Abstract

The installation of artificial reefs serves to enhance marine ecosystems, although it also modifies them. These changes do not have to be irreversible, since it is possible to treat the functional life of an artificial reef (AR) as a variable factor to be determined, with the objective of contributing to the sustainability of the ecosystem.

The quest for sustainability does not end with the manufacture and installation of the AR units. It is also necessary to analyse the sustainability of the modified ecosystem, through the production of services. This leads to consider the medium-term return of the ecosystem to its initial state, once the functional life of the ARs expires.

This paper presents and justifies an AR design/composition for limited functional life. It is the result of acting on the base material, the concrete, with the objective of limiting the useful life to one social generation. Four different dosages were proposed for such a purpose. They were subjected to mechanical tests (compressive strength and absorption after immersion), including an innovative abrasion-resistant one. The results allow estimating the functional life of the four types of concrete from the design variables (density, compactness, and quantity of water and cement as well as its relation). To this end linear regression models and clustering techniques were applied. The described procedure leads to an AR design for limited functional life.

Keywords: Artificial reef, Sustainability ecosystem, Reversible process concept, Design for limited functional life, Linear regression model

Graphical abstract

Highlights

-

•

Changes to the marine ecosystem caused by artificial reefs should be reversible.

-

•

It is possible to treat the functional life of an artificial reef as a variable.

-

•

An AR composition for limited functional life to one social generation is presented.

-

•

The functional life of four concrete types is estimated from the design variables.

1. Introduction

Sustainable development must be accompanied by the conservation and management of the ecosystems and also by the sustainability of the services they generate [1]. Ecosystem services (ES) are defined as the benefits that an ecosystem brings to society, improving the health, economy and quality of life of people [2]. ES extraction and exploitation has increased as a result of economic development, population growth and technological progress, reaching levels that run counter to sustainability principles [3].

Many countries have employed artificial reefs (ARs) with the initial purpose of attracting fish [4,5]. However, the installation of ARs also contributes to biodiversity conservation, aquaculture, fisheries management, and coastal habitat conservation as well as to the promotion of tourism through recreational activities [6].

Consequently, the installation of ARs can be a tool to protect and enhance endangered habitats and their declining biodiversity, improving their ES [7]. On the other hand, ARs can also generate both positive and negative environmental impacts on the ecosystem [8,9]. Therefore, the deployment of ARs must be in line with the necessary sustainability.

1.1. Limits to the economic activity of installing ARs

The concepts of integral sustainability and sustainable development require a balance among the economic performance, the social responsibility and the environmental care [10]. This implies the need to control the use of natural resources and also the need to reduce the consumption of those energy sources that most contribute to environmental degradation.

In fact, sustainability is increasingly present in managing natural resources [[11], [12], [13]]. In this sense, the implementation of well-known and widely used indicators is helpful to obtain a greater knowledge of the current situation. Examples include land use sustainability [[14], [15], [16], [17]], water resources sustainability [18,19], biodiversity sustainability [20,21], and ecosystem sustainability [[22], [23], [24]], among others.

Economic production uses raw materials and energy to obtain products, generating both emissions and waste [25]. According to Farley and Voinov [25], a sustained economic growth could exceed the critical socio-ecological thresholds of the planet, adversely affecting ES. In other words, there can be ultimate ecological limits [26], an idea also reflected in the Brundtland report [27]: “But ultimate limits there are […] At a minimum, sustainable development must not endanger the natural systems that support life on Earth: the atmosphere, the waters, the soils, and the living beings”.

Therefore, sustainability issues must be considered at the time of installing ARs. It is necessary to analyse both manufacturing and transport stages. Carral et al. [28] addressed the first phase by studying the use of alternative materials in the production of AR modules, under the criteria of the circular economy. The supply chain of the modules was also covered by Carral et al. [29]. However, to the best of the authors’ knowledge, there are no studies dealing with the sustainability of the modified ecosystem, through the production of services (zero irreversibility). More information about this novel concept will be provided in the following subsections.

1.2. Principle of zero irreversibility in the process of modifying the ecosystem through the installation of ARs

Economic production contributes to the degradation of the ecosystems. By contrast, ecosystems generate services over time, at a rate that depends on their size and state (ecosystem health). Economic activity and ES are essential for human survival [25]. However, economic activities transform ecosystems and their natural resources into economic products, while ecosystem services perform their function, preserving the environment [25,30,31]. Regarding marine ecosystems, it is essential to promote a rational and balance exploitation of their natural resources taking into account public and private interests.

On the other hand, Daly [32] emphasises the need for environmental economics to move towards a macroeconomic configuration. In this line, sustainable development aims to ensure the reproductive capacities of the biosphere by taking into account different operational criteria, including the principle of zero irreversibility. This principle is based on the idea that any impact caused on the planet should be reversible. Stated another way, the objective is to minimise both cumulative and irreversible impacts derived from human activity, giving the Earth a chance to return to a previous state [33].

It is important to note that the transformation of an ecosystem into an economic production system (or human-dominated system) can make a significant contribution to ecological degradation [25]. The deployment of artificial reefs in marine ecosystems is no exception, since they can also be a source of ecological degradation, if not at the time of the installation, they could be in the future according to the sustainability indicators employed by future generations. This highlights the need of designing ARs according to the principle of zero irreversibility. By doing so, the positive impacts achieved in the short and medium term will not be compromised by potential future ecological degradation.

1.3. Ecosystem resilience

Ecosystems are damaged by natural or human disturbances, although they have some recover capacity (also known as resilience). In other words, ecosystems can withstand some impacts while remaining unchanged. Nevertheless, they can also undergo irreversible changes, persisting in a different state for a long period of time. Consequently, Farley and Voinov [25], based on the study developed by Holling [34], defined the resilience of an ecosystem as “the capacity […] to withstand and adapt to change to remain within the critical thresholds of its current regime”. In fact, according to Fig. 1, there is a critical point (ecological threshold) beyond which the ecosystem loses its ability to return to a previous state [35].

Fig. 1.

Changes in the modified ecosystem due to the introduction of a conventional artificial reef (CAR) and a contrived durability green artificial reef (CD – GAR) Source: own based on Thompson [37].

As a result, we must ensure that economic activities not only meet our needs, but also generate limited impacts that do not exceed the ecological thresholds of the ecosystem [36]. The challenge is to manage economic activities so that their impacts are kept within the limits of the ecosystem resilience [25].

Ecosystem state changes can cause both economic and ecological losses. In this regard, returning an ecosystem to a previous state may require drastic and costly intervention. According to Palumbi et al. [38], weakening the capacity that ecosystems have to shift to alternative stable states can come at a great cost to society. In contrast, it is necessary to enhance those natural characteristics that contribute to ecosystem resilience, such as the resistance to disturbances or the reversibility of the modifications introduced. A process is considered reversible if it can also occur in the reverse direction [11]. However, it is important to clarify that whether a change or modification is considered reversible may depend on the time scale and also whether fundamental ecological processes have happened after the disturbance [38].

Reversibility, resistance and recovery capacity are the three key factors for ecosystem resilience. They are the basis for the preservation of ecosystems against anthropogenic changes [39]. In this line, the design of artificial reefs should consider the potential increase in the resilience of the ecosystem to be enhanced through the principle of reversibility. In other words, by adopting such a principle, the ecosystem will be able to recover its integrity and functionality (left side of Fig. 1, blue colour) after a change that may be considered as severe damage or degradation in a near future (right side of Fig. 1, brown colour).

1.4. Temporal evolution of the environmental impacts caused by different types or ARs

Many authors have carried out literature reviews addressing artificial reefs (ARs). By way of example, Lee et al. [6] analysed the historical evolution of the objective pursued by installing ARs, from the improvement of fish stocks to the rehabilitation of marine ecosystems (ecological potential maximisation). Lima et al. [40] attributes this evolution to social changes coupled with the advances in scientific technology.

