Abstract

This review presents recent advances regarding biomass-based nanomaterials, focusing on their surface interactions. Plant biomass-based nanoparticles, like nanocellulose and lignin from industry side streams, hold great potential for the development of lightweight, functional, biodegradable, or recyclable material solutions for a sustainable circular bioeconomy. However, to obtain optimal properties of the nanoparticles and materials made thereof, it is crucial to control the interactions both during particle production and in applications. Herein we focus on the current understanding of these interactions. Solvent interactions during particle formation and production, as well as interactions with water, polymers, cells and other components in applications, are addressed. We concentrate on cellulose and lignin nanomaterials and their combination. We demonstrate how the surface chemistry of the nanomaterials affects these interactions and how excellent performance is only achieved when the interactions are controlled. We furthermore introduce suitable methods for probing interactions with nanomaterials, describe their advantages and challenges, and introduce some less commonly used methods and discuss their possible applications to gain a deeper understanding of the interfacial chemistry of biobased nanomaterials. Finally, some gaps in current understanding and interesting emerging research lines are identified.

1. Introduction

Worldwide population growth, combined with widespread increases in energy and materials use, contributes significantly to global warming, pollution, and diminution of Earth’s natural resources. To maintain the current standard of living while protecting the environment, there is a demand for a materials paradigm shift to a circular materials bioeconomy. This includes more efficient recycling, upcycling and sustainable use of renewable resources. In the transition from fossil-based resources to renewables, biobased nanomaterials are pursued as one of the most promising alternatives to address these challenges. Cellulose nanomaterials (CNMs) are by far the most researched plant-based nanomaterial,1−4 followed by lignin nanoparticles (LNPs).5,6 Other renewable nanomaterials include chitin and chitosan,7−9 starch,10,11 and hemicelluloses,12−14 but these have, to date, attracted less attention. Biobased nanomaterials combine the possibilities of nanotechnology with the typical advantages of renewables, like abundance, biodegradability, recyclability, biocompatibility, and low production costs. Harnessing their unique inherent properties, advanced materials that not only replace but outperform the current synthetic materials can be developed from biobased nanomaterials.

1.1. Sources for Biobased Nanomaterials

The main biopolymers in nature with the ability to form nanomaterials are polysaccharides, polyphenols, and proteins. Polyphenols are abundantly found in plants, while proteins are mainly synthesized by animals or bacteria. Polysaccharides are widely present in any living material. Wood and vascular plants contain the polysaccharides cellulose and hemicellulose, and lignin, a complex polyphenolic polymer. Wood and plant fibers have been used for centuries in materials like paper and textiles, and plant-based biorefineries have been optimized for high yields at low cost and minimal environmental burden. While there is still high demand for macroscopic pulp fibers for packaging and tissue, and polymeric cellulose for textiles and bioenergy, existing biorefineries are also excellent sources of biomass for CNM and lignin nanomaterial (LNM) production. A sustainably managed forest reduces soil degradation, acts as a carbon sink, has a positive impact on biodiversity, can create income, and provides food and recreation for people.15−17 At the same time, it is an abundant source of timber and fibers. Virgin wood fibers have been used extensively for CNM production with excellent results, but in the interest of efficient use of resources, other feedstocks should be considered. Agriculture waste residues are also common feedstocks for both CNMs and LNMs with the benefits of having more frequent harvests. Lignin is available as a side stream from the pulp and paper industry and biorefineries, but it is currently mainly burned for energy. Efficient utilization of the lignin in materials would boost the transition to more energy-efficient processes and greener energy sources, and lead to a positive carbon handprint by binding the carbon in products for a longer time.18,19

CNMs can also be obtained from nonplant sources like algae, tunicates, and different bacteria species.20−22 In particular, bacterial cellulose has been intensively studied in the last two decades, with a special focus on biomedical applications.23 Nevertheless, the isolation and preparation of nonplant CNMs still need optimization for large-scale production.

Sources for other natural nanomaterials include, for example, crustacean shell waste and fungi for extraction of chitin nanofibrils, or biotechnical means for the controlled preparation of silk nanofibrils.24,25 Their extraction is still more energy intensive (chitin nanofibrils from crustaceans) or available at a smaller scale (silk nanofibrils or chitin from fungi) than the plant-based nanomaterials.26 Therefore, we are focused on nanomaterials derived from plants, and hence the plant cell wall structure is reviewed next.

1.2. The Plant Cell Wall

Plant cell walls are complex, dynamic structures with multiple roles, including providing strength, expandability, modularity, and a barrier against pathogens.27 In nature, elementary constituents range from oligosaccharides and polysaccharides to lignin and fibers found in biomass. Furthermore, they are multifunctional and stereoregular and show a wide variety of complex structures based on small chemical variations. Understanding both the hierarchical structures and function of these constituents in nature is important for the efficient design of functional biobased nanomaterials, hence these are briefly reviewed in this section.

Typically, the plant cell is constituted of primary and secondary cell walls, and the cells are bound together by the middle lamella. The cell wall consists of cellulose, hemicelluloses (xylan, glucuronoxylan, xyloglucan, arabinoxylan, mixed linkage glucan, or glucomannan), lignin, and pectic polysaccharides. The middle lamella is mainly made of lignin and pectin. The main polymer in the cell wall is cellulose. Cellulose is a polysaccharide consisting of chains of β-(1–4)-linked-d-glucose repeating units. These chains assemble into bundles, called microfibrils, held together by hydrogen bonds and van der Waals (vdW) interactions.28 The width of the microfibrils depends on their biological origin, ranging from approximately 3–4 nm for trees to 20 nm for algae. While the smallest fibrils were long thought to consist of 36 cellulose chains, molecular dynamics simulations recently suggest that the smallest microfibrils consist of only 18 cellulose chains.29−31

The crystalline structure of the cellulose microfibrils is another aspect of the cell wall structure that recent advances in measurement methods have been able to shed light on. The measured crystallinity of native cellulose is usually in the range of 50–80%, which has led to the traditional assumption that the microfibril consists of crystalline domains interrupted by amorphous domains along the length of the fibril. However, recent neutron scattering studies have shown that these unordered domains are very short, only 1–2 nm, and should be called defects or disordered regions instead and the crystallinity is in fact much higher.32

Aligned microfibrils form thin discrete layers with randomly changing fibril orientation when traversing through the primary cell wall. The microfibrils are surrounded by hemicelluloses. The hemicelluloses are branched polysaccharides with a backbone consisting of neutral sugar units, while the branches may be neutral or negatively charged. The hemicelluloses are bound to the cellulose fibrils via hydrogen bonds and vdW attraction. It has been suggested that the hemicelluloses facilitate cell wall expansion by preventing the close packing of cellulose fibrils and thus weakening the mechanical strength of the cell wall.27 Measurements of the total sugar composition of cell walls from different tissue of Arabidopsis thaliana has revealed that not only the cell wall composition vary between different plants, but every tissue type has a different polysaccharide composition.33

Polyphenolic lignin is found in the secondary cell wall and is essential for the structural integrity of the cell wall and the stiffness and strength of the stem and root. The monomeric precursors for lignin are p-coumaryl, coniferyl, and sinapyl alcohols. Polymeric lignin is composed of an integrated network of aromatic units derived from the radical coupling of these monomers. The basic units are called p-hydroxyphenyl, guacil, and syringyl, denoted as H, G, and S, respectively. They differ in the level of methoxylation of the aromatic ring: H-lignin being non-methoxylated, G-lignin containing one methoxy group, and S-lignin having two methoxy groups.

Lignin typically comprises 20–30% of the lignocellulosic biomass, however, the exact structure of the complex polymer varies greatly depending on the botanic origin of the lignin and the isolation process. Hardwood lignins contain a similar amount of G- and S-lignins, while softwood lignins contain more G-units. Herbaceous lignins contain all three units. Biorefineries are optimized for high yield of the polysaccharides, which leads to severe changes in the lignin structure. For a detailed understanding of the chemical structure of technical lignins, the reader is referred to recent papers,34−37 here we give a very general overview.

