Abstract

The shelf life of dried garlic powder packaged in high-density polyethylene (HDPE), low-density polyethylene (LDPE), and aluminum laminated pouch (ALP) under accelerated storage temperature (5° to 40 °C) and humidity (70–90% RH) conditions, was predicted using GAB mathematical model. The water activity value reduced significantly from 0.83 to 0.31 as the moisture content reduced. The temperature had a negative effect on color change and the lightness value and whiteness index of garlic powder significantly decreased from 62.21 to 56.06 and 50.67 to 44.91 respectively, when temperature increased from 70° to 90° C. The storage life of garlic powder was 24, 78 and 210 days in LDPE, HDPE, and ALP, respectively under domestic storage conditions (40 °C, 90% RH). Therefore, under industrial storage conditions (5 °C, 70% RH), garlic could be preserved for 1.32, 4.30 and 7.28 years in LDPE, HDPE and ALP, respectively.

Keywords: Hot air drying, HDPE, LDPE, ALP, GAB, Monolayer moisture content

Introduction

Garlic (Allium sativum L.) has been used globally both as food and neutraceutical, dated back to 3000 B.C. Olden civilizations like Chinese, Indian, Egyptian, Babylonian, Roman, Greek, Phoenicians, and Viking use garlic for the treatment of wounds, skin diseases, headache, diarrhea, respiratory infections, ulcers, heart conditions, pulmonary complaints, tumors, symptoms of aging, abdominal growths and arthritis. Recent studies also show that bioactive compounds (allicin, selenium, superoxide dismutase and germanium) in garlic play major roles in its medicinal properties like antidiabetic, antimicrobial, antibiotic, antioxidant, anticancer, immune-boosting, antifibrinolytic and antiplatelet aggregatory activity (Santhosha et al. 2013; Kar and Sutar 2022).Garlic is a semi perishable product and microbial spoilage accounts for 30% loss of fresh garlic, which is induced by the lack of suitable storage and transportation facilities. Under a favourable environment, the sprouting of garlic occurs and it loses its nutritional properties (Kar et al. 2018). Therefore garlic bulbs are dried to make garlic powder. The storage of garlic powder at high temperature and humid condition results in fungal and mould growth and such storage conditions are unfavorable for garlic (Pitt and Hocking 2009). The quality of garlic during storage is dependent on moisture content and water activity (Ramesh et al. 2001; Topuz 2008). The chemical stability and shelf life of any food product can be determined from sorption isotherm, which depicts the relationship between moisture content and water activity and is useful in drying processes modeling, selection of packaging material and sorption enthalpy calculation (Labuza and Altunakar 2020; Fontana Jr and Carter 2020). Sorption isotherms have been proposed by many researchers in form of theoretical, semi-empirical and empirical models but Guggenheim–Anderson-de Boer (GAB) model is found to be more successful and is useful in the calculation of monolayer moisture content (Behera et al. 2017). Shelf life study is essential for food safety as well as consumers’ high-quality experience (Tian et al. 2019). Along with water activity, packaging material (moisture and gas barrier properties) and packaging environment (vacuum packaging, modified atmosphere packaging) play a crucial role in the shelf life of food products (Singh et al. 2019). In India, garlic is subjected to various temperature and humidity conditions due to the unavailability of proper storage at farms and retail stores. Therefore it has a high chance of quality change during storage. Under each storage condition, finding the shelf life of garlic powder by experiment is difficult. Thus, shelf life prediction can be a better solution to find out the shelf life of the product under any storage conditions. However, no literature study is available on shelf life study of dried garlic powder. Since different storage conditions accelerate different physical, chemical and microbiological changes in the product. The shelf life analysis helps to know what changes are likely to occur before testing. Properly conducted shelf life studies ensure that the product quality will be maintained throughout the product life-cycle and greatly reduce the chances of customer complaints related to quality. Hence, the present study was undertaken for shelf life prediction of garlic powder using sorption modeling at different storage conditions so that on an industrial scale, garlic powder storage and transportation will be benefited.

Material and methods

Raw material

Garlic bulbs (Allium sativum) of uniform size, colour, and without injury and infections were bought from a local market of Rourkela, Odisha (India) and were stored at room temperature (22 ± 2 °C) till further use. The initial moisture content of the product was determined (Sharma and Prasad 2006) and found to be 1.86–1.95 g water g−1 dry matter. Garlic clove had 3 axis (l = 26.20 ± 1.76 mm, b = 11.60. ± 1.63 mm, t = 10.80 ± 1.34 mm).The weight of each garlic clove varied from 0.93 ± 0.2 to 0.43 ± 0.4 g, depending on their size.

