Abstract

A full Co20Fe60B20\MgO\ Co20Fe60B20 perpendicular magnetic tunnel junction (pMTJ) with (Co\Pt) multilayers as pinning layers and different functional multilayers stacks were made and annealed at different temperatures. The tunneling magnetoresistance ratio (TMR) and MgO barrier resistance-area product (RA) were measured and analyzed as a function of annealing temperature. The TMR of pMTJs dramatically declines with increasing annealing temperatures from 320 °C to 400 °C while the RA increases with temperature from 375 °C to 450 °C. The pMTJs and partial stacks were also measured in a vibrating sample magnetometer (VSM). We found that the (Co\Pt) multilayers are very stable and maintain a magnetization direction perpendicular to the film plane up to 450 °C. However, the magnetization direction of the CoFeB above and below the MgO barrier rotates from perpendicular to in-plane with increasing annealing temperature. Furthermore, the CoFeB layer influences the adjacent (Co\Pt) layers to rotate at the same time. The pMTJs’ elemental depth profiles in the as deposited and annealed states were determined by Secondary Ion Mass Spectrometry (SIMS). We found that Boron and Tantalum migrate towards the top of the stack. The other elements (Platinum, Cobalt, Ruthenium, and Magnesium) are very stable and do not interdiffuse during annealing up to 450°C.

Introduction

Next generation memory technologies must satisfy the requirements of ever increasing speed and recording density, while maintaining data retention, endurance, and low power consumption. The memory technology of spin-transfer torque (STT) magnetic random access memory (MRAM) has shown the potential to meet all these requirements. The STT effect was first demonstrated in devices with in-plane magnetization. In order to further improve memory density and writing ability, materials with perpendicular magnetic anisotropy (PMA) were introduced into the memory cells and were found to also exhibit the STT effect [1-8].

In fact, faster STT switching and lower write error rates were demonstrated in CoFeB\MgO based pMTJs than those in MTJs with an in-plane easy axis [9-10]. In addition, the pMTJs are expected to operate at lower switching current and to provide a faster switching speed due to their high anisotropy at reduced thickness [11-12]. pMTJs also benefit from having a better thermal stability. pMTJs have been prepared using (Co\Pd) or (Co\Pt) multilayers, superlattices [1, 14-15], or L10-ordered alloys [16] as the ferrimagnets.

First principle calculations have shown that PMA is related to the band structure of the ferromagnets, which depends on the crystalline structure of both the CoFeB and MgO layers. Since annealing improves the crystalline structures, the band structures of CoFeB and MgO will be changed, thereby changing the PMA of the MTJ system [17].

In the CoFeB\MgO\CoFeB system, the PMA and perpendicular TMR (pTMR) follow a similar trend with annealing temperature, but the maximum pTMR appears at 300 °C. At this temperature the switching field of the CoFeB free layer has already dropped about 30% from its peak value, indicating that the maximum TMR and thermal stability may not be achieved at the same annealing temperature [18].

In this paper we will discuss the relationship among pTMR ratio, RA, the Co20Fe60B20 PMA and the inter-diffusion of the various elements after annealing at different temperatures.

Experimental

All samples were deposited onto 20 cm diameter SiO2 wafers using a Singulus TIMARIS [19] physical vapor deposition system with a base vacuum pressure better than 7.9 × 10−7 Pa (6.0 × 10−9 Torr).

In order to determine the effects of different contributions to the magnetic anisotropy on the characteristics of pMTJs, different stacks were prepared and subsequently given a series of different annealing treatments. The stacks were deposited onto thermally oxidized 300 mm Si substrates with an oxide thickness of 100 nm. The stacks are as follows (with the numbers in parentheses being the thicknesses in nanometers)

- SiO2\ Ta (5)\ CuN (30)\Ta (5)\ Co20Fe60B20 (1.1)\ MgO (1.0)\ Co20Fe60B20 (1.4)\ Ta (0.4)\ Co (1)\ Pt (0.8)\ 3x [Co (0.25)\ Pt (0.8)]\ Co (0.6)\ Ru (0.85)\ Co (0.6)\ Pt (0.8)\ 13x [Co (0.25)\ Pt (0.8)]\ Ta (5)\ CuN (10)\ Ru (7)In this full pMTJ stack structure, the bottom Co20Fe60B20 is the free layer (FL) and is perpendicularly magnetized due to interface anisotropies induced by the MgO barrier layer and the Ta seed layer. The reference layer (RL) consists of another Co20Fe60B20 layer acting as a spin polarizer. It is pinned through a thin Ta layer to a synthetic ferrimagnet comprised of 3 repeats of (Co\Pt) which are antiferromagnetically coupled via a Ru layer to another 13 repeats of (Co\Pt). The stack drawing is shown as figure 1 (a).

