Abstract

The world population has crossed seven billion and such a huge population has increased the pressure and considerably affects our ability to feed ourselves. It has now emerged as a new challenge for policy makers, food scientists and other associated people to make food available to everyone. To achieve this, underutilized crops/plants that act as good sources of starch need to be explored. Starch in its native form have certain limitations in its functional properties to be used for different applications. Therefore, it becomes important to explore certain technologies which could be used for modification of properties of starch. During the last decades gamma irradiation has emerged as an efficient processing technique for the modification of starch when compared to the other available processes. This review, aims to summarize the effects of gamma irradiation on various properties of starch such as physicochemical and rheological properties, functional characteristics, thermal behaviour etc. so as to make the starch suitable for various applications in different industries including the food industry.

Electronic supplementary material

The online version of this article (10.1007/s13197-018-3530-2) contains supplementary material, which is available to authorized users.

Keywords: Starch modification, Gamma irradiation, Physicochemical properties

Introduction

Food products containing starch (amylum) are rich sources of energy and are consumed in the form of staple diet by all sections of the society because of their accessibility and comparatively low cost. Starch, a tasteless, odourless white polysaccharide, may be present in the roots, tubers and seeds of plant kingdom (Takeda et al. 1989; Han and BeMiller 2007; Chung and Liu 2009). The starch can be divided into three main groups which include: native starch (includes that starch which after its extraction from its source is not subjected to any treatment, it is white odourless and colourless either powder or liquid), modified starch (includes that starch in which if any one or more of the original characteristics of the native starch has been altered or modified with any of the treatments like physical, chemical or enzymatic or combination of these as per the Good Manufacturing Practices), hydrolysed starch (includes that starch in which the polymeric chains are broken into simple sugars like maltose) (Chung and Liu 2009; Chung et al. 2010). Worldwide, main sources of the starch include maize (73%), tapioca (11%) wheat (9%), potatoes (6%), and others (2–3%). Besides being used as such, as a part of our daily diet, starch also has wide applications for different industries like paper, pharmaceutical, food etc. USA is the major producer of the starch followed by Europe and Asia. At present 52% of starch is being used by the food industries (confectionery, drinks and other processed foods) while 48% starch is being used by the non-food industries (pharmaceuticals, paper, feed and other purposes) (Saunders 2010; Al-Assaf et al. 2007). It is estimated that over the time, the demand for starch by the non-food industries would be higher as compared to the food industries. But there are some limitations associated with the native starch, which prevents its use in the food, pharmaceutical and related sectors. In order to overcome these limitations, several techniques (like copolymerization, crosslinking, annealing etc.) have been developed which can result into the modification of starch (structure), thereby improving its various physico-chemical properties. Value added modified starch derivatives is becoming an area of high interest due to high profits involved and numerous food and other industrial applications (Singh et al. 2007; Wu et al. 2002; Bao et al. 2005; Bashir and Aggarwal 2016a).

Chemical composition and structure of starch

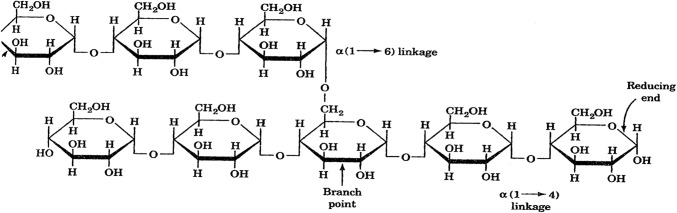

Starch is semi-crystalline in structure, present in granular form in the chloroplasts of green leaves and amyloplasts of tubers and grains (Al-Assaf et al. 2007). Chemically starch (Fig. 1) is composed of two polysaccharide units viz amylose (amorphous) and amylopectin (crystalline). Both amylose and amylopectin are composed of glucose units. Amylose is a linear polymer, linked by α-d-(1-4) glycosidic linkages, constituting about 20–30% of total starch while as amylopectin is a branched chain polymer with α-d-(1-4) glycosidic linkages in linear chain and α-d-(1-6) branched linkages (Takeda et al. 1989; Saunders 2010; Singh et al. 2007, 2008a, b; Bashir and Aggarwal 2017). The waxy starches contain more amylopectin. Some of the commonly cultivated plant varieties contain starch only composed of amylopectin (called as waxy starch e.g. waxy maize, waxy potato). Waxy starches have an advantage that their pastes are more stable towards retrogradation, while high amylose starches are used as resistant starches. There is a wide variation in properties of starch procured from different plant species because of the difference in amylose: amylopectin ratio (Singh et al. 2008a, 2010; Chung and Liu 2009). The starch granule size depends upon the structural compactness of amylopectin. The different shapes and sizes of starch granules are formed in endosperm during the grain development. The amylopectin shape is governed by the ratio of long chain branches to the short chain branches, which further has an impact on the starch compactness and starch granule size. The amount of amylose, distribution of branched chains in amylopectin, granular architecture, amount of phospholipid, phosphate-monoester and lipids have a significant impact on the functional properties of the starch. The size of the starch granules range from 1 to 100 nm diameter and the shape varies from polygonal, spherical, lenticular, oval (Singh et al. 2008a, 2010).

Fig. 1.

Starch structure (Saunders 2010)

Categorisation of starch

Starch can be categorised based upon the X-ray diffraction produced and nutritional characteristics. Based upon the X-ray diffraction produced, starch has been grouped into following categories:

Type A (having amylopectin of chain length 23–29 glucose units e.g. cereal starch).

Type B (having amylopectin of chain length 30–44 glucose units e.g. tubers and amylose rich starches).

Type C (mixture of Type A and B, comprising amylopectin with chain length of 26–29 glucose molecules e.g. legume starch).

Type V (present in swollen granules and is formed upon gelatinization. It is a characteristic of amylose, fatty acids and mono-glycerides).

These different X-ray patterns formed can be attributed to: the presence of bound water within the crystal structure, amylopectin chain length and the compactness of their packing within the granules. Type A is denser as compared to type B, thus binding less water. While type A and B are almost crystalline in structure, type C is a mixture of both crystalline and amorphous particles (Fig. 2) (Singh et al. 2007, 2008b; Chung and Liu 2009; Wu et al. 2002; Bao et al. 2005). Depending upon the nutritional characteristics, starch can be classified into the three groups:

Rapidly Digestible Starch (RDS): It is primarily composed of amorphous starch and is widely present in cooked foods like potatoes, bread etc. It is chemically measured as starch i.e. converted to glucose after 20 min of ingestion by enzymes.