Hot air oven drying of garlic cloves

Garlic cloves were dried in a universal hot air oven at 60°, 70°, 80° and 90 °C at constant air velocities. The ambient air temperature and relative humidity varied from 10° to 25 °C and 40 to 65% relative humidity during drying experiments. 5 g of samples placed in one layer was used in each drying condition. The sample was taken out every 20 min during drying to calculate the weight loss data using a digital balance (SEC, India, with the precision of ± 0.01 g). The hot air oven temperature was set through an already existing temperature controller fitted to the oven and the set temperature was controlled throughout the experiments.

Drying characterization

The moisture content data of garlic cloves at different temperatures during hot air oven heating were converted to moisture ratio using Eq. 1 (Akpinar et al. 2003) which is mentioned below:

| 1 |

From the moisture loss data, the drying rate was calculated by using Eq. 2 (Doymaz 2006)

| 2 |

where MR refers to the moisture ratio, the moisture content on dry basic (g water g−1 dry matter) of garlic at any drying time t and t + dt minutes are represented as Mt and Mt + dt respectively. Mo refers to initial moisture content of raw garlic (g water g−1 dry matter) and equilibrium moisture content (g water g−1 dry matter) is represented as Me and is assumed to be 0.

Modeling drying characteristics

The hot air oven drying data of garlic are fitted to the page model by using curve fitting tool MATLAB software (Ver-2021b, Math works, USA). The R2 (coefficient of determination), SSE (sum square error) and RMSE (root mean square error) were determined to know the curve fitting quality (Doymaz 2005).

| 3 |

Effective moisture diffusivity estimation

Various moisture transport mechanisms like evaporation, condensation, surface diffusion, capillary flow, Knudsen diffusion are involved in the drying. All these processes contribute towards the moisture migration from inside to the surface of products during drying. The mass transfer process can be better explained by Fick’s second law of unsteady state diffusion. The garlic clove can be considered as a thin slab and the Fick’s second law for infinite series was applied to determine the diffusivity by using the following equation.

Where MR is moisture ratio, b = thickness of garlic cloves in m, t = time in second, and effective moisture diffusivity.

| 4 |

The above series terms become negligible for n = 2 or 3 as compared to n = 1 (1.37 × 10–5) thus the equation can be simplified to first term of series

| 5 |

| 6 |

Measurement of water activity (aw) and modeling of sorption phenomena

The garlic procured from the market was subjected to hot air drying at 70 °C at 40% RH to bring the garlic moisture content down to 4.59, 6.18, 8.91, 10.06 and 17.52% d.b., respectively. The dried garlic cloves were powdered and kept in a water activity meter (Rotronic-HC2-Aw, Rotronic Measurement Solutions, and Switzerland) to measure the water activity. Brunauer, Emmett and Teller (BET) and Guggenheim, Anderson and De Boer (GAB), both the isotherm models have an extensive application to water sorption in food products. Both BET and GAB isotherms follow the same statistical model and are closely related but the BET model holds its application to a limited range of water activity (0.3–0.4) whereas the GAB model can apply to adsorption and desorption of foods over a wide range of water activities (Prothon and Ahrné 2004). The versatility of the GAB model is due to the introduction of a second well-differentiated sorption stage for water molecules as it considers water molecules inside the second and higher layers are the same as each other but different from that in the liquid state. This assumption introduces an additional degree of freedom (an additional constant, k) by which the GAB model gains its greater versatility (Timmermann et al. 2001). Therefore the GAB model was selected over the BET model. The monolayer moisture content of garlic powder was determined from the aw and equilibrium moisture content data by using the Guggenheim–Anderson–de Boer (GAB) model (Eq. 7).

| 7 |

| 8 |

Substituting and in place of , and respectively in Eq. 8

| 9 |

By solving Eq. 9 we can get the Kw, Mmo and Cg value

| 10 |

| 11 |

| 12 |

Change in surface colour

The color values (L*, and b*) of dried garlic powder were determined by Hunterlab, Colorflex EZ, USA colorimeter. Hue angle, chroma, total colour change (ΔE), browning index (BI) and whiteness index (WI) were determined from the L*,, b* values using Eqs. 13, 14, 15, 16 and 18, respectively. Lower ΔE value represents better colour retention while BI is associated with enzymatic and non-enzymatic browning and WI is the indicator of whiteness and is related to consumers’ preferences towards white colour (Pathare et al. 2013).

| 13 |

| 14 |

| 15 |

| 16 |

| 17 |

| 18 |

where , and represents L*, and b*of raw garlic.

