Abstract

Increasing consumer demand for foods with high nutritional quality, prolonged shelf life and low environmental impact of the package, is driving innovation towards the development of new packaging. Multifunctional food packaging films, biodegradable, heat-sealable and antimicrobial, were developed. A PLA coating layer incorporating either sodium benzoate, potassium sorbate, or a combination of them was deposited onto a poly(lactic) acid/poly(butylene adipate-co-terephthalate) substrate film. The effectiveness of the developed systems to preserve the quality of foods was tested in shelf-life experiments performed on shredded carrots and pineapple juice, selected as model processed raw foods. The best performance was observed for the active film containing potassium sorbate: microbial populations increased less rapidly and were 0.7–1.8 log CFU/g lower at the end of storage period in this film than in control packs. Of the two model foods, the pineapple juice was better preserved: after 7 days in active packaging, color change and microbial counts of juice were below that of control, observed after one day and after 3 days of storage respectively. Moreover, the incorporation of the active phases did not significantly affect the mechanical, barrier and optical properties of the films, opening new ways to prolong shelf-life of minimally processed foods.

Supplementary Information

The online version contains supplementary material available at 10.1007/s13197-022-05435-y.

Keywords: Active packaging, Biodegradable films, Preservative, Shelf-life, Pineapple, Carrot, Heat-sealability

Introduction

Packaged minimally processed fruit and vegetables are of growing popularity for their high nutritional value and convenience. However, these foods are highly susceptible to microbial growth, which represent the main cause of their spoilage (Ragaert et al. 2007). In fact, minimal processing operations, such as cutting, shredding, juicing, lead to the disruption of subcellular compartmentalization and the release of cellular nutrients, which promote the growth of microorganisms (Klaiber et al. 2005) and cause undesirable biochemical and physiological changes. These changes decrease the safety and the nutritional and sensory quality and thus, shorten food shelf life (Wang et al. 2015).

Among the minimally processed fruit and vegetables, shredded carrots and pineapple juice are among the most widespread and consumed for their sensory and nutritional properties (Klaiber et al. 2005; Leneveu-Jenvrin et al. 2020). Typically, the shelf-life of fresh pineapple juice or shredded carrots stored at 4 °C is comprised between three and eight days (Leneveu-Jenvrin et al. 2020; Mahendran 2015; Piscopo et al. 2019). The decrease in quality of fresh pineapple juice is observed particularly through yeast and mold population increase and modification of color towards browning, leading to sensory descriptors of “fermented” (Leneveu-Jenvrin et al. 2020). On the contrary, quality decrease of shredded carrots during storage is mainly due to gram-negative bacteria development, especially Pseudomonaceae, and surface color change (Klaiber et al. 2005; Xylia et al. 2018). Hence, the limitation of quality loss in the two products has different microbial targets, fungi for pineapple juice and bacteria for shredded carrots.

The feasibility of a single treatment to limit microbial growth in these two foods requires investigations. Lowering temperature is the most potent way to decrease the microbial growth rate, but it cannot be enough. The addition of antimicrobial agents is another approach to limit the growth of microorganisms (Durango et al. 2006). Among the antimicrobials, sorbates and benzoates hold the major share of the market (Kuplennik et al. 2015). Potassium sorbate (PS) is the salt of sorbic acid. It is classified as a food additive (E202) according to EC 1333/2008 and inhibits yeasts and molds and some bacteria, at pH lower than 6.5 (Davidson et al. 2005). Sodium benzoate (SB) is the salt of benzoic acid: it has been classified as a food additive (E211) in EC 1333/2008 and inhibit yeasts, molds and bacteria at pH lower than 4–4.5 (Musyoka et al. 2018). Synergistic effects between these compounds have also been reported (Stanojevic et al. 2009). Usually, these antimicrobial agents are directly added into the food. However, the incorporation of the antimicrobials into a package could be more efficient than their direct addition into the food, because they may gradually migrate from the package onto the food surface. Release rate of antimicrobials depends on temperature, pH, and on the food surface for diffusion, as reported by many authors on several foods and packaging systems (Glicerina et al. 2021; Jin 2017; Uz and Altınkaya 2011; Vasile and Baican 2021). Pineapple juice and shredded carrots differ by their liquid or solid nature, which modifies their interaction with packaging film. For that reason and because of different microbial targets to inhibit, these two minimally-processed products were chosen as model foods for this study.

Different authors reported that the incorporation of PS or SB or their combination at concentration ranging from 10 to 15wt% into biodegradable and non-biodegradable polymeric systems was effective to delay the growth of microorganisms (Careli-Gondim et al. 2020; Jin et al. 2010; Shen et al. 2010). However, most of the existing investigations focused on the antimicrobial activity of the films in vitro, while a few studies are available on in vivo tests that demonstrated the effectiveness of these biodegradable systems on real food such as fresh noodles, strawberry puree, berries and avocado (Careli-Gondim et al. 2020; T. Jin et al. 2010; Junqueira-Gonçalves et al. 2016; Wangprasertkul et al. 2021).

In this work, we intended to develop innovative, multifunctional and environmentally friendly food packaging films able to prolong the shelf-life of minimally processed fruits and vegetables.

To this aim, biodegradable systems consisting of a PLA/PBAT substrate film, coated with an amorphous PLA layer incorporating either PS, SB or a combination of them, were prepared. The coating layer constituents were selected to ensure a biodegradable film structure, combined with heat-sealing ability and antimicrobial activity. The ability to increase food shelf-life and the technical suitability of the developed films were determined.

Materials and Methods

Fruit and vegetable sampling and processing

Carrots (Daucus carota cv. Maestro) and pineapples (Ananas comosus cv. Queen Victoria) were collected from local markets in Reunion island (France). They were transferred to the laboratory and stored at 10 °C until processing, within 24 h. All the equipment used was previously rinsed with sodium hypochlorite solution.