To remove lignin from the biomass, the ester and ether bonds in native lignin are cleaved, breaking the lignin into smaller fragments of different chemical structures.37 However, radical coupling can lead to the formation of new carbon–carbon bonds and condensation into less soluble lignin.34 Some processes also introduce new functional groups, such as the introduction of sulfur during the Kraft or sulfite processes. In general, lignin degradation during various technical processing results in a decrease in aliphatic OH groups, β-O-4 linkages, and total oxygenated aliphatic moieties. In contrast, the amount of phenolic OH and saturated aliphatic moieties increase.37 Due to these various reactions, technical lignins are complex mixtures of molecules with varying molecular weight and chemical structure, and detailed nuclear magnetic resonance (NMR) spectroscopic analysis has identified several hundreds of different signals.37

1.3. Scope and Goals of the Review

There are numerous reviews on the production, properties, and applications of both CNMs2,38−40 and LNPs,5,6 hence these aspects are only briefly discussed here. In contrast, their interfacial interactions have surprisingly garnered less focus even though the properties of nanomaterials are governed by their surface properties. This review aims at describing the specific surface properties of plant-based nanomaterials and how the surface properties affect their interactions with solvents, polymers, proteins, and other compounds relevant to their performance in applications. Although our discussion is centered on CNMs and LNPs, some model thin films from regenerated cellulose or lignin are also mentioned to highlight how differences in surface chemistry and morphology affect the material properties and the interactions with other molecules. We expect that this information will enable efficient choice of the most suitable nanoparticles for specific applications and pave the way for the development of new innovative materials solutions. We furthermore hope that this review will elucidate the potential of surface-sensitive techniques for understanding the behavior of plant-based nanomaterials and inspire more scientists to explore these methods. We focus on the lignocellulosic nanomaterials, so other natural nanoparticles will not be reviewed. Material applications of silk nanofibers is an emerging field that holds great future potential, and we refer the interested reader to some recent papers on the topic.41−44 Starch nanoparticles have attracted interest for their ability to encapsulate, protect, and orally deliver bioactive components because of their diverse functionality, high biocompatibility, and environmental friendliness.45 Their production and application are reviewed in more detail by Qiu et al.45 and Kim et al.46 Chitin and chitosan nanoparticles have been actively explored in biomedical applications.47,48

To facilitate a more thorough discussion on nanoparticle interactions, the basics of intermolecular and surface forces are recapped in section 2. In section 3, cellulose nanomaterials are discussed, first introducing the main points regarding their surface properties that will affect their interactions, then discussing their interactions in various media and finally with polymers, proteins, and cells. Section 4 is devoted to lignin nanomaterials. Because intermolecular interactions play a decisive role in the supramolecular assembly of LNPs, these are first discussed in detail before reviewing the interactions of LNPs with media and other substances. The combination of lignin and cellulose in nanomaterials is discussed in section 5. Our current understanding of the interfacial interactions of nanomaterials is based on the large variety of analysis methods that have been applied. In section 6, these methods are briefly described including their advantages, drawbacks, and especially what information they provide. In the final section, we discuss what main conclusions can be drawn based on the current literature and what are still open questions and possible emerging fields.

2. Intermolecular and Surface Interactions

In this section, some common intermolecular and surface forces are briefly introduced. We focus on forces that are relevant for the systems discussed in this review, such as vdW, electrical double layer (EDL), and hydration forces, as well as interactions induced by adsorbed polymers. For a more comprehensive description, the reader is referred to the textbook by Israelachvili.49

2.1. DLVO Forces

The colloidal stability of nanomaterials can be discussed in the framework of the classical DLVO theory,50,51 named after Derjaguin, Landau, Verwey, and Overbeek. This theory suggests that the interaction between two particles across a liquid at any distance equals the sum of the EDL force and the vdW interactions. The DLVO theory is often a good first estimate for interparticle forces at separations down to about 5 nm. A qualitative overview of the DLVO forces as a function of particle separation is shown in Figure 1.

Figure 1.

Schematic of interaction energy–distance profiles between two negatively charged particles, focusing on the effect of the ionic strength on the DLVO interaction (solid curves). The interaction energy (and consequently the force) is zero when particles are far apart, but when they approach each other, the overlap of their EDLs generates a repulsion of osmotic nature (water flows in between the particles to dilute the accumulation of ions in the overlapped EDLs). At low salt concentrations, the EDL is thick, and the EDL repulsion starts at a larger separation between the particles (I). On the contrary, at high salt concentrations, the EDL is thinner, which allows particles to come closer to one other before the EDL repulsion arises (II). When the salt concentration is high enough, the attractive van der Waals forces can overcome the repulsive EDL force, which leads to particle aggregation.

The vdW forces originate from the correlation between permanent or induced electric dipoles of molecules approaching one another. The vdW interaction energy (WvdW) between two molecules decays quickly with separation (eq 1).

| 1 |

where the molecular properties like dipole moments or polarizabilities are included in β, and D denotes the distance between the molecules. Because even nonpolar molecules can have induced dipole moments, we note that the vdW forces are present between all molecules and surfaces. The vdW interaction energy between particles or surfaces is the sum of the vdW interaction energies between all of their constituting molecules, and it depends on both the geometry and molecular properties of the system. The molecular properties are included in the Hamaker constant AH, which, according to the Lifshitz theory, can be connected to the dielectric permittivity ε and refractive index n of the interacting particles or surfaces and the medium in which they interact. Thus, the nonretarded AH for particle 1 interacting with particle 3 across medium 2 can be expressed by eq 2:

| 2 |

where k is the Boltzmann constant, T is the temperature, h is Planck’s constant, and ν is UV absorption frequency. The expression for interaction energy WvdW between a spherical particle of radius R and a flat surface, assuming that D ≪ R, is given by eq 3:

| 3 |

Considering that force F and

interaction energy W are related by the equation  , the corresponding van der Waals force

is given by eq 4.

, the corresponding van der Waals force

is given by eq 4.

| 4 |

The vdW interaction energy and forces between two spherical particles of radius R1 and R2 are given by eqs 5 and 6, respectively.

| 5 |

| 6 |

From these equations, we note that the vdW forces decay much slower between particles than between molecules, affecting the overall interactions at separations up to a few nm. It can be seen in eqs 2–6 that the vdW interaction is always attractive (WvdW < 0; FvdW < 0) between particles of the same nature, it is stronger in the air or nonpolar media than in water, and it is strong for polar particles.

Figure 2.

(a) Thickness, optical thickness, and mass fractions of water in TEMPO–CNF thin films as a result of water vapor uptake as a function of relative humidity and schematic illustration of the water vapor uptake of TEMPO–CNF thin films at different humidity levels.88 Reproduced with permission from ref (88). Copyright 2017 American Chemical Society. (b) Adsorbed mass as a function of time for anionic (carboxymethyl cellulose, CMC), nonionic (xyloglucan, XG; guar gum galactomannan, GG), and cationic polysaccharides (chitosan, CHI) on CNF.89 Reproduced from ref (89), used under open access from BioResources. (c) Change in dissipation as a function of normalized frequency shift during the adsorption of CMC on CNF model surfaces in aqueous CaCl2 environments.90 (d) Schematic of CMC adsorption in the presence of CaCl2. (c,d) Reproduced with permission from ref (90) under Creative Commons CC-BY license. Copyright 2017 American Chemical Society.

Figure 6.

(a) Average particle diameter, weight-average Mw, and Ph-OH content of different lignin fractions.229 Reproduced with permission from ref (229). Copyright 2021 Royal Society of Chemistry. (b) Effect of Mw on LNPs diameter and surface charge.227 Reproduced with permission from ref (227). Copyright Royal Society of Chemistry. LNPs diameter as a function of Mw and Ph-OH and Aliph-OH content in (c) eucalyptus lignin and (d) spruce lignin.226 Reproduced with permission from ref (226), used under Creative Commons CC-BY license. Copyright 2021 Royal Society of Chemistry.

For charged particles or surfaces in aqueous media, we also have to take into account the contribution of the EDL force, which often dominates the interaction at long distances. The EDL force arises from the overlapping of the EDLs formed around the charged particles, and its magnitude depends on the charge of the particles (the higher the charge, the stronger the EDL repulsion), whereas the range of the repulsion or thickness of the EDL is described by the Debye length κ–1, which correlates inversely with the ionic strength I = (∑ici0zi2)/2 of the aqueous medium as described by eq 7:

| 7 |

where ci0 is the concentration of ions i with valence zi in the bulk, NA is Avogadro’s number, ε0 is the dielectric constant of vacuum, εr is the relative permittivity of the medium, and e is the elementary charge. For particles with similar charge, the EDL force is repulsive, while oppositely charged particles have attractive EDL force.