Shelf life prediction of garlic powder under different storage conditions

The shelf life of garlic powder was predicted at domestic and industrial storage conditions in high density polyethylene (HDPE), low density polyethylene (LDPE) and aluminum laminated packages (ALP). Generally, 40 °C temperature and 90% RH has been considered as the most unfavorable condition for storage in domestic conditions. Whereas industrial storage conditions vary in a wider range of temperatures and RH combinations (5°, 10°, 15°, and 20 °C with 70% RH) (Surkan et al. 2009; Perez-Galvez et al. 2009). For shelf life prediction of garlic, the initial moisture content can be assumed as the monolayer moisture, as garlic powder is most stable at monolayer moisture content. The aw more than 0.55 is considered as the upper limit for unaccepted change (Shirkole and Sutar 2018). Therefore critical moisture content of garlic powder was taken as 8.90% d.b. at 0.63 aw. Equation 19 expresses the change in moisture content of garlic (dM/dθg) during storage (θg) at temperature (Tp).

| 19 |

where Wg is garlic powder dry weight, Rhg refers to the storage environment’s relative humidity in fraction, kg is the permeability of packaging material (kg water m−2 d−1 Pa−1), lg, bg and 2bglg are length (m), width (m) and the package surface area (m2) respectively. M is dry basis moisture content in %, aw refers to the water activity in fraction and θgs refers to the periods of storage in days (d), Tp is the storage temperature (°C) and Pw* refers to the water vapor saturation pressure (Pa) at Tp (°C). The shelf life of garlic powder has been predicted by using Eq. 20.

| 20 |

where θgs is the garlic powder shelf life in days, Mgi and Mgc refers to the moisture content of the garlic powder and critical moisture content of garlic (% d.b.), respectively. The Mgi should be near to the monolayer moisture (Mmo) of the product.

Results and discussions

Effect of temperature on drying characteristics and its modeling

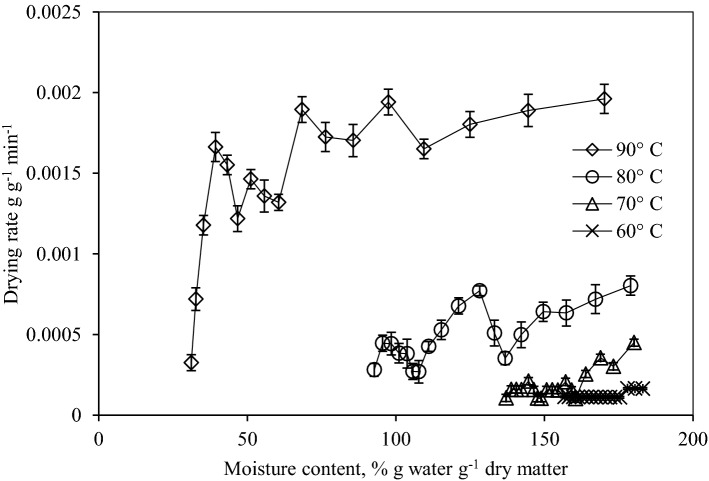

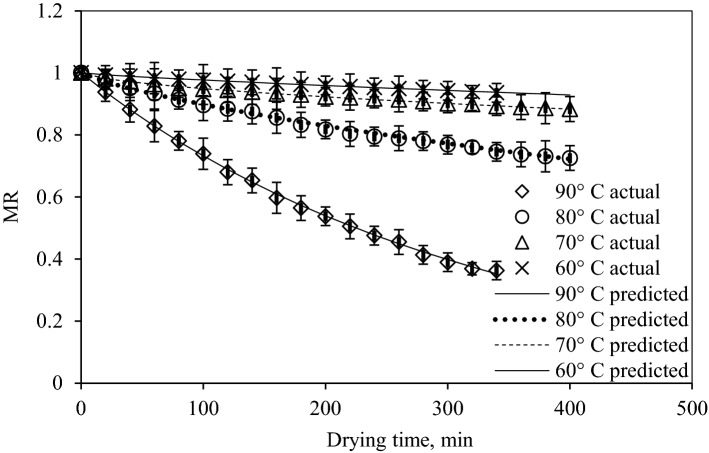

The drying rate shows the variation in moisture content of the product with time under varying conditions. Figure 1 showed that initial drying rates were high and falls as moisture content decreased. The temperature profile of garlic during the hot air oven drying was found to be in 3 distinctive stages, stage I (warm-up period), stage II (rapid heating period), stage III (final isothermal stage). The temperature profile increased drastically in the rapid heating stage resulting from the large amount of thermal energy provided by the hot air oven under the high temperature difference between the hot air and the thin layer of garlic. Therefore initially drying rates were high due to high-temperature gradients along with the availability of more free moisture inside the product which led to a higher rate of moisture removal. Further, the specific heat capacity decreases with the decreasing moisture content, which could have led to initial rapid heating. After particular moisture content, the decrease in drying rate signifies the drying occurred at a falling rate period. It might be due to the isothermal stage appearing after a particular period of drying, where temperature gradient would have fallen with low availability of free moisture. Meanwhile, the drying rate increased drastically when the hot air oven temperature increased from 60 to 90 °C (Fig. 1). The increase in drying rate with the temperature was due to higher thermal energy provided at high temperatures, which is the key requirement for moisture evaporation. The moisture diffusivity at 90 °C varied from 8.01 × 10–10 to 1.04 × 10–9 m2/s and at 80 °C diffusivity value varied from 2.21 × 10–11 to 9.67 × 10–11. The increase in temperature increased the vapour pressure within the garlic thus helping in faster diffusion of moisture and higher drying rate at higher temperatures. Moisture ratio refers to the ratio of moisture amount remaining in garlic to the initial moisture content. Figure 2 shows the effect of temperature on moisture ratio. The drying time is taken to reduce the moisture content from 1.86 to 1.95 g water g−1 dry matter to 0.06 g water g−1 dry matter (approximately) was 8.5 and 28 h at 90 °C and 60 °C hot air oven temperature respectively.

