Abstract

In the past few decades, 2D layer materials have gradually become a central focus in materials science owing to their uniquely layered structural qualities and good optoelectronic properties. However, in the development of 2D materials, several disadvantages, such as limited types of materials and the inability to synthesize large‐scale materials, severely confine their application. Therefore, further exploration of new materials and preparation methods is necessary to meet technological developmental needs. Organic molecular materials have the advantage of being customizable. Therefore, if organic molecular and 2D materials are combined, the resulting 2D organic materials would have excellent optical and electrical properties. In addition, through this combination, the free design and large‐scale synthesis of 2D materials can be realized in principle. Furthermore, 2D organic materials exhibit excellent properties and unique functionalities along with great potential for developing sensors, biomedicine, and electronics. In this review, 2D organic materials are divided into five categories. The preparation methods and material properties of each class of materials are also described in detail. Notably, to comprehensively understand each material's advantages, the latest research applications for each material are presented in detail and summarized. Finally, the future development and application prospects of 2D organic materials are briefly discussed.

Keywords: 2D organic materials, application, preparation methods, properties, synthesis

Organic molecular and two dimensional (2D) materials combined will result into 2D organic materials, which would have unique optical and electrical properties. The free design and large scale synthesis of 2D materials can be realized in principle. This work summarizes status and challenges of 2D organic materials, and the great potential for developing sensors, biomedicine, and electronics.

1. Introduction

The advent of graphene has sparked great interest in the study of other innovative 2D materials, which have become a hot research topic.[ 1 , 2 , 3 , 4 ] The novel inherent physical characteristics of graphene (electronic, mechanical and heat transfer characteristics) make it a pioneer 2D material for the development of science and technology and other practical applications.[ 5 , 6 ] Interestingly, the research on 2D materials is still in the development stage, so the number of 2D material libraries is growing year by year with new materials being introduced every year. Currently, such libraries comprise more than 150 materials.[ 7 ] In addition to the excellent characteristics of graphene, the new 2D materials exhibit extraordinary potential in biomedicine, sensors, transistors, light‐emitting diodes (LEDs) and catalysis.[ 8 , 9 , 10 , 11 , 12 ] The emergence of these new 2D materials can solve the application limitations of different devices. Even though 2D materials have been previously researched because of their atomic‐scale thickness and unique photoelectric properties, some challenges remain to be solved: i) continuous development of new 2D materials and their structures, which could subsequently induce prominent or significant physical, chemical, mechanical, and optoelectronic properties, and ii) the use of different processing methods to prepare large‐area and low‐cost 2D materials.[ 13 , 14 ] The term preparation is often used to express the action or process of making ready to get almost a known compound by a known method. The term synthesis often expresses combination or composition, in particular, the installation or creation of a new compound by a new method. 2D organic materials show unique advantages in meeting the above‐mentioned challenges. For example, organic molecules have tailorable properties that can realize the free design of 2D materials and substantially enrich the number of 2D material families, thus solving the first challenge.[ 15 ] The small organic molecules are connected by noncovalent bonds and have excellent self‐assembly capabilities; thus, large‐area, high‐quality 2D crystals can be prepared via solution processing methods, solving the second challenge.[ 15 ] Moreover, organic materials have many advantages, such as intrinsic flexibility, amenability of 2D materials toward top‐down and bottom‐up lithography methods; their pliability and ability to be mechanically strained to create new structure–property–function relationships; and their unique chemistry, with large surface areas and low weight.[ 16 , 17 ] Therefore, 2D organic materials have obvious advantages.

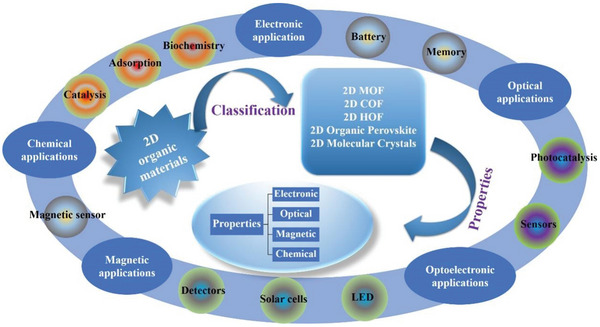

In existing reviews, the research findings are based on a single type of 2D material or certain characteristics, such as the study of 2D transition metal sulfides,[ 18 ] atomic defects in 2D materials[ 19 ] and 2D hybrid perovskite.[ 20 ] These are detailed studies within specific fields, but their research content is limited, and no comparison and summary exist from a broad scope. In this review, considering the entire subject of 2D organic material as a starting point, it is divided into metal‐organic frameworks (MOFs), covalent‐organic frameworks (COFs), hydrogen‐bonded organic frameworks (HOFs), perovskite and molecular crystals according to different structural properties (Figure 1 ). The synthesis, preparation methods, properties and applications in electronics, sensors, biomedicine and other fields of all five types of 2D organic materials, as classified in this study, are explored in detail. Additionally, the challenges and prospects of 2D organic materials are briefly analyzed.

Figure 1.

Classification of 2D organic materials and related applications.

2. 2D Organic Materials

2D organic materials are considered the most attractive new class materials. They have always been the focus of research by scientists and have been widely used in various fields.[ 12 , 21 ] Herein, 2D organic materials are classified into five classes. This section briefly describes each class. The term preparation is often used to express the action or process of making ready to get almost a known compound by a known method.

2.1. Metal‐Organic Frameworks (MOFs)

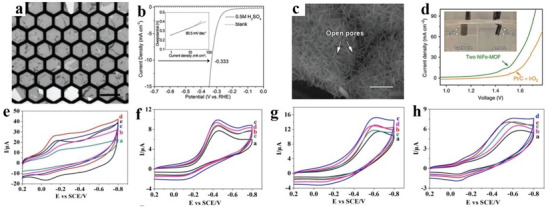

Many researchers are very interested in studying 2D MOFs. MOFs are porous crystalline materials, formed by self‐assembled metal ions and organic ligands. The continuous research and studies on them reveal that there are > 2 × 104 MOFs, where different metal ion‐center and organic junction(s) are linked. MOFs can be grown into different 3D, 2D, 1D, and 0D forms. They can also be used as active materials for electrocatalysis and energy storage applications. Notably, MOFs can be transformed into a huge spectrum of functional materials through various methods, such as pyrolysis and chemical and physical treatments.[ 22 ]

2D MOFs being a branch of MOFs bear many important characteristics of this family. They combine the advantages of MOFs and 2D structure, and show more prominent characteristics in catalysis, bionic enzyme and sensor applications. However, the synthesis processes of 2D MOFs are relatively difficult and time‐consuming.[ 23 ] The most common members of the 2D MOF family are isoreticular MOFs (IRMOFs),[ 24 ] zeolite imidazolate frameworks (ZIFs)[ 25 , 26 , 27 , 28 ] and materials of institute Lavoisier (MIL).[ 29 ] ZIF is often used as a solid‐phase precursor of carbon nanomaterials, and MIL is widely accepted by scholars because of its large specific surface area and stable structure.

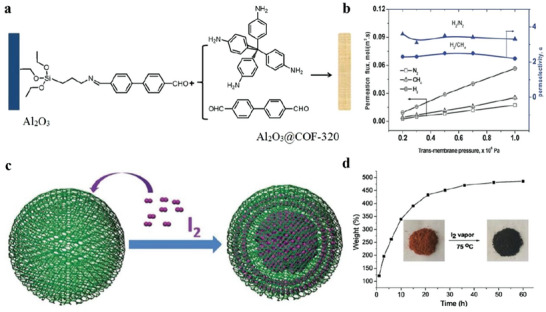

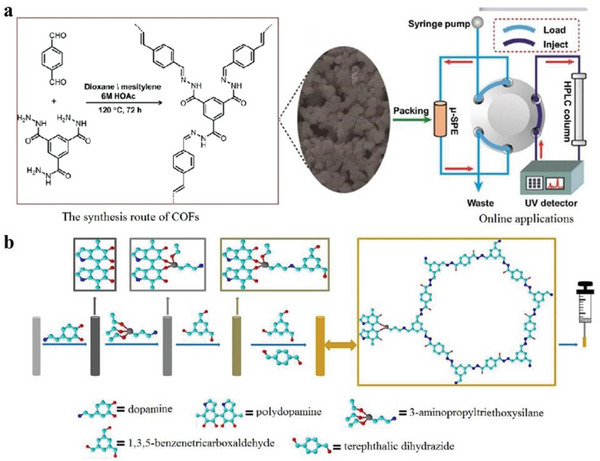

2.2. Covalent‐Organic Frameworks (COFs)

2D COFs are porous materials that have attracted increasing research attention because of their interesting structure, like an organic framework, adjustable porosity and predictable framework. When compared with short‐range covalent polymers connected by irreversible condensation, COFs differ considerably.[ 30 ] 2D COFs reflect a very ordered crystal structure formed through a reversible reaction.[ 31 ] Generally, conventional crystalline porous solids (such as zeolite[ 32 , 33 ]) have precise predesigned structures, and can achieve function‐oriented structure and chemical control.[ 34 ] Additionally, 2D COFs have many advantages, such as structural multiplicity,[ 35 ] low density,[ 36 ] high thermal stability[ 37 , 38 ] and permanent porosity.[ 39 ] Herein, three aspects of 2D COFs are elaborated by considering their unique structure.

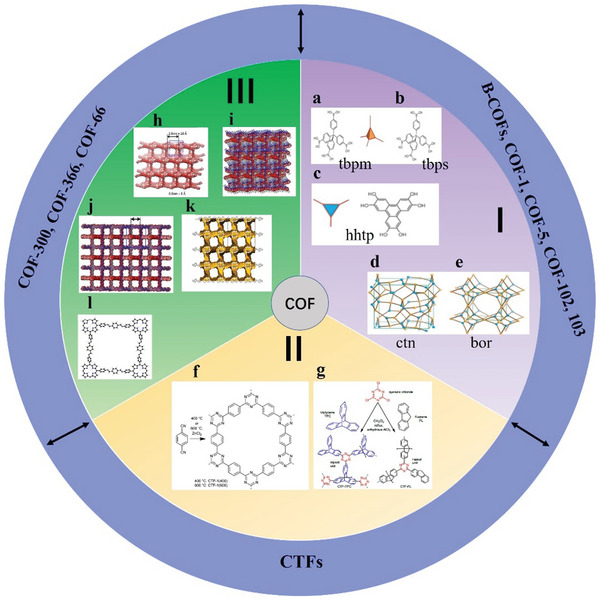

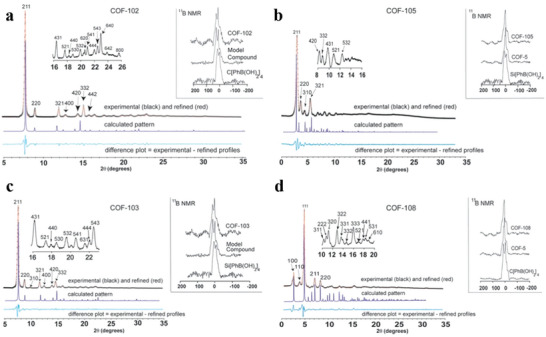

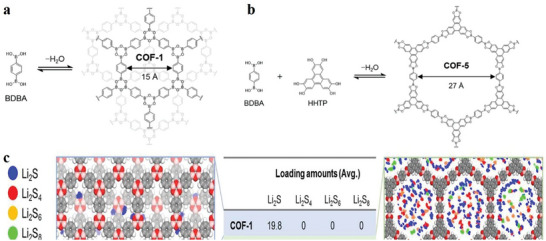

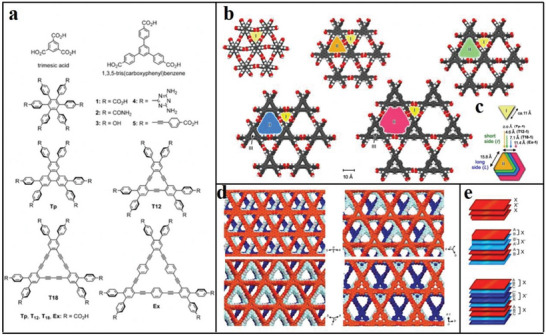

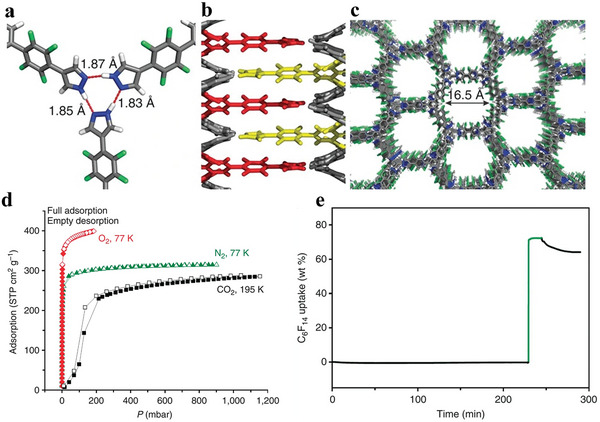

The first category includes highly porous 2D crystalline materials comprising light elements (C, H, N, O, and B) with large surface areas, such as B‐COF, COF‐1, COF‐5, COF‐102 and COF‐103.[ 40 , 41 , 42 , 43 , 44 , 45 , 46 , 47 ] These special properties enable 2D COFs to be used for gas separation and storage applications.[ 40 , 41 , 42 , 43 ] Crystalline 2D COFs comprising 2D COF‐102, COF‐103, COF‐105 and COF‐108 structures are a product of co‐condensation and self‐condensation formed by a rigid molecular structure. These structures comprise four sides (2a–c).