- SiO2\ Ta (5)\ CuN (30)\Ta (5)\ Co (1)\ Pt (0.8)\ 3x [Co (0.25)\ Pt (0.8)]\ Co (0.6)\ Ru (0.85)\ 13x [Co (0.25)\ Pt (0.8)]\ Ta (5)\ Ru (7)This stack consists of the bottom electrode and the synthetic ferrimagnet only. The stack drawing is shown as figure 1 (b).

- SiO2\Ta (5)\ CuN (30)\Ta (5)\ Co20Fe60B20 (0.6)\ MgO (1)\ Co20Fe60B20 (1.4)\ Ta (0.4)\ Co (1)\ Pt (0.8)\ 4x [Co (0.25)\ Pt (0.8)]\ Ta (5)\ CuN (10)\ Ru (7)In this stack, the top Co20Fe60B20 (RL) is magnetically coupled to a perpendicular ferromagnet consisting of (Co\Pt) multilayers. The thin Co20Fe60B20 layer underneath the MgO layer is so thin it is magnetically inactive [20] but serves to provide a similar seed for the MgO as in the full pMTJ stack. The stack drawing is shown as figure 1 (c).

- SiO2\Ta (5)\ CuN (30)\Ta (5)\ MgO (1)\ Co20Fe60B20 (1.4)\ Ta (0.4)\ Co (1)\ Pt (0.8)\ 4x [Co (0.25)\ Pt (0.8)]\ Ta (5)\ CuN (10)\ Ru (7)In this stack, the top Co20Fe60B20 (RL) is magnetically coupled to a perpendicular ferromagnet consisting of (Co\Pt) multilayers. But in this stack there is no thin Co20Fe60B20 seed layer underneath the MgO layer as in stack III. The stack drawing is shown as figure 1 (d).

Fig. 1.

Schematic drawings of the layered structures in (a) Stack I, (b) Stack II, (c) Stack III, and (d) Stack IV examined in this study showing the functions of the different components (left side) and identifying the elements and their thicknesses (in nm) for each component (right side). The top is the stack surface and the bottom contact sits on the SiO2 substrate.

From each of the sample stacks separate pieces were annealed in a vacuum chamber with vacuum better than 6.7 × 10−2 Pa (5.0 ×10−4 Torr) at different temperatures ranging from 300 °C to 450 °C (in 25 °C increments) for one hour in the presence of an out-of-plane magnetic field of 398 kA/m (5 kOe). As the samples were furnace heated and cooled, it also took about 25 and 40 minutes respectively to heat and cool the sample between room temperature and the annealing temperature. For each annealing temperature, pieces from all four stacks were annealed at the same time in order to ensure the same conditions for all stacks. This was particularly important for analyzing stack III and IV samples.

The TMR ratio and RA of stack I (full pMTJ) were measured using a Current-In-Plane Tunneling (CIPT) apparatus at room temperature and applying a perpendicular magnetic field. The magnetic field was varied from −30 kA/m (−376 Oe) to +30 kA/m (+376 Oe) and each sample was measured in two different locations separated by 1.0 cm. The TMR ratio result was the average of these two measurements.

Magnetic properties were measured on 5 mm × 5 mm pieces of the samples in a vibrating sample magnetometer (VSM). These pieces were measured in the presence of a perpendicular magnetic field with respect to the film surface, but components of the magnetization in the perpendicular and in-plane directions were separately measured simultaneously. During the measurement, the sample vibration frequency was 75 Hz, and the measurements were carried out at room temperature.