Fig. 1.

Effect of temperature on drying rate

Fig. 2.

Effect of temperature on moisture ratio (predicted by Page model and actual)

Table 1 shows the page model constants. The drying data had a good fit to the page model as R2 and RMSE values are in the range of 0.9991–0.9988 and 0.0064–0.0001 respectively. The drying rate constant (k) reduced as the temperature decreased. In all the drying conditions, n value was less than 1 which showed sub diffusion phenomena during the drying process (Simpson et al. 2017).

Table 1.

Effect of temperature on page model constant, R2, SSE and RMSE value

| Temperature °C | Page model constant | ||||

|---|---|---|---|---|---|

| k | n | R2 | SSE | RMSE | |

| 90 | 0.0033 | 0.9874 | 0.9991 | 0.0006 | 0.0064 |

| 80 | 0.0027 | 0.7997 | 0.9962 | 0.0001 | 0.0054 |

| 70 | 0.0028 | 0.6271 | 0.9967 | 0.0001 | 0.0019 |

| 60 | 0.0005 | 0.8340 | 0.9988 | 0.0001 | 0.0001 |

Effect of moisture content on aw and GAB constants estimation

The water activity (aw) of the product is responsible for microbial activity and product stability during storage (Staack et al. 2008). Table 2 shows the aw within the experimental moisture content range (4.59–17.52% dry basic). The aw of garlic powder decreased from 0.83 to 0.31, with a decrease in moisture content. At constant temperature, the sorption isotherm shows a decrease in water activity with a decrease in moisture content. At low and intermediate moisture content the rise in water activity was linear due to multilayer sorption whereas, at higher moisture content, the water activity was more due to more availability of water because of capillary condensation (Goula et al. 2008). The correlation was developed between water activity and moisture content of garlic and is given in Eq. 21.

| 21 |

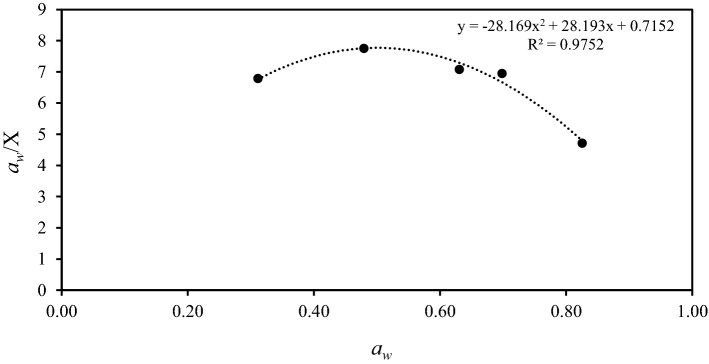

Where aw refers to the garlic powder water activity infraction and M is the moisture content in % d.b. The plot of aw/M vs. aw is shown in Fig. 3. A second-order polynomial equation was fitted and the GAB model constants Kw, Mmo, and Cg were determined using Eqs. 10, 11 and 12, respectively. The Kw, Mmo, and Cg were found to be 0.975, 0.033 and 42.429.

| 22 |

Table 2.

The physicochemical characteristics of garlic at different moisture content

| MC % db | Physical characteristics, 70° C, 40% RH | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| aw | L* | a* | b* | C | h° | BI | WI | ΔE | |

| 4.59 | 0.31 ± 0.002a | 61.32 ± 0.64a | 6.02 ± 0.56a | 19.55 ± 0.02a | 20.57 ± 0.02a | 72.37 ± 0.79a | 45.76 ± 0.37a | 56.51 ± 0.98a | 11.24 ± 0.65d |

| 6.18 | 0.48 ± 0.004b | 62.33 ± 0.12a | 8.24 ± 0.01c | 30.55 ± 0.11d | 31.64 ± 0.10d | 74.89 ± 0.05b | 75.09 ± 0.21d | 50.79 ± 0.05a | 10.71 ± 0.05c |

| 8.91 | 0.63 ± 0.004c | 62.83 ± 0.09a | 8.86 ± 0.32b | 30.86 ± 0.66c | 32.10 ± 0.72c | 73.97 ± 0.22a | 75.96 ± 2.21c | 50.87 ± 0.43a | 10.97 ± 0.48b |