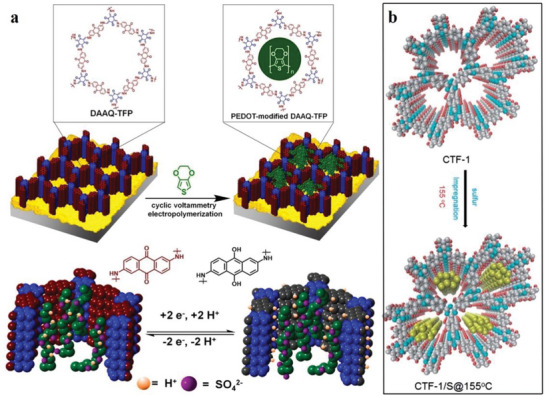

The second category includes the covalent triazine framework (CTF). CTFs have the advantages of a large surface area ratio and high thermal stability.[ 48 , 49 ] CTFs are cheap and easy‐to‐obtain original materials that are easily synthesized and have a certain hydrophilicity. Figure 2f,g shows the structure of CTF‐1, CTF‐TPC and CTF‐FL.

Figure 2.

a,b) Tetrahedral and c) triangular structures (orange polyhedron and blue triangle, respectively). These structures are shown online in c) ctn and d) bor. Reproduced with permission.[ 45 ] Copyright 2007, American Association for the Advancement of Science. f,g) Structure of CTF‐1, CTF‐TPC and CTF‐FL. Reproduced with permission.[ 55 , 56 ] Copyright 2015, The Royal Society of Chemistry. h–k) Rhomboid symmetry, interpenetrating structure and pore diameter, respectively. Reproduced with permission.[ 57 ] Copyright 2016, Wiley‐VCH. l) Unit cell of COF‐366. Reproduced with permission.[ 58 ] Copyright 2013, Elsevier Ltd.

The third category includes 2D COF‐300, COF‐3, and COF‐66. COF‐300 are crystalline and microporous COFs connected by imines. They have large surface areas of ≈1400–1500 m2 g−1 and are highly crystalline.[ 44 ] The pore diameter of the hole is ≈8 Å for interpenetrating structures and 28–30 Å for noninterpenetrating structures (Figure 2h–k). Herein, these structures are classified as amine‐based 2D COFs mainly because imine functional groups bind them together. According to the inspiration of the internal zeolite reaction, this material could be used as the main component of catalysts, such as those used in cross‐coupling reactions.[ 50 , 51 , 52 , 53 ] The relevant parameters of the unit cell of 2D COF‐366 are a = b = 25.696 Å and c = 12.541 Å with the P4/m space group. Its unit cell comprises 16 N, 120 C and 76 H atoms.[ 54 ] The AA stacking sequence is formed by the 2D COF‐366 crystal structure. The AA distance between each layer is 6.27 Å, and the hole diameter is 20 Å.[ 54 ] Tetra(p‐aminophenyl) porphyrin (TAPP) with a periodic framework contains a bond with terephthalaldehyde in each layer (Figure 2l).

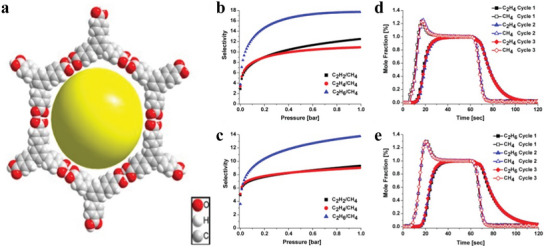

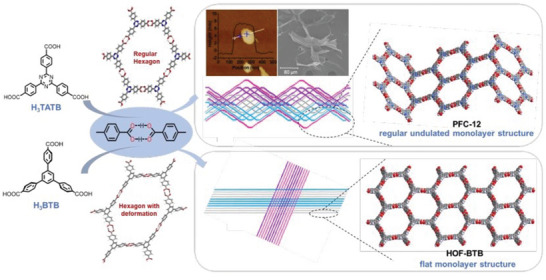

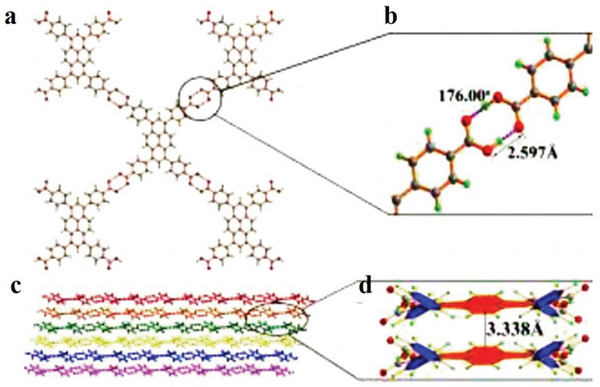

2.3. Hydrogen‐Bonded Organic Frameworks (HOFs)

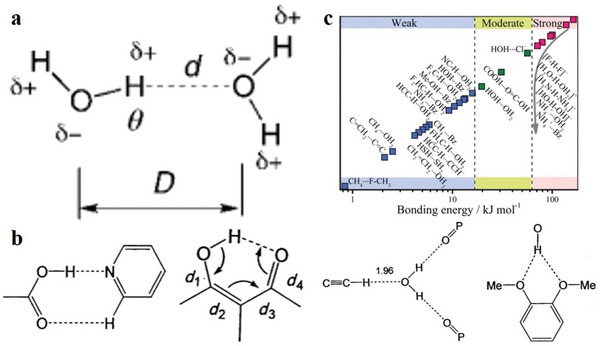

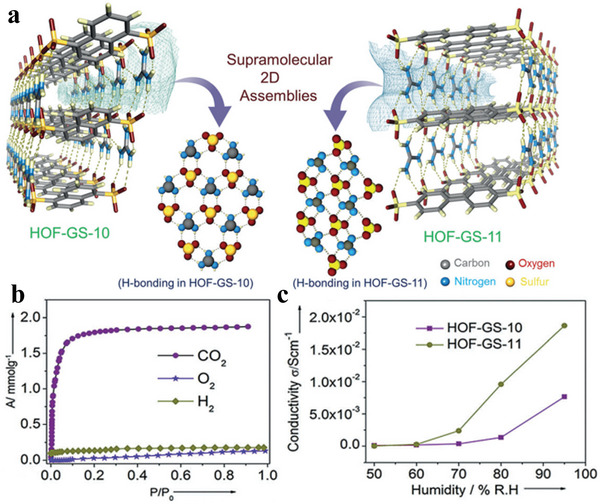

Intermolecular hydrogen bonds are the bridge of organic molecules; simultaneously, crystalline materials assembled under the synergistic action of π–π stacking and other intermolecular forces are called HOFs.[ 59 , 60 , 61 , 62 , 63 ] In 1997, Wuest et al. constructed a crystalline network structure connected by hydrogen bonds through small organic molecules containing 2,4‐diaminotriazinyl (DAT) motifs.[ 64 ] Until 2005, Sozzani et al. constructed the first 2D HOF materials with stable structures and permanent holes, thus actualizing the development of HOF materials.[ 65 ] As an important part of HOF materials, 2D hydrogen‐bonded organic materials have unique superiorities of mild synthesis conditions, high crystallinity, strong solvent machinability and large specific surface area; additionally, they have potential applications in many fields.[ 60 , 66 , 67 , 68 , 69 ] After several years of development, various small organic molecules with hydrogen bond donors or acceptors have been developed to construct 2D HOF materials. However, the skeleton often collapses after losing solvent molecules owing to the low bond energy of hydrogen bonds; hence, the synthesis of 2D HOFs materials with permanent pores is a problem that requires resolution.[ 70 ] Recently, the synthesis of 2D HOF materials with a new structure, new functions, unique properties and lasting porosity has been one of the main topics of research in porous materials.

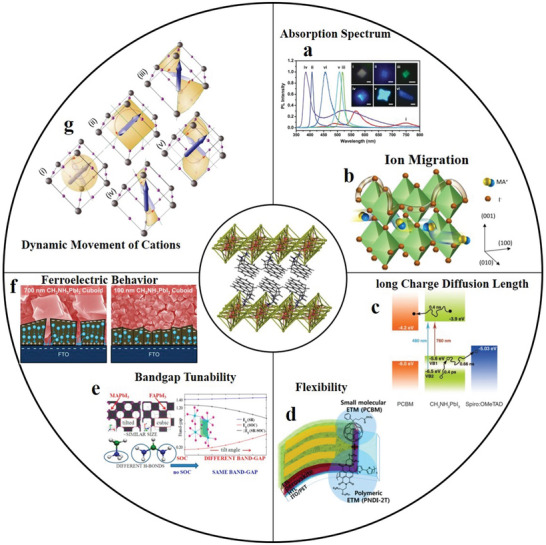

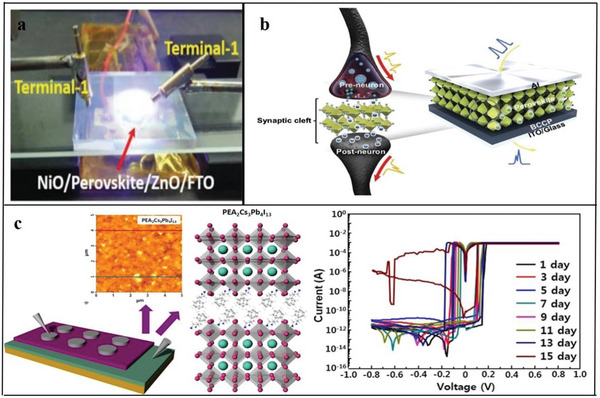

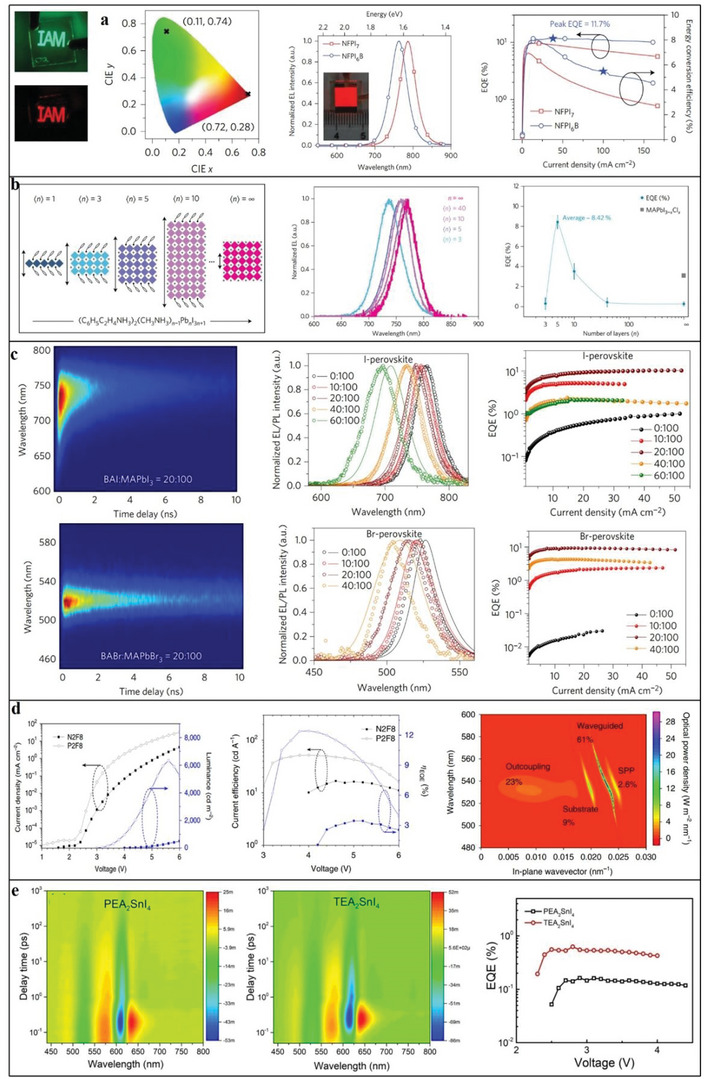

2.4. Perovskite

Perovskite is recognized as the most promising new‐generation photovoltaic material; its structural formula is ABX3. The perovskite family can be expanded by replacing A, B and X with different materials.[ 71 ] Of these, organic perovskite materials are formed by replacing A with organic cations, and 2D organic perovskite materials are obtained using different methods.[ 72 ] Currently, scientists have studied more 2D organic perovskite materials as follows. First, according to different monovalent cations A, it can be divided into (MA)BX3 (MA+ = CH3NH3 +), (PEA)BX3 (PEA is phenyl ethyl ammonium) and (FA)BX3 (FA+ = HC(NH2)2 +). Then, according to different divalent cations B (mainly Pb2+and Sn2+), it can be divided into APbX3 and ASnX3. Finally, according to different anions X (mainly halide ions), it can be divided into ABI3, ABCl3 and ABBr3.[ 72 ] They roughly include all 2D organic perovskite materials.