Carrots were rinsed into chlorinated water 200 ppm for 3 min, washed with distilled water and then allowed to dry naturally. Then, they were subjected to shredding and put into a tray. Fresh lemon juice (100 ± 20 mL for 1 kg of carrots) was added in order to obtain a pH equal to 4.

Pineapple fruit at a similar stage of ripeness were manually peeled and cut and prepared into juice (Extractor Wismer EW-01, CAPAVENIR, France).

Active films

Film composition and production

Active films were developed through a coating technique. The support surface used for the coatings was a commercial biodegradable film named as Biopolymer (Euromaster, Italy). This film is made by a blend of PLA and PBAT, has a medium thickness of 22.0 ± 1.0 μm, an oxygen and water vapor permeability of 5.15 ± 0.35 (cm3 × cm)/(m2 × d × bar) and 9.19 ± 0.37 (g × m)/(m2 × Pa × s) respectively (Apicella et al. 2019). The material selected as matrix for the coating layer was PLA4060D supplied by NatureWorks™ (Minnetonka, USA). The active phases added in the coating layer were potassium sorbate (PS) and sodium benzoate (SB). Acetone and a surfactant (Tween 85) were also used for the coating production. They were all supplied by Sigma Aldrich Co. (Missouri, USA). All organic solvents were analytical grade.

A polymeric solution of consisting of acetone and PLA, in a mass ratio of 80:20, was mixed with an aqueous solution containing the active phases and the surfactant (at a concentration of 1 wt% of the total solid content) in a volumetric ratio of 100:10. Then, the obtained emulsion was applied to the surface of the support, which was the biopolymer film, by means of a threaded hand coater. The active phases were PS, SB and a combination of them in a 50% mass ratio and were added at a concentration of 0 wt%, 5 wt%, 10 wt% or 15 wt% of the total solid content of the coating layer. A level of 15 wt% was the highest limit for the complete solubilization of SB in water.

Film characterization

Mechanical tests were performed on rectangular specimens of the produced films (width = 12.7 mm, length = 30 mm) using a SANS dynamometer equipped with a 100 N load cell. The testing speed was set according to the ASTM 882. A minimum of five specimens for each film were tested.

Oxygen permeability measurement on the films was carried out using a permeabilimeter (GDP-C 165 of Brugger), with a manometric operation, connected to a thermo-controlled bath (ThermoHaake). Before the test, an evacuation was performed on both the upper and lower half-cells to remove the moisture and other residual gases. The test temperature was set at 23 °C and the oxygen flow to 80 mL/min, following ISO 15105-1. Sample area was 16 cm2. The obtained oxygen transmission rate (OTR) was multiplied by the respective thickness of the film to calculate the permeability coefficient (PO2). All tests were made in triplicate and the averaged values are reported (standard deviation < 8%).

The transparency of the films was measured following the ASTM D1746-03 through a UV–Vis spectrophotometer (Lambda 800, USA). Squared samples of the films (length = 5 cm) were placed on the internal side of the spectrophotometer cell and the transmittance was measured at 560 nm. Three replicates of each film were tested. The percentage of transparency (TR) was calculated according to:

| 1 |

where Tr was the transmittance with the specimen in the beam and T0 was the transmittance with no specimen in the beam.

Hot seal strength (hot-tack) tests were performed with a heat seal tester model HSG-C (Brugger), according to standard ASTM F1921-98, Method B. Samples were cut into strips (width = 1.5 cm and length = 30 cm) and then were hot pressed at a temperature of 85 °C under a pressure of 15 N/cm2 with a welding time of 0.5 s. The heat-sealing strength was measured right after the sealing. A minimum of five replicates was tested for each sample.

Food packaging

Films were cut into squared shapes of 11 × 11 cm2 and sealed in pairs on three sides using a Multivac sealing machine. The obtained bags were filled either with 25 g of shredded carrots or with 10 ml of fresh pineapple juice, sealed on the remaining side and stored at 4 °C. One pack was prepared for each date of analysis. All the experiments were performed in triplicate.

Food quality determination

Microbiological counting

For the microbiological analysis, 4.5 ± 0.5 g of shredded carrots or of pineapple juice were removed aseptically from each bag and were transferred into a sterile stomacher bag. Then, the same weight of saline peptone water was added (SPW, Condalab, Torrejón de Ardoz, Madrid, Spain). Carrots and SPW were blended for 60 s by using a stomacher.

Total aerobic plate counts (TPC), and yeast and mold counts (YMC), were determined after plating on Plate Count Agar (PCA, Biokar Diagnostics Solabia, Beauvais, France) incubated at 30 °C for 72 h and Sabouraud glucose agar with 100 mg/L chloramphenicol (SGA, Biokar diagnostic, Solabia, Allonne, France) incubated at 30 °C for 5 days, respectively. Enterobacterium plate counts (EC) were determined on VRBG agar.

(Biokar diagnostic) after 48 h of incubation at 37 °C.

pH and titratable acidity

Shredded carrots (1.5 g) were mixed with 10 mL of distilled water prior to pH and titratable acidity (TA) determination. The pH value was determined by a pH meter (5231 and GLP22, Crison Instruments S.A. Barcelona, Spain), and TA was determined by titration with 0.05 M NaOH (TitroLine easy, Schott, Mainz, Germany). TA was expressed in citric acid equivalents in g/100 mL.

Visual appearance and color determination

Pictures of 3.0 ± 0.5 g of shredded carrots were taken using a viewing booth Just Normlicht in order to have a constant light source.

The color of samples (mixed carrots or juice) was assessed with a spectrophotometer CM 3500d (Minolta®, Carrières-sur-Seine, France). The coordinates L*, a* and b* of the CIELAB space were measured. The total colour variation was calculated as follow:

| 2 |

in which L*a, a*a and b*a refer to the assay condition and L*0, a*0 and b*0 to the initial condition used as a control.

