Abstract

Described in this report is an enantioselective route toward the chamigrene natural product family. The key disconnections in our synthetic approach include sequential enantioselective decarboxylative allylation and ring-closing olefin metathesis to form the all-carbon quaternary stereocenter and spirocyclic core present in all members of this class of compounds. The generality of this strategy is demonstrated by the first total syntheses of elatol and the proposed structure of laurencenone B, as well as the first enantioselective total syntheses of laurencenone C and α-chamigrene. A brief exploration of the substrate scope of the enantioselective decarboxylative allylation/ring-closing metathesis sequence with fully substituted vinyl chlorides is also presented.

1. Introduction

The chamigrene subclass of sesquiterpenes is an abundant and continually expanding family of natural products, with over one hundred members discovered to date (Figure 1).1,2 Isolated from a variety of sources including terrestrial and marine plants, these compounds have demonstrated a diverse array of biological activity and have been suggested to play a chemical defense role in the marine alga genus Laurencia.3 For example, elatol (1), originally isolated from Laurencia eletata,2a has displayed antifeedant activity,3a antifouling activity,4a antibacterial activity (including human pathogenic bacteria),3b–c,4b antifungal activity,3d and cytotoxicity against HeLa and Hep-2 human carcinoma cell lines.4c As a consequence, significant effort has been devoted to the total synthesis of several members of this class;5 nevertheless, no general strategy for their preparation has yet been developed. Inspired by both this lack of a common approach and the overall synthetic challenge posed by these molecules, we sought to generate a new route toward the chamigrene family that would allow ready access to a wide range of its constituents in enantioenriched form. Herein we report in full our efforts toward this goal, culminating in the first enantioselective total syntheses of elatol (1), α-chamigrene (5), laurencenone C (8), and the proposed structure of laurencenone B (7).6

Figure 1.

Examples of chamigrene natural products.

Structurally, chamigrenes are characterized by a spiro[5.5]undecane core bearing an all-carbon quaternary stereocenter at the spirocycle junction. Moreover, this stereocenter is found to occur in both enantiomeric series in nature. The moderately-to-densely functionalized A ring also contains a second, non-stereogenic quaternary carbon that is vicinal to the spirocycle junction, while the B ring often possesses a tri- or tetrasubstituted olefin, or functionality readily derived from such an alkene. We envisioned a strategy toward these challenging motifs based on methodological advances recently reported by our laboratories. Specifically, enantioselective decarboxylative allylation7 could be used to generate either enantiomer of the all-carbon quaternary stereocenter, while ring-closing metathesis (RCM)8 could be employed to concomitantly provide the B-ring tri- or tetrasubstituted olefin and the spirocyclic core of 10 (Eq. 1).

|

(1) |

Through proper functionalization, we anticipated that intermediate 11 could thus serve as a common precursor to a variety of chamigrene natural products.

2. Results and discussion

2.1. Synthesis of the proposed structure of laurencenone B (7)

From the outset, we set as the final goal of our studies the preparation of elatol (1), one of the more biologically interesting and synthetically demanding chamigrenes. Initially, however, we chose to focus on a simpler target in order to validate our synthetic approach. The proposed structure of laurencenone B (7) possesses features identical to those of elatol (1) with respect to our key disconnections, namely the all-carbon quaternary stereocenter and B-ring tetrasubstituted olefin, but contains a less elaborately functionalized A ring. Also like 1,9 no total synthesis of 7 had yet been reported.10 Scheme 1 outlines our retrosynthetic analysis.11 Laurencenone B (7) could ultimately arise from spirocycle 12 through Stork-Danheiser alkylation using an appropriate methyl anion source. Compound 12 in turn could be obtained by RCM of α,ω-diene 13. Although unprecedented in the literature,12,13 we anticipated formation of a fully substituted chlorinated olefin could be achieved with the enhanced reactivity of catalyst 49 (vide infra).8 α,ω-Diene 13 itself could be the product of an enantioselective decarboxylative allylation of racemic β-ketoester (±)-14 using the Pd(0) complex of a phosphinooxazoline (PHOX) ligand.14,15 Finally, intermediate 14 could be prepared from commercially available dimedone (15) via vinylogous ester 11.16

Scheme 1.

We began our synthetic efforts with the condensation of dimedone (15) and isobutyl alcohol to afford known vinylogous ester 11 as shown in Scheme 2.16 Acylation of 11 with carbonate 16 then provided racemic β-ketoester (±)-17, albeit in low yield. Unfortunately, direct alkylation of 17 with 4-iodo-2-methyl-1-butene (18)17 did not yield any of the desired product (±)-14 even under forcing conditions. Alternative routes to (±)-14 were briefly examined; however, concurrent model studies indicated that the proposed β-ketoester (±)-14 would likely not be a viable substrate in the enantioselective decarboxylative allylation step. Racemic β-ketoester analog (±)-22, readily prepared due to the absence of β-dimethyl substitution, surprisingly provided less than 10% conversion to allylated product 24 under our standard reaction conditions at 65 °C after 22 h (Scheme 3). Although a rigorous explanation of this unexpectedly low reactivity awaits further study, we speculated that the presence of the tethered olefin substituent at the α-position may interact with the Pd(0)-PHOX complex, thus interfering with oxidative addition to the allyl ester moiety. Similar retardation of reaction rates has been observed with analogous substrates in our laboratories.18

Scheme 2.

Scheme 3a.

a dmdba = bis(3,5-dimethoxybenzylidene)acetone.

To circumvent the anticipated poor performance of proposed β-ketoester (±)-14 in the enantioselective decarboxylative allylation, we attempted to take advantage of the ability to effect this transformation through one of two other structurally discreet substrates: namely a trimethylsilyl enol ether (25) or enol carbonate (26) (Eq. 2).

|

(2) |

Not only would this approach provide the necessary reactivity to produce α,ω-diene 13, it would also alleviate the need to preform vicinal quaternary carbon centers, allowing such functionality to be installed in the allylation step. To this end, we prepared vinylogous ester (±)-27, the immediate precursor to both 25 and 26 (Scheme 4). Direct conversion of 11 to (±)-27 by alkylation with 4-iodo-2-methyl-1-butene (18) proceeded in only low conversion;19 alternatively, 1,4-addition to methyl vinyl ketone (MVK)20 followed by Wittig methylenation of the crude product mixture led to (±)-27 in good yield over two steps. While an attempt to capture the corresponding lithium enolate of (±)-27 with trimethylsilyl chloride did not generate an isolatable product,21 treatment of the same enolate with TMEDA and chloroformate 20 afforded stable enol carbonate 26 in 73% yield. Gratifyingly, exposure of 26 to our standard allylation conditions22 at 40 °C now provided α,ω-diene (+)-13 in 52% yield by 1H NMR and 78% ee. Slightly higher enantioselectivity (81% ee) could be obtained by reaction at 24 °C,23 but at a significant expense of yield (28% by 1H NMR, 23% isolated).

Scheme 4.

Having achieved base reactivity using enol carbonate 26, we sought to further optimize the enantioselective decarboxylative allylation in order to generate a synthetically viable reaction. Based on the temperature dependence of enantioselectivity in our initial screening, we reasoned that increasing catalyst reactivity should allow access to lower reaction temperatures and thus improved ee. Careful scrutiny of the proposed catalytic pathway24 (Scheme 5) led us to hypothesize that the low reactivity of 26 was likely derived from one of three scenarios: (1) slow oxidative addition of Pd(0)-PHOX complex 29 to allyl enol carbonate 26; (2) slow decarboxylation of Pd(II)-enol carbonate 31 to provide Pd(II)-enolate 32; or (3), slow alkylation of 32 to yield the desired product (+)-13. To differentiate between these possibilities, we conducted the set of control reactions depicted in Scheme 6. Subjection of enol carbonate 26 to conditions developed in our laboratories for enantioselective decarboxylative protonation25 readily afforded olefin 27,26 demonstrating that oxidative addition and decarboxylation proceed as desired. Furthermore, less sterically-hindered deschloro analog 33 underwent facile decarboxylative allylation to yield bis(olefin) 34. From these studies, slow alkylation was determined to be the problematic step in this transformation.

Scheme 5.

Scheme 6a.

a Conditions: (a) HCO2H, Pd(OAc)2 (10 mol%), (−)-23 (12.5 mol%), MS 4Å, benzene, 40 °C, 3.1 h; (b) Pd(dmdba)2 (10 mol%), (−)-23 (13 mol%), benzene, 40 °C, 1.1 h.

In order to enhance the sluggish rate of alkylation identified above, we attempted to increase the electrophilicity of the π-allyl Pd(II) intermediate by incorporating electron-withdrawing substituents into the PHOX ligand framework.27 As shown in Table 1, moving from electron-rich to electron-deficient ligands resulted in a dramatic improvement in conversion from <20% to >99%, with good selectivity for the desired allylation product (+)-13 over the undesired protonation byproduct 27. A solvent screen employing one of the most active PHOX analogs, ligand (−)-40, revealed higher enantioselectivity with aromatic solvents compared to ethereal solvents (Table 2), while a temperature screen using the two most active ligands, (−)-40 and (−)-41, demonstrated the latter to exhibit the sharpest dependence of enantioselectivity on temperature (Table 3). Ultimately, the best compromise between reactivity and selectivity was provided by ligand (−)-41 in benzene at 13 °C (Table 3, entry 5), affording bis(olefin) (+)-13 in 90% isolated yield and 87% ee (Table 4, entry 2). A brief examination of closely related analogs of enol carbonate 26 gave similarly good yields and enantioselectivities for the corresponding α,ω-dienes (Table 4, entries 1, 3–4).

Table 1.

Effect of ligand electronics on enantioselective decarboxylative allylation.

| entry | ligand | conversiona (%) | allylationa,b (%) | eec,d (%) |

|---|---|---|---|---|

| 1 |

|

11 | 6 | n.d. |

| 2 |

|

18 | 14 | n.d. |

| 3 |

|

12 | 6 | n.d. |

| 4e |

|

59 | 52 | 78 |

| 5 |

|

75 | 60 | 76 |

| 6 |

|

98 | 87 | 83 |

| 7 |

|

>99 | 92 | 75 |

| 8 |

|

>99 | >99 | 78 |

Determined by 1H NMR spectroscopic analysis of the crude product mixture.

The remaining mass balance was comprised of protonation byproduct 27.

Determined by chiral HPLC analysis.

n.d. = not determined.

7 h reaction time.

Table 2.

Effect of solvent on enantioselective decarboxylative allylation with ligand (−)-40.

| entry | solvent | conversiona (%) | allylationa,b (%) | eec,d (%) |

|---|---|---|---|---|

| 1 | TEA | 7 | 3 | n.d. |

| 2 | Et2O | >99 | 88 | 67 |

| 3 | THF | >99 | 90 | 71 |

| 4 | 1,4-dioxane | >99 | 87 | 72 |

| 5 | toluene | >99 | 90 | 76 |

| 6 | benzene | >99 | 93 | 77 |

Determined by 1H NMR spectroscopic analysis of the crude product mixture.

The remaining mass balance was comprised of protonation byproduct 27.

Determined by chiral HPLC analysis.

n.d. = not determined.

Table 3.

Effect of temperature on enantioselective decarboxylative allylation with ligands (−)-40 and (−)-41.

| entry | ligand | solvent | T (°C) | t (h) | conversiona (%) | allylationa,b (%) | eec (%) |

|---|---|---|---|---|---|---|---|

| 1 | (−)-40 | benzene | 40 | 13 | >99 | 92 | 75 |

| 2 | (−)-40 | benzene | 30 | 13 | >99 | 93 | 77 |

| 3 | (−)-41 | benzene | 40 | 13 | >99 | >99 | 78 |

| 4 | (−)-41 | benzene | 30 | 15 | >99 | 97 | 83 |

| 5 | (−)-41 | benzene | 13 | 24 | >99 | 95 | 87 |

| 6 | (−)-41 | toluene | 0 | 17 | 72 | 63 | 89 |

Determined by 1H NMR spectroscopic analysis of the crude product mixture.