The 2D perovskites materials are much more stable as compared to 3D due to organic ligands protection. Also as compared to 3D, 2D perovskites possess natural quantum well. Wider energy band and good ambient stability. 2D perovskites possess several tremendous properties such as control quantum wells width. Ultrafast transfer of energy and dense film formation, which shows excellent potential in the field of optoelectronics and spintronics. The combination of organic–inorganic hybrid lead halide perovskite materials would bring tremendous progress in light‐emitting and photovoltaics applications. The efficiency of perovskite solar cells is above 25%, whose power conversion quite better than best silicon solar cell. Additionally, asymmetric lattice structures and extra spacing cations give extra degree of freedom, which enhanced intrinsic physical properties such as exciton binding energy, optical bandgap, and dielectric constant. The photophysical behavior such as charge carrier transport, exciton dynamics and electron–phonon coupling is sturdily enhanced the performance of LEDs and solar cells. The 2D perovskites have strong optical anisotropy, where dipole moments polarized in inorganic framework. Also 2D perovskite crystals at grain boundaries have edge states, which caused exciton dissociation into the free carriers. Like 3D perovskites, 2D perovskites also possess strong electron–phonon coupling. This belongs to ionic nature and materials stiffness.[ 73 , 74 ]

Currently, most research on 2D organic perovskite materials is performed in the field of optoelectronics, especially for solar cells. Related reports continuously explore the photoelectric conversion efficiency and search for materials with low cost, high efficiency and good film‐forming ability. Additionally, because 2D organic perovskite materials have excellent electrical and optical properties,[ 75 ] a new wave of research has been launched in many other fields, such as electronic devices and photovoltaics.[ 76 , 77 ]

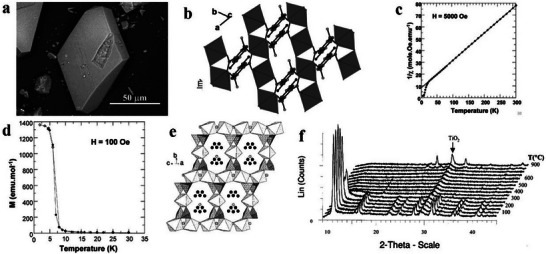

2.5. Molecular Crystals

Molecular crystals are a new type of 2D organic electronic material with highly uniform morphology, horizontally continuous atoms and highly ordered molecules. They are one of the most popular material candidates in recent years. Molecular crystals have an interface interaction that can be well confined in a 2D range, showing the effects of different layers and increasing the efficiency and quality of carrier injection and modulation. Moreover, they have the advantages of minimum charge trap concentration, perfect structure and no grain boundaries. Additionally, 2D molecular crystals effectively enhance field‐effect transistor performance owing to their ultra‐thin structural characteristics and excellent interface quality. 2D molecular crystals have attractive application prospects in advanced electronic technology because of their unique advantages, lightweight structure, material versatility and chemical and environmental stability. Molecular crystals provide new insight into the generation of layered and heterostructures.

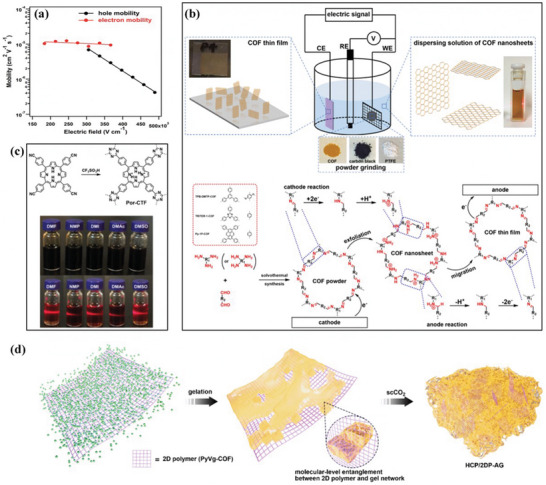

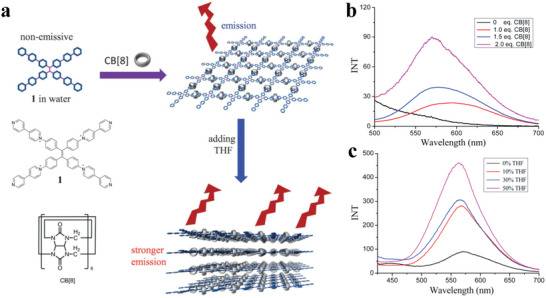

2.6. The Solution‐Processed COFs and Amorphous Porous Materials

In order to design the next generation of 2D materials, covalent organic frameworks (COFs) are emerging materials. COFs are used as processable and insoluble solids for thin film preparation in optoelectronics applications. The highly soluble crystalline COF material is prepared by interlayer interactions. These COFs are significantly soluble in several organic solvents and form truly stable solution form. The solution process‐ability COFs with unique features of large area, high quality can be done on several substrates in efficient manner with control thickness. These materials with such compatibility are used in various device applications. COFs films show electrically anisotropic behavior, which means its intralayer has rare carrier conduction whereas the interlayer has the highest conduction rate, as shown in Figure 3a which opens a novel path for the high‐performance COFs with diverse functions for optoelectronic devices such as transistors, diodes, photocatalysis and energy storage.[ 78 ] Initially, synthesis of covalent organic frameworks (COFs) thin films was a major challenge. For this purpose, an electrocleavage synthesis strategy was introduced, in which at room temperature from electrolyte solutions COF films is directly linked on electrodes, as shown in Figure 3b. This caused COFs cathodic exfoliation, which converts COF powders into nanosheets through electrochemical reduction and protonation. In which nanosheets move towards anode producing COFs structures by anodic oxidation. Such kinds of COF s films provide excellent platform to promoting mass transfer and also have high rate constants due to extraordinarily rapid iodine adsorption.[ 79 ] Another method is to make TPCP solutions, in which synthesis of extremely soluble proton‐exfoliated TPCP into the TPCP skeletons is done. This TPCP solution contains excellent thermoelectric properties. Here charged colloidal spheres possess electrostatic repulsive behavior. Such TPCP charges make ionic bonds, which are highly soluble and cause processability into high‐quality films highest power factor. These significant results an excellent platform for thermoelectric materials.[ 80 ] Generally, proton‐conducting membranes in 3D form are used in fuel cells. Now a day's a new strategy is being used by combing material flexibility and solution processing into porous and amorphous polymers. We prepare nanoporous polymer as the proton‐accepting site to generate heavy charges upon polymer skeletons, which makes organic polymers to significantly disperse into the organic solvents and make amorphous and uniform membranes. Such kinds of membranes contain proton conductivity of 0.30 S cm−1 (298 K and 90% relative humidity), low resistance of 3.02 Ω, and a H+ transport number of 0.98 that was very close to the upper limitation of 1.0.[ 81 ] Hyper cross‐linked polymers (HCPs), in 3D shape, have covalent organic linkage and are promising materials due to easy functionalization and large surface area. But such materials have low processability due to linkage rigidity on covalent crosslinking. But still solution processability for several applications is still challenging. Generally, HCPs form insoluble powder rather than gels. The HCP gels from a thermally induced polymerization, which makes a solubilization, covalent bond. This gel contains hierarchical porosities and mechanical stiffness. Such HCP gels are also used for molecular‐level hybridization with 2D polymers during the formation of HCP gel. This procedure forms functional gels and aerogels, which increase the mechanical stiffness and porosities, as shown in Figure 3d. Hybrid gels can also be used for water contaminants separators with the efficiency of 97.9 and 98.6% for methylene blue and KMnO4, respectively. These results revealed the HCP gel potentials and their hybrid derivatives are used in separation systems requiring macroscopic scaffolds with hierarchical porosity.[ 82 ]

Figure 3.

a) Dependence of the hole (black line) and electron (red line) mobility in the COF films on the electric field in the vertical direction by a TOF method. Reproduced with permission.[ 78 ] Copyright 2019, Royal Society of Chemistry. b) Electrocleavage synthesis of solution‐processed, imine‐linked, and crystalline covalent organic framework thin films. Reproduced with permission.[ 79 ] Copyright 2022, American Chemical Society. c) Schematic representation of protonated TPCP. Reproduced with permission.[ 80 ] Copyright 2021, Wiley‐VCH. d) Photographs of the TPCP dissolved in various solvents. Upper: concentrated solutions under sunlight; lower: dilute solutions under 365 nm UV light showing the Tyndall effect. Reproduced with permission.[ 82 ] Copyright 2022, American Chemical Society.

2.7. Others

2D organic materials have always been the focus of scientific research. In addition to the above five categories, some materials belong to 2D organic polymers, such as 2D hyper‐cross‐linked polymer (HCP), 2D conjugated microporous polymer (CMP) and 2D inherently microporous polymer (PIM).[ 83 ] Porous polymers can be designed and prepared at the molecular level, and have a controllable surface area along with a good pore structure, which is conducive to combining various chemical functional groups into a porous structure. Because of the diversity of the structure of 2D organic materials, they may be used to optimize electronic conductivity and higher carrier conductivity, for example, 2D self‐assembled monolayers (SAMs).[ 84 ] SAMs can form a monolayer molecular film through the self‐assembly of surfactant molecules, and the head and tail groups of the constituent molecules can be tailored to obtain desired properties.

3. Synthesis of 2D Organic Materials

In existing research reports, most 2D organic materials are obtained from the bulk counterpart.[ 85 ] This synthetic method considerably limits the discovery of 2D organic materials and the practical application of 2D material in various fields also in addition to posing huge challenges.[ 86 ] Therefore, scientists are continuously exploring better preparation methods for 2D organic materials, such as the solution, solvent evaporation and diffusion methods. The term synthesis often expresses combination or composition, in particular, the installation or creation of a new compound by a new method. This review explains the synthesis methods of 2D organic materials in detail and discusses more options and challenges for the future of this emerging field.

3.1. Synthesis of MOF

The synthetic methods of 2D MOFs are mainly distributed into two types, top‐down and bottom‐up approaches, which will be introduced in this section. Top‐down methods include ultrasonic stripping and interface synthesis. Bottom‐up methods include the surfactant‐assisted, soft template‐assisted and template methods.[ 87 ]

The mechanism behind the use of 2D materials is that they possess exceptional optical, thermal, mechanical, and electrical properties. These materials include thin sheets, monomer units, covalent in‐plane bonding and layer‐substrate bonding leads to distinguished chemical and physical properties, such as catalysis, sensing, separation, energy storage and conversion, and other related fields.

Also, 2D nanostructures of organic materials possess distinctive features in biofunctionality and are quite sensitive to bioanalytes, Which help to design highly effective biosensors. The 2D organic structure with peculiar properties, such as lightweight, easy production, low cost, and ecofriendly nature, extend their scope in several 2D nanodevices. The organic materials are outstandingly suited to produce sustainable, bendable, and biodegradable ultrathin electronics. Good accessibility of bio/chemical‐functionalities and material softness, 2D organics promise high potential for use in bio/chemical sensing applications. However, like to inorganic 2D materials, 2D organics materials and nanodevices are not much‐studied yet.[ 88 , 89 ]

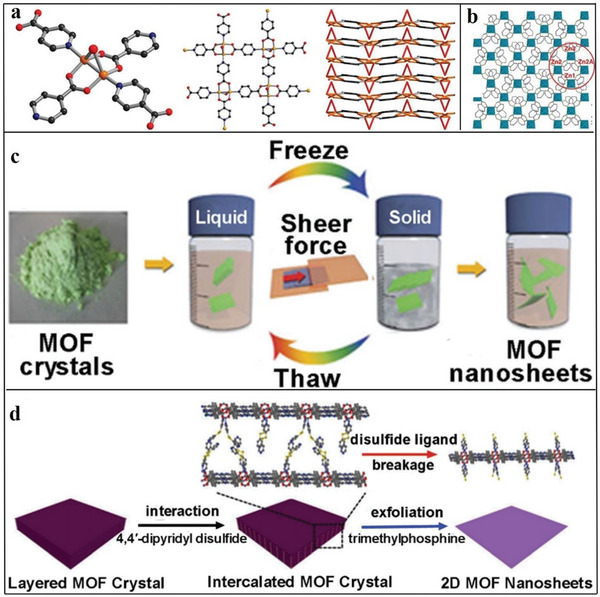

3.1.1. Top–Down Synthesis of 2D MOFs

The top‐down method mainly resists the interlayer interactions of layered MOF and peels the layered MOF into 2D nanometer sheets.[ 90 , 91 ] For example, Zamora et al. prepared [Cu2Br(IN)2] n by a top‐down ultrasonic stripping method, which is 2D MOF.[ 87 ] In the structure of the product demonstrated in Figure 4a, the layered structure comprises a copper dimer, bromide ligands and four isonicotinic acid ligands. The 2D layer along the ɑ shaft is stacked to form the final crystalline state.[ 92 ] Yang et al. stripped a monolayer of 2D MOFs (Zn2(bim)4) using a top‐down method.[ 93 ] The original large MOF crystals are stacked along the axis by interlamellar van der Waals forces. As shown in Figure 4b, a layer of Zn2(bim)4 comprises an irregular geometry formed by zinc ions and four benzimidazole ligands. Large MOF crystals are formed by stacking the layers through Van der Waals forces. First, the original big‐sized crystal was ground by a rotating wet ball at 60 rpm, and stripped using ultrasonic technology. During the stripping process, Yang et al. used a compound of methyl alcohol and n‐propanol (volume rate = 1:1). The grinding process accelerated the spread of methanol molecules into the crystal, and the n‐propanol adhered to the surface of the detached nanometer sheet, thereby protecting the nanometer sheet. Zhao et al. used a top‐down method to synthesize Ni8(5‐BBDC)6(µ‐OH)4 (beseeched as MAMS‐1).[ 99 ] The main method entails adding MAMS‐1 crystal powder to n‐hexane, freezing the solution in liquid nitrogen at ‐196 °C and putting it in water at 80 °C. During the conversion of n‐hexane in the solid and liquid states, a cutting force can be generated to act on the MAMS‐1 crystal, transforming it into a nanosheet structure (Figure 4c). Zhou et al. also used a top‐down approach to strip out MOF nanocrystals.[ 94 ] First, layered Zn2(PdTCPP) was produced, and dipyridine ligands (4,4ʹ‐dipyridine disulfide (DPDS)) were inserted as intercalators into the MOF to obtain intercalated crystal Zn2(PdTCPP)(DPDS). The coordination between DPDS and metal crystals weakens the interlayer interaction of the MOF. Then, the disulfide bond is detrimethyl phosphineylphosphine, and Zn2(PdTCPP)(DPDS) is decomposed into monolayers of MOF nanosheets (Figure 4d).

Figure 4.

a) Position of Cu in [Cu2Br(IN)2] n , construction of monolayer [Cu2Br(IN)2] n and heaping of the layer down the ɑ‐axis. Reproduced with permission.[ 92 ] Copyright 2010, Royal Society of Chemistry. b) Monolayer Zn2(bim)4 nanometre sheet structural graph. Blue represents the irregular polyhedron of zinc coordination, and the bar shape represents the bim ligand. Reproduced with permission.[ 93 ] Copyright 2014, American Association for the Advancement of Science. c) Schematic of freezing and thawing process of MAMS‐1 crystal spalling into dispersed nanosheets. Reproduced with permission.[ 95 ] Copyright 2017, Nature Publishing Group. d) Definition graph of 2D MOF nanosheet synthesis by intercalation and chemical spalling. Reproduced with permission.[ 94 ] Copyright 2017, American Chemical Society.