Statistical analysis

The statistical analysis of the data was performed with XLSTAT software (Addinsoft, Paris, France). A confidence interval of 95% was used for all analyses. The Fisher (LSD) test was applied for ANOVA for carrots. The Bonferroni test was applied for pairwise comparisons for pineapple juice with a p-value of 0.0001.

Results and discussion

The effectiveness of the developed systems was tested on two different foods, shredded carrots and pineapple juice. The foods were packed in active bags produced from films of different compositions and stored in refrigerated conditions. Films having a content of active phase of 5 wt% or 10 wt% were not effective to delay the microbial growth of the selected foods (data not shown). This is in accordance with literature (Shen et al. 2010), in which a minimum content of 15 wt% PS in starch films was required to exhibit in vitro antimicrobial function, due to the hydrogen bonding interaction between the hydroxyl group of the polymer matrix and the carboxyl group of potassium sorbate. Therefore, only the results corresponding to films with an active phase content of 15wt% are presented.

Effect of antimicrobial films on shredded carrot quality

The pH values and titratable acidity of shredded carrots during 10 days of storage are reported in Table 1. Since the antimicrobial activity of both PS and SB is pH-dependent (Davidson et al. 2005; Musyoka et al. 2018), lemon juice was added during processing of carrots. The lemon juice addition led to a decrease in the initial pH value of shredded carrots from 6.2 ± 0.5 to 4.1 ± 0.1, which is consistent with the antimicrobial activity of both PS and SB.

Table 1.

pH value, titratable acidity (TA, g/100 g) and color difference of shredded carrots packed in the different films during refrigerated storage up to 10 days

| Film | Days of storage | pH | TA | ∆E |

|---|---|---|---|---|

| Control | 0 | 4.1 ± 0.1 b | 3.5 ± 0.3 a | 0 ± 0 c |

| Control | 3 | 5.0 ± 0.4 a | 2.0 ± 0.8 ab | 8.5 ± 5.3 ab |

| 15SB | 3 | 4.8 ± 0.1 ab | 2.6 ± 0.4 ab | 10.3 ± 11.4 ab |

| 15PS | 3 | 4.7 ± 0.3 ab | 2.4 ± 0.6 ab | 6.9 ± 3.7 abc |

| 15SB + 15PS | 3 | 4.8 ± 0.3 ab | 2.3 ± 0.6 ab | 7.1 ± 6.7 abc |

| Control | 7 | 5.1 ± 0.2 a | 2.2 ± 0.1 ab | 3.8 ± 4.5 ab |

| 15SB | 7 | 4.8 ± 0.2 ab | 2.9 ± 0.2 ab | 4.8 ± 2.2 abc |

| 15PS | 7 | 4.8 ± 0.3 ab | 2.4 ± 0.1 ab | 6.8 ± 8.3 abc |

| 15SB + 15PS | 7 | 4.7 ± 0.1 ab | 2.8 ± 0.1 ab | 10.3 ± 6.8 ab |

| Control | 10 | 5.1 ± 0.1 a | 1.7 ± 0.4 b | 6.3 ± 4.9 abc |

| 15SB | 10 | 4.6 ± 0.1 ab | 3.0 ± 0.5 ab | 4.5 ± 1.7 abc |

| 15PS | 10 | 4.7 ± 0.1 ab | 2.9 ± 0.1 ab | 8.3 ± 4.0 abc |

| 15SB + 15PS | 10 | 4.5 ± 0.2 ab | 2.9 ± 0.9 ab | 14.8 ± 4.9 a |

Control: no active phase, 15SB: sodium benzoate at 15 wt% in the coating layer, 15PS: potassium sorbate at 15 wt% in the coating layer, 15SB + 15PS: sodium benzoate and potassium sorbate in a 50/50 mass ratio at 15 wt% in the coating layer. Means and standard deviations of triplicates are indicated

Values in the same column with different letters show significant differences at p < 0.05

During the storage of shredded carrots, a pH increase, though not significant for all conditions, was observed during the first three days, followed by a slight decrease until day 10. As expected, TA followed the opposite trend. The changes of pH and TA during the first days can be explained by spatial repartition at the bottom of the pack of the acidic liquid (lemon juice), whereas the further decrease could result from microbial acidification, as previously reported (Alegria et al. 2010; Piscopo et al. 2019; Pushkala et al. 2012).

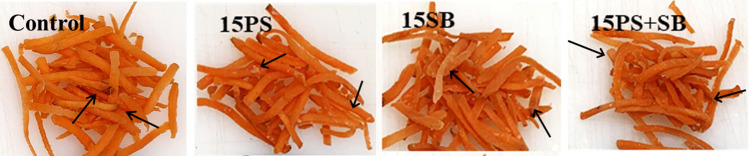

Color measurement of shredded carrots were also performed, since color variation of food during the time is generally perceived by the consumers as a loss of freshness (Piscopo et al. 2019). For shredded carrots, surface dehydration and production of lignin could result in the discoloration of the vegetable during the storage (Alegria et al. 2010; Pushkala et al. 2012). At the initial day, shredded carrots exhibited a low brightness (L*) and an intense red (a*) and yellow (b*) color (Online Resource 1). Fai et al. (Fai et al. 2016) reported comparable values for shredded carrots of a* and b*, but also a higher value of brightness. Poorly significant color differences to day 0 were observed during storage for the control packaging film (Table 1). This could be owed by the presence of the film that acted as a barrier to water, reducing dehydration and thus discoloration of the packed food. Also Piscopo et al. (Piscopo et al. 2019) did not observe any relevant discoloration of shredded carrots packaged in polypropylene (PP) pouches up to 10 days of storage at 4 °C, while Alegria et al. (Alegria et al. 2010) found a fading/whitening of the characteristic color of shredded carrots packed in PP bags, significant after 7 days. A large variability of L*, a* and b*, and thus color difference was observed (Table 1 and Online Resource 1), which can explain the observation. Moreover, as reported in Table 1, no relevant differences in color of carrots packed in the films compared to day 0 were observed, except for the 15 wt% SB + 15 wt% PS film after 10 days, sign that the active phase did not modified the global color of the packed food. To support that data, the visual appearance of shredded carrots stored in the different films for 7 days is reported in Fig. 1. No relevant browning or widespread change was observed during the time, but localized white and black tiny spots appeared on carrot surface whatever the packaging film.

