Abstract

Polymeric materials produced from fossil fuels have been intimately linked to the development of industrial activities in the 20th century and, consequently, to the transformation of our way of living. While this has brought many benefits, the fabrication and disposal of these materials is bringing enormous sustainable challenges. Thus, materials that are produced in a more sustainable fashion and whose degradation products are harmless to the environment are urgently needed. Natural biopolymers—which can compete with and sometimes surpass the performance of synthetic polymers—provide a great source of inspiration. They are made of natural chemicals, under benign environmental conditions, and their degradation products are harmless. Before these materials can be synthetically replicated, it is essential to elucidate their chemical design and biofabrication. For protein-based materials, this means obtaining the complete sequences of the proteinaceous building blocks, a task that historically took decades of research. Thus, we start this review with a historical perspective on early efforts to obtain the primary sequences of load-bearing proteins, followed by the latest developments in sequencing and proteomic technologies that have greatly accelerated sequencing of extracellular proteins. Next, four main classes of protein materials are presented, namely fibrous materials, bioelastomers exhibiting high reversible deformability, hard bulk materials, and biological adhesives. In each class, we focus on the design at the primary and secondary structure levels and discuss their interplays with the mechanical response. We finally discuss earlier and the latest research to artificially produce protein-based materials using biotechnology and synthetic biology, including current developments by start-up companies to scale-up the production of proteinaceous materials in an economically viable manner.

1. Introduction

Polymer materials represent a central aspect of everyday life and advanced technologies, from consumer goods to textiles, from high-performance composites to packaging, and from adhesives to electronic components, to name just a few examples. There is literally no modern human activity that does not depend on classical and more advanced polymers, and their production nowadays exceeds that of steel. Yet we have a fundamental ambivalence with respect to polymers, because they are also perceived as emblematic of a non-sustainable way of life. Indeed, despite our enormous reliance on plastics for every aspect of our modern life,1 they generate much disdain, being perceived as materials that are “cheap” and polluting.2 This perception arises from two fundamental reasons. First, polymers are in their large majority synthesized from fossil fuels, i.e. petro-chemical derived chemicals. And second, many are non-biodegradable and exhibit poor recyclability. Their degradation products can be toxic, which raises serious concerns about their end-of-life disposal,2 not to mention their accumulation in large quantities in the Oceans that badly affect marine ecosystems3,4 or in landfills.5,6 Because of these issues, there is an urgent need to develop new polymeric materials that can be more sustainable, i.e. their fabrication does not fully rely on petro-chemical derived chemicals, they use less energetic resources, and they can degrade into non-harmful chemicals in the environment.

In our quest toward alternative and more sustainable polymer solutions, Nature perhaps represents the best source of inspiration, exhibiting key advantages over fossil-fuel derived polymers. Biological materials are produced in an eco-friendly fashion using natural chemicals. Indeed, the complex machinery of living cells that produces extracellular tissues operates in an aqueous environment and at room temperature and pressure. The degradable products of these materials are harmless, such as amino acids in the case of protein-based biopolymers. Thus, the living world abounds in biopolymers with remarkable mechanical and physical characteristics that can compete or sometimes exceed the best synthetic polymers.7−9 For example, silk has been known for decades to exhibit outstanding mechanical properties10,11 that surpass those of many synthetic fibers,12,13 and there has been an outburst of activity in producing artificial versions of silk using biotechnology processes in the past decade, with a wide range of potential applications explored.14,15 Furthermore, biological polymers are produced via bottom-up “biofabrication” processes that seamlessly exploit the multi-scale self-assembly and supramolecular chemistry afforded by the versatility of the 20 amino acids of proteins and their post-translational modifications (PTMs).16 The end products are typically multi-functional, and when reproduced artificially with de novo gene design, innovative properties can in principle be achieved such as bioactivity and programmed degradability. Altogether, these synergistic characteristics are still unmatched in synthetic polymers.

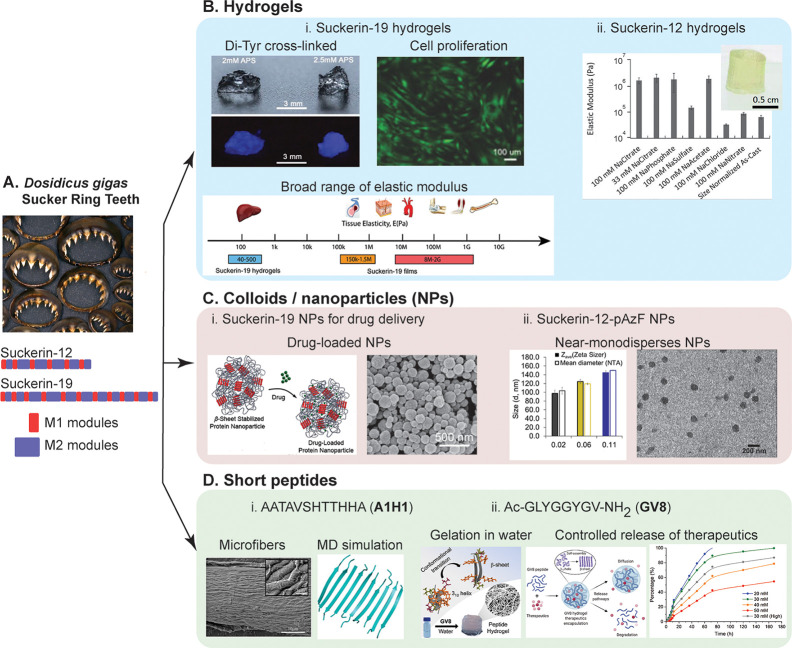

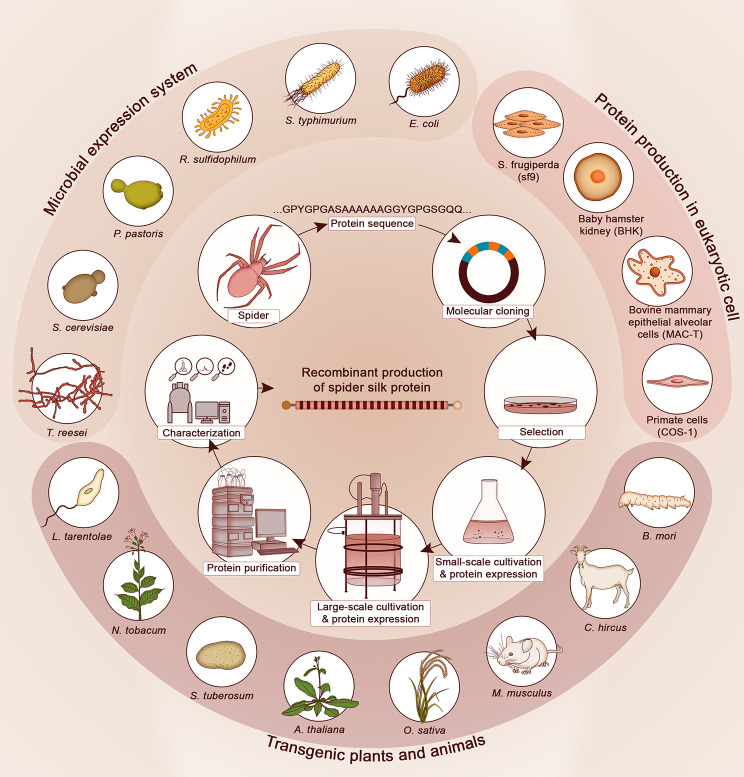

This review is organized in five sections. In Section 2, we present methods of protein sequencing in the field of protein materials, a critical initial step that has traditionally been a major bottleneck in the field. Earlier methods are first described, in particular those still in use today that yield information that cannot be readily obtained with “omics” methods, before moving to latest developments that are relevant to materials discoveries. In Section 3, essential molecular designs of protein-based materials are described, with an emphasis on sequence/structure property relationships and common biochemical and structural features. The materials presented in this section are organized based on their structural functionality and illustrate that protein-based materials utilize the whole spectrum of secondary structures at the disposal of polypeptides. Some load-bearing proteins are mostly intrinsically disordered,17 such as the bioelastomeric elastin (Section 3.2.1), or in their storage glands prior to secretion, e.g. mussel foot proteins (MFPs, Section 3.3.1) or the slime of the velvet worm (Section 3.1.3). Others are dominated by β-sheets that are preferentially aligned along the macroscopic fiber such as silk fibroins (Section 3.1.1) or perpendicular to the fiber in the case of amyloid-like fibrils; for example barnacle cement proteins (Section 3.3.2) or curli filaments (Section 3.3.4). Yet other proteins are mostly made of α-helical coiled-coil regions that are reminiscent of intermediate filaments (IFs), including marine snail egg capsule proteins (ECPs, Section 3.2.4) and hagfish filaments (Section 3.1.2), or contain collagenous triple-helical domains, such as the core of mussel adhesive filaments (Section 3.2.3). And finally, some extracellular structures are built from proteins with both ordered and disordered regions as illustrated by the squid sucker ring teeth proteins called suckerins (Section 3.4.4).

In Section 4, we survey the bioengineering fabrication of protein-based materials presented in Section 3. The different types of living hosts used for biofabrication are compared, including their key respective advantages/disadvantages and current limitations. Methods of purification are also described here as this has been, and remains in many cases, a bottleneck toward scaling-up of protein-based materials. Recent efforts by spin-off companies to fabricate protein materials are described in this section to highlight potential routes for future commercialization. In the final Section 5, we provide a perspective on future developments and major hurdles that will need to be overcome in order to achieve protein materials produced though biotechnology a viable alternative to synthetic polymers.

2. Sequencing of Extracellular Proteins: Historical Perspective

Nature abounds with extracellular tissues with structural (load-bearing) functionalities that are predominantly made of proteins and which are now increasingly exploited to artificially design and produce protein-based materials.18,19 But before such materials can be replicated via synthetic biology fabrication processes, it is critical to carefully identify their building blocks at the molecular level. Traditionally, such investigations have been very time-consuming because they have often been considered tedious and technically challenging. In the case of biological materials, there are two main reasons for these hurdles. First, these extracellular tissues are usually highly cross-linked in order to sustain the aggressive mechanical, chemical, and biological stresses (pathogens, bacterial degradation) to which they are subjected in their natural environment. The covalent bonds between the proteins’ side chains result in highly insoluble polymeric networks, thwarting isolation of intact proteins and complicating subsequent sequencing efforts. Typically, only short peptide fragments could be isolated and in low yields. Historically, such studies would thus take many years to identify only partial sequences of the proteins of interest. Second, while the genomic era and associated technological advances have helped overcome some of these challenges and have accelerated discoveries, there is still a sparse number of genomes available for many organisms used as model systems in the field. As a result, obtaining the complete biochemical characterization of proteinaceous building blocks of biological materials (full-length sequences, PTMs, and cross-links that stabilize the final tissue) remained until recently a lengthy endeavor carried out by a handful of research groups.

