to generate one ton of oxygen per day (TPD) and is expressed in kg ads. O2 TPD−1. As a result, lowering the BSF results in reduced adsorbent inventory and smaller MOC units. Oxygen recovery is calculated by dividing the amount of oxygen recovered at the output by that provided at a cyclic steady state throughout a PSA cycle. Consequently, better oxygen recovery leads to cheaper compression costs and lower ambient air supply flow rates for a given product specification.

When compared to normal PSA operation, MOC is a small appliance with some degree of limitation on adsorbent quantity and rapid cycling, which results in a high energy consumption due to frequent pressure variations. These concentrators have been commercialized, but they are high-priced and difficult to generate in developing countries. For small-scale purposes, however, the comparative uncomplicatedness and dependability of MOCs are important to a greater extent than energy usage (Arora and Hasan, 2021).

3.3. Air separation units (ASUs)

ASUs are energy-intensive plants that produce various grades of nitrogen, oxygen, and argon. ASUs typically have a compression section, a refrigeration section, and a separation section (where separation of air into its constituent compounds takes place based on market demands) (Manenti et al., 2013). ASUs make use of cryogenic distillation for operation, which follows the same ideologies as distillation, except the separation occurs at cryogenic temperatures lower than −150 °C (Frank, 2006).

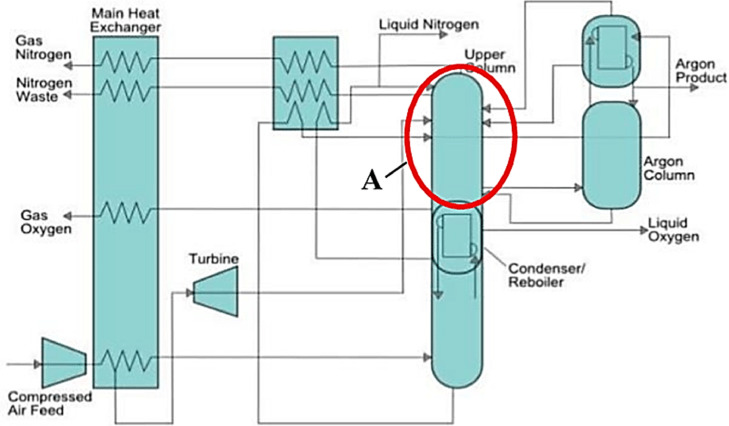

Cryogenic separation is a completely developed technology for separating air at high purity and large production rates (Tesch et al., 2019). The relative volatility of components in a mixture is exploited in this separation process. Nitrogen and argon will vaporize before oxygen when chilled to temperatures that are appropriate for liquefaction. In a distillation column, nitrogen and argon are cooked away, leaving virtually solely oxygen. This separation is able to generate oxygen with a purity of 99.2%, and is a form of in-situ oxygen generation (Frank, 2006). Fig. 2 shows the representation of an ASU.

Fig. 2.

Representation of an ASU (LOX – liquid oxygen, GOX – gaseous oxygen, LIN – liquid nitrogen, GAN – high purity gaseous nitrogen, A – low pressure column) (Pintilie et al., 2019).

The multi-stage compression technique consumes a substantial amount of electricity, costing around $1 billion each year in the United States (before the corona virus pandemic). Due to the pandemic, the demand is much greater.

Different process streams are used for recovering heat/refrigeration inside the system due to the cryogenic operating conditions. This is due to low flexibility. The O2 rich liquid at the bottom of the higher column, for example, is utilized for condensing the N2 rich vapor that leaves the top of the lower column in the main condenser. In a system with pre-existing complexities, such arrangements induce significant degrees of thermal integration and eliminate process degrees of freedom. There also exists inadequate agility. Distillation columns, large, having numerous stages are required to meet the high purity standards. The liquid holdup in these columns causes reaction dynamics to be delayed for quite a long time (Qiao et al., 2012).

3.4. Integrated energy systems (IES)

IES uses advanced technology for converting energy and other resources into different kinds of energy. It is the course of energy development and the cornerstone of the future energy internet, thereby improving energy utilization efficiency and increasing flexibility, safety, economy, and security (Xiang et al., 2020). IES can aid the improvement of the operating flexibility of energy systems because they incorporate a variety of devices and combine heating and electricity systems. As a result, building IES has been viewed as a viable path to reliable and cost-effective renewable energy.

