Abstract

Destruction of bioweapon facilities due to explosion or fire could aerosolize highly pathogenic microorganisms. The post-event air quality assessment is conducted through air sampling. A bioaerosol sample (often collected on a filter for further culture-based analysis) also contains combustion products, which may influence the microbial culturability and, thus, impact the outcome. We have examined the interaction between spores deposited on collection filters using two simulants of Bacillus anthracis [B. thuringiensis (Bt) and B. atrophaeus (referred to as BG)] and incoming combustion products of Al as well as Mg and B·Ti (common ingredient of metalized explosives). Spores extracted from Teflon, polycarbonate, mixed cellulose ester (MCE), and gelatin filters (most common filter media for bioaerosol sampling), which were exposed to combustion products during a short-term sampling, were analyzed by cultivation. Surprisingly, we observed that aluminum combustion products enhanced the culturability of Bt (but not BG) spores on Teflon filters increasing the culturable count by more than an order of magnitude. Testing polycarbonate and MCE filter materials also revealed a moderate increase of culturability although gelatin did not. No effect was observed with either of the two species interacting on either filter media with products originated by combustion of Mg and B·Ti. Sample contamination, spore agglomeration, effect of a filter material on the spore survival, changes in the spore wall ultrastructure and germination, as well as other factors were explored to interpret the findings. The study raises a question about the reliability of certain filter materials for collecting airborne bio-threat agents in combustion environments.

Keywords: Bioaerosol, Anthrax spores, Air sampling, Bio-threat

Introduction:

In the event when a bio-weapon facility is accidentally or intentionally targeted by explosives, it is advisable to perform an ambient air monitoring because even very minor release of highly pathogenic bio-threat agents in the atmosphere resulting from this destruction may cause a catastrophic public health impact. Therefore, appropriate strategies and methods for collecting biological aerosol samples from explosion/combustion environments are being developed as a key component of environmental and defense research programs in the United States (Henderson, 2004; Hogan et al., 2005; Koch, 2006) Tan et al., 2006; Nadasi et al., 2007) as well as in many other countries (Tan et al., 2006; Nadasi et al., 2007). Among different bioaerosol sampling methods, collection on a filter is often a method of choice in the above scenario. The specifics of field conditions and operational objectives of a military or counter-measure operation as well as the fast development and propagation of a released cloud make an investigator rely on a short-term sample collection.

The nature of airborne microorganisms released following a destruction of a bio-weapon facility is vastly different from a typical ambient or indoor bioaerosol. The bio-weapon agents are likely to be bacterial endospores mostly in the dormant spore form. E.g., spores of Bacillus anthracis (the causative agent of anthrax), can remain dormant for decades (Mock & Fouet, 2001). These dormant spores constitute an enhanced risk of pathogenicity because they are more resistant to environmental stresses than non-spore-forming viable bacteria and likely to stay infectious in ambient environment for a much longer period.

Particulate matter and gaseous compounds released during explosion and combustion interact with the released microorganisms in the environment. When a bioaerosol sample is collected on a filter, the combustion products and microorganisms also interact on the collection media, which may affect the culturability and thus cause a bias in the assessment of air contamination by viable bioaerosol. Generally, this interaction may either inactivate the collected spores or break the dormancy of the collected spores, which, in turn, can either decrease or increase the culturable count.

The filter media most commonly utilized for bioaerosol collection include polytetrafluoroethylene (PTFE) or Teflon, polycarbonate, mixed cellulose ester, and gelatin. Some of the above have been used in the past for sampling of airborne B. anthracis spores during suspected environmental contamination episodes (CDC, 2004; Small et al., 2001). Smooth, sticky, or uneven surfaces of these filter media as well as the constituents of fibers and gelatin could influence the interactions between spores and combustion products. Little is known about the performance of these collection filters in the presence of various explosive and combustion products, including metallic compounds widely used in conventional weaponry.