Fig. 1.

Visual appearance of shredded carrots packed into the films containing antimicrobials after 7 days of storage. Arrows indicate black or white spots on the carrot surface. Film names: Control, no active phase; 15SB, sodium benzoate at 15 wt% in the coating layer; 15PS, potassium sorbate at 15 wt% in the coating layer; 15PS+SB, sodium benzoate and potassium sorbate in a 50/50 mass ratio at 15 wt% in the coating layer

Microbial counts of shredded carrots are reported in Fig. 2a and b. The TPC of shredded carrots packed in the control film significantly increased during the storage, being significantly different to day 0 from 3 days of storage, and reaching 11.3 ± 0.1 log CFU/g after 10 days. During the same time, the increase of YMC was significant only after 10 days of storage compared to the initial count. YMC of control conditions reached 4.7 ± 0.1 log CFU/g.

Fig. 2.

Total aerobic plate counts of shredded carrots (a), yeast and mold counts of shredded carrots (b), enterobacterium counts of pineapple juice (c) and yeast and mold counts of pineapple juice (d), packed in the control film (white bars), in 15SB (grey bars), in 15PS (black bars), in 15SB + 15PS (spotted bars) during refrigerated storage. Film names: Control, no active phase; 15SB, sodium benzoate at 15 wt% in the coating layer; 15PS, potassium sorbate at 15 wt% in the coating layer; 15SB + 15PS, sodium benzoate and potassium sorbate in a 50/50 mass ratio at 15 wt% in the coating layer. Means and standard errors are indicated. Same letter in a graph indicates no significant difference at p < 0.05

The European Regulation (EUR-Lex-32005R2073-EN-EUR-Lex 2005) sets a threshold for the total microbial load of minimally processed vegetables equal to 7 log CFU/g. According to this limit, the shelf life of the packed carrots was comprised between 3 and 7 days, because of bacterial development. Different results are reported in literature with a range of shelf-life between 6 and 10 days. Corbo et al. (2004) found a shelf life of shredded carrots treated with chlorinated water equal to 6 days considering a threshold of 7.7 log CFU/g. Alegria et al. (2010) found that shredded carrots treated with chlorinated water reached the European threshold value in 7 days, whereas Piscopo et al. (2019) reported that shredded carrots stored in PP bags reached the limit after 10 days of storage.

The comparison of the microbial counts of shredded carrots according to the different packaging films showed that the presence of the active phases slightly reduced the TPC (Fig. 2a). The strongest inhibitory effect was observed for the film 15 wt% PS after 7 and 10 days. The TPC counts exceeded 7 log CFU/g between 3 and 7 days, as for the control, but a difference of 0.8 log CFU/g was observed between the control and the carrots packed in 15 wt% PS after 7 days. A similar tendency was observed for YMC of carrots packed antimicrobial films, though with lower populations (Fig. 2b). Only the film 15 wt% SB was able to maintain YMC at a level not different from the control at day 0, whatever the storage duration, and the fungal population after 7 days of storage was 3.4 log CFU/g, i.e. 1.3 log CFU/g less than the control.

The results of carrot shelf-life tests suggested that the developed films were able to release the antimicrobial agents, as they exerted their antimicrobial function on TPC reduction for the film containing PS as active agent and on YMC for the film containing SB. No synergistic effect between PS and SB was observed.

Effect of antimicrobial films on pineapple juice quality

The active films were assessed in order to evaluate their impact on the quality of fresh pineapple juice during storage up to 7 days at 4 °C. Fresh pineapple juice is naturally acidic, with a pH value comprised between 3.1 and 4.2 and its main organic acids are citric and malic (Leneveu-Jenvrin et al. 2020). Hence, juice pH was suitable for PS and SB antimicrobial effect. Until now, beverage active packaging has been mostly investigated for shelf-stable beverages which require high barrier properties regarding oxygen (Palomero et al. 2016; Ramos et al. 2015).

Table 2 shows that the pH value of pineapple juice in the control film did not significantly change during storage, whereas a slight decrease of TA was noticed after 7 days. After 7 days of juice storage, pH values were not different according to the packaging film, but differences in TA were observed. In fresh pineapple juice, TA variability is in the range 0.66–1.35 g/100 mL (Leneveu-Jenvrin et al. 2020) and the values obtained in this study were consistent with these data, except for juice stored for 7 days in 15 wt% SB film.

Table 2.

pH value, titratable acidity (TA, g/100 g) and color difference of fresh pineapple juice packed in control film or in antifungal films and stored up to 7 days at 4 °C

