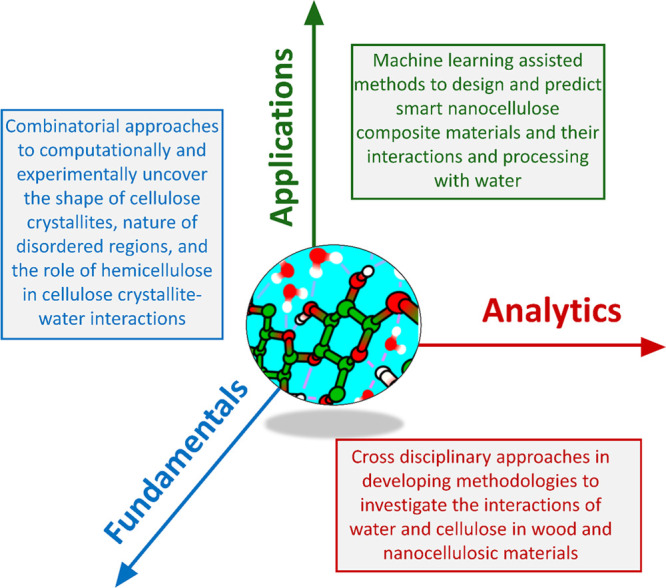

Abstract

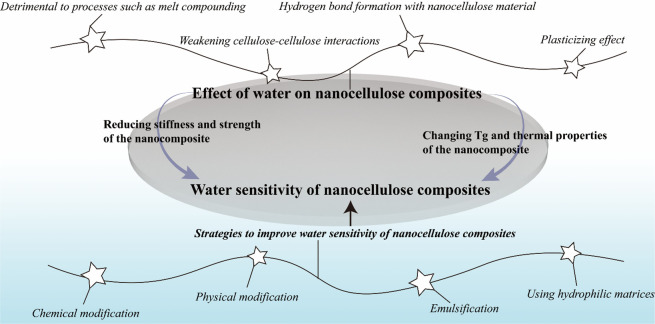

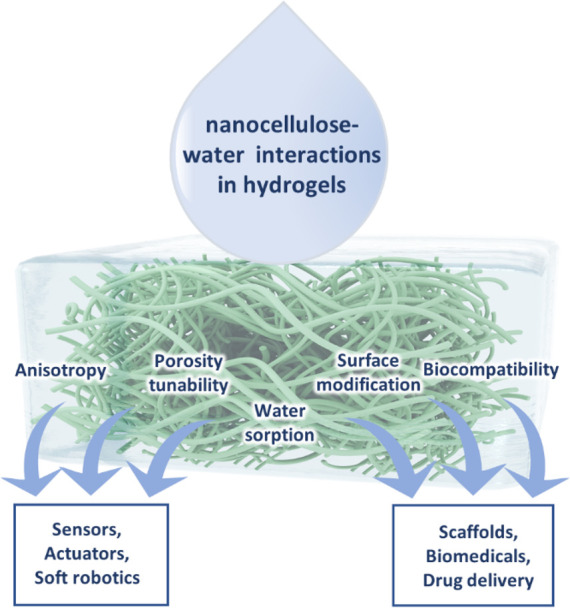

Modern technology has enabled the isolation of nanocellulose from plant-based fibers, and the current trend focuses on utilizing nanocellulose in a broad range of sustainable materials applications. Water is generally seen as a detrimental component when in contact with nanocellulose-based materials, just like it is harmful for traditional cellulosic materials such as paper or cardboard. However, water is an integral component in plants, and many applications of nanocellulose already accept the presence of water or make use of it. This review gives a comprehensive account of nanocellulose–water interactions and their repercussions in all key areas of contemporary research: fundamental physical chemistry, chemical modification of nanocellulose, materials applications, and analytical methods to map the water interactions and the effect of water on a nanocellulose matrix.

1. Introduction

The term nanocellulose refers to anisotropic nanoparticles that can be isolated from, in most cases, a processed plant cell wall. While the early accounts of nanocellulose originate from the mid-20th century, the first decade of the 21st century saw process-related advances that enabled a more facile and efficient isolation of nanocellulose for materials construction.1 This development in nanocellulose preparation and its applications has unleashed an unprecedented scientific interest in cellulose-based materials over the past 15 years.2−14 Although much of the attention has focused on utilizing nanocellulose as a building block in new functional materials, the fundamental progress in cellulose science stemming from nanocellulose research has also been remarkable.15−19

This review presents a comprehensive, critical coverage of a topic which is dominant in both fundamental aspects and materials applications of nanocellulose: cellulose–water interactions. The presence of water or humidity in cellulose-based materials is often seen as a detriment. Everyone knows what happens to paper when you immerse it in water: it disintegrates and loses its mechanical strength. Nanocellulose is made of much smaller entities than pulp fibers, and because of its high surface area, it takes up more water and the effect is even more drastic. As high strength coupled with low density is one of the main assets of nanocellulose, the strength loss in water is a major issue. In general, water is seen as a nuisance, and the ensuing problems are being tackled with “brute force” such as chemical hydrophobization and the like. Quantification, localization, and influence of water within a cellulose matrix has also been subject to a number of analytical challenges throughout the history,20 and it continues to be that way.21

The purpose of this review is to point out how the presence of water can be beneficial as well as detrimental in nanocellulose-based systems, processes, and materials: isolation, chemical modification, biomedical templates, responsive hydrogels, sensors, smart emulsions, and so forth. Although intuitively utilized since the ancient times, for example, Egyptians exploiting wood swelling in water to seal leaking joints in their boats, the systematic usage of water interactions has started to emerge only within the past few years.

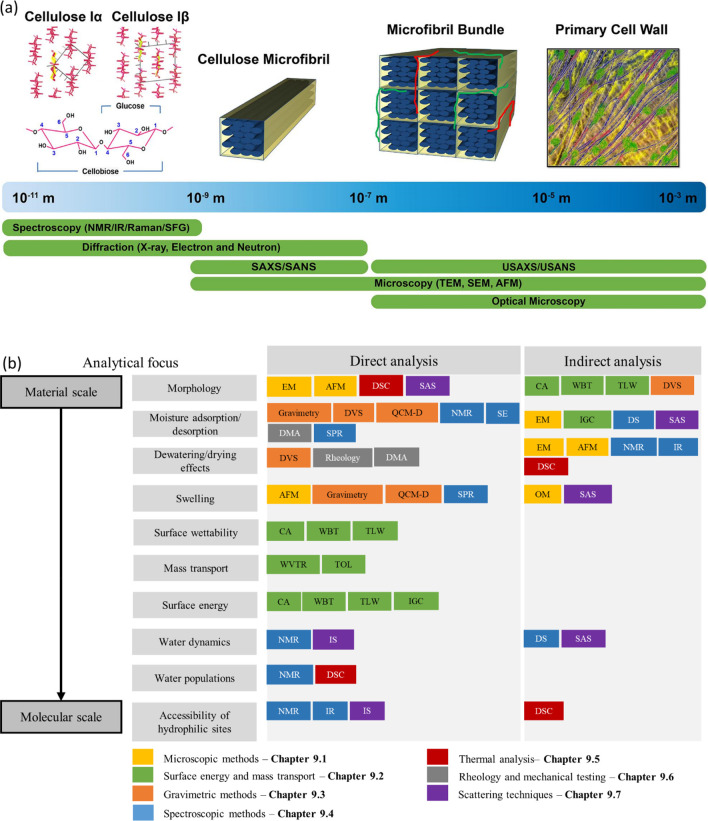

The specific response to water has its roots in the amphiphilic nature of cellulose and its native crystallite structure. The literature on fundamental aspects of cellulose–water interactions spans roughly one century, albeit with a dramatic upsurge during the past decade, fully covered in this review. Understanding the different “types” of bound water and how to measure them, is another crucial step to exploiting nanocellulose–water interactions, and as such, we extensively discuss analytical tools including modeling and experimental approaches to elucidate the relationships between water and nanocellulose.

A number of studies and reviews focus on the interactions of water and other natural polymers such as chitin22,23 and collagen24,25 in the literature. To our knowledge, a comprehensive review on such materials to the extent of the scope of this review has not been published. In addition to presenting fundamentals and characterization, this review focuses on new nanocellulose-based materials which may suffer (but just as well benefit) from the presence of water. We see this as a vital approach in the current research environment where “green” solutions to chemicals and materials are intensively sought after. Accepting (and taking advantage of) the presence of water and the predictability of processing nanocellulose in water is also important when we consider replacing nonaqueous solvents with water in striving toward a more sustainable society. Combined with the comprehensive nature of our approach, spanning fundamentals and analytics, the all-inclusive take on the role of water interactions in nanocellulose production, modification, and applications is what distinguishes this review from other recent reviews that touch on the subject of cellulose–water interactions.3,9,19,26−29

2. Fundamentals of Cellulose– and Nanocellulose–Water Interactions

2.1. Overview of the Properties of Water

Water is usually considered as either a solvation agent or a suspension medium in nanocellulose related research, and the complexity of water is often overlooked. To understand nanocellulose–water interactions, it is pivotal to briefly review some of the relevant characteristics and main features of water. To limit the scope of this discussion, we focus on liquid water at moderate temperatures and pressures. For more comprehensive reviews of water and its properties in more extreme conditions, we guide the reader to relevant publications in the field.30−33 The complex behavior of water results from a combination of hydrogen bonding, dissociation behavior, and the complex structural dynamics, influenced by temperature, pressure, and its interaction with the interfaces and other molecules. As we approach this topic, it should be noted that much controversy still exists regarding the detailed mechanisms and dynamics of water behavior at this level.34 Also, the developments in the simulation of water properties and dynamics35−37 as well as experimental techniques38,39 have been recently reviewed elsewhere.

IUPAC defines a hydrogen bond as “an attractive interaction between a hydrogen atom from a molecule or a molecular fragment X–H in which X is more electronegative than H, and an atom or a group of atoms in the same or a different molecule, in which there is evidence of bond formation”.40 This definition leaves the mechanism of this attractive interaction purposefully open, as no single physical force can be found to be responsible for the phenomena we observe as hydrogen bonding.40 Indeed, the hydrogen bond is either described as a sum of several forces such as electrostatic interactions, polarization, induction interactions between multipoles, charge-transfer-induced covalency, or an independent interaction with unidentified origin.40 The consensus in the scientific community is that there are three-dimensional dynamics and a random network of hydrogen-bonded molecules in liquid water in which the hydrogen bonds are continuously broken and reformed on the time scale of femtoseconds to picoseconds.41 Thus, there is a broad distribution of possible energies and an indefinitely high number of molecules involved in the hydrogen bonding network of bulk liquid water.42 This means that assigning a specific, singular, hydrogen bonding energy to a liquid water system would be misleading. Moreover, as water can be both an acceptor and a donor of multiple hydrogen bonds, a distribution of acceptor–donor states exists.42 The 2 acceptor −2 donor model, resulting in tetrahedral molecular ordering, seems to be the dominant structure on average.43 Due to the random structuring of hydrogen bonds, a water cluster can be identified as a subgroup of water molecules, which form comparatively stable substructures in the time frame of hydrogen bond formation and dissociation. These water clusters can influence the structuring of hydrogen bonds in the surrounding medium outside the cluster.44 Although their very existence is not that controversial, the exact structure, lifetime, and effects that clusters have on the surrounding water medium are still under debate. In addition to water clustering, other phenomena characterized by the hydrogen water dynamics include proton hopping (the exchange of protons between neighboring water molecules)45 and changes in the hydrogen bond structure of water around OH– and H3O+ ions.46 Fluctuations in hydrogen bond networks are experimentally accessible by computer simulations,47 albeit some spectroscopic methods also allow for probing of the phenomena occurring on these time scales.37 For a more detailed discussion on how the various ways the hydrogen bond energy of water has been approximated and investigated we suggest a book chapter by Chaplin48 and a review by Cisneros et al.35 for a more technical-oriented approach.

In addition to water structuring in molecular clusters, the hydrogen bond network of water is altered due to interactions with interfaces or other molecules resulting in the reordering of water molecules. Interesting examples of this phenomenon are the structuring of water in the presence of solutes, at the surface of water-dispersed colloids/particles, and even at hydrophobic surfaces. We address the structuring of water around nanocellulosic materials in section 3.1 when the amphiphilic nature of nanocellulose is discussed.