The evolution of ARs in terms of sustainability starts with those known as opportunity artificial reefs (OARs) [28]. Within this group are alternatives such as the sinking of inertised ships or used tyres. However, these solutions introduce no-biological wastes into marine ecosystems, with the corresponding negative impacts derived from the presence of toxic substances [[41], [42], [43]].

OARs were replaced by conventional artificial reefs (CARs). CARs are specifically designed structures to act as artificial reefs. Nevertheless, they are manufactured following a linear economy approach (take-make-dispose), still predominant in the first decade of this century. Fig. 2 shows that CARs are not good alternatives from sustainability and environmental points of view, since they consume unsustainable resources and they also generate non-biological wastes [28].

Fig. 2.

Evolution of different artificial reef designs in terms of resources and sustainability. OAR: opportunity artificial reef, CAR: conventional artificial reef, GAR: green artificial reef, CD GAR: contrived durability or one generation artificial reef. Source: own.

The next step in the quest for sustainability leads to the concept of green artificial reefs (GARs) [[44], [45], [46]]. GARs are based on a controlled consumption of natural resources (circular economy) and also on the reduction of both emissions and energy use [47]. This implies reducing the size of the ecosystem to proportions acceptable to the biosphere [48], improving the sustainability of created ecosystem (Fig. 2).

Consequently, ARs design has evolved by taking into account environmental and sustainability issues. Nonetheless, sustainability should not be limited to AR itself. The sustainability concept must also be analysed under the lens of the created ecosystem. The proposal of an artificial reef with functional life limited to one generation is in line with the latter issue (Fig. 2).

It is now time to clarify the exact meaning that the term “one generation” takes on this study. In terms of duration, “one generation” within a family could be estimated by taking the average age of the parents on a given date and averaging the birth dates of their children [49]. The duration of one biological generation has varied greatly over the course of history. However, the term “one generation” from a biological point of view does not coincide with the same term from a sociological perspective [49]. In this context, the Spanish philosopher José Ortega y Gasset stated that “one social generation” is made up of individuals who share cultural experiences and who are separated from each other by an average of about seven or eight years, being fifteen the upper limit [50]. Therefore, the duration of “one generation” is assumed to be less than 15 years in this study.

2. Objectives and methodology

Despite the considerable number of research studies addressing ARs published over the last decade, Lima et al. [40] pointed out that more attention should be paid to issues such as the use of alternative manufacturing materials and the assessment of their corresponding environmental impacts. This study is also related to this second objective, as the design of ARs with a limited functional life aims to avoid the potential future impacts on the ecosystem.

2.1. Objectives

The main objective of this study is to propose a GAR design/composition with a limited functional life of 15 years (one generation GAR, OG-GAR). This design allows the reversibility of the ecosystem processes, guaranteeing both the future sustainability and survival of the modified ecosystem.

This goes beyond the traditional approach to marine ecosystems rehabilitation, in which the installation of ARs aims to generate positive impacts in the short and medium term. This traditional approach does not take into account that an initial positive modification on the ecosystem could lead to negative impacts in the long term. Consequently, the target AR design of this work is intended to generate the same positive impacts on the ecosystem caused by traditional designs and, at the same time, to allow the ecosystem to evolve in the reverse direction, avoiding irreversible modifications. In other words, the design presented in this paper contributes to increasing ecosystem resilience.

To achieve the desired composition, four different dosages have been proposed. Each one of them has been tested in order to determine the compressive strength (1, 2, 7 and 28 days), the water absorption after immersion and the abrasion resistance. The final objective is to predict the functional life of the AR proposal from the design variables of the dosage.

On the other hand, the rehabilitation of the marine ecosystems through the installation of this type of artificial reefs (OG-GAR) will serve to promote artisanal fishing. In other words, the degradation of marine ecosystems leads to a decline in catches of certain species. This, in turn, generates negative economic and social (job destruction) impacts, especially in coastal regions that are highly dependent on the services provided by these ecosystems. Consequently, the installation of OG-GAR modules would have a positive impact on society and the economy, two of the pillars of both sustainable development and integral sustainability. Furthermore, they also contribute to a reduction of both present and future environmental impacts (third dimension of sustainability). In contrast to conventional artificial reefs (CARs), OG-GARs incorporate shells as substitute material to aggregates or cement. In this respect, both cement and aggregate production are activities that contribute to several environmental impact categories. This can be therefore mitigated by the use of OG-GARs as an alternative to CARs. Finally, limiting the functional life of artificial reefs will ensure that, once the ecosystem has recovered and each module has served its purpose, the seabed will be free of man-made structures, returning to the state prior to overexploitation.

2.2. Methodology

The methodology followed in this work includes: i) literature review, ii) laboratory tests and, iii) statistical techniques. In particular, the following scheme has been implemented (Fig. 3).

-

•

Literature review and establishment of a functional life target (low and upper limits).

-

•

Proposal of different concrete dosages (different water/cement ratios and cement content), in which part of the conventional materials (aggregates) have been replaced by shells. OG – GAR composition.

-

•

Determination of mechanical properties such as compressive strength and water absorption after immersion. Proposal of an improved abrasion resistance test, with verification of volume withdraw by laser profilometer.

-

•

Application of simple linear regression models and hierarchical and partitive clustering techniques (K-means and Clara) in order to estimate the functional life of each OG – GAR composition.

Fig. 3.

Flowchart of the methodology followed in this study to achieve a concrete dosage for artificial reefs with a limited functional life. Source: own.

3. Industrial design and limited functional life: application to artificial reefs

3.1. Industrial design and limited functional life

Today, there is a growing social awareness of environmental issues. This is leading to manufacturers paying particular attention to the environmental impacts of their products, processes and services [51,52]. In other words, the design process of any product is becoming increasingly important due to its potential impacts in terms of sustainability (economic, social and environmental dimensions) [53,54].

In this sense, ARs directly seek to improve the habitat for marine flora and fauna while preserving the structure of the ecosystem and its services [55]. As previously stated, under the traditional approach of manufacturing and installing ARs, both the sustainability of the ecosystem and its reversibility are ignored. Furthermore, the sustainability in terms of materials and processes is not directly considered. However, it is possible to act on the sustainability of an AR design in both materials and processes. The first line of action involves adding marine-derived aggregates to concrete with the objective of producing biological wastes [46], while the second allows the ecosystem to revert to an early stage [56], and it is also a direct consequence of acting on the base material (concrete).

In the particular case of concrete structures, the service life is established during the design stage, understood as the time the structure fulfills its function without incurring unforeseen maintenance costs [57]. The service or functional life is important to the extent that Satyro et al. [58] pointed out that it conditions the design of any product.

There is no unanimity on the optimal functional life of products. Some authors advocate for limiting the service life with arguments such as boosting innovation, achieving technological advances or even as tool to gain market shares [59,60]. In contrast, other authors highlighted the negative environmental effects derived from limiting function life (death dating) such as the depletion of natural resources, the emission of pollutants or the generation of waste [[61], [62], [63]].

However, in the particular case of ARs, there is an argument based on the ecology of the created ecosystem. Cautiously, it is possible to state that limiting the function life of ARs could favour the reversibility of the ecosystem to a previous state (before the installation).

On the other hand, there are different alternatives at the time of limiting the functional life of a specific product (Table 1): 1) design for X years, 2) eco-design, 3) planned obsolescence and 4) design for limited functional life (DLFL) also known as “death dating” or contrived durability [58,62].

Table 1.