| Film | Days of storage | pH | TA | ∆E |

|---|---|---|---|---|

| Control | 0 | 3.7 ± 0.1 ab | 0.92 ± 0.10 a | 0 ± 0 i |

| Control | 1 | 3.6 ± 0.1 ab | 0.92 ± 0.10 a | 9.1 ± 0.5 c |

| 15SB | 1 | 3.6 ± 0.1 ab | 0.90 ± 0.10 a | 7.5 ± 1.7 cde |

| 15PS | 1 | 3.6 ± 0.1 ab | 0.91 ± 0.10 a | 3.2 ± 1.5 h |

| 15SB + 15PS | 1 | 3.7 ± 0.1 ab | 0.92 ± 0.10 a | 6.4 ± 1.4 gh |

| Control | 3 | 3.6 ± 0.1 ab | 0.92 ± 0.10 a | 14.4 ± 1.1 b |

| 15SB | 3 | 3.7 ± 0.1 ab | 0.90 ± 0.10 a | 8.9 ± 0.2 cd |

| 15PS | 3 | 3.8 ± 0.1 a | 0.91 ± 0.10 a | 6.3 ± 0.2 defg |

| 15SB + 15PS | 3 | 3.5 ± 0.1 b | 0.91 ± 0.10 a | 5.8 ± 0.2 efgh |

| Control | 4 | 3.7 ± 0.1 ab | 0.92 ± 0.10 a | 22.6 ± 1.0 a |

| 15SB | 4 | 3.5 ± 0.1 b | 0.90 ± 0.10 a | 5.7 ± 0.9 efgh |

| 15PS | 4 | 3.6 ± 0.1 ab | 0.90 ± 0.10 a | 3.7 ± 0.2 gh |

| 15SB + 15PS | 4 | 3.6 ± 0.1 ab | 0.91 ± 0.10 a | 5.6 ± 0.2 efgh |

| Control | 7 | 3.5 ± 0.1 b | 0.85 ± 0.10 b | 23.8 ± 1.2 a |

| 15SB | 7 | 3.7 ± 0.1 ab | 0.45 ± 0.10 d | 4.5 ± 0.1 fgh |

| 15PS | 7 | 3.7 ± 0.1 ab | 0.76 ± 0.10 c | 4.4 ± 0.1 fgh |

| 15SB + 15PS | 7 | 3.6 ± 0.1 ab | 0.84 ± 0.10 b | 7.4 ± 0.1 cde |

Means and standard deviations of triplicates are shown. Different letters in the same column indicate significant differences (p-value < 0.0001). Control: no active phase, 15SB: sodium benzoate at 15 wt% in the coating layer, 15PS: potassium sorbate at 15 wt% in the coating layer, 15SB + 15PS: sodium benzoate and potassium sorbate in a 50/50 mass ratio at 15 wt% in the coating layer

The color of the juice stored in the control film changed during storage: a* and b* significantly decreased (Online Resource 2), resulting in a color difference of 23.8 ± 1.2 after 7 days compared to the initial color (Table 2). This difference is high, as a difference above 5 can be assigned to two different colors (Mokrzycki and Tatol 2011). It is also consistent with previous reports indicating color modification and browning during storage of pineapple juice (Leneveu-Jenvrin et al. 2020). For the juice stored in the antimicrobial films, the decrease in a* and b* was less pronounced than for the control film, leading to a color variation compared to the initial juice in the range 4.4 ± 0.1—7.4 ± 0.1. The color change was even less marked for the juice stored in films with 15 wt% SB or 15wt% PS as active phase, compared to the one in films with both the antimicrobial compounds, which behave differently with an increase in L*.

Figure 2c and d shows the development of enterobacteria and yeasts and molds respectively in pineapple juice stored in control or antimicrobial films. For the control film, a significant increase is observed after two days for EC and YMC. Both EC and YMC of the control condition increased by 2 log CFU/g within the 7 days of storage. Initial counts and population increases were consistent with previous observations (Leneveu-Jenvrin et al. 2020). The comparison of microbial counts after two days of storage of juice whatever the antimicrobial packaging film showed lower counts for the two microbial groups compared to the control one. After 7 days of storage, the difference of counts between the control condition and juice packed into antimicrobial films represented 1.4–1.5 log CFU/g and 1.0–1.6 log CFU/g, respectively for EC and YMC. Each antimicrobial proved to be of the same efficacy than their combination for the inhibition of yeast and molds and of enterobacteria.

All together, these results showed that the use of biodegradable films containing antimicrobial compounds at a concentration of 15 wt% in the coating layer is strongly effective to limit microbial development in pineapple juice, but also to limit color modification, extending the juice’s shelf life.

The impact of the active films is much more pronounced on pineapple juice than on shredded carrots, likely because of the lower pH of pineapple compared to carrots that allowed to the active phases to better exert their antimicrobial action. Moreover, the diffusion of the antimicrobials, which are non-volatile but water soluble, was probably favored by the liquid nature of the pineapple juice (Wu et al. 2018). In addition, the ratio food quantity / film surface was more favorable for pineapple juice than for carrots. Among the tested antimicrobial compounds, films containing PS were more effective than SB or their combination to delay the microbial growth in both the analyzed food, in accordance with data literature reported for fresh noodles (Wangprasertkul et al. 2021).

Film properties

The main functional properties of the films and their heat-sealing ability were evaluated in order to analyze the effect of the incorporation of the active phases on the film’s performance and thus on their suitability as food packaging materials. Table 3 reports the mechanical, barrier and optical properties of the films with the highest levels of active phase. All the coated films showed values of the main mechanical parameters in the same range of PLA/PBAT based blends (Pietrosanto et al. 2020a, b; Pietrosanto, Scarfato, Di Maio, Nobile et al. 2020) and comparable to those of polyethylene (PE) (Mangaraj et al. 2009), one of the most used conventional polymers for flexible packaging applications. The presence of the active phases did not significantly affect the stiffness of the films, while it led to a slight increase of the yield stress. Moreover, it caused a slight reduction in the ductility of the films, more pronounced for the SB phase. It may be hypothesized that SB, having aromatic nature, and thus lower chemical affinity than the aliphatic PS towards the PLA matrix of the coating layer, could tend to aggregate into the polymer, creating small particles that act as stress concentration points and reduce the toughness. However, in all cases the change was not large enough to compromise the ductile failure mode of the films (Table 4).

Table 3.