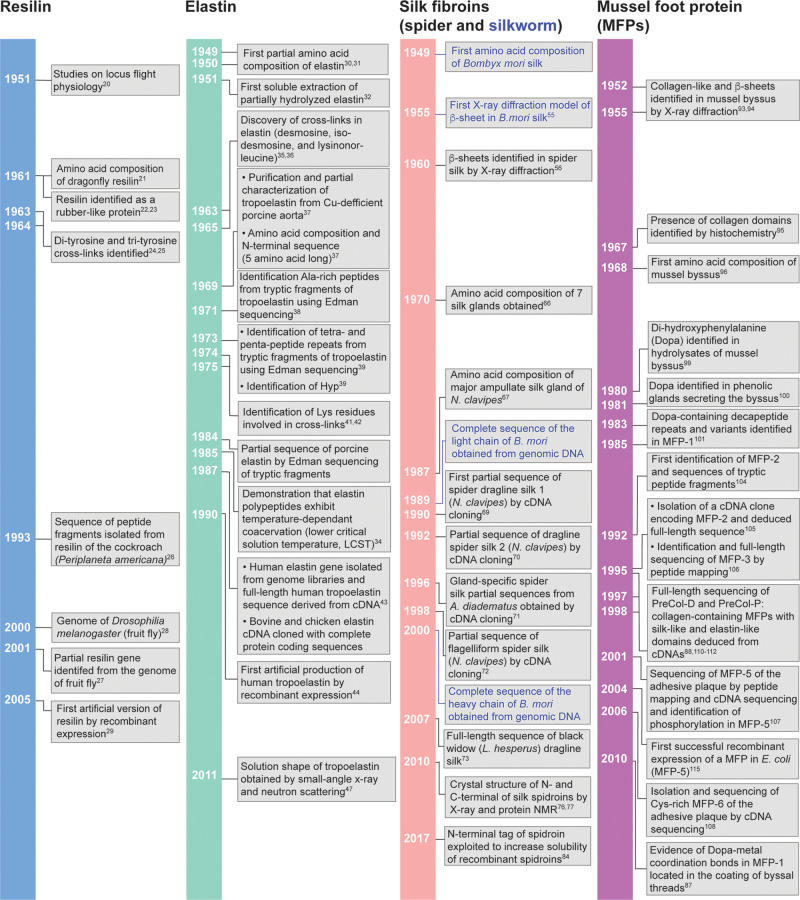

Rapid developments in next-generation sequencing (NGS) and proteomic technologies as well as their associated bioinformatic softwares in the past decade have considerably alleviated these limitations, providing a range of powerful tools that accelerate discoveries, especially when used synergistically. While these advance approaches have undoubtedly taken the center stage of protein discoveries, traditional biochemical and molecular biology methods are still needed to identify important molecular features that regulate the final function of protein-based materials, such as PTMs or cross-linking chemistry. Once this information is available, together with in-depth understanding of sequence-property relationships, it can be translated into artificial fabrication of protein-based materials via DNA recombinant technology. Four extracellular fibrous and elastomeric protein materials that exemplify the extensive timeline that was required to fully identify their end-to-end sequences are highlighted in this section namely: (i) resilin, (ii) elastin, (iii) silk fibroins, and (iv) mussel adhesive proteins, as summarized in the timeline shown in Figure 1.

Figure 1.

Timeline discoveries of several load-bearing proteins that have gathered broad research interest as biological model systems in biomimetic materials engineering.

2.1. Discovery and Sequencing of Resilin (1951–2001)

Resilin, the protein that constitutes the hinge connecting the wings of insects to their thorax, is historically interesting because it was the first structure protein to be investigated in what can be broadly referred as “biomimetic” or “bioinspired” materials. Thus, in 1951, Krogh and Weis-Fogh20 published a study on the physiology of desert locus flight that highlighted the importance of resilin, an insoluble, rubber-like substance in the wing-hinge ligament whose amino acid composition was analyzed 10 years later.21 The same year, Weis-Fogh demonstrated—for the first time for a structural protein—that resilin was a rubber-like material.22,23 A few years later, Andersen identified dityrosine and trityrosine24,25 as the cross-links that stabilize the rubbery resilin network. It was only about 30 years later, in 1992, that sequences of peptide fragments of resilin were obtained by Lombardi and Kaplan.26 They isolated and trypsin-digested resilin from the cockroach Periplaneta americana (P. americana) and subjected the trypsin digests to Edman sequencing, obtaining a dozen peptide sequences 5 to 15 amino acid long. In 2001, Ardell and Andersen27 also sequenced resilin peptide fragments from the desert locust Shistocera gregaria (S. gregaria) using Edman sequencing. By then, however, they benefited from a major scientific breakthrough since the complete genome of Drosophilia melanogaster (D. melanogaster commonly known as the fruit fly) had recently been published.28 Searching the genome with their tryptic peptides, as well as those previously obtained by Lombardi and Kaplan, they identified two candidate genes encoding for pro-resilin, the precursor protein of resilin prior to cross-linking.27 Finally in 2005, Elvin and co-workers29 expressed an exon of one of these genes encoding multiple copies of a putative elastic repeat motif. By inducing dityrosine cross-linking using Ruthenium-mediated photo-cross-linking, they were able to artificially recapitulate the elastomeric properties of native resilin.

2.2. Discovery and Sequencing of (Tropo)elastin (1949–1988)

Elastin is the main structural protein providing elasticity to various tissues of vertebrates. Given its importance for human health, studies on elastin were initiated as early as the late 1940s/early 1950s, starting by its partial amino acid composition by Neumann30 and Partridge and Davis.31 One year later, Partridge and co-workers32 were able to isolate soluble fragments of elastin and demonstrated that the solution turned into a viscous layer made of liquid droplets upon raising the temperature above 25 °C. This was probably the first evidence of the coacervation process of a biomacromolecule—or liquid liquid phase separation (LLPS)—which has since been recognized as a hallmark of tropoelastin33 and synthetic elastin-like polypeptides (ELPs).34 Early biochemical investigations were hampered by the inherent insolubility of mature elastin attributed to the high degree of chemical cross-links between polypeptide chains. As a result, it took more that 10 years to identify these unusual cross-links as the heterocyclic desmosine, isodemosine, and lysinorleucine.35,36

Further advances in elastin biochemistry were achieved in 1969 when its soluble precursor, tropoelastin, was isolated by Sandberg et al.37 from Cu-deficient porcine aorta. Electrophoresis and quantitative amino acid analysis estimated the molecular weight (MW) of tropoelastin to be around 60–70 kDa, and the authors were also able to obtain the first 5 amino acids of the N-terminus by Edman sequencing. By digesting soluble tropoelastin with trypsin and subjecting the tryptic fragments to Edman sequencing, the same group identified Ala-rich peptides that were involved in cross-linking formation,38 followed by the identification39 of tetra-, penta-, and hexapeptide repeats [GGVP], [PGVGV], and [PGVGVA] in the tropoelastin sequence. These repeating sequences were exploited decades later to design ELPs.40 Using similar strategies of enzymatic digestion and Edman sequencing of tryptic peptides, Gerber and Anwar41,42 identified the specific Lys-rich region involved in cross-linking.

Advances in molecular biology methods in the 1980s finally allowed researchers to obtain the complete primary sequence of tropoelastin. Thus, in 1987, Indik et al.43 isolated human mRNA from embryonic aorta and used it as a template to synthesize cDNA, from which three overlapping cDNA clones were identified and combined into a single cDNA sequence that included a Met initiation site and stop codon. The encoded primary sequence had a MW of 72 kDa and included all previously identified short peptides including the hydrophobic cross-linking domains, the pentapeptide repeats, as well as several sequences that were previously not identified. The study also established that elastin mRNA exhibited alternative splicing. With the full-length elastic cDNA clone available, a few years later the same team successfully produced the first human tropoelastin in a recombinant bacterial system,44 paving the way for a wide range of regenerative medicine and tissue engineering applications that have since been demonstrated.45 In parallel, Urry and co-workers34 synthesized ELPs made of the pentapeptide repeat [VPGVG]n and demonstrated their temperature-induced coacervation. Upon increasing the temperature above 25 °C, soluble ELPs phase-separated in two phases: a dense and viscous phase and a diluted phase, with a transition temperature that depended on the MW of the polypeptides, thus establishing the critical role of the pentapeptide repeats in triggering coacervation. Furthermore, Urry et al. also established the ability to broadly modulate the transition temperature of ELPs from 5 °C up to 70 °C by varying the guest residue composition.46 This lower-critical solution temperature (LCST) behavior has since been exploited in biomedical and drug delivery applications, as reviewed elsewhere.40 Despite the long-held view that tropoelastin has mostly a random-coil structure, it is also noteworthy that small-angle X-ray and neutron scattering studies (SAXS and SANS, respectively) later established that tropoelastin seems to display a well-defined shape in solution consisting of an asymmetric coil with a protruding foot-like structure,47−49 as presented in more details in Section 3.2.1.

2.3. Discovery and Sequencing of Spider Silk Fibroins (1960–2007)

Owing to its remarkable physical properties,50−53 spider silk has long attracted the interest of scientists from diverse fields (biologists, chemists, material scientists, etc.). A central goal of these efforts has been to establish how the mechanical properties are linked to the molecular design and the secondary structure of silk fiber proteins (called spidroins). It was more than a century ago that Fisher demonstrated spider silk fibers to be made of proteins.54 The first X-ray diffraction measurements of silks were obtained in 1955 from silkworm (Bombyx mori, B. mori) fibers by Marsh, Correy and Pauling,55 who suggested the β-pleated sheet crystal structure. Then, five years later Warwicker56 reported the first X-ray diffraction measurements of spider silk fibers and confirmed the presence of β-sheets oriented along the fiber axis. Since then, numerous structural studies of silks have been conducted using techniques such as wide angle X-ray spectroscopy (WAXS),57−59 infrared spectroscopy,60,61 solid-state Nuclear Magnetic Resonance (ssNMR) spectroscopy,62 or Raman spectroscopy.63 This large body of work has been extensively reviewed elsewhere.64,65