Secondary Ion Mass Spectrometry (SIMS) was used to determine the concentration of elemental species in the sample as a function of depth. It utilizes an energetic ion beam to sputter away the solid surface and produce ionized sputtered particles which are detected using mass spectrometry. As the SIMS technique relies upon the removal of atoms from the surface, it is ideally suited for depth profiling applications. A depth profile of a sample may be obtained simply by recording sequential SIMS spectra as the surface is gradually eroded away over time by the incident ion beam. A plot of the intensity of a given mass signal as a function of time is a direct representation of the variation of its concentration with depth. One of the main advantages of the SIMS depth profiling technique is its high sensitivity to very low concentrations (sub-ppm, or ppb) of the elements.

In this study, the samples with a size of 20 mm × 30 mm were mounted at an angle of ~100 degree face to the ion gun. During ion milling using Ar the sample was cooled down to 10 °C. Each element's dwell time was set to 100 ms. The ion milling rate varies with the element, and some representative rates were 1.42 nm/min, 0.92 nm/min and 2.7 nm/min for Co, Ta, and Pt respectively.

Results and Discussion

CIPT and Magnetometry

The magnetization (M) vs. applied field (H) hysteresis loop for the full pMTJ stack I, with | H | ≤ 477 kA/m (6 kOe), is shown in Figure 2. One may deduce from this figure the switching fields for the different ferromagnetic parts (i.e., blocks) in the stack. This shows that perpendicular (to the film plane) fields of 30 kA/m are sufficient to switch the magnetization direction of the free layer without switching the magnetization direction of the reference layer. The reference layer requires fields between 160 kA/m (2000 Oe) and 320 kA/m (4000 Oe) to switch its magnetization direction. Figure 3 shows the TMR ratio and RA of pMTJ stack I measured by CIPT as a function of the annealing temperature. From 300 °C to 325 °C the TMR ratio increases slightly. Above 325 °C, the TMR ratio decreases and drops to 0 at 400 °C. Note, the RA has also reduced after annealing between 300 °C to 375 °C. This reduction is most likely due to an improvement in the MgO (100) crystalline structure as atomic mobility increases at higher temperatures. Above 375 °C, however, the RA increases dramatically with increasing annealing temperature. This increase may be due to the development of a rougher interface with increasing temperature. Another possible reason is that elements, like Boron, may diffuse into the MgO barrier layer and destroy both the MgO (100) crystal structure and the smooth layer interfaces during the high temperature annealing [21]. The strength of Hilc increases likely due to interface orange-peel coupling, as indicated in Figure 5, also prove this explanation.

Fig. 2.

Magnetization (M) vs. applied magnetic field (H) perpendicular to the film plane measured in a VSM for the as-deposited stack I. The arrows indicate the orientation of the magnetization in the different functional layers at different applied fields while sweeping from positive to negative saturation.

Fig. 3.

The TMR and RA of the pMTJ stack I as a function of the annealing temperature in a perpendicular field. The TMR result shows the TMR ratio starts to decline when annealing above 325 °C until the TMR reaches zero after annealing at 400 °C. The RA has the reverse behavior as it increases dramatically with increasing temperature above 375 °C.

Fig. 5.

The FL coercivity (Hcf) (black dashed line) and the magnitude and sign of the interlayer coupling (Hilc) (blue solid line) of the FL at different annealing temperatures in a perpendicular field. The curves demonstrate that as the annealing temperature increases, both the FL Hcf and Hilc coupling strength also increase in magnitude.

As might be expected, the magnetization (M) vs field (H) hysteresis loop for the pMTJ (Stack I) changes with annealing. These changes are shown for perpendicular field loops measured in a VSM at low fields in Figure 4. At these low perpendicular fields, only the FL Co20Fe60B20 can be rotated. These data show that at low annealing temperatures, 300 °C – 375 °C, the FL Co20Fe60B20 is magnetized perpendicular to the film plane and the coercivity is very small; as the annealing temperature is increased, the magnetic coercivity increases and the magnetization vector rotates further away from the perpendicular direction toward the in-plane direction. Annealing above 400 °C results in the magnetization being switched to the in-plane direction. (the VSM results measured in an in-plane field shows the FL Co20Fe60B20 in-plane signal increases as annealing temperature increases). The magnetization rotation is also accompanied by a change in the TMR ratio: as the annealing temperature increases the TMR ratio decreases until it becomes zero for annealing at and above 400 °C when the FL magnetization has become oriented in the plane of the film.

Fig. 4.