| 10.06 | 0.70 ± 0.003d | 63.01 ± 0.39a | 6.83 ± 0.12a | 27.30 ± 0.13b | 28.14 ± 0.14b | 75.95 ± 0.20c | 63.39 ± 0.79b | 53.52 ± 0.35a | 8.35 ± 0.36a |

| 17.52 | 0.83 ± 0.005e | 65.57 ± 0.21b | 4.31 ± 0.29a | 17.73 ± 0.42a | 18.25 ± 0.38a | 77.05 ± 0.33d | 35.7 ± 0.88a | 61.03 ± 0.36b | 9.60 ± 0.34a |

| Temperature °C | Garlic powder at 6% d.b. moisture content | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | C | h° | BI | WI | ΔE | ||

| 70 | 62.21 ± 0.09b | 8.26 ± 0.01a | 30.61 ± 0.11b | 31.70 ± 0.08c | 74.89 ± 0.05a | 83.68 ± 0.21b | 50.67 ± 0.05c | 10.80 ± 0.05a | |

| 80 | 56.93 ± 0.26a | 8.06 ± 0.13a | 26.95 ± 0.24a | 28.13 ± 0.27a | 79.17 ± 2.03b | 72.84 ± 1.36a | 48.55 ± 0.36b | 13.96 ± 0.31b | |

| 90 | 56.06 ± 0.13a | 11.6 ± 0.06b | 31.12 ± 0.08c | 33.22 ± 0.08b | 80.07 ± 2.42c | 93.10 ± 0.08c | 44.91 ± 0.05a | 17.42 ± 0.10c | |

Values are mean ± Standard deviation (n = 3) followed with different letter in the same column, differs significantly at a 5% level of significance

Fig.3.

Plot of change of aw/M with respect to aw

The GAB constants Cg and Kw are related to the heat of sorption of the first layer and total heat of sorption of multilayer respectively. Kw represents the interaction in the multilayer between garlic and water vapour. The Kw value for garlic was 0.975 at 70 °C. Shirkole et al. (2021) found out the increase in Kw value from 0.89 to 0.99 due to a rise in temperature of paprika from 30° to 60 °C. The higher Kw value in garlic shows the higher interactions of water molecules during desorption in the multilayer. The monolayer moisture content of 0.033 is near to the previously reported monolayer moisture content of garlic as 0.02–0.025 by (Mohammad et al. 1986). They reported caking of garlic powder above 9% moisture content (5 1.4% RH) and found it to be the critical point of garlic powder. The literature study shows for the prediction of shelf life the initial moisture content should be near to monolayer moisture content.

Effect of temperature and moisture content on surface colour change

The change in colour value at different moisture content during drying of garlic at 70° is presented in Table 2. L* value decreased from 65.57 to 61.32 when the moisture content was reduced from 17.52 to 4.59% d.b. The L*, , and b* values of freshly crushed raw garlic slices were found to be 69.06 ± 3.65, 1.22 ± 0.01, and 26.10 ± 0.004, respectively. Table 2 shows, the L* value dropped significantly (p < 0.05) whereas and b* increased significantly (p < 0.05) due to decrease in moisture content. As L* was the indicator of lightness, the fall in L* value due to decrease in moisture content led to the darkening of the product during dehydration. Below 6% moisture content, the redness and yellowness (b*) values fall after rising to a maximum value of 8.86 and 30.86 at 8.91% d.b. respectively. This shows the destruction of red and yellow pigment due to long time exposure at high temperature (70 °C). Table 2 showed the decrease in L* value from 62.21 ± 0.09 to 56.06 ± 0.13 with an increase in the temperature from 70 to 90 °C. This implied more darkening of garlic powder due to increase in temperature and/or time. It is similar to the study reported by Sharma and Prasad (2001). Chroma determines the intensity of colour perceived by humans. The chroma value and hue angle increased with an increase in temperature from 70 to 90 °C which shows higher temperature saturated the colour of the product during drying.

Effect of temperature and moisture content on the browning index, whiteness index and total colour change

Browning index indicates the purity of brown colour in the food product and measures the browning of food product containing sugar due to Maillard reactions between sugar and amino acids. The low BI value indicates lesser browning and higher BI value shows higher browning. BI value increased significantly (p < 0.05) from 35.79 to 45.76, as the moisture content decreased during the experiment and shown in Table 2. The dried garlic powder obtained at 90 °C showed the highest browning index value of 93.10 ± 0.08. Higher oven temperature accelerated the Maillard reaction and oxidation of ascorbic acid thus resulting in the browning of the product. The BI was also related to redness value and showed similar trends for both BI and a* value. It can be observed from Table 2 that higher hot air oven temperature resulted in severe colour damage to the dried garlic. Whiteness index (WI) refers to the degree of whiteness on a scale from 0 to 100 and is mainly associated with the colour preferences of consumers towards white. Mathematically it combines lightness and yellow–blueness into a single term. The whiteness value was high at 17.52% d.b. moisture content and reduced significantly (p < 0.05) as the moisture content decreased. Table 2 shows the negative effect of temperature on the whiteness of the product. The results of WI value showed that the visual quality of garlic was deteriorated due to high temperature exposure during drying. The total colour change (ΔE) was calculated to characterize the total colour change during processing compared to the initial colour values of raw garlic. It can be shown from Table 2 that ΔE value was more at low moisture content and higher temperature operations which shows the overall colour degradation of the product.