Slowly Digestible Starch (SDS): It consists of crystalline A and C type structures along with amorphous regions. The slow digestion is attributed to complexity in its structure. It is chemically measured as that starch which is converted to glucose after 100 min of ingestion.

Resistant Starch (RS): This type of starch is not digested even after 120 min of ingestion. However, it may support the growth of gut micro-flora in the intestines thus it is also referred as dietary starch (Bao et al. 2005; Yu and Wang 2007; Lee et al. 2008). Resistant starch is further subdivided into four categories including RS1 (found in legumes), RS2 (found in raw potatoes), RS3 (found in cornflakes) and RS4 (found in bread) (Ciesla et al. 1999; Yu and Wang 2007).

Fig. 2.

X-ray diffraction of different starches: Type A, Type B, and Type V (Va: water-free, Vh: hydrated) (Tegge 1987)

Major applications of starch

Starch imparts a wide range of functional properties to both food products as well as the non-food items, in its native form, modified form and hydrolysed form. The various applications of the starch are listed:

Applications of Native starch: It is used for the production of modified starch, hydrolysed starch, thickening agent, provides moisture control, binding agent, salad dressings, toppings, syrups, yogurt etc.

Applications of hydrolysed starch: It is used for the production of organic acids (citric, lactic and malic acid), Sweeteners (maltodextrins, corn syrup, dextrose syrup, oligosaccharides, crystalline dextrose and fructose), Polyols (mannitol, sorbitol, maltitol, and xylitol), Amino acids like cysteine, threonine, lysine, tryptophan, and methionine (using starch hydrolysates as substrate), Alcohol (Ethanol).

Applications of modified starch: The modified starch has found wide applications on the commercial scale which include the development of: potential carriers for the drug delivery (excipient), packaging biofilm (green packaging), edible films, food additives (like stabilizers and thickeners e.g. Hydroxypropyl starch, acid treated starch), wall material for encapsulation of spice oleoresins, paper making, fat replacers in the food products like ice-cream, salad dressings, cheese, baked foods, icings, mayonnaise etc., reduced oil uptake by the foods, improved dough characteristics, pectin replacer (commonly used in canned foods, bakery and frozen foods, sauces, ketchups, jam, jellies etc.).

Starch properties

Some of the important properties of the starch are listed below:

Composition The ratio of amylose and amylopectin in the starch granule varies from species to species and even between the same species cultivated in the different geographical locations. After the extraction process the starch still contains some fractions of the proteins, fibre and lipids. The presence of these components have an impact on the functional properties of the starch. The lipids form complexes with the amylose and can significantly modify the properties like increased gelatinization temperature, reduced water solubility, gel strength, retrogradation and swelling index (Singh et al. 2007; Kumar et al. 2017; Dar et al. 2018).

Gelatinization Starch is insoluble in cold water however, upon heating in water at above 52 °C, it undergoes a process known as gelatinisation (generally studied by Differential Scanning Calorimetry). Gelatinization is a two stage endothermic process, in the first phase starch granules swell due to breakage of hydrogen bonds in the amorphous portions of the starch and in the next event, water acts as a plasticizer, which results in hydration and swelling of the amorphous regions. Gelatinization results in the breakdown of intermolecular bonds of starch and more of the water is absorbed. Upon heating the amylopectin (crystalline) structure is altered which causes decrease in the crystallinity and more of the water is absorbed causing the several changes including starch solubilisation, starch granule swelling and loss of birefringence. The penetration of water swells the starch granule thereby increasing the randomness in the starch granule. The starch granule is finally ruptured and the amylose is released out resulting in the formation of starch paste, thereby increasing the viscosity of the solution. Gelatinization temperature of the starch depends upon the starch source, water present, pH, salts etc. Water acts as a plasticizer during gelatinization (Singh et al. 2011; Mahto and Das 2014; Chung and Liu 2009).

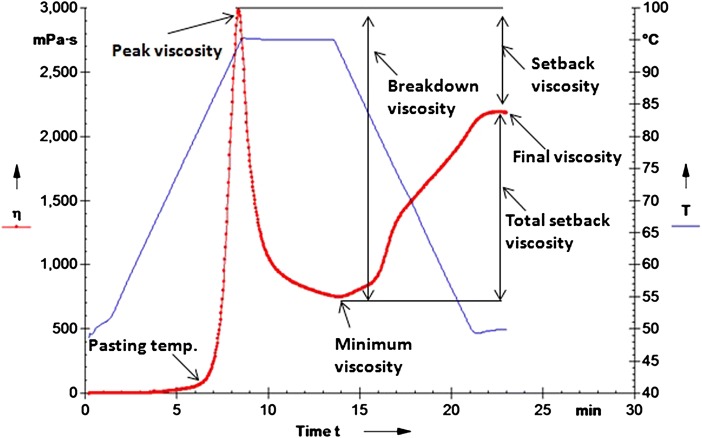

Pasting properties The pasting (rheological) properties of the starch can be studied by Rapid Visco Analyser (RVA) or Rheometer. During the heating of starch with continuous rotational stress, results in the swelling of the starch granules and then bursting, causing the amylose to leach out of the matrix, resulting in the formation of the viscous paste (Chung and Liu 2009; Bashir et al. 2017a). The pasting property of starch is very important in the food and other industries in terms of viscosity (peak viscosity, final viscosity, breakdown viscosity, setback viscosity etc.). A typical pasting curve of the wheat starch as measured by Rheometer (MCR 52, Anton Paar) has been shown in Fig. 3. The temperature at which there is a sharp increase in the viscosity represents the pasting temperature. The maximum viscosity obtained is the peak viscosity. Peak viscosity gives the idea regarding the water binding capacity of the starch and the final textural properties of the starch containing product. Minimum viscosity is the lowest value of viscosity obtained in the constant temperature phase (i.e. maximum temperature). Final viscosity (cold paste viscosity) represents the viscosity obtained at the end of cooling phase and it gives the capacity of starch to form a viscous paste or gel after cooking and cooling. Setback viscosity is obtained by subtracting the values of final viscosity and peak viscosity while as total setback viscosity represents the final viscosity minus minimum viscosity. The values of the setback viscosity act as indicator for the retrogradation/syneresis during storage/thawing. Amylose is the main compound responsible for the higher values of final viscosity and retrogradation. In general, there is a negative relationship between the amylose content and peak viscosity and gelatinization temperature. The other compounds that have an impact on the gel texture include the disulphide linkages of the proteins and proteins itself. The retrogradation is monitored by gel turbidity, light scattering or Fourier Transform Infrared (FTIR) spectroscopy (Sofi et al. 2013; Bashir et al. 2017b).