Different mathematical expressions can be obtained for the EDL interaction energy and force depending on the conditions of the interaction. In the simplest case, the EDL repulsion decays exponentially with the separation between the particles (eqs 8 and 9):

| 8 |

| 9 |

where parameters like the surface potential and radius of the particles, the temperature, and the relative permittivity of the medium are included in factor C.

DLVO theory is often a good first approximation when predicting the stability of biobased nanoparticle dispersions, and a few main conclusions can be made already here, while specific cases are discussed in more detail below (see sections 3.1 and 4.3). A high charge of the particles results in strong EDL repulsion, whereas increasing the ionic strength in the medium leads to shorter κ–1, that is, faster decay of the EDL repulsion. The screening of the EDL repulsion by increasing the ionic strength enables the particles to come close enough for the attractive vdW forces to dominate, leading to aggregation.

2.2. Non-DLVO Forces

Not all systems are well described by the DLVO theory. Hydrophilic surfaces may strongly bind water molecules, leading to a repulsion at short distances, compensating the attractive vdW interactions and enabling colloidal stability even in conditions where aggregation is expected. Hydration forces depend on the ionic species in the media, their concentration, as well as surface roughness.52 Usually it is monotonically repulsive, but oscillatory hydration forces are also possible.53−55 In the presence of polymers, both attractive and repulsive forces that cannot be described by DLVO theory may occur. Very common for plant-based nanomaterials is the presence of steric repulsion. This repulsion is generally present when surfaces are fully covered with polymers that have good solubility in the media and are hence adsorbed in an extended conformation, but it can also be due to the roughness of the model substrates used in the studies. When two such polymer-coated surfaces approach, the polymers need to acquire a new, more collapsed, and energetically less favorable conformation, leading to repulsion. EDL repulsion sometimes enhances the steric repulsion, leading to a more long-ranged repulsion than for pure EDL. This force is often called electrosteric repulsion. Hence the range of steric repulsion may vary between some subnanometers to hundreds of nanometers. If the adsorbed amount of polymer is low and the particles are not fully covered, bridging attraction may be observed. This occurs when a polymer chain adsorbed to one surface or particle is attracted to another particle. The bridging attraction can range to several nm. For a more thorough review on the interactions between surfaces covered with polymers or polyelectrolytes, the reader is referred to the report by Claesson et al.56

The above-mentioned forces are important for colloidal stability in nanoparticle dispersions and adsorption of polymers and proteins because they range over several nm. Intermolecular forces like hydrogen bonds, π–π interactions, Lewis acid/base interactions, and interactions between ions and dipoles play a role in the solubility of polymers and rigidity and mechanical properties of supramolecular assemblies like the CNF, LNPs, or mechanical properties of composites. However, one needs to keep in mind that the range of these interactions is less than 0.5 nm. Hence particles or molecules first need to come very close to one another before they become relevant.

3. Cellulose Nanomaterials

A nanomaterial is defined as a material with any external dimension in the nanoscale (between 1 and 100 nm) or having internal or surface structure in the nanoscale.57 Nanocellulose is the general term for cellulosic nanomaterials (CNMs), which include cellulose nanocrystals (CNCs), cellulose nanofibrils (CNFs), and bacterial cellulose or bacterial nanocellulose (BNC). CNCs are sometimes also called cellulose whiskers or nanocrystalline cellulose, while especially in older literature, microfibrillar cellulose or nanofibrillar/nanofibrillated cellulose are used as synonyms for CNF. In 2011, standard nomenclature for CNMs was suggested, and now the generally used abbreviations are CNC and CNF.58 The morphology and surface properties of these depend on the cellulosic feedstock and production method. A wide range of methods can be combined for a thorough characterization of CNMs, these include electron microscopy and atomic force microscopy (AFM) to determine size and morphology, X-ray diffraction methods for degree of crystallinity, conductometric titration for surface charge, zeta potential measurements, and dynamic light scattering for colloidal stability, among others. Rheology measurements give information on viscoelasticity of hydrogels, and spectroscopy can be used to determine chemical composition, including surface sensitive X-ray photoelectron spectroscopy and Fourier transform infrared and nuclear magnetic resonance spectroscopy for bulk analysis. In this review, we focus on methods used to study interactions of CNMs, including quartz crystal microbalance with dissipation monitoring (QCM-D), surface plasmon resonance (SPR), atomic force microscopy (AFM) force spectroscopy, and calorimetry.

CNCs are mostly produced via acid hydrolysis using sulfuric acid or selective oxidation of the cellulose primary hydroxyl groups using 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) mediated oxidation, leading to highly crystalline whiskers with either sulfate ester groups (−OSO3–) or carboxylic groups (−COO–) at the surface, respectively. The sulfate ester group is a strong acid, hence CNCs produced via sulfuric acid treatment are negatively charged irrespective of the pH. Sulfate content ranging from 200 to 330 mmol/kg of CNCs and zeta potentials from −35 to −45 mV have typically been reported.59,60 The carboxylic groups, on the other hand, are weak acids and protonated at low pH and deprotonated at higher pH, making the charge of TEMPO CNCs pH-dependent. The pKa value of acetic acid is 4.7, but because dissociation of charged groups is impeded by other charged groups in the vicinity, the effective pKa for the carboxylic groups on CNCs is slightly higher. Degrees of oxidation up to 0.1 have been reported.61 The CNCs can be produced via hydrolysis using hydrochloric acid, but these CNCs are, in practice, uncharged and hence have very low colloidal stability.62 Cationic CNCs can be produced by reacting the sulfate ester containing CNCs with 2,3-epoxypropyl trimethylammonium chloride (EPTMAC) resulting in a zeta potential of +30 mV. Recently an alternative method using reactive eutectic media to produce cationic CNCs was introduced.63 For a more thorough assessment of CNC production, chemistry, and applications, the reader is referred to a comprehensive review by Habibi et al.2

CNFs are produced by mechanical disintegration of cellulose pulp, sometimes aided with enzymes. Using bleached pulp as a starting material results in fibrils with a low negative charge, consisting of cellulose and hemicelluloses, with zeta potential around −3 mV at pH 8. The hemicellulose content on the fibril surface is very difficult to experimentally determine but may still affect the interactions, for example, by introducing some charged groups and by adding amorphous structures on the CNF surface. The pulp can also be chemically modified prior to disintegration to introduce a higher charge and facilitate fibrillation using less energy. The two most common approaches are TEMPO-mediated fibrillation and carboxymethylation, which both introduce anionic groups to the fibrils.64,65 Cationic CNF can be produced via reacting the pulp with EPTMAC or periodate and Girard’s reagent T prior to disintegration.66,67 The sign and magnitude of the surface charge affect the interaction of CNF in applications, hence these factors are important to consider. Charge densities of 0.5 and 0.9 mequiv/g have been reported for carboxymethylated and TEMPO-oxidized pulp used for the production of highly anionic CNF.65,68 This resulted in a zeta potential at pH 8 of −39 mV for 0.9 mequiv/g charged TEMPO-oxidized pulp. Just as for CNCs with COOH groups, the charge is pH-dependent for these CNFs.

The surfaces of CNMs provide hydroxyl groups, and for the more anionic variants, also carboxylic groups that are accessible for chemical modification. To combine the advantages of CNMs with the controllability of synthetic chemistry, extensive research has been devoted to tailoring the CNMs for various applications via chemical modification. The challenges concerning accessible surface area, if the colloidal stability is not considered during modification, are discussed in sections 3.1 and 3.2, but for a more comprehensive review of the available types of modified CNMs, we refer the reader to recent reviews.38,69 In the future, green chemistry concepts like chemoenzymatic surface modification70 need to be considered. The toxicity and degradability of CNMs are affected by chemical modification,70,71 and we envision that this will lead to an increased focus on alternative and milder approaches to the tailoring of the surface chemistry of CNMs. One approach in this direction is the use of lignin-containing nanocellulosic materials which are briefly reviewed in section 5.

3.1. Interaction of CNMs with Water and Ionic Solutes

Water interacts with cellulose both at molecular and supramolecular scales, and such water–cellulose interactions are commonly present in Nature (e.g., in wood). Understanding and tailoring those interactions can lead to new, advanced applications of cellulose-based materials.72 Fundamental studies on CNM dispersions using calorimetry, rheology and scattering techniques, and on CNM thin films using surface-sensitive methods like QCM-D, SPR, and AFM with modeling tools, have increased our understanding of how CNMs interact with water and are affected by ionic strength and pH. The main findings from these studies and their implications on applications are addressed here.