Shelf life prediction of garlic powder under different storage conditions

Garlic cloves containing 6% moisture content d.b. has been selected for making garlic powder as the colour analysis showed excellent results at 6% d.b. moisture content. The shelf life of garlic powder was predicted using Eq. 20. For predicting the shelf life of garlic powder, the monolayer moisture content of garlic was determined by using the GAB model and it was found to be 3.3% d.b. Drying till monolayer moisture content can enhance the shelf life of any product but it is not advisable to go till monolayer moisture content as the colour of the garlic powder colour was darkened with a further decrease in moisture content from 6% d.b. Therefore garlic having 6% d.b. (near to Mmo) moisture content was chosen as shelf life prediction as the water activity was low and colour value was good. The packaging materials like HDPE, LDPE and ALP were chosen for shelf life prediction. The surface area of the pouch has been taken as 0.02 m2. The water vapor permeability of ALP, LDPE and HDPE were 6.14 × 10–12, 3.38 × 10–11 and 1.04 × 10–11 kg water m−2 s−1 Pa−1, respectively (Patel and Sutar 2016; Jena and Das 2012). 70 g of garlic powder could be kept in a pouch from which 65.80 g was the dry solid mass. The shelf life of garlic will be minimum during domestic storage (40 °C and 90% RH) condition and the shelf life of garlic having 6.0% d.b. moisture content was found to be 2.61, 0.8 and 7.02 months when stored in HDPE, LDPE and ALP packages, respectively. In industries 5°, 10°, 15°, 20 °C temperature and 70% RH is usually adopted for storage. The shelf life of garlic at 5 °C temperature and 70% RH was found to be 1.32, 4.30 and 7.28 years in LDPE, HDPE and ALP packages, respectively. The predicted shelf life under different storage conditions has been depicted in Table 3.

Table 3.

Predicted shelf life data of garlic cloves at different storage and packaging conditions

| Storage conditions | Shelf life, months | |||

|---|---|---|---|---|

| T (°C) | RH (%) | HDPE | LDPE | ALP |

| 40 | 90 | 2.61 | 0.80 | 7.02 |

| 30 | 70 | 10.59 | 3.26 | 17.94 |

| 20 | 70 | 19.23 | 5.91 | 32.56 |

| 15 | 70 | 26.39 | 8.12 | 44.69 |

| 10 | 70 | 36.68 | 11.28 | 62.11 |

| 5 | 70 | 51.61 | 15.88 | 87.39 |

Under accelerated storage conditions, there was a significant difference (p < 0.05) in the water activity of the garlic powder after the first month in all types of packages. The rise in water activity of the product was because of the moisture migration through the packaging material. The water activity of garlic powder stored in HDPE and LDPE at 40 °C temperature and 90% RH has been estimated at different intervals within the predicted shelf life period, and the water activity was found to be less than 0.5, which proved that the model predicted the shelf life precisely. Shelf life of garlic powder at all storage conditions could not be validated as the time requirement will be too high.

Conclusions

Moisture migration and GAB model were found suitable for shelf life prediction of dried garlic powder under various storage conditions. The garlic shelf life can be extended by storing the garlic at monolayer moisture content at low temperatures. The water activity decreased significantly by lowering the moisture content from 17.52 to 4.59 (% d.b.). Colour characteristics (L*, a*, b*, chroma, hue angle and ΔE) deteriorated with an increase in temperature and decrease in moisture content. Garlic powder can be stored up to 1–5 years at 5 °C temperature and 70% RH in HDPE, LDPE and ALP. Garlic can be stored in ALP for a longer duration as the water vapor permeability of ALP was lower than HDPE and LDPE. This research study can be useful in shelf life prediction of dried garlic powder under different industrial and domestic storage conditions.

Acknowledgements

The authors would like to acknowledge the Science and Engineering Research Board (SERB) and Ministry of Education and, Government of India, for their financial support to this work.