Fig. 3.

Pasting profile of wheat starch by Rheometer

Light Transmittance Light transmittance gives the information regarding the behaviour of starch paste when the light passes through it. The light transmittance of the starch paste is calculated at 640 nm. The phosphate monoesters that are covalently attached to the amylopectin result in the increase in starch paste clarity while as presence of phospholipids bound to the amylose fractions of the starch produces opaque starch pastes with reduced per cent light transmittance. Higher light transmittance implies a more transparent paste. The light transmittance of starch paste is a function of the amount of swollen starch granules in the paste, which refract light (Mahto and Das 2014; Rayas-Duarte and Rupnow 1993).

Freeze–thaw stability It is the ability of the starch or the food containing the starch to uphold its integrity by avoiding the loss of water (syneresis) when the food containing starch is exposed to recurrent thermal cycling between freezing and ambient conditions (Sofi et al. 2013).

Starch modification

Starch in its native form has certain limitations like propensity towards retrogradation, high viscosity even at low concentrations, handling problems, poor freeze–thaw stability, low process tolerance and gel opacity that prevent its use in food processing. In order to overcome these problems starch granules are modified prior to their final use as food or food ingredient. Starch modification has resulted an increase in one or more of the following properties: increased digestibility, emulsifying agent, emulsion stabilizer, encapsulating agent, cold-water swellability, charged starch molecules, increased cooking characteristics, film formation, wall materials for encapsulation, improved gel characteristics (freeze–thaw stability, viscoelasticity, viscosity, adhesiveness), pH, temperature and shear tolerance, water-holding capacity etc. due to which its applications in the food and other industries has increased (Singh et al. 2011; Gani et al. 2012). The modified starch has gained attention in food business because of its ability to be used as dietary fat replacer. Also the consumption of starch within adequate limits has been linked with the prevention of cancer, diverticulitis, coronary heart diseases (Hussain et al. 2014). At present there are several techniques which are being used for the production of modified starch (Singh et al. 2008b; Kaur et al. 2012; Bhat and Karim 2008), they include:

Chemical methods (such as cross-linking, graft copolymerization, cationization, stabilization/substitution, conversion, trans-glycosidation involving the use of various chemicals like phosphoryl-chloride, sodiumtri-polyphosphate, vinylchloride, mono-sodiumphosphate, epichlorohydrin).

Enzymatic methods (including enzymes such as amylomaltases, α and β-amylases, trans-glucosidase, cyclo-maltodextrinase etc.).

Genetic methods (resulting into amylose free starch, high amylose starch, starch with altered amylopectin structure etc.).

Physical methods (e.g. pre-gelatinization, ball milling (pulverizing), annealing, heat-moisture treatment, dry heating of starch, radiation treatments, shear modification etc.).

The enzymatic methods being complex and time consuming have limited applications in the food industry and related sectors. The chemical methods although being faster, pose risks because of leaving certain chemical residues into the final product. Nowadays there has been an escalating interest in physical methods particularly radiation processing which is considered to be a cold process and has been reported as one of the suitable techniques for starch modification. Radiation processing has emerged as an environment-friendly and an economical technique which can be used for bringing about certain changes in some of the physico-chemical and functional properties of certain components of food products. Radiation processing besides having other applications for food processing, is widely employed for the enhancement of the shelf life of food products. Since it is highly effective against all bacteria, insects and other pests, today the use of radiation technology is widely accepted in the international markets for its various applications in the food industries (Singh et al. 2008b; Bashir and Aggarwal 2016b; Bhat and Karim 2008).

Use of gamma irradiation for starch modification

Gamma rays, used for food processing are generated by using radioactive isotopes (either cobalt-60 or cesium-137), which upon decay, emit the gamma rays having high energy and excellent penetrating power, with capacity to penetrate the target food product up to several feet.

Mechanism of starch modification using gamma irradiation

Starch when treated with gamma irradiation interacts with the water molecules present in the food products. The water molecules get broken down into short lived free radicles (·OH and ·H) and high energy electrons. These free radicles and high energy electrons induce molecular changes either by fragmentation or crosslinking of the starch, thus resulting into the modification of the starch. The presence of oxygen facilitates the crosslinking process. Gamma rays may also result in direct breakdown of the glycosidic bonds at the chain ends (Fig. 4). This is the process that has been suggested to be responsible for the changes in physico-chemical and functional properties (e.g. reduced viscosity, increased solubility, increased cooking characteristics etc.) of starch and the food products containing starch (Kang et al. 1999; Bhat and Karim 2008; Bashir and Aggarwal 2016b; Kaur et al. 2012). The production of radiolytic products during the irradiation has been established and during the starch irradiation, the products formed are acetaldehyde, formic acid, formaldehyde. The radiolytic products formed during starch irradiation are similar and do not change with source (like sago, water chest nut, maize, wheat, potato etc.) from which it has been extracted. The gamma irradiation dose required for starch modification depends upon the water content present in the food product, foods containing higher moisture requires lower doses for modification (Bhat and Karim 2008; Bashir and Aggarwal 2016b). In the present review, an attempt has been made to summarize the work carried out so far using the gamma irradiation as one of the techniques for modification of starch for its applications in the food industries.

Fig. 4.

Irradiation impact on starch polymers outlining probable degradation and cross-linking of starch chains (Bhat and Karim 2008)

The pace of growth of human population is a serious concern for sustainable food supply. To achieve the sustainable supply, underutilized crops or plants that are good sources of the starch need to be explored. In 2000, the starch production was 48.5 million tonnes, while in 2008, the production was about 66 million tonnes which reached to about 75 million tonnes in 2012 and is expected to reach 95 million tonnes by 2020. The annual market growth rate for the starch in India and China is expected to be around 4.5%, while for US and EU it is around 2% and 3% for the rest of the world. It becomes quite evident that the demand for the modified starch is going to rise at a faster rate. The review has tried to consolidate the various studies which have been undertaken till date to study the effect of gamma irradiation on the different physicochemical properties of starch and the gap areas identified from therein.