Alternatives for limiting the functional life or artificial reefs. Specific characteristics of each option in terms of resilience, sustainability and reversibility of the ecosystem. Source: own.

| Alternative | Definition and source | Objectives | Applicability | Ecosystem reversibility |

|---|---|---|---|---|

| Design for X | Concern for a number of product requirements [64]. | Design for X years of functional life | Uncertain, too generalist | Uncertain |

| Eco-design or design for the environment | Design that takes environmental issues into account at the time of developing products and their corresponding processes [65]. | Minimising environmental impacts by reducing the consumption of natural resources and energy. | Generalist. No specific application to the sustainability of the ecosystem | Partially and in the long term |

| Avoiding emissions and waste throughout the product life cycle. | ||||

| Maintaining essential product characteristics such as costs, quality or performance, among others [66,67]. | ||||

| Planned obsolescence | Designing a complex product by establishing the lifetime (artificially shortened) of one its components (programmed obsolescence) [58]. | Specific design of one of the components to shorten its lifetime | Not valid for simple products. Negative economic side-effects [[61], [62], [63]]. | Medium term |

| Design for limited functional life (DLFL), death dating or contrived durability | The product is specifically designed to degenerate quickly. Each component is made to last for a short period of time. | Use of materials of inferior quality in key components [68,69]. | Applicable. Product completely designed for a specific functional life | Medium term |

The four options are of different nature. In contrast to the uncertain and generalist application of the first two alternatives, the third and fourth ones could be of interest for the design of ARs. Nevertheless, only DLFL will be suitable for a system with a limited number of components. In such a way, DLFL will serve to limit the functional life of a concrete-AR structure by reducing the durability of the base material [47]. Consequently, this is the option adopted in this study.

3.2. Concrete durability: proposal for artificial reefs

The durability, understood as the capability to withstand the environmental conditions for decades is, together with the mechanical resistance, the main characteristic of concrete constructions [58,70]. In this regard, national building codes define and classify the different types of exposures to which the concrete will be subjected, establishing requirements, indirectly related to durability, for each case [71]. However, durability performance tests are rarely specified. In addition to this, some of the existing ones are not adequate, since they do not assess the performance under real conditions [71]. Therefore, some authors have proposed new test methods as well as improved variations of the existing ones [72,73].

Most of the reinforced concrete structures are designed to achieve a service life between 50 and 100 years [74]. Their durability is limited by the steel and concrete due to their exposure to the environmental agents and, in particular the ones that cause corrosion [75]. However, according to Yu and Jiang [76], the problem of erosion corrosion due to chloride ions is less relevant for mass concrete. In fact, Solis-Carcaño and Alcocer-Fraga [70] pointed out that most of the durability problems concerning reinforced concrete are associated with permeability and porosity as they condition the capability of liquid and gaseous flows to penetrate the concrete.

Permeability can be defined as the capacity of a material to allow the filtration of fluids through its pores. It depends on the total number of pores as well as their size, distribution and interconnectivity [70]. Consequently, permeability, in the particular case of concrete, depends on the cement paste porosity. The latter can be considered as a measure of the total volume of pores found in the internal structure of the hardened concrete. Nonetheless, permeability is not a simple function of porosity, being the interconnectivity of the pores a determinant factor. In other words, for the same porosity levels, concrete can present different permeability degrees depending on whether the pores are uninterruptedly interconnected or not [77]. Consequently, durability will depend mainly on the internal structure of the concrete [78]. In contrast it is less dependent on the aggregates used, as these are usually inert and with low apparent porosity [74,78,79].

Water can flow through the interior of concrete by diffusion or absorption. Diffusion happens due to a concentration gradient of an aggressive agent [80], while capillary absorption allows the entrance to the porous matrix of the cement paste by capillary suction [81]. Absorption is more relevant in the case of marine structures under tidal action, while diffusion appears in those cases of total immersion, for example, with artificial reefs.

In order to achieve certain durability requirements, it is necessary to look for dosages that lead to improved permeability and porosity [82]. Permeability cannot be directly controlled in concrete production, so that certain variables end up playing a major role, such as the water/cement ratio, the cement content [83], the volume of entrapped air (compactness) or the proportions between fine and coarse aggregates [77].

In Spain, the Concrete Standard EHE-08 is the regulatory framework that defines the requirements that concrete structures must satisfy in terms of structural safety, fire safety and environmental protection [84]. This standard describes the procedures that guarantee compliance with technical requirements. Four different concrete dosages based on EHE-08 are proposed in this study with four doses of powder binder (Table 2) and four ratios water/cement: 0.5, 0.54, 0.58 and 0.6, respectively. In all cases, a cement type CEM I was chosen [84], since it does not include additives such as fly ash, blast furnace slag or silica fume. This cement was combined with gravel and both fine and coarse aggregates. Different replacement rates were defined for the fine (particle size below 4 mm) and medium (particle size between 4 and 10 mm) aggregates: 14.3% and 11.6% respectively [46], with a total value of 25.9%. These percentages were substituted by inerted and crushed shells, in particular a combination of both oyster and mussel shells. None of the four dosages contain additives in order to make the concrete as ecological as possible.

Table 2.

Main characteristics of the proposed concrete dosages (1 m3) taking into account EHE-08 requirements [84].

| Specifications | Concrete types |

|||

|---|---|---|---|---|

| Type 1 | Type 2 | Type 3 | Type 4 | |

| EHE-08 designation | HA-30/B/20/IIIb Qb | HA-25/P/20/IIa | HM-20/P/20/I | HM-20 |

| Type of concrete | Reinforced | Reinforced | Mass concrete | Mass concrete |

| Type of exposure | Submerged marine environment | Humid outdoor environment | Non-aggressive outdoor environment | – |

| EHE-08 | Compliance | Partially (temporary elements) | Partially (temporary elements) | Non-compliance |

| Estimated durability (years) | 25–50 | 3–10 | 3–10 | – |

| Characteristic resistance (N/mm2) | 30 | 25 | 20 | 20 |

| Consistency | soft | plastic | plastic | – |

| Maximum aggregate size (mm) | 20 | 20 | 20 | 20 |

| Environment designation | IIIb Qb | IIa | I | – |

| Aggregate between 10 and 20 mm (kg/m3) | 503 | 503 | 503 | 503 |

| Amount of coarse shell (kg/m3) | 200 | 200 | 200 | 200 |

| Amount of fine shell (kg/m3) | 246 | 246 | 246 | 246 |

| Amount of aggregates between 4 and 10 mm (limestone) (kg/m3) | 384 | 384 | 384 | 384 |

| Amount of aggregates between 1 and 4 mm (silica) (kg/m3) | 384 | 384 | 384 | 384 |

| Total amount of aggregates (kg/m3) | 1717 | 1717 | 1717 | 1717 |

| Cement quantity (kg/m3) | 325 | 275 | 240 | 200 |

| Amount of water (l/m3) | 160 | 160 | 130 | 120 |

The first of the proposed dosages (Type 1 or HA-30) strictly complies with the conditions of EHE-08 for concretes in marine environments or permanently submerged with chemical attack by salts (maximum water/cement ratio of 0.5, minimum content of cement equal to 325 kg m−3 and a minimum resistance of 30 N/mm2). This dosage is also the most suitable for the prefabrication of concrete systems due to its high initial resistance. This would make the demoulding process to be very fast [47,85].

The other three dosages (Type 2 (HA-25), Type 3 (HM-20P) and Type 4 (HM-20)) do not conform to the specifications for marine environments or permanently submerged systems, as the water/cement ratio exceeds a value of 0.5. This means that their service lives will not reach the minimum value of 15 years that the EHE-08 establishes for marine projects. In any case, Types 2 (HA-25) and 3 (HM-20P) can be considered as suitable for the intended use and durability. In fact, they can be classified as temporary elements (between 3 and 10 years of functional life) as stated in article 5 of EHE-08 [84].

Type 4 (HM-20) has been proposed with environmental and sustainability objectives in mind: minimum quantity of cement. It is important to note that this dosage does not reach the minimum resistance of 30 N/mm2 required by EHE-08. However, this is not a problem, since it is possible to design AR modules so that they are not subjected to more than 6 N/mm2. The reader can find more information about this latter issue in Lamas Galdo et al. [85].