Abbreviations

- HDPE

High density polyethylene

- LDPE

Low density polyethylene

- ALP

Aluminum laminated pouch

- GAB

Guggenheim–Anderson-de Boer

- RH

Relative humidity

- l

Length

- b

Breadth

- t

Thickness

- mm

Millimeter

- g

Gram

- MR

Moisture ratio

- Mt

Moisture content on dry basis at any drying time t

- Mt+dt

Moisture content on dry basis at any drying time t + dt

- Mo

Initial moisture content of raw garlic

- Me

Equilibrium moisture content

- t

Time

- R2

Coefficient of determination

- SSE

Sum square error

- RMSE

Root mean square error

- aw

Water activity

- d.b

Dry basic

- Mmo

Monolayer moisture content

- h

Hue angle

- C

Chroma

- ΔE

Total colour change

- BI

Browning index

- WI

Whiteness index

- Wg

Dry weight of garlic powder

- lg

Length of package

- bg

Width of package

- kg

Permeability of packaging material

- Rhg

Relative environment of storage environment

- Pw*

Water vapor saturation pressure

- Tp

Storage temperature

- θgs

Periods of storage in days

- m

Meter

- d

Days

- Mgi

Moisture content of the garlic powder

- Mgc

Critical moisture content of garlic

- M

Dry basis moisture content

- h

Hour

- k

Drying rate constant

Author’s contributions

Sudarshanna Kar: Conceptualization, research methodology, experimentation, data analysis, manuscript Writing—Original Draft. P P Sutar: Supervision, conceptualization, project funding acquisition, resources generation, administration, validations, manuscript review and editing.

Funding

Science and Engineering Research Board (SERB) and Ministry of Education and Government of India.

Availability of data and material

All data generated or analyzed during this study are included in the manuscript.

Code availability

Not Applicable.

Declarations

Conflict of interest

We have acknowledged the funding agency as well as all authors involved in the research work has been incorporated in the authors section. We declare no conflict of interest.

Consent to participate

The submission of manuscript to JFST publication has been approved by all authors.

Consent for publication

I, the undersigned, give my consent for the publication of the manuscript to be published in the above Journal and Article. I have discussed this consent form with P.P Sutar, who is an author of this paper.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Akpinar EK, Bicer Y, Yildiz C. Thin layer drying of red pepper. J Food Eng. 2003;59(1):99–104. doi: 10.1016/S0260-8774(02)00425-9. [DOI] [Google Scholar]

- Behera G, Sutar P, Aditya S. Development of novel high power-short time (HPST) microwave assisted commercial decontamination process for dried turmeric powder (Curcuma Longa L.) J Food Sci Technol. 2017;54(12):4078–4091. doi: 10.1007/s13197-017-2882-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Doymaz İ. Drying characteristics and kinetics of okra. J Food Eng. 2005;69(3):275–279. doi: 10.1016/j.jfoodeng.2004.08.019. [DOI] [Google Scholar]

- Doymaz İ. Thin-layer drying behaviour of mint leaves. J Food Eng. 2006;74(3):370–375. doi: 10.1016/j.jfoodeng.2005.03.009. [DOI] [Google Scholar]

- Fontana AJ, Jr, Carter BP. Measurement of water activity, moisture sorption isotherm, and moisture content of foods. Water Act Foods Fundam Appl. 2020 doi: 10.1002/9781118765982.ch8. [DOI] [Google Scholar]

- Goula AM, Karapantsios TD, Achilias DS, Adamopoulos KG. Water sorption isotherms and glass transition temperature of spray dried tomato pulp. J Food Eng. 2008;85(1):73–83. doi: 10.1016/j.jfoodeng.2007.07.015. [DOI] [Google Scholar]

- Jena S, Das H. Shelf life prediction of aluminum foil laminated polyethylene packed vacuum dried coconut milk powder. J Food Eng. 2012;108(1):135–142. doi: 10.1016/j.jfoodeng.2011.06.036. [DOI] [Google Scholar]

- Kar S, Mujumdar AS, Sutar PP. Aspergillus niger inactivation in microwave rotary drum drying of whole garlic bulbs and effect on quality of dried garlic powder. Dry Technol. 2018 doi: 10.1080/07373937.2018.1517777. [DOI] [Google Scholar]

- Kar S, Sutar P. Enhancing the efficacy of microwave blanching-cum-black mould inactivation of whole garlic (Allium sativum L.) Bulbs using ultrasound: higher inactivation of peroxidase, polyphenol oxidase, and Aspergillus niger at lower processing temperatures. Food Bioprocess Technol. 2022;1:21. doi: 10.1007/s11947-022-02769-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Labuza TP, Altunakar B. Water activity prediction and moisture sorption isotherms. Water Act Foods Fundam Appl. 2020 doi: 10.1002/9781118765982.ch7. [DOI] [Google Scholar]

- Mohammad N, Anwar M, Ehteshamuddin A, Jamil M. Moisture sorption studies on garlic powder. J Food Sci. 1986;51(6):1575–1576. doi: 10.1111/j.1365-2621.1986.tb13868.x. [DOI] [Google Scholar]