The top‐down approach is simple, but has a low yield, which makes it more difficult to use practically. Therefore, finding a more effective stripping method is necessary to increase the yield.[ 87 ]

3.1.2. Bottom‐Up Method

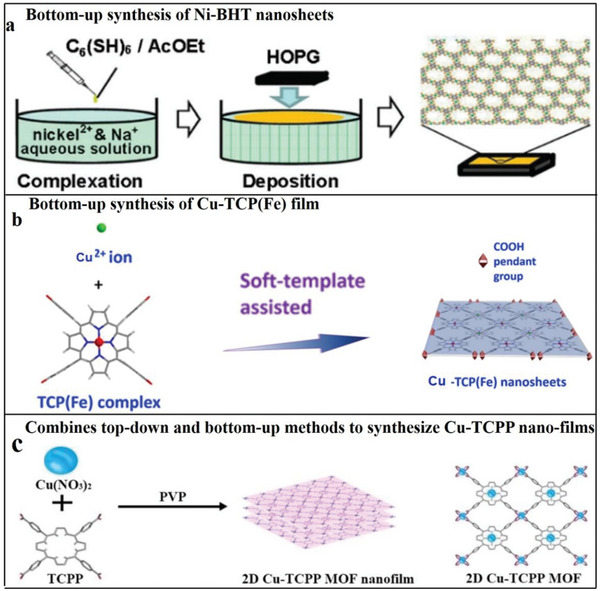

The bottom‐up medium is used to synthesize 2D MOFs nanoflakes from organic ligands and metal ions. This method inhibits the germination of MOF in one direction to form 2D MOFs. Zhu et al. synthesized Cu‐BHT nanosheets at the water–dichloromethane junction surface using a bottom‐up approach.[ 96 ] BHT was added to dichloromethane, and water was added to the admixture to form an oil–water junction surface. Cu and BHT ligands meet at the interface to constitute Cu‐BHT nanosheets. Nishihara et al. synthesized Ni‐BHT nanosheets by the bottom‐up method.[ 97 , 98 ] They inserted the BHT ligand into the ethyl acetate liquor, and added the mixture into aqueous solution. Afterwards, the ethyl acetate was evaporated, and a stratum of BHT ligands was formed on the water skin layer. After 2 h, Ni‐BHT nanocrystal was formed on the liquid‐gas junction surface, and turned into the highly oriented pyrolytic graphite substrate (Figure 5a).

Figure 5.

a) Principle scheme: f Ni‐BHT nanosheet synthesis at water–air interface. Reproduced with permission.[ 97 ] Copyright 2013, American Chemical Society. b) Synthesis graph of polycation‐regulated 2D Cu‐TCP(Fe) membrane. Reproduced with permission.[ 99 ] Copyright 2017, American Chemical Society. c) Framework of Cu‐TCPP nanofilm and synthesis diagram of 2D Cu‐TCPP nanofilm. Reproduced with permission.[ 23 ] Copyright 2019, Royal Society of Chemistry.

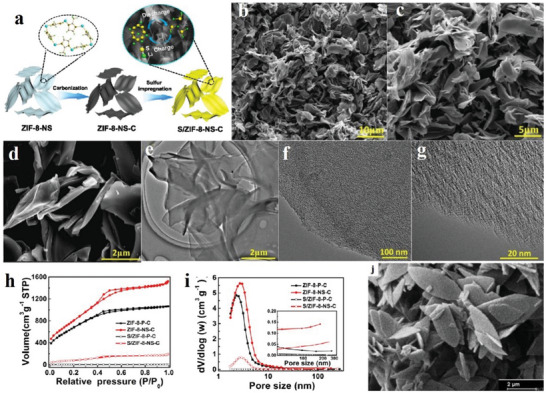

When studying 2D MOFs, Ang et al. synthesized a 2D Cu‐TCP(Fe) membrane by the bottom‐up approach. First, Cu‐TCP(Fe) nanomaterials were made by a soft template‐assisted method comprising Cu2+ and TCP (Fe) complexes, forming a leachy framework. (Figure 5b).[ 99 ] Using the method of preparing the Cu‐TCP (Fe) membrane, Ang and Hong synthesized the Co‐TCP(Fe) and Zn‐TCP(Fe) membranes by replacing Cu bits with Co and Zn bits, respectively.[ 99 ] He et al. synthesized a 2D‐ordered hole IRMOF‐8 (H‐IRMOF‐8) material while studying 2D MOFs. The synthesis method is relatively simple. DMAC was added to a flask, and Zn(OAc)2·2H2O, 2,6‐naphthalene dicarboxylic acid, lanthanum and PVP k‐30 were added to the DMAC. The compound was magnetically stirred at 60 °C for 30 min, separated by centrifugation, and purified with ethanol many times. During the synthesis, the mesopores were introduced into the original IRMOF‐8 via a competitive coordination strategy.[ 25 ] Jiang et al. proposed 2D hierarchically porous carbon (2D‐HPC) nanosheets, which can be applied as the main material in lithium–sulfur batteries. Jiang et al. synthesized monocline ZIF‐8 nanosheets (at room temperature) and further derived 2D‐HPC nanoflakes (ZIF‐8 nanosheet carbon is expressed as ZIF‐8‐NS‐C). The experimental steps are described as follows: Zn(NO3)2•6H2O and 2‐methylimidazole (Aladdin) were added to two clean measuring glasses of deionized (DI) water and stirred for 24 h at normal temperature to become a white solid. The white solid was collected, cleaned and dried to form ZIF‐8 nanosheets (ZIF‐8‐NS) or ZIF‐8 particles (ZIF‐8‐P). Next, the ZIF‐8 nanoflakes or particles were set on a ceramic bowl and heated to 920 °C under argon flow for 2 h. When the product was cooled, it was mixed with potassium hydroxide at a quality rate of 1:4. The compound was heated to 700 °C for 2 h, and then the temperature of the solution was down in an argon gas stream. The products obtained afterwards were rinsed with water and methanol severally and desiccated at 60 °C for a day to obtain ZIF‐8‐NS‐C (ZIF‐8‐P‐C). Next, sulfur was added at a mass ratio of 3:7, and was heated at 155 °C for 20 h. Furthermore, it was cooled by argon flow, and the resulting product was named S/ZIF‐8‐NS‐C (S/ZIF‐8‐P‐C).[ 28 ]

2D ZIF materials have strong adsorption capacities, so researchers aim to synthesize ZIF materials to be used as adsorbents to remove heavy metals, fuels and other harmful substances.[ 25 , 100 , 101 , 102 ] Nasir et al. synthesized 2D leaf‐shaped ZIF (ZIF‐L) using the top‐down approach as an adsorbent. The synthesis method is as follows.[ 25 , 101 ] First, hexahydrate zinc nitrate (Zn(NO3)2·6H2O) and dimethyl sulfoxide were added to DI water. The resulting mixture was stirred for 4 h. After centrifugation for another 10 min, the resulting product was rinsed thrice with fresh methanol and desiccated in the cabinet for a night.[ 25 ] RiouCavellec et al. synthesized 2D trimer iron [Fe(H2O)2(C9O6H4)]H2O via the hydrothermal method, which is a bottom‐up approach, and named it MIL‐67. MIL‐67 was synthesized by mixing iron powder, 1,2,4‐benzene tricarboxylic (or terephthalic) acid and water. Afterwards, the mixture was added to a PTFE‐lined stainless steel acid digester and heated. The mixture was filtered and the resulting solids were rinsed with distilled water and desiccated.[ 103 ] Serre et al. synthesized 2D [Ti3O2(OH)2(HPO4)2(PO4)2]·(NH3‐(CH2)3‐NH3)2·(H2O)2 through a bottom‐up approach and named it MIL‐283.[ 104 ] MIL‐283 is of the 2D structure. Hydrated titanium dioxide, H3PO4, HF, 1,3‐diamino propane and H2O were mixed. By placing the mixture in a Teflon‐lined steel autoclave and leaving it to rest for 4 d, a mixture with pH = 4 can be formed. The resulting white sediment was washed with softened water and dried at room temperature.

3.1.3. Combination of Top‐Down and Bottom‐Up Methods

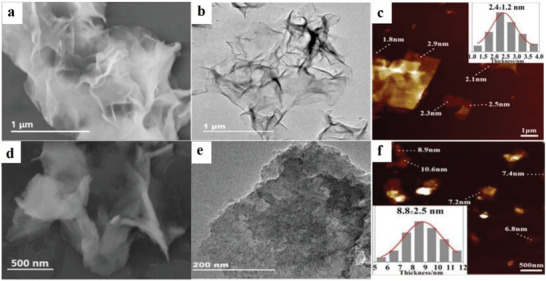

Some studies combine top‐down and bottom‐up approaches to synthesize 2D MOFs. Bai et al. synthesized 2D MOFs Cu‐TCPP nanofilms in the presence of PVP.[ 23 ] The main experimental process entailed preparing the material using a top‐down approach and the auxiliary action of surfactants. Cu was used as the ligand ion, and tetra(4‐carboxyphenyl) porphyrin (TCPP) was the ligand. The preparation process is shown in Figure 5c. A TCPP molecule is connected with four Cu metal nodes of impellers, which can form a layered crystal structure in the form of accumulation in the presence of PVP, thus forming 2D MOF Cu‐TCPP film. The samples synthesized by the top‐down method have a good dispersion structure and high yield.[ 25 , 105 , 106 , 107 , 108 ] The thickness of the obtained 2D MOF Cu‐TCPP film mentioned above is 1–3 nm, which is rare in the reported structures of 2D MOFs. The obtained MOF Cu‐TCPP nanofilms were examined using scanning electron microscopy (SEM), transmission electron microscopy (TEM) and atomic force microscopy (AFM), and Figure 6a–c were obtained. Evidently, the maximum thickness of Cu‐TCPP nanofilm is merely 2 nm, the size is several hundred nanometers to several microns and the structure is folded. Bai et al. also synthesized Cu‐TCPP nanoflakes in the presence of PVP through the same experimental process. The thickest of the synthesized Cu‐TCPP nanosheet is only 6–10 nm, which is a good thickness in reported 2D MOF materials.[ 23 ] Lu et al. synthesized 2D MOF nanosheets by applying the top‐down approach and the surfactant‐assisted growth of Au nanoparticles, but the thicknesses of the nanosheets were relatively thick, ≈20 nm. The thickness of iron porphyrin MOF nanoparticles synthesized by Zhang et al. is thinner than that of Lu et al., about 3–7 nm. The thickness of the majority of 2D MOF nanomaterials exceeds 10 nm, and a small amount of material below 10 nm can be made.[ 23 ] The obtained MOF Cu‐TCPP nanometer sheet was investigated using SEM, TEM and AFM, and Figure 6d–f was obtained. Evidently, the Cu‐TCPP nanometer comprises some anomalous 2D thin sheets with a thickness of ≈8 nm and a size of dozens to hundreds of nanometers. Bai et al. prepared 2D MOF Co‐TCPP nanofilms and Co‐TCPP nanoflakes, respectively, in the absence and presence of PVP by the above experimental method (replacing the Cu bits with Co bits).[ 23 ]

Figure 6.

a–c) SEM, TEM and AFM images of 2D Cu‐TCPP nanofilm. d–f) SEM, TEM and AFM images of 2D Cu‐TCPP nanosheet. Reproduced with permission.[ 23 ] Copyright 2019, Royal Society of Chemistry.

3.2. COFs

In recent years, COFs have attracted great interest,[ 109 , 110 , 111 , 112 ] and several methods have been explored to synthesize COFs, such as the solution method, microwave heating,[ 113 , 114 , 115 , 116 ] and ion thermal method.[ 48 , 117 ] Herein, each method will be discussed in detail.

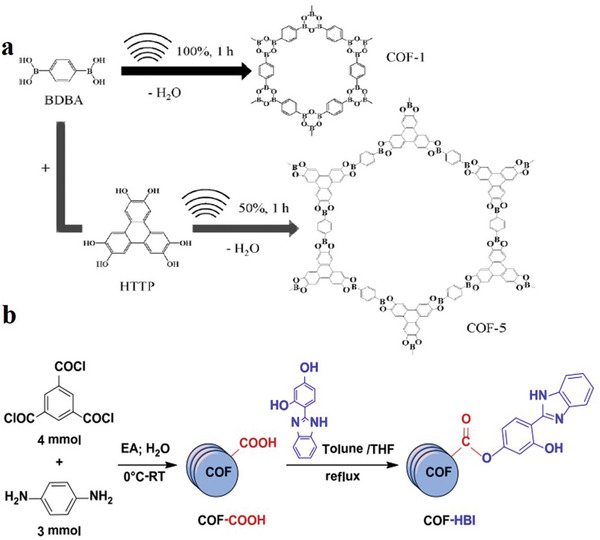

3.2.1. Sonochemical Synthesis Method

Sonochemical is another procedure that results in the production of small MOF crystals with less reaction time. In this process, the crystallization rate rapidly increases owing to the bursting and formation of bubbles in the solution, which is called acoustic cavitation,[ 118 , 119 ] which generates a high temperature (5000 K) and pressure, leading to rapid heating and cooling rates. In previous studies, the synthesis of 2D COFs was mainly conducted using the sonochemical synthesis method. Juan et al. synthesized COF‐1 and COF‐5 by the sonochemical synthesis method: 1,4‐Benzenediboronic acid (BDBA) and 2,3,6,7,10,11‐hexahydroxybiphenyl (HHTP) is a kind of 2D skeleton COF‐5. The B3O3 (boroxine) ring formed by the dehydration reaction of a single BDBA molecule with a planar Hexa‐hydroxyl 2D skeleton is called COF‐1. The operability of the sonochemical synthesis of the COF structure is proved by this process (Figure 7a). Although sonochemical synthesis is a relatively new method, which assists in decreasing the large reaction times and high temperatures, it needs further exploration for better understanding.[ 120 ]

Figure 7.

a) Synthesis of COF‐1 and COF‐5 is accomplished by sonochemical processes. Reproduced with permission.[ 120 ] Copyright 2012, the Royal Society of Chemistry. b) Description of COF‐COOH and COF‐HBI. Reproduced with permission.[ 121 ] Copyright 2014, Elsevier Inc.