Identifying the primary structure of spider silks has been an arduous path largely related to their extremely large MWs, to the presence of highly repetitive peptide sequences, and to the fact that there exist many different types of silks within a single species.11 In 1970, Andersen66 reported the amino acid composition from several silk glands in the European garden spider Araneus diadematus (A. diadematus). For a few years, research into the molecular structure of spider silk fibroins remained rather quiet, until the late 1980s/early 1990s when Work and Young67 and Lombardi and Kaplan68 reported the amino acid composition of silk glands from the golden silk spider Nephila Clavipes (N. clavipes). Then, a breakthrough arose in 1990 when Xu and Lewis69 isolated penta- and hexapeptides from N. clavipes dragline silk using a partial hydrolysis treatment and obtained their sequences with the automated Edman method, from which they designed DNA probes. Concurrently, they built a cDNA library of the major spider ampullate glands (MaSP) that concentrates the precursor of dragline silk and screened it with their DNA probes. They managed to deduce for the first time partial amino acid sequences of a spider silk fibroin (spidroin-1), notably recognizing the presence of highly repetitive peptide domains such as stretches of poly-Ala and Gly-Gly-Xaa peptides (where Xaa is typically Tyr, Ala, or Leu). They also realized the highly biased codon design of fibroin-encoding genes that avoids the use of cytosine and guanine in the third base position. Using the same method, Hinman and Lewis70 later isolated a second partial cDNA clone for another silk protein (spidroin-2) containing multiple pentapeptide repeats rich in Gly, Tyr, and Pro (e.g., GYGPG or GPGGY motifs) that explained the Pro content measured by amino acid analysis (AAA). Building up on this work, a few years later Guerette et al.71 constructed cDNA libraries from the major ampullate glands of A. diadematus that secrete and store specific silks, namely the tough dragline silk, the extensible viscid silk, and the cocoon silk. Screening these cDNA libraries with probes designed from spidroins-1 and -2, they identified a gene family of at least 4 fibroin genes, each of which encoding a distinct silk protein characterized by various proportions of amorphous (Gly-rich) and crystalline (poly-Ala and poly-Gly-Ala) domains. This study established that silk expression is gland-specific and linked the mechanical properties of the different silks to the peptide domains that make up their modular primary structure. Using similar approaches, Hayashi and Lewis72 later obtained the partial sequence of the flagelliform gland silk protein that constitutes the core fiber of the catching spiral. The complete gene sequences for any spider silk remained unknown until 2007, when the full-length gene encoding the dragline silk of the black widow (Latrodectus hesperus) was obtained by Ayoub et al.73 through construction of a genomic library. This study notably revealed N- and C-terminal domains that turned out to be instrumental to explain natural silk biofabrication.

The molecular cloning approaches highlighted above identified the main modular peptide repeats governing the wide diversity of mechanical properties of silks, which subsequently became important tools in the biotechnology of artificial silk proteins. However, the molecular strategy controlling the ability of spiders to stockpile precursor proteins at high concentration prior to rapid spinning and solidification remained unknown for another decade. Many efforts to recombinantly express silk proteins resulted in irreversible protein aggregation,74,75 partly because they were designed from shorter and incomplete cDNAs made of the central repeat regions of silks. Two breakthrough studies published in 2010 provided critical answers to this question. Thus, Hagn et al.76 solved the three-dimensional (3D) structure of the non-repetitive C-terminal (CT) domain—which is highly conserved across species—by solution NMR. Three key findings were identified in this study. First, the CT exhibited a thermoresponsive LCST, transitioning from the soluble to the aggregated state as the temperature increased. Second, NaCl (present in the ampullate glands) increased protein solubility and regulated the LCST. And third, shear forces were shown to trigger aggregation of oligomeric silk assemblies through partial unfolding of the CT domain, which exposed the hydrophobic repeat region of the silk proteins that formed well-defined β-sheet-rich aggregates. Concurrently, Askarieh et al.77 solved the 3D structure of the conserved N-terminus (NT) domain of spidroin-1 from the web spider (Euprosthenos australis, E. australis) by X-ray crystallography. They found that aggregation of silk constructs containing the NT domain was strongly pH-dependent. The protein transited from a soluble state to an aggregation state as the pH dropped below 7, a behavior fully consistent with the intrinsic pH gradient along the spider’s silk extrusion duct that is maintained by carbonic anhydrase.78 Based on these findings, the role of charged residues in controlling pH-triggered aggregation of silk fibroins was precisely identified both experimentally78−81 and through molecular dynamics simulations.82 A unified model explaining the rapid spinning and solidification of spider silk as a function of pH and ionic gradients was proposed.83 Exploiting these mechanisms, Andersson et al.84 designed a recombinant spider silk construct containing NT and CT domains from two different species exhibiting an unprecedented solubility >500 mg/mL in aqueous solutions. Remarkably, continuous fibers as long as 1,000 m could be spun from 1 mL of this solution (see also Section 4.1). This study exemplifies the need to fully understand the molecular mechanisms of assembly in order to replicate natural material fabrication.

2.4. Discovery and Sequencing of Mussel Adhesive Proteins (1952–2006)

A final illustrative example of a load-bearing biological material that has attracted a lot of attention in the biomimetic community in the past two decades is mussel adhesive fibers (byssal threads). These fibers exhibit multi-functional properties, including underwater adhesion,85 the presence of a protective yet extensible coating86,87 or elastomeric gradients along the threads88,89 to name some of the unique biomechanical features identified in mussel byssus. The byssus is a multi-protein complex containing at least four distinct families of MFPs, namely: (i) adhesive proteins located at the distal extremity and in contact with solid substrates; (ii) collagen-like proteins (CLPs) with silk-like and elastin-like domains that constitute the core of the fibers; (iii) matrix proteins that connect the adhesive to the core; and (iv) cuticle proteins that coat the fibers. Comprehensive reviews on mussel adhesive fibers and their bioinspired applications can be found elsewhere.90−92 As above, we focus here on the meticulous efforts undertaken to obtain a comprehensive picture of mussel thread biochemistry, which were primarily conducted by Waite and co-workers. Identification of β-sheet and collagen-like structural features in byssal threads was obtained as early as the 1950s by X-ray diffraction93,94 and later confirmed by histochemical95 and amino acid96 analyses. Subsequent research focused on morphological and ultrastructural studies of the byssal threads, the mussel foot from which the threads are secreted, and the secretory glands.97,98 In 1980, Waite and Tanzer first reported, using AAA, the unusual presence of the post-translated 3,4-dihydroxy-l-phenylalanine (Dopa) amino acid in the mussel threads,99 and a year later, the same authors identified Dopa (11%), as well as 4-hydroxyproline (Hyp) (13%), in the secreting phenolic glands of the foot,100 which sparked further research over a span of three decades to identify and sequence MFPs. The first sequence data were obtained in 1983 by isolating MFP-1 from the phenolic gland and generating peptide fragments by enzymatic digestion, which were subsequently sequenced by automated Edman analysis.101,102 These studies revealed MFP-1 to consist of multiple repeats of the decapeptide [A-K-P/Hyp-S-Y/Dopa-Hyp-Hyp-T-Dopa-K]. Although MFP-1 was the first mussel adhesive protein for which primary sequences were obtained, it was only in 2005 that its location in the coating of byssal threads was corroborated.103

In 1992, MFP-2 (the most abundant component in the adhesive plaque) was the next protein to be isolated from the mussel foot.104 Automated Edman sequencing of tryptic-digested peptides revealed that it was enriched in Cys, had a lower Dopa content than MFP-1 (5 mol % vs 15 mol % for MFP-1), and contained three distinct types of peptide repeats including Gly- and Tyr-rich penta-repeats as well as a Hyp- and Dopa-rich deca-repeats. The complete full-length sequence of MFP-2 was obtained three years later by Inoue et al.,105 who isolated a cDNA clone encoding MFP-2. This study revealed MFP-2 to be a 45 kDa protein consisting of 11 tandem repeats of an epidermal growth factor (EGF) stabilized by disulfide bonds. Another protein from the adhesive plaque, MFP-3, was next to be sequenced.106 MFP-3 is characterized by a high polymorphism, with high variability in Dopa content between polymorphs (from 5 mol % to 20 mol % and MWs ranging from 5 to 7.5 kDa). Owing to its low MW, the entire sequence of a MFP-3 polymorph could be achieved by thoroughly mapping enzymatically digested peptides obtained from purified MFP-3, whose sequences were deduced from automated Edman sequencing, tandem mass spectroscopy (MS/MS), and Matrix-Assisted Laser Desorption/Ionization Time-of-Flight (MALDI-TOF) mass spectroscopy. In contrast to MFP-1 and -2, MFP-3 is not made of repetitive motifs. The complete sequences of the other main plaque proteins (MFP-5 and MFP-6) were obtained in 2001107 and 2006,108 respectively, by combining molecular approaches and peptide mapping. In short, a cDNA library of the mussel foot was prepared and was probed with peptides isolated directly from the adhesive plaque or from the mussel feet. In addition to the high level of Dopa modification (up to 30 mol %), MFP-5 is also phosphorylated. In contrast, MFP-6 has a low content of Dopa but a relatively high amount of Cys and was later demonstrated to protect Dopa residues in MFP-5 from being oxidized into the less adhesive Dopa-quinone form.109

Finally, the family of MFPs constituting the core of the byssal threads are the prepolymerized collagens (PreCols), which were isolated and sequenced from 1995 to 1998.88,110−112 Partial sequences of PreCol-D (located in the distal region of the thread) and PreCol-P (located in the proximal region) were initially identified by automated Edman sequencing of peptide fragments obtained from purified PreCols.110 A cDNA library from a mussel foot was later prepared and screened by polymerase chain reaction (PCR) using primers designed from the partial sequences of PreCols.88,111 These studies revealed that the PreCols are 230 to 240 kDa block copolymer type proteins consisting of a central collagen-like domain flanked by either rigid silk-like domains (PreCol-D) or more flexible elastin-like domains (PreCol-P), thus explaining the early collagenous X-ray diffraction patterns obtained by Rudall.94 These PreCols are distributed in a graded fashion along the thread88 such that the proximal region is mechanically stiffer whereas the distal region of the threads is more compliant (see Section 3.2.3). A third PreCol (PreCol-NG) was subsequently identified and proposed to be evenly distributed along byssal threads.112

Biotechnological efforts to produce recombinant versions of MFPs started in the early 1990s in expression systems such as Escherichia coli (E. coli) and yeast,113,114 but the yields were extremely low. The first successful recombinant expression of a MFP in E. coli was reported in 2004 by Hwang and co-workers,115 who were also able to modify Tyr residues into Dopa by treating MFP-5 with mushroom tyrosinase.

2.5. High-Throughput RNA-Sequencing and Proteomics (2013–Present)

Unsurprisingly, obtaining the complete primary structures of extracellular, highly insoluble proteins has been intimately linked to technological advances. As highlighted above, early efforts in the 1950s started by obtaining the amino acid composition of structural proteins. The development of stepwise N-terminal degradation by Pehr Edman116 and the subsequent automatization of the method117 were quickly adopted by the community, leading to the discovery of partial peptide sequences in elastin,37,41 resilin,26 silks,69 and MFPs.101,102 However, obtaining the full primary structure of these proteins remained an elusive target. This changed in the late 1980s/early 1990s with advances in molecular biology, exemplified by tools such as cDNA libraries, the increasing availability of a broad range of molecular cloning methods, and the rapid development of PCR, which collectively greatly enhanced our ability to obtain the primary structures of structural proteins. Progress in proteomic mass spectroscopy techniques, such as electrospray ionization mass spectroscopy (ESI-MS),118 MS/MS,119 in-gel digestion,120 and MALDI-TOF,121−123 also considerably improved identification of peptide fragments from the precursors or processed tissues.