4. Test results and discussion

The novel abrasion-resistant test used for testing the four proposed dosages is presented in this section. The mechanical properties of the four proposed dosages are also analysed. A minimum compressive strength is required in order to withstand the loads that appear during the process of stripping the AR module [85]. The permeability level of each dosage is also determined by means of an absorption after immersion test.

4.1. Proposal for an improved abrasive erosion test

The abrasive erosion of the hydraulic concrete can be defined as a progressive disintegration of the material due to the transport of water, sand and gravel [86]. The irreversible nature of this damage together with the high costs involved, make it of vital importance to correctly characterise the resistance of a concrete to abrasive erosion [73].

According to Liu et al. [87], the mass loss caused by abrasive erosion in hydraulic concrete is a three-stage process. Initially, the pressure of the water molecules causes pre-abrasive peeling of the concrete surface. Subsequently, the impacts of the solid particles suspended in water cause the removal of the mortar. Finally, aggregate removal happens due to a combined effect of scraping and shearing actions.

The American Society for Testing and Materials (ASTM) has proposed several comparative methods for assessing the abrasive resistance of concrete. One of them is the “underwater method”. It is specifically designed to simulate the abrasive action of waterborne particles under water [88]. However, some authors argue that the existing equipment is far from allowing a realistic simulation of the environment in which this phenomenon occurs or, if possible, it is too complex and expensive [72,73]. This is the reason why both Camba et al. [72] and Messa et al. [73] have developed alternative methods with the aid of computational fluid dynamics (CFD).

In this study the procedure described in Camba et al. [72] is adopted, although in this case, some modifications are introduced. In particular, the sample size, the test time and the procedure for determining the wear produced have been modified. Furthermore, in this study, higher mass losses have also been caused. The size and shape of the test pieces were modified for such a purpose. Fig. 4 shows the testing device. It is a cylindrical steel tank filled with water. The non-standardised concrete sample is placed at the bottom of the tank. The concrete is consolidated inside a cylindrical PVC piece with a diameter of 200 mm and a height of 50 mm (Fig. 5). A stirrer with a specifically designed paddle maintains the rotary motion.

Fig. 4.

Device for the limited durability test. Source: own.

Fig. 5.

Concrete samples after the abrasive erosion test: A shows concrete Type 1, B shows concrete Type 2, C shows concrete Type 3 and, D shows concrete Type 4. Panel E shows the profilometer attached to the robot. Source: own.

As for the abrasive (sand) used during the test, it is difficult to establish a general criterion, since it depends on the diameter of the sediments of the location where the reefs are going to be installed. Therefore, in this study the abrasive was selected for the Ares-Betanzos Estuary (Galicia, NW of Spain) [89]. According to Troncoso and Urgorri [90], in these areas, the predominant sediment is fine sand and, to a lesser extent, very fine sand, with some exceptional areas containing medium-sized sand. Table 3 includes more information about the type of aggregate that can be used for the test. It is based on the Wentworth classification.

Table 3.

Granulometry of the sand to be used in the abrasive erosion test. Source: own.

| Type of sand | Very fine | Fine | Medium |

|---|---|---|---|

| Granulometry D50 | 0.06–0.12 mm | 0.12–025 mm | 0.25–0.5 mm |

| Adopted range | 0.06–0.5 mm | ||

A good size range for the abrasive would be between 0.06 and 0.5 mm. It is expected that the smallest solid particles (0.06–0.1 mm) will be those most easily transported by water currents and, therefore, those with the greatest capacity to affect or erode the AR [90].

Regarding the procedure to determine the wear produced, it has been decided to measure the volume loss or volume withdraw of each testing sample by means of an innovative method. The surface of each concrete sample (Fig. 5) is captured with a laser profilometer (LPS36) attached to a robot (IRB120). They sweep each sample generating a series of profiles separated 3 mm from each other. The table profiles are also obtained in order to determine the reference plane (Fig. 6).

Fig. 6.

Procedure to determine the loss of volume of each concrete sample by using the profilometer and the robot. Source: own.

The profiles are combined with the movement of the robot to reconstruct the surface of each sample. The point values (X, Y, Z) are interpolated to a regular 1 mm sided mesh (X, Y). The mesh is used to estimate the volume loss by double trapezoidal integration in two different ways (Fig. 7).

-

•

Using the height interpolated from the reference plane (the table), and determining the volume below the surface.

-

•

Using the height interpolated to the highest point of the captured surface as a way of obtaining the volume withdraw above the surface.

Fig. 7.

Volume loss by double trapezoidal integration. Panel A shows the interpolation of volume below the created plane. Panel B shows the interpolation of volume above the created plane.

4.2. Results

The concrete samples were cured by water immersion for 28 days. Compression and durability (abrasive erosion) tests were carried out after 28 days, while 90 days elapsed before the permeability-porosity ones were performed. Between days 29 and 90, the samples were in the laboratory with no temperature and humidity control, in a warm sub-humid climate.

The density of each fresh concrete sample was evaluated in order to control the formulation parameters. The workability was also characterised by means of the slump-test, as well as the compactness degree following EN 12350–2:2009 [91]. A compressive strength test was also performed following UNE – EN 12.390–3/AC:2011 [92]. Cubic (edge of 150 mm) and cylindrical (150 × 300 mm) samples were tested after 1, 2, 7 and 28 days. The reader can find more information about those results in Table 4.

Table 4.

Summary of the results for the different concrete samples including mechanical properties, workability, degree of compactness and percentage of water absorption by immersion. The sampling of the fresh concrete was made according to UNE-EN 12350–1:2009 [93]. Source: own.

| Specifications | Concrete types |

|||

|---|---|---|---|---|

| Type 1 | Type 2 | Type 3 | Type 4 | |

| EHE-08 designation | HA-30/B/20/IIIb Qb | HA-25/P/20/IIa | HM-20/P/20/I | HM-20 |

| Consistencya | 7 | 1 | 3 | 9 |

| Water/cement ratio | 0.5 | 0.58 | 0.54 | 0.6 |

| Theoretical density (kg/m3) | 2202 | 2299 | 2087 | 2037 |

| Real density (kg/m3) | 2227 | 2299 | 2173 | 2045 |

| Compactness % b | 0.917 | 0.866 | 0.901 | 0.9374 |

| Compressive strength 1 day (KN) c, d | 177.93 | 0.00 | 83.00 | 0.10 |

| Compressive strength 1 day (N/mm2) c, e | 10.05 | 0.00 | 4.7 | 0.0 |

| Compressive strength 2 days (KN) ,c, d | 280.55 | 271.3 | 146.16 | 76.84 |

| Compressive strength 2 days (N/mm2) c, e | 15.85 | 15.4 | 8.3 | 4.3 |

| Compressive strength 7 days (KN) c, d | 399.13 | 469.54 | 223.69 | 118.86 |

| Compressive strength 7 days (N/mm2) c, e | 22.6 | 26.6 | 12.7 | 6.7 |

| Compressive strength 28 days (KN) c, d | 480.97 | 513.4 | 246.19 | 144.79 |

| Compressive strength 28 days (N/mm2) c, e | 27.2 | 29 | 13.9 | 8.2 |

| Percentage of water absorption by immersion (K) (4 h) f | 0.78 | 1.05 | 1.86 | 2.69 |

| Percentage of water absorption by immersion (K) (96 h) f | 1.79 | 2.41 | 3.54 | 4.98 |

Test UNE-EN 12350–2:2009.

Compactness: the amount of solid material contained in the volume of the concrete sample. It has direct impact on durability, strength and permeability. Linked to the specific weight.

Test UNE-EN 12.390–3:2009/AC:2011.

Concrete sample of 15 × 15 × 15 cm.

Cylindrical concrete sample of 15 × 30 cm.

Water absorption by immersion of the hardened concrete.