Minor M vs H hysteresis loops measured in a perpendicular field of the FL Co20Fe60B20 after annealing at the indicated temperatures. The hysteresis loop results indicate that as the annealing temperature increases the FL coercivity increases and PMA decreases.

Figure 5. shows the coercivity and shift of the FL Co20Fe60B20 after annealing at different temperatures. It clearly shows that the FL coercivity was increased by annealing. At the same time its coupling to the RL also increased monotonically. The coupling increase may be due to an increased grain size at higher temperatures or the development of an inter-diffusion CoFeB-MgO interface at higher temperatures leading to an increased orange-peel type coupling.

In Figure 6 the high field hysteresis loops measured in a VSM for the full pMTJ (stack I) as a function of annealing temperature are shown. For the 300 °C annealed sample, the magnetization of the FL and RL are both oriented perpendicular to the film plane. At 325 °C, the RL Co20Fe60B20 magnetization begins to rotate to the in-plane direction (shown by the red curve between 64 kA/m (800 Oe) and 167 kA/m (2100 Oe) field). At 375 °C, one notes the FL Co20Fe60B20 has also started to rotate to the in-plane direction [shown by the red bump curve between −39 kA/m (−500 Oe) and +39 kA/m (+500 Oe) fields]. Similar to the data in Figure 5, the low field hysteresis loops in Figure 4 also showed the FL Co20Fe60B20 magnetization rotated from the perpendicular direction to the in-plane direction as the annealing temperature increased. In Figure 4 it is shown that at 400 °C the FL Co20Fe60B20 was all magnetized in the plane of the film, consistent with the data shown in Figure 6. At 425 °C, both the FL and RL Co20Fe60B20 are now magnetized in-plane; after the highest temperature anneal even the Co\Pt stack is magnetized in plane.

Fig. 6.

M vs H hysteresis loops of stack I (full pMTJ) measured in a perpendicular magnetic field after annealing at various temperatures. Along the top row from left to right they are for the 300 °C, 325 °C and 350 °C annealed samples respectively. Along the bottom row from left to right they are the data for the 375 °C, 400 °C and 425 °C annealing treatments respectively. Both the out-of-plane component (black curve) and the in-plane component (red curve) are shown.

For the as-deposited sample stack II having the structure of 3 x (Co\Pt)\Co\Ru\13x (Co\Pt), its hysteresis loop measured under a perpendicular field at room temperature is shown in Figure 7. This stack enables one to examine the performance of the synthetic antiferromagnetic Co\Pt layers as a function of annealing temperature. As prepared, this material is primarily magnetized perpendicular to the surface. It is worth mentioning that the ratio of the out-of-plane to in-plane magnetization does not change with the increase in annealing temperature. This means the Co\Pt multilayers do not change their magnetization direction with the high temperature annealing up to 425 °C.

Fig. 7.

M vs H hysteresis loops of stack II measured in a perpendicular field after annealing at various temperatures. Along the top row from left to right are the data for the as deposited and 300 °C annealed samples respectively. Along the bottom row from left to right are the data for the 350 °C and 425 °C annealed samples respectively. Both the out-of-plane component (black curve) and the in-plane component (red curve) are shown.

The data in Figure 8 shows the hysteresis loops for the stack III samples where the top Co20Fe60B20 (acting as the RL) is coupled to the Co\Pt, and there is a thin bottom “dead” layer of Co20Fe60B20 underneath the MgO barrier layer. It shows the Co20Fe60B20 layers started to rotate their magnetization vectors toward an in-plane direction after annealing at 300 °C and above; the 4 x (Co\Pt) layer however, remained perpendicularly magnetized until the stack was annealed at 400 °C. Here again there is some in-plane M component detected in the as-deposited sample, similar to that observed in Figure 6. Figure 9 shows the hysteresis loop data for the Stack IV sample where the top Co20Fe60B20 (RL) is coupled to the Co\Pt multilayer, but without a bottom Co20Fe60B20 layer underneath the MgO layer. The VSM results on the samples after having been annealed at various temperatures vary with temperature similarly to those of Stack III which has the additional Co20Fe60B20 layer under the MgO. However, the magnetization switches from perpendicular to in-plane at a lower temperature when there is no Co20Fe60B20 underneath the MgO layer. Consistent with that result, the ratio of perpendicular to in-plane magnetization at all annealing temperatures for Stack IV is higher than that for Stack III which has the Co20Fe60B20 under layer.