Cellulose can form hydrogen bonds with water molecules through the abundant hydroxyl groups present in the cellulose molecular structure. Due to their larger surface area, there are considerably more accessible hydroxyl groups on the surface of CNFs than on macroscopic fibers, which explains the larger hydration state of cellulose at the nanoscale. Nevertheless, water does not dissolve cellulose. The formation of multiple intra- and intermolecular hydrogen bonds favors the formation of well-packed crystalline assemblies of the cellulose molecules within the nanofibrils that do not dissolve in water. Hydrophobic interactions, due to the amphiphilic nature of cellulose, also contribute to its insolubility in water.73,74 Furthermore, it is estimated that the dissolution of cellulose nanofibrils in water is not entropically favorable. This is because the partial increase in the mobility of the cellulose molecules upon dissolution is overcome by a decrease in the configurational freedom of a larger number of water molecules that are hydrogen-bonded to the cellulose molecules.73,75

Although insoluble in water, cellulose nanomaterials swell in the presence of water. Water molecules cannot penetrate the crystalline nanocellulose assemblies, but they can access the less ordered amorphous regions and the space between nanocellulose building blocks in 2D and 3D networks. QCM-D experiments have revealed that the swelling of cellulosic thin films is both governed by the degree of crystallinity of the cellulose materials and by the morphology and porosity of the films. Thus, comparing cellulose films with different crystallinity, Aulin et al. observed significant swelling of CNC films.76 Because the tightly packed CNCs are not expected to swell, the observed swelling can be explained by the adsorption and accumulation of water molecules on the surface and in the spaces between the nanocrystals, further increasing the separation between them. In the same line, water vapor adsorption experiments carried out by Tammelin et al., also using the QCM-D technique, showed that a cellulose film with a degree of crystallinity of about 60% swelled more than a chemically identical but highly amorphous film when the relative humidity was 97%.77 The reason for this at-first-unexpected result is the nanoscale porosity and, consequently, the larger surface area and higher number of hydroxyl groups accessible for water molecules in the more crystalline film. The importance of the film structure for water adsorption was also pointed out by Reishofer et al., who observed that both the preparation method and the applied treatment (e.g., drying at elevated temperature) affected the water uptake of highly amorphous cellulose thin films, especially at high relative humidities.78 Similarly Niinivaara et al. observed that the ratio between crystalline and amorphous regions was not the only factor determining the swelling of 2D films where CNC and amorphous cellulose were combined to mimic plant cell walls.79 In this system, the total interfacial area between CNC and amorphous cellulose was also suggested to play a role in swelling.

EDL forces also govern the swelling behavior of films and hydrogels made of charged CNMs. Hence charge density of the CNMs, ionic strength, and polarity of the media will play a decisive role in the behavior of CNMs in aqueous media, as has been shown in early studies. Ahola et al. studied the effect of the surface charge on swelling and interactions of CNF model films using QCM-D and AFM measurements.80 They observed a larger swelling in the water of the highly charged (carboxymethylated) CNF compared to the low charged (noncarboxymethylated) counterpart. The repulsion between charged nanofibrils and osmotic effects (Donnan equilibrium) can explain the larger swelling of highly charged CNF. Increasing the salt concentration decreased the swelling of the films because the higher number of ions in the medium screened the repulsion between charged groups and reduced the osmotic pressure difference between the inside and outside of the film. In addition, an increase in film swelling was also observed, more remarkable in the case of carboxymethylated CNF, when increasing the pH from 3.5 to 10, in line with an increase in surface charged groups due to the deprotonation of carboxyl groups. The film swelling detected by QCM-D correlated with the surface forces measured between a cellulose microsphere and the CNF model films using the AFM colloidal probe technique. The observed repulsive forces were of longer range for highly charged CNF, and they changed with the salt concentration and the pH, in agreement with the swelling state of the film. The repulsive force was of longer range than expected for pure EDL repulsion, and it was assumed that steric repulsion between the swollen layers was also present.

Interesting effects of ionic solutes on CNF hydrogels and adsorption of negatively charged polymers onto cellulosic substrates have recently led to a renewed interest in the interactions between ions and cellulose, suggesting that DLVO theory is not enough to describe their behavior. Arola et al. used a combination of small deformation oscillatory rheology and molecular modeling to gain an understanding of the effect of salt on rheological properties of CNF hydrogels.81 They found that already at ion concentrations of 1 mM, various monovalent sodium salts caused crowding of hydrogels and subsequently argue that screening of the EDL repulsion could not explain this phenomenon. Instead, they suggest that the water molecules become more ordered, leading to a stronger hydration layer. This correlates with the results by Ahola et al., who found no deswelling of low-charged native CNF films at 1 mM NaCl and no change in the repulsive force upon approach. However, higher concentrations (10 or 100 mM) of electrolyte resulted in slight deswelling of CNF films, and the water-binding was pH-sensitive, suggesting that, even for very low charged CNF, electrostatics also play a role although the effects were much more pronounced for highly charged CNF.80

Divalent cations, especially Ca2+, are known to be able to form ionic cross-links between carboxylate groups and hence stabilize hydrogels made from either TEMPO-oxidized cellulose nanofibers (TOCNF) or a mixture of alginate and CNF.82 Recently, Ju et al.83 investigated the coordination complexes between various metal ions and carboxylated CNF and showed that the cross-linking density increases in the order Zn2+ < Ca2+ < Cu2+ < Al3+. The interaction between metal ions and CNF was visualized by a shift of the Fourier transform infrared spectroscopy (FTIR) peaks to higher wave numbers for bands associated with the carboxylate group. Ca2+ ions are also efficient coagulants for filaments prepared via wet spinning of TOCNF.84

Lombardo et al.85 used isothermal titration calorimetry to reveal the interactions between divalent cations and CNCs. They showed that the interaction was endothermic and driven by the increase in entropy upon adsorption of ions due to an increase in the degree of freedom for released water molecules. This entropy gain compensated for the unfavorable endothermic enthalpy. A comparison of CNCs with sulfate or carboxylate groups showed that the nature of the ionizable group on the CNC affected the pH dependence of the interactions. The adsorption of cations to CNCs with carboxylic groups was clearly pH-dependent, showing that carboxylic groups needed to be deprotonated, while sulfate groups were less sensitive to the pH. They concluded that the adsorption of ions of the same net charge followed the same mechanism.

As already mentioned, the abundant hydroxyl groups on cellulose surfaces are responsible for the adsorption of water molecules. CNMs are especially hygroscopic due to their larger surface area. Combining QCM-D and spectroscopic ellipsometry in a water vapor adsorption study, Niinivaara et al. concluded that a 1 nm thick layer of water molecules was strongly adsorbed on the surface of the individual CNCs in the film,86 in excellent agreement with the results from Reid et al. on the swelling of CNCs studied by SPR.87 In a similar work, Hakalahti et al. distinguished between three different stages for the adsorption of water vapor on TEMPO–CNF at different relative humidity (RH) values that were well fitted with a Langmuir/Flory–Huggins clustering model. These three stages were the specific adsorption of water molecules at low RH (below 10%), a buildup of water multilayer at intermediate RH (10–75%), and clustering of water molecules at high RH (above 75%) (Figure 2a).88

The water molecules strongly bound to cellulose surfaces have different properties from the bulk water. They cannot freeze due to conformational restrictions; thus this is called nonfreezing water. In contrast, the term freezing water is used to describe the weakly bound water molecules confined in the pores of nanocellulose networks, with a shifted temperature for solid–liquid transition compared to bulk water. Different experimental techniques (nuclear magnetic resonance or NMR, neutron scattering, differential scanning calorimetry or DSC) and molecular dynamics simulations have confirmed the presence of freezing and nonfreezing water in cellulose fibrillar materials.91−96 The properties of these confined water species have been exploited in DSC-based thermoporometry to quantify the porosity of cellulose materials.91,94,95