In this study, we focused mainly on combustion products of aluminum (Al); limited experiments were performed also using combustion products of magnesium (Mg) and boron-titanium (B·Ti). Al-based powders were initially selected because they are widely deployed in energetic formulations for the metallized explosives (Carney et al., 2006; Gogulya et al., 2004; Keshavarz, 2005). Aluminum powders are also widely used in various propellants and pyrotechnics (Pokhil et al., 1972; Kuo & Summerfield, 1984). Combustion of Al powders has been extensively investigated. Its combustion products include (but are not limited to) aluminum oxide, carbon oxides, and soot (Umbrajkar et al., 2008). Previous studies demonstrated that aerosolized Bacillus spores were significantly inactivated when passed through the flame produced by Al-containing materials (Grinshpun et al., 2010; 2012; Ali et al., 2014; Grinshpun, 2014). However, there is a lack of data with respect to the interaction between products of Al combustion with spores collected on filters. Similar to Al, powdered Mg has been widely explored for deployment as metal fuel additive in explosives, propellants, and pyrotechnics (Li et al., 2008). Boron and titanium are also considered as metal fuel additives in different energetic formulations due to their relatively high combustion enthalpies (Yeh & Kuo, 1996; Foelsche et al., 1999; Gogulya & Brazhnikov, 2009; Schoenitz et al., 2003; Trunov et al., 2008).

Several previous studies on microbial inactivation utilized Bacillus thuringiensis (Bt) and B. atrophaeus (also known as BG)] as simulants of B. anthracis (Faille et al., 1999; Beuchat et al., 2005; Rice et al., 2005; Helfinstine et al., 2005; Luna et al., 2008). Therefore, we have tested these two species as challenge aerosols in this investigation.

Materials and Methods:

Experimental setup

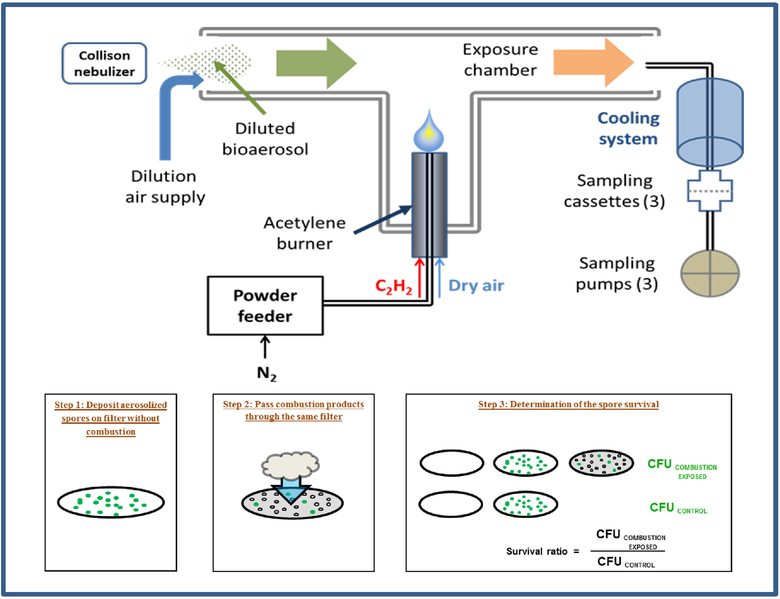

The experimental setup utilized in our previous studies (Grinshpun et al., 2010, 2012, 2013; Grinshpun, 2014; Ali et al., 2014) was modified and adopted for this effort. The main component of the setup is a continuous-flow chamber – a horizontal cylindrical channel of 50 mm inner diameter and 320 mm height. The challenge bioaerosol was generated from a surfactant-free, de-ionized water suspension of spores using a six-jet Collison nebulizer (BGI Inc., Waltham, MA) operating at an air flow rate of 6 L min−1. This flow was diluted with a HEPA-filtered dry air flow of 30 L min−1. After passing through a 10-mCi 85Kr charge equilibrator (model 3012, TSI Inc., St. Paul, MN), the resulting 36 L min−1 flow carrying dry airborne spores (Bt or BG) entered the chamber. Spores were subsequently sampled and collected on a tested filter. In our above-quoted studies, the bioaerosol generation and the powder combustion took place simultaneously, and the airborne spores and combustion products were mixed in the chamber air volume. In the present study, the bioaerosol was collected on the filter after passing the chamber with no combustion products in it. Subsequently, the pre-loaded filter was exposed to the products generated by combustion for 1 minute (this sampling time was established as a reasonable minimum). Combustion products were generated by air-acetylene flames seeded with metallic powders of different compositions (see description in the next section). The powder feeder supplied the tested powder to the combustion chamber by a high-velocity gas jet at a specific mass feed rate. An electro-chemical igniter was used to initiate combustion. The burn time of the electro-chemical igniter was ~0.01 s. To eliminate the influence of the ignition-associated combustion products the bioaerosol sampling was delayed by five seconds after combustion began.

The bioaerosol sampling was performed in three identical cylindrical probes at a flow rate of 5 L min−1 through each probe). The probes were oriented isoaxially to the incoming air flow assuring a sampling efficiency of about 95–100%. Each probe ended with a 25-mm filter containing the collection filter being investigated (Teflon, polycarbonate, MCE, or gelatin). We started our experiments with Teflon filters (also known as Polytetrafluoroethylene or PTFE) because they are more durable than MCE and gelatin filters and they previously showed better efficiency compared to polycarbonate filter for collecting airborne Bacillus subtilis endospores (Burton et al., 2005). Polytetrafluoroethylene is a synthetic fluoropolymer of tetrafluoroethylene and the best known brand name of PTFE is Teflon produced DuPont Co. Teflon is prominently non-reactive due to the strength of carbon-fluorine bonds in its structure; consequently, it is often used in containers and pipe work for reactive and corrosive chemicals. Teflon filters are more preferable than others when sampling during destruction of a bio-weapon facility in a high-temperature, harsh environments.

The experimental setup was installed in a Class II biosafety cabinet (Model 6TX, Baker Co., Inc., Sanford, ME). The experimental protocols used in this study for the determination of the spore survival ratio (described below) are schematically presented in Figure 1.

Figure 1.

Schematical representation of the experimental protocol for determining the survival ratio.

Tested combustion materials

Three materials were burned as powders containing close-to-spherical aluminum particles of 3–4.5 μm in diameter, 97.5 % purity (Alfa Aesar, Ward Hill, MA), equiaxial magnesium particles of <44 μm, 99.8 % purity (Alfa Aesar), and non-spherical B-Ti particles of approximately 12 μm average equivalent diameter (Trunov et al., 2008).

Preparation of microbial suspension

Freeze-dried Bt spores were acquired from Certis USA Inc. (Columbia, MD) [referred to as B. thuringiensis serovar kurstaki, Btk, strain SA-11 (product # SA-11 SDTC; technical grade concentrate developed for US Army and Air Force)]. Freeze-dried BG spores were obtained from the US Army Edgewood Laboratories, Aberdeen Proving Ground, MD). These two simulants are well-characterized as they have been extensively used as simulants of bio-warfare agents (Faille et al., 1999; Beuchat et al., 2005; Rice et al., 2005; Helfinstine et al., 2005; Luna et al., 2008).

The originally purchased Btk spores had approx. 65% protein crystals (referred to as insecticidal crystal proteins). Our aerosolization experiments were conducted with the crystal-containing spore suspension as well as with a crystal-free spore suspension. We wanted to have the crystal removed because the toxic insecticidal proteins could influence the culturability. To purify Btk, freeze-dried spores were suspended in 50% EtOH (pH 9.0), washed two to three times by centrifugation until the supernatant was clear, and resuspended in cold acetone overnight in a refrigerator. The suspension was filtered to complete dryness, dried, and crushed into dry powder in mortar and pestle. This procedure enabled us to lower the crystal amount down to 2% from the initial 65% (by number).