Impact of gamma irradiation on the thermal and physicochemical properties

Kertez et al. (1959), studied the impact of gamma irradiation at a dose level of 1 and 5 kGy on the maize starch. They found that the relative viscosities decreased when compared to the reference sample treated with high temperature of 140 °C for 30 min. Saini (1968) also carried the research studies on the effects of gamma irradiation on corn starch granules. They found that the starch macromolecules were depolymerised and the severity increased as the dose was increased. Several other studies revealed the structural changes and an increase in maltose, maltotetrose, maltotriose and other related saccharide content in wheat and rice starch, when subjected to gamma irradiation. An increase in starch solubility, decreased viscosity, dough stability, swelling capacity and amylograph peak viscosity was also reported as the dosage level increased (Dar et al. 2018; Kumar et al. 2017; Bashir et al. 2017b). The molecular disintegration in starch and proteins of gamma irradiated wheat was reported along with high amylose fraction, decreased amylopectin, formic acid production and elevated retrogradation, which influenced the dough properties, rheological properties, baking qualities of the flour but having almost nil impact on the nutritional value (Vakil et al. 1973, Abd Allah et al. 1974).

The compositional changes in the gamma irradiated (1Mrad) starch extracted from the pigeon pea (Cajanus cajan) was evaluated by Nene et al. (1975). The results revealed decrease in gelatinization temperature, a progressive increase in maltose content with time, increased sensitivity of irradiated starch towards α-amylase. MacArthur and D’Appolonia (1984) studied the impact of low doses gamma rays (0, 50, 100, 200 and 300 krad) on the starch extracted from the three red spring cultivars of wheat. The starch properties were analysed and it was found that the there was a decreasing trend in the peak viscosity and intrinsic viscosity values as the dose was increased. In a study carried out by Kashani and Valadon (1984) on the gamma irradiated Pistacia vera kernels, the authors revealed that the dosage up to 10 kGy did not produce any substantial effect on the total carbohydrates, total starch, dextrin or any of the free sugars. Bhatty and Macgregor (1988) treated the scout hull-less barley with gamma irradiation (10 Mrad) and it was found that viscoamylogram properties were completely lost. Although, SEM results showed no significant alterations in outer structure of the starch granules, the granules were found internally broken. The irradiated starch was also found more susceptible to hydrolysis by both alpha and beta amylase as compared to the non-irradiated starch. Rayas-Duarte and Rupnow (1993) irradiated starch extracted from northern bean (Phaseolus vulgaris) and it was observed that reducing maltose value of the starch molecule was increased besides increased solubility in both water and ethanol. Ciesla et al. (1999) irradiated starch extracted from potato and wheat flour with high doses of gamma rays (20 kGy). They found that the gelatinization temperatures varied between the irradiated starch and non-irradiated one. The differences between the gelatinization temperature was ascribed to the irradiation induced deformation of the amylopectin structures which resulted in the destruction of the crystalline structures. Adeil and Narvaiz (2001) treated agar–agar, kappa-carrageenan and the starches obtained from corn and cassava with the gamma irradiation (2 kGy). Their results showed a significant decrease in the starch viscosity, gel strength (made from agar and carrageenan). Al-Kaisey et al. (2002) evaluated the chemical composition and viscosity of the gamma irradiated (0, 10,50, 100 and 200 kGy) barley (Black barley and Shoaa barley) to be used as diet for broiler chicken. It was found that irradiation did not alter the chemical composition. The viscosities were found to be reduced irrespective of the barley variety. Wu et al. (2002) treated various rice cultivars: japonica, indica, and hybrid with different gamma radiation doses (0, 0.2, 0.4, 0.6, 0.8 and 1 kGy). They reported a significant increase in the gel consistency, deformation in the granular structure, thus confirming that gamma irradiation caused the starch breakdown by cleaving the larger molecules of starch (amylopectin) into smaller fragments. From the results, they concluded that gamma irradiation can be commercialized to improve the sensory parameters of rice.

Graham et al. (2002) studied the quality parameters of Cicer arietinumk (Australian) when subjected to the different gamma irradiation doses (0, 2, 5, 10, 20, 30 and 50 kGy). Their results showed no impact of irradiation on the starch granule structure as analysed by SEM. Although, the peak viscosity was decreased but no significant effect on the gelatinization temperature was observed. They concluded that the functional properties of the starch based foods can be enhanced by employing the gamma irradiation technique. Ciesla and Eliasson (2007) used the DSC for evaluating the properties of the gamma irradiated (0, 1, 2.5, 5, 15 and 30 kGy) wheat. They studied the changes occurring in the properties like retrogradation, gelatinization, amylose–lipid complex between irradiated and non-irradiated samples. It was concluded that radiation induced the different structural changes in polysaccharides.

Bao et al. (2005) carried a detailed investigation of gamma irradiated rice flour starch in which the physical and structural properties were evaluated. The DSC studies revealed that the To, Tp, and Tc values changed slightly while as the enthalpy was significantly reduced as the dose was increased. The starch showed type A X-ray diffraction similar to that of the native starch. However, the molecular weight and radius of the gyration of the amylopectin was decreased. Abu et al. (2006) studied the effects of gamma irradiation (2, 10 and 50 kGy) on the physicochemical and thermal properties of the Vigna unguiculata (cowpea) starch. They employed the equipments like DSC (for checking the gelatinisation properties), FTIR (for checking the crystallinity), SEM (for starch surface structure evaluation) and RVA (for checking the pasting properties of the starch). They concluded that the functional properties of the starch were modified, the pre-gelatinization temperature was increased due to the increased crystallinity.

Yu and Wang (2007) studied the effects of gamma irradiation (0, 2, 5, 8 and 10 kGy) on the physicochemical, rheological and granule structure of rice. It was found that the effects of irradiation on the inner micro-structure were higher than the outer surface. The gelatinization temperature, gel consistency increased while the apparent amylose content decreased with increasing the dosage. A high correlation was found between the irradiation dose and pasting properties (0.961–0.998). Chung et al. (2010) studied the pasting characteristics and in vitro digestibility of gamma irradiated (10, 20, 40 and 100 kGy) waxy maize starches. They found that the resistant starch content decreased as the irradiation dose was increased. The paste viscosity was increased as the dose increased while as the crystalline structures was unchanged. The gelatinized temperature was reduced and the water solubility was increased. They also concluded that the resistant starch having good swelling and pasting abilities could be used stabilizers and thickeners in food systems.