2.2. Cellulose in Nature

2.2.1. Origin and Basic Crystalline Structure of Cellulose

Cellulose is a semicrystalline polysaccharide composed of β-1,4-linked d-anhydroglucopyranose units (C6H10O5), and it is biosynthesized from glucose through a uridine diphosphate glucose intermediate by all higher-order plants,49 green algae,50 as well as some specific marine animals (tunicates)51 and certain bacteria (namely those belonging to the genera Acetobacter, Rhizobium, Agrobacterium, and Sarcina).52 Cellulose is the most ubiquitously present natural polymer in both land and marine ecosystems and functions as a highly effective natural carbon sink in terrestrial ecosystems turning over almost 3.6 gigatons of carbon annually.53 The majority of cellulose is found in higher-order plants, and it typically accounts for 40–50% of the mass of wood material depending on the species of the plant source.54

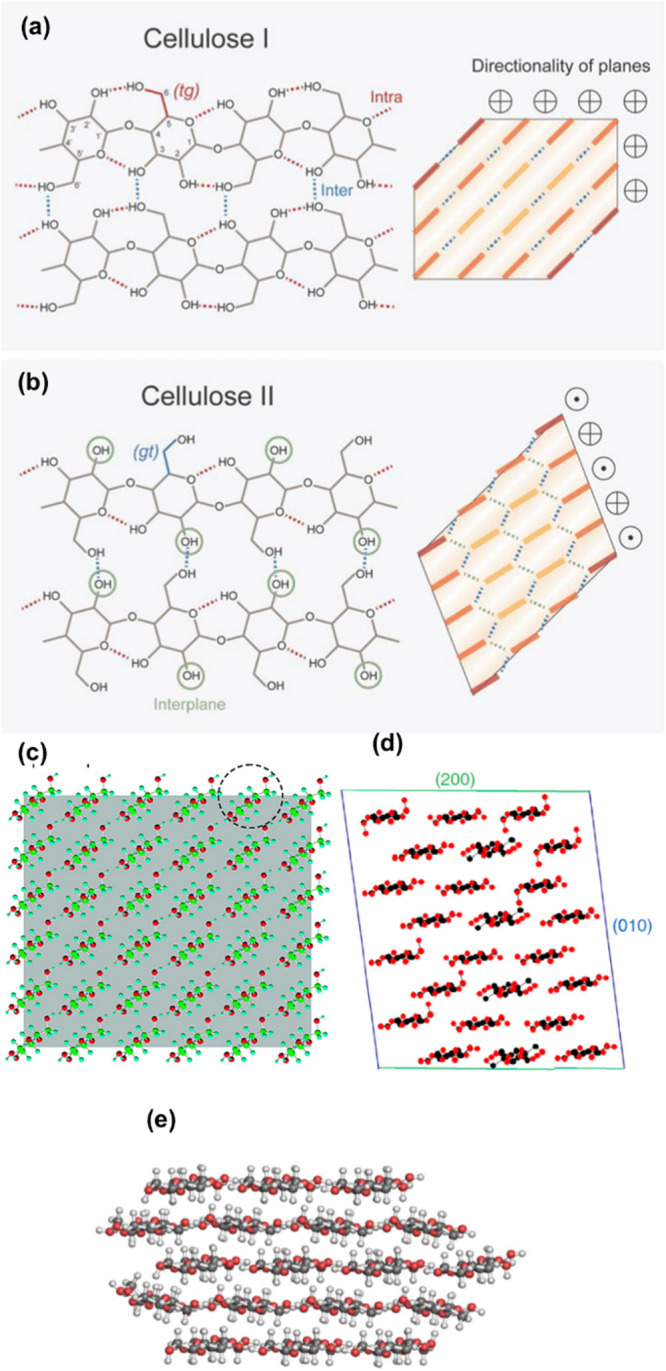

Cellulose biosynthesis is carried out by the cellulose synthase complex or terminal complex (TC),55 where simultaneously upon their synthesis the cellulose polymer chains are assembled into higher-order structures known as microfibrils, which are the smallest supramolecular units of cellulose in nature. Microfibrils are semicrystalline, slender threads that form the structural scaffold of the plant cell wall. In the native cellulose crystal, sheets formed by hydrogen bonding are stacked on top of each other through interplanar van der Waals forces.56 Within the sheets, the intramolecular hydrogen bonds in the native cellulose I crystal are between HO(3)–HO(5) and HO(2)–HO(6), whereas the major intermolecular bond forms between HO(3) and HO(6) (Figure 1a for cellulose I and Figure 1b for cellulose II). Overall, the hydrogen bond energy of cellulose ranges from 17 to 30 kJ mol–1, and the intermolecular hydrogen bond energy is approximated to be around 20 kJ mol–1. In cellulose I, for example, the density of hydrogen bonds is approximately 3.7 × 1018 m–2 along the 1(−1)0 crystallographic plane.57

Figure 1.

(a,b) Hydrogen bonding network in cellulose I and II. (a,b) Reproduced from ref (59) under the terms of the CC-BY Creative Commons Attribution 4.0 International license (CC-BY 4.0). Copyright 2021 Springer Nature. (c–e) Different chain models for cellulose (c) the much debated 6 × 6 chain model. (c) Adapted with permission from ref (60). Copyright 2010 American Chemical Society. (d) 6 × 4 chain model. (d) Reproduced under the terms of PNAS exclusive License to Publish.61 (e) 18-chain model (34443 form). (e) Reproduced from ref (62) under the terms of the CC-BY. Copyright 2018 Springer Nature.

The widths and the shapes of the crystal, which determine the width of the microfibril, differ according to the cellulose source. As a rule of thumb, the higher the plant has climbed on the evolutionary ladder, the thinner the crystal. Trees have the thinnest crystals (∼3 nm), while algae have the widest (>20 nm). This observation can be rationalized by taking into account that the crystallinity and order in the higher plant cell walls are optimized to find a perfect balance between strength and flexibility and to ensure the structural integrity of the organism depending on their growth and environmental condition (e.g., wind, water availability).58

The number of cellulose chains that make up the cellulose crystallite in a microfibril is dependent on the source of the cellulose, and it is still a matter of debate among the cellulose community. For instance, in the case of wood cellulose, it was traditionally accepted that each TC synthesizes microfibrils consisting of 36 cellulose polymer chains (i.e., a 6 × 6 chain cross-section, Figure 1c). Later, however, Jarvis and co-workers suggested that 24 chains make up the crystal (Figure 1d),61 and more recently, models for 18 chain crystals have gained ground (Figure 1e).63 These 24 and 18 chain models appear currently more accepted within crystallographers than the traditional 36 chain model. Regardless of the exact number of chains making up the microfibril, it is important to understand that cellulose in nature exists exclusively in the form of microfibrils and it is never found in nature as single polymer chains or in a fully amorphous form.

Native crystalline cellulose, also referred to as cellulose I, is assembled with the cellulose polymer chains running parallel to one another, and it exists as two different crystal structures (i.e., polymorphs): triclinic Iα or monoclinic Iβ.64 Primarily, the crystal structure of cellulose is governed by the conformation of the TC, which in turn affects the morphology of the resulting microfibril.50 Linear TCs, for example, mostly produce Iα rich cellulose and relatively wide microfibrils with high degree of crystallinity, while rosette-shaped TCs produce thin, Iβ-rich cellulose microfibrils.65,66 Tsekos et al. showed a rough, but indisputable, correlation between the shape of the TC and the resulting cellulose microfibril.67 It is important to note, however, that both polymorphs coexist in all cellulose and their ratio varies depending on the cellulose source.68 Cellulose Iβ is dominant in higher-order plants and tunicate-synthesized cellulose, while cellulose Iα is the main component of celluloses synthesized by algae and bacteria.

Two alternative hypotheses have been proposed to explain the simultaneous presence of the Iα and Iβ forms of cellulose. The first is that cellulose Iα is synthesized by a different type of TC from cellulose Iβ, whereas the second hypothesis is that the different cellulose polyomorphs result from events that occur after the synthesis of the cellulose polymer chains. For example, it has been shown that bending can interconvert the crystalline forms of cellulose I and that their ratio is very sensitive to the angle through which the microfibril is bent.69

Besides the native crystalline form, different cellulose polymorphs exist, in which the crystalline structure of cellulose Iα and Iβ have been altered through physicochemical treatments. Cellulose II can be prepared by reorganizing the hydrogen bonding network such that the cellulose chains run antiparallel to each other in the crystal structure using either a mercerization process where cellulose I is swollen in the presence of NaOH or through the regeneration (i.e., solubilization and subsequent recrystallization) of cellulose (Figure 1b).70 Cellulose I readily converts into cellulose II in an irreversible process, as cellulose II is thermodynamically more stable than cellulose I.71 A third cellulose polymorph called cellulose III can also be reversibly prepared by exposing cellulose I or II to liquid ammonia or certain diamines.72 However, cellulose I and II arguably garner the most research interest because of their biological, industrial, and scientific relevance, and cellulose I is overwhelmingly the most dominant polymorph in all nanocellulose constructs.

2.2.2. Cellulose Morphology and the Hierarchical Structure of the Plant Cell Wall

While cellulose microfibrils are predominantly crystalline, there is direct evidence showing that the microfibril structure in higher plants has regions of disordered cellulose distributed along their length (Figure 2).49,73 The length of the crystalline portions between these disordered regions is primarily governed by the source of the cellulosic material, and this is often depicted using the so-called fringed-fibrillar model.49,56,74−76 For example, the length of the crystalline regions in cotton-derived cellulose is on average 125 nm (i.e., a degree of polymerization (DP) of 250), whereas that of tunicate cellulose can be as high as 3 μm (DP = 6000).77 The inherent length of the crystalline portions of the cellulose structure is linked to the leveling-off degree of polymerization (LODP), corresponding to the DP at which the cellulose structure become inaccessible for further degradation when exposed to strong mineral acids or oxidizing agents at semidilute concentrations.78,79

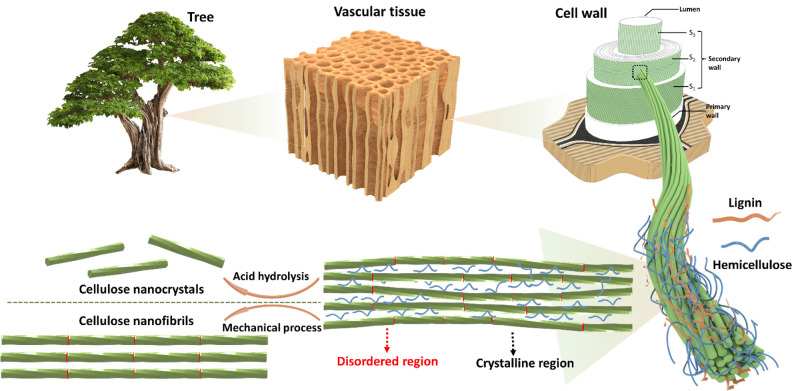

Figure 2.

Schematic representation of the plant cell wall and cellulose fiber structure. CNFs and CNCs are extracted from cellulose fibers using mechanical process and chemical methods (oxidation or acid hydrolysis), respectively.

Isolated native cellulose often gives crystallinity index values between 60% and 90% when analyzed by X-ray diffraction or solid-state NMR spectroscopy. However, such values do not directly indicate that, for example, 70% of the cellulose in the microfibrils would be crystalline and the remaining 30% would be disordered or “amorphous”. In comparison to the crystalline regions, the disordered regions are reportedly very short: accounts of 1–2 nm and 3–6 nm have been proposed,73,80 i.e., they are more like defects in the crystallite rather than bulky amorphous regions as they are often schematically depicted in traditional literature. Much of the response of the disordered cellulose in analytics likely comes from the microfibril surface simply because the chains there have higher degrees of freedom. As a result, the systematically higher crystallinity reported for algae50 or tunicates51 comes largely from the fact that their microfibrils, and therefore their crystallites, are wider than those in higher plants (i.e., there are fewer surface cellulose chains).1,81 Cellulose sample preparation prior to crystallinity measurements can also affect the degree of crystallinity values obtained, at least within a few percent range. Certainly, the frequency of the disordered regions also plays a role here, but we believe that the crystallite width is a more significant factor.