The remaining mass balance was comprised of protonation byproduct 27.

Determined by chiral HPLC analysis.

Table 4.

Scope of enantioselective decarboxylative allylation with ligand (−)-41.

| entry | enol carbonate | R | n | α,ω-diene | yielda (%) | eeb (%) |

|---|---|---|---|---|---|---|

| 1 | 42 | Me | 1 | (+)-45 | 92 | 91 |

| 2 | 26 | Me | 2 | (+)-13 | 90 | 87 |

| 3 | 43 | Me | 3 | (−)-46 | 91 | 90 |

| 4 | 44 | H | 2 | (+)-24 | 80 | 94 |

Isolated yield.

Determined by chiral HPLC analysis.

We next turned our attention to the completion of the chamigrene spirocyclic core via RCM of bis(olefin) (+)-13. In a limited survey of catalysts, second generation complex 47 provided moderate conversion to the desired tetrasubstituted olefinic product (−)-12 and minor unidentified byproducts, while complex 48 yielded comparable reactivity and substantial unknown impurities (Table 5, entries 1 and 2). Catalyst 49, however, afforded rapid and clean conversion under our standard conditions (Table 5, entry 3), furnishing spirocycle (−)-12 in 97% isolated yield (Table 6, entry 2). Interestingly, this catalytic system proved ineffective when applied to the RCM of the α,ω-diene analogs synthesized above. Removal of the dimethyl substitution vicinal to the spirocycle junction led to significantly diminished conversion (Table 6, entry 4), while extension or contraction of the homoallyl chain by a single methylene unit resulted in complete loss of reactivity (Table 6, entries 1 and 3). Similarly, a simplified acyclic substrate (53) produced little of the ring-closed product using catalyst 49 (Eq. 3).

|

(3) |

This seemingly unique reactivity of intermediate (+)-13 was unanticipated, and efforts to understand the basis of these effects are ongoing.

Table 5.

Catalyst comparison in RCM of α,ω-diene (+)-13.

Determined by 1H NMR spectroscopic analysis using 1,4-bis(trimethylsilyl)benzene as an internal standard.

Conversion values are approximate due to overlapping of significant amounts of unknown impurities with (+)-13 in the 1H NMR spectrum.

Table 6.

Scope of RCM with catalyst 49.

| entry | α,ω-diene | R | n | spirocycle | Result |

|---|---|---|---|---|---|

| 1a | (+)-45 | Me | 1 | 50 | no conversionc |

| 2b | (+)-13 | Me | 2 | (−)-12 | 97% yieldd |

| 3a | (−)-46 | Me | 3 | 51 | no conversionc |

| 4b | (+)-24 | H | 2 | 52 | 19% conversionc,e |

C6D6.

Benzene.

Determined by 1H NMR spectroscopic analysis of the crude product mixture.

Isolated yield.

Did not determine optical rotation.

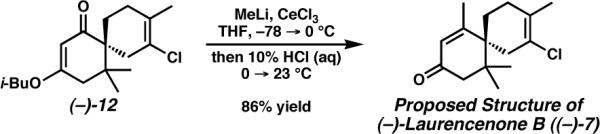

With spirocycle (−)-12 in hand, all that remained to complete Laurencenone B (7) was Stork-Danheiser alkylation using methyl anion. While methyl lithium alone added only very slowly to vinylogous ester (−)-12,28 inclusion of CeCl329 provided a significant increase in reaction rate,30 generating (−)-Laurencenone B ((−)-7) in 86% isolated yield after acid-mediated hydrolysis and elimination (Scheme 7). Overall, the first total synthesis of the proposed structure of (−)-Laurencenone B ((−)-7) was carried out in seven steps and 37% yield from dimedone (15). Unfortunately, discrepancies existed between the published 1H NMR data for the natural product2g and that of the synthetic material, although the single IR peak reported did match. Furthermore, no 13C NMR data or natural sample was available for comparison. 1H NMR, 13C NMR, and IR data for semisynthetic (+)-laurencenone B ((+)-7)10 did however match that of the synthetic material, while the opposite sign of optical rotation was obtained.31 Based on these observations,32 we conclude that the structure of the natural product designated as laurencenone B (7) has been incorrectly assigned.

Scheme 7.

2.2. Syntheses of laurencenone C (8) and α-chamigrene (5)

Having established a viable synthetic route to the chamigrene natural product family, we chose to demonstrate the generality of this strategy by preparing the related compounds laurencenone C (8)2g–h and α-chamigrene (5).2e Although four racemic total syntheses of (±)-laurencenone C ((±)-8)5a–c,e and ten of (±)-α-chamigrene ((±)-5)5a–c,33 have been previously reported, no enantioselective approaches have yet been devised.34,35 Conversion of (±)-8 to (±)-5 has been described by both Takeshita5a and Chen,5b and retrosynthetically we planned the same final two-step sequence to access α-chamigrene (5) (Scheme 8). Laurencenone C (8) could then be traced back to vinylogous ester (±)-27, the same intermediate used for (−)-Laurencenone B ((−)-7), through an analogous set of transformations. In the forward direction, acylation of compound (±)-27 with allyl chloroformate (55) proceeded smoothly to provide enol carbonate 33 in 70% yield (Scheme 9). Now in the absence of a 2-chloro substituent on the allyl moiety (cf. Table 3, entry 6), enol carbonate 33 displayed excellent reactivity at 0 °C in the enantioselective decarboxylative allylation, affording α,ω-diene (+)-34 in 87% yield and 87% ee. RCM, followed by methyl cerium addition29 31, 30 32 and acid-mediated hydrolysis/elimination, then yielded (−)-laurencenone C (8) in seven steps and 31% overall yield from dimedone (15).36 Following a modified variant of the reported procedures,37 (−)-8 was subsequently condensed with ethanedithiol (57) to afford dithiolane (−)-58 in 92% yield. Finally, reduction with Na0 5b provided (−)-α-chamigrene (5) in nine steps and 13% overall yield from 15,38 completing the first enantioselective total syntheses of both (−)-α-chamigrene (5) and (−)-laurencenone C (8).

Scheme 8.

Scheme 9.

2.3. Synthesis of elatol (1)

Following the completion of the syntheses of three simpler chamigrenes, we returned to the preparation of elatol (1) in order to demonstrate the ability of our approach to access a more complex member of this natural product class. Comparison of 1 to the proposed structure of (+)-laurencenone B ((+)-7) revealed the two molecules to be separated by three formal chemical reactions: (1) diastereoselective introduction of the 10-bromide; (2) diastereoselective reduction of the 9-ketone; and (3) transposition of the 7,8-olefin to the 7,14-position. We envisioned a simple two-step procedure to effect these transformations as shown in Scheme 10. Elatol (1) could ultimately be derived from sequential directed reductive olefin transposition and diastereoselective reduction of 10,14-dibromolaurencenone B (59) in a single pot.39 Dibromide 59 in turn could be the product of concomitant allylic and α'-bromination of (+)-laurencenone B ((+)-7).40 Substitution of PHOX ligand (+)-41 for (−)-41 in the initial synthesis of (−)-laurencenone B ((−)-7) would then provide the necessary starting material (+)-7.

Scheme 10.

Repetition of the (−)-laurencenone B ((−)-7) synthesis in the opposite enantiomeric series afforded (+)-7 in comparable yield and 87% ee as expected (Scheme 11). After surveying several electrophilic bromine sources41 and reaction conditions, conversion of (+)-7 to 10,14-dibromolaurencenone B (59) was effected in ≥8:1 dr42 using Br2 in the presence of HBr (aq)/AcOH,40c 42 presumably under thermodynamic control. Double reduction of α-bromoketone 59 with DIBAL39b 41 then provided (+)-elatol (1) in 32% isolated yield over two steps (3.9:1 syn:anti,43 11:1 SN2′:SN2).44 In comparison, reduction with LAH45 or Red-Al®46 provided ≤2:1 SN2′:SN2 for the reductive olefin transposition. The first total synthesis of (+)-elatol (1) was thus completed in only nine steps and 11% overall yield from dimedone (15).

Scheme 11.

3. Conclusion

We have successfully developed a concise and general enantioselective route to the chamigrene natural product family, resulting in the first total syntheses of (+)-elatol (1) and the proposed structure of laurencenone B (7), the first asymmetric total syntheses of (−)-α-chamigrene (5) and (−)-laurencenone C (8), and the first preparation of a fully substituted chlorinated olefin via RCM. Moreover, we have demonstrated the ability of our enantioselective decarboxylative allylation reaction to readily access enantioenriched vinylogous esters bearing vicinal quaternary carbon centers. Efforts to expand the scope of both the enantioselective decarboxylative allylation with vinylogous esters and the RCM with vinyl halides are the focus of ongoing studies.

4. Experimental

4.1. General

Unless stated otherwise, reactions were conducted under an ambient atmosphere. Anhydrous solvents were prepared by passing the solvents through activated alumina columns. Commercially obtained reagents were used as received, unless specified otherwise. Anhydrous diisopropylamine, triethylamine, N,N,N′,N′-tetramethylethylenediamine, and N,N′-dimethylethylenediamine (79) were obtained from distillation over CaH2. Methyl vinyl ketone, boron trifluoride diethyl etherate, and hexamethylphosphoramide were distilled prior to use. 4-Iodo-2-methyl-1-butene (18) was prepared according to the method of Hiersemann.17 Phosphinooxazoline ligands (−)-23 and (−)-35–41 were prepared according to the previously published method.27 28 Anhydrous CeCl3 was prepared according to the method of Imamoto.47 5-Iodo-2-methyl-1-pentene (67) was prepared according to the method of Boyer.48 Olefin 70 was prepared according to the previously published method.49 Salt 75 was prepared according to the method of Drauz.50 Phosphine 7851 was prepared according to the method of Bussaca.52 Thin-layer chromatography (TLC) was conducted with E. Merck silica gel 60 F254 pre-coated plates [0.25 mm (analytical) or 0.5 mm (preparative)] and visualized using a combination of UV light (254 nm), p-anisaldehyde staining, and potassium permanganate staining. TLC data include Rf and eluent (% by volume). ICN silica gel (particle size 0.032–0.063 mm), SiliCycle® SiliaFlash® P60 Academic Silica Gel (particle size 40–63 μm; pore diameter 60 Å), or Florisil® (100–200 mesh) were used for flash column chromatography. All flash column chromatographic purification steps are reported as follows: size of immobile phase column (length × diameter) and eluent (% by volume). Analytical chiral HPLC analyses were performed with an Agilent 1100 Series HPLC instrument. Preparative HPLC purifications were performed with a Beckman System Gold® or an Agilent 1200 Series HPLC instrument. 1H NMR spectra were recorded on a Varian Mercury 300 (at 300 MHz) or a Varian Inova 500 (at 500 MHz) instrument and are reported relative to the residual solvent peak (δ 7.26 for CDCl3, 7.16 for C6D6, and δ 2.05 for acetone-d6) or Me4Si (δ 0.00) in the case of CCl4. Data for 1H NMR spectra are reported as follows: chemical shift (δ ppm), multiplicity, coupling constant (Hz), and integration. 13C NMR spectra were recorded on a Varian Mercury 300 (at 75 MHz), or a Varian Inova 500 (at 126 MHz) instrument and are reported relative the residual solvent peak (δ 77.0 for CDCl3 and 128.06 for C6D6,). Data for 13C NMR spectra are reported in terms of chemical shift (δ ppm), as well as multiplicity and coupling constant (Hz) where applicable. 19F NMR spectra were recorded on a Varian Inova 500 (at 470 MHz) instrument and are reported in terms of chemical shift (δ ppm) without the use of a reference peak. IR spectra were recorded on a Perkin Elmer Spectrum BXII spectrometer and are reported in frequency of absorption (cm−1). Optical rotations were measured with a Jasco P-1010 polarimeter, using a 100 mm path-length cell. High-resolution mass spectra were obtained from the California Institute of Technology Mass Spectral Facility.