At the beginning of the millennium, the genomic revolution made an immediate impact. In the case of resilin, for example, probing the genome of the fruit fly with known partial sequences was sufficient to identify the resilin gene.27 Genomic libraries were also critical to obtain the full sequences of silk-encoding genes. Because of their large size, extreme modularity, and codon-bias, sequencing these genes proved highly challenging to achieve even with the full battery of molecular cloning techniques. For example, despite decades of research, it was only in 2007 that the full-length sequence of a spider silk protein was published.73 Nevertheless, significant challenges remained. First, owing to the inherent structural functionality of biological materials and their exposure to aggressive external environments, extracting proteins or even shorter peptide fragments is exceedingly difficult. Harsh solvents or chemicals are usually employed, such as hexafluoroisopropanol (HFIP) for silk fibers or strong acids for sclerotized tissues, often leading to moderate extraction yields. Second, the complete genomes of many model organisms that serve as a source of inspiration in biomimetic research have not been sequenced.

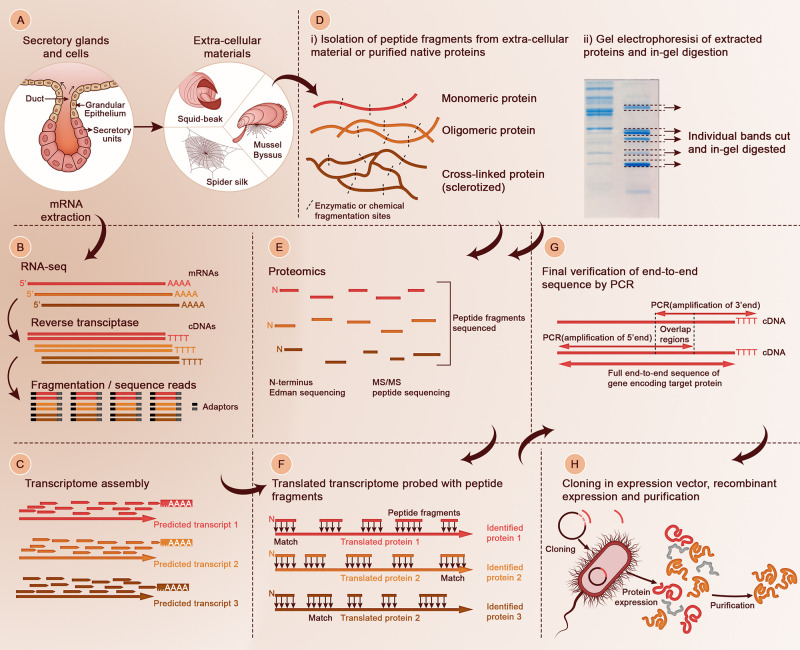

In the early 2010s, next-generation sequencing (NGS) methods were another technological leap that greatly expediated genomic and transcriptomic studies.124 Among NGS technologies, RNA-sequencing (RNA-seq) has had a major impact in accelerating molecular discoveries for biomimetic research. A detailed description of RNA-seq technologies is beyond the scope of this review and can be found elsewhere,125−127 and we only provide a quick overview. Briefly, mRNAs are extracted from specific tissues or from single cells128,129 in the latest developments (Figure 2A). A cDNA library is then constructed by reverse transcriptase (RT), followed by fragmentation into small reads 30–400 base-pairs long (depending on the specific sequencing equipment), to which universal adaptors are added to both ends (Figure 2B). Alternatively, fragmentation can first be carried out on the isolated mRNAs before RT. Each short cDNA read is then sequenced on high-throughput sequencers. In the final stage, reads are aligned to a reference genome or assembled de novo using bioinformatic tools.130 This latter feature is particularly attractive in basic biomimetic research as many model organisms have yet their genomes to be sequenced.

Figure 2.

Overall approach to obtain complete sequences of load-bearing structural proteins. (A) Extraction of mRNAs from the cells and glands where proteins are stockpiled prior to secretion in the extracellular milieu. (B) Construction of cDNA library from mRNAs extracted in the secretory cells and glands. (C) Transcriptome assembly. (D) Isolation of proteins or peptide fragments from the biological material of interest (i) and gel electrophoresis of isolated compounds (ii). In-gel digestion of isolated proteins or protein fragments is carried out for subsequent proteomic studies. (E) High-throughput proteomic of digested peptides from (D). In the past decade, tandem mass spectroscopy (MS/MS) has been the most-used tool, but more traditional tools such as N-terminus sequencing can still provide highly valuable information. (F) Peptide fragments sequenced by proteomic methods are probed against the translated transcriptome using bioinformatic tools. (G) The full sequences of the candidates genes of interest coding for identified proteins in (F) are verified by RACE PCR. (H) The newly identified proteins can be cloned in suitable vectors and recombinantly expressed, for example in E. coli (shown), yeast, or other types of host.

In 2013, we first demonstrated how RNA-seq, in combination with high-throughput proteomic tools, drastically fast-tracked the discovery of proteins constituting the building blocks of biological materials or regulating biofabrication processes such as biomineralization.131 The approach consists in assembling a transcriptome of the secreting glands (or epithelial tissues) containing the cells that secrete the precursors proteins using the Trinity suite developed by Grabherr et al.,132 which allows researchers to assemble a transcriptome from RNA-seq data without a reference genome (Figure 2C). In parallel, proteins from the mature structure or from the secreting glands are extracted and purified (Figure 2D). In many cases, owing to the densely cross-linked nature of extracellular tissues, intact proteins cannot be isolated. However, peptide fragments isolated by harsh chemical degradation can be sufficient, as long as their sequences can be identified by MS/MS (Figure 2E). Alternatively, extracted proteins from the mature tissues can be separated by gel electrophoresis. Separated protein bands are then cut from the gel, in-gel digested with different enzymes,120 and subjected to MS/MS. Traditionally, MS/MS relied on available databases to match MS/MS spectra to known peptides, but here again this approach is not suitable for proteins obtained from organisms with unknown genomes. Thanks to de novo peptide sequencing bioinformatic tools such as the PEAKS software133 or other propriety softwares developed in conjunction with MS equipments, peptide sequencing from MS/MS spectra has been greatly facilitated. Finally, the translated transcriptome can be uploaded as a reference database in these softwares and probed with the sequenced peptide fragments to identify the target proteins (Figure 2F). For highly expressed proteins from extracellular tissues, the full-length transcripts are usually assembled and a small fraction of peptide coverage is sufficient to unambiguously identify the full-length protein. However, structural proteins often have highly repetitive sequences, and in such cases the predicted transcripts are usually fragmented, precluding identification of the complete protein sequence. In such cases, the entire full-length protein is obtained by Rapid Amplification of cDNA Ends (RACE)-PCR, using designing primers based on the partial transcripts and using the cDNAs as a template (Figure 2G). Once the entire end-to-end sequence of the target protein has been obtained, its encoding gene can be cloned in expression vectors, expressed, and purified for downstream applications (Figure 2H), as discussed in Section 4 of this review.