As part of preparation of the suspension for aerosolization, the purified Btk powder, original Btk powder (with crystals), as well as the powder made of BG spores were suspended in sterile filtered deionized water, vortexed to remove clumps, centrifuged at approximately 6,300×g for 7 minutes, and washed again for two times. The concentration of viable spores in the suspension was 107–1010 CFU/mL as determined after making serial dilutions and cultivating aliquots on TSA (BD, Franklin Lakes, NJ) at 30°C (for BG) and 37°C (for Btk) for 24 hours and total spore concentration determined by Acridine Orange staining and epifluorescence microscopy.

Analysis of sample, calculation of the survival ratio, data analysis

Immediately after the filter samples were generated, 10 mL of sterile filtered de-ionized water was used to extract the deposits, including spores covered with combustion products. The spores were extracted from filters by intermittent vortexing for two minutes in sterile deionized water. Aliquots of filter extracts were cultivated on tryptic soy agar medium followed by incubation at 30°C or 37°C, depending on the species, for approx. 24 hours. Aliquot volumes ranging from 200 μL to 5 mL were used. The highest volumes were chosen when the colony counts were expected to be close to the limit of detection due to high microbial inactivation by combustion products. After incubation, the colony forming unit (CFU) enumeration was performed for every sample that was exposed to combustion products as well as to those non-exposed (control). An average CFU value per sample was determined from at least three replicate counts. Based on the sampling flow rate and sampling time, the airborne concentration of culturable spores (CFU m−3) was determined for each sample. By comparing the combustion-exposed and non-exposed (control) values, Cculturable(COMBUSTION EXPOSED) and Cculturable(CONTROL), respectively, the survival ratio was quantified:

| (1) |

With the data log-normally distributed, the geometric mean (GM) of the survival ratio as well as the geometric standard deviation (GSD) were calculated. The survival ratios produced by different materials were compared using ANOVA test. A p-value of 0.05 or less was considered to identify statistically significant differences.

To visualize any readily detectable morphological changes in the coat and outer layers of Btk spores treated with Al combustion products on Teflon filters, we performed transmission electron microscopy (TEM). Samples were fixed and prepared for thin-section TEM essentially as described by Margolis (1993).

Results and Discussions:

Survival of purified Btk spores exposed to Al combustion products on filters

Figure 2 presents the survival ratio for purified Btk spores on four filter media exposed to incoming Al combustion products. It was surprising to observe survival ratios exceeding unity. Ideally, all bacteria should survive sampling, corresponding to a survival ratio of one. Various stresses (e.g., very high temperature and exposure to certain chemical compounds during sampling) may inactivate viable bacteria, thus reducing the survival ratio below one. The values above one suggest that the culturable count increased as a result of exposure to products released during combustion of Al powder, i.e., not only these products did not inactivate the spores but instead increased the numbers of colony forming units. This “reverse” effect was most prominently observed on Teflon filters (with the post-exposure culturable count increased by an order of magnitude). A less pronounced, but significant “reverse effect” was also observed when using polycarbonate and MCE filter materials; however, no increase (or decrease) of culturability of Btk spores was found on a gel medium (gelatin filters) (Fig. 2). Since the most robust “reverse effect” was observed for Teflon filters, we conducted follow-up testing using this filter medium.

Figure 2.

Survival ratio of Btk spores (purified) on four filter media exposed to incoming Al combustion products for 1 min (each bar represent a geometric mean of 10 replicate measurements, the error bars represent geometric standard deviation).

Survival of Btk spores (purified and non-purified) and BG spores exposed to combustion products of Al, Mg, and B·Ti on Teflon filters

Testing with non-purified Btk spores on Teflon filters exposed to Al combustion products produced results similar to the testing with purified Btk: an increase in culturability by an order of magnitude. The similarity between the two cases suggests that protein crystals do not significantly affect the interaction between Al combustion products and Btk spores on a Teflon filter.