Film composition, thickness, and functional properties of the films

| Film | Active phase | Concentration of active phase (wt%) | Coating layer thickness (µm) | Total film thickness (µm) | E (MPa) | σy (MPa) | ɛb (%) | PO2 (cm3 × mm)/(m2 × d × bar) | TR560 (%) |

|---|---|---|---|---|---|---|---|---|---|

| Control | None | 0 | 12.6 ± 3.1 | 35.6 + 3.2 | 290 ± 18 a | 6.4 ± 1.5 a | 305 ± 19 a | 38.5 | 11.0 ± 1.2 a |

| 15SB | SB | 15 | 14.0 ± 3.0 | 37.0 + 3.1 | 295 ± 31 a | 7.3 ± 1.5 a | 263 ± 26 b | 39.1 | 6.4 ± 0.7 b |

| 15PS | PS | 15 | 13.3 ± 3.6 | 36.3 + 3.7 | 292 ± 20 a | 7.2 ± 1.4 a | 290 ± 25 ab | 40.3 | 10.9 ± 0.5 a |

| 15SB + 15PS | SB + PS (50/50 w/w) | 15 | 13.9 ± 2.3 | 36.9 + 2.4 | 293 ± 26 a | 7.1 ± 1.6 a | 270 ± 34 b | 40.9 | 7.3 ± 0.9 b |

Means and SD of triplicates are shown. Different letters in the same column indicate significant differences (p-value < 0.0001). Control: no active phase, 15SB: sodium benzoate at 15 wt% in the coating layer, 15PS: potassium sorbate at 15 wt% in the coating layer, 15SB + 15PS: sodium benzoate and potassium sorbate in a 50/50 mass ratio at 15 wt% in the coating layer

Elastic modulus (E), yield stress (σy), elongation at break (ɛb), oxygen permeability coefficient (PO2), and transparency at 560 nm (TR560)

Table 4.

Hot tack strength (according to ASTM F 1921–98) of the films

| Film | Hot tack strength (g/15 mm) | Failure mode |

|---|---|---|

| Uncoated substrate | Not sealable | – |

| Control | 383 ± 14 | Delamination |

| 15SB | 283 ± 29 | Adhesive |

| 15PS | 245 ± 25 | Adhesive |

| 15SB + 15PS | 267 ± 29 | Adhesive |

Means and SD of triplicates are shown. Different letters in the same column indicate significant differences (p-value < 0.0001). Control: no active phase, 15SB: sodium benzoate at 15 wt% in the coating layer, 15PS: potassium sorbate at 15 wt% in the coating layer, 15SB + 15PS: sodium benzoate and potassium sorbate in a 50/50 mass ratio at 15 wt% in the coating layer

Since the oxygen is one of the main factors that lead to food spoilage, the developed films were also tested for their oxygen permeability. All coated films showed comparable values of permeability coefficients (approx. 40 (cm3 × mm)/(m2 × d × bar)), independently on the formulation of the active layer. These values are in the typical range for food packaging films, far above those of polyolefins, but lower than polyethylene terephthalate (PET) (Piergiovanni and Limbo, 2010). Compared to the uncoated substrate film, which permeability coefficient is equal to 51.5 (cm3 × mm)/(m2 × d × bar), a significant improvement of the oxygen barrier performance of the coated films was observed. This finding can be explained by the lower molecular mobility of the polymer chains of the coating layer (PLA, at glassy state at 23 °C) with respect to those of the substrate (PLA/PBAT blend, where the PBAT constituent is in the rubbery state at 23 °C) (Apicella et al. 2019; Pietrosanto et al. 2020b). On the opposite, the addition of both the preservatives did not lead to significant changes of oxygen permeability of coated films. Different results were reported in literature on other polymer substrates (Wangprasertkul et al. 2021), where the incorporation of PS and SB, which are polar molecules, prevented the permeability to oxygen molecules.

Films optical properties in terms of “see through” possibility were investigated by measuring the transparency, i.e. the transmission of visible light at 560 nm (TR560). The transparency of the developed films was lower than the conventional used polymers (e.g. PE and PET) (Moreno-Vásquez et al. 2017; Nogi et al. 2013), due to the presence of PBAT, which is white and opaque, in the substrate (Wang et al. 2016). Moreover, the addition of the preservatives led to a further reduction of the transparency value, which was more significant for SB than for PS. The transparency of a polymeric system increases with the increase of the dispersed composite size (Schulz et al. 2007). Thus, the lower transparency of 15SB film can be attributable to the lower compatibility of SB active agent with PLA compared to PS, that caused a worse dispersion in the polymer matrix. Since the antimicrobial activity is affected by the dispersion of the active phase in the polymer matrix (Kuplennik et al. 2015), this result can also explain the lower antimicrobial effect on both the shredded carrots and pineapple juice that was observed for films containing SB comparatively to those containing PS.

Finally, to investigate the capability of the coating layer to provide the heat-sealing ability of the films, hot-tack tests were carried out. Packaging systems able to self-adhere at a convenient processing condition and provide a flawless hermetic seal are of fundamental importance for food packaging applications, because it ensures the tightness of the package and thus the protection of the food. Proper heat-sealing ability also makes the packaging suitable for applications in aseptic processing and packaging where special technologies as hot-filling or steam sterilization are used. In the case of the films developed in this work, heat-sealing ability is made possible by the use of an amorphous PLA coating layer able to self-adhere. Table 4 reports the results of the hot tack tests. As it can be seen, the addition of the PLA coating layers to the substrate, which is not sealable, allowed to impart to all of them heat-sealing ability. In the case of the control film sample, the hot seal strength is 383 g/15 mm and the failure happens mainly through a delamination mechanism, which means that the adhesion of the PLA coating layer to the substrate was lower than its seal strength.

The incorporation of the preservatives in the coating layer affected both the seal strength and the failure type. The seal strength of the active films was lower than that of the control one: the presence of active agent salts in the polymer matrix hindered the interactions between the two melted surfaces of the PLA layer during the heat-sealing process. The seal strength was so much reduced that it became lower than the adhesion of the PLA coating to the substrate, resulting in an adhesive failure mechanism of the active films. In addition, films containing PS had a lower seal strength than those containing SB, because the better compatibility and dispersion of PS into the polymer matrix might have exerted a greater hindering effect on the interaction between the PLA layers (Voon et al. 2012).