Furthermore, while nearly all studies assume that the disordered cellulose regions are a part of natural microfibrils, some reports have suggested that these regions of disorder are in fact a result of the processes involved in cellulose isolation. For example, Atalla et al. put forward that native celluloses are irreversibly transformed and develop the semicrystalline character upon isolation at elevated temperatures.82 These issues are still under debate. Nonetheless, the semicrystalline nature of cellulose is a fact of processed cellulosic materials, such as virtually all nanocellulose types, and it adds to their complexity as areas of high order are less susceptible to chemical and biological attack.83

The role of disordered regions in water-induced swelling of cellulosic materials is not straightforward. There is a common consensus that crystalline cellulose is impenetrable by water.84 However, the disordered regions may be somewhat “accessible”, but they are certainly not “swollen” by water because of their short, defect-like texture. It has never been shown that the length of a microfibril would increase when immersed in water. However, small angle neutron scattering data have shown that a somewhat higher concentration of D2O molecules can be observed in the vicinity of the disordered segments.85

Another often misunderstood fundamental issue with cellulose–water interactions is hydrogen bonding. Despite the undisputable importance of hydrogen bonding between water molecules and nanocellulose at the interface in governing the characteristics and properties of cellulose dispersions, we would like to echo the conclusions of Wohlert et al. in their critical review on the general role of hydrogen bonding in nanocellulose structure and properties as a material. They conclude that hydrogen bonding is one interaction among several, and its relative contribution to the nanocellulose properties is highly dependent on the specific conditions and cannot easily be determined by intuition or even by analysis.57,59

In any case, the combination of the insolubility of cellulose in water with its ability to interact with water are fundamentally important to sustaining its structural integrity. Nature has utilized this feature of cellulose to engineer the incredible structure that is the plant cell wall. The plant cell wall is made up of three distinct regions: (i) the primary cell wall, (ii) the secondary cell wall (made up of three layers), and (iii) the middle lamella. Within the primary and secondary plant cell walls, cellulose microfibrils are further assembled into microfibril bundles and form a composite network structure with the two other main plant cell wall components, namely hemicellulose and lignin (Figure 2).86−88

Within the plant cell wall, the microfibrils (and their bundles) are orientated depending on which layer of the cell wall they exist in (Figure 2). In the primary cell wall, the microfibrils form very thin oriented layers with different orientations to one another, forming the impression of a random network.89,90 On the other hand, the highly aligned microfibrils have a unique microfibril angle in each of the three layers of the secondary cell wall. This level of natural hierarchical engineering provides plants with the necessary flexibility required for growth and swelling in the presence of water while ensuring the plant has sufficient axial stiffness.91,92 When discussing the swelling of cellulosic materials in water, one must remember that it is never the individual cellulose microfibril that swells, it is always a scaffold where bulk water clusters between the microfibrils. As a result of axial microfibril orientation in the secondary wall, the plant fibers always swell copiously in a radial direction, but their length of increase when immersed in water is negligible.93

Plant fibers are always swollen by water as the major component in their native growth environment, which imparts the plants with necessary flexibility. It was earlier proposed that water is held in a microporous gel of hemicelluloses and lignin distributed as fine platelets within a cellulose skeleton.94 Yet the water content is strictly controlled by the presence of more hydrophobic lignin in the cell wall. Conventional pulping process including beating and bleaching (delignification) is often undertaken when chemically processing plant fibers to, for example, pulp for paper production. Rheological properties of fiber–water suspensions where water acts as a suspension matrix are of critical importance in many of papermaking process from beating, screening, fractionation, dispersion flow in headbox, sheet forming, and dewatering.95 In general, delignified fibers make up a strong network because the fibers are able to form inter- and intrahydrogen bonds with each other due to cellulose surface exposure after lignin removal.93 Two general water transport mechanisms including diffusion and capillary flow were suggested in cellulosic materials.96 If the fiber network is exposed to water, however, the fibers and the network lose their integrity and mechanical strength because lignin is no longer there to obstruct the water adsorption to cellulose surface due to pore flow accompanied by a surface “hopping” mechanism.96,97 A delignified fiber is also prone to irreversible loss of porosity due to drying. Pores between the cellulose microfibrils are filled with water in a swollen state and the pores disappear due to capillary forces as the water is removed. When the fiber is re-exposed to water, the pores reappear but not to the same extent as before drying. This decrease in the swelling capability of a fiber is referred to as hornification, and it has genuine practical implications not only in papermaking and paper recycling but also in nanocellulose production.98−103 Hornification is often (usually without explicit evidence) attributed to “irreversible hydrogen bond formation between neighboring microfibrils upon drying”. To our perception, a more likely reason could be hydrophobic interactions where the hydrophobic sites of the cellulose crystals in microfibrils partially aggregate. Such hydrophobic bonding is less likely to be cleaved by water upon re-exposure than hydrogen bonding. We must acknowledge, however, that several accounts refer to co-crystallization or association of hydrophilic sites as a culprit for hornification, with obvious involvement of (also) hydrogen bonding between the microfibrils.104,105 The issue remains unsettled within the community. Hornification or similar phenomena with microfibril aggregation have even been reported to occur in air-dried cotton fibers upon exposure to HCl vapor,106 a preliminary phase in one type of nanocellulose isolation procedure.107 Moreover, the loss in swelling capability is not restricted to fully delignified samples and it has also been observed to an extent for lignin-containing samples such as wood and mechanical pulp.108,109 The situation is further complicated by the fact that hornification is known to be at least partially reversible with introduction of mechanical force in the system, a process referred to as beating in the papermaking sciences.110 In addition, the response of the dimensional behavior of paper to relative humidity changes is a reflection of individual cellulose fiber changes in macroscale manner.111 The torsional response, i.e., twist, in drying of a collapsed fiber is a function of the microfibril angle, the fiber length, and the factional linear shrinkage across the microfibrils, which is closely related to the nanoscale twist of nanocellulose (will be explicitly discussed in section 2.3 and section 4.1). All in all, drying of wood and other native specimen is a more complex affair with a series of structural rearrangements taking place, involving physical deformations such as bending, buckling, or twisting of the fibrous cellulose bundles.112−115

2.3. From Cellulose to Nanocellulose

2.3.1. Types of Nanocellulose

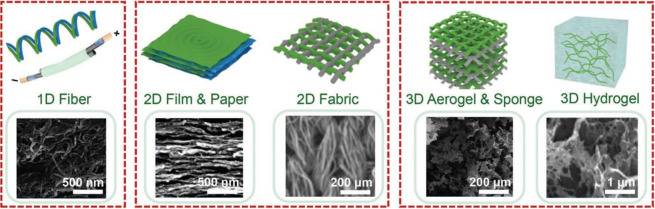

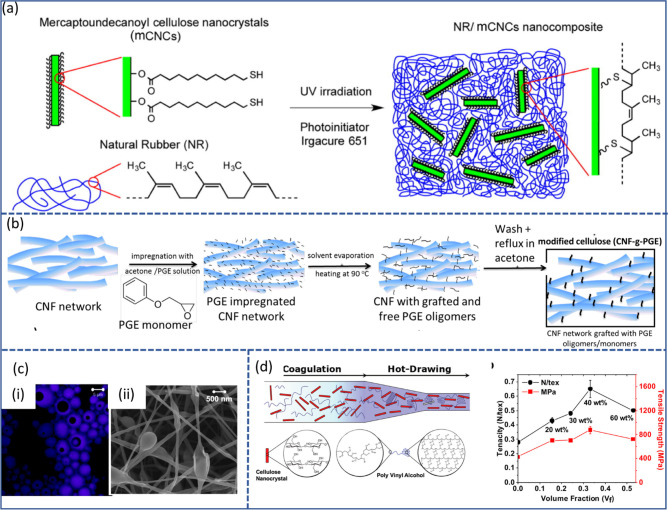

Nanocellulose refers to cellulosic materials which have at least one dimension in the nanoscale. A vast majority of nanocellulose consists of anisotropic nanoparticles with varying aspect ratios although spherical nanocelluloses have also been reported.116,117 Nanocellulose, namely cellulose nanofibrils (CNFs), cellulose nanocrystals (CNCs), and bacterial cellulose (BC), have garnered a vast amount of research attention due to their incredible versatility. Their high aspect ratios, high surface area to volume ratios, abundance of surface hydroxy groups, and high strength enable them to be used in a wide variety of potential applications.118,119 While all nanocellulose grades exhibit the aforementioned properties, CNFs and BC are distinctly different materials to CNCs, as attested visually in Figure 3.120,121

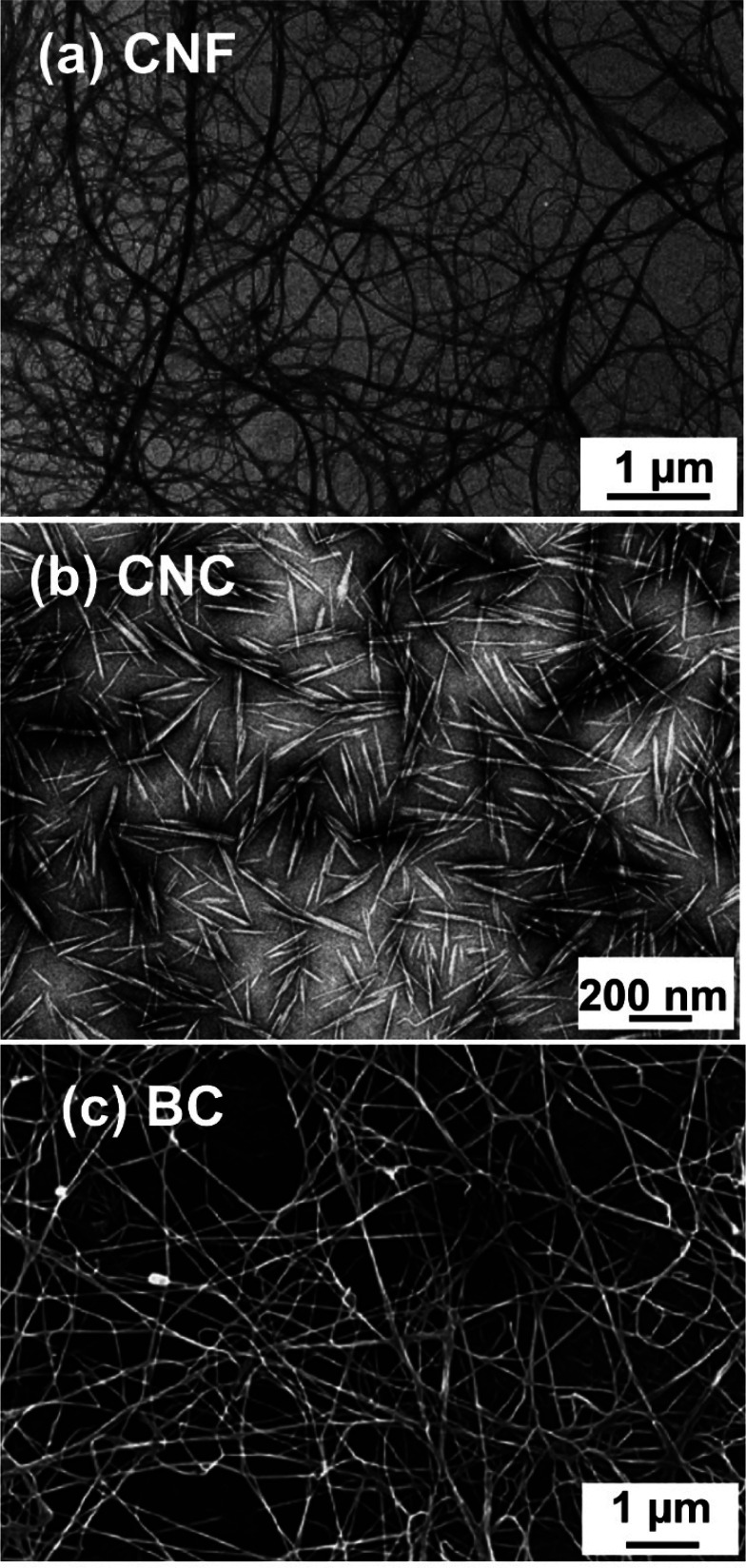

Figure 3.