4.2. Procedures for the synthesis of the proposed structure of (+)-laurencenone B ((+)-7)

4.2.1. Vinylogous ester 1116

To a 500 mL round-bottomed flask equipped with a magnetic stir bar, a Dean-Stark trap, and a condenser was added dimedone (15) (10.0 g, 71.3 mmol), p-toluenesulfonic acid monohydrate (269 mg, 1.41 mmol), anhydrous benzene (120 mL), and isobutanol (33.0 mL, 358 mmol). The resulting solution was then heated to reflux in an oil bath and stirred for 21 h. After cooling to 23 °C, the reaction was washed with saturated NaHCO3 (aq) (100 mL), and the aqueous layer was extracted with EtOAc (3 × 100 mL). The combined organic layers were washed with brine (2 × 100 mL) and dried over MgSO4. Solvent was removed under reduced pressure, and the crude product mixture was azeotroped with toluene (4×) to remove excess isobutyl alcohol. The product was then distilled at 109–110 °C and 1.3 torr to provide vinylogous ester 1116 (12.561 g, 90%) as a slightly yellow liquid. 1H NMR (300 MHz, CDCl3) δ 5.33 (br s, 1H), 3.60 (d, J = 6.6 Hz, 2H), 2.28 (s, 2H), 2.21 (s, 2H), 2.03 (app. septet, J = 6.7 Hz, 1H), 1.07 (s, 6H), 0.97 (d, J = 6.7 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 199.6, 176.4, 101.4, 74.7, 50.7, 42.8, 32.4, 28.3, 27.7, 19.0; IR (neat film, NaCl) ν 2961, 2876, 1660, 1608, 1471, 1404, 1382, 1367, 1320, 1221, 1162, 1145, 1014, 992, 822 cm−1; HRMS (EI+) m/z calcd. for C12H20O2 [M]+: 196.1463, found 196.1463.

4.2.2. Olefin (±)-27

Part 1: Alkylation20

A 250 mL two-neck round-bottomed flask equipped with a 25 mL addition funnel, a stir bar, and two septa was flame dried under vacuum. After refilling with Ar, anhydrous THF (95 mL) and anhydrous diisopropylamine (2.0 mL, 14.3 mmol) were added via syringe, and the solution was cooled to 0 °C in an ice bath. n-BuLi (2.6 M in hexanes, 5.4 mL, 14.0 mmol) was added dropwise via syringe and the solution stirred at 0 °C for 1 h. The resulting LDA solution was then cooled to −78 °C over 16 min. Vinylogous ester 11 (2.50 g, 12.7 mmol) in anhydrous THF (10 mL) was then added dropwise over 16 min via the addition funnel, washing the funnel with THF (5 mL) upon complete addition. A yellow solution was obtained. After stirring at −78 °C for 1 h, methyl vinyl ketone (1.05 mL, 12.9 mmol) was added dropwise quickly via syringe. A slight exotherm was observed. The reaction was stirred for an additional 3 h at −78 °C, whereupon H2O (20 mL) was added. The mixture was warmed to 23 °C, at which time the organic layer was separated. The aqueous layer was extracted with Et2O (2 × 100 mL) and EtOAc (2 × 100 mL), at which point it was completely incorporated into the organic layers. The combined organic layers were washed with saturated NaHCO3 (aq) (300 mL) and brine (2 × 300 mL), respectively, and then dried over MgSO4. Solvent was removed under reduced pressure to provide 3.469 g of ketone (±)-61 as a reddish-orange liquid containing 12.9% by mass starting vinylogous ester 11, 4.1% by mass EtOAc, and 1% by mass Et2O as determined by 1H NMR spectroscopy. The crude yield corrected for impurities was 84%. The crude material was carried directly to Part 2. An aliquot from a separate run was purified by preparative thin-layer chromatography (0.25 mm thickness, eluted twice with 30% EtOAc/hexanes eluent). Rf 0.40 (eluting twice with 30% EtOAc/hexanes eluent); 1H NMR (500 MHz, CDCl3) δ 5.20 (s, 1H), 3.57 (dd, J = 9.4, 6.7 Hz, 1H), 3.54 (dd, J = 9.5, 6.6 Hz, 1H), 2.64 (ddd, J = 18.2, 9.0, 5.2 Hz, 1H), 2.51 (ddd, J = 18.3, 9.0, 6.6 Hz, 1H), 2.36 (d, J = 17.8, 1H), 2.19 (d, J = 17.6 Hz, 1H), 2.13 (s, 3H), 2.01 (app. septet, J = 6.7 Hz, 1H), 1.82–1.92 (m, 2H), 1.53–1.64 (m, 1H), 1.08 (s, 3H), 1.00 (s, 3H), 0.96 (d, J = 6.6 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 209.1, 202.6, 175.0, 100.4, 74.6, 55.9, 42.2, 41.3, 35.0, 30.2, 28.5, 27.7, 24.6, 20.0, 19.1; IR (neat film, NaCl) ν 2962, 2934, 2897, 2876, 1716, 1652, 1611, 1471, 1424, 1406, 1382, 1366, 1324, 1298, 1276, 1221, 1199, 1179, 1155, 1131, 1067, 1056, 1008, 994, 968, 952, 912, 904, 851, 831, 745, 710, 693, 627 cm−1; HRMS (EI+) m/z calcd. for C16H26O3 [M]+: 266.1882, found 266.1928.

Part 2: Wittig olefination

To a flame-dried 500 mL round-bottomed flask equipped with a magnetic stir bar was added methyltriphenylphosphonium bromide (8.00 g, 22.4 mmol). After attaching an oven-dried condenser and sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Anhydrous THF (255 mL) was added via syringe, and the mixture was cooled to 0 °C in an ice bath. Potassium tert-butoxide (2.39 g, 21.5 mmol) was added under positive Ar pressure to give a yellow mixture, and the system was flushed with Ar while being allowed to warm to 23 °C over 25 min. The crude ketone (±)-61 from Part 1 (3.461 g, 82% pure by mass, 10.7 mmol) in anhydrous THF (5 mL) was then added via syringe, washing the original flask with THF (5 mL). The reaction was placed in a 70 °C oil bath and stirred for 2 h. After cooling to 23 °C, the reaction mixture was filtered through a pad of silica gel (2.5 × 10 cm), eluting with THF (1 L). Solvent was removed under reduced pressure. Flash chromatography over silica gel (9 × 5 cm, 20% Et2O/pentane eluent) then provided olefin (±)-27 (2.489 g, 74% over two steps) as a slightly yellow liquid. The isolated yield for Part 2 corrected for impurities in crude ketone (±)-61 was 88%. Rf 0.33 (20% Et2O/pentane eluent); 1H NMR (500 MHz, CDCl3) δ 5.23 (s, 1H), 4.69–4.73 (m, 1H), 4.66–4.69 (m, 1H), 3.57 (d, J = 6.4 Hz, 2H), 2.33 (d, J = 17.6 Hz, 1H), 2.20 (d, J = 17.6 Hz, 1H), 2.08–2.19 (m, 1H), 1.960–2.07 (m, 2H), 1.90–1.96 (m, 1H), 1.72 (s, 3H), 1.55–1.69 (m, 2H), 1.07 (s, 3H), 0.98 (s, 3H), 0.96 (d, J = 6.8 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 202.3, 174.3, 145.9, 109.9, 100.6, 74.6, 56.3, 41.7, 36.6, 35.1, 28.6, 27.7, 24.6, 24.1, 22.6, 19.1; IR (neat film, NaCl) ν 2961, 2933, 2875, 1656, 1613, 1471, 1424, 1404, 1382, 1365, 1297, 1220, 1191, 1153, 1007, 885, 832 cm−1; HRMS (EI+) m/z calcd. for C17H28O2 [M]+: 264.2089, found 264.2081.

4.2.3.Chloroformate 2053

A 500 mL three-neck round-bottomed flask equipped with a 250 mL addition funnel, a stir bar, and three septa was flame dried under vacuum. After refilling with Ar, anhydrous Et2O (30 mL) was added via syringe, and the system was cooled to approx. −10 °C. Diphosgene (63) (7.7 mL, 63.8 mmol) was added dropwise via syringe and the solution was cooled to approx. −20 °C. 2-Chloroallyl alcohol (62) (5.0 mL, 62.8 mmol) in anhydrous Et2O (75 mL) was added dropwise via the addition funnel, and the solution was stirred at approx. −20 °C for an additional 15 min. The reaction was cooled to approx. −30 °C, and anhydrous triethylamine (8.8 mL, 63.1 mmol) in anhydrous Et2O (75 mL) was added dropwise via the addition funnel, generating a white precipitate. The reaction was then cooled to approx. −38 °C and stirred for 3 h, at which time it was allowed to warm to 23 °C while stirring for an additional 15 h. During this time, the reaction mixture became very thick, and Et2O (50 mL) was added to obtain a stirable suspension. Ar was bubbled through the suspension for 2 h to remove excess phosgene, employing a saturated NaHCO3 (aq)/triethylamine trap. The reaction mixture was filtered via vacuum filtration through a fritted funnel, and the filtrate was concentrated by rotary evaporation under reduced pressure. The product was then distilled at 50 °C and 20 torr to provide chloroformate 20 (4.987 g, 51%) as a colorless liquid containing a minor unidentified impurity (1% by area) by 1H NMR spectroscopy; 1H NMR (500 MHz, CDCl3) δ 5.58 (dt, J = 1.0, 2.0 Hz, 1H), 5.53 (d, J = 2.2 Hz, 1H), 4.84 (d, J = 0.7 Hz, 2H); 13C NMR (75 MHz, CDCl3) δ 150.4, 133.5, 117.4, 72.2; IR (CHCl3, KBr) ν 1775 cm−1; HRMS (EI+) m/z calcd. for C4H4Cl2O2 [M]+: 153.9588, found 153.9593.