In contrast to Btk, no “reverse’ effect was observed for BG spores; furthermore, some inactivation occurred due to treatment, which resulted in survival of approximately 30% (geometric mean) of spores on the filter, see Fig. 3.

Figure 3.

Survival ratio for Btk spores (with and without crystals) and BG spores on Teflon filter media when exposed to incoming combustion products of Al, Mg, and B-Ti for 1 min (each bar represent a geometric mean of at least 10 replicate measurements, the error bars represent geometric standard deviation).

No major change in the spore culturability was observed with any of the three microbial challenges (purified and non-purified Btk as well as BG spores) when Teflon filters were exposed to the product of combustion of two other materials, Mg, and B·Ti (Fig. 3). Thus, the increase in colony forming units on Teflon filters was limited to the combination of Btk (either crystal-free or not) and Al combustion products.

Additional experiments were conducted to determine whether the samples extracted from filters were contaminated by bacteria not originally deposited on the filter. For instance, some Btk spores remaining in the walls of the continuous-flow chamber or inside the sampling lines could be re-aerosolized in a subsequent test and be collected on filers, thus increasing the apparent culturable count. A thorough cleaning with a full disassembling of the system was performed between tests, and additional negative and positive controls were introduced in the protocol to rule out the effect of contamination. These additional experiments ruled out the likelihood of contamination at a level that could account for the observed “reverse effect”.

Transmission electron microscopy of Btk spores and interpretation of data

TEM analysis was performed to identify possible morphological changes in the coat and outer layers of Btk spores resulted from their exposure to Al combustion products on Teflon filters. Electron micrographs did not reveal readily detectable differences between exposed and non- exposed samples (Fig. 4 A, B). In particular, there were no obvious differences in the spore exosporium or coat, the outermost structures that would likely to be affected by exposure. While this analysis does not exclude the possibility of subtle effects to the spore due to exposure, we conclude that the reverse culturability effect is unlikely to be the result of a major alteration in spore ultrastructure before extraction of spores from the filters.

Figure 4.

Transmission electron micrographs of Btk spores (purified) collected on Teflon filter: (A) unexposed to combustion products (control sample) and (B) exposed to incoming Al combustion products.

An alternative would be to attribute the enhancement of culturability of Btk spores to their enhanced germination caused, perhaps, by the presence of Al combustion powder coatings on the spores. Since no enhancement was found for BG spores, the effect is believed to be specific to Btk. The enhancement was more evident when collecting spores on a dry filter because in this case the combustion products are likely directly attached to the spore; in contrast, on gelatin filters, the products may have a limited ability to reach to spores embedded more deeply in the gel. The possibility of significant germination of Btk spores assumes that there were a lot of dormant spores in our sample at the start of the experiment. To address this, we analyzed Btk spores using phase contrast microscopy, by which germinated spores that have a dark appearance can be distinguished from dormant (ungerminated) spores that appear bright (Cutting & Vander Horn, 1990). Prior to treatment, all the spores in the sample were bright (or “phase-bright”), indicating that our sample was indeed comprised of dormant, ungerminated spores. For comparison purposes, it would have been meaningful to utilize the phase contrast microscopy for examining also the combustion-treated samples; however, the exposed filter extracts (which developed numerous colonies on agar plates) were not analyzable because of the presence of soot particles. Overall, it was concluded that germination of dormant Btk spores triggered by exposure to Al combustion products could, at least partially, explain the culturability enhancement that was observed on dry filters.