The hygroscopicity of cellulose has very often been seen as a negative property because the integrity and mechanical properties of cellulosic materials (paper, cardboard, composites, etc.) are usually dramatically decreased in the presence of water. To prevent the adsorption of water and degradation of mechanical properties in wet or humid conditions, different approaches have been applied for the hydrophobization of cellulose surfaces to expand the utilization of cellulose to, for example, barrier and packaging materials. Those approaches involve changes in surface chemistry of CNF via the adsorption or covalent attachment of hydrophobic molecules,97 nevertheless, hydrophobized CNFs do not form strong films or nanopapers because the amount of interfibrillar hydrogen bonds responsible for the strength of cellulose networks is severely decreased. A cleverer approach to avoid altering the mechanical properties of the final product is to form the cellulose network first and then hydrophobize its exposed surfaces via vapor deposition, covalent attachment, or simply adsorption of hydrophobic molecules, polymers or nanoparticles, which could be combined with treatments to enhance the roughness of the material at nano- and microscale.98−101 Similarly, it has been shown that CNCs with an increasing lignin content does not result in barrier materials with low water vapor transmission rates because the presence of the hydrophobic lignin makes the materials more porous.102 Nevertheless, it has also been shown that the strength of cellulose fibers and nanocellulose films is increased to some extent by humidity.103−106 Surface-bound water can increase strength by mediating hydrogen bonds between hydrophilic structures that would otherwise be too far away from each other to form hydrogen bonds. This ultimately increases the hydrophilic structures’ reach to interact with one other and therefore increases the number of hydrogen bonds.105−107 Bound water can also act as a plasticizer and allows both sliding, and more importantly, restabilization after deformation.107 Such properties are key to enabling plastic deformation.

Adsorbed water on cellulose materials has also been considered an obstacle to the chemical modification of cellulose surfaces. Water can hinder some chemical reactions by competing with the hydroxyl groups of cellulose for the reagents. However, it has been recently proven that confined water in the nanopores between cellulose fibers can enhance the acetylation of cellulose surfaces.108 Thus, the natural hygroscopicity of cellulose should not always be seen as a negative property. In this line, there are several attempts to exploit the cellulose–water interactions in advanced materials. Examples include cellulose-based humidity sensors and cellulose materials and composites with stimuli-responsive, shape-memory, self-healing, and adhesive properties.38,109 Cellulose–water interactions are also very important in hydrogels used, for instance, in biomedical applications. These are discussed more thoroughly in section 3.4.

Recently Leppänen et al.72 demonstrated the advantage of the hygroscopicity of nanocellulose networks for the entrapment of nanoscaled plastic particles from aqueous dispersions. Interestingly the binding of the plastic nanoparticles was not dependent on any specific chemical interaction. Instead, they showed, with a combination of surface-sensitive methods, nanomicroscopy, and modeling, that the governing factors were the high active surface area and high hygroscopicity of the nanocellulose films, the latter inducing strong capillary flow.

Clearly, the interaction of CNMs with water and ionic solutes is relevant in many practical applications and, consequently, significant efforts have been made to understand these. However, less attention has been given to interactions with other media addressed in section 3.2.

3.2. Interactions of CNMs with Nonpolar Solvents

In the previous section, we learned how cellulose interacts strongly with water and the implications it has on CNM performance in applications. For the same reasons, that is, the high abundance of hydroxyl groups at the surface of CNFs and CNCs, they are poorly dispersible in nonpolar media. Hence chemical functionalization of CNF or CNCs in nonpolar organic solvents like toluene has been challenging, and so reactions that can be performed in aqueous media have been the preferred choice. The reason is that, due to the poor compatibility with nonpolar solvents, the CNMs tend to aggregate and lose their nanostructure. Johansson et al. demonstrated that silylation of CNF in an amphiphilic solvent, dimethylacetamide, resulted in a surface substitution of 0.9 in comparison to only 0.03 in toluene, confirming this hypothesis. For a more comprehensive review on CNF surface modifications, the reader is referred to Missoum, Belgacem, and Bras.110 Here we discuss the topic mainly from the point of view of interactions between CNMs and the media.

In one of the seminal papers on cellulose nanopapers, Henriksson et al.111 noted that the solvent affected density and porosity of the nanopapers and consequently their strength. The densest and strongest nanopapers were formed from aqueous CNF dispersions, while less polar solvents like methanol, ethanol, and acetone resulted in more porous and slightly weaker films. This phenomenon was explained to be caused by the weakening of interfibril bonds due to reduced hydrogen bonding density when films were prepared from less polar liquids. This observation is in line with the hypothesis of Johansson et al. of the tendency of amphiphilic cellulose to adapt its conformation to the media.75

Tuning the interaction with the media is important in many applications, and the ability of some solvents to deswell CNF hydrogels has been applied both in nanocomposite preparation and wet spinning of cellulose filaments.84,112 Capadona et al.112 slowly exchanged water with acetone in a CNC dispersion. This led to densification of the CNC network and gelling. When a polymer solution was subsequently added, and the nanocomposite was dried, surprisingly good mechanical properties were achieved due to an even distribution of the CNC throughout the polymer matrix using this sol–gel approach. While even distribution of the components in composites is a prerequisite to achieve adequate mechanical properties, favorable interactions between fibrils and matrix polymer are needed to gain full advantage of the unique properties of CNF or CNCs. This is discussed further in section 3.3.

Unfortunately, there are very few studies on how CNMs interact with solvents. One positive exception is the work by Wang et al.,84 in which they investigated the influence of different coagulation agents (organic solvents and aqueous electrolytes) on the spinnability of TOCNF suspensions using QCM-D. They observed a significant increase in the resonance frequency (Δf) and a decrease in dissipation factor (ΔD) upon introducing ethanol to the water-swollen TOCNF film. This response can be either due to the exchange of water with less dense ethanol or due to deswelling because of poorer interaction between cellulose and ethanol. Most probably, the observed response was due to both effects. More efforts should be put into exploring CNM interactions with other-than-aqueous media using surface-sensitive techniques. However, QCM-D is very sensitive to the density and viscoelastic properties of the solvents, hence care should be taken to also record the bulk effects using pure gold crystals, for example, before coating with CNMs to enable decoupling between bulk solvent effects and interactions between solvent and cellulose.

3.3. Interactions of CNMs with Polymers

A huge effort is being made in the development of cellulose-based materials to replace synthetic, oil-based products in a wide range of applications, including textiles, packaging, and barrier materials. In many of those cases, CNMs are combined with different polymers with the aim of obtaining composites with superior properties. In this research area, a fundamental understanding of the affinity and surface forces between polymers and cellulose is crucial for the successful design of cellulose composites with tailored properties. Deep comprehension of polymer–cellulose interactions at the molecular level is also very important for the traditional paper industry, where cationic polyelectrolytes are commonly used to flocculate cellulose fines and particle fillers. The success of current trends in replacing oil-derived additives with biopolymers in paper manufacturing and coating will benefit from a thorough understanding of the cellulose–biopolymer interactions.113,114

CNMs are commonly used as reinforcing components in polymer composites. However, blending hydrophobic polymers with cellulose nanomaterials is tricky because the abundant hydroxyl groups on the cellulose surfaces lead to poor polymer–cellulose compatibility. To enhance the affinity of hydrophobic polymers for cellulose nanomaterials, different strategies have been applied involving chemical modification of cellulose surfaces or covalent attachment of polymers.115 Nevertheless approaches avoiding hydrophobization of cellulose surfaces or covalent binding of polymers are often preferred for greener and more sustainable solutions. In this context, the utilization of natural polysaccharides or cellulose derivatives in cellulose-based composites has attracted considerable interest.

Nonionic cellulose derivatives have been observed to adsorb on cellulose substrates to a different extent, which may have interesting applications in textiles.116,117 Nevertheless they are not the only nonionic polymers investigated in relation to cellulose materials. Inspired by the close association between hemicellulose polysaccharides and cellulose fibers in the plant cell walls, several studies have been carried out to better understand hemicellulose–cellulose interactions for the development of natural composites.