4.2.4 Enol carbonate 26

A 250 mL two-neck round-bottomed flask equipped with a 50 mL addition funnel, a stir bar, and two septa was flame dried under vacuum. After refilling with Ar, anhydrous THF (55 mL) and anhydrous diisopropyl amine (1.45 mL, 10.3 mmol) were added via syringe, and the solution was cooled to 0 °C in an ice bath. n-BuLi (2.5 M in hexanes, 3.8 mL, 9.5 mmol) was added dropwise via syringe, and the solution was stirred at 0 °C for 30 min. The resulting LDA solution was then cooled to −78 °C over 15 min. Olefin (±)-27 (2.282 g, 8.63 mmol) in anhydrous THF (10 mL) was then added dropwise over 26 min via the addition funnel, washing the funnel with THF (5 mL) upon complete addition. A yellow solution was obtained. After stirring at −78 °C for 1 h, anhydrous N,N,N′,N′-tetramethylethylenediamine (1.55 mL, 10.3 mmol) was added dropwise over 2 min via syringe. After stirring at −78 °C for an additional 1 h, chloroformate 20 (1.471 g, 9.49 mmol) in anhydrous THF (10 mL) was then added dropwise over 22 min via the addition funnel, washing the funnel with THF (5 mL) upon complete addition. A visible exotherm was observed, and the solution changed from yellow to brownish-red in color. The reaction was stirred for an additional 3 h at −78 °C, whereupon saturated NaHCO3 (aq) (35 mL) and H2O (35 mL) were added. The mixture was allowed to warm to 23 °C, at which time the organic layer was immediately separated. The aqueous layer was extracted with Et2O (2 × 200 mL), and the combined organic layers were washed with brine (2 × 200 mL) and dried over MgSO4. Solvent was removed under reduced pressure. Flash chromatography over Florisil® (12 × 5 cm, 2.5% Et2O/petroleum ether eluent) then provided enol carbonate 26 (2.412 g, 73%) as a colorless liquid containing minor unidentified impurities (2% by area) by 1H NMR spectroscopy. Rf 0.17 (2.5% Et2O/petroleum ether eluent); 1H NMR (300 MHz, CDCl3) δ 5.52–5.56 (m, 1H), 5.43–5.46 (m, 1H), 4.76 (s, 1 H), 4.71–4.74 (m, 2H), 4.66–4.72 (br m, 2H), 3.48 (d, J = 6.6 Hz, 2H), 2.19 (s, 2H), 2.01–2.19 (m, 4H), 1.97 (app. septet, J = 6.7 Hz, 1H), 1.74 (br s, 3H), 1.09, (s, 6H), 0.94 (d, J = 6.7 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 157.7, 153.0, 145.9, 142.0, 135.2, 123.3, 115.2, 109.8, 91.1, 73.9, 69.1, 43.4, 37.9, 35.4, 27.9, 26.0, 24.2, 22.4, 19.2; IR (neat film, NaCl) ν 3074, 2960, 2873, 1762, 1662, 1622, 1470, 1382, 1365, 1329, 1276, 1240, 1183, 1160, 1100, 1046, 1024, 972, 952, 922, 888, 782, 639 cm−1; HRMS (EI+) m/z calcd. for C21H31ClO4 [M]+: 382.1911, found 382.1912.

4.2.5. α,ω-Diene (−)-13

To a flame-dried 500 mL round-bottomed flask equipped with a magnetic stir bar was added phosphinooxazoline ligand (+)-41 (0.36 g, 0.61 mmol) and bis(3,5,3′,5′-dimethoxydibenzylideneacetone)palladium(0) (0.44 g, 0.54 mmol). After sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Anhydrous benzene (150 mL, deoxygenated prior to use by sparging with N2 in a flame-dried flask for 1.9 h) was added via syringe, and the resulting solution was stirred for 30 min at 23 °C during which time it turned dark yellow-brown. The solution was then cooled in an ice bath until solution just begins to freeze (7 min) and transfered to an 11 °C cooling bath. Concurrently, a second flame-dried round bottomed flask was charged with enol carbonate 26 (2.056 g, 5.37 mmol). After sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Deoxygenated anhydrous benzene (6.5 mL) was added via syringe, and the resulting solution was cooled in an ice bath, becoming very viscous at this time. The enol carbonate solution was then transferred via syringe to the catalyst solution at 11 °C, washing the original flask with deoxygenated anhydrous benzene (6.5 mL, allowed to cool briefly before transferring). The reaction, which turned green, was then stirred at 11 °C for 24 h. Solvent was removed under reduced pressure. The residue was suspended in Et2O and filtered through filter paper to remove precipitated Pd. The filtrate was then concentrated under reduced pressure. The residue was suspended in 5% Et2O/petroleum ether (some solid precipitates) and applied to a silica gel column (12 × 5 cm). Flash chromatography (5% Et2O/petroleum ether eluent) then provided α,ω-diene (−)-13 (1.488 g, 82%) as a highly viscous, slightly yellow oil. Observed 87% ee as determined by chiral HPLC analysis (Chiralpak® AD, 1% EtOH/hexanes, 1 mL/min, 254 nm, tR (minor) = 6.1 min; tR (major) = 6.7 min). Rf 0.06 (5% Et2O/petroleum ether eluent); [α]24D −10.55° (c 0.995, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.30 (br s, 1H), 5.28 (s, 1H), 5.23 (s, 1H), 4.67–4.71 (m, 1H), 4.64–4.68 (m, 1H), 3.59 (dd, J = 9.5, 6.6 Hz, 1H), 3.54 (dd, J = 9.3, 6.8 Hz, 1H), 2.94–3.18 (br m, 1H), 2.46–2.83 (br m, 1H), 2.57 (br d, J = 15.6 Hz, 1H), 2.12–2.38 (br m, 1H), 2.12–2.26 (m, 1H), 1.88–2.12 (br m, 1H), 2.01 (app. septet, J = 6.7 Hz, 1H), 1.71 (s, 3H), 1.50–1.82 (br m, 2H), 1.21 (br s, 3H), 1.11 (s, 3H), 0.97 (d, J = 6.8 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 202.6, 172.9, 146.2, 141.7 (br), 116.7, 109.5, 100.2 (br), 74.5, 54.6, 43.1, 38.9, 37.4 (br), 32.9, 28.3, 27.7, 24.8, 24.6, 22.8, 19.0; IR (neat film, NaCl) ν 3073, 2963, 2939, 2877, 1651, 1622, 1471, 1449, 1431, 1406, 1383, 1367, 1298, 1222, 1206, 1172, 1157, 1134, 1069, 1009, 967, 956, 884, 845, 767, 752, 692, 656, 624 cm−1; HRMS (EI+) m/z calcd. for C20H31ClO2 [M]+: 338.2013, found 338.2009.

4.2.6. Chloroalkene (+)-12

To a flame-dried 100 mL round-bottomed flask equipped with a magnetic stir bar was added catalyst 49 (124.9 mg, 0.219 mmol). After attaching an oven-dried condenser and sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Anhydrous benzene (26 mL, deoxygenated prior to use by sparging with N2 in a flame-dried flask for ≥1 h) was added via syringe. To the resulting solution was added α,ω-diene (−)-13 (1.483 g, 4.38 mmol) in deoxygenated anhydrous benzene (6 mL) via syringe, washing the original flask with deoxygenated anhydrous benzene (2 × 6 mL). The reaction was placed in a 60 °C oil bath and stirred for 18 h. After cooling to 23 °C, solvent was removed under reduced pressure. Flash chromatography over silica gel (12 × 5 cm, 20% Et2O/petroleum ether eluent until product begins to elute, then 30% Et2O/petroleum ether eluent) then provided chloroalkene (+)-12 (1.313 g, 97%) as an off-white waxy powder. Rf 0.38 (20% Et2O/petroleum ether eluent); [α]24D +99.27° (c 1.005, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.19–5.23 (m, 1H), 3.59 (dd, J = 9.3, 6.3 Hz, 1H), 3.52 (dd, J = 9.5, 6.6 Hz, 1H), 2.50–2.70 (br m, 1H), 2.47 (br d, J = 17.1 Hz, 1H), 2.19–2.33 (br m, 1H), 1.61–2.14 (br m, 5 H), 2.01 (app. septet, J = 6.7 Hz, 1H), 1.76 (br s, 3H), 1.06 (s, 3H), 0.97 (d, J = 6.8 Hz, 6H), 0.95 (s, 3H); 13C NMR (75 MHz, CDCl3) δ 202.3, 172.5, 127.3, 125.5 (br), 99.7, 74.5, 52.6, 41.5, 37.5, 34.4 (br), 29.5, 27.7, 25.7 (br), 24.1, 23.8, 19.7, 19.1; IR (neat film, NaCl) ν 2961, 2931, 2876, 2838, 1657, 1618, 1470, 1434, 1404, 1383, 1365, 1344, 1297, 1220, 1169, 1137, 1045, 1008, 965, 908, 858, 830, 817, 742, 685, 621 cm−1; HRMS (FAB+) m/z calcd. for C18H28ClO2 [M + H]+: 311.1778, found 311.1789.

4.2.7. Proposed structure of (+)-laurencenone B ((+)-7)29 31

In a glove box, anhydrous CeCl3 (3.973 g, 16.1 mmol) was added to a flame-dried 250 mL round-bottomed flask equipped with a magnetic stir bar. The flask was sealed with a septum and removed from the glove box. The flask was placed under high vacuum and refilled with Ar. Anhydrous THF (39 mL) was added via syringe, and the suspension was stirred for 3 h at 23 °C. The suspension was cooled to −78 °C over 15 min, and MeLi (1.37 M in Et2O, 9.0 mL, 12.3 mmol) was added dropwise over 10 min via syringe. An exotherm was observed, and the liquid phase turned yellow. After stirring for 35 min at −78 °C, chloroalkene (+)-12 (1.286 g, 4.14 mmol) in anhydrous THF (5 mL) was added dropwise over 3 min via syringe, washing the original flask with THF (2 × 4 mL). The reaction was stirred for 30 min at −78 °C and then placed in an ice bath. After stirring an additional 68 min at 0 °C, 10 wt% HCl (aq) (52 mL) was added, during which time a significant exotherm was observed. The mixture was then allowed to warm to 23 °C as it was stirred for 66 min. The reaction mixture was extracted with Et2O (3 × 150 mL), and the combined organic layers were washed with brine (2 × 250 mL) and dried over MgSO4. Solvent was removed under reduced pressure. Flash chromatography over silica gel (10 × 4 cm, 15% Et2O/pentane eluent until product begins to elute, then 30% Et2O/pentane eluent) then provided (+)-laurencenone B ((+)-7) (929 mg, 89%) as a white powder. Discrepancies existed between the published 1H NMR data reported in the original isolation paper2g and that of the synthetic material. IR data matched that reported for the natural product. No 13C NMR or optical rotation data were reported. 1H NMR, 13C NMR, and IR data matched that reported for semisynthetic material obtained from the degradation of elatol.10 The optical rotation matched in sign, but not in magnitude. These comparisons are outlined in the supplementary data. Rf 0.26 (30% Et2O/petroleum ether eluent); [α]24D +47.08° (c 0.36, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.89 (s, 1H), 2.50–2.69 (br m, 2H), 2.26 (br d, J = 18.3 Hz, 1H), 2.13–2.23 (br m, 1H), 1.99–2.14 (br m, 2H), 1.98 (d, J = 0.98 Hz, 3H), 1.93 (ddd, J = 12.3, 12.3, 5.4, Hz, 1H), 1.81 (br s, 3H), 1.72–1.80 (m, 1H), 1.06 (s, 3H), 0.97(s, 3H); 1H NMR (500 MHz, acetone-d6) δ 5.80 (s, 1H), 2.52–2.69 (br m, 2H), 2.31 (dd, J = 18.1, 0.98 Hz, 1H), 2.19–2.27 (br m, 1H), 2.02–2.16 (br m, 1H), 1.88–2.02 (m, 2H), 1.98 (d, J = 1.2 Hz, 3H), 1.76–1.88 (br m, 1H), 1.80 (br s, 3H), 1.09 (s, 3H), 0.96 (s, 3H); 13C NMR (126 MHz, CDCl3) δ 198.2, 168.6, 129.6, 127.5, 126.2 (br), 48.8, 46.3, 40.4, 36.3, 30.4 (br), 30.1, 24.8, 23.9 (two overlapping CH3 peaks as determined by gHSQC and DEPT NMR spectroscopy; second peak appears as an upfield shoulder), 19.7; IR (neat film, NaCl) ν 3025, 2963, 2933, 2855, 1667, 1612, 1462, 1439, 1417, 1392, 1375, 1350, 1331, 1319, 1306, 1282, 1257, 1207, 1192, 1171, 1150, 1137, 1125, 1106, 1070, 1048, 1023, 1010, 988, 972, 954, 930, 913, 869, 834, 818, 684 cm−1; HRMS (EI+) m/z calcd. for C15H21ClO [M]+: 252.1281, found 252.1270.