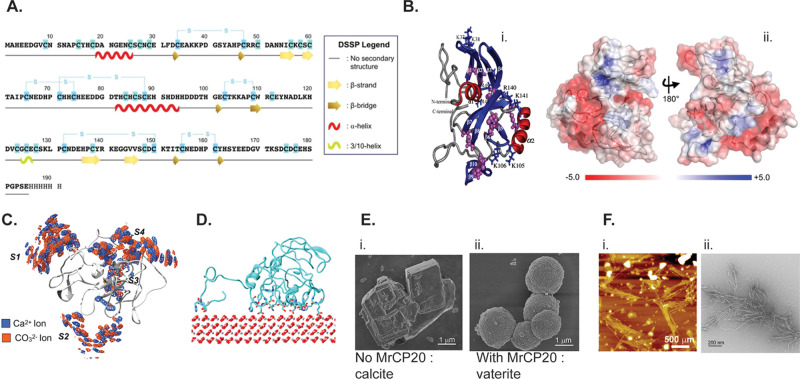

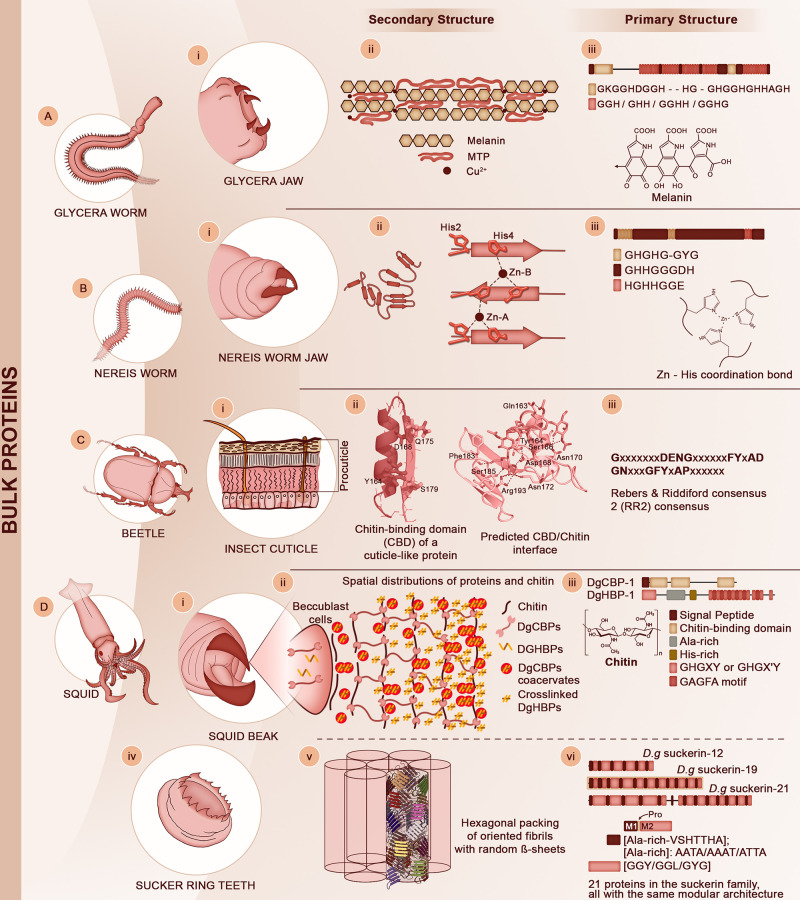

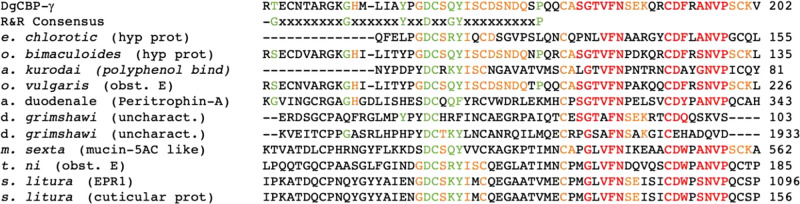

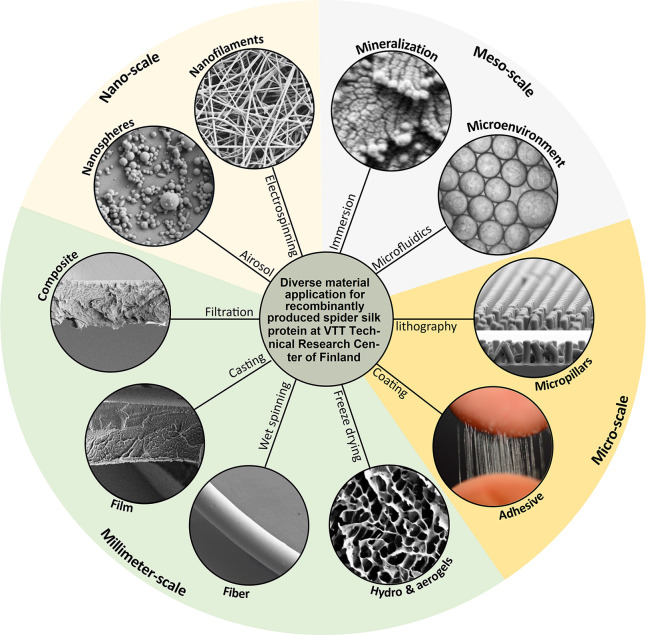

This high-throughput RNA-seq/proteomic integrative platform has enabled the complete identification of dozens of unknown proteins from biological materials in just a few years, an endeavor to be compared with the decades of research it took to sequence other structural proteins of biomimetic interest (Figure 1). For example, Guerette et al.131 sequenced most MFPs from the Asian green mussel (Perna viridis, P. viridis) as well as the native tyrosinase enzymes that convert Tyr to Dopa in MFPs. Other newly identified load-bearing proteins of interest included coiled-coil proteins from the egg case membrane of marine snails that exhibit unique elastomeric properties. In a follow-up study,134 we revealed that the hard sucker ring teeth (SRT) that line up the tentacles and arms of squids135 are entirely made of a family of structural proteins, dubbed “suckerins”, and fully sequenced the 21 suckerins comprising SRT of the jumbo squid (Dosidicus gigas, D. gigas), as well as 17 suckerins from SRT of other species of squids. More details on the primary structure design of suckerins are presented in Section 3.4.4. Using the same approach, Tan et al.136 were able to elucidate the complete sequences of the proteins that constitute the squid beak,137,138 a very hard, yet unmineralized structure whose densely cross-linked nature138 had until then precluded any sequence identification and is discussed in Section 3.4.3. In this specific case, the chemical hydroxylamine was used to liberate short peptide fragments from the beak as other harsh chemicals or enzymes failed to release peptide fragments suitable for MS/MS analysis. As another example of the versatility of the approach, Amini et al.139 obtained the complete sequence of the main protein that regulates mineralization of the mantis shrimp dactyl club, an impact-resistant hunting appendage140−144 that has generated much interest in the bioinspired materials community in recent years.145,146

The integrative RNA-seq/proteomic approach has been adopted by other researchers to identify and characterize extracellular structural proteins of interest and has been particularly successful in studies of biological adhesives,147,148 For example, Hennebert and co-workers149 sequenced a sea star footprint protein that is secreted by sea star tube feet to mediate adhesion to solid surfaces, while Wunderer et al.150 sequenced the adhesive proteins involved in the temporary adhesion of the flatworm. Likewise, DeMartini et al.151 identified new MFPs from the Californian blue mussel by conducting transcriptomic analyses of the different glandular tissues that express and secrete MFPs. Altogether, the advent of high-throughput omics methods has undoubtedly opened unprecedented opportunities in the discovery of structural proteins, which once reproduced artificially may have the potential to replace polymers derived from fossil fuels in various applications, as discussed in Section 4.

3. Molecular Design of Natural Protein-Based Materials

3.1. Fibrous Proteins

3.1.1. Silk Fibroins

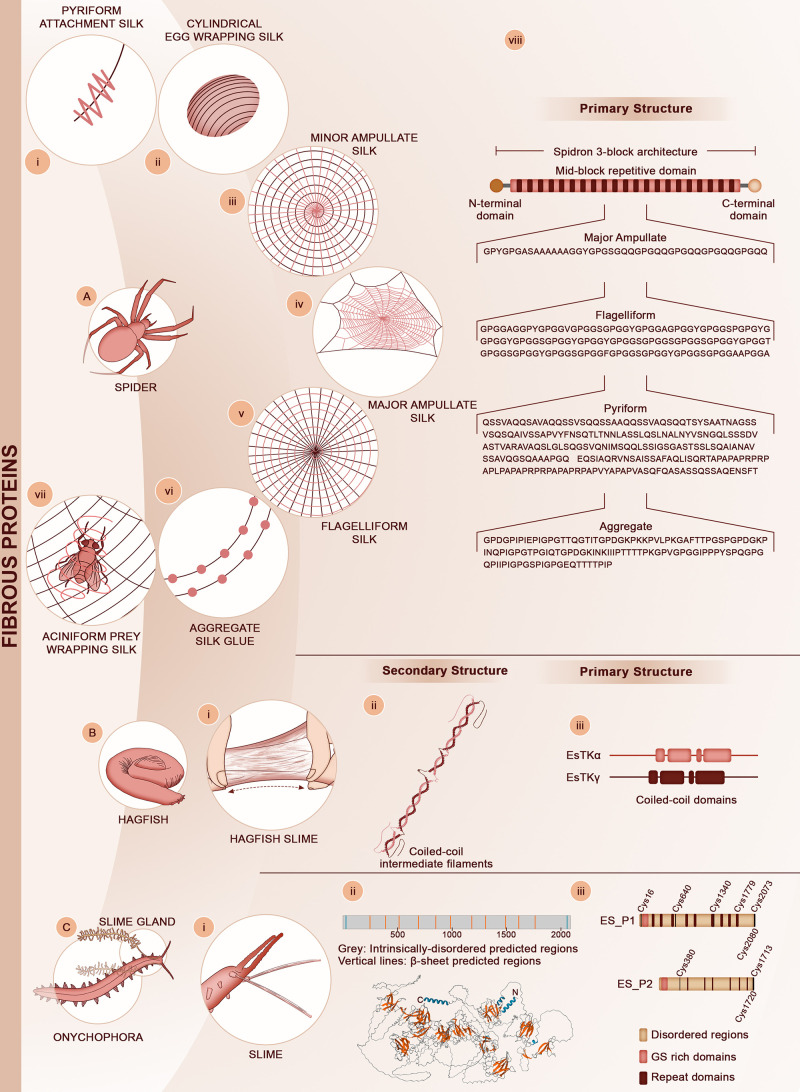

Silk-producing arthropods have evolved to produce fibers whose designs and functions are as diverse as their material needs, with a broad range of mechanical responses, from highly extensible and elastomeric-like to stiff and strong.152 The variety of uses for silk among spiders is much larger than that among other insects such as silkworms which mainly use it to make cocoons.13 Orb-weaving spiders, in particular, produce up to seven different types of silk, as well as a glue substance for various ecological functions, each of which is expressed and secreted in specific glands (Figures 3A-i to 3A-vii).153,154 Mechanically strong silks including the dragline and auxiliary silks are produced in the major and minor ampullate glands, respectively, whereas viscid and aciniform silks produced in the flagelliform and aciniform glands are weaker but show substantially greater extensibility. In addition, female spiders secrete very special silk from their cylindriform glands as a protective eggs sac.83 Also, spiders have evolved to produce a rather unexplored set of adhesive silks, namely pyriform adhesive silk and aggregate silk glue, which can outperform man-made cyanoacrylate-based glues in certain applications.155,156

Figure 3.

Fibrous protein materials. (A) Orb-weaving spiders can produce up to seven different silk types, namely (i) pyriform attachment silk, (ii) cylindrical egg wrapping silk, (iii) minor ampullate silk, (iv) major ampullate silk, (v) flagelliform silk, (vi) aggregate silk glue, and (vii) aciniform prey wrapping silk. Schematic representation of the 3-block spidroin architecture consisting of the non-repetitive N- and C-terminal domains and the long central repetitive block, which is shared among all silk types. (viii) Small portions of the amino acid sequences for the repeating units of four major silks described in the text are presented: Araneus ventricosus Dragline spidroin-1 (UniProtKB - A0A090BQB1); Latrodectus hesperus Pyriform spidroin-1 (UniProtKB - C7T5D2); Nephila clavipes Flagelliform spidroin-1 (UniProtKB - Q9NHW4); Latrodectus hesperus Aggregate glue spidroin-1 (UniProtKB - A0A140DL44). These sequences are from refs (157−160), respectively. (B) Hagfish (here the pacific hagfish (Eptatretus stoutii is represented) secrete a two-component viscous slime when threatened by predators. (i) The tough slime is made of mucins and fibrous proteins. (ii) The proteins are heterodimeric coiled-coil intermediate filaments. (iii) Primary architecture of the two coiled-coil proteins EsTKα and EsTKβ. The solid rectangles represent the coiled-coil regions. Adapted with permission from ref (161). Copyright 2017 Royal Society of Chemistry. (C) Velvet worms (onychophora) swiftly eject (i) proteinaceous fibers to capture their prey. Adapted with permission from ref (162). Copyright 2018 American Chemical Society. (ii) The fibers consist of a multi-protein complex, and the dominant proteins in the complex are large MW proteins (180–250 kDa) that are mostly disordered in solution, with a few short β-sheet domains predicted in silico. (iii) The primary structure of the main slime proteins can be divided into three main domains, i.e. long disordered domains, low sequence complexity domains enriched in Gly and Ser at the N-terminus, and interspersed repeat domains 20–30 amino acid long. Adapted from ref (163). Creative Commons CC BY.

The mechanical properties such as adhesion, strength, toughness, and elasticity are highly tunable and uniquely altered by spiders depending on the environmental conditions and ecological needs.164 For example, dragline silk is stiff and has a high ultimate tensile strength in dry conditions but supercontracts and becomes elastomeric in the hydrated state.165−168 Such a diverse range of function and material performance is based on the interplay of (1) highly optimized molecular architecture; (2) intermixing of various building blocks; (3) hierarchical structure–property interactions at multiple length scales; and (4) unique physiochemical processing steps.83 The main types of silks and the link with their molecular architecture are briefly discussed below.