Another possible explanation for the increase in the Btk spore count on filter samples is clumping. A spore agglomerate could produce only a single colony when placed on solid agar, even though it consists of multiple spores. A deagglomerated sample is expected to produce more colonies. Thus, some deagglomeration of spores occurring on dry filters or during extraction could affect the count. To examine this possibility, we initiated the deaggregation of spores by briefly sonicating filter extracts prior to plating. This increased the plate count of Btk colonies as much as 4-fold. While the above effect may help understand increase of the culturability of Btk on the treated samples, it can only partially explain the “reverse” effect because even the highest measured (4-fold) increase in the colony count due to deaggregation is insufficient to account for the entirety of the Al-induced enhancement (e.g., 10-fold for Teflon filters).

One may hypothesize that the products of Al combustion could improve the efficiency of Btk spore extraction from filters, which would increase the spore count on the filter samples exposed to Al. We have not found any evidence of the above in the literature. However, even the extraction was somehow enhanced, it does not seem plausible that this effect would increase the culturable count by as much as an order of magnitude.

At this point, we have not developed a fair understanding of the mechanistic basis for the “reverse” effect, and do not know why it was observed only for spores exposed to combustion products of Al, but not Mg and B·Ti. Possibly, the mechanism is specific to the interaction of Al with the Btk spore surface. Due to a lack published studies on this topic, it is challenging to suggest possible chemical interactions with metals. An even more speculative possibility is raised by previous reports of aluminum-induced changes of microbial membrane phospholipid (Jones & Kochian, 1997). We hypothesize therefore that combustion of Al may generate chemical species that are able to penetrate deep into spore and reach the inner membrane, altering the lipid and, indirectly, proteins involved in spore germination. Regardless of the mechanism, our data, taken as a whole, demonstrate that interactions between spores and combustion products are clearly more complex than we presently understand, and require more extensive analysis and likely additional experiments.

Conclusions:

Collection of aerosolized spores on filters in presence of chemicals in the air (e.g., combustion products) may inactivate some collected viable bacteria, which decreases the culturable count in the sample, thus causing bias in assessing the air bio-contamination. In this study, we discovered a “reverse” effect: exposure of Btk spores to products of combustion of an Al powder on collection filter media such as Teflon, MCE, and polycarbonate was found to increase the spore culturability (up to about 10-fold as was determined for Teflon filters). No similar increase was observed for gelatin filters. No enhancement of culturability was found for BG spores. Neither species produced the effect after exposure to combustion products of Mg and B-Ti. Altogether, the “reverse” effect observed in our experiments was limited to a combination of Btk (purified and non-purified) and Al combustion products. The data suggest that, in light of this effect, gelatin filters may be considered as a better alternative to Teflon and other tested filters when collecting viable Btk spores from combustion air environments. This finding is important as Btk is utilized in many research efforts as a well-established simulant of B. anthracis. Since no “reverse” effect was documented for another B. anthracis simulant, BG spores, the data suggest no similar limitations concerning the filter material for collecting BG from post-explosion/combustion air environments.

Highlights.

Aluminum combustion products may enhance the culturability of spores on dry filters

This effect was observed for B. thuringiensis, but not for B. atrophaeus

No similar effect was found for other materials (Mg or B·Ti) or for Gelatin filters

Acknowledgements:

This study was funded by the Defense Threat Reduction Agency (DTRA, US Department of Defense) through Grants HDTRA-1-08-1-0012 and HDTRA1-11-1-0017. The authors are grateful for this financial support. We are also thankful to Dr. Peter Setlow for his valuable suggestions concerning the data interpretations.