4.3. Procedures for the synthesis of the proposed structure of (−)-laurencenone B ((−)-7)

4.3.1. α,ω-Diene (+)-13

Following a similar procedure to that for the preparation of α,ω-diene (−)-13, enol carbonate 26 (299.9 mg, 0.783 mmol) was converted to α,ω-diene (+)-13 (240.2 mg, 90%) using phosphinooxazoline ligand (−)- 41 (52.3 mg, 0.0884 mmol), bis(3,5,3′,5′-dimethoxydibenzylideneacetone)palladium(0) (63.7 mg, 0.0781 mmol), and deoxygenated anhydrous benzene (24 mL total) at 12 °C. Observed 87% ee as determined by chiral HPLC analysis (Chiralpak® AD, 1% EtOH/hexanes, 1 mL/min, 254 nm, tR (major) = 6.0 min; tR (minor) = 6.6 min). 1H NMR data matched that of α,ω-diene (−)-13. [α]25D +10.46° (c 1.005, CHCl3).

4.3.2. Chloroalkene (−)-12

Following a similar procedure to that for the preparation of chloroalkene (+)-12, α,ω-diene (+)-13 (229.7 mg, 0.678 mmol) was converted to chloroalkene (−)-12 (204.7 mg, 97%) using catalyst 49 (19.3 mg, 0.0338 mmol) and deoxygenated anhydrous benzene (7 mL total). 1H NMR data matched that of chloroalkene (+)-12. [α]26D −101.03° (c 1.0, CHCl3).

4.3.3. Proposed structure of (−)-laurencenone B ((#x2212;)-7

Following a similar procedure to that for the preparation of the proposed structure of (+)-laurencenone B ((+)-7), chloroalkene (−)-12 (99.9 mg, 0.321 mmol) was converted to the proposed structure of (−)-laurencenone B ((−)-7) (69.6 mg, 86%) using anhydrous CeCl3 (312 mg, 1.27 mmol), MeLi (1.3 M in Et2O, 0.74 mL, 0.962 mmol), anhydrous THF (4 mL total), and 10 wt% HCl (aq) (4 mL). A minor unidentified impurity was observed by 1H NMR spectroscopy (≤3 mol% as determined by DEPT NMR spectroscopy). 1H NMR data matched that of (+)-laurencenone B ((+)-7). [α]25D −42.01° (c 0.357, CHCl3).

4.4. Procedures for the synthesis of (−)-laurencenone C (8)

4.4.1. Enol carbonate 33

A 250 mL two-neck round-bottomed flask equipped with a 50 mL addition funnel, a stir bar, and two septa was flame dried under vacuum. After refilling with Ar, anhydrous THF (40 mL) and anhydrous diisopropylamine (1.45 mL, 10.3 mmol) were added via syringe, and the solution was cooled to 0 °C in an ice bath. n-BuLi (2.51 M in hexanes, 3.8 mL, 9.54 mmol) was added dropwise via the addition funnel over 22 min, washing the funnel sequentially with anhydrous hexanes (5 mL) and anhydrous THF (5 mL) upon complete addition. The reaction was then stirred at 0 °C for 30 min. The resulting LDA solution was cooled to −78 °C over 30 min. Olefin (±)-27 (2.285 g, 8.64 mmol) in anhydrous THF (10 mL) was then added dropwise over 11 min via the addition funnel, washing the funnel with anhydrous THF (5 mL) upon complete addition. A yellow solution was obtained. After stirring at −78 °C for 66 min, anhydrous N,N,N′,N′-tetramethylethylenediamine (1.55 mL, 10.3 mmol) was added dropwise over 2 min via syringe. After stirring at −78 °C for an additional 69 min, allyl chloroformate (55) (1.0 mL, 9.41 mmol) in anhydrous THF (10 mL) was then added dropwise over 21 min via the addition funnel, washing the funnel with THF (5 mL) upon complete addition. The reaction was stirred for an additional 3 h at −78 °C, at which time saturated NaHCO3 (aq) (35 mL) and H2O (35 mL) were added. The mixture was allowed to warm to 23 °C with the aid of a 23 °C water bath, at which time the organic layer was immediately separated. The aqueous layer was extracted with Et2O (2 × 200 mL), and the combined organic layers were washed with brine (2 × 200 mL) and dried over MgSO4. Solvent was removed under reduced pressure. Flash chromatography over Florisil® (12.5 × 5 cm, 2.5% Et2O/petroleum ether eluent) then provided enol carbonate 33 (2.101 g, 70%) as a slightly pale yellow liquid containing residual Et2O (<1% by mass) and minor unidentified impurities (5% by area) by 1H NMR spectroscopy. Rf 0.21 (2.5% Et2O/petroleum ether eluent); 1H NMR (500 MHz, CDCl3) δ 5.96 (ddt, J = 17.1, 10.5, 5.7 Hz, 1H), 5.39 (ddt, J = 7.1, 1.5, 1.5 Hz, 1H), 5.28 (ddt, J = 10.5, 1.2, 1.2 Hz, 1H), 4.76 (s, 1H), 4.66–4.71 (m, 2H), 4.66 (ddd, J = 5.7, 1.4, 1.4 Hz, 2H), 3.47 (d, J = 6.6 Hz, 2H), 2.19 (s, 2H), 2.09–2.17 (m, 2H), 2.01–2.09 (m, 2H), 1.97 (app. septet, J = 6.7 Hz, 1H), 1.74 (br s, 3H), 1.08 (s, 6H), 0.94 (d, J = 6.8 Hz, 6H); 13C NMR (75 MHz, CDCl3) δ 157.5, 153.5, 146.0, 141.9, 131.5, 123.1, 119.0, 109.7, 91.3, 73.8, 68.6, 43.4, 37.9, 35.4, 27.8, 26.0, 24.1, 22.4, 19.2; IR (neat film, NaCl) ν 2960, 2874, 1758, 1662, 1622, 1470, 1422, 1382, 1363, 1330, 1292, 1241, 1160, 1146, 1109, 1041, 1024, 994, 970, 952, 887, 784 cm−1; HRMS (EI+) m/z calcd. for C21H32O4 [M]+: 348.2301, found 348.2307.

4.4.2. α,ω-Diene (+)-34

To a flame-dried 250 mL round-bottomed flask equipped with a magnetic stir bar was added phosphinooxazoline ligand (−)-41 (192 mg, 0.325 mmol) and bis(3,5,3′,5′-dimethoxydibenzylideneacetone)palladium(0) (234 mg, 0.287 mmol). After sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Anhydrous toluene (77 mL) was added via syringe, and the resulting solution was stirred for 31 min at 23 °C. The solution was then cooled to 0 °C over 15 min in an ice bath. Concurrently, a second flame-dried round bottomed flask was charged with enol carbonate 33 (1.003 g, 2.88 mmol). After sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Anhydrous toluene (5 mL) was added via syringe, and the resulting solution was cooled to 0 °C in an ice bath. The enol carbonate solution was then transferred via cannula under positive N2 pressure to the catalyst solution, washing the original flask with anhydrous toluene (5 mL, allowed to cool briefly before transferring). The reaction was then stirred at 0 °C for 9.5 h, at which point solvent was removed under reduced pressure. Flash chromatography over silica gel (12.5 × 5 cm, 5% Et2O/petroleum ether eluent) then provided α,ω-diene (+)-34 (760 mg, 87%) as a yellow liquid. Observed 87% ee as determined by chiral HPLC analysis (Chiralcel® OD-H, 0.25% EtOH/hexanes, 1 mL/min, 254 nm, tR (minor) = 9.0 min; tR (major) = 10.3 min). Rf 0.07 (5% Et2O/petroleum ether eluent); [α]24D +25.52° (c 0.995, CHCl3);1H NMR (500 MHz, CDCl3) δ 5.85–6.04 (br m, 1H), 5.24 (d, J = 0.97 Hz, 1H), 5.03–5.10 (m, 1H), 4.96–5.01 (m, 1H), 4.65–4.69 (m, 1H), 4.64 (br s, 1H), 3.58 (dd, J = 9.5, 6.6 Hz, 1H), 3.54 (dd, J = 9.3, 6.8 Hz, 1H), 2.35–2.90 (br m, 2H), 2.28 (dd, J = 15.4, 8.1 Hz, 1H), 1.94–2.10 (br m, 2H), 2.01 (app. septet, J = 6.7 Hz, 1H), 1.62–1.89 (br m, 3H), 1.69 (s, 3H), 1.10 (s, 3H), 1.07 (s, 3H), 0.96 (d, J = 6.8, 6H); 13C NMR (75 MHz, CDCl3) δ 203.2, 173.0, 146.5, 137.1 (br), 116.1, 109.3, 100.7, 74.5, 53.5, 42.7, 38.7, 33.7 (br), 32.8, 28.7, 27.7, 25.5, 25.3, 22.8, 19.1; IR (neat film, NaCl) ν 3072, 2961, 2937, 2876, 1653, 1621, 1471, 1449, 1405, 1383, 1366, 1297, 1221, 1207, 1172, 1149, 1009, 995, 967, 955, 907, 885, 846, 833, 768, 755, 654 cm−1; HRMS (EI+) m/z calcd. for C20H32O2 [M]+: 304.2402, found 304.2388.

4.4.3. Olefin (−)-56

To a flame-dried 50 mL round-bottomed flask equipped with a magnetic stir bar was added catalyst 49 (70.6 mg, 0.124 mmol). After attaching an oven-dried condenser and sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Anhydrous benzene (20 mL, deoxygenated prior to use by sparging with N2 in a flame-dried flask for 1 h) was added via syringe. To the resulting solution was added α,ω-diene (+)-34 (750 mg, 2.46 mmol) in deoxygenated anhydrous benzene (3 mL) via syringe, washing the original flask with deoxygenated anhydrous benzene (2 × 1 mL). The reaction was placed in a 60 °C oil bath and stirred for 11.5 h. After cooling to 23 °C, solvent was removed under reduced pressure. Flash chromatography over silica gel (9 × 3 cm, 20% Et2O/petroleum ether eluent until product begins to elute, then 30% Et2O/petroleum ether eluent) then provided olefin (−)-56 (663 mg, 97%) as a white powder. Rf 0.23 (20% Et2O/petroleum ether eluent); [α]25D −91.53° (c 1.00, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.38–5.50 (br m, 1H), 5.17–5.24 (m, 1H), 3.58 (dd, J = 9.3, 6.8 Hz, 1H), 3.52 (dd, J = 9.5, 6.6 Hz, 1H), 2.40–2.82 (br m, 1H), 2.13–2.23 (br m, 1H), 1.87–2.13 (br m, 2H), 2.00 (app. septet, J = 6.7 Hz, 1H), 1.58–1.87 (br m, 4H), 1.64 (d, J = 1.5 Hz, 3H), 1.03 (s, 3H), 0.96 (d, J = 6.3 Hz, 6H), 0.94 (s, 3H); 13C NMR (75 MHz, CDCl3, overlapping of resonances was observed) δ 203.7, 172.3, 132.1 (br), 120.4 (br), 99.9, 74.4, 49.9, 41.5, 37.6, 27.72, 27.68, 26.1 (br), 24.2, 23.9, 23.4, 19.1; IR (neat film, NaCl) ν 3066, 3017, 2960, 2923, 2901, 2876, 2835, 1657, 1620, 1470, 1445, 1403, 1383, 1364, 1294, 1262, 1218, 1201, 1169, 1133, 1077, 1033, 1009, 968, 944, 906, 860, 830, 797, 765, 730, 714, 656 cm−1; HRMS (FAB+) m/z calcd. for C18H29O2 [M + H]+: 277.2168, found 277.2155.