Typical appearance of nanocellulose observed by TEM (a,b) and SEM (c). (a) CNF122 and (b) CNC.123 (a) Adapted with permission from ref (122). Copyright 1998 John Wiley and Sons. (b) Adapted with permission from ref (123). Copyright 1991 The Royal Society of Chemistry. (c) SEM image of BC membrane.124 (c) Adapted with permission from ref (124). Copyright 2008 Elsevier.

CNFs are essentially isolated cellulose microfibrils (Figure 2 and Figure 3a). In consequence, they are flexible and semicrystalline threads, with diameters in the nanoscale (average width of 2–50 nm) but lengths in the micrometer range (1–15 μm).51,102 A series of chemical (e.g., a 2,2,6,6-tetramethylpiperidin-1-yl)oxyl (TEMPO)-mediated oxidation125) and/or enzymatic pretreatments (e.g., cellulases),126 followed by substantial mechanical defibrillation,127 are necessary to liberate CNFs from their biological matrix, i.e., the plant fiber, given the strong interactions between cellulose microfibrils and the tightly knit hierarchical structure of the cell wall.128 During the mechanical defibrillation, high shear forces are applied to isolate single CNFs which have dimensions dependent on both the isolation method and the source of the cellulose. The surface charge of CNFs depends on the amount of residual hemicellulose, namely xylan with methylglucuronic acid groups, and the choice of pretreatment. Specifically, the CNFs prepared by TEMPO-mediated oxidation pretreatment (TOCNF) carry very high charge densities, with approximately every second anhydroglucose unit on the surface bearing a carboxylic group when the maximum degree of oxidation is applied. Full details on CNF isolation can be found in the relevant reviews.102,129 TEMPO-mediated oxidation is also the only pretreatment method that manages to truly individualize microfibrils into CNFs. With other isolation methods, the CNFs always consist of (at least partially) microfibrillar bundles.129

CNCs (sometimes called nanowhiskers) on the other hand, are highly crystalline, rod-shaped nanoparticles, with widths between 3 and 50 nm and lengths ranging from 50 nm to 10 μm (Figure 3b) depending on the cellulose source.130 The most common source for CNCs is cotton because of the wide availability and relative purity of ordinary laboratory filter paper; the typical widths of cotton CNCs range from 5 to 20 nm and lengths from 50 to 300 nm (with an average at ∼120 nm). Similar to CNFs, CNCs are also prepared using a top-down approach. By contrast, however, CNCs are typically isolated using an acid-catalyzed hydrolysis, which selectively degrades the more reactive disordered regions of the cellulose microfibril and leaves intact the crystalline regions.79,131−133 The length (or DP) of CNCs is largely governed by the LODP of their source material (see section 2.2.2 for a description of LODP and Figure 2). The conventional method to isolate CNCs is to perform a hydrolysis reaction in the presence of concentrated sulfuric acid at elevated temperatures, which in addition to hydrolyzing the disordered regions introduces charged sulfate half ester groups on the CNC surface, thus imparting colloidal stability.134−137 Recently, many alternative isolation methods for CNCs have surfaced, based on, e.g., oxidation and esterification, but these approaches often require the additional presence of a strong mineral acid to perform the hydrolysis of disordered regions.138 A critical factor is that CNCs require some type of a surface charge group to come up with a stable colloidal dispersion in water. While sulfated CNCs are still overwhelmingly the most produced and studied, CNCs stabilized by phosphate139,140 and carboxylate groups107,133,141,142 have gained ground in recent years. For comprehensive accounts of CNC preparation, the interested reader is referred to recent reviews on the topic.138,143,144 One of the distinguishing characteristics of CNC dispersions is that they spontaneously form (lyotropic) chiral nematic liquid crystals,145 a feature that has spawned a sizable branch of CNC research over the past 30 years.146−148

The current trend in the literature is to regard BC as the third member of the nanocellulose family because it is produced by various bacterial species from low molecular weight sugars using a bottom-up approach (Figure 3c). BC is directly synthesized as a hydrated nanofiber network, i.e., a hydrogel,149,150 and unlike CNF and CNC preparation, it requires no isolation steps apart from washing away the bacteria and growth culture medium with mild alkali. Although the bottom-up preparation route for BC is distinctly different from the other nanocellulose types, BC is essentially a form of CNF as it consists of semicrystalline, flexible threads. In contrast to plant-based CNFs, BC nanofibers are like flat ribbons, that is, their cross-sectional dimensions are rectangular: ca. 7 nm high and 20–140 nm wide.119 After rinsing off the bacteria, BC is also the purest form of nanocellulose without remnants of hemicellulose or lignin and virtually without any charge. The chemical purity is among the reasons why BC has been popular, particularly in biomedical applications.151

Both CNCs and CNFs show a longitudinal twist with a right-handed chirality, which ultimately originates from the crystalline structure of cellulose.152,153 Molecular dynamics (MD) simulations have established the twist in molecular cellulose154 as well as in cellulose I crystal.155,156 Combining computational and experimental data, Conley et al. quantified a twist of 800 nm period for wood-based CNC.154 As the CNCs from typical sources like wood, cotton, or ramie have lengths spanning 50–300 nm, the long periodicity in the twist may be the reason as to why the twist is rarely visually evident in microscopy images of common CNCs. Despite this, the twisting of the cellulose crystal ultimately causes the formation of chiral nematic liquid crystals in CNC dispersions.

A noteworthy physical distinction in aqueous dispersions of CNFs and CNCs is that CNFs form gels at very low concentrations (<1 wt %), whereas CNCs are fluid dispersions of fairly low viscosity.9 CNCs do gel, but usually the gelling point is above the critical concentration for liquid crystal formation (ca. 10 wt %).157 These differences in water binding capacity are a partial reason for the different approaches in applications-related research concerning CNFs and CNCs. CNFs are often applied as scaffold structures in hydrogels, or as entangled networks, whereas CNCs are utilized when, for example, discrete particles are needed or sophisticated chemical modifications are deployed for self-assembly or responsive materials.2,27 This distinction in applications is by no means a strict one, but it has set an underlying trend for research over the past 15 years.

2.3.2. Role of Water in Nanocellulose Production

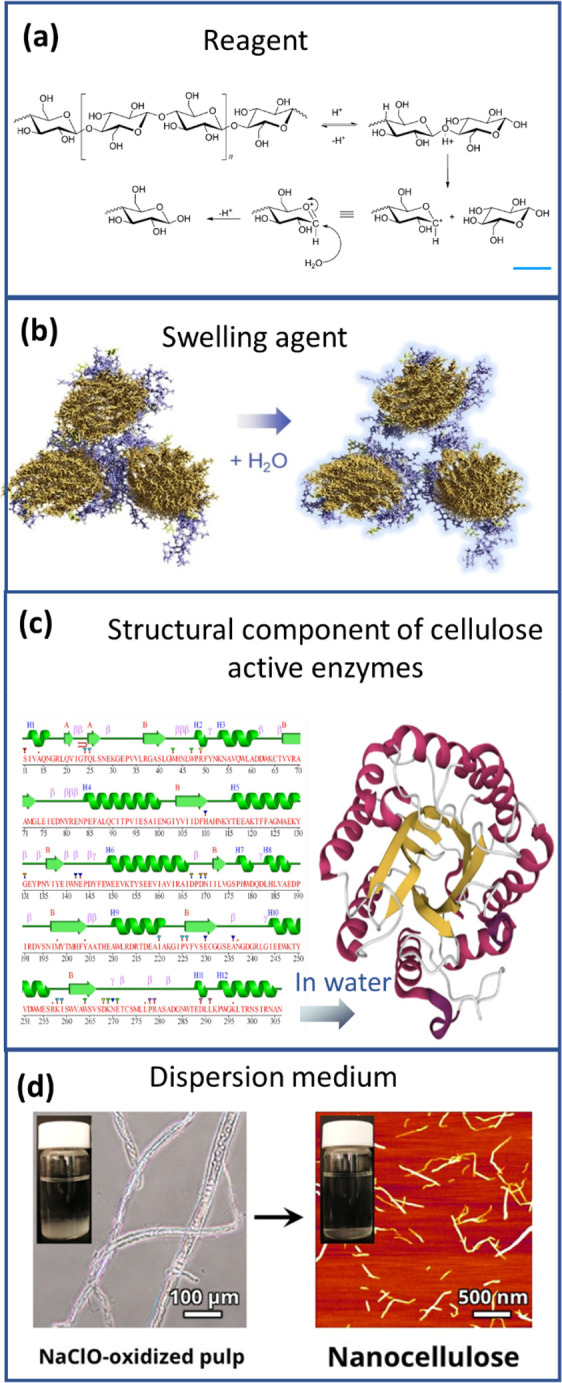

There is no doubt that water plays an important role in the production of nanocellulose, particularly in the hydrolysis reaction utilized to isolate CNCs (discussed in detail in section 2.3.2.2).158 However, even when not directly involved in chemical reactions of nanocellulose production, the presence of water is pivotal. Figure 4 summarizes the role of water in nanocellulose preparation.

Figure 4.

Schematic summary of the role of water in nanocellulose production. Water serves as (a) reagent198 and (b) swelling agent,199 (c) an essential medium for tertiary structures of enzymes200 used for nanocellulose production, and (d) medium195 in the hydrolysis reaction, (a) Adapted with permission from ref (198). Copyright 2011 John Wiley and Sons. (b) Adapted from ref (199) under the terms of CC-BY. Copyright 2021 Elsevier. (c) Adapted from ref (200) under the terms of CC-BY 4.0. Copyright 2021 Springer Nature. (d) Adapted from ref (195) under the terms of CC-BY. Copyright 2020 American Chemical Society.

2.3.2.1. Cellulose Hydrolysis

Hydrolysis is a chemical reaction of a substance with water, leading to the decomposition of both the substance and water.159 The isolation of CNCs typically occurs through a controlled hydrolysis reaction in which the β-1,4-glycosidic bonds in the disordered regions of the microfibril are cleaved by the addition of a water molecule (Figure 4a). Therefore, all CNC production routes rely on the presence of water as a reagent. Ultimately, as a result of hydrolysis of cellulose, glucose is released in a process called saccharification. However, under ambient conditions, this is a very slow reaction, and it is not applicable for practical purposes.160 The hydrolysis of cellulose can be expedited via different catalysts such as acids and bases, enzymes, or by using subcritical and supercritical water as a reaction medium. While the hydrolysis in subcritical and near critical conditions of water has been rarely used for the isolation of CNFs,161,162 it has been more actively demonstrated in the production of CNCs. For example, the use of subcritical water (120 °C and 20.3 MPa for 60 min) allows higher diffusion, activity, and ionization of water but leads to relatively low yields of CNCs (around 20%).163,164 Also, in a recent study, supercritical carbon dioxide and enzymes were studied to hydrolyze the disordered regions of the cellulose microfibrils to produce CNCs.165 As mentioned earlier, the most common method to isolate CNCs is through an acid catalyzed hydrolysis using concentrated aqueous mineral acids such as sulfuric acid, phosphoric acid, and hydrochloric acid to yield charged or uncharged CNCs (such as the case for HCl hydrolyzed CNC). Recently, Pääkkönen et al. reported the production of carboxylated CNCs via HCl gas hydrolysis, followed by a TEMPO-mediated oxidation, leading to lower acid consumption and more effortless process steps toward easier CNC purifications.79,107 The use of HCl gas to produce CNCs from cellulose fibers relies on the water naturally present on the cellulose surface: water is able to dissociate the HCl and carry out the acid hydrolysis.79,107 In addition, solid acid catalysts (such as carbon catalysts with weakly acidic groups, polymer-based acids, magnetic solid acids, and lignin-based catalysts) have been used.166−171 Bronsted acid active sites on the solid catalysts offer advantages such as selective cellulose hydrolysis, long catalyst lifetime, reusability, reduction of acid pollutants, and reduction of the cost of wastewater treatment. However, the contact between the active sites and cellulose remains a challenge because both reactant and catalyst are present in solid phase. The role of water as the reaction medium is crucial to improve the accessibility of catalyst to cellulose. Additionally, water can act as a catalyst for a autohydrolysis process, as hydronium ions (H3O+) formed on the surface of catalyst further promote cellulose hydrolysis.172−174 Despite the multiple reports on gas or solid based methods to hydrolyze cellulose into nanocellulose, these processes remain to be less common in comparison to liquid acid hydrolysis.