3.2.2. Solution Method

The solution method is the most common method used for material synthesis that separates the precipitate from the solution. The study of Juan et al. is based on the solution method. In Figure 7b, the preparation method of solid‐phase extractant is shown, which is explained in three steps as presented below: COF matrix preparation, HBI (2‐(2,4‐hydroxyphenyl)‐benzimidazole) synthesis and functionalization. First, ethyl acetate (EA) and trimethyl chloride were used to prepare a transparent and colorless solvent. Next, o‐phenylenediamine was dissolved in a solvent (using Na2S2O5 as a catalyst), and vacuum filtration was performed to obtain a solid product.[ 122 ] Then, a mixed solvent of CHCl3 and CH3OH was used for recrystallization to obtain yellow crystals. Finally, a COF‐based solid‐phase extractant was prepared to obtain COF‐HBI.

3.2.3. Ionothermal Synthesis

The study of Sophie et al. used the ionothermal synthesis of an acid‐catalyzed triazine network (pre‐CTF). First, the appropriate ratio of CHCl3 and tri‐fluorosulfonate was put into a dry round bottom flask in an inert atmosphere. When the mixture changed from colorless to yellow, a solid precipitate appeared. Afterwards, it was cooled to room temperature, and an appropriate amount of DI water containing 25% ammonia was added. The solid precipitate was vacuum filtered, and the impurities were washed.

The synthesis of CTF‐1 was performed in a crucible. The pre‐CTF and ZnCl2 mixture was placed in a crucible in an appropriate ratio, and it was stored in an enclosed space of inert Rn gas. Next, the mixture was placed in an argon furnace that had been preheated for 30 min. The crude product was ground, and DI water was added to wash excess impurities repeatedly.

3.2.4. Microwave Synthesis

Nowadays, most researchers use atmospheric pressure microwave high‐temperature ion heating to prepare CTF‐based magnetic composite materials. During the experiment, according to different reaction conditions, an appropriate amount of ferric chloride hexahydrate (FeCl3·6H2O) is dissolved in ethanol, 1,4‐dicyanobenzene (DCB) and anhydrous zinc chloride (ZnCl2) to form a mixed solution, and was put it into a crucible. Finally, the crucible is placed in the microwave oven for the experiment.

3.3. HOFs

Nowadays, most HOFs are synthesized by solvent evaporation, diffusion and solvothermal synthesis. However, each method has its advantages and inevitable defects. There are different synthesis methods used to produce HOFs materials with different structures; some are given below.

3.3.1. Solvent Evaporation Method

The so‐called solvent volatilization method dissolves the organic ligand in a small beaker in an appropriate solvent according to a certain proportion, and crystallizes the framework through the slow volatilization of the solvent.[ 66 , 123 , 124 , 125 , 126 ] To grow a single crystal with better crystal form, filter paper or plastic film is used to slow down the volatilization speed (poking 3–5 small holes with needles). The operating principle of this method is relatively simple, and it is relatively easy to obtain the product with better crystal form and larger particles. However, it must be performed at a static room temperature, usually using a solvent with a lower boiling point, and generally require a longer reaction time. Luo et al. reported a super stable 2D microporous organic framework material (HOF‐8), which was assembled using an amide pyridine compound containing a hydrogen bond donor and acceptor in the structure.[ 123 ] In 2017, Hong took 3,3′,5,5′‐tetrakis‐(4‐carboxyphenyl)‐1,1′‐biphenyl (H4TCBP) as the ligand, dissolved it in N‐N‐N‐di‐methyl‐formamide and left the solution open at room temperature to volatilize slowly. After a few days, the hydrogen‐bonded organic skeleton material HOF‐TCBP with ultra‐high thermal stability was obtained.[ 66 ]

3.3.2. Diffusion Method

Vapor Diffusion Method

The organic ligand is dissolved in a benign solvent with a high boiling point and volatilized. Then, another low‐volatile solvent (such as triethylamine, pyridine and acetone) is diffused into the former solution in a closed container to reduce the solubility of the solute and precipitate the framework. The most generally used method is the big‐bottle and small‐bottle method, and the solvents chosen must be mutually dissolved.[ 59 , 127 ] In 2011, Chen's research group used the steam diffusion method to construct the first hydrogen‐bonded organic skeleton material (HOF‐1) with a stable structure.[ 59 ]

Liquid‐Phase Diffusion Method

The reactants are diffused through the solvent near the interface, and another solvent is added in the middle to slow down the diffusion rate. This method of operation is based on the low solubility of the reactants in the solvent, which slows the reaction and obtains better crystal quality and morphology.[ 128 , 129 ] Nugent et al. synthesized 2D MPM‐1‐TIFSIX by the liquid‐phase diffusion method. At room temperature, adenine dissolved in acetonitrile/H2O was placed above the aqueous solution containing Cu(NO3)2·2.5H2O and (NH4)2TiF6, and acetonitrile/H2O was placed in the layer between the top and bottom solutions to slow down the reaction rate. After 4 d, purple rectangular prisms were formed.[ 128 ]

3.3.3. Solvothermal Synthesis

Solvothermal synthesis cultivates high‐quality crystals under relatively harsh conditions. Some organic ligands that are insoluble or insoluble at normal temperatures have increased solubility under the high temperature and pressure of the solvothermal reaction, which is beneficial to the reaction.[ 125 , 130 ] The reaction process is often accompanied by some chemical reactions that are difficult to occur under normal conditions, making it possible for solvents to extract solid components and crystal growth. Choosing the appropriate solvent is conducive to obtaining well‐oriented and perfect crystals.[ 131 , 132 , 133 ] In solvothermal reactions, the commonly used solvents are dimethyl sulfoxide (DMSO), N‐methylpyrrolidone (NMP), dimethylformamide (DMF), dimethylacetamide (DMA) and anhydrous ethanol.[ 70 , 125 , 134 , 135 ] In 2013, Yoon et al. prepared 2D HOF‐BTB with unimodal 3‐c honeycomb (HCB) topology by the solvothermal synthesis.[ 134 ] Excess H3BTB was dissolved completely in a small amount of DMF in a hot oven and cooled in a refrigerator. The obtained crystals were collected and dried in the air and immersed in methanol. The methanol solution was left standing in an oven to obtain a highly strong micro‐porous hydrogen‐bonded 2D organic skeleton material HOF‐BTB. In 2014, Miljanic et al. prepared 2D HOF materials with stable structures by solvothermal synthesis.[ 130 ] The 2D HOF materials with light weight and stable heat and hydrolysis were obtained by dissolving fluoropyrazole molecules as ligands in the mixed solution of N‐N‐N‐di‐methyl‐formamide and methanol and heated at 80 °C for a day.

3.4. Perovskite Synthesis

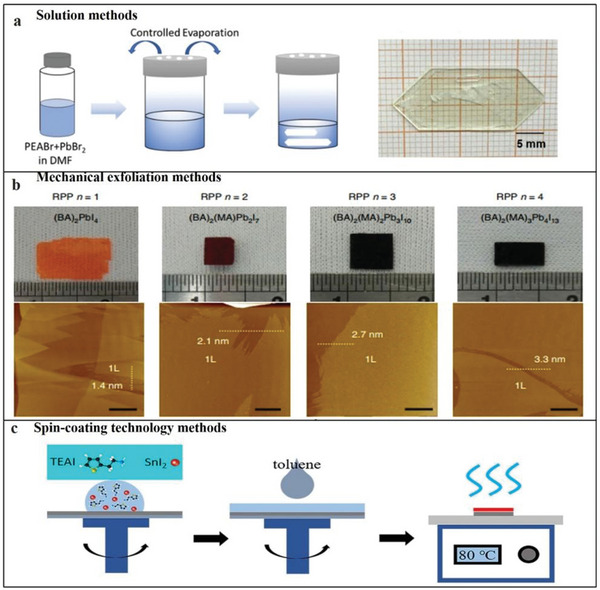

Depending on the source material (2D or 3D perovskite), different methods can be used to process the material. First, the perovskite raw material is formulated into a precursor solution, and the solvent is evaporated to obtain an excellent single‐crystal thin film. Next, the mechanical exfoliation method can also be used to peel the 2D organic perovskite material of the van der Waals stack structure into a 2D Ruddlesden–Popper perovskites (RPP) with a single quantum well thickness. Additionally, the spin‐coating technology method is the most common film synthesis method, which can help reduce the film thickness.

3.4.1. Solution Methods

In previous studies, 2D organic perovskite materials were mainly synthesized using solution methods. Zhang et al. developed a solvent evaporation technique controlled at a constant temperature to obtain the best single‐crystal quality.[ 136 ] First, the three substances (DMF, PEABr and PbBr2) were fully dissolved at 23 ± 0.5 °C to form a (PEA)2PbBr4 precursor solution, and filtered to produce a clear solution. Then, a closed plastic container was used to hold 6 mL of the precursor solution, and a hole punch was used to design an array of two openings with a 1 mm diameter on the plastic container. Finally, the container was placed in an oven (23 ± 0.5 °C) to grow for ≈20 d, thereby obtaining a centimeter‐level (PEA)2PbBr4 single crystal (Figure 8a). Also, Cohen et al. synthesized 1,4‐benzenedimethanamonium iodide in an ice bath.[ 137 ] After adding the acid, it was left to stand for 20 min to produce a precipitate. The precipitate was washed with ether and anhydrous ethanol to recrystallize the precipitate. Next, the solution was added to the perovskite solution mixture by controlling the stoichiometric ratio to successfully prepare the (BzDA)A9Pb10 2D perovskite solution. The solution synthesis method is the most effective method to synthesize 2D organic perovskites.

Figure 8.

a) Schematic of growing (PEA)2PbBr4 single crystal using solution method. Reproduced with permission.[ 136 ] Copyright 2019, Royal Society of Chemistry. b) Photographs of centimeter‐sized RPP single crystals and AFM images after mechanical peeling. Reproduced with permission.[ 138 ] Copyright 2018, Nature Publishing Group. c) Schematic of manufacturing process of 2D organic perovskite thin‐film spin‐coating process. Reproduced with permission.[ 139 ] Copyright 2020, American Chemical Society.

3.4.2. Mechanical Exfoliation

Mechanical exfoliation is also an effective method for obtaining perovskite thin films by exfoliating bulk RPP crystals between organic layers. Leng et al. studied a temperature‐programmed solution precipitation method, and the perovskite material was successfully prepared using this method.[ 138 ] 2D lead Ruddlesden–Popper perovskites sing crystals were successfully synthesized using three solid precursors: PbO, BAI, and MAI. Then, the thin molecular layer of large molecules was peeled from the single crystal (Figure 8b).

3.4.3. Spin‐Coating Technology

The spin‐coating process results in the production of smooth and dense films. Wang et al. reported using spin‐coating technology to obtain good PEA2SnI4 and TEA2SnI4 films (Figure 8c).[ 139 ] The mixed solution of PEAI (or TEAI) and SnI2 were dissolved in DMF and DMSO to obtain the perovskite precursor solution. According to previous reports, the perovskite has no excellent film‐forming ability. Therefore, Wang et al. prepared a dense film using toluene to obtain smoother and denser PEA2SnI4, and DMF was used as a solvent to obtain a good TEA2SnI4 film.[ 139 ]

Through these methods, 2D organic perovskite materials can be successfully synthesized. However, so far, the obtained film thickness still has a gap in practical applications, so achieving a thinner film remains a challenge.

3.5. Molecular Crystals

Self‐assembled 2D molecular crystal materials with weak van der Waals bonds have a single‐layer or multilayer molecular structure.[ 141 ] By using the solution preparation technology, the high precision and large‐size 2D molecular crystal films can be conveniently and efficiently prepared. Currently, the main solution technologies are drop casting, spin coating, dip coating and many other different methods used to prepare different 2D molecular crystals.

3.5.1. Solution‐Immersion Assembly

The solution‐immersion assembly technology is mainly a technology that spontaneously forms organized nanostructures or patterns in functional, structural components, which is mainly driven by a stable, uniform and nondirectional solvent evaporation process. The thickness of the produced 2D molecular crystal reaches the nanometer level, forming a thin film or a single‐crystal semiconductor.

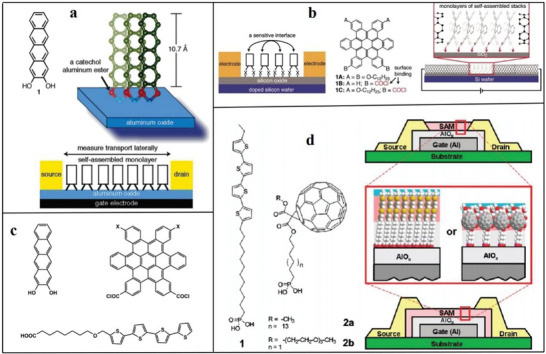

In 2004, Tulevski et al. studied a new tetraene derivative that can form a dense, upright monolayer film on the surface of alumina.[ 142 ] This new tetraene derivative single‐layer film can spontaneously self‐organize to form the active layer in nano‐field effect transistor devices (Figure 9a). In 2006, Guo et al. reported a unique single‐molecule layer of polycyclic aromatic hydrocarbons with multifunctional molecules, which are assembled laterally into pillars and attached to the silicon oxide surface of silicon wafers.[ 143 ] An effective transistor comprises many single molecules; when the molecules lacking electrons are exposed, the electrical properties will change significantly, thus creating a new environment (Figure 9b). In 2010, Mathijssen et al. synthesized a semiconductor molecule in which pentathiophene and monochlorosilane were the core and anchor groups.[ 144 ] Solution‐submerged assembly organic field‐effect transistors (OFETs) were prepared by the liquid crystal molecular method, and the test device results revealed that the carrier structure does affect the channel length (Figure 9c). With technological development, in 2011, Novak et al. synthesized multifunctional molecules with self‐assembly capabilities based on tetra‐thiophene and fullerene units. Based on tetra‐thiophene and fullerene units, multifunctional materials with self‐assembling abilities were synthesized.[ 145 ] This research enabled the low‐voltage operation of self‐assembled single‐layer transistors (Figure 9d).