4.4.4. (−)-Laurencenone C (8)

In a glove box, anhydrous CeCl3 (689 mg, 2.80 mmol) was added to a flame-dried 50 mL round-bottomed flask equipped with a magnetic stir bar. The flask was sealed with a septum and removed from the glove box. The flask was placed under high vacuum and refilled with Ar. Anhydrous THF (7 mL) was added via syringe, and the suspension was stirred for 2 h at 23 °C. The suspension was cooled to −78 °C over 15 min, and MeLi (1.30 M in Et2O, 1.7 mL, 2.21 mmol) was added dropwise over 5 min via syringe. An exotherm was observed, and the liquid phase turned yellow. After stirring for 30 min at −78 °C, olefin (−)-56 (200.3 mg, 0.725 mmol) in anhydrous THF (1 mL) was added dropwise over 7 min via syringe, washing the original flask with THF (1 mL). The reaction was stirred for 35 min at −78 °C and then placed in an ice bath. After stirring an additional 65 min at 0 °C, 10 wt% HCl (aq) (9 mL) was added, during which time a significant exotherm was observed. The mixture was then allowed to warm to 23 °C as it was stirred for 1.5 h. The reaction mixture was extracted with Et2O (3 × 50 mL), and the combined organic layers were washed with brine (2 × 150 mL) and dried over MgSO4. Solvent was removed under reduced pressure. Flash chromatography over silica gel (10 × 3 cm, 10% Et2O/pentae eluent until product begins to elute, then 30% Et2O/pentane eluent) then provided (−)-laurencenone C (8) (127 mg, 80%) as a colorless oil containing a minor unidentified impurity (2% by area) by 1H NMR spectroscopy. Discrepancies existed between the published 1H NMR data reported in the original isolation paper2g and that of the synthetic material. IR data matched that reported for the natural product. No 13C NMR or optical rotation data were reported. 1H NMR, 13C NMR, and IR data matched that reported for isolation of the natural product from a second source,2h with the exception of one 13C NMR resonance. The optical rotation matched in sign, but not in magnitude. These comparisons are outlined in the supplementary data. Rf 0.28 (30% Et2O/petroleum ether eluent); [α]26D −87.98° (c = 1.00, CHCl3);1H NMR (500 MHz, CDCl3) δ 5.87 (br s, 1H), 5.47–5.53 (br m, 1H), 2.48–2.76 (br m, 1H), 2.19–2.28 (br m, 1H), 1.82–2.14 (br m, 5H), 1.97 (d, J = 1.5 Hz, 3H), 1.71–1.82 (br m, 1H), 1.68 (br s, 3H), 1.03 (s, 3H), 0.95 (s, 3H);1H NMR (500 MHz, acetone-d6) δ 5.76 (br s, 1H), 5.49–5.55 (br m, 1H), 2.46–2.73 (br m, 1H), 2.21–2.31 (br m, 1H), 1.74–2.12 (br m, 6H), 1.97 (d, J = 1.5 Hz, 3H), 1.65–1.69 (br m, 3H), 1.03 (s, 3H), 0.93 (s, 3H); 13C NMR (126 MHz, CDCl3) δ 198.6, 170.4, 134.1, 127.0, 121.6, 48.9, 43.4, 40.4, 30.6 (br), 28.2, 27.9, 24.8, 24.2, 23.9 (br), 23.3; IR (neat film, NaCl) ν 3016, 2963, 2928, 2907, 2879, 2853, 1667, 1610, 1447, 1437, 1418, 1390, 1376, 1332, 1320, 1282, 1257, 1209, 1190, 1170, 1146, 1122, 1074, 1036, 1022, 977, 944, 912, 870, 834, 818, 800, 767 cm−1; HRMS (EI+) m/z calcd. for C15H22O [M]+: 218.1671, found 218.1673.

4.5. Procedures for the synthesis of (−)-α-chamigrene (5)

4.5.1. Dithiolane (−)-5837 39

To a flame-dried 1 dram screw-cap vial equipped with a stir bar and a septum-bearing cap was added laurencenone C (8) (88.3 mg, 0.404 mmol). The flask was placed under high vacuum and refilled with Ar. Anhydrous MeOH (3 mL) followed by ethanedithiol (57) (60 μL, 0.715 mmol) were added via syringe. Boron trifluoride diethyl etherate (60 μL, 0.486 mmol) was then added via syringe in two portions (41 and 19 μL, respectively) 20 min apart, and the reaction was stirred for a total of 27 h at 23 °C. During this time, a fine dark precipitate was observed. MeOH was removed under reduced pressure, and the residue was dissolved in EtOAc (50 mL). The solution was washed sequentially with saturated NaHCO3 (aq) (2 × 25 mL), H2O (2 × 25 mL), and brine (2 × 25 mL) and then dried over MgSO4. Solvent was removed under reduced pressure. Flash chromatography over silica gel (7.5 × 2 cm, 2.5% Et2O/pentane eluent) then provided dithiolane (−)-58 (109.6 mg, 92%) as a colorless oil containing minor unidentified impurities (3% by area by 1H NMR spectroscopy) which were present in the starting ethanedithiol. 1H NMR data matched that of the reported racemic compound.5a–b R f 0.29 (2.5% Et2O/petroleum ether eluent); [α]25D −51.47° (c 1.015, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.53–5.56 (m, 1H), 5.42–5.46 (m, 1H), 3.26–3.44 (m, 4H), 2.63 (d, J = 14.7 Hz, 1H), 2.06–2.16 (m, 2H), 1.81–1.95 (m, 3H), 1.60–1.71 (m, 2H), 1.69 (d, J = 0.98 Hz, 3H), 1.64 (bs, 3H), 0.97 (s, 3H), 0.91 (s, 3H).

4.5.2. (−)-α-Chamigrene (5)5b

A 100 ml three-neck round-bottomed flask equipped with a cold finger, a stir bar, and three septa was flame-dried under vacuum. After refilling with Ar, the flask was placed in a dry ice/CHCl3 bath which was used to maintain a reaction temperature between −60 and −45 °C, while the cold finger was maintained at −78 °C with dry ice and acetone. NH3 (g) was condensed within the flask to give a solvent volume of approx. 10 mL. A solution of dithiolane (−)-58 (110 mg, 0.373 mmol) in anhydrous Et2O (14 mL) cooled to −60 °C was then added via cannula under positive N2 pressure, washing the original flask with anhydrous Et2O (6 mL, allowed to cool briefly before transferring). Na0 (approx. 146 mg, 6.35 mmol) was added portion-wise under positive Ar pressure in small pieces, during which time the solution turned a persistent purple color. After complete addition, the reaction was stirred for 15 min, and the cold bath was then removed giving a gentle reflux while stirring for an additional 55 min. MeOH (1.5 mL) was added portion-wise via syringe to minimize any exotherm, and a mixture of a colorless solution and a white precipitate was obtained. The cold finger was then allowed to warm to 23 °C while the NH3 (l) and Et2O evaporated overnight. H2O (40 mL) was added to dissolve most solids, and the reaction was extracted with Et2O (3 × 50 mL). The organic layer was washed with brine (2 × 150 mL) and dried over MgSO4. Solvent was removed under reduced pressure. The crude product was then split into two approximately equal portions, each of which was subjected to preparative thin-layer chromatography (0.5 mm thickness, 100% hexanes eluent). The product was extracted from the silica with hexanes, and solvent was removed under reduced pressure to provide a combined yield of 33.6 mg (44%) of (−)-α-chamigrene (5) as a colorless oil. 1H NMR and IR data matched that reported in the original isolation paper,2e and these comparisons are outlined in the supplementary data. Rf 0.80 (100% hexanes eluent); [α]25D −64.60° (c 0.21, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.44–5.48 (m, 1H), 5.31–5.35 (br m, 1H) 2.12 (dddd, J = 18.1, 5.1, 2.4, 2.4 Hz, 1H), 1.80–2.01 (br m, 5H), 1.60–1.79 (m, 9H), 1.19 (ddd, J = 13.7, 6.1, 4.39 Hz, 1H), 0.89 (s, 3H), 0.83 (s, 3H); 1H NMR (300 MHz, CCl4) δ 5.36–5.43 (m, 1H), 5.23–5.29 (m, 1H), 2.09 (dddd, J = 18.1, 4.9, 2.4, 2.4 Hz, 1H), 1.55–2.02 (m, 14H), 1.17 (ddd, J = 13.3, 4.9, 4.9 Hz, 1H), 0.89 (s, 3H), 0.82 (s, 3H); 13C NMR (126 MHz, CDCl3) δ 140.3, 133.8, 122.8, 122.5, 40.5, 35.9, 32.8, 30.7, 29.1, 28.9, 25.1, 23.47, 23.46, 23.3 (br), 23.0; IR (neat film, NaCl) ν 3055, 3015, 2958, 2923, 2841, 2729, 2675, 1683, 1655, 1640, 1473, 1463, 1448, 1436, 1386, 1380, 1366, 1342, 1320, 1312, 1280, 1258, 1248, 1220, 1188, 1163, 1148, 1129, 1088, 1072, 1029, 1020, 1006, 978, 954, 943, 901, 832, 810, 800, 760, 688, 661, 605 cm−1; HRMS (EI+) m/z calcd. for C15H24 [M]+: 204.1878, found 204.1883.

4.6. Procedures for the synthesis of (+)-elatol (1)

4.6.1. (+)-Elatol (1)

Part 1: Bromination40c 42

A half-dram screw-cap vial equipped with a stir bar and a septum-bearing cap was charged with (+)-laurencenone B ((+)-7) (9.9 mg, 0.0392 mmol). A solution of 48% HBr (aq) in glacial acetic acid [250:1 v/v AcOH:48% HBr (aq), 0.2 mL] was then added. To the resulting solution was added in one portion a stock solution of bromine in 250:1 v/v AcOH:48% HBr (aq) (0.501 M, 157.5 μL, 0.0789 mmol), resulting in a deep red color. After stirring for approx. 10 min, the reaction turned an orange-red color. After stirring for a total of 31 min, the solution was added to ice water (5 mL). The resulting mixture was extracted with Et2O (4 × 10 mL), and the combined organic layers were washed with saturated NaHCO3 (aq) (2 × 20 mL) and brine (2 × 20 mL). After drying over MgSO4, solvent was removed under reduced pressure, ultimately isolating the crude dibromide 59 in a 1 dram screw-cap vial. The crude material was carried directly to Part 2. A scalemic mixture from additional runs was partially purified (approx. 93% pure by area by 1H NMR spectroscopy) by preparative HPLC (Phenomenex® Gemini™, 25®100% CH3CN/0.1% TFA (aq), 8 mL/min, 250 nm, tR = 70–72 min). 1H NMR (500 MHz, C6D6) δ 6.05 (s, 1H), 4.55 (s, 1H), 3.67 (d, J = 10.7 Hz, 1H), 3.36–3.41 (m, 1H), 2.56–2.67 (m, 1H), 2.22–2.32 (br m, 1H), 1.52–1.56 (br m, 3H), 1.35–1.44 (br m, 1H), 1.14–1.25 (br m, 1H), 1.08 (ddd, J = 12.5, 12.5, 5.1 Hz, 1H), 0.80 (s, 3H), 0.68–0.76 (br m, 1H), 0.74 (s, 3H);13C NMR (126 MHz, CDCl3) δ 190.1, 164.1, 129.9, 129.8, 126.1, 65.7, 49.1, 47.1, 36.5, 30.9, 30.3, 29.7, 24.3, 19.8, 18.7; IR (neat film, NaCl) ν 2979, 2932, 1678, 1438, 1396, 1376, 1284, 1251, 1216, 1170, 1133, 1007, 911, 868, 818, 760, 733 cm−1; HRMS (EI+) m/z calcd. for C15H19ClOBr81Br [M]+: 409.9471, found 409.9482. A minor diastereomer was not isolated. The dr was determined to be ≥8:1 by 1H NMR spectroscopic analysis of the crude product of a third run. This minimal value was based upon resonances that could not be ruled out as corresponding to a minor diastereomer based on the preparative HPLC separation above.