Singh et al. (2011) carried out research on the effects of gamma irradiation (0.01, 0.05, 0.1 and 0.5 kGy) on the granule morphology, thermal, structural, rheological and gel texture properties of starch extracted from potatoes. They found that the crystalline structure was completely destroyed and the formation of carboxyl content (0.09–0.11%). The gelatinization parameters (To, Tp and Tc) were increased while as viscosity (peak, trough, breakdown and final) decreased. They also found that the gel hardness decreased while as its cohesiveness increased with irradiation dose. The impact of irradiation on textural properties (chewiness, gumminess and adhesiveness) and retrogradation changed with the variety and they concluded that irradiation can be used as efficient and faster method for the starch modification as compared to the chemical and enzymatic modifications.

The modification of maize starch structure and physiochemical properties was studied by Liu et al. (2012). The maize starch powder was irradiated over a wide range of 0, 1, 2, 5, 10, 20, 50, 100, 200 and 500 kGy. They found that the viscosities (peak, trough, breakdown and final), gelatinization temperature and enthalpy were significantly reduced while as solubility was increased with increase in dosage. The crystallinity was found to be reduced relatively while there were no signs of physical damage to starch granule surface. They concluded that irradiation was a positively correlated to solubility while as negatively correlated to pasting properties, relative crystallinity and thermal properties.

Gani et al. (2012) carried out the modification of kidney bean starch by gamma irradiation and studied its impact on the functional and morphological properties. The starches isolated from the different beans (red, white, yellow and black) were treated with different doses (5, 10 and 20 kGy). The results revealed that the solubility, carboxyl content, transmittance and water absorbing capacity were increased while as the apparent amylose content, pasting properties, swelling power and syneresis decreased. The results also revealed that the irradiation doses were positively correlated with the solubility index and water absorption capacity and negatively correlated with peak viscosity, swelling index, trough viscosity, breakdown viscosity and final viscosity. The crystallinity was reduced as the dose increased but no change in the X-ray diffraction was observed. The granule structure was destroyed by irradiation doses. They concluded that the irradiated bean starch could be used in the frozen foods to prevent syneresis and enhance their shelf life. Hussain et al. (2014) also studied the gamma irradiation modification of bean polysaccharides and its impact on the morphological, physicochemical and antioxidant properties. The dosage was given from 5 to 25 kGy. They found a positive correlation between gamma irradiation and water absorption capacity (r = 0.82), gamma irradiation and solubility (r = 0.91), and negative correlation was observed between irradiation and thermal properties (r = − 0.89), swelling power (r = − 0.92) and pasting properties (r = − 0.91). High doses induced surface cracking on the starch granules. The results also revealed increased content of antioxidants as the dose was increased.

Lee et al. (2013) studied the formation of resistant corn starch induced by gamma irradiation. Three different corn starches were selected including normal corn starch, high amylose corn starch and waxy corn starch. The irradiation was done at the rate of 5, 10, 25 and 50 kGy. The results revealed that the gamma irradiation (5 kGy) induced formation of more amylose like molecules in the starch thereby increasing the resistant starch content in each type of starch. The highest resistant starch was produced at higher doses of radiation (50 kGy). The resistant starch so produced was more in waxy corn followed by high amylose corn starch and normal corn starch. Gani et al. (2013) irradiated starch extracted from the lotus stem and evaluated its physicochemical and morphological properties. The starch after its extraction was treated with gamma rays (5, 10, 20 kGy). The results showed that the water absorption, carboxyl content, transmittance and amylose leaching increased while as the apparent amylose content, swelling power, syneresis and pasting properties decreased. Higher doses resulted in the destruction of the starch granule surface. They concluded that the decrease in the swelling index could be constructive for improving the texture during cooking.

Sofi et al. (2013) studied the effects of gamma irradiation on the physicochemical properties of starch extracted from Vicia faba L. The starch was treated with gamma irradiation dosage of 0, 5, 10 and 15 kGy. The results showed significant increase in carboxyl content, solubility, freeze thaw, water absorption capacity as the dose was increased while as syneresis, pasting properties and pH was reduced significantly. C type pattern was observed in both native and irradiated starches, but the intensity of the peaks in irradiated was reduced. From Pearson co-relation, it was observed that water absorption capacity and solubility index were positively related to irradiation whereas freeze thaw, syneresis, pasting properties and swelling index were negatively correlated. Ocloo et al. (2014) studied the effects of gamma irradiation (2.5, 5 and 10 kGy) on the functional properties of tiger nut flour. They found that the viscosity values decreased significantly with increasing the irradiation dose. It was also found that the titratable acidity increased.

Wani et al. (2014) studied the effect of gamma irradiation on the starch extracted from (Aesculus indica) Indian horse chestnut, the starch was treated with dosage of 0, 5, 10, 15 kGy. The results revealed an increased trend in the freeze thaw, carboxyl content (0–0.06%), water absorption capacity (0.94–1.0 g/g), solubility (0.15–0.535 g/g) while as decreasing trend was followed by peak viscosity, syneresis (3.47–0.64%) when stored for 120 h, set back viscosity. A type pattern was shown by X-ray diffraction in native as well as irradiated samples. They concluded that Indian horse chestnut could be used for the production of starch, which is an underutilized plant. The non-irradiated starch possess high viscosity hence can be used in the food products subjected to refrigeration. Similar, results were reported by for brown rice starch (Kumar et al. 2017), buckwheat starch (Dar et al. 2018), wheat starch (Bashir et al. 2017a) and chickpea starch (Bashir and Aggarwal 2017). Bettaïeb et al. (2014) studied the impact of the gamma irradiation (3, 5, 10, 20 and 50 kGy) on the physico-chemical properties of starch obtained from corn. They concluded that the gelatinization temperature was decreased as the dose increased. They also found that the crystallinity of the starch was not affected up to 50 kGy, as no change in the X-ray diffraction was observed.

Kumar et al. (2017) studied the impact of gamma irradiation (5, 10, 15 and 20 kGy) on the starch granule structure and physicochemical and antioxidant properties of the brown rice starch. They reported a decrease in the overall crystallinity, apparent amylose content and pasting properties of the starch, however the antioxidant properties increased with an increase in the dose. Similar results were reported by Dar et al. (2018) for buckwheat starch and oat starch and Verma et al. (2018) for potato starch.