Fig. 8.

M vs H hysteresis loops of stack III measured in a perpendicular field after annealing at various temperatures. Along the top row from left to right, are the data for the as deposited, 300 °C, and 350 °C annealed samples respectively. Along the bottom row from left to right, are the data for the 375 °C, 400 °C and 425 °C annealed samples respectively. Both the out-of-plane component (black curve) and the in-plane component (red curve) are shown.

Fig. 9.

M vs H hysteresis loops of stack IV measured in a perpendicular field after being annealed at various temperatures. Along the top row from left to right are the data for the as deposited, 300 °C, and 350 °C annealed samples respectively. Along the bottom row from left to right are the data for the 375 °C, 400 °C and 425 °C annealed samples respectively. Both the out-of-plane component (black curve) and the in-plane component (red curve) are shown.

Earlier investigations [22-25] have shown that MgO deposited on amorphous Co20Fe60B20 will grow in the (100) direction and have a smooth interface. Without this Co20Fe60B20 base layer, the MgO will be rougher and will not be as well ordered. This may be one reason why the presence of the Co20Fe60B20 underlayer delays the CoFeB\ (Co\ Pt) magnetization switch from out-of-plane to in-plane.

From Figures 8 and 9, it is clear that the 4 layers of (Co\Pt) are strongly coupled to the RL Co20Fe60B20 and that they switch at the same coercive field in the perpendicular direction. The RL Co20Fe60B20, however, enables the 4x (Co\Pt) multilayer to rotate its magnetization from perpendicular to in-plane more easily.

Results of Secondary Ion Mass Spectrometry

In order to determine whether composition variations with elevated temperature annealing might explain the decrease of the TMR ratio, the increase in RA, and/or the rotation of the magnetic anisotropy from perpendicular to in-plane by annealing the pMTJ at successively higher temperatures, SIMS measurements were conducted on Stack I after various annealing treatments, and are shown in Figures 10(a) - (e).

Fig. 10.

Intensity (i.e., concentration) vs ion milling time (i.e., depth) profiles of several elements, obtained from SIMS spectra, in the full pMTJ stack I after annealing at various temperatures. Along the top row from left to right are the data for stack I (a) as deposited, and after a one hour anneal at (b) 300 °C and (c) 350 °C; along the bottom row from left to right are the profiles after a one hour anneal at (d) 400 °C and (e) 450°C. Different colors are used to indicate the profiles for different elements.

The ion milling started from the top Ru layer followed by the next layer of CuN, etc. The spectra clearly show the same layer by layer trend listed for Stack I. Since the number of secondary ions created are not the same for all elements, one cannot just compare the count values of the different mass peaks to obtain the mass fractions for the different elements. But when comparing the spectra for the different annealing treatments, for the same element one can compare the element peak counts to deduce the relative change in that element's concentration and the ion milling time can be used to determine the depth. Consequently, the diffusion of species can be determined.

From Fig 10. one can see that Platinum (Pt), Ruthenium (Ru), Copper (Cu) and Magnesium (Mg) did not change their concentration profile much during the annealing. However, there was significant diffusion of Boron (B) and Tantalum (Ta). We will now discuss the motion of each of these elements separately.

1) Boron (B)

The source of the boron is the Co20Fe60B20 alloy. An amorphous as-deposited Co20Fe60B20 is critical for obtaining a high TMR ratio for both in-plane and perpendicular MTJs, as it helps form the oriented MgO (100) barrier layer. In the as-deposited spectrum, the Boron has two peaks, one at the x-axis position of 1100 s and the other at position 1200 s. These two peaks are from two Co20Fe60B20 layers: The Co20Fe60B20 reference layer above the MgO and the Co20Fe60B20 free layer below the MgO barrier layer respectively. After annealing at 300 °C, the Boron peaks were shifted slightly to the left and the left hand peak in the doublet (i.e., the RL Co20Fe60B20) increased in intensity. There was also the beginning appearance of an additional peak at x-axis position around 700 s which is where the interface between the Tantalum cap of the RL and the (Co\Pt) multilayer is located. After the 350 °C anneal, the small Boron peak at 700 s increased significantly. Further increase in the annealing temperature up to 450 °C resulted in a further increase in the 700 s peak, and a significant shift in the intensity of the doublet from the right hand peak at 1200 s to the left hand peak at 1100 s. In none of these profiles was there a clear Boron peak at x-axis position 1800 s where the interface exists between the bottom Tantalum layer and the SiO2. From these spectra it is clear that during the high temperature annealing much of the Boron in the FL migrates through the MgO barrier layer in an upward direction. It then either stays in the RL, accumulates at the RL\Ta interface, or accumulates at the upper (Co\Pt)\Ta interface. There is no obvious indication that Boron stays inside the MgO barrier layer, as was initially suspected due to the drop in TMR with annealing. It is also interesting to note that the Boron passed through the (Co\Pt) multilayer and accumulated at the (Co\Pt)\Ta interface without leaving much residue inside the (Co\Pt) multilayer. Boron must form a stable configuration with Tantalum at that upper interface.