Part 2: Reduction39b 41

The 1 dram screw-cap vial containing the crude dibromide 59 from Part 1 was equipped with a stir bar and a septum-bearing cap and placed under high vacuum. After refilling with Ar, anhydrous THF (0.3 mL) was added via syringe, and the solution was cooled to −78 °C. Concurrently, a second 1 dram screw-cap vial equipped with a septum-bearing cap was flame-dried under high vacuum and refilled with Ar. A stock solution of diisobutylaluminum hydride in anhydrous THF (1.59 M, 0.15 mL, 0.239 mmol) was added via syringe, and the solution was cooled to −78 °C. The precooled stock solution was then added to the crude dibromide 59 solution at −78 °C in one portion via cannula under positive N2 pressure, whereupon gas evolution was observed. The colorless solution was stirred for 2 h at −78 °C, at which point the reaction was placed in a 60 °C heating block, and the Ar inlet was removed. After stirring for an additional 2 h at 60 °C, the reaction was cooled to 23 °C with the aid of a 23 °C water bath. Et2O (0.5 mL) was added, and the reaction was quenched with a saturated solution of potassium sodium tartrate (aq) (0.5 mL), whereupon gas evolution was observed. After stirring vigorously for 1 h, the opaque biphasic mixture was transferred to a 25 mL round-bottomed flask with Et2O (5 mL) and a saturated solution of potassium sodium tartrate (aq) (5 mL). The mixture was then stirred vigorously until both layers were transparent. The organic layer was separated, and the aqueous layer was extracted with Et2O (2 × 10 mL). The combined organic layers were washed with brine (2 × 20 mL) and dried over MgSO4. Solvent was removed under reduced pressure. The ratio of SN2′:SN2 reduction was determined to be 11:1 by 1H NMR spectroscopic analysis of the crude reaction mixture. The crude product was azeotroped with hexanes (4×) and then subjected to preparative thin-layer chromatography (0.5 mm thickness, eluted four times with 15% Et2O/petroleum ether eluent, then once with 15% EtOAc/hexanes eluent). The product was extracted from the silica with EtOAc and azeotroped with hexanes (3×). Finally, flash chromatography over silica gel (5.3 × 0.5 cm, 5% EtOAc/hexanes eluent until product begins to elute, then 30% EtOAc/hexanes eluent) then provided (+)-elatol (1) (4.4 mg) as a colorless oil containing 6% of the undesired SN2 reduction product by 1H NMR spectroscopy. The corrected yield was 32% over two steps. The dr of the initial ketone reduction was determined to be 3.9:1 syn:anti (relative to the bromide) by 1H NMR spectroscopic analysis of the crude product of separate run quenched at −78 °C after 2 h. 1H NMR data matched that reported in the original isolation paper,2a and this comparison is outlined in the supplementary data. Rf 0.64 (eluted four times with 15% Et2O/petroleum ether eluent, then once with 15% EtOAc/hexanes eluent); [α]23D +92.09° (c 0.22, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.13 (s, 1H), 4.80 (s, 1H), 4.61 (d, J = 2.9 Hz, 1H), 4.13–4.17 (m, 1H), 2.55–2.66 (br m, 2H), 2.51 (dd, J = 14.6, 2.7 Hz, 1H), 2.33–2.41 (br m, 1H), 2.16–2.20 (m, 1H), 1.92–2.00 (br m, 1H), 1.75–1.86 (br m, 2H), 1.70 (br s, 3H), 1.58–1.67 (m, 1H), 1.08 (s, 3H), 1.07 (s, 3H); 13C NMR (126 MHz, CDCl3) δ 140.7, 128.1, 124.1, 115.9, 72.2, 70.9, 49.1, 43.1, 38.6, 37.9, 29.3, 25.6, 24.2, 20.8, 19.4; IR (neat film, NaCl) ν 3564, 3475, 3086, 2975, 2949, 2913, 2831, 1808, 1724, 1681, 1643, 1470, 1453, 1430, 1394, 1372, 1354, 1340, 1319, 1292, 1254, 1225, 1207, 1188, 1165, 1141, 1130, 1106, 1086, 1073, 1031, 1014, 982, 956, 943, 897, 879, 826, 811, 761, 737, 685, 706, 667, 642, 615 cm−1; HRMS (EI+) m/z calcd. for C15H22BrClO [M]+: 332.0543, found 332.0546.

4.6.2. Analysis of a natural sample of (+)-elatol (1)

A natural sample of (+)-elatol (1) provided by Prof. Mercedes Cueto was identical in all respects to the synthetic material except for its optical rotation: [α]25D +109.78° (c 0.045, CHCl3).

4.6.3. Characterization data for diastereomers from the initial ketone reduction of crude dibromide 59

cis-Bromohydrin 60

Rf 0.54 (30% EtOAc/hexanes eluent); 1H NMR (500 MHz, CDCl3) δ 6.14 (d, J = 3.9 Hz, 1H), 4.79 (d, J = 5.1 Hz, 1H), 4.22–4.27 (br m, 1H), 4.04–4.11 (m, 2H), 2.73–2.81 (br m, 1H), 2.50–2.59 (br m, 1H), 2.38 (d, J = 3.4 Hz, 1H), 2.10–2.18 (br m, 1H), 1.92–2.03 (br m, 1H), 1.76–1.85 (m, 4H), 1.53–1.60 (m, 1H), 1.14 (s, 3H), 1.07 (s, 3H); 13C NMR (126 MHz, CDCl3) δ 143.3, 130.9, 129.6, 127.0, 68.6, 65.9, 47.7, 41.1, 36.9, 33.5, 30.2, 29.8, 24.3, 19.8, 19.0; IR (neat film, NaCl) ν 3541, 3455, 2976, 2932, 1678, 1438, 1219, 731 cm−1; HRMS (EI+) m/z calcd. for C15H21ClOBr81 Br [M]+: 411.9627, found 411.9620. The relative stereochemistry of the bromohydrin functionality was established by NOESY1D NMR spectroscopy and subsequent conversion to elatol (1).

trans-Bromohydrin 64

Rf 0.44 (30% EtOAc/hexanes eluent); 1H NMR (500 MHz, CDCl3) δ 6.00 (d, J = 3.4 Hz, 1H), 4.48 (d, J = 9.0 Hz, 1H), 4.35–4.41 (br m, 1H), 4.03–4.11 (m, 2H), 2.77–2.84 (br m, 1H), 2.54–2.63 (br m, 1H), 2.43 (d, J = 3.7 Hz, 1H), 2.10–2.19 (br m, 1H), 1.89–2.00 (br m, 1H), 1.87 (ddd, J = 12.2, 12.2, 5.0 Hz, 1H), 1.80–1.84 (br m, 3H), 1.62–1.69 (m, 1H), 1.16, (s, 3H), 1.05 (s, 3H); 13C NMR (126 MHz, CDCl3) δ 143.6, 131.6, 129.6, 126.9, 73.3, 70.5, 47.4, 44.3, 36.3, 33.8, 31.4, 29.7, 24.6, 19.8, 17.6; IR (neat film, NaCl) ν 3383, 2977, 2932, 1677, 1438, 1039, 733 cm−1; HRMS (EI+) m/z calcd. for C15H21ClOBr81 Br [M]+: 411.9627, found 411.9621.

4.7. Procedures for the syntheses of enantioselective decarboxylative allylation products (+)-45, (+)-46, and (+)-24

4.7.1. Olefin (±)-66

A 250 mL round-bottomed flask equipped with a stir bar and a septum was flame dried under vacuum. After refilling with Ar, anhydrous THF (42 mL) and anhydrous diisopropylamine (1.6 mL, 11.4 mmol) were added via syringe, and the solution was cooled to 0 °C in an ice bath. n-BuLi (2.57 M in hexanes, 4.1 mL, 10.5 mmol) was added dropwise via syringe, and the solution was stirred at 0 °C for 33 min. The resulting LDA solution was then cooled to −78 °C over 15 min. Vinylogous ester 11 (2.0 g, 10.2 mmol) in anhydrous THF (2 mL) was then added dropwise over 2 min via syringe, washing the original flask with anhydrous THF (2 × 2 mL). The reaction was then stirred for 1 h at −78 °C to provide a yellow solution. Methallyl bromide (65) (1.0 mL, 9.92 mmol) was added dropwise over 2 min via syringe. The cold bath was removed, and the reaction was allowed to warm to 23 °C as it was stirred for 26.6 h. Saturated NH4Cl (aq) (40 mL) was added, and the organic layer was separated. The aqueous layer was extracted with Et2O (2 × 150 mL), and the combined organic layers were washed with brine (2 × 200 mL). After drying over MgSO4, solvent was removed under reduced pressure. Flash chromatography over silica gel (15.5 × 5 cm, 15% Et2O/petroleum ether eluent) then provided olefin (±)-66 (2.135 g, 84%) as a slightly yellow liquid. Rf 0.10 (15% Et2O/petroleum ether eluent); 1H NMR (300 MHz, CDCl3) δ 5.24 (br s, 1H), 4.71–4.76 (br m, 1H), 4.64–4.69 (br m, 1H), 3.57 (d, J = 6.4 Hz, 2H), 2.12–2.40 (m, 5H), 2.02 (app. septet, J = 6.7 Hz, 1H), 1.78 (br s, 3H), 1.09 (s, 3H), 0.99 (s 3H), 0.97 (d, J = 6.6 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 201.4, 174.1, 144.6, 111.4, 100.5, 74.5, 41.6, 35.1, 34.7, 28.6, 27.7, 24.5, 22.3, 19.07, 19.06; IR (neat film, NaCl) ν 3074, 2962, 2933, 2875, 1661, 1615, 1471, 1425, 1404, 1382, 1364, 1315, 1299, 1278, 1222, 1192, 1178, 1152, 1131, 1008, 968, 954, 885, 834, 815, 686, 626 cm−1; HRMS (EI+) m/z calcd. for C16H26O2 [M]+: 250.1933, found 250.1945.