QCM-D and SPR analyses have shown that nonionic polysaccharides of the hemicellulose family, xyloglucan (XG), galactoglucomannan (GGM), arabinoxylans, and galactomannans, adsorb well and irreversibly on CNF films (Figure 2b).89,118−120 The adsorption of XG and other nonionic polysaccharides on CNC has also been reported.121,122 The amount and conformation of the polysaccharide in the adsorbed layers do not depend only on the polysaccharide molecular weight123−126 but also on their concentration and molecular structure.89,118,122 Thus, Villares et al.122 observed that the amount of adsorbed XG on CNC increased with the XG concentration in solution, indicating that the lateral rearrangement of adsorbed XG molecules to a flat conformation in diluted solutions was prevented when more XG molecules competed for adsorption in more concentrated solutions. Consequently more crowded adsorbed layers with loops and tails exposed to the solution were expected in the latter case.122 Furthermore, Eronen et al. observed that the adsorption of galactomannans on CNF decreased when the number of galactose side groups increased, showing that the molecular structure of the polysaccharide affected the adsorption more than the molecular weight.118 The reason for that could be a more coiled conformation of the polysaccharides with fewer amounts of galactose side groups, which eventually resulted in a larger number of GGM molecules adsorbed per unit of area. Chemical modifications of the polysaccharides can also affect their affinity for cellulose. Thus, enzymatically oxidized guar gum galactomannan (GG) was observed to adsorb quickly on CNF films, but the adsorption rate decreased when polyethylene glycol (PEG) chains were covalently grafted to the GG molecule,119 probably due to some steric hindrance associated with the PEG chains. On the other hand, the addition of different, short hydrophobic tails did not hinder the adsorption of GGM on CNF,127 while the oxidation of GGM by TEMPO decreased significantly its affinity for cellulose.128 The latter could be explained by electrostatic repulsions between CNF and the carboxyl groups introduced in GGM during TEMPO oxidation, as confirmed by the fact that GGM with a high degree of oxidation did not adsorb on CNF in water but adsorbed to some extent when the electrostatic repulsions were screened in the presence of 0.1 M NaCl.

The adsorption of nonionic polymers to cellulose has commonly been ascribed to hydrogen bonds and vdW forces. However, several authors have argued that the adsorption of nonionic polymers like XG is in fact entropically driven by the release of structured water around the polymer and the cellulose surface. Hydrogen bonds can be formed after the polymer is adsorbed, but their contribution to the adsorption process is negligible.129−132 The driving force for the adsorption of anionic polymers is also expected to be entropically driven due to the release of water and counterions, but in this case, the polymer charge also plays an important role. Thus, anionic polysaccharides like xylan (hemicellulose) and carboxymethyl cellulose (CMC) have been observed to adsorb on CNF to a lesser extent and form more swollen (hydrated) layers than nonionic polysaccharides (Figure 3a).118 In line with the assumption that the electrostatic repulsions with the negatively charged cellulose substrates can prevent or weaken the adsorption of highly charged anionic polymers, CMC was observed to adsorb irreversibly to CNF at pH 4.5,118 but it desorbed upon rinsing at pH 8 when all of its carboxyl groups were deprotonated.133 The swelling of the adsorbed polymer layer also depends on the polymer charge. Anionic polymers swell to a larger extent than nonionic ones because of the electrostatic repulsion between polymer charged groups and the osmotic pressure associated with the accumulation of counterions around the charged polymers. Therefore, in contrast to nonionic polymers, factors like the pH or the ionic strength have a very pronounced effect on the adsorption and the swelling of ionic polymers. An interesting case is the effect of divalent cations on the adsorption of CMC on cellulose substrates. Ca2+ ions have been observed to affect CMC structure in solution and favor the CMC adsorption on cellulose more than Mg2+ ions (Figure 2c,d), which was ascribed to the different polarity of those ions.90,134

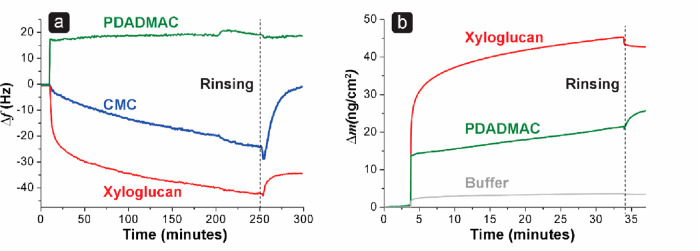

Figure 3.

Adsorption of PDADMAC, CMC, and XG on CNF. (a) Change in frequency (Δf) from QCM-D experiments, and (b) adsorbed mass (Δm) from SPR experiments.133 Adapted from ref (133). Used under open access from BioResources.

Although also affected by the pH and the ionic strength, the adsorption of cationic polymers on cellulose surfaces is driven by attractive electrostatic interactions between oppositely charged groups and, especially, the remarkable gain in entropy associated with the release of bound counterions.135 The adsorption of cationic polymers like poly(diallyldimethylammonium chloride) (PDADMAC) and chitosan on CNF has been monitored in real-time by QCM-D and SPR.118,133 At low pH and ionic strength, chitosan has been observed to adsorb on CNF in lower amounts than nonionic polysaccharides, suggesting a flat conformation for the adsorbed chitosan molecules.118 Adsorption in flat conformation is generally expected in conditions where the electrostatic attraction between polymer and cellulose is enhanced, that is, at low ionic strength and pH values where the involved groups, both on the cellulose surface and in the polymer, are charged. Furthermore, a collapse of CNF films by the release of trapped water is often observed upon adsorption of cationic polymers, which is observed as an increase in frequency in QCM-D (Figure 3).133,136 Dehydration of cellulose surfaces and screening of electrostatic repulsion between charged cellulose fibrils could explain the collapse of CNF films induced by cationic polymers.

The preparation and the final macroscopic properties of composites and hydrogels are intimately connected to the surface forces between the constituting materials at micro- and nanoscales. Due to the large area-to-volume ratio of CNF and CNC, surface forces play a very important role in the formation and behavior of composites and hydrogels that include those CNMs. The surface forces govern the colloidal stability of CNM suspensions and, consequently, affect their rheological behavior. Thus, rheological measurements can provide indirect information on the stability or aggregated state of CNM suspensions and how factors like the CNM concentration, the ionic strength, or the presence of other polymers affect the interactions.137,138 Nevertheless the direct quantification of surface forces has only been possible thanks to very sensitive instruments like the surface force apparatus (SFA) and AFM.139,140 The SFA and the AFM, especially in combination with the colloidal probe technique,141 have tremendously advanced our understanding of the surface forces in lignocellulosic systems.142 Thus, it has been observed that the interaction forces measured when approaching different cellulose model surfaces are generally well described by the DLVO theory at long separations, whereas a steric repulsion usually appears at short distances when the cellulose surfaces come into contact.143 The intensity and range of the repulsive double-layer forces increase with the cellulose surface charge, and they decrease when increasing the ionic strength, as the DLVO theory predicts.133,144 Attractive vdW forces between cellulose surfaces have been detected in conditions where the double-layer repulsion was negligible.144,145

The adsorption of polymers affects the surface forces between cellulose substrates. In fact, very different interaction forces can arise depending on the amount and conformation of the adsorbed polymer. DLVO forces are typically observed when a cationic polymer adsorbs in flat conformation on cellulose surfaces, with the double layer repulsions modulated by the extent of surface charge neutralization or reversal caused by the adsorbed polymer. This behavior is typically the case of highly charged, cationic polyelectrolytes like PDADMAC, polyvinylamine (PVAm), and PVAm derivatives.146−148 On the other hand, nonionic polysaccharides, anionic polymers like xylan and CMC, and cationic polyelectrolytes with low charge density and high molecular weight like cationic polyacrylamide (C-PAM) usually adsorb on cellulose surfaces in an extended conformation with loops and tails. This extended conformation results in long-range steric repulsions when the polymer molecules adsorbed on two approaching surfaces overlap and compress each other.149 The intensity and range of the electrosteric repulsion are directly related to the swelling of the adsorbed polymer layer. The larger the swelling of the adsorbed layer, the longer the range and stronger the intensity of the electrosteric repulsion are.119,146,150−153 Because the pH, the ionic strength, and the polymer concentration affect the swelling of adsorbed charged polymers, the electrosteric repulsion can be modulated by changing those magnitudes.