Impact on the functional properties

The starch digestibility varies according to the source and this varying property of its digestibility has found a great importance for developing the foods for diabetic persons. The variations in the digestibility of starch is ascribed to its source, chemical structure and composition. There have a lot of research suggesting that the in vitro digestibility of the starch can be increased by irradiation (Bravo et al. 1998; Rombo et al. 2001). Some of the studies pertaining to the starch digestibility as affected by the gamma irradiation are discussed hereunder.

Kume et al. (1988) demonstrated that the gamma irradiated corn starch enhanced the digestion besides decreasing the cooking temperature. The viscosities of porridges made from gamma irradiated maize, beans and their composite flours decreased with increase in dosage level (0, 2.5, 5, 7.5 and 10 kGy) (Rombo et al. 2001). They also found that starch digestibility was higher at dosage of 2.5 kGy in case of maize, with subsequent increase in the dosage level the starch digestibility was reduced. The digestibility of the maize was found higher as compared to the bean starch for the same treatments. The effects of the gamma irradiation (0, 5, 10, 20 and 40 kGy) on the polysaccharides of bean and maize flours were studied by Rombo et al. (2004). They employed the techniques like NMR, polarized light microscopy, DSC and X-ray diffraction for investigating the effects of irradiation treatment. They concluded that the beta bonded starch content was increased with irradiation dose which is responsible for the reduced starch digestibility. The degradation of amylopectin was also observed. Degradation of amylopectin and formation of beta bonded starch increased the crystallinity.

Chung and Liu (2009) demonstrated that the gamma irradiation decreased the RDS content when subjected to 10 kGy while at 50 kGy the RDS content was increased. While the RS content decreased up to 2 kGy but showed an increasing trend afterwards up to 50 kGy. They also reported that the swellability and carboxyl content reduced with slower irradiation doses.

The in vitro digestibility of the corn starch treated with gamma irradiation (5, 10, 15 and 20 kGy) was studied by Yoon et al. (2010). They found that the average molecular weight of the starches was decreased but the fractions of rapidly digestible and resistant starch was increased. Waxy starch was found more sensitive towards irradiation as compared to normal corn starch. They concluded that the increase in the resistant starch content indicates that the starch has undergone structural modification and chain degradation as well. Chung et al. (2010) studied the in vitro digestibility and pasting characteristics of the gamma irradiated (10, 20, 40 and 100 kGy) starches obtained from the waxy maize. They demonstrated that RS content was decreased by about 20% when compared to the initial values. However, the RDS was increased significantly. They also concluded that the alpha amylase activity was higher from inside as compared to the outside granule.

Other studies

Nowadays, due to the increased concerns regarding the environmental pollution the use of plastic materials has been avoided and the development of the alternative packaging materials has gained interest having the properties of eco-friendly, non-pollutant and biodegradable. Starch has been studied extensively to develop starch based polymeric packaging materials. Although, the mechanical properties are less as compared to the plastics. But the advancement in newer technologies like gamma irradiation has minimized these limitations. Zhai et al. (2002) studied the effects of gamma irradiation and electron beam irradiation (0, 10, 30, 50, 70, 90, and 110 kGy) on the starch and polyvinyl alcohol blended hydrogels. They found that the irradiation resulted in the cross linking between starch and polyvinyl alcohol. Jo et al. (2005) used gamma irradiation (0, 10, 20, and 30 kGy) for the development of biodegradable film. The raw materials selected were pectin and gelatine. They found that the irradiation dose of 10 kGy produced film with highest tensile strength. Al-Assaf et al. (2007) used gamma irradiation for the controlled modification of the film structure of Acacia Senegal (gum arabic). They also used acetylene as a mediating gas for the systematic modification. They initially used a dosage of 6.2 kGy which was then compared to the higher doses of 10.5 and 26.5 kGy. The higher doses resulted in the formation of hydrogels. They concluded that irradiation could be used for the development of films with desired characteristics. Kim et al. (2008) studied the impact of gamma irradiation on the development of corn starch based film using locust bean gum (0%, 0.75%, and 1.5%, w/v), sucrose, polyvinyl alcohol, and glycerol. The samples were irradiated at doses of 0, 3, 6, 12, and 24 kGy. The results revealed in the development of smooth, intact and yellowish coloured film. The results showed that the tensile strength of a 1.5% (w/v) locust bean gum when irradiated with 3 kGy resulted in 85% more elongation when compared to non-irradiated samples. The addition of 0.75% locust bean gum along with irradiation at 6 kGy for a starch-based film was estimated to be the optimum value. They concluded that irradiation could be an important tool for enhancing the mechanical properties of starch based films.

Conclusion

The pace of growth of human population is a serious concern for sustainable food supply. To achieve it, a safe and inexpensive method needs to be developed and gamma irradiation has proved till now as an efficient alternative for the chemical and microbial modification of starch. In future research needs to be done for using the ionizing radiations in combinations in order to have efficient cross linking and desired functional properties of modified starch. Further standards need to be set for giving the dosage and also development of techniques to check whether the food has been irradiated or not. It is evident from the research available that starch modification by gamma irradiation is a booming sector in the area of food technology.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

The first author is thankful to Council of Scientific and Industrial Research (CSIR) (Grant No. 09/1159/0001/2017/EMR I), India for providing financial assistance in the form of Senior Research Fellowship.

References

- Abd Allah MA, Foda YH, El Saadany R. Effect of gamma rays on starch extracted from irradiated wheat flour. Starch. 1974;26:89–93. [Google Scholar]

- Abu JO, Duoda KG, Minnaar A. Effect of gamma irradiation on some physicochemical and thermal properties of cow pea starch. Food Chem. 2006;95:386–393. [Google Scholar]

- Adeil PMS, Narvaiz P. Examination of some protective conditions on technological properties of irradiated food grade polysaccharides. Radiat Phys Chem. 2001;60(195):201. [Google Scholar]

- Al-Assaf S, Phillips GO, Williams PA, duPlessis TA. Application of ionizing radiations to produce new polysaccharides and proteins with enhanced functionality. Nucl Instrum Methods Phys Res Sect B. 2007;265:37–43. [Google Scholar]

- Al-Kaisey MT, Mohammed MA, Alwan AKH, Mohammed MH. The effect of gamma irradiation on the viscosity of two barley cultivars for broiler chicks. Radiat Phys Chem. 2002;63:295–297. [Google Scholar]