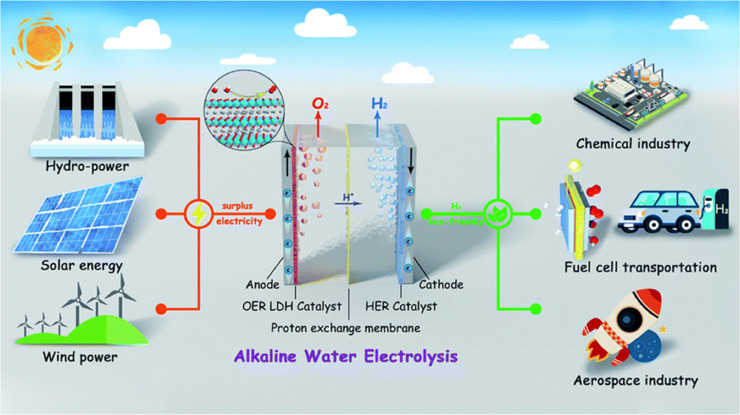

Recently, power to hydrogen (P2H) has been identified as an assuring option for improving IES economics and reducing renewable curtailments owing to hydrogen's ability to create both heat and electricity. P2H is produced in IES by electrolyzing water, which generates hydrogen as well as a considerable quantity of oxygen-enriched gas that is yet to be exploited to a full extent. Medical oxygen can be obtained from oxygen-enriched gas in a cheap way using an oxygen-enriched gas purification system.

The traditional technique of generating medical oxygen with cryogenic ASUs uses 0.61 kWh of electricity per kg of oxygen, whereas purification of oxygen-enriched gas uses 0.04 kWh of electricity per kg of oxygen. As a result, considering the combined generation of hydrogen and medical oxygen could improve the economics of IES in the long run. The schematic diagrammatic representation of the IES system is illustrated in Fig. 3 .

Fig. 3.

The IES system (OER LDH – Oxygen Evolution Reaction Layered Double Hydroxide, HER – Hydrogen Evolution Reaction) (Cai et al., 2019).

When compared to traditional techniques of synthesis, a (P2HO) power-to-hydrogen-and-oxygen system can completely use the P2H system oxygen-enriched gas produced by the and convert it to medical-grade oxygen at minimal prices. The P2HO system, which is built on P2H, allows for the synthesis of both hydrogen and medical oxygen. An alkaline electrolyzer, a hydrogen storage tank, and an oxygen-enriched gas purification system are all included. For electrolyzing water, the alkaline electrolyzer is the most established and practical approach. One portion of the electrical energy from the source(s) is used to generate hydrogen, while the other is transformed to thermal energy by the electrolyzer's electrochemical reaction. The entire electrolyzer is a heat storage device since electrolysis alters the operating temperature, which may be considered as a means of storing heat. Only two contaminants exist in the oxygen-enriched gas: H2 and H2O. H2 and O2 can be converted to H2O with the help of a catalyst. In the end, high-purity oxygen can be created using a molecular sieve to filter H2O. The cryogenic separation also has more steps than the oxygen-enriched gas purification process, leading the latter to be more efficient (Ding et al., 2020).

Dissolved oxygen is indicative of the quality of water. The water is said to be contaminated and its quality is low if the level of dissolved oxygen significantly less. Organic and inorganic contaminants can reduce the level of dissolved oxygen (Bozorg-Haddad et al., 2021) and this is likely to lead to a lower rate of oxygen production.