4.7.2. Enol carbonate 42

A 250 mL two-neck round-bottomed flask equipped with a 10 mL addition funnel, a stir bar, and two septa was flame dried under vacuum. After refilling with Ar, anhydrous THF (25 mL) and anhydrous diisopropylamine (0.67 mL, 4.78 mmol) were added via syringe, and the solution was cooled to 0 °C in an ice bath. n-BuLi (2.57 M in hexanes, 1.7 mL, 4.37 mmol) was added dropwise via syringe, and the solution was stirred at 0 °C for 33 min. The resulting LDA solution was then cooled to −78 °C over 18 min. Olefin (±)-66 (1.0 g, 3.99 mmol) in anhydrous THF (5 mL) was then added dropwise over 8 min via the addition funnel, washing the funnel with THF (2.5 mL) upon complete addition. After stirring at −78 °C for 1 h, anhydrous N,N,N′,N′-tetramethylethylenediamine (0.72 mL, 4.80 mmol) was added dropwise over 2 min via syringe. After stirring at −78 °C for an additional 1 h, chloroformate 20 (0.68 g, 4.39 mmol) in anhydrous THF (5 mL) was then added dropwise over 19 min via the addition funnel, washing the funnel with THF (2.5 mL) upon complete addition. The reaction was stirred for an additional 3 h at −78 °C, whereupon saturated NaHCO3 (aq) (17 mL) and H2O (17 mL) were added. The mixture was allowed to warm to 23 °C with the aid of a 23 °C water bath, at which time the organic layer was immediately separated. The aqueous layer was extracted with Et2O (2 × 100 mL), and the combined organic layers were washed with brine (2 × 100 mL) and dried over MgSO4. Solvent was removed under reduced pressure. Flash chromatography over Florisil® (100–200 mesh, 13.5 × 5 cm, 1% Et2O/petroleum ether eluent until product begins to elute, then 2.5% Et2O/petroleum ether eluent) then provided enol carbonate 42 (973 mg, 66%) as a somewhat viscous colorless liquid containing residual Et2O (<1% by mass) and a minor unidentified impurity (4% by area) by 1H NMR spectroscopy. Rf 0.27 (2.5% Et2O/petroleum ether eluent); 1H NMR (500 MHz, CDCl3) δ 5.50–5.54 (m, 1H), 5.42–5.46 (m, 1H), 4.80 (s, 1H), 4.76–4.80 (br m, 1H), 4.72–4.76 (br m, 1H), 4.68–4.72 (m, 2H), 3.49 (d, J = 6.6 Hz, 2H), 2.76 (s, 2H), 2.19 (s, 2H), 1.98 (app. septet, J = 6.7 Hz, 1H), 1.71 (br s, 3H), 1.04 (s, 6H), 0.95 (d, J = 6.8 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 158.1, 152.7, 144.0, 142.6, 135.0, 120.5, 115.3, 111.3, 91.0, 73.8, 69.1, 43.4, 35.5, 33.4, 27.8, 25.6, 22.5, 19.2; IR (neat film, NaCl) ν 3077, 2960, 2932, 2913, 2874, 1763, 1663, 1648, 1638, 1620, 1470, 1465, 1444, 1421, 1382, 1367, 1363, 1331, 1276, 1242, 1217, 1174, 1150, 1099, 1040, 1023, 997, 969, 890, 782 cm−1; HRMS (EI+) m/z calcd. for C20H29ClO4 [M]+: 368.1754, found 368.1738.

4.7.3. α,ω-Diene (+)-45

To a flame-dried 100 mL round-bottomed flask equipped with a magnetic stir bar was added phosphinooxazoline ligand (−)-41 (54.4 mg, 0.0920 mmol) and bis(3,5,3′,5′-dimethoxydibenzylideneacetone)palladium(0) (66.2 mg, 0.0812 mmol). After sealing with a septum, the flask was placed under high vacuum and refilled with Ar. Anhydrous benzene (22.5 mL, deoxygenated prior to use by sparging with N2 in a flame-dried flask for 2 h) was added via syringe, and the resulting solution was stirred for 30 min at 23 °C, during which time it turned dark yellow-brown. The solution was then cooled to 11 °C over 13 min. Concurrently, a flame-dried 1 dram screw-cap vial was charged with enol carbonate 42 (300.1 mg, 0.814 mmol). After sealing with a septum-bearing cap, the vial was placed under high vacuum and refilled with Ar. Deoxygenated anhydrous benzene (1 mL) was added via syringe, and the resulting solution was cooled to 11 °C. The enol carbonate solution was then transferred via cannula under positive N2 pressure to the catalyst solution, washing the original flask with deoxygenated anhydrous benzene (1 mL, allowed to cool briefly before transferring). The reaction, which turned green, was then stirred at 12 °C for 21.5 h. Solvent was removed under reduced pressure. The residue was suspended in Et2O and filtered through a plug of cotton to remove precipitated Pd. The filtrate was then concentrated under reduced pressure. The residue was suspended in 10% Et2O/pentane and applied to a silica gel column (11 × 2.5 cm). Flash chromatography (10% Et2O/pentane eluent) then provided α,ω-diene (+)-45 (242.9 mg, 92%) as an off-white solid. Observed 91% ee as determined by chiral HPLC analysis (Chiralpak® AD, 0.5% EtOH/hexanes, 1 mL/min, 254 nm, tR (major) = 10.4 min; tR (minor) = 12.6 min). Rf 0.16 (10% Et2O/petroleum ether eluent); [α]24D +7.15° (c 1.015, CHCl3); 1H NMR (500 MHz, CDCl3) δ 5.10–5.52 (br m, 1H), 5.28 (s, 1H), 5.27 (d, J = 0.97 Hz, 1H), 4.87 (br s, 1H), 4.85 (br s, 1H), 3.51–3.63 (m, 2H), 1.85–3.10 (br m, 6H), 2.02 (app. septet, J = 6.7 Hz, 1H), 1.72 (br s, 3H), 1.22 (br s, 3H), 1.16 (s, 3H), 0.97 (d, J = 6.8 Hz, 6H); 13C NMR (126 MHz, C6D6, overlapping of resonances was observed) δ 200.4 (br), 171.4, 142.6 (br), 117.5, 116.5 (br), 101.7, 74.2, 55.9, 43.6, 39.9 (br), 39.1, 27.9, 24.9 (br), 24.5 (br), 19.0; IR (neat film, NaCl) ν 3073, 2962, 2935, 2877, 1655, 1622, 1471, 1445, 1429, 1406, 1383, 1366, 1341, 1298, 1280, 1222, 1199, 1172, 1151, 1134, 1053, 1010, 968, 892, 856, 832, 789, 691, 653, 622 cm−1; HRMS (EI+) m/z calcd. for C19H29ClO2 [M]+: 324.1856, found 324.1865.

4.7.4. Olefin (±)-68

A 100 mL round-bottomed flask equipped with a stir bar and a septum was flame dried under vacuum. After refilling with Ar, anhydrous THF (26 mL) and anhydrous diisopropylamine (1.0 mL, 7.14 mmol) were added via syringe, and the solution was cooled to 0 °C in an ice bath. n-BuLi (2.57 M in hexanes, 2.65 mL, 6.81 mmol) was added dropwise via syringe, and the solution was stirred at 0 °C for 30 min. The resulting LDA solution was then cooled to −78 °C over 20 min. Vinylogous ester 11 (1.29 g, 6.57 mmol) in anhydrous THF (1 mL) was then added dropwise over 1 min via syringe, washing the original flask with anhydrous THF (2 × 1 mL). The reaction was then stirred for 1 h at −78 °C to provide a yellow solution. Anhydrous hexamethylphosphoramide (1.25 mL, 7.18 mmol) was added in one portion via syringe over 1 min, and the reaction was stirred for 1 h at −78 °C. 5-Iodo-2-methyl-1-pentene (67)48 50 (1.67 g, 82.6% pure by mass [contained 15.8% pentane and 1.6% benzene by mass], 6.57 mmol) was added in one portion via syringe, washing the original flask with anhydrous THF (2 × 2 mL). The cold bath was removed, and the reaction was allowed to warm to 23 °C as it was stirred for 45 h. Saturated NH4Cl (aq) (40 mL) was added to give a colorless biphasic mixture, and the organic layer was separated. The aqueous layer was extracted with Et2O (2 × 150 mL), and the combined organic layers were washed with brine (2 × 200 mL). After drying over MgSO4, solvent was removed under reduced pressure. Flash chromatography over silica gel (15.5 × 5 cm silica, 10% Et2O/petroleum ether eluent until product begins to elute, then 20% Et2O/petroleum ether eluent) then provided olefin (±)-68 (1.261 g, 69%) as a very slightly yellow liquid. Rf 0.11 (10% Et2O/petroleum ether eluent); 1H NMR (500 MHz, CDCl3) δ 5.22 (s, 1H), 4.66–4.70 (m, 1H), 4.64–4.68 (m, 1H), 3.53–3.60 (m, 2H), 2.35 (d, J = 17.6 Hz, 1H), 2.16 (d, J = 17.8 Hz, 1H), 1.95–2.08 (m, 3H), 1.92 (dd, J = 6.5 Hz, 1H), 1.70 (s, 3H), 1.51–1.62 (m, 1H), 1.35–1.51 (m, 3H), 1.06 (s, 3H), 0.97 (s, 3H), 0.96 (d, J = 6.6 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 202.7, 174.4, 145.7, 109.9, 100.4, 74.5, 57.0, 41.2, 37.8, 34.9, 28.6, 27.7, 26.5, 25.8, 24.9, 22.3, 19.1; IR (neat film, NaCl) ν 3072, 2960, 2933, 2873, 1654, 1612, 1471, 1424, 1403, 1382, 1364, 1317, 1297, 1218, 1189, 1179, 1153, 1130, 1008, 968, 884, 842, 826 cm−1; HRMS (EI+) m/z calcd. for C18H30O2 [M]+: 278.2246, found 278.2250.

4.7.5. Enol carbonate 43

A 250 mL two-neck round-bottomed flask equipped with a 10 mL addition funnel, a stir bar, and two septa was flame dried under vacuum. After refilling with Ar, anhydrous THF (28 mL) and anhydrous diisopropylamine (0.72 mL, 5.14 mmol) were added via syringe, and the solution was cooled to 0 °C in an ice bath. n-BuLi (2.57 M in hexanes, 1.85 mL, 4.75 mmol) was added dropwise via syringe, and the solution was stirred at 0 °C for 41 min. The resulting LDA solution was then cooled to −78 °C over 20 min. Olefin (±)-68 (1.20 g, 4.31 mmol) in anhydrous THF (5 mL) was then added dropwise over 6 min via the addition funnel, washing the funnel with THF (2.5 mL) upon complete addition. After stirring at −78 °C for 1 h, anhydrous N,N,N′,N′-tetramethylethylenediamine (0.78 mL, 5.20 mmol) was added dropwise over 1 min via syringe. After stirring at −78 °C for an additional 1 h, chloroformate 20 (737 mg, 4.76 mmol) in anhydrous THF (5 mL) was then added dropwise over 15 min via the addition funnel, washing the funnel with THF (2.5 mL) upon complete addition. The reaction was stirred for an additional 3 h at −78 °C, whereupon saturated NaHCO3 (aq) (17 mL) and H2O (17 mL) were added. The mixture was allowed to warm to 23 °C with the aid of a 23 °C water bath, at which time the organic layer was immediately separated. The aqueous layer was extracted with Et2O (2 × 100 mL), and the combined organic layers were washed with brine (2 × 100 mL) and dried over MgSO4. Solvent was removed under reduced pressure. Flash chromatography over Florisil® (100–200 mesh, 12 × 5 cm, 2.5% Et2O/petroleum ether eluent) then provided enol carbonate 43 (1.074 g, 63%) as a colorless liquid containing residual Et2O (<1% by mass) and a minor unidentified impurity (4% by area) by 1H NMR spectroscopy. Rf 0.21 (2.5% Et2 O/petroleum ether eluent); 1H NMR (500 MHz, CDCl3) δ 5.53–5.56 (m, 1H), 5.43–5.47 (m, 1H), 4.75 (s, 1H), 4.71–4.74 (m, 2H), 4.68–4.71 (br m, 1H), 4.65–4.68 (br m, 1H), 3.47 (d, J = 6.6 Hz, 2H), 2.18 (s, 2H), 1.92–2.05 (m, 5H), 1.71 (s, 3H), 1.47–1.55 (m, 2H), 1.07 (s, 6H), 0.94 (d, J = 6.6 Hz, 6H); 13C NMR (126 MHz, CDCl3) δ 157.6, 153.0, 145.6, 141.8, 135.1, 123.5, 115.4, 110.0, 91.0, 73.8, 69.1, 43.4, 38.0, 35.3, 27.8, 27.5, 26.0, 25.0, 22.3, 19.2; IR (neat film, NaCl) ν 3073, 2958, 2913, 2873, 2823, 1762, 1661, 1648, 1639, 1621, 1470, 1420, 1382, 1367, 1362, 1329, 1280, 1240, 1183, 1157, 1109, 1054, 1023, 1003, 965, 922, 887, 782 cm−1; HRMS (EI+) m/z calcd. for C22H33ClO4 [M]+: 396.2067, found 396.2083.

4.7.6. α,ω-Diene (−)-46