In acid catalyzed hydrolysis, the reaction mechanism involves the activation of the glycosidic oxygen by protonation before water addition,175 and the rate of hydrolysis is dependent on both the acid concentration (i.e., fraction of water) and the temperature. At very high acid concentrations and temperatures, cellulose undergoes complete degradation into singular sugars.176 Therefore, for the purposes of implementing acid catalyzed hydrolysis in CNC production, reaction conditions must be strictly controlled.177 Both the temperature and acid concentration must be sufficiently high to cleave the glycosidic bonds in the disordered regions of the microfibril in a timely manner but low enough to keep the crystalline regions intact (Figure 3b). In the conventional sulfuric acid hydrolysis to produce CNCs, the concentration is generally set to 64–65 wt %, which is fairly close to the value where total hydrolysis/dissolution of crystalline cellulose occurs (72 wt %). Here, the water content is very low because of the formation of oxonium ions, and this is integral for enabling the esterification of sulfate groups which must take place in order to ensure the necessary colloidal stability of CNCs. Furthermore, it is important to note that during the acid hydrolysis of cellulose there exists a competition between the dehydration of cellulose (i.e., cleaving of the glycosidic bonds) and the dissolution of lower DP sugars resulting from the hydrolysis.79,178−180

While the use of enzymes has been reported for the isolation of CNCs, they are typically implemented in the pretreatment of cellulosic substrates prior to high shear mechanical treatments.181 Hydrolysis of the cellulosic substrates through enzymatic hydrolysis significantly decreases the amount of energy required to mechanically isolate individual cellulose microfibrils from cellulose fibers. In nature, the degradation of cellulose is accelerated by more than 17 orders of magnitude by cellulases, which include a variety of enzymes called glycoside hydrolases (or glycosidases) that catalyze the hydrolysis of the β-1,4-glycosidic bonds of cellulose.182 Enzymatic hydrolysis involves complex interactions between enzyme, cellulose, and the reaction environment, and although the complete mechanism of action of the above-mentioned enzymes is still unknown183 it has been shown that enzyme folds and crevices are formed in water into which the substrates fit.184 Different cellulases will catalyze the hydrolysis at different locations along the cellulose polymer chain, and all of these enzymes act synergistically in order to fully degrade cellulose to glucose for the production of biofuels, for example.185 In the production of CNFs, however, the enzymatic activity of cellulases is carefully controlled to minimize undesired cellulose degradation. Furthermore, the isolation of CNFs is often aided by the introduction of enzymes such as xylanases, laccases, and lytic polysaccharide monooxygenases, which have an affinity for the glycosidic bonds in other polysaccharides (hemicelluloses in particular).186−190

2.3.2.2. Water as a Medium in Nanocellulose Production

Cellulose and cellulosic fibers are insoluble and relatively inert in water under ambient conditions. Nonetheless, the hygroscopic nature of cellulose enables the swelling of cellulose fibers as a result of water sorption, which is key in the production of CNFs. Water-induced swelling of cellulosic fibers “opens” their structure (Figure 4b), increasing their accessibility, and in turn facilitates the penetration of chemical reagents and activity of enzymes (Figure 4c) during the pretreatment stages of CNF production. Additionally, these pretreatment methods often rely heavily on the water present to act as the reaction medium (e.g., in the case of TEMPO-mediated (Figure 4d) or enzymatic oxidation).191 Pretreatment methods such as swelling or partial dissolution in ionic liquids or deep eutectic solvents (DES) are also heavily dependent on water, further highlighting its importance in the many possible routes available for nanocellulose production.192−195 It is important to note that even in production methods where water does not play an active role in the breakdown of the cellulose structure to the nanoscale (e.g., nanocellulose production through oxidation using an electron beam), water is omnipresent in the purification, workup (e.g., alkaline treatment, sonication, and high-pressure homogenization), and often storage stages of nanocellulose production.195−197

2.4. Nanocellulose–Water Systems: Properties and Dynamics

Before introducing the interactions between water and nanocellulose specifically, it is important to highlight the distinction between the swelling of cellulosic (plant-based) fibers and nanocellulose networks in water. In nature, the geometrical constraints of the cell wall set by their hierarchical structure, especially with rigorous microfibril alignment in the secondary wall, greatly restrict the swelling capacity of fibers. As already stated, swelling in water is highly anisotropic for fibers, as the volume increase occurs solely in the lateral dimension. The isotropic nature of most nanocellulose networks, together with the significant increase in specific surface area (SSA), leads to a much higher water sorption capacity per mass of cellulose. In conjunction with this increase in SSA comes an increase in the accessibility of surface hydroxy groups which can easily interact with water. Furthermore, any charged groups introduced to the surface of the nanocellulose during isolation will also alter its ability to interact with water. Phenomenologically, the nanocellulose–water interaction involves multiple overlapping phenomena such as hydration, condensation, wetting, and diffusion, which are all mediated by various interaction forces including hydrogen bonding, electrostatic interactions, and van der Waals forces. These processes unfold along different length scales, which ultimately gives nanocellulose its extraordinary hygroscopic character.

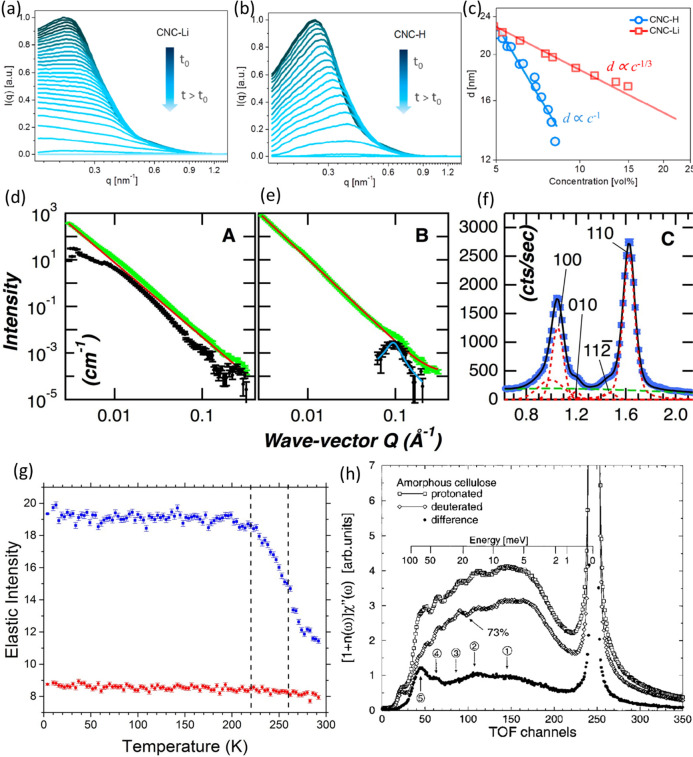

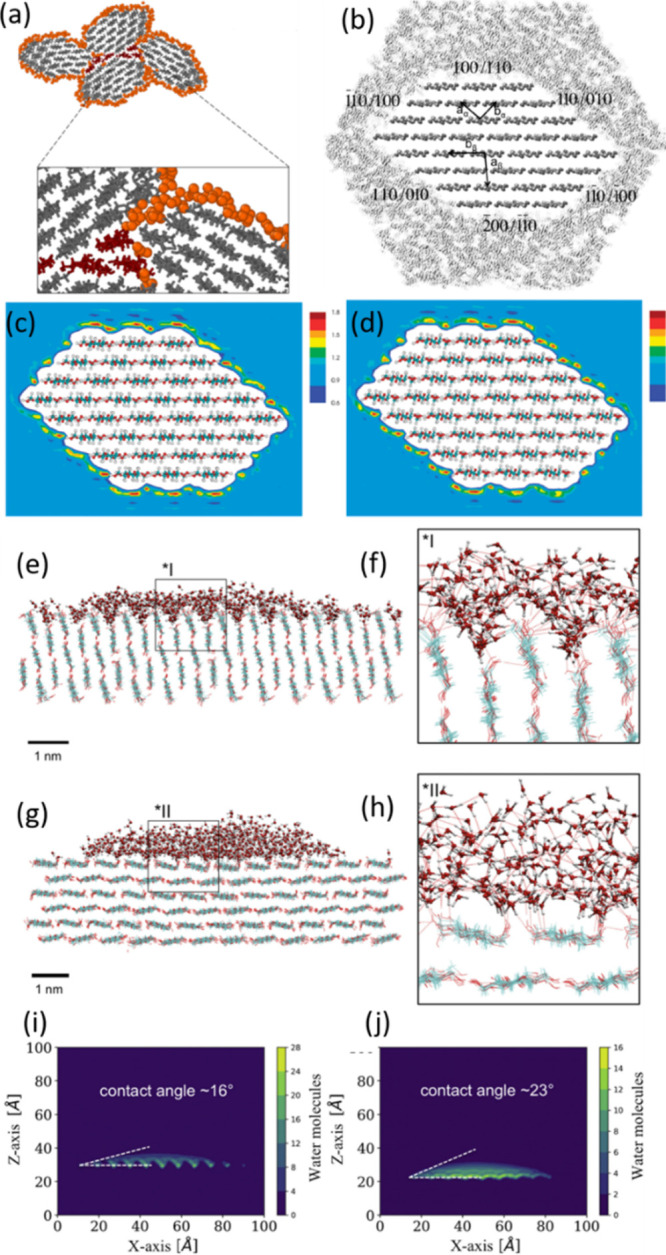

2.4.1. Water and Nanocellulose Interactions at the Molecular and Supramolecular Level

2.4.1.1. Accessibility of Cellulose Chains to Water

The accessibility of cellulose chains to water is governed by the availability of hydroxy groups on the surface of a cellulose crystal. While cellulose–cellulose hydrogen bonds often take precedence over cellulose–water hydrogen bonds (hence the insolubility of cellulose in water), there is also an abundance of hydroxy groups on the crystallite surface that have the propensity to hydrogen bond with water.201 A common method by which to quantify the availability of hydroxy groups in cellulosic materials is to substitute the hydrogen in available hydroxy groups for deuterium through a water/deuterium oxide (H–D) solvent exchange.202 The availability of hydroxy groups for solvent exchange is dependent on a number of factors: (i) their position in the cellulose chain (i.e., 2-, 3-, or 6-position), (ii) whether they are within the ordered or disordered region of the cellulose microfibril, and (iii) whether they are located on the surface or embedded within the crystallite (microfibril). The hydrogen atoms in the HO(2) and HO(6) hydroxy groups can act as hydrogen-bond donors to water, but the HO(3) behaves as a hydrogen-bond acceptor from water and donor to their intrachain neighbors O(5) (see, Figure 1). The accessibility of these hydroxy groups on the surface of cellulose crystals correlates with the H–D exchange behavior. For a specific hydroxy group to be available for the H–D exchange, it must be able to donate a hydrogen atom via hydrogen bond to a water molecule.203 For this reason, the HO(3) does not participate in the H–D exchange.203 Indeed, the HO(2) and HO(6) are more prone to moisture absorption, while the HO(3) has a lower accessibility, given the fact that the intramolecular hydrogen bond with O(5) has a predominant role in stabilizing the cellulose structure.204 In addition to the molecular position of each hydroxy group, the crystalline structure of cellulose plays a crucial role in the cellulose–water interactions (and therefore −OH group accessibility). On the crystallite itself, water accessibility is also based on the geometrical requirements of the available hydroxy groups of the cellulose that come into contact with water molecules.155

The degree of crystallinity of the cellulose substrate plays a role in extreme cases: the accessibility of hydroxy groups in amorphous cellulose (as measured through deuteration using dynamic vapor sorption (DVS)) is estimated to be 63%, whereas the equivalent accessibility for microcrystalline cellulose is 51%, indicating that a higher crystallinity leads to lower −OH group accessibility.205 Similarly, multiple works in the literature correlate the difference in water uptake capacity of CNFs and CNCs to the difference in their degree of crystallinity and (supposedly) consequent hydroxy group accessibility.206,207 As mentioned earlier, CNFs are isolated cellulose microfibrils which exhibit the semicrystalline structure, whereas CNCs represent the crystalline portion of the cellulose microfibril. As such, it has been speculated that the more frequent presence of the disordered region leads to a higher water uptake capacity in CNFs than CNCs.208,209 Yet there is no evidence of increased swelling due to an increased number of disordered regions in microfibrils, although (as already mentioned) data published by Nishiyama et al. showed the hydrogen atoms in the hydroxy groups of the disordered domains were in fact susceptible to deuteration.73 It is also evident that water interacts solely with the surface of CNCs and is unable to penetrate (at least to any significant degree) into the crystal structure,208,210 and deuteration is indicative of the number of available surface hydroxy groups206,211 unless substantial temperature and pressure is applied.212

Instead of the disputed role of the crystallinity index, the hydroxy group availability in native cellulosic structures is rather governed by the size of the cellulose crystallite, as shown by Driemeier and Bragatto in their seminal work on microcrystalline cellulose with varying crystallite widths.213 Also, the amount of residual hemicellulose plays a marked role in general water uptake and must not be confused with hydroxy group accessibility in cellulose per se.213 Particularly with CNFs, hemicellulose is often intentionally left in the structure because it facilitates the separation of microfibrils from one another.214 Another factor in accessibility with water is the imperfect packing of aggregated crystallites that may allow a concentration of water molecules in voids created by the phenomenon.213 Therefore, when examining the differences in hydroxy group availability and subsequent water uptake capacity, it is important to also consider differences in morphology, chemical composition, and flexibility. We will discuss the difference in water uptake capacity of assemblies of different nanocelluloses in section 2.4.1.2.