- Bao J, Ao Z, Jane J-L. Characterization of physical properties of flour and starch obtained from gamma irradiated white rice. Starch/Stärke. 2005;57:480–487. [Google Scholar]

- Bashir K, Aggarwal M. Effects of gamma irradiation on the physicochemical, thermal and functional properties of chickpea flour. LWT Food Sci Technol. 2016;69:614–622. [Google Scholar]

- Bashir K, Aggarwal M. Effects of gamma irradiation on cereals and pulses—a review. Int J Recent Sci Res. 2016;7(12):14680–14686. [Google Scholar]

- Bashir K, Aggarwal M. Physicochemical, thermal and functional properties of gamma irradiated chickpea starch. Int J Biol Macromol. 2017;97:426–433. doi: 10.1016/j.ijbiomac.2017.01.025. [DOI] [PubMed] [Google Scholar]

- Bashir K, Jan K, Aggarwal M. Thermo-rheological and functional properties of gamma irradiated whole wheat flour. Int J Food Sci Technol. 2017;52(4):927–935. [Google Scholar]

- Bashir K, Swer TL, Prakash KS, Aggarwal M. Physico-chemical and functional properties of gamma irradiated whole wheat flour and starch. LWT Food Sci Technol. 2017;76:131–139. [Google Scholar]

- Bettaïeb NB, Jerbi MT, Ghorbel D. Gamma radiation influences pasting, thermal and structural properties of corn starch. Radiat Phys Chem. 2014;103:1–8. [Google Scholar]

- Bhat R, Karim AA. Impact of radiation processing on starch. Compr Rev Food Sci Food Saf. 2008;8:44–58. [Google Scholar]

- Bhatty RS, Macgregor AW. Gamma irradiation of hulless barley: effect on grain composition, β-glucans and starch. Cereal Chem. 1988;65:463–470. [Google Scholar]

- Bravo L, Siddhuraju P, Saura-Calixto F. Effect of various processing methods on the in vitro starch digestibility and resistant starch content of Indian pulses. J Agric Food Chem. 1998;46:4667–4674. [Google Scholar]

- Chung H-J, Liu Q. Effect of gamma irradiation on molecular structure and physicochemical properties of corn starch. J Food Sci. 2009;74:353–361. doi: 10.1111/j.1750-3841.2009.01159.x. [DOI] [PubMed] [Google Scholar]

- Chung H-J, Lee S-Y, Kim J-H, Lee J-W, Byun M-W, Lim S-T. Pasting characteristics and in vitro digestibility of gamma irradiated RS-4 waxy maize starch. J Cereal Sci. 2010;52:53–58. [Google Scholar]

- Ciesla K, Eliasson A-C. DSC studies of retrogradation and amylose–lipid complex transition taking place in gamma irradiated wheat starch. Nucl Instrum Methods Phys Res Sect B Beam Interact Mater Atoms. 2007;265:399–405. [Google Scholar]

- Ciesla K, Svensson E, Eliasson A-C. Preliminary differential scanning calorimetry studies of radiation-induced transformations in starch and flour. J Therm Anal Calorim. 1999;56:1197–1202. [Google Scholar]

- Dar MZ, Deepika K, Jan K, Swer TL, Kumar P, Verma R, Verma K, Prakash KS, Jan S, Bashir K. Modification of structure and physicochemical properties of buckwheat and oat starch by γ-irradiation. Int J Biol Macromol. 2018;108:1348–1356. doi: 10.1016/j.ijbiomac.2017.11.067. [DOI] [PubMed] [Google Scholar]

- Gani A, Bashir M, Wani SM, Masoodi FA. Modification of bean starch by gamma irradiation: effect on functional and morphological properties. LWT Food Sci Technol. 2012;49:162–169. [Google Scholar]

- Gani A, Gazanfar T, Jan R, Wani SM, Masoodi FA. Effect of gamma irradiation on the physicochemical and morphological properties of starch extracted from lotus stem harvested from Dal lake of Jammu and Kashmir, India. J Saudi Soc Agric Sci. 2013;12:109–115. [Google Scholar]

- Graham JA, Panozzo JF, Lim PC, Brouwer JB. Effects of gamma irradiation on physical and chemical properties of chickpeas (Cicer arietinum) J Sci Food Agric. 2002;82:1599–1605. [Google Scholar]

- Han JA, BeMiller JN. Preparation and physical characteristics of slowly digesting modified food starches. Carbohyd Polym. 2007;67:366–374. [Google Scholar]

- Hussain PR, Wani IA, Suradkar PP, Dar MA. Gamma irradiation induced modification of bean polysaccharides: Impact on physicochemical, morphological and antioxidant properties. Carbohyd Polym. 2014;110:183–194. doi: 10.1016/j.carbpol.2014.03.028. [DOI] [PubMed] [Google Scholar]

- Jo C, Kang H, Lee NY, Kwon JH, Byun MW. Pectin- and gelatin-based film: effect of gamma irradiation on the mechanical properties and biodegradation. Radiat Phys Chem. 2005;72(6):745–750. [Google Scholar]

- Kang I-J, Byun M-W, Yook H-S, Bae C-H, Lee H-S, Kwon J-H, Chung C-K. Production of modified starches by gamma irradiation. Radiat Phys Chem. 1999;54:425–430. [Google Scholar]

- Kashani GG, Valadon LRG. Effects of gamma irradiation on the lipids, carbohydrates and proteins of Iranian pistachio kernels. Int J Food Sci Technol. 1984;19:631–638. [Google Scholar]

- Kaur B, Ariffin F, Bhat R, Karim A. Progress in Starch Modification in the Last Decade. Food Hyrdocolloids. 2012;26:398–404. [Google Scholar]

- Kertez ZI, Schulz ER, Fox G, Gibson M. Effects of ionizing radiation on plant tissues. IV. Some effects of gamma radiation on starch and starch fractions. J Food Sci. 1959;24(6):609–617. [Google Scholar]

- Kim JK, Jo C, Park HJ, Byun MW. Effect of gamma irradiation on the physicochemical properties of a starch-based film. Food Hydrocolloids. 2008;22:248–254. [Google Scholar]