4.2.1. Compressive strength

The results show that two of the concrete dosages resulted to have a soft consistency (Type 1 (HA-30) and Type 4 (HM-20)), while the other two samples (Type 2 (HA-25) and Type 3 (HM-20P)) obtained plastic consistency (Abrahams cone −7, 1, 3, 9). The samples also presented different levels of compactness varying from 0.87 to 0.93 (Table 4). In order to achieve the same initial strength of 8.2 N/mm2, Type 1 needed 1day, while Types 2, 3 and 4 required 2, 2 and 28 days, respectively. In any case, the compressive strength is lower than it should be in normal conditions due to the replacement of aggregates by shells. The absence of additives also contributed to reduce the compressive strength of the four samples.

4.2.2. Absorption by immersion

The coefficient of water absorption by immersion (K) of the hardened concrete was estimated as the percentage of the periodic measurement of the gain weight experienced by a sample immersed in a 40 cm sheet of water. For such a purpose, cubic samples (edge of 150 mm) were cut into three slices (5 cm of height) before being immersed. The weight gain was monitored by removing the samples from the container at time intervals of 1, 2, 4, 8 24, 72, 96 and 168 h. Each sample was dried with a cloth before its weighing. Table 4 includes the results after 4 and 96 h of immersion.

4.2.3. Abrasion resistance

Two samples were tested for each one of the proposed dosages following the procedure (profilometer and the robot) described in Section 4.1. The measurements were repeated by taking 5 captures of each sample but, rotating them a fifth of a turn each time with the objective of minimising systematic errors and, at the same time, estimating random errors.

At the time of calculating the volume of the upper part, the height at which 99% of the surface is below was taken as reference instead of using the highest point. Measurements were also carried out between 90 and 100%. However, the results confirm that using a value of 99% serves to eliminate the point peaks of coarse aggregates protruding from the surface. The volume loss or volume withdraw results are included in Table 5.

Table 5.

Abrasion resistance (volume loss) results. In particular, volume withdraw above the reference plane for each sample corresponding to a percentage of the cumulative probability curve of 99. Source: own.

| Concrete types | |||||||

|---|---|---|---|---|---|---|---|

| Type 1 |

Type 2 |

Type 3 |

Type 4 |

||||

| Sample 1 | Sample 1b | Sample 2 | Sample 2b | Sample 3 | Sample 3b | Sample 4 | Sample 4b |

| 0.1932 ± 0.0027 | 0.08854 ± 0.00096 | 0.1073 ± 0.0075 | 0.2258 ± 0.0065 | 0.1422 ± 0.0031 | 0.1939 ± 0.0100 | 0.1816 ± 0.0065 | 0.1930 ± 0.0099 |

4.3. Discussion

All the dosages obtained an adequate performance in terms of compressive strength and limited functional life, although they presented different curing times as well as different permeability. From the results, it is clear that from the sample Type 1 (HA-30), it is possible to reduce the amount of cement between 15.5 and 39% depending of the environmental exposure type [84].

The concrete sample Type 4 (HM-20) resulted to be the most eco-efficient alternative, although it is outside the durability criteria established in the EHE-08 standard [84]. Among the samples that comply with EHE-08 standard, Type 3 (HM-20P) is the best option, as its functional life (10 years) is adequate for mass concretes.

Takin into account the study developed by Lamas Galdo et al. [85] for the production phase, the demoulding process of samples Type 1, 2 and 3 is possible after 1 day, while for Type 4, it takes 2 days before the concrete reaches the required conditions for its demoulding without risk of breakage.

Regarding the water absorption by immersion, the reader should bear in mind that both compactness and the water/cement ratio have a considerable influence on this parameter, although the influence of the latter is somewhat smaller [74]. In the first case, the higher the compactness, the lower the absorption. However, the water/cement ratio presents the opposite tendency.

All the samples obtained low absorption percentages (1.8–4.98%). In more detail, it is possible to say that samples with a high amount of cement and a low water/cement ratio present lower values for the absorption coefficient. This is the case of Type 1. As the amount of cement decreases and the water/cement ratio experiences the opposite effect, the absorption tends to increase. In this sense, Types 2 and 3 obtained intermedium results, while Type 4 presented the highest coefficient.

The compactness (amount of solid material contained in the volume of each sample) and the water/cement ratio (capillary space between cement particles) resulted to be the most relevant factors for the abrasion resistance. The higher the water/cement ratio is, the higher is the permeability and, thus, the concrete is more exposed to potential damage. On the other hand, in hardened cement pastes, an increase in total porosity as a result of increasing the water/cement ratio only happens in large pores.

The four dosages obtained acceptable results in the abrasion resistance test, albeit with minor differences. In fact, the concrete Type 4 (HM-20) is an example with higher volume loss than the one experienced by the other three samples. In terms of abrasion resistance, for mass concretes, Type 3 (HM-20P) allows to achieve sustainability characteristics while it also ensures the required functional life for temporary structures.

5. Estimating the functional life from the results of the durability test

This section accounts for the application of statistical learning techniques to properly define the relation between the different variables that define the concretes for AR applications, in addition to model these relationships. These models provide enriched information about the degradation of the concretes and the possibility to make predictions about its degree, type or magnitude. Thus, the statistical modelling contributes to improve the knowledge about the concrete degradation for AR and, consequently, about its durability or lifetime.

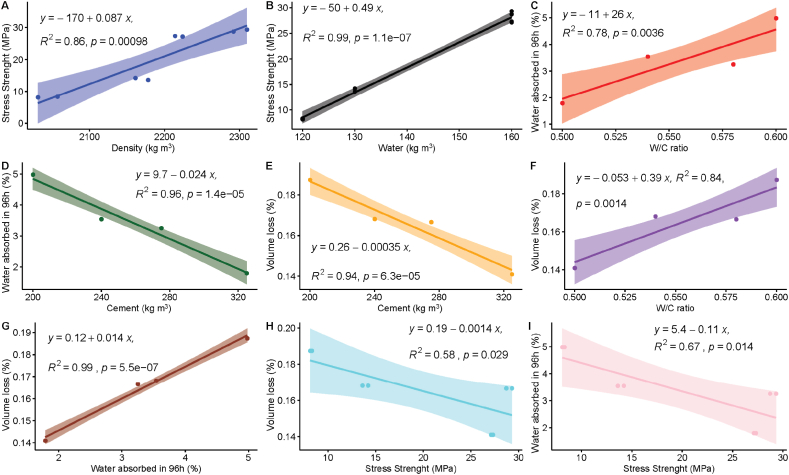

The first step is to measure the degree of dependence between the variables that define the AR concretes, whether they are design variables or variables defining the physical properties of the concretes. Fig. 8 shows the relationship between the different quantitative features that characterise the four types of concrete. Pearson linear correlation coefficient and a scatterplot matrix with fitted linear regression models (including 95% confidence intervals) are provided.

Fig. 8.

Study of the linear relation between the variables that define the AR concretes. The histogram of each variable is included in the diagonal. The Pearson linear correlation coefficients are included (with p-values of the test defined by ), in addition to the scatterplots corresponding to each pair of features with the corresponding linear regression fitting (95% confidence interval is also provided).

Fig. 8 shows that the volume loss (defined from the 99% more central specimen heights) has a strong linear relation with concrete design features such as the amount of cement, the amount of water, and ratio of water and cement. In addition, it is important to note that the volume loss is also strongly correlated with other properties of concrete such as the water absorption during 96 h and the compression stress strength. Summarising, the volume loss tends to decrease when increasing the density, content of cement, content of water, and compression strength, whereas the volume loss tends to increase when increasing the ration of water and cement (W/C) and the absorbed water.