2) Tantalum (Ta)

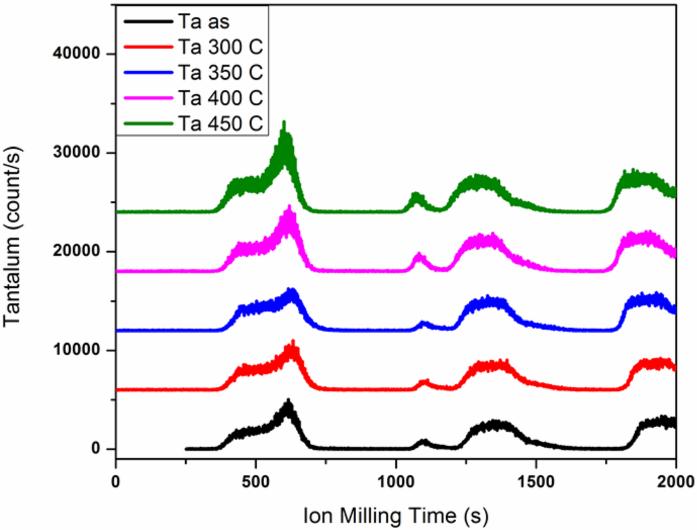

From the concentration profiles in Fig. 12, one notes there are Tantalum peaks at several x-axis positions: between 350 s to 700 s (the top 5 nm thick Ta just above the Co\Pt multilayers), at position 1100 s (the 0.4 nm thick Ta layer just above the RF Co20Fe60B20), between 1200 s and 1450 s (the 5 nm thick Ta layer just below the FL Co20Fe60B20), and between 1800 s and 2200 s (the 5 nm thick Ta layer on top of the SiO2 substrate).

Figure 12.

Tantalum intensity from the SIMS spectra measured after annealing at the indicated temperatures for one hour as a function of milling time (i.e., depth from the sample surface).

In the SIMS experiment, the 0.4 nm Ta above the RL Co20Fe60B20 should be milled off before the Co20Fe60B20 layer. But the Tantalum is shown in Figure 10 to be located at an x-axis position a little to the right of the left hand peak of the Boron doublet (i.e., deeper than the Co20Fe60B20). This finding indicates the Tantalum can be a good milling time reference for the SIMS data. In Figure 12. the Tantalum spectra did not change much between the as-deposited and 350 °C measurements, but as the annealing temperatures were raised above 350 °C, the Tantalum peak intensity at the 1100 s position was dramatically increased. Interestingly, the Boron peak intensity (Fig. 11) at that x-axis position was also increased. It is likely that the Boron in both Co20Fe60B20 layers and the Tantalum below the Co20Fe60B20 free layer diffuses to the thin Ta layer position at 1100 s and forms a stable TaxBy alloy.

Fig. 11.

Boron intensity from the SIMS spectra measured after annealing at the indicated temperatures for one hour as a function of milling time (i.e., depth from the sample surface).

Several previous studies have already mentioned that tantalum is a Boron absorbing layer [26-28] and that Boron both dissolved in the upper Tantalum layers and segregated in the bottom crystalline Tantalum layer [23]. We found similar results here: both Boron and Tantalum accumulated in the Tantalum (0.4 nm) layer capping the RL. Also, since the Tantalum peak intensity increased significantly at that position with annealing, more Tantalum must have migrated there from the other layers. The Boron also not only accumulated in this 0.4 nm thick Tantalum layer but also diffused through all the (Co\Pt) multilayers to the top 5 nm thick Tantalum layer at x-axis position of 700 s. Interestingly, the Tantalum also redistributed during the annealing in that top 5 nm thick layer such that there was motion of Tantalum away from the top to the bottom of that layer, probably so it could form more of the Tantalum boride as more Boron diffused up to that interface. This further suggests the Tantalum boride is more stable than pure Tantalum.