3.1.1.1. Dragline Silk

Spidroins, the constituents of all spider silks, are a family of structural proteins characterized by a 3-block protein architecture with an overall MW of 250–350 kDa (Figure 3A-viii).169 It includes an exceptionally long and highly repetitive central section (midblock) flanked by two relatively small and highly conserved globular N- and C-terminal domains.83 This molecular architecture is shared among all the spidroins and is critical to enhance solubility and prevent premature crystallization/aggregation.77,170−172 While the midblock provides the basis for the diversity of function and material properties of the different silk types, the terminal domains remain highly conserved and play central roles in the end-to-end polymerization of the spidroins.83

The core region of the load-bearing spidroins is rich in hydrophobic poly-Ala and hydrophilic Gly residues (Figure 3A-viii).169,173−176 The sequence arrangement highly resembles the architecture of a diblock copolymer in which 8–10 consecutively arranged Ala stretches are segregated from the Gly-rich blocks. The poly-Ala repeat motifs form about one-quarter of the sequences. In contrast, poly-Gly motifs are the dominant feature in the sequence. During spinning, Ala-rich sequences undergo conformational transitions into the relatively short anisotropic β-crystallites that are needed to provide strength and stiffness. Another key feature of the Gly-rich block is the high Pro content. Pro and Gly are known to be secondary structure breakers. Therefore, the presence of both contributes to the formation of largely expanded isotropic amorphous structures that provide extensibility and resilience to the fibers.169,173−176

3.1.1.2. Flagelliform Silk

Flagelliform silk, also commonly known as viscid silk, is the most elastic and extensible silk fiber.177 It forms the capturing spiral treads (Figure 3A-v). As the name suggests, the impact of the prey on the web is mainly dissipated through flagelliform silk. The midblock region of the viscid spidroin completely lacks the presence of any Ala residues (Figure 3A-viii).178 Instead, the core sequence is almost entirely formed from poly-Gly repeating motifs and Pro. In a most simplistic view, flagelliform is dragline silk with no crystalline domain and a 100% amorphous domain. This results in a substantially high elastic and stretchable response as high as 1000% but also in supercontraction when hydrated to 50% of its original length.178

3.1.1.3. Adhesive Silk

While pyriform and aggregate silk glues remain the least studied silk types, they can be considered as one of the most unique biological glues.179−181 The pyriform adhesive is made from fast-curing sticky fibrils (Figure 3A-i). It is brushed into elaborated patterns that fasten dragline silk threads tightly to the substrates using a minimal amount of materials. It can form strong adhesion even to surfaces with low surface energy, such as Teflon. The most striking difference between pyriform spidroin and other spidroin family members is the lack of the commonly available repeating motif rich in Gly or Pro (Figure 3A-viii). In addition, the pyriform repetitive mid-blocks contain sequence motifs with distinctive stretches of polar and charged amino acids including Glu, Arg, and Gln.158 The abundance of such charged residues enables desirable properties such as high water solubility of the spidroin, strong interaction with the substrate, and self-assembly to fibers. Furthermore, the pyriform exhibits much shorter poly-Ala stretches with only three consecutive Ala residues.

It is important to note that pyriform adhesive is uniquely optimized to be used on dried surfaces and lacks performance on semi or fully hydrated surfaces.158 In contrast, the aggregate glue is a wet adhesive with the function to retain prey upon impact with the web (Figure 3A-vi).182 It is completely different from all the other spider silks. Instead of forming solid filaments, it tends to form specific suspended viscoelastic amorphous microdroplets on the axial capture spiral threads.183 Its arrangement highly resembles beads on a string. The aggregate glue exhibits strong hygroscopic features with an interior glycoprotein core and an exterior aqueous shell. The mid-block exhibits low complexity and a highly repetitive nature similar to other spidroins. While its sequence is less biased toward Gly, Pro, and Gln, Ala residues are almost absent from the mid-block (Figure 3A-viii).156 What makes the mid-block distinctly different from that of any other spidroin is that it has a substantially higher content of Ser and Thr. These are found to be prone to O-glycosylation and directly reflect the hygroscopic properties, as well as the stickiness of the aggregate glue.

3.1.2. Hagfish Filaments

Hagfish (Figure 3B) are ancient benthic fish that have evolved a peculiar defense mechanism against predators. When threatened by predators (for instance sharks), specialized cells located on their epidermis evict a viscous slime that rapidly swells upon contact with seawater and can clog the gills of the attacker.184 The slime (shown in Figure 3B-i) is mechanically robust as well as slippery. In an infamous example featured in the popular press,185 containers of hagfish spilled onto a highway in Oregon, leading to chain-reaction crashes of multiple vehicles. The culprit was the hagfish slime that was rapidly released by hundreds of scared hagfishes that fell on the road, rending it slippery. The slime is composed of two main components secreted by two specific sets of gland thread cells,186 namely the mucus and proteinaceous fibers. The mucus is secreted by gland mucus cells (GMCs) and composed mostly of proteins (77% dry weight), carbohydrates (12%), lipid (5%), and sulfate (6%). Whereas the sequence of the mucus proteins has remained unknown to date, some authors have suggested on the basis of these data that the mucus is made up of glycoproteins. However, what is clear is that mucin vesicles from the mucus swell very fast upon encountering seawater, with swelling occurring as fast as 100 ms in some species.

The second component of the mucus, secreted by the gland threads cells (GTCs),187 are proteinaceous fibers188−190 made of keratin-like fibers first sequenced by Koch and co-workers.191 Slime proteins’ molecular architectures are reminiscent of intermediate filaments (IFs) from the cell’s cytoskeleton:191,192 they form long α-helical coiled-coil rods intervened by flexible linkers that self-assemble into nanofilaments193 as illustrated in Figures 3B-ii and 3B-iii (keratins also belong to IFs, which is why hagfish threads are referred as “keratin-like”). In the Pacific hagfish Eptatretus stouti (E. stouti), the filaments are heterodimers comprised of two proteins called E. stoutii thread keratins α (EsTKα) and γ (EsTKγ).

In the native state, synchrotron WAXS has revealed that hagfish threads exhibit an α-helical coiled-coil to β-sheet transition (α → β transition) when the whole slime is strained in the dry state.193 The resulting β-sheet-reinforced fibers exhibit remarkable mechanical properties that rival silk and approach Kevlar, with an elastic modulus as high as 8 GPa, an ultimate tensile strength (UTS) of ca. 700 MPa, and an energy to failure approaching 200 MJ m–3.194 These elevated mechanical properties are a direct consequence of the presence of β-sheet nanocrystals that are also the source of the remarkable mechanical performance of spider silks.195

3.1.3. Velvet Worm Slime

Velvet worms are ancient terrestrial carnivores that are classified within their own phylum, the Onychophora (which means “claw bearers” in Greek).196 They are divided in two families, the Peripatidae found in tropical and subtropical regions and the Peripatopsidae distributed in more temperate climates. Both families of velvet worms employ a peculiar hunting strategy: they swiftly evict a stream of sticky proteinaceous fibers (the slime) from their oral papillae, which undergo a rapid liquid-to-solid transition, thus hardening in a few seconds to capture and immobilize their prey (Figure 3C). The slime is initially stored as a highly concentrated protein solution in elongated slime glands (Figure 3C-i),197 and solidifies first into a gel and eventually into stiff fibers exhibiting a stiffness on par with Nylon. Early studies197 proposed the slime to be made of collagenous proteins based on the high content of Pro amino acid. This hypothesis was unambiguously disproved by Haritos and co-workers,198 who obtained partial sequences of the main slime proteins by constructing a cDNA library of the slime gland and probing it with tandem MS/MS of the slime. This study resulted in the identification of fragments of Pro-rich (20 mol %) proteins (with MW > 200 Da based on SDS-PAGE) with low sequence complexity predicted to be largely unstructured. The classical sequence pattern of collagens (GX1X2)n where X2 is usually Pro was not observed in these sequences. However, the full-length sequence was not achieved. That study also established that the mature slime contains additional mid-size MW (∼55–65 kDa by SDS-PAGE) as well as low MW (<20 kDa) proteins.

In a series of studies, Baer and co-workers provided first insights into the biofabrication process of slime fibers. This team observed that drawn slime fibers are made of a mostly proteinaceous core covered by a sheet of nanoglobular protein/lipids complexes.199 Upon prolonged exposure to water they also showed that the slime could be fully redissolved, forming a colloidal suspension made of near-monodispersed nanoglobules about 50 nm in diameter as detected by AFM and DLS studies, and new fibers could be drawn from the dissolved colloidal solution. Lipids were proposed to stabilize slime proteins into soluble complexes, thereby preventing aggregation. During fiber drawing, the protein/lipid nanoglobules were suggested to segregate on the outside coating whereas the core of the fiber is mostly protein-based. This biofabrication process thus provides remarkable “green processing” lessons, because strong fibers are drawn from an aqueous solution under ambient conditions with minimum postprocessing. In a follow-up study,162 the same team established that some of the proteins are phosphorylated and proposed that the zwitterionic nature of the slime proteins (with alternate positively charged and negatively charged patches) may facilitate fiber formation by electrostatic interactions, with phosphorylated residues mediating assembly by electrostatic complexation with divalent ions such as Ca2+ and/or Mg2+. Using WAXS, Fourier transform infrared spectroscopy (FTIR), and Raman spectroscopy, Baer et al.200 also detected the presence of β-sheet crystallites in the crude slime, protein droplets, and dried fibers. On this basis, they suggested that slime proteins may be stored as β-sheet-containing droplets that transition first into an intermediate viscoelastic gel and then into the final solid fibers by water loss.

Very recently, using the integrative transcriptomic/proteomic approach highlighted in Figure 2, our team obtained the complete sequences of the major slime proteins from a species (which is yet to be fully identified) from the Peripatidae family.163 This study revealed that proteins detected in the high-MW region by electrophoresis are in fact multi-protein complexes linked by intermolecular disulfide bonding, which are dominated by two high-MW proteins called Eoperipatus slime proteins 1 and 2 (ES_P1 and ES_P2) and linked to mid-MW Eoperipatus slime proteins 5 and 6 (ES_P5 and ES_P6). The primary structures of ES_P1 and ES_P2 unveiled four noteworthy features that may be critical for slime fabrication, as highlighted in Figure 3C-ii and iii. First, using bioinformatic tools for intrinsically disordered proteins (IDPs), they were predicted to be largely disordered as previously envisioned (Figure 3C-ii).198 However, it is noteworthy that predictions with AlphaFold201 supported the ability of both proteins to locally acquire short β-sheet structures. Second, both proteins contain repeat motifs (30 and 20 amino acids long for ES_P1 and ES_P2, respectively) made of basic dipeptides (RR, RK, and KK), short Pro-rich motifs (PP, IP, IIP, PI, and IP), as well as single acidic residues that are however found only in the repeats of ES_P1 (Figure 3C-iii). Third, the N-termini contain low complexity (LC) domains dominated by Gly and Ser amino acids (GS-rich domains, Figure 3C-iii). And fourth, Cys residues are mostly segregated at the termini of the primary structures. Despite their low abundance, Cys residues are likely to play a key role in slime assembly, by providing sites for disulfide bonding that maintain the multi-protein complexes together. Interestingly, the LC domains of the N-termini share homology with the fused in sarcoma (FUS) RNA-binding protein, a ribonucleoprotein that is well-known to exhibit LLPS.202,203 A recombinant construct of this domain for ES_P1 was established to exhibit LLPS, indicating that the N-termini of ES_P1 and ES_P2 may also promote LLPS, enabling the slime proteins to be concentrated in the gland while preventing premature aggregation, which would impede efficient slime ejection.