Conclusion

Multifunctional, eco-friendly active packaging films were developed by coating a biodegradable PLA/PBAT substrate with a heat-sealable layer loaded with antimicrobial agents. The incorporation of the active phases did not relevantly affect the mechanical and barrier properties of the films, while it led to a slight reduction of transparency and hot-tack strength. Only the films at highest level of active agents showed effective antimicrobial activity in shelf-life test performed on shredded carrots and fresh pineapple juice.

The film with PS was very efficient to reduce microbial development and color modification of pineapple juice. A better dispersion of PS in the polymer matrix probably explains its better performance compared to films containing SB or a combination of both antimicrobials.

The better impact on shelf-life of pineapple juice compared to shredded carrots, probably owed to the liquid state and the lower pH of pineapple juice, that may have favored both the diffusion of the antimicrobial into the food and the antimicrobial activity of the active compounds. In conclusion, these results open new possibilities for the development of sustainable active packaging for beverages with a short shelf-life.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

This work was supported by European Union and Region Reunion (FEDER, RE0002361) and by the Ministero dell'Istruzione, dell'Università e della Ricerca (MIUR).

Abbreviations

- TA

Titratable acidity

- PS

Potassium sorbate

- SB

Sodium benzoate

- PLA

Poly(lactic) acid

- PBAT

Poly(butylene adipate-co-terephthalate)

- TR

Transparency

- TPC

Total plate counts

- YMC

Yeast and mold counts

- EC

Enterobacterium counts

Authors’ contributions

AP: Conceptualization, methodology, investigation, data curation, writing—original draft, writing—review and editing; CLJ: Conceptualization, methodology, investigation, supervision, writing—review and editing; LI: Conceptualization, funding acquisition, validation, writing—review and editing; PS: Project administration, supervision, writing—review and editing; FR: Conceptualization, funding acquisition, project administration, validation, writing—review and editing.

Funding

This work was supported by European Union and Region Reunion (FEDER, RE0002361) and by the Ministero dell'Istruzione, dell'Università e della Ricerca (MIUR).

Data availability and materials

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

Declarations

Conflict of interest

The authors declare that they have no competing interests.

Consent for publication

All authors approve publication of this work.

Ethical approval

The authors respect the international standards for responsible research publication.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Alegria C, Pinheiro J, Gonçalves EM, Fernandes I, Moldão M, Abreu M. Evaluation of a pre-cut heat treatment as an alternative to chlorine in minimally processed shredded carrot. Innov Food Sci Emerg Technol. 2010;11(1):155–161. doi: 10.1016/j.ifset.2009.10.008. [DOI] [Google Scholar]

- Apicella A, Adiletta G, Matteo MD, Incarnato L. Valorization of olive industry waste products for development of new eco-sustainable, multilayer antioxidant packaging for food preservation. Chem Eng Trans. 2019;75:85–90. doi: 10.3303/CET1975015. [DOI] [Google Scholar]

- Careli-Gondim Í, Mesquita TC, Vilas Boas EVDB, Caliari M, SoaresJúnior MS. The effect of active coating and refrigerated storage on the quality of avocado cultivar, Quintal. J Food Sci Technol. 2020;57(1):143–151. doi: 10.1007/s13197-019-04039-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Corbo MR, Altieri C, D’Amato D, Campaniello D, Del Nobile MA, Sinigaglia M. Effect of temperature on shelf life and microbial population of lightly processed cactus pear fruit. Postharvest Biol Technol. 2004;31(1):93–104. doi: 10.1016/S0925-5214(03)00133-9. [DOI] [Google Scholar]

- Davidson PM, Sofos JN, Branen AL, Sofos JN, Branen AL. Antimicrobials in food. CRC Press. 2005 doi: 10.1201/9781420028737. [DOI] [Google Scholar]

- Durango AM, Soares NFF, Andrade NJ. Microbiological evaluation of an edible antimicrobial coating on minimally processed carrots. Food Control. 2006;17(5):336–341. doi: 10.1016/j.foodcont.2004.10.024. [DOI] [Google Scholar]

- EUR-Lex—32005R2073—EN - EUR-Lex, (2005). https://eur-lex.europa.eu/eli/reg/2005/2073/oj

- Fai AEC, Alves de Souza MR, de Barros ST, Bruno NV, Ferreira MSL, de Andrade Gonçalves ÉCB. Development and evaluation of biodegradable films and coatings obtained from fruit and vegetable residues applied to fresh-cut carrot (Daucus carota L.) Postharvest Biol Technol. 2016;112:194–204. doi: 10.1016/j.postharvbio.2015.09.021. [DOI] [Google Scholar]

- Glicerina V, Siroli L, Canali G, Chinnici F, Capelli F, Lanciotti R, Colombo V, Romani S. Efficacy of biodegradable, antimicrobial packaging on safety and quality parameters maintenance of a pear juice and rice milk-based smoothie product. Food Control. 2021;128:108170. doi: 10.1016/j.foodcont.2021.108170. [DOI] [Google Scholar]

- Jin TZ. Current state of the art and recent innovations for antimicrobial food packaging. In: Juneja VK, Dwivedi HP, Sofos JN, editors. Microbial control and food preservation: theory and practice. New York: Springer; 2017. pp. 349–372. [Google Scholar]

- Jin T, Zhang H, Boyd G. Incorporation of preservatives in polylactic acid films for inactivating Escherichia coli O157:H7 and extending microbiological shelf life of strawberry puree. J Food Prot. 2010;73(5):812–818. doi: 10.4315/0362-028X-73.5.812. [DOI] [PubMed] [Google Scholar]

- Junqueira-Gonçalves MP, Alarcón E, Niranjan K. The efficacy of potassium sorbate-coated packaging to control postharvest gray mold in raspberries, blackberries and blueberries. Postharvest Biol Technol. 2016;111:205–208. doi: 10.1016/j.postharvbio.2015.09.014. [DOI] [Google Scholar]