Conclusion

TMR values for the pMTJs in this study were found to decrease with increasing annealing temperature up to 400 °C. The reason for the decrease is found to be due to a gradual change in the magnetic moment direction of both the RL and FL Co20Fe60B20 from out-of-plane to in-plane. When both RL and FL are completely magnetized in the plane of the film, like after the 400 °C anneal, the pTMR value was zero. This is totally different from the reason for the TMR ratio decrease found for in-plane MTJs’ after high temperature annealing. For in-plane MTJs, during high temperature annealing, Mn atoms from the antiferromagnetic exchanged biased layer, IrMn or PtMn, diffused into the MgO barrier layer, thereby increasing its resistance and destroying it [29]. For the pMTJs of the present study, the MgO barrier layer resistance increased only after annealing above 375 °C, well above the temperature where the TMR ratio began to drop. After annealing, the coercivity and interlayer coupling of the FL Co20Fe60B20 increased with increasing annealing temperature. The reason may be the development of rougher interfaces due to atomic motion to the interfaces as the annealing temperature increased, leading to an increase in orange-peel coupling. By comparing the annealing effects on the different sample stacks, it is clear that the (Co\Pt) multilayers remained perpendicularly magnetized up to 425 °C. Ultimately, the RL Co20Fe60B20 will drag the 3x (Co\Pt) multilayer's magnetization into the plane of the film during annealing. But the improved crystallinity of the MgO barrier layer with a Co20Fe60B20 seed by the high temperature annealing will also improve the (Co\Pt) thermal stability.

The SIMS results prove that except for Boron and Tantalum most other elements, Co. Pt. Mg and Cu are very stable and do not inter-diffuse between layers during high temperature annealing. The Boron will migrate and pass through the (Co\Pt) multilayers to the top Tantalum layer interface and accumulate there. Some Tantalum will migrate from various places in the stack to the RL Co20Fe60B20 interface and accumulate. The Boron and Tantalum may form some kind of stable configuration at the Tantalum interface.

Acknowledgements

This work was in part supported by National Institute of Standards and Technology research award 70NANB16H011

Reference

- 1.Berger L. Phys. Rev. B. 1996;54:9353. doi: 10.1103/physrevb.54.9353. [DOI] [PubMed] [Google Scholar]

- 2.Parkin SSP, Kaiser C, Panchula A, Rice PM, Hughes B, Samant M, Yang SH. Nature Mater. 2004;3:862. doi: 10.1038/nmat1256. [DOI] [PubMed] [Google Scholar]

- 3.Yuasa S, Nagahama T, Fukushima A, Susuki Y, Ando K. Nature Mater. 2004;3:868. doi: 10.1038/nmat1257. [DOI] [PubMed] [Google Scholar]

- 4.Djayaprawira DD, Tsunekawa K, Nagai M, Maehara H, Yamagata S, Watanabe N, Yuasa S, Suzuki Y, Ando K. Appl. Phys. Lett. 2005;86:092502. [Google Scholar]

- 5.Ikeda S, Hayakawa J, Ashizawa Y, Lee YM, Miura K, Hasegawa H, Tsunoda M, Matsukura F, Ohno H. Appl. Phys. Lett. 2008;93:082508. [Google Scholar]

- 6.Mangin S, Ravelosona D, Katine JA, Carey MJ, Terris BD, Fullerton EE. Nature mater. 2006;5:210. doi: 10.1103/PhysRevLett.96.186604. [DOI] [PubMed] [Google Scholar]

- 7.Meng H, Wang JP. Appl. Phys. Lett. 2006;88:172506. [Google Scholar]

- 8.Nakayama M, Kai T, Shimomura N, Amano M, Kitagawa E, Nagase T, Yoshikawa M, Tatsaya K, Sumio I, Yoda H. J. Appl. Phys. 2008;103:07A710. [Google Scholar]