Slime proteins are also characterized by a high occurrence of PTMs, including phosphorylation, glycosylation, as well as Pro hydroxylation. These modifications must undoubtedly play an important function in slime biofabrication and properties, but their roles to date remain speculative. Baer et al.162 have suggested that phosphorylation of slime proteins could help mediate nanoglobules’ charge–charge attractive interactions with positively charged domains as well as forming ionic bridges with divalent cations (Ca2+ and Mg2+). Solid state NMR of the slime suggested that glycosylation occurs on Ser residues primarily located in flexible regions of the slime, and an adhesive function—which would help prey capture—has been proposed, similar to the case of pyriform silk. With regard to Hyp, it is known to increase the thermal stability of collagens and other structural proteins, but here again, it is yet unclear why ES_P1 and ES_P2 contain a high abundance of Hyp. Overall, while the full-length sequence of the large slime proteins is a critical first step to understand the biofabrication of the slime, much remains to be done to understand the liquid-to-solid transition as well as how the sequences are correlated to the mechanical properties of the slime. Open questions include the role of PTMs, namely phosphorylation, glycosylation, Pro hydroxylation, and disulfide bonds. The role of lower MW slime proteins is also unknown. As we have highlighted for spider silk and mussel adhesives, understanding the primary structure/property relationships of these proteinaceous fibers has been ongoing for decades and researchers are still discovering important biochemical and structural features associated with biofabrication.204−206 The slime of the velvet worm is as complex as these extracellular fibers and will require similar research efforts to achieve the same level of understanding.

3.1.4. Comparative Overview

The fibrous proteins described in this section display rather diverse primary sequences but also structural conformations (Figure 3). This can be comprehended considering that they originated from organisms that are evolutionarily distinct and that operate in significantly different environments. Thus, their sequences are evolutionarily optimized for very specific ecological functions. Nevertheless, despite this broad diversity, they share several similarities at the molecular scale as well as in terms of biofabrication conditions. The key function of these fibrous proteins is mainly to capture prey or as a line of defense against predators. Thus, the survival of the organism relies on the activation of the materials in a matter of seconds. Here, activation is referred to as the transition of the preassembled building block from a liquid or a weak gel phase to a solid phase that can be rapidly deployed by the animal. This hierarchical process originates at the molecular scale and primarily involves conformational transitions from random coils or α-helices to β-sheets during the physicochemical processing steps that harden the material in a matter of few seconds. Broadly speaking, this process can be divided into five key steps, starting from gland secretion and ending with the cured material:

-

(i)

The first insight is that expression of the core proteins takes place in very dedicated secretion glands. Expression is seemingly followed by PTMs such as phosphorylation, hydroxylation, and glycosylation. It has become distinctively evident with advances in non-invasive molecular characterization methods that almost all of these glands co-express smaller proteins, glycoproteins, or polysaccharides and secrete lipids or waxes with important functions during storage or processing and to optimize the material functionalities. PTMs as well as co-expression of other polymers seem to be a common molecular strategy enhancing solubility and preventing premature crystallization/aggregation that would clog the glands. The other key function of PTMs is related to fine-tuning the material properties by altering the hydration level of the fibers after curing. Furthermore, spider silk and velvet worm adopt a similar strategy of producing large MW complexes from the core proteins, which is carried out by covalently linking the extremities of the proteins via disulfide bridges using Cys residues localized at the terminal regions. The resulting higher aspect ratio complexes significantly enhance the mechanical performance of the final materials compared to the monomeric building blocks.

-

(ii)

The second commonality is that the colloidal solutions in the glands are stored at high concentrations (25–50% w/v) by actively pumping water molecules out and increasing the overall biopolymeric mass during storage. This results in the preorganization of the components in the slime or the spinning dope into intermediate assemblies that are crucially important for fiber formation. The nature of this assembly state is not completely understood. Two theories have been put forward associated with their micellar or liquid crystal nature; however, neither can fully explain the complexity of the assemblies. A more comprehensive mechanism has recently been formulated based on coacervation, which is built upon multiple pieces of evidence that under controlled conditions, most naturally occurring structural proteins can undergo LLPS, resulting in the formation of condensed liquid droplets. Thus, there is growing awareness that LLPS of structural proteins represents a ubiquitous transient mechanism underlying structural assemblies toward the fabrication of natural structural materials.

-

(iii)

The glands of these organisms are very sophisticated machineries In addition to being able to pump water out, they have the capability to simultaneously change the solution conditions, such as altering the pH and tuning the cationic/anionic balance to modulate the solubility of the core proteins. As described earlier, divalent Ca and Mg ions can form salt bridges between acidic amino acids and cross-link the velvet worm slime core proteins. A similar chemistry may be expected during the formation of IFs in the slime-producing glands of the hagfish. The major difference is that, in addition to the co-secreted ions, the mechanical properties of the filaments may be quickly adjusted upon encountering seawater due to the abundance of divalent ions that can be taken up from the environment. The process can be facilitated as the filaments may initially adopt a more expanded conformation at the higher pH (8–8.2) of seawater. Furthermore, an added advantage for the velvet worm is that the addition of ions is an energetically favorable strategy to increase the slime viscosity without increasing the polymer content, which may enable researchers to optimize the distance of projection during slime ejection. Spiders, on the other hand, use monovalent ions such as potassium. This has an inverse effect on the viscosity since the spinning dope requires passing through a very long and thin spinning duct, and the biomechanics of the gland is not capable of generating backpressure, which is why the silk spinning is based on a pulling mechanism and not a pushing one.

-

(iv)

Primarily weak hydrogen bonding networks and hydrophobic interactions appear to be the main stabilizing inter- and intramolecular interactions, both in the preassembled state of the core proteins and in the final material. This distinctive characteristic is important not only to create sacrificial bonds for energy dissipation during mechanical deformation but also for self-healing, hydration, and adhesion of the fibers. Charged side chains seem to impart important characteristics to the core proteins by forming ion pairs, but also other less specific electrostatic interactions. This comes with the added advantage that by altering the pH, phosphorylation and dephosphorylation can be modulated, which can significantly contribute to conformational switches.

-

(v)

Finally, mechanical forces (extensional flow, elongation, or shear) all trigger molecular alignment and crystallization of the proteins. For instance, under such conditions spidroins form a classical block copolymer structure, with nanoconfined β-sheets enabling stiffness and rigidity and the amorphous domains providing extensibility and resilience. Moreover, the anisotropic orientation of the β-sheets allows to fine-tune the load-bearing characteristics during uniaxial tension. The slime of the worm seems to adopt a similar transition during self-assembly, with crystallization also directly linked to drying of the fibers. Likewise in the hagfish slime fibers, simultaneous pulling and drying can be used to artificially trigger the formation of β-sheets dominated fibers with an exceptional combination of stiffness, strength, and toughness, although this draw-processing is not directly used by the animal.

3.2. Elastomeric Proteins

The ability of some tissues to sustain large reversible deformation is critical for their biological function. These elastomeric properties are provided by proteins that are usually in a random-coil conformation and cross-linked into 3D networks via side-chain-mediated covalent cross-linking, although as presented below there are some exceptions of proteins that adopt well-defined secondary structures and yet exhibit large reversible elastic deformation. The molecular design of such proteins is presented and discussed in this section. The thermodynamic and polymer physics framework used to describe bioelastomeric properties is based on entropic elasticity, and the detailed formalism can be found elsewhere.11,207,208 Briefly, the retracting force on an elastomeric network f arises from two contributions, namely the internal energy component fU and the entropic component fS, expressed as

|

1 |

where (∂U/∂L) is the change in internal energy U by unit extension L and (∂S/∂L) is the change in entropy S per unit extension L, which using the Maxwell relationship is equal to the negative change in force f with temperature T, −(∂f/∂T). At high strains, the entropic component fS is larger than the internal energy component fU, hence the term “entropic elasticity”. In elastomeric materials and at a given strain, the force increases with temperature and the thermoelastic coefficient (∂f/∂T) can be experimental obtained from a series of stress–strain curves at different temperatures.11,209 Because the thermoelastic coefficient is positive, a classical result of entropic elasticity is that at a fixed strain, the force on an elastomeric fiber increases with temperature, a characteristic that is useful to differentiate non-entropic bioelastomers described in Section 3.2.4.