The accessibility of cellulose to water may also be governed by its polymorphism. Some studies have indicated that nanocelluloses of cellulose II have higher water sorption capacity than those with a cellulose I crystal structure due to the possible changes in the crystallite dimensions and the decrease in overall crystallinity as a result of the mercerization process used to convert cellulose I to cellulose II.215,216 Therefore, unlike cellulose I that has small disordered regions that cannot generally be regarded as fully “amorphous”, cellulose II has been speculated to exhibit genuine crystalline–amorphous transition, akin to many synthetic polymers.217

Water uptake is also substantially influenced by the number of charged groups in the cellulose matrix because they directly contribute to the osmotic pressure.218 Intrinsically linked to the osmotic pressure, the induced electrostatic forces direct the water molecules and determine much of the texture of the nanocellulose matrix, as governed by the Derjaguin–Landau–Verwey–Overbeek (DLVO) theory219 The counterion on the charged group also has a pronounced impact. For example, the sulfate half ester group’s counterion on CNCs directly affects the critical coagulation concentration following the Hofmeister series (N(CH3)4+ < NH4+ < Cs+ < Rb+ < K+ < Na+ < Li+), which also correlates with the interactions they have with water molecules.220−222

2.4.1.2. Wettability of Cellulose

The mundane definition of hydrophilic/hydrophobic character of a surface is to have the static water contact angle below or above 90°, respectively. Striving for higher thermodynamic accuracy, alternative takes on the issue have used Gibbs free energy of hydration (ΔGsl): van Oss, for example, proposed that hydrophobic compounds attract each other in water when their ΔGsl > −113 mJ m–2 and repel each other when ΔGsl < −113 mJ m–2.223 Moreover, factors such as surface roughness and morphology, porosity, and fouling all play an important role in the spreading of a liquid at the air/solid interface.224

In addition to, and intrinsically linked to, the hydroxy group availability, native cellulose crystals are amphiphilic (as demonstrated in the cross-sectional schemes of the microfibril in Figure 1).225−228 This amphiphilicity is present at molecular and supramolecular level of cellulose,229−231 and it is governed by the structural and conformational order in addition to the roughness, purity, and porosity of the assembled nanocellulose structures. Cellulose can also undergo conformational changes to accommodate the surrounding medium.231,232 The distinction between hydrophilic and hydrophobic faces in the cellulose I crystallite is straightforward (Figure 1), but their behaviors are not. For example, molecular dynamic (MD) simulations have shown that the hydrophilic 110 face, which is the most represented in the external morphology of the native fibers, possesses a water contact angle of 43°, while the other hydrophobic 100 face shows a contact angle of 95°.233

As a side note, the noncellulosic materials adsorbed on the surface of cellulose can change the surface characteristics. Dried CNFs have been reported to accumulate a layer of noncellulosic material on the surface, which renders them less reactive than one might expect of a material rich in hydroxy groups.232 As a conclusion, it is fair to define nanocellulose as a family of cellulosic materials with amphiphilic nature, whereby the free energy of hydration depends on morphological factors on all length scales.

Materials with similar surface energies are inherently compatible, suggesting that understanding the surface energies of both water and nanocelluloses can give us a rough picture of their potential interactions. Surface energy can be divided into a dispersive (i.e., hydrophobic) and a polar (i.e., hydrophilic) component, the former describing the ability of a surface to participate in long-range London type nonpolar interactions and the latter in short-range “polar” interactions. In the case of liquids interacting with surfaces of differing surface energies, one can discuss their interfacial compatibility in terms of wettability (or the ability of water to spread over a surface). A surface can be considered wettable when its θ with a liquid is between 0° and 90° and not wettable at θ above 90°.234 We will discuss the water sorption capacity (or wettability) of nanocellulose assemblies in sections 2.4.2.4, 4.1.1, and 4.2.2. Simply put, the wettability and the water retention of nanocellulose assemblies is highly dependent on their overall crystallinity, surface chemistry (i.e., charged, uncharged, or chemically modified), and purity of the nanocellulose along with the roughness, morphology, and porosity of its assemblies.235

In section 2.4.1.1, we described the ambiguous role of crystallinity in the accessibility of hydroxy groups in cellulosic materials. One can imagine that on the nanoscale the wettability of crystalline cellulose with water is also dependent on its crystal structure and the subsequent degree of amphiphilicity. However, a comparison of the surface energies of nanocelluloses extracted from several plants did not reveal a significant difference (regardless of variability in crystallinity), most likely due to the analogous surface chemistries as a result of the similarity between the biological processes of cellulose production in nature.236 To provide the reader with an idea of the order of magnitude of the surface energy of cellulose, a few reported values are shown in Table 1.

Table 1. Values for the Dispersive and Polar Surface Energies (γ) of Various Cellulosic Materialsa.

| cellulosic material | γD (mN m–1) | γp (mN m–1) | γT (mN m–1) | method of quantificationb | ref |

|---|---|---|---|---|---|

| hardwood α-cellulose | 31.9 | iGC-SEA | (237) | ||

| hardwood α-cellulose extracted with acetone | 47.4 | iGC-SEA | (237) | ||

| Avicel MCC | 31.8 | 23.9 | 55.7 | CA | (238) |

| Avicel MCC | 51.8 | 0 | 51.8 | TLC | (239) |

| Sigmacell 20 | 52.9 | 4.2 | 57.2 | TLC | (239) |

| Whatman paper | 32.1 | 20.2 | 52.3 | CA | (238) |

| Technocel fibers | 20 | CA | (240) | ||

| amorphous cellulose beads | 70.5 | iGC-SEA | (241) | ||

| TEMPO-oxidized CNF | 42–46 | iGC-SEA | (242) | ||

| enzymatic CNF | 51.5 | iGC-SEA | (242) | ||

| cellulose II, critical CO2 dried | 49.6 | 6.1 | 55.8 | iGC-SEA | (243) |

| cellulose II, freeze-dried from t-BuOH | 52.3 | 6.9 | 59.1 | iGC-SEA | (243) |

| bacterial cellulose | 47.2–58.3 | iGC-SEA | (244) | ||

| amorphous cellulose | ca. 35 | ca. 17 | ca. 52 | CA | (245) |

γD refers to the dispersive component, γP to the polar component, and the γT to the total surface energy.

Abbreviations for method of surface energy quantification: inverse gas chromatography–surface energy analyzer (iGC-SEA); thin layer chromatography (TLC); contact angle measurements (CA).

In general, the total surface energy of cellulose is between 50 and 60 mN m–1 although the contribution of the dispersive and polar components can be significantly different, depending on the type of the cellulose in question.

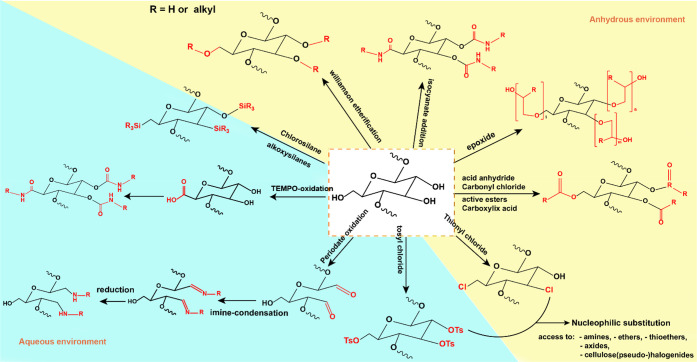

It is evident that altering the surface chemistry of cellulose will have a significant impact on its interactions with water. The surface energies of nanocelluloses are highly tunable through a multitude of surface modification routes,3,118,119,246−252 which can render the material more hydrophilic or less hydrophilic. These modification pathways will be discussed in detail in section 2.1.

It should also be noted that nanocellulose structures can readily swell upon exposure to water. However, the dynamic changes caused by the wetting and consecutive drying of these structures may significantly alter the perceived surface energies of the nanocellulose surfaces.232,245,253,254 For example, CNFs and CNCs dried through freeze-drying tend to have a lower surface energy than those dried by air-drying, spray-drying or supercritical-drying, which is linked to their different state of aggregation.255

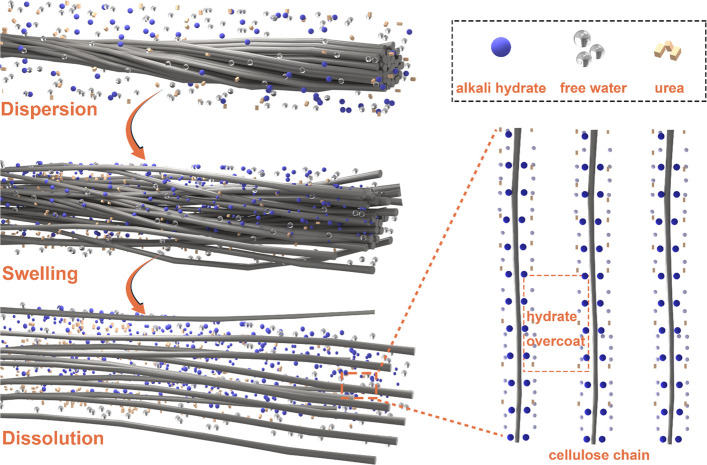

2.4.1.3. Water Insolubility and the Effect of Water on Cellulose Dissolution

Cellulose is insoluble in water and other conventional solvents, inorganic and organic alike. However, several solvent systems for cellulose include water as a central component. N-Methylmorpholine N-oxide (NMMO)/water, NaOH/water, and urea/NaOH/water are among the most commonly used water-containing cellulose solvents. Unusually rapid dissolution of cellulose has been reported in urea/LiOH/water and urea/NaOH/water,256 albeit at temperatures below 0 °C (Figure 5). The role of water in cellulose dissolution differs a great deal depending on the solvent. In NMMO, for example, a rather precise water content of 13.7 wt % is necessary to establish the monohydrate form of NMMO, necessary for dissolving cellulose. In many recipes for dissolving cellulose, water plays a role in swelling and improving the accessibility of the chains to the solvent. Chen et al. have studied the kinetics of the dissolution and swelling of different cellulose fibers in the ionic liquid 1-ethyl-3-methylimidazolium acetate ([EMIM][OAc]) and reported that the solvent power was modified from very good (neat ionic liquid) to moderate (with 5 wt % water) and weak (15 wt % water). They showed that while the rate of fiber dissolution in neat ionic liquid depends on fiber accessibility and solvent viscosity, the water-induced decrease in solvent power dominates the general fiber behavior.257 Furthermore, factors such as cellulose DP, degree of crystallinity, morphology, surface chemistry, degree of substitution, and the surface tension of the solvent all play a pivotal role in the solubility of cellulose. Because dissolution is not a prominent or often-utilized phenomenon with nanocellulose (it obviously destroys the nanoscale morphology), we shall not discuss it further. Several reviews discussing the mechanism of cellulose dissolution in various solvent systems are available in the literature.258−263

Figure 5.

Schematic representation of dispersion, swelling, and dissolution of cellulose in water.