- Patel J, Sutar P. Acceleration of mass transfer rates in osmotic dehydration of elephant foot yam (Amorphophallus paeoniifolius) applying pulsed-microwave-vacuum. Innov Food Sci Emerg Technol. 2016;36:201–211. doi: 10.1016/j.ifset.2016.06.018. [DOI] [Google Scholar]

- Pathare PB, Opara UL, Al-Said FA-J. Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. 2013;6(1):36–60. doi: 10.1007/s11947-012-0867-9. [DOI] [Google Scholar]

- Perez-Galvez A, Hornero-Mendez D, MaI M-M. Stability of paprika without supplementary antioxidants during storage under industrial controlled conditions. J Agric Food Chem. 2009;57(11):4718–4723. doi: 10.1021/jf804058m. [DOI] [PubMed] [Google Scholar]

- Pitt JI, Hocking AD. Fungi and food spoilage. Berlin: Springer; 2009. [Google Scholar]

- Prothon F, LlM A. Application of the Guggenheim, Anderson and De Boer model to correlate water activity and moisture content during osmotic dehydration of apples. J Food Eng. 2004;61(3):467–470. doi: 10.1016/S0260-8774(03)00119-5. [DOI] [Google Scholar]

- Ramesh M, Wolf W, Tevini D, Jung G. Influence of processing parameters on the drying of spice paprika. J Food Eng. 2001;49(1):63–72. doi: 10.1016/S0260-8774(00)00185-0. [DOI] [Google Scholar]

- Santhosha S, Jamuna P, Prabhavathi S. Bioactive components of garlic and their physiological role in health maintenance: a review. Food Biosci. 2013;3:59–74. doi: 10.1016/j.fbio.2013.07.001. [DOI] [Google Scholar]

- Sharma G, Prasad S. Drying of garlic (Allium sativum) cloves by microwave–hot air combination. J Food Eng. 2001;50(2):99–105. doi: 10.1016/S0260-8774(00)00200-4. [DOI] [Google Scholar]

- Sharma G, Prasad S. Optimization of process parameters for microwave drying of garlic cloves. J Food Eng. 2006;75(4):441–446. doi: 10.1016/j.jfoodeng.2005.04.029. [DOI] [Google Scholar]

- Shirkole S, Mujumdar A, Sutar P. Studies on thermal stability of high-power short time microwave dried paprika (Capsicum annuum L.) considering the interaction of water molecules with sorption sites. Dry Technol. 2021;39(1):52–65. doi: 10.1080/07373937.2019.1693399. [DOI] [Google Scholar]

- Shirkole S, Sutar P. Modeling sorption phenomena and moisture migration rates in paprika (Capsicum annuum L.) using physicochemical characteristics. J Food Sci Technol. 2018;55(2):678–688. doi: 10.1007/s13197-017-2977-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Simpson R, Ramírez C, Nuñez H, Jaques A, Almonacid S. Understanding the success of Page's model and related empirical equations in fitting experimental data of diffusion phenomena in food matrices. Trends Food Sci Technol. 2017;62:194–201. doi: 10.1016/j.tifs.2017.01.003. [DOI] [Google Scholar]

- Singh S, Gaikwad KK, Lee YS. Development and application of a pyrogallic acid-based oxygen scavenging packaging system for shelf life extension of peeled garlic. Sci Hortic. 2019;256:108548. doi: 10.1016/j.scienta.2019.108548. [DOI] [Google Scholar]

- Staack N, Ahrné L, Borch E, Knorr D. Effects of temperature, pH, and controlled water activity on inactivation of spores of Bacillus cereus in paprika powder by near-IR radiation. J Food Eng. 2008;89(3):319–324. doi: 10.1016/j.jfoodeng.2008.05.010. [DOI] [Google Scholar]

- Surkan S, Albani O, Ramallo L. Influence of storage conditions on sensory shelf life of yerba mate. J Food Qual. 2009;32(1):58–72. doi: 10.1111/j.1745-4557.2008.00236.x. [DOI] [Google Scholar]

- Tian H-X, Zhang Y-J, Chen C, Qin L, Xiao L-Z, Ma H-R, Yu H-Y. Effects of natural ingredients on the shelf life of chicken seasoning. Food Chem. 2019;293:120–126. doi: 10.1016/j.foodchem.2019.03.084. [DOI] [PubMed] [Google Scholar]

- Timmermann EO, Chirife J, Iglesias H. Water sorption isotherms of foods and foodstuffs: BET or GAB parameters? J Food Eng. 2001;48(1):19–31. doi: 10.1016/S0260-8774(00)00139-4. [DOI] [Google Scholar]

- Topuz A. A novel approach for color degradation kinetics of paprika as a function of water activity. LWT-Food Sci Technol. 2008;41(9):1672–1677. doi: 10.1016/j.lwt.2007.10.004. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

All data generated or analyzed during this study are included in the manuscript.

Code availability

Not Applicable.