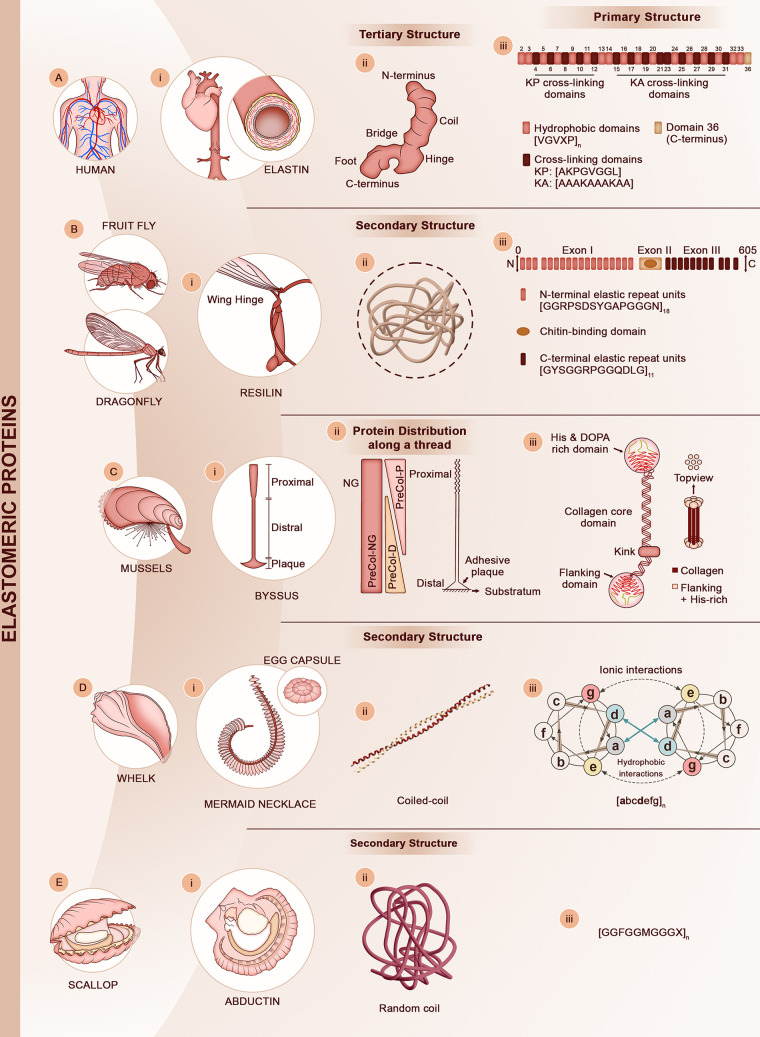

3.2.1. Elastin

Elastin is the principal protein responsible for the elasticity of vertebrate structures, notably skin, cardiovascular tissues, cartilage, etc. (Figure 4A-i). As discussed in Section 2.2, the soluble precursor of elastin tropoelastin, a 72 kDa protein which after extracellular secretion is stabilized by hydrophobic cross-links, forms a 3D random network that protects the material against chemical and enzymatic degradation. The primary structure of tropoelastin consists of alternative hydrophobic and cross-linking blocks with low complexity sequence,210 as illustrated in Figures 4A-iii. The hydrophobic blocks are typically made of short (4 to 6 residues long) GVP-rich peptides, such as [GGVP], [PGVGV], or [PGVGVA]. On the other hand, the cross-linking domains contain Lys residues that are flanked either by stretches of poly-Ala on both sides (KA domains) or by the hydrophobic motif [PGVGGL] (KP) domain (Figure 4A-iii).

Figure 4.

Bioelastomeric protein materials. (A) Human elastin provides elasticity to vascular organs, lungs, and skin (i). (ii) Despite its high molecular mobility, the tropoelastin molecule (the precursor of elastin) has a defined tertiary structure consisting of an elongated asymmetric coil connected to a foot-like protrusion by a hinge domain. Adapted from ref (47). Copyright 2011 National Academy of Sciences. (iii) The primary structure of tropoelastin is made of alternative blocks of hydrophobic and cross-linking (KA and KP) domains. Representative peptide motifs for each domain are shown. (B) In flying insects, such as the fruit fly and the dragonfly, the hinge of wings is made of the resilin protein (i). (ii) The secondary structure of resilin is largely disordered. (iii) The primary structure of resilin has three main regions. The N- and C-terminus providing elasticity are highly repetitive (consensus motifs shown) while the central region has a Rebers & Riddiford (R&R) chitin binding domain. Adapted with permission from ref (218). Copyright 2012 Springer-Nature. (C) Mussel byssal threads are (i) mechanically graded fibers that transition from a stiff proximal region to an elastomeric distal region. (ii) The core of a thread is made of three main proteins (PreCol-P, PreCol-NG, and PreCol-D) with different spatial distributions along the thread as schematically illustrated. Adapted with permission from ref (89). Copyright 2004 American Chemical Society. (iii) PreCols consist of a central collagenous core flanked by either stiff, silk-like domains (PreCol-D) or flexible, elastin-like domains (PreCol-P) that are packed into regular lattices. The termini of the PreCols contain His- and Dopa-rich domains that enable cross-linking via either metal ion coordination bonds or Di-Dopa covalent bonds (see Figure 5 for details on the cross-linking chemistry). Adapted with permission from ref (219). Copyright 2021 American Chemical Society (D) Marine snails (here a whelk) lay their embryos within (i) elastomeric egg capsules. During deposition, a female will deposit a single string of egg capsules attached to a central filament (mermaid necklace). (ii) Egg capsules are made of coiled-coil intermediate filaments bundling together to form the macroscopic capsules. (iii) Coiled-coil domains are made of heptad repeats [abcdefg] where a and d are hydrophobic residues. (E) In scallop and other bivalves, the adductor muscle is made of the abductin protein (i), which is the only documented bioelastomer to work under compression loading. (ii) Abductin has been found to have random coil structure. (iii) The primary structure consists of multiple repeats of a Gly-rich motif that has a central Meth residue.

The hydrophobic blocks, exemplified by the pentapeptide motif [VGVXP], drive the coacervation process34,211,212 during which tropoelastin concentrates at the cell surface following secretion. At low temperatures, tropoelastin is in the monomeric state, with a network of clathrate water molecules surrounding the hydrophobic blocks and preventing aggregation.33 Above a critical temperature, the H-bonded network of water molecules is disrupted, exposing hydrophobic blocks and triggering aggregation in the form of microdroplets (coacervates). Earlier studies of tropoelastin structural fluctuations during coacervation relied on low-resolution spectroscopy methods and solid-state NMR studies.213−216 More recently, solution NMR combined with magic angle spinning (MAS) solid-state NMR studies of ELPs comprising of alternative hydrophobic and cross-linking domains have refined our molecular understanding of elastin coacervation.217 In the solution (non-coacervated state), Nuclear Overhauser Effect Spectroscopy (NOESY) experiments determined that β-turns of [VPGV] and [GVGV] domains form short-range intramolecular interactions mediated by the proton backbone. After coacervation, the hydrophobic domains retain disordered and transient interactions, but these intermolecular interactions are stronger and attributed to multiple non-specific hydrophobic contacts between Gly, Val, and Pro residues. Furthermore, the cross-linking domains are also disordered. After cross-linking, on the other hand, whereas hydrophobic domains are still disordered, cross-linking domains adopt a helical conformation.

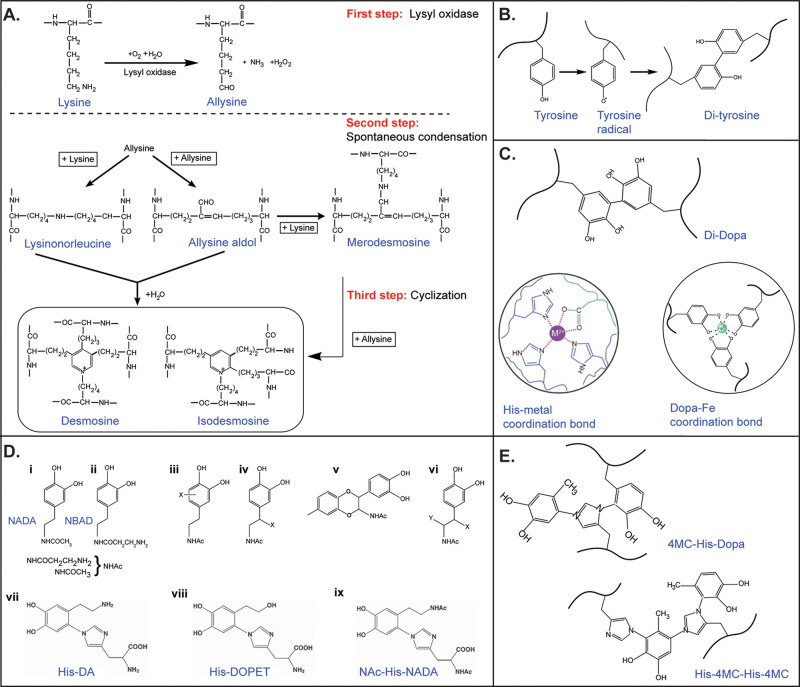

Lys chemistry is central to the cross-linking and stabilization of tropoelastin into a 3D elastomeric network, which occurs in 3 steps displayed in Figure 5A.35,36 In the first step, Lys side-chains are converted by a lysine oxidase (LOX) enzyme to the semi-aldehyde allysine (ALys).220 In the second spontaneous step, either a Schiff base reaction occurs between one Lys and one ALys side-chain to form a lysinonorleucine cross-link or two ALys react through an aldol condensation to give rise to the allysine aldol cross-link. In the third step, the bifunctional cross-links undergo a cyclization condensation reaction to form the final desmosine or isodesmosine cross-links, which can thus be viewed as a four-Lys ring structure. The sequence patterns of cross-link domains are thought to promote the four-Lys ring in the following ways.208 In the KA domain, the tendency of Ala to form α-helical segments leads to the exposure of Lys side-chains to one side of the helix, whereas in the KP domain, the Pro residues may favor a poly-Pro helical segment that may also expose Ala side-chains on one side of the segment. In both cases, the structural conformations result in two pairs of Lys emerging on one side of two helical segments, thus enabling the formation of the tetra-cross-links from the four Lys/ALys side-chains.

Figure 5.

Cross-linking chemistry in various protein-based biological materials. (A) In elastin, cross-linking is initiated on Lys residues that are converted into allysine (ALys) by the lysyl oxidase enzyme (top panel). Spontaneous condensation between Lys and ALys leads to the intermediate cross-links lysinonorleucine, ALys aldol, and merodesmosine (middle panel). In the final step, cyclization condensation results in the cyclic cross-links desmosine and isodesmosine (bottom panel). Adapted with permission from ref (221). Copyright 1998 John Wiley & Sons. (B) Cross-links in resilin are simpler and consist of dityrosine, triggered by enzymatic oxidation of Tyr residues with peroxidase that leads to oxidative phenolic coupling. (C) Cross-links in the PreCol proteins of mussel threads are Di-Dopa and His-Metal coordination bonds. The Dopa-Fe3+ coordination bonds are particularly prominent in the protective coating of the byssus made of MFP-1. (D) In insect cuticles, cross-linking starts by oxidation of Tyr amino acids into Dopa, which is subsequently decarboxylated to dopamine and then acylated to either N-acetyldopamine (NADA) (i) or N-β-alanyldopamine (NBAD) (ii) resulting in acyldopamine derivatives. These compounds are enzymatically oxidized into o-quinones, which are then isomerized to quinone methides that can subsequently react with nucleophiles (X) on the aromatic ring (iii) or with the side-chain (iv) to produce catecholic-based cross-links. Alternatively, cross-links can be formed by reaction of the quinone methide intermediates with another available NADA (v) or other nucleophilic reactants (Y and X, vi). (i-vi) Adapted with permission from ref (222). Copyright 2010 Elsevier. Catecholamine-His adducts with covalent attachment between the imidazole and aromatic rings have also been identified as cross-links in insect cuticles, including His-dopamine (His-DA, vii), His-dihydroxylphenyl ethanol (His-DOPET, viii), and N-acetyl-His-NADA (NAc-His-NADA, ix). (vii-ix) Adapted with permission from ref (223) Copyright 1999 Elsevier. (E) Identified cross-links in squid beak proteins include covalent adducts between His side-chains with either the low MW compound 4-methyl catechol (4MC) or Dopa side-chains. Adapted with permission from ref (138). Copyright 2010 American Society for Biochemistry and Molecular Biology.