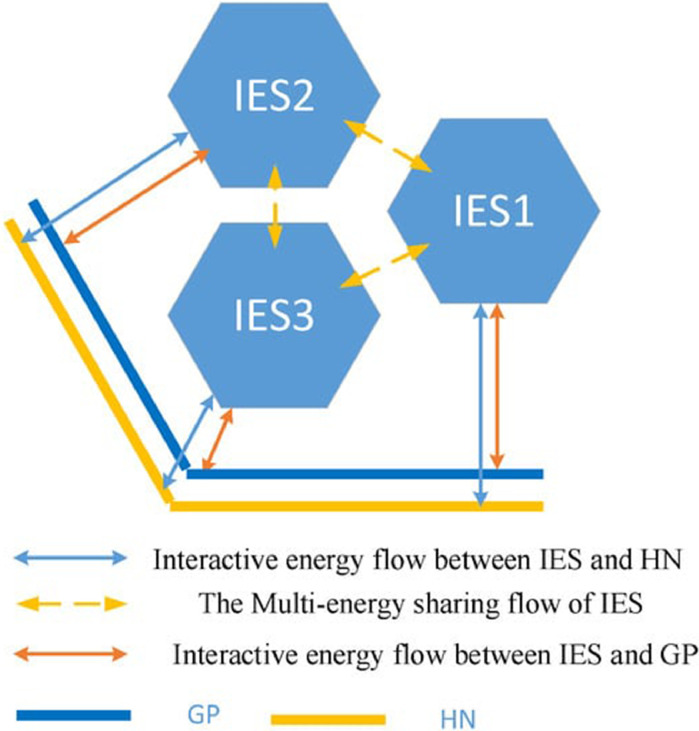

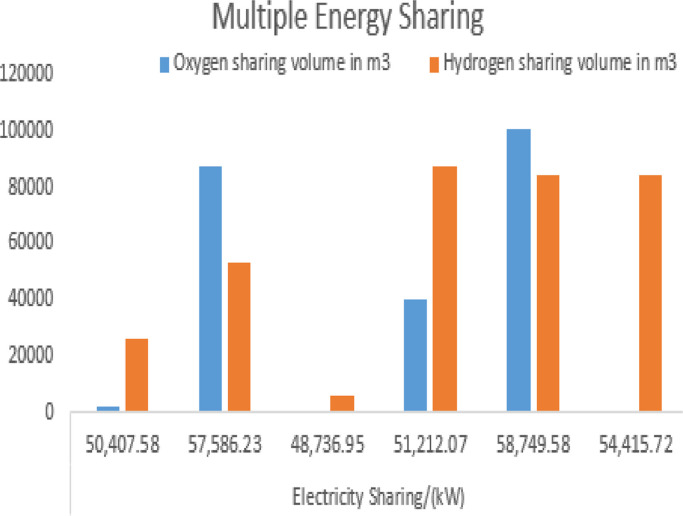

A study on the development of energy planning based on the demand for a dispersed oxygen supply. an IES was built by coupling hydrogen, electricity, oxygen and heat, DRE, ASU and IES was used to improve the traditional IES to achieve very low carbon emissions and improve consumption levels. A multiple energy sharing mechanism of the IES cluster (Fig. 4 ) was adopted to assess hydrogen and oxygen sharing. The cluster cost was reduced and provided a higher economic advantage Fig. 5 shows the multiple energy sharing data and Table 1 shows the comparison of the cluster energy supply revenue (Cui et al., 2022).

Fig. 4.

Multiple energy sharing architecture (HN – Hydrogen Networks, GP – Grid Power) (Cui et al., 2022).

Fig. 5.

Multiple Energy Sharing (Cui et al., 2022).

Table 1.

. Energy supply revenue (Cui et al., 2022).

| Income/(RMB) |

||||

|---|---|---|---|---|

| Electricity Supply | Oxygen Supply | Heat Supply | Hydrogen Supply | |

| IES Cluster Price | 1552,777.50 | 317,194.00 | 537,174.10 | 308,350.30 |

| Market Price | 1645,868.40 | 1185,047.03 | 961,179.10 (G) | 705,210.02 |

| 921,750.00 (E) | ||||

Current applications of IES include the analysis and development of a niche IES based on geothermal energy renewable source for multistage subsystem desalination for freshwater production and production of hydrogen using Copper Chlorine (CuCl) thermochemical cycle (Gevez and Dincer, 2022; Shao et al., 2022).

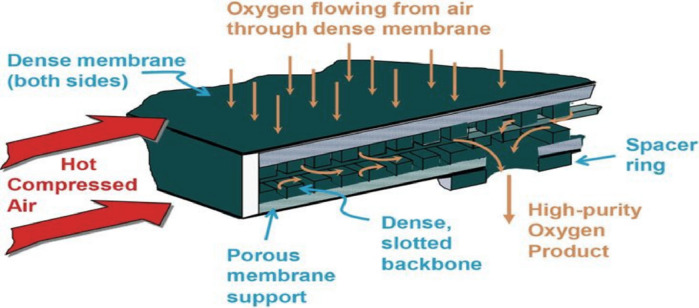

Low-Cost High Purity Oxygen can be obtained by Ion Transport Membranes (ITM) at high temperatures. ITMs can extract oxygen from the air (above 700 °C) Fig. 6 represents an ITM system. In conventional membrane technology, air passes through a membrane filter. Slow gasses will be caught in the filter while fast gasses will pass through it. Different degrees of purity can be reached by varying the length of time the gas is filtered and collected at an outlet. ITM Oxygen can produce oxygen streams with a volume and extremely high purity (over 99.9%) (equal to cryogenic slurry volumetric flow).