Cationic polymers are typically used to increase paper strength and as retention aids to flocculate cellulose fines and mineral filler particles with cellulose fibers in papermaking. Several works have been devoted to the analysis of the forces between cellulose surfaces in the presence of different cationic polymers to shed light on the mechanisms underlying papermaking processes.146−148,153−155 In addition to the forces observed on approach discussed previously in this section, the adhesion measured when retracting the surfaces is especially relevant in this case. Both concentration and conformation of the adsorbed polymer have important impacts on the adhesion between cellulose surfaces and between cellulose and mineral surfaces like mica, silica, or glass used as models for filler particles. The partial coating of the surfaces at low polymer concentrations gives rise to adhesion by charge neutralization or polymer bridging. Polymer bridging is enhanced in the case of polymers with high molecular weight adsorbed in an extended conformation. However, increasing the polymer concentration results in strong electrosteric repulsions and no adhesion between fully coated surfaces, confirming that polymer overdosage should be avoided for effective polymer-induced flocculation.146,153,154 Polyelectrolyte complexes formed by the combination of cationic and anionic polymers have been observed to enhance the adhesion between cellulose surfaces, in line with empirical observations in the paper industry.156 The combination of colloidal assemblies of a cationic block copolymer with carboxymethylated CNF has also been explored as an alternative strategy for the preparation of biomimetic nanocomposites.157

Friction forces at micro- and nanoscales also play a very important role in material properties. The mechanical performance of CNF-based materials, for instance, is highly dependent on the friction between cellulose fibrils. Quantitative measurements of friction forces using an AFM and the colloidal probe technique have revealed that, in general, the adsorption of polymers reduced the friction between cellulose surfaces. A correlation between surface forces, adhesion, and friction can be established. Low friction forces have been measured between surfaces with strong repulsion and weak (or lack of) adhesion. Thus, swollen, hydrated polymer layers adsorbed in an extended conformation enhance the lubrication between cellulose surfaces. Remarkably low friction coefficients have been obtained with highly charged anionic polymers like CMC, CMC with grafted PEG (CMC-PEG), and hyaluronic acid at pH and ionic strengths where the adsorbed polymer layers are charged and very swollen, which is associated with strong electrosteric repulsions and no adhesion between the surfaces.151,158,159 Additionally, CMC-PEG was shown to reduce the adhesion and friction between cellulose surfaces in dry conditions.160 The cationic polymer chitosan has also been observed to reduce considerably the friction between cellulose surfaces at pH 3 when the repulsion induced by the fully charged polymer is stronger (Figure 4).150 Thus, charged polymers can be utilized to prepare highly lubricating cellulose materials that could be used, for instance, as implants to replace damaged cartilage.158,159

Figure 4.

Friction measurements between (a) two neat cellulose spheres (closed squares) and (b) after adsorption of chitosan for 8 h (open squares). Measurements were conducted in aqueous solutions at pH 3. Inset: corresponding normal approach force profiles on a linear scale.150 Reproduced with permission from ref (150). Copyright 2009 American Chemical Society.

Nonionic polysaccharides like XG, GGM, or modified GG can also reduce the friction between cellulose surfaces, but to a lower extent than highly charged polymers.119,149,161 Nevertheless, the moderate lubrication combined with certain adhesion provided by these polymers has been observed to be beneficial for the mechanical properties of CNF-based composites. The interfibrillar lubrication favors the homogeneous distribution of CNF during composite formation (preventing CNF aggregates or clusters that are detrimental to the composite strength), whereas the adhesion helps to keep the fibrils together, contributing to material integrity. Thus, the addition of only 2 wt % on nonionic (XG, GGM, or modified GG) or anionic (CMC) polymers have been seen to significantly improve the tensile strength and toughness of CNF films in dry conditions, in agreement with a more even distribution of CNF in the film aided by polymer lubrication.119,162,163 However, very different trends have been observed in wet conditions. The high lubrication and null adhesion between cellulose fibrils induced by CMC adsorption resulted in very poor mechanical integrity of CNF–CMC films in aqueous media.162 On the contrary, XG, GGM, and chemically or enzymatically modified GG improved the mechanical properties of CNF films in wet conditions. The highest tensile strength and toughness values were obtained for CNF–GGM films, indicating that the lower the water content of the adsorbed polymer layer, the better the mechanical properties in aqueous media.119

The formation of multilayers through the sequential adsorption of oppositely charged polymers or nanoparticles (layer-by-layer deposition) is a useful approach for controlled surface modification. This approach has been applied to modify cellulose substrates for different applications. For example, highly hydrophobic CNF films and cellulose textiles were obtained after depositing poly-l-lysine and negatively charged wax nanoparticles.98 On the other hand, the sequential adsorption of poly(amideamine) epichlorohydrin (PAE) and CNF on pulp fibers has been observed to improve paper strength, but the adsorption of preformed PAE-CNF aggregates did not.164 QCM-D has been successfully employed to monitor, in real-time, multilayer formation using cationic and anionic cellulose derivatives, chitosan, cationic starch, polyethylenimine, poly(allylamine hydrochloride), C-PAM, PDADMAC, CNC, CNF, and cationized CNF.68,160,165−167 The structure of the multilayers (adsorbed material and swelling) can be tuned by the number of adsorbed layers, the charge density of polyelectrolytes or nanoparticles, and the pH of the medium. Accordingly, the intensity and range of the measured electrosteric repulsions have been seen to correlate with the thickness and swelling of the multilayers.68,165,167 In some cases, attractive bridging forces have been detected when the swelling of the multilayer led to the exposure of underlying polymer layers.68,168

As can be observed from the works cited here, a considerable amount of research has been dedicated to understanding the interactions of CNMs with polymers at the molecular level and the surface forces at the nano-/microscale responsible for the macroscopic properties of CNM-based materials. That knowledge has a direct impact on the optimization of industrial products and processes. Nevertheless, there is still work to do in this field. In particular, environmental concerns urge for the utilization of more sustainable raw materials to replace the oil-derived additives commonly used in paper manufacturing and coatings for cellulose-based barrier materials. Biopolymers like cellulose derivatives, hemicellulose, starch, chitosan, and other polysaccharides are very good candidates to replace fossil additives, but their widespread utilization at the industrial scale has generally been hindered due to their poor resistance against water, lack of optimized industrial processing technology, and relatively higher costs with respect to fossil-based additives.113,114,169−171 Chemical modification of the biopolymers and a deeper understanding of their interactions with cellulose and CNMs could boost the industrial utilization of biopolymers from natural resources. The research already carried out on the interactions of hemicellulose and other natural polysaccharides with CNMs provides very valuable information to advance that path.

3.4. Interactions of CNMs with Proteins and Cells

Lignocellulose is naturally degraded by fungi, bacteria, or protozoans through the action of different enzymes. This degradation can be utilized in industrial processes, for example, for fuel production, and hence it is of interest to investigate the adsorption of enzymes onto cellulose. Cellulases (including endoglucanases, cellobiohydrolases, and β-glucosidases) and lytic polysaccharide monooxygenases (LPMO) can decompose cellulose following different routes.172,173 The synergistic combination of cellulases and LPMO can efficiently degrade cellulose fibers into glucose molecules. The presence of carbohydrate binding modules in some of these cellulose-degrading enzymes enhance their selective attachment to cellulose substrates.174 The adsorption and degradation activity of several enzymes on different model cellulose films have been monitored in real time using different techniques, including QCM-D, SPR, ellipsometry, AFM, and fluorescence-confocal microscopy.175−183

Under controlled conditions, cellulases and LPMO can be used to produce CNMs from cellulosic biomass.184−188 The enzyme-aided production of CNMs is more environmentally friendly than other common procedures because it does not require harsh chemical reactions (e.g., acid hydrolysis or chemical oxidation) nor intensive mechanical fibrillation. Cellulose degrading enzymes could also be used in applications where CNM constructs are meant to be disintegrated at the end of their lifetime, for example hydrogels or 3D scaffolds for some biomedical applications.

The utilization of CNMs in biomedical applications has been intensively explored in the last two decades. The natural hydration of cellulose hydrogels, their mechanical properties, and their ability to adsorb or encapsulate different molecules are attractive characteristics for drug delivery and wound healing or 3D scaffolds for tissue engineering. Although some studies have reported a certain level of pulmonary inflammation and toxicity upon exposure to CNMs (especially in the case of CNC), numerous works have confirmed that CNMs, and CNF in particular, are nontoxic and biocompatible materials.189−191 The animal-free origin of CNMs has also been an advantageous property for biomedical applications. Plant-derived CNF or BNC has been successfully used in 3D cell cultures and 3D printed bioink scaffolds either alone or in combination with other polymers and nanoparticles.192−199

The structure and surface chemistry of a material affects its interaction with cells. Although CNF hydrogels can mimic the fibrillar structure of the extracellular matrix (ECM), the polysaccharide nature of cellulose is very different from the protein nature of ECM. Consequently, AFM measurements applying the colloidal probe technique (Figure 5a) have revealed that the adhesion of human hepatocellular carcinoma cells (HepG2) and human pluripotent stem cells to CNF is considerably weaker than to ECM proteins like collagen I, collagen IV, and laminin-521 (Figure 5b).200 The adhesion of cells to CNF was also observed to be nonspecific, that is, it is not mediated by cell receptors like integrins.201 Due to the low affinity of cells for CNF, this material is not a good substrate for traditional 2D cell culture.200 However, CNF hydrogels have proven to be good material for 3D cell spheroid formation, where the adhesion between cells is expected to be stronger than between cells and material.193,194

Figure 5.