On the other hand, a strong relation is observed between the volume loss (or the water absorption) and the lifetime reported by the standards (for those standardized concretes). This means the volume loss and water absorption provide information about the durability of the concrete. Moreover, it is also important to stress the strong correlation between the critical to quality variables for the concrete, i.e. absorbed water, volume loss, and compression stress strength. Thus, the compression stress feature, in addition to the water absorption and the volume loss, share an important part of the information about the durability and reliability of concrete. These results support the use of volume loss feature (as obtained in the proposed test), apart from stress strength and water absorption, as a relevant variable to characterise the durability of the concrete to be used in AR.

We also study the relationship between the quantitative critical to quality features of the concrete and important qualitative features (factors) such as the type of concrete (fourth levels) and age (four levels). Regarding the compression stress strength, we can observe some differences depending on the type of concrete (see the bar chart with 95% confidence interval in Fig. 9A). In fact, the strength against compression stress is significant different for all the types of concrete, excepting for the Type 2 (HA-25) and Type 1 (HA-30), that could be defined by similar compression strength, although Type 2 (HA-25) concrete tends to have very slightly higher strength values. We can sort the different types from higher to lower strength as follows: HA-25 (Type 2) ≥ HA-30 (Type 1) > HM-20P (Type 3) > HM-20 (Type 4). Moreover, Fig. 9C shows the dependence that the water absorption also depends on the type of concrete following the sequence HM-20 > HM-20P > HA-25 > HA-30. The same trend is observed for the concrete volume loss in Fig. 9B.

Fig. 9.

Dependence between critical to quality variables for the concrete and the type of concrete. Panel A shows the influence of the type and age of concrete on the concrete compression strength. In the panel C the dependence between the water absorption and type is observed, whereas the panel B shows the volume loss of concrete depending on the type.

Next step is to fit a regression model that estimates the effects of each concrete feature on the durability of the concrete. In the following lines, processes of variable selection and parameter estimation are implemented. In Fig. 10, the graphical output of the simple regression models that define the most relevant linear relationships between critical variables are shown. On the one hand, the response variables are those critical to quality features of the concrete, compression stress strength, absorbed water, and volume loss. They are connected with the reliability and durability of the concrete. On the other hand, the predictors or independent variables (X) are those corresponding to design features, such as amount of cement added, density or ratio between water and cement mass. The expressions of the fitted regression models, in addition to the R2 goodness of fit coefficients, are also included in the plots (all the effects of predictors over the responses are significant, indeed p-values of t-test for the models’ slope are less than 0.05). Moreover, the 95% prediction confidence interval for the regression lines are included, showing the degree of precision of the predictions provided by each linear model. Taking into account this information, all the models included in Fig. 10 can be used to provide relatively precise predictions of each response variable, instead in the case of those models shown in Fig. 10H and I. It is important to note that the predictions provided by these models will be more reliable the closer the value of the predictor or covariate X is to the experimental range of data used in this study.

Fig. 10.

Panels A–F: Scatterplots with the relation between the concrete critical to quality variables (stress strength, volume loss, water absorbed) and the concrete design variables, that act such as predictors (in the X axis). Panels G–I: Linear relation between the 3 critical to quality variables. Linear regression fittings with 95% prediction confidence intervals, linear regression equations, the p-values of the slope parameters, and the corresponding determination coefficients are also shown.

We observe that the 86% of the changes in the compression stress strength could be explained using a linear model as a function of the theoretical density, increasing in 0.087 MPa when the density increases in 1 kg m−3 (Fig. 10A). Moreover, the 99% of the variation of the compression stress strength is explained using a linear model depending on the mass of water, increasing in 0.49 MPa when increasing the water mass in 1 kg m−3 (Fig. 10B). Focusing on those variables more correlated with the concrete lifetime reported by the standards (Fig. 8), i.e. volume loss and water absorption mass (in a test during 96h), they strongly correlated. In fact, the 99% of the information of the concrete volume loss can be explained by a linear function of the concrete water absorbed (Fig. 10G). Thus, they explain almost the same information and, consequently, are most correlated with the same design variables, such as the W/C ratio and cement amount. For instance, the water absorbed and the volume loss of the concrete are almost totally explained using linear models depending on the mass of cement (R2 = 0.96, and R2 = 0.94, respectively). When the cement is increased about 1 kg m−3, the water absorbed decreases in 0.024% and the volume loss in 0.00035% (Fig. 10D–E). On the other hand, the W/C ratio also plays a significant role in the durability of concrete, measured by the volume loss and the water absorption. In fact, there are also strong linear relations between the durability features and the W/C ratio, making possible to estimate predictive models. Taking into account the estimates, the water absorption and the volume loss tend to increase (2.6% and 0.039%, respectively) when increasing 0.1 the W/C ratio (Fig. 10C,F). It is also important to note the moderate to strong relationship between the compression stress strength with respect to durability variables such as the volume loss and water absorption percent ( [94]. In fact, Fig. 10H–I shows that moderately explicative models estimated from the compression strength can be used to predict the volume loss (R2 = 0.67) or water absorption (R2 = 0.58). Therefore, the compression strength is a property of concrete that is also connected with the measure of its durability, in some extent, in addition to the concrete water absorption and the volume loss percent.

The role of the design variables and their influence on the variables that define concrete durability could be summarized as follows. On the one hand, the density (Fig. 10), the amount of water (Fig. 10) and the amount of cement in the concrete (Fig. 9) strongly influence its resistance to stress and, the higher they are, the higher its resistance will be, as long as the W/C ratio does not increase. These relations can be modelled by means of linear models, and can be used as an aid in the production of concrete with a specific strength by modifying its density or the amount of cement. On the other hand, the concrete volume loss is strongly determined by the W/C ratio in addition to the amount of concrete added. Thus, an increase in the W/C ratio will cause a linearly proportional increase in volume loss (greater degradation), while an increase of cement amount is related to a proportional decrease in volume loss (greater stability to degradation). Similarly, water absorption by concrete is determined by the amount of cement and the W/C ratio. An increase of concrete amount or a decrease in the W/C ratio is related to a linearly proportional decrease of water absorbed amount and, therefore, in the stability of the concrete against degradation. In short, an increase of cement quantity and a decrease in the W/C ratio of the concrete help the concrete to have a higher resistance to degradation in a marine environment. All these dependences can be modelled using linear regression that also could help us to develop concrete with specific durability.

The volume loss and water absorption percent (and, in a lesser extent, the compression strength) have been identified as informative variables to estimate the durability of a concrete for AR. In addition, these properties have been statistically modelled to be predicted from the concrete design features. The next step is to assign a more likely lifetime level to each sample of concrete, from its durability features obtained in laboratory, specifically volume loss, water absorption percent. The first approach to make lifetime predictions is by fitting simple linear regression models (assuming linear relationships between variables), in fact, the lifetime can be expressed as a function of the concrete volume loss as follows (increasing 0.1% the absorbed water corresponds to a decreasing of 1.9765 years in concrete lifetime) (Eq. (1)):

| (1) |

In addition, the lifetime can be also expressed as a function of water absorption (increasing 0.001% the volume loss corresponds to a decreasing of years in concrete lifetime) (Eq. (2)):

| (2) |

As pointed out, we can observe that the relations of dependence between the concrete lifetime, on the one hand, and the concrete water absorption or volume loss, on the other hand, are inverse, as shown by the negative slope of the linear regression expressions shown in ((1), (2). Therefore, the greater the volume loss of the concrete or, alternatively, the greater the amount of water absorbed, the shorter the estimated life of the concrete. Assuming the simplest regression model, the linear one, to model such dependence relationships, models (1), (2) serve to provide estimates of the lifetime of concrete for a given volume loss or a given amount of absorbed water in standard laboratory tests. In these specific cases, the intercept parameters mean the value of lifetime when there is not water absorption or in the case the concrete volume loss be 0.