Figure 9.

Solution‐immersion assembly technique. a) Reproduced with permission.[ 142 ] Copyright 2014, American Chemical Society. b) Reproduced with permission.[ 143 ] Copyright 2006, American Chemical Society. c) Reproduced with permission.[ 144 ] Copyright 2010. d) Probing dynamic interfaces in organic electronics. Reproduced with permission.[ 145 ] Copyright 2011, American Chemical Society.

3.5.2. Drop‐Casting and Spin‐Coating

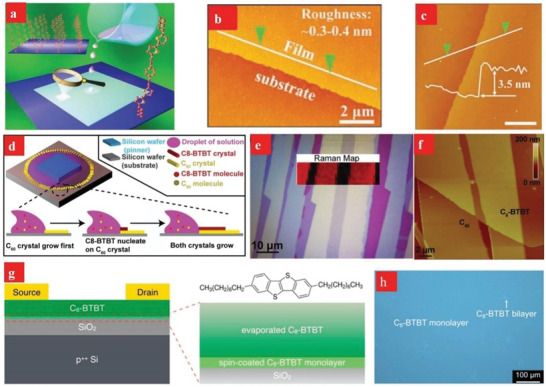

Drop‐casting methods and spin‐coating methods are common solution treatment methods. Among them, the drop‐casting method is commonly used to deposit organic semiconductor crystal films. In 2011, Jiang et al. used drop‐casting to successfully prepare 2D crystals of organic semiconductors on the millimeter scale for the first time.[ 146 ] First, the chlorobenzene solution on different substrates (e.g., SiO2, quartz and even other amorphous substrates) cast millimeter‐sized 2D 1,4‐bis((5ʹ‐hexyl‐2,2 ʹ ‐bithiophen‐5‐yl)ethynyl)benzene (HTEB) crystal films (Figure 10a). The film prepared via drop‐casting was very smooth and had a perfect structure. More importantly, through TEM images and selected area electron diffraction patterns, it can be found that high‐quality 2D films have superior electrical properties (Figure 10b,c), which effectively confirms that the number of layers of 2D materials affects the charge carrier mobility. In addition, Fan et al. developed a droplet‐pinned crystallization method for preparing organic single‐crystal p–n junctions from solutions of organic semiconductor mixtures (Figure 10d–f).[ 147 ] Drop‐casting greatly improves the mobility of electrons, provides a platform for single‐crystal p–n junctions and provides a good foundation for manufacturing high‐performance electronic devices of organic semiconductors.

Figure 10.

a–f) Drop‐casting technique for fabricating HTEB and C8‐BTBT crystals, respectively. a–c) Reproduced with permission.[ 146 ] Copyright 2011, Wiley‐VCH. d–f) Reproduced with permission.[ 147 ] Copyright 2013, Wiley‐VCH. g,h) Spin‐casting technique for fabricating C8‐BTBT monolayer. Reproduced with permission.[ 148 ] Copyright 2018, American Chemical Society.

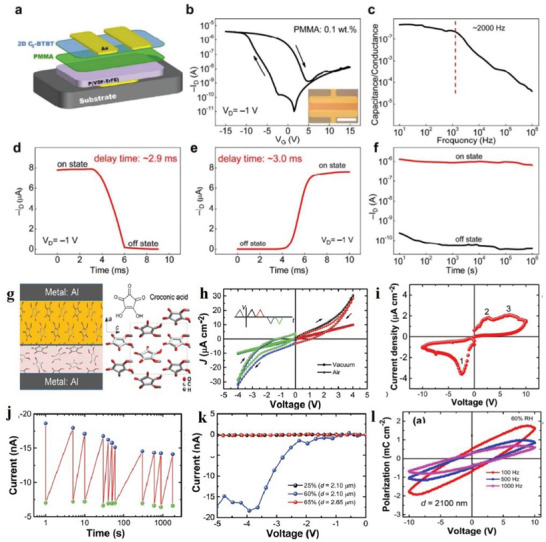

To better reflect the inherent advantages of uniform deposition and large‐area molecular films, Wang et al. developed a technique involving antisolvent crystallization to grow spin‐coating monolayer molecular Ar crystals (Figure 10g,h).[ 148 ] The spin coating method is always used to deposit an aligned dioctylbenzothienobenzothiophene (C8‐BTBT) single layer on an SiO2 substrate. This study proves that a thin, smooth, single‐layer film deposited on the dielectric layer by spin coating can grow a highly ordered upper layer.

3.5.3. Self‐Assembly Method

The epitaxial growth of 2D molecular crystals on functional substrates is very attractive and challenging. Because of the low surface roughness and strong diffusivity of water and air, its assembled 2D molecular crystals can be effectively transferred to the required substrate. This method has attracted special attention. Recently, the solution epitaxial growth technique has been widely used.

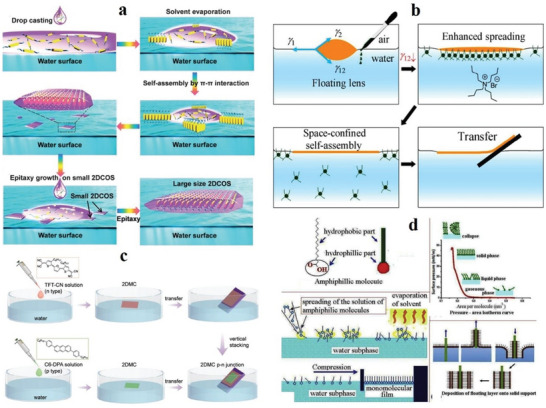

The solution epitaxial growth method effectively achieves the epitaxial growth of 2D molecular crystals. Two commonly used technologies are molecular beam epitaxy and physical vapor transport.[ 149 ] The 2D molecular crystal prepared by Xu et al. using the solution epitaxy method has a large surface area and high quality.[ 150 ] It includes two steps: i) self‐assembly of micronized 2D molecular crystals on the water surface, and ii) epitaxial growth into 2D molecular crystals with a thickness of several millimeters or centimeters (Figure 11a).

Figure 11.

a) Schematic of growing 2DCOS. Reproduced with permission.[ 150 ] Copyright 2016, Wiley‐VCH. b) Sketches of SCS method. Reproduced with permission.[ 151 ] Copyright 2018, American Chemical Society. c) Preparation of 2DMC bilayer p–n junctions. Reproduced with permission.[ 152 ] Copyright 2019, Wiley‐VCH. d) LB technique. Reproduced with permission.[ 157 ] Copyright 2018, Elsevier Ltd.

In 2018, Wang et al. used the space‐confined self‐assembly (SCS) method to produce centimeter‐sized 2D molecular crystals.[ 151 ] The two key steps of the preparation method are i) using DI water as the liquid substrate to minimize the core density, and ii) enhancing the diffusion of the solution on the water surface. A spatialized 2D crystal growth mode is shown in Figure 11b. In 2019, Zhu et al. reported bipolar OFETs based on the two‐layer p–n junction of 2D molecular crystals, which offers high performance and good balance.[ 152 ] They used the solution epitaxy method to synthesize 2,6‐bis (4‐hexyl phenyl) anthracene (C6‐DPA)[ 150 , 151 , 153 ] and a furan–thiophene‐based quinoidal compound (TFT‐CN).[ 154 , 155 ] The specific steps are shown in Figure 11c. This type of unipolar semiconductor is based on thin 2D molecular crystals with double‐layer p–n junction, and a bipolar OFET with high performance and good balance is constructed.

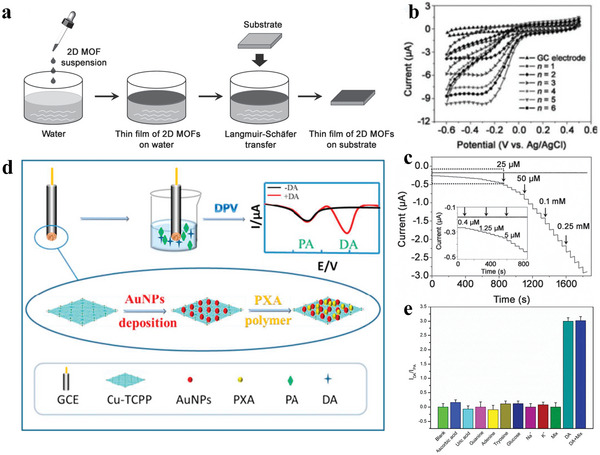

3.5.4. Langmuir–Blodgett (LB)

The LB technique has a greater advantage for single‐layer or few‐layer molecular crystals.[ 156 , 157 ] LB‐compatible materials have a hydrophilic head group and a hydrophobic tail group. This feature gives the material a unique advantage in synthesizing molecular crystals (Figure 10d). Here, various LB parameters can be controlled to change the deposition scheme. Therefore, LB technology provides a way to connect the macroscopic effects for molecular‐scale control and manipulation. So far, LB films have been widely used in microelectronics and optoelectronics.

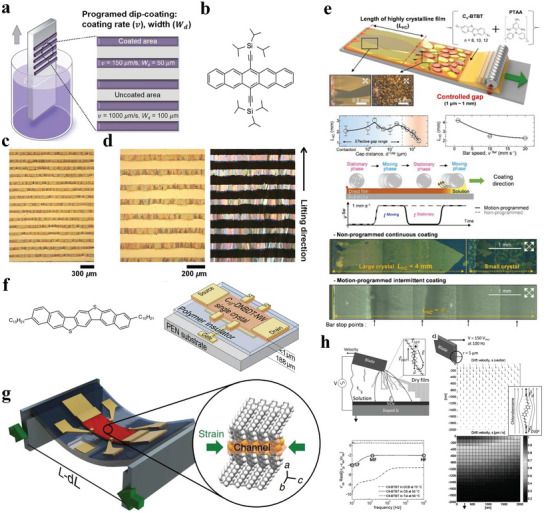

3.5.5. Dip and Bar Coating

Meniscus‐guided unidirectional coating strategies are mainly used to precisely control morphological carrier transport activities. Dip‐coating can uniquely take advantage of the meniscus and the sliding rod movement of aluminum to pattern the coating material over a large area so that organic semiconductor crystals can grow on curved surfaces. Consequently, it has attracted the attention of many researchers. Nam et al. used a new programmed dip‐coating technique to directly print stripes of highly crystalline soluble propylene crystals.[ 158 ] Figure 12a,b shows the specific flow of the dip‐coating process. The 6,13‐bis(tri‐isopropylsilylethynyl) pentacene (TIPS‐PEN) crystal successfully forms a pattern on the substrate in the form of micro‐strips with a clear gap. The width (W d) and gap of the TIPS‐PEN pattern are almost the same as the W d programming values of the coated (50 µm) and non‐coated areas (100 µm) (Figure 12c,d).

Figure 12.

a–d) Programmed dip‐coating process. Reproduced with permission.[ 158 ] Copyright 2017, Royal Society of Chemistry. e) Wire‐bar coating. Reproduced with permission.[ 159 ] Copyright 2019, American Chemical Society. f,g) Edge‐casting technique. Reproduced with permission.[ 160 ] Copyright 2016, Nature publishing group. (h) Application of dielectrophoresis to solution shearing C8‐BTBT. Reproduced with permission.[ 161 ] Copyright 2017, WILEY‐VCH.

Bar coating is an effective and attractive technology for preparing highly uniform molecular films with low‐cost, high‐throughput manufacturing roll‐coating technology.[ 132 ] Lee et al. used gap‐controlled motion to program the bar‐coating layer method and mixed organic semiconductor inks, carefully adjusted the gap and the rod length, extended the crystalline area at the front end of the film and obtained a continuously connected high crystalline C8‐BTBT‐PTAA film (Figure 12e).[ 159 ] This study confirmed the existence of anisotropic crystal structures and polymorphisms with dense unit cells, high uniformity of the strain microstructure and excellent electrical properties. It provides a good idea for promoting the commercialization of organic materials based on next‐generation electronics. Edge‐casting and solution‐shearing are also commonly used techniques. To obtain large‐area single‐crystal thin films, Kubo et al. used edge‐casting to prepare molecular crystals (Figure 12f).[ 160 ] In this method, the solution is applied between the shear blade and the substrate, and the solution evaporates to form a crystal film. Molina‐Lopez et al. used the solution shearing technology to prepare C8‐BTBT (Figure 12h).[ 161 ] Shearing the blade at the top moves the solution, leaving the meniscus of the solution, and when the solution evaporates, organic molecular crystals are formed.