2.4.2. Behavior and Dynamics of Water within Nanocellulose Matrices

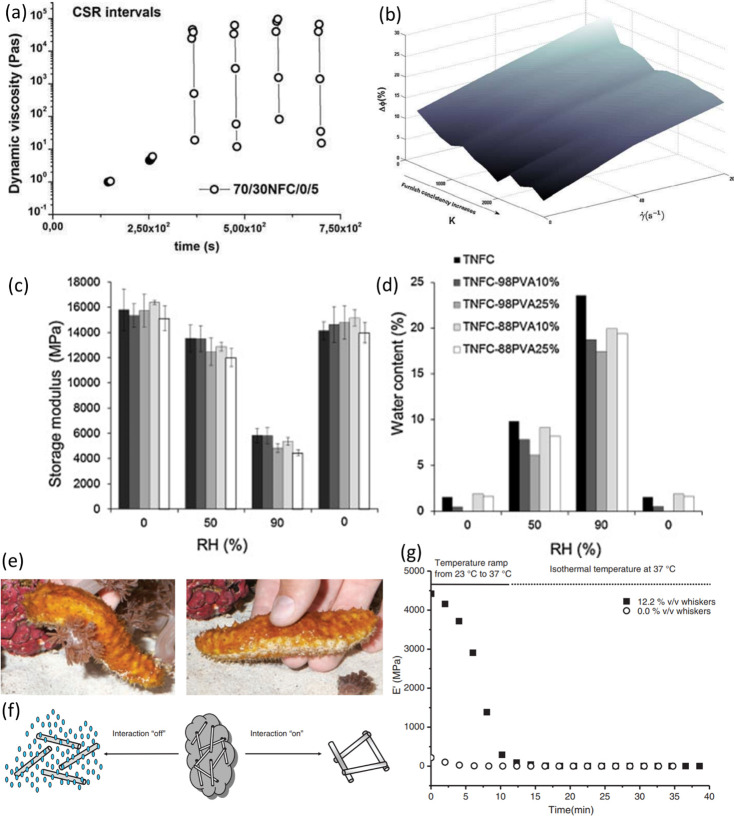

2.4.2.1. Network Formation and Viscoelastic Behavior

Nanocellulose dispersions form arrested phases (i.e., a state of kinetic arrest), in the case of CNFs even at very low solids contents. Different factors such as nanocellulose aspect ratio and flexibility, surface charge density, counterion of surface charge groups, along with ionic strength of the dispersion, contribute to critical concentration at which this phenomenon occurs.130,264−266 The formation of an arrested phase is driven by the decrease of nanocellulose mobility either by increasing the suspension concentration or by reducing the effects of electrostatic or steric repulsion between nanocellulose fibrils/crystals.265 In either case, once the nanocellulose suspension reaches a critical concentration, it will go through a transition from a dispersed liquid-like state to an arrested solid-like phase. Depending on the dominant interparticle forces, two kinds of ideal arrested phases exist. In a system dominated by electrostatic Coulomb repulsion (more specifically from electrostatic double-layer repulsion due to osmotic pressure), a decrease in the interparticle distance is hindered by so-called caging effects, which leads to the formation of a colloidal glass.265,267,268 When van der Waals attractive forces are the dominant forces, the increase in concentration leads to the formation of a gel characterized by a percolated network often with a given fractal dimension.265,267,268 In nanocellulose suspensions, both repulsive and attractive forces play a role. For dilute suspensions (i.e., volume fractions below 0.05 wt %), concentrating the nanocellulose suspension will lead to the formation of a mostly reversible colloidal glass with a threshold concentration that is inversely proportional to the aspect ratio of the nanocellulose. On the other hand, increasing the ionic strength of a dilute nanocellulose suspension will result in a screening of repulsive forces between nanocellulose fibrils/crystals and the suspension will transition into an irreversible gel.265 At higher solids content, the dynamics involving the formation of an arrested phase may be more complicated. For example, the colloidal interactions of carboxylated CNF suspensions with concentrations ranging between 0.5 and 4.9 wt % are dominated by electrostatic Coulomb repulsion in the lower range of concentrations and by van der Waals attraction forces in higher range.121

The transition from a suspension to an arrested phase is quite different between CNF and CNC suspensions. Due to their rod-shaped structure and inflexibility, CNCs form a gel at relatively high concentrations. The critical gelation concentration of CNC suspensions is approximately 10 wt %. However, this is of course dependent on their aspect ratio, purity, ionic strength, and surface charge density. At critical concentrations below their gelation concentration, CNCs have a tendency to phase separate into a chiral nematic (anisotropic) phase in which the alignment of CNCs results in birefringence and an isotropic phase where the CNCs remain in suspension and repulsive electrostatic interactions dominate.130 In the case of CNFs, the formation of an anisotropic phase is hindered by the early onset of an arrested phase promoted by their tendency to form entanglements as a consequence of their higher aspect ratios and their flexibility. Nevertheless, CNFs can form anisotropic nematic phases under some conditions.121,269

2.4.2.2. “Types of Water” within Nanocellulose Networks

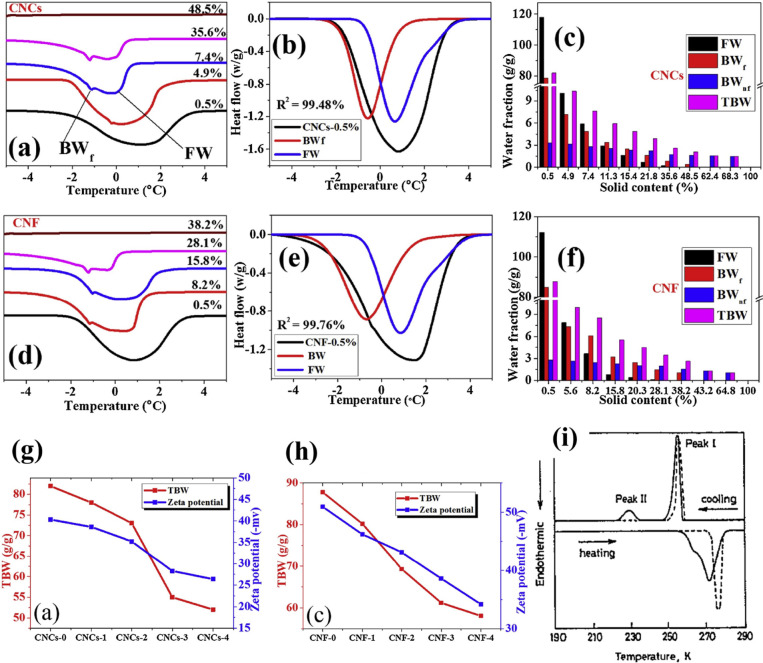

Water within a nanocellulose network exists either as free water, which fills any voids due to capillary forces, and bound water, which interacts with the cellulose at specific sorption sites. At this stage, it is important to make a clear distinction in terminology: any water that is taken up by a cellulosic matrix is absorbed. However, absorbed water does not necessary interact with the cellulose through molecular interactions. When an interaction between the cellulose and water does occur, water is said to adsorb on the cellulose. Another means by which to distinguish the nature of water within a cellulose matrix, is that bound (or adsorbed) water is water present at moisture contents far below capillary condensation (i.e., the saturation point), while free (or absorbed) water is the water present in the matrix far above capillary condensation (i.e., close to saturation) (Figure 6a).270 With many routine experimental methods, such as dynamic vapor sorption (DVS) or water retention value (WRV), it is difficult, if not impossible, to distinguish between absorbed and adsorbed water, and hence, the predominant term for quantified water uptake is often “water sorption”.

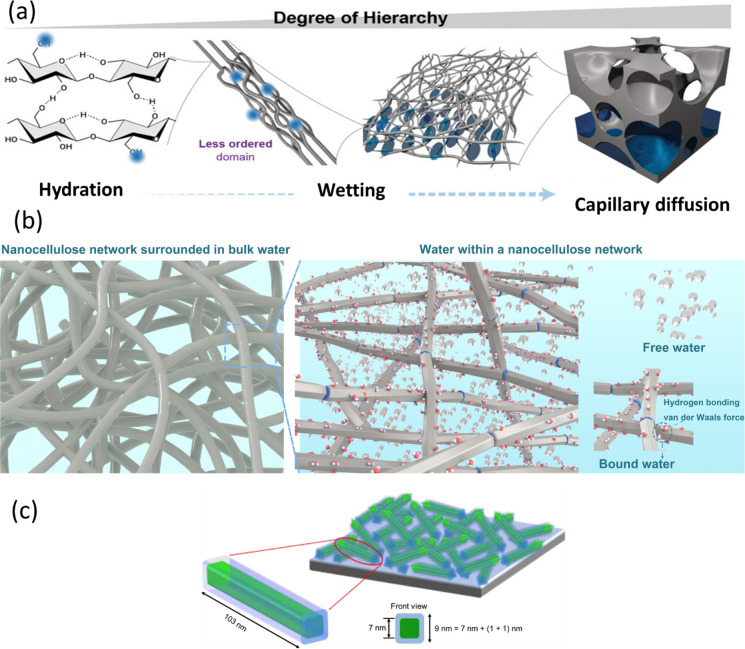

Figure 6.

Schematic representation of wetting and hydration of nanocellulose. (a) Water and nanocellulose interactions from a supramolecular hierarchical point of view.26 (a) Adapted from ref (26) under the terms of CC_BY. Copyright 2020 John Wiley and Sons. (b) Wetting of cellulose nanofibers, highlighting the different states of water (bulk, free, and bound water) within nanocellulose networks. (c) Wetting of cellulose nanocrystals (in green) surrounded by adsorbed water (light blue)271 (c) Adapted with permission from ref (271). Copyright 2015 American Chemical Society.

Interestingly, the properties of water within a nanocellulose network are highly dependent on whether the water is free (absorbed) or bound (adsorbed) (Figure 6b) based on the melting and freezing behavior of water within a nanocellulose network (as measured through differential scanning calorimetry (DSC) and explained in detail in section 4.2.5), water can be categorized as (i) free water, (ii) nonfreezing bound water, or (iii) freezing bound water.272,273 The thermal properties of free water are the same as pure water, while bound water shows lower transition temperatures due to its strong interaction with cellulose surfaces (primarily hydroxy groups) mediated by hydrogen bonding and the consequent restructuring of local water environments and nanoconfinement.270,274 Bulk water surrounding nanocellulose is distinguishable from free water, as it does not cause observable swelling in the cellulose matrix as in the case of free water.275

It is possible to detect whether water bound to cellulose is freezing bound water (or surface bound water) or nonfreezing bound water (or confined bound water) depending on its mobility as measured through 2H NMR and 1H NMR.270 This classification is particularly interesting (explained in more detail in section 4.2.4), as it allows one to directly connect the properties of water with its distribution inside cellulosic matrices such as fibers and nanocellulose networks. The characteristics of these networks have a great effect on the physicochemical properties of nanocellulose derived materials and on the properties of sorbed water.208 Another way to distinguish different types of water is thermoporosimetry, also discussed in detail in section 4.2.

CNFs form percolated fractal networks due to the formation of arrested phases upon an increase in concentration during which the 3D network of nanofibers shrink, decreasing the packing space between CNFs and forming agglomerates.121 Alternatively, phenomena such as coagulation, cross-linking, or ion exchange can be used to promote the formation of CNF networks. At the fiber saturation point, all of the intra-agglomerate (CNF–CNF interface) and interagglomerate (agglomerate–agglomerate interface) pores are fully hydrated.208 At the interagglomerate level, the surface bound water is located at the surface of the nanofiber belonging to two different agglomerates, while at the intra-agglomerate level, the confined bound water is present at the nanofibers interface belonging to the same agglomerates.270 Upon increasing hydration, the surface bound water becomes gradually more and more mobile due to the high accessibility between cellulose agglomerates. In contrast, the confined bound water is only marginally influenced by the hydration level due to the lower accessibility within the agglomerates270 Due to these dynamics, the surface bound water also is sometimes called “movable or mobile bound water”, while the confined bound water as “fixed or immobile bound water”.