In addition to estimating the parameters of the models, it is also essential to carry out a study of their significance, in order to be able to evaluate whether there really is a linear dependence between each pair of variables studied. Table 6 shows the signification study of the parameters of all the models shown in Fig. 10. The objective of this study is to verify whether the estimated parameters are significantly different from zero. Table 6 shows that, indeed, all the estimated parameters are significantly different from zero, since the corresponding p-values are greater than the significance level, 0.05. Only the constant at the origin corresponding to the model explaining the volume lost as a function of the W/C ratio has a p-value >0.05. Therefore, we can infer that there is indeed a linear relationship between each pair of variables shown in Fig. 10.

Table 6.

The linear models’ parameter estimates, their 95% confidence intervals, the values of the t-test statistic, the corresponding p-values, the linear regression equation, and .

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | −170.021 | −247.63 | −92.412 | −5.361 | 0.002 |

| Density | 0.087 | 0.051 | 0.122 | 5.983 | 0.001 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | −50.305882 | −56.196814 | −44.41495 | −20.895515 | 0.0000008 |

| Water | 0.4903922 | 0.449373 | 0.5314113 | 29.2532962 | 0.0000001 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | −11.078 | −18.738 | −3.417 | −3.539 | 0.012 |

| W/C ratio | 26.068 | 12.298 | 39.837 | 4.632 | 0.004 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | 9.682308 | 8.461412 | 10.903203 | 19.405225 | 0.000001 |

| Cement | −0.024201 | −0.028825 | −0.019577 | −12.806538 | 0.000014 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | 0.2562833 | 0.2334194 | 0.2791471 | 27.4277238 | 0.0000002 |

| Cement | −0.0003484 | −0.000435 | −0.0002618 | −9.845447 | 0.0000633 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | −0.053 | −0.148 | 0.043 | −1.355 | 0.224 |

| W/C ratio | 0.394 | 0.222 | 0.565 | 5.614 | 0.001 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | 0.11659195 | 0.11088712 | 0.12229678 | 50.0085499 | 4E-09 |

| Water absorption | 0.01448394 | 0.01288781 | 0.01608007 | 22.2042888 | 5.46E-07 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | 5.4477 | 3.8487 | 7.0467 | 8.3366 | 0.0002 |

| Stress strenght | −0.1051 | −0.1796 | −0.0306 | −3.4515 | 0.0136 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | 0.19361 | 0.167411 | 0.219808 | 18.082753 | 0.000002 |

| Stress strenght | −0.001426 | −0.002647 | −0.000205 | −2.858 | 0.028877 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | 210.252997 | 196.94646 | 223.559534 | 43.86986 | 0.000002 |

| Volume loss | −1226.6999 | −1310.3992 | −1143.0005 | −40.691647 | 0.000002 |

| Estimates | 2.50% | 97.50% | t | p-value | |

| Intercept | 72.361979 | 59.64987 | 85.074089 | 15.804542 | 0.000094 |

| Water absorption | −19.765261 | −24.058798 | −15.471724 | −12.78134 | 0.000216 |

In addition, linear regression models must comply with a series of starting hypotheses such as normality, homoscedasticity and independence of their residuals or errors. This is necessary to be able to trust the estimates of the confidence intervals, the results of the contrasts and their p-values, even the prediction intervals. Consequently, Table 7 shows the result of the diagnosis of compliance with the hypotheses of the model, carried out by applying the Kolmogorov-Smirnov test (to evaluate normality), the Breush-Pagan test (homoscedasticity) and the Breush-Pagan test (homoscedasticity). In addition, the t based test in order to detect the presence of outliers has been applied. We can observe that all the p-values are greater than a signification level of 0.05, thus, assuming this criterion, we cannot reject the null hypotheses of the linear regression model. Therefore, the estimates of confidence intervals and signification analysis of the models’ parameters are reliable.

Table 7.

The meeting of the model hypothesis of normality, homocedasticity, and independence of the residuals are assessed by the application of the corresponding statistical tests. In addition, the hypothesis of absence of atypical values is tested. All the corresponding p-values are shown.

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.8001 | 0.8582 | 0.6096 | 0.1948 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.9534 | 0.2177 | 0.6892 | 0.12585 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.09045 | 0.4141 | 0.2425 | 0.16934 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.2553 | 0.5353 | 0.1723 | 0.15299 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.4933 | 0.7799 | 0.0968 | 0.1708 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.3822 | 0.7367 | 0.2383 | 0.21991 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.09188 | 0.7573 | 0.3629 | 0.15151 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.2841 | 0.2441 | 0.06728 | 0.19094 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.6408 | 0.1529 | 0.07321 | 0.18093 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.574 | 0.2257 | 0.517 | 0.2974 |

| p-value of normality test (Kolmogorov-Smirnov) | p-value of homocedasticity test (Breusch-Pagan) | p-value of independence test (Box-Pierce) | p-value of oulier test (t-test based) |

| 0.3075 | 0.2516 | 0.4653 | 0.27871 |

Taking into account that, in this study, lifetime has been defined by two different values (can be studied as a dichotomic variable), the classification methods are an alternative to make predictions of concrete durability. The volume loss and water absorption percent (and, in a lesser extent, the compression strength) have been identified as informative variables to estimate the durability of a concrete for AR. In addition, these properties have been statistically modelled to be predicted from the concrete design features. The next step is to assign a more likely lifetime level to each sample of concrete, from its durability features obtained in laboratory, specifically volume loss, water absorption percent. Indeed, in this study, we have defined two levels of lifetime, as specified by the standards: HA-30 (Type 1) has a high lifetime (25–50 years), whereas HM-20P (Type 3) and HA-25 (Type 2) are characterised by a low lifetime (3–10 years). This dataset can be used to estimate the lifetime level (high or low), by applying unsupervised classification techniques. In fact, the class or more likely lifetime level of HM-20 concrete can be estimated using these techniques. Firstly, hierarchical and partitive clustering techniques have been used. Hierarchical clustering is an unsupervised classification tool very useful to identify groups in a small dataset [95]. In this case, we have used this technique assuming Euclidean distance and Ward agglomerative method. Fig. 11A shows a silhouette graph (that implements the Elbow method) [96] used for identifying the number of different groups in the dataset from the information of the volume loss and water absorption. The optimal number of groups is 4 (maximum of the average silhouette width), that are shown in the dendogram of Fig. 11B. We can observe that the groups perfectly match with the concrete types. In addition, a partitive k-Means cluster method [95] has been applied assuming these 4 groups. The graphical output is shown in Fig. 11C, where the groups are identified in a scatterplot of the original variables. The more central and similar are HA-25 (Type 2) and the HM-20P (Type 3), whereas HM-20 (Type 4) is close to HM-20P (Type 3) but defined by a higher volume loss and water absorption percentage. The H-30 (Type 1) concrete is the one with lower values of water absorption and volume loss, thus it is the one with a higher durability.

Fig. 11.

Graphical outputs of the clustering analysis performed from the volume loss and water absorption of concrete for AR. Panel A: silhouette plot for detecting the number of clusters. Panel B: dendogram from applying hierarchical clustering with 4 groups. Panel C: graphical output of the k-Means method for 4 groups. Panel D: dendogram from applying hierarchical clustering with 2 groups. E: biplot from the application of the k-Means method for 2 groups using water absorption and volume loss. Panel F: water absorption trends of different types of concrete. Panel D: biplot from the application of the Clara method for 2 groups (from only the water absorption trends).

If we apply the hierarchical method only to those features more related with the lifetime or durability (volume loss and water absorption) and assuming just two different groups, these perfectly match with the two levels of lifetime: on the one hand the HA-30 (Type 1), with high lifetime, and, on the other hand, the remaining types of concrete, including also the samples corresponding to the HM-20 (Type 4), close to that samples corresponding to the HM-20P (Type 3) concrete. Consequently, these samples are within the group of low lifetime of Fig. 11D, in green, and in the area in blue of Fig. 11E corresponding to the group of low lifetime. In fact, Fig. 11E is a biplot obtained from the application of the k-Means cluster method, where all the observations are plot in a scatterplot of the two first principal components of the dataset and, in addition, the importance (arrow length) and direction of the original variables (volume loss and water absorption) are plot in the centre of the graph. Fig. 11E shows that the two groups are identified mainly due to the differences in volume loss. Thus, the volume loss obtained in the experimental setup performed in this study is strongly correlated with the durability of the concrete.