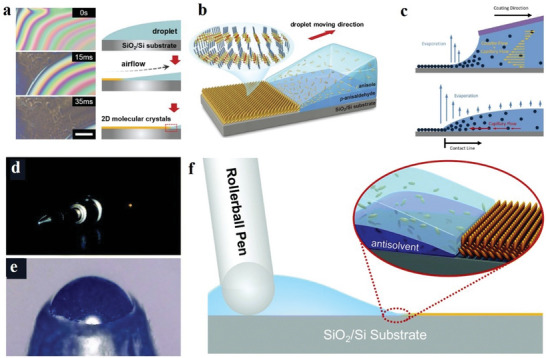

3.5.6. Floating‐Coffee‐Ring‐Driven Assembly Technology and Pen Writing

In addition to the several preparation techniques mentioned above, there are several other methods.[ 162 , 163 , 164 ] 2D molecular crystals prepared by the fluid flow assisted crystallization technology have the advantages of good control of domain arrangement and substrate coverage. This technology controls the morphology of the film to a certain extent. In 2016, Wang et al. prepared a 2D molecular single‐crystal semiconductor C8‐BTBT with precise layer defects using floating‐coffee‐ring‐driven assembly technology, laying the foundation for preparing large‐area, low‐cost and high‐performance 2D molecular crystals. In this preparation method, first the solution is dropped on the substrate, and a mechanical pump is used to drag the solution around to form 2D molecular crystals (Figure 13a,b).[ 162 ] In the same year, Qu et al. used the Marangoni flow‐directed crystal growth to prepare molecular crystals, enhancing nucleation and patterning and easing crystal growth defects. (Figure 13c).[ 163 ] Pen‐writing technology is also commonly used to prepare 2D molecular crystals in large quantities. Zhang et al. used this technology to prepare 2D molecular crystals with large areas, strong flatness and uniformity. First, the solution is injected into the filled tube, and 2D molecular crystals are manually deposited on the SiO2–Si substrate at a stable speed (Figure 13d–f).[ 164 ]

Figure 13.

a,b) Schematic of floating‐coffee‐ring‐driven assembly method. Reproduced with permission.[ 162 ] Copyright 2016, Wiley‐VCH. c) Schematic of unidirectional coating driven by evaporation and droplet undergoing coffee ring effect. Reproduced with permission.[ 163 ] Copyright 2016, American Chemical Society. d–f) Pen‐writing technology. Reproduced with permission.[ 164 ] Copyright 2017, the Royal Society of Chemistry.

4. Properties, Theory and Calculations of 2D Organic Materials

Because of their unique structure and excellent electrical and optical properties, 2D organic materials are the super materials that will lead the future of high‐tech competition.[ 165 , 166 , 167 , 168 ] Here, the electrical, optical, magnetic and chemical properties of 2D organic materials (MOFs, COFs, HOFs, perovskite and molecular crystals) are explained.

4.1. Electronic Properties of 2D Materials

Electrical properties are one of the most basic properties of materials because the atoms and molecules that make up the material are produced by the interaction of electrons. Understanding the electrical properties of materials is greatly significant for the preparation and application of materials.[ 168 , 169 ] The electrical properties of each material are described in detail as follows:

4.1.1. Electronic Properties of MOFs

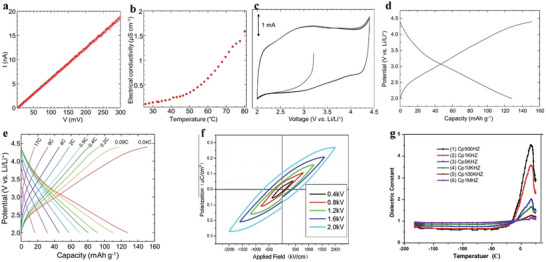

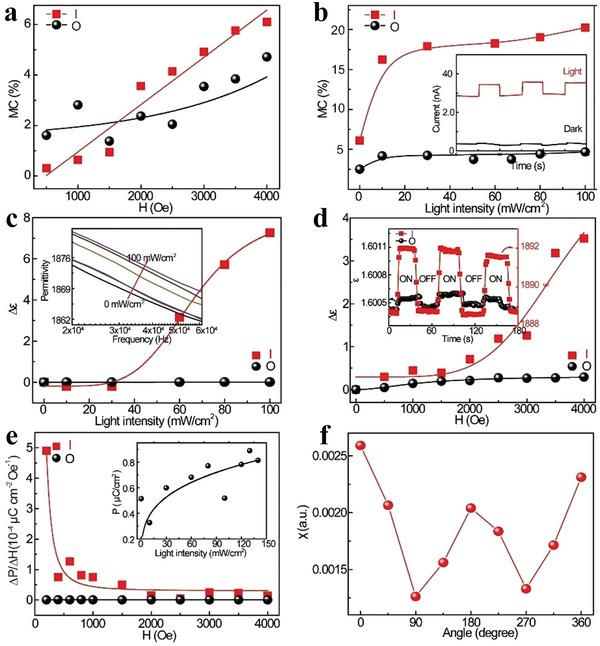

Electrical property is an important property of 2D MOF materials. Nagatomi et al. studied the electrical performance of 2D MOF Cu‐CuPc.[ 170 ] During the experiment, the Cu‐CuPc powder was stressed to spherules, and the I–V curve of the spherules was sounded with a gold wire double probe. At room temperature, the ohmic resistance ranging from 0 to 300 mV is shown in Figure 14a. The conductivities at a constant voltage (150 mV) and different temperatures are shown in Figure 14b. They mixed Cu‐CuPc, a poly‐tetra‐fluoro‐ethylene (PTFE) adhesive, and carbon black. Next, the mixture was cast into a pollution‐free grid to make the cathode, which was installed on a simple LiB battery device. Afterwards, the cathode capacity was estimated through charge–discharge processes. During the experiment, volt–ampere tests were conducted on Li/Li+ at a potential range of 2.0–4.4 V, and wide reduction–oxidation (REDOX) peaks appeared at a scanning speed and voltage of 1 mV s−1 and 3.0 V, respectively (Figure 13c). Similarly, the voltage was maintained between 2.0 and 4.4 V, and the current was constant at 0.04 C. After the charge–discharge cycles, the capacitance was undegraded, and the charging and discharging capacities reached 151 and 128 mAh g−1, respectively (Figure 13d). The results show that the cathode has a large and stable charging and discharging capacities and cycle, respectively. Low conductivity directly affects the high coulomb rate of the MOF‐based cathode. Figure 14e shows the capacity of Cu‐CuPc at different charging and discharging rates. The electro‐conductibility of Cu‐CuPc plays a significant role in achieving a jarless charge–discharge cycle. Tan et al. researched the ferroelectric performance of a 2D MOF, which was a typical ferroelectric compound.[ 171 ] They plotted the hysteresis loops of the complex at the voltages of 0.4, 0.8, 1.2, 1.6 and 2.0 kV (Figure 14f). Figure 14f shows the residual polarization (Pr) and the coercive field (Ec) values of 0.029 µC cm−2 and 0.4 kV cm−1, respectively. Tan et al. also plotted the relationship between the dielectric constant and temperature at different frequencies (Figure 14g).[ 171 ] Evidently, the permittivity below –21 °C is ≈0.5 and remains constant. When the frequency decreases below 500 Hz, the frequency of the AC electric field greatly influences the permittivity changes with temperature.

Figure 14.

a) I–V curve of globose Cu‐CuPc measured at room temperature. b) Conductivity of globose Cu‐CuPc varies with temperature in the range of 25 °C–80 °C. c) Cyclic voltammogram of Cu‐CuPc cathode. d) Charge–discharge curve of Cu‐CuPc cathode. e) Charge–discharge curves of Cu‐CuPc cathode at different C rates. Reproduced with permission.[ 170 ] Copyright 2017, John Wiley and Sons. f) Electromagnetic loop at different frequencies. g) Relationship between temperature and dielectric constant at different frequencies. Reproduced with permission.[ 171 ] Copyright 2014, Elsevier Science.

4.1.2. Electronic Properties of COFs

2D COFs are a new electroactive material mainly used in electronics and chemical resistance sensing. However, 2D COFs still have unresolved issues, mainly with their structure, chemistry and conductivity.[ 172 ] Pyridine 2D COFs containing Zn and Cu have been synthesized by condensation reaction. Metal pyridine (M = Zn and Cu) and pyrethroid derivatives were used as raw materials. The specific mobility parameter is 5 cm2 (V s)−1, which was measured under the DC limit.[ 173 ] The metal center from copper to zinc in phthalocyanine is very small for related parameters. These parameters are divided into three aspects, namely conductivity (conductivity parameter ≅ 5 × 10−7 S cm−1), carrier scattering rate (scattering rate ≅3 × 1013 s−1) and carrier density (density ≅1012 cm−3). The carrier density has little effect, which is related to the effective mass (≈2.3 mg) of most loads (holes). This conclusion is based on the measurement of terahertz (THz) spectroscopy, Hall effect measurement and density functional theory.[ 167 ] Note that carrier transport is anisotropic; for this 2D COF, the fluidity of the hole in the plane is zero, which is limited outside the plane.

4.1.3. Electronic Properties of HOFs

Proton conduction is one of the most important characteristics of 2D HOFs. A proton conductor is a kind of electrolyte that conducts electricity. There are two ways of conducting the protons: first, the conduction between the proton conductor and the anion, called the Grotthuss Gr mechanism. Second, the proton conductor conducts electricity with other ions, called the mediation mechanism.[ 174 ] Because 2D HOF materials have acid–base electron pairs, which can form intramolecular hydrogen bonds with each other, a network structure interacting with hydrogen bonds is formed. Besides, this structure is the channel of proton conduction. 2D HOF materials use hydrogen bonding as one of the main forces connecting organic structural units with electron donors and acceptors, and self‐assembly and dipole–dipole interaction with the help of other weak interactions, such as π–π and van der Waals interaction.[ 175 ] Because hydrogen bonds have great freedom, organic structural units can form different hydrogen bond models in different solvents or temperatures, thus obtaining hydrogen‐bonded organic skeleton materials with different structures. Therefore, HOF materials are highly sensitive to solvents.[ 176 ] In addition, π–π stacking, CH·π interaction and van der Waals force can further enhance the stability of the skeleton structure, and obtain HOF skeleton materials with excellent stability.[ 66 , 177 , 178 ]

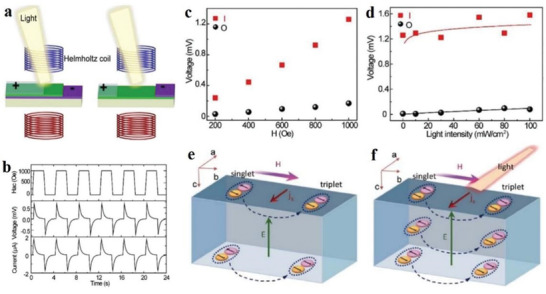

4.1.4. Electronic Properties of Perovskites

Perovskite materials are widely used in many fields owing to their composition, flexibility and structural variability. The chemical formula of organic perovskite materials is ABX3, where A is replaced by organic cations. A, B, and X can be replaced by various elements. Therefore, the material structure can be changed by replacing the position of elements to adjust the bandgap to obtain different electronic properties. Amat et al. studied the perovskite materials of A = FA and MA through first‐principles calculations. They proved that the bandgap change in perovskite materials was induced by replacing the A sites with FA (1.5 eV) and MA (1.55 eV).[ 179 ] The excellent physical properties of 2D organic perovskite materials are attributed to the rapid migration of ions. Since the ions in the perovskite have low migration activation energy (EA), the Schottky defect promotes ion migration.[ 180 ] Eames et al. studied the activation energy of ion migration in MAPbI3.[ 181 ] The EA values of MA+ and Pb2+ ions are 0.84 and 2.31 eV. Since defects are mobile and abnormal defect properties can cause high ionicity of perovskite materials, it will participate in ion migration under external bias. Besides, ion migration is an essential characteristic of perovskite materials. In addition, Fu et al. studied the effect of perovskite cations on the structure and photoelectric properties of the device.[ 182 ] The tolerance factor in perovskites restricts the number of cations that enter its cage. However, a special cationic, ethylammonium, can be stretched into the cage of 2D halide perovskites. Based on this principle, several cationic‐engineered 2D RPP iodized perovskites were prepared. The single‐crystal structural analysis shows that the Pb‐1 bond stretching can be observed in the perovskite material doped with ethylammonium, which enlarges the cage and causes larger octahedral deformation. This conclusion once again enriches the types of 2D organic perovskites.