Fig. 6.

ITM System.

Previously, membrane technology was limited to purities of about 50%. The ITM was developed by chemicals and products of air, the US Department of Energy, and Ceramatec. Reportedly, this process can produce 99.9% pure O2 at a fraction of the cost of cryogenic separation. Table 2 represents the comparison between ITM system and cryogenic ASU (Sudhakar and Kadam, 2021; Gevez and Dincer, 2022).

Table 2.

Comparison between ITM system and cryogenic ASU (Sudhakar and Kadam, 2021).

| Area Description | ITM Oxygen Plant | Cryogenic ASU |

|---|---|---|

| Oxygen Plant | 41,600 | 61,200 |

| $ / metric ton per day Oxygen produced | 14,300 | 22,200 |

| Cost of installation ($) | 41.6 million | 61.2 million |

The need for medical oxygen has escalated rapidly due to COVID-19 and many people use ventilators or extracorporeal membrane oxygenation (ECMO) for breathing this oxygen, which has only increased the demand further (Ding et al., 2020). Thus, at this moment, it is necessary to consider combining energy systems to facilitate increased supply of medical oxygen for COVID-19 patients.

4. Conclusion

Purity of the product stream (oxygen) and economic aspects of a process are both very important in determining the most efficient method for the synthesis of medical oxygen.

PSA yields high purity oxygen, but is very expensive due to its many components and maintenance costs. Oxygen concentrators are cheaper than PSA and comparable to cryogenic ASUs, but this is true only when they are utilized on a large-scale. Portable MOCs are more effective for small scale applications as they consume a large amount of energy and are high-priced even though they have been commercialized. ASUs use up a large amount of electricity and this affects the economics of the process, resulting in high prices, whereas IES offers the dual benefit of high purity oxygen at low costs as well as renewable-powered energy. It not only uses less electricity, but the devices used for this process are cheaper than those used for cryogenic air separation. Although oxygen-enriched gas purification is not used often due to large electricity consumption by the electrolysis process, in an IES, hydrogen and oxygen-enriched gas are being produced simultaneously, which is why it is more economical than ASUs. ITMs produce large volumes of extremely high purity oxygen at low costs, which means that the issue of production rate could potentially be solved. They are also much more economical than cryogenic air separation.

Oxygen supply is key to overcoming this pandemic and it should be made available to those in need. Everyone must be able to access it and research should continue not only to make the synthesis and production processes less expensive, but also to achieve high large-scale production rates and on-site oxygen generation.

Conflicts of Interest

All the authors declare that there are no conflicts of interests.

Acknowledgement

The authors thank RV College of Engineering for providing the facility for this review studies.

References

- Adhikari B., Orme C.J., Klaehn J.R., Stewart F.F. Technoeconomic analysis of oxygen-nitrogen separation for oxygen enrichment using membranes. Sep. Purif. Technol. 2021;268 doi: 10.1016/j.seppur.2021.118703. [DOI] [Google Scholar]

- Arora A., Hasan M.M.F. Flexible oxygen concentrators for medical applications. Sci. Rep. 2021;11:1–14. doi: 10.1038/s41598-021-93796-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bozorg-Haddad O., Delpasand M., Loáiciga H.A. In: Econ. Polit. Soc. Issues Water Resour. Bozorg-Haddad O, editor. Elsevier; 2021. 10 - water quality, hygiene, and health; pp. 217–257. [DOI] [Google Scholar]

- Cai Z., Xiuming B., Wang P., Ho J., Yang J., Wang X. Recent advances on layered double hydroxide electrocatalysts for oxygen evolution reaction. J. Mater. Chem. A. 2019;7 doi: 10.1039/C8TA11273H. [DOI] [Google Scholar]

- Cui S., Zhu R., Gao Y. Distributionally robust optimization of an integrated energy system cluster considering the oxygen supply demand and multi-energy sharing. Energies. 2022;15 doi: 10.3390/en15228723. [DOI] [Google Scholar]

- Ding H., Hu Q., Ge Y., Wu Q., Dou X., Li Y. Economic operation of integrated energy systems considering combined production of hydrogen and medical oxygen. IET Renew. Power Gener. 2020;14:3309–3316. doi: 10.1049/iet-rpg.2020.0331. [DOI] [Google Scholar]