A classification study has been also performed taking into account only the information corresponding to the water absorption trends. For this purpose, the time series of water absorption shown in Fig. 11F, obtained and replicated for all the 4 types of concrete, are used as starting information to apply the Clara cluster classification method [97], highly recommended for datasets with higher number of variables and observations. From the biplot of the Clara method, we can observe that two groups have been identified. The first one corresponds to the H-30 (Type 1) concrete, the one with higher lifetime, whereas the remaining concretes belongs to the other group (group of low lifetime). The differences between groups are connected with differences in the water absorption at high times, equal or more than 24 h, as shown in Fig. 11G. Summarising, the cluster methods can be applied to identify the lifetime of a concrete for AR applications, assuming, in this case, two groups, upper durability and low durability, and this classification can be performed from the volume loss and the water absorption, or alternatively from the water absorption time series trends.

6. Conclusions, limitations and future developments

Introducing modifications such as the installation of artificial reefs in marine ecosystems can cause the loss of both ecological and economic resources, even if the changes are intended to enhance the ecosystem in the short or medium term. Modifications can also be contrary to the interests of future generations. Therefore, it is necessary to analyse the possibility of introducing changes that can be reversed, allowing the ecosystem to return to an earlier stage. This is related to the sustainability of the ecosystem itself and thus to its resilience.

This study explores the possibility of limiting the functional life of the base material (concrete) employed in the manufacture process of artificial reefs to one social generation (15 years). Four different concrete dosages were proposed for such a purpose. They are different in terms of the amount of cement, the water/cement ratio, or the compactness, among other properties. However, in all the dosages a percentage of the conventional materials (aggregates) are replaced by a mixture of shells. They were subjected to different mechanical tests (compressive strength and absorption after immersion), including an innovative abrasion-resistant one that is completely described in the study.

This study can be of interest for decision-makers, politicians and also for other researches working in the same field. The latter can take this study as a starting point, adapting it to other estuaries where the abrasive action may differ from the one considered here. It is also possible to adapt the functional life to the needs of the ecosystem under consideration. In other words, the level of degradation of the marine ecosystems varies and also does the time (functional life of the module) required for their rehabilitation.

From the results obtained, it is clear that although the four samples obtained acceptable results for the objective sought, one of them (Type 3, HM-20P) turned out to be better than the others. This concrete sample complies with EHE-08 standard. It obtained an adequate service life (10 years) for mass concrete and it also achieved good results in all the mechanical tests. Furthermore, it has been observed that from the sample Type 1 (HA-30), it is possible to reduce the amount of cement between 15.5 and 39% depending of the environmental exposure type. This is a significant contribution to the environmental dimension of sustainability, as cement production is an activity that contributes to several environmental impact categories (especially global warming through the emission of greenhouse gases). Regarding the water absorption by immersion, the samples with high cement dosage and low water/cement ratios obtained the lowest coefficients (sample Type 1).

On the other hand, a comprehensive statistical analysis of the concretes for AR, from their design variables (density, amount of concrete and water, W/C ratio, compactness) and properties such as the volume loss percent, the water absorption percent, and the compression stress strength has been performed. In addition, we have related the latter with the concrete lifetime reported by standards, when they are available. The correlation analysis has shown that the properties most closely related to the lifetime or durability of the concrete were the volume loss and the mass of water absorbed, although the compressive strength is also strongly related to the latter and therefore has information on the durability of the concrete. These three variables are also strongly correlated with the design variables. This is the case for compression stress strength, which is strongly correlated with the amount of water and with density, while both the volume loss and the amount of water absorbed depend strongly on the W/C ratio and the amount of cement. Summarising, the volume loss and water absorption tend to decrease when increasing the density, content of cement, content of water, and compression strength, whereas tends to increase when increasing the W/C ratio. In addition, the compression strength increases when increasing density and amount of water and cement, while it tends to decreases when increases compactness and W/C ratio. Therefore, highly explicative simple linear regression models have been estimated in order to be able to predict the values of the volume loss and water absorption from the amount of cement or W/C ration, in addition to the values of compression stress strength from the density or the amount of water. These models can be useful to predict those properties related with the durability from design variables, in a first step of the elaboration of concrete. It is also important to note the significant linear relation between the three studied properties of concrete, the volume loss, the water absorption, and the compression strength, mainly between the first two. The volume loss and water absorption are directly proportional, whereas the compression strength tends to decrease when increasing the volume loss or the water absorption. Consequently, linear regression models have been estimated, making possible to predict accurately the value of volume loss from water absorption and vice versa. Taking into account that, in this study, lifetime has been defined by two different values (can be studied as a dichotomic variable), the classification methods are an alternative to make predictions of concrete durability.

Moreover, the lifetime of the concretes has been estimated using clustering techniques such as hierarchical and partitive (k-Means and Clara) cluster methods. Two levels of lifetime (as defined by the standards) or durability have been defined, upper (25–50 years) corresponding the HA-30 (Type 1), and low (3–10 years), corresponding to the remaining known types of concrete. At this point, there is one type of concrete without lifetime assigned, the HM-20 (Type 4). Assuming that the volume loss and the water absorption are those variables more correlated with the lifetime, hierarchical and partitive cluster algorithms have been applied from the information of these features. As a result, two different classifications were performed, the first one considering the estimated optimal number of groups, 4, and the second one assuming 2 groups (equivalent to the number of studied lifetime levels). On the one hand, the 4 groups estimated from the application of hierarchical and k-Means algorithms perfectly match with the four types of concrete studied (HA-25, HA-30, HM-20P, and HM-20), therefore, the volume loss and water absorption have information that allow us to distinguish among the different types of concretes, these variables perfectly characterise the performance of the concretes. On the other hand, assuming 2 groups, these perfectly match with the two levels of durability previously defined: one group is composed of the HA-30 concrete, with the higher lifetime, and the remaining are grouped in the second cluster, related to a low level of lifetime. It is important to note that the HM-20 concrete, with no previous information of lifetime, has been assigned to the group of low durability, close to the H-M20P (Type 3), that is in fact the closer in terms of composition. These methods provide graphical outputs that allows to compare the different elements of the groups, if they are close or far in terms of the analysed properties (in this case connected with the durability), providing also regions for each group of durability. It is also important to stress that the differences between the two groups of durability are mainly due to the volume loss variable. Finally, other alternative to perform the classification and estimate the level of durability of the concrete is applying the partitive Clara cluster algorithm to the time series of water absorption. The same result is obtained; the two groups perfectly match with lifetime levels. It is interesting to stress that the differences between them are connected with differences in the water absorption at high times, equal or more than 24 h. Summarising, the cluster methods can be applied to identify the lifetime of a concrete for AR applications, assuming two groups, one of upper durability and other defined by a low durability. This classification can be performed from the volume loss and the water absorption, on the one hand, or alternatively from the water absorption time series trends, on the other hand.

Finally, this paper presents several limitations that can be addressed in future research studies. First, four different dosages have been analysed. However, this number could be increased by proposing and studying new dosages. Similarly, oyster and mussel shells were used to partially replace aggregates. Another possible future development would involve the use of other shells to partially replace both aggregates and cement. Furthermore, the abrasion resistance test proposed in this study was designed according to the characteristics of the Ares-Betanzos estuary. Consequently, this test could be adapted to other estuaries with different abrasive actions. In the same vein, it can also be improved with the aim of achieving a higher rate of mass loss. The use of chemical compounds could be appropriate for such a purpose. Another alternative for future research studies would involve controlling alkalinity, as it plays a key role in terms of reef colonisation.