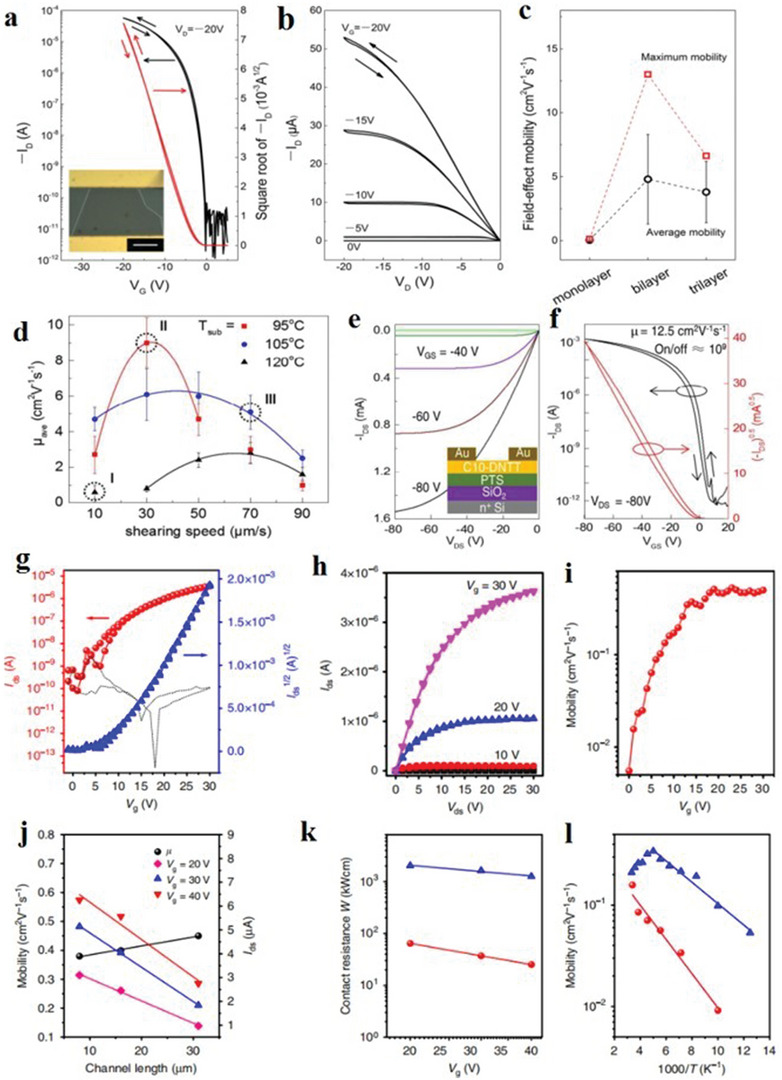

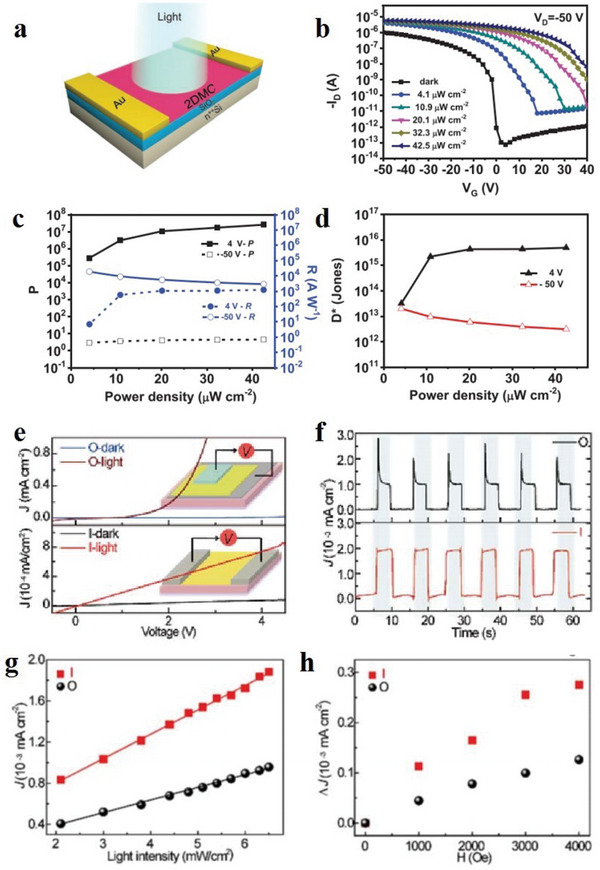

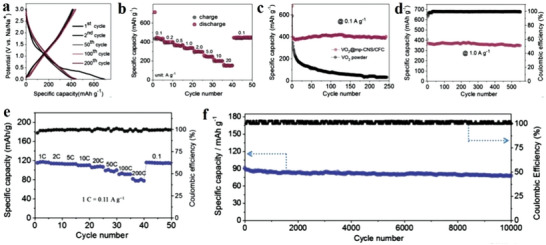

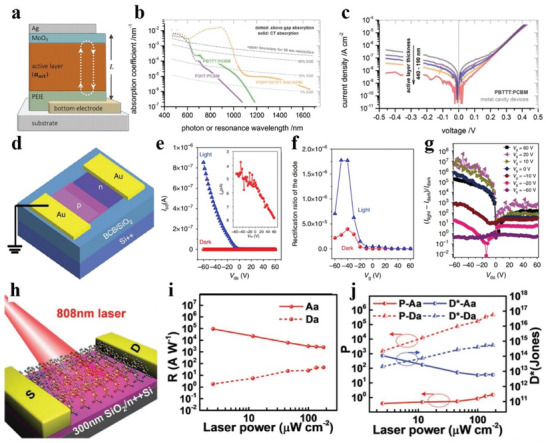

4.1.5. Molecular Crystals

Charge carrier transport is an important electrical characteristic that often occurs at the semiconductor dielectric interface. Wang et al. prepared a double‐layer C8‐BTBT crystal film and performed electrical measurements.[ 162 ] Figure 15a shows the transmission characteristics of the device at a drain voltage of ‐20 V. Evidently, the double‐layer C8‐BTBT device has higher field‐effect mobility, which can reach 5.2 cm2 V−1 s−1. Figure 15b shows the output characteristics of the device. Evidently, the device has good FET behavior. Also, the average carrier mobility is 4.8 cm2 V−1 s−1, and the highest value reaches 13.0 cm2 V−1 s−1 (Figure 15c). Peng et al. further quantified the key parameters to observe the effect of molecular crystals to better understand the crystal mechanism.[ 183 ] First, a quasi‐balanced low‐speed solution was used to shear deposit C10‐DNTT. Second, the optimal shear rate for crystal growth based on mass conservation was calculated (Equation 1), and 30 devices were selected at different temperatures and shear rates for test verification. Furthermore, the mean and standard deviation of the saturation mobility were calculated and fitted (Figure 15d). The fitting curve shows a large gap in the saturation mobility at different temperatures and shear speeds. Among them, the highest mobility and the best crystal morphology can be obtained by setting the temperature at 95 °C and the shear rate at 30 µm s−1. On this basis, the I–V curve is fitted to its output and input (Figure 15e,f). Its saturation mobility can reach 12.5 cm2 V−1 s−1, and the switching ratio is 2 × 109. Some key parameters were simulated, and Equation 1 was used as follows:[ 183 ]

| (1) |

where ρ is the crystal density of C10‐DNTT, t is the thickness of the organic semiconductor crystals (32 nm) and l is the unit length.

Figure 15.

a–c) Transistor characteristics for 2D crystalline C8‐BTBT. Reproduced with permission.[ 162 ] Copyright 2016, Wiley‐VCH. d) Mean values of saturated mobility and standard deviations. e,f) Output and transfer I–V curves. Inset of (e) is the structure of OFET device. d–f) Reproduced with permission.[ 183 ] Copyright 2016, the Royal Society of Chemistry. g–l) Electrical properties of MMC FETs. g–l) Reproduced with permission.[ 184 ] Copyright 2018, Nature publishing group.

The Navier‐Stokes equation is given as follows:

| (2) |

The heat transfer equation is given as follows:

| (3) |

The diffusion equation is given as follows:

| (4) |

Shi et al. used the gravity‐assisted 2D space constraint method to prepare high‐quality molecular crystals.[ 184 ] The electrical characteristic curve is shown in Figure 15g,h. Evidently, its saturation mobility reached 0.51 cm2 V−1 s−1, proving that it has a lower contact resistance, which can also be seen in Figure 15k. Figure 15i shows that when V g > V th, electron mobility changes insignificantly. Also, the electron mobility slightly affects V g, indicating that the device performance is less affected by the contact resistance and interface traps. The channel length was further measured, and the relationship between the electron mobility and the leakage current is shown in Figure 15j. As the channel length increases, no obvious change in electron mobility occurs, and the leakage current changes linearly, indicating that the molecular crystal has a higher quality and the channel resistance decreases uniformly. Figure 15l shows that the mobility decreases with increasing temperature, but between 200 and 300 K, BCB‐SiO2 substrates have obvious band‐like transport characteristics, while no banding is observed for the silicon dioxide substrate. This research forms the foundation for realizing high‐performance crystal, gate/optically tuned lateral organic p–n diode. Equation (5) is used to calculate and fit the saturation.[ 184 ]

| (5) |

4.1.6. Others

2D CMPs are considerably researched owing to their unique structure and electronic properties. Wen et al. systematically studied the electronic properties of 2D π‐CMP materials.[ 185 ] Wen et al., in their study, showed that 2D π‐CMP is more delocalized than 1D materials. Besides, the structural reorganization of the hole and electron transport is very close in a highly delocalized system, and the charge polarization effect exceeds that of 1D materials. These conclusions indicate that this material has good prospects in semiconductors and non‐linear optics. Zhang et al., in their study, showed that CMP (as an advanced porous material) has the advantages of greater substitution, high stability and scalability, and has several applications.[ 186 ] Additionally, Chen et al. showed that alternative strategies can improve the conductivity and electrochemical stability of the framework structure, and provide multiple electrochemical active sites, providing insights into the energy field.[ 187 ]

4.2. Optical Properties

The optical performance of a material refers to its response to electromagnetic radiation and visible light, which is mainly measured by the material's absorption, reflection and transmission characteristics of electromagnetic waves.[ 188 ] Because of the various complex conditions of energy exchange between electrons and photons, different materials have completely different optical properties.

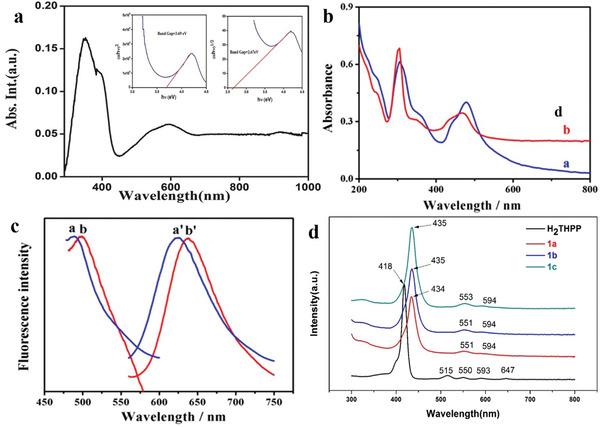

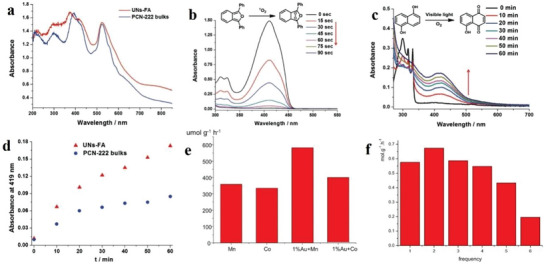

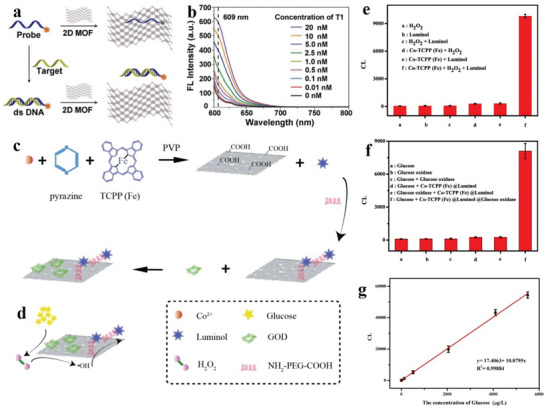

4.2.1. MOFs

2D MOFs can absorb a range of photons and generate a photocurrent when revealed to visible light. Roy et al. synthesized a novel thiocyanate bridging 2D MOF, and performed a spectral analysis.[ 189 ] Figure 16a reveals the assimilation spectra of the composition, which shows the absorption of energy in the UV region of ≈348 nm. The fundamental absorption is very similar to the excitation of electrons from the valence band to the conduction band, so the optical bandgap for the film can also be calculated practically.[ 181 ] The film bandgap can be calculated as follows:[ 189 , 190 ]

| (6) |

where α represents the absorption rate, E g represents the bandgap, h represents Planck's constant, n represents the nature of conversion dependent constant and A represents a capacity‐irrelevant number. When n = 2 and 0.5, the bandgap numbers are 3.69 and 2.67 eV, respectively. This configuration can act as an “active” material and conduces to exciton movement by charge detachment. The material absorbs photons at 345–390 nm and produces a light current when exposed to visible light.[ 189 ] Yan et al. prepared 2D MOFs nanosheets (Ru‐MOFNSs) using Zn2+ and Ru(dcbpy)3 2+. Ru(dcbpy)3 2+ has an electrochemical luminescence function. The curve in Figure 16b shows the absorption spectrum of light with different wavelengths. Ru‐MOFNSs shows three peaks. The peak positions are at 305, 342–367 and 478 nm, respectively. Curve b in Figure 16b shows the light absorption spectra at different wavelengths of the Ru(dcbpy)3 2+ ligand. Compared with the two curves, the absorption peak of curve a is slightly shifted, indicating coordination between Ru(dcbpy)3 2+ and the carboxyl convergence of Zn2+. The fluorescence spectrum is shown in Figure 16c. Evidently, the maximum excitation wavelength and emission wavelength of Ru‐MOFNSs are all shifted to the right compared with pure Ru(dcbpy)3 2+, indicating that some photons have energy transfer.[ 191 ] Niu et al. used 2D Co‐based MOF with H2THPP ligands and porphyrin skeletons and poly‐vinylpyrrolidone (PVP) to form crystalline slices (1a), flower‐like clusters (1b) and ultrathin membranes (1c). Figure 16d shows the ultraviolet–visible (UV–Vis) spectra of 1a, 1b, 1c and free H2THPP ligands. At 435 nm, there is a strong sorbet band of the porphyrin skeleton, which is red‐shifted compared to the free H2THPP ligand. Owing to the higher D4h symmetry after metallization, there are two collapses at 553 and 594 nm in 1a–c, and the light absorption characteristics of these four substances at 532 nm are negligible.[ 192 ]

Figure 16.

a) Absorption spectrum of materials made using Tauc's plots (inset). Reproduced with permission.[ 189 ] Copyright 2015, Royal Society of Chemistry. b) UV–Vis absorption spectrum of a) Ru‐MOFNSs and b) Ru(dcbpy)3 2+. c) Fluorescence incentive and shot spectra of a,aʹ) Ru(dcbpy)3 2+ and b,bʹ) Ru‐MOFNSs. Reproduced with permission.[ 191 ] Copyright 2019, John Wiley. (d) UV–Vis absorption spectra for ligand and 1a–c. Reproduced with permission.[ 192 ] Copyright 2019, Royal Society of Chemistry.

4.2.2. COFs

COF‐5 with type II heterojunction arrangement shows obvious valence and lead band shifts, indicating that the space carrier electrons and cavitation agents are effectively separated.[ 193 ] In TP‐COF, the conduction band shift is still obvious due to the effective confinement of photoexcited electrons. The valence deviation is close to zero owing to the dispersion of the optical excitation holes in the entire structure. Zhou et al. proposed an type‐I heterogeneous junction alignment method in which the side‐wave function is located in the same region, thereby enabling effective spatial carrier aggregation.[ 194 ] Additionally, because the calculated light absorption peaks of the frameworks are the same as the experimental measurement results, TP‐COF and NiPc‐PBBA‐COF provide reference schemes for the experimental observation of the transmission spectra of these frameworks.[ 194 ]