- Ferreira D., Boaventura M., Bárcia P., Whitley R.D., Mendes A. Two-stage vacuum pressure swing adsorption using AgLiLSX Zeolite for producing 99.5+% oxygen from air. Ind. Eng. Chem. Res. 2016;55:722–736. doi: 10.1021/acs.iecr.5b03535. [DOI] [Google Scholar]

- Frank D. 2006. Technical Report and Market Analysis. [Google Scholar]

- Gevez Y., Dincer I. Investigation of a new integrated energy system with thermochemical hydrogen production cycle and desalination. Appl. Therm. Eng. 2022;203 doi: 10.1016/j.applthermaleng.2021.117842. [DOI] [Google Scholar]

- Karlis G., Barouxis D., Georgiopoulos G., Mitropoulou P., Mastora Z., Xanthos T. Oxygen therapy practices in the acutely ill medical patients: a social media-based nationwide study of clinicians’ preferences and summary of current recommendations. Emerg. Care J. 2020;16 doi: 10.4081/ecj.2020.8867. [DOI] [Google Scholar]

- Madaan N., Paul B., Guleria R. Meeting oxygen requirements of rural India: a self-contained solution. Indian J. Public Health. 2021;65:82–84. doi: 10.4103/ijph.IJPH_1405_20. [DOI] [PubMed] [Google Scholar]

- Manenti F., Rossi F., Croce G., Grottoli M.G., Altavilla M. Intensifying air separation units. Chem. Eng. Trans. 2013;35:1249–1254. doi: 10.3303/CET1335208. [DOI] [Google Scholar]

- Organization WH Technical specifications for pressure swing adsorption (PSA) oxygen plants. Interim Guid. 2020:1–5. [Google Scholar]

- Paul C., Paul J., Babu A. Hospital oxygen supply : a survey of disaster preparedness of Indian hospitals. Indian J. Respir. Care. 2020;9:216–220. doi: 10.4103/ijrc.ijrc. [DOI] [Google Scholar]

- Pintilie M., Șerban A., Popa V., Popa C.L. Design analysis of low pressure distillation column for cryogenic air separation. {IOP} Conf. Ser. Mater. Sci. Eng. 2019;595:12023. doi: 10.1088/1757-899x/595/1/012023. [DOI] [Google Scholar]

- Pravda N.S., Pravda M.S., Kornowski R., Orvin K. Extracorporeal membrane oxygenation therapy in the COVID-19 pandemic. Future Cardiol. 2020;16:543–546. doi: 10.2217/fca-2020-0040. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Qiao Z., Wang Z., Zhang C., Yuan S., Zhu Y., Wang J. PVAm–PIP/PS composite membrane with high performance for CO2/N2 separation. AIChE J. 2012;59:215–228. doi: 10.1002/aic. [DOI] [Google Scholar]

- Rao V.R., Kothare M.V., Sircar S. Novel design and performance of a medical oxygen concentrator using a rapid pressure swing adsorption concept. AIChE J. 2014;60:3330–3335. doi: 10.1002/aic.14518. [DOI] [Google Scholar]

- Shao C., Zhao Y., Qu L. Recent advances in highly integrated energy conversion and storage system. SusMat. 2022;2:142–160. doi: 10.1002/sus2.48. [DOI] [Google Scholar]

- Sudhakar R., Kadam SBDBPAW. IRJET- efficient low cost oxygen generation technique. Irjet. 2021;8:3792–3796. [Google Scholar]

- Su C.L., Lee C.N., Chen H.C., Feng L.P., Lin H.W., Chiang L.L. Comparison of domiciliary oxygen using liquid oxygen and concentrator in northern Taiwan. J. Formos. Med. Assoc. 2014;113:23–32. doi: 10.1016/j.jfma.2012.03.013. [DOI] [PubMed] [Google Scholar]

- Tesch S., Morosuk T., Tsatsaronis G. Comparative evaluation of cryogenic air separation units from the exergetic and economic points of view 2019:1–20.

- Wikimedia Commons contributors. File:pressure swing adsorption principle.svg n.d.

- Xiang Y., Cai H., Gu C., Shen X. Cost-benefit analysis of integrated energy system planning considering demand response. Energy. 2020;192 doi: 10.1016/j.energy.2019.116632. [DOI] [Google Scholar]