(a) Schematic of interactions between biomaterial-coated probes and living cells: a typical probe with a tip (left) and a colloidal probe (right). (b) Representative retraction curves on HepG2 cells.200 Reproduced from ref (200), under Creative Commons CC-BY license. Single-molecule force spectroscopy (SMFS) histograms representing (c) the binding interaction force and (d) contour length between cellulose binding protein module CBM1 and CNCs from sulfuric acid hydrolysis. (e) Schematic of the SMFS experiment for the system studied.202 Reproduced from ref (202), under Creative Commons CC-BY license. Copyright 2019 American Chemical Society.

The weak and nonspecific interaction of CNFs with stem cells results in a lack of signaling for cell differentiation. Thus, CNF and BNC hydrogels have been observed to be excellent materials to keep the stemness of stem cells for several weeks.193,203 Nevertheless, CNF and BNC hydrogels have to be modified if stronger cell adhesion and cell differentiation are desired. Proteins from the ECM can enhance cell adsorption and differentiation through their specific interactions with cell membrane receptors, and therefore a logical strategy to extend the applications of CNF in tissue engineering is to adsorb ECM proteins on the surface of the CNFs. Quantitative adhesion experiments between CNF and ECM proteins by the AFM-colloidal probe technique have shown affinity of collagen I, collagen IV, and laminin-521 for CNF to a different extent (stronger in the case of collagen I).204 AFM, fluorescence microscopy, and SPR studies have confirmed that the adsorption or immobilization of collagen I, collagen IV, laminin-521, and fibronectin on nanocellulose substrates enhanced the adhesion of stem cells, fibroblasts, and HepG2 cells.205,206 Strong immobilization of fibronectin, vitronectin, or collagen I on nanocellulose hydrogels via avidin–biotin or covalent conjugation has also been proved to promote integrin-mediated cell adhesion and facilitate the proliferation of fibroblasts, endothelial cells, and mesenchymal stem cells.207,208 Incorporation of growth factors into 3D CNF scaffolds is another approach to enhance fibroblast proliferation.209 The quantification of the interaction forces between cellulose binding proteins (CBM1) and cellulosic nanomaterials has also been demonstrated using single molecule force spectroscopy experiments employing a combination of click chemistry and protein engineering (Figure 5c,d,e).202 All of these studies undoubtedly support the promising future foreseen for CNMs in tissue engineering applications.

The interaction of CNMs with bacteria and viruses has also been under research for the development of new antimicrobial materials. Different surface modification and functionalization strategies of CNMs have been proposed to achieve materials with excellent antimicrobial properties and membrane filters against microbes.210−212

Importantly, nanocellulose–protein interactions can be exploited beyond biomedical applications. Thus, the combination of CNC with bovine serum albumin or CNF with soy protein has been observed to stabilize emulsions (Pickering emulsions), which is of interest to the food and pharmaceutical industries, for example.213,214 Furthermore, proteins like casein and zein have been used to improve the mechanical properties and thermal stability of composites containing CNFs.215,216 Casein, soy protein, zein, gluten, and whey proteins have also been proposed to replace fossil-based additives in paper manufacturing and coatings for cellulose-based packaging materials.113,169 These are just a few examples of the unlimited potential of protein-modified CNMs.

4. Lignin Nanoparticles

Efficient valorization of a large amount of technical lignins available as side streams from the pulping industry has challenged the industrial and academic community for centuries. The transformation of technical lignins into nanoparticles offers an interesting alternative to fractionation and depolymerization. Lignin nanoparticles solve the main drawbacks of technical lignins. Their morphology can be made homogeneous, they can be used without solvents, and they have a very large surface area, which increases their capacity to interact with their surroundings.217 Concurrently it would be significant to find a nanoparticle formation method that offers the desired lignin properties for specific applications but is also simple and reproducible in its approach, and economically and environmentally viable. Both research and industrial communities have collaborated broadly in their efforts to produce LNMs for a variety of applications. As a result, various methods have been introduced to produce nanoscale lignin (LNPs) or colloidal lignin particles (CLPs).

The preparation of LNPs with well-defined surface chemistry, controlled nanoarchitecture, and long-term stability is important for high-value applications. LNPs fabricated using different approaches tend to present different surface morphology, size, polydispersity, surface charge, etc., which is a hallmark of its specific fabrication processes. Acid neutralization and solvent shifting have been the most frequent routes adopted to prepare LNPs, acidification being the first reported218 method. Several recent review articles reveal the existence of many other approaches, such as acid-catalyzed precipitation, flash precipitation, water-in-oil microemulsion methods, homogenization, ultrasonication, and sono-solvent shifting.6,219−223 Among the developed LNP fabrication methods, the critical analysis points to the solvent shifting approach as the method of choice due to its simplicity, viability, high yield, and excellent control over morphological features in terms of spherical geometry, with uniform size and smooth surfaces. Hence we focus mostly on that method in the following section.

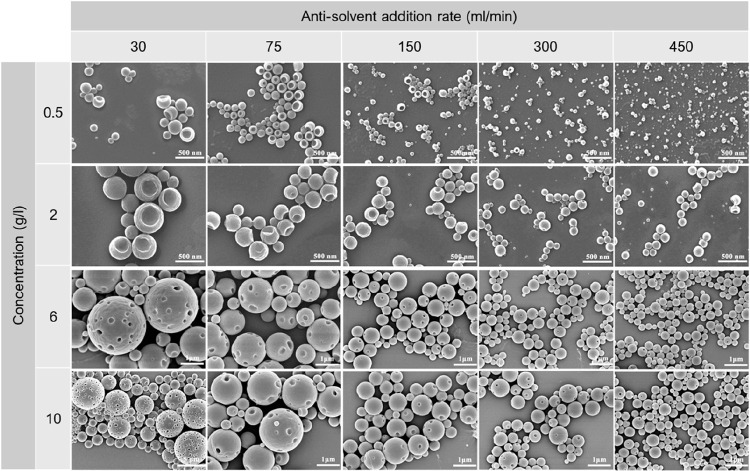

Various analogous terminologies for solvent shifting like nanoprecipitation, dialysis, solvent exchange, and antisolvent process are frequently used to describe the same approach.6 During LNP preparations, the assembly conditions have been found to significantly affect the surface properties, mainly particle size, particle shape (geometry), surface charge, and stability.6 Solvent shifting and acid neutralization (also called pH shifting) have been investigated vigorously, compared to other reported methods, to elucidate the effect of different parameters on the nanoparticle’s specific surface properties.224,225 Multiple factors can influence the formation of the LNPs using different approaches but more precisely during solvent shifting. These include lignin source and its chemical structure, interaction with solvents, molecular weight, initial lignin concentration, dropping speed of the lignin solution, antisolvent feed rate, stirring speed, temperature, pH, and salt concentration, among others.6 A systematic elucidation of each parameter on LNP formation is necessary to determine the ideal synthesis conditions because these factors directly or indirectly affect the self-assembly of lignin molecules by influencing their solubility, surface charge, nucleation, and growth. This section discusses the physiochemical aspects of the formation of lignin particles, their interactions in aqueous media, customization strategies, and applications.

4.1. Structural Factors Affecting LNP Properties

Because LNPs are formed by the assembly of lignin molecules into nanostructures, interactions during the particle formation process strongly affect their properties. Hence factors affecting these interactions, and consequently also the final properties of the particles, are reviewed. The intrinsic chemical structure of lignin from different sources, such as hardwood, softwood, or grass, possesses different ratios of monomeric units, ultimately affecting the self-assembly process of lignin into LNPs through noncovalent forces like hydrogen bonding, hydrophobic interactions, and π–π interactions. For instance, guaiacyl units are more abundant in softwood lignin, whereas hardwood and grass lignins are rich in syringyl and p-hydroxyphenyl units.