References:

- Aly Y, Zhang S, Schoenitz M, Hoffmann V, Dreizin EL, Yermakov M, Indugula R, Grinshpun SA. 2014. Iodine-containing aluminum-based fuels for inactivation of bioaerosols. Combustion and Flame 161:303–310. [Google Scholar]

- Beuchat LR, Pettigrew CA, Tremblay ME, Roselle BJ, Scouten AJ. 2005. Lethality of chlorine, chlorine dioxide, and a commercial fruit and vegetable sanitizer to vegetative cells and spores of Bacillus cereus and spores of Bacillus thuringiensis. Ind Microbiol Biotechnol 32:301–308. [DOI] [PubMed] [Google Scholar]

- Carney JR, Miller JS, Gump JC, Pangilinan GI. 2006. Time-resolved optical measurements of the post-detonation combustion of aluminized explosives, Rev. Sci. Instrum, 77: Article No. 063103. [Google Scholar]

- CDC (Centers for Disease Control and Prevention), National Institute for Occupational Safety and Health, NIOSH evaluation of air sampling methodologies for Bacillus anthracis in a United States Postal Service processing and distribution center–Trenton, New Jersey, HETA; 2002-0109-2927, 2004. [Google Scholar]

- Cutting SM, Vander Horn PB (Eds.). 1990. Molecular Biological Methods for Bacillus. John Wiley & Sons Ltd., Chichester, United Kingdom. [Google Scholar]

- Faille C, Dennin L, Bellon-Fontaine MN, Benezech T. 1999. Cleanability of stainless steel surfaces soiled by Bacillus thuringiensis spores under various flow conditions. Biofouling, 14:143–151. [Google Scholar]

- Foelsche RO, Burton RL, Krier H. 1999. Boron particle ignition and combustion at 30–150 atm, Combust Flame 117:32–58. [Google Scholar]

- Gogulya MF, Makhov MN, Dolgoborodov AY, Brazhnikov MA, Arkhipov VI, Shchetinin VG. 2004. Mechanical sensitivity and detonation parameters of aluminized explosives. Combust Explos Shock Waves 40:445–457. [Google Scholar]

- Gogulya MF, Brazhnikov MA. 2009. Detonation of metalized composite explosives Shock Wave Sci Tech Ref Lib. Vol. 4 (Ed.: Zhang F), Springer, Berlin, 2009, Chapter 4. [Google Scholar]

- Grinshpun SA. 2014. Inactivation of viable bioaerosol particles: from indoor air quality to bio-defense applications [Keynote presentation]. Abstracts of the International Aerosol Conference (Busan, South Korea, August 28 – September 2, 2014), PO69–1. [Google Scholar]

- Grinshpun SA, Li C, Adhikari A, Yermakov M, Reponen T, Schoenitz M, Dreizin E, Hoffmann V, Trunov M. 2010. Method for studying survival of airborne viable microorganisms in combustion environments: development and evaluation. Aerosol & Air Quality Res 10(5):414–424. [Google Scholar]

- Grinshpun SA, Adhikari A, Yermakov M, Reponen T, Dreizin E, Schoenitz M, Hoffmann V, Zhang S. 2012. Inactivation of aerosolized BG endospores and MS2 viruses by combustion of reactive materials. Environ Sci Technol 46 (13):7332–7341. [DOI] [PubMed] [Google Scholar]

- Grinshpun SA, Yermakov M, Indugula R, He K, Reponen T, Dreizin E, Schoenitz M, Zhang S, Aly Y. 2013. Inactivation of aerosolized spores in combustion environments using filled nanocomposite materials: study with two surrogates of Bacillus anthracis. Abstracts of the European Aerosol Conference (Prague, Czech Republic, September 1–6, 2013). [Google Scholar]

- Helfinstine SL, Vargas-Aburto C, Uribe RM, Woolverton CJ. 2005. Inactivation of Bacillus endospores in envelopes by electron beam irradiation. Appl Environ Microbiol 71 (11):7029–7032. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Henderson DA. 2004. The threat of aerosolized biological weapons. ASHRAE J 46:50–53. [Google Scholar]

- Henningson EW, Ahlberg MS. 1994. Evaluation of microbiological aerosol samplers: A review. J Aerosol Sci 25(8):1459–1492. [Google Scholar]

- Hogan CJ Jr1, Kettleson EM, Lee MH, Ramaswami B, Angenent LT, Biswas P. 2005. Sampling methodologies and dosage assessment techniques for submicrometre and ultrafine virus aerosol particles. J Appl Microbiol 99(6):1422–1434. [DOI] [PubMed] [Google Scholar]