2.4.2.3. Water Sorption Dynamics

The dynamics of water sorption by nanocelluloses are highly dependent on whether the nanocellulose is exposed to water vapor or liquid water as the sorption of liquid water is governed by hydrostatic pressure and capillary forces, which are not present in the sorption of water vapor. Generally speaking, the degree of water vapor sorption by nanocellulose is significantly lower than its liquid counterpart.276−278

Nanocelluloses can uptake a significant amount of water due to their extremely high surface area to volume ratio and their abundance of accessible hydroxy groups. Furthermore, the swelling of nanocellulose networks exposes even more surface, resulting in a higher number of hydroxy groups available for water sorption. Because they are the primary sites of interaction for water on the nanocellulose surface, rate of sorption, and desorption of water in nanocelluloses has been associated with the accessibility of hydroxy groups.215 The accessibility is governed by factors such as surface charge content (and charge counterion), degree of aggregation, geometric constraints, porosity, crystallinity, and the thermal history of the nanocellulose (see also section 2.4.1.1).

A number of quartz crystal microbalance with dissipation (QCM-D) and surface plasmon resonance spectroscopy (SPR) studies have been carried out on CNC271,279 and CNF280−282 model films to understand the swelling of nanocellulose networks. The kinetics of CNC film swelling as a function of solvent ionic strength and CNC surface charge was evaluated in an SPR study by Reid et al.283,284 Interestingly, in this work, the total water uptake capacity of the CNC films was independent of both CNC surface charge and the ionic strength of the solvent, seemingly due to the restrictions on swelling capacity resulting from the presence of van der Waals forces. However, it was clear that the rate of swelling was greatly impacted by surface charge and ionic strength. Niinivaara et al. gained quantitatively similar results in a combined QCM and ellipsometry study on CNC thin films: apparently a 1 nm layer of water surrounds the CNCs at high (>90%) relative humidity values (Figure 6c).271 Similarly, other works have also demonstrated that the water sorption capacity of (nano)celluloses generally increases with increasing surface charge content, in addition to changes in charge counterion, ionic strength, and pH.134,285

Hakalahti et al. studied the water vapor absorption mechanism and dynamics into model carboxylated CNF films.282 They showed that below 10% relative humidity (RH) water vapor is adsorbed mainly onto the surface of CNFs through specific interaction (e.g., hydrogen bonding), whereas at humidity values between 10% and 75%, multilayers of water molecules were built up inside the CNF network following a Flory–Huggins model. When the RH exceeded 75%, the water vapor condensed in the CNF network via cluster formation, promoting the swelling of the thin film. During sorption, the water volume fraction increased from 0.21 at 75%RH to 0.59 at 97%RH.282

The water vapor uptake capacity of CNFs is generally higher than CNCs due to the flexibility of the network, higher hydroxy group accessibility, and residual lignocellulosic components such as hemicellulose. At 95%RH, CNFs have at least 10% more moisture than CNCs. Because of their rigidity, CNCs do not form entangled networks such as CNFs. Comparing celluloses I and II, cellulose II has higher uptake due to the difference in crystallinity, texture, and overall morphology of the samples.215

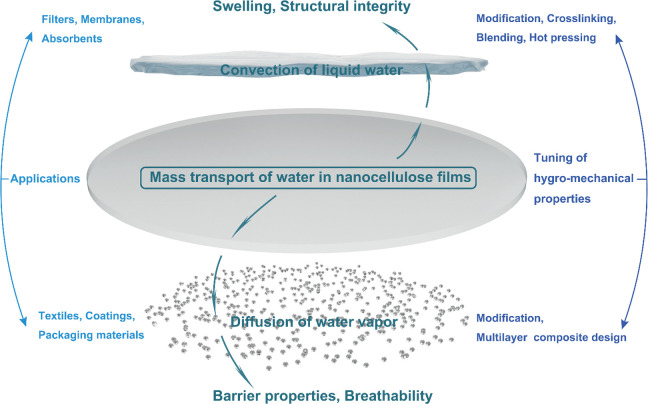

2.4.2.4. Mass Transport

The mass transport of liquid water in porous cellulosic materials occurs as a result of capillary flow (or wicking), which is often modeled using eq 1 as established independently by both Richard Lucas286 and Edward W. Washburn,287 which provides information on how liquids move through porous media and can be used to characterize the surface energies of powdered solids.254,288,289

| 1 |

where x is the distance traveled, γl is surface tension of the liquid (i.e., water), r is the radius of the (circular) flow channel, θ is the contact angle (assumed static) between the solid surface and the liquid (i.e., cellulose and water), η is the dynamic viscosity of the liquid (i.e., water), and t is time.

On the contrary, the mass transport of water vapor through porous materials proceeds via diffusion; for dense materials, a solution-diffusion mechanism is usually assumed.290 The diffusion driven mass transport of water vapor through porous materials is sensitive to changes in temperature and in relative humidity (and thereby partial pressure).291 As in the case of wetting and sorption, material properties such as thickness,292 crystallinity,293 hydrophilicity,294 along with porosity, and pore size and structure,295 all influence the rate of mass transport and are all applicable to materials such as nanocelluloses.

As most assembled nanocellulosic structures are porous, the relevant phenomena for water vapor transport through nanocellulose materials are Fickian diffusion, Knudsen diffusion, and surface diffusion. Fickian diffusion refers to classic diffusion governed by local differences in chemical potential, where the interactions between the diffusing molecule and the solid material are insignificant (i.e., when the porosity is high and pore size is large).296 Knudsen diffusion, on the other hand, occurs when the pore size of the solid material is comparable to or smaller than the mean free path of the diffusing molecule, leading to significant interactions between the vapor and the solid.297 Surface diffusion, on the other hand, occurs when molecules are mostly adsorbed on a surface, only to jump to the next adsorption site.290 All of these mechanisms may be found in water vapor mass transport across cellulosic materials and nanocelluloses, depending on their porosity, pore size, and surface energy.253 While some efforts have been made to model the observed water vapor transport of various cellulosic materials by these mechanisms, most of the literature on the uptake of water vapor by cellulose does not offer a full theoretical explanation to the experimentally observed behavior.290,291,298

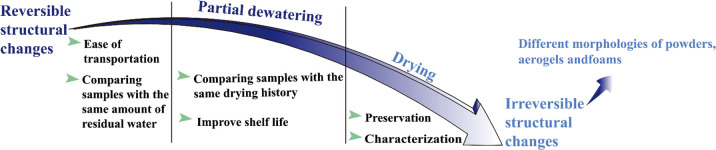

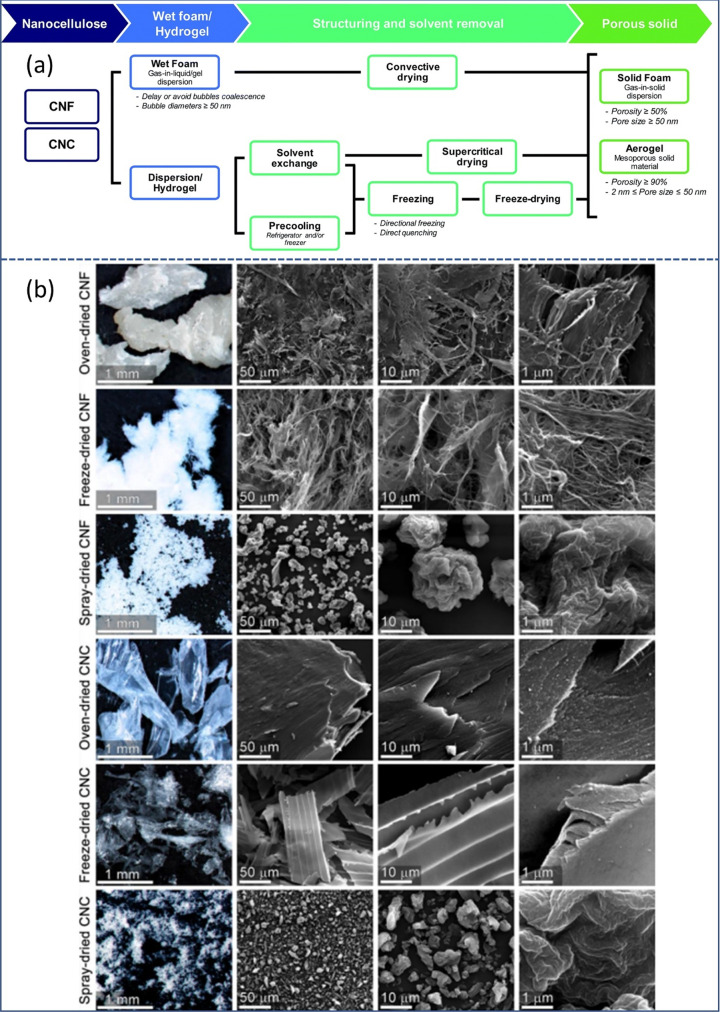

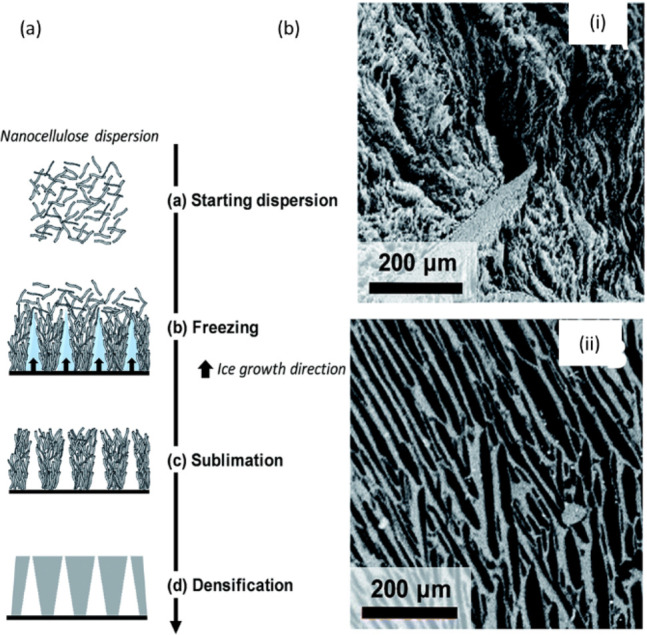

2.4.2.5. Dewatering of Nanocellulose

Recently, Sinquefield et al. published an exhaustive review on the dewatering and drying of nanocellulose.299 Maintaining the nanoscale properties of nanocelluloses upon dewatering/drying represents a distinct challenge, given the structural changes and irreversible aggregation which occur during the process. The most common dewatering procedures used for nanocelluloses include centrifugation,300 pressing,301,302 filtration,303−306 shear stress induced dewatering,307−311 and solvent exchange followed by solvent evaporation.312,313 More recently, Guccini et al. have used forward osmosis to reproducibly dewater CNFs suspensions into hydrogels with a solid content up to 12 wt %. Using this approach, they were able to retain the viscoelastic properties of the CNFs upon redispersion.314 After dewatering, a further drying stage is often required to bring nanocellulose to the dried state. The most common technologies used for drying are air and oven drying,126,315−317 freeze-drying,318−325 supercritical CO2 drying,21,315,326,327 and spray drying.315,327−329 Each of these drying techniques results in nanocellulose structures with different properties, such as thermal stability, degree of crystallinity, and char residue (upon heating or carbonization). For example, CNF films/aerogels prepared through supercritical drying have a lower stability and degree of crystallinity than those prepared by air drying or spray drying.327 As such, it is important to note that the drying history of nanocelluloses and nanocellulose-based materials must be carefully taken into consideration, given the influence of the drying method on their physicochemical properties.

Hornification is one of the main phenomena leading to the changes in nanocellulose materials upon drying, presumably by co-crystallization or irreversible binding of hydrophobic sites in the microfibril (see also section 2.2.2). Compared to fibers, hornification is exacerbated to a great deal in a nanocellulose networks because of the immense surface area of CNFs or CNCs. Nanocelluloses can be efficiently dried at temperatures below 100 °C under vacuum or by freeze-drying, but upon exposure to ambient conditions, atmospheric moisture will promptly be resorbed into the material.330,331 In fact, in ambient conditions, air-dried nanocelluloses contain between 2 and 5 wt % residual moisture.327 Hornification usually becomes dominant already at higher water contents, however, leading to a permanent decrease in hydroxy group accessibility. Additionally, nanocelluloses with surface moieties such as carboxyl and aldehyde groups may undergo chemical cross-linking under these conditions, further enhancing the effects of hornification.332 As a result, the dehydrated nanocelluloses are unable to be returned to their initial state upon rehydration.