- Kumar P, Prakash KS, Jan K, Swer TL, Jan S, Verma R, Deepika K, Dar MZ, Verma K, Bashir K. Effects of gamma irradiation on starch granule structure and physicochemical properties of brown rice starch. J Cereal Sci. 2017;77:194–200. [Google Scholar]

- Kume T, Rahman S, Ishigaki I. Change in digestibility of gamma-irradiated starch by low temperature cooking. Starch. 1988;40(4):155–158. [Google Scholar]

- Lee JW, Kim JH, Oh SH, Byun EH, Yook HS, Kim MR, Kim KS, Byun MW. Effect of gamma irradiation on viscosity reduction of cereal porridges for improving energy density. Radiat Phys Chem. 2008;77:352–356. [Google Scholar]

- Lee J-S, Ee M-L, Chung K-H, Othman Z. Formation of resistant corn starches induced by gamma-irradiation. Carbohyd Polym. 2013;97(2):614–617. doi: 10.1016/j.carbpol.2013.05.047. [DOI] [PubMed] [Google Scholar]

- Liu T, Ma Y, Xue S, Shi J. Modifications of structure and physicochemical properties of maize starch by gamma irradiation treatments. LWT Food Sci Technol. 2012;46:156–163. [Google Scholar]

- MacArthur LA, D’Appolonia BL. Gamma radiation of wheat. II. Effects of low dosage radiations on starch properties. Cereal Chem. 1984;61:321–326. [Google Scholar]

- Mahto R, Das M. Effect of gamma irradiation on the physicochemical mechanical and chemical properties of potato (Solanum tuberosum) in non-refrigerated storage conditions. Postharvest Biol Technol. 2014;92:37–45. [Google Scholar]

- Nene SP, Vakil UK, Sreenivasan A. Effect of gamma radiation on physico-chemical character of red gram (Cajanus cajan) Starch. J Food Sci. 1975;40:943–947. [Google Scholar]

- Ocloo FCK, Okyere AA, Asare IK. Physicochemical, functional and pasting properties of flour produced from gamma irradiated tiger nut (Cyperus esculentus L.) Radiat Phys Chem. 2014;103:9–15. [Google Scholar]

- Rayas-Duarte P, Rupnow JH. Gamma-irradiation affects some physical properties of dry bean (Phaseolus vulgaris) starch. J Food Sci. 1993;58:389–394. [Google Scholar]

- Rombo GO, Taylor JRN, Minnaar A. Effect of irradiation, with and without cooking of maize and kidney bean flours, on porridge viscosity and in vitro starch digestibility. J Sci Food Agric. 2001;81:497–502. [Google Scholar]

- Rombo GO, Taylor JRN, Minnaar A. Irradiation of maize and bean flours: effects on starch physicochemical properties. J Sci Food Agric. 2004;84:350–356. [Google Scholar]

- Saini V. Ionizing radiation effects on starch as shown by Staudinger index and differential thermal analysis. J Food Sci. 1968;33:136–138. [Google Scholar]

- Saunders J (2010) Physicochemical properties of wheat starches and their relationship to liquefaction and fermentative bioethanol performance. MSc Thesis, University of Manitoba, Winnipeg, Manitoba, Canada

- Singh N, Nakaura Y, Inouchi N, Nishinari K. Fine structure, thermal and viscoelastic properties of starches separated from indica rice cultivars. Starch/Stärke. 2007;59(1):10–20. [Google Scholar]

- Singh N, Isono N, Srichuwong S, Noda T, Nishinari K. Structural, thermal and viscoelastic properties of potato starches. Food Hydrocolloids. 2008;22(6):979–988. [Google Scholar]

- Singh N, Nakaura Y, Inouchi N, Nishinari K. Structure and viscoelastic properties of starches separated from different legumes. Starch/Stärke. 2008;60(7):349–357. [Google Scholar]

- Singh S, Singh N, Isono N, Noda T. Relationship of granule size distribution and amylopectin structure with pasting, thermal, and retrogradation properties in wheat starch. J Agric Food Chem. 2010;58(2):1180–1188. doi: 10.1021/jf902753f. [DOI] [PubMed] [Google Scholar]

- Singh S, Singh N, Ezekiel R, Kaur A. Effects of gamma-irradiation on the morphological, structural, thermal and rheological properties of potato starches. Carbohyd Polym. 2011;83(4):1521–1528. [Google Scholar]

- Sofi BA, Wani IA, Masoodi FA, Saba I, Muzaffar S. Effect of gamma irradiation on physicochemical properties of broad bean starch. LWT Food Sci Technol. 2013;54:63–72. [Google Scholar]

- Takeda C, Takeda Y, Hizukuri S. Structure of amylomaize amylase. Cereal Chem. 1989;66:22–25. [Google Scholar]

- Tegge G. Starch: properties and potential. Chichester, UK: Wiley; 1987. [Google Scholar]

- Vakil KU, Aravindakshan M, Srinivas H, Chauhan PS, Sreenivasan A (1973) Nutritional and wholesomeness studies with irradiated foods-India’s program. In: Radiation preservation of food. International Atomic Energy Agency, Vienna, pp 673–702

- Verma R, Jan S, Rani S, Jan K, Swer TL, Prakash KS, et al. Physicochemical and functional properties of gamma irradiated buckwheat and potato starch. Radiat Phys Chem. 2018;144:37–42. [Google Scholar]

- Wani IA, Jabeen M, Geelani H, Masoodi FA, Saba I, Muzaffar S. Effect of gamma irradiation on physicochemical properties of Indian Horse Chestnut (Aesculus indica) starch. Food Hydrocolloids. 2014;35:253–263. [Google Scholar]

- Wu D, Shu Q, Wang Z, Xia Y. Effect of gamma irradiation on starch viscosity and physico-chemical properties of different rice. Radiat Phys Chem. 2002;65:79–86. [Google Scholar]

- Yoon H-S, Yoo J-Y, Kim J-H, Lee J-W, Byun M-W, Baik B-K, Lim S-T. In vitro digestibility of gamma irradiated corn starches. Carbohyd Polym. 2010;81:961–963. [Google Scholar]

- Yu Y, Wang J. Effect of γ -ray irradiation on starch granule structure and physicochemical properties of rice. Food Res Int. 2007;40(2):297–303. [Google Scholar]

- Zhai ML, Yoshii F, Kume T, Hashim K. Synthesis of PVA/Starch grafted hydrogels by irradiation. Carbohyd Polym. 2002;50:295–303. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.