- Jones DL, Kochian LV. 1997. Aluminum interaction with plasma membrane lipids and enzyme metal binding sites and its potential role in Al cytotoxicity. FEBS Lett 400(1):51–57. [DOI] [PubMed] [Google Scholar]

- Keshavarz MH. 2005. New method for predicting detonation velocities of aluminized explosives. Combust Flame 142:303–307. [Google Scholar]

- Koch A 2006. US makes quiet progress on ‘agent defeat’. Jane’s Defense Weekly JAN: 405–406. [Google Scholar]

- Kuo KK, Summerfield M (Eds.), Fundamentals of Solid Propellant Combustion, AIAA, New York, 1984. [Google Scholar]

- Li G, Yuan CM, Zhang PH, Chen BZ. 2008. Experiment-based fire and explosion risk analysis for powdered magnesium production methods. J Loss Prevent Proc 21:461–465. [Google Scholar]

- Luna VA, Cannons AC, Amuso PT, Cattani J. 2008. The inactivation and removal of airborne Bacillus atrophaeus endospores from air circulation systems using UVC and HEPA filters. J Appl Microbiol 104(2):489–498. [DOI] [PubMed] [Google Scholar]

- Margolis P 1993. Establishment of cell type during sporulation in Bacillus subtilis [Ph.D.]: Harvard University. [DOI] [PubMed] [Google Scholar]

- Mock M, Fouet A. 2001. Anthrax. Annu Rev Microbiol 55:647–671. [DOI] [PubMed] [Google Scholar]

- Nadasi E, Varjas T, Prantner I, Virag V, Ember I. 2007. Bioterrorism: Warfare of the 21st century. Gene Ther Mol Biol 11: 315–320. [Google Scholar]

- Pokhil PF, Belyaev AF, Frolov YV, Logachev VS, Korotkov AI. 1972. Combustion of powdered metals in active media. Nauka, Moscow, 1972. [Google Scholar]; See also FTD-MT-24-551-73 translated from Russian by Foreign Technology Division. Wright Patterson Air Force Base. Ohio. Oct. 1973.

- Rice EW, Adcock NJ, Sivaganesan M, Rose LJ. 2005. Inactivation of spores of Bacillus anthracis Sterne, Bacillus cereus, and Bacillus thuringiensis subsp. israelensis by chlorination. Appl Environ Microbiol 71(9):5587–5589. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schoenitz M, Dreizin EL, Shtessel E. 2003. Constant volume explosion of aerosols of metallic mechanical alloys and powder blends. J Propul Power 19:405–412. [Google Scholar]

- Small D, Klusaritz B, Muller P, and NIOSH, NCID, EIS, Officers, CDC. 2001. Evaluation of Bacillus anthracis contamination inside the Brentwood mail processing and distribution center - District of Columbia, October 2001. Morbidity Mortality Weekly Rep 50(50):1129–1133. [Google Scholar]

- Tan B, Peng R, Chen X, Li H, Yu W, Chu S. 2006. Evaluation of destruction methods of chemical and biological warfare agents. J Chongqing University (Natural Science Edition) [in Chinese] 29: 127–131. [Google Scholar]

- Trunov M, Hoffmann V, Schoenitz M, Dreizin EL. 2008. Combustion of boron-titanium nanocomposite powders in different environments. J Propul Power 24:184–191. [Google Scholar]

- Umbrajkar SM, Seshadri S, Schoenitz M, Hoffmann VK, Dreizin EL. 2008. Aluminum-rich Al-MoO3 nanocomposite powders prepared by arrested reactive milling. J Prop Power 24:192–198. [Google Scholar]

- Yeh CL, Kuo KK. 1996. Ignition and Combustion of Boron Particles. Prog Energ Combust 22: 511–541. [Google Scholar]