- 9.Worledge DC, Hu G, Abraham DW, Sun JZ, Trouilloud PL, Nowak J, Brown S, Gaidis MC, O'Sullivan EJ, R.P. Robertazzi RP. Appl. Phys. Lett. 2011;98:022501. [Google Scholar]

- 10.Nowak JJ, Robertazzi RP, Sun JZ, Hu G, Abraham DW, Trouilloud PL, Brown S, Gaidis MC, O'Sullivan EJ, Gallagher WJ, Worledge DC. IEEE Magn. Lett. 2011;2:3000204. [Google Scholar]

- 11.Katine JA, Fullerton EE. J. Magn. Magn. Mater. 2008;320:1217. [Google Scholar]

- 12.Sun JZ, Kuan TS, Katine JA, Koch RH. In: Quantum Sensing and Nanophotonic Devices. Razeghi M, Brown GJ, editors. Vol. 5359. SPIE; San Jose, CA: 2004. 2004. p. 445. [Google Scholar]

- 13.Mizunuma1 K, Yamanouchi M, Ikeda S, Sato H, Yamamoto H, Gan HD, Miura K, Hayakawa J, Matsukura F, Ohno H. App. Phys. Exp. 2011;4:023002. [Google Scholar]

- 14.Chang YJ, Canizo-Cabrera A, Garcia-Vazquez V, Chang YH, Wu TH. J. Appl. Phys. 2013;113:17B909. [Google Scholar]

- 15.Park JH, Park C, Jeong T, Moneck MT, Nufer NT, Zhu JG. J. Appl. Phys. 2008;103:07A917. [Google Scholar]

- 16.Yakushiji K, Saruya T, Kubota H, Fukushima A, Nagahama T, Yuasa S, Ando K. Appl. Phys. Lett. 2010;97:232508. [Google Scholar]

- 17.Yoshikawa M, Kitagawa E, Nagase T, Daibou T, Nagamine M, Nishiyama K, Kishi T, Yoda H. IEEE Trans. Magn. 2008;44:2573. [Google Scholar]

- 18.Meng H, Sbiaa R, Wang CC, Lua SYH, Akhtar MAK. J. Appl. Phys. 2011;110:103915. [Google Scholar]

- 19.Manufacturer names are used here to more properly describe the experimental conditions, and in no way does it constitute an endorsement by the authors or their organizations

- 20.Jang Soo Young, Lim SH, Lee SR. J. Appl. Phys. 2010;107:09C707. [Google Scholar]

- 21.Ikeda1 S, Hayakawa J, Ashizawa Y, Lee YM, Miura K, Hasegawa H, Tsunoda M, Matsukura F, Ohno H. Appl. Phys. Lett. 2008;93:082508. [Google Scholar]

- 22.Park C, Zhu JG, Moneck MT, Peng Y, Laughlin DE. J. Appl. Phys. 2006;99:08A901. [Google Scholar]

- 23.Bae JY, Lim WC, Kim HJ, Lee TD, Kim KW, Kim TW. J. Appl. Phys. 2006;99:08T316. [Google Scholar]

- 24.Tsunekawa K, Djayaprawira DD, Nagai M, Maehara H, Yamagata S, Watanabe N, Yuasa S, Suzuki Y, Ando K. Appl. Phys. Lett. 2005;87:072503. [Google Scholar]

- 25.Chen PJ, Feng G, Shull RD. IEEE Trans. Magn. 2013;49:4379. [Google Scholar]

- 26.Miyajima T, Ibusuki T, Umehara S, Sato M, Eguchi S, Tsukada M, Kataoka Y. Appl. Phys. Lett. 2009;94:122501. [Google Scholar]

- 27.Karthik SV, Takahashi YK, Ohkubo T, Hono K, Ikeda S, Ohno H. J.Appl. Phys. 2009;94:023920. [Google Scholar]

- 28.Ibusuki T, Miyajima T, Umehara S, Eguchi S, Sato M. Appl. Phys. Lett. 2009;94:062509. [Google Scholar]

- 29.Ikeda S, Hayakawa J, Ashizawa Y, Lee YM, Miura K, Hasegawa H, Tsunoda M, Matsukura F, Ohno H. Appl. Phys. Lett. 2008;93:082508. [Google Scholar]