- Klaiber RG, Baur S, Wolf G, Hammes WP, Carle R. Quality of minimally processed carrots as affected by warm water washing and chlorination. Innov Food Sci Emerg Technol. 2005;6(3):351–362. doi: 10.1016/j.ifset.2005.03.002. [DOI] [Google Scholar]

- Kuplennik N, Tchoudakov R, Ben-Barak Zelas Z, Sadovski A, Fishman A, Narkis M. Antimicrobial packaging based on linear low-density polyethylene compounded with potassium sorbate. LWT Food Sci Technol. 2015;62(1):278–286. doi: 10.1016/j.lwt.2015.01.002. [DOI] [Google Scholar]

- Leneveu-Jenvrin C, Quentin B, Assemat S, Remize F. Maintaining physicochemical, microbiological, and sensory quality of pineapple juice (Ananas comosus, var. ‘Queen Victoria’) through mild heat treatment. Processes. 2020;8(9):1186. doi: 10.3390/pr8091186. [DOI] [Google Scholar]

- Mahendran T (2015) Quality and shelf life of minimally processed shredded carrots in modified atmosphere packaging http://ir.kdu.ac.lk/handle/345/1027

- Mokrzycki WS, Tatol M. Colour difference DELTA(E)—a survey. Mach Graph Vision Int J. 2011;20(4):383–411. [Google Scholar]

- Musyoka JN, Abong GO, Mbogo DM, Fuchs R, Low J, Heck S, Muzhingi T. Effects of acidification and preservatives on microbial growth during storage of orange fleshed sweet potato puree. Int J Food Sci. 2018;2018:e8410747. doi: 10.1155/2018/8410747. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pietrosanto A, Scarfato P, Di Maio L, Incarnato L. Development of eco-sustainable PBAT-based blown films and performance analysis for food packaging applications. Materials. 2020;13(23):5395. doi: 10.3390/ma13235395. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pietrosanto A, Scarfato P, Di Maio L, Nobile MR, Incarnato L. Evaluation of the suitability of poly(lactide)/poly(butylene-adipate-co-terephthalate) blown films for chilled and frozen food packaging applications. Polymers. 2020;12(4):804. doi: 10.3390/polym12040804. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Piscopo A, Zappia A, Princi MP, De Bruno A, Araniti F, Antonio L, Abenavoli MR, Poiana M. Quality of shredded carrots minimally processed by different dipping solutions. J Food Sci Technol. 2019;56(5):2584–2593. doi: 10.1007/s13197-019-03741-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pushkala R, Parvathy KR, Srividya N. Chitosan powder coating, a novel simple technique for enhancement of shelf life quality of carrot shreds stored in macro perforated LDPE packs. Innov Food Sci Emerg Technol. 2012;16:11–20. doi: 10.1016/j.ifset.2012.03.003. [DOI] [Google Scholar]

- Ragaert P, Devlieghere F, Debevere J. Role of microbiological and physiological spoilage mechanisms during storage of minimally processed vegetables. Postharvest Biol Technol. 2007;44(3):185–194. doi: 10.1016/J.POSTHARVBIO.2007.01.001. [DOI] [Google Scholar]

- Shen XL, Wu JM, Chen Y, Zhao G. Antimicrobial and physical properties of sweet potato starch films incorporated with potassium sorbate or chitosan. Food Hydrocoll. 2010;24(4):285–290. doi: 10.1016/j.foodhyd.2009.10.003. [DOI] [Google Scholar]

- Stanojevic D, Comic L, Stefanovic O, Solujic-Sukdolak S. Antimicrobial effects of sodium benzoate, sodium nitrite and potassium sorbate and their synergistic action in vitro. Bulgarian J Agr Sci. 2009;15(4):308–312. [Google Scholar]

- Uz M, Altınkaya SA. Development of mono and multilayer antimicrobial food packaging materials for controlled release of potassium sorbate. LWT Food Sci Technol. 2011;44(10):2302–2309. doi: 10.1016/j.lwt.2011.05.003. [DOI] [Google Scholar]

- Vasile C, Baican M. Progresses in food packaging, food quality, and safety—controlled-release antioxidant and/or antimicrobial packaging. Molecules. 2021;26(5):1263. doi: 10.3390/molecules26051263. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Voon HC, Bhat R, Easa AM, Liong MT, Karim AA. Effect of addition of halloysite nanoclay and SiO2 nanoparticles on barrier and mechanical properties of bovine gelatin films. Food Bioprocess Technol. 2012;5(5):1766–1774. doi: 10.1007/s11947-010-0461-y. [DOI] [Google Scholar]

- Wang X, Kong D, Ma Z, Zhao R. Effect of carrot puree edible films on quality preservation of fresh-cut carrots. Irish J Agric Food Res. 2015;54(1):64–71. doi: 10.1515/ijafr-2015-0007. [DOI] [Google Scholar]

- Wangprasertkul J, Siriwattanapong R, Harnkarnsujarit N. Antifungal packaging of sorbate and benzoate incorporated biodegradable films for fresh noodles. Food Control. 2021;123:107763. doi: 10.1016/j.foodcont.2020.107763. [DOI] [Google Scholar]

- Wu Y-M, Wang Z-W, Hu C-Y, Nerín C. Influence of factors on release of antimicrobials from antimicrobial packaging materials. Crit Rev Food Sci Nutr. 2018;58(7):1108–1121. doi: 10.1080/10408398.2016.1241215. [DOI] [PubMed] [Google Scholar]

- Xylia P, Chrysargyris A, Botsaris G, Tzortzakis N. Mint and pomegranate extracts/oils as antibacterial agents against Escherichia coli O157:H7 and Listeria monocytogenes on shredded carrots. J Food Saf. 2018;38(1):e12423. doi: 10.1111/jfs.12423. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.